REMKO LWM Series, LWM 80, LWM 110, LWM 150, LWM 110 Duo Operating And Installation Instructions

...

Operating and

installation instructions

REMKO LWM series

Monobloc heat pumps

Air/water system for heating and cooling

LWM 80, LWM 110, LWM 150, LWM 110 Duo, LWM 150 Duo

Instructions for Technicians

0205-2019-07 Edition 1, en_GB

Read the instructions prior to performing any task!

R454B

Refrigerant

Read these operating instructions carefully before commissioning / using this device!

These instructions are an integral part of the system and must

always be kept near or on the device.

Subject to modifications; No liability accepted for errors or misprints!

Translation of the original

Table of contents

1 Safety and usage instructions............................................................................................................. 4

1.1 General safety notes....................................................................................................................... 4

1.2 Identification of notes...................................................................................................................... 4

1.3 Personnel qualifications.................................................................................................................. 4

1.4 Dangers of failure to observe the safety notes................................................................................ 4

1.5 Safety-conscious working............................................................................................................... 5

1.6 Safety notes for the operator........................................................................................................... 5

1.7 Safety notes for installation, maintenance and inspection.............................................................. 5

1.8 Unauthorised modification and changes......................................................................................... 5

1.9 Intended use................................................................................................................................... 5

1.10 Warranty........................................................................................................................................ 6

1.11 Transport and packaging............................................................................................................... 6

1.12 Environmental protection and recycling........................................................................................ 6

2 Technical data........................................................................................................................................ 7

2.1 Unit data.......................................................................................................................................... 7

2.2 Product data.................................................................................................................................. 11

2.3 Unit dimensions of indoor units..................................................................................................... 13

2.4 Diagram, cooling cycle.................................................................................................................. 15

2.5 Heat pump usable limits in monovalent operation........................................................................ 16

2.6 Pump characteristics and circulation pump pressure losses........................................................ 16

2.7 Total sound power level................................................................................................................. 18

2.8 Characteristic curves..................................................................................................................... 21

3 Unit description................................................................................................................................... 31

4

Assembly............................................................................................................................................. 35

4.1 System layout................................................................................................................................ 35

4.2 General installation notes.............................................................................................................. 36

4.3 Set-up and assembly of the heat pump........................................................................................ 37

5 Hydraulic connection.......................................................................................................................... 42

6 Emergency-heat operation................................................................................................................. 46

7 Cooling with room temperature/humidity probe.............................................................................. 47

8 Water treatment................................................................................................................................... 48

9 Commissioning the refrigeration system......................................................................................... 50

10 Electrical wiring................................................................................................................................... 52

11 Before commissioning....................................................................................................................... 52

12 Commissioning................................................................................................................................... 53

13 Care and maintenance........................................................................................................................ 54

14 Temporary shutdown.......................................................................................................................... 54

15 Troubleshooting and customer service............................................................................................ 55

16 General view of unit and spare parts................................................................................................ 56

16.1 Exploded view of the unit LWM 80-150....................................................................................... 56

16.2 Spare parts LWM 80-150............................................................................................................ 57

17 General terms...................................................................................................................................... 59

18 Index..................................................................................................................................................... 61

3

REMKO LWM series

1 Safety and

usage instructions

1.1 General safety notes

Carefully read the operating manual before commissioning the units or their components for the

first time. It provides useful tips and notes such as

hazard warnings to prevent injury and material

damage. Failure to follow

manual can endanger persons, the environment

and the equipment itself or its components and will

void any claims for liability.

Store this manual and the information required for

the operation of this system (e.g. refrigerant datasheet) in the vicinity of the unit.

The refrigerant used in the system is flammable. If

applicable, observe the local safety conditions.

the directions in this

DANGER!

This combination of symbol and signal word

warns of a situation in which there is immediate

danger

cause serious injury.

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may be fatal or cause

serious injury

, which if not avoided may be fatal or

WARNING!

.

Warning of inflammable substances!

Identification of notes

1.2

This section provides an overview of all important

safety aspects for proper protection of people and

safe and fault-free operation.The instructions and

safety notes contained within this manual must be

observed in order to prevent accidents, personal

injury and material damage.

Notes attached directly to the units must be

observed in their entirety and be kept in a fully

legible condition.

Safety notes in this manual are indicated by symbols. Safety notes are introduced with signal words

which help to highlight the magnitude of the danger

in question.

CAUTION!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause injury or material and environmental damage.

NOTICE!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause material and

environmental damage.

This symbol highlights useful tips and recommendations as well as information for efficient

and fault-free operation.

DANGER!

Contact with live parts poses an immediate

danger of death due to electric shock. Damage

to the insulation or individual components may

pose a danger of death.

1.3 Personnel qualifications

Personnel responsible for commissioning, operation, maintenance, inspection and installation must

be able to demonstrate that they hold a qualification which proves their ability to undertake the

work.

Dangers of failure to observe

1.4

the safety notes

Failure to observe the safety notes may pose a risk

to people, the environment and the units. Failure to

observe the safety notes may void any claims for

damages.

4

In particular, failure to observe the safety notes

may pose the following risks:

n The failure of important unit functions.

n The failure of prescribed methods of mainte-

nance and repair

n Danger to people on account of electrical and

mechanical effects.

.

1.5 Safety-conscious working

The safety notes contained in this manual, the

existing national regulations concerning accident

prevention as well as any internal company

working, operating and safety regulations must be

observed.

Safety notes for the operator

1.6

The operational safety of the units and components is only assured providing they are used as

intended and in a fully assembled state.

n The units and components may only be set up,

installed and maintained by qualified personnel.

n Protective covers (grille) over moving parts

must not be removed from units that are in

operation.

n Do not operate units or components with

obvious defects or signs of damage.

n Contact with certain unit parts or components

may lead to burns or injury

n The units and components must not be

exposed to any mechanical load, extreme

levels of humidity or extreme temperature.

n Spaces in which refrigerant can leak sufficient

to load and vent. Otherwise there is danger of

suffocation.

n All housing parts and device openings, e.g. air

inlets and outlets, must be free from foreign

objects, fluids or gases.

n The units must be inspected by a service tech-

nician at least once annually. Visual inspections and cleaning may be performed by the

operator when the units are disconnected from

the mains.

.

1.7 Safety notes for installation, maintenance and inspection

n Appropriate hazard prevention measures must

be taken to prevent risks to people when performing installation, repair

cleaning work on the units.

n The setup, connection and operation of the

units and its components must be undertaken

in accordance with the usage and operating

conditions stipulated in this manual and comply

with all applicable regional regulations.

, maintenance or

n Regional regulations and laws as well as the

ater Ecology Act (WHG) must be observed.

W

n Only install and store the units in rooms larger

than 4 m2. With a failure to comply, leaks may

result in the room filling with a flammable mixture! The minimum room size of 4 m2 required

for installation and storage pertains to the basic

fill quantity of the unit. This varies according to

the installation type and total fill quantity of the

system. The calculation must take place in

accordance with valid DIN standards. Make

sure that the installation site is suitable for safe

unit operation.

n The electrical power supply should be adapted

to the requirements of the units.

n Units may only be mounted at the points pro-

vided for this purpose at the factory. The units

may only be secured or mounted on stable

structures, walls or floors.

n Mobile units must be set up securely on suit-

able surfaces and in an upright position. Stationary units must be permanently installed for

operation.

n The units and components should not be oper-

ated in areas where there is an increased risk

of damage. Observe the minimum clearances.

n The units and components must be kept at an

adequate distance from flammable, explosive,

combustible, abrasive and dirty areas or

atmospheres.

n Safety devices may not be modified or

bypassed.

1.8 Unauthorised modification and changes

Modifications or changes to units and components

are not permitted and may cause malfunctions.

Safety devices may not be modified or bypassed.

Original replacement parts and accessories

authorised by the manufactured ensure safety

use of other parts may invalidate liability for

resulting consequences.

. The

1.9 Intended use

Depending on the model, the equipment and the

additional fittings with which it is equipped is only

intended to be used as an air-conditioner for the

purpose of cooling or heating the air in an

enclosed room.

Any different or additional use shall be classed as

non-intended use. The manufacturer/supplier

assumes no liability for damages arising from such

use. The user bears the sole risk in such cases.

Intended use also includes working in accordance

with the operating and installation instructions and

complying with the maintenance requirements.

5

REMKO LWM series

Under no circumstances should the threshold

values specified in the technical data be exceeded.

1.10

For warranty claims to be considered, it is essential

that the ordering party or its representative complete and return the "certificate of warranty" to

REMKO GmbH & Co. KG at the time when the

units are purchased and commissioned.

The warranty conditions are detailed in the "General business and delivery conditions". Furthermore, only the parties to a contract can conclude

special agreements beyond these conditions. In

this case, contact your contractual partner in the

first instance.

Warranty

1.11 Transport and packaging

The devices are supplied in a sturdy shipping container. Please check the equipment immediately

upon delivery and note any damage or missing

parts on the delivery and inform the shipper and

your contractual partner. For later complaints can

not be guaranteed.

1.12 Environmental protection and recycling

Disposal of packaging

All products are packed for transport in environmentally friendly materials. Make a valuable contribution to reducing waste and sustaining raw materials. Only dispose of packaging at approved

collection points.

Disposal of equipment and components

Only recyclable materials are used in the manufacture of the devices and components. Help protect

the environment by ensuring that the devices or

components (for example batteries) are not disposed in household waste, but only in accordance

with local regulations and in an environmentally

safe manner, e.g. using certified firms and recycling specialists or at collection points.

WARNING!

Plastic films and bags etc. are dangerous

toys for children!

Why:

- Leave packaging material are not around.

- Packaging material may not be accessible to

children!

6

2 Technical data

2.1 Unit data

Series LWM 80 LWM 110 LWM 150

Function Heating or Cooling

System Air/water

Heat pump manager Smart Control Touch

Drinking water tank enamelled optional

Auxiliary heater installed/rated output kW optional 7.5

Domestic hot-water heating (changeover valve)

Connection oil/gas boiler changeover

valve

Heating capacity min./max. kW 0.6-8.0 2.0-10.7 3.0-14.5

Heating capacity/COP

with A12/W35 kW/COP 7.5/5.65 9.18/5.57 11.0/5.58

with A7/W35 kW/COP 6.25/5.10 8.04/5.02 10.28/5.03

with A2/W35 kW/COP 4.33/4.09 6.35/4.04 8.33/4.11

with A-7/W35 kW/COP 3.82/3.55 5.57/3.42 7.85/3.57

with A-15/W35 kW/COP 2.6/2.95 4.47/2.82 6.5/2.97

with A7/W45 kW/COP 6.05/3.96 7.87/3.88 10.09/3.89

with A-7/W45 kW/COP 3.73/2.96 5.51/2.83 7.76/2.98

with A7/W55 kW/COP 5.68/3.20 7.50/3.12 9.72/3.13

with A-7/W55 kW/COP 3.64/2.49 5.42/2.36 7.67/2.51

with A10/W35 kW/COP 6.80/5.43 8.55/5.31 10.60/5.32

Cooling capacity min./max. kW 1.1-8.9 3.3-11.9 5.5-14.0

Cooling capacity/EER

1)

2)

optional

optional

with A35/W7 kW/EER 4.90/2.81 7.63/2.73 12.20/2.65

with A35/W18 kW/EER 5.70/3.61 8.24/3.71 12.77/3.81

with A27/W18 kW/EER 5.80/3.92 10.71/4.00 18.20/4.11

Usable limits, heating °C -23 to +37

Service limits, cooling °C +15 to +45

Inlet temperature, heating water, max. °C 65

Min. inlet temperature for cooling °C 7

Heat pump power supply V/Ph/Hz 230/1~/50 400/3~/50

Electrical heating element power supply

(Smart Serv)

Control board power supply V/Ph/Hz 230/1~/50

7

V/Ph/Hz 400/3~/50

REMKO LWM series

Series LWM 80 LWM 110 LWM 150

Heater for anti-freeze protection power

supply (optional)

V/Ph/Hz 230/1~/50

Max. current consumption per phase A 5.8 4.7 6.6

Rated current consumption for A7/W35 A 5.30 2.57 3.27

Rated power consumption for A7/W35 kW 1.22 1.60 2.04

Rated power consumption for A2/W35 kW 1.06 1.57 2.03

Max. power consumption kW 1.3 3.2 4.5

Power factor at A7/W35 (cosφ) -- 0.9

Customer-provided electrical protection

Refrigerant

A slow-

acting

16 3 x 20

R454B

3)

Refrigerant, basic capacity kg 1.3 1.4 1.6

Medium flow rate

water(according to EN 1451

1, at ∆t 5 K)

m3/h

1.1 1.4 1.6

Pressure loss (heating system), outdoor kPa 80 70 60

Max. airflow volume

m3/h

3000 3500 4000

Max. operating pressure, water bar 3

Hydraulic connection,

inlet/return flow (flat-sealing)

Recommended diameter for copper

piping to be used by the customer

Inches (DN) 1 1/4 (32)

mm 28

Max. sound power level in acc. with

dB(A) 54 56 58

DIN EN 12102:2008-09 and ISO 9614-2

Sound pressure level, LpA

4)

dB(A) 32 34 36

Tonality dB(A) 0

Sound power level/sound pressure

level

night operations/lowering mode

dB(A) 47/25 49/27 51/29

Dimensions (height/width/depth) mm 1600 x 1000 x 850

Enclosure class -- IP X4

Weight kg 200 220

1)

COP = coef

ficient of performance in accordance with EN 14511, VDE tested, rated compressor frequency

60 Hz

2)

EER = energy efficiency ratio in accordance with EN 14511, rated compressor frequency 60 Hz

3)

Contains greenhouse gas according to Kyoto protocol, GWP 466

4)

Distance 5 m, VDE tested, A7/W55, with half-spherical propagation

Information provided without guarantee! We reserve the right to make technical changes within the framework of technical advancement.

8

Series LWM 110 Duo LWM 150 Duo

Function Heating or Cooling

System Air/water

Heat pump manager Smart Control Touch

Drinking water tank enamelled optional

Auxiliary heater/rated output per heat pump kW 7.5

Domestic hot-water heating (changeover valve) optional

Connection oil/gas boiler optional

Heating capacity min./max. kW 2.0-21.4 3.0-29.0

Heating capacity/COP

1)

with A12/W35 kW/COP 18.36/5.57 22.00/5.58

with A7/W35 kW/COP 16.08/5.02 20.56/5.03

with A2/W35 kW/COP 12.70/4.04 16.66/4.11

with A-7/W35 kW/COP 11.14/3.42 15.70/3.57

with A-15/W35 kW/COP 8.94/2.82 13.00/2.97

with A7/W45 kW/COP 15.74/3.88 20.18/3.89

with A-7/W45 kW/COP 11.02/2.83 15.52/2.98

with A7/W55 kW/COP 15.00/3.12 19.44/3.13

with A-7/W55 kW/COP 10.84/2.36 15.34/2.51

with A10/W35 kW/COP 17.10/5.31 21.20/5.32

Cooling capacity min./max. kW 3.3-23.8 5.5-28.0

Cooling capacity/EER

2)

with A35/W7 kW/EER 15.26/2.65 24.40/2.65

with A35/W18 kW/EER 16.48/3.71 25.54/3.81

with A27/W18 kW/EER 21.42/4.00 36.08/4.11

Usable limits, heating °C -23 to +37

Service limits, cooling °C +15 to +45

Inlet temperature, heating water, max. °C 65

Min. inlet temperature for cooling °C 7

Power supply per heat pump V/Ph/Hz 400/3~/50

Power supply per electrical heating element

V/Ph/Hz 400/3~/50

(Smart Serv)

Power supply per control board V/Ph/Hz 230/1~/50

Power supply per heater for anti-freeze protection

(optional)

V/Ph/Hz 230/1~/50

Max. current consumption per phase and heat pump A 4.7 6.6

Rated current consumption for A7/W35 per heat pump A 2.57 3.27

9

REMKO LWM series

Series LWM 110 Duo LWM 150 Duo

Rated power consumption for A7/W35 kW 1.60 2.04

Rated power consumption for A2/W35 per heat pump kW 1.57 2.03

Max. power consumption per heat pump kW 3.2 4.5

Power factor at A7/W35 (cosφ) per heat pump -- 0.9

Fuse protection provided by the customer per heat pump

Refrigerant

Max. refrigerant basic filling quantity per heat pump kg 1.4 1.6

Medium flow rate water(according to EN 14511, at ∆t 5 K)

per heat pump

Outdoor pressure loss (heating system) per heat pump kPa 70 60

Max. airflow volume per heat pump

Max. water operating pressure per heat pump bar 3

Hydraulic connection inlet/return flow, flat-sealing

per heat pump

Copper collector line diameter

to be used by the customer per heat pump

Max. sound power level in acc. with

DIN EN 12102:2008-09 and ISO 9614-2

Sound pressure level LpA 4)per heat pump

Tonality dB(A) 0

Sound power level/sound pressure

levelnight operations/lowering mode

per heat pump

per heat pump

A slow-

acting

m3/h

m3/h

Inches (DN) 1 1/4 (32)

mm 42

dB(A) 56 58

dB(A) 34 36

dB(A) 49/27 51/29

1.4 1.6

2x3500 2x4000

3 x 20

R454B

3)

Dimensions per heat pump (height/width/depth) mm 1600 x 1000 x 850

Enclosure class -- IP X4

Weight per heat pump kg 200 220

1)

COP = coef

60 Hz

2)

EER = energy efficiency ratio in accordance with EN 14511, rated compressor frequency 60 Hz

3)

Contains greenhouse gas according to Kyoto protocol, GWP 466

4)

Distance 5 m, VDE tested, A7/W55, with half-spherical propagation

Information provided without guarantee! We reserve the right to make technical changes within the framework of technical advancement.

ficient of performance in accordance with EN 14511, VDE tested, rated compressor frequency

10

2.2 Product data

Average condition

1)

Series LWM 80 LWM 110 LWM 150

Energy efficiency ratio, heating 35°C/55°C A++/A++

Nominal heating power P rated kW 5 7 10

Room heating energy efficiency hs 35°C/55°C

% 161/136 161/142 164/138

Contribution to the seasonal room heating

% 4

energy ef

Yearly energy consumption QHE 35°C/ 55°C

Sound power level L

Warmer condition

ficiency of the REMKO Smart-Control

4)

A

W

2)

2629/3173 3395/3797 4588/5780

dB(A) 56 58 60

Series LWM 80 LWM 110 LWM 150

Energy efficiency ratio, heating 35°C/55°C A++/A++

Nominal heating power P rated kW 4 6 8

Room heating energy efficiency hs 35°C/55°C

Yearly energy consumption QHE 35°C/ 55°C

4)

% 182/160 187/167 169/164

1326/1379 1668/1638 2550/2537

Colder condition

3)

Series LWM 80 LWM 110 LWM 150

Energy efficiency ratio, heating 35°C/55°C A++/A++

Nominal heating power P rated kW 7 9 13

Room heating energy efficiency hs 35°C/55°C

Yearly energy consumption QHE 35°C/ 55°C

1)

verage condition = Moderate temperature periods

A

2)

Warmer condition = Warm temperature periods

3)

Colder condition = Cold temperature periods

4)

The specified value is based on results from standard testing.

4)

% 147/114 145/122 148/120

4158/6135 5485/7278 7319/10700

The actual consumption depends on the use and location of the unit

11

REMKO LWM series

Average condition

1)

Series LWM 110 Duo LWM 150 Duo

Energy efficiency ratio, heating 35°C/55°C A++/A++

Nominal heating power P rated kW 14 20

Room heating energy efficiency hs 35°C/55°C

% 161/142 164/138

Contribution to the seasonal room heating

% 4

energy ef

Yearly energy consumption QHE 35°C/ 55°C

Sound power level L

Warmer condition

ficiency of the REMKO Smart-Control

4)

per heat pump

A

W

2)

6790/7594 9176/11560

dB(A) 58 60

Series LWM 110 Duo LWM 150 Duo

Energy efficiency ratio, heating 35°C/55°C A++/A++

Nominal heating power P rated kW 12 16

Room heating energy efficiency hs 35°C/55°C

Yearly energy consumption QHE 35°C/ 55°C

4)

% 187/167 169/164

3336/3276 5100/5074

Colder condition

3)

Series LWM 110 Duo LWM 150 Duo

Energy efficiency ratio, heating 35°C/55°C A++/A++

Nominal heating power P rated kW 18 26

Room heating energy efficiency hs 35°C/55°C

Yearly energy consumption QHE 35°C/ 55°C

1)

verage condition = Moderate temperature periods

A

2)

Warmer condition = Warm temperature periods

3)

Colder condition = Cold temperature periods

4)

The specified value is based on results from standard testing.

4)

% 145/122 148/120

10970/14556 14638/21400

The actual consumption depends on the use and location of the unit

12

2.3 Unit dimensions of indoor units

40+20

840

934

1600

845

985

40

180

110 140

180

130

734

700

A

C

B

Unit dimensions

Fig. 1: Unit dimensions (all dimensions in mm)

A: Front view

B: Bird´s eye view

13

C: Side view

845

985

40

180

110 140

180

130

2

1

4

3

2

3

A

B

a

b

b

a

0

31

71

111

76

181

221

199

153

0

57

106

166

113

262

377

REMKO LWM series

Designations of the pipe connections

Fig. 2: Designations of the pipe connections

A: Rear view

B: Bird´s eye view

1: Condensate drain

2: Inlet heat pump 1 1/4"

3: Return flow heat pump 1 1/4"

4: Cable inlets

a: Air inlet

b: Air outlet

14

2.4 Diagram, cooling cycle

2

1

4

3

8

9

14

13

15

16

17

18 19

20

6

5

7

12

EEV

10

11

Fig. 3: Diagram, cooling cycle

1: Refrigerant dryer

2: Refrigerant inspection glass

3: Electr. expansion valve

4: Finned heat exchanger air suction probe

5: Finned heat exchanger fan

6: Finned heat exchanger air outlet probe

7: Refrigerant probe suction-side

8: Low pressure switch

9: Compressor

10: Refrigerant collector

11: Hot gas probe/Suction gas probe

12: High pressure switch 45 bar

13: 4-way changeover valve

14: Safety valve

15: Water outlet probe/Heat pump inlet

16: Smart Serv 7.5 kW

17: Manual bleeder valve

18: Water outlet probe/Heat pump return flow

19: Cap valve

20: Circulation pump

15

A

B

-23°C; 45°C

-7°C; 65°C

37°C; 60°C

37°C; 35°C

-23°C; 24°C

20

25

30

35

40

45

50

55

60

65

70

-30 -20 -10 0 10 20 30 40

REMKO LWM series

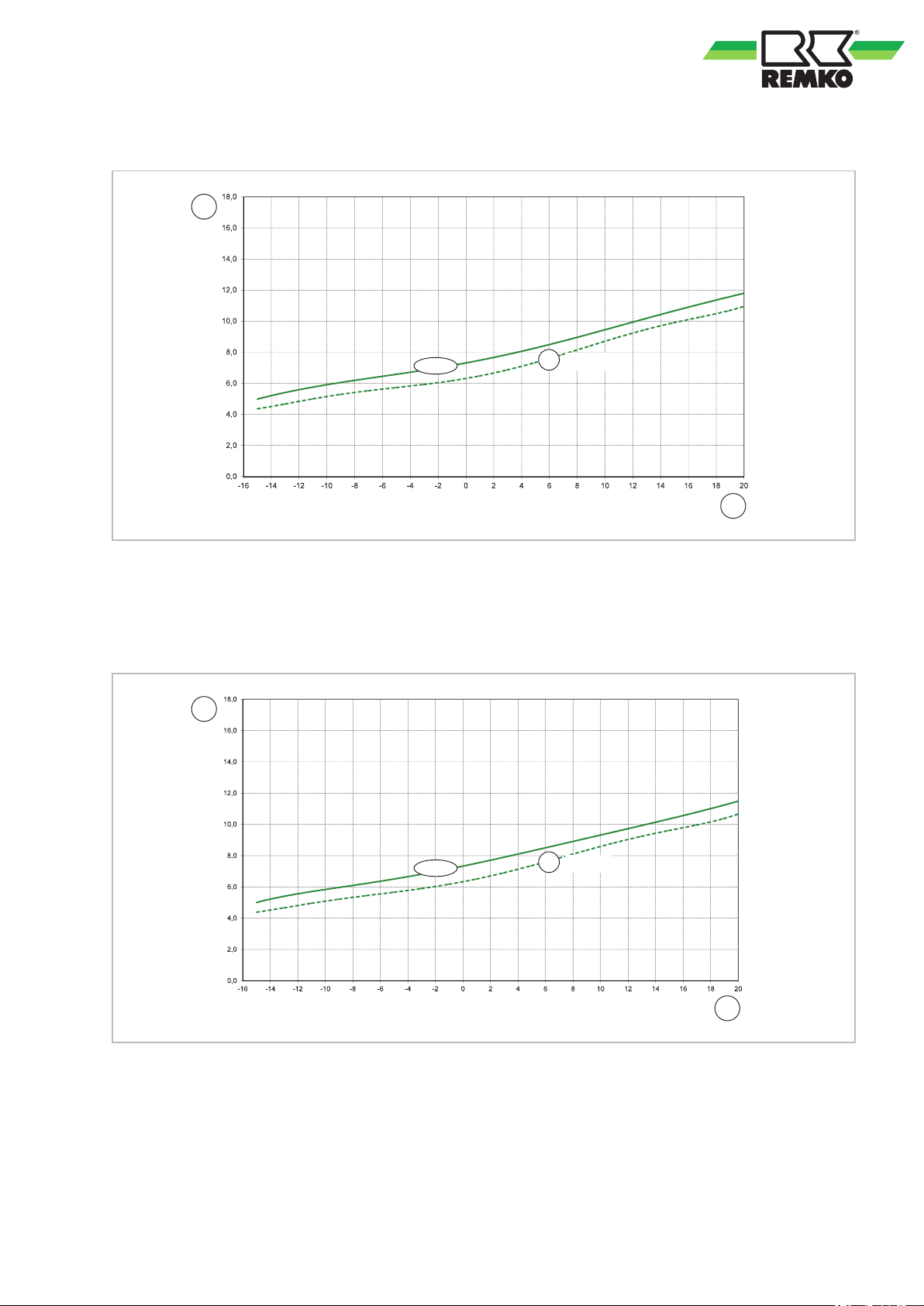

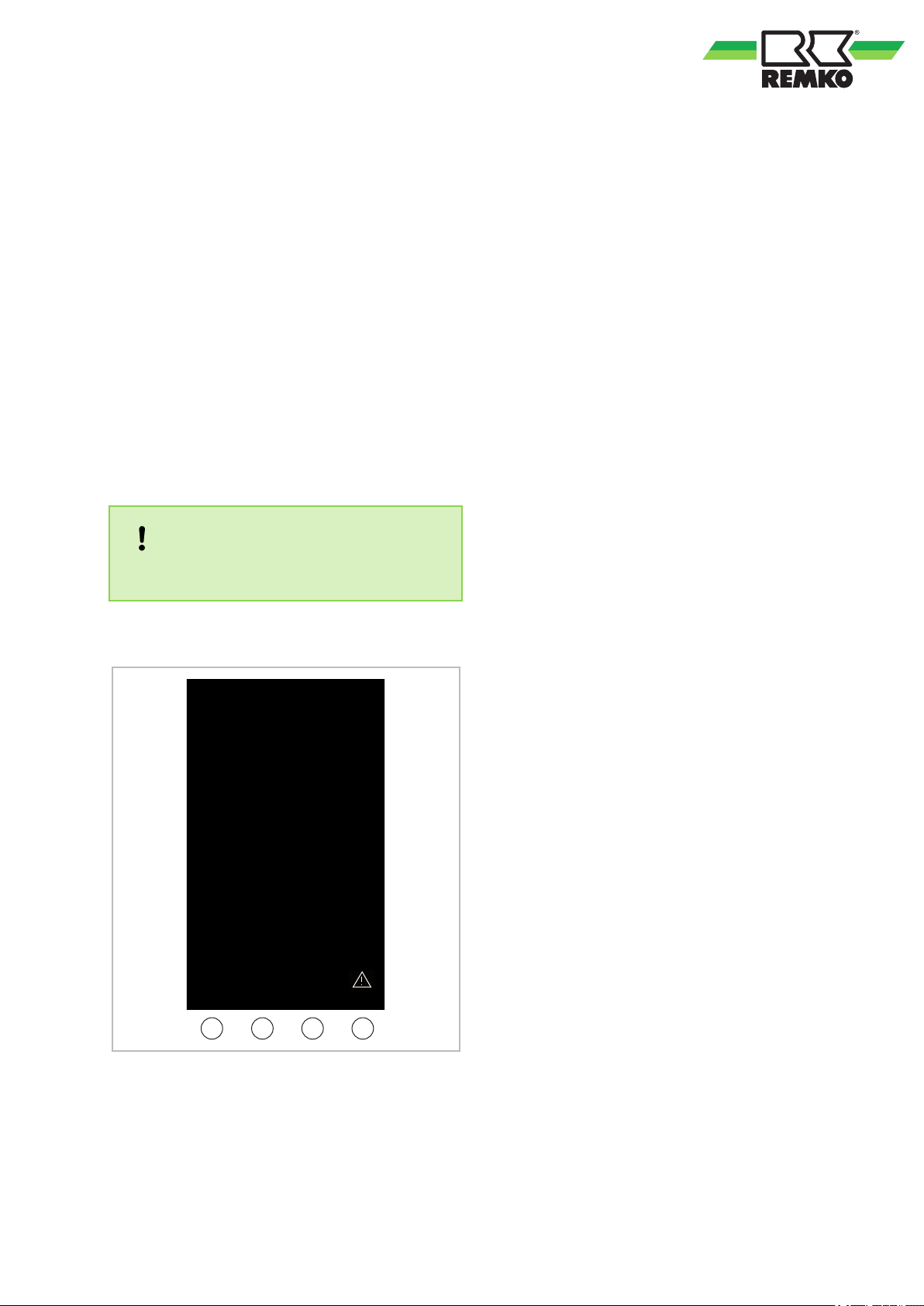

2.5 Heat pump usable limits in monovalent operation

Fig. 4: Usable limits LWM

A: Outside temperature [°C] B: Heating water inlet temperature [°C]

Outside temperature [°C] -23 -23 -7 37 37

Inlet temperature [°C] 24 45 65 60 35

2.6 Pump characteristics and circulation pump pressure losses

Fig. 5: Capacity range of the UPMXL 25-125

p: Power consumption [kPa]

H: Delivery height [m]

External control via analogue-In PWM signal. The tolerances of each curve are in acc. with EN 1151-1:2006

Q:

Requirement [l/s or m3/h ]

16

Stage Effective power consumption [W] Current consumption [A] Motor protection

min. 7 0.07 blocking current

resistant

max. 136 1.03 blocking current

resistant

Technical data

Pump type Grundfos UPMXL 25-125

Installation length mm 180

Connecting threads Inche

R 1 / G 1 1/2

s

Internally controlled via PP/CP/CC -

Control signal

Digital bidirectional

low voltage PWM signal

l

Power supply voltage+ 10/- 15 % 50 Hz V 1 x 230 V

The heating system must be dimensioned in such a way that at least the nominal heating water flow rate can

be achieved with the residual head of the circulation pump.

Residual head LWM

Series LWM 80 LWM 110 LWM 150

Nomin. 1) heating water throughput per heat pump m3/h

Residual head 2) per heat pump

3-way changeover valve pressure loss

3)

kPa 80 70 60

kPa 7 8 10

1.1 1.4 1.6

Spread K 5 5 5

1)

Nominal volume flow rates according to DIN EN 1451

1, for efficient and safe operation do not fall below the

nominal value.

2)

Residual head with pumps according to accessories (without pressure loss of the 3-way changeover valve)

3)

REMKO changeover valve DN 25

The pipe dimensions from the heat pump to the on-site hydraulic connection must be designed according to

the design medium flow rate.

The minimum diameter is DN 25.

Duo collector

Heat pump pipe length to on-site hydraulic system 1-13 m 13-20 m

Smooth pipe with inside diameter DN 25 DN 32

*)

The copper pipe of the Duo variant collector line must have an inside diameter of at least 42 mm.

line

DN 40

*)

In the case of metal composite pipes, the higher individual resistances of the fittings mean that a design with

residual head must be carried out.

17

0,0

10,0

20,0

30,0

40,0

50,0

60,0

100 125 160 200 250 315 400 500 630 800 1000 1250 1600 2000 2500 3150 4000 5000 6300 8000 10000

A

B

2

1

3

REMKO LWM series

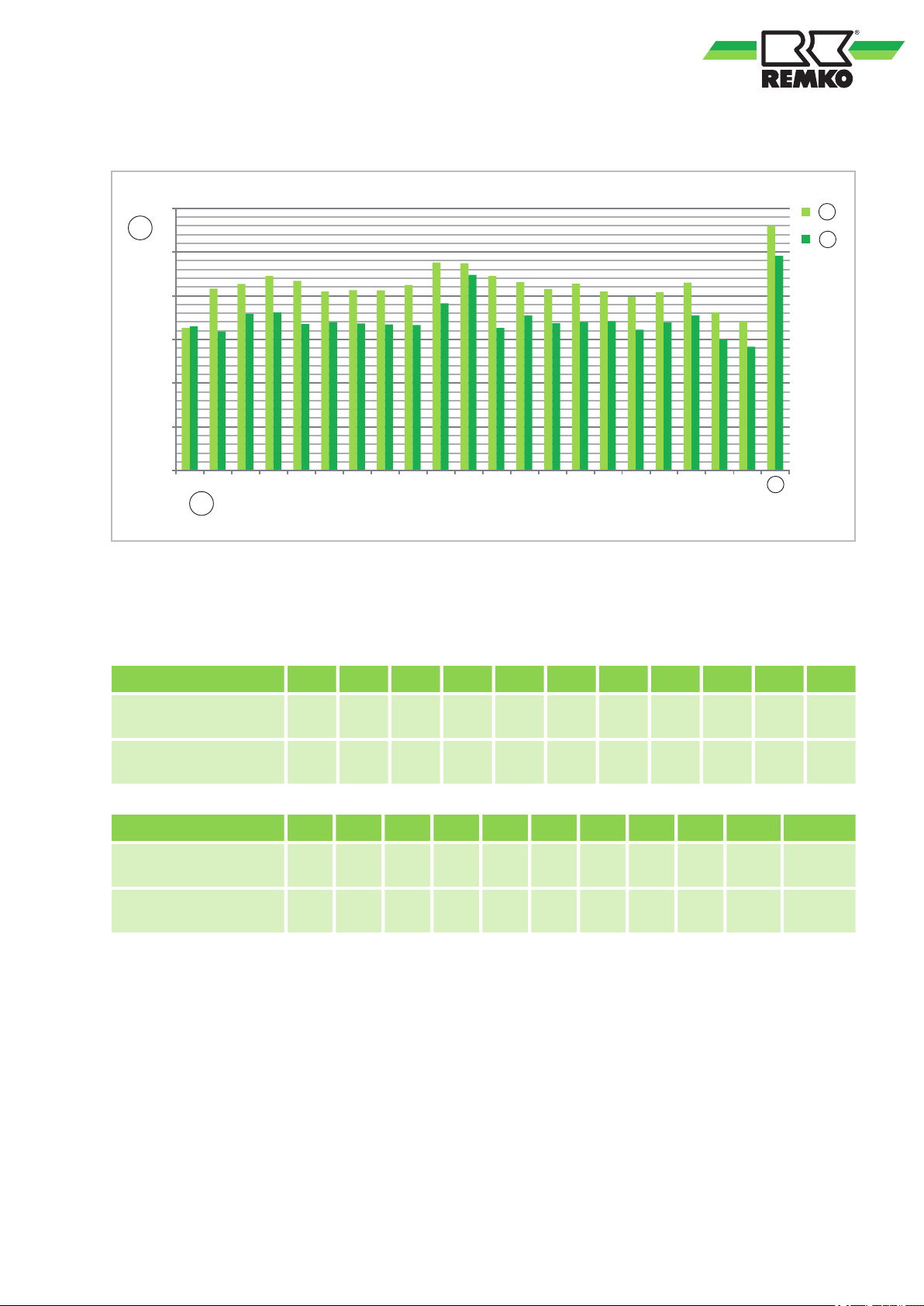

2.7 Total sound power level

LWM 80

Fig. 6:

T

otal sound power level L

A: Sound power level LwAre 1pW [dB(A)]

B: Frequency [Hz]

P

2: Night mode 60% A7/W55

3: A total [dB(A)]

1: Nominal/max. A7/W55

Middle frequency [Hz] 100 125 160 200 250 315 400 500 630 800 1000

Nominal/max.

A7/W55 [dBA]

Night mode 60%

A7/W55 [dBA]

30.6 39.6 40.6 42.4 41.3 38.9 39.2 39.2 40.4 45.5 45.4

30.9 29.8 33.8 34.1 31.5 31.9 31.6 31.4 31.2 36.2 42.7

Middle frequency [Hz] 1250 1600 2000 2500 3150 4000 5000 6300 8000 10000 A total

Nominal/max.

A7/W55 [dBA]

Night mode 60%

A7/W55 [dBA]

The sound power conforms to accuracy class 2.

The standard deviation of the aforementioned A-valued sound power levels amounts to 1.5 dB.

42.4 41.1 39.6 40.7 38.9 37.9 38.8 41.0 34.1 32.0 53.9

30.6 33.4 31.6 31.9 32.1 30.2 31.8 33.4 28.0 26.3 47.1

18

LWM 110/LWM 110 Duo

A

B

2

1

3

0,0

10,0

20,0

30,0

40,0

50,0

60,0

100 125 160 200 250 315 400 500 630 800 10 00 1250 1600 2000 2500 3150 4000 5000 6300 8000 10000

Fig. 7:

T

otal sound power level L

A: Sound power level LwAre 1pW [dB(A)]

B: Frequency [Hz]

P

2: Night mode 60% A7/W55

3: A total [dB(A)]

1: Nominal/max. A7/W55

Middle frequency [Hz] 100 125 160 200 250 315 400 500 630 800 1000

Nominal/max.

A7/W55 [dBA]

Night mode 60%

A7/W55 [dBA]

32.6 41.6 42.6 44.4 43.3 40.9 41.2 41.2 42.4 47.5 47.4

32.9 31.8 35.8 36.1 33.5 33.9 33.6 33.4 33.2 38.2 44.7

Middle frequency [Hz] 1250 1600 2000 2500 3150 4000 5000 6300 8000 10000 A total

Nominal/max.

A7/W55 [dBA]

Night mode 60%

A7/W55 [dBA]

44.4 43.1 41.5 42.7 40.9 39.6 40.8 43.0 36.1 34.0 55.9

32.6 35.4 33.6 33.9 34.1 32.2 33.8 35.4 30.0 28.3 49.1

The sound power conforms to accuracy class 2.

The standard deviation of the aforementioned A-valued sound power levels amounts to 1.5 dB.

19

A

B

3

0,0

10,0

20,0

30,0

40,0

50,0

60,0

70,0

100 125 160 200 250 31 5 40 0 500 630 800 1000 1250 1600 2000 2500 3150 4000 5000 6300 80 00 10000

2

1

REMKO LWM series

LWM 150/LWM 150 Duo

Fig. 8:

T

otal sound power level L

A: Sound power level LwAre 1pW [dB(A)]

B: Frequency [Hz]

P

2: Night mode 60% A7/W55

3: A total [dB(A)]

1: Nominal/max. A7/W55

Middle frequency [Hz] 100 125 160 200 250 315 400 500 630 800 1000

Nominal/max.

A7/W55 [dBA]

Night mode 60%

A7/W55 [dBA]

34.6 43.6 44.6 46.4 45.2 42.9 43.2 43.2 44.4 49.5 49.4

34.9 33.8 37.8 38.1 35.3 35.9 35.6 35.4 35.2 36.2 46.7

Middle frequency [Hz] 1250 1600 2000 2500 3150 4000 5000 6300 8000 10000 A total

Nominal/max.

A7/W55 [dBA]

Night mode 60%

A7/W55 [dBA]

46.4 45.1 43.5 44.7 42.9 41.6 42.8 45.0 38.1 36.0 57.9

34.6 37.4 35.6 35.9 36.1 34.2 35.8 37.4 32.0 30.8 51.1

The sound power conforms to accuracy class 2.

The standard deviation of the aforementioned A-valued sound power levels amounts to 1.5 dB.

20

2.8 Characteristic curves

60 Hz

A

B

n-max

C

60 Hz

A

B

n-max

C

Heating capacity LWM 80 at inlet temperature of 35°C

Fig. 9: Heating capacity at inlet temperature of 35 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

Heating capacity LWM 80 at inlet temperature of 45 °C

C: Rated frequency [Hz]

Fig. 10: Heating capacity at inlet temperature of 45 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

21

C: Rated frequency [Hz]

60 Hz

A

B

n-max

C

A

35° C

45° C

55° C

D

E

E

E

REMKO LWM series

Heating capacity LWM 80 at inlet temperature of 55 °C

Fig. 11: Heating capacity at inlet temperature of 55 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

COP LWM 80 at inlet temperature 35 °C, 45 °C and 55 °C

C: Rated frequency [Hz]

Fig. 12: COP at inlet temperature 35°C, 45°C and 55°C

A: Outside temperature [°C]

D: COP [-]

E: Inlet temperature [°C]

22

Heating capacity LWM 110 at inlet temperature of 35 °C

60 Hz

A

B

n-max

C

A

B

n-max

60 Hz

C

Fig. 13: Heating capacity at inlet temperature of 35 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

Heating capacity LWM 110 at inlet temperature of 45 °C

C: Rated frequency [Hz]

Fig. 14: Heating capacity at inlet temperature of 45 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

23

C: Rated frequency [Hz]

A

B

n-max

60 Hz

C

A

35° C

45° C

55° C

D

E

E

E

REMKO LWM series

Heating capacity LWM 110 at inlet temperature of 55 °C

Fig. 15: Heating capacity at inlet temperature of 55 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

COP LWM 110 at inlet temperature 35 °C, 45 °C and 55 °C

C: Rated frequency [Hz]

Fig. 16: COP at inlet temperature 35°C, 45°C and 55°C

A: Outside temperature [°C]

D: COP [-]

E: Inlet temperature [°C]

24

Heating capacity LWM 150 at inlet temperature of 35 °C

A

B

n-max

60 Hz

C

A

B

n-max

60 Hz

C

Fig. 17: Heating capacity at inlet temperature of 35 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

Heating capacity LWM 150 at inlet temperature of 45 °C

C: Rated frequency [Hz]

Fig. 18: Heating capacity at inlet temperature of 45 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

25

C: Rated frequency [Hz]

A

B

n-max

60 Hz

C

A

35° C

45° C

55° C

D

E

E

E

REMKO LWM series

Heating capacity LWM 150 at inlet temperature of 55 °C

Fig. 19: Heating capacity at inlet temperature of 55 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

COP LWM 150 at inlet temperature 35 °C, 45 °C and 55 °C

C: Rated frequency [Hz]

Fig. 20: COP at inlet temperature 35°C, 45°C and 55°C

A: Outside temperature [°C]

D: COP [-]

E: Inlet temperature [°C]

26

Heating capacity LWM 110 Duo at inlet temperature of 35 °C

60 Hz

A

B

n-max

C

A

B

n-max

60 Hz

C

Fig. 21: Heating capacity at inlet temperature of 35 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

Heating capacity LWM 110 Duo at inlet temperature of 45 °C

C: Rated frequency [Hz]

Fig. 22: Heating capacity at inlet temperature of 45 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

27

C: Rated frequency [Hz]

A

B

n-max

60 Hz

C

A

35° C

45° C

55° C

D

E

E

E

REMKO LWM series

Heating capacity LWM 110 Duo at inlet temperature of 55 °C

Fig. 23: Heating capacity at inlet temperature of 55 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

COP LWM 110 Duo at inlet temperature 35 °C, 45 °C and 55 °C

C: Rated frequency [Hz]

Fig. 24: COP at inlet temperature 35°C, 45°C and 55°C

A: Outside temperature [°C]

D: COP [-]

E: Inlet temperature [°C]

28

Heating capacity LWM 150 Duo at inlet temperature of 35 °C

A

B

n-max

60 Hz

C

A

B

n-max

60 Hz

C

Fig. 25: Heating capacity at inlet temperature of 35 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

Heating capacity LWM 150 Duo at inlet temperature of 45 °C

C: Rated frequency [Hz]

Fig. 26: Heating capacity at inlet temperature of 45 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

29

C: Rated frequency [Hz]

A

B

n-max

60 Hz

C

A

35° C

45° C

55° C

D

E

E

E

REMKO LWM series

Heating capacity LWM 150 Duo at inlet temperature of 55 °C

Fig. 27: Heating capacity at inlet temperature of 55 °C

A: Outside temperature [°C]

B: Heating capacity/total thermal load [kW]

COP LWM 150 Duo at inlet temperature 35 °C, 45 °C and 55 °C

C: Rated frequency [Hz]

Fig. 28: COP at inlet temperature 35°C, 45°C and 55°C

A: Outside temperature [°C]

D: COP [-]

E: Inlet temperature [°C]

30

1

3

4

2

3 Unit description

Description

The LWM series is a monobloc heat pump in which

refrigeration components are installed in a hermetically sealed refrigeration circuit. In addition, a

highly ef

and an electric volume flow monitor are integrated.

Furthermore, an optional electric Smart-Serv auxiliary heater can be installed to realise monoenergetic operation. The Smart-Serv can also be used

for screed drying, hygiene functions or emergency

heat-operation.

If the on-site pressure loss does not exceed the

maximum available, a heating buffer tank can be

dispensed with. If necessary, only a drinking water

storage tank and changeover valve should then be

installed.

A district heating pipe is recommended as the

water-bearing pipe from the heat pump into the

house. This can be supplied as an option. The

Smart-Control Touch controller is supplied in an

attractively designed housing for wall mounting or

as a built-in controller in an indoor unit with a

storage tank. The touch display can optionally be

installed in a double flush-mounted or double surface-mounted box. With the Smart-Control Touch,

three heating cycles can be activated, two of which

act as a mixing cycle. Further functions such as

solar thermal, second heat generator as bivalent

system, cooling, external heating cycle pumps can

be controlled as standard. A combination with a PV

system to increase its own power requirement is

integrated as standard.

ficient speed-controlled circulation pump

Function of the heat pump

A heat pump is a unit which makes use of a

working medium to absorb ambient heat under low

temperatures and transports this heat to a place

where it can be of use for heating purposes. Heat

pumps work according to the same principles as a

refrigerator. The difference is that heat, the “byproduct” of the refrigerator, is the goal of the heat

pump.

The main components of the cooling circuit consist

of an evaporator, a compressor, a condenser and

an expansion valve. In a finned evaporator, the

refrigerant evaporates both because of lower pressure and because of lower heat-source temperatures through absorption of energy from the environment. In the compressor, the refrigerant is

brought to a higher pressure and temperature by

the application of electrical energy. Next, the hot

refrigerant gas reaches the condenser, a plate heat

exchanger. Here the heat gas condenses, transferring heat to the heating system. The liquefied

refrigerant then expands and cools in a flow regulator, the expansion valve. Then the refrigerant

flows into the evaporator once more and the cycle

is complete.

Smart-Control Touch is used for regulation, and it

assures the independent operation of all safety

devices. The water circulation system consists of a

circulation pump, plate heat exchangers, dirt traps,

safety valve, a manometer, filling and drain valves,

a flow switch and a service water storage tank.

A 3-way changeover valve, overflow protection

valve, additional probes and storage systems are

available as accessories.

Fig. 29: Functional diagram heating

1: Condensing

2: Liquefying

3: Decompression

4: Evaporation

31

REMKO LWM series

Layout

A precise calculation of the building’s heating load

according to EN 12831 is required for the design

and dimensioning of a heating system. However

approximate requirements can be determined

based on the year of construction and the type of

Ä

building. This table

approximate specific heating load for a few types

of building. The required heating system output

can be calculated by multiplying the area to be

heated with the given values.

For a precise calculation, various factors must be

considered. The transmission-heat requirement,

the infiltration heat-loss and an allowance for water

heating comprise the total heating capacity which

the heating system must provide.

The total area of the floor surfaces, exterior wall

windows, doors and roofing is required in order to

determine the transmission heat requirement. In

addition, information about the materials used in

the building is required, as well as about the different thermal transmission coefficients (known as

the K value). Also required are the room temperature and the standard outside temperature, that is,

the lowest outside temperature on average that will

occur during the year. The equation for determining the thermal transmission requirement is

Q=A x U x (tR-tA) and must be calculated for all

enclosed room floor areas.

The infiltration heat requirement takes into consideration how often the heated room air is

exchanged for cold external air. The room volume

“V”, the air exchange frequency “n” and the specific heat capacity “c” of the air is also required in

addition to the room temperature and average low

temperature. The equation is: Q = V x n x c (tR-tA)

An approximate addition for the preparation of

domestic water per person amounts in acc. with

VDI 2067: 0.2 kW.

on page 32 provides an

,

Design example

By way of a design example, a residential home

with a living area of 150 m2 and a heating requirement of approx. 40 W/m2 was selected. A total of

five persons live in the house. The heat load

amount to 6.0 kW

ance of 0.2 kW results in a required heating

capacity of 7.0 kW. Depending on the power company, an additional charge must then be made in

order to factor in any service time-out periods that

may apply. The rating and determination of the

heat pump’s balance-point temperature derives

graphically from the heat pump’s inlet temperature

specific heat-output diagram (in this example 35 °C

for underfloor heating). Next, the heat load for the

standard outdoor temperature (the lowest temperature of the year locally) and the heat threshold are

marked on the graph. The outside-temperaturedependent heating requirement, (Fig. 30) simplified

here as a straight-line relationship between heatload and the start of the heating season, is

recorded in the graph of heat-load curves. The

intersection of the two straight lines with the rated

heat-load curve is plotted on the X axis, where the

balance-point temperature is read (in this example

approx. -3 °C). The minimum performance of the

2nd heat source is the difference between heat

load and the heat pump’s maximum heating

capacity on these days (in this example, the

required power required to cover peak load

requirements is approx. 3 kW).

. Adding a drinking water allow-

Building type

Passive energy house 10

Low-energy house built in 2002 40

According to energy conservation order regarding heat insulation

1995

Modern building constructed around 1984 80

Partially renovated old building constructed pre-1977 100

Non-renovated old building constructed pre-1977 200

Specific heating capacity in W/m

60

2

32

14.0

Outside temperature [°C]

Heating capacity/totalheat requirement [kW]

Bivalence point - 3 °C

Standard outside temperature

Heating load in accordance with DIN EN 12831

Rated frequency

n-max

Total thermal load

Bivalence point determination at inlet temperature 35 °C

Fig. 30: Heating performance diagram of the heat pump LWM

Monobloc heat pump

The REMKO inverter heat pump is connected to

the house via water-carrying pipes. The water-carrying pipes must be laid to be frost proof. If this is

not possible from a structural point of view

, other

frost protection measures must be implemented,

e.g. glycol, trace heating, etc.

REMKO inverter technology

The heat pump's compressor is equipped with are

equipped with a speed control system, as needed.

The power control on conventional heat pumps

provides only two states, either “ON” (full output) or

“OFF” (no output). The heat pump turns on below

a specified temperature and turns off when this

temperature is reached. Heat regulation in the

REMKO monobloc heat pump is modulated to the

actual need and is adjusted to suit actual needs.

The electronics system has an integrated frequency-converter which serves to modify the compressor speed and the speed of the fan as

required. The compressor works at a higher speed

when under full load than under partial load. The

lower speeds ensure a longer operational lifetime

for the components, improved coefficient of performance and lower noise. Lower speeds also

result in lower energy consumption (electricity) and

longer service life. I.e.: Monobloc heat-pumps will

run practically throughout the heating season. In

all, the highest efficiency possible.

33

1/3

When it is switched on, the inverter only requires

one-third of the time of conventional systems

Time

Minimal temperature fluctuations

mean energy savings

Conventional

Inverter

Temperature

10 12 14 16 18 20 22 24 26 28 30

uncomfortably

humid

comfortable

still comfortable

uncomfortably

dry

Relative humidity in %

Room air temperature in °C

REMKO LWM series

Fig. 31: Modern inverter technology

Cooling mode

Because of circuit reversal, cooling is also possible. In cooling mode, the components of the

refrigeration circuit are used to produce cold water

with which heat can be extracted from a building.

This can be accomplished with dynamic cooling or

passive cooling.

With dynamic cooling the refrigerating capacity is

actively transferred to the indoor air. This is achieved by means of water-based fan convectors. In

doing so, it is desirable that the inlet temperatures

are under the dew point, in order to transfer a

higher refrigerating capacity and to dehumidify the

indoor air.

Passive cooling refers to the absorption of heat

via cooled floors, walls or ceiling surfaces. In doing

so, water-carrying pipes make the structural sections into thermally effective heat exchangers. In

order to achieve this, the refrigerant temperature

has to lie above the dew point, in order to avoid the

formation of condensation. Dew-point monitoring is

required for this purpose.

We recommend dynamic cooling with fan convectors, in order to achieve increased cooling capacity

and in order to dehumidify the air on muggy

summer days. You will find corresponding devices

in the KWD, KWK and WLT-S series on our website: “www.remko.de”. The advantage here is that

dew point monitoring is not required.

The comfort zone in the illustration below shows

which values for temperature and humidity are

considered comfortable for people. This range

should ideally be met when heating or air-conditioning buildings.

Fig. 32: Comfort zone

34

4 Assembly

A

C

B

21 3

Außenfühler

B1

C

D

21 3 54

B2

E

A1 A2

6

4.1 System layout

System layout for heat pump assembly LWM 300 IM Stuttgart

A: Outdoor unit

B: Indoor unit with storage tank

C: External probe

System layout for heat pump assembly LWM Duo Mannheim

1: Unmixed cycle

2: Cold water

3: Hot water

A1/A2: Heat pump 1 and 2

B1: Hot water storage tank

B2: Buffer tank

C: External probe

D: Boiler/wall heating unit (optional)

E: Smart Control Touch

35

1: Hot water

2: Cold water

3: Unmixed cycle

4: Mixed cycle

5: Mixed cycle

6: Collector line (min. DN 40)

2

1

3

REMKO LWM series

4.2 General installation notes

DANGER!

All electrical installation work must be done by

an electrician.

WARNING!

All electric lines are in accordance VDE regulations to dimension and to lay

DANGER!

The connection of refrigerant pipes and the

handling of refrigerant may be only be carried

out by qualified personnel (competence category I).

n These instructions are to be observed when

installing the heat pump.

n The unit should be delivered as near as pos-

sible to the site of installation in its original

packaging in order to avoid transport damage.

n The unit is to be checked for visible signs of

transport damage. Possible faults are to be

reported immediately to the contractual partner

and the haulage company

n Suitable sites for installation are to be selected

with regard to machinery noise and the set-up

process.

n It is recommended to place the heat pump as

close as possible to the building to be heated,

observing the minimum distances.

n Establish all electrical wiring in accordance

with the relevant DIN and VDE standards.

n The electrical power cables must always be

fastened to the electrical terminals in the

proper manner. Otherwise there is a risk of

damage.

n Ensure that no water-carrying pipes pass

through living or sleeping areas.

.

.

Wall opening

n A wall opening of approx. 200 mm diameter

and 10 mm incline from the inside to the outside must be created.

o prevent damage, the interior of the wall

n T

opening should be padded or, for example,

lined with PVC pipe (see figure).

n After installation has been completed, use a

suitable sealing compound to close off the wall

opening provided by the customer, taking

account of fire protection regulations and local

conditions.

n District heating pipelines are recommended

(see accessories).

Fig. 33: Wall opening

1: Inlet/return flow, heat pump

2: Power supply, heat pump

3: Smart-Control control cable (shielded)

36

4.3 Set-up and assembly

1

20 cm

1

of the heat pump

Set-up site

n The unit may be attached only to a load-

bearing structure or wall. Ensure that the unit is

installed only vertically

should be well ventilated.

n To minimise noise, install floor consoles with

vibration dampers and a considerable distance

from acoustically-reflective walls to minimise

noise.

n The minimum clearances specified on the next

page should be maintained when carrying out

the installation. These minimum distances

serve to ensure unrestricted air inlet and outlet.

The air that has discharged may not be drawn

in again. Take the performance data of the

units into account. Additionally, there must be

adequate space available for installation, maintenance and repair.

n If the unit is erected in an area of strong winds,

then it must be protected against them and

additional stabilisation is recommended. This

can be realised for example with wire ropes or

other constructions (Fig. 34). The snow line is

to be observed during installation (Fig. 35).

n REMKO recommends always placing the unit

on vibration dampers. Vibration dampers prevent the transmission of vibrations through the

floor or walls.

n If there is insufficient space under the device

for the lines, then the pre-cut recesses can be

removed from the rear enclosure-panel and the

pipes guided through these openings.

n During installation, add about 20 cm to the

expected snow depth to guarantee unimpeded

intake and exhaust of outdoor air year round

(Fig. 35).

n The installation site of the outdoor unit should

be agreed together with the operator primarily

so that ’non-concerning levels of operating

noise’ are achieved, rather than in respect

of ’short distances’.

. The installation site

NOTICE!

The site for the unit must be selected so that

machinery noise that occurs disturbs neither the

residents nor the facility operator

TA-noise specifications as well as the table containing the drawings relating to sound pressure

levels!

The quick calculator of the "Bundesverbandes

Wärmepumpe e.V." (German Federal Association of Heat Pumps) can be used for theoretical

calculations (www.waermepumpe.de/schallrechner/).

Fig. 35: Protection against snow

1: Snow

. Observe the

Fig. 34: Protection against wind

1: Wind

37

REMKO LWM series

Assessment level in accordance

with T

Point of emissions

Daytime in

dB(A)

Industrial areas 70 70

Commercial areas 65 50

Core areas, village areas and mixed zones 60 45

General residential areas and small housing estates 55 40

Exclusively residential areas 50 35

Spa areas, hospitals and mental institutions 45 35

Isolated noise peaks of short duration may not exceed 30 dB(A) during the day and 20 dB(A) at night.

A noise

Night-time in

dB(A)

Definition of the Danger Area

WARNING!

Access to the unit is only permitted for authorised and trained persons. If unauthorised persons can approach the danger areas, these

areas must be identified with corresponding

signs, barriers, etc.

n The external danger area surrounds the unit up

to a distance of 2 m, measured in all directions

from the unit housing.

n The external danger area on-site can dif

a result of the setup. The specialist company

performing the installation work bears the

responsibility for this.

n The internal danger area is located inside the

machine and can only be reached with the use

of an appropriate tool. Access is prohibited for

unauthorised persons!

fer as

38

1

2

43

>= 250

>= 2000

>= 250

>= 1000

>= 1000

>= 900

>= 250

2

3

>= 600 >= 600 >= 600 >= 600

>= 250

>= 2000

>= 2000 >= 3000>= 600 >= 250

1

Minimum distances during construction

of a heat pump

Minimum distances during construction

of multiple heat pumps

Fig. 36: Minimum distances during construction of

a heat pump in mm

1: Next to a wall, air outlet open to the front, flow

restriction behind

2: Next to a wall, air outlet toward the wall, flow

restriction to the front

3: In a niche, air outlet open to the front, flow

restriction behind and on both sides

4: Next to a covered wall, air outlet open to the

front, flow restrictions behind and above

Fig. 37: Minimum distances during construction of

multiple heat pumps in mm

1: Next to a wall, air outlet toward the wall, flow

restriction to the front

2: In a niche, air outlet open to the front, flow

restriction behind and on both sides

3: Between two walls, air outlet toward the wall

and in the direction of other devices, open

sides: flow restriction front and rear

39

2

3

7

5

1

9 1010

44

8 8

6

A

D

C

4

4

EB

B

1

9

5

5

REMKO LWM series

Condensate drainage connection and safe

drainage - strip foundation

Fig. 38: Condensate drainage, seepage of condensate and strip foundation (cross-section)

1: Heat pump (air outlet)

2: Vibration dampers

3: Floor bracket (accessory)

4: Reinforced strip foundation, frost free

5: Gravel layer for seepage

6: Protective tube for lines and

electrical connecting line

(temperature resistant up to at least 80 °C)

7: Drainage channel

8: Frost line

9: Drainage pipe

10: Soil

NOTICE!

When installing an L

minimum distances must be observed and an

air short circuit must be prevented.

WM-Duo heat pump, the

Fig. 39: Dimensions for the strip foundation (bird's

eye view)

1: Heat pump

4: Reinforced strip foundation, frost free

5: Gravel layer for seepage

9: Drainage pipe

dimensioning the strip foundation

(all dimensions in mm)

Dime

nsion LWM 80 LWM 110 LWM 150

A 1000 1000 1000

B 200 200 200

C 840 840 840

D 700 700 700

E 600 600 600

NOTICE!

Anti-freeze protection

In the case of heat pump systems, in which

frost-free conditions are not assured, a

drainage facility should be provided. If control

and heating circulation pump are ready for

operation, the anti-freeze protection function of

the controller works. The system must be emptied when the heat pump is shut down or there

is a power failure. For heat pump systems in

which a power failure cannot be detected (e.g.

holiday home), the heating circuit must be operated with a suitable anti-freeze protection.

40

Condensate drainage connection

If the temperature falls below the dewpoint on the

finned evaporator

heating operation.

The condensate water must be drained off frostfree via a condensation pipe with a diameter of at

least 50 mm.

n The condensate drainage line must be pro-

vided by the customer and have an incline of at

least 2 %. If necessary

proof insulation.

n When operating the unit at outside tempera-

tures below 4 °C, ensure the condensate

drainage line is laid to protect it against frost. If

necessary, the lower part of the housing and

condensate tray is to be kept frost free in order

to ensure permanent draining of the condensate. If necessary, fit a pipe heater.

n If the substrate is permeable to water, it is suffi-

cient to lead the pipe vertically at least 90 cm

deep into the ground.

n In the case of condensate drainage in drains or

into the sewer system, the installation must be

frost-free and with an incline.

n The condensate may only be discharged into

the sewer system via a funnel siphon, which

must be accessible at all times.

Regional laws must be observed.

n Following installation, check that the conden-

sate run off is unobstructed and ensure that the

line is durably leak tight.

, condensation occurs during the

, fit vapour-diffusion-

Heater for anti-freeze protection

The heater for anti-freeze protection is used to

control the temperature of the interior space of the

hydraulic unit. This ensures that in the event of a

fault, the last step in the freezing of the medium

and thus defects due to frost can be prevented. A

temperature of >+3 °C is established through recirculated air operation. It is essential that a separate

UPS is used for the power supply

Safe drainage in the event of leakages

NOTICE!

Local regulations or environmental laws, for

example the German W

(WHG), can require suitable precautions to protect against uncontrolled draining in case of

leakage to provide for safe disposal of escaping

refrigerator oil or hazardous media.

NOTICE!

With the connection of an external drain line to

the oil separator

, it must be kept frost-free.

ater Resource Law

.

Pipe heater

A pipe heater can be mounted on water-carrying

pipes to ensure frost protection in the pipes.

Install a pipe heater if there is a risk of frost.

When installing on the mounting bracket or on a

foundation, we recommend the installation of a

pipe heater if the condensate drain or the inlet/

return flow heat pipes cannot be laid in a frost-free

manner or if they are heavily exposed to weather

conditions.

The pipe heater must be connected to a separate power supply (UPS).

41

2

1

3

REMKO LWM series

5 Hydraulic connection

A separate interpretation of nominal flow rate

must be made for every system (see technical

data).

n W

e recommend installing a buffer tank as a

hydraulic compensator for hydraulic isolation of

the heating cycle. Hydraulic isolation is

required when:

- different inlet temperatures need to be achieved, e.g. underfloor heating/radiators

- the pressure drop in the heating distribution

system is greater than stated in the technical

data

- the use of other heat generators, e.g. combustible burner for solid fuel, solar or bivalent

(dual-fuel) systems.

n Perform a pipe-network calculation before

installing the heat pump. After installing the

heat pump, it is necessary to perform a

hydraulic balancing of the heating circuit.

n Protect underfloor heating systems against

excessively high inlet temperatures.

n Do not reduce pipe diameters for the inlet and

return flow connections to the heat pump

before connecting a buffer tank.

n Plan for air bleed valves and drain-off taps at

appropriate places.

n Flush the system’s entire pipe network before

connecting the heat pump.

n One or, where necessary, several expansion

vessels must be designed for the entire

hydraulic system.

n The system pressure of the entire pipe network

is to be matched to the hydraulic system and

must be checked when the heat pump is

turned off. Also update the static-pressure form

supplied with the heat pump.

n As delivered, the safety assembly consists of a

pressure gauge, a bleeding valve and a safety

valve. This must be installed by the customer

in the hydraulic system.

n During installation, the minimum cross-sections

of the collector line must be 42 mm or larger.

Fig. 40: Safety assembly

1: Pressure gauge

2: Automatic bleeding valve

3: Safety valve

n All exposed metallic surfaces must be addition-

ally insulated.

n Cooling mode via the heating circuit requires a

complete vapour density insulation along the

entire length of the pipework.

n All outgoing heating cycles, including the con-

nections for water heating, are to be secured

against the ingress of circulating water by

means of check valves.

n Before being placed in service, the system

must be thoroughly flushed. Conduct a seal

test and perform a thorough bleeding of the

entire system - repeatedly

with DIN standards.

Actual schemas for hydraulic integration can be

found on the internet at www

, if necessary, in acc.

.remko.de

42

A

C

B

21 3

Hydraulic diagram for heat pump assembly LWM Stuttgart

Functions: Heating/cooling and hot water, operating mode: monoenergetic

This hydraulic cycle diagram serves solely to assist in planning activities;

the customer-provided hydraulic system on site must be planned and installed by the installation contractor!

Fig. 41: Example hydraulic diagram

A: Heat pump

B: Indoor unit LWM 300 IM

C: External probe

LWM compact heat pump models are ideal for use in new construction, where the heat pump is the sole heat

generator

Smart Control.

The indoor unit consists of an enamelled 300 l drinking water storage tank of the EWS series. In addition, a

3-way changeover valve and an electric bypass valve are installed.

The Smart-Control installed in the indoor unit switches all electrical components. Due to the pre-installed

components, considerable assembly time is saved.

The highly efficient primary pump in the outdoor unit [A] can be used as a heating cycle pump and its speed

is regulated according to requirements. There is a pressure drop present on site (see technical data). If the

pressure losses on site exceed this, a separate storage tank, e.g. REMKO KPS, must be used as a hydraulic

compensator. Then a REMKO heating cycle group unmixed, type HGU, and two mixed heating cycle groups,

type HGM, are available. Moreover, the hot water and cold water supply connections are all connected to the

indoor unit on the top.

A circulation line can optionally be connected to the storage tank.

So that the heat pump can efficiently and smoothly supply the heating water system directly (without buffer

tank), the following basic prerequisites must be fulfilled:

n The heating system must be able to be operated with an inlet temperature

n The maximum pressure drop in the heating system must not be exceeded

n A minimum water flow volume of 20 l/KW must be assured. If this is not possible, then a valve must be

n The pipe cross sections of the lines from the heat pump to the heating manifolds shall not be reduced

n The min. water volume of 5 l/kW cooling capacity with active cooling must be observed

. In an emergency, an electr. auxiliary heater (mono-energetic variant) can be switched on by the

installed at a suitable location (last heating manifold)

1: Unmixed cycle

2: Cold water

3: Hot water

(e.g. only floor heating)

43

Außenfühler

B1

C

D

21 3 54

B2

E

A1 A2

6

REMKO LWM series

Hydraulic diagram for heat pump assembly LWM Duo Mannheim

Functions: Heating/cooling and hot water, operating mode: monoenergetic

This hydraulic cycle diagram serves solely to assist in planning activities;

the customer-provided hydraulic system on site must be planned and installed by the installation contractor!

A1: Heat pump 1

A2: Heat pump 2

B1: Hot water storage tank

B2: Buffer tank

C: External probe

D: Boiler/wall heating unit (optional)

E: Smart Control Touch

The LWM compact heat pump models are ideal for use in new or in existing buildings, where the heat pump

is the sole heat generator

The Smart-Control regulation switches all electrical components.

The highly efficient primary pump inside the heat pump is used as the circulation pump. The combination

buffer tank consists of an enamelled 300 l hot water tank [B1] and a 100 l vapour diffusion-tight buffer tank

[B2] which is integrated into the system. The buffer tank is the hydraulic compensator if the pressure losses

of the heating system are too high (see “Technical data”).

n An air short circuit of the external units must be prevented

n The pressure loss available on site from both heat pumps must not be exceeded.

n The collector line of the heat pumps must be at least DN 40

n The hydraulic connection of the individual heat pumps must be at least DN 25

n The pipe cross sections of the lines from the heat pump to the connection to the storage tank shall not be

reduced

n The min. water volume with active cooling must be observed.

n The hydraulic connection of the L

. An additional heat generator can be installed to cover peak loads.

WM-Duo variant must always be made via a suitable buffer tank

1: Hot water

2: Cold water

3: Unmixed cycle

4: Mixed cycle

5: Mixed cycle

6: Collector line (min. DN 50)

44

KWS 300

A

B1

C

B2

E

21 3 54

D

Hydraulic diagram for heat pump assembly LWM Mannheim

Functions: Heating/cooling and hot water, operating mode: monoenergetic

This hydraulic cycle diagram serves solely to assist in planning activities;

the customer-provided hydraulic system on site must be planned and installed by the installation contractor!

Fig. 42: Example hydraulic diagram

A: Heat pump

B1: Hot water storage tank

B2: Buffer tank

C: External probe

D: Boiler/wall heating unit (optional)

E: Smart Control Touch

The LWM compact heat pump models are ideal for use in new or in existing buildings, where the heat pump

is the sole heat generator

The Smart-Control regulation switches all electrical components.

The highly efficient primary pump inside the heat pump is used as the circulation pump. The combination

buffer tank consists of an enamelled 300 l hot water tank [B1] and a 100 l vapour diffusion-tight buffer tank

[B2] which is integrated into the system. The buffer tank is the hydraulic compensator if the pressure losses

of the heating system are too high (see “Technical data”).

n The heating cycles connected must be hydraulically balanced.

n The pressure drop between heat pump and storage tank must not be exceeded.

n A minimum water flow volume of 20 l/KW must be assured.

n The pipe cross sections of the lines from the heat pump to the storage tank may not be reduced.

n The min. water volume of 5 l/kW cooling capacity with active cooling must be observed.

. An additional heat generator can be installed to cover peak loads.

1: Hot water

2: Cold water

3: Unmixed cycle

4: Mixed cycle

5: Mixed cycle

45

REMKO LWM series

6 Emergency-heat

operation

If the compressor fails, you can start emergencyheat operation as follows:

1. Activation of emergency-heat operation is

only possible in the expert level of the SmartControl regulation. T

"Expert" level on the basic display.

2. After activating the expert level by touching

the REMKO logo, a password is required (the

password is: "0321").

3. After confirmation, +/- symbols are displayed

at the bottom. The password can be set by

touching the +/- symbols. After the entry

confirm with "OK".

The REMKO default password for the expert

level is "0321". If this password has not

already been changed, the expert level is

enabled after entering this password.

After the expert level has been enabled, various parameter levels are visible.

4. Select the "Settings" level by touching the

"Settings" icon.

5. After selecting the "Settings" level, select the

"Basic settings" parameter

6. The "System configuration" parameter

appears in the "Basic settings" level. Select

this icon by touching it.

7. After selecting the "System configuration"

level, select the "Heat pump" parameter

8. Then deactivate the heat pump in the “Heat

pump” level by touching the “activated” icon

and changing the operating mode setting

from “activated” to “deactivated”.

The heat pump is now deactivated.

o do this, select the

,

.

.

With deactivation of the heat pump, the second

heat generator

iary heater or a condensing unit installed in the

system is active.

NOTICE!

If the heat pump is switched of

gering the fuse, the water must be drained

manually to prevent freezing.

, e.g. the REMKO Smart-Serv auxil-

f, e.g. by trig-

46

7 Cooling with room tem-

perature/humidity probe

Description of the Cooling Installation

Cooling via the mixed heating cycle

(surface heating cycle )

If the heat pump is to be used for cooling, then this

must be possible via the heating cycle. The

hydraulic connection is identical to the connection

for the heating cycle. If the mixed cycle is used for

heating or cooling, it will be connected as shown in

Fig. 42 and Fig. 41. The probes S12 and S1

measure the inlet and return flow temperatures, if a