RT6211A/B

RT6211A/B

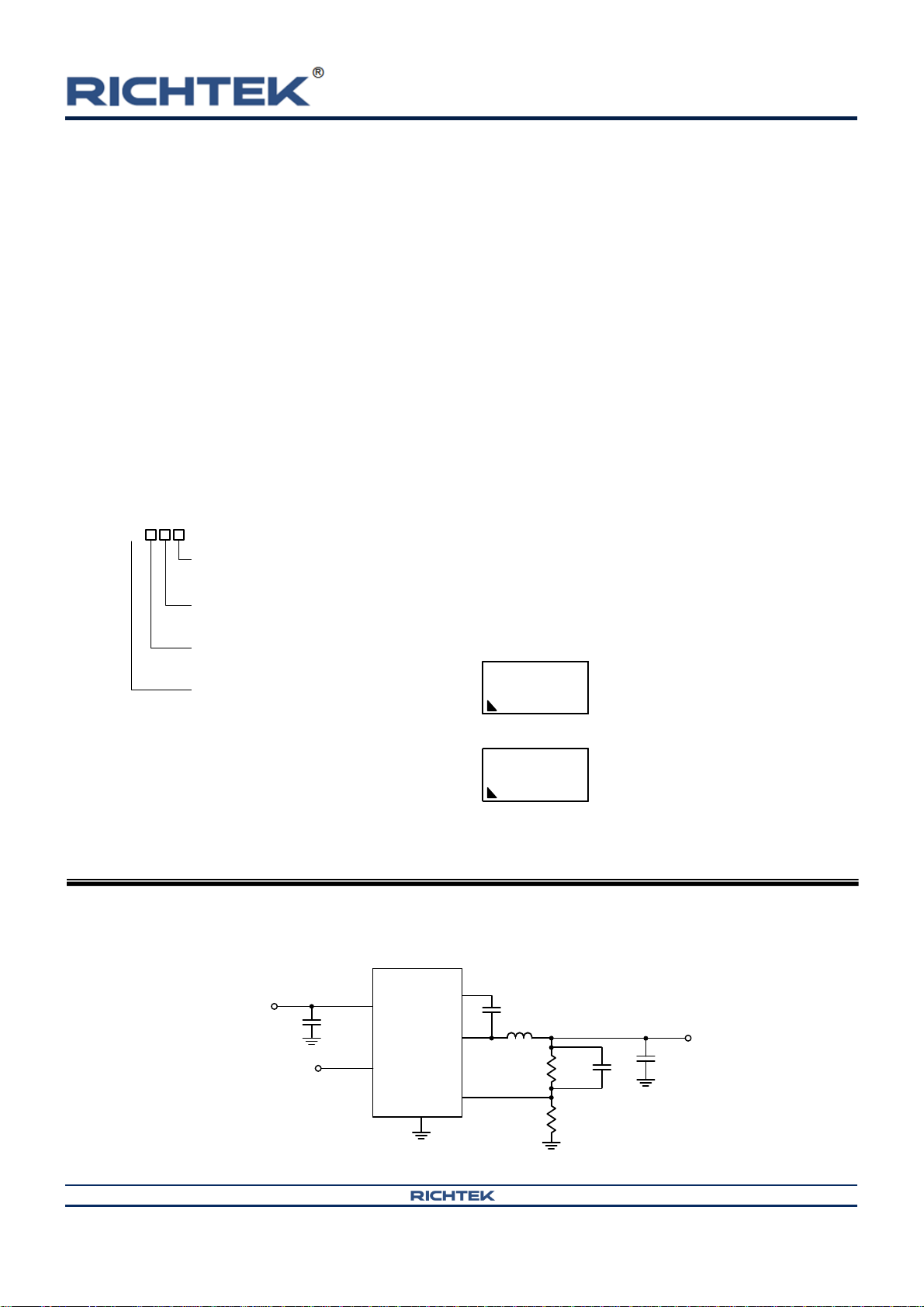

Package Type

E : SOT-23-6

Lead Plating System

G : Green (Halogen Free and Pb Free)

UVP Option

H : Hiccup

A : PSM Mode

B : PWM Mode

3J=DNN

3J= : Product Code

DNN : Date Code

RT6211AHGE

39=DNN

39= : Product Code

DNN : Date Code

RT6211BHGE

EN

RT6211A/B

GND

VIN

V

IN

C

IN

BOOT

L

C

BOOT

LX

Enable

FB

C

OUT

V

OUT

R1

R2

C

FF

1.5A, 18V, 500kHz, ACOTTM Step-Down Converter

General Description

The RT6211A/B is a high-efficiency, monolithic

synchronous step-down DC/DC converter that can

deliver up to 1.5A output current from a 4.5V to 18V

input supply. The RT6211A/B adopts ACOT

architecture to allow the transient response to be

improved and keep in constant frequency.

Cycle-by-cycle current limit provides protection against

shorted outputs and soft-start eliminates input current

surge during start-up. Fault conditions also include

output under voltage protection, output over current

protection, and thermal shutdown.

Ordering Information

Features

Integrated 230m/130m MOSFETs

4.5V to 18V Supply Voltage Range

500kHz Switching Frequency

ACOT Control

0.8V 1.5% Voltage Reference

Internal Start-Up into Pre-biased Outputs

Compact Package : SOT-23-6 pin

High/Low Side Over-Current Protection and

Hiccup

V

Range 0.8V to 6.5V

OUT

Applications

Set-Top Boxes

Portable TVs

Access Point Routers

DSL Modems

LCD TVs

Marking Information

Note :

Richtek products are :

Simplified Application Circuit

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6211A/B-01 March 2015 www.richtek.com

RoHS compliant and compatible with the current

requirements of IPC/JEDEC J-STD-020.

Suitable for use in SnPb or Pb-free soldering processes.

1

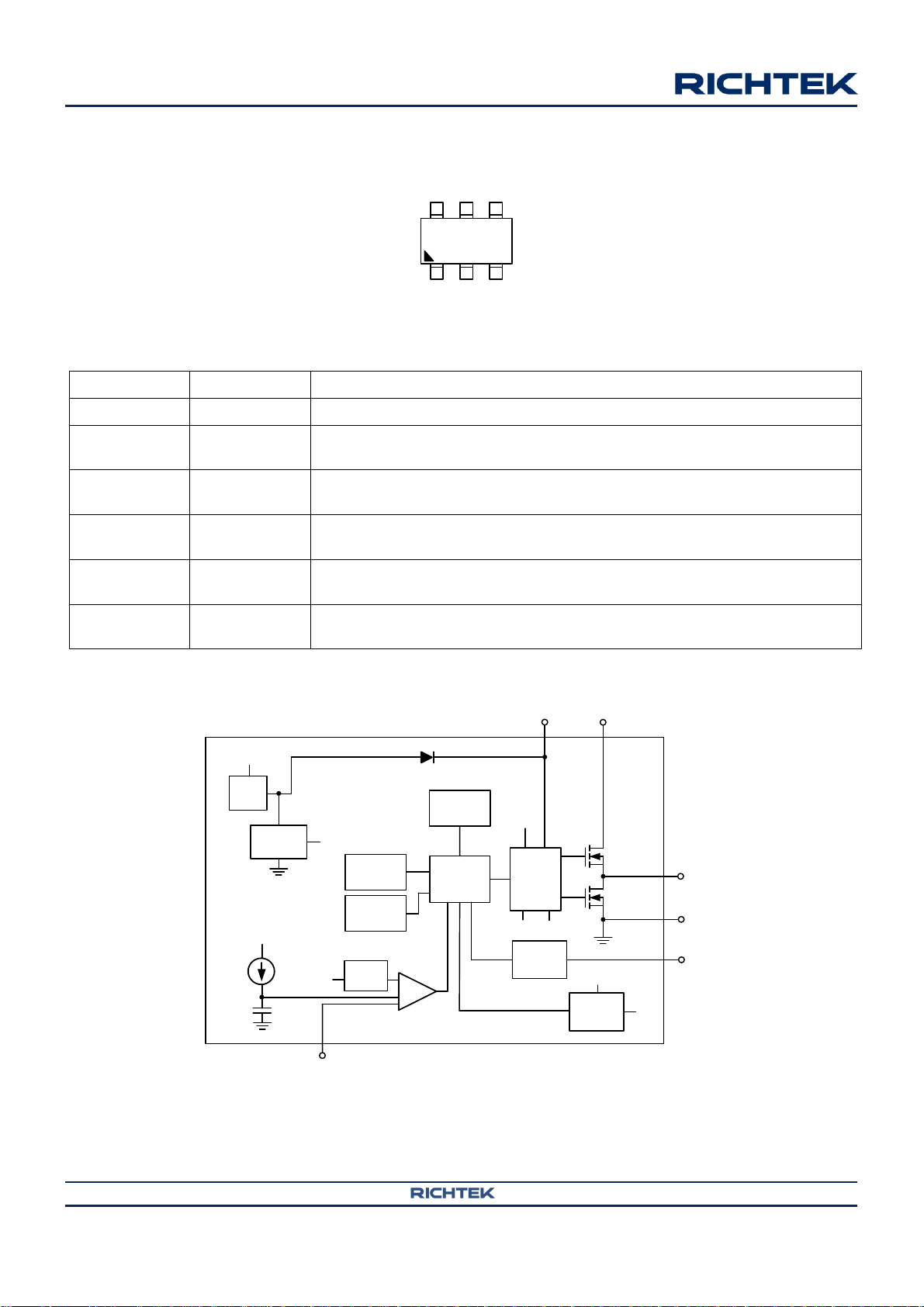

RT6211A/B

VIN

GND

LX

FB

ENBOOT

4

23

56

Pin No.

Pin Name

Pin Function

1

VIN

Power Input. Supplies the power switches of the device.

2

GND

System Ground. Provides the ground return path for the control circuitry and

low-side power MOSFET.

3

LX

Switch Node. LX is the switching node that supplies power to the output and

connect the output LC filter from LX to the output load.

4

BOOT

Bootstrap Supply for High-Side Gate Driver. Connect a 100nF or greater

capacitor from LX to BOOT to power the high-side switch.

5

EN

Enable Control Input. Floating this pin or connecting this pin to logic high can

enable the device and connecting this pin to GND can disable the device.

6

FB

Feedback Voltage Input. This pin is used to set the desired output voltage via

an external resistive divider. The feedback voltage is 0.8V typically.

UGATE

LGATE

Driver

LX

BOOT

PVCC

Control

On-Time

EN

Comparator

LX

GND

Reg

VIBIAS

VREF

PVCC

+

--

LX

PVCC

Ripple

Gen.

VIN

FB

Minoff

EN

VIN

GND

LX

VIN

UV &OV

OC

Pin Configurations

(TOP VIEW)

Functional Pin Description

Function Block Diagram

SOT-23-6

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6211A/B-01 March 2015

2

RT6211A/B

Detailed Description

The RT6211A/B are high-performance 500kHz 1.5A

step-down regulators with internal power switches and

synchronous rectifiers. They feature an Advanced

Constant On-Time (ACOTTM) control architecture that

provides stable operation with ceramic output

capacitors without complicated external compensation,

among other benefits. The input voltage range is from

4.5V to 18V and the output is adjustable from 0.8V to

6.3V.

The proprietary ACOTTM control scheme improves

upon other constant on-time architectures, achieving

nearly constant switching frequency over line, load, and

output voltage ranges. The RT6211A/B are optimized

for ceramic output capacitors. Since there is no internal

clock, response to transients is nearly instantaneous

and inductor current can ramp quickly to maintain

output regulation without large bulk output capacitance.

Constant On-Time (COT) Control

The heart of any COT architecture is the on-time

one-shot. Each on-time is a pre-determined “fixed”

period that is triggered by a feedback comparator. This

robust arrangement has high noise immunity and is

ideal for low duty cycle applications. After the on-time

one-shot period, there is a minimum off-time period

before any further regulation decisions can be

considered. This arrangement avoids the need to make

any decisions during the noisy time periods just after

switching events, when the switching node (LX) rises or

falls. Because there is no fixed clock, the high-side

switch can turn on almost immediately after load

transients and further switching pulses can ramp the

inductor current higher to meet load requirements with

minimal delays.

Traditional current mode or voltage mode control

schemes typically must monitor the feedback voltage,

current signals (also for current limit), and internal

ramps and compensation signals, to determine when to

turn off the high-side switch and turn on the

synchronous rectifier. Weighing these small signals in a

switching environment is difficult to do just after

switching large currents, making those architectures

problematic at low duty cycles and in less than ideal

board layouts.

Because no switching decisions are made during noisy

time periods, COT architectures are preferable in low

duty cycle and noisy applications. However, traditional

COT control schemes suffer from some disadvantages

that preclude their use in many cases. Many

applications require a known switching frequency

range to avoid interference with other sensitive circuitry.

True constant on-time control, where the on-time is

actually fixed, exhibits variable switching frequency. In

a step-down converter, the duty factor is proportional to

the output voltage and inversely proportional to the

input voltage. Therefore, if the on-time is fixed, the

off-time (and therefore the frequency) must change in

response to changes in input or output voltage.

Modern pseudo-fixed frequency COT architectures

greatly improve COT by making the one-shot on-time

proportional to V

and inversely proportional to VIN.

OUT

In this way, an on-time is chosen as approximately

what it would be for an ideal fixed-frequency PWM in

similar input/output voltage conditions. The result is a

big improvement but the switching frequency still varies

considerably over line and load due to losses in the

switches and inductor and other parasitic effects.

Another problem with many COT architectures is their

dependence on adequate ESR in the output capacitor,

making it difficult to use highly-desirable, small,

low-cost, but low-ESR ceramic capacitors. Most COT

architectures use AC current information from the

output capacitor, generated by the inductor current

passing through the ESR, to function in a way like a

current mode control system. With ceramic capacitors,

the inductor current information is too small to keep the

control loop stable, like a current mode system with no

current information.

ACOTTM Control Architecture

Making the on-time proportional to V

and inversely

OUT

proportional to VIN is not sufficient to achieve good

constant-frequency behavior for several reasons. First,

voltage drops across the MOSFET switches and

inductor cause the effective input voltage to be less

than the measured input voltage and the effective

output voltage to be greater than the measured output

voltage. As the load changes, the switch voltage drops

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6211A/B-01 March 2015 www.richtek.com

3

RT6211A/B

change causing a switching frequency variation with

load current. Also, at light loads if the inductor current

goes negative, the switch dead-time between the

synchronous rectifier turn-off and the high-side switch

turn-on allows the switching node to rise to the input

voltage. This increases the effective on-time and

causes the switching frequency to drop noticeably.

One way to reduce these effects is to measure the

actual switching frequency and compare it to the

desired range. This has the added benefit eliminating

the need to sense the actual output voltage, potentially

saving one pin connection. ACOTTM uses this method,

measuring the actual switching frequency (at SW) and

modifying the on-time with a feedback loop to keep the

average switching frequency in the desired range.

To achieve good stability with low-ESR ceramic

capacitors, ACOTTM uses a virtual inductor current

ramp generated inside the IC. This internal ramp signal

replaces the ESR ramp normally provided by the output

capacitor's ESR. The ramp signal and other internal

compensations are optimized for low-ESR ceramic

output capacitors.

ACOTTM One-shot Operation

The RT6211A/B control algorithm is simple to

understand. The feedback voltage, with the virtual

inductor current ramp added, is compared to the

reference voltage. When the combined signal is less

than the reference the on-time one-shot is triggered, as

long as the minimum off-time one-shot is clear and the

measured inductor current (through the synchronous

rectifier) is below the current limit. The on-time

one-shot turns on the high-side switch and the inductor

current ramps up linearly. After the on-time, the

high-side switch is turned off and the synchronous

rectifier is turned on and the inductor current ramps

down linearly. At the same time, the minimum off-time

one-shot is triggered to prevent another immediate

on-time during the noisy switching time and allow the

feedback voltage and current sense signals to settle.

The minimum off-time is kept short (240ns typical) so

that rapidly-repeated on-times can raise the inductor

current quickly when needed.

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6211A/B-01 March 2015

4

Discontinuous Operating Mode (RT6211A Only)

After soft-start, the RT6211B operates in fixed

frequency mode to minimize interference and noise

problems. The RT6211A uses variable-frequency

discontinuous switching at light loads to improve

efficiency. During discontinuous switching, the on-time

is immediately increased to add “hysteresis” to

discourage the IC from switching back to continuous

switching unless the load increases substantially.

The IC returns to continuous switching as soon as an

on-time is generated before the inductor current

reaches zero. The on-time is reduced back to the

length needed for 500kHz switching and encouraging

the circuit to remain in continuous conduction,

preventing repetitive mode transitions between

continuous switching and discontinuous switching.

Current Limit

The RT6211A/B current limit is a cycle-by-cycle “valley”

type, measuring the inductor current through the

synchronous rectifier during the off-time while the

inductor current ramps down. The current is

determined by measuring the voltage between Source

and Drain of the synchronous rectifier, adding

temperature compensation for greater accuracy. If the

current exceeds the current limit, the on-time one-shot

is inhibited until it drops below the current limit level. If

the output current exceeds the available inductor

current (controlled by the current limit mechanism), the

output voltage will drop. If it drops below the output

under-voltage protection level (see next section) the IC

will stop switching to avoid excessive heat.

The RT6211B also includes a negative current limit to

protect the IC against sinking excessive current and

possibly damaging the IC. If the voltage across the

synchronous rectifier indicates the negative current is

too high, the synchronous rectifier turns off until after

the next high-side on-time. The RT6211A does not sink

current and therefore does not need a negative current

limit.

Hiccup Mode

The RT6211AHGE / RT6211BHGE, use hiccup mode

UVP. When the protection function is triggered, the IC

will shut down for a period of time and then attempt to

recover automatically. Hiccup mode allows the circuit to

RT6211A/B

operate safely with low input current and power

dissipation, and then resume normal operation as soon

as the overload or short circuit is removed.

Input Under-Voltage Lockout

To protect the chip from operating at insufficient supply

voltage, the UVLO is needed. When the input voltage

of VIN is lower than the UVLO falling threshold voltage,

the device will be lockout.

Shut-down, Start-up and Enable (EN)

The enable input (EN) has a logic-low level. When VEN

is below this level the IC enters shutdown mode and

supply current drops to less than 6A. When VEN

exceeds its logic-high level the IC is fully operational.

External Bootstrap Capacitor

Connect a 0.1F low ESR ceramic capacitor between

BOOT and SW. This bootstrap capacitor provides the

gate driver supply voltage for the high side N-channel

MOSFET switch.

Over-Temperature Protection

The RT6211A/B includes an over-temperature

protection (OTP) circuitry to prevent overheating due to

excessive power dissipation. The OTP will shut down

switching operation when the junction temperature

exceeds 150C. Once the junction temperature cools

down by approximately 20C the IC will resume normal

operation. For continuous operation, provide adequate

cooling so that the junction temperature does not

exceed 150C.

UVP Protection

The RT6211A/B detects under-voltage conditions by

monitoring the feedback voltage on FB pin. The

function is enabled after approximately 1.7 times the

soft-start time. When the feedback voltage is lower

than 50% of the target voltage, the UVP comparator will

go high to turn off both internal high-side and low-side

MOSFETs.

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6211A/B-01 March 2015 www.richtek.com

5

RT6211A/B

Parameter

Symbol

Test Conditions

Min

Typ

Max

Unit

Supply Voltage

VIN Supply Input Operating

Voltage

VIN 4.5

--

18

V

Under-Voltage Lockout

Threshold

V

UVLO

3.6

3.9

4.2

Under-Voltage Lockout

Threshold Hysteresis

V

UVLO

--

340

--

mV

Supply Current

Supply Current (Shutdown)

I

SHDN

VEN = 0V

--

-- 6 µA

Supply Current (Quiescent)

IQ

VEN = 2V, VFB = 0.85V

--

0.8

--

mA

Soft-Start

Soft-Start Time

--

1000

--

µs

Enable Voltage

EN Rising Threshold

V

EN_Rising

1.38

1.5

1.62

V

EN Falling Threshold

V

EN_Falling

1.16

1.28

1.4

Absolute Maximum Ratings (Note 1)

Supply Input Voltage --------------------------------------------------------------------------------- 0.3V to 20V

Switch Voltage, SW ----------------------------------------------------------------------------------- 0.8V to (V

+ 0.3V)

IN

<10ns ----------------------------------------------------------------------------------------------------- 5V to 25V

Switch Node Voltage, LX ---------------------------------------------------------------------------- 0.3V to (V

BOOT Pin Voltage ------------------------------------------------------------------------------------ (V

Other Pins ----------------------------------------------------------------------------------------------- 0.3V to 6V

Power Dissipation, P

@ TA = 25C

D

– 0.3V) to (VIN + 6.3V)

LX

+ 0.3V)

IN

SOT-23-6 ------------------------------------------------------------------------------------------------ 0.48W

Package Thermal Resistance (Note 2)

SOT-23-6, JA ------------------------------------------------------------------------------------------ 208.2C/W

Lead Temperature (Soldering, 10 sec.) ---------------------------------------------------------- 260C

Junction Temperature -------------------------------------------------------------------------------- 150C

Storage Temperature Range ----------------------------------------------------------------------- 65C to 150C

ESD Susceptibility (Note 3)

HBM (Human Body Model) ------------------------------------------------------------------------- 2kV

Recommended Operating Conditions (Note 4)

Supply Input Voltage --------------------------------------------------------------------------------- 4.5V to 18V

Ambient Temperature Range----------------------------------------------------------------------- 40C to 85C

Junction Temperature Range ---------------------------------------------------------------------- 40C to 125C

Electrical Characteristics

(VIN = 12V, TA = 25C, unless otherwise specified)

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6211A/B-01 March 2015

6

RT6211A/B

Parameter

Symbol

Test Conditions

Min

Typ

Max

Unit

Feedback Threshold Voltage

Feedback Threshold Voltage

V

FB_TH

4.5V ≤ VIN ≤ 18V

0.788

0.8

0.812

V

Internal MOSFET

High-Side On-Resistance

R

DS(ON)_H

V

BOOT

− VLX = 4.8V

--

230

--

mΩ

Low-Side On-Resistance

R

DS(ON)_L

--

130

--

Current Limit

Current Limit

I

LIM

Valley Current

2

2.5

--

A

Switching Frequency

Switching Frequency

f

OSC

420

520

620

kHz

On-Time Timer Control

Maximum Duty Cycle

D

MAX

85

88

--

%

Minimum On Time

t

ON(MIN)

--

60

--

nS

Minimum Off Time

t

OFF(MIN)

--

240

--

Output Under Voltage Protections

UVP Trip Threshold

UVP Detect

45

50

55

%

Hysteresis

--

10

--

Thermal Shutdown

Thermal Shutdown Threshold

TSD --

150

--

°C

Thermal Shutdown Hysteresis

TSD --

20

--

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may affect

device reliability.

Note 2. JA is measured at TA = 25C on a high effective thermal conductivity four-layer test board per JEDEC 51-7.

Note 3. Devices are ESD sensitive. Handling precaution recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6211A/B-01 March 2015 www.richtek.com

7

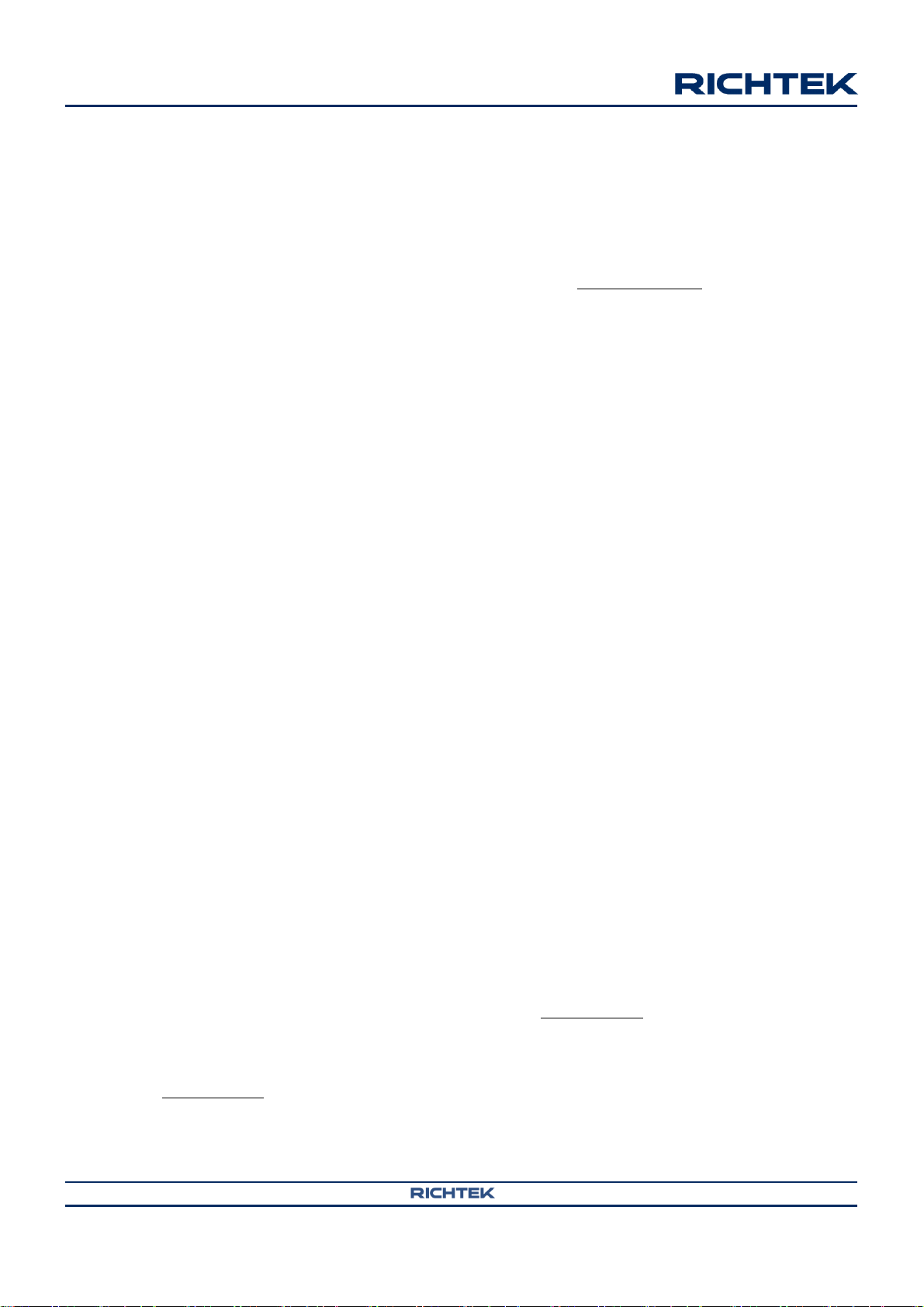

RT6211A/B

EN

RT6211A/B

FB

GND

VIN

V

IN

22μF

C

IN

BOOT

L

0.1μF

C

BOOT

22μF

C

OUT

LX

V

OUT

R1

R2

1

5

2

3

4

6

Enable

C

FF

2.2μH

12k

24k

Open

1.2V/1.5A

V

OUT

(V)

R1 (k)

R2 (k)

L (H)

C

OUT

(F)

CFF (pF)

1.05

10

32.4 2 22

--

1.2

20.5

41.2 2 22

--

1.8

40.2

32.4

3.3

22

--

2.5

40.2

19.1

4.7

22

22 to 68

3.3

40.2

13

6.5

22

22 to 68

5

40.2

7.68

6.5

22

22 to 68

Typical Application Circuit

Table 1. Suggested Component Values (VIN = 12V)

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6211A/B-01 March 2015

8

RT6211A/B

Efficiency vs. Output Current

0

10

20

30

40

50

60

70

80

90

100

0 0.3 0.6 0.9 1.2 1.5

Output Current (A)

Efficiency(%)

RT6211AH, I

OUT

= 0 to 1.5A

V

OUT

= 1.2V

V

OUT

= 5V

Output Voltage vs. Input Voltage

1.10

1.12

1.14

1.16

1.18

1.20

1.22

1.24

1.26

1.28

1.30

4 6 8 10 12 14 16 18

Input Voltage (V)

Output Voltage (V)

I

OUT

= 0.6A

I

OUT

= 0.9A

I

OUT

= 1.5A

V

OUT

= 1.2V

Output Voltage vs. Output Current

1.00

1.05

1.10

1.15

1.20

1.25

1.30

1.35

1.40

1.45

1.50

0 0.3 0.6 0.9 1.2 1.5

Output Current (A)

Output Voltage (V)

VIN = 12V

VIN = 18V

V

OUT

= 1.2V

Quiescent Current vs. Input Voltage

300

400

500

600

700

800

900

1000

1100

1200

4 6 8 10 12 14 16 18

Input Volatage (V)

Quiescent Current (μA)

1

V

OUT

= 1.2V

Frequency vs. Input Voltage

400

420

440

460

480

500

520

540

560

580

600

4 6 8 10 12 14 16 18

Input Voltage (V)

Frequency (kHz)

1

V

OUT

= 1.2V

Frequency vs. Temperature

400

420

440

460

480

500

520

540

560

580

600

-50 -25 0 25 50 75 100 125

Temperature (°C)

Frequency (kHz)

1

V

OUT

= 1.2V

VIN = 12V

VIN = 18V

Typical Operating Characteristics

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6211A/B-01 March 2015 www.richtek.com

9

RT6211A/B

VIN= 12V, V

OUT

= 1.2V,

I

OUT

= 0.75A to 1.5A, L = 2.3H

Load Transient Response

Time (100s/Div)

V

OUT

(50mV/Div)

I

OUT

(1A/Div)

VIN= 12V, V

OUT

= 5V,

I

OUT

= 0.75A to 1.5A, L = 6.8H

Load Transient Response

Time (100s/Div)

V

OUT

(200mV/Div)

I

OUT

(1A/Div)

VIN= 12V, V

OUT

= 1.2V, I

OUT

= 0.5A

Output Ripple Voltage

Time (1s/Div)

V

OUT

(10mV/Div)

I

LX

(500mA/Div)

V

LX

(5V/Div)

VIN= 12V, V

OUT

= 5V, I

OUT

= 1.5A, L = 6.8H

Output Ripple Voltage

Time (1s/Div)

V

LX

(5V/Div)

V

OUT

(10mV/Div)

I

LX

(500mA/Div)

VIN= 12V, V

OUT

= 5V, I

OUT

= 1.5A

Power On from EN

Time (500s/Div)

V

EN

(5V/Div)

V

OUT

(2V/Div)

VIN= 12V, V

OUT

= 1.2V, I

OUT

= 1.5A

Power Off from EN

Time (10s/Div)

V

EN

(5V/Div)

I

LX

(1A/Div)

V

LX

(20V/Div)

V

OUT

(1V/Div)

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6211A/B-01 March 2015

10

RT6211A/B

OUT IN OUT

IN SW L

V V V

L =

V f I

OUT IN OUT

L

L L(PEAK) OUT(MAX)

IN SW

V V V

I

I = and I = I

V f L 2

1.2 12 1.2

L 4.8μH

12 500kHz 0.45A

L

1.2 12 1.2

I = = 0.45A

12 500kHz 4.8μH

L(PEAK)

0.45A

and I = 1.5A = 1.725A

2

OUT

IN

RMS OUT(MAX)

IN OUT

V

V

I = I 1

VV

Application Information

Inductor Selection

Selecting an inductor involves specifying its inductance

and also its required peak current. The exact inductor

value is generally flexible and is ultimately chosen to

obtain the best mix of cost, physical size, and circuit

efficiency. Lower inductor values benefit from reduced

size and cost and they can improve the circuit's

transient response, but they increase the inductor

ripple current and output voltage ripple and reduce the

efficiency due to the resulting higher peak currents.

Conversely, higher inductor values increase efficiency,

but the inductor will either be physically larger or have

higher resistance since more turns of wire are required

and transient response will be slower since more time

is required to change current (up or down) in the

inductor. A good compromise between size, efficiency,

and transient response is to use a ripple current (IL)

about 20% to 50% of the desired full output load

current. Calculate the approximate inductor value by

selecting the input and output voltages, the switching

frequency (fSW), the maximum output current

(I

OUT(MAX)

) and estimating a IL as some percentage of

that current.

meet the desired output current. If needed, reduce the

inductor ripple current (IL) to increase the average

inductor current (and the output current) while ensuring

that I

L(PEAK)

does not exceed the upper current limit

level.

For best efficiency, choose an inductor with a low DC

resistance that meets the cost and size requirements.

For low inductor core losses some type of ferrite core is

usually best and a shielded core type, although

possibly larger or more expensive, will probably give

fewer EMI and other noise problems.

Considering the Typical Operating Circuit for 1.2V

output at 1.5A and an input voltage of 12V, using an

inductor ripple of 0.45A (30%), the calculated

inductance value is :

The ripple current was selected at 0.45A and, as long

as we use the calculated 4.8H inductance, that should

be the actual ripple current amount. The ripple current

and required peak current as below :

Once an inductor value is chosen, the ripple current

(IL) is calculated to determine the required peak

inductor current.

To guarantee the required output current, the inductor

needs a saturation current rating and a thermal rating

that exceeds I

L(PEAK)

. These are minimum requirements.

To maintain control of inductor current in overload and

short circuit conditions, some applications may desire

current ratings up to the current limit value. However,

the IC's output under-voltage shutdown feature make

this unnecessary for most applications.

I

L(PEAK)

should not exceed the minimum value of IC's

upper current limit level or the IC may not be able to

For the 4.8H value, the inductor's saturation and

thermal rating should exceed 1.725A. Since the actual

value used was 4.8H and the ripple current exactly

0.45A, the required peak current is 1.725A.

Input Capacitor Selection

The input filter capacitors are needed to smooth out the

switched current drawn from the input power source

and to reduce voltage ripple on the input. The actual

capacitance value is less important than the RMS

current rating (and voltage rating, of course). The RMS

input ripple current (I

) is a function of the input

RMS

voltage, output voltage, and load current :

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6211A/B-01 March 2015 www.richtek.com

11

RT6211A/B

RIPPLE RIPPLE(ESR) RIPPLE(C)

RIPPLE(ESR) L ESR

L

RIPPLE(C)

OUT SW

V = V V

V = I R

I

V =

8 C f

RIPPLE(ESR)

RIPPLE(C)

RIPPLE

V = 0.45A 5m = 2.25mV

0.45A

V = = 2.557mV

8 44μF 500kHz

V = 2.25mV 2.557mV = 4.807mV

11

OUT

IN

3 5.23 10

C

VL

Ceramic capacitors are most often used because of

their low cost, small size, high RMS current ratings, and

robust surge current capabilities. However, take care

when these capacitors are used at the input of circuits

supplied by a wall adapter or other supply connected

through long, thin wires. Current surges through the

inductive wires can induce ringing at the RT6211A/B

input which could potentially cause large, damaging

voltage spikes at VIN. If this phenomenon is observed,

some bulk input capacitance may be required. Ceramic

capacitors (to meet the RMS current requirement) can

be placed in parallel with other types such as tantalum,

electrolytic, or polymer (to reduce ringing and

overshoot).

Choose capacitors rated at higher temperatures than

required. Several ceramic capacitors may be paralleled

to meet the RMS current, size, and height requirements

of the application. The typical operating circuit uses two

10F and one 0.1F low ESR ceramic capacitors on

the input.

Output Capacitor Selection

The RT6211A/B are optimized for ceramic output

capacitors and best performance will be obtained using

them. The total output capacitance value is usually

determined by the desired output voltage ripple level

and transient response requirements for sag

(undershoot on positive load steps) and soar

(overshoot on negative load steps).

Output Ripple

Output ripple at the switching frequency is caused by

the inductor current ripple and its effect on the output

capacitor's ESR and stored charge. These two ripple

components are called ESR ripple and capacitive ripple.

Since ceramic capacitors have extremely low ESR and

relatively little capacitance, both components are

similar in amplitude and both should be considered if

ripple is critical.

For the Typical Operating Circuit for 1.2V output and an

inductor ripple of 0.45A, with 2 x 22F output

capacitance each with about 5m ESR including PCB

trace resistance, the output voltage ripple components

are :

Output Capacitors Stability Criteria

The e RT6211A/B's ACOTTM control architecture uses

an internal virtual inductor current ramp and other

compensation that ensures stability with any

reasonable output capacitor. The internal ramp allows

the IC to operate with very low ESR capacitors and the

IC is stable with very small capacitances. Therefore,

output capacitor selection is nearly always a matter of

meeting output voltage ripple and transient response

requirements, as discussed in the previous sections.

For the sake of the unusual application where ripple

voltage is unimportant and there are few transients

(perhaps battery charging or LED lighting) the stability

criteria are discussed below.

The equations giving the minimum required

capacitance for stable operation include a term that

depends on the output capacitor's ESR. The higher the

ESR, the lower the capacitance can be and still ensure

stability. The equations can be greatly simplified if the

ESR term is removed by setting ESR to zero. The

resulting equation gives the worst-case minimum

required capacitance and it is usually sufficiently small

that there is usually no need for the more exact

equation :

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6211A/B-01 March 2015

12

The worst-case high capacitance requirement is for low

VIN and small inductance, so a 12V to 1.2V converter

is used for an example. Using the inductance equation

in a previous section to determine the required

inductance :

RT6211A/B

1.2 12 1.2

L = = 5.4μH

12 500kHz 0.4A

11

OUT

OUT

3 5.23 10

C

12V 5.4μH

C 2.42μF

RT6211A/B

GND

FB

R1

R2

V

OUT

C

ff

BW

ff

1

C

2 3.1412 R1 BW 0.8

RT6211A/B

EN

GND

V

IN

R

EN

C

EN

EN

RT6211A/B

EN

GND

100k

V

IN

R

EN

Q1

Enable

RT6211A/B

EN

GND

V

IN

R

EN1

R

EN2

Therefore, the required minimum capacitance for the

12V to 1.2V converter is :

Feed-forward Capacitor (Cff)

The RT6211A/B are optimized for ceramic output

capacitors and for low duty cycle applications. However

for high-output voltages, with high feedback attenuation,

the circuit's response becomes over-damped and

transient response can be slowed. In high-output

voltage circuits (V

> 3.3V) transient response is

OUT

improved by adding a small “feed-forward” capacitor

(Cff) across the upper FB divider resistor (Figure 1), to

increase the circuit's Q and reduce damping to speed

up the transient response without affecting the

steady-state stability of the circuit. Choose a suitable

capacitor value that following below step.

Get the BW the quickest method to do transient

response form no load to full load. Confirm the

damping frequency. The damping frequency is BW.

Enable Operation (EN)

For automatic start-up the high-voltage EN pin can be

connected to VIN, through a 100k resistor. Its large

hysteresis band makes EN useful for simple delay and

timing circuits. EN can be externally pulled to VIN by

adding a resistor-capacitor delay (REN and CEN in

Figure 2). Calculate the delay time using EN's internal

threshold where switching operation begins.

An external MOSFET can be added to implement

digital control of EN when no system voltage above 2V

is available (Figure 3). In this case, a 100k pull-up

resistor, REN, is connected between VIN and the EN

pin. MOSFET Q1 will be under logic control to pull

down the EN pin. To prevent enabling circuit when VIN

is smaller than the VOUT target value or some other

desired voltage level, a resistive voltage divider can be

placed between the input voltage and ground and

connected to EN to create an additional input under

voltage lockout threshold (Figure 4).

Figure 1. Cff Capacitor Setting

C

can be calculated base on below equation :

ff

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6211A/B-01 March 2015 www.richtek.com

Figure 2. External Timing Control

Figure 3. Digital Enable Control Circuit

Figure 4. Resistor Divider for Lockout Threshold

Setting

13

RT6211A/B

RT6211A/B

GND

FB

R1

R2

V

OUT

OUT REF

REF

R2 (V V )

R1

V

LX

BOOT

5V

0.1μF

RT6211A/B

Output Voltage Setting

Set the desired output voltage using a resistive divider

from the output to ground with the midpoint connected

to FB. The output voltage is set according to the

following equation :

V

= 0.8V x (1 + R1 / R2)

OUT

Figure 5. Output Voltage Setting

Place the FB resistors within 5mm of the FB pin.

Choose R2 between 10k and 100k to minimize

power consumption without excessive noise pick-up

and calculate R1 as follows :

For output voltage accuracy, use divider resistors with

1% or better tolerance.

External BOOT Bootstrap Diode

When the input voltage is lower than 5.5V it is

recommended to add an external bootstrap diode

between VIN (or VINR) and the BOOT pin to improve

enhancement of the internal MOSFET switch and

improve efficiency. The bootstrap diode can be a low

cost one such as 1N4148 or BAT54.

External BOOT Capacitor Series Resistance

The internal power MOSFET switch gate driver is

optimized to turn the switch on fast enough for low

power loss and good efficiency, but also slow enough

to reduce EMI. Switch turn-on is when most EMI occurs

since VLX rises rapidly. During switch turn-off, LX is

discharged relatively slowly by the inductor current

during the dead time between high-side and low-side

switch on-times. In some cases it is desirable to reduce

EMI further, at the expense of some additional power

dissipation. The switch turn-on can be slowed by

placing a small (<47) resistance between BOOT and

the external bootstrap capacitor. This will slow the

high-side switch turn-on and VLX's rise. To remove the

resistor from the capacitor charging path (avoiding poor

enhancement due to undercharging the BOOT

capacitor), use the external diode shown in Figure 6 to

charge the BOOT capacitor and place the resistance

between BOOT and the capacitor/diode connection.

Figure 6. External Bootstrap Diode

Thermal Considerations

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and

difference between junction and ambient temperature.

The maximum power dissipation can be calculated by

the following formula :

P

where T

TA is the ambient temperature, and

D(MAX)

= (T

J(MAX)

TA) / JA

J(MAX)

is the maximum junction temperature,

is the junction to

JA

ambient thermal resistance.

For recommended operating condition specifications,

the maximum junction temperature is 125C. The

junction to ambient thermal resistance, JA, is layout

dependent. For SOT-23-6 package, the thermal

resistance, JA, is 208.2C/W on a standard four-layer

thermal test board. The maximum power dissipation at

TA = 25C can be calculated by the following formula :

P

= (125C 25C) / (208.2C/W) = 0.48W for

D(MAX)

SOT-23-6 package

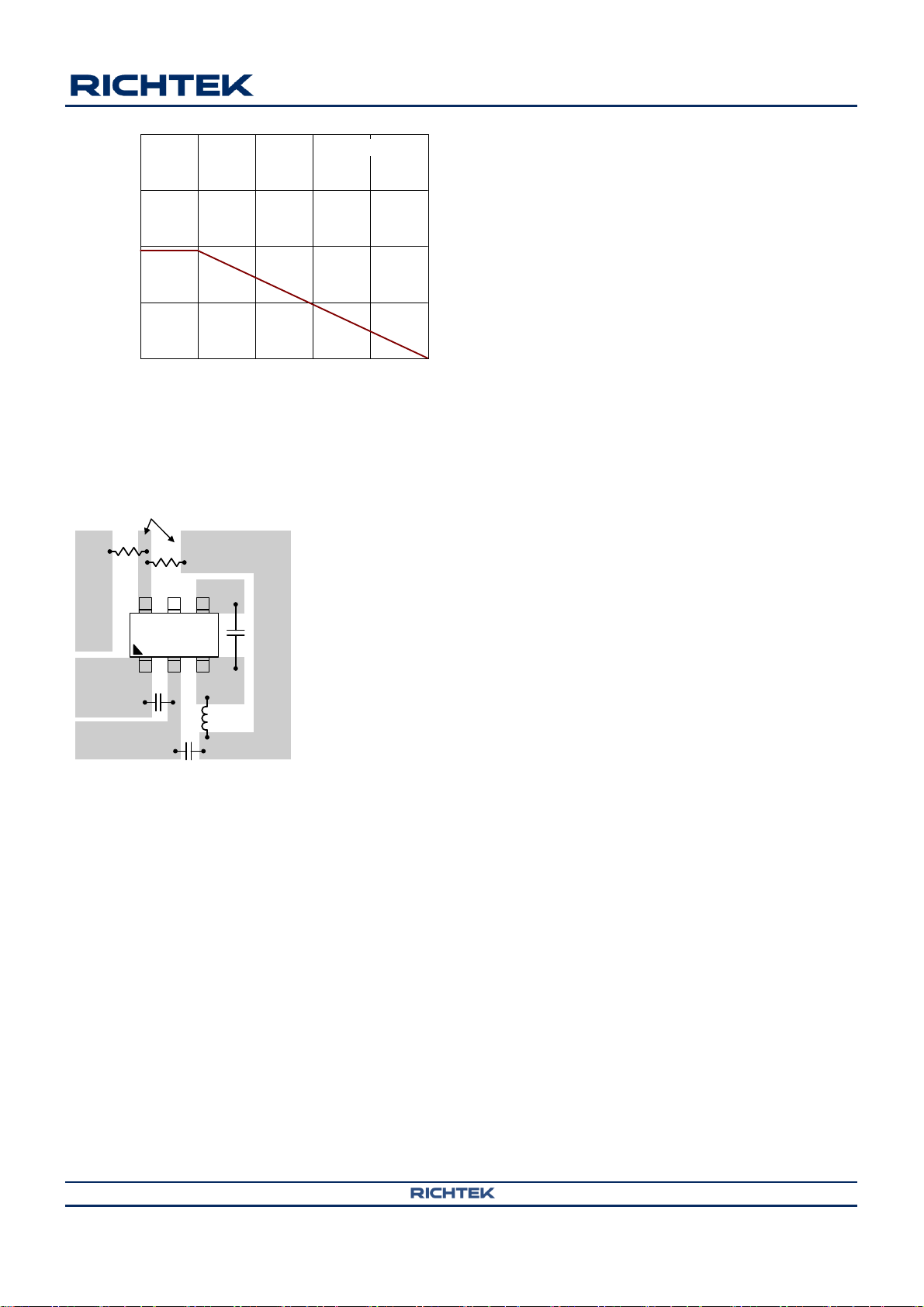

The maximum power dissipation depends on the

operating ambient temperature for fixed T

J(MAX)

and

thermal resistance, JA. The derating curve in Figure 7

allows the designer to see the effect of rising ambient

temperature on the maximum power dissipation.

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6211A/B-01 March 2015

14

RT6211A/B

V

OUT

GND

VIN

GND

LX

FB

EN BOOT

4

2 3

56

Place the feedback as close

to the IC as possible.

R1

R2

C

BOOT

L

V

OUT

GND

V

IN

C

IN

C

OUT

Place the input and output capacitors

as close to the IC as possible.

LX should be connected

to inductor by wide and

short trace, and keep

sensitive components

away from this trace.

0.00

0.25

0.50

0.75

1.00

0 25 50 75 100 125

Ambient Temperature (°C)

Maximum Power Dissipation (W)

1

Four-Layer PCB

Figure 7. Derating Curve of Maximum Power

Dissipation

Figure 8. PCB Layout Guide

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6211A/B-01 March 2015 www.richtek.com

15

RT6211A/B

Symbol

Dimensions In Millimeters

Dimensions In Inches

Min

Max

Min

Max

A

0.889

1.295

0.031

0.051

A1

0.000

0.152

0.000

0.006

B

1.397

1.803

0.055

0.071

b

0.250

0.560

0.010

0.022

C

2.591

2.997

0.102

0.118

D

2.692

3.099

0.106

0.122

e

0.838

1.041

0.033

0.041

H

0.080

0.254

0.003

0.010

L

0.300

0.610

0.012

0.024

Outline Dimension

SOT-23-6 Surface Mount Package

Richtek Technology Corporation

14F, No. 8, Tai Yuen 1st Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot assume

responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be accurate and

reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may

result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

Copyright © 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6211A/B-01 March 2015

16

Loading...

Loading...