Assembly and operating instructions

REMKO LTE 50, 60, 80

Dehumidifier

0153-2017-07 Edition 1, en_GB

Read the instructions prior to performing any task!

Read these operating instructions carefully before commissioning / using this device!

These instructions are an integral part of the system and must

always be kept near or on the device.

Subject to modifications; No liability accepted for errors or misprints!

Installation and operating instructions (translation of the original)

Table of contents

1 Safety and usage instructions............................................................................................................. 4

1.1 General safety notes....................................................................................................................... 4

1.2 Identification of notes...................................................................................................................... 4

1.3 Personnel qualifications.................................................................................................................. 4

1.4 Dangers of failure to observe the safety notes................................................................................ 4

1.5 Safety-conscious working............................................................................................................... 4

1.6 Safety instructions for the operator................................................................................................. 5

1.7 Safety notes for installation, maintenance and inspection work...................................................... 5

1.8 Unauthorised modification and changes......................................................................................... 6

1.9 Intended use................................................................................................................................... 6

1.10 Warranty........................................................................................................................................ 6

1.11 Transport and packaging............................................................................................................... 6

1.12 Environmental protection and recycling........................................................................................ 6

2 Technical data........................................................................................................................................ 7

2.1 Unit data.......................................................................................................................................... 7

3 Design and function.............................................................................................................................. 9

3.1 Air dehumidification - general note.................................................................................................. 9

3.2 Unit description............................................................................................................................. 12

4 Assembly............................................................................................................................................. 14

4.1 Setting up the unit......................................................................................................................... 14

4.2 Unit transport................................................................................................................................. 14

5 Electrical wiring................................................................................................................................... 15

5.1 General notes................................................................................................................................ 15

5.2 Electrical wiring diagram............................................................................................................... 15

6 Commissioning................................................................................................................................... 16

7

Condensate removal........................................................................................................................... 21

8 Troubleshooting and customer service............................................................................................ 24

9 Shutdown............................................................................................................................................. 25

10 Care and maintenance........................................................................................................................ 26

10.1 Care and maintenance................................................................................................................ 26

10.2 Maintenance protocol.................................................................................................................. 28

11 Exploded view of unit and spare parts............................................................................................. 29

11.1 Exploded view of the unit LTE 50/60/80...................................................................................... 29

11.2 Spare parts list LTE 50/60/80...................................................................................................... 30

12 Index..................................................................................................................................................... 32

3

REMKO LTE

1 Safety and

usage instructions

1.1 General safety notes

Carefully read the operating manual before commissioning the units for the first time. It contains

useful tips and notes such as hazard warnings to

prevent personal injury and material damage.

Failure to follow the directions in this manual not

only presents a danger to people, the environment

and the system itself, but will void any claims for

.

liability

Keep this operating manual and the refrigerant

data sheet near to the units.

1.2 Identification of notes

This section provides an overview of all important

safety aspects for proper protection of people and

safe and fault-free operation.The instructions and

safety notes contained within this manual must be

observed in order to prevent accidents, personal

injury and material damage.

Notes attached directly to the units must be

observed in their entirety and be kept in a fully

legible condition.

Safety notes in this manual are indicated by symbols. Safety notes are introduced with signal words

which help to highlight the magnitude of the danger

in question.

DANGER!

CAUTION!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause injury or material and environmental damage.

NOTICE!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause material and

environmental damage.

This symbol highlights useful tips and recommendations as well as information for efficient

and fault-free operation.

1.3 Personnel qualifications

Personnel responsible for commissioning, operation, maintenance, inspection and installation must

be able to demonstrate that they hold a qualification which proves their ability to undertake the

work.

Contact with live parts poses an immediate

danger of death due to electric shock. Damage

to the insulation or individual components may

pose a danger of death.

DANGER!

This combination of symbol and signal word

warns of a situation in which there is immediate

danger

cause serious injury.

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may be fatal or cause

serious injury

, which if not avoided may be fatal or

WARNING!

.

1.4

Dangers of failure to observe the safety notes

Failure to observe the safety notes may pose a risk

to people, the environment and the units. Failure to

observe the safety notes may void any claims for

damages.

In particular, failure to observe the safety notes

may pose the following risks:

n The failure of important unit functions.

n The failure of prescribed methods of mainte-

nance and repair

n Danger to people on account of electrical and

mechanical effects.

.

1.5 Safety-conscious working

The safety notes contained in this manual, the

existing national regulations concerning accident

prevention as well as any internal company

working, operating and safety regulations must be

observed.

4

1.6 Safety instructions for the operator

The operational safety of the units and components is only assured providing they are used as

intended and in a fully assembled state.

This unit can be used by children above the age of

8, as well as by people with impaired physical,

sensory or mental capabilities or a lack of experience and knowledge if they are supervised or have

received instruction in the safe operation of the

unit, and if they understand the associated potential hazards. Children must never play with the

device. Cleaning and user maintenance must not

be carried out by unsupervised children.

n The units and components may only be set up,

installed and maintained by qualified personnel.

n If the mains power supply line of this unit is

damaged, this must be replaced by the manufacturer or their customer services department

or a similarly qualified person in order to avoid

any hazard.

n Do not operate units or components with

obvious defects or signs of damage.

n The units may not be installed or operated in

explosive environments.

n The units must not be installed or operated in

atmospheres containing oil, sulphur

salt.

n The units must be installed upright and in a

stable position.

n The units and components must not be

exposed to any mechanical load, extreme

levels of humidity or extreme temperatures.

n All housing parts and device openings, e.g. air

inlets and outlets, must be free from foreign

objects. An unobstructed air inlet and air outlet

must be guaranteed at all times.

n The units must not be covered during opera-

tion.

n Never stick foreign objects into the units.

n The units must not be transported while they

are running.

n The units must only be transported when the

condensate container is empty and the evaporator is dry.

n All electrical cables on the outside of the units

must be protected against damage (e.g. by animals etc.).

n Before each change of location, the conden-

sate container must be emptied.

n The units must be inspected by a service tech-

nician to ensure that they are safe to use and

fully functional at least once yearly. Visual

inspections and cleaning may be performed by

the operator when the units are disconnected

from the mains.

, chlorine or

NOTICE!

Extensions to the connection cable must only

be conducted by authorised specialist electricians, taking into consideration the unit power

consumption, cable length and local use.

NOTICE!

W

ork on the refrigerant system and on the electrical equipment must only be conducted by a

specially-authorised specialist!

1.7 Safety notes for installation, maintenance and inspection work

n Appropriate hazard prevention measures must

be taken to prevent risks to people when performing installation, repair

cleaning work on the units.

n The setup, connection and operation of the

units and its components must be undertaken

in accordance with the usage and operating

conditions stipulated in this manual and comply

with all applicable regional regulations.

n If the mains power supply line of this unit is

damaged, this must be replaced by the manufacturer or their customer services department

or a similarly qualified person in order to avoid

any hazard.

n The units must be installed upright and in a

stable position.

n The units must not be exposed to direct jets of

water, e.g. pressure washers etc.

n Safety devices may not be modified or

bypassed.

n The units and components may only be set up,

installed and maintained by qualified personnel.

n Do not operate units or components with

obvious defects or signs of damage.

n The units may not be installed or operated in

explosive environments.

n The units must not be installed or operated in

atmospheres containing oil, sulphur, chlorine or

salt.

n The units and components must not be

exposed to any mechanical load, extreme

levels of humidity or extreme temperatures.

n All housing parts and device openings, e.g. air

inlets and outlets, must be free from foreign

objects. An unobstructed air inlet and air outlet

must be guaranteed at all times.

, maintenance or

5

REMKO LTE

n All electrical cables on the outside of the units

must be protected against damage (e.g. by animals etc.).

n The units must be inspected by a service tech-

nician to ensure that they are safe to use and

fully functional at least once yearly

inspections and cleaning may be performed by

the operator when the units are disconnected

from the mains.

. Visual

1.8 Unauthorised modification and changes

Modifications or changes to units and components

are not permitted and may cause malfunctions.

Safety devices may not be modified or bypassed.

Original replacement parts and accessories

authorised by the manufactured ensure safety

use of other parts may invalidate liability for

resulting consequences.

. The

1.9 Intended use

The units are designed exclusively for drying and

dehumidification purposes in industrial or commercial situations on the basis of their structural design

and equipment. The units must only be operated

by appropriately instructed personnel.

Any different or additional use is a non-intended

use. The manufacturer/supplier assumes no liability for damages arising from non-intended use.

The user bears the sole risk in such cases.

Intended use also includes working in accordance

with the operating and installation instructions and

complying with the maintenance requirements.

The threshold values specified in the technical

data must not be exceeded.

1.10 Warranty

For warranty claims to be considered, it is essential

that the ordering party or its representative complete and return the "certificate of warranty" to

REMKO GmbH & Co. KG at the time when the

units are purchased and commissioned.

The warranty conditions are detailed in the "General business and delivery conditions". Furthermore, only the parties to a contract can conclude

special agreements beyond these conditions. In

this case, contact your contractual partner in the

first instance.

1.11 Transport and packaging

The devices are supplied in a sturdy shipping con-

. Please check the equipment immediately

tainer

upon delivery and note any damage or missing

parts on the delivery and inform the shipper and

your contractual partner. For later complaints can

not be guaranteed.

WARNING!

Plastic films and bags etc. are dangerous

toys for children!

Why:

- Leave packaging material are not around.

- Packaging material may not be accessible to

children!

1.12 Environmental protection and recycling

Disposal of packaging

All products are packed for transport in environmentally friendly materials. Make a valuable contribution to reducing waste and sustaining raw materials. Only dispose of packaging at approved

collection points.

Disposal of equipment and components

Only recyclable materials are used in the manufacture of the devices and components. Help protect

the environment by ensuring that the devices or

components (for example batteries) are not disposed in household waste, but only in accordance

with local regulations and in an environmentally

safe manner

cling specialists or at collection points.

, e.g. using certified firms and recy-

6

2 Technical data

2.1 Unit data

Unit type LTE 50 LTE 60 LTE 80

Operating range, temperature °C 3 to 32

Operating range, humidity % RH 40 to 100

Dehumidification capacity max. l/day 51 62 80

at 30 °C / 80% RH

(DER)

1)

45.2 54.0 70.1

l/day

l/day

at 20 °C / 70% RH

(DER)

1)

25.6 31.9 40.7

l/day

at 10 °C / 60% RH

Max. airflow volume

(DER)

m3/h

1)

8.0 10.1 12.3

380 465 490

Condensate container capacity l 10.0

Compressor / condenser - design Rotary piston

Refrigerant

2)

R410A

Refrigerant quantity g 420 540 750

Power supply V/Hz 230/1~/50

Max. rated current consumption A 2.86 3.61 4.01

Max. power consumption kW 0.63 0.76 0.91

At 20 °C / 70% RH kW 0.48 0.60 0.68

Customer-provided electrical protection A 16

Type of connection Y

Enclosure class IP20

Sound pressure level LpA 1m

3)

dB(A) 49 53 52

Electronic start safeguard Series

Operating hours counter Series

Power meters Series

Hot gas defrosting Series

Hygrostat Series

Room temperature sensor Series

Condensate pump, built-in Option

Hose length (condensate pump) m

5 (10 4))

Delivery height (condensate pump) m 5

For more, see the next page.

7

REMKO LTE

Unit type LTE 50 LTE 60 LTE 80

Dimensions

Depth mm 512

Width mm 540

Height mm 795

Height incl. transportation bracket mm 945

Weight kg 38.5 40.0 45.0

EDP no. 618500 618600 618800

EDP no. Unit with condensate pump 618505 618605 618805

1)

(DER) = Dehumidification output figure in accordance with DIN EN 810

2)

Contains greenhouse gas according to Kyoto protocol.

3)

Noise level measurement DIN 3744 - KL 2

4)

Max. permissible hose length

W

e reserve the right to modify the dimensions and design as part of the ongoing technical development

process.

8

A

B

3 Design and function

3.1 Air dehumidification general note

The correlations occurring when air is dehumidified

are based on physical laws. These are depicted

here in graphical form in order to provide you with

a brief overview of the principles of air dehumidification

The use of REMKO air dehumidifiers

n Even if windows and doors are well insulated,

water and moisture are still capable of penetrating thick concrete walls.

n The water required for setting in the production

of concrete, mortar and plaster etc. may only

fused after 1-2 months.

be dif

n Even moisture trapped in the masonry after

high-water or a flood is released very slowly.

n The same is also true of moisture contained in

stored materials for example.

The moisture (water vapour) released from parts of

a building or materials is absorbed by the surrounding air

increases, which ultimately gives rise to corrosion,

mould, rot, peeling of paint and other unwanted

damage. By way of example, the diagram below

shows the corrosion rate of metal in different levels

of humidity.

. As a result, the moisture content

1. By heating and air exchange: The air in the

room is heated in order for moisture to be

removed and then this air is fed outside. All

of the energy that is involved is lost together

with the moist air that is released.

2. By air dehumidification: The moist air that is

present within an enclosed space is continuously dehumidified in accordance with the

condensation principle.

With regard to energy consumption, air dehumidification has one distinct advantage:

Energy expenditure is limited exclusively to the air

volumes present. The mechanical heat that is

released by the dehumidification process is fed

back into the room.

NOTICE!

Under normal use, the air dehumidifier uses

approximately 25% of the energy that is

required for the "heating and ventilating" principle.

Fig. 1: Corrosion rate in relation to relative humidity

A: Corrosion rate

B: Relative humidity [%]

It is evident that the corrosion rate below 50% relative humidity (RH) is low

gible.

The corrosion rate increases significantly above

60% RH. This threshold for damage as the result

of humidity also applies to other materials, such as

powdery substances, packaging, wood and electronic units.

Buildings may be dried in a variety of ways:

9

, and below 40% is negli-

REMKO LTE

Relative air humidity

Our ambient air is a gaseous mixture which always

contains a certain volume of water in the form of

water vapour

per kg of dry air (absolute moisture content).

1m3 of air weighs approx. 1.2 kg at 20 °C

Depending on the temperature, each kg of air is

only capable of absorbing a certain volume of

water vapour. Once this capacity has been

reached, the air is referred to as "saturated" and

has a relative humidity (RH) of 100%.

Relative humidity is understood to mean the ratio

between the current quantity of water vapour in the

air and the maximum possible quantity of water

vapour at the same temperature. The ability of the

air to absorb water vapour increases as the temperature rises. I.e. the maximum possible (absolute) water content becomes greater as the temperature rises.

Temp.

°C 40% 60%

. This volume of water is specified in g

Water vapour content in g/m

at humidity of

3

Drying materials

Building materials and structures are capable of

absorbing considerable volumes of water

brick 90-190 l/m³, heavy concrete 140-190 l/m³ and

limestone 180-270 l/m³. The drying of moist materials such as masonry is effected as follows:

The moisture moves from the inside of the material

to its surface.

, such as

-5 1.3 1.9

+10 3.8 5.6

+15 5.1 7.7

+20 6.9 10.4

+25 9.2 13.8

+30 12.9 18.2

°C 80% 100%

-5 2.6 3.3

+10 7.5 9.4

+15 10.2 12.8

+20 13.8 17.3

+25 18.4 23.0

+30 24.3 30.3

Fig. 2: Drying damp masonry

n Evaporation occurs on the surface = T

of water vapour to the ambient air

n The air containing water vapour is constantly

circulated through the REMKO air dehumidifier.

The air is dehumidified and, slightly heated,

leaves the unit in order to re-absorb water

vapour

n In this way, the moisture contained in the mate-

rial is reduced gradually

The material is dried!

The accumulated condensate is collected in the

unit and drained of

f from there.

ransfer

Fig. 3: Extracting and collecting condensate

10

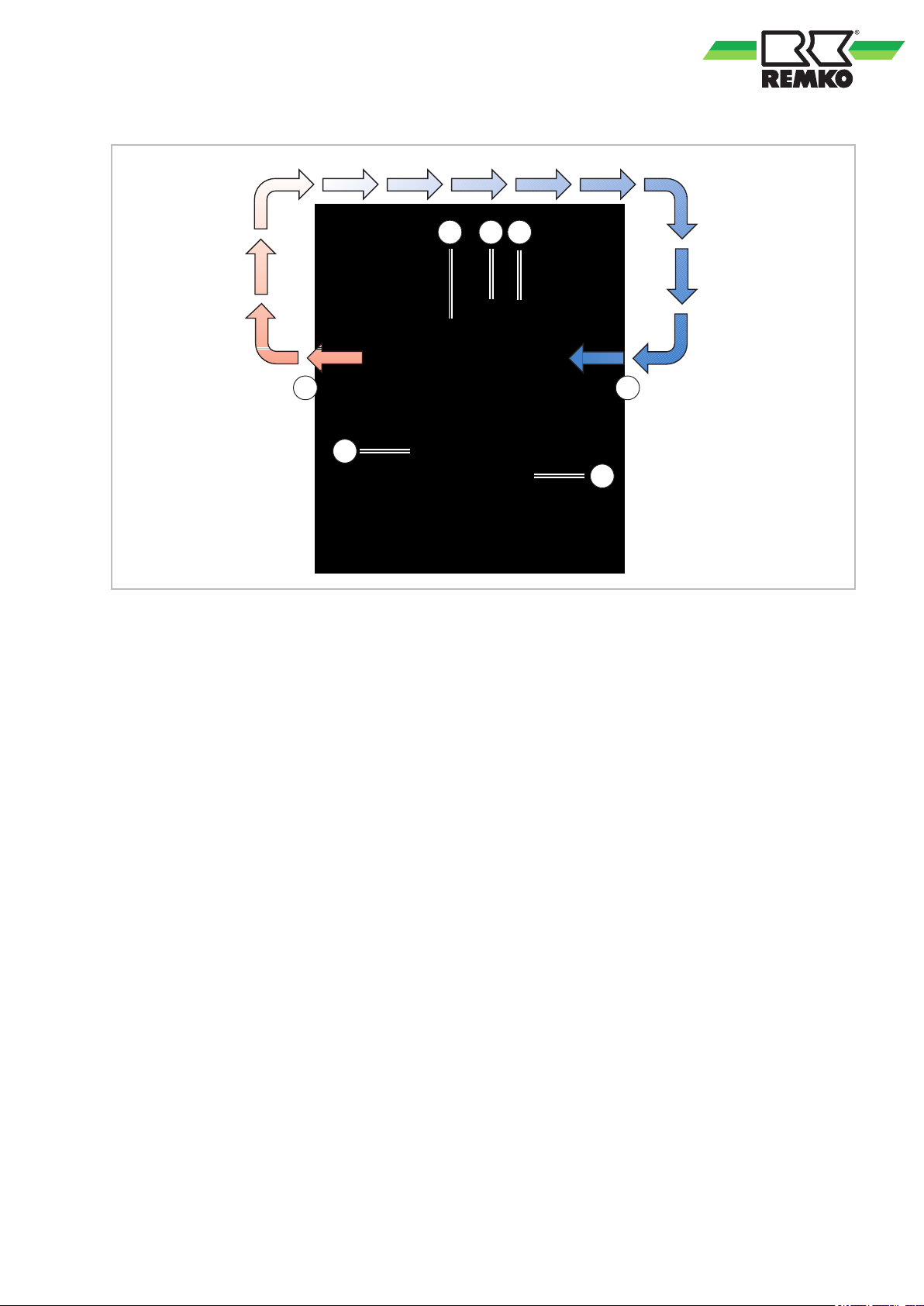

Functional principle of the air dehumidifier

2

1

A

B

C

a

As it flows through or over the evaporator, the air stream is cooled to dew point. The water vapour condenses, and is collected in a condensate trap from where it is drained of

f.

Fig. 4: Functional principle of the air dehumidifier

1: Evaporator

2: Condenser

A: Air temperature

The condensation of water vapour

Because the capacity for the maximum possible

volume of water vapour increases as the air is

heated, the volume of water vapour contained

remains constant and so relative humidity falls.

In contrast, because the capacity for the maximum

possible volume of water vapour decreases as the

air is cooled, the volume of water vapour contained

remains constant and so relative humidity

increases. If the temperature continues to fall, the

capacity for the maximum possible volume of water

vapour is reduced so much so that it is ultimately

equal to the volume of water vapour contained in

.

the air

This temperature is referred to as the dew point. If

the air is cooled to below dew point, the volume of

water vapour in the air will become greater than

the maximum possible volume of water vapour. At

this point, the water vapour begins to precipitate. It

then condenses to water. Humidity is then

removed from the air.

B: Air direction

C: Humidity

a: Progression

Examples of condensation include steamed-up

window panes in winter, or the moisture on the outside of a cold drinks bottle.

As the relative humidity of the air increases, so too

does the dew point, making it easier for the temperature to fall below it.

Condensation heat

The energy transferred to the air from the condenser consists of:

1. the amount of heat derived beforehand in the

evaporator

2. the electrical drive energy

3. the condensation heat released by the lique-

fying of the water vapour

.

11

REMKO LTE

Energy must be supplied when liquid is converted

into a gas. This energy is designated as evaporation heat. It does not cause any increase in temperature, but is required to convert a liquid into a

gas. Conversely

liquefied, this is designated as condensation heat.

The amount of energy from evaporation heat and

condensation heat is the same.

For water, this is: 2250 kJ/kg (4.18 kJ = 1kcal)

From this it is evident that the condensation of

water vapour causes a large quantity of energy to

be released. With drying operations, a heat cycle is

created, whereby heat is consumed for evaporation and released for condensation.

Generally speaking, the time required for the

drying process is not only dependent on the

output of the unit, but is determined to a greater

extent by the speed at which the material or

building section loses its moisture.

, energy is released when gas is

3.2 Unit description

The units have been designed for universal and

straightforward air dehumidification.

Their compact dimensions allow the unit to be

transported and set up with ease.

The units operate in accordance with the condensation principle and are equipped with a hermetically sealed refrigerant system, low-noise and lowmaintenance fan, operating hours and energy

counter as well as a connection cable with plug.

Fully-automatic electronic controller

container with integrated overflow protection in

addition to connection ports for direct condensate

drainage help to ensure continuous fault-free operation.

The units conform to the fundamental health and

safety requirements of the appropriate EU stipulations. The units are dependable and offer ease of

operation.

Locations at which units are used

The units are used in all locations, where dry air is

a must and where economic consequential

damage (such as that caused by mould) must be

prevented.

, a condensate

The units may be used for the drying and dehumidification of areas such as:

n New buildings, industrial buildings

n Basements, storage rooms

n Archives, laboratories

eekend homes, caravans

n W

n Bathrooms, wash rooms and changing rooms

etc.

Operating sequence

Switching on the unit puts the electrical control into

operation. The green "COMP

on the control panel illuminates. Due to an automatic pressure equalisation, the units start with a

time delay of around 10 seconds.

The fan extracts the moist room air through the

dust filter, evaporator and the condenser behind.

Heat is removed from the room air on the cold

evaporator. The air is then cooled to below dew

point. The water vapour contained in the room air

is then deposited as condensate or rime on the

evaporator fins.

If the temperature sensor here measures a pre-set

minimum, it activates a timer with a 30 minute

delay. If the evaporator temperature stops

increasing during this period, the cooling cycle

switches to hot gas defrosting after the timer cycle.

The fan remains out of operation during the

defrosting phase.

As soon as the rime (ice) has been defrosted and

the temperature at the probe has increased, the

unit switches back to normal dehumidification

mode.

If the room temperature is sufficiently high, the surface of the fins will not be cold enough for rime formation to occur, rendering defrosting unnecessary.

Therefore, the air dehumidifiers work economically.

The cooled and dehumidified air is re-heated by

the condenser (heat exchanger), and blown back

into the room through the outlet grille. The processed, dry, heated air then re-mixes with the room

air.

Continuous circulation of the room air through the

unit gradually reduces the relative humidity (% RH)

in the room to the desired humidity level.

Depending on the room temperature and the

humidity, only 30-40% electrical energy is required,

in accordance with the output of the unit.

. ON" indicator light

12

21

4

3

5

A

B

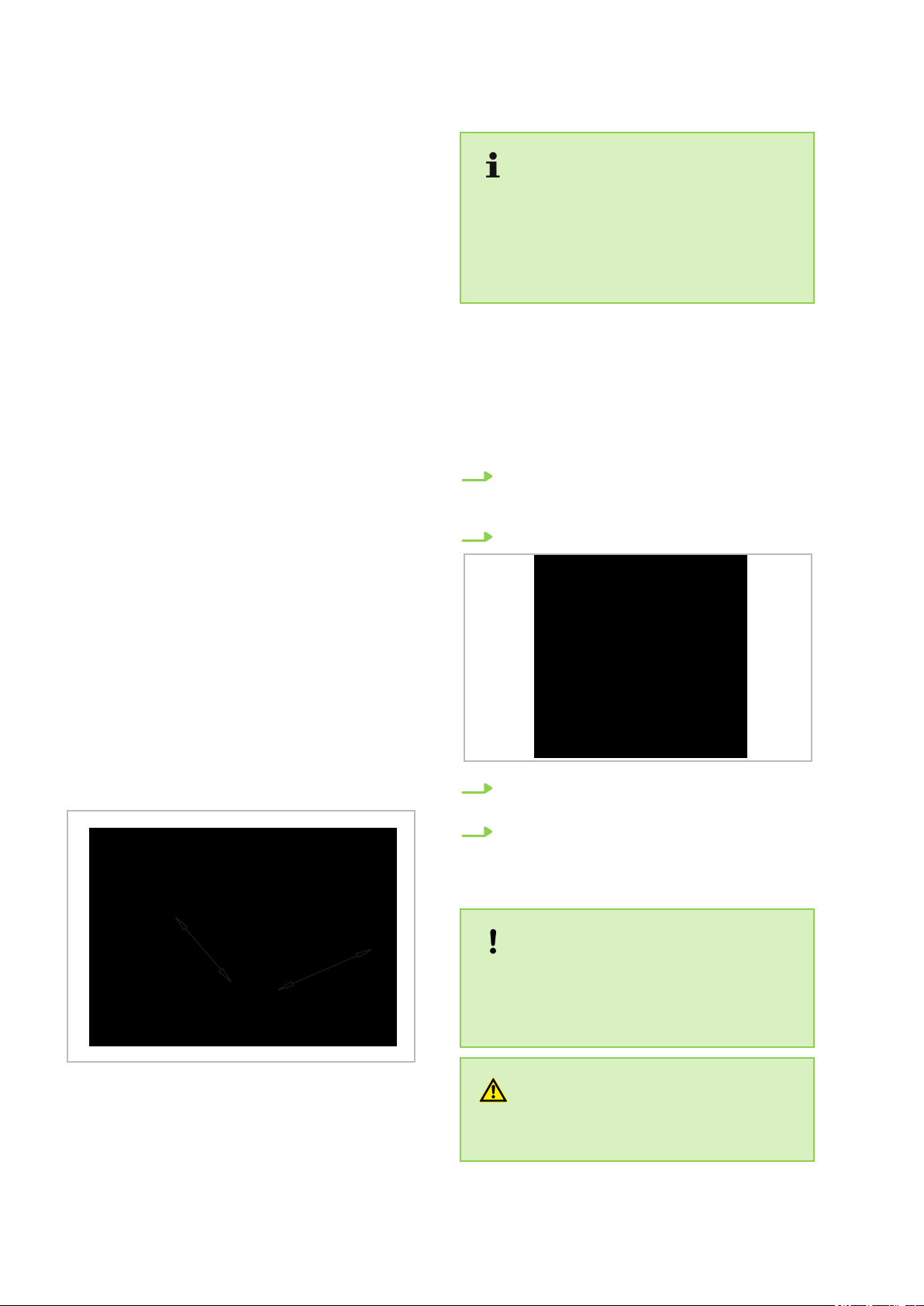

Fig. 5: Air dehumidification operating principle

A: Dehumidified room air

B: Moist room air

1: Fan

2: Condenser

3: Evaporator

4: Compressor

5: Condensate container

13

0,5 m

0,5 m

REMKO LTE

4 Assembly

4.1 Setting up the unit

For the best economic and safe use of the units,

the following notes must be followed in full:

n The units must be set up in an upright and

level position, to ensure that the condensate

can drain freely

o ensure optimum air circulation, the units

n T

should be set up in the centre of the room,

where possible

n It must be ensured that the air can be sucked

in on the front of the unit and blown out of the

rear of the unit without obstruction

n Observe a minimum clearance of 50 cm from

walls at all times

n Units must never be set up in the immediate

vicinity of heaters or other sources of heat

n The room being dried or dehumidified must be

closed to the surrounding atmosphere

n Air circulation is improved if the unit is set up

approx. 1 m above the ground

n Avoid having opened windows and doors etc.,

and avoid frequent entry to or exit from the

room as much as possible

n If the units are to be used in dusty environ-

ments, appropriate care and maintenance

measures should be taken in accordance with

the relevant conditions

n The output of the unit is entirely dependent on

the conditions inside the room, room temperature, relative humidity and observance of the

set-up instructions

n The units may not be used in environments

containing a great deal of dust or chlorine, or in

places with atmospheres containing ammonia

NOTES:

– Keep windows and doors closed!

– Keep at least 0.5 m away from walls.

– Maintain adequate clearance from heaters

or other sources of heat.

4.2 Unit transport

For easy transportation, the units are equipped

with 2 large wheels and an ergonomic transportation handle and protective frame. This can also be

dismantled easily if required.

When transporting the units, observe the following:

1. Before each change of location, switch of

the unit and remove the power plug from the

mains socket.

2. Drain the condensate container

3. Only transport the units in an upright position

where possible.

4. If the unit was transported on its side, you

must wait 1 hour with the unit in an upright

position before switching on.

.

f

Fig. 6: Setting up the unit

NOTICE!

Beware of dripping condensate. After switching

of

f the units, the evaporator may continue to

defrost under the influence of the ambient temperature.

WARNING!

The mains cable must never be used as a pull

cord or fixing device.

14

5 Electrical wiring

~

A

B

21 4

3

5 6 7 8 9

1 2 3 4 5 6 7 8

PE

PE

PE

10

C

PE L N

11

12

PE

5.1 General notes

n The units are operated with 230 V / 50 Hz

alternating current

n The electrical connection is made using a built-

in mains cable with earthed safety plug

WARNING!

The electrical connection to the units must be

made at feed-points with residual current

devices in accordance with VDE 0100, Section

704. When installing the units in extremely

damp environments such as laundry rooms,

showers etc., the unit must secured with a

residual current device provided by the customer in accordance with the regulations.

5.2 Electrical wiring diagram

n Extensions to the connection cable may only

be carried out by authorised electricians, subject to the length of the cable, connected load

of the unit and taking into consideration how

the unit is used at its location

CAUTION!

All cable extensions must only be used in fully

un-reeled or reeled of

f condition.

Fig. 7: Electrical wiring diagram

A: Control board

B: Display circuit board

C: Optional

1: Power supply

2: Compressor

3: Solenoid valve

4: Fan motor

5: Evaporator probe

We reserve the right to modify the dimensions and design as part of the ongoing technical development

process.

15

6: Condenser probe

7: Water stop probe

8: RESET button

9: Humidity probe

10: Fuse 3.15A 250V

11: Mains adapter

12: Condensate pump

REMKO LTE

6 Commissioning

Before commissioning the unit or if local requirements dictate, the air-inlet grille and air-outlet grille

must be checked for contamination.

NOTICE!

A contaminated grille or filter must be cleaned

or replaced immediately

Important notes prior to commissioning

n All extensions to the electrical connection must

be of a suf

used fully rolled out or unrolled.

n Never use the power supply connection cable

as a pull cord.

n After being switched on, the units operate fully-

automatically until switched off by the float

when the condensate container is full.

n The condensate container must be inserted

properly.

n In order to prevent damage to the condenser,

the units are equipped with a mechanism that

prevents the compressor from being immediately switched back on after it is switched off

The compressor does not switch back on

until after a waiting time of ca. 1 minute!

ficient cable size and must only be

.

Starting the unit

Start the unit as follows:

1. Plug the unit's power plug into a properly

installed and fused mains socket (230V/50

Hz).

If you connect the dehumidifier to the mains,

the unit should be switched of

ating). The segment display and LED indicators illuminate for 3 seconds (the humidity

display shows "88" and the hour counter display shows "88888.8"). After that the segment display for the humidity [3] shows the

environmental humidity and the display for

the operating hours counter and the energy

counter [6] shows the operating hours

counted for the compressor.

2. Actuate the "ON/OFF" key

The green "COMP. ON" indicator light illuminates. The unit switches on with a time delay

of around 10 seconds and then runs in continuous operating mode.

The unit will now operates fully-automatically

until the desired relative humidity (% RH) has

been reached or until the unit is switched off

by the float when the condensate container is

full. In this case, the red "FULL TANK" indicator light illuminates.

f (not oper-

.

NOTICE!

In room temperatures below 10 °C and relative

humidity below 40%, economical use of the unit

can no longer be guaranteed.

Automatic restart after power failure:

If the electrical power fails or if the power plug is

pulled out during operation, the unit switches off.

When the unit is switched back on again or if the

power plug is put back in again the unit starts up

again automatically after a safety delay time of 70

seconds.

16

Control and display panel:

2 14

3

56

789101112

1

2

3

Fig. 8: Control panel

ON / OFF key:

After actuating the ON / OFF key whilst switched

of

f, the unit starts as soon as the humidity in the

room (RH) is 4% higher than the target value set

for the humidity in the room. The start sequence is:

Fan motor ON → solenoid valve ON 10 seconds

and then OFF → compressor ON. If the room

humidity is lower than the target value set for the

humidity in the room, then the "COMP. ON" indicator flashes and the unit is in standby mode (not

operating).

If the ON / OFF key is actuated during operation,

the unit and the COMP ON" display switch off. The

ON / OFF delay time of the compressor is 1

minute.

SET HUMIDITY - Desired humidity setting:

After the unit is switched on, the target room

humidity can be adjusted up or down by pressing

the arrow keys. As soon as the room humidity reaches the target humidity set, the compressor and

the fan motor stop. The target room humidity set is

displayed for 3 seconds during the adjustment and

then reverts to the current measured room

humidity

.

NOTE:

If the humidity lies below the target humidity set

(i.e.: rRH <-3%), the compressor and the fan

motor stop. If the humidity is higher than the target

humidity set (i.e.: rRH >+4%), the unit restarts

with a 3 minute delay

.

Example: If the target humidity = 50% RH, but the

room humidity is 47% RH, then the compressor

and fan motor stop and the "COMP. ON" indicator

flashes (standby display!). While the room humidity

rises to 54% RH, the unit restarts with a 3 minute

delay time in accordance with the start function

sequence.

The target room humidity value must be set within

3 seconds by pressing the up arrow or down arrow

keys. Then the current room humidity is displayed

again.

Segment display for humidity

, room temper-

ature and malfunction code:

The standard display is the current measured room

humidity. The humidity value to be changed is displayed for 3 seconds by pressing one of the arrow

keys [2] to set the target room humidity. If the

ROOM TEMP key is pressed, the current measured room temperature is shown in the display for

5 seconds and then the display automatically

switches back to the current measured room

humidity.

n If the unit is restarted it reverts to the pre-

vious setting

n The adjustment steps for the target humidity

are 5% ( RH) per key press. The adjustment

range for the target humidity should lie

between 30% and 70% ( RH)

17

4

5

6

7

8

9

REMKO LTE

Function or situation Segment display

Power plug is plugged in, the unit is

switched of

f

Current measured room humidity is displayed

The unit starts Current measured room humidity is displayed

During the adjustment of the target room

The target room humidity set is displayed

humidity

Upon actuation of the ROOM TEMP. Key

The current measured room temperature is

displayed for 5 secs

Is a malfunction is present Error code is displayed

Room temperature key (RT) - T

o display the

room temperature:

By actuating the "ROOM TEMP." key, the red RT

°C indicator illuminates and the current room temperature is displayed for 5 seconds in the segment

display [3]. Then the current measured room

humidity appears again automatically.

COMP

. ON INDICATOR:

If the compressor is running, this indicator is illuminated. If the compressor is stops, the indicator

flashes.

The unit has a 3 minute restart delay for the compressor as a safety function. This means that the

compressor requires 3 minutes to restart after it

has stopped due to having reached the target

COUNTED key - to display the electrical

power consumed or the compressor run-time

room humidity set. The "COMP. ON" indicator

flashes during the 3-minute protection period

counted:

By actuating the "COUNTED" key

, the "kWh" indicator illuminates and the electrical power (kW) consumed by the unit is displayed in the segment display [6].

Actuating the "COUNTED" key again switches off

the "kWh" indicator and the operating hours (h) of

the compressor are displayed in the segment display [6].

DEFROST INDICA

If the temperature of the evaporator (Te) is <= 1 °C

and the compressor runs for more than 5 minutes,

the DEFROST indicator flashes and the 30-minute

delay timer for the defrost function starts.

Defrost function: Compressor still ON, fan motor

OFF, solenoid valve ON, DEFROST indicator illuminates. If the temperature of the evaporator (Te)

TOR:

is >= 3 °C then the defrost function stops and the

Segment display - display of the electrical

power consumed or the compressor run-time

counted:

In standby mode, the current compressor run-time

(h) is displayed in the segment display [6] or

, by

actuating the "COUNTED" key, the electrical power

consumed (kWh).

The segment display [6] shows the operating hours

of the compressor or the electrical power consumed by the unit. The display shows values from

"0.0" to "99999.9"

DEFROST indicator extinguishes.

Function of the unit after defrost: Compressor ON,

fan motor ON, solenoid valve OFF, DEFROST indicator off

"CHECK" indicator:

If there is an abnormal situation (malfunction), the

CHECK indicator [9] illuminates or flashes. If the

temperature probe (T

e or Tc) or the humidity probe

is defective, the unit switches off and the indicator

light [9] illuminates. Then the error code (E1, E2,

E4 or E5) is displayed in the segment display [3]. If

the water tank is full (FULL TANK), the indicator

light (CHECK) flashes.

If the temperature of the condenser (Tc) is over

50 °C while the unit is running, the indicator light

(CHECK) flashes.

There are two types of protective function for the

Tc over-temperature (50 °C):

18

10

11

12

If Tc is >50 °C and the compressor runs within 5

minutes, the unit switches of

f and the error code

"E3" is shown in the segment display [3] and the

CHECK indicator [9] flashes. In this case, the fault

cannot be reset with a key press. The unit power

plug must be removed from the socket so that the

unit is completely de-energised. Then, the dehumidifier can be restarted after a restart delay of 70

seconds.

If Tc is > 50 °C and the compressor runs over 5

minutes, the compressor stops but the fan motor

continues to run for a further 30 minutes. The segment display flashes with fault code E3 during this

time. After 30 minutes the unit is restarted for

normal function with the previous setting.

NOTE:

n Within this 30 minute protective period, the

"ON / OFF" key can be pressed in order to

switch the unit of

f. If the "ON / OFF" key is

then pressed, the unit restarts after a delay

time of 1 minute.

RT °C INDICATOR:

If the "ROOM TEMP" key is pressed, the RT indicator [10] illuminates for 5 seconds.

"FULL T

ANK" DISPLAY:

If the water tank is full the "FULL TANK" and

"CHECK" indicators illuminate. The compressor

and the fan motor are automatically switched off at

this time.

In order to reset the messages described, the condensate water must be removed from the water

tank. Then the water tank must be properly

inserted back into the unit. After that the unit will

start again after a 3 minute delay time.

If the unit is switched off while the "FULL TANK"

and "CHECK" indicators are illuminated, both indicators switch off.

If the unit is switched on, but is in standby mode

(i.e.: room humidity is lower than the target room

humidity set), the compressor and the fan motor

are switched off and the "COMP. ON" indicator illuminates. If the water tank is full at this time, the

"FULL TANK" and "CHECK" indicators flash.

kWh INDICA

TOR:

By actuating the "COUNTED" key, the "kWh" indicator illuminates and the electrical power in kW

consumed by the unit is displayed in the segment

display [6].

19

REMKO LTE

Function table:

Functions

A Comp. ON LED OFF Flashes ON ON ON OFF

B Check LED OFF OFF OFF OFF OFF Flashes

C Defrost LED OFF OFF OFF Flashes

D Full Tank LED OFF OFF OFF OFF OFF Flashes

E Solenoid valve OFF OFF

F Fan motor OFF OFF

Power plug

inserted

OFF

(no opera-

tion)

Operating status: Unit

operating or in standby

Standby

(no opera-

tion)

r RH <-3%

The unit

starts

r

RH >+4%

ON

for 10 sec.

then OFF

ON

after

10 sec.

Defrost function

30 min. timer

expires if

e<=1 °C

T

OFF

ON

After the

30 mins.

defrost timer

function has

passed

ON

If

T

e >=3 °C,

then OFF

ON

If

T

e >=3 °C,

then OFF

OFF

If

T

e >=3 °C,

then ON

Full tank

function

OFF

OFF

OFF

G Compressor OFF OFF

Humidity seg-

H

ment display [3]

Operating

hours / power

I

consumption

segment display [6]

Operating hours or power consumption are displayed

(changeover by actuating the "h/kWh" key)

ON

after

10+0.5 sec

Current room humidity is displayed

ON ON OFF

20

7 Condensate removal

A

B

Depending on the air temperature and the relative

humidity

densate container either continuously or only

during the defrosting phases.

A float is located inside the condensate container.

In the event that the container is full, the float will

activate a water stop switch which will switch off

dehumidification mode.

To guard against accidental stops caused by water

sloshing around etc., this switch does not activate

until after a time delay of 10 seconds. The unit will

switch off and the red "TANK FULL" indicator light

on the control panel will flash.

In order to empty the condensate tank, proceed as

follows:

1. Actuate the "ON/OFF" switch.

2. Remove the filled condensate tank. T

, condensed water will drip into the con-

o do

this, lift the container slightly using the

embedded recessed grip and then pull it

carefully forwards and out.

NOTICE!

5. Close the pouring opening [B] and carefully

insert the condensate container back into the

unit.

6.

NOTICE!

After being emptied, the condensate container incl. float must be checked for

damage, contamination etc.

Switch the unit on again with the "ON/OFF"

key .

Beware of dripping condensate. After switching

of

f the units, the evaporator may continue to

defrost under the influence of the ambient temperature.

3.

Place the container carefully outside the unit

and pull of the sealing cover [A] of the

pouring opening [B].

4. Pour the water into a drain.

NOTICE!

The units are only fully functional if the condensate container is inserted properly

Unit operation with hose connection

The hose connection is implemented directly on

the 12 mm Ø screw-in hose nozzle that is placed

on the top edge of the condensate tank when

shipped.

Connect the hose as follows:

1. Remove the condensate tank.

2. Remove the screw-in hose nozzle from the

place-holder [D] and swap this for the sealing

screw in the 3/8" inside thread [C]. Then

tighten the screw-in hose nozzle hand-tight.

Ensure that the connection is sealed!

3. Plug hose with inside diameter 12 mm onto

the screw-in hose nozzle and secure this with

a hose clamp to prevent it slipping off.

4. Then fit the condensate tank back into place.

Ensure that there are no kinks in the hose!

.

21

C

D

E

F

REMKO LTE

Unit operation with condensate pump

(optional)

The condensate tank with integrated pump has two

magnetic contacts [E] on the rear to establish the

electrical connection with the unit. If the unit is supplied with power

at the contacts on the unit side. This provides the

power supply for the condensate pump.

, 12 V DC is continuously present

Fig. 9: Detailed view

Fig. 10: Placeholder

Fig. 11: Sealing screw

Fig. 13: Condensate tank at the rear

The following steps should be carried out for unit

operation with condensate pump:

1. Remove the condensate tank.

2. Plug the hose supplied onto the pass-though

hose nozzle [F] fitted previously and secure

this with a hose clamp to prevent it slipping

of

f.

3. Ensure that the connection is sealed.

4. Fit the condensate tank back into place. The

pump is immediately ready for use. If the

water level in the condensate tank is suf

ciently high, this starts to pump out the water.

Ensure that there are no kinks in the hose!

fi-

Fig. 12: Screw-in hose nozzle

In unattended permanent operating mode, the condensate should preferably be drained into a lowerlevel drain. If using a collection container (pan,

bucket, etc.), the unit must be placed at a correct

height.

Fig. 14: Condensate tank and hose

NOTICE!

Unit operation with condensate pump is only

possible with units that were shipped with the

pump installed.

22

NOTICE!

If the condensate pump runs for an extended

period of time, the condensate tank must be

checked for contamination at regular intervals.

Unit operation with a condensate tank without

pump is possible at any time.

23

REMKO LTE

8 Troubleshooting and customer service

The unit and components are manufactured using state-of-the-art production methods and tested several

times to verify that they function correctly

detailed in the list below. Please inform your dealer if the unit is still not working correctly after all function

checks have been performed!

Operational malfunctions

Malfunction Remedial measures

Check the setting of the "ON/OFF" switch. The green "COMP. "ON" indicator must illuminate

Check the power supply and the power fuse provided by the customer

230V/1~/50 Hz

The unit does not start

Check the power plug and the cable for damage

. However, if alarms should occur, please check the functions as

The red CHECK (malfunction)

indicator light illuminates

The unit runs but does not

form any condensate

Check the level and correct seating of the condensate tank

Check the setting of the desired humidity. The pre-set value must be lower

than the relative humidity in the room

The cooling cycle is overloaded or overheated (see "CHECK" indicator

Ä

on page 18)

Before starting the unit again, first identify the cause of the malfunction.

(see "CHECK" indicator

Check the room temperature. The operating range of the unit is between

3 °C and 32 °C

Check humidity of the air, min. 40% RH required

Check the dust filter for contamination and clean or replace if necessary

Check the evaporator and condenser fins for contamination and clean if

necessary

Check the evaporator for ice or rime formation. If ice has formed, check the

functionality of the automatic defrost and the temperature sensor

If the unit fails to function correctly after the checks have been carried out,

contact an authorised specialist

Ä

on page 18)

WARNING!

ork on the refrigerant system and on the electrical equipment must only be conducted by a specially-

W

authorised specialist!

24

Display of error codes

1

Error codes are displayed in the segment display [1].

Fig. 15: Segment display

Error code description:

Error code Error description

E1 Evaporator temperature probe (Te) defective

E2 Condensate temperature probe (Tc) defective

E3 Compressor runs within 5 minutes and the condenser temperature (Tc) > 50 °C

E3 flashes Compressor runs over 5 minutes and the condenser temperature (Tc) > 50 °C

E4 Humidity/temperature probe (hygrostat) defective (room humidity measured > 100% RH)

E5 Humidity/temperature probe (room temperature Rt)

9 Shutdown

Actuate the "ON/OFF" key, the "COMP. ON" indicator must extinguish.

If the units are inactive for longer periods, disconnect them from the mains power supply

Empty the condensate container and dry with a

clean cloth.

Beware of dripping condensate!

When storing the unit, cover with a plastic sheet/

foil if necessary and store in an upright position in

a sheltered and dry location.

To save space when storing, the units can be

stacked on top of one another (max. two units

stacked on top of each another). For this purpose,

they are equipped with rubber pads on the base

plate.

.

Fig. 16: Stacking with max. 2 units

NOTICE!

The units must be protected against falling

down and unauthorised access after stacking.

25

REMKO LTE

10 Care and maintenance

10.1 Care and maintenance

General notes

Regular care and maintenance is fundamental

to a long service life and fault-free operation of

the unit.

All moving parts have a low-maintenance permanent coat of lubricant. The refrigerant system is

designed as a hermetically sealed system and may

only be repaired by a specialist.

DANGER!

Before undertaking any work on the units, the

mains plug must be removed from the mains

socket.

n Observe the regular care and maintenance

intervals

Cleaning the dust filter

NOTICE!

Check the inlet and outlet grille and the dust

filter for contamination on a regular basis.

Pull the protection grid forwards and then remove

upwards.

Then remove the dust filter which has now been

released. Light contamination of the dust filter may

be remedied with careful blowing or suction.

Heavier contamination may be remedied by rinsing

the filter in a lukewarm (max. 40 °C) soap solution.

Finally

, always rinse the filter carefully with clear

water and allow to dry!

Before refitting the dust filter, ensure that its fully

dry and that no damage has been sustained.

NOTICE!

Heavily contaminated dust filters must be

replaced with new parts. Only original replacement parts may be used.

NOTICE!

Check the inlet and outlet grille for contamination on a regular basis.

n In accordance with the operating conditions,

the units must be checked as and when

required, but at least once per year

cialist to ensure that they are in a condition that

is safe to use

n Keep the units free of dust and other debris

n Only clean the units with a dry or moistened

cloth

n Never subject to direct jets of water

(e.g. pressure washers etc.)

n Never use abrasive or solvent-based cleaners

n Even with heavy contamination, use only suit-

able cleaners

, by a spe-

The units may only be operated with the dust filter

in place.

26

C

Cleaning the units

The unit housing must be opened to allow the

inside of the unit to be cleaned and to provide

access to electrical components.

NOTICE!

Adjustment and maintenance work may only be

carried out by authorised qualified technicians.

1. Loosen the two fastening screws [C].

2. Lift up the service flap and unhook the top

lugs.

4. Clean the evaporator fins, for example with a

lukewarm soap solution (or similar).

NOTICE!

When cleaning the exchanger

must be taken because the fine aluminium fins

bend very easily.

5. Never subject to direct jets of water

6. Rinse with clean water to remove any

remaining soap.

7. Clean the internal surfaces of the unit and

the fan blade.

8. Clean the condensate trap and the connection nozzle.

9. Once cleaning has been completed, the unit

should be dried. T

electrical components!

10. Re-install all dismantled components in

reverse order

11. Carry out a unit function check and electrical

safety check.

ake particular care with

.

, particular care

.

3. Clean the condenser fins by blowing, with

suction or using a smooth brush.

WARNING!

An electrical safety check must be carried out in

accordance with VDE 0701 after any work on

the units.

27

REMKO LTE

10.2 Maintenance protocol

Unit type:

--------------------------------

010203040506070809101112131415161718192

Unit cleaned - outside -

Unit cleaned - inside -

Fan blade cleaned

Fan housing cleaned

Condenser cleaned

Evaporator cleaned

Fan function checked

Air-inlet grid with filter cleaned

Unit checked for damage

Safety devices checked

All fastening screws checked

Electrical safety check

Unit number:

---------------------------------------

0

Test run

Comments: ...................................................................................................................................................

.............................................................................................................................................................................

01. Date: .............

...............................

Signature

06. Date: ............

...............................

Signature

11. Date: ............

...............................

Signature

16. Date: ............

...............................

Signature

02. Date: .............

...............................

Signature

07. Date: .............

...............................

Signature

12. Date: .............

...............................

Signature

17. Date: .............

...............................

Signature

03. Date: .............

...............................

Signature

08. Date: .............

...............................

Signature

13. Date: .............

...............................

Signature

18. Date: .............

...............................

Signature

04. Date: .............

...............................

Signature

09. Date: .............

...............................

Signature

14. Date: .............

...............................

Signature

19. Date: .............

...............................

Signature

05. Date: .............

...............................

Signature

10. Date: .............

...............................

Signature

15. Date: .............

...............................

Signature

20. Date: .............

...............................

Signature

Unit to be maintained only by authorised specialists in accordance with the statutory regulations.

28

11 Exploded view of unit and spare parts

5

6

4

3

2

1

7

8

9

10

11

12

13

14

15

16

17

19

18

20

21

22

23

24

25

26

27

28

29

30

31

25

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

50

51

52

53

54

49

11.1 Exploded view of the unit LTE 50/60/80

We reserve the right to modify the dimensions and design as part of the ongoing technical development

process.

29

REMKO LTE

11.2 Spare parts list LTE 50/60/80

No. Designation LTE 50 LTE 60 LTE 80

1 Lock for sealing flap

2 Air-inlet grille

3 Dust filter

4 Unit housing

5 Control panel

6 Filter grill, interior

7 Evaporator fin package cpl.

8 Top separating panel

9 Transportation bracket

10 Side covering, right

11 Support frame

12 Fan blade

13 Engine mounting cpl.

14 Drive clutch

15 Fan motor

16 Hose clamp 3/8" x 12 mm with O-ring

17 Condensate container cpl.

18 Taper plug

19 Magnetic float compl.

20 Dry filter

21 Humidity / temp. probe cover

22 Humidity / temp. probe

23 Humidity / temp. probe holder

24 NTC evaporator probe

25 NTC condenser probe

26 Condensate tank slide rail (left, right)

On request by providing the

serial number

27 Condensate guide panel (left, right)

28 Magnetic contact retaining plate

29 Pump mains power unit with magnetic contact and cable

30 Fastening plate for water stop switch

31 Water stop switch (reed contact)

32 Side covering, left

33 Hub cover cap

34 Wheel screw

30

No. Designation LTE 50 LTE 60 LTE 80

35 Wheel

36 Wheel

37 Triangular bracket

38 Condensate tank fastening plate

39 Base plate

40 Compressor, cpl.

41 Solenoid valve

42 Coil for solenoid valve

43 Housing cover

44 Operating condenser

45 Control board

46 Switch cabinet housing

47 Rear wall, housing parts

48 Stand

49 Rubber stopper, stand (2 pieces / set)

50 Strain relief

51 Axle

52 Axle fastening plate

53 Rubber stopper, base plate (4 pieces / set)

54 Mains cable with plug

Spare parts not illustrated

Sealing screw with O-ring

Magnetic float brake

O-ring

Condensate tank with pump cpl.

Tank pass-through

On request by providing the

serial number

On request by providing the

serial number

Check valve

Hose 1m

To assure the correct delivery of spare parts, please always provide the unit type with its corresponding

serial number (see name plate).

31

REMKO LTE

12 Index

A

Air dehumidification, description ............. 9

Automatic restart after power failure ......... 16

C

Care ................................. 26

Care and maintenance ................... 26

Clean dust filter ......................... 26

Clean units ............................ 27

Cleaning the dust filter ................... 26

Cleaning the units ....................... 27

Commissioning ......................... 16

Condensate removal ..................... 21

Condensate trap, function ................. 1

Condensation heat ...................... 11

Condensation of water vapour ..............11

Control and display panel: .................17

Customer service ....................... 24

1

D

Display of error codes .................... 25

Disposal of equipment .....................6

Drying materials ........................ 10

E

Electrical wiring ......................... 15

Electrical wiring diagram .................. 15

Environmental protection ...................6

Error codes, display and description ......... 25

Exploded view drawing ................... 29

Exploded view of the unit ................. 29

L

Locations for use ........................12

M

Maintenance ........................... 26

Malfunction ............................ 24

O

Operating sequence ..................... 12

Operational malfunctions ..................24

Ordering spare parts ..................... 30

R

Relative air humidity ..................... 10

S

Safety

Dangers of failure to observe the safety

notes ............................... 4

General ............................. 4

Identification of notes ................... 4

Instructions for the operator .............. 5

Note for inspection work .................5

Note for installation work ................ 5

Note for maintenance work .............. 5

Personnel qualifications ................. 4

Safety-conscious working ................4

Unauthorised modification ...............6

Unauthorised replacement part manufacture . 6

Setting up the unit ....................... 14

Shutdown ............................. 25

Spare parts list ......................... 30

Starting the unit .........................16

T

Transporting the unit ..................... 14

Troubleshooting and customer service ....... 24

U

Unit transport .......................... 14

W

Warranty ............................... 6

Water vapour content .................... 10

Water vapour, condensation ............... 11

32

33

REMKO LTE

34

Consulting

Thanks to intensive training,

our consultants are always

completely up-to-date in terms

of technical knowledge. This has

given us the reputation of being

more than just an excellent,

reliable supplier:

REMKO, a partner

helping you find solutions to

your problems.

Distribution

REMKO offers not just a well

established sales network both

nationally and internationally, but

also has exceptionally highlyqualified sales specialists.

REMKO field staff are more than

just sales representatives: above

all, they must act as advisers to

our customers in air conditioning

and heating technology.

SFlbCustomer Service

Our equipment operates

precisely and reliably. However,

in the event of a fault, REMKO

customer service is quickly at

the scene. Our comprehensive

network of experienced dealers

always guarantees quick and

reliable service.

REMKO INTERNATIONAL

… and also right in your neighbourhood!

Make use of our experience and advice

We reserve the right to make technical changes, and provide no guarantee as to the accuracy of this data!

REMKO GmbH & Co. KG

Air conditioning and heating technology

Im Seelenkamp 12 D-32791 Lage

Postfach 1827 D-32777 Lage

Telephone +49 5232 606-0

Telefax +49 5232 606-2 60

E-mail info@remko.de

Website www.remko.de

Loading...

Loading...