Renault 400, 440, 480 Service Manual

NE 3/3914 AN

english edition

MAGNUM

E–TECH

400 – 440 – 480

50 21 014 670 – 11/03

édition anglaise

contents

Chapter

ALPHABETICAL INDEX A. . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS B. . . . . . . . . . . . . . . . . . . . . . . . . . . .

USE OF THE VEHICLE C. . . . . . . . . . . . . . . . . . . . . . .

AIR CONDITIONING D. . . . . . . . . . . . . . . . . . . . . . . . .

CONSUMABLE PRODUCTS E. . . . . . . . . . . . . . . . . . .

SERVICING F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL EQUIPMENT G. . . . . . . . . . . . . . . . . . .

SUPPLEMENT AT END OF HANDBOOK

WELCOME ON BOARD YOUR NEW RENAULT

You have now taken possession of your new vehicle.

W e trust that it will give you the entire satisfaction you have the right to expect and which was

the reason for your original choice.

This driving and servicing handbook has been compiled to provide all the information you

need and will enable you to:

– Get to know your Renault better to derive maximum benefit from its advanced technical

features in optimum working conditions.

– Permanently guarantee optimum operations by following the maintenance recommenda–

tions.

– Cope with any minor problems not requiring assistance from a specialist, without losing

too much time.

NOTE

This handbook covers all the options proposed to customers. T ake into consideration only the

indications regarding the model owned by you.

The few moments devoted to reading this handbook will be well worthwhile for the information it contains and by the new technical features you will discover. If any details remain unclear, our Dealer Staff will be pleased to provide you with any further information you may

require.

HOW TO READ CROSS–REFERENCES

The reference numbers, figures and letters mentioned in the text refer back to two types of

illustration:

– figures correspond to figur es or photographs situated in proximity to the text

– letters, sometimes followed by a figure, correspond to the Instrument Panel diagram to be

found inside the handbook.

“Bon voyage” at the wheel of your Renault !

RENAULT TRUCKS AND BUSES: FRONTIER–FREE SER VICE

Renault Service 24 has been in operation in Europe for several years now.

19 emergency call centres are listening in for you 365 days a year.

Spare parts officially approved by RENAULT TRUCKS meet both the requirements of the

vehicle specification and the regulations in force. Only premium Renault parts will ensure:

– Original Equipment safety standards.

– Maintenance of original characteristics and performance.

– Full Manufacturer’s Warranty.

The manufacturer reserves the right to make any modifications deemed necessary during production. This handbook

should not be considered as a specification for the model in question.

RENAULT V.I. – 2003 – Imprimé en France

GENERAL USAGE INSTRUCTIONS FOR COMMERCIAL VEHICLES

If you are a professional driver using your own vehicle, or a haulier entrusting one of your

vehicles to a member of your staff, it is essential to follow and ensure the application of the

following instructions. They are only a reminder of the basics of the trade and standard professional practice and in no way are to be taken as exhaustive. In this way you will obtain the

maximum profit from your material and prevent any risk of accidents and incidents.

1. BASIC INSTRUCTIONS

– Every driver must possess all necessary licences and should only drive when physically

fit and sufficiently rested.

– The vehicle must be in conformity with current legislation in the country or countries

in which it is used.

– Any signs or panels indicating hazardous substances must be affixed and be in good

condition.

– Loads:

. All–up or per–axle weights (regulatory or technical) must not be exceeded.

. Loading and securing of loads must be carried out using conventional procedures,

tarpaulins and side curtains must be correctly stretched and fastened and doors and

sideboards locked, etc.

– In the cab:

. Never carry dangerous products (such as petroleum, trichlorethylene, thinner, etc.).

. If an animal Is carried, it must be kept away from the driving position.

– Getting in and out of the vehicle:

. Use the steps and the handles provided. Never jump down from the vehicle.

. When leaving the vehicle, observe the traffic flow, particularly if you have been driving

for a long t ime.

. T ake extra care when the climatic conditions are bad (rain, snow, ice) and at night.

2. BEFORE GETTING INTO THE VEHICLE, CHECK

– General condition of your vehicle, visually (as per handbook).

– Tyre condition, tyre pressures (including the spare wheel), and that nothing is jammed

between the twin wheels.

– Cleanliness of cab windows, rearview mirrors, headlights and other lights and number

plates.

– Regulatory and optional lighting systems for correct operation.

– Semi–trailer and/or trailer for correct coupling (hook, brake hoses – colour coding –

electrical connector...).

– For the presence and contents of the onboard tool kit.

– In winter, for the presence of anti–skid chains and that they are securely fastened.

– Vehicles equipped with side guard panels and beams should be permanently provided

with this equipment. At the time of removal, make sure that the locks are correctly

locked and tighten the setbolts moderately.

3. ONCE ONBOARD

– Check the condition of the non–slip pedal covers.

– Ensure that the safety controls. steering wheel, pedals, gear lever etc. are never

cleaned with a slippery product like silicone.

– Adjust your driving position:

. Steering wheel: check that the steering column is locked.

. Seat: check that the seat is firmly locked.

. Rearview mirrors.

. If the vehicle is fitted with a seat belt, use it.

– Prior to starting the engine. ensure that the gear lever is in neutral.

– Check that all instrument panel indications are normal (if you are not certain of what

the nominal readings are supposed to be, refer to the driving handbook) and that the

tachograph disc is in place and that the unit is working properly.

4. WHEN DRIVING

– If you detect any anomaly in the way the vehicle is operating, stop and locate the mal–

function.

Do not move off again until you are sure that the incident has not impaired technical

performance and safety.

– When driving, the use of some of the standard–fitted equipment, and other optional or

added equipment is strictly forbidden (CB, telephone, i.e. hand–operated sun–roofs,

television sets, etc.) or only permitted if all necessary precautions are taken so as not

to affect road safety (cigar lighter, manual selection of radio stations...).

– Adapt your driving style to suit your load (cant or bend, if the centre of gravity is high,

etc.) to take account of weather conditions and the time of day.

If necessary, adjust the headlight beam levels.

– Never shut down the engine when the vehicle is moving (as this will cut off the supply

to the power–assisted steering system and could decrease brake effectiveness).

5. WHEN PARKING

– Check that the vehicle is correctly parked (i.e. that it does not obstruct traffic flow or

threaten the security of neighbouring installations).

– If the vehicle is going to remain stationary for some time, use one or more wheel chocks

to Prevent it from moving (e.g. semi–trailer compressed air leakage, or in black ice

conditions...).

– Check that:

. parking brake is locked and immobilizes the road train or rig,

. gear lever is in neutral,

. battery isolating switch is OFF,

. electromagnetic retarder is switched OFF,

. air vents are not blocked (i.e. if an independent heating system is used),

. parking lights are on at night.

– Check that you have not left in the cab:

. important documents (personal, vehicle, load),

. unaccompanied animals.

6. WHEN REP AIRING / SERVICING THE VEHICLE

IMPORTANT

Prior to carrying out any work on the electronic air suspension (other than calibration),

place axle stands under the chassis.

– Check the tightness of the wheel nuts according to recommendations.

– Prior to tilting the cab:

. Check that there is enough space in front of the vehicle and take care that during this

manipulation nobody tries to cross this area or park in it.

. Stop the engine, put the gear lever into neutral and make sure that no object is likely

to fall onto the windscreen. If a refrigerator is fitted, drain it. Close the doors.

. Tilt the cab as far as possible. If the cab is only partially tilted, wedge it to prevent

accidental movement.

– If the engine is running:

. Do not approach moving parts (fan, drive belts, etc.).

. Do not turn off the electrical power supply (shut down the engine first).

– When climbing up onto or down from the catwalk behind the cab (tractor), use the steps

and grab handles provided. Never jump down from the catwalk. T ake care not to burn

yourself (on the vertical exhaust pipe and silencer).

– Fuel is inflammable, if the fuel filler cap is open, smoking is forbidden and there must

be no naked flame in the vicinity.

– Batteries are filled with acids which can cause serious injuries. They must be handled

with great care.

– If you start the engine using an external power source:

. Use cables of the correct dimensions.

. Make sure that the + and – polarities are connected properly.

– When changing a fuse, it is vital to use another fuse of the same size.

– Only specialists should install additional power lines.

– The installation of additional air lines requires a technical study to be carried out or

approved by the manufacturer.

– It is strictly forbidden to heat polyamide hoses (braking circuit pipes).

– Raising the vehicle with a jack: chock the wheels prior to jacking.

– Immobilizing the vehicle: use one or several wheel chocks as necessary.

– Wheels and tyres:

. Never check tyre pressures or inflate or deflate a tyre which is hot.

. Never stand in front of a tyre when checking the pressure or inflating it.

. When fitting a roadwheel, take great care to centre wheels fitted with centring clamps

(for trilex wheels, position the clamp at the segment crossover point).

– Repairs on the open road: collect all fluids which have been drained (such as oil, fuel,

coolant...).

– With an eye to environmental protection, take into consideration the laws in force

(recovery of oil / anti–freeze / cartridges).

– When draining oils (engine / gearbox / drive axles), you run the risk of burning yourself

(hot oil).

– Independent heater, use vehicle diesel fuel only.

– If anti–skid chains are used, the rear wings should be removed, road speed should be

reduced and chain tension should he tested at regular intervals.

Any modification to circuits (electrical, electronic or compressed air) may have serious

consequences. Such work should only be undertaken in agreement with the manufacturer. RENAULT TRUCKS decline any responsibility in the event of non–conformity

in assembly.

Only original RENAULT TRUCKS parts and circuits defined by the manufacturer

guarantee quality, safety and reliability.

By observing the above instructions, you will be using your vehicle in the best possible way.

However, you must also carefully read the driving handbook and consult the RENAULT

TRUCKS network whenever you need any further information.

W e remind you that application of the contractual warranty by RENAULT TRUCKS is subject, among other things, to proof by the customer that servicing and maintenance of the

vehicle have been carried out according to our recommendations (frequency , operations to be

performed, quality of expendable and consumable products guaranteed by genuine certified

or recommended spare parts, quality and training of repair staff and use of specific tools...).

Observance of these recommendations will also guarantee long–term reliability of the

vehicle.

Servicing and maintenance conducted by the RENAULT TRUCKS network is a guarantee

of observance of these recommendations. If the operations are conducted outside our network, the customer must provide formal proof that our recommendations have been observed.

A1 alphabetical index

A

Adjusting the steering wheel, C50

Adjustment of head lights, G11

ADR vehicle, C66

Air bag, C51

Air dryer, F33

Air filters, F10

Air tanks, C33, C34

Airbag, C51

Alarm, C39

Electrical equipment, G12

Alarm clock, C73

Anti–lock braking system, C118

Anti–spin regulation ”ASR”, C118

A vailable power supply, G5

Axle

Servicing, F29

Specifications, B1

Use of the vehicle, C135

B

Batteries, G2

Bodywork

Servicing, F36

Specifications, B3

Brakes, Specifications, B2

Braking system, Servicing, F33

Bulbs, G7

C

Cab tilting, C128

Capacities, B5, B6

Clutch

Servicing, F23

Specifications, B1

Consumable products, E1

Coolant temperature gauge, C97

Cooling system, F16

Cylinder head(s), F14

D

Dashboard, C3, C5

Diesel fuel, E1

Differential, C124

Drive belt tension, F21

Driving monitoring system, C93

E

Electric window winders control, C69

Electrically operated rearview mirrors, C72

Electrics, Specifications, B3

Electronic air suspension, C136

Electronic speed limiter, C97

Emergency brake, C76

Engine

Oil level, F1

Servicing, F9

Specifications, B1

Engine oil level and pressure indicator, C82

Engine operating speed, C93

F

Fifth wheel coupling, C89, F37

Fire extinguisher, C64

Front suspension

Servicing, F31

Specifications, B2

Fuel system, F13

Fuel tank, C35

Fuses, G13, G15, G16, G17

G

Gearbox

Servicing, F24, F25

Specifications, B1

Use of the vehicle, C98, C100

H

Headlight adjustment, C72

Heating – ventilation, D1, F37

I

Independent heating, D7

Servicing, F38

J

Jack, C132

K

Key to switches, C13

Key to tell–tale pictograms, C11

Key to warning lights, C6, C7, C8, C9

Key to warning pictograms, C10, C14

A2 alphabetical index

M

Main switch, C35

Multi–function display, C6, C15

O

Oil filters, F9

On the road, C93

Optidriver, C110

P

Parking brake, C75

Power take–off

Specifications, B1

Use of the vehicle, C123

Preh eating the eng ine cooling system , C65

Prior to starting, C78

Prop shaft, Specifications, B1

Prop shafts, Servicing, F26

R

Radio, C74

Rear drive axle

Servicing, F26, F27

Specifications, B2

Rear suspension, C136

Servicing, F31

Specifications, B2

Retarder, C119

Servicing, F35

Specifications, B3

Running–in, C88

S

Seat belts, C50

Spare wheel carrier, C131

Special conditions, C87

Starting, C83

Starting switch, C78

Starting using an external power source, G3

Steering

Servicing, F30

Specifications, B2

Stopping

Emergency shut–down, C127

Engine, C126

Sun blinds, C70, C71

Switches

Combined lights, C67, C68

Direction indicator, C67, C68

T

T achograph, C81

T owing, C145

Trailer brake, C76

Turbocharger, F20

Tyres

Specifications, B7

Use of the vehicle, C130

W

Warranty, F1

Wash/wipe and headlamps washer

control stalk, C68

Welding, B4

Windscreen washer control stalk, C68

Windscreen washer reservoir, C35

B1 specifications

ENGINE

Depending on your vehicle’s equipment

Capacity 11 929 cm3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bore / stroke 124/165 mm. . . . . . . . . . . . . . . . . . . . . . . . . .

Injection equipment “BOSCH” PLD 20 CCRS. . . . . . . . .

Firing order 1.5.3.6.2.4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum no–load speed 2 350 rpm. . . . . . . . . . . . . . . . .

Idling speed 700 rpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLUTCH

Depending on your vehicle’s equipment

GEARBOX

Depending on your vehicle’s equipment

Depending on your vehicle’s equipment

POWER T AKE–OFF

*: continuous service

**: intermittent service < 30 mins (30 minute break between two periods of use)

MIDR 06.24.65 A66/B66/C66+J01

430 DTE

MFZ 2–400

ZF 16.S 181

ZF 16.S 221

ZF ASTRONIC

NH.1B/C *

NH.4B/C **

N221–10.B/C *

HYDROCAR S81Z1 B/C *

HYDROCAR S81Z2 C *

HYDROCAR S84Z1 B/C **

HYDROCAR S84Z3 **

PROPELLER SHAFTS

Tubular shafts fitted with universal joints.

FRONT AXLE

E81

B2 specifications

REAR DRIVE AXLE

Depending on your vehicle’s equipment

PMR 2141

With inter–wheel and inter–axle differential locks.

Depending on your vehicle’s equipment

LIFT–UP AXLE

HENDRICKSON

Depending on your vehicle’s equipment

SELF–TRACKING LIFT–UP AXLE

AUSTERAS

STEERING

Hydraulic power assisted

P 1345

P 1370

ER8

ER11

ZF 8098

FRONT SUSPENSION

Depending on your vehicle’s equipment

Leaf springs, hydraulic shock absorbers and anti–roll bars.

Air suspension.

REAR SUSPENSION

Depending on your vehicle’s equipment

Leaf springs, hydraulic shock absorbers and anti–roll bars.

Leaf springs, hydraulic shock absorbers, anti–roll bars and air springs.

Air suspension.

Leaf springs and reaction rods.

Leaf springs swivelling on pivots

BRAKES

Air

“EBS” braking system

B3 specifications

RETARDER

Depending on your vehicle’s equipment

Exhaust brake

Electric retarder

“J” engine–brake

ZF “INTARDER” Hydrodynamic

ELECTRICS

Depending on your vehicle’s equipment

24 Volts

2 batteries 190/230 Ah. . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternator: “BOSCH” NL1 80 A . . . . . . . . . . . . . . . . . . .

Starter: “MITSUBISHI” P 105 D. . . . . . . . . . . . . . . . . . .

IMPORTANT

Vehicle equipped with “EBS” braking system:

– the alternator and batteries form part of the system – their specifications are inte–

grated in the vehicle type approval dossier. For any modification, contact your

dealer or nearest approved agent.

BODYWORK

It is essential to obtain 1/20 scale chassis drawings from your dealer when fitting bodywork

or special equipment (loading crane, fifth wheel, etc.). For the attachment of this bodywork

or equipment and also electrical connections, we ask manufacturers and body builders to comply with the RENAULT TRUCKS specifications and standards drawn up for this purpose.

These are readily available from your dealer.

B4 specifications

WELDING ON VEHICLE

Important precautions

The vehicle is equipped with numerous electronic circuits.

Prior to carrying out any electric welding

work, disconnect the positive (+) cable from

the terminals of the battery and connect it to

earth.

Place the earthing clamp as close as possible

to the weld, but never attach it to a rotating part

(prop shaft, hub, fan, etc.), nor to any sub–

assembly having moving parts (air compressor, turbocharger, etc.).

Nearby plastic pipes and electrical cables are

to be protected or removed. This also applies

for grinding or drilling work.

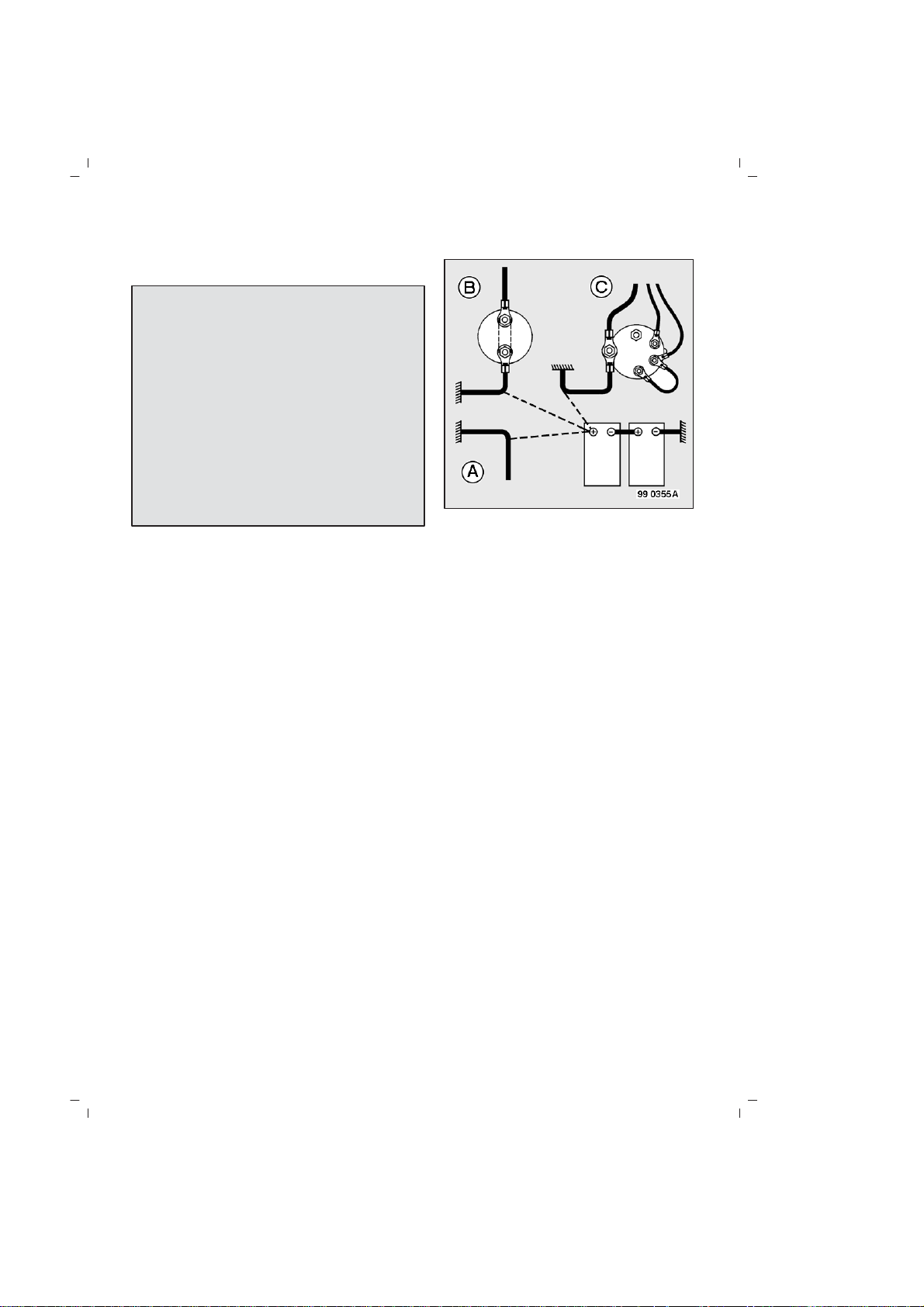

Diagram A: Vehicle without master switch

Diagram B: V ehicle with mechanical master

switch

The master switch must be closed.

Diagram C: Vehicle with electrical master

switch

Disconnect the two cables and connect them

together.

Soundproofing screen(s)

Any damage to the interior protective film of the screen requires replacement of the film.

See that no flammable products are applied to the screen protective films. The screens are to

be cleaned using a cloth. If necessary, use soapy water (any other product is strictly forbidden).

The application of solvent or paint to either inner or outer faces of soundproofing screens is

to be prohibited.

B5 specifications

CAPACITIES

Litres

OIL

Engine

– engine dry 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

– without filter change 32. . . . . . . . . . . . . . . . . . . . . . . . . .

– with filter change 36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gearbox ZF 16 S 181 / 221

Normal oil change 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dry oil sump 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power take–off 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gearbox ZF 16 S 181 / 221 + INTARDER

Normal oil change 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dry oil sump 21.5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power take–off 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gearbox ZF ASTRONIC 16 AS 2601

Normal oil change 10.5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Dry oil sump 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power take–off 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gearbox ZF ASTRONIC 16 AS 2601 + INTARDER

Normal oil change 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dry oil sump 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power take–off 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear drive axle P 1345

Pan 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hub reduction units 2 x 0.8. . . . . . . . . . . . . . . . . . . . . . . .

Rear drive axle P 1370

Pan 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel hub 2 x 0.5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear drive axle PMR 2141

Middle with adaptation 18. . . . . . . . . . . . . . . . . . . . . . . . .

Rear 14.5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hub reduction units 4 x 0.8. . . . . . . . . . . . . . . . . . . . . . . .

B6 specifications

CAPACITIES

Litres

OIL

Suspension swivels 2 x 0.9. . . . . . . . . . . . . . . . . . . . . . . .

Lift–up axle ER 8

Wheel hub 2 x 0.7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lift–up axle ER 11

Wheel hub 2 x 0.6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power steering hydraulic system 4.5. . . . . . . . . . . . . . . . .

Clutch hydraulic system 0.5. . . . . . . . . . . . . . . . . . . . . . . .

Cab tilt mechanism hydraulic system 1.5. . . . . . . . . . . . .

COOLANT

Cooling system 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling system + ZF Intarder retarder 54. . . . . . . . . . . . .

WATER

Windscreen washer reservoir 26. . . . . . . . . . . . . . . . . . . . .

FUEL

Depending on your vehicle’s equipment

Fuel tank 410. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extra fuel tank 275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Depending on your vehicle’s equipment

Independent heating system tank 18.5. . . . . . . . . . . . . . . .

KEYS:

Make a note of your key numbers here:

– Ignition key:

– Door key:

420

555

595

735

410

420

555

595

B7 specifications

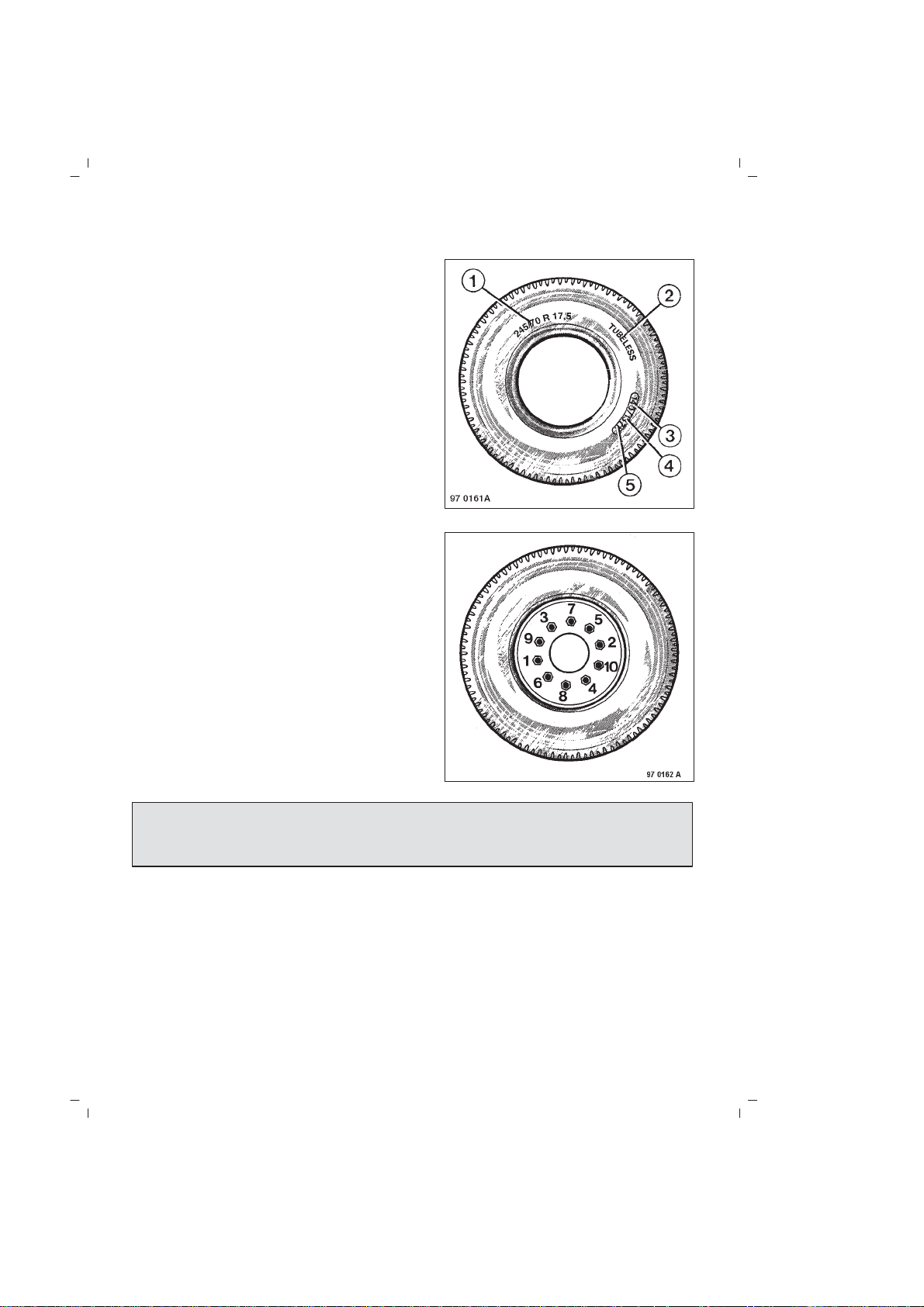

TYRES

1 – T yre type

2 – “Tubeless”

3 – Load index: single fitment

4 – Load index: twin fitment

5 – Symbol indicating maximum speed

authorized for tyre

Tyre pressures

NOTE

These pressures are given for guidance. Consult the manufacturer’s data concerning specific type and usage information. Respect the

load/speed indices marked on the sidewalls of

the tyres.

Tightening sequence

– Disc wheels

Steel wheels

Wheel nuts tightening torque

450 → 550 N.m

Light alloy wheels

Tightening torque of wheel nuts

450 → 550 N.m

IMPORTANT

For any modification to tyre type. you must redefine the braking system parameters

without fail. Contact your dealer or nearest approved agent.

Depending on your vehicle’s equipment

Tyre type: fitting at front only

Tyre type Single Twin Pressure in Bars

385/65 R 22.5 7 000 7.0

Load in kg as per fitment

6 500 6.5

7 500 7.5

8 000 8.0

B8 specifications

Depending on your vehicle’s equipment

Tyre type Single Twin Pressure in Bars

295/60 R 22.5 6 020 11 050 8.0

305/60 R 22.5 6 300 11 900 8.5

315/60 R 22.5 6 390 11 920 8.0

305/70 R 22.5 6 395 11 920 8.0

315/70 R 22.5 6 755 12 675 8.0

295/80 R 22.5 6 330 11 240 7.5

315/80 R 22.5 7 140 12 640 7.5

12 R 22.5 5 950 10 560 7.0

13 R 22.5 7 070 12 630 7.5

**: according to load index and speed symbol.

Load in kg as per fitment

5 330 9 800 7.0

5 680 10 420 7.5

6 360 11 680 8.5

6 700 12 300 9.0

5 900 11 500 8.0

6 700 12 300 9.0

5 560 10 550 7.0

6 030 11 240 7.5

6 760 12 600 8.5

7 100 9.0

5 660 10 555 7.0

6 030 11 240 7.5

6 760 12 600 8.5

7 100 9.0

6 700 12 300 8.5**

5 980 11 225 7.0

6 370 11 955 7.5

7 140 13 400 8.5

7 500 9.0

7 100 12 600 8.5**

5 560 9 880 6.5

5 950 10 560 7.0

6 720 11 920 8.0

7 100 12 600 8.5

6 270 11 090 6.5

6 700 11 860 7.0

7 570 13 400 8.0

8 000 8.5

7 500 13 400 8.0**

5 560 9 880 6.5

6 330 11 240 7.5

6 720 11 920 8.0

7 100 12 600 8.5

5 790 10 340 6.0

6 210 11 100 6.5

6 640 11 870 7.0

7 500 13 400 8.0

8 000 13 400 8.0**

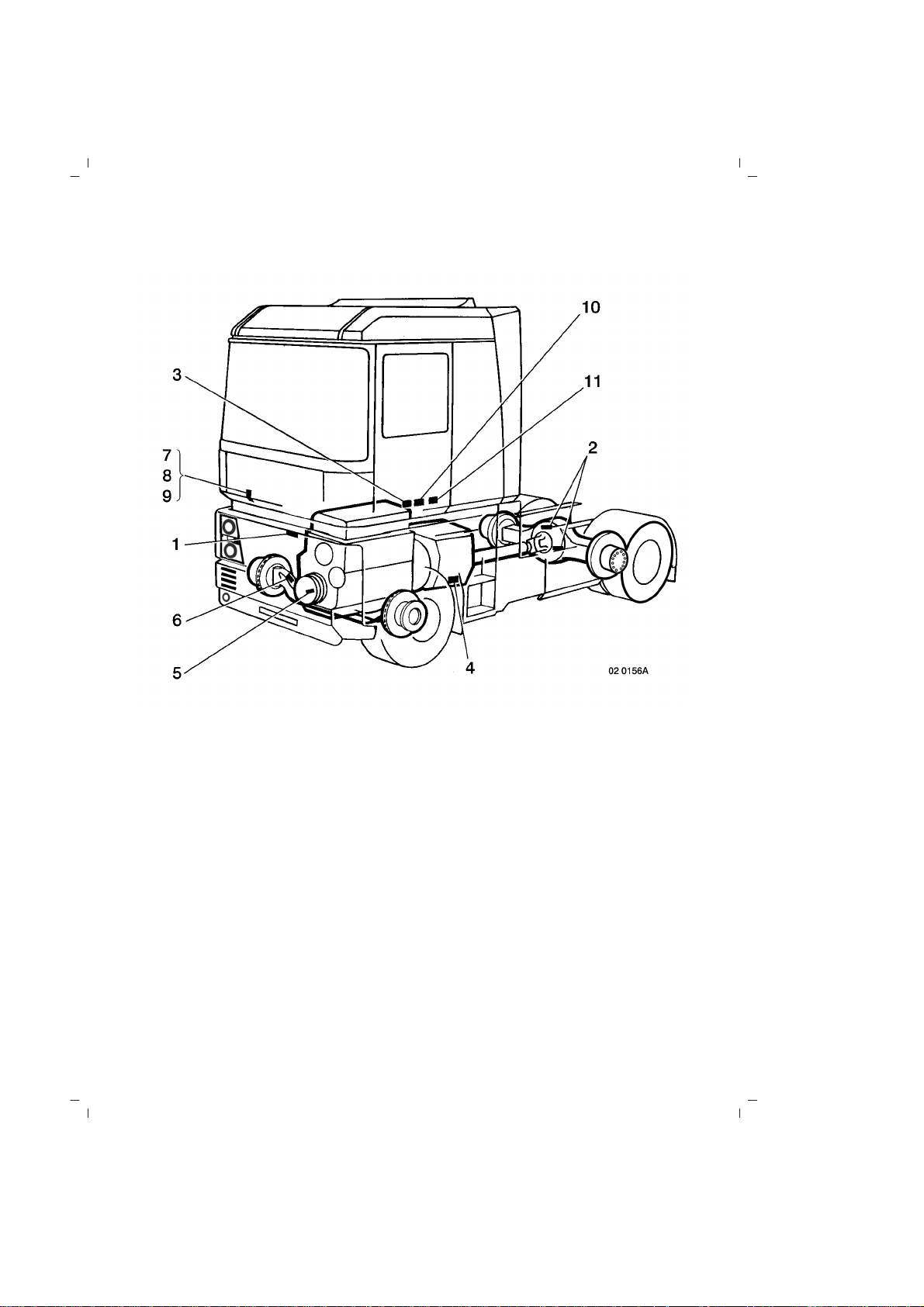

B9 specifications

Depending on your vehicle’s equipment

VEHICLE IDENTIFICA TION

1 – Chassis

2 – Drive axle

3 – T achograph plate

4 – Gearbox

5 – Engine

6 – Axle

7 – CAM reference

8 – Paint reference

9 – Manufacturer’s production number

10 – Manufacturer’s identity plate

11 – Conformity plate

C1 use of the vehicle

C2 use of the vehicle

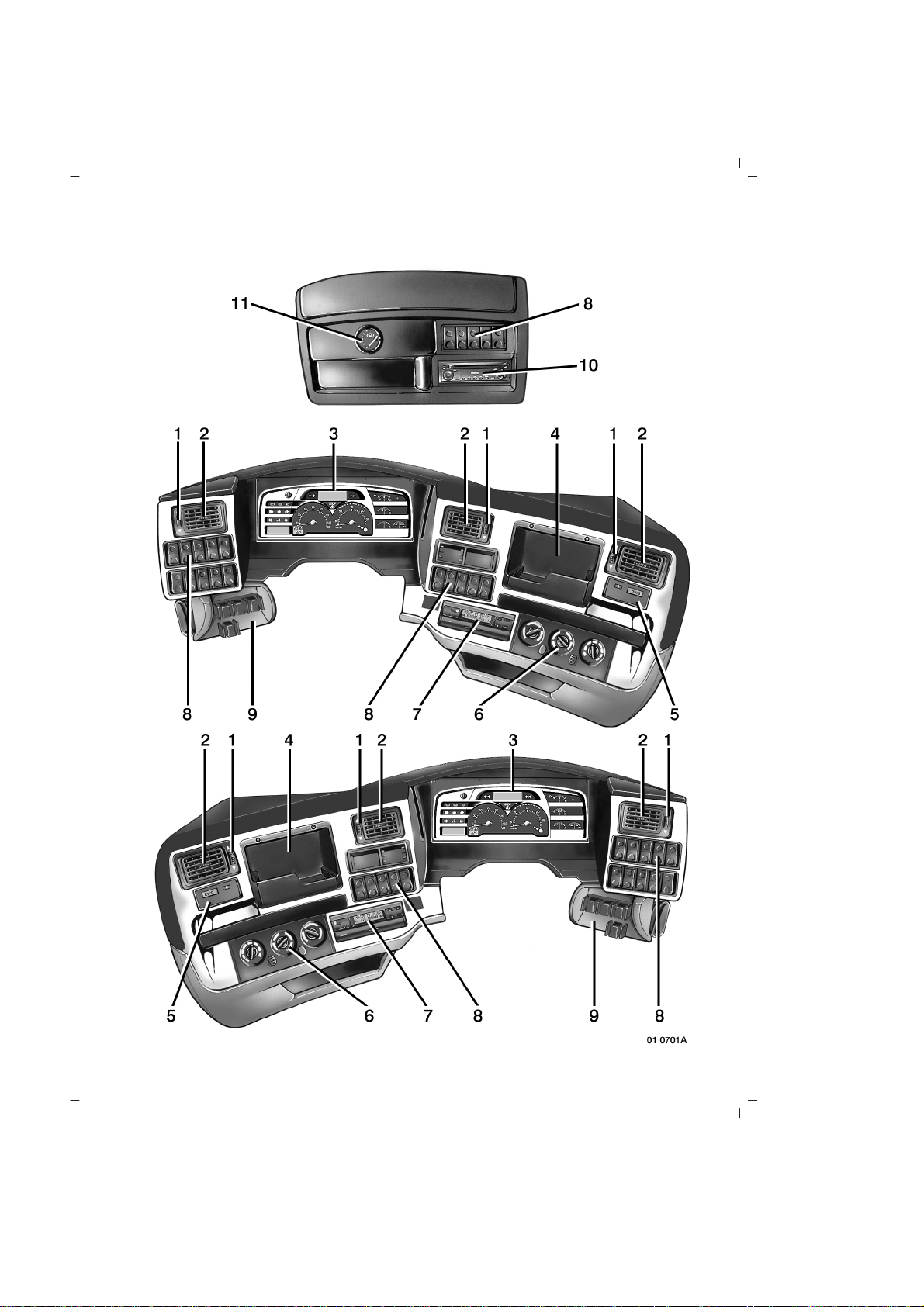

C3 use of the vehicle

DASHBOARD

Depending on your vehicle’s equipment

1 – Air vent(s) control

2 – Air vent

3 – Display

4 – Driver’s map pocket

5 – Clock

6 – Climate control panel

7 – T achograph

8 – Switches (see page C12 / C13)

9 – Control cluster (see page C14)

10 – Space for radio

11 – Brakes air pressure gauge

C4 use of the vehicle

C5 use of the vehicle

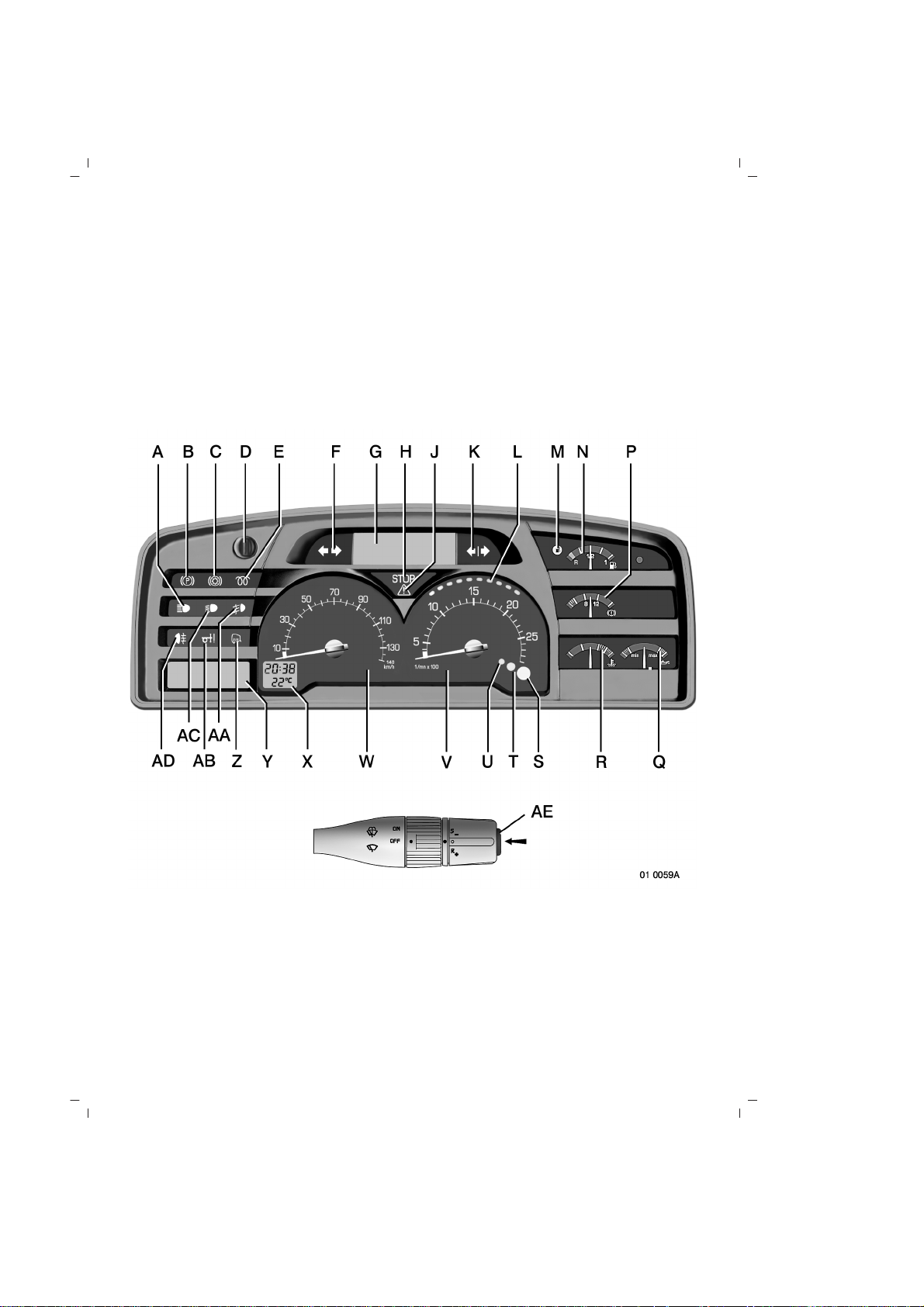

DASHBOARD

A – Main beam headlights warning light

B – Parking brake warning light

C – Electric retarder warning light

D – Menu selection control

E – Preheating warning light

F – T ractor direction indicator lights warning light

G – Multi–function display (see page C15 → C30)

H – “DANGER” warning light: immediate stop

J – “SERVICE” warning light: drive to your dealer or nearest approved agent

K – Trailer direction indicators warning light

L – Engine operating speed zone

M – Fuel minimum reserve warning light

N – Fuel level gauge

P – Air pressure gauge

Q – Engine oil level and pressure gauge

R – Engine cooling system temperature gauge

S – Engine overspeed warning light

T – Engine brake in operation warning light

U – Engine–brake pre–selection and in operation warning light

V – Rev counter

W – Speedometer

X – Comfort display:

. clock

. external temperature indicator

Y – Radio display

Z – Windscreen defrosting warning light

AA – Fog driving lights warning light

AB – Electronic air suspension “Information” warning light

– Axle load shedding “Information” warning light

AC – Dipped beam headlights warning light

AD – Rear fog lights warning light

AE – Driving information selection button

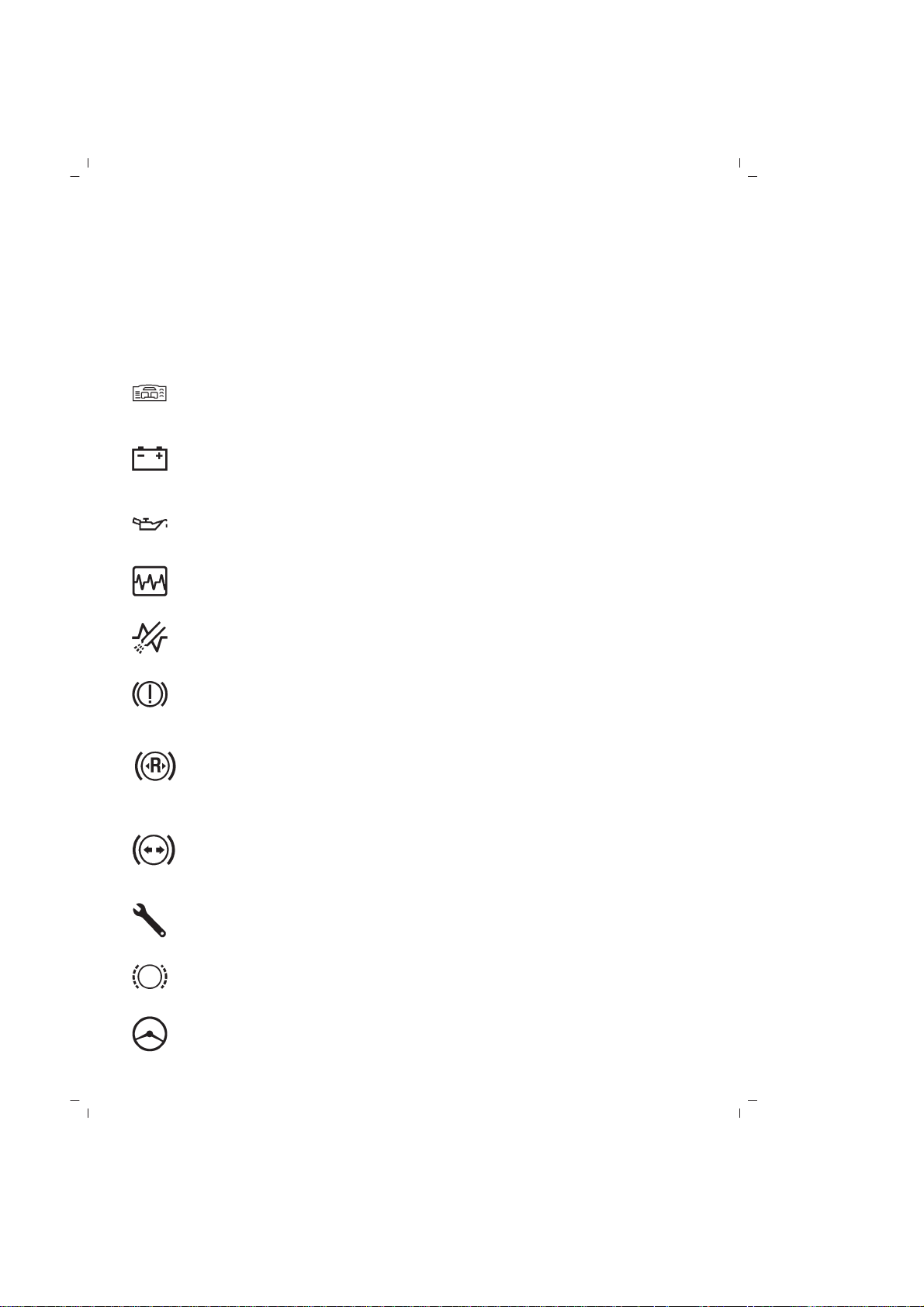

C6 use of the vehicle

MUL TI–FUNCTION DISPLAY

Key to illuminated warning pictograms

Depending on your vehicle’s equipment

G1 – Display defect

G2 – Batteries:

. small pictogram: complementary information

. large pictogram: charging defect

G3 – Engine oil pressure

G4 – Vehicle electronics

G5 – Engine electronics

G6 – Minimum air pressure “Alert”

– EBS defect

G7 – Trailer “ABS/EBS”:

. small pictogram: check–out of device upon ignition switch–on

(no defect)

. large pictogram: device defect “alert”

G8 – Tractor “ABS/EBS”:

. small pictogram: check–out of device upon ignition switch–on

(no defect)

. large pictogram: device defect “alert”

G9 – Maintenance alert

G10 – Brake pads wear

G11 – Servo steering oil insufficient level or pressure defect

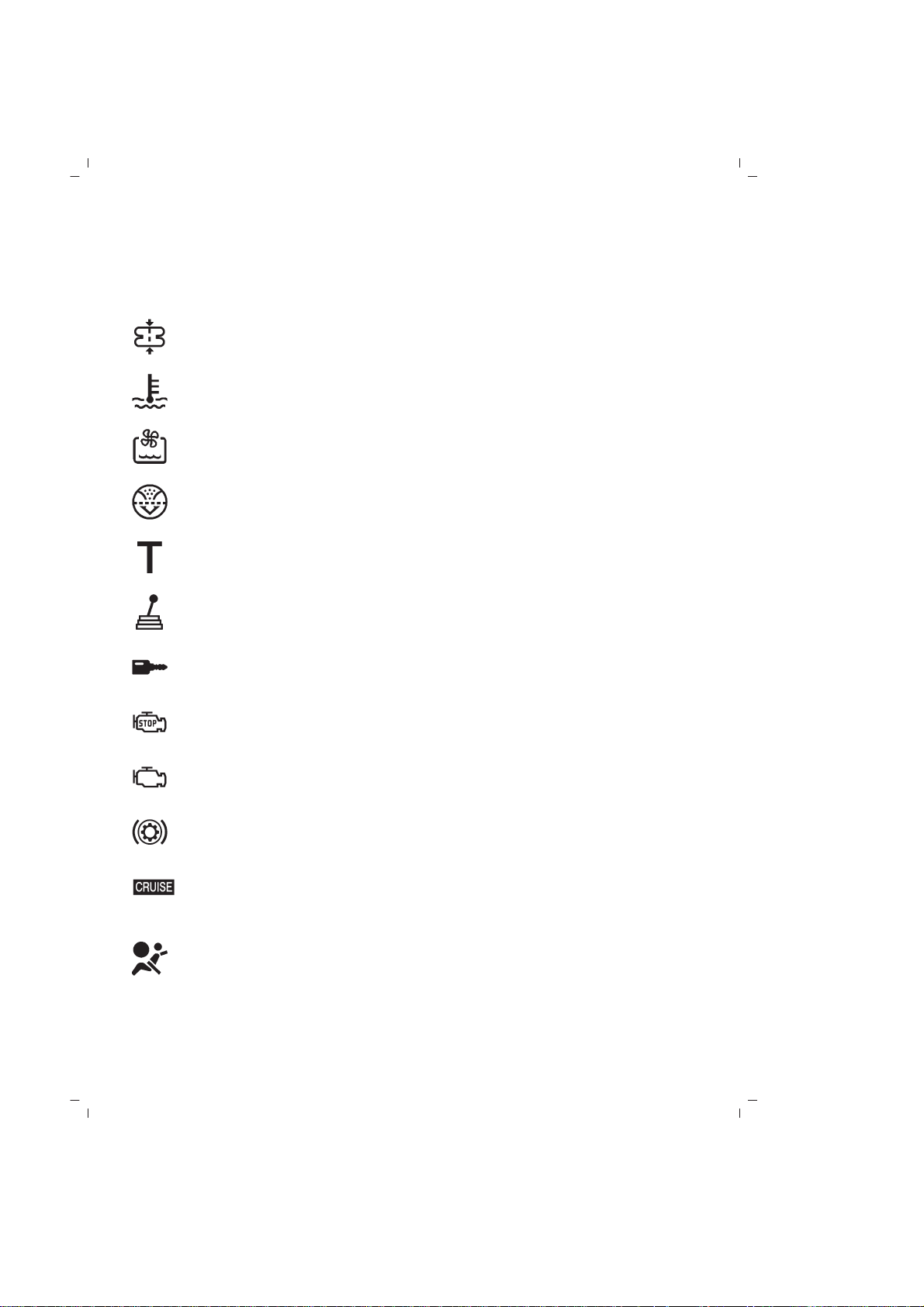

C7 use of the vehicle

Key to illuminated warning pictograms

Depending on your vehicle’s equipment

G12 – Electronic air suspension “Alert”

G13 – Engine cooling system temperature “Alert”

G14 – Engine coolant low level

G15 – Air filter clogging and/or fuel filter clogging

G16 – Tachograph defect

G17 – Gearbox defect

G18 – Electronic anti–theft defect

G19 – Engine overspeed

G20 – Engine downrated (fall–back mode)

G21 – Retarder defect

G22 – Cruise control activated

G23 – AIRBAG

. small pictogram: check–out of device upon ignition switch–on

(no defect)

. large pictogram: device defect “alert”

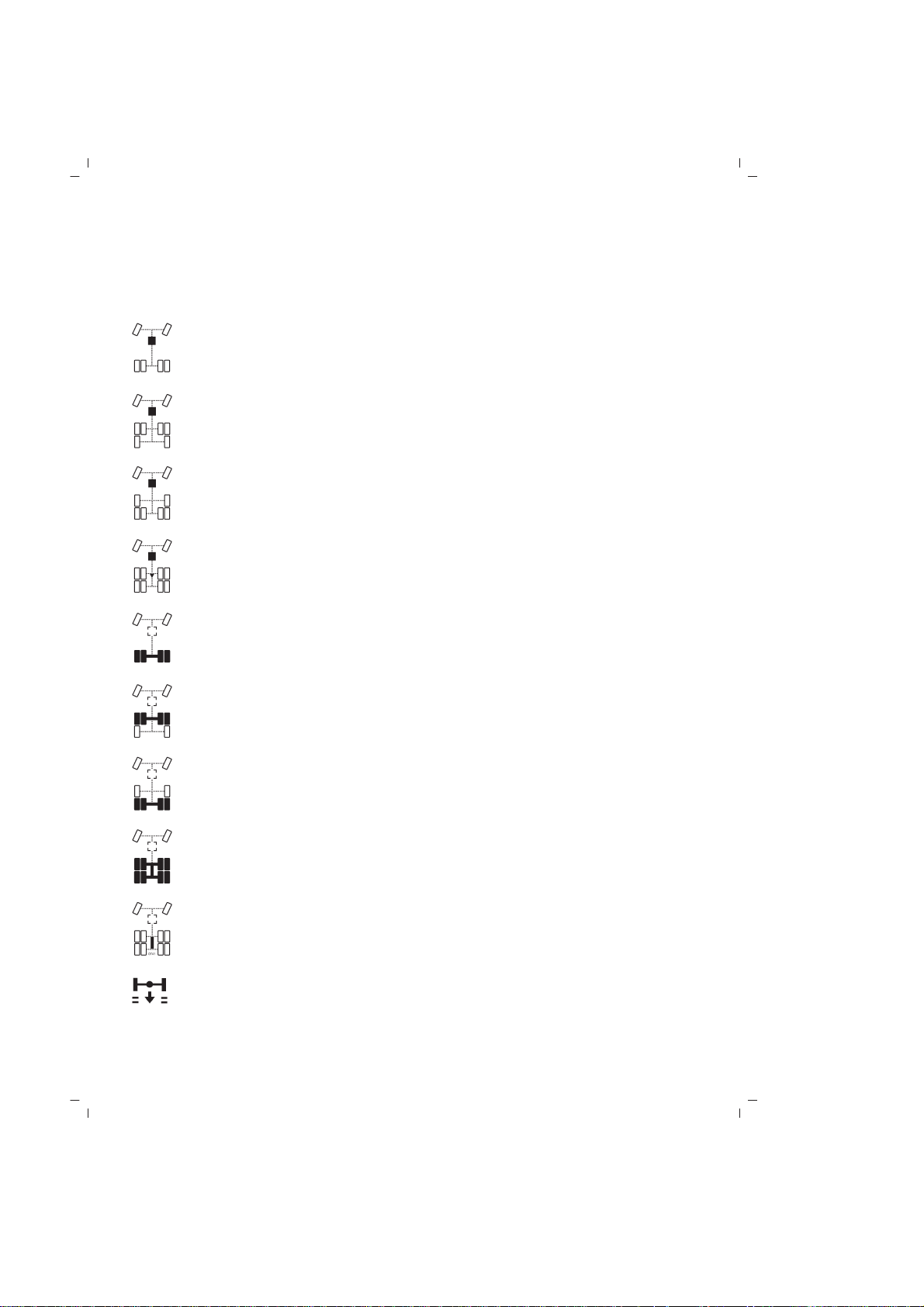

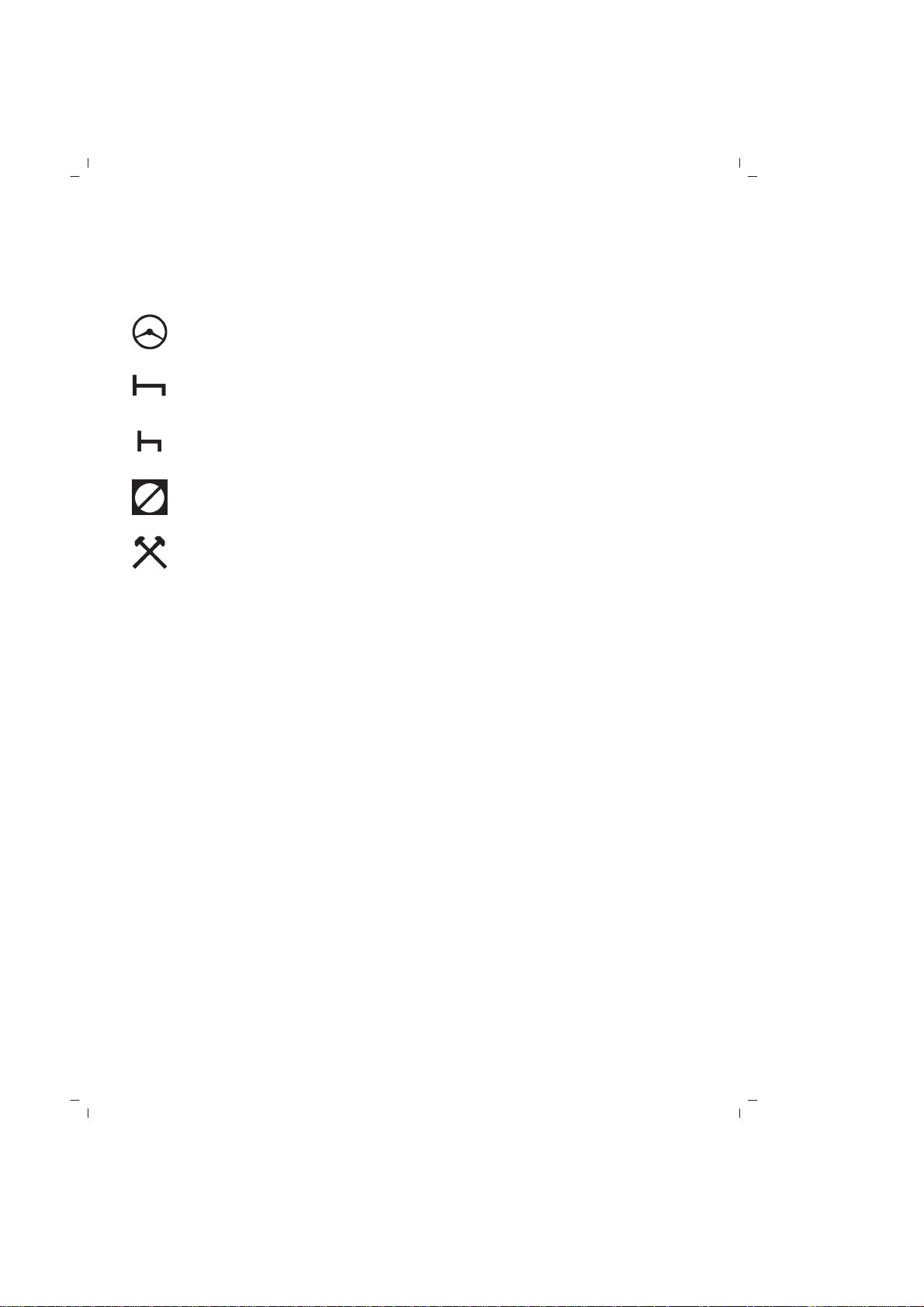

C8 use of the vehicle

Key to illuminated warning pictograms

Depending on your vehicle’s equipment

G24 – Gearbox PTO in operation

G24 – Gearbox PTO in operation

G24 – Gearbox PTO in operation

G24 – Gearbox PTO in operation

G25 – Inter–wheel diff. lock in operation

G25 – Inter–wheel diff. lock in operation

G25 – Inter–wheel diff. lock in operation

G25 – Inter–wheel diff. lock in operation

G26 – Inter–axle diff. lock in operation

G27 – Wheel slip or “ASR” in operation

C9 use of the vehicle

Key to illuminated warning pictograms

Depending on your vehicle’s equipment

G28 – “ASR” threshold change

G29 – Self–tracking axle lock in operation

G30 – Working spotlight

G31 – Tailgate in dangerous position

G32 – T ipper raised “Information”

G33 – Special machine (tanker handrail) deployed

G34 – Sideboard open

G35 – Crane / tower platform deployed

G36 – Message received (fleet management)

G37 – Centralized lubrication in operation

C10 use of the vehicle

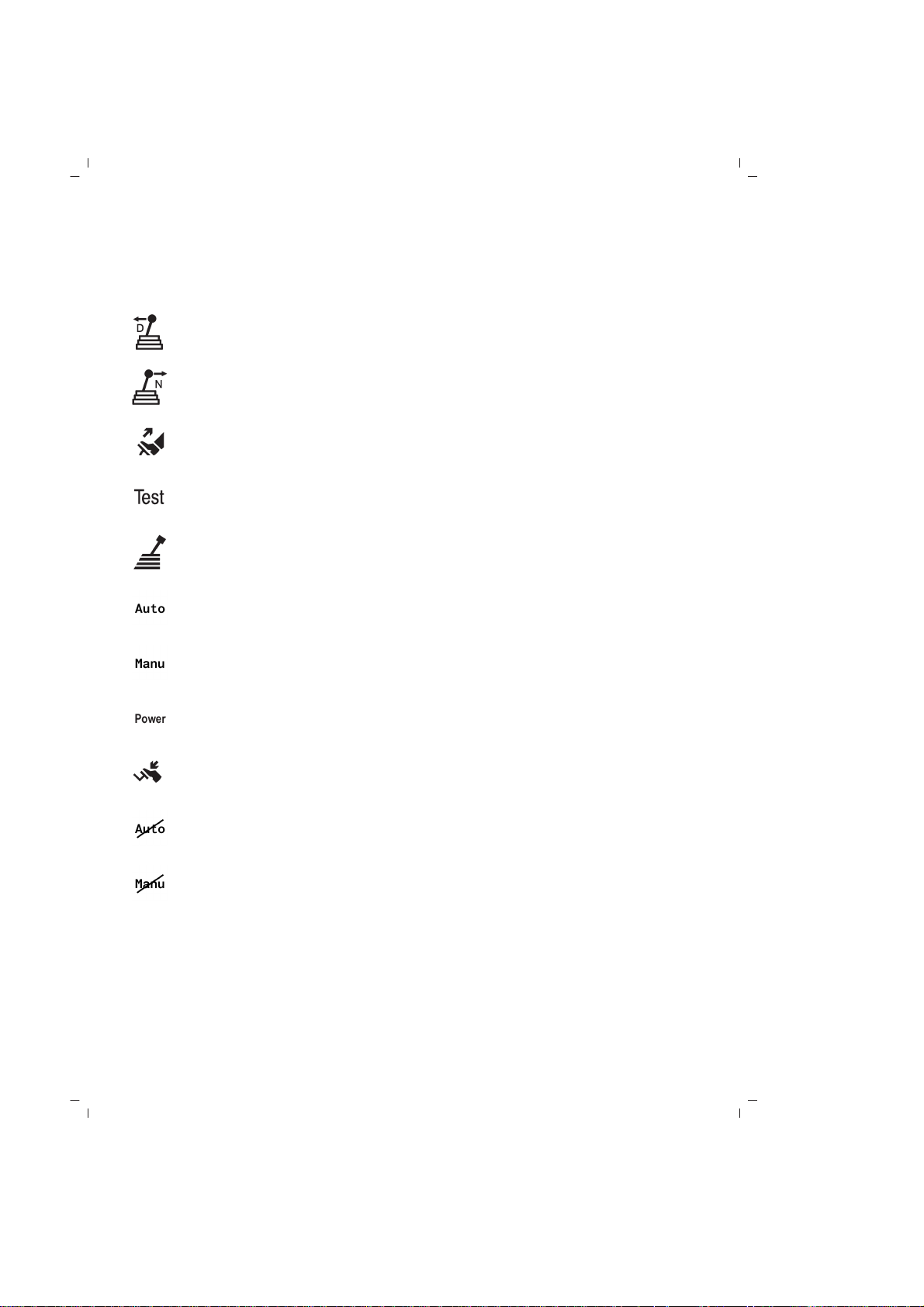

Key to gearbox warning pictograms

Depending on your vehicle’s equipment

G38 – ASTRONIC selector moved to (D)

G39 – ASTRONIC selector moved to (N)

G40 – ASTRONIC accelerator pedal released

G41 – ASTRONIC test

G42 – “ASTRONIC” gearbox defect

G43 – OPTIDRIVER: “integral automatic mode”

G44 – OPTIDRIVER: “permanent or temporary manual mode”

G45 – OPTIDRIVER: “maximum vehicle mobility”

G46 – OPTIDRIVER: “use brakes or retarders”

G47 – OPTIDRIVER: “automatic mode unavailable”

G48 – OPTIDRIVER: “manual mode unavailable”

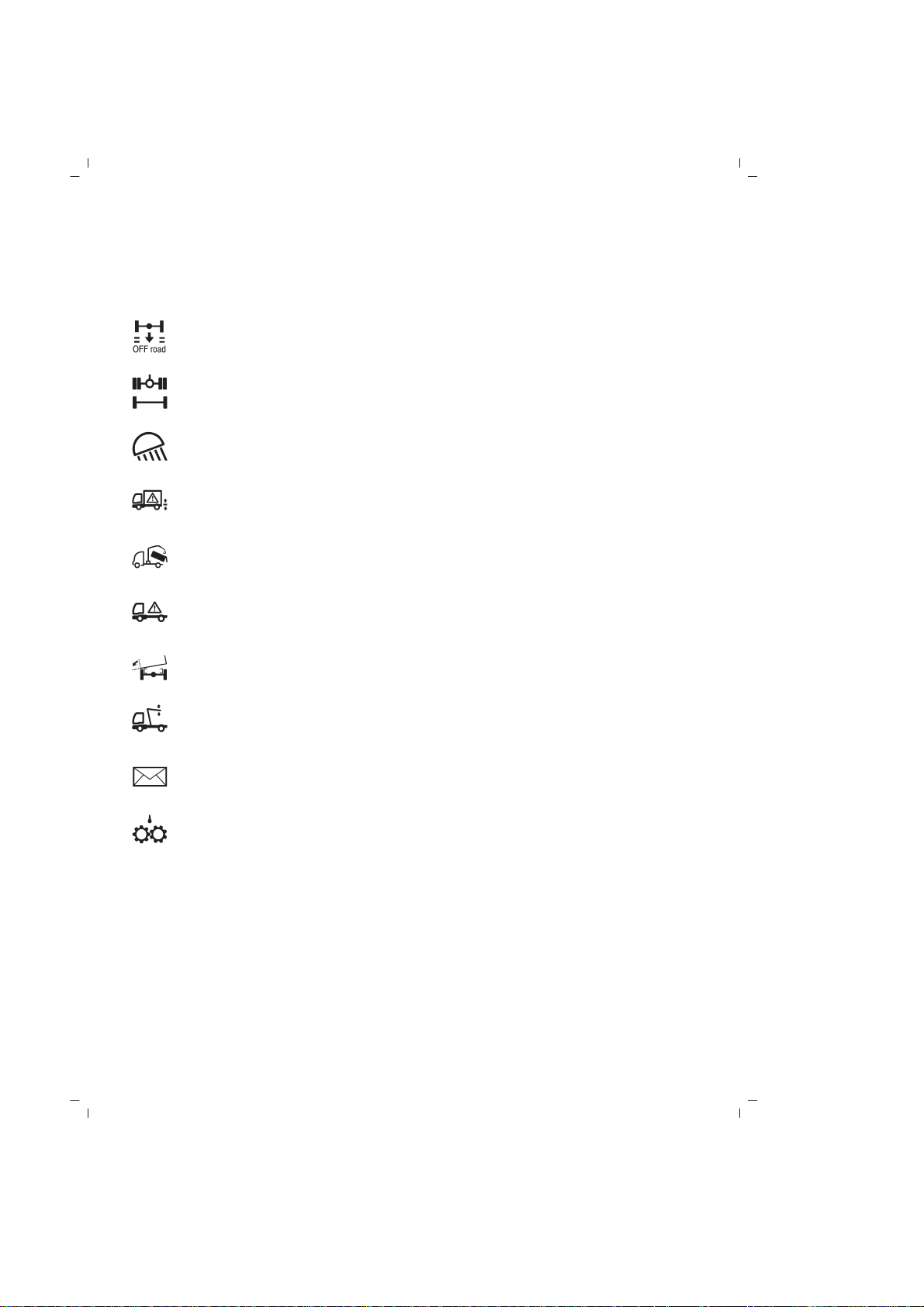

C11 use of the vehicle

Key to tachograph tell–tale pictograms

Depending on your vehicle’s equipment

G49 – Cumulated driving time indication

G50 – Cumulated rest time indication

G51 – Rest in progress indication

G52 – Availability time indication

G53 – Working time indication

C12 use of the vehicle

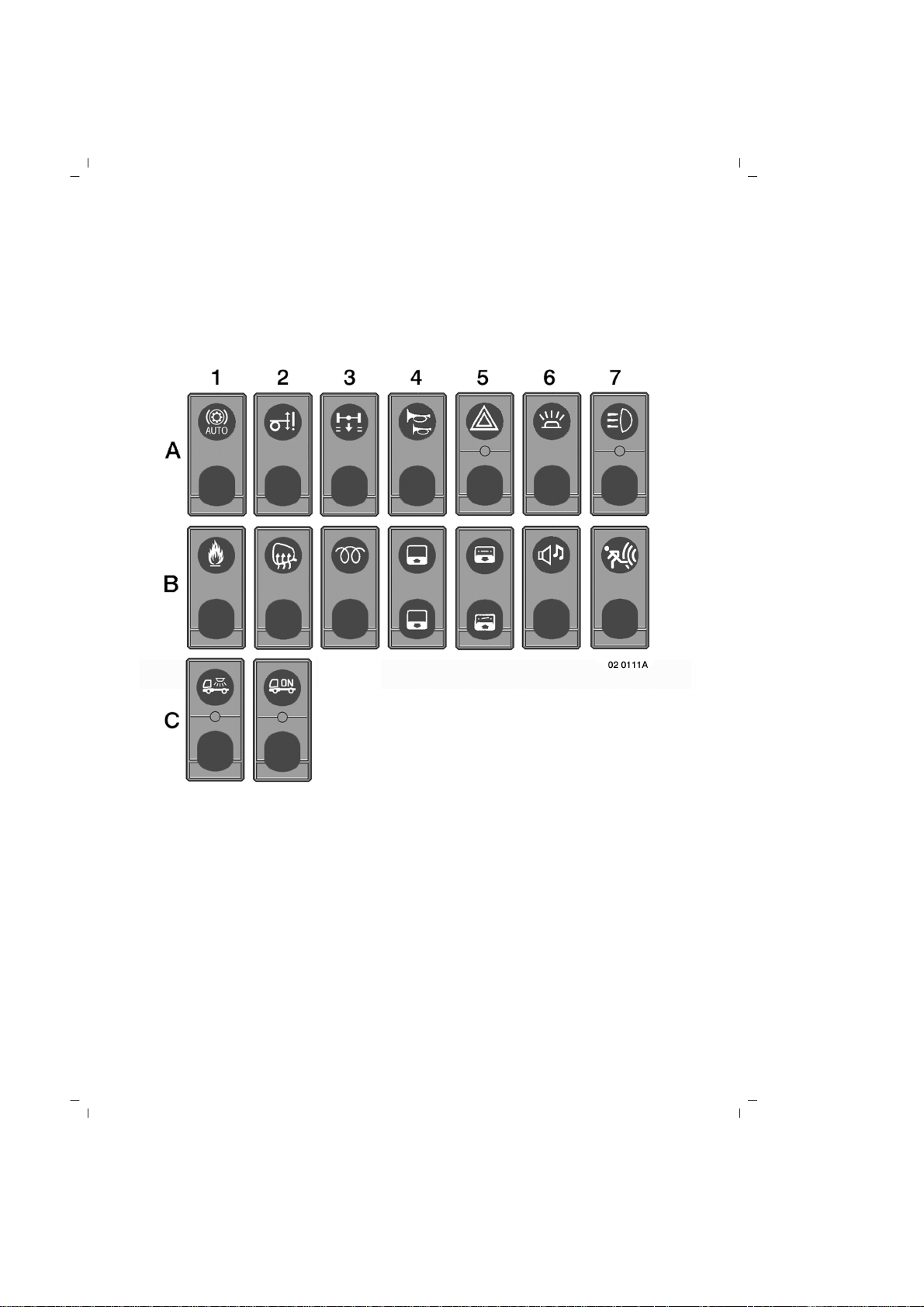

C13 use of the vehicle

KEY TO SWITCHES

Depending on your vehicle’s equipment

A1 – Retarder control (manual / automatic)

A2 – Axle load shedding switch

A3 – “ASR” switch

A4 – Horns selection switch

A5 – Hazard lights control

A5 – Hazard lights warning light

A6 – Roof light switch

A7 – Long beam driving lights switch

A7 – Long beam driving lights warning light

B1 – Independent heating switch

B2 – Rearview mirrors and heated windscreen switch

B3 – Engine preheat switch

B4 – Front sun visor control

B5 – Sun–roof switch

B6 – Cab rear radio power switch

B7 – “Panic” alarm button

C1 – Bodybuilder’s lighting switch

C1 – Bodybuilder’s lighting warning light

C2 – Bodybuilder’s equipment control

C2 – Bodybuilder’s equipment warning light

Loading...

Loading...