Rheem R97V Installation Manual

INSTALLATION INSTRUCTIONS

FOR UPFLOW CONDENSING MODULATING,

COMMUNICATING GAS FURNACES W/ECM BLOWER

(-)97V SERIES

U.L. and/or C.S.A. recognized fuel gas and CO (carbon monoxide) detectors are recommended in all applications, and their installation should be in accordance with the

manufacturer’s recommendations and/or local laws, rules, regulations, or customs.

SUPERSEDES 92-24161-126-03

92-24161-126-04

TABLE OF CONTENTS

1 TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . 2

2 GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . 3

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

California Proposition 65 Note . . . . . . . . . . . . . . . . . . 4

Efficiency Testing Notice. . . . . . . . . . . . . . . . . . . . . . . 4

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 SAFETY INFORMATION. . . . . . . . . . . . . . . . . . . . . . 6

Contents

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Important Information About Efficiency and Quality. . 7

Commonwealth of Massachusetts Note . . . . . . . . . . 8

4 LOCATION REQUIREMENTS . . . . . . . . . . . . . . . . . 9

Freeze Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Site Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Clearance Accessibility. . . . . . . . . . . . . . . . . . . . . . . 10

Clearance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 FIELD CONVERSIONS . . . . . . . . . . . . . . . . . . . 12-18

General Conversion Instructions and Tips. . . . . . . . 12

Lists of Materials for Parts Bag and

Conversion Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conversion Table of Contents . . . . . . . . . . . . . . . . . 14

Upflow with Vertical Vent. . . . . . . . . . . . . . . . . . . 15-16

Upflow with Left Side Vent . . . . . . . . . . . . . . . . . 17-18

6 DUCTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 VENTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

General Venting Requirements and Guidelines

(All Instructions) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Venting and Combustion Air Piping

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Piping Requirements . . . . . . . . . . . . . . . . . . . . . . 23

Vent Pipe Sizing and Maximum Lengths . . . . . . . 25

Equivalent Vent Length. . . . . . . . . . . . . . . . . . . . . 25

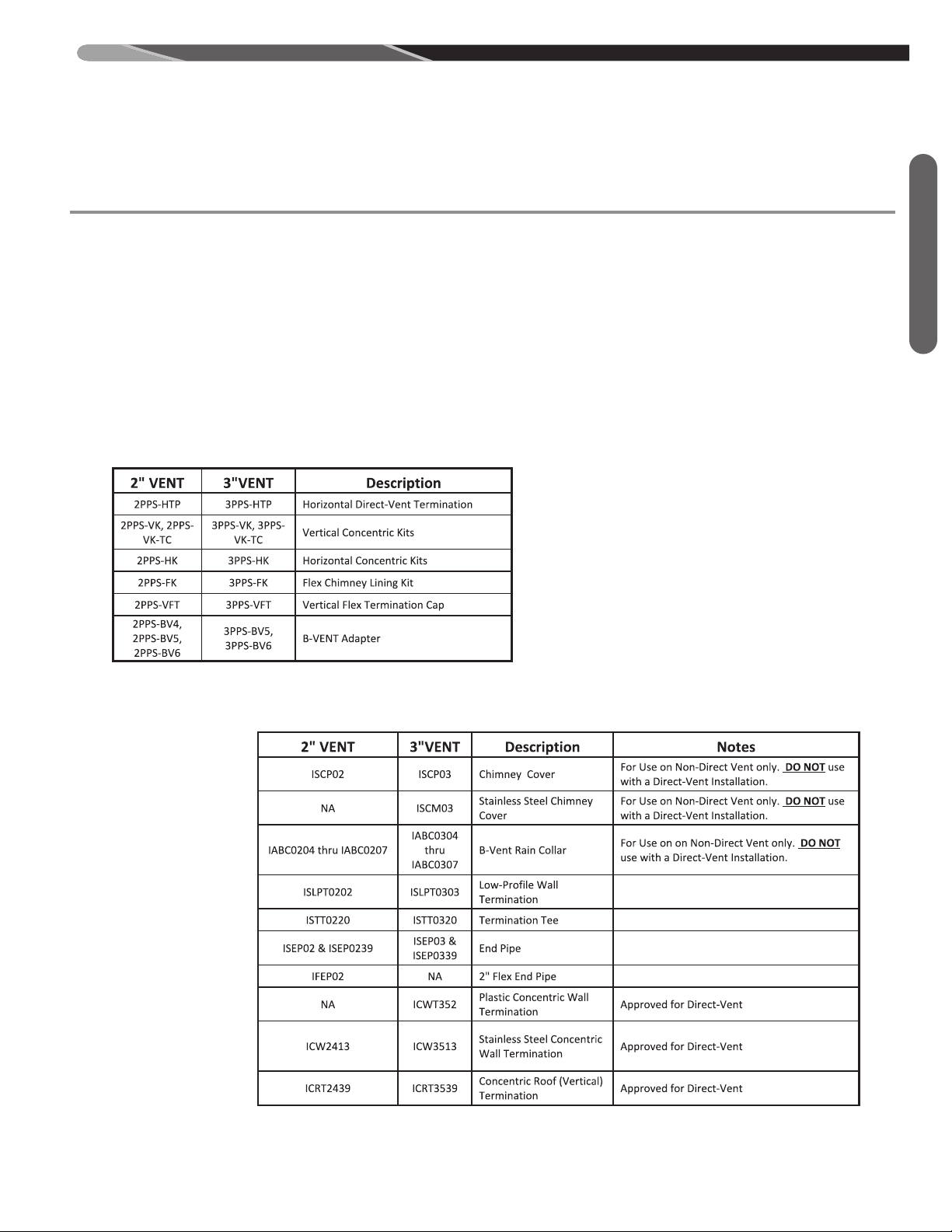

Polypropylene Vent Products . . . . . . . . . . . . . . . . 27

Termination Requirements . . . . . . . . . . . . . . . . . . 28

Non-Direct Venting. . . . . . . . . . . . . . . . . . . . . . . . . 29

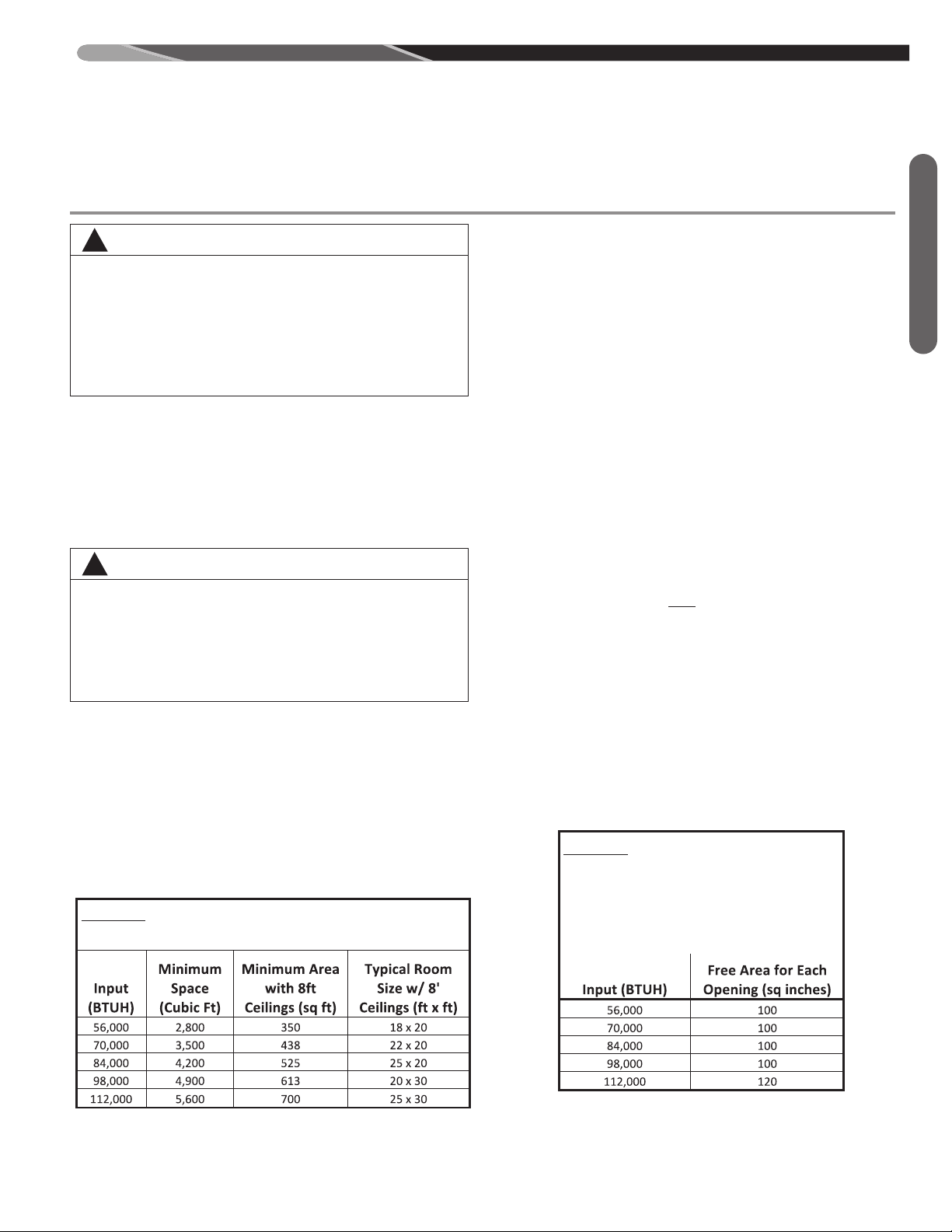

Furnace Located in an Unconfined Space. . . . . . 29

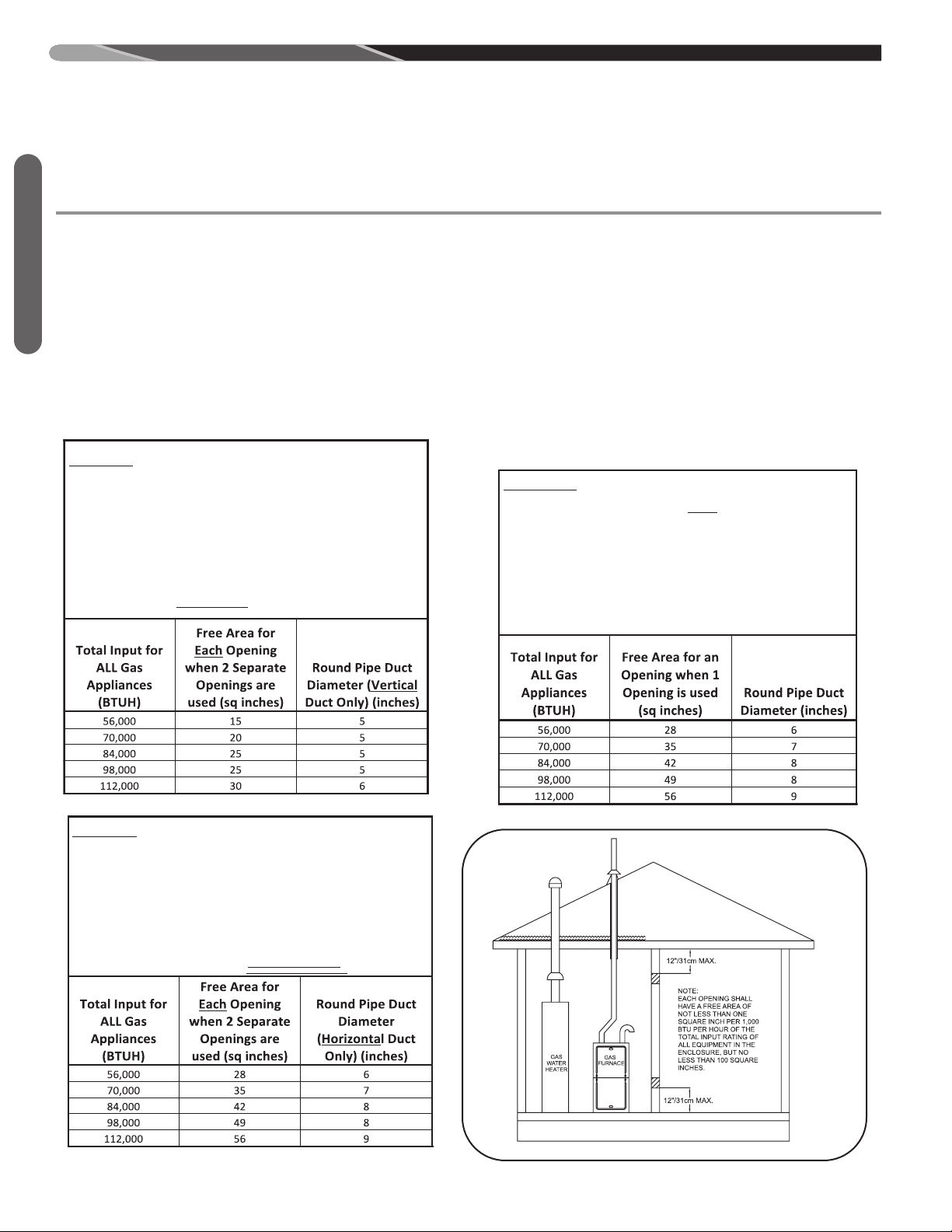

Furnace Located in a Confined Space. . . . . . . . . 29

Non-Direct Venting Terminations . . . . . . . . . . . . . 32

Direct Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Option 1:

Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Option 2: Standard Horizontal Direct Vent

Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Option 3: Variant of Standard Horizontal

Direct Vent Termination. . . . . . . . . . . . . . . . . . . 35

Option 4: Alternate Horizontal Direct Vent

Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Option 5: Variant of Alternate Horizontal

Direct Vent Termination. . . . . . . . . . . . . . . . . . . 36

Optional Termination Angles for Alt.

Horizontal and Variant of Alt. Horizontal

Direct-Vent Terminations (Options 4 and 5) . . . 37

Option 6 & 7:

Concentric Vent Termination (RXGY-E02A and

RXGY-E03A) . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Options 8 & 9: Sidewall Vent Kit for Direct Vent

Termination (RXGY-G02 & RXGY-G01). . . . . . 39

Direct Venting Termination Clearances . . . . . . . . 40

Multiventing of Direct Vent Furnaces . . . . . . . . . . 41

Standard Vertical Direct Vent

Vertical and Horizontal

8 CONDENSATE DRAIN AND DRAIN

NEUTRALIZER . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9 GAS SUPPLY AND PIPING

Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10 LP CONVERSION . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11 FURNACE ADJUSTMENTS . . . . . . . . . . . . . . . . . . 50

Orifice Selection/Altitude Adjustment. . . . . . . . . . . . 50

Adjust The Gas Pressure. . . . . . . . . . . . . . . . . . . . . 51

Verify The Input Rate . . . . . . . . . . . . . . . . . . . . . . . . 54

Adjust The Gas Heat Temperature Rise . . . . . . . . . 55

Temperature Rise Verification . . . . . . . . . . . . . . . . . 56

12 ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . . . . 58

Reversing the Electrical Connection . . . . . . . . . . . . 58

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

13 ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Electronic Air Cleaner. . . . . . . . . . . . . . . . . . . . . . . . 60

Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Twinning (Not Permitted) . . . . . . . . . . . . . . . . . . . . . 60

Air Temperature Sensors . . . . . . . . . . . . . . . . . . . . . 60

14 STARTUP AND SEQUENCE OF OPERATIONS. . 62

15 INTEGRATED FURNACE CONTROL . . . . . . . . . . 67

Humidification/Dehumidification. . . . . . . . . . . . . . . . 69

Dipswitches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Model Data Card . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Dual 7-Segment Display . . . . . . . . . . . . . . . . . . . . . 76

Pushbutton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Supply & Outdoor Air Temp Sensors . . . . . . . . . . . . 80

Auxiliary Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Thermostat Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Thermostat Wiring Diagrams . . . . . . . . . . . . . . . . . . 83

Communicating. . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Legacy AC Condensing (Non-Communicating). . 85

Legacy Heat Pump (Non-Communicating) . . . . . 87

16 TIMING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . 90

17 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Annual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . 93

18 DIAGNOSTICS AND TROUBLESHOOTING. . . . . 94

Normal Operation Codes . . . . . . . . . . . . . . . . . . . . . 94

Fault Codes with Descriptions and Solutions. . 95-104

Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Replacing the Furnace Control . . . . . . . . . . . . . . . 105

Diagnosing Blower Motor Issues . . . . . . . . . . . . . . 105

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

2

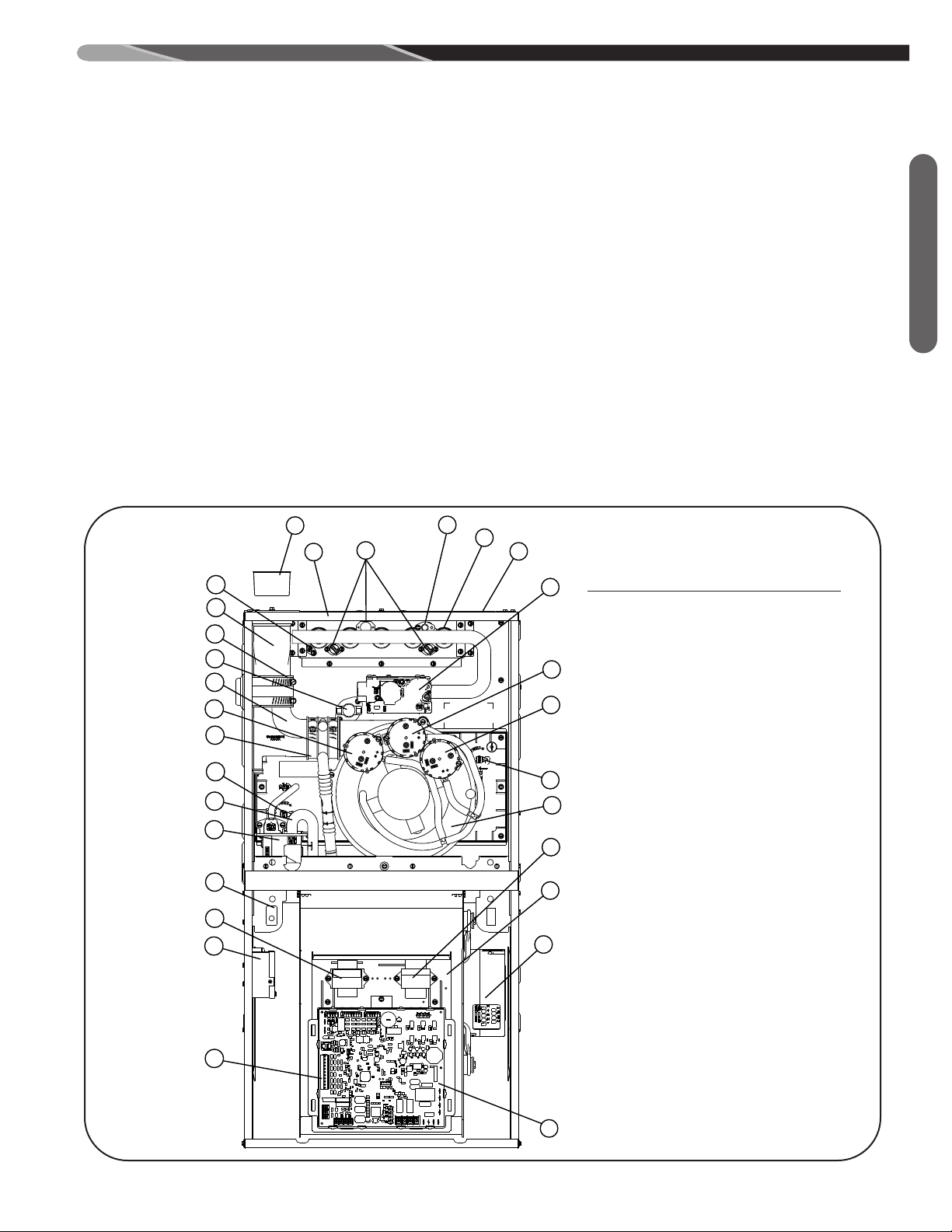

GENERAL INFORMATION

1

0

1

11

12

13

14

16

24

7

8

9

23

6A

5

2

4

3

22

25

20

21

19

18

5

17

15

26

6B

6C

NOTE: A heat loss calculation should be performed to

properly determine the required furnace BTU size for the

structure. Also, the duct must be properly designed and in-

talled for proper airflow. Existing ductwork must be in-

s

spected for proper size and to make sure that it is properly

sealed. Proper airflow is necessary for both user comfort

and equipment performance.

Before opening the furnace carton, verify that the data

tags on the carton specify the furnace model number

that was ordered from the distributor and are correct

for the installation. If not, return the unit without opening the carton. If the model number is correct, open

the carton and verify that the furnace rating label

specifies the same furnace model number that is

specified on the carton label. If the model numbers do

not match, return the furnace to the distributor.

IMPORTANT: Proper application, installation and maintenance of this furnace and system is a must if consumers

are to receive the full benefits for which they have paid.

The (-)97V series furnaces are design-certified by CSA for

use with natural and propane gases as follows:

1. As non-direct vent central forced air furnaces taking

combustion air from the installation area or using air

ducted from the outside.

2. As direct vent central forced air furnaces with all combustion air supplied directly to the furnace burners

through a special air intake system outlined in these

instructions.Install this furnace in accordance with the

American National Standard Z223.1 – latest edition

entitled “National Fuel Gas Code” (NFPA54) or, for

Canada, CSA B149.1; Canadian Natural Gas and

Propane Installation Code and requirements or codes

of the local utilities or other authorities having jurisdiction. This is available from the following:

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

CSA-INTERNATIONAL

5060 Spectrum Way

Mississauga, Ontario

Canada L4W5N6

General Information

Online: www.csa.ca

FIGURE 1

FURNACE COMPONENTS

ITEM

NO. DESCRIPTION

1. CONDENSATE TRAP

2. DOOR SWITCH

3. JUNCTION BOX

4. TRANSFORMER

5. WATER SENSOR (2)

6. PRESSURE SWITCH STAGES

A. HIGH

B. MEDIUM

C. LOW

7. EXHAUST TRANSITION

8. COUPLING (ELBOW TO TRANSITION)

9. EXHAUST

10. SHIPPING PLUG

11. FLAME SENSOR

12. OVER TEMPERATURE SWITCH

13. TOP PLATE

14. BURNER

15. IGNITER

16. COMBUSTION AIR INLET

17. GAS VALVE

18. INDUCED DRAFT BLOWER (IDB)

19. POWER FACTOR CORRECTION CHOKE

(PFC) (NOT USED ON THE 60K BTU

AND 70K BTU)

20. CONTROL MOUNTING PLATE

21. BLOWER

22. LOW VOLTAGE TERMINAL

23. COUPLING (IDB TO ELBOW)

24. MAIN LIMIT

25. FURNACE CONTROL

26. AUXILIARY TRAP

ST-A1194-67-00

3

GENERAL INFORMATION (cont.)

In Canada installations must comply with CSA B149.1.

Install units in Canada in accordance with CSA-B149,

ocal installation codes and authorities having jurisdiction.

l

CSA-B149.1 is available from:

CSA INTERNATIONAL

5060 Spectrum Way

Mississauga, Ontario

Canada L4W 5N6

online: www.csa.ca

General Information

NOTICE: Any equipment immersed in water (including by

flooding) must be replaced. Equipment and products immersed in water will have operation adversely affected

thereby voiding the warranty.

RECEIVING

Immediately upon receipt, all cartons and contents should

be inspected for transit damage. Units with damaged cartons should be opened immediately. If damage is found, it

should be noted on the delivery papers, and a damage

claim filed with the last carrier.

• After unit has been delivered to job site, remove carton

taking care not to damage unit.

• Check the unit rating plate to be sure equipment

matches job specifications.

• Read the entire instructions before starting the installation.

• Install the unit in such a way as to allow necessary access for service.

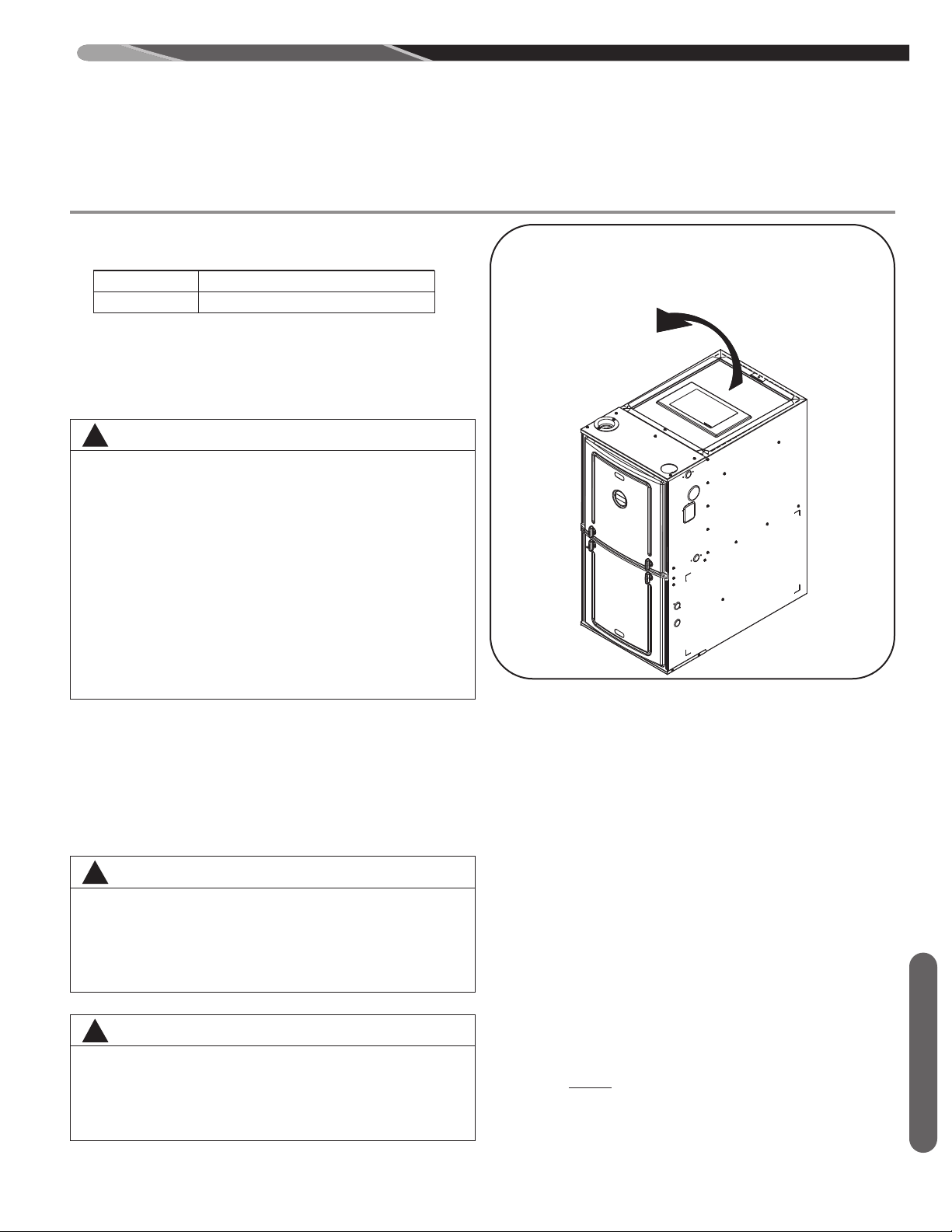

• Always remove the solid metal base pan from the top of

the furnace. The base pan is installed in this location for

shipping purposes only and should never remain in the

as-shipped location after installation.

• Install the unit with a 1/4” to 1/2” forward slope (toward

front) to ensure proper drainage.

• Install the unit in accordance with any local code which

may apply and the national codes. Latest editions are

available from: “National Fire Protection Association,

Inc., Batterymarch Park, Quincy, MA 02269.” These

publications are:

• ANSI/NFPA No. 70-(Latest Edition) National Electrical

Code.

• NFPA90A Installation of Air Conditioning and Ventilating Systems.

• NFPA90B Installation of warm air heating and air conditioning systems.

• In Canada CSA 22.2 Canadian Electrical Code.

• In Canada CSA B149.1; Canadian Natural Gas and

Propane Installation Code.

CALIFORNIA RESIDENTS ONLY

IMPORTANT: All manufacturer products meet current

Federal OSHA Guidelines for safety. California Proposition

65 warnings are required for certain products, which are

not covered by the OSHA standards.

California's Proposition 65 requires warnings for products

sold in California that contain, or produce, any of over 600

listed chemicals known to the State of California to cause

cancer or birth defects such as fiberglass insulation, lead

in brass, and combustion products from natural gas.

All “new equipment” shipped for sale in California will have

labels stating that the product contains and/or produces

Proposition 65 chemicals. Although we have not changed

our processes, having the same label on all our products

facilitates manufacturing and shipping. We cannot always

know “when, or if” products will be sold in the California

market.

You may receive inquiries from customers about chemicals found in, or produced by, some of our heating and airconditioning equipment, or found in natural gas used with

some of our products. Listed below are those chemicals

and substances commonly associated with similar equipment in our industry and other manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO)

• Formaldehyde

• Benzene

More details are available at the Websites for OSHA (Occupational Safety and Health Administration), at

www.osha.gov and the State of California's OEHHA (Office of Environmental Health Hazard Assessment), at

www.oehha.org. Consumer education is important since

the chemicals and substances on the list are found in our

daily lives. Most consumers are aware that products present safety and health risks, when improperly used, handled and maintained.

EFFICIENCY TESTING NOTICE

For purposes of verifying or testing efficiency ratings, the

test procedure in Title 10 APPENDIX N to Subpart B of

Part 430 (Uniform Test Method for Measuring the Energy

Consumption of Furnaces and Boilers) and the clarifying

provisions provided in the AHRI Operations Manual for

Residential Furnaces that were applicable at the date of

manufacture should be used for test set up and performance.

4

Installation Instructions remain with the furnace as a reference guide to the servicing contractor. We recommend

that performance and installation data be recorded for future reference on this sheet to meet service and warranty

obligations so that job site information is available when required.

Installation Checklist

REFER TO INSTALLATION INSTRUCTIONS

GAS SUPPLY

______ Correct pipe size (record size)

______ Correct supply pressure (during furnace operation)

______ (record pressure)

______ Low fire manifold pressure (see page 52 for

instructions)

______ High fire manifold pressure (see page 53 for

instructions)

______ No gas leaks

______ L.P. Kit Number (if applicable) (record kit number)

ELECTRICAL

______ 115 V.A.C. supply (Dedicated Circuit)

(record voltage)

______ Polarity observed

______ Furnace properly grounded

______ Correct wire size (record type and gauge)

FURNACE INSTALLATION

______ Correct clearance to combustibles (record

______ clearance)

______ Correct clearance for service (at front) (record

______ clearance)

DUCT STATIC PRESSURE

______ no. of elbows – intake air (record number of

______ elbows)

______ ft. of pipe – exhaust pipe (record length)

______ no. of elbows – exhaust pipe (record number of

______ elbows)

______ Exhaust Vent Temperature (record temperature)

TERMINATIONS – DIRECT VENT

VERTICAL

______ Intake – 12" [305mm] min. above roof/snow level

(record height above anticipated snow level)

or, in Canada, intake and exhaust vents conform

with CSA B149.1; Canadian Natural Gas and

Propane Installation Code

______ Correct relationship – exhaust to intake

HORIZONTAL/VERTICAL – CONCENTRIC (RXGY-E03A)

______ Intake – 12" [305mm] min. above roof/snow level

(record height above anticipated snow level)

or, in Canada, intake and exhaust vents conform

with CSA B149.1; Canadian Natural Gas and

Propane Installation Code

______ Exhaust sloped down toward furnace

______ Correct distances (horizontal and vertical) –

exhaust to intake

______ 12" [305mm] min. above grade/snow level (record

height above anticipated snow level) or, in

Canada, intake and exhaust vents conform

with CSA B149.1; Canadian Natural Gas and

Propane Installation Code

General Information

______ in. w.c. on heating speed (record static pressure)

______ in. w.c. on cooling speed (record static pressure)

______ Air temperature rise in heat (record air temperature

______ rise)

______ Air temperature rise in cool (record air temperature

______ rise)

CONDENSATE LINE

______ Trap filled with water

______ Vented

______ Sloped toward drain

______ Condensate drain line hoses connected and

______ clamped

______ Freeze protection (if necessary)

VENTING – DIRECT VENT

______ in. diameter – intake pipe (record diameter)

______ in. diameter – exhaust pipe (record diameter)

______ ft. of pipe – intake air (record length)

______ Above anticipated snow level (record maximum

______ anticipated snow level)

VENTING – NON-DIRECT VENT (Vertical Venting

Only)

______ in. diameter – exhaust pipe (record diameter)

______ ft. of pipe – exhaust (record length)

______ no. of elbows (record number of elbows)

TERMINATION – NON-DIRECT VENT

VERTICAL

______ 12" [305mm] min. above roof/snow level (record

height above anticipated snow level) or, in

Canada, intake and exhaust vents conform

with CSA B149.1; Canadian Natural Gas and

Propane Installation Code

5

SAFETY INFORMATION

WARNING

!

DO NOT INSTALL THIS FURNACE IN A MOBILE HOME!!

THIS FURNACE IS NOT APPROVED FOR INSTALLATION

IN A MOBILE HOME. DOING SO COULD CAUSE FIRE,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

INSTALL THIS FURNACE ONLY IN A LOCATION AND POSITION AS SPECIFIED IN THE LOCATION REQUIREMENTS AND CONSIDERATIONS SECTION OF THESE

INSTRUCTIONS.

WARNING

!

IMPROPER INSTALLATION, OR INSTALLATION NOT

MADE IN ACCORDANCE WITH THE CSA INTERNATIONAL

(CSA) CERTIFICATION OR THESE INSTRUCTIONS, CAN

RESULT IN UNSATISFACTORY OPERATION AND/OR

DANGEROUS CONDITIONS AND ARE NOT COVERED BY

THE MANUFACTURER’S WARRANTY.

Safety Information

WARNING

!

DO NOT BYPASS, JUMPER, OR REMOVE ANY SAFETY

SWITCH FROM THE FURNACE CONTROL CIRCUIT. IF A

SAFETY SWITCH CAUSES THE FURNACE TO SHUT

DOWN OR OPERATE INTERMITTENTLY, IT IS AN INDICATION OF A POTENTIAL SAFETY HAZARD THAT MUST

BE ADDRESSED BY A QUALIFIED TECHNICIAN, SERVICE AGENCY OR THE GAS SUPPLIER. DO NOT RESET

SAFETY CONTROLS WITHOUT CORRECTIVE ACTION

AND/OR VERIFICATION OF PROPER SAFE OPERATION

BY A QUALIFIED INSTALLER, SERVICE AGENCY OR

THE GAS SUPPLIER.

REPLACE ANY SAFETY CONTROL COMPONENT ONLY

WITH IDENTICAL OEM REPLACEMENT PARTS. WHEN A

NEW SAFETY SWITCH IS INSTALLED, IT MUST BE

TESTED FOR A MINIMUM OF 15 MINUTES WITH THE

FURNACE OPERATING AT MAXIMUM INPUT RATE AND

WITH BOTH BLOWER AND BURNER DOOR INSTALLED.

IF THE FURNACE IS INSTALLED IN A CLOSET, THE

CLOSET DOOR MUST ALSO BE CLOSED FOR THIS

TEST. REPEAT THE TEST AT THE MINIMUM INPUT RATE

IF THE FURNACE IS A MULTI-STAGE FURNACE.

WARNING

!

USE ONLY WITH THE TYPE OF GAS APPROVED FOR

THIS FURNACE. REFER TO THE FURNACE RATING

PLATE.

WARNING

!

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

USE A COMMERCIALLY AVAILABLE SOAP SOLUTION

MADE SPECIFICALLY FOR THE DETECTION OF LEAKS

TO CHECK ALL CONNECTIONS, AS SPECIFIED IN GAS

SUPPLY AND PIPING SECTION OF THESE INSTRUCTIONS.

WARNING

!

COMBUSTION AND VENTILATION AIR MUST BE PROVIDED TO THE FURNACE AS REQUIRED BY THE NATIONAL FUEL-GAS CODE (U.S.) AND CSA B149.1

(CANADA) AND THE COMBUSTION AND VENTILATION

AIR SECTION OF THESE INSTRUCTIONS.

WARNING

!

COMBUSTION PRODUCTS MUST BE DISCHARGED OUTDOORS. CONNECT THIS FURNACE TO AN APPROVED

VENT SYSTEM ONLY, AS SPECIFIED IN THE VENT PIPE

INSTALLATION SECTION OF THESE INSTRUCTIONS.

WARNING

!

WHEN A FURNACE IS INSTALLED SO THAT SUPPLY

DUCTS CARRY AIR CIRCULATED BY THE FURNACE TO

AREAS OUTSIDE THE SPACE CONTAINING THE FURNACE, THE RETURN AIR SHALL ALSO BE HANDLED BY

DUCT(S) SEALED TO THE FURNACE CASING AND TERMINATING OUTSIDE THE SPACE CONTAINING THE FURNACE.

WARNING

!

WHENEVER THE FACTORY RETURN-AIR CONNECTION

IS NOT USED IT MUST BE SEALED. A SOLID METAL

BASE PLATE MUST BE INSTALLED AND SEALED. FACTORY BASE PLATES ARE AVAILABLE AS ACCESSORY

ITEMS. (PART NUMBERS ARE LISTED IN THE SPEC

SHEET FOR THE FURNACE.) FAILURE TO INSTALL AND

SEAL THE BASE PLATE AND RETURN AIR DUCT CONNECTIONS MAY ALLOW CARBON MONOXIDE AND

OTHER CONTAMINANTS TO BE DRAWN INTO THE CONDITIONED AIR SPACE AND DISTRIBUTED THROUGHOUT

THE HEATED SPACE.

WARNING

!

DO NOT OPERATE THE SYSTEM WITHOUT FILTERS. A

PORTION OF THE DUST ENTRAINED IN THE AIR MAY

TEMPORARILY LODGE IN THE AIR DUCT RUNS AND AT

THE SUPPLY REGISTERS. ANY CIRCULATED DUST PARTICLES WILL BE HEATED AND CHARRED BY CONTACT

WITH THE FURNACE HEAT EXCHANGER. THIS SOOTY

RESIDUE WILL SOIL CEILINGS, WALLS, DRAPES, CARPETS AND OTHER HOUSEHOLD ARTICLES. SOOT DAMAGE MAY ALSO RESULT WITH, OR WITHOUT, FILTERS IN

PLACE, WHEN CERTAIN TYPES OF CANDLES ARE

BURNED, OR CANDLEWICKS ARE LEFT UNTRIMMED.

WARNING

!

IN COMPLIANCE WITH RECOGNIZED CODES, IT IS RECOMMENDED THAT AN AUXILIARY DRAIN PAN BE INSTALLED UNDER THIS FURNACE AND ANY INSTALLED

EVAPORATOR COIL THAT IS LOCATED IN ANY AREA OF

A STRUCTURE WHERE DAMAGE TO THE BUILDING OR

BUILDING CONTENTS MAY OCCUR AS A RESULT OF AN

OVERFLOW OF THE FURNACE CONDENSATE DISPOSAL SYSTEM OR THE COIL DRAIN PAN OR A STOPPAGE IN THE PRIMARY CONDENSATE DRAIN PIPING.

6

SAFETY

WARNING

!

ALWAYS INSTALL THE FURNACE TO OPERATE WITHIN

THE FURNACE’S INTENDED TEMPERATURE-RISE

RANGE WITH A DUCT SYSTEM WHICH HAS AN EXTERNAL STATIC PRESSURE WITHIN THE ALLOWABLE

RANGE, AS SPECIFIED IN THE DUCTING SECTION OF

THESE INSTRUCTIONS. SEE ALSO FURNACE RATING

PLATE.

THE FURNACE MAY BE USED FOR HEATING OF BUILDINGS OR STRUCTURES UNDER CONSTRUCTION.

INSTALLATION MUST COMPLY WITH ALL INSTALLATION

INSTRUCTIONS INCLUDING:

PROPER VENT INSTALLATION;

-

FURNACE OPERATING UNDER THERMOSTATCONTROL;

RETURN AIR DUCT SEALED TO THE FURNACE;

-

AIR FILTERS IN PLACE;SET FURNACE INPUT RATE AND TEMPERA-TURE RISE PER RATING PLATE MARKINGS;

MEANS FOR PROVIDING OUTDOOR AIR RE-

-

QUIRED FOR COMBUSTION;

RETURN AIR TEMPERATURE MAINTAINED BE-

-

TWEEN 55°F (13°C) AND 80°F (27°C); AND

CLEAN FURNACE, DUCT WORK AND COMPO-

-

NENTS UPON SUBSTANTIAL COMPLETION OF

THE CONSTRUCTION PROCESS, AND VERIFY

THAT THE FURNACE OPERATING CONDITIONS

INCLUDING IGNITION, INPUT RATE, TEMPERATURE RISE AND VENTING, ACCORDING TO THE

INSTRUCTIONS AND CODES.

IMPORTANT

!

CANADIAN INSTALLATIONS

GAS FURNACES MANUFACTURED ON OR AFTER MAY

1, 2017 ARE NOT PERMITTED TO BE USED IN CANADA

FOR HEATING OF BUILDINGS OR STRUCTURES UNDER

CONSTRUCTION.

IMPORTANT INFORMATION

ABOUT EFFICIENCY AND

WARNING

!

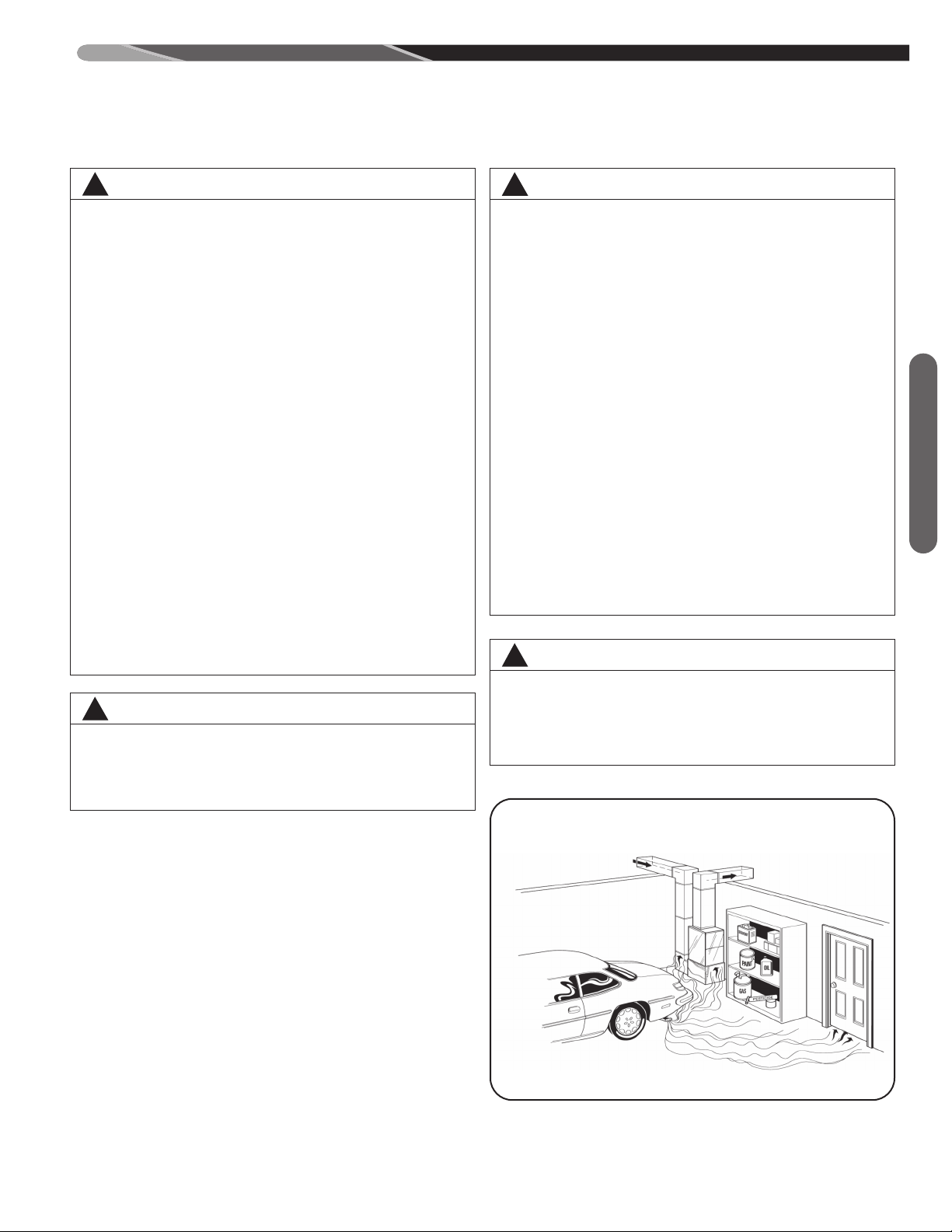

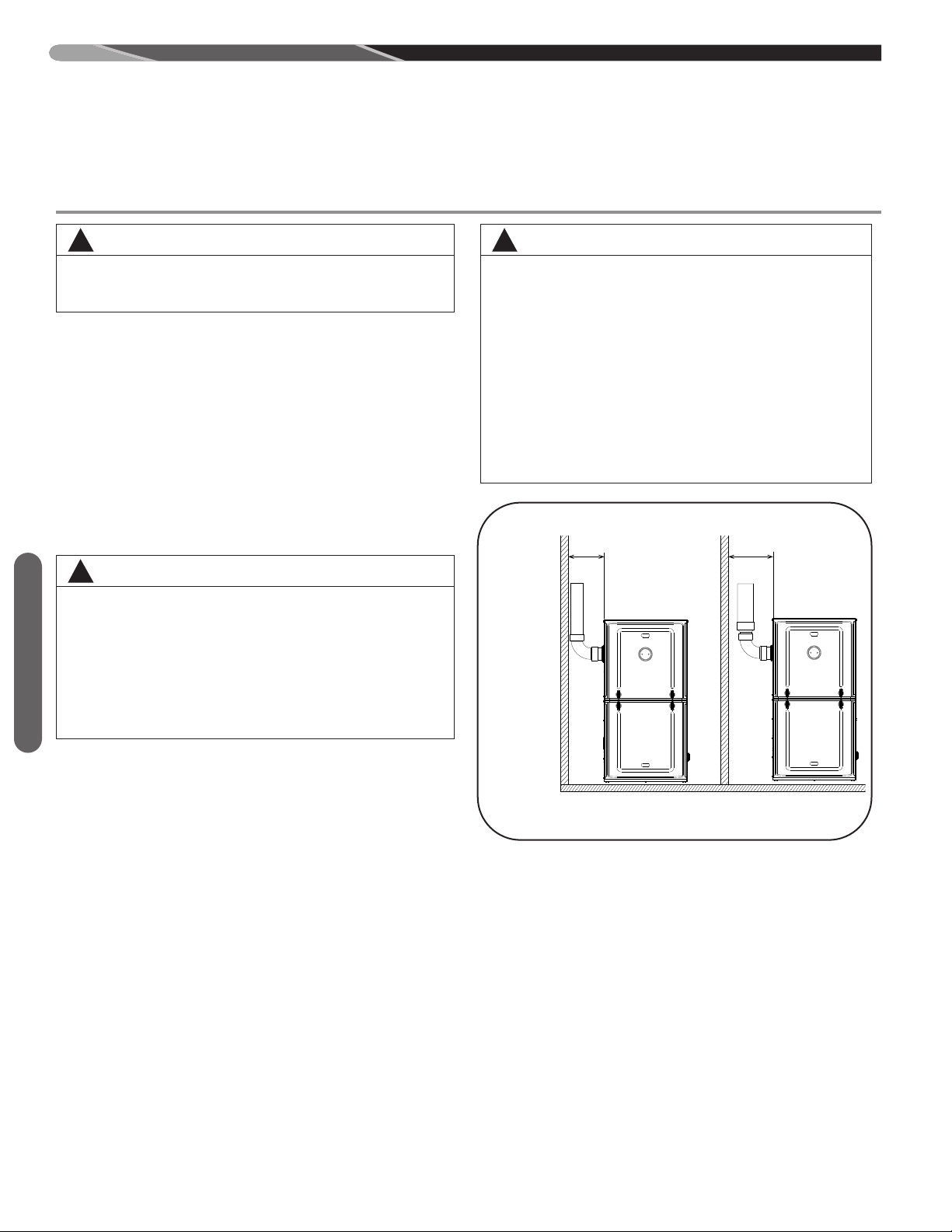

DUCT LEAKS CAN CREATE AN UNBALANCED SYSTEM

AND DRAW POLLUTANTS SUCH AS DIRT, DUST, FUMES

AND ODORS INTO THE HOME CAUSING PROPERTY

DAMAGE. FUMES AND ODORS FROM TOXIC, VOLATILE

OR FLAMMABLE CHEMICALS, AS WELL AS AUTOMOBILE EXHAUST AND CARBON MONOXIDE (CO), CAN BE

DRAWN INTO THE LIVING SPACE THROUGH LEAKING

UCTS AND UNBALANCED DUCT SYSTEMS CAUSING

D

PERSONAL INJURY OR DEATH (SEE FIGURE 2).

• IF AIR-MOVING EQUIPMENT OR DUCTWORK IS LOCATED IN GARAGES OR OFF-GARAGE STORAGE

AREAS - ALL JOINTS, SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST BE SEALED TO LIMIT

THE MIGRATION OF TOXIC FUMES AND ODORS INCLUDING CARBON MONOXIDE FROM MIGRATING

INTO THE LIVING SPACE.

• IF AIR-MOVING EQUIPMENT OR DUCTWORK IS LOCATED IN SPACES CONTAINING FUEL BURNING APPLIANCES SUCH AS WATER HEATERS OR BOILERS ALL JOINTS, SEAMS, AND OPENINGS IN THE EQUIPMENT AND DUCT MUST ALSO BE SEALED TO PREVENT DEPRESSURIZATION OF THE SPACE AND

POSSIBLE MIGRATION OF COMBUSTION BYPRODUCTS INCLUDING CARBON MONOXIDE INTO THE LIVING SPACE.

WARNING

!

BLOWER AND BURNERS MUST NEVER BE OPERATED

WITHOUT THE BLOWER DOOR IN PLACE. THIS IS TO

PREVENT DRAWING GAS FUMES (WHICH COULD CONTAIN HAZARDOUS CARBON MONOXIDE) INTO THE

HOME THAT COULD RESULT IN PERSONAL INJURY OR

DEATH.

FIGURE 2

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO

LIVING SPACES

Safety Information

INDOOR AIR QUALITY

Central cooling and heating equipment is only as efficient

as the duct system that carries the cooled or heated air.

To maintain efficiency, comfort and good indoor air quality, it is important to have the proper balance between the

air supplied to each room and the air returning to the

cooling and heating equipment.

Proper balance and sealing of the duct system improves

the efficiency of the heating and air conditioning system

and improves the indoor air quality of the home by reducing the amount of airborne pollutants that enter homes

from spaces where the ductwork and / or equipment is

located. The manufacturer and the U.S. Environmental

Protection Agency’s Energy Star Program recommend

that central duct systems be checked by a qualified contractor for proper balance and sealing.

Adapted from Residential Duct Diagnostics and Repair, with permission of Air Conditioning

Contractors of America (ACCA).

7

COMMONWEALTH OF MASSACHUSETTS NOTE

IMPORTANT! THE COMMONWEALTH OF MASSACHUSETTS REQUIRES COMPLIANCE WITH REGULATION

248 CMR 4.00 AND 5.00 FOR INSTALLATION OF

THROUGH-THE-WALL VENTED GAS APPLIANCES AS

FOLLOWS:

(a) For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used

in whole or in part for residential purposes, including

those owned or operated by the Commonwealth and

where the side wall exhaust vent termination is less than

seven (7) feet above finished grade in the area of the

venting, including but not limited to decks and porches,

the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizon-

tal vented gas fueled equipment, the installing plumber or

gasfitter shall observe that a hard wired carbon monoxide

detector with an alarm and battery back-up is installed on

the floor level where the gas equipment is to be installed.

In addition, the installing plumber or gasfitter shall ob-

Safety Information

serve that a battery operated or hard wired carbon

monoxide detector with an alarm is installed on each additional level of the dwelling, building or structure served

by the side wall horizontal vented gas fueled equipment.

It shall be the responsibility of the property owner to secure the services of qualified licensed professionals for

the installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas

fueled equipment is installed in a crawl space or an attic,

the hard wired carbon monoxide detector with alarm and

battery back-up may be installed on the next adjacent floor

level.

b. In the event that the requirements of this subdivision

can not be met at the time of completion of installation,

the owner shall have a period of thirty (30) days to comply

with the above requirements; provided, however, that during said thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

Each carbon monoxide detector as required in accordance with the above provisions shall comply with NFPA

720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall

be permanently mounted to the exterior of the building at

a minimum height of eight (8) feet above grade directly in

line with the exhaust vent terminal for the horizontally

vented gas fueled heating appliance or equipment. The

sign shall read, in print size no less than one-half (1/2)

inch in size, “GAS VENT DIRECTLY BELOW. KEEP

CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the

side wall horizontally vented gas fueled equipment shall

ot approve the installation unless, upon inspection, the

n

inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248

CMR 5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is exempt

from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment

Not Required To Be Vented” in the most current edition of

NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate

from the dwelling, building or structure used in whole or in

part for residential purposes.

(c) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the manufacturer of Product Approved side wall horizontally vented

gas equipment provides a venting system design or venting system components with the equipment, the instructions provided by the manufacturer for installation of the

equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting

system design or the venting system components; and

2. A complete parts list for the venting system design or

venting system.

(d) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When the

manufacturer of a Product Approved side wall horizontally

vented gas fueled equipment does not provide the parts

for venting the flue gases, but identifies “special venting

systems”, the following requirements shall be satisfied by

the manufacturer:

1. The referenced “special venting system” instructions

shall be included with the appliance or equipment installation instructions; and

2. The “special venting systems” shall be Product Approved by the Board, and the instructions for that system

shall include a parts list and detailed installation instructions.

(e) A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions, all parts lists for venting

instructions, and/or all venting design instructions shall remain with the appliance or equipment at the completion of

the installation.

8

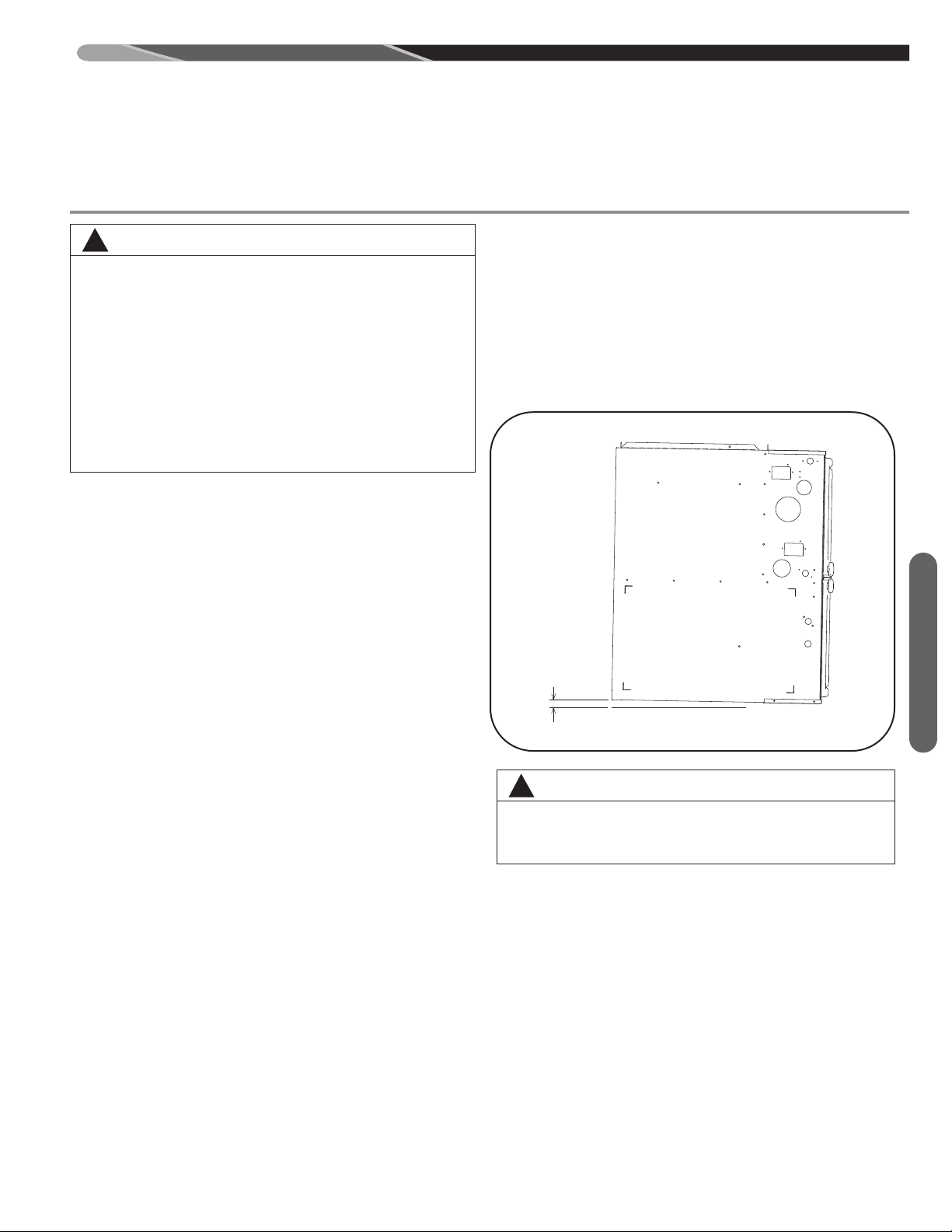

1/4" MIN. TO 1/2" MAX. TILT

TOWARD THE FRONT

OF THE CABINET IN ALL

INSTALLATIONS AND

O

RIENTATIONS

UPFLOW / DOWNFLOW

LOCATION REQUIREMENTS

GENERAL INFORMATION

1. IMPORTANT: If installing the unit over a finished ceil-

2. IMPORTANT: If using a cooling evaporator coil with

If these are manual dampers, they must be equipped to

prevent heating or cooling operation unless the damper is

in the full heat or cool position.

3. IMPORTANT: Furnace must be installed level from

NOTE: These furnaces are approved for installation in attics, as well as alcoves, utility rooms, closets and crawlspaces. Provisions must be made to prevent freezing of

condensate.

FREEZE PROTECTION

For installations where the furnace may reach temperatures below 32°F (0°C) (such as an alcove or attic installation), the installer must take precautions to ensure that the

drain trap and connected drain pipe do not freeze. Local

codes and practices should be followed in order to prevent

freezing.

If the drain trap is installed within the furnace cabinet, no

freeze protection is required. When the trap is mounted

outside or partially outside the cabinet, it must be protected from freezing. Regardless of the location of the

drain trap, any exposed drain piping must be protected

from freezing as required by local practices or codes. A UL

WARNING

!

WHEN THIS FURNACE IS INSTALLED IN A RESIDENTIAL GARAGE, IT MUST BE INSTALLED SO

THE BURNERS AND IGNITION SOURCE ARE LOCATED NO LESS THAN 18 INCHES [450MM] ABOVE

THE FLOOR. THIS IS TO PREVENT THE RISK OF IGNITING FLAMMABLE VAPORS WHICH MAY BE

PRESENT IN A GARAGE. ALSO, THE FURNACE

MUST BE LOCATED OR PROTECTED TO AVOID

PHYSICAL DAMAGE BY VEHICLES. FAILURE TO

FOLLOW THESE WARNINGS CAN CAUSE A FIRE

OR EXPLOSION, RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

ing or living area, be certain to install an auxiliary condensate drain pan under the entire unit. This auxiliary

drain pan should extend under any evaporator coil installed with the furnace and the open portion of the

condensate drain assembly. See “Condensate

Drain/Neutralizer” section for more details.

this furnace, be sure the air passes over the heat exchanger before passing over the cooling coil. The

cooled air passing over the warm ambient air inside

the heat exchanger tubes can cause condensation inside the tubes resulting in corrosion and eventual failure.

front-to-back or with a slight tilt such that the back of

the furnace is up to 1/2” higher than the front of the

furnace as shown in Figure 3.

or CSA listed heat tape or UL or CSA approved heating

cable with a rating of 3-6 watts per foot is acceptable protection when installed and maintained in accordance with

the manufacturer’s instructions. Good installation practices

necessitate that the installer verify heat tape operation in

accordance with the manufacturer’s instructions at the

time of installation.

IMPORTANT: Support this unit when installed. Since this

furnace is suitable for attic or crawl space installation, it

may be installed on combustible wood flooring or by using

support brackets as required.

FIGURE 3

BACK FRONT

0-1/2( HIGHER

THAN FRONT

OF FURNACE

WARNING

!

UPFLOW

ST-A1194-13-X0

THIS FURNACE IS NOT APPROVED OR RECOMMENDED FOR INSTALLATION ON ITS BACK, WITH

ACCESS DOORS FACING UPWARDS.

SITE SELECTION

1. Select a site in the building near the center of the proposed, or existing, duct system.

2. Give consideration to the vent system piping when selecting the furnace location. Be sure the venting system can get from the furnace to the termination with

minimal length and elbows.

3. Locate the furnace near the existing gas piping. Or, if

running a new gas line, locate the furnace to minimize

the length and elbows in the gas piping.

4. Locate the furnace to maintain proper clearance to

combustibles as shown in following Figure 5.

Location

9

6” 8”

OPTION - A

2” PIPE

OPTION - B

2”-3” PIPE

C

LOCATION REQUIREMENTS

GENERAL INFORMATION (cont.)

WARNING

!

DO NOT LIFT THE UNIT BY THE HEAT EXCHANGER TUBES. DOING SO CAN DAMAGE THE

HEAT EXCHANGER ASSEMBLY.

CLEARANCE – ACCESSIBILITY

The design of forced air furnaces with input ratings as

listed in the tables under Figure 5 are certified by CSA-International for the clearances to combustible materials

shown in inches.

See name/rating plate and clearance label for specific

model number and clearance information.

Service clearance of at least 24” (61 cm) is recommended

in front of all furnaces.

NOTE: Use recommended 24” (61 cm) clearance if accessibility clearances are greater than fire protection clearances.

WARNING

!

UPFLOW FURNACES ARE DESIGNFOR INSTALLATION ON COMBUSTIBLE FLOORS.

NOTE, HOWEVER, THAT FURNACES MUST NOT

BE INSTALLED DIRECTLY ON CARPETING, TILE

OR OTHER COMBUSTIBLE MATERIAL OTHER

THAN WOOD FLOORING. INSTALLATION ON A

Location

COMBUSTIBLE MATERIAL CAN RESULT IN FIRE,

CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

CERTIFIED

WARNING

!

COMBUSTIBLE MATERIAL MUST NOT BE

PLACED ON OR AGAINST THE FURNACE

JACKET. THE AREA AROUND THE FURNACE

MUST BE KEPT CLEAR AND FREE OF ALL COMBUSTIBLE MATERIALS INCLUDING GASOLINE

AND OTHER FLAMMABLE VAPORS AND LIQUIDS. PLACEMENT OF COMBUSTIBLE MATERIALS ON, AGAINST OR AROUND THE FURNACE

JACKET CAN CAUSE AN EXPLOSION OR FIRE

RESULTING IN PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH. THE HOMEOWNER SHOULD

BE CAUTIONED THAT THE FURNACE AREA

MUST NOT BE USED AS A BROOM CLOSET OR

FOR ANY OTHER STORAGE PURPOSES.

FIGURE 4

NOTE: THESE

DIMENSIONS

REFER TO

FURNACE

CLEARANCE

ONLY. FOR REQUIRED VENT

CLEARANCES

AND SUPPORTS, REFER

TO VENT MANUFACTURER’S

INSTRUCTIONS.

CLEARANCE FLUE VENT TO WALL

10

NOTE: THESE ILLUSTRATIONS ARE INTENTIONALLY GENERIC.

NOTE: SOME PARTS OF YOUR FURNACE MAY APPEAR DIFFERENT.

ST-A1194-86-00

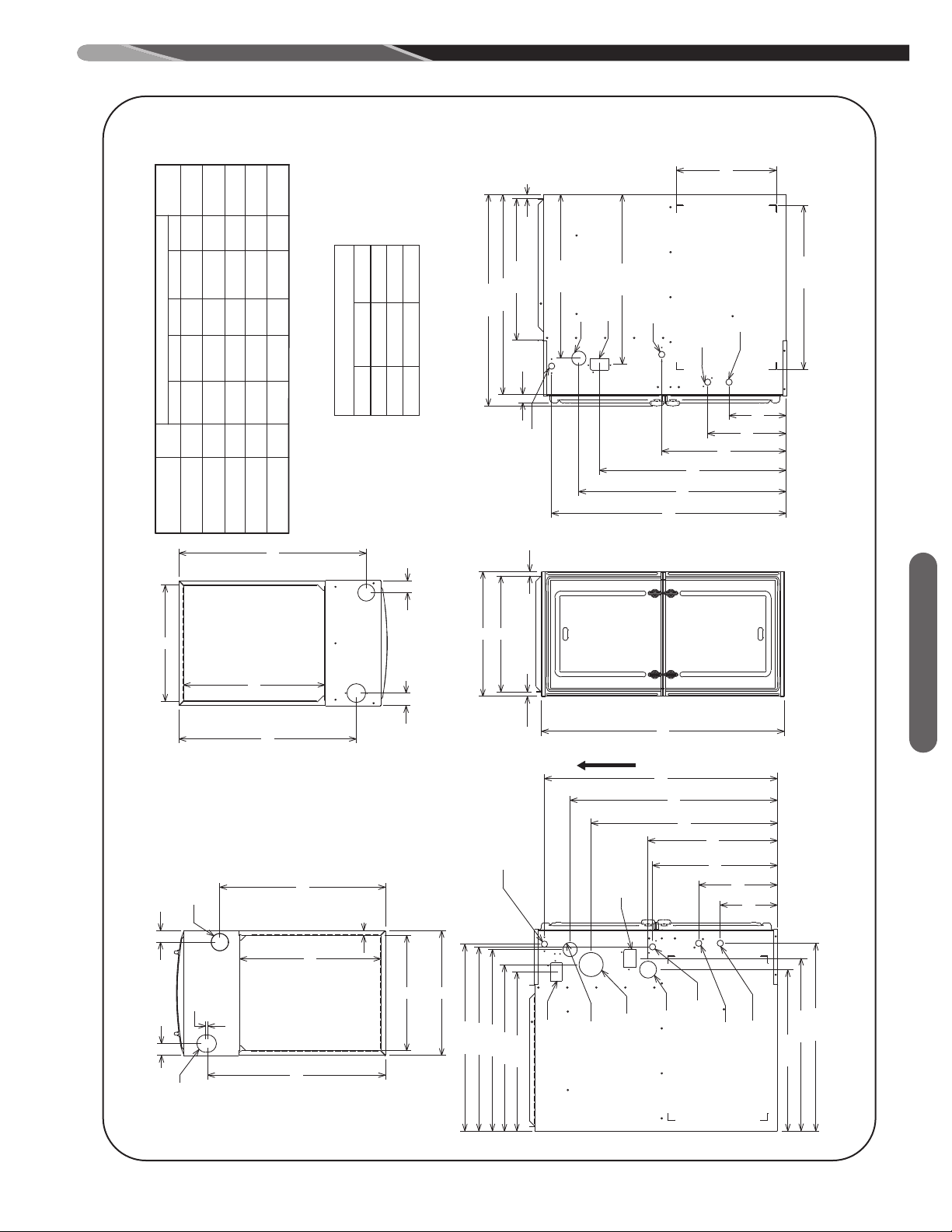

FIGURE 5

TOPBOTTOM

FRONTLEFT SIDE RIGHT SIDE

RIGHT BACK TOP FRONT VENT

(-)97VA060

(-)(-)97MDV060

(-)97VA070

(-)(-)97MDV070

(-)97VA085

(-)(-)97MDV085

(-)97VA100

(-)(-)97MDV100

(-)97VA115

(-)(-)97MDV115

0 0 0 1 2 0

0 0 0 1 2 0

0 0 0 1 2 0

SHIPPING

WEIGHTS

MINIMUM CLEARANCE (IN.)

MODEL

LEFT

SIDE

UNIT DIMENSIONS

(CLEARANCE TO COMBUSTIBLES)

A

I

R

F

L

O

W

A

B

.62

.62

34.00

23.33

25.44

26.19

22.63

25.81

26.31

8.00

11.03

17.50

18.13

26.11

29.05

32.65

24.19

22.31

OPTIONAL TRAP

LOCATION

(HORIZONTAL)

OPTIONAL CONDENSATE

DRAIN (DOWNFLOW)

GAS

CONNECTION

OPTIONAL COMBUSTION

VENT LOCATION

OPTIONAL TRAP

LOCATION

(HORIZONTAL)

OPTIONAL VENT

AIR INLET

CONDENSATE DRAIN

(UPFLOW)

ELECTRICAL CONNECTION

LINE VOLTAGE

ELECTRICAL CONNECTION

LOW VOLTAGE

22.96

23.80

8.00

11.00

17.44

29.05

26.17

32.88

23.00

14.00

28.06

1.12

29.62

.62

19.83

OPTIONAL LINE VOLTAGE

WIRING

OPTIONAL LOW VOLTAGE

WIRING

OPTIONAL CONDENSATE

DRAIN (UPFLOW)

TRAP LOCATION

(HORIZONTAL)

OPTIONAL

GAS CONNECTION

OPTIONAL

CONDENSATE DRAIN

(DOWNFLOW)

1.76

1.66

24.86

26.26

B

19.83

SUPPLY

AIR

23.21

1.62

1.67

24.91

.30

C

19.77

A

.65

RETURN

AIR

OPTIONAL

VENT OUTLET

KNOCKOUT

OPTIONAL COMBUSTION

AIR INLET KNOCKOUT

SUPPLY AND RETURN DEPICTED AS UPFLOW CONFIGURATION.

FLANGE CONFIGURATION WILL VARY DEPENDING ON IN STALLATION ORI ENTATION.

A B C

17 1/2 16 17/64 16 13/64

21 19 49/64 19 45/64

24 1/2 23 17/64 23 13/64

FLANGE DIMENSIONS

*A SERVICE CLEARANCE OF AT LEAST 24” IS RECOMMENDED IN FRONT OF ALL FURNACES

0 0 0 1 2 0

0 0 0 1 2 0

UNIT DIMENSIONS (CLEARANCE TO COMBUSTIBLES – SOME MEASUREMENTS DO NOT APPLY TO UPFLOWS)

ST-A1194-01-X0

Location

11

FIELD CONVERSIONS

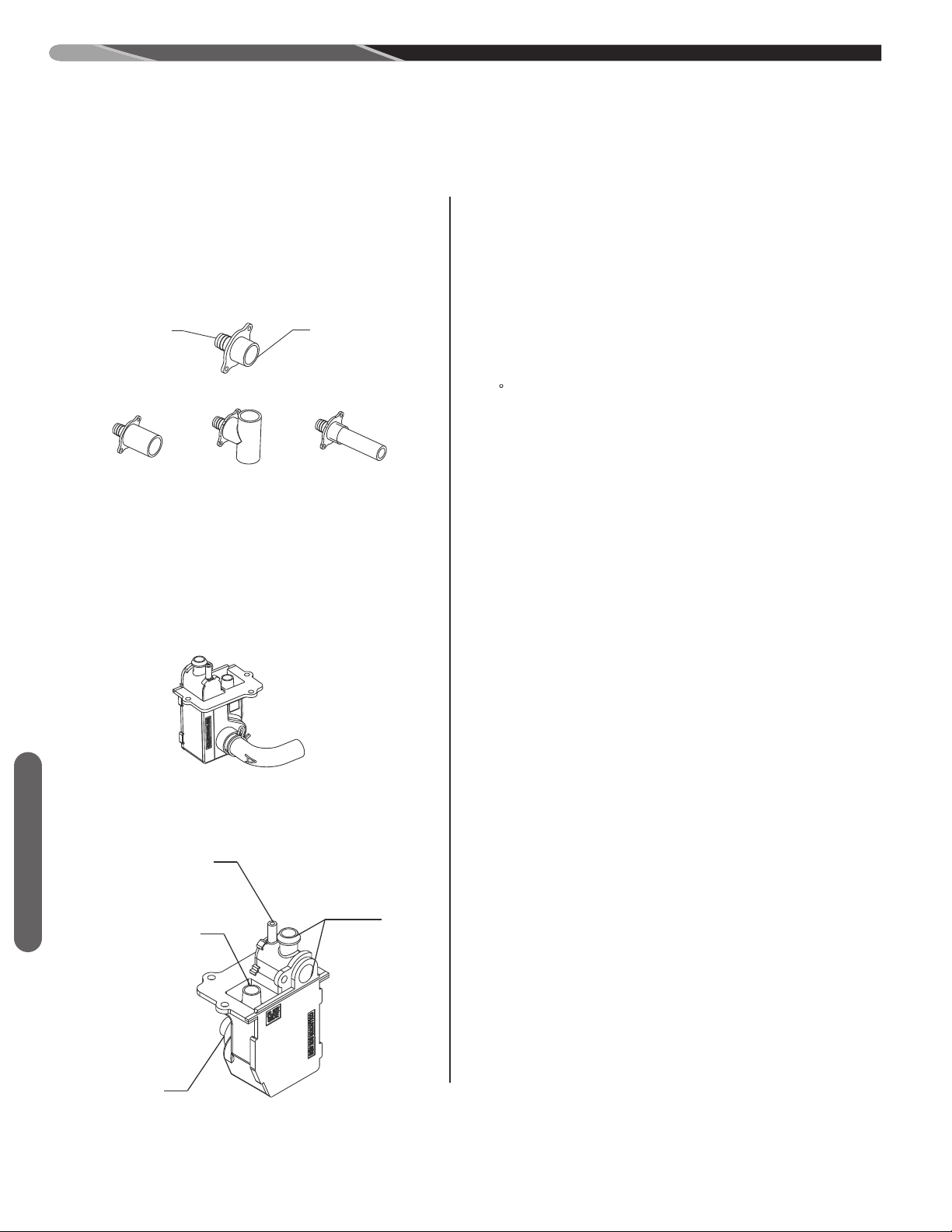

CONDENSATE PVC/HOSE OPTIONS

B

ULKHEAD COUPLING

CONDENSATE DRAINIAGE HAS OPTIONS FOR 3/4" OR 1/2"

PVC CONNECTIONS. THE BULKHEAD COUPLING CONNECTS THE

RUBBER HOSES FROM INSIDE THE UNIT TO THE PVC PIPE

EXTERIOR OF THE UNIT. PVC PIPE CAN BE CEMENTED

DIRECTLY TO THE COUPLING AND THE TRAP WITH PROPER

PVC CEMENT AND PRIMER.

1/2" PVC

PIPE

3/4" PVC

TEE

RUBBER HOSE

CONNECTION

P

VC FITTING/PIPE

3/4" PVC

COUPLING

NOTE: IMPROPER HOSE CONNECTIONS WILL PREVENT

CONDENSATE FROM DRAINING.

CONDENSATE TRAP

THE CONDENSATE TRAP HAS 2 SIDES PLEASE NOTE THEIR

LOCATIONS FOR DRAIN CONNECTIONS DURING CONVERSION.

OUT TO DRAIN

COLLECTOR BOX

IN FROM

IN FROM FLUE

ELBOW OR COUPLING

1/4" VENT IN

FROM COLLECTOR BOX

GENERAL CONVERSION INSTRUCTIONS

ST-A1194-37-02

-2010°

CONVERSION AND INSTALLATION

C

ONSIDERATIONS

ALL CONVERSIONS REQUIRE THE CONDENSATE PLUMBING TO

HAVE DECLINE IN THE DIRECTION OF THE WATER FLOW.

WHEN INSTALLING AND MOVING CONDENSATE PLUMBING THE

HOSES SHOULD BE FREE OF KINKS FOR PROPER WATER FLOW.

WHEN DRAIN HOSE OR CONDENSATE TRAP HOSE

ROUTING CHANGES ARE NECESSARY BE SURE TO PLUG OR CAP

ANY UNUSED HOSE TAPS.

THE INDUCER COUPLING COMES FROM THE FACTORY WITH

A 10

TILT FOR UP FLOW INSTALLATIONS. WHEN

CONVERTED TO DOWN FLOW THE COUPLING REQUIRES A

ROTATION A MINIMUM OF 10

FROM HORIZONTAL AS SHOWN.

HORIZONTAL INSTALLATIONS REQUIRE CONDENSATE TRAP TO BE

MOUNTED EXTERNALLY BELOW THE UNIT:

-USE CAUTION-MOUNT THE TRAP AFTER THE UNIT IS AT

THE POINT OF INSTALLATION TO PREVENT DAMAGE TO THE

TRAP DURING TRANSPORT.

-HAND TIGHTEN SCREWS WHEN MOUNTING THE TRAP OR THE

BULKHEAD COUPLING TO THE CABINET TO PREVENT DAMAGE

TO THE MOUNTING FLANGE.

-USE PROPER FREEZE PROTECTION IF REQUIRED.

-ALLOW MINIMUM OF 6" BELOW THE FURNACE FOR CLEARANCE.

10-20°

TILT ON INDUCER COUPLING

GROUND

GROUND

LEVEL

MIDLINE

WORM

DRIVE

CLAMP

COUPLING

THE WORM DRIVE FOR THE HOSE CLAMPS

USED ON THE FLUE TRANSITION COUPLING

OR THE IDB COUPLING MUST BE ABOVE THE

LEVEL MIDLINE WHEN IN THE HORIZONTAL

POSITION AS DETAILED HERE.

IF THE IDB COUPLING IS REMOVED, IT MUST BE REPLACED IN THE

PROPER ORIENTATION. AN ARROW IS PRESENT ON THE COUPLING

TO INDICATE THE DIRECTION OF EXHAUST FLOW. MAKE SURE THE

ARROW POINTS IN THE CORRECT DIRECTION.

NOTE:

T

HE CONDENSATE TRAP IS DESIGNED WITH MULTIPLE OUTLET

DRAIN CONNECTIONS THAT CAN BE UTILIZED. THE SAME OUTLET

CAN BE USED FOR BOTH STANDARD PVC AND A 5/8" RUBBER

HOSE.

WHEN THE TRAP IS LOCATED INSIDE THE UNIT A 5/8" RUBBER

HOSE CAN BE SECURED WITH A HOSE CLAMP TO MAKE HOSE

CONNECTIONS TO THE BULKHEAD COUPLING. PLIERS ARE

NEEDED TO ADJUST OR REMOVE THE CLAMP.

WHEN THE TRAP IS LOCATED OUTSIDE OF THE UNIT STANDARD

PVC FITTINGS CAN BE CEMENTED DIRECTLY TO THE OUTLET

WITH PROPER PVC CEMENT AND PRIMER.

Field Conversions

12

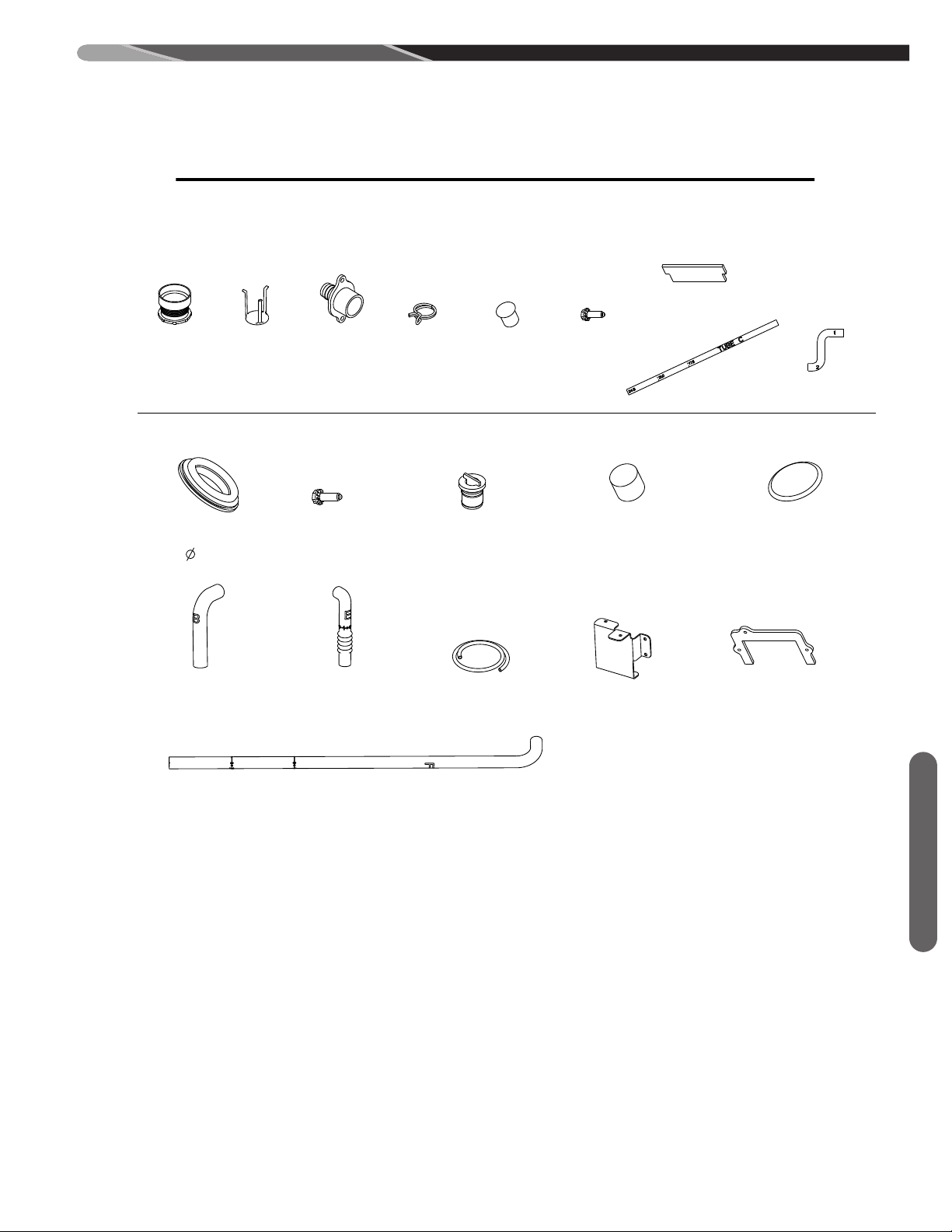

FIELD CONVERSIONS

PARTS BAG (PROVIDED WITH UNIT)

CONVERSION KIT RXGY-CK

CONVERSION KIT RXGY-ZK

(X2)

2-5/8" FLUSH

MOUNT PLUG

1/2" DRAIN

HOSE E

INTAKE

C

OUPLING

.559" CONDENSATE

TRAP DRAIN PLUG

#8 X 1/2"

SCREW

(X2)

INTAKE

PIPE

1/4" BLACK

VENT TUBE

BULKHEAD

COUPLING

HOSE DOUBLE ELBOWTUBE C

HOSE CLAMP

INTAKE AIR

DIFFUSER

#8 X 1/2"

SCREW

(

X4)

#8 X 1/2"

SCREW

(X10)

5/8" DRAIN

HOSE B

CONDENSATE TRAP

BRACKET (DOWN FLOW)

2" PVC VANE

1/4" HOLE

PLUG

1/2" DRAIN

HOSE F

1/2" DRAIN

HOSE G

CONDENSATE

TRAP GASKET

2" PIPE GROMMET

(

3.375)

1/2" VINYL

CAP (YELLOW)

PIPE COLLAR

GASKET ASSEMBLY

(X2)

ST-A1194-38-03

GENERAL PARTS REQUIRED FOR CONVERSIONS

(X3)

FLUE PIPE

ASSEMBLY

W/ O-RING

O-RING

Field Conversions

SEE NEXT PAGE FOR APPLICABLE CONFIGURATIONS

13

FIELD CONVERSIONS

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

FIELD CONVERSION TO VARIOUS CONFIGURATIONS

Furnaces can be converted to two different upflow configurations as follows. There are two different venting options, including a zero-clearance option, to give the installer flexibility in locating the venting for this furnace.

LISTS OF MATERIALS FOR PARTS BAGS AND CONVERSION KITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 12

GENERAL CONVERSION INSTRUCTIONS AND TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 13

UPFLOW WITH VERTICAL VENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 15-16

UPFLOW WITH LEFT SIDE VENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 17-18

(REQUIRES CONVERSION

KIT RXGY-CK)

DOWNFLOW WITH RIGHT VENT (NON-ZERO CLEARANCE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 19-22

(REQUIRES CONVERSION

KIT RXGY-CK)

DOWNFLOW ZERO-CLEARANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 23-27

(REQUIRES CONVERSION

KIT RXGY-CK AND ZERO-

CLEARANCE KIT RXGY-ZK)

HORIZONTAL RIGHT WITH RIGHT VENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 28-30

(REQUIRES CONVERSION

KIT RXGY-CK)

HORIZONTAL RIGHT WITH VERTICAL VENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 31-33

(REQUIRES CONVERSION

Field Conversions

KIT RXGY-CK)

HORIZONTAL LEFT WITH RIGHT VENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 34-38

(REQUIRES CONVERSION

KIT RXGY-CK AND ZERO-

CLEARANCE KIT RXGY-ZK)

HORIZONTAL LEFT WITH LEFT VENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pg 39-41

14

(REQUIRES CONVERSION

KIT RXGY-CK)

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

NOTE: THESE CONVERSION INSTRUCTIONS ARE INTENTIONALLY GENERIC, SOME PARTS MAY BE DIFFERENT IN YOUR FURNACE

ST-A1194-68-00

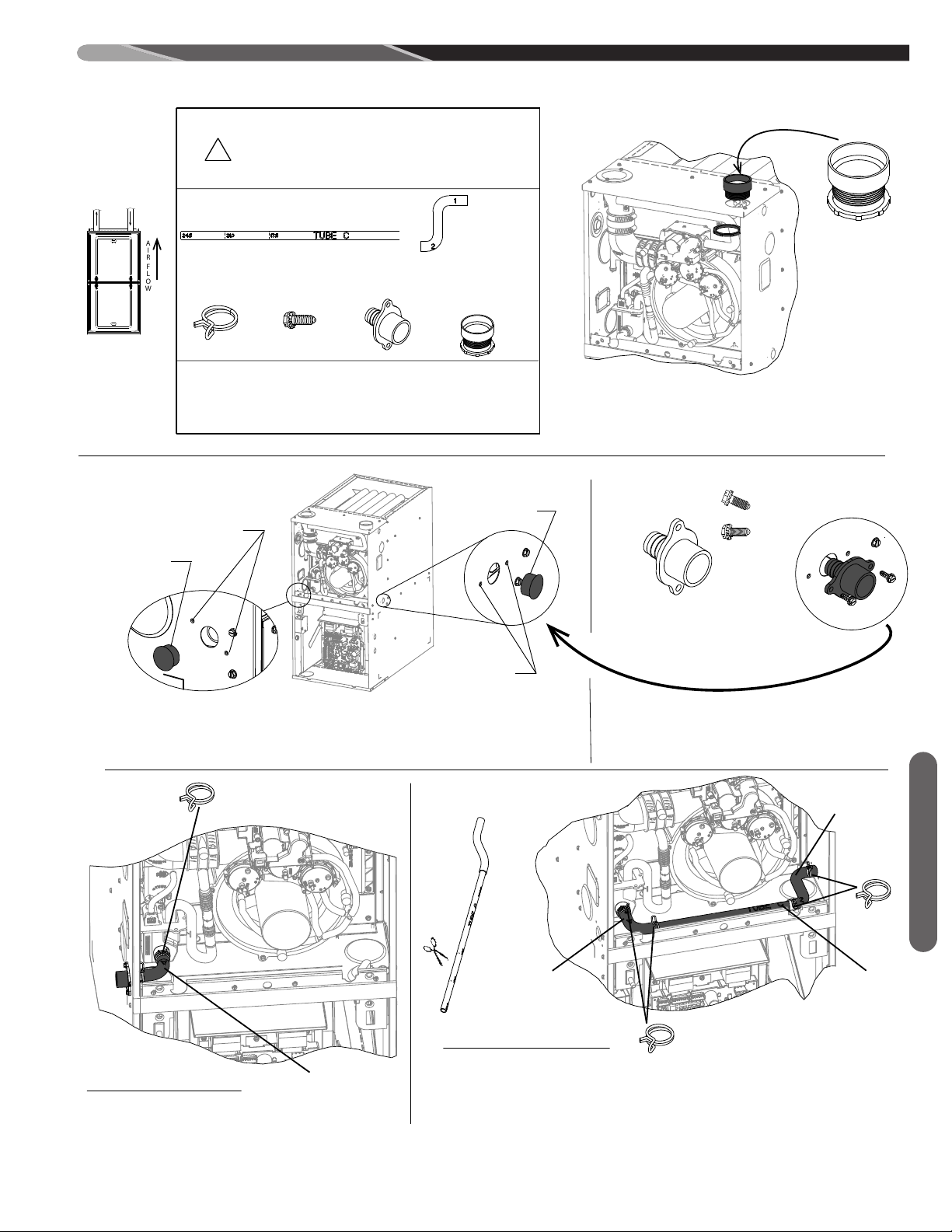

NOTE: PLIERS NECCESSARY TO ADD OR REMOVE CLAMPS

PARTS NEEDED:

PARTS NEEDED FOR THIS CONVERSION REQUIRE ITEMS

FROM THE PARTS BAG ONLY. NO OTHER CONVERSION

KITS ARE NEEDED.

!

TUBE C

B

ULKHEAD

COUPLING

FROM PARTS BAG (PROVIDED WITH UNIT)

(X2)

#8 X 1/2"

SCREW

H

OSE

CLAMP

INTAKE

COUPLING

W/ NUT

DRILL

1/8" DRILL BIT

PLIERS

1/4" HEX HEAD DRIVER

TUBING CUTTER

TOOLS/MATERIALS NEEDED:

(X3)

HOSE -

DOUBLE ELBOW

UPFLOW VERTICAL VENT

"

*

3

'

-

0

8

INSTALL INTAKE COUPLING IN TOP PLATE

1

INSTALL

DETERMINE RIGHT OR LEFT DRAIN OPTION.

LOCATE 7/8” HOLE IN JACKET SIDE.

REMOVE PLUG - DISCARD

DRILL (2) Ø 1/8” HOLES FOR THE BULKHEAD COUPLING.

2

3

OPTION DRAIN LEFT

DRILL 1/8”

7/8” PLUG

D

ISCARD

DRILL 1/8”

7/8” PLUG

DISCARD

INSTALL BULKHEAD COUPLING USING (2) SCREWS.

INSTALL IN JACKET WITH THE BARBED FITTING

POINTED INTO THE VESTIBULE.

INSTALL

OPTION DRAIN RIGHT

4a - LEFT SIDE DRAIN OPTION

ATTACH HOSE A (PRE-INSTALLED) TO BULKHEAD COUPLING.

INSTALL HOSE CLAMP ON HOSE OVER BULK HEAD COUPLING.

4b - RIGHT SIDE DRAIN OPTION

4b1 - CUT TUBE “C” TO FIT CORRESPONDING CABINET WIDTH.

4b2 - INSERT TUBE “C” INTO END “2” OF HOSE- DOUBLE ELBOW

4b3 - SLIDE TWO WIRE CLAMPS OVER TUBE “C”, SLIDE ONE WIRE CLAMP OVER

END “1” OF HOSE - DOUBLE ELBOW.

4b4 - INSTALL TUBE “C” WITH HOSE CLAMP AS SHOWN TO HOSE “A” “PRE ASSEMBLED”.

4b5 - ATTACH HOSE - DOUBLE ELBOW TO BULKHEAD COUPLING POSITION WIRE HOSE

CLAMP.

4A

4B

TUBE C

CUT TO FIT

CABINET WIDTH

2

HOSE A

TUBE C

HOSE-DOBLE

ELBOW

HOSE A

(X2)

Field Conversions

15

ST-A1194-68-00

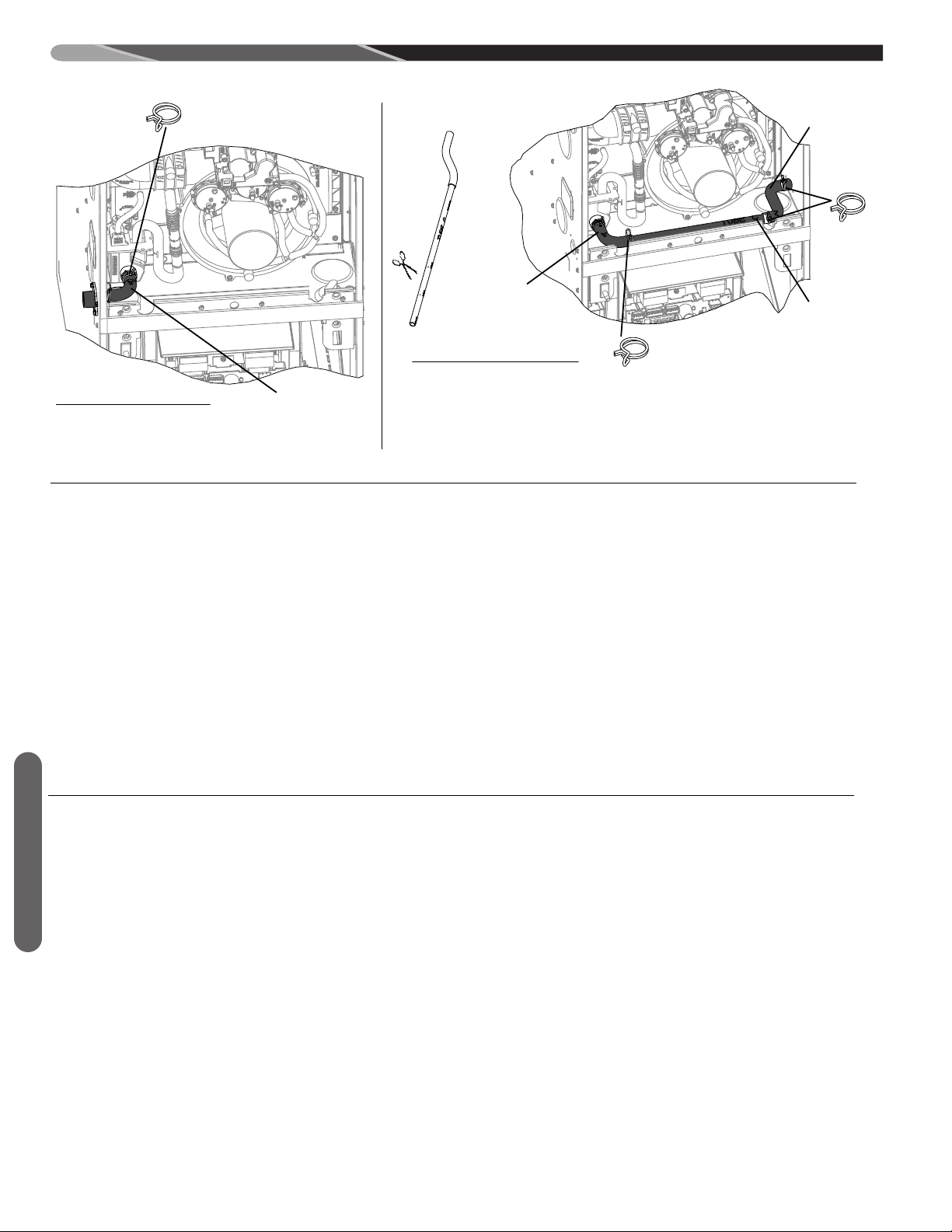

Notes:

Checklist:

__ VERIFY ALL HOSES ARE SECURE AND FULLY SEATED.

__ CONFIRM THAT ALL HOSES ARE FREE OF KINKS.

_

_ CONFIRM ALL HOSES AND OTHER DRAIN PARTS HAVE A

SLOPE IN DIRECTION OF WATER FLOW

__ BOTH WORM DRIVES ON THE HOSE CLAMPS OF THE IDB COUPLING

MUST BE LOCATED ON THE TOP OF THE COUPLING. SEE LOCATION

DETAIL IN THE GENERAL CONVERSION INSTRUCTIONS AT THE

BEGINNING OF THIS SECTION.

__ ALL CLAMPS AND COUPLINGS ARE TIGHTENED

__ ALL DRAIN PORTS ARE PLUGGED

_

_ UNIT HAS FORWARD PITCH

__ HEAT TAPE INSTALLED (IF REQUIRED)

Field Conversions

16

DRILL

1/8" DRILL BIT

P

LIERS

FLAT HEAD SCREWDRIVER

5/16 HEX HEAD DRIVER

1/4" HEX HEAD DRIVER

TUBING CUTTER

TOOLS/MATERIALS NEEDED:

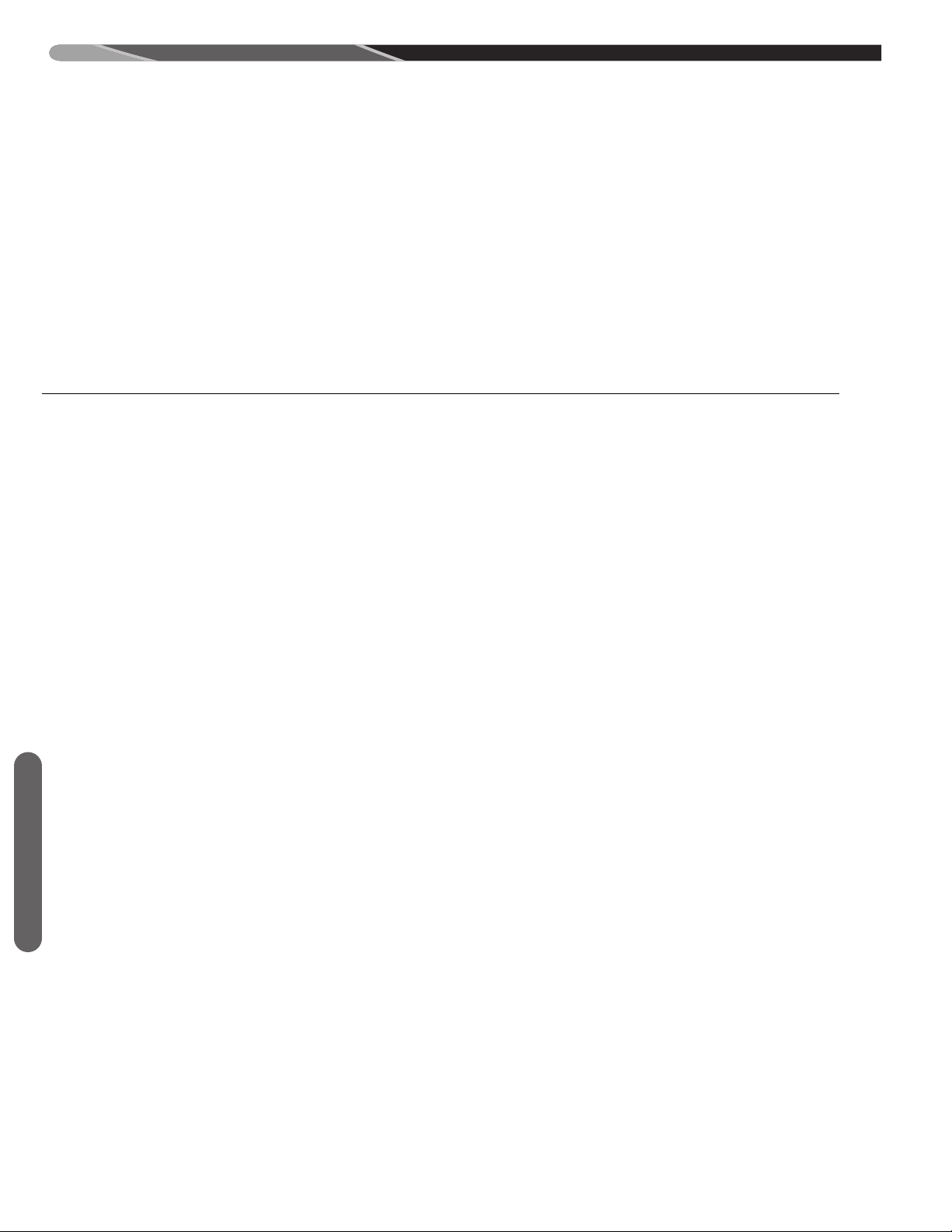

UPFLOW LEFT VENT

NOTE: THESE CONVERSION INSTRUCTIONS ARE INTENTIONALLY GENERIC, SOME PARTS MAY BE DIFFERENT IN YOUR FURNACE

ST-A1194-69-00

PARTS NEEDED:

(X2)

F

ROM PARTS BAG (PROVIDED W/UNIT)

I

NTAKE

COUPLING

W/ NUT

BULKHEAD

COUPLING

#

8 X 1/2"

SCREW

TUBE C

HOSE

CLAMP

F

ROM CONVERSION KIT RXGY-CK

2-3/8" PIPE

GROMMET

2-5/8" FLUSH

MOUNT PLUG

PARTS NEEDED FOR THIS

CONVERSION REQUIRE THE

O

UTLINED ITEMS FROM THE PARTS BAG

A

ND CONVERSION KIT RXGY-CK. YOU

M

UST HAVE THESE PARTS BEFORE

P

ROCEEDING.

!

Î

*

3

(X3)

H

OSE DOUBLE

ELBOW

1a - REMOVE FLUE TRANSITION, TRANSITION COUPLING, AND ELBOW.

(NOTE: REMOVE INDUCER COUPLING W/ELBOW FOR EASIER REMOVAL).

1b - REMOVE 3-3/8" FLUSH MOUNT PLUG FROM JACKET - DISCARD.

1c - RELOCATE 2-3/8" FLUSH MOUNT PLUG FROM JACKET TO TOP PLATE.

2

2a - INSTALL 2-5/8" FLUSH MOUNT PLUG IN TOP PLATE.

2b - INSTALL 2" PIPE GROMMET AS SHOWN.

2c - INSTALL INTAKE COUPLING AS SHOWN.

2b

2c

2

a

2

-5/8”

IF THE IDB

C

OUPLING IS

R

EMOVED, IT

MUST BE

REPLACED IN

THE PROPER

ORIENTATION.

AN ARROW IS

PRESENT ON

THE COUPLING

TO INDICATE

THE DIRECTION

OF EXHAUST

FLOW. MAKE

SURE THE

ARROW POINTS

IN THE

CORRECT

DIRECTION.

NOTE:

1

IDB COUPLING

(RETAIN)

FLUE TRANSITION

(DISCARD)

TRANSITION

C

OUPLING

(

DISCARD)

ELBOW

(DISCARD)

1a

1b

1c

R

E

-LOC

A

T

E

DISCARD

DETERMINE RIGHT OR LEFT DRAIN OPTION.

LOCATE 7/8” HOLE IN JACKET SIDE.

REMOVE PLUG - DISCARD

DRILL (2) Ø 1/8” HOLES FOR THE BULKHEAD COUPLING.

3

4

DRILL 1/8”

DISCARD

DRILL 1/8”

DISCARD

INSTALL BULKHEAD COUPLING USING (2) SCREWS.

INSTALL IN JACKET WITH THE BARBED FITTING

POINTED INTO THE VESTIBULE.

INSTALL

SEE CRITICAL HOSE CLAMP LOCATION NOTE

IN THE GENERAL CONVERSION INSTRUCTIONS.

Field Conversions

17

ST-A1194-69-00

Notes:

NOTE: PLIERS NECCESSARY TO ADD OR REMOVE CLAMPS

Checklist:

__ VERIFY ALL HOSES ARE SECURE AND FULLY SEATED.

__ CONFIRM THAT ALL HOSES ARE FREE OF KINKS.

__ CONFIRM ALL HOSES AND OTHER DRAIN PARTS HAVE A

SLOPE IN DIRECTION OF WATER FLOW

__ BOTH WORM DRIVES ON THE HOSE CLAMPS OF THE IDB COUPLING

MUST BE LOCATED ON THE TOP OF THE COUPLING. SEE LOCATION

DETAIL IN THE GENERAL CONVERSION INSTRUCTIONS AT THE

BEGINNING OF THIS SECTION.

__ ALL CLAMPS AND COUPLINGS ARE TIGHTENED

__ ALL DRAIN PORTS ARE PLUGGED

__ UNIT HAS FORWARD PITCH

__ HEAT TAPE INSTALLED (IF REQUIRED)

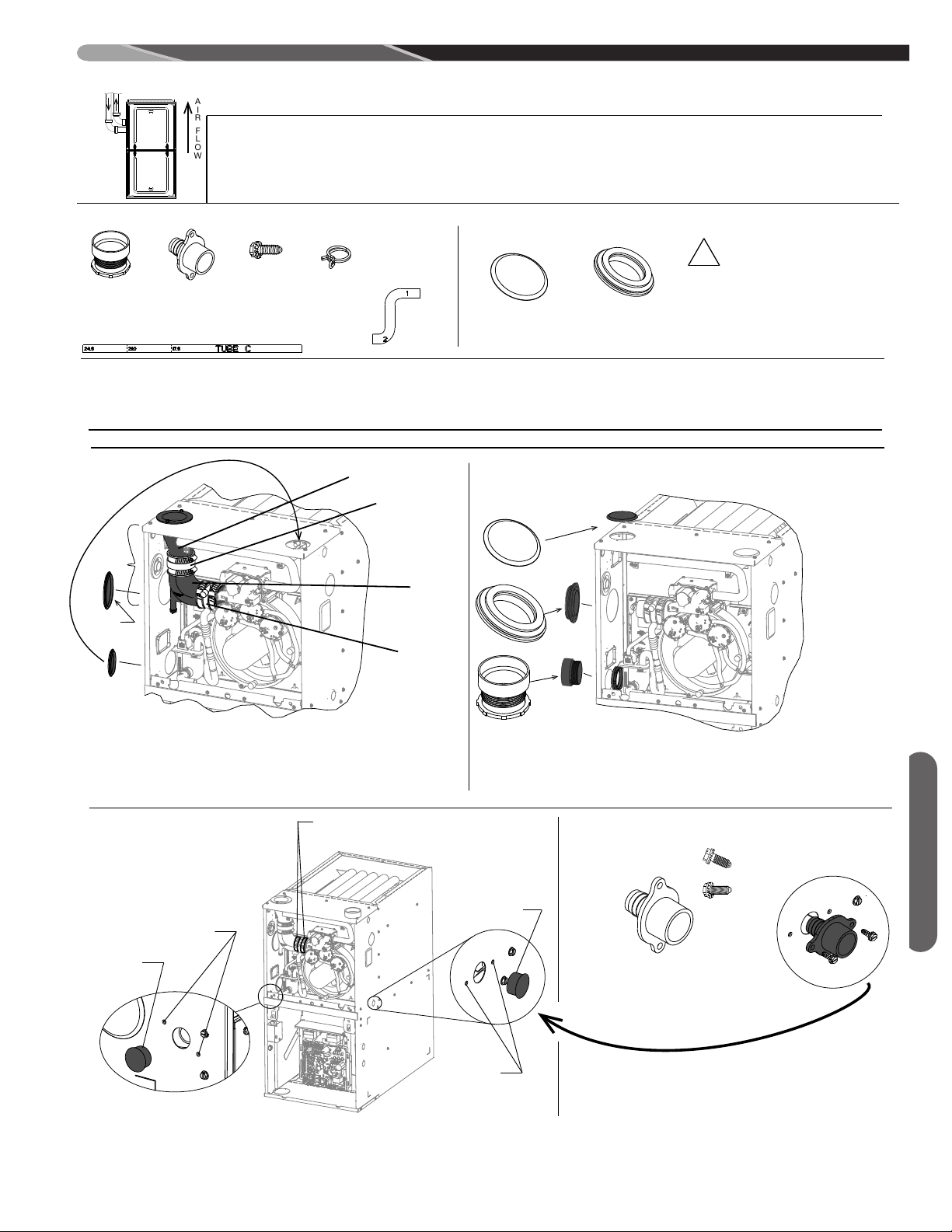

5a - LEFT SIDE DRAIN OPTION

ATTACH HOSE A (PRE-INSTALLED) TO BULKHEAD COUPLING.

I

NSTALL HOSE CLAMP ON HOSE OVER BULK HEAD COUPLING.

5

b - RIGHT SIDE DRAIN OPTION

5b1 - CUT TUBE “C” TO FIT CORRESPONDING CABINET WIDTH.

5b2 - INSERT TUBE “C” INTO END “2” OF HOSE- DOUBLE ELBOW

5

b3 - SLIDE TWO WIRE CLAMPS OVER TUBE “C”, SLIDE ONE WIRE CLAMP OVER

END “1” OF HOSE - DOUBLE ELBOW.

5

b4 - INSTALL TUBE “C” WITH HOSE CLAMP AS SHOWN TO HOSE “A” “PRE ASSEMBLED”.

5b5 - ATTACH HOSE - DOUBLE ELBOW TO BULKHEAD COUPLING POSITION WIRE HOSE

CLAMP.

5A

5B

H

OSE A

TUBE C

HOSE-DOBLE

ELBOW

TUBE C

CUT TO FIT

CABINET WIDTH

2

HOSE A

(

X2)

Field Conversions

18

DUCTING

REMOVE SOLID

BASE FROM TOP

OF UNIT.

2

REMOVE SOLID BASE PANEL FROM THE

TOP BEFORE INSTALLING FURNACE

External filter racks are available from the distributor. Use

the following part numbers when ordering:

RXGF-CA External Side Filter Rack Kit

RXGF-CB External Bottom Filter Rack Kit

Proper air flow is required for the correct operation of this

furnace. Restricted air flow can cause erratic operation

and can damage the heat exchanger. The duct system

must carry the correct amount of air for heating and cooling if summer air conditioning is used.

WARNING

!

SOME HEATING AIRFLOW VALUES MAY BE

HIGHER THAN THOSE REQUIRED FOR COOLING.

BE SURE TO SIZE DUCT FOR THE MAXIMUM POSSIBLE AIRFLOW VALUE.

SIZE AIRFLOW DISTRIBUTION SYSTEM TO ACCEPTABLE INDUSTRY STANDARDS AND METHODS. TOTAL STATIC PRESSURE DROP OF THE AIR

DISTRIBUTION SYSTEM SHOULD NOT EXCEED 1.0

INCHES W.C. THIS WILL INCLUDE ANY AIR CONDITIONER COIL, AIR FILTRATION SYSTEM, ZONING

SYSTEM, DUCTWORK, ETC. REFER TO ADDED

EQUIPMENT TECHNICAL INFORMATION TO OBTAIN PRESSURE DROP INFORMATION WHEN

EQUIPMENT IS OPERATING AT RECOMMENDED

HEATING OR COOLING CFMS.

IMPORTANT: When using outside air, design and adjust

the system to maintain a return air temperature ABOVE

55° F during the heating season.

NOTE:Return air grilles and warm air registers must not

be obstructed or closed.

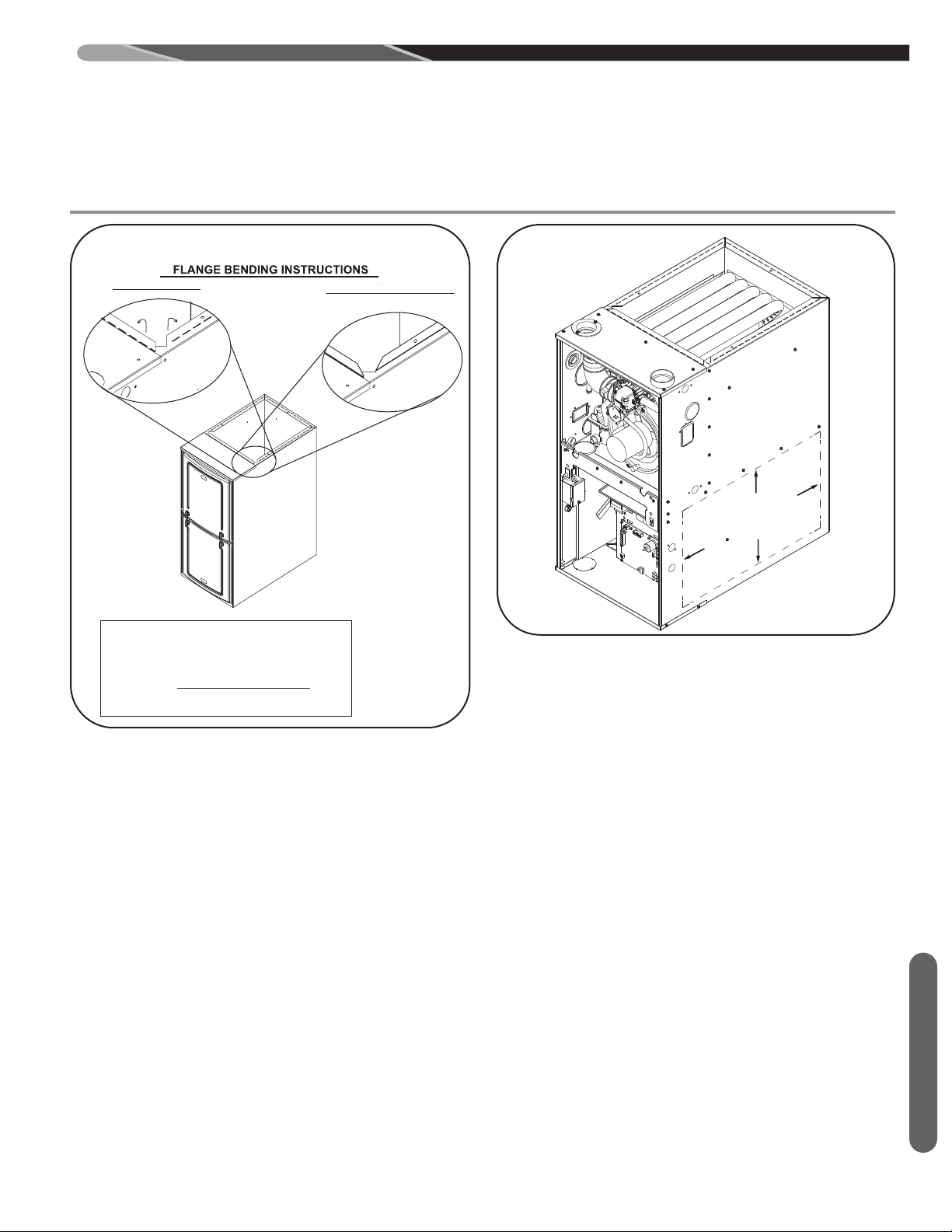

NOTE:Both flanges on the supply and return openings

must be bent either up or down but cannot remain flat as

shipped from the factory. See Figure 8 for details.

WARNING

!

THE SOLID METAL BASE PAN MUST BE REMOVED

FROM THE TOP OF THE FURNACE BEFORE INSTALLING THE FURNACE. FAILURE TO REMOVE

THIS PAN FROM THE SHIPPING POSITION CAN RESULT TO DAMAGE TO THE FURNACE OR EQUIPMENT.

WARNING

!

BLOWER AND BURNERS MUST NEVER BE OPERATED

WITHOUT THE BLOWER DOOR IN PLACE. THIS IS TO

PREVENT DRAWING GAS FUMES (WHICH COULD CONTAIN HAZARDOUS CARBON MONOXIDE) INTO THE

HOME THAT COULD RESULT IN PERSONAL INJURY OR

DEATH.

FIGURE 6

ST-A1194-49

UPFLOW INSTALLATIONS

1. Position the unit to minimize long runs of duct or runs

of duct with many turns and elbows.

2. For side return: Cut an opening in the side. The opening should be cut the full width and height of the

knockouts on the unit. See Figure 9.

3. If summer air conditioning is desired, position the indoor coil on the supply-air side of the unit. Ensure

that no air can bypass the coil.

4. Connect the furnace to the supply air plenum.

5. Connect the return air ducting to the return-air opening at the bottom and/or side of the unit. Make the

connections air-tight to prevent the migration of toxic

fumes and odors including carbon monoxide from migrating into the living space.

6. If a filter is installed near the furnace, be sure to have

adequate space for installation and removal of the

unit filter.

7. NOTE: Where the maximum airflow is 1800 CFM or

more, BOTH sides or the bottom must be used for the

return air.

NOTE: DO NOT take return air from furnace rooms,

garages or cold areas. Avoid return air from utility rooms,

kitchens, laundry rooms and bathrooms.

Ducting

19

DUCTING

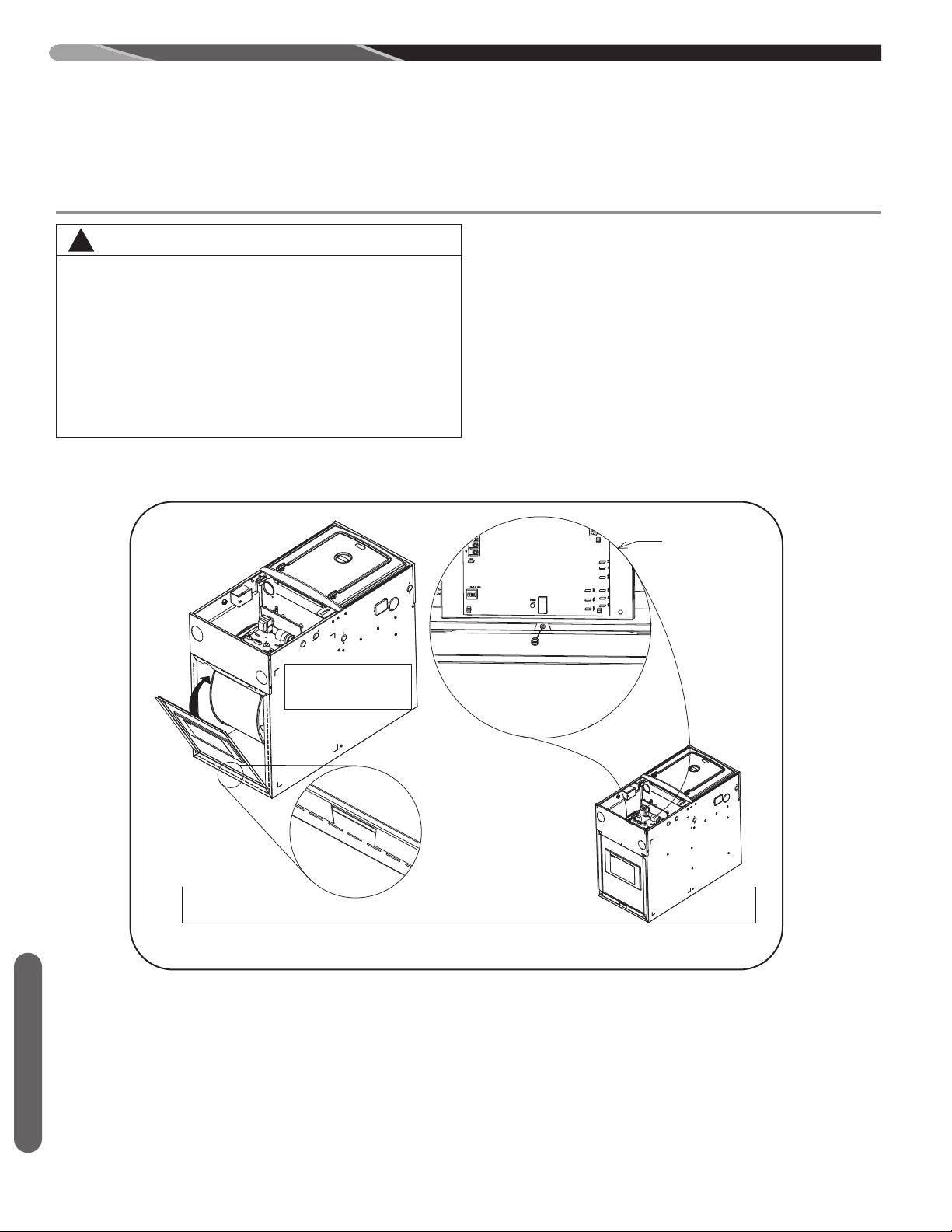

1 REMOVE BLOWER

DOOR AS SHOWN

RETAINING TAB

DETAIL

INSTALLATION OF SOLID METAL BASE FOR SIDE

RETURN APPLICATIONS

INTERNAL VIEW

OF BLOWER

COMPARTMENT

2 INSERT TAB ONTO

FLANGE AND PUSH

PANEL INTO PLACE

3 INSTALL SCREW IN TAB LOCATED

IN THE BLOWER COMPARTMENT

TAPE ALL EDGES OF BOTTOM

TO COVER GAPS

4 AFTER

INSTALLATION

OF BOTTOM

PLATE, SEAL ALL

SEAMS TIGHT

WITH METAL

TAPE

WARNING

!

UPFLOW FURNACE: THE SOLID METAL BASE

PLATE (SHIPPED WITH THE FURNACE) MUST BE

INSTALLED IN THE FURNACE BOTTOM WHEN

USING SIDE AIR RETURN. FAILURE TO INSTALL A

BASE PLATE COULD CAUSE THE PRODUCTS OF

COMBUSTION TO CIRCULATE INTO THE LIVING

SPACE AND CREATE POTENTIAL LY HAZARDOUS

CONDITIONS, INCLUDING CARBON MONOXIDE POISONING OR DEATH. FOR BOTTOM RETURN, A

SOLID METAL BASE PAN MUST NOT BE INSTALLED.

FIGURE 7

Ducting

20

ST-A1194-49

CUT - OUT USING

EMBOSSED ANGLES AS

A GUIDE FOR PROPER

SIZE 23” x 14”

DUCTING

INSTALLER BENT - UP

FIGURE 8

AS - SHIPPED FLAT

NOTES:

THIS VIEW IS REPRESENTATIVE OF BOTH SUPPLY AND RETURN OPENINGS.

DUCT FLANGES MUST BE FIELD-BENT ALONG PERFORATIONS

EITHER INTO OR OUT OF THE FURNACE AS NECESSARY FOR

INSTALLATIONS BUT NEITHER FLANGE CAN REMAIN FLAT.

INSTALLER SHOULD USE DUCK BILLED PLIERS (AKA FOLDING

PLIERS) TO BEND THE FLANGE ALONG THE PERFORATIONS.

ALTERNATE - BENT (DOWN)

FIGURE 9

INSTALLER BENT - UP

ST-A1194-04-X0

ST-A1194-39-00

Ducting

21

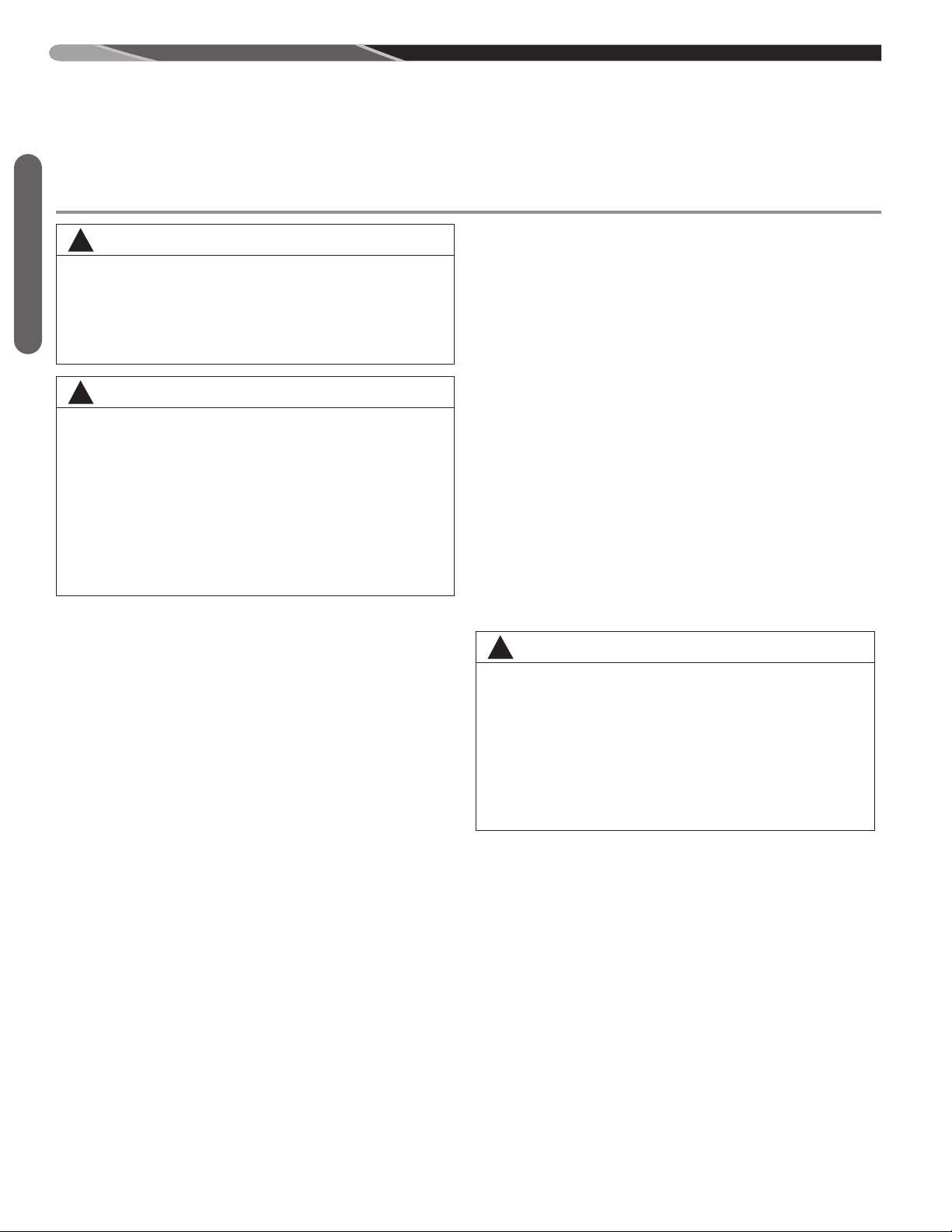

GENERAL VENTING REQUIREMENTS AND

GUIDELINES

VENTING & COMBUSTION AIR REQUIREMENTS

WARNING

!

READ AND FOLLOW ALL INSTRUCTIONS IN THIS

Venting

SECTION. FAILURE TO PROPERLY VENT THIS

FURNACE CAN CAUSE CARBON MONOXIDE POISONING, OR AN EXPLOSION OR FIRE, RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH.

WARNING

!

THIS FURNACE AND ANY OTHER FUEL-BURNING

APPLIANCE MUST BE PROVIDED WITH ENOUGH

FRESH AIR FOR PROPER COMBUSTION AND

VENTILATION OF THE FLUE GASES. MOST

BUILDINGS WILL REQUIRE THAT OUTSIDE AIR BE

SUPPLIED INTO THE FURNACE AREA. FAILURE

TO DO SO CAN CAUSE PERSONAL INJURY OR

DEATH FROM CARBON MONOXIDE POISONING.

REFER TO SECTION TITLED “NON-DIRECT VENT-

ING” TO DETERMINE IF THE FURNACE MUST USE

OUTSIDE AIR FOR COMBUSTION.

This furnace removes both sensible and latent heat from

the combustion gases. Removal of latent heat results in

the condensation of flue gas water vapor. This condensed

water vapor drains from the secondary heat exchanger

and out of the unit into the drain trap.

When installed as a non-direct vent furnace, only exhaust

piping is required and inside combustion air may be used.

Refer to the section on “NON-DIRECT VENTING.”

Direct vent installations require a dedicated combustion

air and venting system. All air for combustion is taken

from the outside atmosphere and all combustion products

are discharged to the outdoors.

Adequate facilities for providing air for combustion and

ventilation must be provided in accordance with Section

5.3, “Air for Combustion and Ventilation” of the National

Fuel Gas Code, ANSI Z223.1 (latest edition), in Canada

CSA B149.1; Canadian Natural Gas and Propane Installation Code and The National Fire Code of Canada, or

applicable provisions for the local building codes, and not

obstructed so as to prevent the flow of air to the furnace.

IMPORTANT: Air for combustion and ventilation must not

come from a corrosive atmosphere. Any failure due to

corrosive elements in the atmosphere is excluded from

the warranty coverage.

Combustion air must be free of acid-forming chemicals

such as sulfur, fluorine and chlorine. These elements are

found in aerosol sprays, detergents, bleaches, cleaning

solvents, air fresheners, paint and varnish removers, refrigerants and many other commercial and household

products. When burned in a gas flame, vapors from these

products form acid compounds. The acid compounds increase the dew point temperature of the flue products and

are highly corrosive after they condense.

The following types of installations (but not limited to the

following) may require outdoor air for combustion (direct

vent) due to chemical exposures:

If combustion air is exposed to the following substances

(but not limited to the following), it should not be used and

the furnace may require outdoor air for combustion (direct

vent).

!

ALL FURNACE INSTALLATIONS MUST COMPLY

WITH THE NATIONAL FUEL GAS CODE, IN

CANADA CSA B149.1; CANADIAN NATURAL GAS

AND PROPANE INSTALLATION CODE AND THE

NATIONAL FIRE CODE OF CANADA, NFPA 54 AND

LOCAL CODES TO PROVIDE ADEQUATE COMBUSTION AND VENTILATION AIR FOR THE FURNACE.

FAILURE TO DO SO CAN RESULT IN EXPLOSION,

FIRE, PROPERTY DAMAGE, CARBON MONOXIDE

POISONING, PERSONAL INJURY OR DEATH.

Combustion air requirements are determined by whether

the furnace is in an open (unconfined) area or in a confined space such as a closet or small room.

When the furnace is installed in the same space with

other gas appliances, such as a water heater, be sure

there is an adequate supply of combustion and ventilation

air for the furnace and the other appliances. Do not delete

or reduce the combustion air supply required by the other

gas appliances in this space. See Z223.1, National Fuel

Gas Code (NFPA 54), in Canada CSA B149.1; Canadian

Natural Gas and Propane Installation Code and The National Fire Code of Canada, for determining the combustion air requirements for gas appliances. An unconfined

space must have at least 50 cubic feet (volume) for each

1,000 BTUH of the total input of all appliances in the

space. If the open space containing the appliances is in a

building with tight construction (contemporary construction), outside air may still be required for the appliances to

burn and vent properly. Outside air openings should be

sized the same as for a confined space.

Commercial buildingsBuildings with indoor poolsFurnaces installed in laundry roomsFurnaces in hobby or craft roomsFurnaces installed near chemical storageareas

Permanent wave solutionsChlorinated waxes and cleanersChlorine-based swimming pool chemicalsWater softening chemicalsDe-icing salts or chemicalsCarbon tetrachlorideHalogen type refrigerantsPrinting inks, paint removers, varnishes etc.Cleaning solvents (such as perchloroethyl-ene)

Hydrochloric acidCements and gluesAntistatic fabric softeners for clothes dryersMasonry curing and acid washing materials-

WARNING

22

GENERAL VENTING REQUIREMENTS AND

GUIDELINES

VENTING & COMBUSTION AIR REQUIREMENTS (cont.)

MPORTANT: ONLY THE CURRENT VENT INSTRUC-

I

TIONS APPLY. All 90 Plus Gas Furnaces cannot be com-

mon-vented.

OVERTEMPERATURE SAFETY

SWITCHES

Furnaces are equipped with safety switches in the burner

compartment to protect against over-temperature conditions caused by inadequate combustion air supply. The

switches are located in the burner compartment. If a

switch is tripped it must be manually reset after clearing

the fault condition which caused it to open.

!

WARNING

DO NOT BYPASS, JUMPER, OR REMOVE ANY

SAFETY SWITCH FROM THE FURNACE CONTROL

CIRCUIT. IF A SAFETY SWITCH CAUSES THE FURNACE TO SHUT DOWN OR OPERATE INTERMITTENTLY, IT IS AN INDICATION OF A POTENTIAL

SAFETY HAZARD THAT MUST BE ADDRESSED BY

A QUALIFIED TECHNICIAN, SERVICE AGENCY OR

THE GAS SUPPLIER. DO NOT RESET SAFETY

CONTROLS WITHOUT CORRECTIVE ACTION

AND/OR VERIFICATION OF PROPER SAFE OPERATION BY A QUALIFIED INSTALLER, SERVICE

AGENCY OR THE GAS SUPPLIER.

REPLACE ANY SAFETY CONTROL COMPONENT

ONLY WITH IDENTICAL OEM REPLACEMENT

PARTS

MATERIAL REQUIREMENTS

PIPING REQUIREMENTS

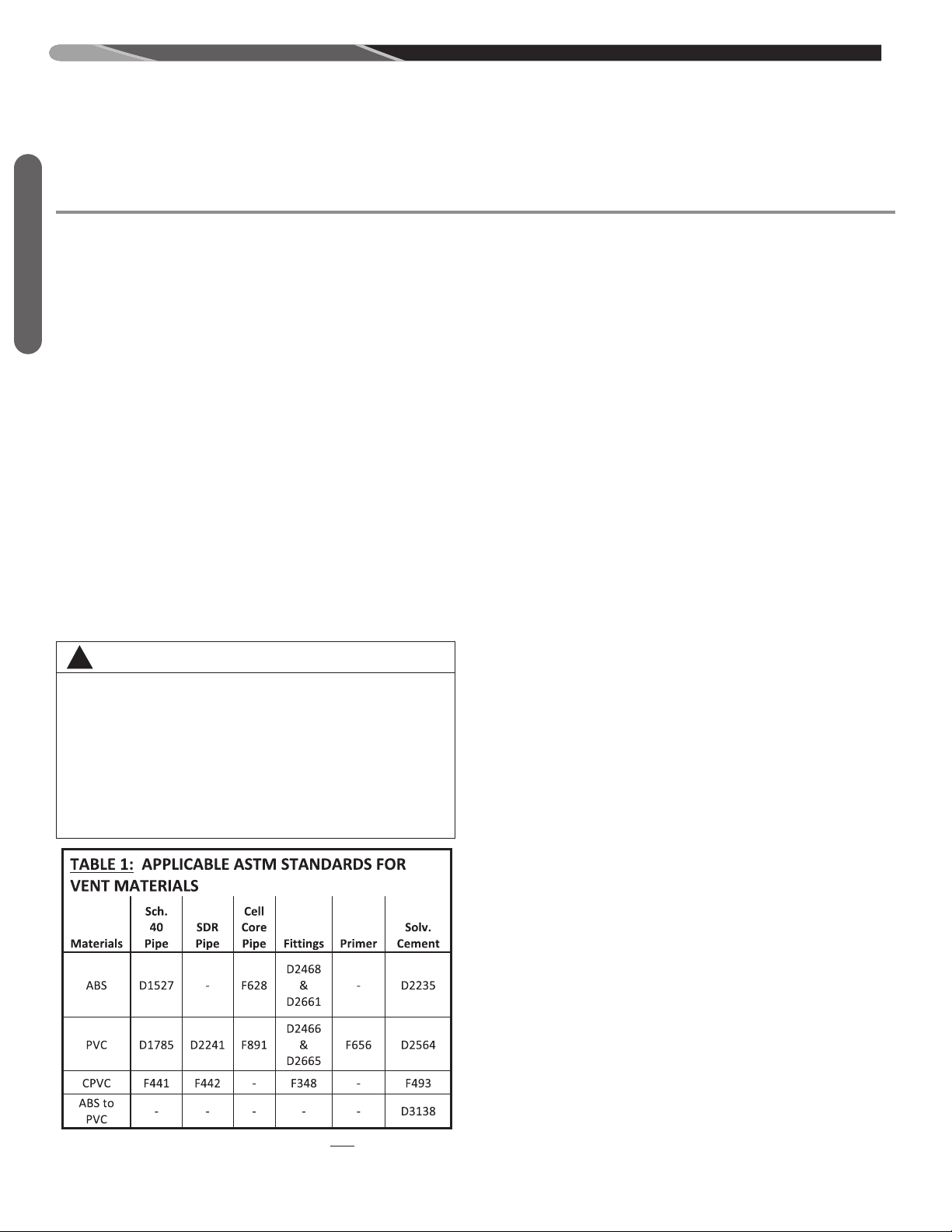

The combustion air and vent pipe fittings must conform to

American National Standards Institute (ANSI) and American Society for Testing Materials (ASTM) standards

D1785 (Schedule 40 PVC), D2665 (PVC-DWV), D2241

(SDR-21 & SDR26-26 PVC), D2661 (ABS-DWV) or F628

(Schedule 40 ABS-DWV). For Canada PVC, CPVC and

polypropylene venting can be used and must conform

with ULCS-636C requirements.

IMPORTANT: The plastic combustion air and venting

components are of Schedule 40 PVC. If using ABS piping, ensure that the solvent cement is compatible for joining PVC to ABS components or use a mechanical

connection that can withstand the vent temperatures and

is corrosion resistant.

NOTE: Schedule 40 ABS-DWV pipe and fittings may be

used as an alternate to PVC pipe for the combustion air

inlet and vent pipes.

NOTE: Cellular core PVC is also approved for use. It

must be Schedule 40PVC-DWV cellular pipe for nonpressure applications and manufactured under ASTM-F-

891.

All exhaust piping must be installed in compliance with

the chapter titled; “Venting of Appliances” in the latest

dition of the National Fuel Gas Code, NFPA-54/ANSI

e

Z223.1, CSA B149.1; Canadian Natural Gas and Propane

Installation Code (Canada), local codes or ordinances

and these instructions.

WARNING

!

IN CANADA, PRODUCTS CERTIFIED FOR INSTALLATION AND INTENDED TO BE VENTED WITH PLASTIC

VENT SYSTEMS (PVC, CVPC & POLYPROPYLENE)

MUST USE VENT SYSTEMS THAT ARE CERTIFIED

TO THE STANDARD FOR TYPE BH GAS VENTING

SYSTEMS, ULC S636.

THE COMPONENTS OF THE CERTIFIED MATERIAL

MUST NOT BE INTERCHANGED WITH OTHER VENT

SYSTEMS OR UNLISTED PIPE/FITTINGS.

PLASTIC COMPONENTS AND SPECIFIED PRIMERS

AND GLUES OF THE CERTIFIED SYSTEM MUST BE

FROM A SINGLE SYSTEM MANUFACTURER AND

NOT INTERMIXED WITH OTHER SYSTEM MANUFACTURER’S PARTS.

VENT TERMINATIONS ARE NOT REQUIRED TO BE

FROM THE SAME MANUFACTURER AS THE REST

OF THE VENTING BUT VENT TERMINATIONS MUST

BE ULC S636 APPROVED.

NOTE: WITH THE EXCEPTION OF THE TERMINATION

INLET AIR PIPING IS NOT CONSIDERED TO BE A

PART OF THE “VENTING SYSTEM”. THE REQUIREMENT THAT VENT MATERIAL BE CERTIFIED TO ULC

S636 DOES NOT APPLY TO INLET AIR PIPING.

REGARDLESS, ALL TERMINATIONS ON BOTH INLET

AND OUTLET PIPES MUST BE CONSTRUCTED

FROM COMPONENTS BUILT TO ULC-S636 REQUIREMENTS.

1. All horizontal piping must slope upward from the fur-

nace with a minimum slope of ¼ inch per foot of horizontal vent so that condensate drains back toward the

furnace.

2. All horizontal runs must be supported at least every 4

feet. No sags or dips are permitted.

3. IMPORTANT: Do not common vent with any other

appliance. Do not install in the same chase or chimney with a metal or high temperature plastic pipe from

another gas or fuel-burning appliance unless the required minimum clearances to combustibles are maintained between the plastic pipe and other pipes. For

Canada PVC, CPVC and polypropylene can be used

as long as they conform with ULCS-636C requirements.

4. All vent installed through unconditioned spaces where

below-freezing temperatures are expected must be insulated with an approved insulating material. Materials such as Armaflex or Rubatex insulation may also

be used as long as there is no heat tape applied to

the vent pipe. For horizontal runs where water may

collect, wrap the vent pipe with self-regulating 3 watt

or 6 watt heat tape. The heat tape must be U.L. listed

Venting

23

GENERAL VENTING REQUIREMENTS AND

GUIDELINES

VENTING & COMBUSTION AIR REQUIREMENTS (cont.)

and installed per the manufacturer’s instructions.

NOTE: Never cover heat tape with insulation.

5. The minimum vent pipe length is 5 feet [1.5m].

Venting

6. IMPORTANT: No part of the combustion air and/or

vent pipes may be installed underground.

7. Piping at a roof, wall or other penetration must be immobilized to prevent pipes from disconnecting. Disconnected pipes may allow flue products to be

released inside the structure.

8. For Direct Vent systems, all pipe penetrations through

roof or sidewall must be installed so that the vent and

combustion air intake pipes terminate in the same atmospheric pressure zone.

9. Vent terminations must be installed with the minimum

clearances specified in the TERMINATION REQUIREMENTS sections of this manual and Figure 15 (for

Non-Direct Vent) and Figures 16, 17 & 26 (for direct

Vent installations).

10. Piping external to the structure (excluding approved

venting terminations) and vent passing through unheated crawl-spaces, attics, verandas, patios or decks

must be insulated with approved insulating material to

prevent freezing as required for local climate.

JOINING PIPE AND FITTINGS

WARNING

!

PVC/CPVC SOLVENT CEMENTS AND PRIMERS

ARE HIGHLY FLAMMABLE. PROVIDE ADEQUATE

VENTILATION AND DO NOT ASSEMBLE NEAR A

HEAT SOURCE OR AN OPEN FLAME. DO NOT

SMOKE. AVOID SKIN OR EYE CONTACT. OBSERVE ALL CAUTIONS AND WARNINGS PRINTED

ON MATERIAL CONTAINERS. FAILURE TO FOLLOW THESE GUIDELINES MAY RESULT IN FIRE,

EXPLOSION OR ASPHYXIATION CAUSING PERSONAL INJURY OR DEATH.

(U.S. Only)

All pipe, fittings, solvent cement, primers and procedures

must be installed following the vent manufacturer’s installation instructions and must conform to American National

Standards Institute and American Society for Testing Materials (ANSI/ASTM) standards as shown in the Table 1

below:

CEMENTING JOINTS

Properly seal all joints in the PVC vent using the following

materials and procedures.

PVC CLEANER-PRIMER AND PVC

MEDIUM-BODY SOLVENT CEMENT

IMPORTANT: After cutting pipe, remove all ragged

edges and burrs. This is important to prevent reduction in

pressure drop throughout the system.

1. Cut pipe end square. Chamfer edge of pipe. Clean

fitting socket and pipe joint area of all dirt, grease and

moisture.

2. After checking pipe and socket for proper fit, wipe

socket and pipe with cleaner-primer. Apply a liberal

coat of primer to inside surface of socket and outside

of pipe. Read instructions included with the primer for

proper application.

3. Apply a thin coat of cement evenly within the socket.

Quickly apply a heavy coat of cement to the pipe end

and insert pipe into the fitting with a slight twisting

movement until it bottoms out.

NOTE: Cement must be fluid. If not, re-coat.

4. Hold the pipe in the fitting for 30 seconds to prevent

the tapered socket from pushing the pipe out of the fitting.

5. Wipe all excess cement from the joint with a rag.

Allow 15 minutes before handling. Cure time varies

according to fit, temperature and humidity.

NOTE: Stir the solvent cement frequently while using.

Use a natural bristle brush or the dauber supplied with the

can. The proper brush size is one inch.

IMPORTANT: For proper installation:

DO NOT use solvent cement that has become cur-

dled, lumpy or thickened.

DO NOT thin. Observe shelf precautions printed on

containers. For applications below 32°F, use only lowtemperature type solvent cement.

For Canadian installations all exhaust venting materials must be certified to

ULCS-636C.

24

GENERAL VENTING REQUIREMENTS AND

GUIDELINES

VENT PIPE SIZING AND MAXIMUM VENT LENGTHS

E

T

i

s

l

p

t

u

l

v

T

u

t

(

S

t

A

h

e

h

T

w

o

m

l

Q

e

h

p

n

c

u

n

e

e

r

e

h

e

s

n

e

n

e

e

h

e

s

e

h

4

/

1

p

g

n

i

o

l

s

a

h

t

i

s

a

i

h

h

t

u

u

n

e

V

I

U

c

n

o

c

g

n

i

p

i

s

a

h

f

o

h

t

g

e

r

u

s

s

v

i

u

q

e

o

t

p

u

f

o

h

t

g

g

n

e

l

t

r

a

e

r

h

w

d

d

n

a

t

s

n

r

u

t

a

c

i

f

i

c

e

t

a

P

s

FIGURE 10

ELBOWS

w

s

-

g

n

e

n

a

i

2

r

e

e

n

a

u

q

e

s

t

i

e

r

e

o

e

d

i

s

n

o

i

t

a

l

o

s

h

t

g

E

L

A

e

f

o

t

p

e

m

e

t

s

y

s

.

s

w

o

b

l

e

g

i

a

r

t

s

a

n

i

p

o

r

d

e

l

t

n

e

l

a

a

m

e

h

t

h

g

i

a

r

t

s

o

n

s

i

h

t

r

e

v

e

s

e

s

n

o

c

n

e

m

i

d

d

r

a

w

o

b

l

e

)

r

o

f

n

o

i

t

.

s

n

r

e

t

STANDARD 90°

2” D = 2 5/16”

3” D = 3 1/16”

A

(

p

e