Page 1

Rheem Classic®Series

Air Conditioners

FORM NO. A11-221 REV. 1

• New composite base pan – dampens sound, captures louver

panels, eliminates corrosion and reduces number of fasteners

needed

• Powder coat paint system – for a long lasting professional finish

• Scroll compressor – uses 70% fewer moving parts for higher

efficiency and increased reliability

• Modern cabinet aesthetics – increased curb appeal with visually appealing design

• Curved louver panels – provide ultimate coil protection,

enhance cabinet strength, and increased cabinet rigidity

• Optimized fan orifice – optimizes airflow and reduces unit

sound

• Rust resistant screws – confirmed through 1500-hour salt

spray testing

• PlusOne™ Expanded Valve Space – 3"-4"-5" service valve

space – provides a minimum working area of 27-square

inches for easier access

• PlusOne™ Triple Service Access – 15" wide, industry lead-

ing corner service access – makes repairs easier and faster.

The two fastener removable corner allows optimal access to

internal unit components. Individual louver panels come out

once fastener is removed, for faster coil cleaning and easier

cabinet reassembly

• Diagnostic service window with two-fastener opening –

provides access to the high and low pressure.

• External gauge port access – allows easy connection of

“low-loss” gauge ports

• Single-row condenser coil – makes unit lighter and allows

thorough coil cleaning to maintain “out of the box”

performance

• 35% fewer cabinet fasteners and fastener-free base – allow

for faster access to internal components and hassle-free

panel removal

• Service trays – hold fasteners or caps during service calls

• QR code – provides technical information on demand for

faster service calls

• Fan motor harness with extra long wires allows unit top to be

removed without disconnecting fan wire.

Air

Air Conditioners

RA13 Series

“Proper sizing and installation of equipment is critical to achieve

optimal performance. Ask your Dealer for details or visit

www.energystar.gov.”

RA13 Series

Efficiencies 13-15.5 SEER/11.5-13 EER

Nominal Sizes 1

1

/2 to 5 Ton [5.28 to 17.6 kW]

Cooling Capacities 17.3 to 60.5 kBTU

[5.7 to 17.7 kW]

15.5

Page 2

Air

Table of Contents

RA13 Series

2

TABLE OF CONTENTS

Standard Feature ......................................................................................................3

Available SKUs ........................................................................................................3

Features & Benefits ..............................................................................................4-5

Model Number Identification ................................................................................6-7

General Data/Electrical Data ....................................................................................8

Accessories ............................................................................................................9

Weighted Sound Power............................................................................................9

Thermostats..............................................................................................................9

Unit Dimensions......................................................................................................10

Clearances..............................................................................................................11

Wiring Diagrams ....................................................................................................12

Application Guidelines ............................................................................................12

Refrigerant Line Size Information ......................................................................13-14

Performance Data ............................................................................................15-40

Guide Specifications ..............................................................................................41

Limited Warranty ....................................................................................................42

Page 3

Air

Standard Feature/Available SKUs

RA13 Series

3

STANDARD FEATURES

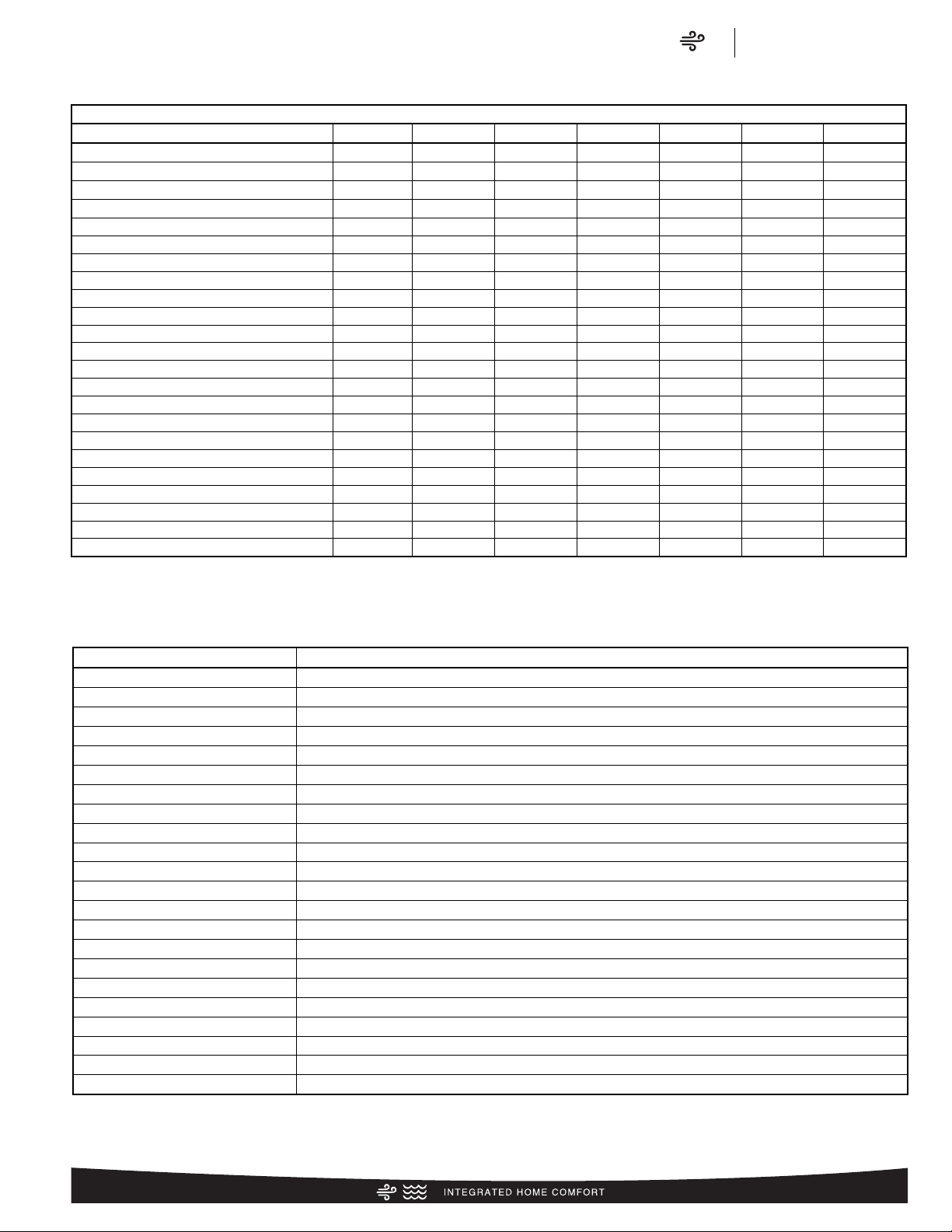

Feature 18 24 30 36 42 48 60

R-410a Refrigerant √ √ √ √ √ √ √

Maximum SEER 15.1 15.0 15.5 15.1 14.5 14.5 14.0

Maximum EER 12.5 12.5 13.0 12.5 12.0 12.0 11.5

Scroll Compressor √ √ √ √ √ √ √

Field Installed Filter Drier √ √ √ √ √ √ √

Front Seating Service Valves √ √ √ √ √ √ √

Internal Pressure Relief Valve √ √ √ √ √ √ √

Internal Thermal Overload √ √ √ √ √ √ √

Long Line capability √ √ √ √ √ √ √

Low Ambient capability with Kit √ √ √ √ √ √ √

3-4-5 Expanded Valve Space √ √ √ √ √ √ √

Composite Basepan √ √ √ √ √ √ √

2 Screw Control Box Access √ √ √ √ √ √ √

15" Access to Internal Components √ √ √ √ √ √ √

Quick release louver panel design √ √ √ √ √ √ √

No fasteners to remove along bottom √ √ √ √ √ √ √

Optimized Venturi Airflow √ √ √ √ √ √ √

Single row condenser coil √ √ √ √ √ √ √

Powder coated paint √ √ √ √ √ √ √

Rust resistant screws √ √ √ √ √ √ √

QR code √ √ √ √ √ √ √

External gauge ports √ √ √ √ √ √ √

Service trays √ √ √ √ √ √ √

√ = Standard

Standard Feature Table

Available SKUs

Available Models Description

RA1318AJ1NA

Classic

®

Series 1 1/2 ton 13 SEER Single-Stage Air Conditioner-208/230/1/60

RA1324AJ1NA

Classic

®

Series 2 ton 13 SEER Single-Stage Air Conditioner-208/230/1/60

RA1330AJ1NA

Classic

®

Series 2 1/2 ton 13 SEER Single-Stage Air Conditioner-208/230/1/60

RA1336AJ1NA

Classic

®

Series 3 ton 13 SEER Single-Stage Air Conditioner-208/230/1/60

RA1342AJ1NA

Classic

®

Series 3 1/2 ton 13 SEER Single-Stage Air Conditioner-208/230/1/60

RA1348AJ1NA

Classic

®

Series 4 ton 13 SEER Single-Stage Air Conditioner-208/230/1/60

RA1360AJ1NA

Classic

®

Series 5 ton 13 SEER Single-Stage Air Conditioner-208/230/1/60

RA1318AJ1NB

Classic

®

Series 1 1/2 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/1/60

RA1324AJ1NB

Classic

®

Series 2 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/1/60

RA1330AJ1NB

Classic

®

Series 2 1/2 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/1/60

RA1336AJ1NB

Classic

®

Series 3 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/1/60

RA1342AJ1NB

Classic

®

Series 3 1/2 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/1/60

RA1348AJ1NB

Classic

®

Series 4 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/1/60

RA1360AJ1NB

Classic

®

Series 5 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/1/60

RA1336AC1NB

Classic

®

Series 3 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/3/60

RA1342AC1NB

Classic

®

Series 3 1/2 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/3/60

RA1348AC1NB

Classic

®

Series 4 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/3/60

RA1360AC1NB

Classic

®

Series 5 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-208/230/3/60

RA1336AD1NB

Classic

®

Series 3 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-460/3/60

RA1342AD1NB

Classic

®

Series 3 1/2 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-460/3/60

RA1348AD1NB

Classic

®

Series 4 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-460/3/60

RA1360AD1NB

Classic

®

Series 5 ton 13 SEER Single-Stage Air Conditioner w/ High/Low Pressure-460/3/60

Page 4

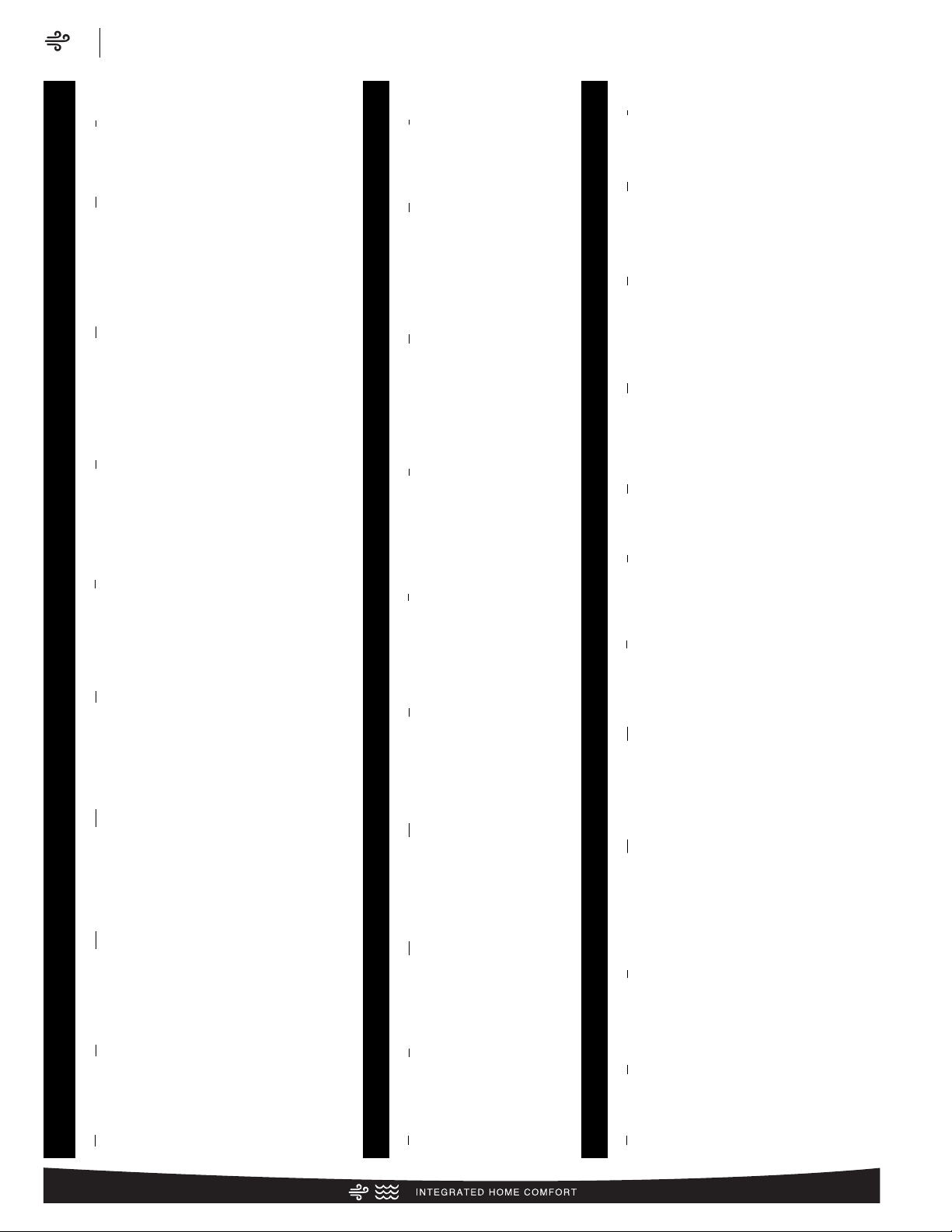

The RA13 is our 13 SEER air conditioner and is part of the

Rheem air conditioner product line that extends from 13 to 20

SEER. This highly featured and reliable air conditioner is

designed for years of reliable, efficient operation when matched

with Rheem indoor aluminum evaporator coils and furnaces or

air handler units with aluminum evaporators.

Our unique composite base ( ) reduces sound emission, eliminates rattles, significantly reduces fasteners, eliminates corrosion and has integrated brass compressor attachment inserts

()

. Furthermore it has incorporated into the design, water

management features, means for hand placement

()

for unit

maneuvering, screw trays

()

and inserts for lifting off unit

pad. ( )

Service Valves ( ) are rigidly mounted in the composite base

with 3" between suction and discharge valves, 4" clearance

below service valves and a minimum of 5" above the service

valves, creating industry leading installation ease. The minimum

27 square-inches around the service valves allows ample room

to remove service valve schrader prior to brazing, plenty of

clearance for easy brazing of the suction and discharge lines to

service valve outlets, easy access and hookup of low loss refrigerant gauges ( ), and access to the service valve caps for

opening. For applications with long-line lengths up to 250 feet

total equivalent length, up to 200 feet condenser above evaporator, or up to 80 feet evaporator above condenser, the long-line

instructions in the installation manual should be followed.

Controls are accessed from the corner of the unit by removing

only two fasteners from the control access cover, revealing the

industry’s largest 15" wide and 14" tall control area

()

. With all

this room in the control area the high voltage electrical whip ( )

can easily be inserted through the right size opening in the bottom of the control area. Routing it leads directly to contractor

lugs for connection. The low voltage control wires

()

are easily

connected to units low voltage wiring. If contactor or capacitor

( ) needs to be replaced there is more than adequate space to

make the repair. Furthermore, if high pressure and low pressure

model was not purchased but is desired to be installed in the

field, the service window ( ) can be removed by removing two

screws, to access the high and low side schrader fittings for easy

field installation. The entire corner can be removed providing

ultimate access to install the high and low pressure switch.

()

If in the rare event, greater access is needed to internal components, such as the compressor, the entire corner of the unit can

be removed along with the top cover assembly to have unprecedented access to interior of the unit

()

. Extra wire length is

incorporated into each outdoor fan and compressor so top

cover and control panel can be positioned next to the unit. With

minimal effort the plug can be removed from the compressor

and the outdoor fan wires can be removed from the capacitor to

allow even more uncluttered access to the interior of the unit

()

.

Outdoor coil heights range from as short as 22" to 28", aiding

access to the compressor. Disassembly to this degree and complete reassembly only takes a first time service technician less

than 10 minutes. ( )

All units utilize strong formed louver panels which provide industry leading coil protection. Louver removal for coil cleaning is

accomplished by removing one screw and lifting the panel out of

the composite base pan.

()

All RA13 units utilize single row

coils ( ) making cleaning easy and complete, restoring the

performance of the air conditioner back to out of the box performance levels year after year.

The outdoor fan motor has sleeve bearings and is inherently

protected. The motor is totally enclosed for maximum protection

from weather, dust and corrosion. Access to the outdoor fan is

made by removing four fasteners from the fan grille. The outdoor

fan can be removed from the fan grille by removing 4 fasteners

in the rare case outdoor fan motor fails.

Each cabinet has optimized composite ( ) fan orifice assuring

efficient and quiet airflow.

1

2

3

4

7

8

9

10

12

13

6

11

5

14

15

15

17

16

19

Air

Features & Benefits

RA13 Series

4

Introduction to RA13 Air Conditioner

1

4

6

4

3 5

2

8

11

9

10

13

12

16

14

18

15

19

7

17

Page 5

Air

Features & Benefits

RA13 Series

5

The entire cabinet has powder post paint ( ) achieving 1000

hour salt spray rating, allowing the cabinet to retain its aesthetics

throughout its life.

Scroll compressors with standard internal pressure relief and

internal thermal overload are used on all capacities assuring

longevity of high efficient and quiet operation for the life of the

product.

Each unit is shipped with filter drier for field installation and will

trap any moisture or dirt that could contaminate the refrigerant

system.

All cabinets have industry leading structural strength due to the

composite base pan

()

, interlocking corner post ( )

, formed

curved louver panels ( ) and drawn top cover ( ) making it

the most durable cabinet on the market today.

Each RA13 capacity has undergone rigorous psychometric testing to assure performance ratings of capacity, SEER

and EER per AHRI Standard 210/240 rating conditions. Also each unit bears the UL mark and each unit

is certified to UL 1995 safety standards.

Each unit has undergone specific strain and modal testing to

assure tubing

()

is outside the units natural frequency and that

the suction and discharge lines connected to the compressor

withstand any starting, steady state operation or shut down

forces imposed by the compressor.

All units have been sound tested in sound chamber to AHRI 270

rating conditions, and A-weighted Sound Power Level tables

produced, assuring units have acceptable noise qualities (see

page 9). Each unit has been ran in cooling operation at 95°F

and 82°F and sound ratings for the RA13 range from as low as

73 dBA to 79 dBA.

All units have been ship tested to assure units meet stringent

“over the road” shipping conditions.

As manufactured all units in the RA13 family have cooling capability to 55 °F. Addition of low ambient control will allow the unit

to operate down to 0°F. Factory testing is performed on each

unit. All component parts meet well defined specification and

continually go through receiving inspections. Each component

installed on a unit is scanned, assuring correct component utilization for a given unit capacity and voltage. All condenser coils

are leak tested with pressurization test to 550#’s and once

installed and assembled, each units’ complete refrigerant

system is helium leak tested. All units are fully charged from the

factory for up to 15 feet of piping. All units are factory run tested.

The RA13 has a 10-year conditional compressor and parts warranty (registration required).

Optional Accessories

(Refer to accessory chart for model #)

Compressor Crankcase Heater

Protects against refrigerant migration that can occur during low

ambient operation

Compressor Sound Cover

• Reinforced vinyl compressor cover containing a 1½ inch thick

batt of fiberglass insulation

• Open edges are sealed with a one-inch wide hook and loop

fastening tape

Compressor Hard Start Kit

• Single-phase units are equipped with a PSC compressor

motor, this type of motor normally does not need a potential

relay and start capacitor

• Kit may be required to increase the compressor starting

torque, in conditions such as low voltage

Low Ambient Kit

• Air conditioners operate satisfactorily in the cooling mode

down to 55°F outdoor air temperature without any additional

controls

• This Kit can be added in the field enabling unit to operate

properly down to 0° in the cooling mode

• Crankcase heater and freezestat should be installed on compressors equipped with a low ambient kit

3"/6"/12"

• Gray high density polyethylene feet are available to raise unit

off of mounting surface away from moisture

Low Pressure

• Can be added in field enabling the unit to shut off compressor

on loss of charge

NOTE: Unit can be purchased with high and low pressure

installed at factory. (Refer to SKU list)

High Pressure

• Can be added in field enabling unit to shut off compressor if

unit loses outdoor fan operation.

NOTE: Unit can be purchased with high and low pressure

installed at factory. (Refer to SKU list)

Decorative Top

• Can be installed on fan grille

25

20

2221

2423

20

24

23

22

21

25

Page 6

R

A 13 24 A

J

1 N A *

Brand Product

Category

SEER Capacity

BTU/HR

Major Series* Voltage Type Controls Minor Series** Option

Code

Rheem A - Air Conditioners

13 - 13 SEER

14 - 14 SEER

16 - 16 SEER

17 - 17 SEER

20 - 20 SEER

18 - 18,000 [5.28 kW]

24 - 24,000 [7.03 kW]

30 - 30,000 [8.79 kW]

36 - 36,000 [10.55 kW]

42 - 42,000 [12.31 kW]

48 - 48,000 [14.07 kW]

60 - 60,000 [17.58 kW]

A - 1st Design

J - 1ph, 208-230/60

C - 3ph, 208-230/60

D - 3ph, 460/60

1 - Single-stage

2 - Two-stage

V - Inverter

C - Communicating

N - Non-Communicating

A - 1st Design N/A

R

P 14 24 A

J

1 N A *

Brand Product

Category

SEER Capacity

BTU/HR

Major Series* Voltage Type Controls Minor Series** Option

Code

Rheem P - Heat Pump

13 - 13 SEER

14 - 14 SEER

15 - 15 SEER

17 - 17 SEER

20 - 20 SEER

18 - 18,000 [5.28 kW]

24 - 24,000 [7.03 kW]

30 - 30,000 [8.79 kW]

36 - 36,000 [10.55 kW]

42 - 42,000 [12.31 kW]

48 - 48,000 [14.07 kW]

60 - 60,000 [17.58 kW]

A - 1st Design

J - 1ph, 208-230/60

C - 3ph, 208-230/60

D - 3ph, 460/60

1 - Single-stage

2 - Two-stage

V - Inverter

P - Piston

C - Communicating

N - Non-Communicating

A - 1st Design N/A

R

C F 24 17

S

T A M C A *

Brand Product

Category

Type Capacity

BTU/HR

Width Efficiency Metering

Device

Major

Series*

Orientation Casing Minor Series** Option

Code

Rheem

C - Evap Coil F - Furn Coil

H - Air-Handler

Coil

24 - 24,000 [7.03 kW]

36 - 36,000 [10.55 kW]

48 - 48,000 [14.07 kW]

60 - 60,000 [17.58 kW]

14 - 14"

17 - 17.5"

21 - 21"

24 - 24.5"

S- Standard Eff.

M- Mid Eff.

H- High Eff.

T-TXV

E-EEV

P-Piston

A - 1st Design M - Multipoise

V - Vertical only/

convertible

H - Ded.

Horizontal only

C - Cased

U - Uncased

A - 1st Design N/A

Air

Model Number Identification

RA13 Series

6

Heat Pumps (For Reference)

Furnace Coils (For Reference)

Air Conditioners

[ ] Designates Metric Conversions

Page 7

R

96 V A

70

2 3 17 M S A

Brand Series Motor Major Rev Input

BTU/HR

Stages Air Flow Cabinet

Width

Configuration Nox Minor Rev

Rheem

90 - 90 AFUE

92 - 92 AFUE

95 - 95 AFUE

96 - 96 AFUE

97 - 97 AFUE

V - Variable speed

T - Constant

Torque

(X-13)

P - PSC

A - 1st Design

040 - 42,000 [12.31 kW]

060 - 56,000 [16.41 kW]

070 - 70,000 [20.51 kW]

085 - 84,000 [24.62 kW]

100 - 98,000 [28.72 kW]

115 - 112,000 [32.82 kW]

1 - Single-stage

2 - Two-stage

M - Modulating

3 - up to 3 ton

5 - 3 1/2 up to 5 ton

14 - 14"

17 - 17.5"

21 - 21"

24 - 24.5"

M - Multi X - Low Nox

S - Standard

A - 1st Design

Air

Model Number Identification

RA13 Series

7

R

80 2 V A

075

3 17 M S A

Brand Series Stages Motor Major Rev Input

BTU/HR

Air Flow Cabinet

Width

Configuration Nox Minor Rev

Rheem

80 - 80+ AFUE 1 - Single-stage

2 - Two-stage

V - Variable speed

T - Constant Torque (X-13)

P - PSC premium

S - PSC standard

A - 1st Design

050 - 50,000 [15 kW]

075 - 75,000 [22 kW]

100 - 100,000 [29 kW]

125 - 125,000 [37 kW]

150 - 150,000 [44 kW]

3 - up to 3 ton

4 - 2 1/2 to 4 ton

5 - 3 1/2 up to 5 ton

14 - 14"

17 - 17.5"

21 - 21"

24 - 24.5"

M - Multi

D - Down

Z - Down &

zero clearance

down flow

X - Low Nox

S - Standard

A - 1st Design

R

H 1 T 36

17

S T A N A A 000 *

Brand Product

Category

Stages of

Airflow

Motor Type Capacity

BTU/HR

Width Coil Size Metering

Device

Major

Series*

Controls Voltage Minor

Series**

Factory Heat

Cap

Option

Code

Rheem

H - Air

Handler

1 - Single-Stage

2 - Two-Stage

M - Modulating

V - Variable

Speed

T - Constant

Torque

P - PSC

24 - 24,000 [7.03 kW]

36 - 36,000 [10.55 kW]

48 - 48,000 [14.07 kW]

60 - 60,000 [17.58 kW]

14 - 14"

17 - 17.5"

21 - 21"

24 - 24.5"

S - Standard

Eff.

M -Mid Eff.

H - High Eff.

T - TEV

E - EEV

P - Piston

A - 1st Design C -Communicating

N -Non-comm

A - 1ph, 115/60

J - 1ph, 208-240/60

D - 3ph, 480/60

A - 1st Design 00 - no

factory heat

with option

code

*TBD

90%+ AFUE Gas Furnaces (For Reference)

80% AFUE Gas Furnaces (For Reference)

Air Handlers (For Reference)

[ ] Designates Metric Conversions

Page 8

Air

General Data/Electrical Data

RA13 Series

8

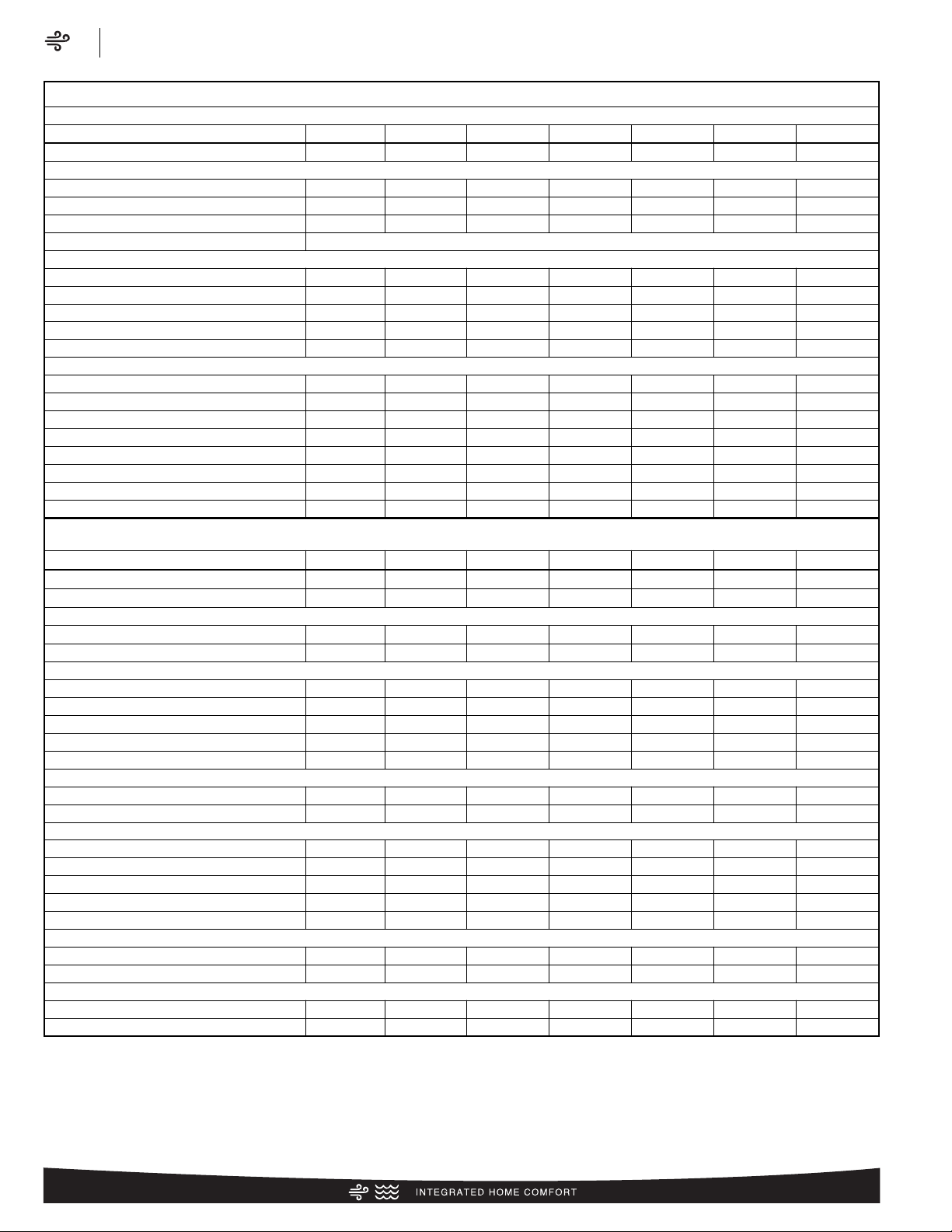

Physical Data

PHYSICAL DATA

Model No. RA1318A RA1324A RA1330A RA1336A RA1342A RA1348A RA1360A

Nominal Tonnage 1.5 2.0 2.5 3.0 3.5 4.0 5.0

Valve Connections

Liquid Line O.D. – in. 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Suction Line O.D. – in. 3/4 3/4 3/4 3/4 7/8 7/8 7/8

Refrigerant (R410A) furnished oz.¹ 56 66 78 92 111 112 154

Compressor Type Scroll

Outdoor Coil

Net face area – Outer Coil 5.9 9.1 9.1 12.1 14.2 14.8 18.8

Net face area – Inner Coil — — — — — — —

Tube diameter – in. 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Number of rows 1 1 1 1 1 1 1

Fins per inch 22 18 22 22 22 22 22

Outdoor Fan

Diameter – in. 20 20 20 20 20 24 26

Number of blades 2 2 3 3 2 3 2

Motor hp 1/8 1/8 1/4 1/4 1/8 1/6 1/5

CFM 2040 2325 2795 2900 2465 4145 3870

RPM 1075 1075 1075 1075 1075 850 820

watts 144 137 189 186 176 280 233

Shipping weight – lbs. 127 129 140 150 173 182 192

Operating weight – lbs. 120 122 133 143 166 175 185

Electrical Data

Line Voltage Data (Volts-Phase-Hz) 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

Maximum overcurrent protection (amps)² 20 25 30 35 40 50 60

Minimum circuit ampacity³ 13 15 18 21 24 29 35

Compressor

Rated load amps 9.7 11.2 12.8 15.4 17.9 21.8 26.4

Locked rotor amps 46 60.8 64 83.9 112 117 134

Condenser Fan Motor

Full load amps 0.7 0.7 1.3 1.3 0.7 1 1.2

Locked rotor amps 1.3 1.3 2.5 2.5 1.3 2 2

Line Voltage Data (Volts-Phase-Hz) — — — 208/230-3-60 208/230-3-60 208/230-3-60 208/230-3-60

Maximum overcurrent protection (amps)²

— — — 20 30 30 35

Minimum circuit ampacity³

— — — 15 18 19 22

Compressor

Rated load amps — — — 10.4 13.2 13.7 16

Locked rotor amps — — — 73 88 83.1 110

Condenser Fan Motor

Full load amps — — — 1.3 0.7 1 1.3

Locked rotor amps — — — 2.5 1.3 2 2

Line Voltage Data (Volts-Phase-Hz) — — — 480-3-60 480-3-60 480-3-60 480-3-60

Maximum overcurrent protection (amps)²

— — — TBD TBD TBD TBD

Minimum circuit ampacity³

— — — TBD TBD TBD TBD

Compressor

Rated load amps — — — TBD TBD TBD TBD

Locked rotor amps — — — TBD TBD TBD TBD

Condenser Fan Motor

Full load amps — — — TBD TBD TBD TBD

Locked rotor amps — — — TBD TBD TBD TBD

¹Refrigerant charge sufficient for 15 ft. length of refrigerant lines. For longer line set requirements see the installation instructions for information about set length and additional

refrigerant charge required.

²HACR type circuit breaker of fuse.

³Refer to National Electrical Code manual to determine wire, fuse and disconnect size requirements.

Page 9

Air

Accessories/Weighted Sound Power/Thermostats

RA13 Series

9

Accessories

Model No. RA1318 RA1324 RA1330 RA1336 RA1342 RA1348 RA1360

Compressor crankcase heater* 44-17402-44 44-17402-44 44-17402-44 44-17402-44 44-17402-45 44-17402-45 44-17402-45

Low ambient control RXAD-A08 RXAD-A08 RXAD-A08 RXAD-A08 RXAD-A08 RXAD-A08 RXAD-A08

Compressor sound cover 68-23427-26 68-23427-26 68-23427-26 68-23427-26 68-23427-25 68-23427-25 68-23427-25

Compressor hard start kit SK-A1 SK-A1 SK-A1 SK-A1 SK-A1 SK-A1 SK-A1

Low pressure control RXAC-A07 RXAC-A07 RXAC-A07 RXAC-A07 RXAC-A07 RXAC-A07 RXAC-A07

High pressure control RXAB-A07 RXAB-A07 RXAB-A07 RXAB-A07 RXAB-A07 RXAB-A07 RXAB-A07

Liquid Line Solenoid

(24 VAC, 50/60 Hz)

Solenoid Valve 200RD2T3TVLC 200RD2T3TVLC 200RD2T3TVLC 200RD2T3TVLC 200RD2T3TVLC 200RD3T3TVLC 200RD3T3TVLC

Solenoid Coil 61-AMG24V 61-AMG24V 61-AMG24V 61-AMG24V 61-AMG24V 61-AMG24V 61-AMG24V

Liquid Line Solenoid

(120/240 VAC, 50/60 Hz)

Solenoid Valve 200RD2T3TVLC 200RD2T3TVLC 200RD2T3TVLC 200RD2T3TVLC 200RD2T3TVLC 200RD3T3TVLC 200RD3T3TVLC

Solenoid Coil 61-AMG120/240V 61-AMG120/240V 61-AMG120/240V 61-AMG120/240V 61-AMG120/240V 61-AMG120/240V 61-AMG120/240V

Top Cap w/Label 91-101123-21 91-101123-21 91-101123-21 91-101123-21 91-101123-21 91-101123-21 91-101123-21

*Crankcase Heater recommended with Low Ambient Kit.

Weighted Sound Power Level (dBA)

RA13 Sound Power Level

Model

Sound Power

Level [dB(A)]

Full Octave Linear Sound Power Level dB - Center Frequency - Hz

Sound Power

Level [dB(A)]

with Sound

Blanket

125 250 500 1000 2000 4000 6300 8000

RA1318 79.1 57.3 63.1 69.8 69.5 65.6 60.5 56.3 53.3 NR

RA1324 75.5 55.4 60.3 64.7 66.4 62.6 58.0 54.3 52.4 NR

RA1330 78.1 51.4 67.4 67.5 68.2 65.5 59.8 55.6 53.6 NR

RA1336 77.5 55.1 66.1 66.9 68.2 64.6 60.7 57.4 55.6 NR

RA1342 72.7 48.9 56.1 62.9 62.2 61.1 55.2 51.9 50.2 NR

RA1348 75.8 51.4 59.6 65.2 65.9 64.3 58.5 55.2 53.7 75.2

RA1360 77.7 51.7 60.9 66.9 70.4 63.5 57.4 55.4 53.8 NR

NOTE: Tested in accordance with AHRI Standard 270-08 (not listed in AHRI)

* Photos are representative. Actual models may vary.

For detailed thermostat match-up information,

see specification sheet form number T11-001.

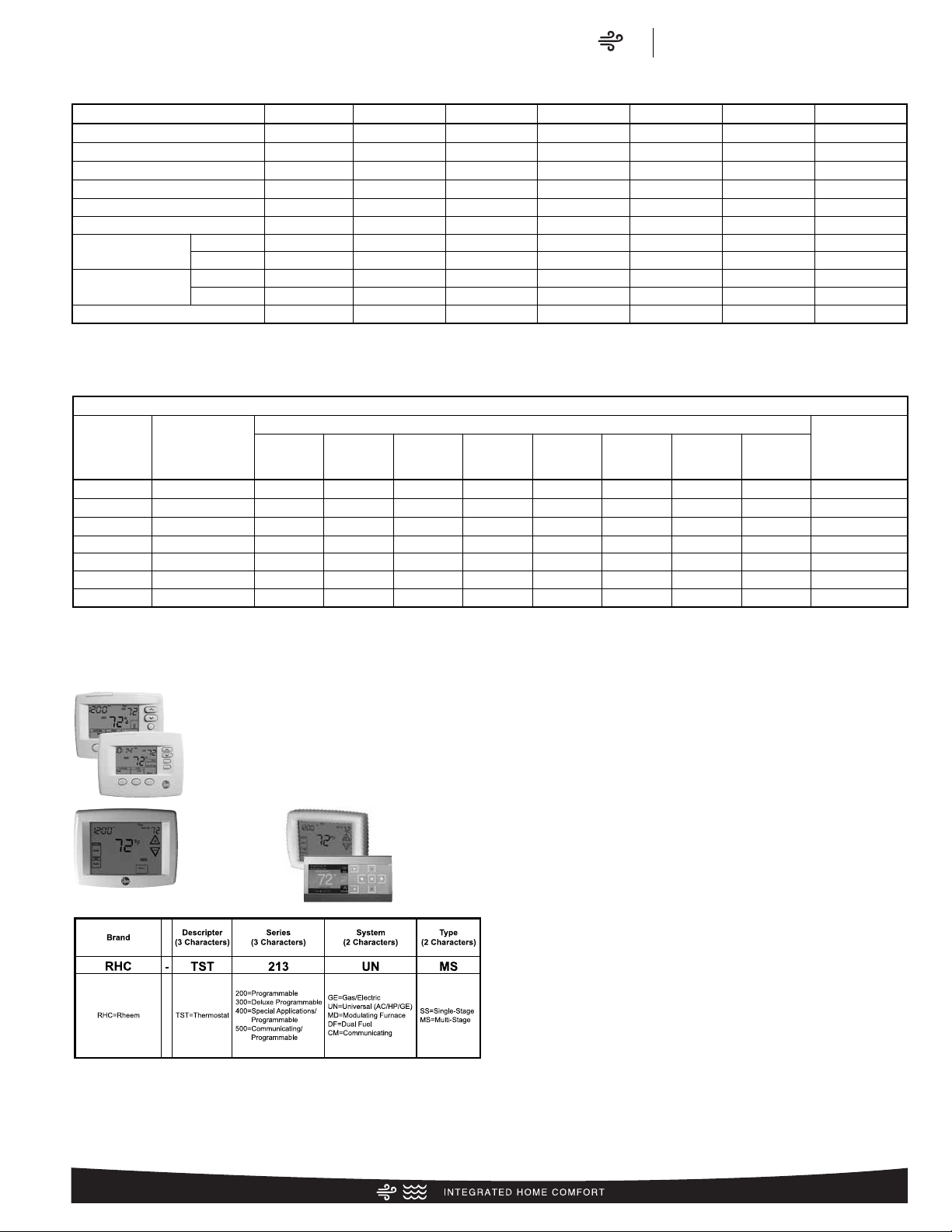

300-Series *

Deluxe

Programmable

400-Series *

Special Applications/

Programmable

500-Series *

Communicating/

Programmable

200-Series *

Programmable

Thermostats

Page 10

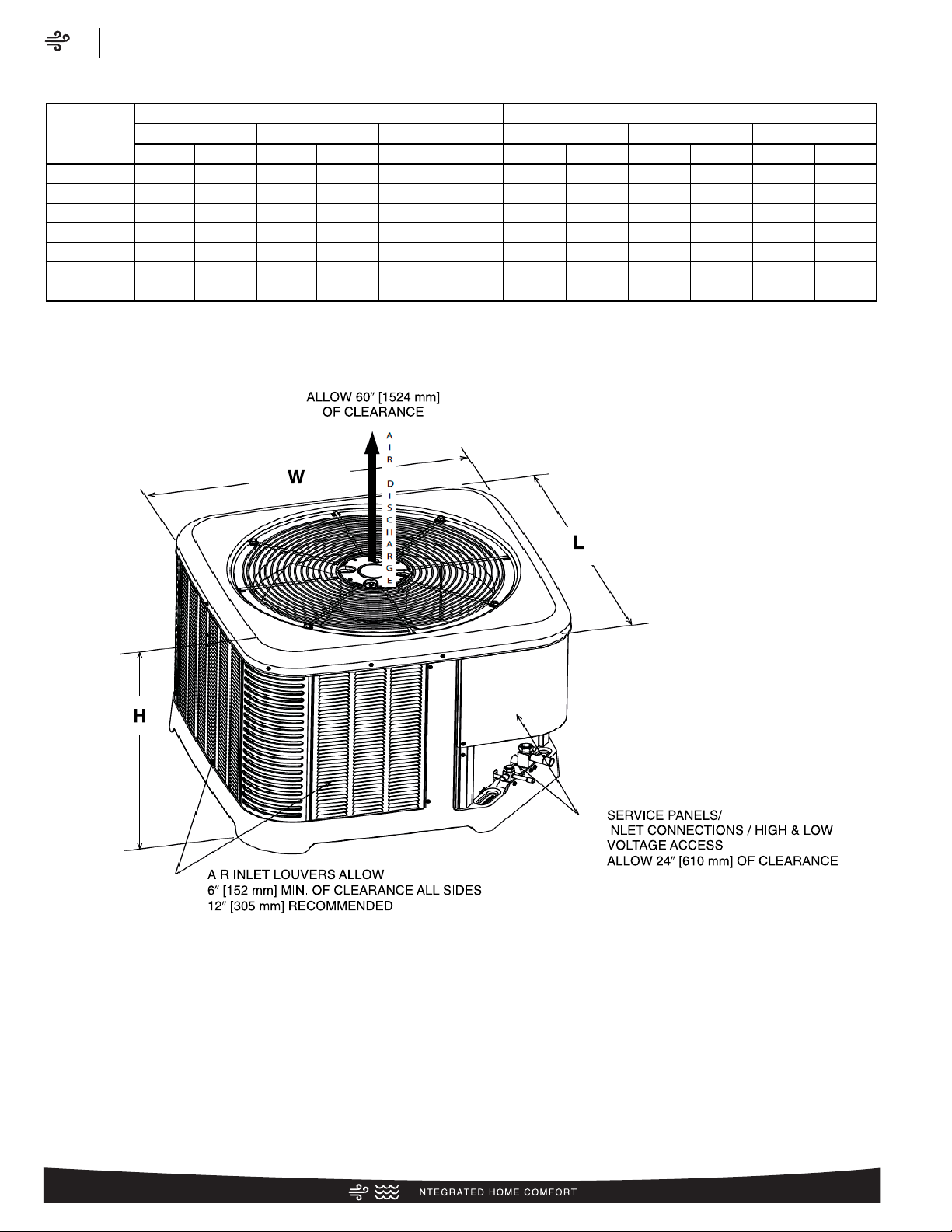

Unit Dimensions

MODEL

NO.

OPERATING SHIPPING

H (Height) L (Length) W (Width) H (Height) L (Length) W (Width)

INCHES mm INCHES mm INCHES mm INCHES mm INCHES mm INCHES mm

RA1318 27 685 29.75 755 29.75 755 28.75 730 32.38 822 32.38 822

RA1324 25 635 29.75 755 29.75 755 26.75 679 32.38 822 32.38 822

RA1330 25 635 29.75 755 29.75 755 26.75 679 32.38 822 32.38 822

RA1336 27 685 29.75 755 29.75 755 28.75 730 32.38 822 32.38 822

RA1342 31 787 29.75 755 29.75 755 32.75 831 32.38 822 32.38 822

RA1348 27 685 33.75 857 33.75 857 28.75 730 36.38 924 36.38 924

RA1360 31 787 35.75 908 35.75 908 32.75 831 38.38 974 38.38 974

[ ] Designates Metric Conversions

ST-A1226-02-00

Air

Unit Dimensions

RA13 Series

10

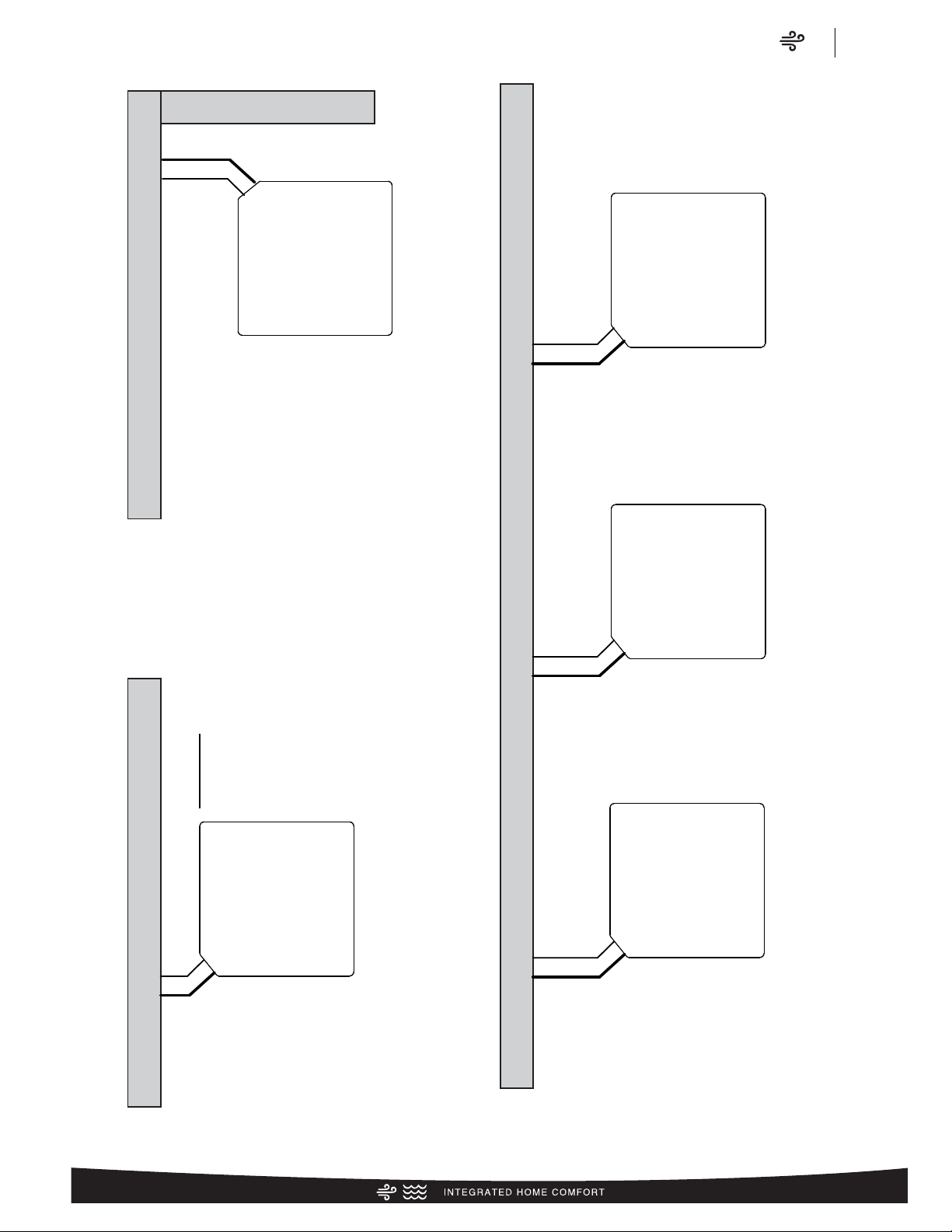

Page 11

6⬙

(152.4)

24⬙

(609.6)

Service

12⬙

(304.8)

6⬙

(152.4)

24⬙

(609.6)

Service

24⬙

(609.6)

24⬙ recommended

9⬙ minimum

12⬙

(304.8)

12⬙

(304.8)

6⬙

(152.4)

24⬙

(609.6)

Service

24⬙

(609.6)

Service

24⬙

(609.6)

Service

18⬙

(457.2)

WALL

WALL

WALL

WALL

NOTE: NUMBERS IN () = mm

CLEARANCES

IMPORTANT: When installing multiple units in an alcove, roof well or partially enclosed area, ensure there is adequate ventillation to prevent re-circulation of discharge air.

ST-A1225-01-00

24⬙

(609.6)

24⬙ recommended

9⬙ minimum

Air

Clearances

RA13 Series

11

Page 12

Application Guidelines

1. Intended for outdoor installation with free air inlet and outlet. Outdoor fan external static pressure available is less than 0.01 -in. wc.

2. Minimum outdoor operation air temperature for cooling mode without low-ambient operation accessory is 55°F (12.8°C).

3. Maximum outdoor operating air temperature is 125°F (51.7°C).

4. For reliable operation, unit should be level in all horizontal planes.

5. Use only copper wire for electric connections at unit. Aluminum and clad aluminum are not acceptable for the type of connector

provided.

6. Do not apply capillary tube indoor coils to these units.

7. Factory – supplied filter drier must be installed.

Air

Wiring Diagram/Application Guidelines

RA13 Series

12

Control Wiring

FIGURE 2

CONTROL WIRING FOR GAS OR OIL FURNACE

IF MAXIMUM OUTLET TEMPERATURE RISE IS DESIRED, IT IS RECOMMENDED THAT

*

W1 (W/BK) AND W2 (W/BL) BE JUMPERED TOGETHER.

FOR TYPICAL GAS OR OIL HEAT

BR – BROWN WIRE

YL – YELLOW WIRE

X – WIRE CONNECTION

TYPICAL CONDENSING

UNIT

YL

X

BR

X

TYPICAL THERMOSTAT

SUBBASE

YGWR

TYPICAL GAS OR

OIL FURNACE

R

W

G

Y

C

FOR TYPICAL ELECTRIC HEAT

BR – BROWN WIRE

R – RED WIRE

YL – YELLOW WIRE

W/BK – WHITE WIRE WITH BLACK STRIPE

G/BK – GREEN WIRE WITH BLACK STRIPE

PU – PURPLE WIRE (NOT USED)

X – WIRE CONNECTION

TYPICAL CONDENSING

UNIT

YL

BR

*

X

X

TYPICAL THERMOSTAT

SUBBASE

YGWR

TYPICAL ELECTRIC HEAT

LOW VOLTAGE JUNCTION BOX

X

•

X

X

X

X

X

W/BL

R

W/BK

G/BK

YL

BR

PU

Page 13

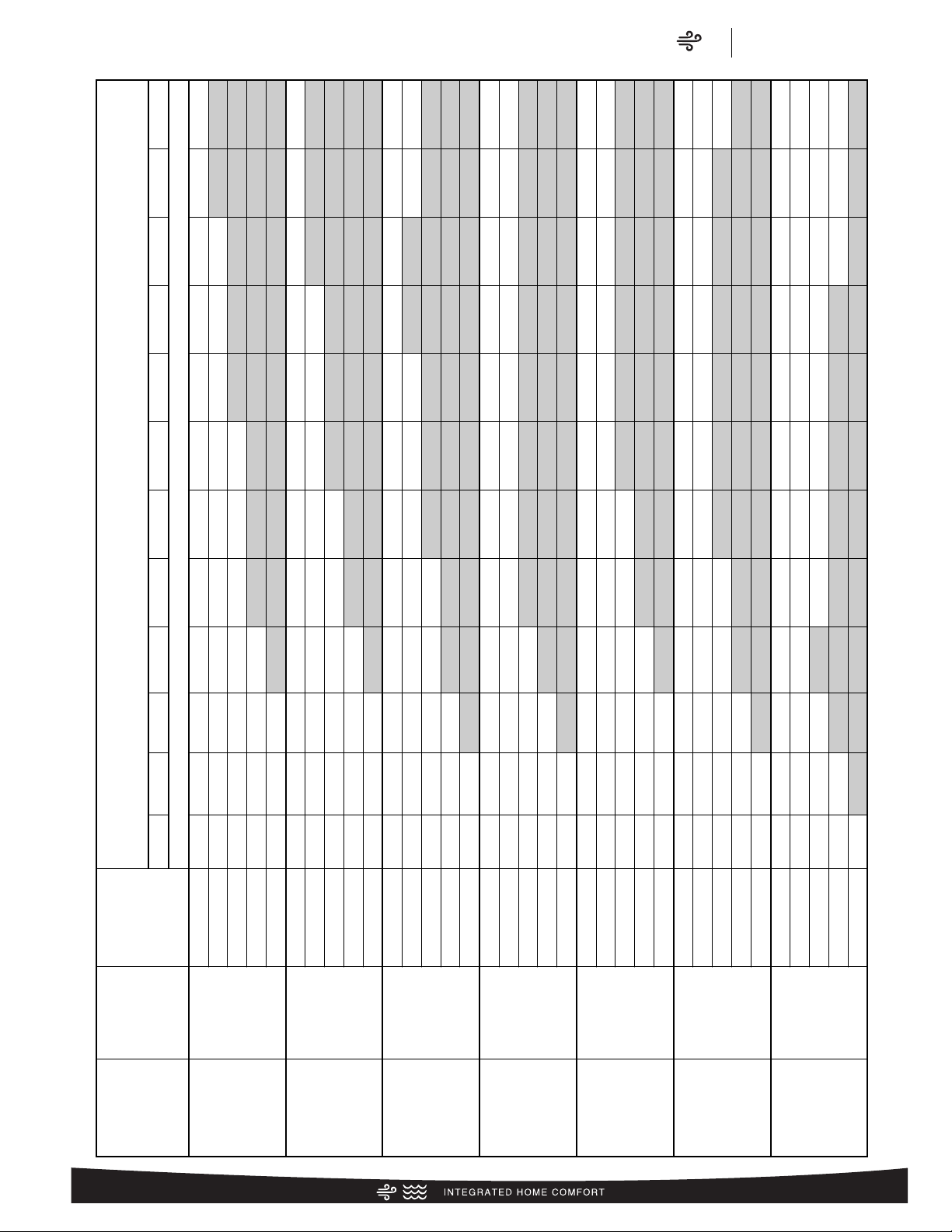

Air

Refrigerant Line Size Information

RA13 Series

13

R-410A System

Capacity Model

Liquid Line Size

Connection Size

(Inch I.D.) [mm]

Liquid Line Size

(Inch O.D.) [mm]

Liquid Line Size

Elevation (Above or Below) Indoor Coil

Tot al Equivalent Length - Feet [m]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

Maximum Vertical Separation – Feet [m]

18 3/8" [9.53]

1/4 [6.35] 25 [7.62] 50 [15.24] 65 [19.81] 50 [15.24] 40 [12.19] 25 [7.62] 10 [3.05]

N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 80 [24.38] 75 [22.86] 75 [22.86] 70 [21.34] 65 [19.81]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 105 [32] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 110 [33.53] 110 [33.53] 110 [33.53] 110 [33.53] 105 [32] 105 [32] 105 [32] 105 [32]

24 3/8" [9.53]

1/4 [6.35] 25 [7.62] 50 [15.24] 35 [10.67] 10 [3.05]

N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 75 [22.86] 70 [21.34] 65 [19.81] 55 [16.76] 50 [15.24] 45 [13.72] 40 [12.19] 30 [9.14]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 80 [24.38]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 105 [32] 105 [32] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 95 [28.96]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32]

30 3/8" [9.53]

1/4 [6.35] 25 [7.62] 25 [7.62]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 65 [19.81] 55 [16.76] 45 [13.72] 35 [10.67] 25 [7.62] 15 [4.57] 5 [1.52]

N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 90 [27.43] 90 [27.43] 85 [25.91] 80 [24.38] 80 [24.38] 75 [22.86] 70 [21.34] 65 [19.81] 65 [19.81]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43] 85 [25.91]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96]

36 3/8" [9.53]

1/4 [6.35] 25 [7.62]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 65 [19.81] 50 [15.24] 35 [10.67] 25 [7.62] 10 [3.05] N/R

N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 80 [24.38] 75 [22.86] 70 [21.34] 65 [19.81] 60 [18.29] 60 [18.29] 55 [16.76] 50 [15.24]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43]

42 3/8" [9.53]

1/4 [6.35] 25 [7.62]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 50 [15.24] 30 [9.14] 15 [4.57]

N/R N/R N/R N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 70 [21.34] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24] 40 [12.19] 35 [10.67] 30 [9.14]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 80 [24.38] 80 [24.38] 75 [22.86] 75 [22.86] 70 [21.34]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43] 90 [27.43]

48 3/8" [9.53]

1/4 [6.35] 5 [1.52]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 30 [9.14] 5 [1.52]

N/R N/R N/R N/R N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 65 [19.81] 60 [18.29] 50 [15.24] 45 [13.72] 35 [10.67] 25 [7.62] 20 [6.1] 10 [3.05]

N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 80 [24.38] 80 [24.38] 75 [22.86] 70 [21.34] 70 [21.34] 65 [19.81] 60 [18.29] 60 [18.29]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 90 [27.43] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 80 [24.38]

60 3/8" [9.53]

1/4 [6.35]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 20 [6.1]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 30 [9.14] 20 [6.1] 5 [1.52] N/R

N/R N/R N/R N/R N/R N/R N/R

7/16 [11.12] 25 [7.62] 45 [13.72] 40 [12.19] 35 [10.67] 30 [9.14] 25 [7.62] 20 [6.1] 15 [4.57] 10 [3.05] N/R N/R N/R

1/2 [12.71] 25 [7.62] 50 [15.24] 45 [13.72] 45 [13.72] 40 [12.19] 40 [12.19] 35 [10.67] 35 [10.67] 30 [9.14] 30 [9.14] 25 [7.62] 25 [7.62]

Refrigerant Line Size Information

NOTES: [ ] Designates Metric Conversions

N/R = Application not recommended.

Grey =This application is acceptable, but the long line guidelines must be followed. Reference Long Line Set section in the I&O

Page 14

Air

Refrigerant Line Size Information

RA13 Series

14

R-410A System

Capacity Model

Vapor Line

Connection Size

(Inch I.D.) [mm]

Vapor Line Size

(Inch O.D.) [mm]

Vapor Line Selection Chart

Capacity Multiplier Table

Tot al Equivalent Length - Feet [m]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

18 3/4" [19.06]

5/8 [15.88]

1.00 0.99 0.99 0.98 0.98 0.98 0.97 0.97 0.96 0.96 0.96 0.95

3/4 [19.05]

1.00 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99 0.99 0.99 0.99

7/8 [22.23]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1-1/8 [28.58]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

24 3/4" [19.06]

5/8 [15.88]

1.00 0.99 0.99 0.98 0.98 0.98 0.97 0.97 0.96 0.96 0.96 0.95

3/4 [19.05]

1.00 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99 0.99 0.99 0.99

7/8 [22.23]

1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

1 [25.4]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1-1/8 [28.58]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

30 3/4" [19.06]

5/8 [15.88]

1.00 0.99 0.99 0.98 0.98 0.98 0.97 0.97 0.96 0.96 0.96 0.95

3/4 [19.05]

1.00 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99 0.99 0.99 0.99

7/8 [22.23]

1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

1 [25.4]

1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.01 1.01 1.01

1-1/8 [28.58]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

36 3/4" [19.06]

5/8 [15.88]

1.00 0.99 0.99 0.98 0.98 0.98 0.97 0.97 0.96 0.96 0.96 0.95

3/4 [19.05]

1.00 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99 0.99 0.99 0.99

7/8 [22.23]

1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

1 [25.4]

1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.01 1.01 1.01

1-1/8 [28.58]

1.00 1.00 1.00 1.00 1.00 1.00 1.01 1.01 1.01 1.01 1.01 1.01

42 7/8" [22.23]

5/8 [15.88]

1.00 0.99 0.99 0.98 0.98 0.98 0.97 0.97 0.96 0.96 0.96 0.95

3/4 [19.05]

1.00 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99 0.99 0.99 0.99

7/8 [22.23]

1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

1 [25.4]

1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.01 1.01 1.01

1-1/8 [28.58]

1.00 1.00 1.00 1.00 1.00 1.00 1.01 1.01 1.01 1.01 1.01 1.01

48 7/8" [22.23]

5/8 [15.88]

1.00 0.99 0.99 0.98 0.98 0.98 0.97 0.97 0.96 0.96 0.96

N/R

3/4 [19.05]

1.00 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99 0.99 0.99

N/R

7/8 [22.23]

1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

N/R

1 [25.4]

1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.01 1.01

N/R

1-1/8 [28.58]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

60 7/8" [22.23]

5/8 [15.88]

1.00 0.99 0.99 0.98

N/R N/R N/R N/R N/R N/R N/R N/R

3/4 [19.05]

1.00 1.00 1.00 1.00

N/R N/R N/R N/R N/R N/R N/R N/R

7/8 [22.23]

1.00 1.00 1.00 1.00

N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4]

1.00 1.00 1.00 1.00

N/R N/R N/R N/R N/R N/R N/R N/R

1-1/8 [28.58]

1.00 1.00 1.00 1.00

N/R N/R N/R N/R N/R N/R N/R N/R

Refrigerant Line Size Information (con’t.)

NOTES: [ ] Designates Metric Conversions

N/R = Application not recommended.

All calculations assume a 3/8" liquid line

Page 15

Air

Performance Data

RA13 Series

Performance Data @ AHRI Standard Conditions – Cooling

High Sales Volume Tested Combination (HSVTC)

Outdoor

Unit

Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1318AJ1 RCF2417STAM 17600 [5.2] 13100 [3.8] 4500 [1.3] 13 11 600 [283.2] 7507439

RA1324AJ1 RCF2417STAM 23600 [6.9] 17600 [5.2] 6000 [1.8] 13 11 800 [377.6] 7507649

RA1330AJ1 RCF3617STAM 28400 [8.3] 21600 [6.3] 6800 [2.0] 13 11 1000 [471.9] 7507846

RA1336AC1 RCF3617STAM 34600 [10.1] 24500 [7.2] 10100 [3.0] 13 11 1025 [483.7] 7508191

RA1336AJ1 RCF3617STAM 34600 [10.1] 24500 [7.2] 10100 [3.0] 13 11 1025 [483.7] 7508557

RA1342AC1 RCF4821STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13 11 1400 [660.7] 7511558

RA1342AJ1 RCF4821STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13 11 1400 [660.7] 7511792

RA1348AC1 RCF4821STAM 47500 [13.9] 34100 [10.0] 13400 [3.9] 13 11 1500 [707.9] 7508923

RA1348AJ1 RCF4821STAM 47500 [13.9] 34100 [10.0] 13400 [3.9] 13 11 1500 [707.9] 7509148

RA1360AC1 RCF6024STAM 56000 [16.4] 39600 [11.6] 16400 [4.8] 13 11 1600 [755.1] 7509314

RA1360AJ1 RCF6024STAM 56000 [16.4] 39600 [11.6] 16400 [4.8] 13 11 1600 [755.1] 7509436

Coil Only Ratings

Outdoor

Unit

Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1318AJ1

RCF2414STAM+RXMD-C04 17600 [5.2] 12600 [3.7] 5000 [1.5] 13 11 600 [283.2] 7507408

RCF2417HTAM+RXMD-C04 17500 [5.1] 12300 [3.6] 5200 [1.5] 13 11 600 [283.2] 7507423

RCF2417MTAM+RXMD-C04 17500 [5.1] 12300 [3.6] 5200 [1.5] 13 11 600 [283.2] 7507438

RCF2421MTAM+RXMD-C04 17500 [5.1] 12300 [3.6] 5200 [1.5] 13 11 600 [283.2] 7507491

RA1324AJ1

RCF2414STAM+RXMD-C04 23800 [7.0] 17100 [5.0] 6700 [2.0] 13 11 800 [377.6] 7507612

RCF2417HTAM+RXMD-C04 23400 [6.9] 16500 [4.8] 6900 [2.0] 13 11 800 [377.6] 7507630

RCF2417MTAM+RXMD-C04 23400 [6.9] 16500 [4.8] 6900 [2.0] 13 11 800 [377.6] 7507648

RCF2421MTAM+RXMD-C04 23400 [6.9] 16500 [4.8] 6900 [2.0] 13 11 800 [377.6] 7507716

RA1330AJ1

RCF3621MTAM+RXMD-C04 29800 [8.7] 21900 [6.4] 7900 [2.3] 13.5 11.5 1000 [471.9] 7507895

RCF3621STAM+RXMD-C04 28400 [8.3] 20500 [6.0] 7900 [2.3] 13 11 1000 [471.9] 7507926

RCF3624HTAM+RXMD-C04 30400 [8.9] 22200 [6.5] 8200 [2.4] 13.5 11.5 1000 [471.9] 7507950

RCF3624MTAM+RXMD-C04 29800 [8.7] 21900 [6.4] 7900 [2.3] 13.5 11.5 1000 [471.9] 7507973

RA1336AC1

RCF3621MTAM+RXMD-C04 36600 [10.7] 24900 [7.3] 11700 [3.4] 13.5 11.5 1025 [483.7] 7508240

RCF3621STAM+RXMD-C04 34400 [10.1] 23100 [6.8] 11300 [3.3] 13 11 1025 [483.7] 7508271

RCF3624HTAM+RXMD-C04 37400 [11.0] 25600 [7.5] 11800 [3.5] 13.5 11.5 1025 [483.7] 7508298

RCF3624MTAM+RXMD-C04 36600 [10.7] 24900 [7.3] 11700 [3.4] 13.5 11.5 1025 [483.7] 7508325

RA1336AJ1

RCF3621MTAM+RXMD-C04 36600 [10.7] 24900 [7.3] 11700 [3.4] 13.5 11.5 1025 [483.7] 7508606

RCF3621STAM+RXMD-C04 34400 [10.1] 23100 [6.8] 11300 [3.3] 13 11 1025 [483.7] 7508637

RCF3624HTAM+RXMD-C04 37400 [11.0] 25600 [7.5] 11800 [3.5] 13.5 11.5 1025 [483.7] 7508664

RCF3624MTAM+RXMD-C04 36600 [10.7] 24900 [7.3] 11700 [3.4] 13.5 11.5 1025 [483.7] 7508691

RA1342AC1

RCF4824HTAM+RXMD-C04 41500 [12.2] 29400 [8.6] 12100 [3.5] 13 11.5 1400 [660.7] 7511616

RCF4824STAM+RXMD-C04 40000 [11.7] 28000 [8.2] 12000 [3.5] 13 11 1375 [648.9] 7511643

RA1342AJ1

RCF4824HTAM+RXMD-C04 41500 [12.2] 29400 [8.6] 12100 [3.5] 13 11.5 1400 [660.7] 7511850

RCF4824STAM+RXMD-C04 40000 [11.7] 28000 [8.2] 12000 [3.5] 13 11 1375 [648.9] 7511877

RA1348AC1

RCF4824HTAM+RXMD-C04 49500 [14.5] 34200 [10.0] 15300 [4.5] 13 11.5 1500 [707.9] 7508968

RCF4824STAM+RXMD-C04 47500 [13.9] 34100 [10.0] 13400 [3.9] 13 11 1500 [707.9] 7509019

RA1348AJ1

RCF4824HTAM+RXMD-C04 49500 [14.5] 34200 [10.0] 15300 [4.5] 13 11.5 1500 [707.9] 7509188

RCF4824STAM+RXMD-C04 47500 [13.9] 34100 [10.0] 13400 [3.9] 13 11 1500 [707.9] 7509210

RA1360AC1

RCF6024HTAM+RXMD-C04 56000 [16.4] 39600 [11.6] 16400 [4.8] 13 11 1600 [755.1] 7509313

RCF6024HTAM+RXMD-C04 56000 [16.4] 39600 [11.6] 16400 [4.8] 13 11 1600 [755.1] 7509435

[ ] Designates Metric Conversions

15

Page 16

Air

Performance Data

RA13 Series

16

Performance Data @ AHRI Standard Conditions – Cooling (con’t.)

R801T Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1318AJ1 R801TA050314MSA

RCF2414STAM 18100 [5.3] 13100 [3.8] 5000 [1.5] 14.5 12 625 [295.0] 7507407

RCF2417HTAM 18000 [5.3] 12800 [3.8] 5200 [1.5] 14.5 12 625 [295.0] 7507409

RCF2417MTAM 18000 [5.3] 12800 [3.8] 5200 [1.5] 14.5 12 625 [295.0] 7507424

RCF2417STAM 18000 [5.3] 13500 [4.0] 4500 [1.3] 14.5 12 625 [295.0] 7507440

RA1318AJ1 R801TA075317ZSA

RCF2417HTAM 18300 [5.4] 13200 [3.9] 5100 [1.5] 14.5 12 650 [306.8] 7507410

RCF2417MTAM 18300 [5.4] 13200 [3.9] 5100 [1.5] 14.5 12 650 [306.8] 7507425

RCF2417STAM 18300 [5.4] 13900 [4.1] 4400 [1.3] 14.5 12 650 [306.8] 7507441

RCF2421MTAM 18300 [5.4] 13200 [3.9] 5100 [1.5] 14.5 12 650 [306.8] 7507473

RA1324AJ1 R801TA050314MSA

RCF2414STAM 24400 [7.2] 17700 [5.2] 6700 [2.0] 14.5 12 800 [377.6] 7507611

RCF2417HTAM 24400 [7.2] 17700 [5.2] 6700 [2.0] 14.5 12 875 [413.0] 7507613

RCF2417MTAM 24200 [7.1] 17500 [5.1] 6700 [2.0] 14.5 12 850 [401.2] 7507631

RCF2417STAM 24200 [7.1] 18300 [5.4] 5900 [1.7] 14 11.5 825 [389.4] 7507650

RA1324AJ1 R801TA075317ZSA

RCF2417HTAM 24400 [7.2] 17700 [5.2] 6700 [2.0] 14 11.5 875 [413.0] 7507614

RCF2417MTAM 24400 [7.2] 17700 [5.2] 6700 [2.0] 14 11.5 875 [413.0] 7507632

RCF2417STAM 24200 [7.1] 18400 [5.4] 5800 [1.7] 14 11.5 850 [401.2] 7507651

RCF2421MTAM 24400 [7.2] 17700 [5.2] 6700 [2.0] 14 11.5 875 [413.0] 7507692

RA1330AJ1 R801TA050314MSA RCF3617STAM 28800 [8.4] 22000 [6.4] 6800 [2.0] 14 11.5 1000 [471.9] 7507847

RA1330AJ1 R801TA075317ZSA

RCF3617STAM 28400 [8.3] 21200 [6.2] 7200 [2.1] 14 11.5 875 [413.0] 7507848

RCF3621MTAM 30800 [9.0] 23200 [6.8] 7600 [2.2] 14.5 12 1075 [507.3] 7507865

RCF3621STAM 28400 [8.3] 21200 [6.2] 7200 [2.1] 14 11.5 875 [413.0] 7507896

RA1330AJ1 R801TA075417MSA

RCF3617STAM 29000 [8.5] 22200 [6.5] 6800 [2.0] 14 11.5 1000 [471.9] 7507849

RCF3621MTAM 30800 [9.0] 23100 [6.8] 7700 [2.3] 14.5 12 1050 [495.5] 7507866

RCF3621STAM 29200 [8.6] 22500 [6.6] 6700 [2.0] 14 11.5 1025 [483.7] 7507897

RA1330AJ1 R801TA075521ZSA

RCF3621MTAM 30600 [9.0] 22700 [6.7] 7900 [2.3] 15 12.5 1000 [471.9] 7507867

RCF3621STAM 29000 [8.5] 22100 [6.5] 6900 [2.0] 14 11.5 975 [460.1] 7507898

RCF3624HTAM 31200 [9.1] 23000 [6.7] 8200 [2.4] 15.5 13 1025 [483.7] 7507927

RCF3624MTAM 30600 [9.0] 22700 [6.7] 7900 [2.3] 15 12.5 1000 [471.9] 7507951

RA1330AJ1 R801TA100521MSA

RCF3621MTAM 30800 [9.0] 23100 [6.8] 7700 [2.3] 15.1 12.5 1050 [495.5] 7507868

RCF3621STAM 29000 [8.5] 22200 [6.5] 6800 [2.0] 14 11.5 1000 [471.9] 7507899

RCF3624HTAM 31800 [9.3] 24000 [7.0] 7800 [2.3] 15.5 13 1100 [519.1] 7507928

RCF3624MTAM 30800 [9.0] 23100 [6.8] 7700 [2.3] 15.1 12.5 1050 [495.5] 7507952

RA1330AJ1 R801TA100521ZSA

RCF3621MTAM 30600 [9.0] 22600 [6.6] 8000 [2.3] 15.1 12.5 975 [460.1] 7507869

RCF3621STAM 29000 [8.5] 22100 [6.5] 6900 [2.0] 14 11.5 975 [460.1] 7507900

RCF3624HTAM 31200 [9.1] 23000 [6.7] 8200 [2.4] 15.5 13 1025 [483.7] 7507929

RCF3624MTAM 30600 [9.0] 22600 [6.6] 8000 [2.3] 15.1 12.5 975 [460.1] 7507953

RA1330AJ1 R801TA125524ZSA

RCF3624HTAM 31200 [9.1] 22900 [6.7] 8300 [2.4] 15.5 13 975 [460.1] 7507930

RCF3624MTAM 30200 [8.9] 22000 [6.4] 8200 [2.4] 15 12.5 925 [436.6] 7507954

RA1336AC1 R801TA050314MSA RCF3617STAM 35000 [10.3] 24700 [7.2] 10300 [3.0] 13.5 11.5 1000 [471.9] 7508192

RA1336AC1 R801TA075317ZSA

RCF3617STAM 35000 [10.3] 25000 [7.3] 10000 [2.9] 13.5 11.5 1050 [495.5] 7508193

RCF3621MTAM 38000 [11.1] 27300 [8.0] 10700 [3.1] 14 11.5 1250 [589.9] 7508210

RCF3621STAM 35000 [10.3] 25000 [7.3] 10000 [2.9] 13.5 11.5 1050 [495.5] 7508241

RA1336AC1 R801TA075417MSA

RCF3617STAM 36000 [10.6] 26800 [7.9] 9200 [2.7] 13.5 11.5 1225 [578.1] 7508194

RCF3621MTAM 38000 [11.1] 27100 [7.9] 10900 [3.2] 14.5 12 1200 [566.3] 7508211

RCF3621STAM 36000 [10.6] 26900 [7.9] 9100 [2.7] 13.5 11.5 1250 [589.9] 7508242

RA1336AC1 R801TA075521ZSA

RCF3621MTAM 37200 [10.9] 25300 [7.4] 11900 [3.5] 14.5 12 1000 [471.9] 7508212

RCF3621STAM 35800 [10.5] 26300 [7.7] 9500 [2.8] 13.5 11.5 1175 [554.5] 7508243

RCF3624HTAM 38000 [11.1] 26200 [7.7] 11800 [3.5] 15.1 12.5 1025 [483.7] 7508272

RCF3624MTAM 37200 [10.9] 25300 [7.4] 11900 [3.5] 14.5 12 1000 [471.9] 7508299

[ ] Designates Metric Conversions

Page 17

Air

Performance Data

RA13 Series

17

Performance Data @ AHRI Standard Conditions – Cooling (con’t.)

R801T Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1336AC1 R801TA100521MSA

RCF3621MTAM 37200 [10.9] 25500 [7.5] 11700 [3.4] 14.5 12 1050 [495.5] 7508213

RCF3621STAM 35200 [10.3] 24900 [7.3] 10300 [3.0] 14 11.5 1000 [471.9] 7508244

RCF3624HTAM 38500 [11.3] 27000 [7.9] 11500 [3.4] 15.1 12.5 1100 [519.1] 7508273

RCF3624MTAM 37200 [10.9] 25500 [7.5] 11700 [3.4] 14.5 12 1050 [495.5] 7508300

RA1336AC1 R801TA100521ZSA

RCF3621MTAM 38000 [11.1] 27200 [8.0] 10800 [3.2] 14.5 12 1225 [578.1] 7508214

RCF3621STAM 35800 [10.5] 26300 [7.7] 9500 [2.8] 13.5 11.5 1175 [554.5] 7508245

RCF3624HTAM 38000 [11.1] 26200 [7.7] 11800 [3.5] 15.1 12.5 1025 [483.7] 7508274

RCF3624MTAM 38000 [11.1] 27200 [8.0] 10800 [3.2] 14.5 12 1225 [578.1] 7508301

RA1336AC1 R801TA125524MSA

RCF3624HTAM 39000 [11.4] 28000 [8.2] 11000 [3.2] 15.1 12.5 1200 [566.3] 7508275

RCF3624MTAM 38000 [11.1] 26900 [7.9] 11100 [3.3] 14.5 12 1175 [554.5] 7508302

RA1336AC1 R801TA125524ZSA

RCF3624HTAM 39000 [11.4] 27800 [8.1] 11200 [3.3] 15.1 12.5 1150 [542.7] 7508276

RCF3624MTAM 37600 [11.0] 26200 [7.7] 11400 [3.3] 14.5 12 1100 [519.1] 7508303

RA1336AJ1 R801TA050314MSA RCF3617STAM 35000 [10.3] 24700 [7.2] 10300 [3.0] 13.5 11.5 1000 [471.9] 7508558

RA1336AJ1 R801TA075317ZSA

RCF3617STAM 35000 [10.3] 25000 [7.3] 10000 [2.9] 13.5 11.5 1050 [495.5] 7508559

RCF3621MTAM 38000 [11.1] 27300 [8.0] 10700 [3.1] 14 11.5 1250 [589.9] 7508576

RCF3621STAM 35000 [10.3] 25000 [7.3] 10000 [2.9] 13.5 11.5 1050 [495.5] 7508607

RA1336AJ1 R801TA075417MSA

RCF3617STAM 36000 [10.6] 26800 [7.9] 9200 [2.7] 13.5 11.5 1225 [578.1] 7508560

RCF3621MTAM 38000 [11.1] 27100 [7.9] 10900 [3.2] 14.5 12 1200 [566.3] 7508577

RCF3621STAM 36000 [10.6] 26900 [7.9] 9100 [2.7] 13.5 11.5 1250 [589.9] 7508608

RA1336AJ1 R801TA075521ZSA

RCF3621MTAM 37200 [10.9] 25300 [7.4] 11900 [3.5] 14.5 12 1000 [471.9] 7508578

RCF3621STAM 35800 [10.5] 26300 [7.7] 9500 [2.8] 13.5 11.5 1175 [554.5] 7508609

RCF3624HTAM 38000 [11.1] 26200 [7.7] 11800 [3.5] 15.1 12.5 1025 [483.7] 7508638

RCF3624MTAM 37200 [10.9] 25300 [7.4] 11900 [3.5] 14.5 12 1000 [471.9] 7508665

RA1336AJ1 R801TA100521MSA

RCF3621MTAM 37200 [10.9] 25500 [7.5] 11700 [3.4] 14.5 12 1050 [495.5] 7508579

RCF3621STAM 35200 [10.3] 24900 [7.3] 10300 [3.0] 14 11.5 1000 [471.9] 7508610

RCF3624HTAM 38500 [11.3] 27000 [7.9] 11500 [3.4] 15.1 12.5 1100 [519.1] 7508639

RCF3624MTAM 37200 [10.9] 25500 [7.5] 11700 [3.4] 14.5 12 1050 [495.5] 7508666

RA1336AJ1 R801TA100521ZSA

RCF3621MTAM 38000 [11.1] 27200 [8.0] 10800 [3.2] 14.5 12 1225 [578.1] 7508580

RCF3621STAM 35800 [10.5] 26300 [7.7] 9500 [2.8] 13.5 11.5 1175 [554.5] 7508611

RCF3624HTAM 38000 [11.1] 26200 [7.7] 11800 [3.5] 15.1 12.5 1025 [483.7] 7508640

RCF3624MTAM 38000 [11.1] 27200 [8.0] 10800 [3.2] 14.5 12 1225 [578.1] 7508667

RA1336AJ1 R801TA125524MSA

RCF3624HTAM 39000 [11.4] 28000 [8.2] 11000 [3.2] 15.1 12.5 1200 [566.3] 7508641

RCF3624MTAM 38000 [11.1] 26900 [7.9] 11100 [3.3] 14.5 12 1175 [554.5] 7508668

RA1336AJ1 R801TA125524ZSA

RCF3624HTAM 39000 [11.4] 27800 [8.1] 11200 [3.3] 15.1 12.5 1150 [542.7] 7508642

RCF3624MTAM 37600 [11.0] 26200 [7.7] 11400 [3.3] 14.5 12 1100 [519.1] 7508669

RA1342AC1 R801TA075317ZSA RCF4821STAM 40000 [11.7] 29000 [8.5] 11000 [3.2] 13.5 11.5 1250 [589.9] 7511559

RA1342AC1 R801TA075417MSA RCF4821STAM 40000 [11.7] 29100 [8.5] 10900 [3.2] 13.5 11.5 1275 [601.7] 7511560

RA1342AC1 R801TA075521ZSA

RCF4821STAM 40000 [11.7] 28800 [8.4] 11200 [3.3] 13.5 11.5 1225 [578.1] 7511561

RCF4824HTAM 41500 [12.2] 28600 [8.4] 12900 [3.8] 14 11.5 1250 [589.9] 7511589

RCF4824STAM 40000 [11.7] 28800 [8.4] 11200 [3.3] 13.5 11.5 1225 [578.1] 7511617

RA1342AC1 R801TA100521MSA

RCF4821STAM 40500 [11.9] 29900 [8.8] 10600 [3.1] 14 11.5 1325 [625.3] 7511562

RCF4824HTAM 42000 [12.3] 29600 [8.7] 12400 [3.6] 14.5 12 1350 [637.1] 7511590

RCF4824STAM 40500 [11.9] 29900 [8.8] 10600 [3.1] 14 11.5 1325 [625.3] 7511618

RA1342AC1 R801TA100521ZSA

RCF4821STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13.5 11.5 1425 [672.5] 7511563

RCF4824HTAM 42500 [12.5] 30700 [9.0] 11800 [3.5] 14 11.5 1450 [684.3] 7511591

RCF4824STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13.5 11.5 1425 [672.5] 7511619

RA1342AC1 R801TA125524MSA

RCF4824HTAM 42500 [12.5] 30400 [8.9] 12100 [3.5] 14.5 12 1400 [660.7] 7511592

RCF4824STAM 40500 [11.9] 30000 [8.8] 10500 [3.1] 14 11.5 1350 [637.1] 7511620

[ ] Designates Metric Conversions

Page 18

18

Air

Performance Data

RA13 Series

18

Performance Data @ AHRI Standard Conditions – Cooling (con’t.)

R801T Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1342AC1 R801TA125524ZSA

RCF4824HTAM 41500 [12.2] 28100 [8.2] 13400 [3.9] 14.5 12 1150 [542.7] 7511593

RCF4824STAM 39500 [11.6] 27700 [8.1] 11800 [3.5] 14 11.5 1100 [519.1] 7511621

RA1342AJ1 R801TA075317ZSA RCF4821STAM 40000 [11.7] 29000 [8.5] 11000 [3.2] 13.5 11.5 1250 [589.9] 7511793

RA1342AJ1 R801TA075417MSA RCF4821STAM 40000 [11.7] 29100 [8.5] 10900 [3.2] 13.5 11.5 1275 [601.7] 7511794

RA1342AJ1 R801TA075521ZSA

RCF4821STAM 40000 [11.7] 28800 [8.4] 11200 [3.3] 13.5 11.5 1225 [578.1] 7511795

RCF4824HTAM 41500 [12.2] 28600 [8.4] 12900 [3.8] 14 11.5 1250 [589.9] 7511823

RCF4824STAM 40000 [11.7] 28800 [8.4] 11200 [3.3] 13.5 11.5 1225 [578.1] 7511851

RA1342AJ1 R801TA100521MSA

RCF4821STAM 40500 [11.9] 29900 [8.8] 10600 [3.1] 14 11.5 1325 [625.3] 7511796

RCF4824HTAM 42000 [12.3] 29600 [8.7] 12400 [3.6] 14.5 12 1350 [637.1] 7511824

RCF4824STAM 40500 [11.9] 29900 [8.8] 10600 [3.1] 14 11.5 1325 [625.3] 7511852

RA1342AJ1 R801TA100521ZSA

RCF4821STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13.5 11.5 1425 [672.5] 7511797

RCF4824HTAM 42500 [12.5] 30700 [9.0] 11800 [3.5] 14 11.5 1450 [684.3] 7511825

RCF4824STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13.5 11.5 1425 [672.5] 7511853

RA1342AJ1 R801TA125524MSA

RCF4824HTAM 42500 [12.5] 30400 [8.9] 12100 [3.5] 14.5 12 1400 [660.7] 7511826

RCF4824STAM 40500 [11.9] 30000 [8.8] 10500 [3.1] 14 11.5 1350 [637.1] 7511854

RA1342AJ1 R801TA125524ZSA

RCF4824HTAM 41500 [12.2] 28100 [8.2] 13400 [3.9] 14.5 12 1150 [542.7] 7511827

RCF4824STAM 39500 [11.6] 27700 [8.1] 11800 [3.5] 14 11.5 1100 [519.1] 7511855

RA1348AC1 R801TA075417MSA RCF4821STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13 11.5 1375 [648.9] 7508924

RA1348AC1 R801TA075521ZSA

RCF4821STAM 47000 [13.8] 33000 [9.7] 14000 [4.1] 13 11.5 1400 [660.7] 7508925

RCF4824HTAM 50000 [14.7] 34300 [10.1] 15700 [4.6] 13.5 11.5 1450 [684.3] 7508939

RCF4824STAM 47000 [13.8] 33000 [9.7] 14000 [4.1] 13 11.5 1400 [660.7] 7508970

RA1348AC1 R801TA100521MSA

RCF4821STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13.5 11.5 1375 [648.9] 7508926

RCF4824HTAM 50000 [14.7] 34200 [10.0] 15800 [4.6] 14 11.5 1425 [672.5] 7508940

RCF4824STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13.5 11.5 1375 [648.9] 7508973

RA1348AC1 R801TA100521ZSA

RCF4821STAM 47000 [13.8] 33000 [9.7] 14000 [4.1] 13 11.5 1400 [660.7] 7508927

RCF4824HTAM 49500 [14.5] 33700 [9.9] 15800 [4.6] 13.5 11.5 1425 [672.5] 7508941

RCF4824STAM 47000 [13.8] 33000 [9.7] 14000 [4.1] 13 11.5 1400 [660.7] 7508975

RA1348AC1 R801TA125524MSA

RCF4824HTAM 49500 [14.5] 33300 [9.8] 16200 [4.7] 14 11.5 1375 [648.9] 7508942

RCF4824STAM 47000 [13.8] 32500 [9.5] 14500 [4.2] 13.5 11.5 1325 [625.3] 7508977

RA1348AC1 R801TA125524ZSA

RCF4824HTAM 49500 [14.5] 33300 [9.8] 16200 [4.7] 13.5 11.5 1375 [648.9] 7508943

RCF4824STAM 47000 [13.8] 32500 [9.5] 14500 [4.2] 13 11.5 1325 [625.3] 7508979

RA1348AJ1 R801TA075417MSA RCF4821STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13 11.5 1375 [648.9] 7509149

RA1348AJ1 R801TA075521ZSA

RCF4821STAM 47000 [13.8] 33000 [9.7] 14000 [4.1] 13 11.5 1400 [660.7] 7509150

RCF4824HTAM 50000 [14.7] 34300 [10.1] 15700 [4.6] 13.5 11.5 1450 [684.3] 7509164

RCF4824STAM 47000 [13.8] 33000 [9.7] 14000 [4.1] 13 11.5 1400 [660.7] 7509189

RA1348AJ1 R801TA100521MSA

RCF4821STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13.5 11.5 1375 [648.9] 7509151

RCF4824HTAM 50000 [14.7] 34200 [10.0] 15800 [4.6] 14 11.5 1425 [672.5] 7509165

RCF4824STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13.5 11.5 1375 [648.9] 7509190

RA1348AJ1 R801TA100521ZSA

RCF4821STAM 47000 [13.8] 33000 [9.7] 14000 [4.1] 13 11.5 1400 [660.7] 7509152

RCF4824HTAM 49500 [14.5] 33700 [9.9] 15800 [4.6] 13.5 11.5 1425 [672.5] 7509166

RCF4824STAM 47000 [13.8] 33000 [9.7] 14000 [4.1] 13 11.5 1400 [660.7] 7509191

RA1348AJ1 R801TA125524MSA

RCF4824HTAM 49500 [14.5] 33300 [9.8] 16200 [4.7] 14 11.5 1375 [648.9] 7509167

RCF4824STAM 47000 [13.8] 32500 [9.5] 14500 [4.2] 13.5 11.5 1325 [625.3] 7509192

RA1348AJ1 R801TA125524ZSA

RCF4824HTAM 49500 [14.5] 33300 [9.8] 16200 [4.7] 13.5 11.5 1375 [648.9] 7509168

RCF4824STAM 47000 [13.8] 32500 [9.5] 14500 [4.2] 13 11.5 1325 [625.3] 7509193

RA1360AC1 R801TA075521ZSA

RCF6024HTAM 56000 [16.4] 38500 [11.3] 17500 [5.1] 13 11 1450 [684.3] 7509291

RCF6024STAM 56000 [16.4] 38500 [11.3] 17500 [5.1] 13 11 1450 [684.3] 7509315

[ ] Designates Metric Conversions

Page 19

19

Air

Performance Data

RA13 Series

19

Performance Data @ AHRI Standard Conditions – Cooling (con’t.)

R801T Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1360AC1 R801TA100521MSA

RCF6024HTAM 57000 [16.7] 41100 [12.0] 15900 [4.7] 13.5 11.5 1650 [778.7] 7509292

RCF6024STAM 57000 [16.7] 41100 [12.0] 15900 [4.7] 13.5 11.5 1650 [778.7] 7509316

RA1360AC1 R801TA100521ZSA

RCF6024HTAM 57000 [16.7] 41500 [12.2] 15500 [4.5] 13 11 1700 [802.3] 7509293

RCF6024STAM 57000 [16.7] 41500 [12.2] 15500 [4.5] 13 11 1700 [802.3] 7509317

RA1360AC1 R801TA125524MSA

RCF6024HTAM 57000 [16.7] 41100 [12.0] 15900 [4.7] 13.5 11.5 1650 [778.7] 7509294

RCF6024STAM 57000 [16.7] 41100 [12.0] 15900 [4.7] 13.5 11.5 1650 [778.7] 7509318

RA1360AC1 R801TA125524ZSA

RCF6024HTAM 57000 [16.7] 41300 [12.1] 15700 [4.6] 13 11 1675 [790.5] 7509295

RCF6024STAM 57000 [16.7] 41300 [12.1] 15700 [4.6] 13 11 1675 [790.5] 7509319

RA1360AJ1 R801TA075521ZSA

RCF6024HTAM 56000 [16.4] 38500 [11.3] 17500 [5.1] 13 11 1450 [684.3] 7509413

RCF6024STAM 56000 [16.4] 38500 [11.3] 17500 [5.1] 13 11 1450 [684.3] 7509437

RA1360AJ1 R801TA100521MSA

RCF6024HTAM 57000 [16.7] 41100 [12.0] 15900 [4.7] 13.5 11.5 1650 [778.7] 7509414

RCF6024STAM 57000 [16.7] 41100 [12.0] 15900 [4.7] 13.5 11.5 1650 [778.7] 7509438

RA1360AJ1 R801TA100521ZSA

RCF6024HTAM 57000 [16.7] 41500 [12.2] 15500 [4.5] 13 11 1700 [802.3] 7509415

RCF6024STAM 57000 [16.7] 41500 [12.2] 15500 [4.5] 13 11 1700 [802.3] 7509439

RA1360AJ1 R801TA125524MSA

RCF6024HTAM 57000 [16.7] 41100 [12.0] 15900 [4.7] 13.5 11.5 1650 [778.7] 7509416

RCF6024STAM 57000 [16.7] 41100 [12.0] 15900 [4.7] 13.5 11.5 1650 [778.7] 7509440

RA1360AJ1 R801TA125524ZSA

RCF6024HTAM 57000 [16.7] 41300 [12.1] 15700 [4.6] 13 11 1675 [790.5] 7509417

RCF6024STAM 57000 [16.7] 41300 [12.1] 15700 [4.6] 13 11 1675 [790.5] 7509441

[ ] Designates Metric Conversions

Page 20

Air

Performance Data

RA13 Series

20

Performance Data @ AHRI Standard Conditions – Cooling (con’t.)

R95T Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1318AJ1 R95TA0401317MSA

RCF2417HTAM 18200 [5.3] 13100 [3.8] 5100 [1.5] 14.5 12 650 [306.8] 7507411

RCF2417MTAM 18200 [5.3] 13100 [3.8] 5100 [1.5] 14.5 12 650 [306.8] 7507426

RCF2417STAM 18200 [5.3] 13800 [4.0] 4400 [1.3] 14.5 12 650 [306.8] 7507442

RCF2421MTAM 18200 [5.3] 13100 [3.8] 5100 [1.5] 14.5 12 650 [306.8] 7507474

RA1324AJ1 R95TA0401317MSA

RCF2417HTAM 24400 [7.2] 17700 [5.2] 6700 [2.0] 14 11.5 875 [413.0] 7507615

RCF2417MTAM 24400 [7.2] 17700 [5.2] 6700 [2.0] 14 11.5 875 [413.0] 7507633

RCF2417STAM 24200 [7.1] 18400 [5.4] 5800 [1.7] 14 11.5 850 [401.2] 7507652

RCF2421MTAM 24400 [7.2] 17700 [5.2] 6700 [2.0] 14 11.5 875 [413.0] 7507693

RA1324AJ1 R95TA0601317MSA

RCF2417HTAM 24200 [7.1] 17500 [5.1] 6700 [2.0] 14 11.5 850 [401.2] 7507616

RCF2417MTAM 24000 [7.0] 17300 [5.1] 6700 [2.0] 14 11.5 850 [401.2] 7507634

RCF2417STAM 23400 [6.9] 17200 [5.0] 6200 [1.8] 14 11.5 700 [330.4] 7507653

RCF2421MTAM 24000 [7.0] 17300 [5.1] 6700 [2.0] 14 11.5 850 [401.2] 7507694

RA1324AJ1 R95TA0701317MSA

RCF2417HTAM 24000 [7.0] 17300 [5.1] 6700 [2.0] 14 11.5 850 [401.2] 7507617

RCF2417MTAM 24000 [7.0] 17300 [5.1] 6700 [2.0] 14 11.5 850 [401.2] 7507635

RCF2417STAM 24000 [7.0] 18100 [5.3] 5900 [1.7] 13.5 11.5 825 [389.4] 7507654

RCF2421MTAM 24000 [7.0] 17300 [5.1] 6700 [2.0] 14 11.5 850 [401.2] 7507695

RA1330AJ1 R95TA0401317MSA

RCF3617STAM 28600 [8.4] 21600 [6.3] 7000 [2.1] 14 11.5 925 [436.6] 7507850

RCF3621MTAM 30800 [9.0] 23300 [6.8] 7500 [2.2] 14.5 12 1100 [519.1] 7507870

RCF3621STAM 28800 [8.4] 21900 [6.4] 6900 [2.0] 14 11.5 950 [448.4] 7507901

RA1330AJ1 R95TA0601317MSA

RCF3617STAM 28800 [8.4] 22100 [6.5] 6700 [2.0] 13.5 11.5 1025 [483.7] 7507851

RCF3621MTAM 30000 [8.8] 21700 [6.4] 8300 [2.4] 14.5 12 900 [424.8] 7507871

RCF3621STAM 29000 [8.5] 22400 [6.6] 6600 [1.9] 13.5 11.5 1050 [495.5] 7507902

RA1330AJ1 R95TA0701317MSA

RCF3617STAM 28400 [8.3] 21400 [6.3] 7000 [2.1] 13.5 11.5 925 [436.6] 7507852

RCF3621MTAM 29800 [8.7] 21400 [6.3] 8400 [2.5] 14.5 12 875 [413.0] 7507872

RCF3621STAM 28400 [8.3] 21400 [6.3] 7000 [2.1] 13.5 11.5 925 [436.6] 7507903

RA1336AC1 R95TA0401317MSA

RCF3617STAM 35000 [10.3] 25000 [7.3] 10000 [2.9] 13.5 11.5 1050 [495.5] 7508195

RCF3621MTAM 37800 [11.1] 26700 [7.8] 11100 [3.3] 14 11.5 1175 [554.5] 7508215

RCF3621STAM 35200 [10.3] 25300 [7.4] 9900 [2.9] 13.5 11.5 1075 [507.3] 7508246

RA1336AC1 R95TA0601317MSA

RCF3617STAM 34800 [10.2] 24500 [7.2] 10300 [3.0] 13 11.5 1000 [471.9] 7508196

RCF3621MTAM 36800 [10.8] 25100 [7.4] 11700 [3.4] 14 11.5 1050 [495.5] 7508216

RCF3621STAM 34800 [10.2] 24700 [7.2] 10100 [3.0] 13 11.5 1025 [483.7] 7508247

RA1336AC1 R95TA0701317MSA

RCF3617STAM 34600 [10.1] 24500 [7.2] 10100 [3.0] 13 11 1025 [483.7] 7508197

RCF3621MTAM 37000 [10.8] 25500 [7.5] 11500 [3.4] 14 11.5 1075 [507.3] 7508217

RCF3621STAM 34200 [10.0] 23700 [6.9] 10500 [3.1] 13 11.5 925 [436.6] 7508248

RA1336AC1 R95TA1151524MSA

RCF3624HTAM 39500 [11.6] 29100 [8.5] 10400 [3.0] 14 11.5 1325 [625.3] 7508277

RCF3624MTAM 38000 [11.1] 27400 [8.0] 10600 [3.1] 13.5 11.5 1275 [601.7] 7508304

RA1336AJ1 R95TA0401317MSA

RCF3617STAM 35000 [10.3] 25000 [7.3] 10000 [2.9] 13.5 11.5 1050 [495.5] 7508561

RCF3621MTAM 37800 [11.1] 26700 [7.8] 11100 [3.3] 14 11.5 1175 [554.5] 7508581

RCF3621STAM 35200 [10.3] 25300 [7.4] 9900 [2.9] 13.5 11.5 1075 [507.3] 7508612

RA1336AJ1 R95TA0601317MSA

RCF3617STAM 34800 [10.2] 24500 [7.2] 10300 [3.0] 13 11.5 1000 [471.9] 7508562

RCF3621MTAM 36800 [10.8] 25100 [7.4] 11700 [3.4] 14 11.5 1050 [495.5] 7508582

RCF3621STAM 34800 [10.2] 24700 [7.2] 10100 [3.0] 13 11.5 1025 [483.7] 7508613

RA1336AJ1 R95TA0701317MSA

RCF3617STAM 34600 [10.1] 24500 [7.2] 10100 [3.0] 13 11 1025 [483.7] 7508563

RCF3621MTAM 37000 [10.8] 25500 [7.5] 11500 [3.4] 14 11.5 1075 [507.3] 7508583

RCF3621STAM 34200 [10.0] 23700 [6.9] 10500 [3.1] 13 11.5 925 [436.6] 7508614

RA1336AJ1 R95TA1151524MSA

RCF3624HTAM 39500 [11.6] 29100 [8.5] 10400 [3.0] 14 11.5 1325 [625.3] 7508643

RCF3624MTAM 38000 [11.1] 27400 [8.0] 10600 [3.1] 13.5 11.5 1275 [601.7] 7508670

RA1342AC1 R95TA0401317MSA RCF4821STAM 39500 [11.6] 28100 [8.2] 11400 [3.3] 13.5 11.5 1175 [554.5] 7511564

[ ] Designates Metric Conversions

Page 21

21

Air

Performance Data

RA13 Series

Performance Data @ AHRI Standard Conditions – Cooling (con’t.)

R95T Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1342AC1 R95TA0601317MSA RCF4821STAM 39000 [11.4] 26900 [7.9] 12100 [3.5] 13.5 11.5 1050 [495.5] 7511565

RA1342AC1 R95TA0701317MSA RCF4821STAM 39000 [11.4] 27300 [8.0] 11700 [3.4] 13 11.5 1125 [530.9] 7511566

RA1342AC1 R95TA0851521MSA

RCF4821STAM 40000 [11.7] 29400 [8.6] 10600 [3.1] 13 11.5 1325 [625.3] 7511567

RCF4824HTAM 42500 [12.5] 31000 [9.1] 11500 [3.4] 13.5 11.5 1500 [707.9] 7511594

RCF4824STAM 40000 [11.7] 29400 [8.6] 10600 [3.1] 13 11.5 1325 [625.3] 7511622

RA1342AC1 R95TA1001521MSA

RCF4821STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13 11.5 1400 [660.7] 7511568

RCF4824HTAM 42000 [12.3] 30200 [8.9] 11800 [3.5] 13.5 11.5 1450 [684.3] 7511595

RCF4824STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13 11.5 1400 [660.7] 7511623

RA1342AC1 R95TA1151524MSA

RCF4824HTAM 42000 [12.3] 30200 [8.9] 11800 [3.5] 13.5 11.5 1450 [684.3] 7511596

RCF4824STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13 11.5 1425 [672.5] 7511624

RA1342AJ1 R95TA0401317MSA RCF4821STAM 39500 [11.6] 28100 [8.2] 11400 [3.3] 13.5 11.5 1175 [554.5] 7511798

RA1342AJ1 R95TA0601317MSA RCF4821STAM 39000 [11.4] 26900 [7.9] 12100 [3.5] 13.5 11.5 1050 [495.5] 7511799

RA1342AJ1 R95TA0701317MSA RCF4821STAM 39000 [11.4] 27300 [8.0] 11700 [3.4] 13 11.5 1125 [530.9] 7511800

RA1342AJ1 R95TA0851521MSA

RCF4821STAM 40000 [11.7] 29400 [8.6] 10600 [3.1] 13 11.5 1325 [625.3] 7511801

RCF4824HTAM 42500 [12.5] 31000 [9.1] 11500 [3.4] 13.5 11.5 1500 [707.9] 7511828

RCF4824STAM 40000 [11.7] 29400 [8.6] 10600 [3.1] 13 11.5 1325 [625.3] 7511856

RA1342AJ1 R95TA1001521MSA

RCF4821STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13 11.5 1400 [660.7] 7511802

RCF4824HTAM 42000 [12.3] 30200 [8.9] 11800 [3.5] 13.5 11.5 1450 [684.3] 7511829

RCF4824STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13 11.5 1400 [660.7] 7511857

RA1342AJ1 R95TA1151524MSA

RCF4824HTAM 42000 [12.3] 30200 [8.9] 11800 [3.5] 13.5 11.5 1450 [684.3] 7511830

RCF4824STAM 40500 [11.9] 30300 [8.9] 10200 [3.0] 13 11.5 1425 [672.5] 7511858

RA1348AC1 R95TA0851521MSA

RCF4821STAM 46500 [13.6] 31900 [9.3] 14600 [4.3] 13 11 1300 [613.5] 7508928

RCF4824HTAM 49000 [14.4] 32700 [9.6] 16300 [4.8] 13.5 11.5 1350 [637.1] 7508944

RCF4824STAM 46500 [13.6] 31900 [9.3] 14600 [4.3] 13 11 1300 [613.5] 7508982

RA1348AC1 R95TA1001521MSA

RCF4821STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13 11 1375 [648.9] 7508929

RCF4824HTAM 49500 [14.5] 33700 [9.9] 15800 [4.6] 13.5 11.5 1425 [672.5] 7508945

RCF4824STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13 11 1375 [648.9] 7508984

RA1348AC1 R95TA1151524MSA

RCF4824HTAM 50000 [14.7] 35400 [10.4] 14600 [4.3] 13 11.5 1600 [755.1] 7508946

RCF4824STAM 46500 [13.6] 31700 [9.3] 14800 [4.3] 13 11.5 1275 [601.7] 7508986

RA1348AJ1 R95TA0851521MSA

RCF4821STAM 46500 [13.6] 31900 [9.3] 14600 [4.3] 13 11 1300 [613.5] 7509153

RCF4824HTAM 49000 [14.4] 32700 [9.6] 16300 [4.8] 13.5 11.5 1350 [637.1] 7509169

RCF4824STAM 46500 [13.6] 31900 [9.3] 14600 [4.3] 13 11 1300 [613.5] 7509194

RA1348AJ1 R95TA1001521MSA

RCF4821STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13 11 1375 [648.9] 7509154

RCF4824HTAM 49500 [14.5] 33700 [9.9] 15800 [4.6] 13.5 11.5 1425 [672.5] 7509170

RCF4824STAM 47000 [13.8] 32800 [9.6] 14200 [4.2] 13 11 1375 [648.9] 7509195

RA1348AJ1 R95TA1151524MSA

RCF4824HTAM 50000 [14.7] 35400 [10.4] 14600 [4.3] 13 11.5 1600 [755.1] 7509171

RCF4824STAM 46500 [13.6] 31700 [9.3] 14800 [4.3] 13 11.5 1275 [601.7] 7509196

RA1360AC1 R95TA0851521MSA

RCF6024HTAM 55500 [16.3] 38200 [11.2] 17300 [5.1] 13 11 1475 [696.1] 7509296

RCF6024STAM 55500 [16.3] 38200 [11.2] 17300 [5.1] 13 11 1475 [696.1] 7509320

RA1360AC1 R95TA1001521MSA

RCF6024HTAM 56000 [16.4] 39300 [11.5] 16700 [4.9] 13 11 1550 [731.5] 7509297

RCF6024STAM 56000 [16.4] 39300 [11.5] 16700 [4.9] 13 11 1550 [731.5] 7509321

RA1360AC1 R95TA1151524MSA

RCF6024HTAM 55500 [16.3] 37900 [11.1] 17600 [5.2] 13 11 1425 [672.5] 7509298

RCF6024STAM 55500 [16.3] 37900 [11.1] 17600 [5.2] 13 11 1425 [672.5] 7509322

RA1360AJ1 R95TA0851521MSA

RCF6024HTAM 55500 [16.3] 38200 [11.2] 17300 [5.1] 13 11 1475 [696.1] 7509418

RCF6024STAM 55500 [16.3] 38200 [11.2] 17300 [5.1] 13 11 1475 [696.1] 7509442

RA1360AJ1 R95TA1001521MSA

RCF6024HTAM 56000 [16.4] 39300 [11.5] 16700 [4.9] 13 11 1550 [731.5] 7509419

RCF6024STAM 56000 [16.4] 39300 [11.5] 16700 [4.9] 13 11 1550 [731.5] 7509443

RA1360AJ1 R95TA1151524MSA

RCF6024HTAM 55500 [16.3] 37900 [11.1] 17600 [5.2] 13 11 1425 [672.5] 7509420

RCF6024STAM 55500 [16.3] 37900 [11.1] 17600 [5.2] 13 11 1425 [672.5] 7509444

[ ] Designates Metric Conversions

Page 22

22

Air

Performance Data

RA13 Series

Performance Data @ AHRI Standard Conditions – Cooling (con’t.)

RGFG Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1318AJ1 RGFG-06?MCK?

RCF2417HTAM 18000 [5.3] 12800 [3.8] 5200 [1.5] 14.5 12 575 [271.4] 7507412

RCF2417MTAM 18000 [5.3] 12800 [3.8] 5200 [1.5] 14.5 12 575 [271.4] 7507427

RCF2417STAM 17900 [5.2] 13400 [3.9] 4500 [1.3] 14.5 12 575 [271.4] 7507443

RCF2421MTAM 18000 [5.3] 12800 [3.8] 5200 [1.5] 14.5 12 575 [271.4] 7507475

RA1318AJ1 RGFG-07?MCK?

RCF2417HTAM 18300 [5.4] 13200 [3.9] 5100 [1.5] 14.5 12 650 [306.8] 7507413

RCF2417MTAM 18200 [5.3] 13100 [3.8] 5100 [1.5] 14.5 12 650 [306.8] 7507428

RCF2417STAM 18200 [5.3] 13800 [4.0] 4400 [1.3] 14.5 12 650 [306.8] 7507444

RCF2421MTAM 18200 [5.3] 13100 [3.8] 5100 [1.5] 14.5 12 650 [306.8] 7507476

RA1318AJ1 RGFG-09?ZCM? RCF2421MTAM 18400 [5.4] 13300 [3.9] 5100 [1.5] 14.5 12 675 [318.6] 7507477

RA1318AJ1 RGFG-10?ZCM? RCF2421MTAM 18000 [5.3] 12800 [3.8] 5200 [1.5] 14.5 12 600 [283.2] 7507478

RA1324AJ1 RGFG-06?MCK?

RCF2417HTAM 24000 [7.0] 17100 [5.0] 6900 [2.0] 14 11.5 800 [377.6] 7507618

RCF2417MTAM 24000 [7.0] 17100 [5.0] 6900 [2.0] 14 11.5 800 [377.6] 7507636

RCF2417STAM 23800 [7.0] 17800 [5.2] 6000 [1.8] 14 11.5 800 [377.6] 7507655

RCF2421MTAM 24000 [7.0] 17100 [5.0] 6900 [2.0] 14 11.5 800 [377.6] 7507696

RA1324AJ1 RGFG-07?MCK?

RCF2417HTAM 24200 [7.1] 17500 [5.1] 6700 [2.0] 14 11.5 850 [401.2] 7507619

RCF2417MTAM 24200 [7.1] 17500 [5.1] 6700 [2.0] 14 11.5 850 [401.2] 7507637

RCF2417STAM 24000 [7.0] 18000 [5.3] 6000 [1.8] 14 11.5 800 [377.6] 7507656

RCF2421MTAM 24200 [7.1] 17500 [5.1] 6700 [2.0] 14 11.5 850 [401.2] 7507697

RA1324AJ1 RGFG-09?ZCM? RCF2421MTAM 24000 [7.0] 17000 [5.0] 7000 [2.1] 14.5 12 775 [365.8] 7507698

RA1324AJ1 RGFG-10?ZCM? RCF2421MTAM 23600 [6.9] 16500 [4.8] 7100 [2.1] 14.5 12 725 [342.2] 7507699

RA1330AJ1 RGFG-06?MCK?

RCF3617STAM 28000 [8.2] 20500 [6.0] 7500 [2.2] 14 11.5 800 [377.6] 7507853

RCF3621MTAM 29600 [8.7] 21000 [6.2] 8600 [2.5] 14.5 12 800 [377.6] 7507873

RCF3621STAM 28000 [8.2] 20500 [6.0] 7500 [2.2] 14 11.5 800 [377.6] 7507904

RA1330AJ1 RGFG-07?MCK?

RCF3617STAM 28200 [8.3] 20900 [6.1] 7300 [2.1] 14 11.5 850 [401.2] 7507854

RCF3621MTAM 29800 [8.7] 21400 [6.3] 8400 [2.5] 14.5 12 850 [401.2] 7507874

RCF3621STAM 28200 [8.3] 20900 [6.1] 7300 [2.1] 14 11.5 850 [401.2] 7507905

RA1330AJ1 RGFG-09?ZCM?

RCF3621MTAM 30400 [8.9] 22500 [6.6] 7900 [2.3] 14.5 12 1025 [483.7] 7507875

RCF3621STAM 29000 [8.5] 22100 [6.5] 6900 [2.0] 14 11.5 975 [460.1] 7507906

RCF3624HTAM 31200 [9.1] 22900 [6.7] 8300 [2.4] 15.1 12.5 975 [460.1] 7507931

RCF3624MTAM 30400 [8.9] 22500 [6.6] 7900 [2.3] 14.5 12 1025 [483.7] 7507955

RA1330AJ1 RGFG-10?ZCM?

RCF3621MTAM 30600 [9.0] 22900 [6.7] 7700 [2.3] 14.5 12 1050 [495.5] 7507876

RCF3621STAM 28800 [8.4] 22000 [6.4] 6800 [2.0] 14 11.5 1000 [471.9] 7507907

RCF3624HTAM 31200 [9.1] 23200 [6.8] 8000 [2.3] 15.1 12.5 1050 [495.5] 7507932

RCF3624MTAM 30600 [9.0] 22900 [6.7] 7700 [2.3] 14.5 12 1050 [495.5] 7507956

RA1330AJ1 RGFG-12?RCM?

RCF3624HTAM 31200 [9.1] 22900 [6.7] 8300 [2.4] 15.5 13 975 [460.1] 7507933

RCF3624MTAM 30600 [9.0] 22600 [6.6] 8000 [2.3] 15 12.5 975 [460.1] 7507957

RA1336AC1 RGFG-06?MCK?

RCF3617STAM 34800 [10.2] 24500 [7.2] 10300 [3.0] 13 11.5 1000 [471.9] 7508198

RCF3621MTAM 37000 [10.8] 25100 [7.4] 11900 [3.5] 14 11.5 1000 [471.9] 7508218

RCF3621STAM 34800 [10.2] 24500 [7.2] 10300 [3.0] 13 11.5 1000 [471.9] 7508249

RA1336AC1 RGFG-07?MCK?

RCF3617STAM 34600 [10.1] 24300 [7.1] 10300 [3.0] 13 11 1000 [471.9] 7508199

RCF3621MTAM 36800 [10.8] 24900 [7.3] 11900 [3.5] 14 11.5 1000 [471.9] 7508219

RCF3621STAM 34800 [10.2] 24500 [7.2] 10300 [3.0] 13 11.5 1000 [471.9] 7508250

RA1336AC1 RGFG-09?ZCM?

RCF3621MTAM 37800 [11.1] 26900 [7.9] 10900 [3.2] 14 11.5 1200 [566.3] 7508220

RCF3621STAM 34800 [10.2] 24700 [7.2] 10100 [3.0] 13.5 11.5 1025 [483.7] 7508251

RCF3624HTAM 39000 [11.4] 28000 [8.2] 11000 [3.2] 14.5 12 1200 [566.3] 7508278

RCF3624MTAM 37800 [11.1] 26900 [7.9] 10900 [3.2] 14 11.5 1200 [566.3] 7508305

[ ] Designates Metric Conversions

Page 23

23

Air

Performance Data

RA13 Series

Performance Data @ AHRI Standard Conditions – Cooling (con’t.)

RGFG Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

AHRI#

RA1336AC1 RGFG-10?ZCM?

RCF3621MTAM 37200 [10.9] 25300 [7.4] 11900 [3.5] 14.5 12 1000 [471.9] 7508221

RCF3621STAM 35000 [10.3] 25000 [7.3] 10000 [2.9] 13.5 11.5 1050 [495.5] 7508252

RCF3624HTAM 39000 [11.4] 28000 [8.2] 11000 [3.2] 14.5 12 1200 [566.3] 7508279

RCF3624MTAM 37200 [10.9] 25300 [7.4] 11900 [3.5] 14.5 12 1000 [471.9] 7508306

RA1336AC1 RGFG-12?RCM?