Reznor SFT-100 Installation Manual

NOTICE:

The information contained on the following page(s) was produced

prior to May 1, 2014. On that date Reznor became part of

Nortek, Inc.

References to any other company afliations are no longer valid.

©2014 Reznor, LLC. All Rights Reserved.

Trademark notice: Reznor is registered in at least the United States.

0514 PDF Form Cover1

Sizes 45, 60 and 75

are certified to

CSA Requirement

10-96 for

RESIDENTIAL

INSTALLATION

®

APPLIES TO: Installation/Operation/Service

Separated-Combustion,

Power-V ented

INST ALLA TION FORM RZ-I-SFT

Obsoletes Form RZ 432 (V ersion C)

Model SFT

Gas-Fired,

Unit Heaters

Models SFT 45, 60 and 75 are certified for both residential and commercial/industrial installations.

Models SFT 100-300 are certified for commercial/industrial installations only.

Table of Contents

Installation and Operation......................................................... Paragraphs 1-17....................Pages 1-15

Check Installation and Start-Up ....................................................Paragraph 18 ..................Pages 16-17

Maintenance/Troubleshooting/Service ................................... Paragraphs 19-31 ..................Pages 18-24

Index By Page No.

Burner Orifices ........................................ 19

Burner Removal....................................... 18

Burners .................................................... 14

Check Installation and Start-Up .............. 16

Clearances.................................................. 3

Combustion Air ......................................... 6

Combustion Air Proving Switch........ 14, 21

Concentric Adapter Box ............................ 6

Dimensions ................................................ 5

Downturn Nozzles (Option Kit) ................ 2

Electrical Supply and Connections.......... 13

Fan ........................................................... 20

Fan Motor ................................................ 13

Flame Rollout Switch .............................. 21

Gas Piping and Pressures ........................ 12

Gas V alve........................................... 14, 21

REFERENCES: Replacement Parts, Form RZ-NA-P-FT/SFT

Index By Page No.

General .................................................... 1

Hazard Intensity Levels ........................... 2

Heat Exchanger ..................................... 19

High Altitude Combustion Air

Pressure Switch ...................... 3, 13

High Altitude Operation ........................ 3

Ignition Control Module ....................... 14

Ignition Control Module LED

Codes ..................................... 14, 21

Ignition System................................ 14, 19

Installation Codes .................................... 2

Limit Control ......................................... 21

Location (Heater)..................................... 3

Louvers, Vertical (Option Kit)................. 2

Maintenance .......................................... 18

Manifold Pressure.................................. 13

Gas Conversion, Form RZ-NA-I-FT/SFT -GC

FOR YOUR SAFETY

What to do if you smell gas:

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier,

call your fire department.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

Index By Page No.

Rating Plate .......................................... 23

Serial No. .............................................. 23

Service .................................................. 18

Start-Up ................................................ 16

Suspending ............................................. 3

Thermostat ............................................ 13

Troubleshooting.................................... 21

Uncrating and Preparation...................... 2

V ent/Combustion Air System ........... 6, 21

Horizontal Vent Terminal/

Combustion Air Inlet (Opt CC6) ...... 7-9

Vertical Vent T erminal/Combustion

Air Inlet (Opt CC2) .................... 10-11

Venter Motor ........................................ 20

Warranty ................................................. 2

Wiring Diagram .................................... 15

WARNING: Gas-fired appliances are not

designed for use in hazardous atmospheres

containing flammable vapors or combustible

dust. See Hazard Levels, page 2.

GENERAL

Installation should be done by a qualified agency in accordance with

the instructions in this manual and in compliance with all codes and

requirements of authorities having jurisdiction. The instructions in this

manual apply to the separated-combustion unit heater model shown

below.

Model Description

SFT Separated-Combustion,

Fan-Type, Suspended

Unit Heater

WARNING: Improper installation, adjustment,

alteration, service, or maintenance can cause

property damage, injury, or death. Refer to this

manual. For assistance or additional information,

consult a qualified installer, service agency, or

the gas supplier.

All sizes of Model SFT heaters are design-certified by the Canadian

Standards Association (CSA) to ANSI Z83.8a and CGA 2.6a for industrial/commercial installations in the United States and Canada. Models SFT 45, 60 and 75 are approved by the Canadian Standards Association to CSA 10-96 for residential installations in both the United

States and Canada. All heaters are available for use with either natural

or propane gas. The type of gas, the firing rate, and the electrical characteristics are on the unit rating plate.

Form RZ -NA-I-SFT, Mfg No. 173474 (Rev 6), Page 1

GENERAL (Cont'd)

These separated combustion units are designed and manufactured in

accordance with the ANSI definition of separated combustion. That

definition reads, "Separated Combustion System Appliance: A system

consisting of an appliance and a vent cap(s) supplied by the manufacturer, and (1) combustion air connections between the appliance and

the outside atmosphere, and (2) flue gas connections between the appliance and vent cap, of a type(s) specified by the manufacturer but

supplied by the installer, constructed so that, when installed in accordance with the manufacturer's instructions, air for combustion is obtained from the outside atmosphere and flue gases are discharged to

the outside atmosphere."

Separated combustion units are designed to separate the air for combustion and the flue products from the environment of the building in

which the unit is installed. Separated combustion appliances are recommended for use in dust laden and some corrosive fume environments or in buildings with negative pressure (up to .15" w.c.). As the

definition states, all separated combustion, power-vented equipment

must be equipped with both combustion air and exhaust piping to the

outdoors.

WARNING: Model SFT separated combustion

units are not designed or approved for use in

atmospheres containing flammable vapors or

combustible dust. See Hazard Levels, below.

W ARNING: Should overheating occur or the gas

supply fail to shut off, shut off the manual gas

valve to the appliance before shutting off the

electrical supply .

garages in accordance with ANSI/NFPA No. 88A (latest edition), S tandard for Parking Structures; and for repair garages in accordance with

ANSI/NFPA No. 88B (latest edition), Standard for Repair Garages.

ANSI/NFPA-88 (latest edition) specifies overhead heaters must be installed at least eight feet above the floor. In Canada, installations in

aircraft hangars should be in accordance with the requirements of the

enforcing authorities, and in public garages in accordance with CAN/

CGA B149 codes.

ANSI/NFPA 409 (latest edition) specifies a clearance of ten feet to the

bottom of the heater from the highest surface of the top of the wing or

engine enclosure of whatever aircraft would be the highest to be housed

in the hangar, and a minimum clearance of eight feet from the floor in

other sections of aircraft hangars, such as the offices, and shops which

communicate with areas used for servicing or storage. The heaters must

be located so as to be protected from damage by aircraft or other objects such as cranes and movable scaffolding. In addition, the heaters

must be located so as to be accessible for servicing, adjustment, etc.

2. W arranty

Refer to the limited warranty information on the warranty form in the

"Owner's Envelope".

Warranty is void if ...

a. Wiring is not in accordance with the diagram furnished with the

heater.

b. The unit is installed without proper clearance to combustible

materials.

c. The heater is connected to a duct system or if the air delivery

system is modified.

W ARNING: Do not use this appliance if any part

has been under water. Immediately call a

qualified service technician to inspect the

appliance and replace any gas control which has

been under water.

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal injury or death and/or property damage.

2. WARNING: Failure to comply could result in severe personal

injury or death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal

injury and/or property damage.

1. Installation Codes

These units must be installed in accordance with local building codes.

In the absence of local codes, in the United States, the unit must be

installed in accordance with the National Fuel Gas Code ANSI Z223.1a

(latest edition). A Canadian installation must be in accordance with the

CAN/CGA B149.1 and B149.2 Installation Code for Gas Burning Appliances and Equipment. These codes are available from CSA Information Services, 1-800-463-6727. Local authorities having jurisdiction should be consulted before installation is made to verify local codes

and installation procedure requirements.

Special Commercial Installations (Aircraft

Hangars/Repair Garages/Parking Garages)

Installations in aircraft hangars should be in accordance with ANSI/

NFP A No. 409 (latest edition), S tandard for Aircraft Hangars; in public

Form RZ -NA-I-SFT, Page 2

3. Uncrating and Preparation

This unit was test operated and inspected at the factory prior to crating

and was in operating condition. If the heater has incurred any damage

in shipment, document the damage with the transporting agency and

immediately contact your Reznor Distributor .

Check the rating plate for the gas specifications and electrical characteristics of the heater to be sure that they are compatible with the gas

and electric supplies at the installation site.

Read this booklet and become familiar with the installation requirements of your particular heater . If you do not have knowledge of local

requirements, check with the local gas company or any other local agencies who might have requirements concerning this installation.

Before beginning, make preparations for necessary supplies, tools, and

manpower. If the installation includes optional vertical louvers or a

downturn nozzle, install these options before the heater is suspended.

Follow the instructions included in the option package; option packages are shipped separately .

If the heater is to be operated at an altitude above 2000 ft (610M), a

pressure adjustment may be required. See Paragraph 4.

Concentric Adapter Kits for combustion air and

venting (Option CC2 or Option CC6)

The concentric adapter is a required component in the installation of

all Model SFT heaters. The kit is shipped in a separate carton. Be sure

that the concentric adapter carton is at the installation site. A horizontal

vent/combustion air kit including the concentric adapter is identified

as Option CC6. A vertical vent/combustion air kit including the concentric adapter is identified as Option CC2. See the parts lists in Paragraph 9.

4. High Altitude Operation

If the heater is being installed in an altitude above 2000 ft (610M),

check the rating plate to determine what must be done to prepare the

heater for high altitude operation.

Check the rating plate, determine which circumstance below applies,

and follow the instructions.

• If the altitude range on the rating plate agrees with the altitude at

the site, no further action is required. Proceed with the installation.

• If the altitude range on the rating plate reads "Sea Level" and the

altitude at the site is between 2000 ft and 6000 ft (610M to

1830M), install the heater and follow the instructions in Paragraph

10 to derate by manifold gas pressure adjustment.

• If the altitude range on the rating plate reads "Sea Level" and the

altitude at the site is above 6000 ft (1830M), in addition to adjusting the manifold pressure, it will be necessary to replace the combustion air pressure switch. Order the appropriate switch from the

list below and replace the switch before suspending the heater.

After the heater is installed, follow the instructions in Paragraph

10 to derate by adjusting the manifold gas pressure.

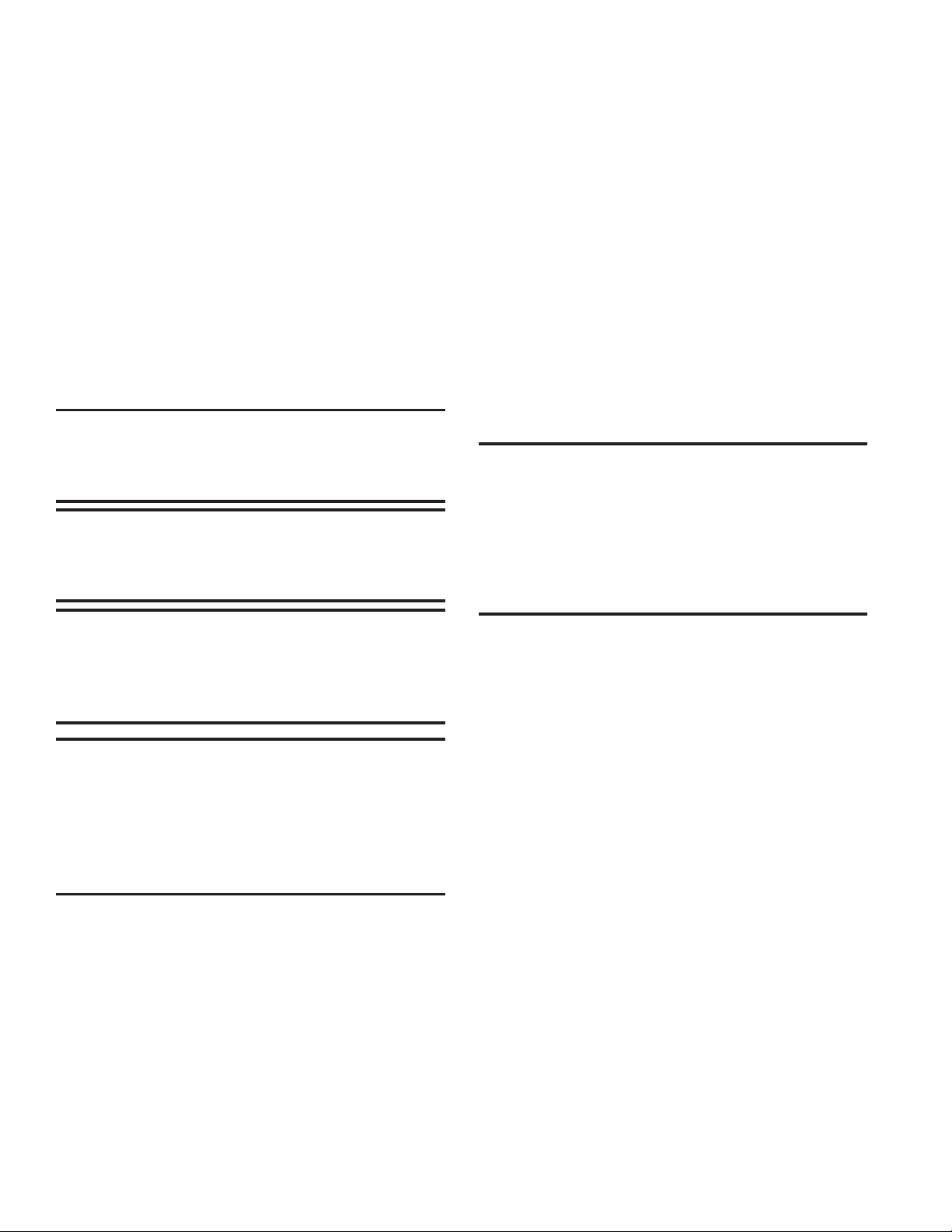

High Altitude (above 6000 ft) Combustion Air Pressure Switches

SFT P/N Description

45-75 173316 Orange Label, -.55", #PPS10143-2908

100-125 173315 Gray Label, -.35", #PPS10143-2907

150-300 173312 White Label, -.60", #PPS10143-2904

Figure 1 - Model SFT with Access Panel Open showing

Combustion Air Pressure Switch

(flexible combustion air hose removed

for clarity)

Combustion Air

Pressure Switch

When units are located in the center of the space to be heated, the air

should be discharged toward the exposed walls. In large areas, units

should be located to discharge air along exposed walls with extra units

provided to discharge air in toward the center of the area.

At those points where infiltration of cold air is excessive, such as entrance doors and shipping doors, it is desirable to locate the unit so that

it will discharge directly toward the source of cold air from a distance

of 15 to 20 feet (4.5 to 6 M) .

CAUTION: Do not locate the heater where it may be

exposed to water spray, rain, or dripping water.

6. Clearances

This heater must be installed so that the clearances in the table below

are provided for required spacing from combustible construction and

for service and inspection. Clearance to combustibles is defined as the

minimum distance from the heater to a surface or object that is necessary to ensure that a surface temperature of 90°F above the surrounding ambient temperature is not exceeded.

Required Clearances - inches (mm)

Model SFT 45, 100, 125, 250,

60, 75 150, 200 300

Top 1 (25) 6 (152) 6 (152)

Flue Connector 6 (152) 6 (152) 6 (152)

Access Panel 20 (508) 24 (610) 24 (610)

Non-Access Side 1 (25) 6 (152) 6 (152)

Bottom* 1 (25) 1 (25) 1 (25)

Rear 18 (457) 18 (457) 24 (610)

*A Model SFT 45, 60, or 75 installed in a residential garage must be

installed with a minimum clearance above the floor of 18 inches

(457mm). Sizes 100-300 are not certified for residential installations.

Gas

Valve

If the heater is going to be de-rated by adjusting the manifold pressure,

find the label in the owner's envelope. When the adjustment is completed, fill-in the correct pressure setting with permanent marker and

adhere the label to the heater in a conspicuous location close to the gas

valve.

5. Unit Heater Location

For best results, the heater should be placed with certain rules in mind.

In general, a unit should be located from 8 to 12 feet (2.4 to 3.6 M)

above the floor. Units should always be arranged to blow toward or

along exposed wall surfaces, if possible. Where two or more units are

installed in the same room, a general scheme of air circulation should

be maintained.

Suspended heaters are most effective when located as close to the working zone as possible, and this fact should be kept in mind when determining the mounting heights. However, avoid directing the discharged

air directly on the room occupants.

Partitions, columns, counters, or other obstructions should be taken

into consideration when locating the unit heater so that a minimum

quantity of airflow will be deflected by such obstacles.

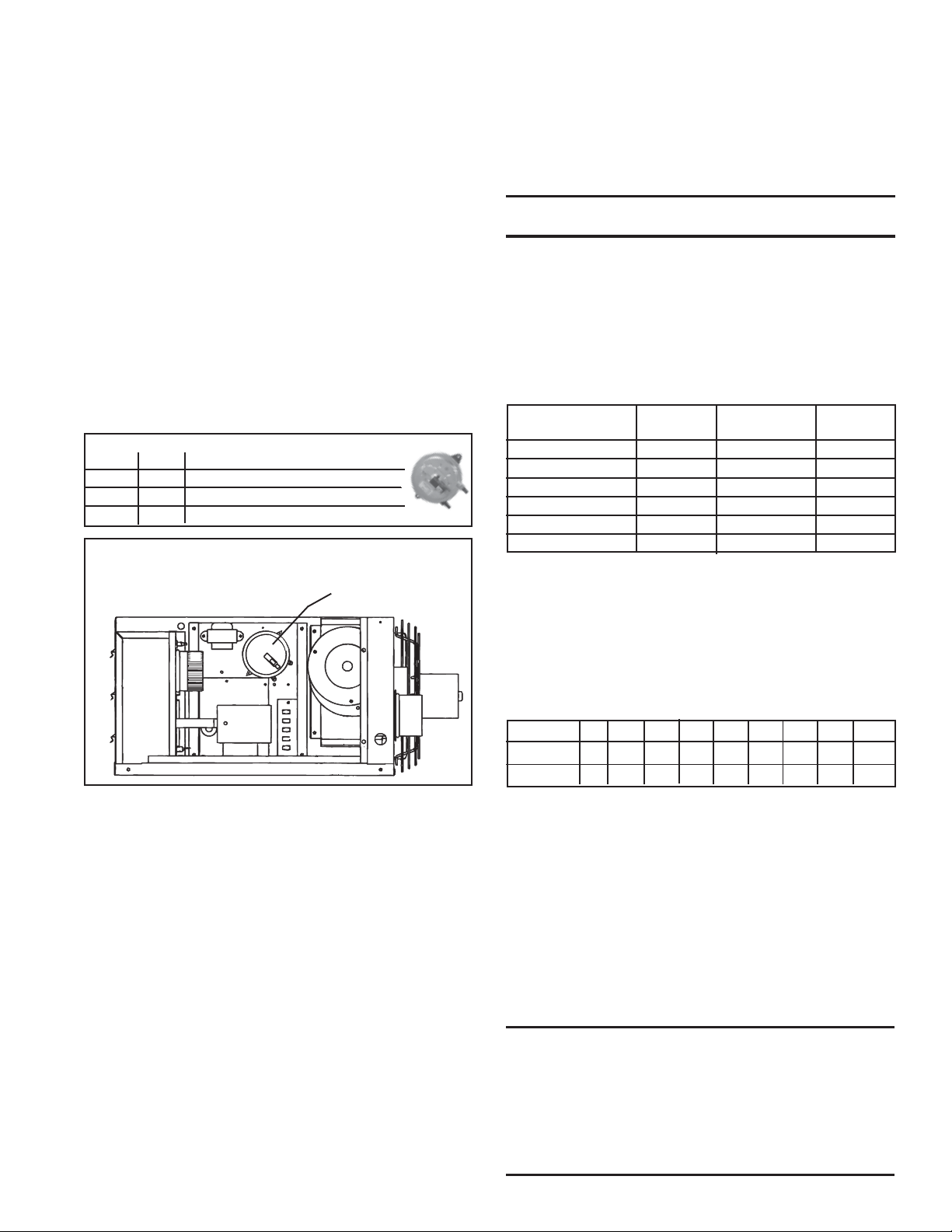

7. Suspending the Heater

Before suspending the heater, check the supporting structure to be used

to verify that it has sufficient load-carrying capacity to support the

weight of the unit.

Net Weight - lbs and kg

Size 45 60 75 100 125 150 200 250 300

lbs 85 110 120 148 153 216 226 272 294

kg 39 50 54 67 69 98 103 123 133

When the heater is lifted for suspension, support the bottom of the

heater with plywood or other appropriately placed material. If the bottom is not supported, damage could occur.

Determine type of suspension to be used:

• All Sizes - The heater is equipped with four-point suspension. Two

3/8"-16 threaded nut retainers are located on each side of the heater.

See Dimensions in Paragraph 8 and illustration in Figure 2A.

• Sizes 45, 60, and 75 may be installed with two-point suspension.

Follow the illustrated instructions in Figure 2B, page 4.

• Sizes 45, 60, and 75 may be suspended using an optional ceiling

suspension kit. Refer to Figure 2C. Step-by-step instructions are

included with the option kit.

WARNING: Suspend any size of Model SFT

heater from the threaded nut retainers (Figure

2A). Or , suspend a Size 45, 60, or 75 as illustrated

in Figure 2B or using the Ceiling Suspension Kit

in Figure 2C.

DO NOT suspend any heater from the heater

cabinet panels.

Form RZ -NA-I-SFT, Mfg No. 173474 (Rev 6), Page 3

7. Suspending the Heater

(cont'd)

WARNING: Unit must be level for

proper operation. Do not place or add

additional weight to the suspended

heater. See Hazard Levels, page 2.

Figure 2A - Four-point Suspension

(applies to all sizes)

Be sure that the

threaded hanger rods

are locked to the

heater as illustrated.

Recommended

maximum hanger rod

length is 6 feet

(1829mm).

Add a 3/8 nut

to lock the hanger

rod to the heater

3/8 Threaded Rod

Figure 2B - Two-point

Suspension - Applies to

Sizes 45, 60, and 75 only

On the bottom of the heater, use a washer

and double nuts to attach each threaded rod.

Use double nuts. Lock lower nut to upper by

holding upper nut while tightening lower nut.

9-9/16

(243mm)

C

L

5/16 or 3/8 threaded rods

(maximum length above

the heater is 18/457mm )

17-15/16

(456mm)

C

L

Sizes 45 --

12-1/8 (308mm)

Sizes 60/75 --

18-1/8 (591mm)

Sizes 45 --

21-1/4 (540mm)

Sizes 60/75 --

23-1/4 (591mm)

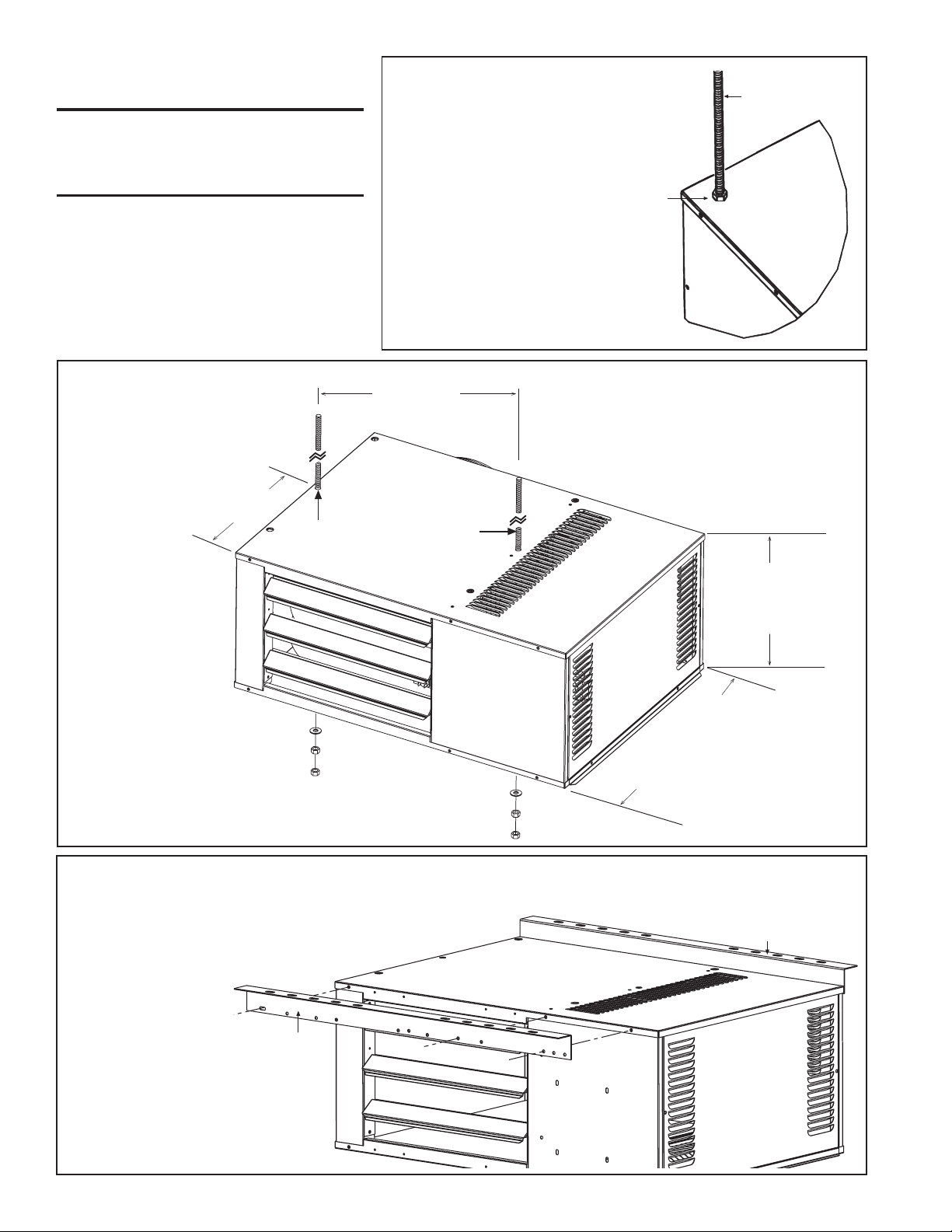

Figure 2C - Suspending with Ceiling Suspension Kit, Option CK22.

When suspending, use a minimum of two anchor points per angle.

NOTES: Quantity of screws used to attach the suspension angles

will vary by heater size and from front to rear of

cabinet. If optional vertical louvers

are being added,

install louvers

after suspension

angles are attached.

Attach suspension angle -

(1) Remove ALL screws

across top edge of cabinet.

(2) Position suspension angle, aligning

holes with same holes emptied in Step (1).

(3) Using ALL screws that were

removed and the same cabinet

holes, attach suspension angle.

Form RZ -NA-I-SFT, Page 4

Suspension angle

attached to rear

of heater

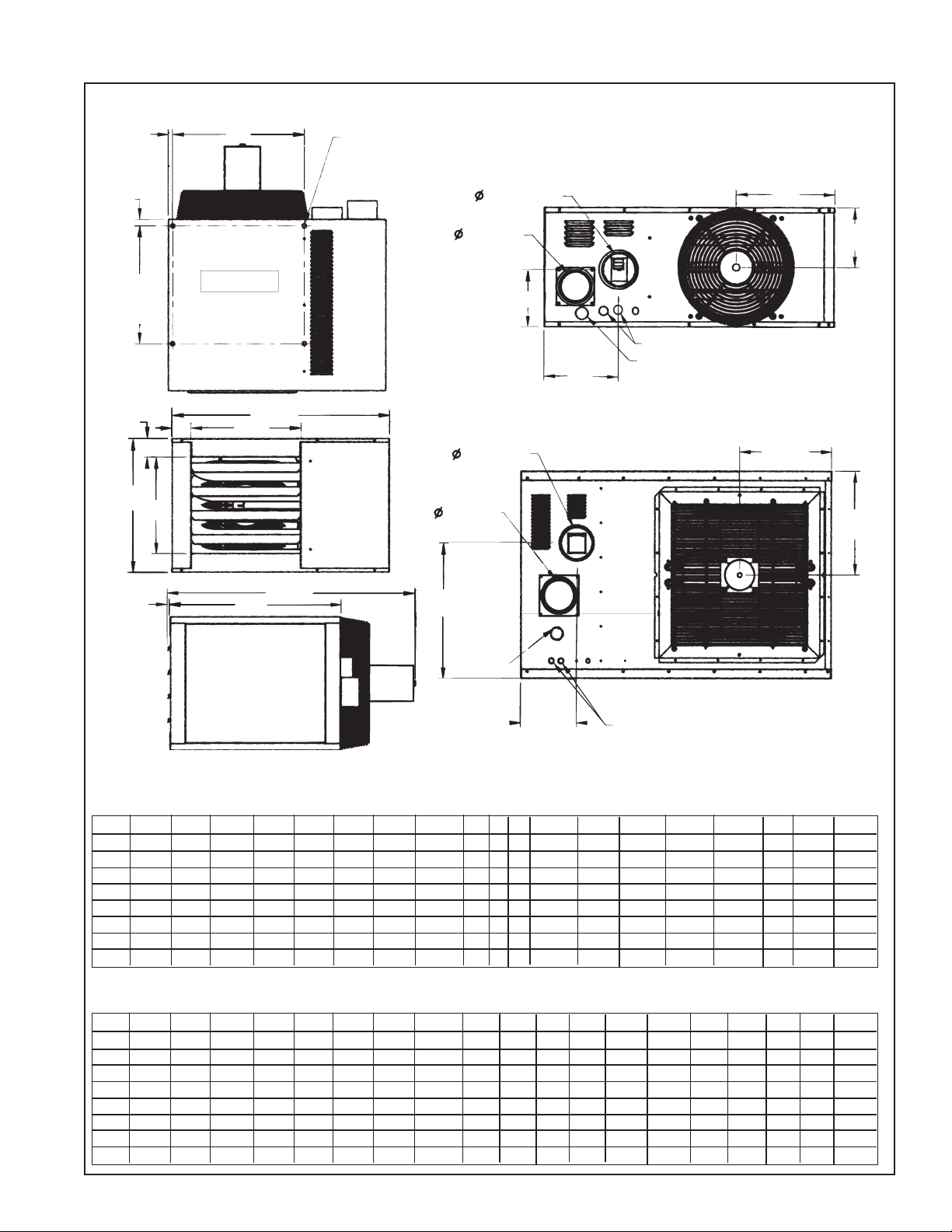

8. Dimensions

Figure 1

U

V

T

Hanger

Location

E

B

F

S

Top View

C

A

4-pt suspension points

3/8-16 cage nuts

Front

View

Air Inlet

Flue Outlet

L

Air Inlet

K

Flue Outlet

L

M

K

P

R

Field wiring connections

Gas Connection 1/2

N

Rear View - Model SFT 45-125

P

R

G

J

H

Right Side

View

M

Gas

Connection

1/2 Sizes 150-200

3/4 Sizes 250-300

N

Rear View - Model SFT 150-300

Field wiring connections

Dimensions (inches ± 1/8")

Size A B C D E F G H J K L M N P R S T U V

45 29-5/8 12-1/8 15 2-5/8 1 10-1/8 26-1/4 21-1/4 3/8 4 3 5-3/4 7-5/8 10 6 18 16 1/ 2 3/4

60-75 29-5/8 18-1/8 15 2-5/8 2-1/2 16-1/8 31-3/8 23-1/4 3 / 8 5 4 10-1/2 8 10 9 18 16 1/ 2 3/4

100 38 22 20-5/8 2-1/4 5 12 33-1/2 25-3/8 1 5 4 11 9-1/2 13-1/4 11 24-1/4 16 1/2 4-5/8

125 38 22 20-5/8 2-1/4 3-5/8 14-3/4 33-1/2 25-3/8 1 5 4 11 9-1/2 13-1/4 11 24-1/4 16 1/ 2 4-5/8

150 38 33 20-5/8 2 6 21 34 25-3/8 1 5 5 21-3/4 9-1/4 13 16-1/2 24-1/4 1 6 1/2 4-5/8

200 38 33 20-5/8 2 4-1/2 24 34 25-3/8 1 5 5 21-3/4 9-1/4 13 16-1/2 24-1/4 16 1/2 4-5/8

250 51-1/4 33 34-1/2 2 4-1/2 21 35-3/8 25-3/8 1 5 5 21-1/2 9-1/4 15-1/8 16-1/2 29-3/8 16 8-1/2 4-5/8

300 51-1/4 33 34-1/2 2 4-1/2 24 35-3/8 25-3/8 1 6 6 22 9-1/4 15-1/8 16-1/2 29-3/8 16 8-1/2 4-5/8

Dimensions (mm ± 3)

Size A B C D E F G H J K L M N P R S T U V

45 752 308 381 67 25 257 667 540 10 102 76 146 194 254 152 457 406 13 19

60-75 752 308 381 67 64 410 797 591 10 127 102 267 203 254 229 457 406 13 19

100 965 559 524 57 127 305 851 645 25 127 102 279 241 337 279 616 406 13 117

125 965 559 524 57 92 375 851 645 25 127 102 279 241 337 279 616 406 13 117

150 965 559 524 51 152 533 864 645 25 127 127 552 241 330 419 616 406 13 117

200 965 559 524 51 114 610 864 645 25 127 127 552 241 330 419 616 406 13 117

250 1302 559 876 5 1 114 533 899 645 25 127 127 546 241 384 419 746 406 216 117

300 1302 559 876 5 1 114 610 899 645 25 152 152 559 241 384 419 746 406 216 117

Form RZ -NA-I-SFT, Mfg No. 173474 (Rev 6), Page 5

9. V enting and Combustion Air

All separated combustion, power vented units MUST BE equipped with both combustion air and exhaust piping to the outdoors. The unique

concentric adapter assembly required with this heater allows for both combustion air and exhaust piping with only one horizontal or vertical

penetration hole in the building.

Installation should be done by a qualified agency in accordance with these instructions. The qualified service agency installing this separatedcombustion system is responsible for the installation.

The systems illustrated in this manual are the only venting/combustion air systems approved for a Model SFT heater.

Hazards of Chlorine - The presence of chlorine vapors in the combustion air of gas-fired heating equipment presents a potential corrosion hazard.

Chlorine found usually in the form of freon or degreaser vapors, when exposed to flame will precipitate from the compound, and go into solution

with any condensation that is present in the heat exchanger or associated parts. The result is hydrochloric acid which readily attacks all metals

including 300 grade stainless steel. Care should be taken to separate these vapors from the combustion process. This may be done by wise location

of unit vent terminals with regard to exhausters or prevailing wind directions. Remember, chlorine is heavier than air. This fact should be kept in

mind when determining installation location of these heaters and building exhaust systems.

WARNING: Do not use an existing venting system. This heater requires installation of the combustion

air/vent system ordered with the unit (either Option CC2 or Option CC6).

Specific Venting Requirements (read all before installing)

1. Concentric Adapter Kit (ordered with the heater as either Option CC2 or Option CC6)

All Model SFT installations require a concentric adapter kit. Each kit includes the concentric adapter box (See Figure 4), a vent terminal cap, and

an inlet air guard or cap. Follow the instructions on pages 7 - 9 to install a horizontal vent/combustion air system (Option CC6). Follow the

instructions on pages 10 - 11 to install a vertical vent/combustion air system (Option CC2).

The vent/combustion air systems illustrated in Figure 6D or 7E are the only venting/combustion air systems appr oved for this heater.

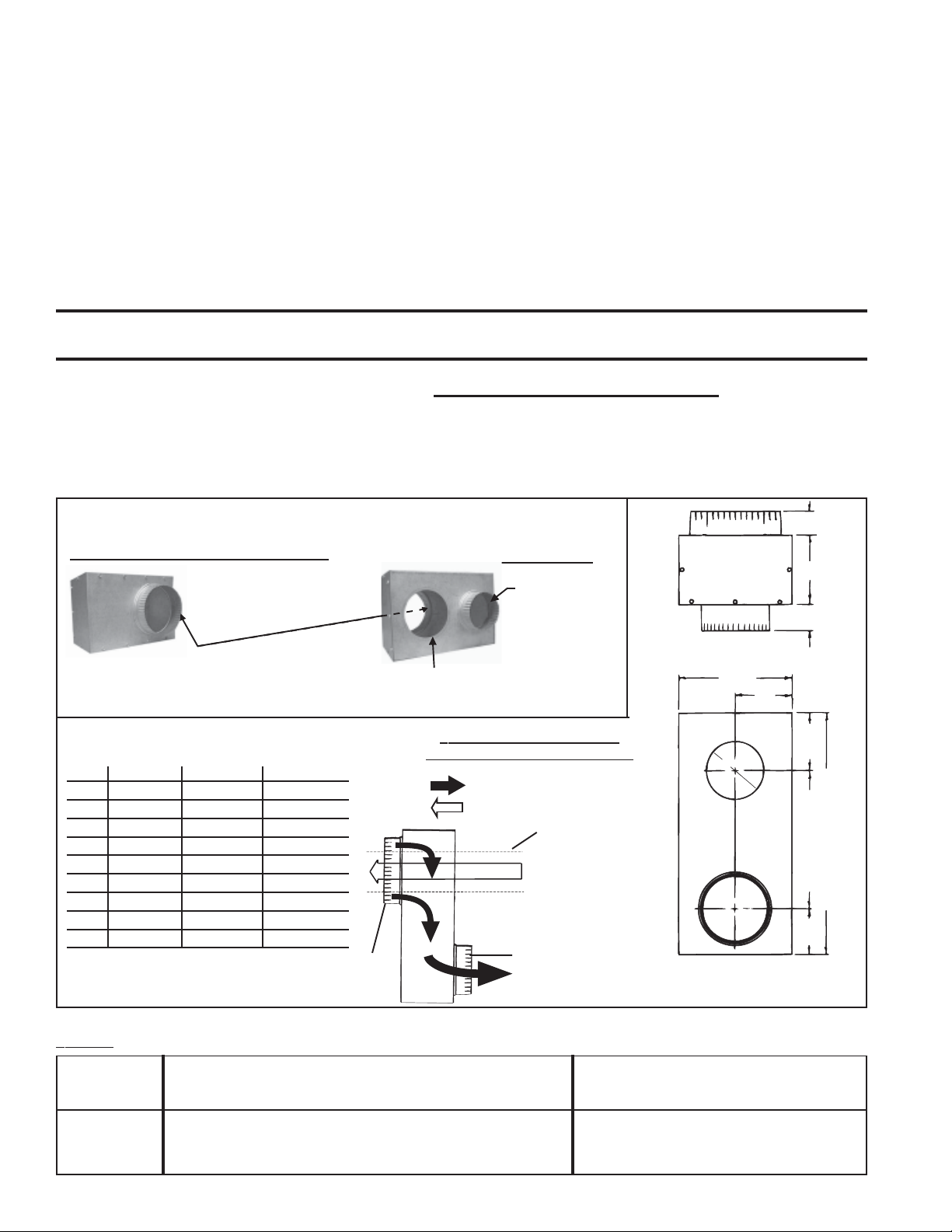

Figure 4A - Concentric Adapter Box Required with all Model SFT Installations

(included in both Option CC2 and Option CC6)

View of Vent Terminal Connection Side

Collar for outside portion of the combustion

air pipe (vent pipe extends through the box

internally concentric to the outside portion

of the combustion air pipe)

View of Heater Connection Side

Collar for

connecting

indoor portion

of the

combustion air

Install rubber

seal for vent pipe

pipe

End View

H

2 (51mm)

6 (152mm)

2 (51mm)

F

Figure 4B - Concentric Adapter Box

Dimensions - inches (mm)

SFT 45-125 150-250 30 0

A 4 (102) 5 (127) 6 (152)

B 4 (102) 4 (102) 5 (127)

C 3 (76) 4 (102) 4 (102)

D 5-1/2 (140) 7-1/2 (191) 7-1/2 (191)

E 3-1/2 (89) 5 (127) 5 (127)

F 4 (102) 4 (102) 5 (127)

G 12 (305) 16-1/2 (419) 16-1/2 (419)

H 8 (203) 8 (203) 10 (254)

J 6 (152) 6 (152) 8 (203)

J = Diameter of the Collar for

attaching the "Outside" Portion of

the Combustion Air Pipe

Top View of the Concentric

Adapter Box Showing Air Flow

= Combustion Air Flow

= Exhaust (Vent) Gas Flow

Field-supplied vent

pipe passes through

the rubber seal and

extends out both sides

of the concentric

adapter box.

A = Diameter of the

Collar for attaching the

Combustion Air Pipe

from the Heater

E

B

D

C

Side View - Side of the

Adapter Box that

Connects to the Heater

2. Type of Pipe (field-supplied)

Vent Pipe - the type of vent pipe required depends on the type of installation.

Type of COMMERCIAL/INDUSTRIAL (Harmonized ANSI Z83.8-1996 RESIDENTIAL (CSA Requirement 10-96)

Installation and Canadian Standard CAN/CGA A 2.6-M96) - Applies to all Applies to Model SFT 45, 60, and 75 ONLY

sizes of Model SFT Heaters

Type of VENT Use either vent pipe approved for a Category III appliance OR Vent pipe approved for a Category III

Pipe Required single-wall, 26-gauge or heavier galvanized (or a material of appliance is required.

equivalent durability and corrosion resistance) vent pipe.

Form RZ -NA-I-SFT, Page 6

G

2. Type of Pipe (field-supplied) (cont'd)

Combustion Air Inlet Pipe Between the Heater and the Concentric

Adapter - Sealed, single-wall galvanized pipe is recommended.

Combustion Air Pipe Between the Adapter Box and the Combustion

Air Inlet - The vent pipe is internally concentric to the combustion air

pipe; use single-wall galvanized pipe for the combustion air pipe.

3. Pipe Diameter and Length - ft (M)

Maximum Pipe Length from Heater to Concentric

Adapter - minimum length is five feet (1524 mm)

Model Pipe Diameter Maximum 90° Elbow 45° Elbow

SFT V ent Inlet Air Length Equals* Equals*

45 3" or 4" 3" 30 ft (9.1M) 5 ft (1.5M) 2.5 ft (.8M)

60, 75, 4" or 4" 40 ft 5 ft 2.5 ft

100, 125 5" (12.1M) (1.5M) (.8M)

150, 200 5" 5" 40 ft (12.1M) 5 ft (1.5M) 2.5 ft (.8M)

250 5" 5" 50 ft (15.2M) 5 ft (1.5M) 2.5 ft (.8M)

300 6" 6" 50 ft (15.2M) 5 ft (1.5M) 2.5 ft (.8M)

*Reduce maximum length by this amount for each elbow .

Concentric Pipes (the vent pipe runs through the concentric adapter

extending internally concentric through the outdoor portion of the combustion air pipe) - Sizes 45 - 250 require 6" diameter combustion air pipe

for the outdoor portion and a 4" vent pipe through the concentric adapter

to the terminal; Size 300 requires an 8" diameter combustion air pipe for

the outdoor portion and a 5" diameter vent pipe through the concentric

adapter to the terminal. Refer to the installation instructions for the concentric adapter kit for length requirements.

4. Joints/Seals

In Pipe Runs - provide pipe as specified in Requirement No. 2 and make

joints as follows:

• If using single wall, 26-gauge or heavier galvanized pipe, secure

slip-fit pipe connections using sheetmetal screws or rivets. Seal all

joints. Seal combustion air pipe with pressure sensitive tape ordinarily used for warm-air ductwork. Wrap two full turns around each

joint. Seal flue exhaust pipe with either tape suitable for 550°F (such

as Option FA1, P/N 98266) or high-temperature (450°F) silicone sealant.

• If using Category III vent pipe, follow the pipe manufacturer's in-

structions for joining and sealing vent pipe sections.

In Concentric Pipes (outdoor portion) from the Adapter Box to Air

Inlet and Vent Terminal - Follow the instructions for concentric adapter

kit (pages 7 - 9 for a horizontal system or pages 10 - 110 for a vertical

system).

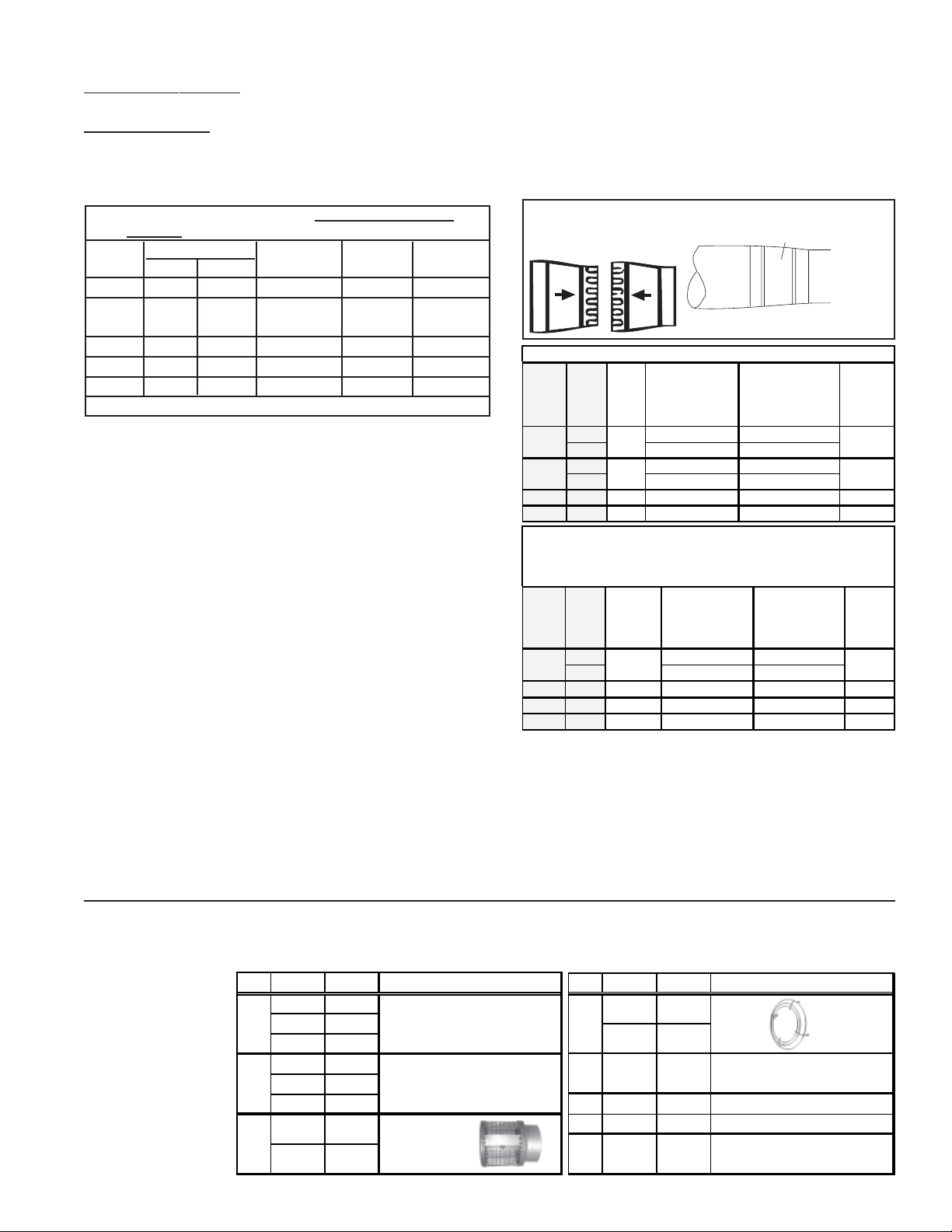

Joints Requiring Taper-type Connections (See Figure 5 and Tables

that follow) - When the diameter of the pipe in the inlet air or vent pipe

run is different from the connections at either the heater or the concentric adapter box, the joint must be made with a taper-type pipe

connector.

When the diameter change is at the heater, install the connector at

the collar or no more than 6" (152mm) from the heater.

When the diameter change is at the concentric adapter box, install

the connector no more than 6" (152mm) from the opening or collar

on the concentric adapter box.

Figure 5 - Use taper-type connections (see where

they are required below)

Reducer

Airflow

Tap er-type connector(s) required in the

SFT

Size

45

60-125

150-250 5" dia

300 6" dia

A taper-type connector is always

AIR PI PE

concentric adapter. When using 4" pipe, install th e r ed u cer at the heater. Other

sizes do n ot r equire a taper-type connection in the inlet air pip e r un.

Size

SFT

45

60-125 4" dia

150-250 5" dia

300 6" dia

Enlarger

Airflow

Venter

Vent

Pipe

Run

3" dia 4" to 3" Reducer 3" to 4" Enlarger

4" dia

4" dia 5" to 4" Reducer

5" dia

on Mo d el SFT 45. When using 3" pip e, install the reducer at t he

Inlet

Air

Pipe

3" dia 4" to 3" Reducer

4" dia

Reducer

Collar

to join venter collar

on

Heater

4" dia

5" dia

5" dia None

6" dia None

Air Inlet

Collar on

Concentric

Adapter

4" dia 3" dia

4" dia None None 4" dia

5" dia None None 5" dia

6" dia None None 6" dia

Reducer

to join concentric

adapter collar and

Taper-type Connector

Secure joints with sheetmetal

screws and seal.

VENT PIPE RUN

required

and pipe

None None

None

required

required

pipe

None

Taper-type

connection

to join different

diameter vent pipes

5" to 4" Reducer

5" to 4" Reducer

6" to 5" Reducer

in the indoor portion of the

Reducer

t o jo in heater

collar and pipe

4" to 3" Reducer

required

None

None

Either collar

or smaller

diameter pipe

req u ire d

Vent Pip e

through

Adapter

Box

4" dia

4" dia

4" dia

5" dia

INLET

Inlet Air

Collar at

Heater

5. Support

Support horizontal runs every six feet (1829mm); do not rely on the

heater or the adapter box for support of either horizontal or vertical

pipes. Use non-combustible supports on vent pipe.

6. Clearance

Do not enclose the vent pipe or place pipe closer than 6" (152mm)

to combustible material.

Instructions and Requirements for Installing a Horizontal Vent T erminal/Combustion Air

Inlet (Requires Concentric Adapter Kit, Option CC6)

Horizontal Vent

Terminal/Combustion

Air Package

(Option CC6)

includes:

Qty Size P/N Description

1 45-125 157157

150-250 157158

300 82131

1 45-125 155118

150-250 155392

300 68404

1 45-250 155096 Screened

300 53316

Complete Horizontal Vent Kit

(Same as Option CC6)

Concentric Adapter Box

Assemby (See Figure 3A)

Exhaust Assy

Qty S ize P/N Description

1 45-250 151755 Inlet

300 124940

4 45-300 37661

1 45-250 164492 4" I.D. Rubbe r Seal

1 300 1 64493 5" I.D. Rubber Sea l

1 45-300 53335

Form RZ -NA-I-SFT, Mfg No. 173474 (Rev 6), Page 7

Guard

#10-16 x 1/2" lg Screws to

attach the in let guard

Tube of High Temperature

(450°F) Silicon e Sealant

Loading...

Loading...