Page 1

REMKO

WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Operation - Technology - Spare parts

Edition GB –B09

Page 2

Page 3

Contents

Safety notes

Environmental protection and recycling

Warranty

Intended use

Transportation and packaging

Unit description

Operation

Troubleshooting and customer service

Installation

Commissioning

Changing the battery

System bus

Technical data

4

4

4

4

4

5

5-25

26-27

28

28

29

29

30

Made by REMKO

Read these operating instructions carefully before commissioning/

using the unit!

These instructions are an integral part of the unit and must always be

kept in the vicinity of the installation location or on the

unit itself.

This operating manual is a translation of the German original.

Subject to modifications; no liability accepted for errors or misprints!

3

Page 4

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Safety notes

Carefully read the operating

instructions before commissioning

the unit for service. It provides

useful tips and information as

well as hazard warnings to prevent

injury or material damage .

Failure to follow the directions

in this manual can endanger

persons, the environment and

the equipment itself and will void

any claims for liability.

■ Keep this manual close to

the equipment.

■ Modification of the units

and components supplied

by REMKO is not permitted and

can cause malfunctions.

■ Operating equipment

or components with obvious

defects or damage is not

permitted.

■ Do not operate units or

components if there are obvious

defects or signs of damage.

■ Repairs may only be carried out

by authorised personnel, while

cleaning may be carried out by

the operating company.

■ The units or components

are not to be exposed to

any mechanical stresses,

extreme levels of humidity

or direct sunlight.

Environmental

protection

and recycling

Disposing of packaging

All products are packed for

transport in environmentally

friendly materials. You can make

a valuable contribution to reducing

waste and sustaining raw materials

by only disposing of packaging at

approved collection points.

Disposing of the units

and their components

Only recyclable materials are used

in the manufacture of the units

and components.

Help protect the environment

by ensuring that the units

or components (for example

batteries) are not disposed of in

household waste, but only in

accordance with local regulations

and in an environmentally safe

manner, e.g. using authorised

disposal and recycling specialists or

council collection points.

Warranty

The precondition for all warranty

claims is that the orderer or his

customer has fully filled out the

"warranty registration card"

supplied with the unit, at the

time when it was purchased and

commissioned, and returned it to

REMKO GmbH & Co. KG.

The warranty conditions are

listed in the "General terms and

conditions". Furthermore, only the

parties to a contract can conclude

special agreements beyond these

conditions. For this reason, please

contact your contractual partner

first.

Intended use

The purpose of the units is

the entry and display of system

parameters for the Multitalent heat

pump manager.

Any different or additional

use is a non-intended use.

The manufacturer/supplier assumes

no liability for damages arising from

a non-intended use. The user bears

the sole risk in such cases.

Intended use also includes working

in accordance with the operating

and installation instructions and

complying with the maintenance

requirements.

Transport and

packaging

The units are shipped in sturdy

transport packaging. Immediately

check the units on delivery and

make a note of any damage or

missing parts on the delivery note.

Inform the forwarding agent and

contractual partner. Warranty

claims at a later date will not be

accepted.

4

Page 5

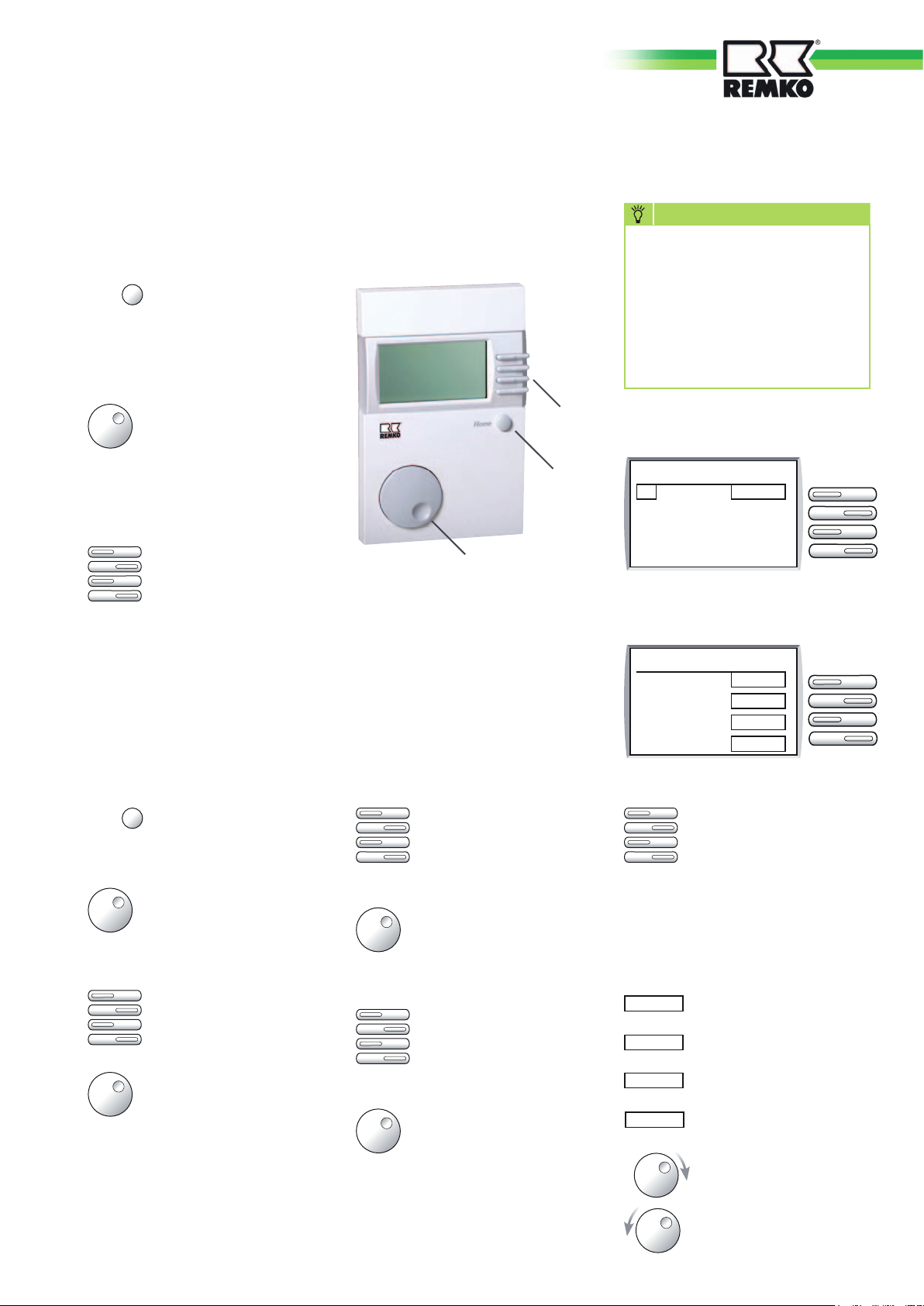

Unit description

The wireless remote control allows

the Multitalent heat pump manager

to be regulated by weather

conditions or room temperature.

It makes it possible for the owner

to easily input and view system

parameters (e.g. time, current hot

water target temperature) and

heating circuit parameters (e.g.

heating times and desired room

temperature) from their living

space. This allows the heating

system to be regularly monitored

and optimised.

With the wireless remote control, it

is also possible to make a correction

to the weather-driven control

system by means of a roomtemperature-controlled cutout.

Operation

After inserting the batteries, the

Installation menu appears once

only. After adjusting the values

contained on the menu, the

controller is ready for operation.

If the menu appears later, e.g.

after a power cut, the function can

simply be exited.

Installation is initiated by

pressing “OK” (see the chapter

“Installation”).

Installation can be cancelled by

pressing “Cancel”.

C

B

A

Controls during

normal operation

The wireless remote control is

controlled with the following keys.

The rotary knob (A)

can be used to toggle

between the displayed

menu points or to change

the settings.

Pressing the Home key

Home

(B) always returns you to

the standard display.

Each of the four function

keys (C) stands for one

of the four rows on the

display. Pressing an F-key

serves to select a menu

item or setting.

NOTE

The current heating

programme and hot water

programme for the room

controller are permanently

displayed on row [2] of

the Favourites menu.

The associated heating circuit

number of displayed in

brackets. You can program all

the other favourites yourself.

NOTE

Due to the tolerances

of the sensors, deviations of

+/- 2K (2°C) between different

temperature indicators are

normal. In the case of rapid

temperature changes, these

deviations will intermittently

be higher due to the differing

time response of different

sensors.

Display / function keys

The standard display of the

wireless remote control of the

heat pump manager is comprised

of four rows.

Mon 08:3030 Mar 09

0

Room temp.

Standby

12 24

1

(1)

20.5 °C

External

Row 1: This displays the day of the

week, the date and time.

By pressing the F-key you can

adjust the date, time and holidays.

Row 2: Display the favourites.

You can select from the currently

displayed favourites with the

rotary knob (A).

By pressing the F-key you can

adjust the Favourites or the

additional indicator.

The following predefined options

are stored:

- Hot water programme

- Heating programme (HC number)

- Outdoor temp.

- HA temp.

- HW temp.

- Supply temp.

- Enable heating circuit

- HW demand

- Burner 1

Row 3: Room temperature

indicator.

Pressing the F-key allows you

to adjust the selected room

temperature.

Row 4: Displays the operating

mode and the current situation

(Heating, Reduction, Party, eco or

Holiday).

By pressing the F-key, you can

adjust the operating mode and

select the Party, Reduction, or

Holiday function (this applies to all

internal heating circuits).

NOTE

Deviations in the respective

parameters can no

longer be displayed after

the wireless remote control is

commissioned.

5

Page 6

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

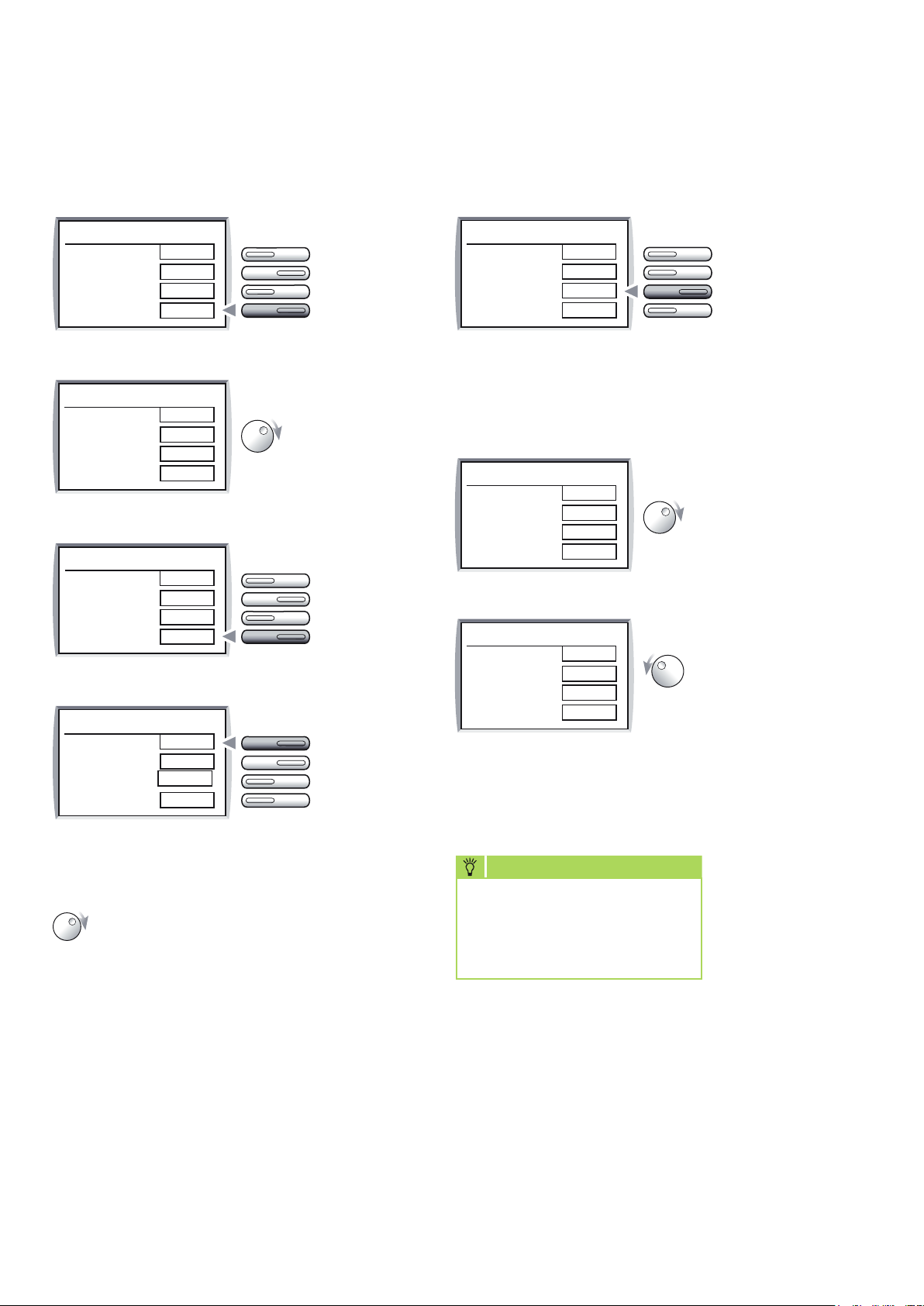

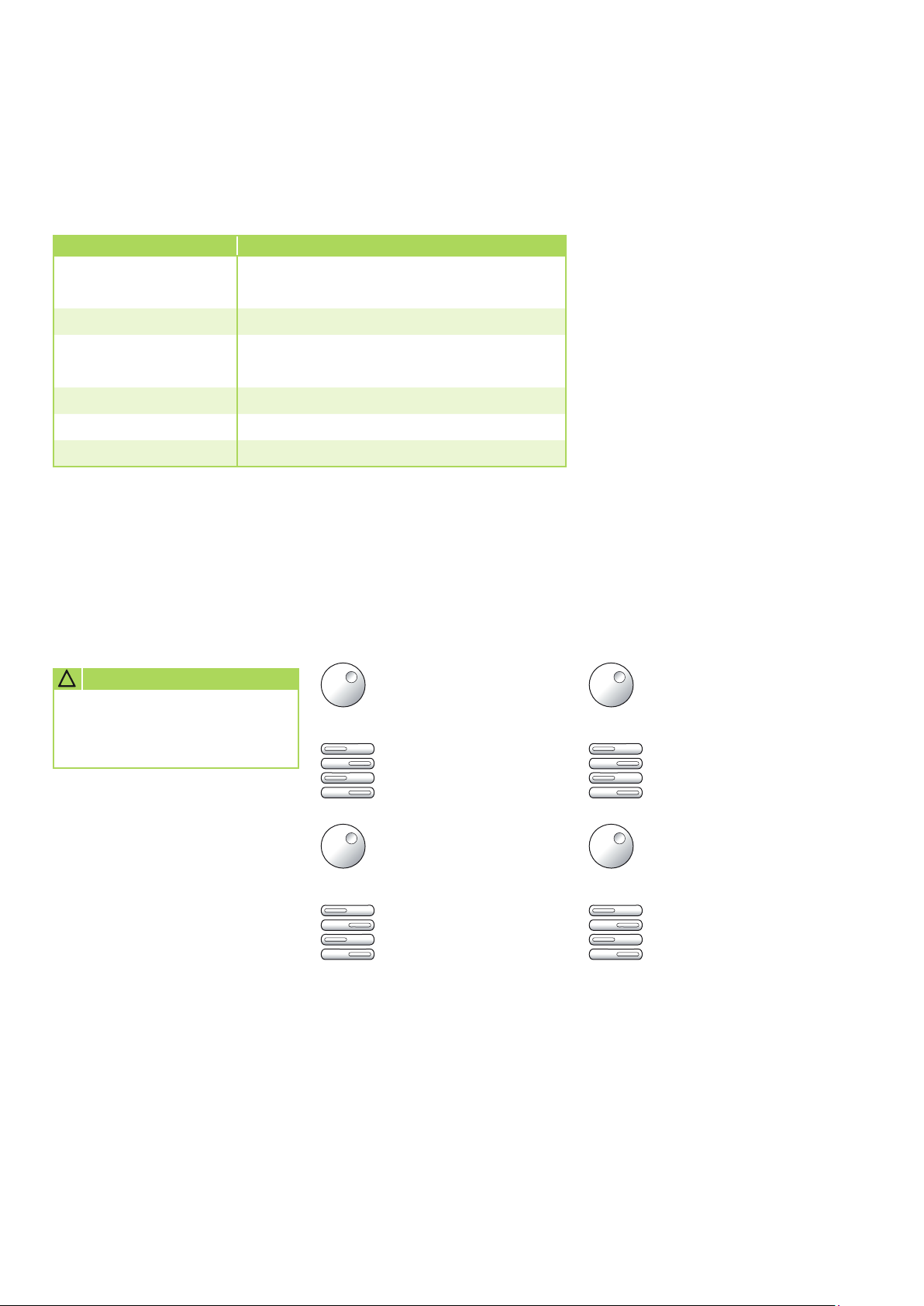

Setting the operating mode

Operating mode

Cancel

Automatic 1

Party

Reduction

OK

Operating mode

Cancel

Automatic 1

Party

Reduction

OK

Operating mode

Cancel

Automatic 1

Party

Reduction

OK

Operating mode

Cancel

Automatic 1

Party

Reduction

OK

During normal

operation, press

the F-key next

to “OK”.

Set the desired

operating mode

with the rotary

knob.

The selected

mode is

confirmed

and saved by

pressing the

F-key next to

“OK”.

The action

is cancelled

without saving

by pressing the

F-key next to

“Cancel”.

Setting the Party, Reduction, and

“Immediate Holiday” function

Pressing the

Operating mode

Cancel

Reduction

01 h 00 min

Party

Reduction

OK

F-keys next

to “Party”

(heating time

extension) or

“Reduction”

(heating time

interruption)

selects the

corresponding

operating mode.

Operating mode

Cancel

Reduction

01 h 00 min

Party

Reduction

OK

Operating mode

Cancel

Reduction

05 days

Party

Reduction

OK

Turning the

rotary knob

clockwise sets

the hours.

Turning the

rotary knob

clockwise sets

the hours.

This makes it easy to quickly raise or reduce

the heating temperature for the rest of the day,

or to set a holiday programme starting immediately

(e.g. Reduction 5 days).

Overview of the operating modes

When an operating mode is selected, it is shown

on the screen. It takes effect once the setting

has not been modified for 5 seconds.

You can choose from the following operating modes:

Standby / OFF

(Heating OFF and Water

heating OFF, Frost

protection function only)

Automatic

operation 1

(Heating acc. to Time

programme 1; HW acc.

to HW programme)

Automatic

operation 2

(Heating acc. to Time

programme 2; HW acc.

to HW programme)

6

NOTE

Eco Comfort switchover: occurs at <> 1 K from target

room temp. to actual room

temp.

Summer operation

Heating/

Eco Comfort

Heating/

Reduction

(Heating OFF, HW acc.

to HW programme).

(24h heating with Comfort

temperature 1, HW acc. to

HW programme)

(24h heating with Reduction

temperature, HW acc. to

HW programme)

Page 7

Controls in operating mode

The wireless remote control used to regulate the heat pump manager

is controlled in operating mode with the following keys.

Home

Pressing the Home

key (B) takes you from

operating the controller

to normal operation

(standard display)

Using the rotary knob

C

(A), you can move

through the menus,

move through settings/

B

parameters, or adjust

the selected value.

Each of the four function

keys (C) stands for one

A

of the four rows on the

display. Pressing an

F-key selects the adjacent

menu, value or function.

NOTE

If a parameter, a function/

display or a parameter menu

is not supported by the

connected heating circuit

controller, it is hidden or this

is indicated on screen with

dashes.

Display in operating mode

Main menu

01

Display

User

Time programmes

Cancel

Display during value entry

Target room temp. 1

20.0 °C

Cancel

Favourite

Default

OK

Basic operating procedure

Home

Pressing the Home key

takes you to operating

mode.

Move through the menu

items (types of setting)

with the rotary knob,

e.g. Display, User, etc.

Use the corresponding

F-key to select the item

you chose above.

With the rotary knob,

choose a sub-menu (Appliance / Consumer),

e.g. System (heating

appliance), Hot water,

Heating circuit.

Use the corresponding

F-key to select the submenu you chose above,

e.g. Hot water.

Choose the setting/display value with the rotary

knob. The current value

is displayed.

Use the corresponding Fkey to select the setting/

display value you chose

above.

Use the rotary knob to

change the setting.

Select the function with

the corresponding F-key.

Confirm the change

or cancel by pressing

“Cancel”, “Favourite”,

“Default” or “OK”

The function keys perform the

following roles:

Cancel

Cancel the current

function without saving

Favourite

Carry over setting to

Favourites menu

Default

Change setting value to

factory setting

OK

Cancel the current

function and save

Next setting (e.g. time:

Hour->Minute)

Previous setting (e.g.

date: Month<-Year)

7

Page 8

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

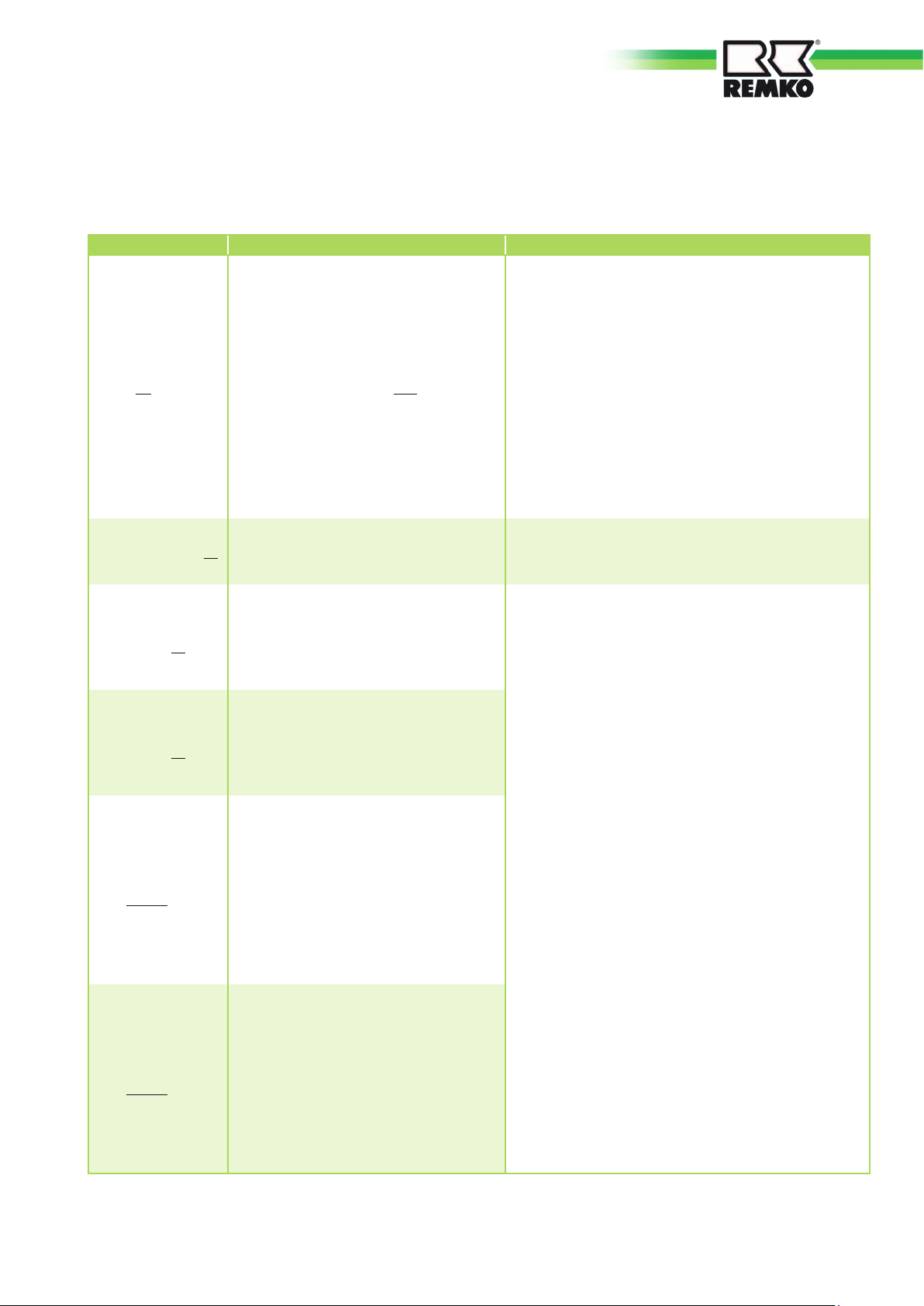

Overview of the operating menus

Menus Description Sub-menus Description

System

All display values and settings relating to the heating

appliance or the system as a whole, or which cannot

be assigned to another consumer circuit.

Display

User

Time

programme

Displays system values

(e.g. sensor and target values).

Adjustment is not possible.

This means that operating errors

in this menu are not possible.

Summary of settings that can be

adjusted by the operator.

Summary of the time

programmes for the heating

circuits, the hot water circuit

and additional functions, as

applicable

Hot water

Heating circuit 1/2

Solar / MF

System

Hot water

Heating circuit 2

Heating circuit x

Prog 1

Heating circuit x

Prog 2

Hot water

Time Set hour

All internal display values and settings of the controller,

relating to water heating.

All display values and settings relating to the associated

consumer circuit (even as a decentralised hot water

circuit, for example).

All display values and settings relating to solar energy

generation and setting the multifunction relay.

All display values and settings relating to the heating

appliance or the system as a whole, or which cannot

be assigned to another consumer circuit.

All internal display values and settings of the controller,

relating to water heating.

All display values and settings relating to the associated

consumer circuit (even as a decentralised hot water

circuit, for example).

All display values and settings relating to the associated

consumer circuit (even as a decentralised hot water

circuit, for example).

All display values and settings relating to the associated

consumer circuit (even as a decentralised hot water

circuit, for example).

All internal display values and settings of the controller,

relating to water heating.

Time

Date

Service

Specialist

Time, date, holiday programme

and data on daylight savings

time

Summary of the values for

service technicians

Summary of the values which

require a specialist to adjust

them (installer).

Values in the Specialist menu

are protected by a code no.

(damage/operating errors

possible)!

Date Set date

Start holiday Set date for start of holiday period

End holiday Set date for end of holiday period

Start daylight savings Set date for start of daylight savings time

End daylight savings Set date for end of daylight savings time

Software number Software number with index

Reset user Reset all user parameters to factory settings

Reset specialist Reset all specialist parameters to factory settings

Reset time

programme

Communication KM Heating appliance on the bus

Communication MM Mixer module on the bus

System

Heating circuit

Reset all time programmes to factory settings

All display values and settings relating to the heating

appliance or the system as a whole, or which cannot

be assigned to another consumer circuit.

All display values and settings relating to the associated

consumer circuit (even as a decentralised hot water

circuit, for example).

On the following pages you will find detailed descriptions of the different menus and their parameters.

8

Page 9

Display menu

This menu only activates the display itself. No adjustments can be made here. The values are only shown if the

sensor is connected or the values are available, otherwise “----” or nothing are displayed.

You can leave the menu by pressing “Cancel”.

System

The parameters are selected using the rotary knob.

(HA = heating appliance)

Parameter Function Comments

Outdoor temp. Displays the outdoor temperature

Actual/Target HA

temp.

Modulation

Burner 1 Burner relay 1 status (On/Off)

Burner 2 Burner relay 2 status (On/Off)

Error Error number; 00 = no errors

Temperature of the heating appliance

Modulation depth of the heating appliance

(bus)

The measured outdoor temperature is smoothed for

the controller. The smoothed value is displayed here.

After pressing the F-key, the target value appears.

The target value corresponds to the highest temperature

requested of the heating system by the consumer circuits

(incl. water heating). The mixer circuits request your

required temperature + heating curve distance (specialist

value)

Only if a modulating heating appliance is connected via

a bus and is transmitting values.

Hot water

Parameter Function Comments

Actual/Target HW

temp.

Current hot water temperature and current

target hot water temperature depending on

heating programme and operating mode

Display of the measured upper tank temperature

Lower HW temp. Lower HW tank temperature (infeed/solar)

HW demand

HW pump

Enable HW

Demand for water heating

On => Temperature not reached

Operation of hot water charging pump

On => e.g. after charge pump lock

Enable water heating

On => Enable according to time programme

Lower tank temperature

Only if a sensor is connected for the lower tank and

the charging function is activated

Hot water status indicator

Hot water status indicator

Hot water status indicator

9

Page 10

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Heating circuit 1/2

Parameter Function Comments

Actual/Target room

temp.

Actual/Target supply

temp.

Enable heating circuit Heating circuit in heating mode (On/Off) Heating circuit status indicator

Heating circuit pump Heating circuit pump status (On/Off) Heating circuit status indicator

R. warm-up time

Current room temperature according to

heating programme and operating mode

Current supply temperature and

current target supply temperature

Last required warm-up time

with warm-up optimisation activated

Room temperature and target room temperature

For mixed heating circuits only

Display of the last required warm-up time

Solar / MF

The following table only lists parameters for which the corresponding function has both been implemented and

activated

Parameter Function Comments

MF1 temp. Temperature of MF sensor 1

MF2 temp. Temperature of MF sensor 2

MF3 temp. Temperature of MF sensor 3

MF4 temp. Temperature of MF sensor 4

A sensor is allocated to each multifunction relay.

The corresponding value is displayed here. In certain

cases, e.g. if the functions “Solid fuel boiler” or “Collector

pump” are selected, the measured value is also displayed

as the Solid fuel temp. or Collector temp.

Actual/Target HW temp.

Lower HW temp. Lower HW tank temperature (infeed/solar)

Temperature of upper HW tank

10

Page 11

User menu

This menu contains all the settings which can be adjusted by the user of the system.

System

Parameter Value range Default OV*) Comments

Language Depends on variant English Set the language for the controller

LCD contrast (-20) - (20) 04 Set the intensity of the display

LCD brightness Off/On On Switch display backlight ON/OFF

Since the display is the biggest consumer, while it is not

being operated, it switches into a power-saving mode (only

displaying the time and date).

In the interests of saving even more power to increase

battery life, the parameter [LCD Status] will switch off the

display altogether when the controller is in certain states:

LCD status 1 - 5 1

1: Display ON

2: Display ON, with heating programme enabled

3: Display ON, if demand exists for heating

4: Display ON/OFF with time interval (10s OFF/ 5s ON)

5: Display OFF

If a control is operated, the display switches back on

automatically.

*) OV = Own values: space to enter you settings for each parameter in the system

Hot water

Parameter Value range Default OV*) Comments

On => The tank is enabled for charging (e.g. for showering

1x hot water Off/On Off

*) for KM1/6/9 and bus code 00/01 only

outside hot water time periods).

Charge begins when “Target temperature 1” is fallen below

by the switching hysteresis.

11

Page 12

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Heating circuit 2

Parameter Value range Default OV Comments

Target room temp. 1 *) 5°C - 40°C 20°C

Target room temp. 2 *) 5°C - 40°C 20°C

Target room temp. 3 *) 5°C - 40°C 20°C

Reduction temp. *) 5°C - 40°C 15°C Desired room temperature for nighttime heat reduction

Away temp. 5°C - 40°C 15°C Desired room temperature during the holidays

BoB value 0K - 20K 0K

Day heating threshold ----, (-5)°C - 40°C 19°C

Night heating threshold ----, (-5)°C - 40°C 10°C

Adjust the desired room temperature

Target room temp. 1 => operates during the first enable time,

Target room temp. 2 => operates during the second enable time,

Target room temp. 3 => operates during the third enable time

of the heating programme active for this heating circuit.

At a value >0, no burner is permitted to start up, provided that

the room temperature is still above the set target room temperature (BoB value).

This function can be influenced by external,

alternative energy-producing appliances, which have a bus

connection (e.g. SD3 CAN)!

Only applicable if the function is activated => setting

“Specialist/Heating circuit/Pump function = Heating thresholds

=> Pump switching according to heating threshold”

If the outdoor temperature measured and determined by the

controller exceeds the heating threshold set here, the heating

will lock, the pumps shut off and the mixers close. The heating

will be enabled again if the outdoor temperature falls below

the set heating threshold by 1K (= 1°C).

Day heating threshold => operates during heating periods

Day heating threshold => operates during reduction periods

“----” => Heating threshold is deactivated. The circulation

pump is switched in accordance with the default function (see

chapter “Circulation pump switching”)

NOTE

At commissioning, check

the heating circuit curve

setting:

Setting 1.20 to 0.6

12

*) or depending on the function selected in the Specialist => “HC function” sub-menu

for the heating circuit, also

Const. day supply temp. (constant supply temperature, heating periods)

Const. night supply temp. (constant supply temperature, reduction periods)

Page 13

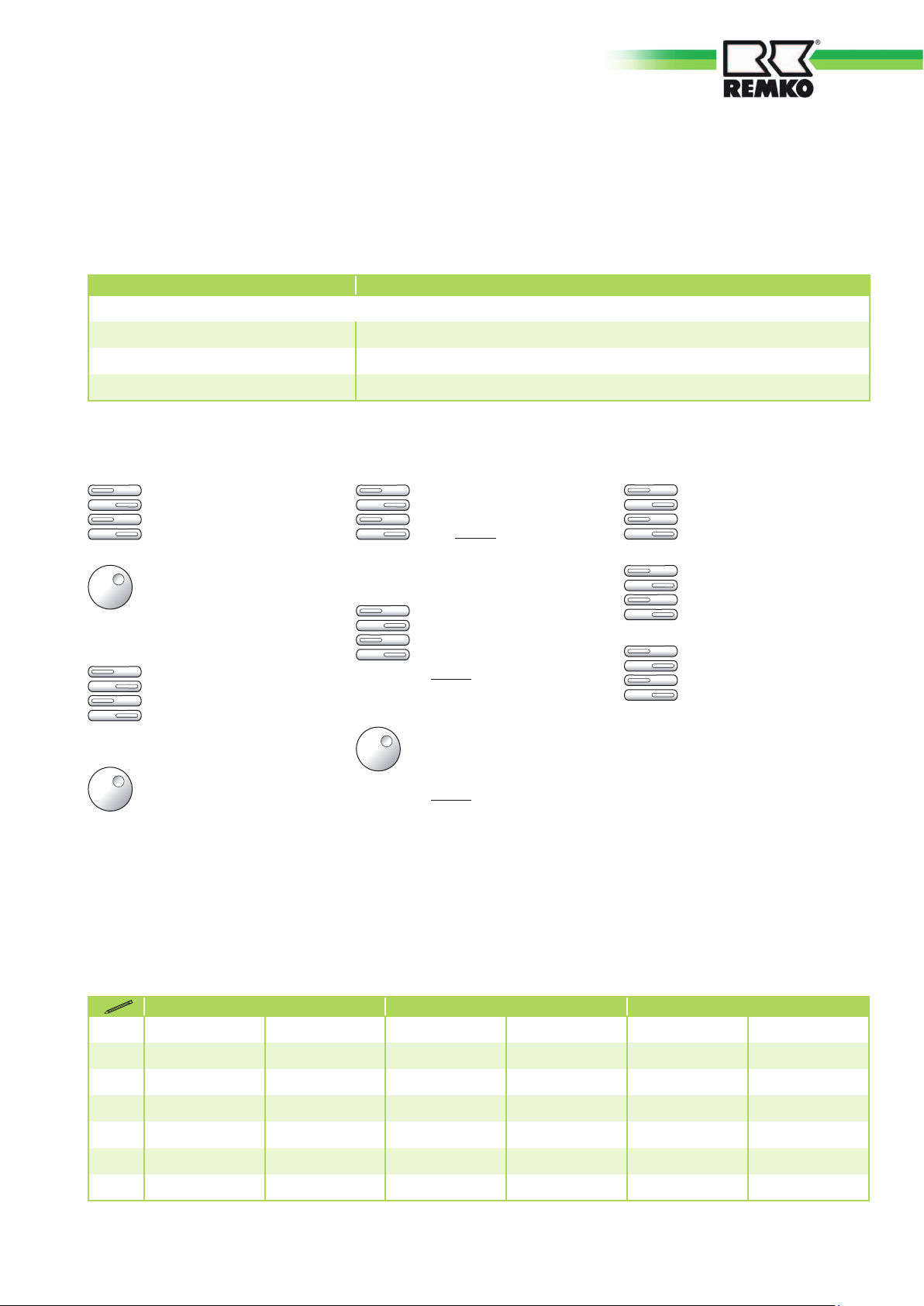

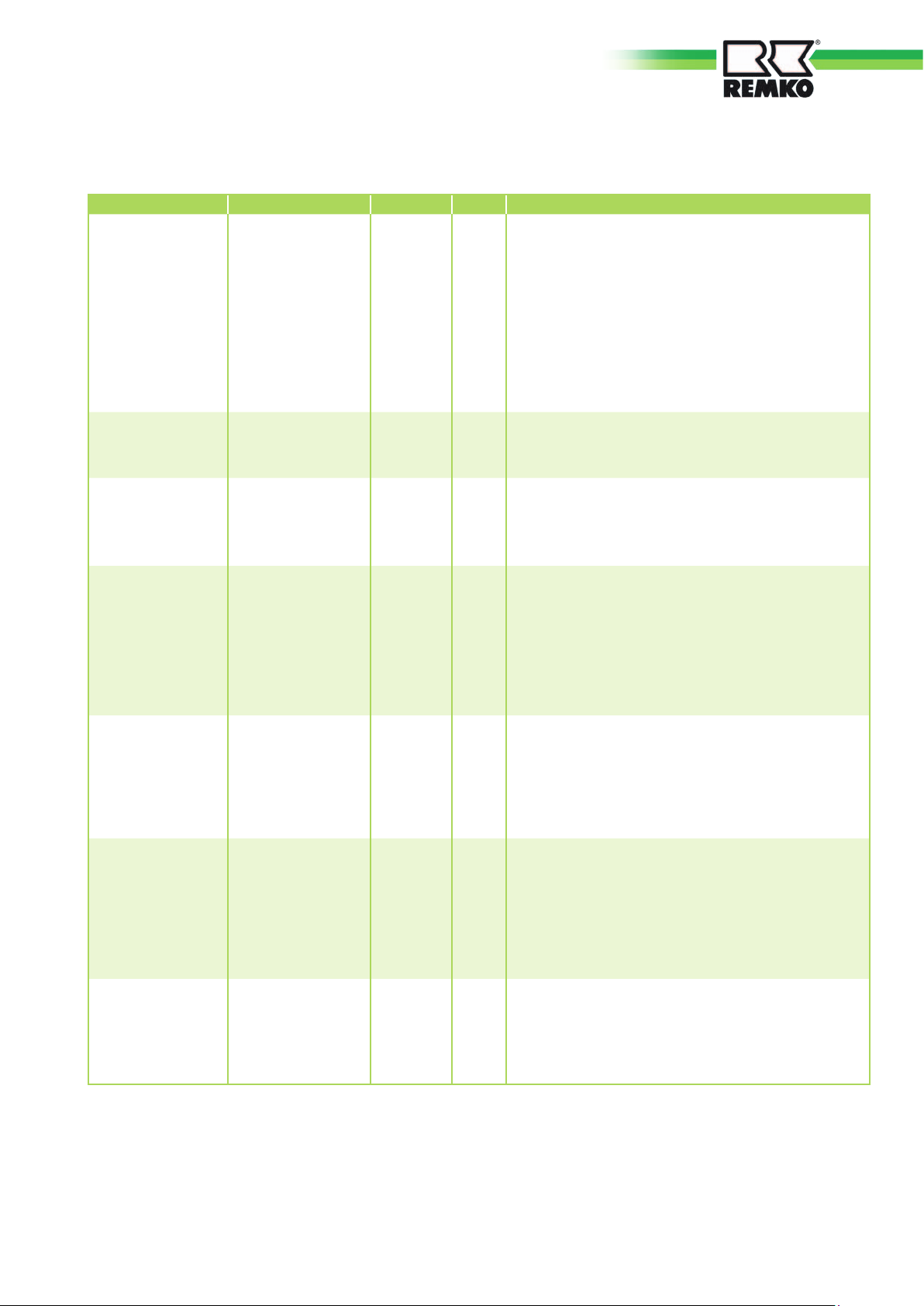

0,2

0,4

0,6

0,811,2

1,5

2

2,5

3

20

40

60

80

100

20 16 12 8 4 0 -4 -8 -12 -16

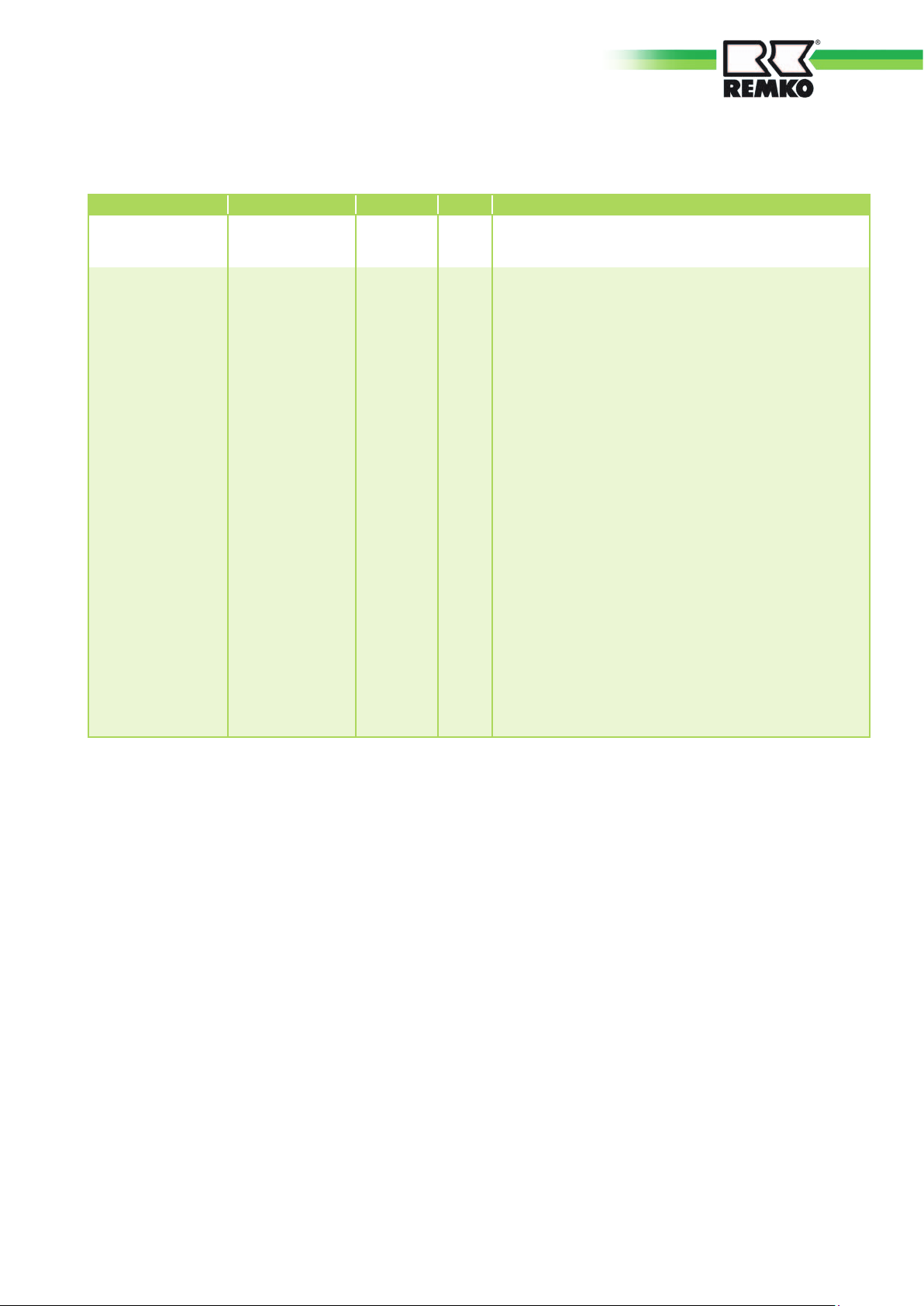

Heating circuit 2 (continued)

Parameter

Value

range

Default OV Comments

Heating curve 0.00 - 3.00 1.20

The curve's slope indicates by how many degrees the supply

temperature will change if the outdoor temperature rises or falls by 1 K.

Information on adjustment:

With cold outdoor temperatures and a low room temperature =>

increase heating curve (and vice-versa)

With high outdoor temperatures (e.g. 16°C) and a low room

temperature => correction using the target room temperature

Heating curve diagram (adjustment aid)

Supply temperature [°C]

Outdoor temperature [°C]

Setting 0 => Purely room-based regulation

The heating curve is best adjusted when the outdoor

temperature is below 5°C. Changing the heating curve setting must

be carried out in small steps and in larger time intervals (at least 5

to 6 hours), because the system must first adjust to the new values

after every change in the heating curve.

Reference values:

- Floor heating S = 0.4 to 0.6

- Radiator heating S = 1.0 to 1.5

Only active when the analogue room device FBR (room sensor +

mode selection) and an outdoor sensor are connected.

Function to automatically set the heating curve

Start-up requirements:

- Outdoor temperature < 8°C

- Operating mode Automatic (I or II)

- Duration of the reduction phase at least 6 hours

The current room temperature is measured at the beginning of the

Heating curve

adaptation

OFF/ON OFF

reduction period. This temperature is used over the following 4 hours

as the target value for room-based regulation. The heating curve

is calculated from the values captured by the controller in this time

period for the target supply temperature and outdoor temperature.

If adaptation is interrupted, e.g. by a start-up unloading device or

the hot water demand of an external heating circuit, the warning

triangle appears on the display until the function has been

successfully performed on the following day or, for example, until

operation is ended by adjusting the operating mode switch.

The controller's water heating and warm-up optimisation functions

are blocked during adaptation.

13

Page 14

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Heating circuit 2 (continued)

Parameter Value range Default OV Comments

The room sensor influence is only active when the analogue

room device FBR (room sensor + mode selection) is

connected.

The HA temperature is increased by the set value if the

Room influence 00 - 20 10

Room sensor adj. (-5.0)K - (5.0)K 0.0K

desired room temperature is fallen below by 1K.

=> High values will result in rapid regulation with large

variations in HA temperature.

- - - - => Purely weather-based regulation

0 => Purely weather-based regulation *)

20 => Purely room-temperature-based regulation

In the case of room-temperature-based regulation, the

measurement can be corrected (adjusted) using this setting

value, if a measuring error occurs in the connected room sensor.

Off, Outdoor

Warm up opt.

Max. warm-up time 0:00 - 3:00 [h] 2:00 [h]

Reduction opt. 0:00 - 3:00 [h] 0:00 [h]

temp.,

Room temp.

Off

Warm-up optimisation activates the function to automatically

bring forward the start of the heating period.

Example: Heating programme 6:00am – 10:30pm

OFF: at 6:00am the heating in the property is switched on.

ON: based on the weather and the current room

temperature, the heating is switched on early enough

to ensure that the property reaches the set target room

temperature at 6:00am.

00 => no bringing forward the start of heating

01 => brought forward based on the weather

02 => brought forward based on the room temperature

Warm-up optimisation only takes place if the

reduction period of the heating circuit is at least 6 hours.

Bringing the start of heating forward by the maximum

amount is only active if “Warm-up optim. = Outdoor temp.

or Room temp”.

The start of heating is brought forward by no more than this

amount.

Automatic optimisation of the locking of the burner at

the end of the set heating period.

During the set heating period before the heating ends

(for the last heating period only), the burner is no longer

started if it is not already in operation.

Function prevents the heating appliance from heating up

for a short period at the end of the heating period.

PC enable 0000 - 9999 0000

*) Special function for room influence = 0

If there is a one-off demand for heating during the night reduction period, the heating circuit pump continues to run until the next heating period

(see chapter Circulation pump switching).

14

Code no. to allow access to the heating circuit data via PC

“0000” => access is blocked.

Page 15

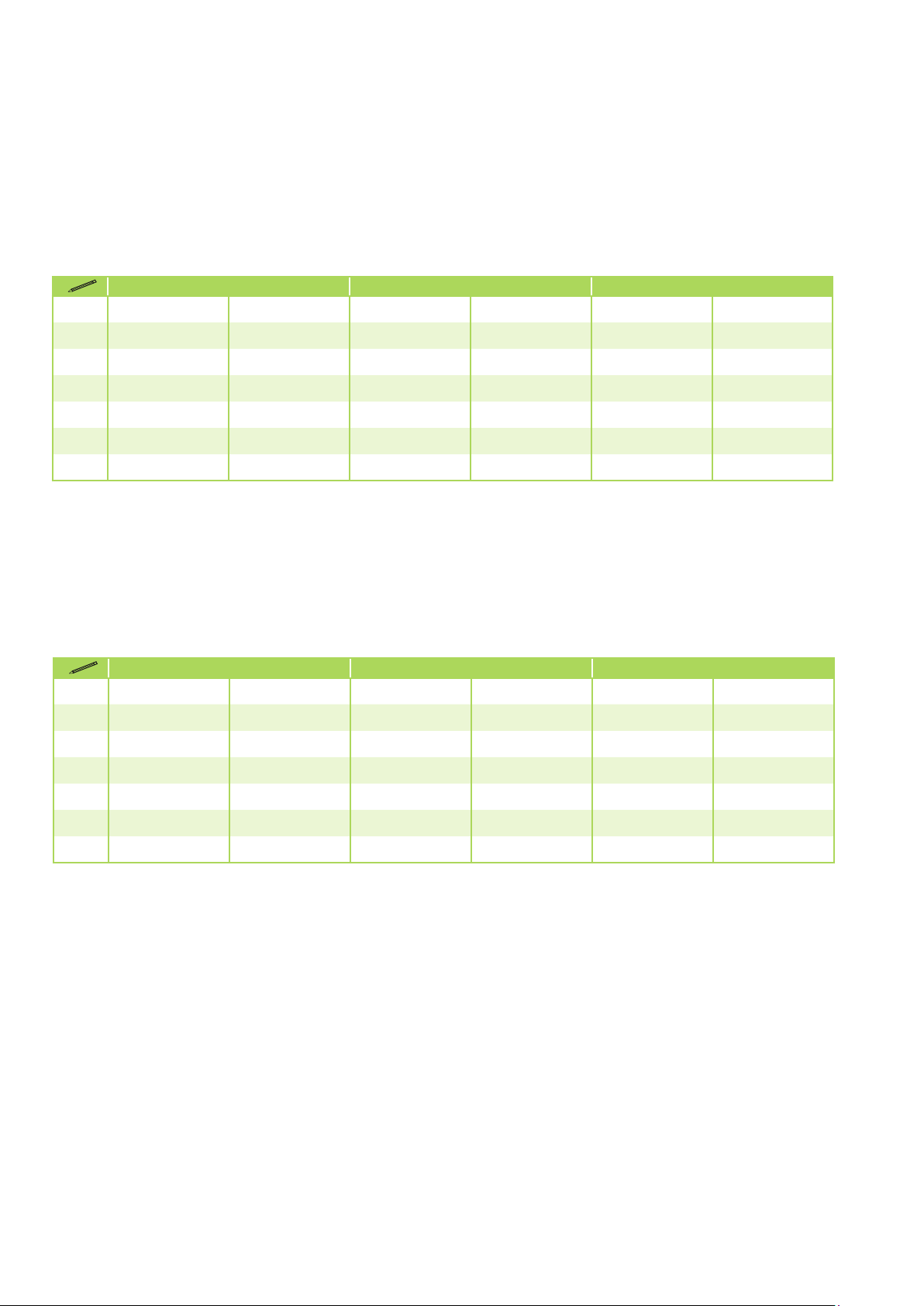

Time programmes menu

All time programmes can be set in this menu.

Adjusting a time programme

Parameter Comments

Programmes with the controller at its maximum configuration

Heating circuit x Prog 1 1st heating programme

Heating circuit x Prog 2 2nd heating programme

Hot water Programme for hot water charging

Adjusting a time programme works as follows:

Press the “Time programme” F-key

Choose the desired time

programme using the rotary

knob => e.g. “Heating

circuit x Prog 2”

Use the F-key (in this case

the second key down) to

select the time programme

=> “Heating circuit x Prog 2”

“Monday”

Use the rotary knob to

choose the day of the

week or block

=> e.g. “Mon - Fri”

(Monday - Friday)

Heating circuit

Heating programme 1 => Factory setting:

Mon to Fri: 6:00am to 10:00pm

Sat and Sun: 7:00am to 11:00pm

Select the block with Fkey [OK]

=> „06:00 -- 08:00“,

„16:00 -- 22:00“,

--:-- -- --:--„

Select Time with the Fkey [==>]

=> „06:00 -- 08:00“,

„16:00 -- 22:00“, --:-- --

--:--„

Adjust the time with the

rotary knob

=> „06:00 -- 08:00“,

„17:00 -- 22:00“, --:-- --

--:--„

Select the next time using

the F-key [==>]

Use the F-key [OK] to

save the new programme

Use the F-key [Cancel] to

leave the block without

saving

Mon

Tues

Wed

Thurs

Fri

Sat

Sun

Heating period 1 Heating period 2 Heating period 3

15

Page 16

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Heating circuit (continued)

Heating programme 2 => Factory setting:

Mon to Fri: 6:00am to 8:00am, 4:00pm to 10:00pm

Sat and Sun: 7:00am to 11:00pm

Heating period 1 Heating period 2 Heating period 3

Mon

Tues

Wed

Thurs

Fri

Sat

Sun

Hot water

Factory setting:

Mon to Fri: 5:00am to 9:00pm

Sat and Sun: 6:00am to 10:00pm

Heating period 1 Heating period 2 Heating period 3

Mon

Tues

Wed

Thurs

Fri

Sat

Sun

16

Page 17

Time/Date menu

Various values (parameters) are summarised here for the user, in order to provide quick access.

Parameter Function Comments

(Not with a time master or DCF in the system)

The clock may lose up to 2 minutes each month

(if necessary, please correct the time). If a DCF receiver is

connected, the correct time is always displayed.

Time master for all controllers

Time (hh:mm) Set hour, F-key [==>], hh:mm, set minutes

If one controller in the heating system has been set as

a time master (to provide the time for all controllers,

see Specialist/System) or if a DCF (radio time receiver)

is installed in the system, the option to enter the time is

hidden on all the other controllers.

A maximum of one time master can be set on the bus.

Date (dd. Month yy)

Start holiday

(dd. Month yy)

End holiday

(dd. Month yy)

Start daylight savings

(dd. Month)

End daylight savings

(dd. Month)

Set year, F-key [<==], set month, F-key

[<==], set day

Set date for start of holiday period

Set date for end of holiday period

Set date for start of daylight savings time

Set date for end of daylight savings time

Please set the year and month first. Then the correct

number of days in the month is calculated for the selected

values.

Holiday function

Please do not enter the date of your departure as the

start date, but rather the first full day of the holiday

(the heating will be switched off on this day).

Please do not enter the date of your return as the end

date, but rather the last day on which the heating should

be switched off. When you arrive home, your residence

and the water for your shower should already be warm.

Cancel the holiday function => e.g. if you arrive home

prematurely, by pressing the Programme key.

Automatic daylight savings switchover

The current day of the week is calculated automatically.

You can check this using the freely selectable additional

indicator on the standard display => setting to “Day of the

week”.

The automatic daylight savings switchover is made possible

by entering the date.

The default setting is for central European time zones.

It need only be changed if legislation is passed to change

the date on which daylight savings takes effect.

The earliest date on which the switchover will take place

must be set. The controller will carry out the switch

change on the Sunday following the set date at 2:00 or

3:00 in the morning.

If you do not want the switchover to take place, please

set the Stop month to the Start month and the Stop day to

the Start day.

17

Page 18

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Service menu

Values (parameters) are summarised here in order to enable quick access for customer service.

Parameter Comments

Software number XXX.XX

Reset user Reset all user parameters to factory settings

Reset specialist

(only with code no.)

Reset time programme Reset all time programmes to factory settings

Communication KM Heating appliance on the bus

Communication MM Mixer module on the bus

Specialist menu

These settings for use by specialists

can only be modified after entering

the code no.

CAUTION ! CAUTION

Setting these values wrongly

could lead to malfunctions and

damage to the system.

Software number with index (please provide if you

have any problems/questions about the controller)

Reset all specialist parameters to factory settings

The code number is entered as

follows:

Set the first figure with

the rotary knob.

Select the next figure

using the F-key [==>]

Set the second figure

with the rotary knob.

Select the next figure

using the F-key [==>]

Set the third figure with

the rotary knob.

Select the next figure

using the F-key [==>]

Set the fourth figure with

the rotary knob.

Save the code number

with the F-key [OK]

18

Page 19

System

Parameter Value range Default OV Comments

Change code 0000 - 9999 0000

Bus code 1 (00), 01-15 01

This is where you can change the default code number

[0000] => protection against unauthorised access.

Bus code 1 (=> Heating circuit number)

The heating circuits are numbered sequentially, starting with

“01”. Heating circuit numbers must not be assigned more

than once. However, please set the exact same heating

circuit numbers in replacement controllers as were used in

the controller which was replaced.

During commissioning, each wireless remote control must

first be taught in with the corresponding HF-CAN.

After setting the bus code, the wireless remote control goes

into registration mode. For registration to work, the HF-CAN

must also be in registration mode (see HF-CAN installation

instructions).

The display of the wireless remote control displays the

selected bus code and the field strength.

If (“--”) is shown for the field strength, there is no HF-CAN

within range and in registration mode.

Sufficient reception quality is guaranteed in a range from

0 to (– 80) dBm.

If the field strength indicator is < (- 80) dBm, e.g. (– 96)

dBm, check the installation position of the HF-CAN and

the position of the wireless remote control and modify as

necessary. If it is not possible to obtain a better connection,

you can test to determine whether the field strength is

still sufficient for the exchange of data to occur. For more

instructions, see the “HF-CAN installation instructions”

*) With an appropriate KM only

19

Page 20

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

System (continued)

Parameter Value range Default OV Comments

HA minimum limit

(not in cascade operation)

Reduces condensate formation in the HA when demand for

heat is low. Shut-off of the HA takes place in all cases at the

earliest when HA minimum temperature (HA1 min temp.) +

Hysteresis (5K) is reached.

00 = minimum limit on heating curve

The HA switches on once the temperature falls below that

required by the consumers.

01 = minimum limit if demand exists for heating

If demand exists for heating (pump enabled), the HA maintains at least the set minimum temperature

HA1 min temp.

02 = permanent minimum limit (24h)

The HA maintains the set minimum temperature (HA1 min

temp.) for at least 24h.

Min limit *)

00 = On

01 = Off

02 = Permanent

00

Function to optimise heating appliance operation at various

levels of demand.

After the burner is switched on, the effective switching

Hysteresis *)

Hysteresis period *) 0 - 30 min 10 min

Clock inhibition *) 0 - 30 min 0 min Idle time of the second burner stage

Burner 2 hyst. *) 2K - 20K 2K

*) With an appropriate KM only

5 - 20K 5K

hysteresis is reduced linearly from the set hysteresis to the

minimum hysteresis (= 5K) during the hysteresis period

“Hyst. period”.

Low heat transfer

In this case, the hysteresis which is set higher is effective.

This prevents short runtimes and frequent synchronising of

the burner.

High heat transfer

In the case of extended burner operation (high heating load),

the hysteresis is automatically reduced to 5K. This prevents

the heating appliance from heating up to unnecessarily high

temperatures.

Hysteresis for second burner stage

Switches on the 1st burner stage if the temperature of the

heating appliance falls below the target temperature.

Switches off the 1st burner stage if the target temperature is

exceeded by the HYSTERESIS.

Switches on the 2nd burner stage

- after the 1st burner stage starts

- and the temperature falls below the target by 5K

(= start the idle time / enable 2nd burner stage)

- and the idle elapses

Switches off the 2nd burner stage if the target temperature is

exceeded by the HYSTERESIS.

Switches the 2nd burner stage back on if the temperature of

the heating appliance falls below the target temperature.

Switches off the 1st burner stage when the 2nd stage is

enabled

after the target temperature has been exceeded by

[HYSTERESIS + BURNER 2 HYST.]

20

Page 21

Hot water *)

Parameter Value range Default OV Comments

The charge pump is only switched on once the HA

temperature has exceeded the tank temperature by 5K. It is

Charge pump lock Off/On On

PPO

HW partial priority,

On, Off, PPO all

HW partial

priority

switched off when the HA temperature falls below the tank

temperature. This prevents cooling of the tank by the HA at

the beginning of water heating.

Pump parallel operation

HW partial priority: the heating circuits are locked during

water heating. The mixers close and the heating circuit

pumps switch off. The mixer circuits are enabled again once

the HA has reached the hot water target temperature + HA

target increase [HW temp. + HA HW temp.]. The mixer

circuits lock again if the HA temperature falls below the

enable temperature by the amount of the switching

hysteresis [HW hysteresis].

On => pump parallel operation: Only the direct heating

circuits are locked during water heating. The mixer circuits

continue to be heated. The water heating is extended with

this function.

Off => hot water priority mode: the heating circuits

are locked during water heating. The mixers close and

the heating circuit pumps switch off.

PPO all => pump parallel operation also for the direct

heating circuit: all heating circuits continue to be heated

during water heating. The water heating is extended with

this function. If the HA temperature exceeds the maximum

supply temperature of the direct heating circuit by 8K,

the heating circuit pump is of this circuit is switched off

(overheating protection). The heating circuit pump switches

on again if the HA temperature falls below the temperature

[maximum supply temperature + 5K].

HA HW temp. 0K - 50K 20K

*) Only with KM and bus code 00/01

Target increase during HW mode)

Heating appliance target temperature during water heating =

Hot water target temperature + HA HW temp.

The HA must be operated at an increased temperature

during water heating so that the hot water temperature in

the tank can be reached with the heat exchanger!

21

Page 22

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Heating circuit 1/2

Parameter Value range Default OV Comments

Heating circuit function selection

Default => default heating circuit

Const. supply temp. => regulation based on fixed supply

temperatures

HC function

Default,

Const. supply

temp.

Default

During the heating periods (see heating programme),

the heating circuit is operated with set fixed supply

temperature [Day supply temp.]; during reduction periods

on the other hand, it is operated accordingly with set fixed

supply temperature [Night supply temp.]. These parameters

appear after selecting [Const. supply temp.] in the User

menu under Heating circuit.

Pump operating mode

The circulation pumps are shut off if there is no heating

requirement. Mixers are closed at the same time => “The

heating circuit is shut off”.

(Switch on with 1K hysteresis)

HCP operation

Default,

Heating limits,

Time prog. only,

Continuous

operation

Default

Default => default circulation pump switching

- Room-based regulation

OFF: Room temperature > Set room target value + 1K

- Weather-based regulation during heating mode

OFF: Outdoor temperature > Set room target value

- Weather-based regulation during reduction mode

(Room influence =0)

OFF: The switching off takes place during the transition

to reduction mode. After switching on, the pump runs

continuously.

ON: Room temperature < Room target value

(Room influence =“--”)

OFF: Target supply temperature < 20°C.

Heating limits => pump switching based on heating limits

- Heating period

OFF: Outdoor temperature < Set day heating limit

- Reduction period

OFF: Outdoor temperature < Set night heating limit

Time prog only => pump switching based on heating

programme

Heating period: pump is ON; heating circuit is free

Reduction period: pump is OFF; heating circuit is locked

Continuous operation

The pump runs 24hrs a day! The heating circuit is

continuously free.

22

Page 23

Heating circuit (continued)

Parameter Value range Default OV Comments

The calculated target supply temperature for the heating

circuit is limited by the set maximum supply temperature

(overheating protection).

Max supply temp. 20°C - 110°C 55°C

Min supply temp. 10°C - 110°C 18°C

Frost protection

temp.

Outdoor temp. delay 0:00 - 24:00 1:00

----;(-15)°C – (5)°C 5°C

The heating circuit pump for the direct heating circuit is

only switched off if the HA temperature exceeds the set

maximum supply temperature by 8K. The heating circuit

pump is switched back on again if the

HA temperature falls below the temperature [maximum

supply temperature + 5K]!

The calculated target supply temperature for the heating

circuit is increased to the set minimum supply temperature

(e.g. for air heating).

If the outdoor temperature falls below the programmed

value, the system switches into frost protection mode

(pumps switch on).

“----” Frost protection function is deactivated!

The outdoor temperature delay selected must take the

building design into account. Because a change in outdoor

temperature subsequently impacts the room temperature,

for a building of heavy construction (thick walls), a long

delay must be selected. For a building of lightweight

construction (in which the walls do not store heat), the

delay should be set to (0 hrs).

Curve distance 0K - 50K 0.0K

Demand requirement Off/On On

I-controller

Off, 3:00am 0:15am

Off

Heating curve distance

The required HA temperature for a mixer circuit is

calculated by adding the calculated target temperature for

the heating circuit supply to the heating curve distance.

The heating curve distance equalises sensor tolerances and

heat losses as far as the mixer.

Enable the circuit

On => The heating circuit can be used with higher-level

functions (e.g. cooling function of a heating appliance to

protect against overheating; heat dissipation in service

mode) as a heat sink/consumer. The heating circuit is

heated to the set maximum supply temperature for the

duration of the function.

Integrated controller part (e.g. 30 min)

If there is a difference in room temperature of 1K for the

set period, the supply temperature is increased by the

value “Room sensor influence”.

Usual value: “30 min”.

23

Page 24

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

General mode of operation

Heating circuit regulation

Weather-based regulation

The set heating curve is used to

determine the boiler or supply

temperature appropriate to the

measured outdoor temperature,

such that with a properly

configured heating system in the

reference room, approximately the

set room target temperature value

is achieved.

=> The precise setting of the

heating curve is extremely

important for weather-based

regulation.

The circulation pump is

regulated based on the weather.

The circulation pump is switched on

when there is demand for heating

and in frost protection mode.

Room sensor influence

The current room temperature can

be factored into the calculation of

the required supply temperature by

installing a room temperature sensor.

The influence factor (parameter

list) can be set between 0

(regulation purely based on

the weather) and 20 (room

temperature-based regulation

with only a slight influence from

the outdoor temperature). In the

position “----” room temperaturebased regulation is deactivated.

The positions “----” and “0” show

differences for demand-oriented

circulation pump switching.

Water heating

The hot water programme of

the control module affects Hot

water target temperature I of the

connected main controller. The

hot water programme of the main

controller is a separate programme.

Frost protection function

The frost protection mechanism

prevents the heating system from

freezing by automatically switching

on heating mode.

Outdoor frost protection sensor

If the measured outdoor

temperature drops below the set

frost protection temperature, the

room target temperature for the

corresponding heating circuit is

set to 5°C. The heating circuit is

enabled:

- Pumps are switched on

- Request for heat is sent

to the boiler

“----” => Outdoor frost protection

sensor is deactivated

The function is cancelled if the

outdoor temperature climbs

above the set frost protection

temperature by 1K.

Frost protection via the room

sensor

If the room temperature drops

below 5°C, the frost protection

function is activated.

The room target temperature for

the corresponding heating circuit

is set to 5°C. The heating circuit is

enabled:

- Pumps are switched on

- Request for heat is sent to the

boiler

EEPROM check

Every 10 minutes, an automatic

check is performed to determine

that the settings values of the

controller are within the specified

limits. If a value is found to be

outside of the limits, then it is

replaced by the associated default

value. Error 81 appears in the

Favourites line on the standard

display to indicate that a value

exceeded the permissible range.

In this case, the user should check

the key settings of the controller.

The warning symbol goes out after

the unit is restarted (RESET).

Circulation pump switching

Heating demand-dependent

switching

Demand-dependent circulation

pump switching shuts down the

circulation pumps if there is no

demand for heating. At the same

time, the mixers are closed.

Condition for shutdown:

Room temperature-based regulation

The room temperature exceeds

the set target value.

Weather-based regulation

The outdoor temperature exceeds

the target room temperature value

or the target supply temperature

value by 20°C.

NOTE

If the room sensor influence is

“0”, after a one-off demand

for heating during the

reduction period, the pump

runs continuously.

Pump lag

When the circulation pumps are

shut down, there is a lag period

of 5 minutes, if the burner was

switched on in the last 5 minutes

before the pump shutdown.

Pump seizing protection

The controller effectively prevents

the pumps from seizing due to

extended shutdown periods.

The integrated protection function

switches on all pumps, which have

not been run in the past 24 hours,

daily at 12:00pm for 5 seconds.

Mixer seizing protection

If the mixer has not moved for

24 hours, is is fully opened once

at approx. 3:00am. During this

time, the heating circuit pump is

switched off. The maximum supply

temperature is monitored. The

process is cancelled if maximum

supply temperature – 5K.

24

Page 25

Troubleshooting and customer service

General troubleshooting vinformation

If the system does not operate

correctly, first check the cabling

in the controller and controller

components.

The wireless remote control must

be registered properly with a field

strength between 0 and (-80) dBm.

Bus connection (see Service menu)

In control panels on connection to

the mixer => Communication MM

= On

In control panels on connection

to the heating appliance =>

Communication KM = On

In the boiler controller on

connection to the control panel =>

Displays

the room temperature and

hides the current target room

temperature

“----” (see “Display/Heating

circuit”)

In the mixer expansion controller

on connection to the boiler

controller => Displays the outdoor

and the boiler temperature (see

“Display/System”) on the control

panel => Displays the room

temperature and hides the current

target room temperature “----”

(see “Display/Heating circuit”)

Restart / Reset

Restart

1. Remove the battery and

turn the rotary knob.

2. Refit the battery.

Use the F-key [4] [Continue]

to ignore or cancel the

message “Bus code assigned”.

Reset

1.

For individual parameters using

F-key [3] = [Default]

2. For the menus User, Specialist

or Time programmes, this can

be selected via the Service

menu, e.g. “Reset time

programme” menu item,

then adjusting the value from

Off to On with the rotary knob

and the pressing the F-key [4]

= [OK]. The unit restarts.

3. For the unit as a whole (incl. all

parameters), remove battery

and turn the rotary knob.

When reinserting the battery,

hold down the Home key.

The units and components are manufactured using state-of-the-art production methods and tested several times

to verify their correct function. However, if malfunctions should occur, please check the functions as detailed

in the list below. Please inform your dealer if the unit is still not working correctly after all function checks have

been performed!

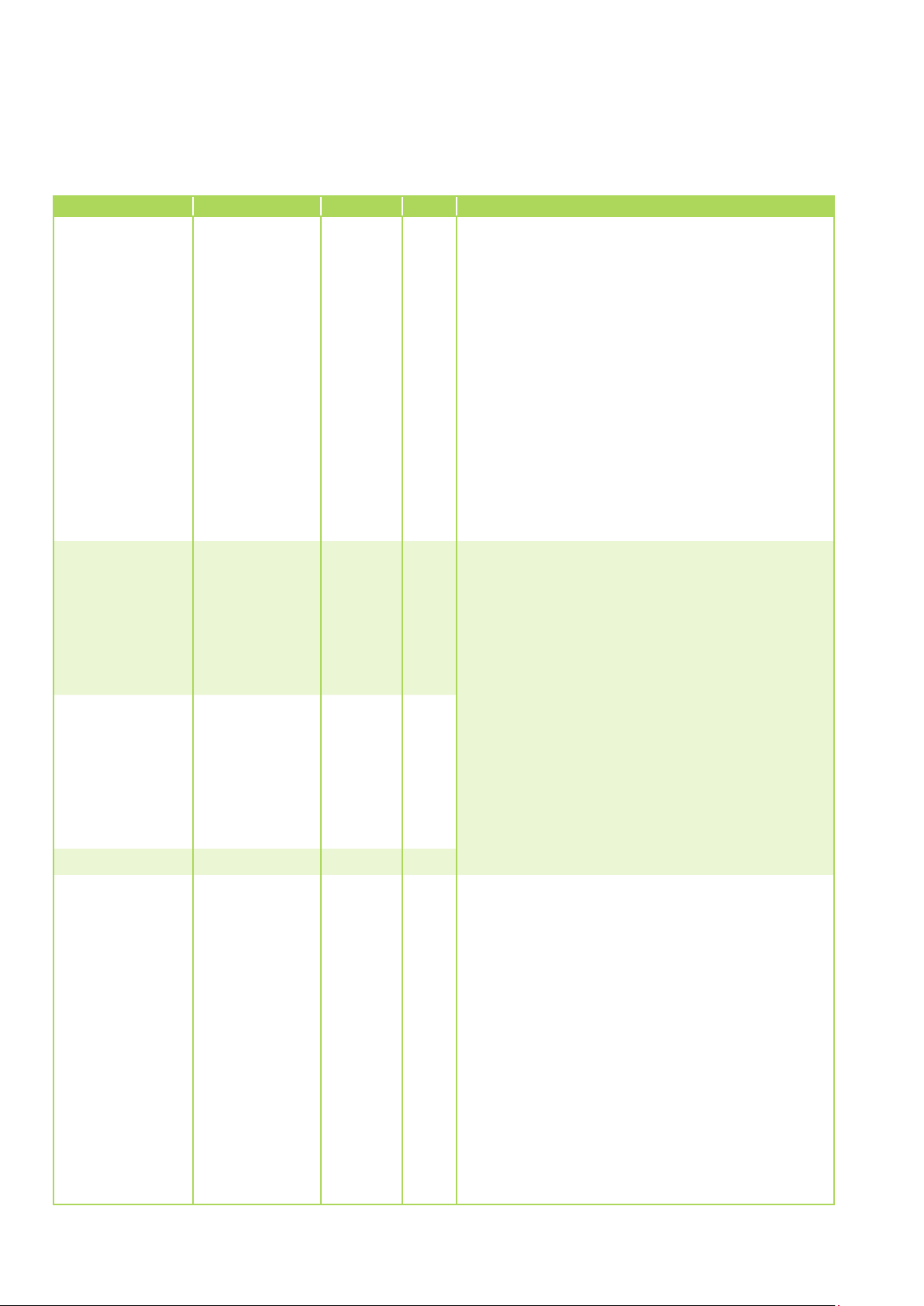

Malfunctions

Error Possible cause Checks Remedial measures

Check operating mode => Default

( set?). Check “HCP OPERATION”

setting value (default 00).

Check operating mode => Default

( test).

Check time and heating programme

=> Heating period

Check pump switching => Type of

pump switching

Default => Outdoor temperature >

Room target temperature?

Heating thresholds => Outdoor

temperature > Valid heating limit?

Room-temperature-based regulation

=> Room temperature > Target

temperature + 1K

Additional test with the relay test

function of the controller.

Check all settings values, then

restart!

Pumps do not switch off

Pumps fail to switch on

Error number 81

Operating mode / settings

changed

Operating mode / time

and heating programme

/ pump switching /

heating thresholds /

room temperature-based

regulation changed

Change in the tank of the

controller (e.g. due to EMC)

Check operating mode /

settings

Check operating mode

/ time and heating

programme / pump

switching / heating

thresholds / room

temperature-based

regulation

Check all settings values

Other error numbers

Error caused by boiler or

mixer controller

Check the meaning of these

error in the corresponding

error tables

Look up the meaning in the boiler

error tables

25

Page 26

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Error indication by code

Only the error with the highest priority is displayed.

- The message "Error" appears on the standard display and the error number in the Favourites line.

The error can be rotated out of view and rotated back into view on the display => see Favourites.

- In the Display menu, at the end of the System sub-menu the parameter Error appears, which displays the latest

error.

Type of error Code Cause Required action

E 90 Addr. 0 and 1 on bus Bus codes 0 and 1 may not be used simultaneously

Communications

error

Internal error E 81

E 91 Bus code assigned The set bus code is already being used by another device

E 241 No communication with HA Check range from HF-CAN

EEPROM error. The invalid

value has been replaced

by the default value

Check parameter values!

E 67 Collector sensor 2 Contact specialist dealer

E 68 Collector sensor 1 Contact specialist dealer

E 69 Supply sensor, HC2 Contact specialist dealer

E 70 Supply sensor, HC1 Contact specialist dealer

E 75 Outdoor sensor Contact specialist dealer

E 76 Tank sensor Contact specialist dealer

Sensor error

(break/short-circuit)

Message W 85 Battery needs changing Insert new batteries

E 77 Boiler sensor Contact specialist dealer

E 78 Collector sensor Contact specialist dealer

E 79 Sensor, multifunction relay 1 Contact specialist dealer

E 80 Room sensor, HC1 Contact specialist dealer

Room sensor, HC2 / Lower

E 83

E 84 Humidistat Contact specialist dealer

buffer sensor / Swimming pool

sensor

Contact specialist dealer

26

Page 27

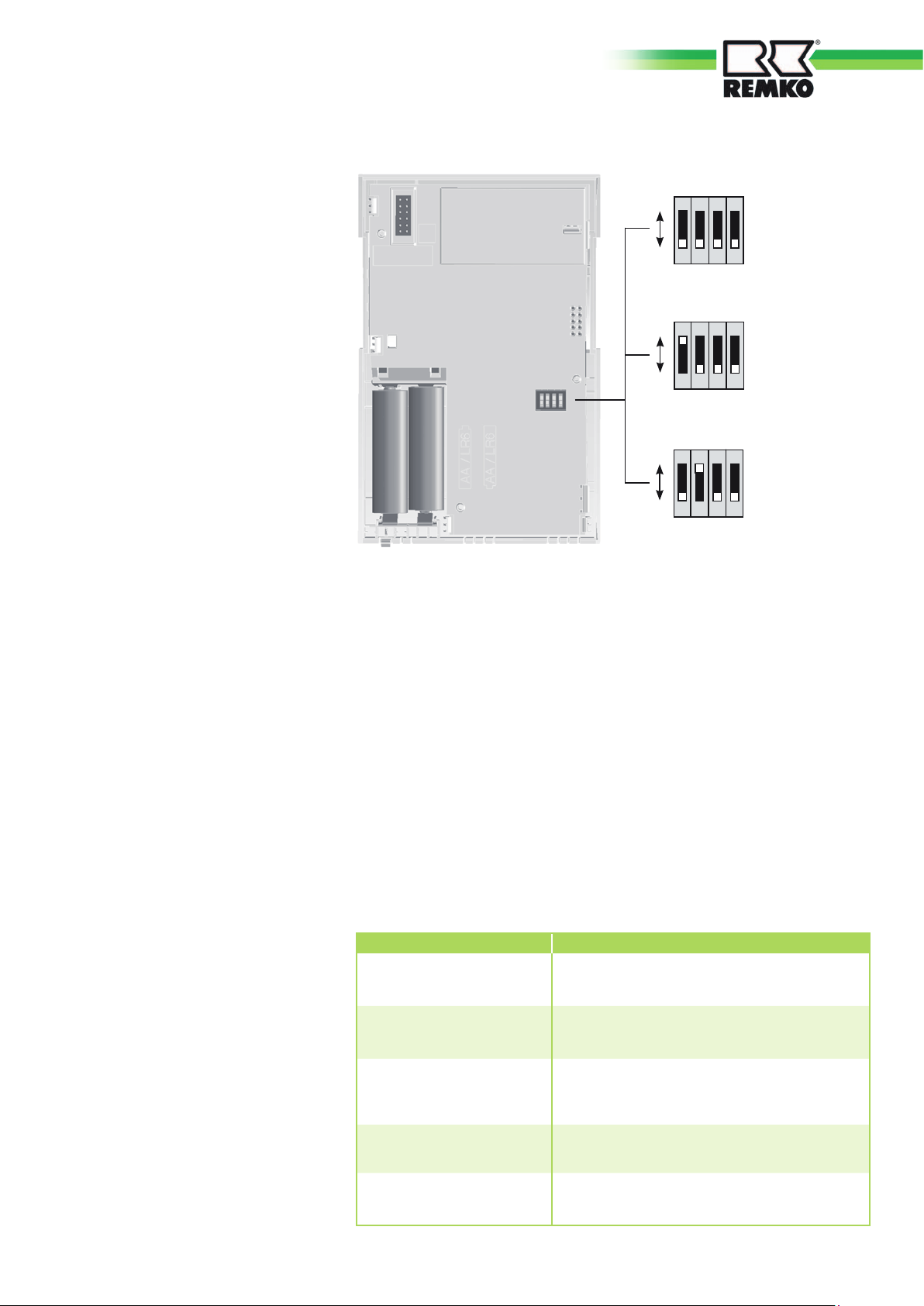

Installation

Assembly

1. Secure the base to the wall.

ON

Channel setting 0

2. Setting the channel:

On the back of the wireless

remote control the channel

(0 – 2) must be set, while the

batteries are removed.

The setting must match that on

the HF-CAN.

3. Insert the batteries.

4. Snap the top of the controller

into place; to do so, position/

hook in the left-hand side so it

is centred and then pivot the

right-hand side down onto the

base using light pressure and

engage.

The dimensions of the unit are: 147mm x 97mm x 32mm

The mounting holes are suited for fitting to a switch box

A cable feedthrough is provided.

Commissioning

1 2

3

Dip 1-4

Dip 1-4

Dip 1-4

4

Channel setting 1

3

4

Channel setting 2

3

4

OFF

ON

OFF

ON

OFF

1 2

1 2

Disassembly

1. Lift the upper section off

the base on the right-hand side.

2. Unscrew the base from the wall.

The following steps must be

followed when commissioning:

1. Read this manual carefully

before commissioning.

2. Fit the controller (see chapter

“Installation”).

3. Wait until the message

Installation appears on the

display.

4. Start installation with the F-key

[4] = OK.

5. Set the value with the rotary

knob.

6. Press F-key [4] = OK => Saves

the value and moves to the

next value.

7. Continue until installation is

complete => Standard display

8. Set the Programme switch to

the desired operating mode,

e.g. Automatic 1 (see chapter

“Operation/Mode selection”)

BUS CODE (heating circuit number):

The heating circuits are numbered sequentially, starting with “01”. Heating circuit numbers must not be assigned more than once. Please only

use “00” for replacement controllers (see chapter “System bus”).

For information on registration, see chapter “Specialist menu”.

In the Commissioning menu, all values must be entered successively –

without interruption!

Values Required action

English Set language, then “OK”

Set time

Set date

Bus code

(see chapter System bus)

Registration Registration on the HF-CAN

1. Hour then “==>”

2. Minute then “OK”

1. Year then “<==”

2. Month then “<==”

3. Day then “OK”

Enter number for heating circuit:

00-15 => Default 01, then “OK”

27

Page 28

REMKO WIRELESS REMOTE CONTROL

FOR MULTITALENT HEAT PUMP MANAGER

Changing the battery

If the battery symbol shown below

displays 0%, the battery should be

changed within the next week.

100% 50% 0%

System bus

Heating system bus system

This controller can be expanded

modularly by connecting additional

modules to the integrated bus.

As supplied, the system can be

used to control the following

components of a heating system

1-8 Heating appliances (

modulating or switching)

1-15 Mixed weather-based

heating circuits

0-15 Room controller (digital

or analogue)

1 Solar energy system (2

collectors, 2 tanks)

1 Solid fuel boiler

The different components are

simply connected to the system

bus. The modules register with the

system automatically and search

for their communication partners

using the set bus code (heating

circuit number or boiler number).

Bus code

On mixer controllers and control

panels

The bus code (00-15; parameter

in the Specialist menu) is a means

of numbering the system's heating

circuits. Each control module and

each mixer module contains the

number of the associated heating

circuit, in the form of a bus code.

- Heating circuit numbers

(00-15) must not be assigned

twice.

- Heating circuit numbers 00 and

01 must not both be used

at the same time.

- The heating circuits are

numbered sequentially, starting

with “01”.

- Please only use heating

circuit number 00 for replacement

controllers, if “00” has been

used in the replaced controller.

Preassigned numbers

Heating circuit 1 01

NOTE

After setting all bus codes,

the heating system must

be fully powered down once.

28

Page 29

Technical data

Radio frequency MHz 868,0 - 868,6

Max. transmission power mW 4

Supply voltage 2x LR6 alkaline cell

Power consumption mA 0,15

Protection category in accordance with EN 60529 IP 40

Protection class according to EN 60730 III

Permitted ambient temperature during operation °C 0 - 50

Permitted ambient temperature in storage °C -20 - +60

Permitted humidity, non-condensing R.H. in % 95

The range is approx. 300 m in

the open air, i.e. the range if

there is visual contact between

the transmitter and receiver.

However, in real-world conditions,

there are walls, ceilings, etc.

between the transmitter and the

receiver, which reduces range

accordingly.

NOTE

Although the product only

emits relatively weak radio

signals, these can still cause

malfunctions to life-sustaining

systems (e.g. medical devices).

NOTE

Radio signals from unrelated

devices, e.g. cordless

telephones or mobile phones

can impair the transmission

of the wireless remote control

and the receiver.

29

Page 30

Notes

Page 31

Notes

Page 32

REMKO INTERNATIONAL

... and also right in your neighbourhood!

Take advantage of our experience and advice

REMKO GmbH & Co. KG

Klima- und Wärmetechnik

Im Seelenkamp 12 D-32791 Lage

Postfach 1827 D-32777 Lage

Telephone +49 5232 6 06-0

Fax +49 5232 606-2 60

e-mail info@remko.de

Website www.remko.de

Hotline

Air conditioning and

heating technology

+49 5232 606-0

Export

+49 5232 606-130

Consultation

Thanks to intensive training,

our consultants are always

completely up-to-date when

it comes to technical expertise.

This has given us the reputation

of being more than just an

excellent, reliable supplier:

REMKO, a partner

that helps you find solutions to

your problems.

Sales

REMKO offers not just a well

established sales network both

nationally and internationally, but

also has exceptionally highlyqualified sales specialists.

REMKO field staff are more than

just sales representatives: above

all, they must act as advisers to

our customers in air conditioning

and heating technology.

Customer Service

Our units operate precisely and

reliably. However, in the event

of a fault REMKO customer

service is quickly on the scene.

Our comprehensive network

of experienced dealers always

guarantees quick and

reliable service.

We reserve the right to make technical changes and provide no warranty as to the accuracy of this data!

Loading...

Loading...