Page 1

R95TC

Parts List

24-July-2018

This parts list is current as of the above revision date.

See http://www.rheempartslists.net/92-42800-R95TC.pdf for the current revision.

95% Gas Furnaces

Page 2

Table of Contents

Model Explanation.. ... ................... ... ... ... ... ... ... ... ... ... ... ................ ... ... ... ... ... ... ... ... ... ... ............... Page 3

Parts Numbers

Panels - Miscellaneous .. ... ... ................... ... ... ... ... ... ... ... ... ... ... ................ ... ... ... ... ... .. Page 4

Field Conversions . ... ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... .. Page 5

Electrical Group . ... ... ... ................ ... ... ... ... ... ... ... ... ... ... ................ ... ... ... ... ... ... ... ... . Page 6

Blower Group.. ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... ... ... ... Page 6

Heat Exchanger-Burner Group.. ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... . Page 7

Gas Controls .. ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... ... ... ... Page 7

Orifice Selection Chart.. ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... Page 8

Drawings/Photographs

Exploded View ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... ... ... ... ................... ... Page9

Cabinet Insulation and Plugs. ... ... ................... ... ... ... ... ... ... ... ... ... ... ................ ... ... ... ... Page 10

Junction Box ... ... ... ... ... ... ... ... ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... . Page 11

Burner Assembly (1).. ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... . Page 12

Burner Assembly (2).. ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... . Page 13

Pressure Switch - Tubing .. ... ... ... ... ... ... ... ................ ... ... ... ... ... ... ... ... ... ... ................ .. Page 14

Trap - Hose Assembly ... ... ... ... ... ... ... ................... ... ... ... ... ... ... ... ... ... ... ................ ... . Page 15

Blower Shelf. ... ... ................... ... ... ... ... ... ... ... ... ... ... ................ ... ... ... ... ... ... ... ... ... . Page 16

Blower Assembly ... ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... ... Page 17

Control Board Mounting .. ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... ... ... ... .......... Page 18

Heat Exchanger - Collector Box.. ... ... ................... ... ... ... ... ... ... ... ... ... ... ................ ... ... .. Page 19

Field Conversion Kits ... ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... .. Page 20

Notes/Disclaimer . ... ... ... ................ ... ... ... ... ... ... ... ... ... ... ................... ... ... ... ... ... ... ... ... ... ... .......... Page 21

Page 2 of 21

24-July-2018

92-42800-R95TC

Page 3

MODEL EXPLANATION

R 9 5 T C 0 6 0 1 3 1 7 M S A

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

(1) TRADEBRAND IDENTIFICATION (7) AIRFLOW

3 = Up to 3 tons

(2) SERIES 5 = Up to 5 tons

95 % Efficient

(8) CABINETWIDTH

(3) MOTOR TYPE 14 = 14.0 inch

T = X-13 (Constant Torque) 17 = 17.5 inch

21 = 21.0 inch

(4) MAJOR REVISION 24 = 24.5 inch

C = 3rd Design Series

(9) CONFIGURATION

(5) HEATING INPUT DESIGNATION M = Multi-Position

040 = 42,000 BTU/HR

060 = 56,000 BTU/HR (10) STANDARD/Nox

070 = 70,000 BTU/HR S = Standard

085 = 84,000 BTU/HR N = NOx

100 = 98,000 BTU/HR

115 = 112,000 BTU/HR (11) MINOR REVISION

A = First Time Release

(6) STAGE - SINGLE

SERIAL NUMBER EXPLANATION

W 0 8 1 3 9 9 9 9

(1) (2) (3) (4)

(1) PLANT CODE

(2) WEEK (DATE CODE)

(3) YEAR

(4) PRODUCTION NUMBER

Note: For Gas Code, see Control System Gas Code on Rating Plate

Page 3 of 21

24-July-2018

92-42800-R95TC

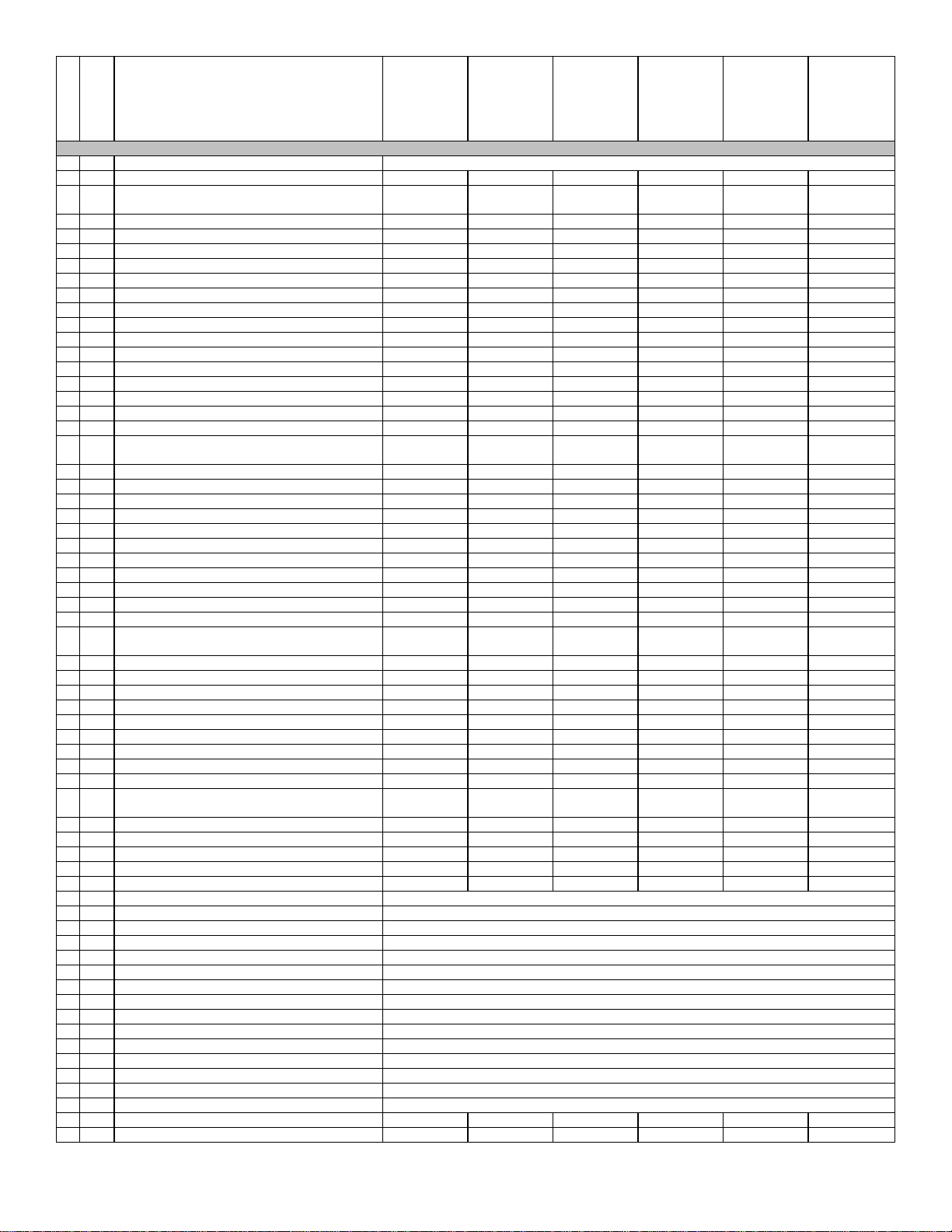

Page 4

MODEL

INPUT

No. Notes

1 Jacket Assembly See Note 1

1a Round Flush Mount Plug -7/8 in. (6) 45-103596-06 45-103596-06 45-103596-06 45-103596-06 45-103596-06 45-103596-06

1b

1c Round Flush Mount Plug - 2 in. 45-103596-03 45-103596-03 45-103596-03 45-103596-03 45-103596-03 45-103596-03

1d Round Flush Mount Plug -2-3/8 in. 45-103596-04 45-103596-04 45-103596-04 45-103596-04 45-103596-04 45-103596-04

1e Round Flush Mount Plug -3-7/16 in. 45-103596-01 45-103596-01 45-103596-01 45-103596-01 45-103596-01 45-103596-01

1f Star Bushing 45-18515-01 45-18515-01 45-18515-01 45-18515-01 45-18515-01 45-18515-01

1g Vinyl Grommet - 7/8in. 56-22114-06 56-22114-06 56-22114-06 56-22114-06 56-22114-06 56-22114-06

1h Insulation - FoilBack 68-103536-01 68-103536-01 68-103536-01 68-103536-02 68-103536-02 68-103536-03

1i Insulation - Sound 68-103537-01 68-103537-01 68-103537-01 68-103537-02 68-103537-02 68-103537-03

1j Insulation Retainer (2) AE-67925-01 AE-67925-01 AE-67925-01 AE-67925-01 AE-67925-01 AE-67925-01

2a Top Plate Assembly AS-104134-01 AS-104134-01 AS-104134-01 AS-104134-02 AS-104134-02 AS-104134-03

2b Left JacketBaffle AE-104192-02 AE-104192-03 AE-104192-01 AE-104192-04 AE-104192-01 AE-104192-06

2c Right Jacket Baffle AE-104191-02 AE-104191-03 AE-104191-01 AE-104191-04 AE-104191-01 AE-104191-06

2d Rear JacketBaffle AE-104190-01 AE-104190-01 AE-104190-01 AE-104190-02 AE-104190-02 AE-104190-03

3 Burner Compartment Door - Upper Door AS-104042-01 AS-104042-01 AS-104042-01 AS-104042-02 AS-104042-02 AS-104042-03

4 Blower/Filter Door - Lower Door AS-104043-01 AS-104043-01 AS-104043-01 AS-104043-02 AS-104043-02 AS-104043-03

Door Filler (with integral molded alignment pins) 68-104374-11 68-104374-11 68-104374-11 68-104374-12 68-104374-12 68-104374-13

Sight Glass - Door 68-21893-04 68-21893-04 68-21893-04 68-21893-04 68-21893-04 68-21893-04

5 Control Board Mounting Plate AE-103589-01 AE-103589-01 AE-103589-01 AE-103589-01 AE-103589-01 AE-103589-01

6a Junction Box AE-61475-03 AE-61475-03 AE-61475-03 AE-61475-03 AE-61475-03 AE-61475-03

6b Juncton BoxCover AE-61476-03 AE-61476-03 AE-61476-03 AE-61476-03 AE-61476-03 AE-61476-03

7 Transiton - Outlet Air 68-104133-02 68-104133-02 68-104133-02 68-104133-02 68-104133-02 68-104133-02

8 Transition - Gasket 68-24022-03 68-24022-03 68-24022-03 68-24022-03 68-24022-03 68-24022-03

9 Transition - Outlet Air Elbow 68-104145-03 68-104145-03 68-104145-03 68-104145-03 68-104145-03 68-104145-03

9a Exhaust Coupling 68-104146-02 68-104146-02 68-104146-02 68-104146-02 68-104146-02 68-104146-02

9b Rubber Plug 56-104377-01 56-104377-01 56-104377-01 56-104377-01 56-104377-01 56-104377-01

9c Bushing - Inducer Coupling Insert (2) 68-104520-01 68-104520-01 68-104520-01 68-104520-01 68-104520-01 68-104520-01

9d Coupling - IDB PD703024 PD703024 PD703024 PD703024 PD703024 PD703024

10 Stk,3

Stk,3 CondensateTrap Gasket (See Note 3) 68-104151-01 68-104151-01 68-104151-01 68-104151-01 68-104151-01 68-104151-01

11a Drain Tube (from Collector Box) AE-61737-06 AE-61737-06 AE-61737-06 AE-61737-06 AE-61737-06 AE-61737-06

11b Drain Tube D (from Outlet AirElbow) 79-104393-01 79-104393-01 79-104393-01 79-104393-01 79-104393-01 79-104393-01

11c Drain Tube A (from CondensateTrap) 79-104394-01 79-104394-01 79-104394-01 79-104394-01 79-104394-01 79-104394-01

11d Hose Clamp (5/8 in. forDrain Tube A) 64-104619-01 64-104619-01 64-104619-01 64-104619-01 64-104619-01 64-104619-01

11e Water Trap Mounting Bracket AE-104385-01 AE-104385-01 AE-104385-01 AE-104385-01 AE-104385-01 AE-104385-01

11f Rubber Plug 56-104377-01 56-104377-01 56-104377-01 56-104377-01 56-104377-01 56-104377-01

12a Bottom Plate Assembly AS-104314-11 AS-104314-01 AS-104314-01 AS-104314-02 AS-104314-02 AS-104314-03

12b Solid Bottom Assembly AS-104772-01 AS-104772-01 AS-104772-01 AS-104772-02 AS-104772-02 AS-104772-03

12c

12d Bracket Door Mounting AE-104332-01 AE-104332-01 AE-104332-01 AE-104332-02 AE-104332-02 AE-104332-03

12e Round Flush Mount Plug - 2-3/8 in.(2) 45-103596-04 45-103596-04 45-103596-04 45-103596-04 45-103596-04 45-103596-04

12f Support - Heat Exchanger AE-104127-01 AE-104127-01 AE-104127-01 AE-104127-02 AE-104127-02 AE-104127-03

12g Gasket - Blower Shelf 68-104382-01 68-104382-01 68-104382-01 68-104382-02 68-104382-02 68-104382-03

12h Gasket - Door AE-61951-54 AE-61951-54 AE-61951-54 AE-61951-55 AE-61951-55 AE-61951-56

20a Pressure Switch See Electrical Group

21 Door Switch - Push Button See Electrical Group

22 Limit - Main Limit (HeatExchanger Panel) See Electrical Group

23 Limit - Manual Reset (Burner Compartment) See Electrical Group

24 Transformer See Electrical Group

25a Induced Draft Blower (IDB) See Electrical Group

29a Wiring Harness Assembly (Twist-Lock) See Electrical Group

30 Blower Assembly See Blower Group

31a Housing w/Blower Wheel See Blower Group

40 Heat Exchanger Assembly See Heat Exchanger/Burner/Manifold Group

41f O-Ring (fits over tapand seats on Collector Box) See Heat Exchanger/Burner/Manifold Group

42 Burner Assembly See Heat Exchanger/Burner/Manifold Group

47 Manifold (w/o Orifices) See Heat Exchanger/Burner/Manifold Group

50 Gas Valve See Gas Controls

51 Integrated Furnace Control Board (IFC) See Gas Controls

Touch-up Paint - Granite/Steel Gray (Aerosol) PD523018 PD523018 PD523018 PD523018 PD523018 PD523018

Touch-up Paint - Granite/Steel Gray (Paint Pens) PD523019 PD523019 PD523019 PD523019 PD523019 PD523019

STAGE

AIRFLOW

CABINETWIDTH

CONFIGURATION

PANELS, SHEET METAL, ANDMISCELLANEOUS

Rectangular Flush Mount Plug -1-27/32 x 2-1/2 in.

(3)

Door Latch Kit (includes twoof each: Latch Cam,

Latch Handle, O-Ring, RetainerScrew)

WaterTrap -Condensate Drain (See Note 3 for

Gasket)

Blower Shelf Assembly(includes items 12d, 12e,

12f)

R95TC

040

1

3

17

MSA

45-104315-01 45-104315-01 45-104315-01 45-104315-01 45-104315-01 45-104315-01

PD644035 PD644035 PD644035 PD644035 PD644035 PD644035

68-104346-01 68-104346-01 68-104346-01 68-104346-01 68-104346-01 68-104346-01

AS-104135-04 AS-104135-01 AS-104135-01 AS-104135-02 AS-104135-02 AS-104135-03

R95TC

060

1

3

17

MSA

R95TC

070

1

3

17

MSA

R95TC

085

1

5

21

MSA

R95TC

100

1

5

21

MSA

R95TC

115

1

5

24

MSA

Page 4 of 21

24-July-2018

92-42800-R95TC

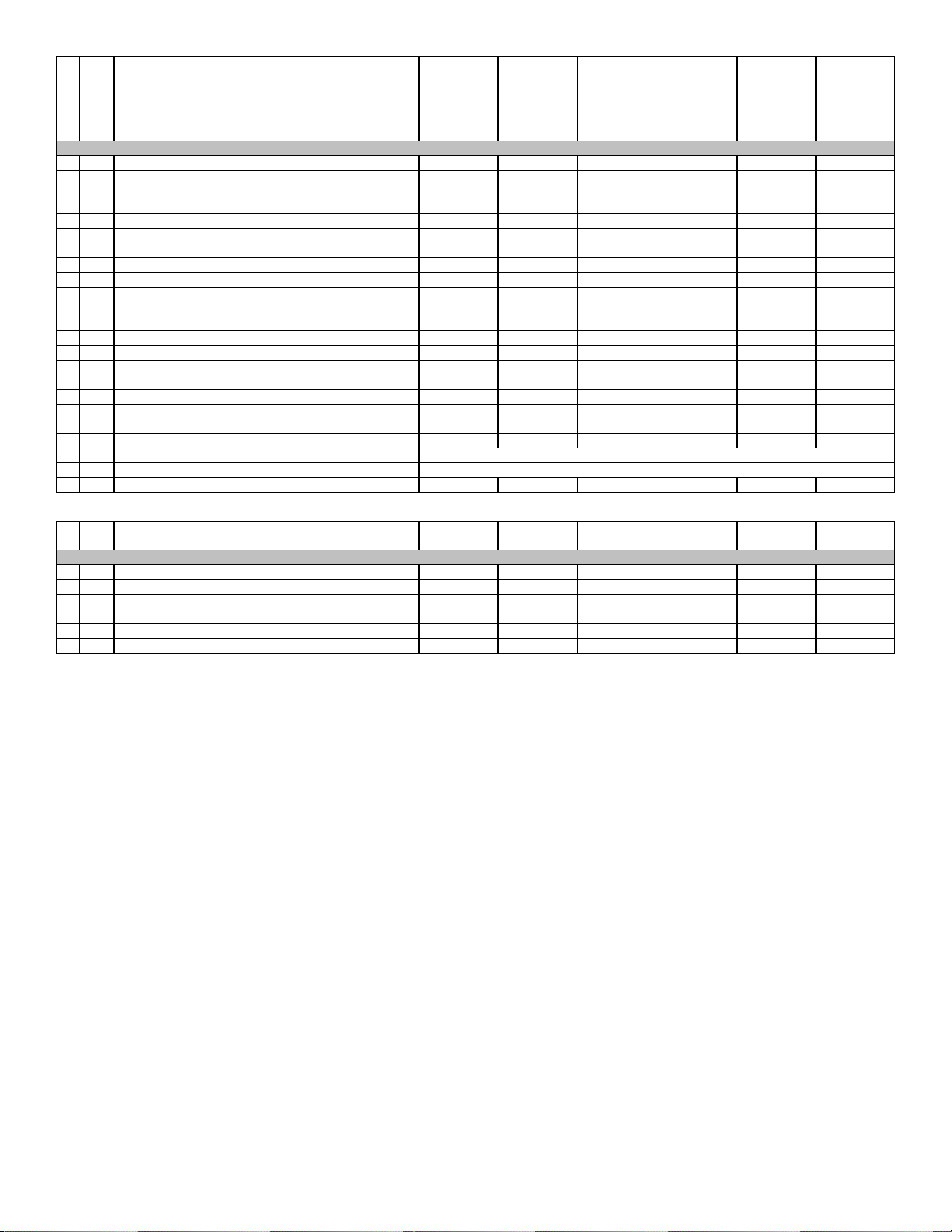

Page 5

MODEL

INPUT

No. Notes

Stk Complete Parts Bag (includes items1 - 9) 68-104446-01

1 Intake Coupling / Locknut Assy with O-Ring (2 in.) 68-24114-02

2 Air Diffuser 68-104515-01

3 Bulkhead Coupling 68-104005-01

4 Hose Clamp (5/8 in.) (3) 64-103686-03

5 Shorty Plug (1/4 in.) 45-24125-01

6 Screw (2) 63-24368-03

7 PVC Vane 68-23473-01

8 Tube C 79-105213-01

9 Hose - Double Elbow 79-105212-01

No. Notes

Stk Conversion Kit (includesitems 1 - 11) RXGY-CK

1 Pipe Grommet (2-3/8 in.) 56-22114-08

2 Screw (#8 x 1/2in.) (4) 63-24368-03

3 EPDM Trap Plug (.559in.) 56-104377-02

4 Vinyl Cap (1/2 in.) 56-103685-02

5 Flush Mount Plug - (2-5/8in.) 45-103596-05

6 Drain Hose (Hose B -5/8 in.) 79-104394-02

7 Drain Hose (Hose E -1/2 in.) 79-104393-02

8 VentTube (1/4 in.) AE-61737-36

9 Condensate Trap Bracket (Down Flow) AE-104363-01

10 Condensate Trap Gasket 68-104151-01

11 Drain Hose (Hose F -1/2 in.) 79-104393-03

No. Notes

Stk Zero Clearance DownflowKit (includes items 1 - 5) RXGY-ZK

1 Screw (#8 x 1/2in.) (10) 63-24368-03

2 Pipe Collar Gasket Assembly 68-103580-03

3 Drain Hose (Hose G -1/2 in.) 79-104393-04

4 Air Intake Pipe 68-104074-01

5 Flue Pipe Assembly w/O-ring 68-104193-01

STAGE

AIRFLOW

CABINETWIDTH

CONFIGURATION

MODEL

INPUT

STAGE

AIRFLOW

CABINETWIDTH

CONFIGURATION

MODEL

INPUT

STAGE

AIRFLOW

CABINETWIDTH

CONFIGURATION

ZERO CLEARANCE DOWNFLOW KIT

R95TC

All

All

All

All

All

PARTS BAG

R95TC

All

All

All

All

All

CONVERSION KIT

R95TC

All

All

All

All

All

Page 5 of 21

24-July-2018

92-42800-R95TC

Page 6

MODEL

INPUT

No. Notes

20a Stk

20a Stk

20b Silicon Tubing - Pressure Switch AE-61737-15 AE-61737-15 AE-61737-15 AE-61737-15 AE-61737-15 AE-61737-15

21 Door Switch - Push Button 42-22692-09 42-22692-09 42-22692-09 42-22692-09 42-22692-09 42-22692-09

22 Stk Limit - Main Limit (Heat Exchanger Panel) 47-104465-02 47-104465-01 47-104465-02 47-104465-01 47-104465-01 47-104465-03

23 Stk Limit - Manual Reset (Burner Compartment)

Bracket (Limit - Manual Reset) SeeHeat Exchanger/Burner Manifold Group

24 Stk Transformer 46-24124-06 46-24124-06 46-24124-06 46-24124-06 46-24124-06 46-24124-06

25a Stk IDB - Induced Draft Blower(with Gasket) 70-104157-02 70-104157-02 70-104157-02 70-104157-02 70-104157-02 70-104157-02

25b Gasket - Induced Draft Blower 68-104152-01 68-104152-01 68-104152-01 68-104152-01 68-104152-01 68-104152-01

27 Capacitor - Blower Motor N/A N/A N/A N/A N/A N/A

28 Strap - BlowerMotor Capacitor N/A N/A N/A N/A N/A N/A

29a Wiring Harness Assembly (Twist-Lock) 45-104090-01 45-104090-01 45-104090-01 45-104090-01 45-104090-01 45-104090-01

29b Wire Assembly (Junction Box to Twist Lock) 45-24371-58 45-24371-58 45-24371-58 45-24371-58 45-24371-58 45-24371-58

Wiring Harness - IFC toBlower Motor 45-105282-01 45-105282-01 45-105282-01 45-105282-01 45-105282-01 45-105282-01

52 Flame Sensor See Gas Controls

Water Sensor (2) SeeHeat Exchanger/Burner Manifold Group

53 Spark Ignitor See Gas Controls

No. Notes

30 Stk Blower Assembly (Includes items listed below): AS-105812-01 AS-105812-02 AS-105812-03 AS-105809-04 AS-105809-05 AS-105812-06

31a Housing w/Blower Wheel 70-104182-03 70-104182-05 70-104182-05 70-104182-07 70-104182-07 70-104182-09

31b Stk Blower Wheel PD703026 PD703027 PD703027 PD703028 PD703028 PD703029

32 Stk Blower Motor 51-102172-08 51-102172-09 51-102172-10 51-104357-01 51-104357-02 51-102280-13

Capacitor - Blower Motor See Electric Group

Stk

33 ECM Motor Mount (Belly Band) 70-19927-04 70-19927-04 70-19927-04 70-19927-04 70-19927-04 70-19927-04

34 Motor Mount Arm (4) 70-19929-10 70-19929-10 70-19929-10 70-19929-10 70-19929-10 70-19929-10

35 Screw - Motor MountArm (4) 63-101978-01 63-101978-01 63-101978-01 63-101978-01 63-101978-01 63-101978-01

STAGE

AIRFLOW

CABINETWIDTH

CONFIGURATION

Pressure Switch Assembly -Before approximate Date

Code 5116

Pressure Switch Assembly -On or After approximate Date

Code 5116

Wiring Harness - 5 pin to 5terminals (IFC to Motor

Control)

MODEL

INPUT

STAGE

AIRFLOW

CABINETWIDTH

CONFIGURATION

Belly Band Motor Mount Kit(includes Motor Mount Arms,

Belly Band and Mounting Hardware)

R95TC

040

1

3

17

MSA

ELECTRIC GROUP

42-102069-01 42-102069-01 42-102069-01 42-102069-10 42-102069-02 42-102069-08

42-105499-06 42-105499-06 42-105499-06 42-105499-01 42-105499-04 42-105499-09

47-104888-02

(2)

45-103551-01 45-103551-01 45-103551-01 45-103551-01 45-103551-01 45-103551-01

R95TC

040

1

3

17

MSA

BLOWER GROUP

AS-53148-91 AS-53148-91 AS-53148-91 AS-53148-91 AS-53148-91 AS-53148-91

R95TC

060

1

3

17

MSA

47-104888-02

(2)

R95TC

060

1

3

17

MSA

R95TC

070

1

3

17

MSA

47-104888-01

(2)

R95TC

070

1

3

17

MSA

R95TC

085

1

5

21

MSA

47-104888-02

(2)

R95TC

085

1

5

21

MSA

R95TC

100

1

5

21

MSA

47-104888-02

(2)

R95TC

100

1

5

21

MSA

R95TC

115

1

5

24

MSA

47-104888-02

(3)

R95TC

115

1

5

24

MSA

Page 6 of 21

24-July-2018

92-42800-R95TC

Page 7

MODEL

INPUT

No. Notes

40 Stk Heat Exchanger Assembly AS-104120-01 AS-104120-02 AS-104120-05 AS-104120-17 AS-104120-15 AS-104120-21

41a Stk

41b Stk Collector Box Gasket 68-103546-03 68-103546-03 68-103546-03 68-103546-02 68-103546-02 68-103546-01

41c Rubber Plug (2) 56-104377-01 56-104377-01 56-104377-01 56-104377-01 56-104377-01 56-104377-01

41d Vinyl Cap 56-103685-01 56-103685-01 56-103685-01 56-103685-01 56-103685-01 56-103685-01

41e Stk Water Sensor (2) 47-104184-01 47-104184-01 47-104184-01 47-104184-01 47-104184-01 47-104184-01

41f O-Ring (fits over tapand seats on Collector Box) 68-104386-02 68-104386-02 68-104386-02 68-104386-02 68-104386-02 68-104386-02

42

43 Burner Rack (One Piece Assemby) AE-104121-01 AE-104121-02 AE-104121-03 AE-104121-04 AE-104121-05 AE-104121-06

44 Burner Rack Cover AE-104122-01 AE-104122-02 AE-104122-03 AE-104122-04 AE-104122-05 AE-104122-06

44a Screw - Burner Cover (2) 63-22153-01 63-22153-01 63-22153-01 63-22153-01 63-22153-01 63-22153-01

45 Igniter Bracket AE-61885-02 AE-61885-02 AE-61885-02 AE-61885-02 AE-61885-02 AE-61885-02

45a Bracket (Limit - ManualReset) N/A N/A N/A N/A N/A AE-61913-02

46 Stk Burner AS-61984-03 AS-61984-04 AS-61984-05 AS-61984-06 AS-61984-07 AS-61984-08

46a Screw - Burner to Burner Rack

47 Manifold (w/o Orifices) 81-104526-01 81-104526-02 81-104526-03 81-104526-04 81-104526-05 81-104526-06

Burner Orifice - NaturalGas See Orifice Selection Chart

Burner Orifice - LP See Orifice Selection Chart

Number of Orifices (3) (4) (5) (6) (7) (8)

No. Notes

50 Stk Gas Valve- Natural Gas 60-103901-01

Stk,2 GasValve - LP See Note 2

51 Stk Integrated Furnace Control Board (IFC) 62-105217-01

52 Stk Flame Sensor 62-23543-08

53 Stk Spark Ignitor 62-24141-05

Stk LP Conversion Kit- U.S./Canadian Models FP-36

STAGE

AIRFLOW

CABINETWIDTH

CONFIGURATION

HEAT EXCHANGER, BURNER / MANIFOLD

Collector Box Kit(includesCollector Box Gasket, Rubber

Plugs, Water Sensors, O-Ring, VinylCap, IDB Gasket and

Mounting Screws)

Burner Assembly (Rack, Cover, Burner Halves, Ignitor

Bracket)

MODEL

GAS CODE

R95TC

040

1

3

17

MSA

68-104111-81 68-104111-84 68-104111-85 68-104111-86 68-104111-82 68-104111-83

AS-104123-01 AS-104123-02 AS-104123-03 AS-104123-04 AS-104123-05 AS-104123-06

63-22153-05

(5)

R95TC

KA

GAS CONTROLS

R95TC

060

1

3

17

MSA

63-22153-05

(6)

R95TC

070

1

3

17

MSA

63-22153-05

(7)

R95TC

085

1

5

21

MSA

63-22153-05

(8)

R95TC

100

1

5

21

MSA

63-22153-05

(9)

R95TC

115

1

5

24

MSA

63-22153-05

(10)

Page 7 of 21

24-July-2018

92-42800-R95TC

Page 8

CAUTION: Selection ofthe correct Natural Gas Orifice requires the following information for the specific installation:

1) Altitude in of the installation (ft.).

2) Average sea level energy content of the Natural Gas fuel from the local supplier (BTU/cu. ft.).

For detailed information and instructions for Orifice selection, see the Gas Furnace LPConversion Kit Index 92-21519-69 and thelatest edition of the

National Fuel Gas Code Handbook, or the National Standard of Canada, Natural Gas andPropane Installation Code, CAN B149.1.

CAUTION:This information is provided for replacement purposes and altitude adjustment of rates other than 0 - 2000 feet only.

NOTE:This Orifice sizing chart is based on 14,000 BTU/HR per burner atsea level and conforms to a4% degradaton per thousand feet in elevation.

NOTE: Factory installed orifices are calculated and sized based on aNatural Gas heating value of 1100 BTU/cu. ft.and an elevation of 0 -2000 ft.

Elevation (ft.)

EnergyValue

(BTU/cu. ft.)

850 62-22175-48 62-22175-49 62-22175-49 62-22175-49 62-22175-50 62-22175-50 62-22175-50 62-22175-51

900 62-22175-49 62-22175-50 62-22175-50 62-22175-51 62-22175-51 62-22175-51 62-22175-52 62-22175-52

975 62-22175-50 62-22175-51 62-22175-52 62-22175-52 62-22175-52 62-22175-52 62-22175-53 62-22175-53

1075 62-22175-51 62-22175-51 62-22175-52 62-22175-52 62-22175-52 62-22175-52 62-22175-53 62-22175-53

1170 62-22175-52 62-22175-52 62-22175-53 62-22175-53 62-22175-53 62-22175-53 62-22175-53 62-22175-54

CAUTION: Selection ofthe correct LP Orifice requires the altitude of the specific installation (ft.).

For detailed information and instructions for Orifice selection, see the Gas Furnace LPConversion Kit Index 92-21519-69 and thelatest edition of the

National Fuel Gas Code Handbook (NFG), or the National Standard of Canada, Natural Gasand Propane Installation Code, CAN B149.1.

CAUTION:This information is provided for replacement purposes only. Conversion to LP or for operation at High Altitude should be doneusing the

kit(s) specified on the product specification sheet for the unit.

NOTE:This Orifice sizing chart is based on 14,000 BTU/HR per burner. Also, the chart is developed using the specified pressure setting of 10 in.water column

instead of the 11.0 inwater column used by the NFG and CANB149.1.

NOTE: Orifices supplied inthe LP Conversion Kit are calculated andsized based on an altitude of 0 - 2000ft.

Elevation (ft.) Orifice

0 to 2000 ft. 62-22175-90

2001 to 3000 62-22175-58

3001 to 4000 62-22175-59

4001 to 5000 62-22175-59

5001 to 6000 62-22175-60

6001 to 7000 62-22175-60

7001 to 8000 62-22175-61

8001 to 9000 62-22175-62

9001 to 10000 62-22175-63

0 - 1999 2000 - 2999 3000 - 3999 4000 - 4999 5000 - 5999 6000 - 6999 7000 - 7999 8000 - 8999

95% GAS FURNACE - ORIFICE SELECTION CHART - NATURAL GAS

95% GAS FURNACE - ORIFICE SELECTION CHART - LP

Page 8 of 21

24-July-2018

92-42800-R95TC

Page 9

Exploded View

Page 9 of 21

24-July-2018

92-42800-R95TC

Page 10

Cabinet Insulation and Plugs

Page 10 of 21

24-July-2018

92-42800-R95TC

Page 11

Junction Box

Page 11 of 21

24-July-2018

92-42800-R95TC

Page 12

Burner Assembly (1)

Page 12 of 21

24-July-2018

92-42800-R95TC

Page 13

Burner Assembly (2)

Page 13 of 21

24-July-2018

92-42800-R95TC

Page 14

Pressure Switch - Tubing

Page 14 of 21

24-July-2018

92-42800-R95TC

Page 15

Trap - Hose Assembly

Page 15 of 21

24-July-2018

92-42800-R95TC

Page 16

Blower Shelf

Page 16 of 21

24-July-2018

92-42800-R95TC

Page 17

Blower Assembly

Page 17 of 21

24-July-2018

92-42800-R95TC

Page 18

Control Board Mounting

Page 18 of 21

24-July-2018

92-42800-R95TC

Page 19

Heat Exchanger - Collector Box

Page 19 of 21

24-July-2018

92-42800-R95TC

Page 20

Field Conversion Kits

Page 20 of 21

24-July-2018

92-42800-R95TC

Page 21

NOTES

Stk It is recommended that stock be maintained for this part.

N/A Not Applicable

1 Jacket is not available for replacement.

2 Order Gas Valve for Natural Gas along with LP spring kit. (If the original valve has been replaced, order the spring

kit for the replacement valve.)

3 For horizontal installations, it is recommended that the CondensateTrap Gasket (68-104151-01) also be ordered

when replacing theWaterTrap - Condensate Drain.

DISCLAIMER: This document is intended to provide general replacement parts information to aid qualified

service personnel in the repair of these models. The complete Model and Serial Number of the unit under repair

should be specified when selecting and ordering replacement parts. Specifications and illustrations are subject

to change without notice. Document 92-42800-R95TC supersedes all previous parts lists for these models. See

http://www.rheempartslists.net/92-42800-R95TC for the latest revision of this document. The manufacturer

assumes no obligation for errors or omissions. Service personnel must verify the proper and safe operation of

equipment after the replacement of any original components.

P.O. Box 17010

Fort Smith, AR 72917-7010

Loading...

Loading...