Remington M35016AW User Manual

ELECTRmC CHAnN SAW

OWNER'S MANUAL

MODELS: M15012US, M15014AS, M30016US, M30016AS,

M30016AW, M35016AW

IMPORTANT: Read and understand this manual before

assembling or operating this chain saw. Improper use of

saw can cause severe injury. Keep this manual for future

reference.

DO NOT RETURN PRODUCT TO STORE.

CALL 1-800-626-2237 FOR TECHNICAL ASSISTANCE

For more information, visit www.remingtonpowertoois.com

This manual is your' guide to safe and proper' operation of the saw,,

SAVE THESE iNSTRUCTIONS.

Keep your purchase receipt for warranty coverage.

i ill i ill l illllllii illllllltllllllllll

NO DEVUELVA EL PRODUCTO A LA TIENDA

Para mrs informacibn, wwworemingtonpowertools.com

PARA AYUDA TI_CNICA LLAME AL 1-800-626-2237

Este manual es su guia para utilizar esta sierra e!6ctrica de

manera adecuada y segura.

GUARDE ESTAS BNSTRUCCIONES.

Guarde su recibo de compra para cobertura de la garantia.

i i iiii iiiiiillllllll,, i i

NE RETOURNEZ PAS LE PRODUIT AU DETAILLANT

FAITES LE 1 800 626-2237 POUR OBTENIR

DE L'ASSISTANCE TECHNIQUE

Pour plus de d_tails, visitez le www.remingtonpowertools.com.

C'est un guide pour rutilisation s_curttaire et correcte de latron_:onneuse,

CONSERVER CES DIRECTIVES

Conservez votre re_:ud'achat pour obtenir le service sous garantie.

CONTENTS

IMPORTANT SAFETY INFORMATION .................... 4

Before Operating Saw .................................................. 4

While Operatir_g Saw ......................................... 4

Kickback ............................................... 5

Maintenance and Storage of Chain Saw ........................ 6

UNPACKING .............................. 6

PRODUCT IDENTIFICATION .................. 7

CHAIN SAW NAMES AND TERMS ........................... 8

QUICK START GUIDE ......................................... 9

ASSEMBLY ................................................ 10

SAW CHAIN TENSION ADJUSTMENT ..................................... 12

OPERATING CHAIN SAW ................................ 13

FiIling Oil Tank ........................................................... t 3

Oiling Chain ............................................................. !3

Clearing sprocket cover of debris ............................. 13

Extension Cords ............................. t 4

Cutting wilh the Chain Saw t 4

Felling a Tree (Cutting Down a Tree) .............................. 15

Limbing a Tree t 6

Bucking a Log .................................................................. t6

Trimming aTree (Pruning) ......... 17

CLEANING AND MAINTENANCE 18

Cleaning Saw Body ...................... t 8

Care of Guide Bar .............................................. t8

Sharpening Saw Chain ........................... t 8

Replacing Saw Chain t9

STORAGE ...................................... 20

REPLACEMENT PARTS AND ACCESSORIES 20

REPAIR SERVICE .............. 20

Warranty Service ............................................ 20

Non-Warranty Service

TROUBLESHOOTING

TECHNICAL SERVICE

WARRANTY INFORMATION .........

ILLUSTRATED PARTS BREAKDOWN

PARTS CENTRAL

2O

2t

2t

22

72

74

3 www, t'erning_,anpowerfools, con'_

IMPORTANT SAFETY INFORMATION

£k

,_A WARNING: When usingan electric

chain saw, basic safety precautions

should always be followed to reduce

the risk of fire, electric shock, and

injury to persons, including the fol-

lowing:

READ ALL INSTRUCTIONS°

Make sure you read and understandall

instructions in Important Safety Infor-

mation. Improper useof this chain saw

can cause severe injury or death from

fire, electrical shock, body contact with

moving chain, or falling wood.

BEFORE OPERATING SAW

l Read and understand this owners m:mual

before operating chain sa_.

2 Watch what you are doing Use common

sense Do not operate saw when you are

tired

3 Use chain saw for cutting wood only Do not

use chain saw for purpose not intended Do

not use for cutting plastic, masonry, etc

4 Only welIqnstructed adults shoutd operate

chain saw Never allow children to operate

chain saw

5 Use only electrical voltage noted on model

plate of chain saw

6 Use only extension cords marked for outdoor

use, See Exwn_ion Coat Requiremems

7 Do not operate chain saw

• while under the influence of alcohol, medi-

cation, or drags

* in rain or in damp or wet areas

. where highly flammable liquids or gases are

present

. if saw is damaged, adjusted wrong, or not

fully and securely assembled

• if trigger does not turn saw on anti off' Chain

must stop moving when you release trigger

Have fauIty switch replaced by authorized

service center (sec Technical Service)

• while in a hurry

• while in tree or on a ladder unless trained to

do so

8 Wear snug-fitting clothes when operating

chain saw Do not were" loose clothing or

jewelry They can get caught in moving saw

chain

9 Wear the following saraty gear when operating

chain saw

www.romlngtonpower_ools, cr_rn 4

• heavy-duly gloves (wear rubber gloves

when working outdoors)

, steel-toed safety footwear with non-skid

soles

• eye protection such as safety glasses,

goggles, or Ii_cescreen

" safety hard hat

- ear mufflers or ear plugs

. hair covering to contain long hair

• face or dust mask (if working in dusty

areas)

10 Before cutting, always provide the follow-

ing:

. clem" work area

• secure fooling

- planned retreat path from falling tree

11 Inspect _'e before cutting down, M_Lkesure there

,areno dead limbs or branches lfmt may litll on

you

12 To reduce the risk of electric shock, this saw

has a polarized plug (one blade is wider than

the other) This plug will fit in a polarized

outM only one way, 11the plug does not lit

fully in the outlet of your extension cord,

reverse the plug If it still does not Iit, a polar-

ized extension cord will be necessa'y Do not

change the plug in any way

WHILE OPERATING SAW

1 Stay alert Use common sense while oper,afing

clmin saw

2 Keep work area clean Cluttered areas invite

injuries

3 Be aware ofextension cord while operating

chain saw Be careful not to lrip over cord

Keep cord away from chain and operator at

all times

4 Keep children, animals, and bystanders away

from chain saw and extension cord Only

chain saw user should be in work area

5 Do not cut down a tree unless you are trained

or have expert help

6 If two or more persons perform bucking and

felling operations at the same time, provide

plenty oIdistance between operations Provide

distance of at least twice the height of tree

being felled

7 Secure wood you are cutting by using clamps

or chocks

8. Grip chain saw firmly with both h:mds Never

operate chain saw with one hand Never use

hand guard ashandle,

9 Keep linger off trigger until ready to make

cuL

IMPORTANT SAFETY INFORMATION

I0 Before st-'t,"tingchain saw, make sure chain is

not touching _ything

l ! To guard against electrical shock, avoid body

contact with grounded objects such as pipes.

fences, and metal posts

t2 Keep all parts of body :away from chain when

saw is running

t3 Do not [brce chain saw u,hile cutting Apply

light pressure, it will do tile job better and

safer at file rate for which it was intended

14 Cut small brush and saplings with extreme

care Slender material may catch in chain and

be whipped toward you [his could also pu!l

you off balance

I5 When cutting limb or tree trunk that is under

tension, use extreme caution Be alert for

wood springing back When wood tension is

released, limb could spring back and strike

operator causing severe injury or dead1

16 Carry chain saw from one place to .'another

. with saw stopped and unplugged

• by holding front handle (never use hand

guard as handle)

• with Iinger off trigger

• with guide bar and chain to rear

/k

"WARNING:This product contains

chemicals known to the State of Cali-

fornia to cause cancer or birth defects,

or other reproductive harm.

/k

WARNING: Some dust created by

power sanding, sawing, grinding, drill-

ing, and other construction activities

contains chemicals known (to thestate

of California) to cause cancer, birth

defects, or other reproductive harm°

Some examples of these chemicals

are:

° lead from lead-based paints

. crystalline silica from bricksand ce-

ment and other masonry products

• arsenic and chromium from chemi-

cally-treated lumber

Your risk from these exposures varies,

depending on how often you do this

type ofwork. To reduce your exposure

tothese chemicals: work in a wellven-

tilated area, and work with approved

safety equipment, such as those dust

masks that are specially designed to

filter out microscopic particles.

KICKBACK

/k

_u_ WARNING: Kickback may occur

when the nose or tip of the guide bar

touches an object, or when the wood

closes in and pinches the saw chain

in the cut. Tip contact in some cases

may cause a lightning fast reverse

reaction, kicking the guide bar up and

backtowardstheoperator. Pinchingthe

saw chain along the top of the guide

bar may push the guide bar rapidly

back towards the operator, Either of

these reactions may cause you to lose

control of the saw which could result

in serious injury to user.

Kickback Safety Devices On This

Saw

This saw has a low-kickback chain lind reduced

kickback guide bar Both items reduce the chance

of kickback Kickback can still occur with this

saw

Follow assembiy instructions Do not remove

front hand guard Do not replace front htmd guard

with substitute

Tbe following steps will reduce the risk of kick-

back

• Use both hands to grip saw while s,_w is

• Keep all safety items ill pl;Jce on saw Make

• Do not overreach or cut above shoulder

• Keep solid footing and bahmce at all

• Stand slightly to left sideof saw "rhis keeps

Dfrecti°L _t_,_\ ', \Do Not Let

90°ouad,any_!

Figure f - Kickback HazardExample: DoNot

Let Nose of Guide Bar Touch Object While

Chainis Moving

5 www, t'omillglonpttwortoo¢s.com

running Use lirm grip 'Ihumbs and lingers

must wrap around slaw handles

sure d_ey work properly

height

times,

your body from being in direct line with

chain,

_,_ Guide Bar

IMPORTANT SAFETY INFORMATION

• Do not let guide bar nose touch anything

when chain is moving (see Figure 1)

• Never try.cutting th_ough two togs at same

time Only cut one log at a time

• Do not bury guide bar nose or try phmge cut

{boring into wood using guide bar nose)

• Watch for shifting of wood or other forces

that may pinch chain.

• U_ extreme caution when recn!ering aprevious

cut.

- Use low-kickback chai,l and guide bar sup-

plied with this chain saw Only replace these

pans with chains and guide bars listed in this

manual

• Never use dull or loose chain Keep chain

sharp with proper tension

Saw Maintenance and Kickback

Safety

Follow maimenance instructions in this manual.

Proper cleaning of saw and chain and guide bar

maintenance can reduce chances ofkickback. Inspect

and maintain saw after each use This will increase

the sen'ice life ofyour saw Note: Even with proper

sharpening, risk of kickback can increase with each

sharpening

MAINTENANCE AND STORAGE

OF CHAIN SAVV

1 Unplug chain saw from power source

• when not in use

• before moving from one place to another

• before servicing

• before changing accessoriesorattachments,

such as saw chain and guard

2 Inspect ch_dn saw before and after each use

Check saw closely if guard or other part

has been damaged Check for any d:mmge

that may affizct operator safely or operation

of saw Check for alignment or binding of

moving pans Check for broken or damaged

paris Do not use chain saw if damage affects

safety or operation Have damage repaired by

authorized ser,cice center

3 Maintain chain say, with care

,Nevet expose saw to rain

• Keep chain sharp, clean, and tubfic.'_ted for

better and safer performance

• Follow steps outlined in this manual to

sIx.u'pen chain

• Keep handles dry. clean. :rod fi'ee of oil and

grease.

• Keep all screws and nuts tight

• Inspect power cord often. If damaged, have

repaired by authorized service center

www_ _mingtc, npowe_oo/s, earn

• Never carry chain saw by power cord

• Never yank power cord to unplug it

• Keep power cord from heat, oil. and shm-p

edges

• Inspect extension cords often and replace if

damaged

4

When servicing, use only identical repIace-

ment parts

5

When not in use. always store chain saw

• in a high or locked place, out of children's

reach

, in a dry place

UNPACKING

t Remove all items from canon

2 Check all items for _my shipping damage

If you lind _my damage or if any parts are

missing, call Tectmic_d Sen, ices at 1-800-626-

2237 for prompt service

Save these instructions.

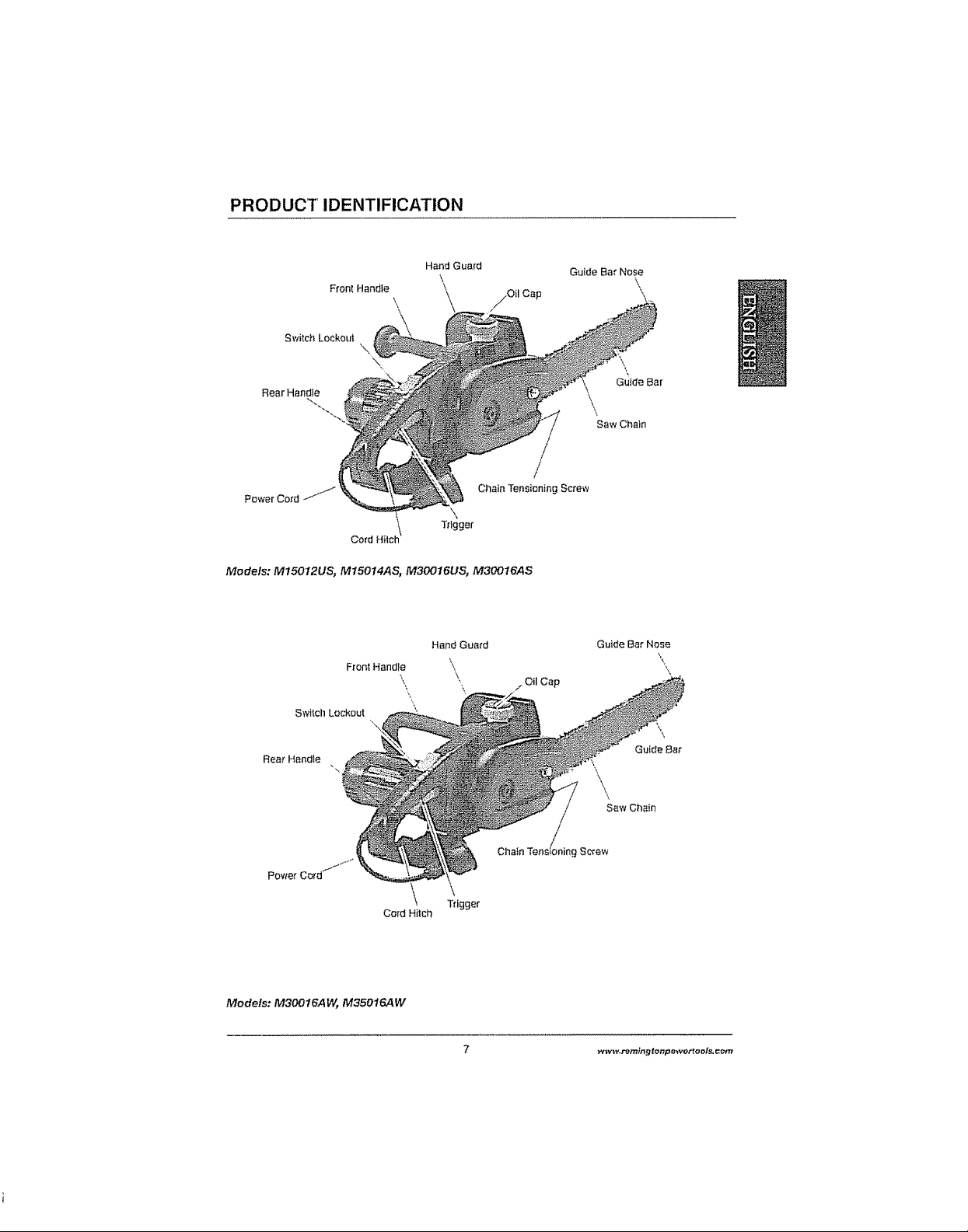

PRODUCT IDENTIFICATION

Hand Guard

Front Handle

Switch Lockout

Rear Handle

Power Cord f'J"_

Models: M15012US, M15014AS, M30016US, M30016AS

Switch Lockout

\

Front Handle

\

\

/Oil Cap

Chain Tensiening Screw

/

,/Oil Cap

Guide Bar Nose

\

Guide Bar

\

Saw Chain

Guide Bar Nose

\

\

\

Saw Chain

'\

\

Guide 8at

\

Models: M30016AW, M35016AW

ning Screw

7 www, remlrf 9 fo_p OWertO Ol& COrn

CHAIN SAW NAMES AND TERMS

Bucking Process of cutting a telled tree or log

into lengths

Chock Block or wedge used to secure wood from

moving

l:elting Process of cutting down a ace

Felling Cut Fimfl cut when fetling ,'ttree Make this

cut on opposite side of tree from notci_ing cut

l;ront ltandle Located at front of saw body

Front Hand Guard Shield between from handle

and guide bar Protects left tland while using

saw

Guide Bar Metal bar that extends from saw body

Tile guide bar supports and guides chain

Guide Bar Nose [ ip or end of guide bar

Guide Bar Retainer Bolt-like thstener that holds

guide bar in ph|ce during assembly and operation

of chain saw

Kickback Quick backward and uDsard motion

of guide bar Kickback may occur when tip of

guide bar touches an object while chain is mov-

ing The guide bar will kick up and back towards

operator

lambing Process of cutting limb(s) from a felled

tt'ee

Luw-Kiekb'-lek Cbuin Chain that reduces chance o[

kickback as required b_, ANSI B 175 1

Nurmal Cutting Position Stance used while making

bucking and fcIling cuts

Natd_ing Cut Notch cut in tree that direct'; ftd] of

tree

Oiler Control System [br oiling guide bar and

chain.

Power' ltead Chain saw without cb:fin and guide

bar Also known as saw body

Pushbaek (Kickback, Pinch) Rapid pushback of

chain saw Pushback may occur if chain along

lop of guide bar is pinched, caught, or contacts a

fbreign object

Rear llalldle Handle located at rear of saw

body

Reduced Kickback Guide Bar Guide bar that

reduces chance of kickback

Replacement Chain Chain that complies with

ANSI B175 1 when used whh a specific saw It

may not meet ANSI requirements when used with

other saws

Saw Chain (Clmin) Loop of chain having cutting

teeth for cutting wood The motor drives chain

The guide bar supports chain

Spiked Bumper (Spike) Pointed teeth at front of

saw body beside guide bar Keep spiked bumper

in contact with wood when felling or bucking It

helps maintain position of saw while cutting

Sprueket Toothed wheel that drives chain

Switch Device thatcompletes or interrupL_ electri-

cal circuit to motor of saw

Switch Linkage Ibis device connects switcb

to trigger It moves switch when you squeeze

trigger

Switch Loektmt De_ice that reduces accidental

starting of saw

l-rigger Device that turns saw on and off Squeez-

ing trigger turns saw on Releasing trigger turns

saw off

]rimming (Pruning) Process el' cutting limb(s}

from a living tree

Undercut An upward cut from underside of log or

limb This is done while in normal cutting position

and cutting with top of guide bar

Unibody Main body of cflain saw

www.rumMgt_npowerfool_, eor_

QUICK START GUIDE

If you _re familiar with chain saws, their proper usage, and the saw you purchased is fully assembled,

use this Quick St_ut Guide te quickly begin using your new Remington bnmd chtdn saw

@

Oil Squeeze Bulb

/

OIlBottle

Pour motor oil (see Filling Oil 'Tank, page

I0. for correct oil type! in oil tank (do not

use standard bar and chain oil) DO NOT

iea'_,e oil in lank when not in use.

@

Power

Cord

/

Cord" ,'

Hitch Slot

Extension

@

L SwitchLockout Bullon

Tdggi_r

Use both hands to grip chain saw Push

lockout button forward with right thumb and

squeeze trigger Make sure saw is running

at full speed before starting a cut

Connect extension cord to power cordand

power supply Use built-in cord hitch or

knot method tinsel) to secure together See

Extension Cords for correct size,

For complete intbrmation concerning your'saw and its proper

usage, read and understand this owner's manual thoroughly.

N °

When chain becomes loose due to stretching,

tension properly. See Saw Chaia Tension

Adjustment for correct tensioning o1: saw

chain

9 WW _'V.remi,q 9 _'r_t_P Ow6"_G ef,_ corn

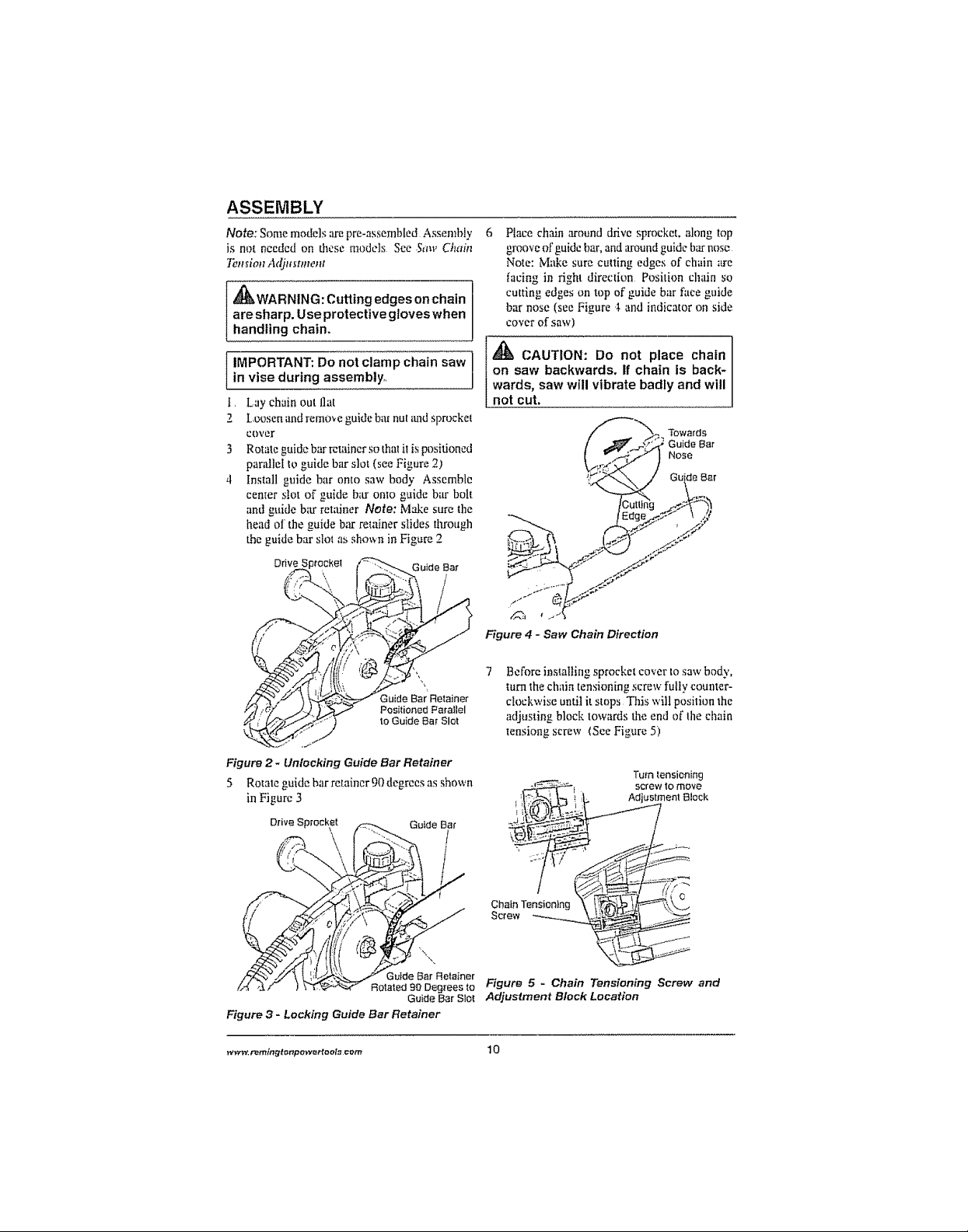

ASSEMBLY

Note: Some models are pre-assemb[ed Assembly

is not needed on these models See Sow Chain

Ten_ion Adjumnent

WARNING: Cutting edges on chain ]

are sharp, Use protective gloves when

IMPORTANT: Do not clamp chain saw |

in vise during assembly,

l,

Lay chain out flat

2

Loosen and remm, e guide bar nut _mdsprocket

cover

3

Rotate guide bar retainer so that it ispositioned

parallel to guide bar slot (see Figure 2)

,1

Install guide bar onto saw body Assemble

center slot of guide bar onto guide bar bolt

and guide bar rot;finer Note: M',d,:esure the

head of the guide Ntr retainer slides through

the gukle bar slot as shm_n in Figure 2

GuideBa_

/

Ptace chain around drive sprocket, along top

groove of guide bar, and around guide bar nose

Note: Make sure cutting edges of chain are

teeing in right direction Position chtdn so

cutting edges on top of guide bar face guide

bar nose (see Figure 4.and indicator on side

cover of saw)

!handling chain.

,l'k

3

1

CAUTION: Do not place chain

on saw backwards, If chain is back-

wards, saw will vibrate badly and will

not cut.

Figure 4 - Saw Chain Direction

Towards

Bar

Nose

Guide8ar

GuideBarRetainer

PositionedParallel

to GuideBar Slot

Figure 2 - Unlocking Guide Bar Retainer

5 Rotate guide bar retainer 90 degrees as shown

in Figure 3

Drive Sprocket _ GuideBar

L-:{ ,3,/ ! \"_._ _ Rotated90 Degreesto

Figure 3 - Locking Guide Bar Retainer

w_ _minglonpowart_ols com 10

Nar'Reta_ner

GuideBar Slot

Before installing sprocket cover to saw body,

turn the chain tensioning screw fully counter-

clockwise until it stops This will position the

adjusting block towards the end of the chain

tensiong screw (See Figure 5)

Turn tensioning

screw to move

Adjustment Block

ChainTensioning " <_'_._<

Screw - _ _

Figure 5 - Chain Tensioning Screw and

Adjustment Block Location

ASSEMBLY

Pull the guide bar away from the saw body

so thatthe guide bar is fullyextended and the

slack i'_removed from the chain (See Figure

6)

Figure 6 - Pulling Guide Bar

Insert the sprocket cover tab into the saw body

tab slot, Step 1 Then lower sprocket cover

onto guide bar bolt, 5uT 2 [See Figure 7)

NOTE: At this point tile sprockel cover will

no___Jbe flush against the saw body

\

TabSlot SprocketCoverTab

10 Finger tighten the guide bar nut onto the guide

bar bolt (See Figure 81

J

....... Guide

Bar Nut

Figure 8 - Guide Bar Belt

t 1. Slowly slide guide bar into saw body until the

adjustment block goes into 1.11oround adjusting

hole on the guide bar (See Figure 6) NOTE:

This locks the guide bar in place You should

not be able to push or pull the guide bar

I2 Retighten the b.'tr nut linger tight.

13. Adjust the saw chain lension Follow the steps

under Sm_ Chait, Tett_ion Adju_tttl_nt

J:i

Sprocket Cover Tab

Figure 7 - Installing Sprocket Cover

11 www,mmlngtonpowerf_olscorn

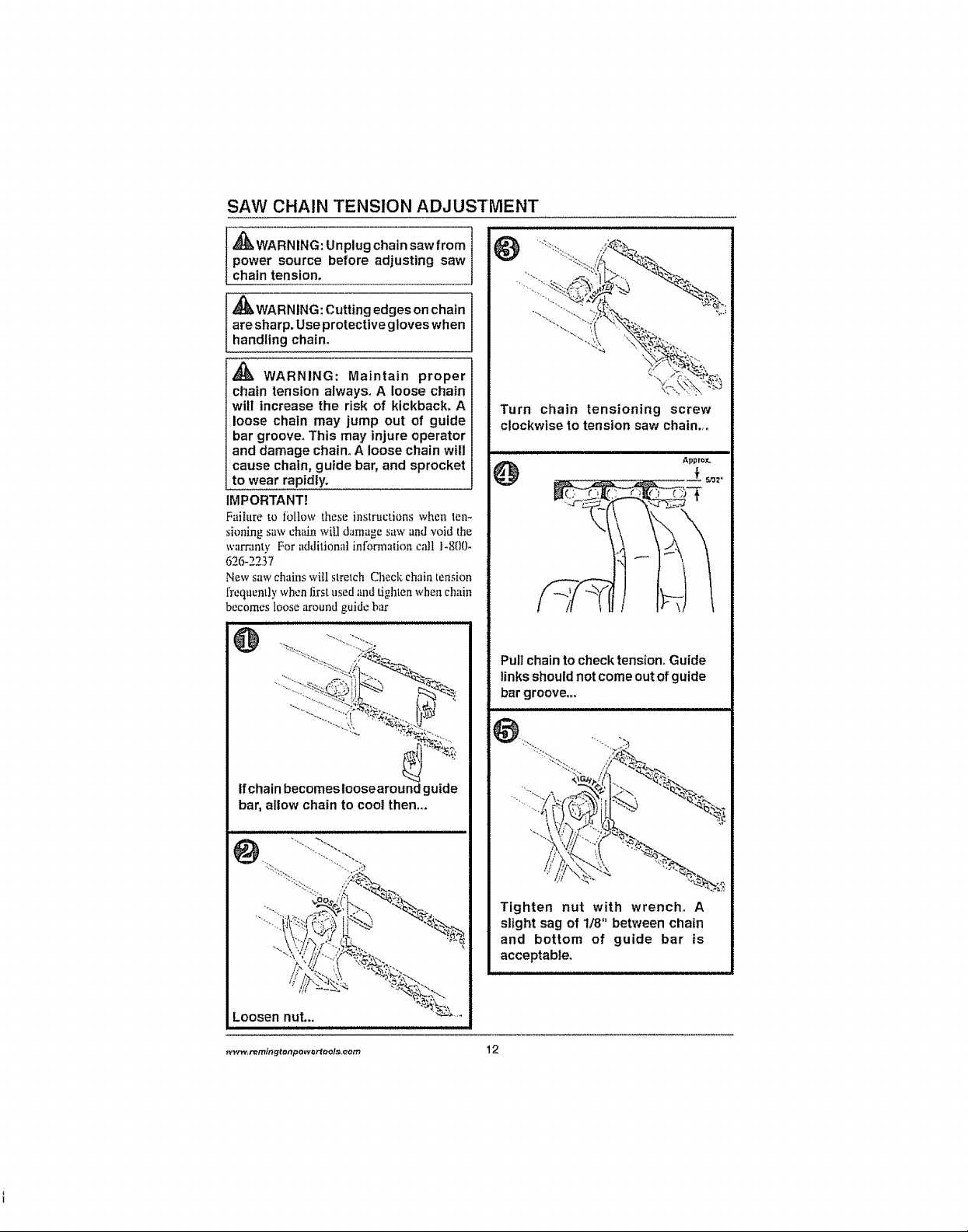

SAW CHAIN TENSION ADJUSTMENT

WARNING: Unplug chain saw from

power source before adjusting saw

chain tension.

A_,WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

/1,

_J_ WARNING: Maintain proper

chain tension always. A loose chain

will increase the risk of kickback, A

loose chaln may jump out of guide

bar groove., This may injure operator

and damage chain. A loose chain will

cause chain, gutde bar, and sprocket

to wear rapidly.

IMPORTANT]

Failure to fbllow these instructions when ten-

sioning saw oh;finwill damage saw andvoid the

warranty For additional information call !-8(10-

626-2237

New sawchainswill stretch Check chain tension

frequently whenlirst used ;rodtighten when chain

becomes loose around guide bar

@

Turn chain tensioning screw

clockwise to tension saw chain.,.

i,ii,lllli iii,ii

Approx.

Pull chain to check tension. Guide

links should not come outof guide

bar groove.,,

Ifchain becomes loosearound guide

bar, allow chain to cool then ....

Loosen nut...

ww_ r_mingtonpowottt_olt__om 12

Tighten nut with wrench. A

slight sag of 1/8" between chain

and bottom of guide bar is

acceptable,

OPERATING CHAIN SAW

.¢k

_J_ WARNING: Read and understand

this owner's manual before operat-

ing this saw. Make certain you read

and understand all important Safety

Information. Improper use of this

chain saw can cause severe injury

or death from fire, electrical shock,

or body contact with moving chain,

or falling wood.

FILLING OIL TANK

1 Removeoil cap.

2 Fill oil tank with SAE #30 motor oil Note:

For temperatures below 30_F, use SAE #10

oil, For temperatures above 75°F, use SAE

CklOoil

DO NOT use standard bar and chah'_ oil

3. Replace oil cap at once Tighten oil cap firmly

for good seal "t'his wil! avoid oil seepage from

cap

4. Wipe off excess oil..

not In use.. It is necessary to empty oll

nk after each use to prevent seepage_

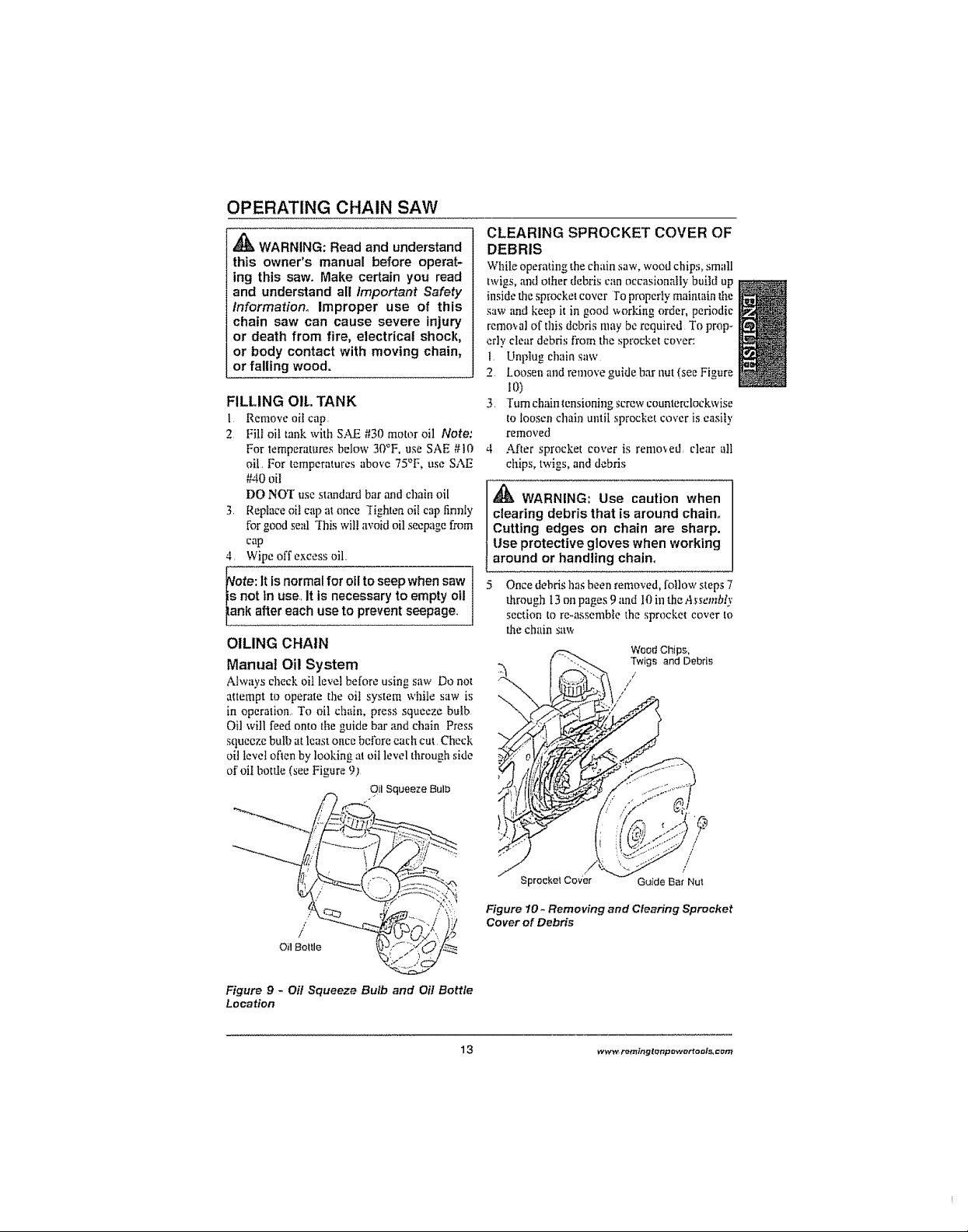

OILING CHAIN

Manual Oil System

Always check oil level before using saw Do not

attempt to operate tile oil system while saw is

in operation,. To oil chain, press squeeze bulb

Oil will feed onto the guide bar and chain Press

squeeze bulb at least once belbre each cut Check

oil level oiien by looking at oil level through side

of oil bottle (see Figure 9)

OilSqueeze Bulb

CLEARING SPROCKET COVER OF

DEBRIS

While operating the chain saw, wood chips, small

twigs, and other debris ctm occasionally build up

inside the sprocket cover re properly maintain the

saw and keep it in good v, orking order, periodic

rome',el of this debris may be required To prop-

erly clear debris from the sprocket cover:

1, Unplug chain saw

2 Loosen and remove guide bar nut (see Figure

I0)

3, Turn chain tensioning screw counterclockwise

to loosen chain until sprocket cover is easily

removed

4 After sprocket cover is remo'.ed, clear till

chips, twigs, and debris

WARNING: Use caution when

clearing debris that is around chain.

Cutting edges on chain are sharp.

Use protective gloves when working

around or handling chain.

Once debris has been removed, follow steps 7

tl_rough t3 on pages 9 and 10 in the Assembty

section to re-assemble the sprocket cover to

the chain sa_,

WoodChips,

Twigs and Debris

/

\

/

Oil_3ottle

Figure 9 - Oil Squeeze Bulb and Oil Bottle

Location

Sprocket Cover

Figure !0 - Removing and Clearing Sprocket

Cover of Debris

13

GuideBar Nut

wwy_rotrthlg_ctopow_rrools, corlt

./

/

//

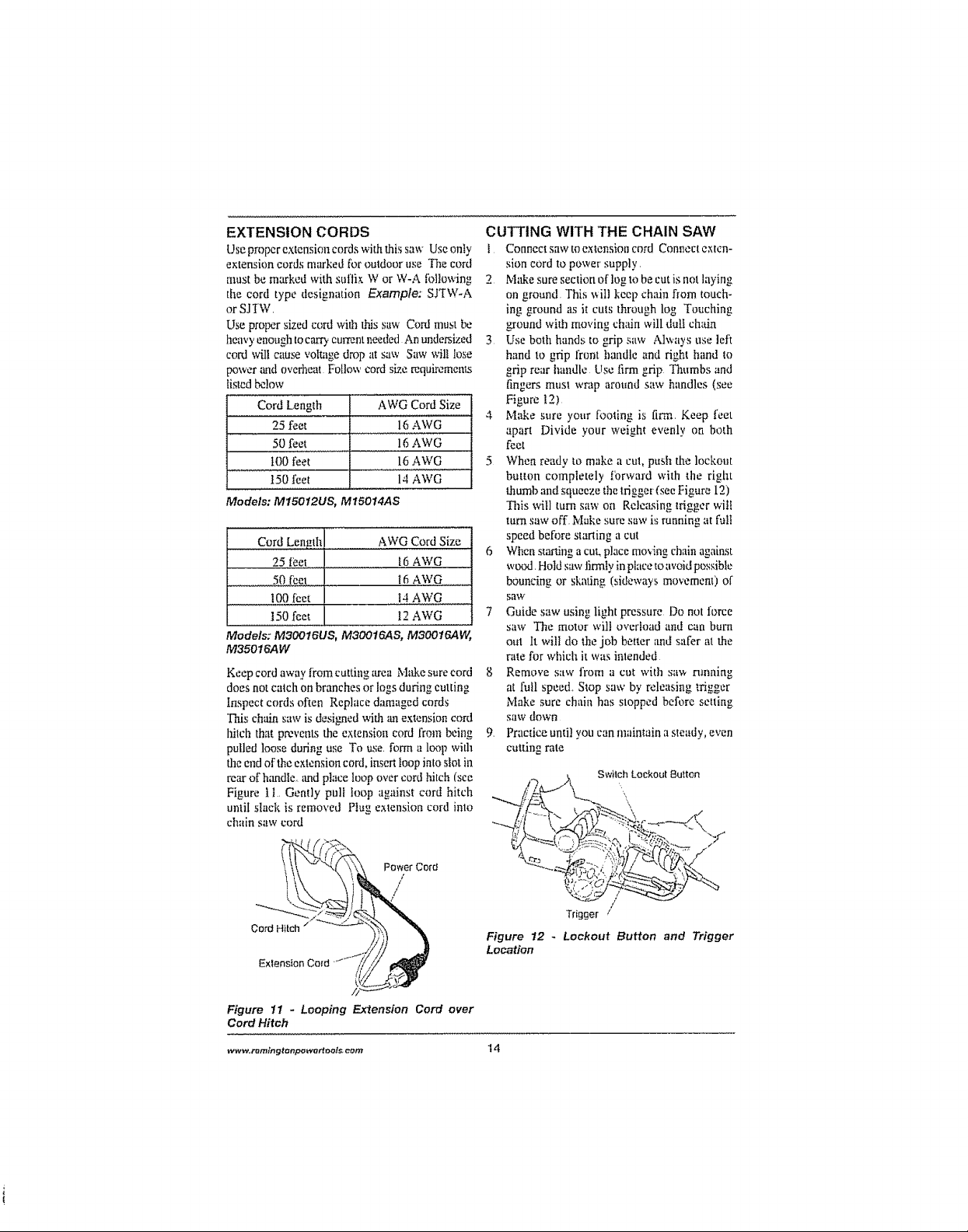

EXTENSION CORDS

Use proper extension cords with this sa',_ Use only

extension cords marked for outdoor use The cord

must be marked with suflir,. W or W-A tbllowing

the cord type designation Example: SHW-A

or SJIW.

Use proper sized cord with this saw Cord must be

heavy enough tocord current needed An undersized

cord will cause voltage drop at saw Saw wil! lose

power lind ovefl_ea! Follow cord size requiremenLs

listed below

CordLength

25 feet

50 feet

t0(1 feet

150 feet

AWG Cord Size

16 AWG

16 AWG

16 AWG

14 AWG

Models: M15012US, MISOI4AS

Cord Leng!h AWG Cord Size

25,fe,¢t......... 16 AWG

50 feel t6 AWG .............

100 feet t4 AWG ....

150 feet 12 AWG

Models: M30016US, M30016AS, M30016AH

M35016AW

Keep cord away from cutting area Make sure cord

does not catch on branches or logs during cutting

inspect cords often Replace damaged cords

This chitin saw is designed with an extension cord

ttilch that prcvenls the extension cord from being

pulled loose during use To use, form a loop with

the end of the extension cord, insert loop into slot in

rear of handle trod place loop over cord hitch (see

Figure 1L Gently pull loop against cord hitch

until slack is removed Plug extension cord into

chain saw cord

CUTTING WITH THE CHAIN SAW

I Connect saw toextension cord Con_ectextcn-

sign cord to power supply,

2 Make sure section of log to be cut is not laying

on ground, This v, ill keep chain from touch-

ing ground as it cuts through log Touching

ground with moving chain will dul! chain

3 Use both hands to grip saw Always use left

hand to grip front handle and right hand to

grip rear handle Use lima grip Thumbs and

fingers must wrap around saw handles (see

Figure 12}

4 Make sure your fboting is firm. Keep feet

apart Divide your weight evenly on both

feet

5 When ready to make a cut, push the lockout

button completely forward with the right

thumb and squeeze the trigger (see Figure 12)

This will turn saw on Releasing trigger wilt

turn saw off. Make sure saw is running at full

speed before starting a cut

6 When starting a cut, place moving chain against

wt_d, Hold saw firmly in place to avoid possible

bouncing or skating (sideways movement) of

saW

7 Guide saw using light pressure Do not force

saw The motor will overload and can bum

out It will do tl_e job better and safer at the

rate for which it was intended

8 Remove saw from a cut with saw nmning

at full speed, Stop saw by releasing trigger

Make sure chain has stopped before setting

saw down

9, Practice until you can maintain a steady, even

cutting rate

CordHt _\ "_"_

ExlensionCord ._-I_/_//

Figure 11 - Looping Extension Cord over

Cord Hitch

www.mmingtonpow_rtoots.eom 14

Trigger /

Figure 12 - Lockout Button and Trigger

Location

OPERATING CHAIN SAW

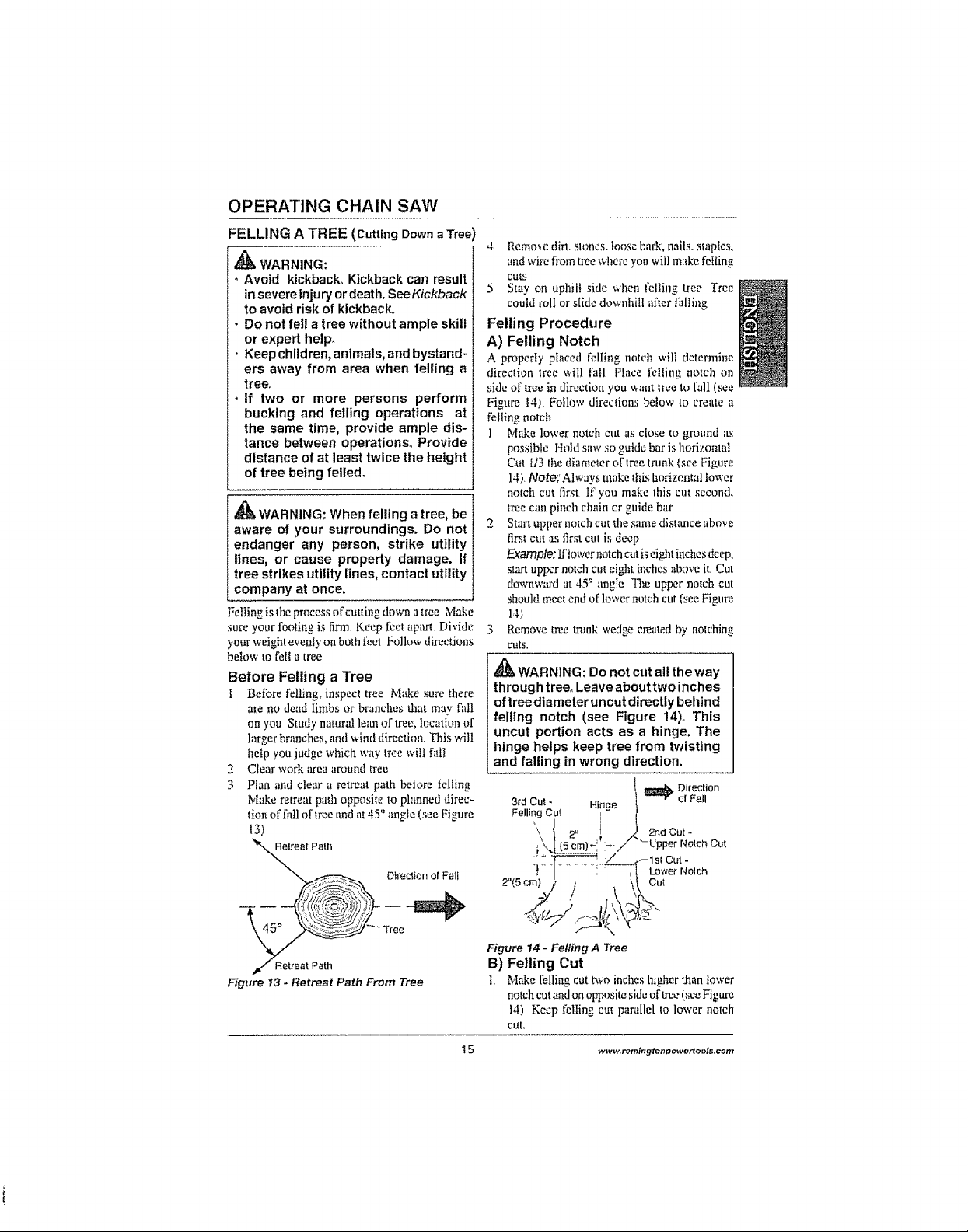

FELLING A TREE (CuttingDownaTree)

•_ WARNING:

• Avoid kickback° Kickback can result

insevereinjuryordeath. SeeKickback

to avoid risk of kickback.

• Do not fell a tree without ample skill

or expert helpo

• Keepchildren, animals, and bystand=

ers away from area when felling a

tree.

• if two or more persons perform

bucking and felling operations at

the same time, provide ample dis-

tance between operations. Provide

distance of at least twice the height

of tree being felled_

WARNING: When felling a tree, be

aware of your surroundings. Do not

endanger any person, strike utility

lines, or cause property damage. If

tree strikes utility lines, contact utility

company at once.

Felling is _he process of cutting down a tree Make

sure your footing is firm Keep feet apart. Divide

your weight even|y on bmh feet Follow directions

below to fetl a tree

Before Felling a Tree

i Before felling, inspect tree Make sure there

are no dead limbs or branches that may fall

on you Study natural lean of tree, location of

larger branches, and wind directkm This will

help you judge which way tree wilt fall

2 Clem" work erea around tree

3 Plan and clear a retreat path before felling

Make retreat path opposite to phmned direc-

tion of lhtl of tree and at 45" angle (see Figure

13)

eatPatt_ Dkectiono[ Fall

4 Remo_e din. stones, loose bark, nails, staples,

and wire from tree v, here you will make felling

cuts

5 Stay on uphill side when lblling tree Tree

could roll or slide downhill after falling

Felling Procedure

A) Felling Notch

A pmperIy placed felling notch will determine

direction tree _ill fall Pbace felling notch on

side of tree in direction you v,ant tree to fall (see

Figure 14) Follow directions betow to create a

felling notch

l Make lower notch cut as close to ground as

possible Hold saw so guide bar is horizontal

Cut 113 the diameter of tree trunk (see Figure

14).Note:' Always make _his horizontal lovmr

notch cut first. If' you make this cut second,

tree can pinch chain or guide bar

2 Start upper notch cut the same distance above

first cut as first cut is deep

Example: If'tower notch cut isei_lt inches deep.

start upper notch cut eight inches above it. Cut

downward at 45 _ angle The upper notch cut

should meet end of lower notch cut (see Figure

14)

3 Remove tree trunk wedge created by notching

culs.

,¢k

WARNING: Do not cut all the way

through tree. Leave abouttwo inches

oftreediameter uncut directly behind

felting notch (see Figure 14). This

uncut portion acts as a hinge. The

htnge helps keep tree from twisting

and falling in wrong direction.

Direction

3_dCut-

FellingCut

2"(5cm)

Hinge

\

\

I_ot Fall

2nd Cut -

'_Upper Notch Cut

Lower Notch

Cut

Figure 13 - Retreat Path From Tree

Figure 14 - Felling A Tree

B) Felling Cut

1 b,'I_e felling cut t_o inches hi_her than lower

notch cut and on opposite side of tree (see Figure

14) Keep felling cut paraIM to lower notch

cut,

5 www_rernlngtot_powertoo/s,com

OPERATING CHAIN SAW

2 Cut towards notch

3 As fellhlg cutne;_ hinge, treeshe uld begin to fall

Note: Ifneeded, drive wedges into felling cut to

control direction of fall ff tree settles back (rod

pinches chain, drive wedges into felling cut to

remove saw Only use wedges made of wood,

phtsfic, or aluminum Never usewedge m_de of

steel This could cause kickback and dam_tge to

chain

-'I When tree begins to fall, quiddy

• remove saw from felling cut

" release trigger to turn saw off

• put saw down

• exit area using retreat path

/'t

WARNING: Be alert for falling

overhead limbs° Watch your footing

while exiting area.

LIMBING A TREE

WARNING: Avoid kickback. Kick-

back can result in severe injury or

death+ See Kickback to avoid risk of

kickback.

,tL

BA_WARNING: When cutting limb that

isunder tension, useextreme caution.

Be alert for wood springing back.

When wood tension is released, limb

could spring back and strike operator

causing severe injury or death.

Limbing is removing br:mehesfrom a f;dlentree

Make sure your footing is firm+Keep feet apart.

Divide your weight evenly on both feet Do not

remove larger limbs under tree that support tog

offground Remove each limb with one cut/see

Figure 15).Clear cutlimbs from workarea often

This wil! help maintain a safe work area

Make sure you start your cut where limb will

not pinch saw during cutting To avoidpinching,

start cut on freely hanging limbs from above

limb Start cut on limbs undertension from under

limb If pinch occurs, turn saw off, liftlimb. and

remove saw

BUCKING A LOG

WARNING: Avoid kickback.

Kickback can result in severe injury

or death+ See Kickback to avoid risk

of kickback.

WARNING:

• If on slope, make sure log will not

roll down hill+ Secure log by us-

ing wooden stakes. Drive wooden

stakes into ground on downhlll side

of log+Stand on uphill stde of log

while cutting, Log may roll after

cutting,

- Never try cutting through two logs

at same time. This could increase

the risk of kickback,

• While cutting log, never hold log

with your hand, leg, or foot.

+While cutting log, never allow an-

other person to hold log.

. Turnoffand unplug saw before mov-

ing from one place to another,,

Bucking a log is cutting a log into sections Make

sure your footing is firm Keep {eel apart Divide

your weight evenly on both feet When possible.

raise log or section offground Do this by using

limbs, logs, chocks, ete

When cutting through log, maimt,in control by

reducing cutting pressure near end of cut Do not

relax your grip on chain saw handles Do not let

moving chain touch ground, Ground will dull

moving chain After cutting through log+ release

trigger to turn saw off before moving saw

Follow directions below to buck a log

Entire Length Of Log On Ground

Cut log from top (see [:'igure 16)

Figure 15 - Limbing A Tree

www+r_mingtonpewertoa/s.corn 16

Figure 16 +Bucking Log With Entire Length

On Ground

OPERATING CHAIN SAW

Log Supported On One End

I M;&e firstcut onunderside oflog (see Figure

f7} Usetop ofguide barto make thiscut, Cut

1/3through diameter of log This cutwillkeep

section fromsplintering when cut

2 Make second cut directly above firstcut Cut

down to meet firstcut This cut willkeep log

from pinching guide bar and chain

Log Supported On Both Ends

!,. /vI:_efirstcut fromabove tog see Figure 18)

Cut 1/3through diameter oflog Thiscut will

keep section from splintering wizencut.

2 Make secondcut on underside oflog, directly

under lirst cut. Use top of guide bar to make

tiffscut.,Cut up to meetfirstcut This wilt keep

log from pinching guide bar artdchain

TRIMMING A TREE (Pruning)

A WARNING: Avoid kickback.,

Kickback can result in severe injury

or death. See Kickback to avoid risk

of kickback°

,,.- cut.._/ %11

Figure 17 - Bucking Leg When Log Is

Supported On One End

k 1st Cut

Zk

WARNING: Do not operate chain

saw while

• in a tree

- on a ladder or any other unstable

surface

• in any awkward position

You may lose control of saw causing

severe injury°

£t

WARNING: Do not cut limbs higher

than your shoulders,

A CAUTION: Seek professional

help if facing conditions beyond your

ability°

Trimming a tree is the process of cutting limbs

froma living tree Make sure your footingis tirm

Keepfeetapart Divide your'weighte_enly onboth

feet Follow directions below to trim :ttree

1 Make first cut six inches t}om tree trunkon

underside of limb Use top of'guide bar to

make this cut. Cut 113through di_uneterel

limb {seeFigure 19)

2 Move two to four inches farther out on limb

Make second cut from above limb Continue

cut until you cut fimboff

3 Make thh'dcut asclosetotreemink aspossible

on undersideo[limb stub Usetopof guidebar

m make this cut Cut 1/3 throughdiameter of

stub

4 Make fburth cut directly above third cut Cut

down to meet thirdcut 1his willremove limb

stub

2nd Cut - Pruning

Cut (to avoid

4th Cut - Final Stub _\

pinching)

2odcu, ,

Figure t8 - Bucking Leg When Log is

Supported On Both Ends

f ,) I-- ,

/ _ 2" to 4"

/ 15 a t0 cm)

--_ 1st Cul - Pruning

(to avoid spiintering)

3rd Cut - Stub Undercut

(_ Undercut

{1oavoid splintering)

Figure 19 - Cutting A Limb

t 7 www,_ern_ngtenpowett_ol&corn

CLEANING AND MAINTENANCE

NOTICE: Below are instructions for

servicing your chain saw. Any ser-

vicing not mentioned below should

be done by an authorized service

center.

CLEANING SAW BODY

,tx

_l_ WARNING: Unplug chain saw from

power source before servicing° Severe

injury or death could occurfrom electri-

cal shock or body contactwith moving

chain°

ZX

WARNING: Cutting edges onchain

are sharp. Use protective gloves when

handling chain.

/x

_IL WARNING: When cleaning saw

body,

do not submerge saw in any liq-

uids

. do not use products that contain

ammonia, chlorine, or abrasives

. do not use chlorinated cleaning

solvents, carbon tetrachloride,

kerosene, or gasoline

Keep sm_. body clean Use a soft cloth dampened

with a mild soap _md',_ater mixture Wipe saw body

tode;m,

CARE OF GUIDE BAR

Uneven bar wear causes most guide bar problems

Incorrect sharpening of chain cutter and depth

gauge settings often cause this When bar wears

unevenly, it widens guide bar groove (see Figure

20) This causes chain clatter and rivet popping,

Saw will not cut slraigh! Replace guide bar iI

this occurs

Inspect guide bar before sharpening ch_dn, A worn

or damaged guide bar is uns,'fl_ A worn or damaged

guide bar will damage chitin It will also make cut-

ling harder Guid_BarGr_vo

Normal Guide Bar Maintenance

1 Remove guide bar from chain saw

2 Remove sawdust fi'om guide bar groove peri-

odically Use putty knife or wire (see Figure

2t)

3,, CLean oil slots after each day of use

4 Remove burrs from sides of guide bar Use

flat file to make side edges square

Replace guide bar v,hen

• bar is bent or cracked

• inside groove of bar is badly worn

Note: When replacing guide bar, see Reph_cement

Part_ and Accessories for proper bar

SHARPENING SAW CHAIN

,'x

WARNING: Unplug chain saw from

power source before servicing. Severe

injuryor death could occur from electri-

cal shock or body contact with moving

chain.

are sharp° Use protective gloves when

I _WARNING: Cuttingedgeson chain t

handling chain.

Keep chain sharp Your saw will cut faster and

more safely A dull chain will cause madue sprock-

et, guide bar, chain, and motor _ear If you must

force chain into wood and cutting creates only

sawdust with few large chips, chain is &ill

Burr

-GuideBa_

-_'_'_\Cleant_g GrooveW_thPuttyKnife

j / -

Nomn_ G.ide J[lu,r Guide B;_rWitt_ U_le',e_ \_'¢:kr

Figure 20 - Guide Bar Cross Section Showing

Uneven Bar Wear

www, rorntngtonpoworfr_o/s.com t 8

/

Figure 21 - Guide Bar Maintenance

CLEANING AND MAINTENANCE

Items Needed to Sharpen Chain

Purchase these items from your local dealer, hard-

ware store, or chain saw supplies outlet

• 5t32' round file

• Depth gauge tool

" File guide

• Vise

. Medium sized ltat file

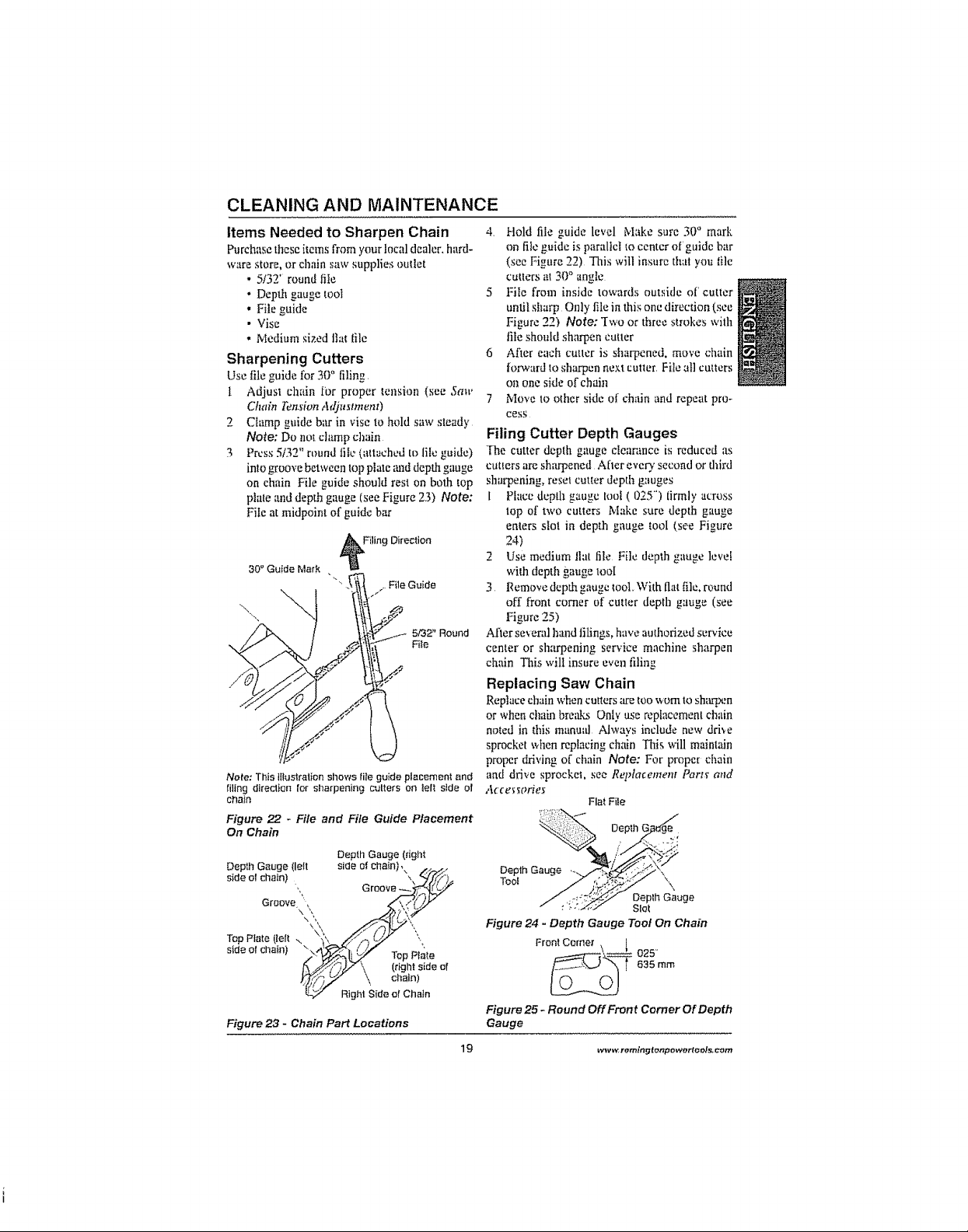

Sharpening Cutters

Use lile guide for 30" filing

1 Adjust chain for proper tension (see Star

Chain l'¢mivn Adju,_mwm)

2 Clamp guide bar in vise to hold saw steady

Note: Do not clamp chain

3 Press 5132" round li[e (attached to lile guide)

into groove between top plate zmddepth gauge

on chain File guide should rest on both top

plate and depth gauge (see Figure 23) Note;

File at midpoint of guide bar

5/32" Round

File

Note: This Illustration sllows file guide placement and

fii_ng direction for sharpening cutters on loll side o!

chain

Figure 22 - File and File Guide Placement

On Chain

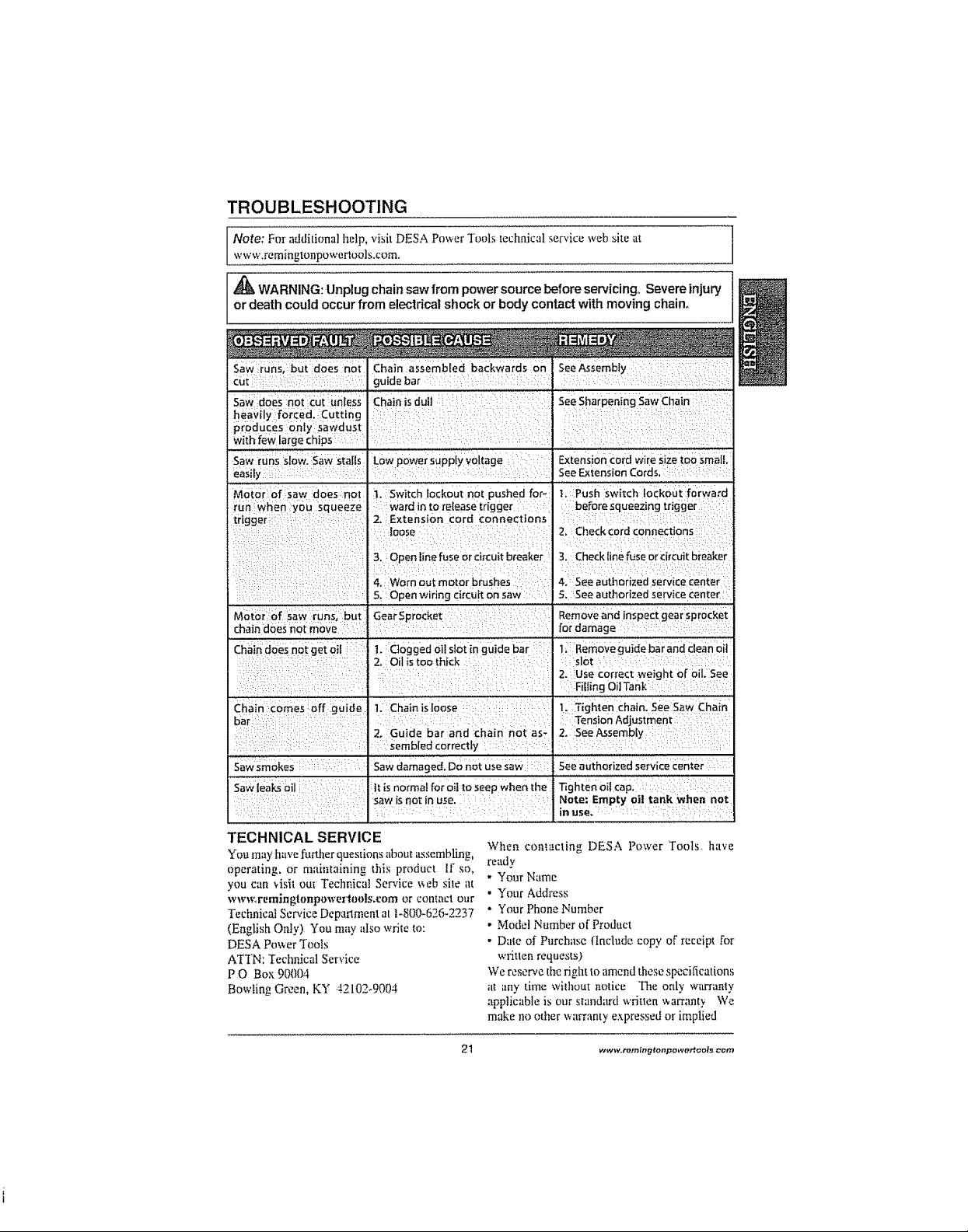

Deptt_Gauge(lelt side otchain),, .....

sideof chain) ',. _/_)_

DepthGauge(right

,, Groove_

4, Hold file guide level Make sure 30 ° mark

on file guide is paralM to center of guide bar

(see Figure 22) This will insure that you tile

cutters at 31Y'angle =

5 File from inside towards outside of cutter i

until sMrp Only file in this one direction (see

Figure 22) Note: "l'wo or three strokes with

tile should sharpen cutter

6 Af)er eacf_ cutter is sharpened, move chain

forward to sharpen next cutter, File all cutters

on one side of chain

7 Move to other side of chain and repeat pro-

cess

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced as

cutters are sharpened After eve_' second or third

sharpening, reset cutter depth gauges

I Place depth gauge roof (025') tirmly across

top o1['two cutters Make sure depth gauge

enters slot in depth gauge tool (see Figure

24)

2 Use medium flat lile File depth gauge level

with depth gauge ton

3 Remove depth gauge tool. With flat file. round

off front comer of cutter depth gauge (see

Figure 25)

After se',eral hand tilings, have authorized service

center or sharpening service machine sharpen

chain This will insure even 5ling

Replacing Saw Chain

Replace chain when cutters are too _om to shmpen

or when chain breaks Only use replacement chain

noted in this manuid Always include new drbe

sprocket v,hen replacing chain This will maintain

proper driving of chain Note: For proper chain

and drive sprocket, see Replacement Parts and

Accessories

FlatFile

DepthG_g_e

,oo,y/j ,,

TopPlate(Ielt -.. '__"_"',.

sideelchain) "-."_i, U/ ..... Lo

_,_" Righl_ide of Chain

Figure 23 - Chain Part Locations

Figure 24 - Depth Gauge Tool On Chain

FrontCerne_"\,___.L

635mm

_ 025'

Figure 25 - Round Off Front Corner Of Depth

Gauge

19 wlv,_remingtenpowertools.com

REPLACEMENT CHAINS

Replacement saw chains may be aw_il_ble utyour

local hardware or home improvement store

Ihe lollowing list gives tile specifications for

replacement chains

All chains will be 050 gauge. 3/8 pitch.

10' chains have 42 drive links

12" chains have 48 drive links

14" chains have 52 drive links

16" chains have 58 drive links

You may also order tile replacement saw chains

from the "Online Outlet" at www.remington-

powertonls_com using the part nmnber listed in

the illustrated parts list on pages 72-73 of this

manual

STORAGE

If storing saw for more than 30 days, follow steps

below

1 Drain oil tank ;filer each use

2 Remove and clean guide bar and chain Clean

guide bar and chain by sotddng in petroleum

based solvent or mild soap and water mix-

lure

3 Dry guide bar and chain

4 Place chain in container filled with oil This

wilt prevent rest.

5 Wipe a lhin coating of oil over surface ol guide

bar

6 Wipe off outside of saw body. Do this with soft

cloth dampened with a mild soap and water

mixture

7 Storechain saw

• in ,_high or locked place, out of children's

reach

• in a dry place

REPLACEMENT PARTS AND

ACCESSORIES

A_ WARNING: Use only replacement

parts and accessories described in

this manual Use of other parts or ac-

cessories could damage saw or injure

operator.

For original replacement parts and accessories,

contact your nearest Authorized Dealer or Au-

thorized Service Center for this product if they

can not supply the part or accessory, contact your

nearest Parts Central listed on page 74 Each Au-

thorized Dealer. Authorized See'ice Center, and

Parts Central is independently owned and oper-

ated You may also order parts from the "Online

Outlet" at www_remingtonpnwertools.eom.

See pages 72 through 73 for a,l Illustrated Parts

List

if you need additional mfcmfl infomlation, contact

our ].echnicat Service Department (see Technical

Service)

In Canada call 1-800-561_3372 for part'_and service

information

REPAIR SERVICE

Note: Only use original replacement parts ]'his

wilt protect your warranty coverage for parts

replaced under wammty

Each Authorized Service Center is independently

owned and operated

Warranty Service

It' product requires warranty seeice, return it to

nearest Authorized Service Center.. You must show

pmofofpurcha.se If faulty materials or _orkmanship

caused damage, we will repair or replace product

without charge Note: Normal wear. misuse, abuse,

neglect, or accidental damage is not covered under

warranty

Non-Warranty Service

If product requires service, return it to nearest

Authorized Service Center Repairs wilt be billed

to you at regular repair list prices

For additional Service Center or warranty informa-

tion, call 1-800-626-2237 or visit our Technical

Service web site at wwworemingtonpowertools.

corn,,

www, t_m#_gtonpow_rlr_oln_,com 20

TROUBLESHOOTING

Note: For additional help, visit DESA Prover Tools technical service web site at

www,remingtonpowertools.com.

WARNING: Unplug chain saw from power source before servicing,, Severeinjury

or death could occur from electrical shock or body contact with moving chain,

Saw:runs, but does not Chain assembled backwards On " seeAssembty : ! i i : :

cut : :: :: guidebar : : : : ii:

SaW::does not cut unless Chain iS dull :; :: : j See Sharpening Saw chain i:

heavily forced. Cutting '

pri0duces 0nly _awdu__t : : : : .... : :

w th fewlarge chips ...... . : . .::...:... : : :i : ::

saw runs slow. Saw Stalls LOWpowersupply v_ltage : : Extension cord wire Size t00 small,:

easily:: i : : :: I : i _: : i:: i seeEx;[ensionCortJs, :i:

Mot0r of Saw does not 11, Switch lockout not pushed for_ 1, : Push switch 10c:k0ut forward

run:when you squeeze I :wardin torelease trigger : J : beforelsqueezing trigger i:

t?igger : 12, ExtensiOn L:0rd connection51 = : :

: ..... ..... oose : ....... : 2 Check cord connect ons :

: : 3. Open line fuse or ci_cuR breaker 3, Check line fuse or circuit breaker

i : : I 4 :Worn out m0tor brushes 4 See aut 1or zed serv cecenter

: Z : : :: 5. Openwiring circuit on saw 5, S_e authorized service Center :

Motor :of saw runs, but I Gear Spi'0cket : ::: Remove and inspect gear spr6cket

chain does not m0ve : :: , _ :: :: fordamage :: :

chan does not get oit 1. clogged oil slotinguide bar :::: 1, Remove guide bar and clean 0 t

: :::: : : : Filling Oil Tank i

Chain Come.s off guide, t. Chain is loose : :: 1. Tigl_ten ichain. See SaW Chain

bar i :i : I :i :iTensionAdjustment i

: i J 2, Guide bar and chain not as- 2. SeeAssembty

:: :1 semb ed correct y : : : i

sawsm0k_s " Saw damaged, Do not use saw see authorized service cen{er

20 stoothck : I :slot

: :: : : : 2, Use correct weight of oiL See

It is normal for oil to seep when the Tighten oil cap. : : ::: i

saw s not n use, i : Note: Empty oil tank when not

.... : i in use.

TECHNICAL SERVICE

Youmayhave furtherquestionsabout assembling,

operating, or maimaining this product ff so,

youcan visit oreTechnical Service _eb site at

www,,remingtonpowe_tooIs,com or contact our

TechnicalServiceDeparlment at 1-800-626-2237

(English Only) You may also write to:

DESA Po\ver'l"oots

ATTN: Technical Service

P O Box 90004

Bowling Green, KY 42102-9004

:1

When contacting DESA Power Tools. have

ready

, Your Name

• Your Address

, Your Phone Number

-Model Number of Product

• Date of Purchase (Include copy of receipt for

written requests)

We reservetheright toamend thesespecifications

at any time without notice The only wammty

applicable is our stand_miwritten warranty We

make no other wammty expressed or implied

21 www.remlnptonpoweFt_ol$corQ

WARRANTY INFORMATION

REMINGTON BRAND ELECTRIC CHAIN SAW

LIMITED WARRANTIES

_E_O U CTS

Standard YYar ra.tB_[y

DESA Power "['o_ls warrant.,, Ibls _ew pmducl aml any parts thereuf m be free rrum d,ffecls in mmerial and

worknmnship for a perk'd of one (l) year fzom fl_e da_e of first pu[chaxe from m_ amhodzed dealer pmvhled the

product has been rnair_tailled and _pevated in accordance wilh DESA Pm_er 7boIs' warnings and insvrucdnl_s

Limited Warranty

DESA Power Tools _,vurran_s facm_" _c_mdilioned pmdncls ;rod ;m,_ par_ thereof to be fi'_e from defet:_s in

malcfial and w_rkmanship fi_r 90 days from _he date ol" first pureh;l.se from an amhorized dealer provided the

prnduc_ Ires been iastaItefl, m;dn_ained and operatud in ac:ordance _ith I)ESA Prover "[onls' wamil_gs and

insm_cfioas

TERMS COMMON TO ALL WARRANTIES

_[][___oJ]P_flgd._,_In_!y in atl i_f tile abm'e warrnnfiest

Always _preify tltodel number when c_mtaeting the manuhtcturvr To make a clahn under lifts wammty lhe

billof saleur olherproofoi"pucch,_c must be prescmed

• I'hiswarranty ise,x_endedonly m the odgh_al retailpurd_aserwhen purd_ased |7orean a_thofizeddealer

• rhis warramy covers fl_e cosl of pan(st rcqnlred IO restore lifts product Io proper operating condition and an

allow;race for labour when provided by a DESA Pnwer Tools Authorized Service Cen_ur Warranty p_rts must

be ,4btained through authorized deaicr_ of this product anent DESA power To'ols who Mll provide original

factory repl;tecment paris Failure to use nrigi_ml factory feplaceli_,c_ll palls eoids LIds warr;Inty

- Travel. h:mdlioLa, transpunatlun, diagm_stic material labor ,_md incidenlal cast4 associated with warranty

repairs, unless expressly colered by tills wammty ere lm_ reimbursable under 1his warranty wild :are the

respm_sibi)i_y nf the owlter

• Excluded from thls wammty are products or paris that £fil or become damaged due to misuse, accidents lack

of proper maintenance, lamperlng or al_erado_s

• Excluded fi'nm dfis wart;rely are pr_duc_.s purchased f_r ctm_mcrelal, hlduslrial sr rental usage

• fhis is DESA Power tt_ols' exclusive wammty, and w d_e full exlenl allnwed by law; this express warranly

excludes ,'_n) and all other warranliCS_ e,xpress or implied wriuen or verbal aI_d limits the durmiotl of any and

all impficd wam,mak,_,hlcluding watt,redes of mc_ehamability ;rod Illness for a panic*alur parposc to tree ( I )

year on _lew products and 90 days on facto_' recondiliot_cd products from file date of first purchase DESA

Power Tools Ittakes no nther wamlmies regarding dais pmducl

• DESA Pnwer ] onls" liabi_ky is tim]ted m fl_e put'chase price of fl_c product, and DESA Puwer ]'_mls shall

I101 be liable for alfy _ther dafnages whaksuever utlder any ¢]D2unlslallces including indkect incidental, or

consequential damages

- Some suues do m.4 anow limhaduns on how hmg an hl_pfled w_tmmty Ira,L4or the excluskm or llmltaL_nn of

incidental or cv_tscquet_limd dam,_ges, so the above limil;aiun or exclusion may not apply to you

• ]_aiS warn;filly _\'es yoR speeffic legal rights, and you may ;ds_) have _d_er rights which vur3,' frvm slate let

skqle

For ilffonnatiolt :l[:_out this wamlmv cnntact:

Model

Date Purchased

POWER TOOLS

Bowling Green, KY 42102-9004

800-626-2237 (English Only)

www remingtonpowertools corn

www.tomlngtonpower_oots.com 22

lndusuies of Canada. Inc

82 Akron Road

Toronto, Ontario

M8W 1T2

416-255-5333

Fax: 416-255-5677

www remingtonpoweflools corn

f

S ERRA IELECTRUCA

MANUAL PARA EL USUARIO

®

MODELOS: M15012US, M15014AS, M30016US, lVi30016AS,

M30016AW, M35016AW

IMPORTANTE: Lea cuidadosamente este manual antes de

armar u operar esta sierra el_ctrica. El uso indebido de

la misma puede provocar graves lesiones. Guarde este

manual para consuitarlo cuando !o necesite.

23 i'_ww,trtmingt_enpowertools,com

Loading...

Loading...