Rheem RA1460AJ1NA, RA1448AJ1NA, RA1442AJ1NA, RA1436AJ1NA, RA1430AJ1NA Installation Instructions Manual

...

WARNING:

earth friendly refrigerant

e

arthry r

dly

n

fr

RECOGNIZE THIS SYMBOL

AS AN INDICATION OF

IMPORTANT SAFETY

INFORMATION

WARNING

THESE INSTRUCTIONS

ARE INTENDED AS AN AID

TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR

PROPER INSTALLATION,

ADJUSTMENT, AND

OPERA TION OF THIS

UNIT . READ THESE

INSTRUCTIONS

THOROUGHLY

BEFORE ATTEMPTING

INSTALLATION OR

OPERATION. FAILURE

TO FOLLO W THESE

INSTRUCTIONS MAY

RESULT IN IMPROPER

INSTALLATION,

ADJUSTMENT, SERVICE,

OR MAINTENANCE

POSSIBLY RESULTING IN

FIRE, ELECTRICAL SHOCK,

PROPERTY DAMAGE,

PERSONAL INJURY, OR

DEATH.

AIR COOLED

CONDENSING UNITS

INSTALLATION INSTRUCTIONS

RA14 MODEL SERIES – 14 SEER

FEATURING INDUSTRY STANDARD

R-410A REFRIGERANT

Do not destroy this manual.

Please read carefully

and keep in a safe place

for future reference by a

serviceman.

[ ] indicates metric conversions.

92-104921-01-01 (11/14) Printed in USA

CONTENTS

Important

Safety Information ��������������������������������������������� 3

General Information ����������������������������������������4-6

Checking Product Received ����������������������������������������4

Contents

Application �������������������������������������������������������������������4

Electrical and Physical Data �����������������������������������������5

Specifications ���������������������������������������������������������������6

Proper Installation ��������������������������������������������������������6

Installation ���������������������������������������������������� 7-17

Choosing a Location ����������������������������������������7-8

Operational Issues��������������������������������������������������������7

Corrosive Environment �������������������������������������������������7

For Units With

Space Limitations ���������������������������������������������������������8

Customer Satisfaction Issues ��������������������������������������8

Unit Mounting ���������������������������������������������������������������8

Factory-Preferred

Tie-Down Method���������������������������������������������������������8

Tools and Refrigerant

Tools Required for Installing and

Servicing R-410A Models ��������������������������������������������9

Specifications of R-410A ���������������������������������������������9

Quick-Reference

Guide for R-410A ���������������������������������������������������������9

Replacement Units �������������������������������������������10

Indoor Coil ��������������������������������������������������������10

Location ����������������������������������������������������������������������10

Interconnecting Tubing �������������������������������� 10-20

Vapor and Liquid Lines ����������������������������������������������10

Maximum Length of Lines ������������������������������������������10

Outdoor Unit Installed

Above or Below Indoor Coil ��������������������������������� 13-15

Tubing Installation ������������������������������������������������ 18-19

Tubing Connections ��������������������������������������������� 19-20

Leak Testing ���������������������������������������������������������������20

Wiring ���������������������������������������������������������21-22

Control Wiring ������������������������������������������������������������21

Conventional 24 VAC

Thermostat Control Wiring �����������������������������������������21

Thermostat Wiring Diagrams ������������������������������� 21-22

Power Wiring �������������������������������������������������������������� 22

Grounding ������������������������������������������������������������������� 22

���������������������������������������� 9

Start-Up

Start-Up ����������������������������������������������������������������������23

Checking Airflow ��������������������������������������������������������23

Evacuation Procedure ����������������������������������������������� 24

Final Leak Testing �������������������������������������������������������24

Checking

Refrigerant Charge �������������������������������������� 25-27

Charging Units

With R-410A Refrigerant ��������������������������������������������25

Confirm ID Airflow

and Coils Are Clean ���������������������������������������������������25

Measurement Device Setup ��������������������������������������� 25

Charging by Weight ���������������������������������������������������� 25

Gross Charging by Pressures ������������������������������������ 26

Final Charge by Subcooling ��������������������������������������� 26

Finishing Up Installation ��������������������������������������������� 27

Components and Controls �������������������������� 28-29

Compressor

Crankcase Heat (CCH) ��������������������������������������28

High- and Low-Pressure

Controls (HPC and LPC) ������������������������������������28

Hard-Start Components ������������������������������������29

Accessories ����������������������������������������������������� 29

Time-Delay Control ����������������������������������������������������29

Hard Start Components ���������������������������������������������29

Low Ambient Control (LAC) ���������������������������������������29

Diagnostics ������������������������������������������������� 30-38

Cooling Mechanical

Checks Flowchart ������������������������������������������������������30

General Troubleshooting Chart ����������������������������������32

Service Analyzer Charts ��������������������������������������� 33-37

Cooling/Heating Tips ��������������������������������������������������38

Wiring Diagrams �����������������������������������������39-40

������������������������������������������������������23–27

2

IMPORTANT SAFETY INFORMATION

WARNINGS:

• These instructions are intended as an aid to

qualified, licensed service personnel for proper

installation, adjustment, and operation of this

unit� Read these instructions thoroughly before

attempting installation or operation� Failure to

follow these instructions may result in improper

installation, adjustment, service, or maintenance

possibly resulting in fire, electrical shock,

property damage, personal injury, or death.

• The unit must be permanently grounded. Failure

to do so can cause electrical shock resulting in

severe personal injury or death.

• Turn off electric power at the fuse box or service

panel before making any electrical connections.

• Complete the ground connection before making

line voltage connections. Failure to do so can

result in electrical shock, severe personal injury,

or death.

• Disconnect all power to unit before starting

maintenance. Failure to do so can cause

electrical shock resulting in severe personal

injury or death.

• Never assume the unit is properly wired and/or

grounded. Always test the unit cabinet with a

noncontact voltage detector available at most

electrical supply houses or home centers before

removing access panels or coming into contact

with the unit cabinet.

• Do not use oxygen to purge lines or pressurize

system for leak test. Oxygen reacts violently with

oil, which can cause an explosion resulting in

severe personal injury or death.

• The top of the scroll compressor shell is hot�

Touching the compressor top may result in serious

personal injury�

• The manufacturer’s warranty does not cover

any damage or defect to the unit caused by the

attachment or use of any components, accessories,

or devices (other than those authorized by the

manufacturer) into, onto, or in conjunction with

the heat pump� You should be aware that the

use of unauthorized components, accessories,

or devices may adversely affect the operation

of the heat pump and may also endanger life

and property. The manufacturer disclaims any

responsibility for such loss or injury resulting

from the use of such unauthorized components,

accessories, or devices�

CAUTIONS:

• R-410A systems operate at approximately 60%

higher pressures (1�6 times) than R-22 systems� Do

not use R-22 service equipment or components on

R-410A equipment� Use appropriate care when using

this refrigerant� Failure to exercise care may result in

equipment damage or personal injury�

• Only match this outdoor unit with a matched indoor

coil or air handler approved for use with this outdoor

unit per the unit manufacturer’s specification sheet�

The use of unmatched coils or air handler will likely

result in a charge imbalance between the cooling

and heating modes which can cause unsatisfactory

operation including a high-pressure switch lockout

condition�

• Only use indoor coils approved for use on R-410A

systems� An R-22 coil will have a TXV or fixed

restrictor device that is not designed to operate

properly in an R-410A system and will result in

serious operational issues� The R-22 coil could also

contain mineral oil which is incompatible with the

POE oil used in R-410A systems and could result in

reliability issues with the compressor and TXVs�

• When coil is installed over a finished ceiling and/or

living area, it is required that a secondary sheet metal

condensate pan be constructed and installed under

the entire unit� Failure to do so can result in property

damage�

• The compressor has an internal overload protector�

Under some conditions, it can take up to 2 hours for

this overload to reset� Make sure overload has had

time to reset before condemning the compressor�

Safety

3

GENERAL INFORMATION

WARNING:

Improper installation, or installation not made in

accordance with these instructions, can result

in unsatisfactory operation and/or dangerous

conditions and can cause the related warranty

not to apply.

The condensing unit is designed to operate with

standard 24 VAC thermostats and air handlers or

gas furnaces�

This installation instruction manual contains

complete instructions for installation and setup

General Information

using conventional 24 VAC controls� Please refer

to the manufacturer’s specification sheets for

complete performance data, thermostat, and

accessory listings�

The information contained in this manual has

been prepared to assist in the proper installation,

operation, and maintenance of the air conditioning

system�

Read this manual and any instructions packaged

with separate equipment required to make up the

system prior to installation� Homeowner should

retain this manual for future reference�

To achieve optimum efficiency and capacity,

the matching indoor cooling coils listed in the

manufacturer’s specification sheet should be used�

Checking Product Received

Upon receiving unit, inspect it for any shipping

damage� Claims for damage, either apparent or

concealed, should be filed immediately with the

shipping company� Check model number, electrical

characteristics, and accessories to determine if they

are correct� Check system components (indoor coil,

outdoor unit, air handler/furnace, etc�) to make sure

they are properly matched�

Application

Before specifying any air conditioning equipment,

a survey of the structure and a heat gain

calculation must be made� A cooling heat gain

calculation determines the amount of heat needed

to be removed� A heat gain calculation also

calculates the extra heat load caused by sunlight

and by humidity removal� These factors must be

considered before selecting an air conditioning

system to provide year-round comfort� The Air

Conditioning Contractors of America (ACCA)

J Manual method of load calculation is one

recognized procedure for determining the heating

and cooling load�

After the proper equipment combination has

been selected, satisfying both sensible and

latent requirements, the system must be properly

installed� Only then can the unit provide the

comfort it was designed to provide�

There are several factors that installers must

consider�

• Outdoor unit location

• Indoor unit blower speed and airflow

• Proper equipment evacuation

• Supply and return air duct design and sizing

• Refrigerant charge

• System air balancing

• Diffuser and return air grille location and sizing

4

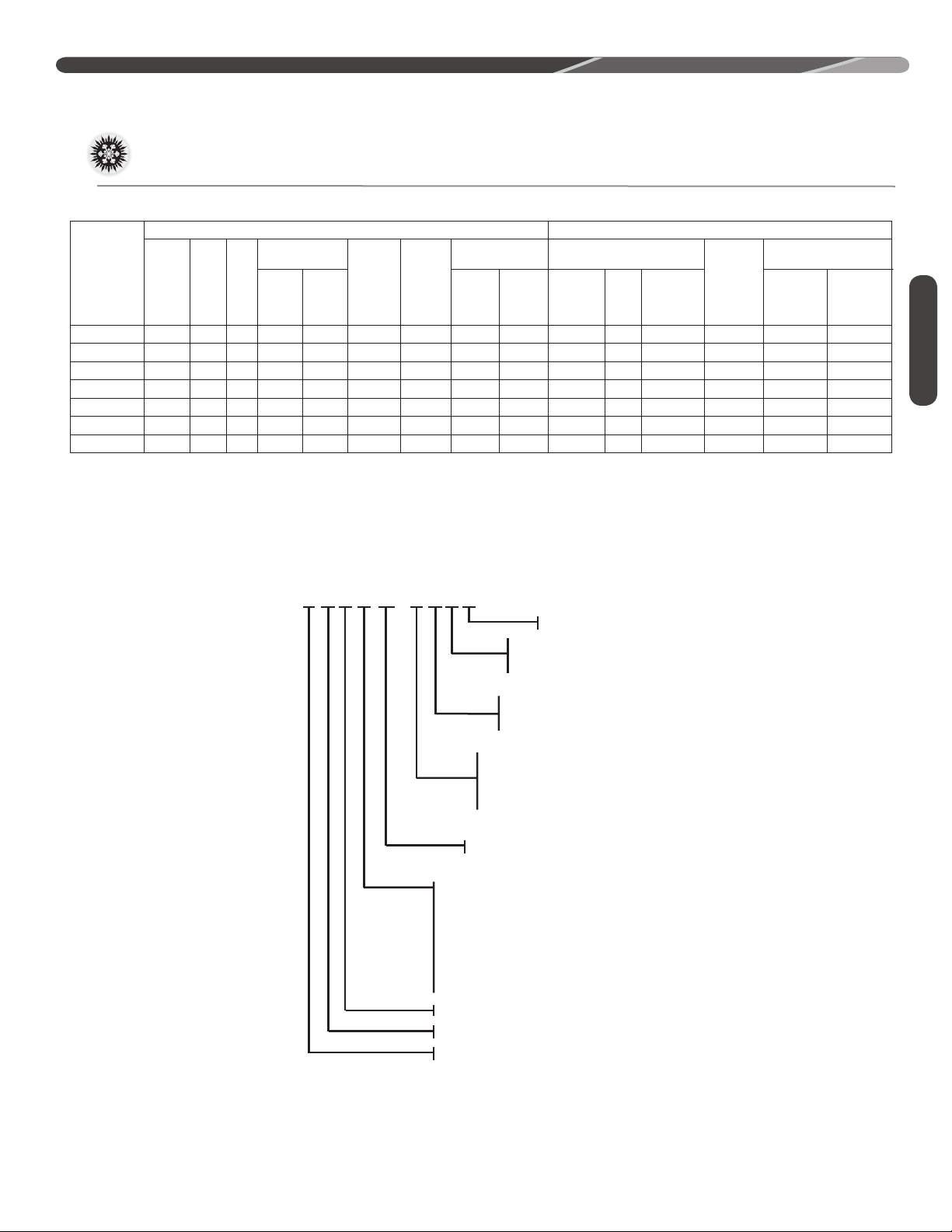

GENERAL INFORMATION

Electrical and Physical Data

PHYSICALELECTRICAL

Circuit

Fuse or HACR Circuit

Breaker

Minimum

Maximum

Amperes

Amperes

20/20

25/25

25/25

30/30

40/40

45/45

40/40 21.54 [2.00] 1 4139 [1953] 168 [4762] 202 [91.6] 209 [94.8]

50/50

Face

Area Sq.

Ft [m]

No.

Rows

CFM [L/s]

Refrig.

Per

Circuit

(oz.) [g]

Compressor

Model Number

RA1418AJ1NA 208-230 160 9.7/9.7 46.00.60 13 20/209.06 [0.84] 1 2225 [1050] 74 [2097] 122 [55.3] 129 [58.5]

RA1424AJ1NA 208-230 16011.2/11.2 60.80.70 15 20/20 11.14 [1.03] 1 2505 [1182] 78.4 [2222] 125 [56.7] 132 [59.9]

RA1430AJ1NA 208-230 16012.8/12.8 64.00.70 17 20/20 12.15 [1.13] 1 2605 [1229] 93.0 [2636] 141 [64.0] 148 [67.1]

RA1436AJ1NA 208-230 16014.1/14.1 77.00.60 19 25/25 14.82 [1.38] 1 3104 [1464] 112 [3175] 150 [68.0] 157 [71.2]

RA1442AJ1NA 208-230 16017.9/17.9 112.01.00 24 30/30 16.15 [1.5]13954 [1866] 125 [3543] 189 [58.7] 196 [88.9]

RA1448AJ1NA 208-230 16019.9/19.9 109.01.00 26 35/35 18.84 [1.75] 1 4264 [2012] 135 [3827] 192 [87.1] 199 [90.3]

RA1460AJ1NA 208-230 16023.7/23.7 152.51.00 31

Voltage Phase Freq

Rated

Load

Amperes

(RLA)

Locked

Rotor

Amperes

(LRA)

Fan Motor

Full Load

Amperes

(FLA)

Minimum

Ampacity

Amperes

Net Lbs.

[kg]

WeightOutdoor Coil

Shipping

Lbs. [kg]

General Information

UNIT MODEL NUMBER EXPLANATION

R

24

A

14

AJ1NA

MINOR SERIES

TYPE

C - COMMUNICATING

N - NON-COMM

TYPE

1 - SINGLE STAGE

VOLTAGE

J= 1 PH, 208-230/60

C= 3 PH, 208-230/60

D= 3 PH, 460/60

MAJOR SERIES

CAPACITY

18 = 18,000 BTU/HR [5.28 kW]

24 = 24,000 BTU/HR [7.03 kW]

30 = 30,000 BTU/HR [8.79 kW]

36 = 36,000 BTU/HR [10.55 kW]

42 = 42,000 BTU/HR [12.31 kW]

48 = 48,000 BTU/HR [14.07 kW]

60 = 60,000 BTU/HR [17.58 kW]

SEER

HEAT PUMP

BRAND

5

GENERAL INFORMATION

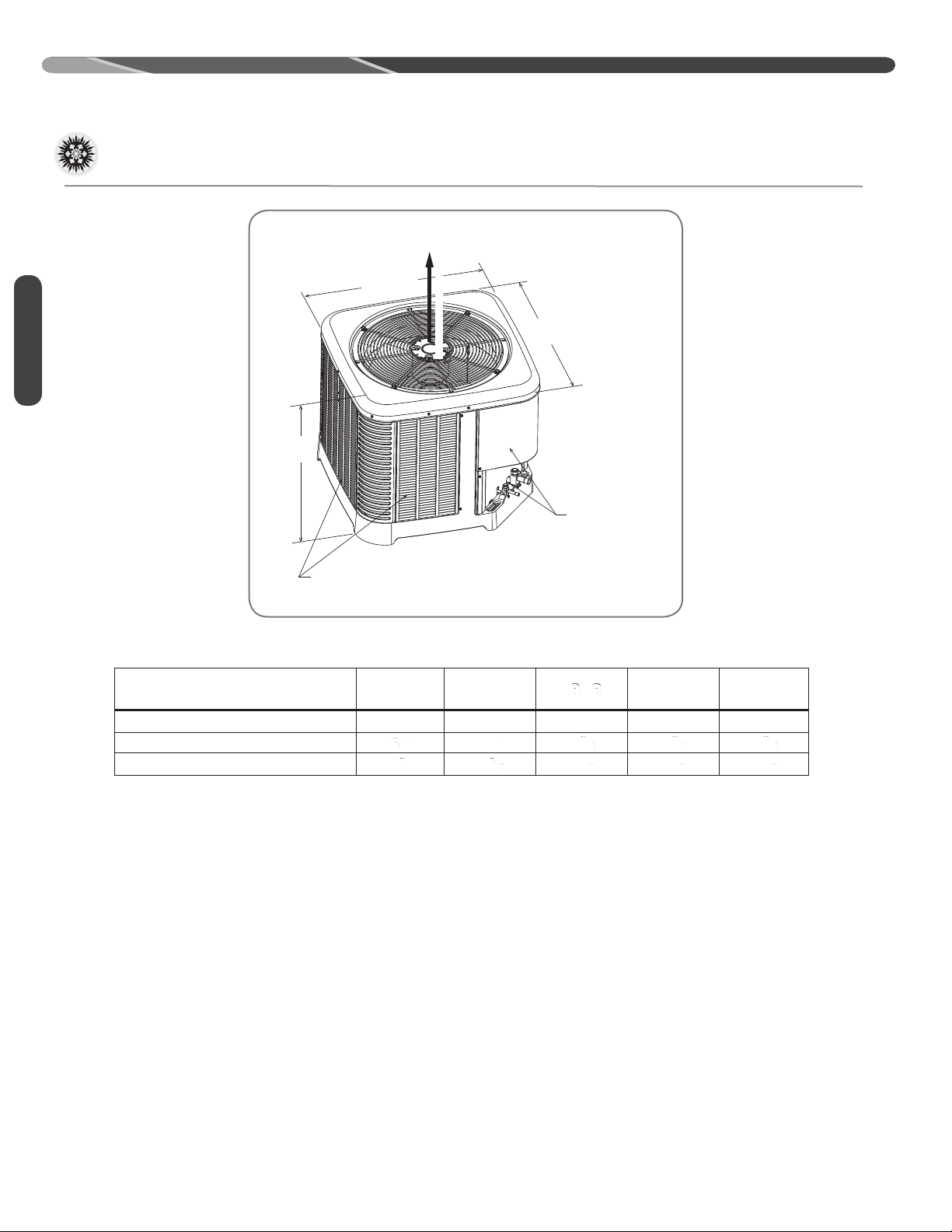

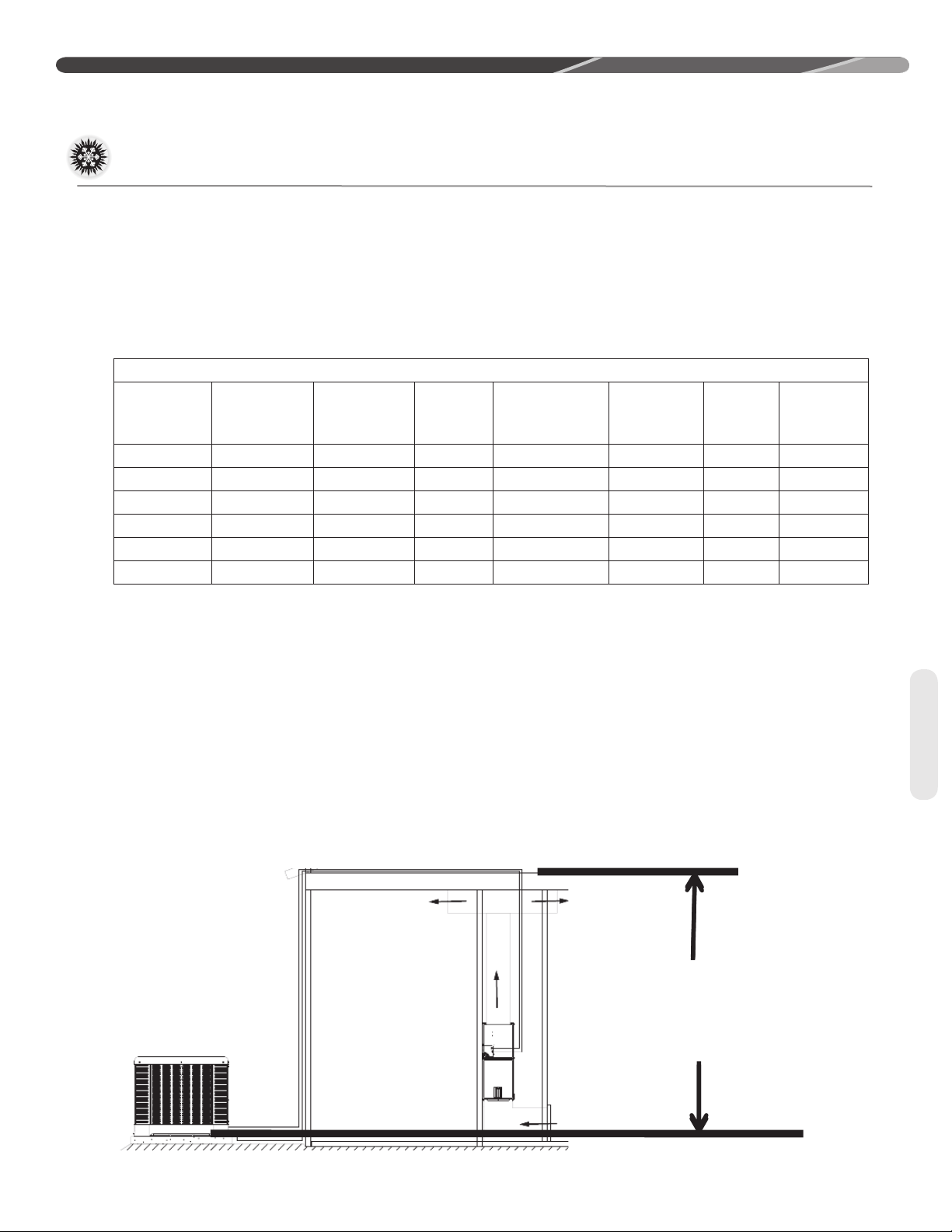

“ L”

“W”

“H”

A

I

R

D

I

S

C

H

A

R

G

E

ALLOW 60” [1524mm]

OF CLEARANCE

AIR INLET LOUVERS ALLOW

6” [152mm] Min. OF CLEARANCE ALL SIDES

12” [305mm] RECCOMMENDED

SERVICE PANELS/

INLET CONNECTIONS / HIGH & LOW

VOLTAGE ACCESS

ALLOW 24” [ 610 mm] OF CLEARANCE

ST-A1226-02-00

DIMENSIONAL DATA

Specifications

General Information

AIR INLET LOUVERS ALLOW

6" [152 mm] OF CLEARANCE ALL SIDES

12" [305 mm] RECOMMENDED

ALLOW 60" [1524mm] OF

CLEARANCE

SERVICE PANELS/

INLET CONNECTIONS /

HIGH & LOW VOLTAGE

ACCESS ALLOW

24" [610 mm] OF

CLEARANCE

CONDENSING UNIT MODEL

LENGTH “H” (INCHES)

LENGTH “L” (INCHES)

WIDTH “W” (INCHES)

Proper Installation

Proper sizing and installation of this equipment is

critical to achieve optimal performance� Use the

information in this Installation Instruction Manual

and reference the applicable manufacturer’s

specification sheet when installing this product�

IMPORTANT: This product has been

designed and manufactured to meet ENERGY

STAR criteria for energy efficiency when matched

with appropriate indoor components� However,

proper refrigerant charge and proper airflow are

critical to achieve rated capacity and efficiency�

Installation of this product should follow the

manufacturer’s refrigerant charging and airflow

instructions� Failure to confirm proper charge

and airflow may reduce energy efficiency and

shorten equipment life�

RA14

0

18, 24

25

19" 19" 29"23" 33"

29.75

351⁄2" 401⁄2" 443⁄8"443⁄8" 443⁄8"

29.75

243⁄4"

18

0

30

27

29.75

29.75

275⁄8"

36, 42

27

33.75

33.75

49043/037 060

48

31

33.75

33.75

311⁄2"311⁄2" 311⁄2"

35.75

35.75

MATCH ALL COMPONENTS:

• OUTDOOR UNIT

• INDOOR COIL

• INDOOR AIR HANDLER/FURNACE

• REFRIGERANT LINES

• INDOOR THERMOSTAT

60

35

6

Choosing a Location

INSTALLATION

IMPORTANT:

national building codes and ordinances for special

installation requirements� Following location

information will provide longer life and simplified

servicing of the outdoor unit�

Consult local and

NOTICE: These units must be installed

outdoors� No ductwork can be attached, or

other modifications made, to the discharge grille�

Modifications will affect performance or operation�

Operational Issues

IMPORTANT: Locate the unit

in a manner that will not prevent, impair, or

compromise the performance of other equipment

installed in proximity to the unit� Maintain all

required minimum distances to gas and electric

meters, dryer vents, and exhaust and inlet

openings� In the absence of national codes or

manufacturers’ recommendations, local code

recommendations and requirements will take

precedence�

• Refrigerant piping and wiring should be properly

sized and kept as short as possible to avoid

capacity losses and increased operating costs�

• Locate the unit where water runoff will not create

a problem with the equipment� Position the unit

away from the drip edge of the roof whenever

possible� Units are weatherized, but can be

affected by the following:

• Water pouring into the unit from the junction

of rooflines, without protective guttering�

Large volumes of water entering the unit while

in operation can impact fan blade or motor

life, and coil damage may occur if moisture

cannot drain from the unit under freezing

conditions�

• Closely follow the clearance recommendations

on page 8�

• 24" [61.0 cm] to the service panel access

• 60" [152.4 cm] above fan discharge (unit top)

to prevent recirculation

• 6" [15.2 cm] to coil grille air inlets

with 12" [30.5 cm] minimum recommended

Corrosive Environment

The metal parts of this unit may be subject to

rust or deterioration if exposed to a corrosive

environment� This oxidation could shorten the

equipment’s useful life�

Corrosive elements include, but are not limited to,

salt spray, fog or mist in seacoast areas, sulphur or

chlorine from lawn watering systems, and various

chemical contaminants from industries such as

paper mills and petroleum refineries�

If the unit is to be installed in an area where

contaminants are likely to be a problem, special

attention should be given to the equipment

location and exposure�

• Avoid having lawn sprinkler heads spray directly

on the unit cabinet�

• In coastal areas, locate the unit on the side of

the building away from the waterfront�

• Shielding provided by a fence or shrubs may

give some protection, but cannot violate

minimum airflow and service access clearances�

• Elevating the unit off its slab or base enough to

allow air circulation will help avoid holding water

against the base pan�

WARNING: Disconnect all power

to unit before starting maintenance� Failure to do

so can cause electrical shock resulting in severe

personal injury or death�

Regular maintenance will reduce the buildup of

contaminants and help to protect the unit’s finish�

• Frequent washing of the cabinet, fan blade, and

coil with fresh water will remove most of the salt

or other contaminants that build up on the unit�

• Regular cleaning and waxing of the cabinet with

a good automobile polish will provide some

protection�

• A good liquid cleaner may be used several times

a year to remove matter that will not wash off

with water�

Location

7

INSTALLATION

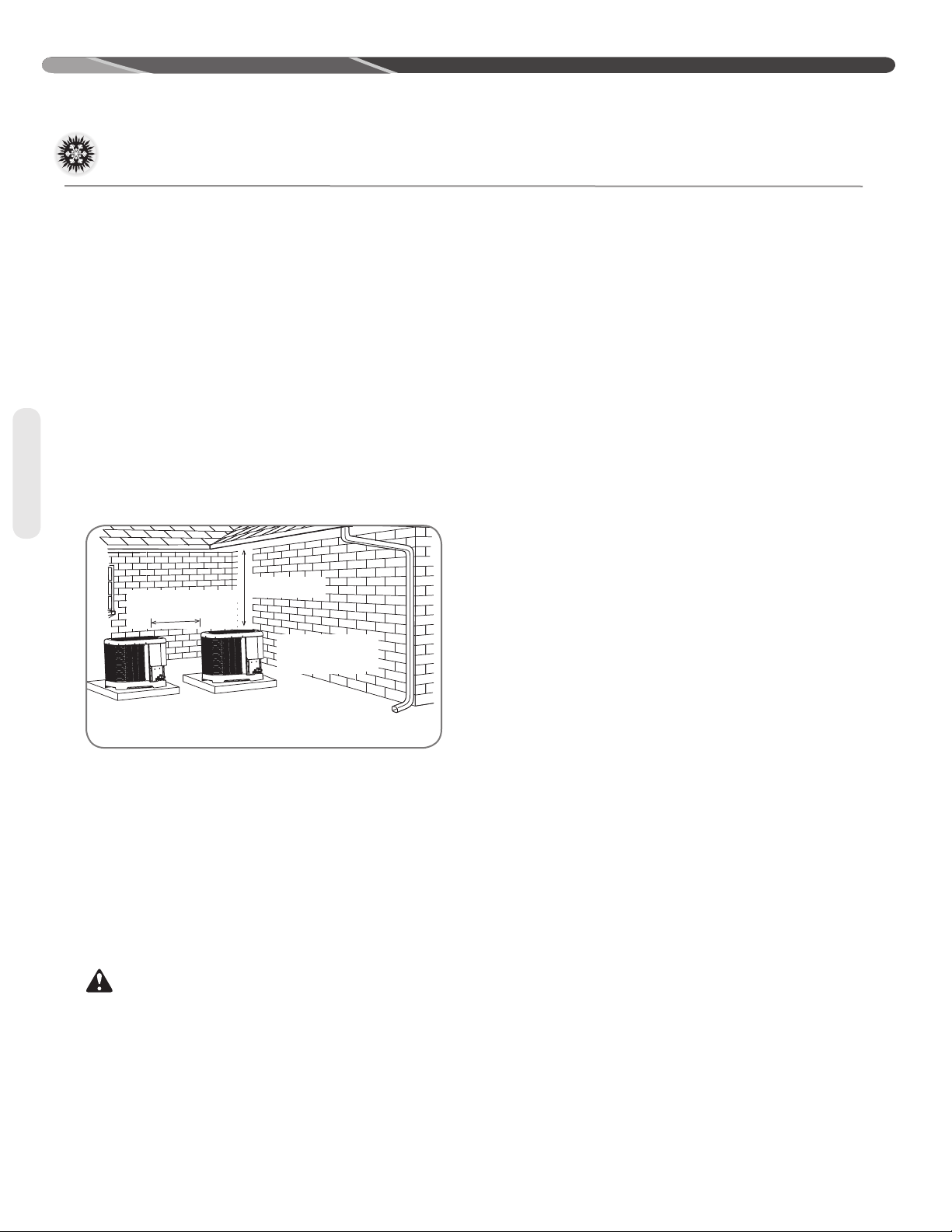

6” MIN. [152mm] FOR 1.5 & 2 TON

9”MIN [229mm] FOR 2.5 – 5 TON

24” [610mm]

SERVICE PANELS/INLET CONNECTIONS/

HIGH & LOW VOLTAGE ACCESS

ALLOW 24” [610 mm] OF CLEARANCE

ALLOW 60” [1524 mm]

OF CLEARANCE

AIR INLET LOUVERS ALLOW

6” [152 mm] Min. OF

CLEARANCE ALL SIDES

12” [305 mm] RECOMMENDED

ST-A1226-04-00

Choosing a Location (cont�)

Location

For Units With Space

Limitations

In the event that a space limitation exists, we will

permit the following clearances:

Single-Unit Applications: Side clearances below 6"

[15.2 cm] will reduce unit capacity and efficiency.

Do not reduce the 60" [152.4 cm] discharge or the

24" [61.0 cm] service clearances.

Multiple-Unit Applications: When multiple

condenser grille sides are aligned, a 6" [15.2

cm] clearance is recommended for 1.5 and 2

ton models and 9" [22.9 cm] for 2.5 ton to 5 ton

models� Two combined clearances below the

minimum will reduce capacity and efficiency� Do

not reduce the 60" [152.4 cm] discharge or 24"

[61.0 cm] service clearances.

• If installing a unit on a flat roof, use 4" x 4"

[10.2 cm x 10.2 cm] or equivalent stringers

positioned to distribute unit weight evenly and

prevent noise and vibration�

Factory-Preferred Tie-Down

Method for High Wind or

Seismic Loads

IMPORTANT: The manufacturer-

approved/recommended method is a guide to

securing equipment for wind and seismic loads�

Other methods might provide the same result, but

the manufacturer method is the only one endorsed

by the manufacturer for securing equipment where

wind or earthquake damage can occur� Additional

information is available in the PTS (Product

Technical Support) section of the manufacturer’s

Web sites MyRheem�com or MyRuud�com and

can be found as a listing under each outdoor

model� If you do not have access to this site, your

distributor can offer assistance�

Customer Satisfaction Issues

• The unit should be located away from the living,

sleeping, and recreational spaces of the owner

and those spaces on adjoining property�

• To prevent noise transmission, the mounting pad

for the outdoor unit should not be connected to

the structure and should be located a sufficient

distance above grade to prevent ground water

from entering the unit�

Unit Mounting

WARNING: Secure an elevated unit

and its elevating stand in order to prevent tipping�

Failure to do so may result in severe personal

injury or death�

8

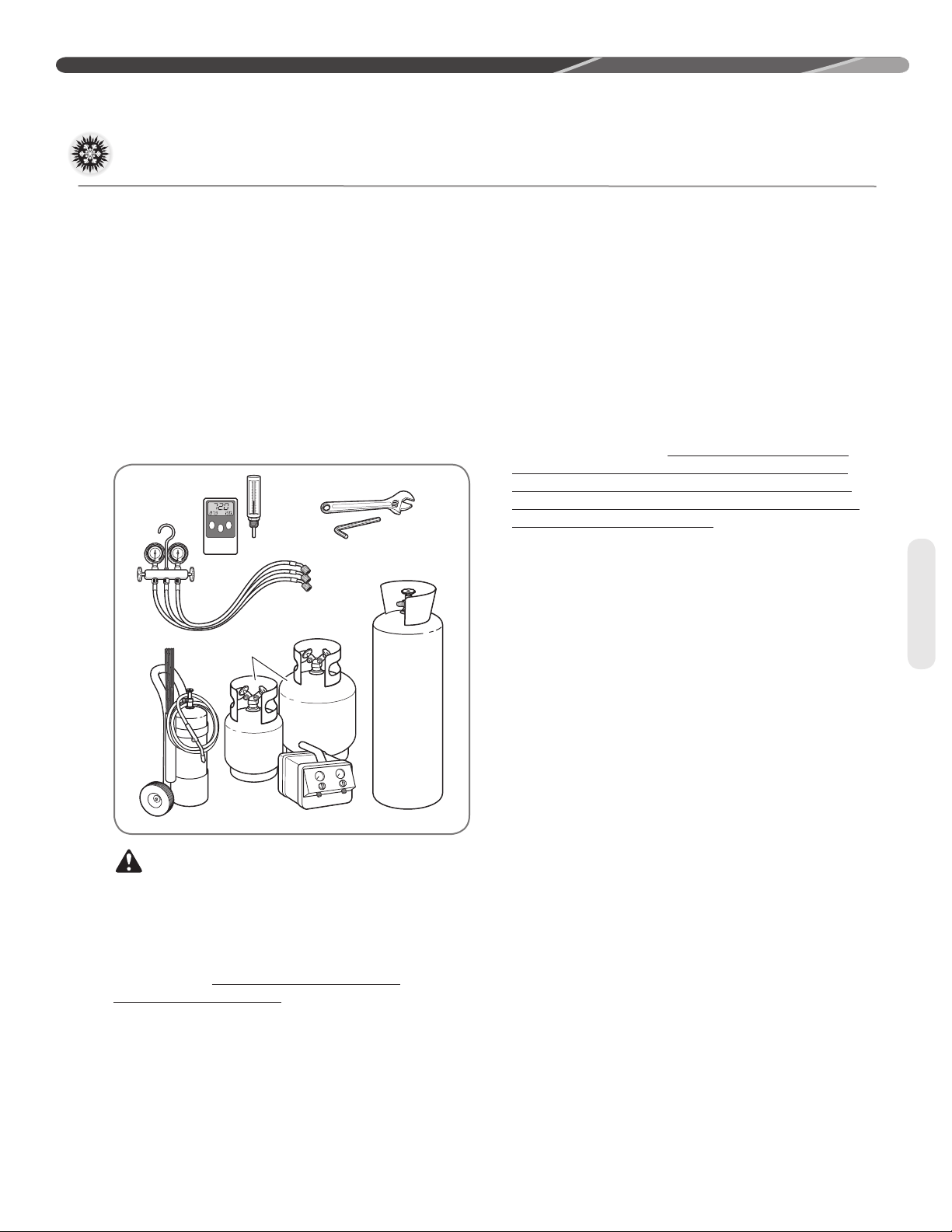

Tools and Refrigerant

Ambient and Tube

Thermometers

Manifold

Gauge

Set

Brazing

Rods

Torch Nitrogen

Reclaimer

Recovery

Cylinders

Allen Wrench

Crescent Wrench

INSTALLATION

Tools Required for Installing

and Servicing R-410A Models

Manifold Sets:

– Up to 800 PSIG High-Side

– Up to 250 PSIG Low-Side

– 550 PSIG Low-Side Retard

Manifold Hoses:

– Service Pressure Rating of 800 PSIG

Recovery Cylinders:

– 400 PSIG Pressure Rating

– Dept� of Transportation 4BA400 or BW400

CAUTION: R-410A systems operate

at higher pressures than R-22 systems� Do not

use R-22 service equipment or components on

R-410A equipment�

Specifications of R-410A

Application: R-410A is not a drop-in

replacement for R-22� Equipment designs must

accommodate its higher pressures� It cannot be

retrofitted into R-22 heat pumps�

Physical Properties: R-410A has an atmospheric

boiling point of -62.9°F [-52.7°C] and its saturation

pressure at 77°F [25°C] is 224.5 psig.

Composition: R-410A is a near-azeotropic

mixture of 50% by weight difluoromethane (HFC-

32) and 50% by weight pentafluoroethane (HFC-

125)�

Pressure: The pressure of R-410A is

approximately 60% (1�6 times) greater than

R-22� Recovery and recycle equipment, pumps,

hoses, and the like must have design pressure

ratings appropriate for R-410A� Manifold sets

need to range up to 800 psig high-side and 250

psig low-side with a 550 psig low-side retard.

Hoses need to have a service pressure rating of

800 psig. Recovery cylinders need to have a 400

psig service pressure rating, DOT 4BA400 or DOT

BW400.

Combustibility: At pressures above 1

atmosphere, a mixture of R-410A and air can

become combustible� R-410A and air should

never be mixed in tanks or supply lines or

be allowed to accumulate in storage tanks�

Leak checking should never be done with a

mixture of R-410A and air� Leak-checking can

be performed safely with nitrogen or a mixture of

R-410A and nitrogen�

Quick-Reference Guide For

R-410A

• R-410A refrigerant operates at approximately

60% higher pressure (1�6 times) than R-22�

Ensure that servicing equipment is designed to

operate with R-410A�

• R-410A refrigerant cylinders are light rose in

color�

• R-410A, as with other HFCs, is only compatible

with POE oils�

• Vacuum pumps will not remove moisture from

POE oil used in R-410A systems�

• R-410A systems are to be charged with liquid

refrigerants� Prior to March 1999, R-410A

refrigerant cylinders had a dip tube� These

cylinders should be kept upright for equipment

charging� Post-March 1999 cylinders do not

have a dip tube and should be inverted to ensure

liquid charging of the equipment�

• Do not install a suction line filter drier in the

liquid line�

• A factory-approved biflow liquid line filter drier

is shipped with every unit and must be installed

in the liquid line at the time of installation� Only

manufacturer-approved liquid line filter driers can

be used� These are Sporlan (CW083S) and Alco

(80K083S) driers� These filter driers are rated for

minimum working pressure of 600 psig� The filter

drier will only have adequate moisture-holding

capacity if the system is properly evacuated�

• Desiccant (drying agent) must be compatible for

POE oils and R-410A refrigerant�

Tools

9

INSTALLATION

Replacement Units

To prevent failure of a new unit, the existing line set

must be correctly sized and cleaned or replaced�

Care must be exercised that the expansion device

is not plugged� For new and replacement units, a

liquid line filter drier must be installed and refrigerant

tubing must be properly sized� Test the oil for acid� If

positive, a suction line filter drier is mandatory�

Indoor Coil

CAUTION: Only use evaporators

approved for use on R-410A systems that are

specifically matched with the outdoor unit per

the manufacturer’s specification sheets� Use

of existing R-22 evaporators can introduce

mineral oil to the R-410A refrigerant, forming two

different liquids and decreasing oil return to the

compressor� This can result in compressor failure�

REFER TO INDOOR COIL MANUFACTURER’S

INSTALLATION INSTRUCTIONS.

IMPORTANT: The manufacturer is not

responsible for the performance and operation of

a mismatched system or for a match listed with

another manufacturer’s coil�

IMPORTANT: When replacing an

R-22 unit with an R-410A unit, either replace

the line set or ensure that residual mineral oil is

drained from existing lines, including oil trapped in

low spots�

The thermostatic expansion valve in the

matching coil is specifically designed to operate

with R-410A� DO NOT use an R-22 TXV or

evaporator� The existing evaporator must

be replaced with the factory-specified TXV

evaporator specifically designed for R-410A�

Location

Do not install the indoor coil in the return duct

system of a gas or oil furnace� Provide a service

inlet to the coil for inspection and cleaning� Keep

the coil pitched toward the drain connection�

CAUTION: When coil is installed

over a finished ceiling and/or living area, it is

required that a secondary condensate pan be

installed under entire unit� Failure to do so can

result in property damage�

Tubing

10

Interconnecting Tubing

The purpose of this section is to specify the

best construction/sizing practices for installing

interconnection tubing between the indoor and

outdoor unit�

Refrigerant Level Adjustment

All units are factory-charged with R-410A

refrigerant to cover 15 feet of standard size

interconnecting liquid and vapor lines with a

required eld installed lter drier. Adjustment of

charge may be necessary even if the application

has exactly 15 feet of line set due to other

installation variables such as pressure drop,

vertical lift, and indoor coil size. For dierent

lengths, adjust the charge as indicated below�

adjust the charge as indicated below�

• 1/4” ± .3 oz./foot [6.4 mm ± 8.5 g/.30 m]

• 5/16” ± .4 oz./foot [7.9 mm ± 11.3 g/.30 m]

• 3/8” ± .6 oz./foot [9.5 mm ± 17.0 g/.30 m]

• 1/2” ± 1.2 oz./foot [12.7 mm ± 34.0 g/.30 m]

• 6 oz. Required factory supplied eld installed

• lter dry

Charge Adjustment = (Line Set (oz. /ft.) x Total

Length) – Factory Charge for Line Set

Example: A three ton condensing unit with factory

installed 3/8” liquid service valve

requires 75 ft of line set with a liquid line diameter

of 1/2”.

Factory Charge for Line Set = 15ft x �6 oz� = 9 oz�

Charge Adjustment = (1�2 oz� x 75 ft�) – 9 oz� =

+81 oz�

Interconnecting Tubing (cont�)

INSTALLATION

Interconnecting Tubing and

Fitting Losses

Refrigerant tubing is measured in terms of actual

length and equivalent length� Actual length is used

for refrigerant charge applications� Equivalent

length takes into account pressure losses from

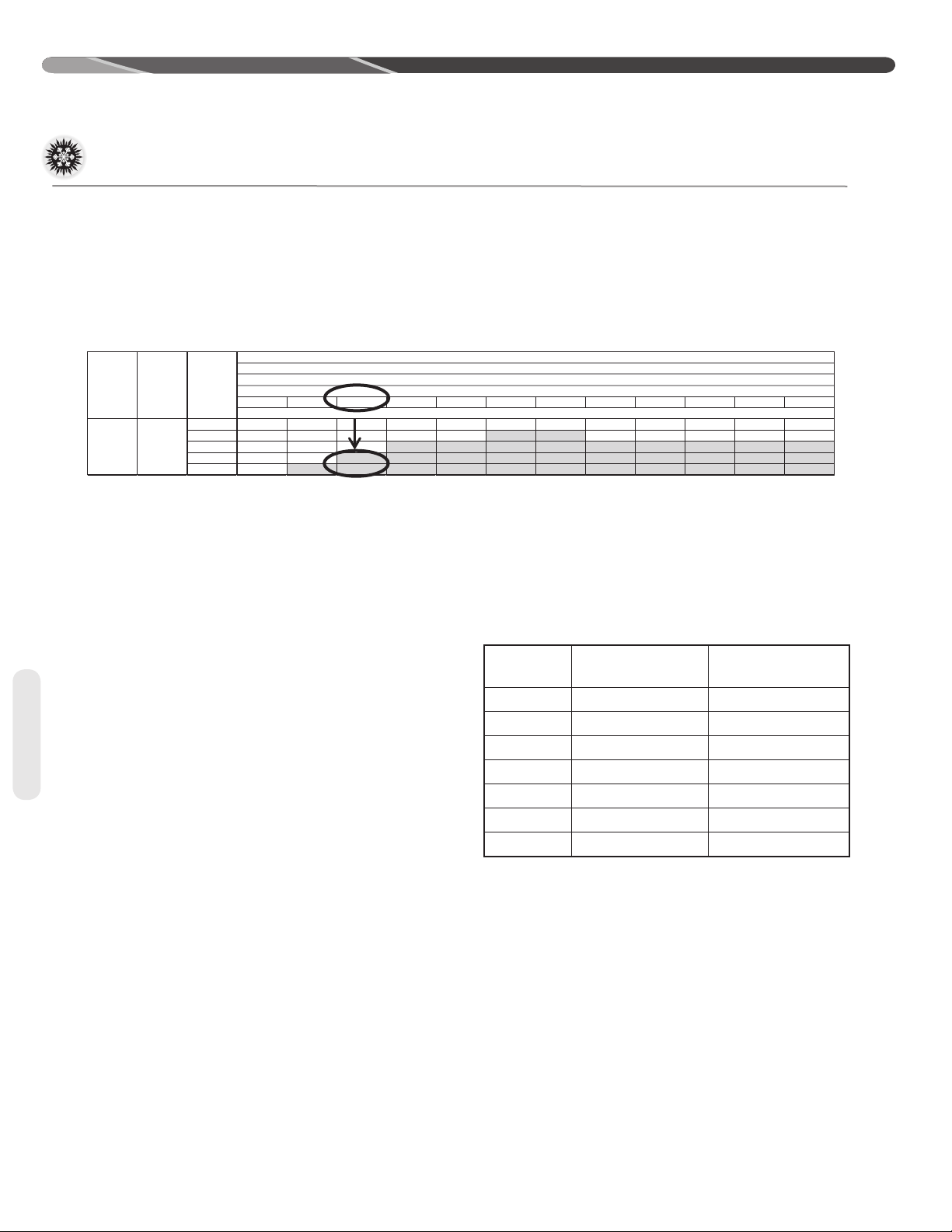

Equivalent Length for Fings ()

90° Short

Line Size

(in)

3/8 1.3 0.8 0.3 6 4 0.4 6

1/2 1.4 0.9 0.4 9 5 0.6 6

5/8 1.5 1 0.5 12 6 0.8 6

3/4 1.9 1.3 0.6 14 7 0.9 6

7/8 2.3 1.5 0.7 15 8 1 6

1-1/8 2.7 1.8 0.9 22 12 1.5 6

Radius

Elbow

90° Long

Radius

Elbow

45°

Elbow

Liquid Line Selection

The purpose of the liquid line is to transport warm

sub-cooled liquid refrigerant from the outdoor unit

to the indoor unit� It is important not to allow the

refrigerant to ash any superheated vapor prior

to the expansion device of the indoor coil� The

ashing of refrigerant can occur for the following

reasons:

• Low refrigerant charge

• Improperly selected liquid line size

• Absorption of heat prior to expansion device

• Excessive vertical rise between the condenser

and evaporator

tubing length, ttings, vertical separation, accessories, and lter dryers. The table below references

dierent commonly used equivalent lengths.

Table 1

Solenoid

Valve

Table 2 lists the equivalent length per 25’ of liquid

line at various diameters up to 300’� The total pressure drop allowed for the liquid line is 50 PSI� The

procedure for selecting the proper liquid line is as

follows:

• Measure the total amount of vertical rise

• Measure the total amount of liquid line needed

• Add all of the equivalent lengths associated with

any ttings or accessories using the table above.

• Add the total length and tting pressure drop.

This will equal your total equivalent length�

• Reference Table 2 to verify the calculated

equivalent length is compatible with the required

vertical rise and diameter of liquid line�

Check

Valve

Site

Glass

Filter

Dryer

Tubing

Note: Elevaon is defined as the

highest point of the line set to the

lowest

11

INSTALLATION

Interconnecting Tubing (cont�)

Example: A 3-Ton condensing unit is installed 50’

below the ID unit, requires a 75’ of 1/2” diameter

liquid line, and 4 90° LR elbows�

• Fitting Equivalent Length (ft�) = 4 x �9 = 3�6’

• Total Equivalent Length (ft.) = 75’ + 3.6’ = 78.6’

Tubing

Liquid Line

R-410A

System

Capacity

Model

(excerpt fromTable 2, page 16)

Size

Connection

Size (Inch

I.D.) [mm]

37 3/8" [9.53]

Liquid Line

Size (Inch

O.D.) [mm]

1/4 [6.35] 25 [7.62]

5/16 [7.94] 25 [7.62] 50 [15.24] 60 [18.29] 45 [13.72] 35 [10.67] 20 [6.1] 5 [1.52]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 80 [24.38] 75 [22.86] 70 [21.34] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 80 [24.38]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

This application is acceptable because the 50’

vertical rise is less than the maximum rise of 75’ for

this application� The application is also considered

to have a long line set� Reference the long line set

section of the I&O for detail�

Long Line Set Applications

Long line set applications are dened as applications that require accessories or alternate

construction methods� The following are special

considerations that need to be addressed when

installing a long line set application:

• Additional refrigerant charge

• Fitting losses and maximum equivalent length

considerations

• Refrigerant migration during the o cycle

• Oil return to the compressor

• Capacity losses

• System oil level adjustment

Table 2 is used to determine if the application is

considered to have a long line set� The region of

the chart that is shaded grey is considered to

be a long line set application.

Liquid Line Size

Elevation (Above or Below) Indoor Coil

Total

Maximum

Length - Feet [m]

Equivalent

Vertical Separation - Feet [m]

N/R N/R N/R N/R N/R

Oil Level Adjustments for

Long Line Set Applications

Additional oil will need to be added for long line set

applications� (Ref� Table 2)� Below is the equation

for the oil level adjustment and the compressor

name plate oil charge for the dierent od units.

OD Model

RP1518

RP1524

RP1530

RP1536

RP1542

RP1548

RP1560

Compressor

ZP16K5E-PFV-13R 21

ZP21K5E-PFV-13R 21

ZP25K5E-PFV-13R 25

ZP31K6E-PFV-130 21

ZP36K5E-PFV-13R 42

ZP40K6E-PFV-130 42

ZP49K6E-PFV-130 42

Oil to be Added = [(Charge Adjustment + OD

Unit Name Plate Charge (oz.)) x (0.022) – [(0.10)

x (Compressor Name Plate Oil Charge (oz.))]

Example: An application requires 125ft of line set

with a liquid line diameter of 3/8”, Charge Adjustment = 52�4 oz�, Name Plate Charge = 107 oz�,

Name Plate Oil Charge = 25 oz�, Oil to be Added =

((52�4 oz� +107 oz�) x �022) – (�10 x 25 oz�) = 1�0 oz�

Name Plate Oil

Charge (oz)

12

Interconnecting Tubing (cont�)

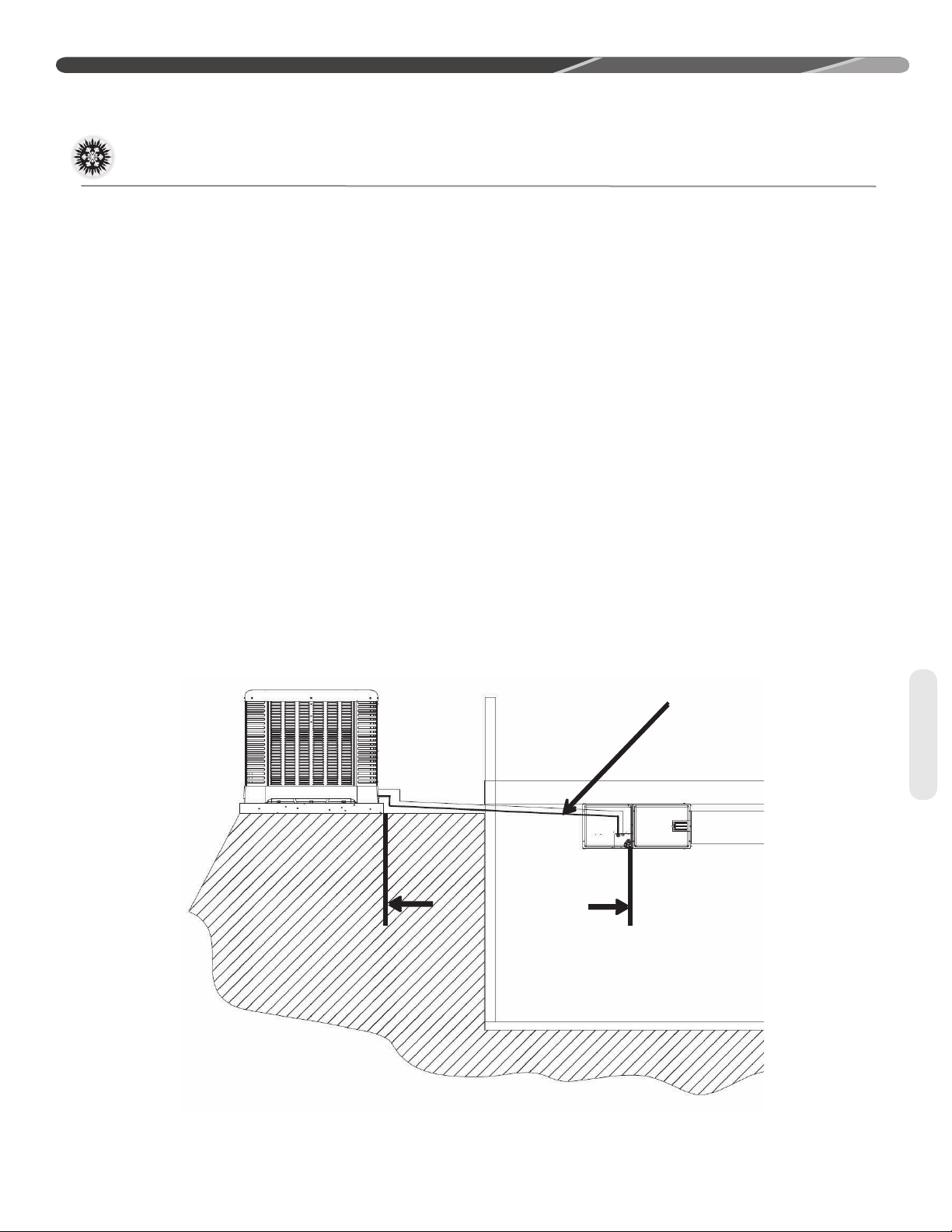

Outdoor and Indoor Same Level

INSTALLATION

Suction Line Selection

Purpose of the suction line is to return superheated

vapor to the condensing unit from the evaporator�

Proper suction line sizing is important because it

plays an important role in returning oil to the compressor to prevent potential damage to the bearings, valves, and scroll sets� Also, an improperly

sized suction line can dramatically reduce capacity

and performance of the system� The procedure for

selecting the proper suction line is as follows:

• The total amount of suction line needed

• Add all of the equivalent lengths associated with

any ttings or accessories using the table on

previous page�

• Add the total length and tting pressure drop.

This will equal your total equivalent length�

• Reference Table 2 to verify that the calculated

equivalent length falls within the compatibility

region of the chart�

• Verify Table 3 to verify the capacity dierence is

compatible with the application�

Refrigerant Migration During

Off Cycle

Long line set applications can require a considerable amount of additional refrigerant� This additional refrigerant needs to be managed throughout the

entire ambient operating envelope that the system

will go through during its life cycle. O-Cycle migration is where excess refrigerant condenses and

migrates to the lowest part of the system� Excessive build-up of refrigerant at the compressor will

result in poor reliability and noisy operation during

startup� This section demonstrates the required

accessories and unit conguration for dierent applications�

Ideally, line set slopes

away from outdoor.

Verify sub-cooling prior

to throling device,

Insulated liquid line

Tubing

Reference Table 2 for

maximum length

limitaons

Figure 3

13

INSTALLATION

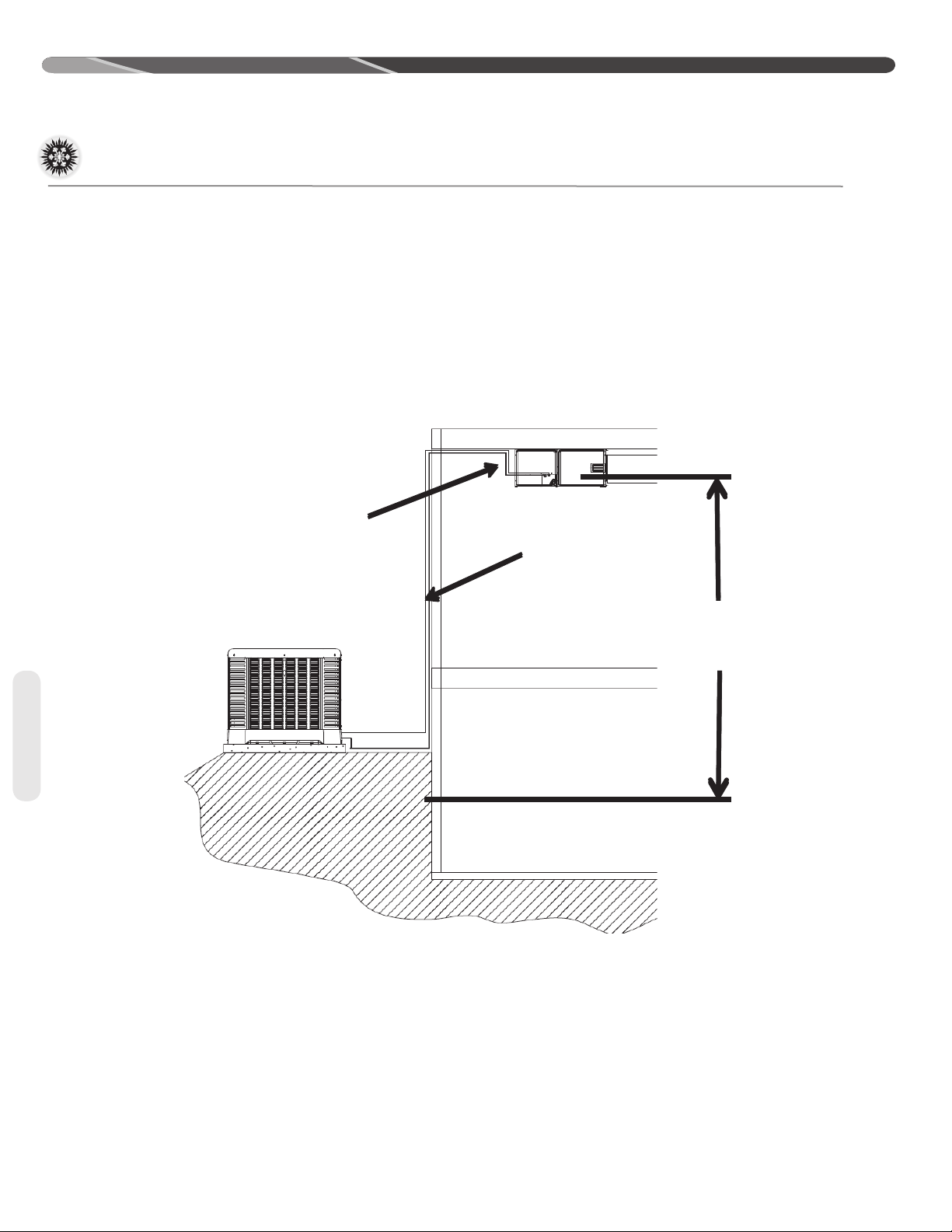

Indoor Unit Above Outdoor Coil

Interconnecting Tubing (cont�)

For applications that are considered to have a long

line set with the outdoor unit and indoor unit on the

same level the following is required:

• TXV or EEV on the indoor unit

• Start components may be required depending

upon quality of voltage

• Crankcase heater

• Insulated liquid and suction line

Inverted trap even with

top of the coil

• Vapor line should slope toward the indoor unit

• Follow the proper line sizing, equivalent length,

charging requirements, and oil level adjustments

spelled out in this document and the outdoor

units I&O

• Verify adequate sub-cooling at the ID unit prior

to throttling device

Insulated liquid and

sucon line

Reference Table 2

for elevaon

limitaons

Tubing

For applications that are considered to have a long

line set with the outdoor unit below the indoor unit

the following is required:

• TXV or EEV at the IDunit

• Crankcase heater

• Start components may be required depending

upon quality of voltage

• Inverted vapor-line trap (Reference Figure 3)

• Insulated liquid and suction line

Figure 4

• Follow the proper line sizing, equivalent length,

charging requirements, and oil level adjustments

spelled out in this document and the outdoor

units I&O

• Measure pressure at the liquid line service valve

and prior to expansion device� Verify that it is

not greater than 50 PSI

• For elevations greater that 25’ can expect a

lower sub-cooling

14

Loading...

Loading...