REMEHA Quinta Ace 30, Quinta Ace 45, Quinta Ace 115, Quinta Ace 55, Quinta Ace 65 Installation And User Manual

...

United Kingdom

en

Installation and user manual

High-efficiency wall-hung gas boiler

Quinta Ace 30 - 45 - 55 - 65 - 90 - 115

Dear Customer,

Thank you very much for buying this appliance.

Please read through the manual carefully before using the product, and keep it in a safe place for later reference. In order to

ensure continued safe and efficient operation we recommend that the product is serviced regularly. Our service and customer

service organisation can assist with this.

We hope you enjoy years of problem-free operation with the product.

Contents

7684359 - v.06 - 10012019 3

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.1 Circulating pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Installation regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Choice of the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 Location of the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Requirements for CH water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5 Requirements for condensate drain line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.6 Requirements for gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.7 Requirements for the electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.8 Requirements for the flue gas outlet system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.8.1 Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.8.2 Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.8.3 Dimensions of flue gas outlet pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.8.4 Length of the air and flue gas pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.8.5 Additional guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.9 Water quality and water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.10 Water flow in process heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.11 Increasing standard ΔT setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

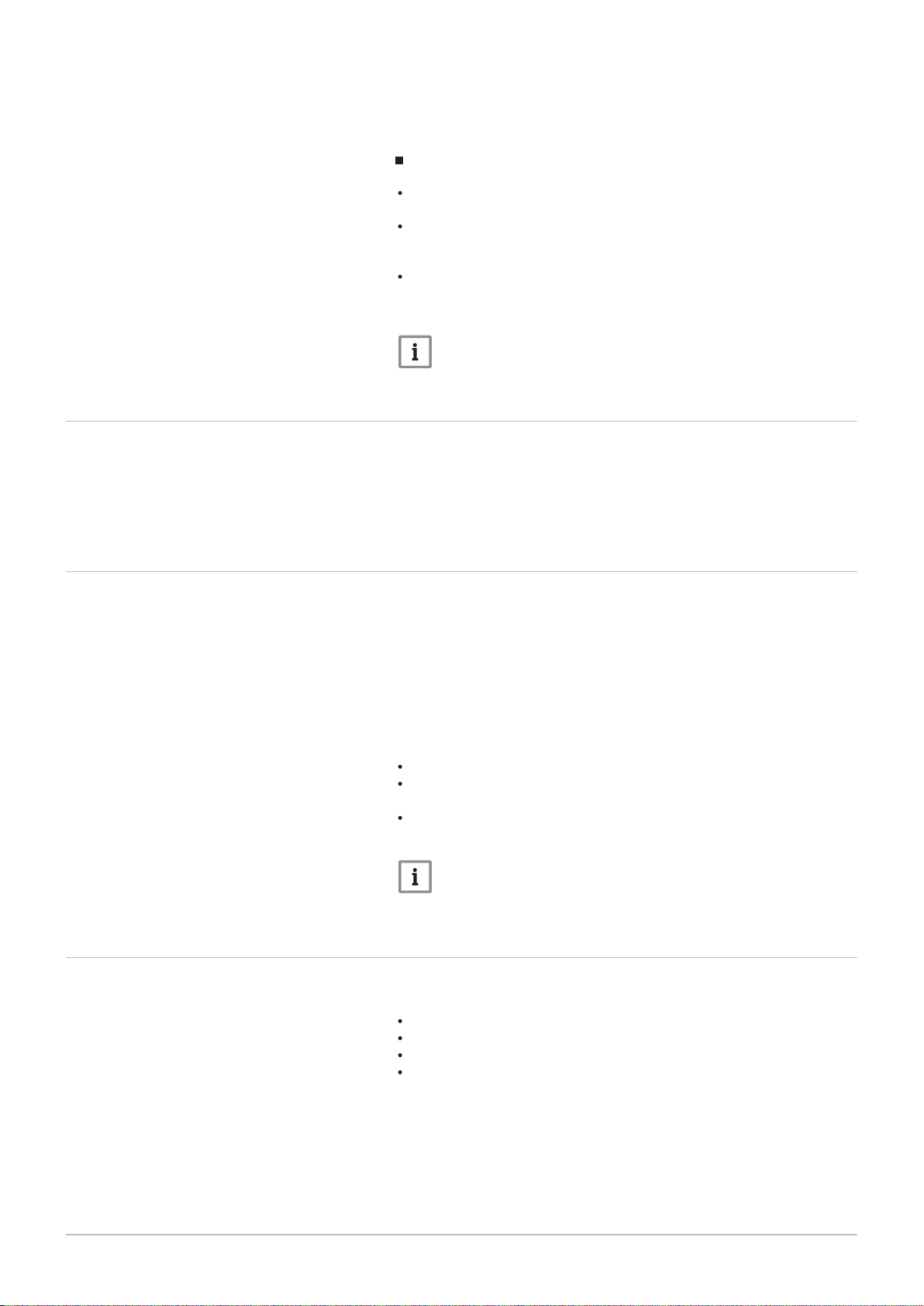

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Positioning the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.2 Rinsing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Connecting the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.4 Connecting the condensate discharge pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5 Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.6 Air supply/flue gas outlet connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.6.1 Connecting the flue gas outlet and air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.7 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.7.1 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.7.2 Access to the connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.7.3 Connection options for the standard PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.7.4 Additional control PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6 Before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.1 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1.1 Description of the components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1.2 Description of the home screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.1.3 Description of the main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Checklist before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.1 Filling the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.2 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.2.3 Gas circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.4 Hydraulic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2.5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Contents

4 7684359 - v.06 - 10012019

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1 Commissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2.1 Adjusting to a different gas type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2.2 Checking and setting the gas/air ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3 Final instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1 Changing the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1.1 Accessing the installer level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.2 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.2.1 Description of parameters CU-GH08 control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.2 Maintenance message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.3 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.3.1 Checking the water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

9.3.2 Checking the ionisation current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.3.3 Checking the flue gas outlet/air supply connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.3.4 Checking the combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.3.5 Cleaning the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.4 Specific maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.4.2 Removing the front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

9.4.3 Checking the non-return valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

9.4.4 Reassembling the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

10.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.1.1 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.1.2 Blocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1.3 Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.2 Error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

11 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11.1.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11.1.2 Unit categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

11.1.3 Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11.1.4 Factory test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11.2 Dimensions and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.3 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.4 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

12 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

12.1 ErP information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

12.1.1 Product fiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

12.1.2 Package sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

12.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

12.2.1 Disposal and recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

12.3 EC declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

12.4 Optional electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

12.4.1 Electronics extension box for extension PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

1 Safety

7684359 - v.06 - 10012019 5

1.1 General safety instructions

For the installer:

1 Safety

Danger

If you smell gas:

1. Do not use naked flames, do not smoke and

do not operate electrical contacts or switches

(doorbell, lighting, motor, lift etc).

2. Shut off the gas supply.

3. Open the windows.

4. Trace possible leaks and seal them off

immediately.

5. If the leak is upstream of the gas meter, notify

the gas company.

Danger

If you smell flue gases:

1. Switch the boiler off.

2. Open the windows.

3. Trace possible leaks and seal them off

immediately.

Caution

After maintenance or repair work, check the

entire heating installation to ensure that there are

no leaks.

For the end user:

1 Safety

6 7684359 - v.06 - 10012019

Danger

If you smell gas:

1. Do not use naked flames, do not smoke and

do not operate electrical contacts or switches

(doorbell, lighting, motor, lift etc).

2. Shut off the gas supply.

3. Open the windows.

4. Report any leaks immediately.

5. Evacuate the property.

6. Contact a qualified installer.

Danger

If you smell flue gases:

1. Switch the boiler off.

2. Open the windows.

3. Report any leaks immediately.

4. Evacuate the property.

5. Contact a qualified installer.

Warning

Do not touch the flue gas pipes. Depending on

the boiler settings, the temperature of the flue gas

pipes can rise to over 60°C.

Warning

Do not touch radiators for long periods.

Depending on the boiler settings, the temperature

of the radiators can rise to over 60°C.

Warning

Be careful when using the domestic hot water.

Depending on the boiler settings, the temperature

of domestic hot water can rise to over 65°C.

Warning

The use of the boiler and the installation by you

as the end-user must be limited to the operations

described in this manual. All other actions may

only be undertaken by a qualified fitter/engineer.

Warning

The condensation drain must not be changed or

sealed. If a condensate neutralisation system is

used, the system must be cleaned regularly in

accordance with the instructions provided by the

manufacturer.

1.2 Recommendations

7684359 - v.06 - 10012019 7

1 Safety

Caution

Ensure that the boiler is regularly serviced.

Contact a qualified installer or arrange a

maintenance contract for the servicing of the

boiler.

Caution

Only genuine spare parts may be used.

Important

Regularly check for the presence of water and

pressure in the heating installation.

Danger

This appliance can be used by children aged

eight and above and people with a physical,

sensory or mental disability, or with a lack of

experience and knowledge, provided they are

supervised and instructed in how to use the

appliance in a safe manner and understand the

associated dangers. Children must not be

allowed to play with the appliance. Cleaning and

user maintenance should not be carried out by

children without adult supervision.

Warning

Installation and maintenance of the boiler must be

carried out by a qualified installer in accordance

with local and national regulations.

Warning

The installation and maintenance of the boiler

must be undertaken by a qualified installer in

accordance with the information in the supplied

manual, doing otherwise may result in dangerous

situations and/or bodily injury.

Warning

Removal and disposal of the boiler must be

carried out by a qualified installer in accordance

with local and national regulations.

Warning

If the mains lead is damaged, it must be replaced

by the original manufacturer, the manufacturer's

dealer or another suitably skilled person to

prevent hazardous situations from arising.

1 Safety

8 7684359 - v.06 - 10012019

Warning

Always disconnect the mains supply and close

the main gas tap when working on the boiler.

Warning

Check the entire system for leaks after

maintenance and servicing work.

Danger

For safety reasons, we recommend fitting smoke

and CO alarms at suitable places in your home.

Caution

Make sure the boiler can be reached at all

times.

The boiler must be installed in a frost-free area.

If the power cord is permanently connected, you

must always install a main bipolar switch with

an opening gap of at least 3 mm (BS EN

60335-1).

Drain the boiler and central heating system if

you are not going to use your home for a long

time and there is a chance of frost.

The frost protection does not work if the boiler is

out of operation.

The boiler protection only protects the boiler,

not the system.

Check the water pressure in the system

regularly. If the water pressure is lower than 0.8

bar, the system must be topped up

(recommended water pressure between 1.5 and

2 bar).

Important

Keep this document near to the boiler.

Important

Only remove the casing for maintenance and

repair operations. Refit all panels when

maintenance work and servicing are complete.

Important

Instruction and warning labels must never be

removed or covered and must be clearly legible

throughout the entire service life of the boiler.

Damaged or illegible instructions and warning

stickers must be replaced immediately.

Important

Modifications to the boiler require the written

approval of Remeha.

1.3 Liabilities

7684359 - v.06 - 10012019 9

1 Safety

1.3.1 Manufacturer's liability

Our products are manufactured in compliance with the

requirements of the various Directives applicable. They

are therefore delivered with the marking and any

documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We

therefore reserve the right to modify the specifications

given in this document.

Our liability as manufacturer may not be invoked in the

following cases:

Failure to abide by the instructions on installing and

maintaining the appliance.

Failure to abide by the instructions on using the

appliance.

Faulty or insufficient maintenance of the appliance.

1.3.2

Installer's liability

The installer is responsible for the installation and initial

commissioning of the appliance. The installer must

observe the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Install the appliance in compliance with prevailing

legislation and standards.

Carry out initial commissioning and any checks

necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the

obligation to check the appliance and keep it in good

working order.

Give all the instruction manuals to the user.

1.3.3 User's liability

To guarantee optimum operation of the system, you

must abide by the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Call on a qualified professional to carry out installation

and initial commissioning.

Get your installer to explain your installation to you.

Have the required inspections and maintenance

carried out by a qualified installer.

Keep the instruction manuals in good condition close

to the appliance.

2 About this manual

10 7684359 - v.06 - 10012019

2 About this manual

2.1 General

This manual describes the installation, use and maintenance of the Quinta

Ace boiler. This manual is part of all the documentation supplied with the

boiler.

2.2

2.3

Additional documentation

The following documentation is available in addition to this manual:

Water quality instructions

Symbols used

2.3.1 Symbols used in the manual

This manual uses various danger levels to draw attention to special

instructions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

Danger

Risk of dangerous situations that may result in serious personal

injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations that may result in minor personal

injury.

Caution

Risk of material damage.

Important

Please note: important information.

See

Reference to other manuals or pages in this manual.

AD-4000070-01

17

14

13

10

9

6

7

8

2

1

12

3

4

11

5

18

19

20

16

15

3 Description of the product

7684359 - v.06 - 10012019 11

3 Description of the product

The Quinta Ace boiler is delivered with a combination of the control panel,

control unit and extension PCB. The contents of this manual are based on

the following software and navigation information:

Tab.1 Software and navigation information

Name visible in display Software version

Boiler Quinta Ace CU-GH08 1.4

Control panel HMI T-control MK3 1.29

3.1

General description

3.2 Main components

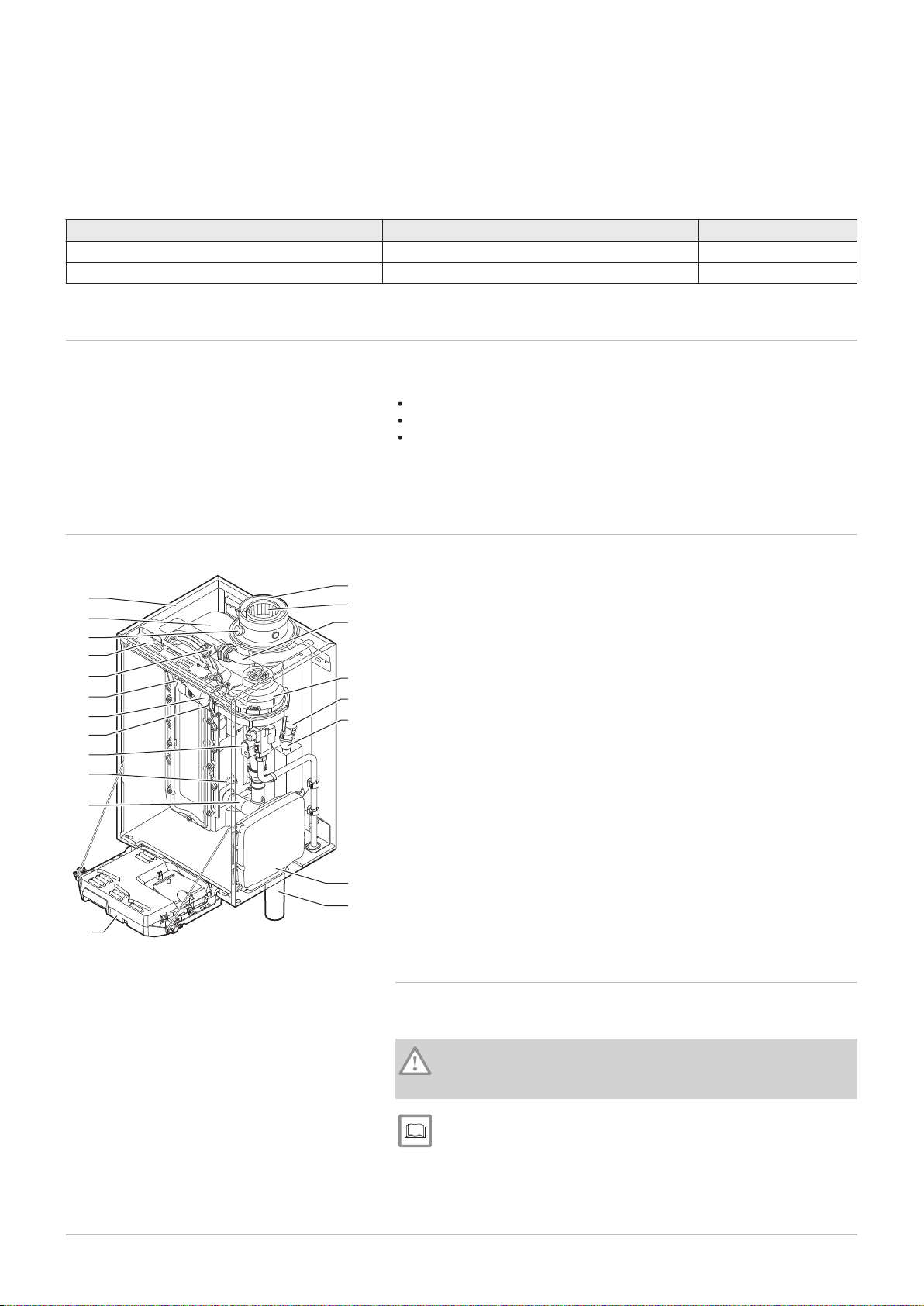

Fig.1

Main components

The Quinta Ace boiler is a high-efficiency wall-hung gas boiler with the

following properties:

High-efficiency heating.

Limited emissions of polluting substances.

Ideal choice for cascade configurations.

All Quinta Ace boiler models are supplied without a pump, but with the

required pump connection cables.

1

Casing/air box

2

Heat exchanger (CH)

3

Flue gas measuring point

4

Interior light

5

Flow sensor

6

Ionisation/ignition electrode

7

Mixing tube

8

Non-return valve

9

Combined gas valve unit

10

Return sensor

11

Air intake silencer

12

Instrument box

13

Siphon

15

Automatic air vent

16

Hydraulic pressure sensor

17

Fan

18

Supply line

19

Flue gas discharge pipe

20

Air supply

3.2.1 Circulating pump

A circulation pump is not supplied with this boiler. Take the boiler

resistance and system resistance into account when selecting a pump.

Caution

The pump may have a maximum input of 200 W. Use an auxiliary

relay for a pump with greater power.

See

Technical data, page 65

If possible, install the pump directly under the boiler on the return

connection.

AD-0000103-01

AD-0000014-02

500

min.1000

500

min.

400

350

min.

250

750

4 Before installation

12 7684359 - v.06 - 10012019

4 Before installation

4.1 Installation regulations

Warning

The installer must be registered with Gas Safe and have the

correct ACS qualifications.

Important

Practical guidelines - see the latest version.

4.2

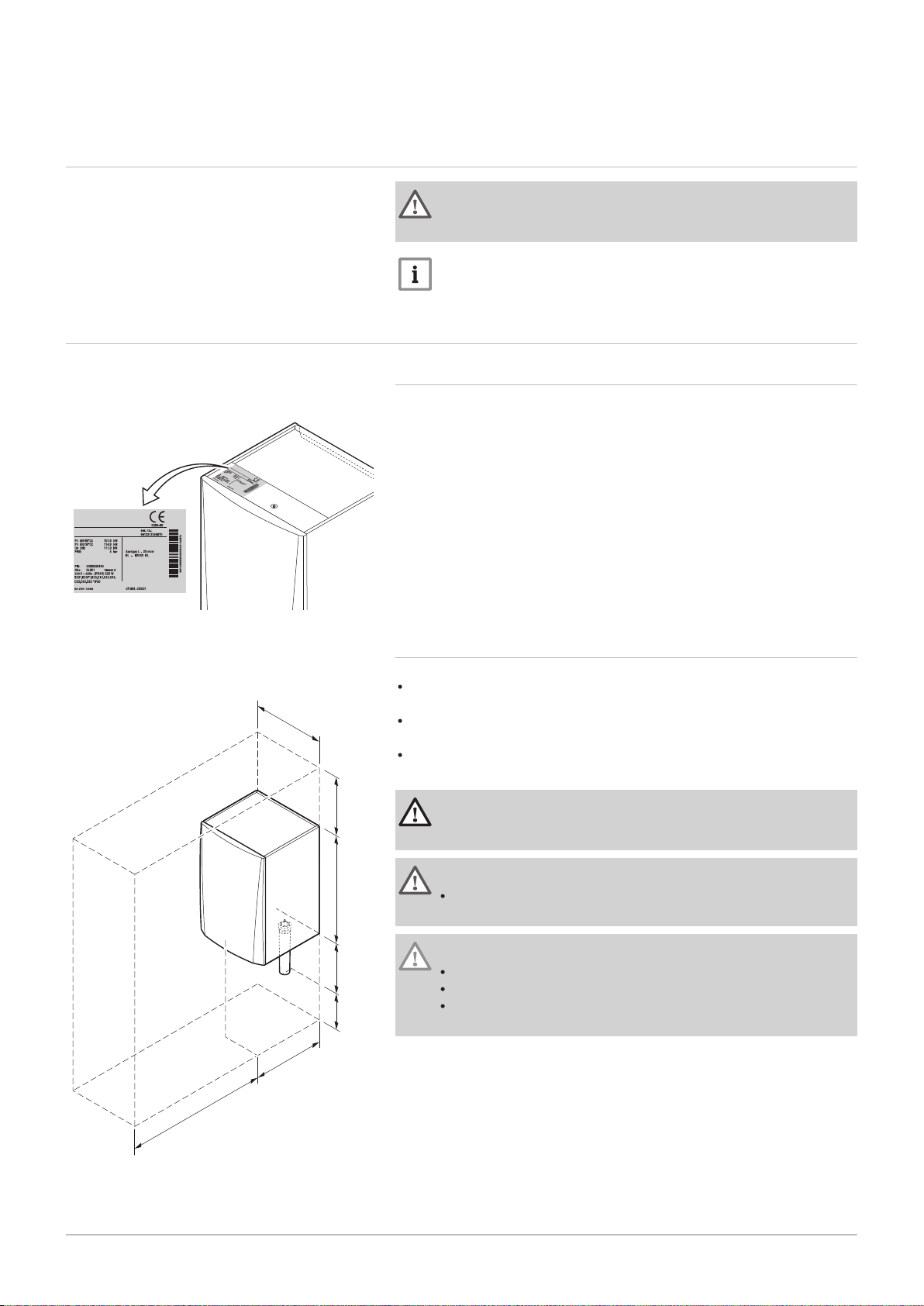

Fig.2 Position of type plate

Fig.3 Installation area

Choice of the location

4.2.1 Type plate

The type plate on top of the boiler features the boiler serial number and

important boiler specifications, for example the model and unit category.

The factory setting codes CN 1 and CN 2 are also stated on the type plate.

4.2.2 Location of the boiler

Use the guidelines and the required installation space as a basis for

determining the correct place to install the boiler.

When determining the correct installation space, take account of the

permitted position of the flue gas discharge and/or air supply outlet.

Ensure that there is sufficient space around the boiler for good access

and ease of maintenance.

Danger

It is forbidden to store, even temporarily, combustible products

and substances in the boiler or near the boiler.

Warning

Fix the appliance to a solid wall capable of bearing the weight of

the boiler when full of water and fully equipped.

Caution

The boiler must be installed in a frost-free area.

The boiler must have an earthed electrical connection.

A connection to the drain must be present for the condensate

drain close to the boiler.

4.3 Ventilation

7684359 - v.06 - 10012019 13

The installation must comply with BS 5540 (part 1 + 2), BS 6644 and

IGEM/UP/10.

4.4 Requirements for CH water connections

When fitting service shut-off valves, position the filling and drain valve,

the expansion vessel and the safety valve between the shut-off valve

and the boiler.

Carry out any welding work required at a safe distance from the boiler or

before the boiler is fitted.

For filling and tapping the boiler, install a filling and drain valve in the

system, preferably in the return.

Install an expansion vessel in the return pipe.

When installing open-vented systems, the cold feed and expansion tank

heights must comply with the requirements laid down in the Health and

Safety Executive publication PM5. The Quinta Ace boilers require a

minimum static height of 3 m (Quinta Ace 30/45/55/65/90 or 5 m ( 115).

4 Before installation

4.5

4.6

Requirements for condensate drain line

The siphon must always be filled with water. This prevents flue gases

from entering the room.

Never seal the condensate drain.

The drain pipe must slope down at least 30 mm per metre, the maximum

horizontal length is 5 metres.

Condensed water must not be discharged into a gutter.

Requirements for gas connection

Before starting work on the gas pipes, turn off the main gas tap.

Before installing, check that the gas meter has sufficient capacity. Take

into account the consumption of all appliances.

Notify the local energy company if the gas meter has insufficient

capacity.

Remove dirt and dust from the gas pipe.

Always perform welding work at a sufficient distance from the boiler.

We recommend installing a gas filter to prevent clogging of the gas

valve unit.

4.7 Requirements for the electrical connections

Establish the electrical connections in accordance with all local and

national current regulations and standards.

Electrical connections must always be made with the power supply

disconnected and only by qualified installers.

The boiler is completely pre-wired. Never change the internal

connections of the control panel.

Always connect the boiler to a well-earthed installation.

The wiring must comply with the instructions in the electrical diagrams.

Follow the recommendations in this manual.

Separate the sensor cables from the 230 V cables

AD-3000924-01

AD-3000925-01

AD-3000926-01

4 Before installation

14 7684359 - v.06 - 10012019

4.8 Requirements for the flue gas outlet system

4.8.1 Classification

Important

The installer is responsible ensuring that the right type of flue

gas outlet system is used and that the diameter and length are

correct.

Always use connection materials, roof terminal and/or outside

wall terminal supplied by the same manufacturer. Consult the

manufacturer for compatibility details.

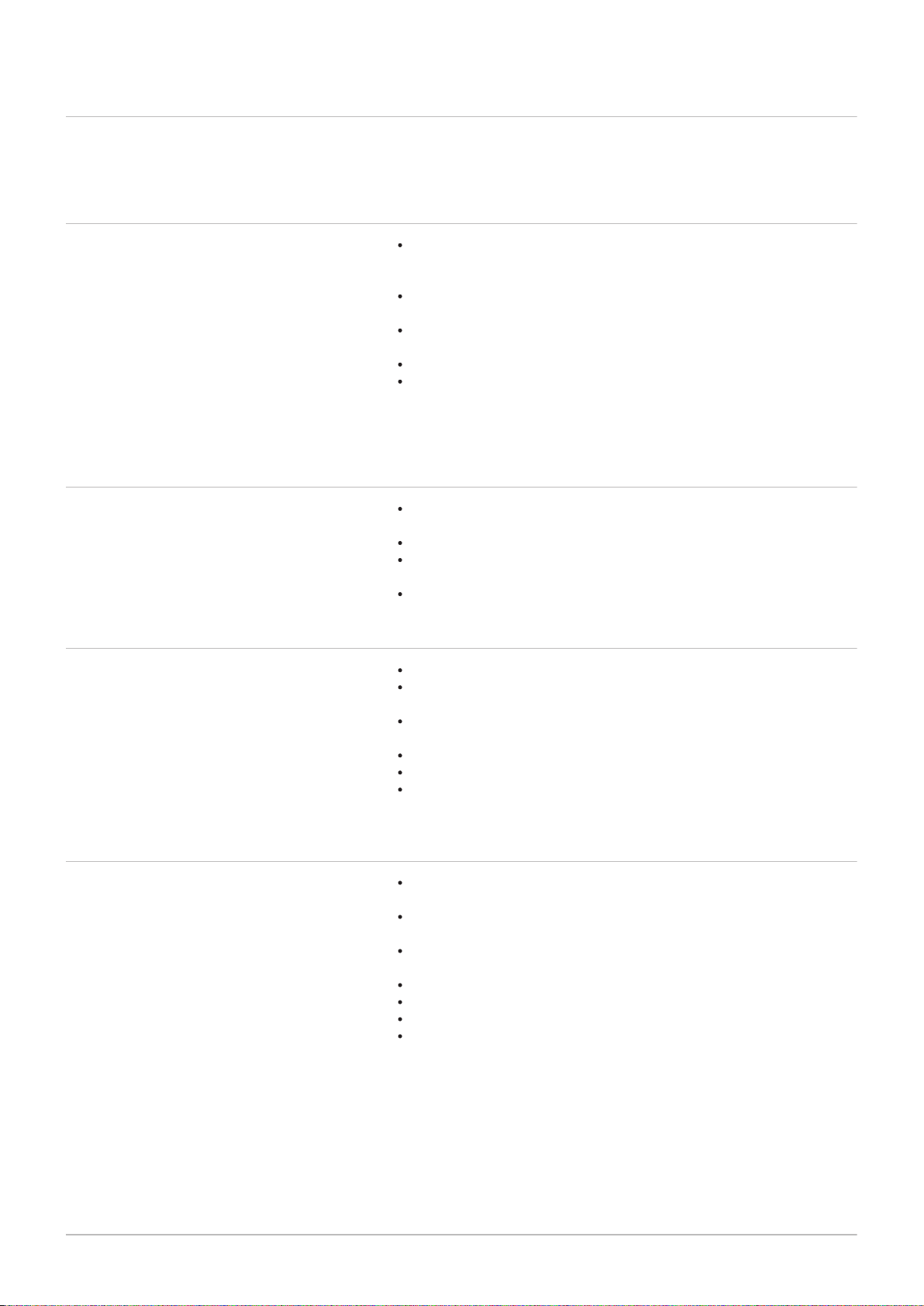

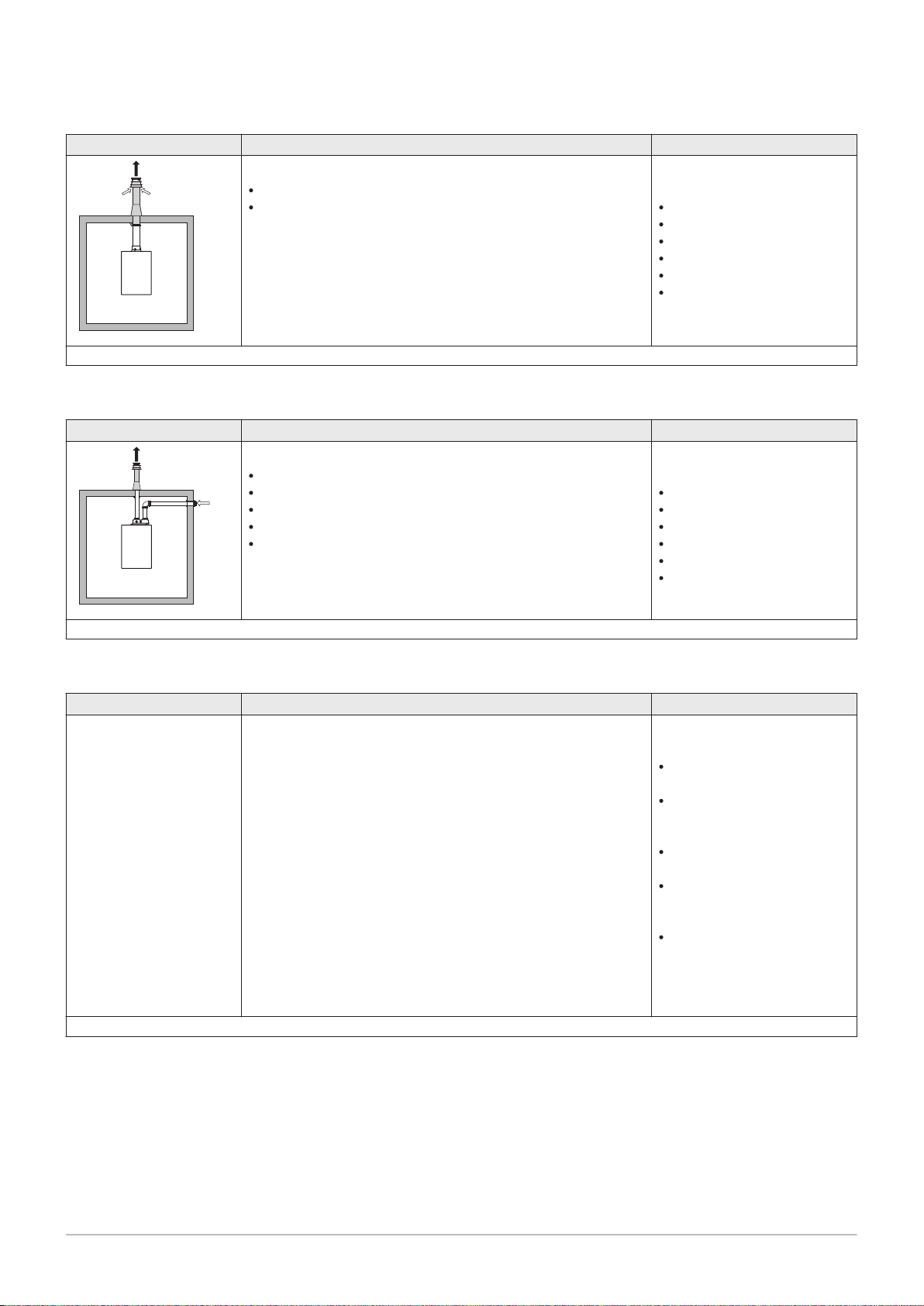

Tab.2 Type of flue gas connection: B

23P

Principle Description

Room-ventilated version

Without down-draught diverter.

Flue gas discharge via the roof.

Air from the installation area.

The IP rating of the boiler is lowered to IP20.

(1) The material must also satisfy the material property requirements from the relevant chapter.

Tab.3 Type of flue gas connection: B

33

Principle Description

Room-ventilated version

Without down-draught diverter.

Joint flue gas discharge via the roof, with guaranteed natural

draft (at all times underpressure in the joint discharge duct).

Flue gas discharge rinsed with air, air from the installation

area (special construction).

The IP rating of the boiler is lowered to IP20.

Permitted manufacturers

(1)

Connection material and roof

terminal:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Ubbink

Permitted manufacturers

(1)

Connection material:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Ubbink

(1) The material must also satisfy the material property requirements from the relevant chapter.

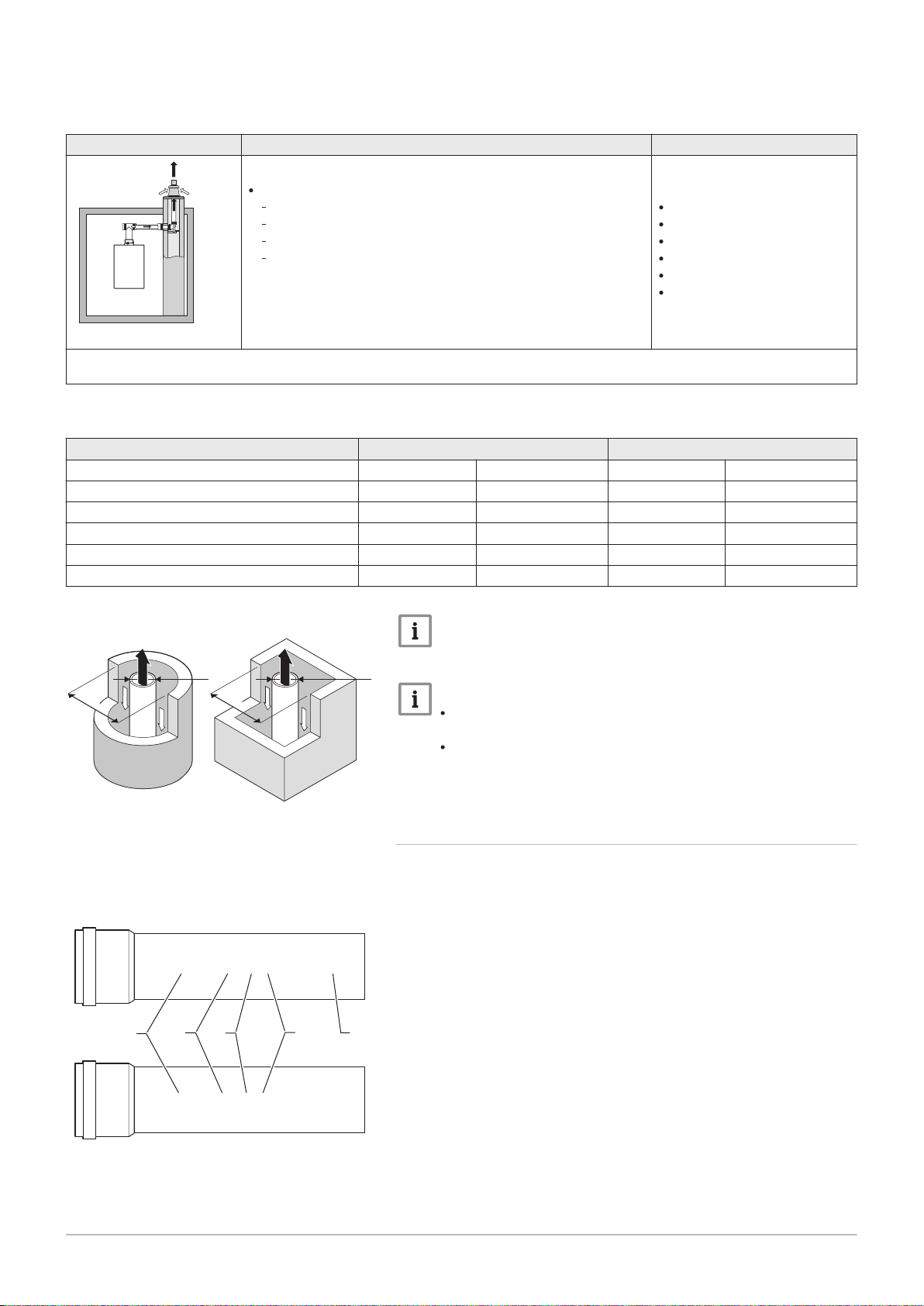

Tab.4 Type of flue gas connection: C

Principle Description

Room-sealed version

Discharge in the outside wall.

Air supply opening is in the same pressure zone as the dis

charge (e.g. a combined outside wall terminal).

Parallel not permitted.

13

Permitted manufacturers

Outside wall terminal and con

nection material:

Remeha, combined with con

nection material from Muelink

& Grol

Cox Geelen

Muelink & Grol

(1) The material must also satisfy the material property requirements from the relevant chapter.

(1)

AD-3000927-01

AD-3000929-02

4 Before installation

7684359 - v.06 - 10012019 15

Tab.5 Type of flue gas connection: C

33

Principle Description

Room-sealed version

Flue gas discharge via the roof.

Air supply opening is in the same pressure zone as the dis

charge (e.g. a concentric roof terminal).

(1) The material must also satisfy the material property requirements from the relevant chapter.

Tab.6 Type of flue gas connection: C

53

Principle Description

Connection in different pressure zones

Closed unit.

Separate air supply duct.

Separate flue gas discharge duct.

Discharging into various pressure areas.

The air supply and the flue gas outlet must not be placed on

opposite walls.

Permitted manufacturers

(1)

Roof terminal and connection

material

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Ubbink

Permitted manufacturers

(1)

Connection material and roof

terminal:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Ubbink

(1) The material must also satisfy the material property requirements from the relevant chapter.

Tab.7 Type of flue gas connection: C

63

Principle Description

This type of unit is supplied by the manufacturer without an air

supply system and flue gas system.

(1) The material must also satisfy the material property requirements from the relevant chapter.

Permitted manufacturers

(1)

When selecting the material,

please note the following:

Condensed water must flow

back to the boiler.

The material must be resist

ant to the flue gas tempera

ture of this boiler.

Maximum permissible recir

culation of 10%.

The air supply and the flue

gas outlet must not be placed

on opposite walls.

Minimum permitted pressure

difference between the air

supply and the flue gas outlet

is -200 Pa (including -100 Pa

wind pressure).

AD-3000931-01

AD-3000330-03

□

D

Ø

D

AD-3001120-01

EN 14471 - T120 P1 W 1 O50 LI E U0

EN 1856-1 - T120 P1 W VxL40045 G(xx)

1

3

2

4

5

4 Before installation

16 7684359 - v.06 - 10012019

Tab.8 Type of flue gas connection: C

Principle

(1)

Description

Room-sealed version

Air supply and flue gas discharge duct in shaft or ducted:

93

Concentric.

Air supply from existing duct.

Flue gas discharge via the roof.

Inlet opening for the air supply is in the same pressure zone

as the discharge.

Permitted manufacturers

Connection material and roof

terminal:

Centrotherm

Cox Geelen

Muelink & Grol

Natalini

Poujoulat

Ubbink

(1) See table for shaft or duct requirements.

(2) The material must also satisfy the material property requirements from the relevant chapter.

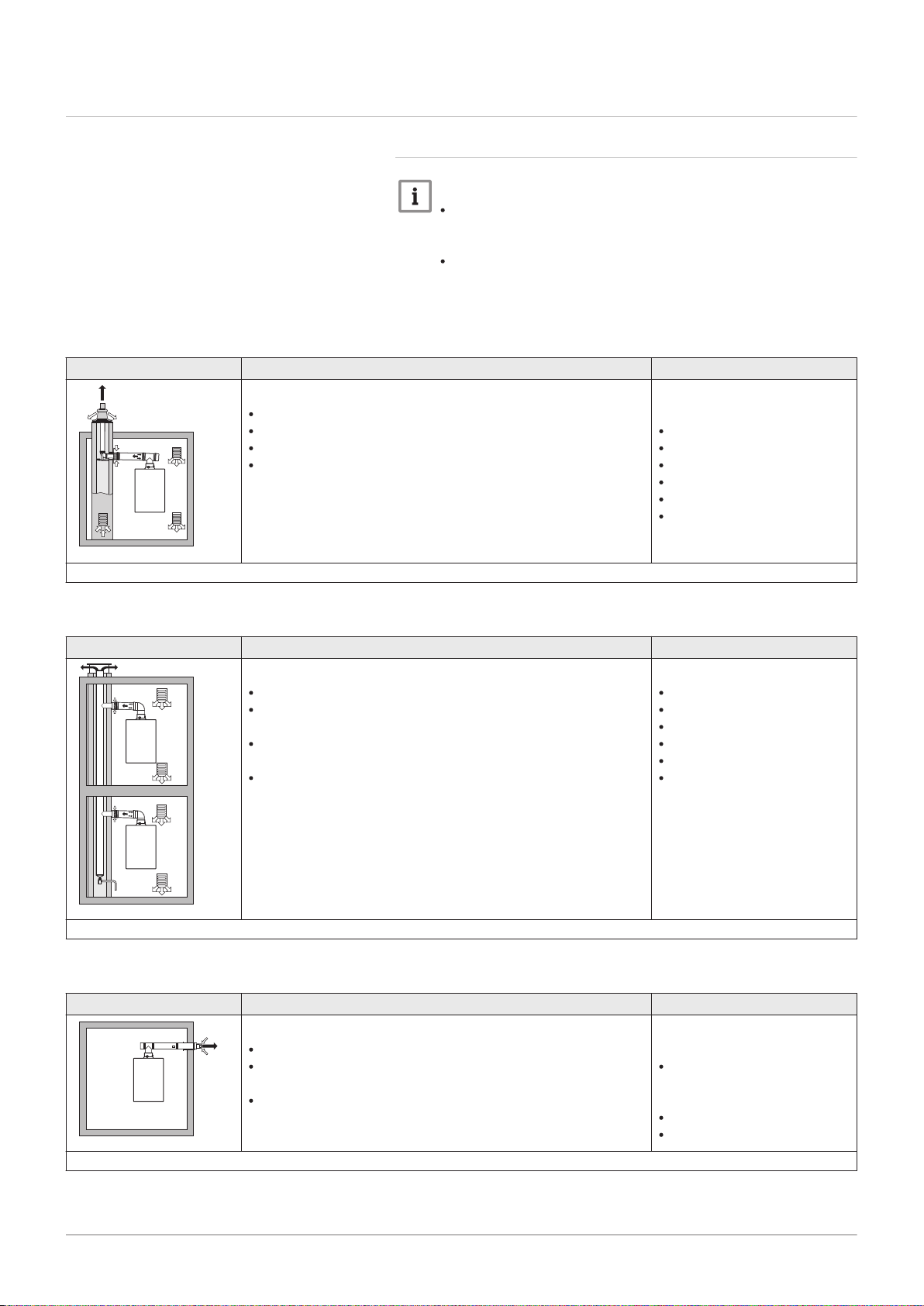

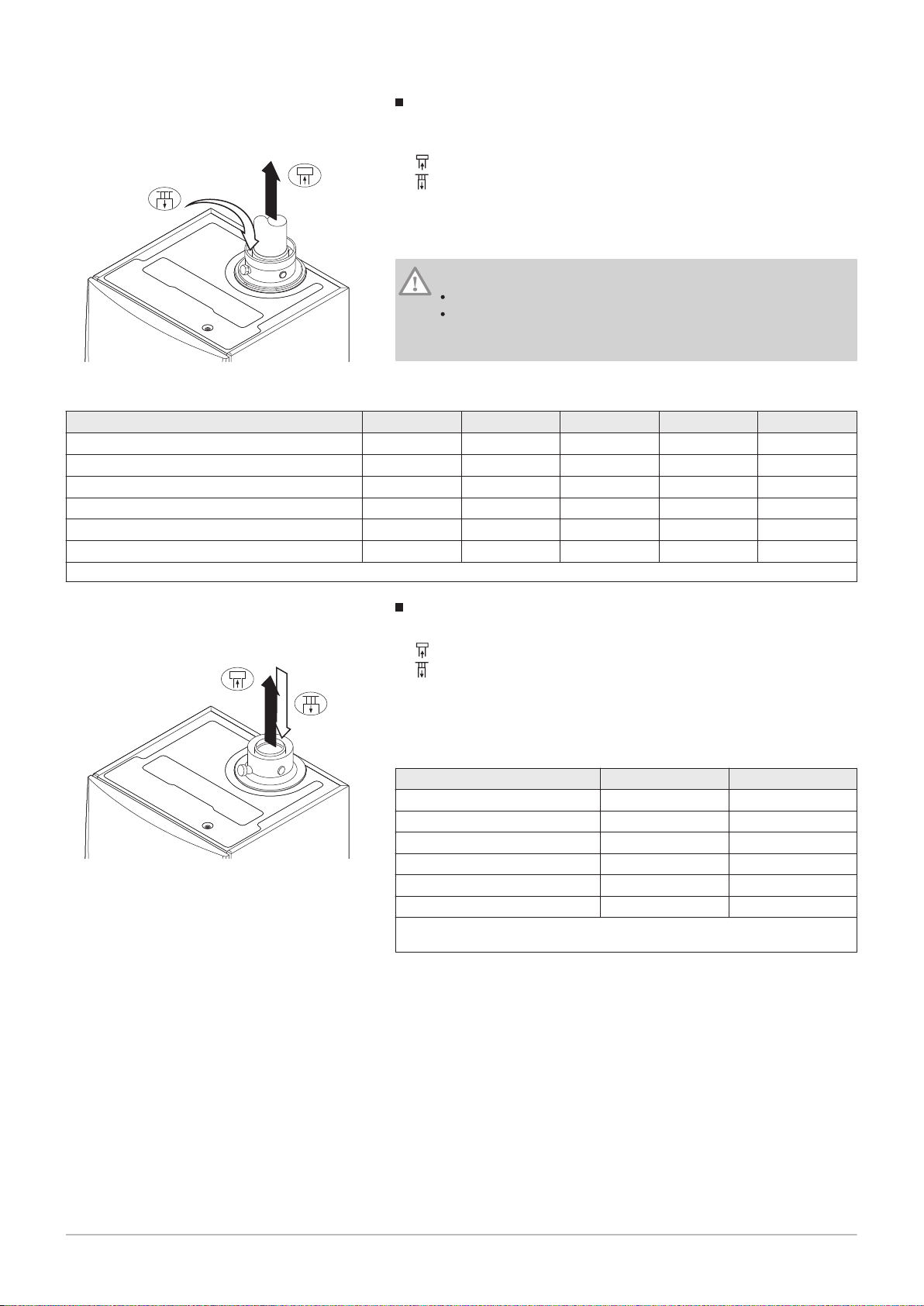

Tab.9 Minimum dimensions of shaft or duct C

93

Version (D) Without air supply With air supply

Rigid 80 mm Ø 130 mm □ 130 x 130 mm Ø 140 mm □ 130 x 130 mm

Rigid 100 mm Ø 160 mm □ 160 x 160 mm Ø 170 mm □ 160 x 160 mm

Rigid 150 mm Ø 200 mm □ 200 x 200 mm Ø 220 mm □ 220 x 220 mm

Concentric 80/125 mm Ø 145 mm □ 145 x 145 mm Ø 145 mm □ 145 x 145 mm

Concentric 100/150 mm Ø 170 mm □ 170 x 170 mm Ø 170 mm □ 170 x 170 mm

Concentric 150/200 mm Ø 270 mm □ 270 x 270 mm - -

(2)

Fig.4 Minimum dimensions of shaft or

duct C

93

Fig.5 Sample string

Important

The shaft must comply with the air density requirements of the

local regulations.

Important

Always clean shafts thoroughly when using lining pipes and/or

an air supply connection.

It must be possible to inspect the lining duct.

4.8.2 Material

Use the string on the flue gas outlet material to check whether it is suitable

for use on this appliance.

1

EN 14471 of EN 1856–1: The material is CE approved according to

this standard. For plastic this is EN 14471, For aluminium and

stainless steel this is EN 1856-1.

2

T120: The material has temperature class T120. A higher number

is also allowed, but not lower.

3

P1: The material falls into pressure class P1. H1 is also allowed.

4

W: The material is suitable for draining condensation water

(W=’wet’). D is not allowed (D=’dry’).

5

E: The material falls into fire resistance class E. Class A to D are

also allowed, F is not allowed. Only applicable to plastic.

Warning

AD-3000962-01

ød

1

L

1

øD

1

7684359 - v.06 - 10012019 17

The coupling and connection methods may vary depending on

the manufacturer. It is not permitted to combine pipes, coupling

and connection methods from different manufacturers. This also

applies to roof feed-throughs and common channels.

The materials used must comply with the prevailing regulations

and standards.

Please contact us to discuss using flexible flue gas outlet

material.

Tab.10 Overview of material properties

Version Flue gas outlet Air supply

Material Material properties Material Material properties

Single-wall, rigid

(1)

Plastic

Stainless steel

Thick-walled,

aluminium

(2)

With CE marking

(2)

Temperature class T120 or

higher

Condensate class W (wet)

Plastic

Stainless steel

Aluminium

Pressure class P1 or H1

Fire resistance class E or bet

(3)

ter

(1) according to EN 14471

(2) according to EN 1856

(3) according to EN 13501-1

4 Before installation

With CE marking

Pressure class P1 or H1

Fire resistance class E or bet

(3)

ter

Fig.6 Dimensions of concentric

connection

4.8.3 Dimensions of flue gas outlet pipe

Warning

The pipes connected to the flue gas adapter must satisfy the

following dimension requirements.

d

External dimensions of flue gas outlet pipe

1

D

External dimensions of air supply pipe

1

L

Length difference between flue gas outlet pipe and air supply pipe

1

Tab.11 Dimensions of pipe

d1 (min-max) D1 (min-max)

(1)

L

(min-max)

1

80/125 mm 79.3 - 80.3 mm 124 - 125.5 mm 0 - 15 mm

100/150 mm 99.3 - 100.3 mm 149 - 151 mm 0 - 15 mm

(1) Shorten the inner pipe if the length difference is too great.

4.8.4 Length of the air and flue gas pipes

The maximum length of the flue gas outlet and air supply channel vary

depending on the appliance type; consult the relevant chapter for the

correct lengths.

Important

When using bends, the maximum chimney length (L) must be

shortened according to the reduction table.

For adaptation to another diameter use approved transitions

The boiler is also suitable for longer chimney lengths and

diameters other than those specified in the tables. Contact us

for more information.

AD-0000028-02

L =

AD-0000029-02

L =

4 Before installation

18 7684359 - v.06 - 10012019

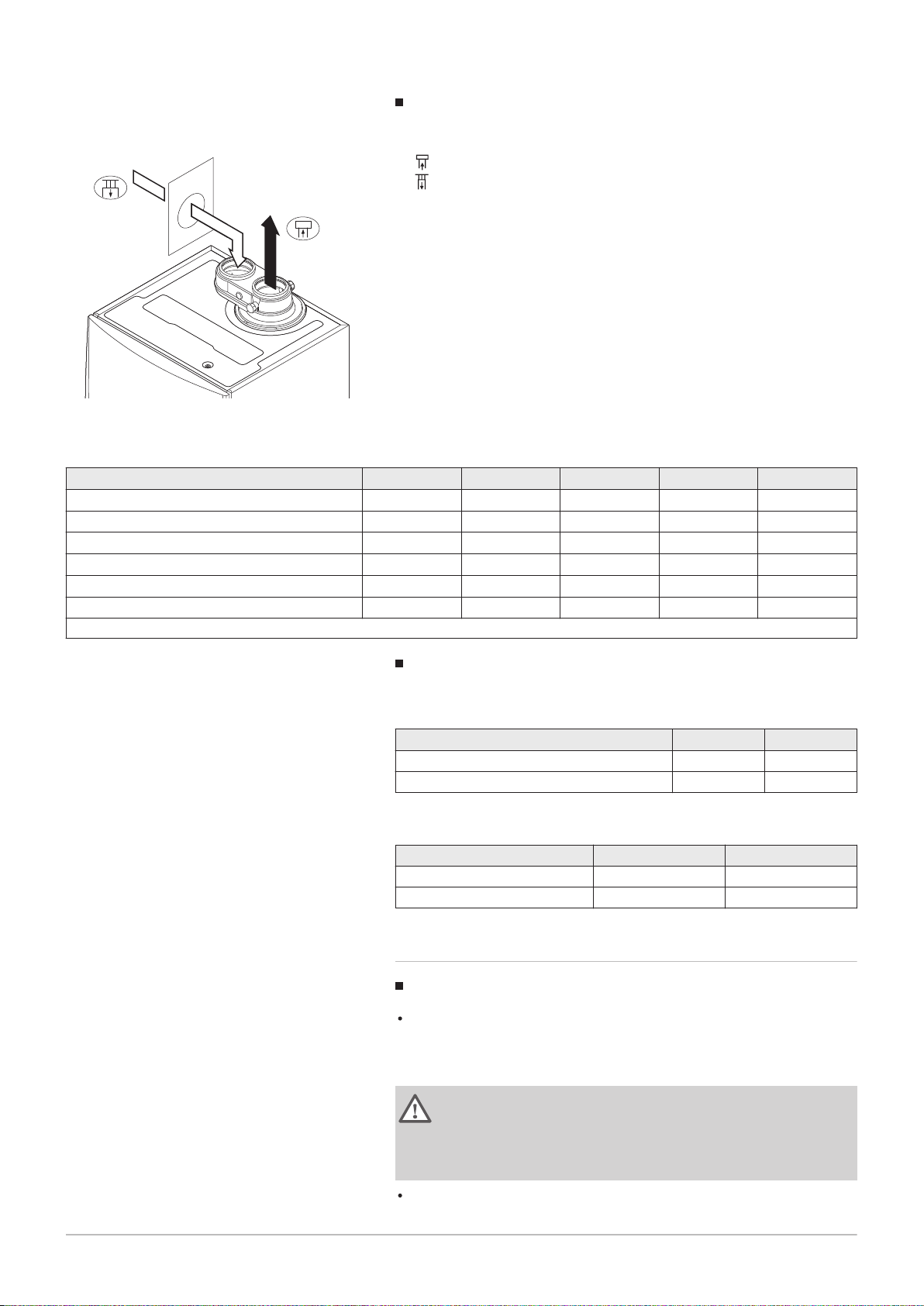

Fig.7 Room-ventilated version

Room-ventilated model (B

L

Length of the flue gas outlet channel to roof feed-through

23P

, B33)

Connecting the flue gas outlet

Connecting the air supply

With a room-ventilated version, the air supply opening stays open; only the

flue gas outlet opening is connected. This will ensure that the boiler

obtains the necessary combustion air directly from the installation area.

Caution

The air supply opening must stay open.

The installation area must be equipped with the necessary air

supply openings. These openings must not be obstructed or

shut off.

Tab.12 Maximum length (L)

Diameter

(1)

Quinta Ace 30 33 m 40 m 40 m

Quinta Ace 45 39 m

Quinta Ace 55 16 m 26 m 39 m

80 mm 90 mm 100 mm 110 mm 130 mm

40 m

40 m

(1)

40 m

(1)

40 m

40 m

Quinta Ace 65 11 m 17 m 26 m 40 m

Quinta Ace 90 10 m 16 m 24 m 40 m

Quinta Ace 115 8 m 13 m 19 m 38 m

(1) Retaining the maximum chimney length it is possible to use an extra 5 x 90º or 10 x 45º elbows.

(1)

(1)

(1)

40 m

40 m

40 m

40 m

40 m

40 m

(1)

(1)

(1)

(1)

(1)

(1)

Fig.8 Room-sealed version (concentric)

Room-sealed model (C13, C33, C63, C93)

Connecting the flue gas outlet

Connecting the air supply

With a room-sealed version, both the flue gas outlet and the air supply

openings are connected (concentrically).

Tab.13 Maximum chimney length (L)

Diameter

(1)

Quinta Ace 30 20 m 20 m

Quinta Ace 45 20 m

Quinta Ace 55 8 m

Quinta Ace 65 4 m 18 m

Quinta Ace 90 4 m 17 m

Quinta Ace 115 - 13 m

(1) Retaining the maximum chimney length it is possible to use an extra 5 x 90º

or 10 x 45º elbows.

80/125 mm 100/150 mm

(1)

20 m

(1)

20 m

Connection in different pressure areas (C53)

AD-0000030-02

= L +

7684359 - v.06 - 10012019 19

4 Before installation

Fig.9

Different pressure areas

L

Total length of the flue gas outlet and air supply duct

Connecting the flue gas outlet

Connecting the air supply

An 80/80 or 100/100 mm flue gas adapter (accessory) must be fitted for

this connection.

Combustion air supply and flue gas discharge are possible in different

pressure areas and semi-CLV systems, with the exception of the coastal

area. The maximum permitted height difference between the combustion

air supply and the flue gas outlet is 36 m.

Tab.14 Maximum length (L)

Diameter

(1)

Quinta Ace 30 17 m 29 m 40 m

Quinta Ace 45 29 m 40 m

80 mm 90 mm 100 mm 110 mm 130 mm

40 m

(1)

40 m

40 m

Quinta Ace 55 9 m 17 m 27 m 40 m

Quinta Ace 65 5 m 10 m 16 m 34 m

Quinta Ace 90 - - 17 m 37 m

Quinta Ace 115 - - 14 m 31 m

(1) Retaining the maximum chimney length it is possible to use an extra 5 x 90º or 10 x 45º elbows.

(1)

(1)

40 m

40 m

40 m

40 m

40 m

40 m

(1)

(1)

(1)

(1)

(1)

(1)

Reduction table

Tab.15 Pipe reduction for each element used (parallel)

Diameter 80 mm 100 mm

45° bend 1.2 m 1.4 m

90° bend 4.0 m 4.9 m

Tab.16 Pipe reduction for each element used (concentric)

Diameter 80/125 mm 100/150 mm

45° bend 1.0 m 1.0 m

90° bend 2.0 m 2.0 m

4.8.5 Additional guidelines

Installation

For installing the flue gas outlet and air supply materials, refer to the

instructions of the manufacturer of the relevant material. After

installation, check at least all flue gas outlet and air supply parts for

tightness.

Warning

If the flue gas outlet and air supply materials are not installed in

accordance with the instructions (e.g. not leak-proof, not correctly

bracketed), this can result in dangerous situations and/or physical

injury.

Make sure that the flue gas outlet pipe towards the boiler has a sufficient

gradient (at least 50 mm per metre) and that there is a sufficient

4 Before installation

20 7684359 - v.06 - 10012019

condensate collector and discharge (at least 1 m before the outlet of the

boiler). The bends used must be larger than 90° to guarantee the

gradient and a good seal on the lip rings.

Condensation

Direct connection of the flue gas outlet to structural ducts is not

permitted because of condensation.

If condensate from a plastic or stainless steel pipe section can flow back

to an aluminium part in the flue gas outlet, this condensate must be

discharged via a collector before it reaches the aluminium.

Newly installed aluminium flue gas pipes with longer lengths can

produce relatively larger quantities of corrosion products. Check and

clean the siphon more often in this case.

Important

Contact us for more information.

4.9

Water quality and water treatment

4.10 Water flow in process heat

The quality of the CH water must comply with certain limit values, which

can be found in our Water quality instructions. The guidelines in these

instructions must be followed at all times.

In many cases, the boiler and central heating system can be filled with

normal tap water and water treatment will not be necessary.

In process heat applications (for example pasteurisation and drying and

washing processes), the boiler is being used for industrial purposes and

not for central heating. With process heat, the nominal flow (at ΔT 20°C) in

the primary CH circuit must be guaranteed. The flow in the secondary

circuit may vary.

To ensure that this is the case, a flow rate sensor can be fitted, which

locks out the boiler if the flow falls below a specified level (due to a

defective pump or valve, for example).

For this application, adjust the following parameters:

Set parameter DP140 to Process heat .

Set parameters DP005 and DP070 to the required value for this

installation.

If using a DHW sensor; set parameters DP034 and DP006 to the

required value for this installation.

Important

The service life of the boiler may be reduced if it is used for

process heat applications.

4.11

Increasing standard ΔT setting

In some cases, the standard ΔT setting of the boiler will need to be

increased, for example in systems with:

underfloor heating

air heating

district heating

a heat pump.

4 Before installation

7684359 - v.06 - 10012019 21

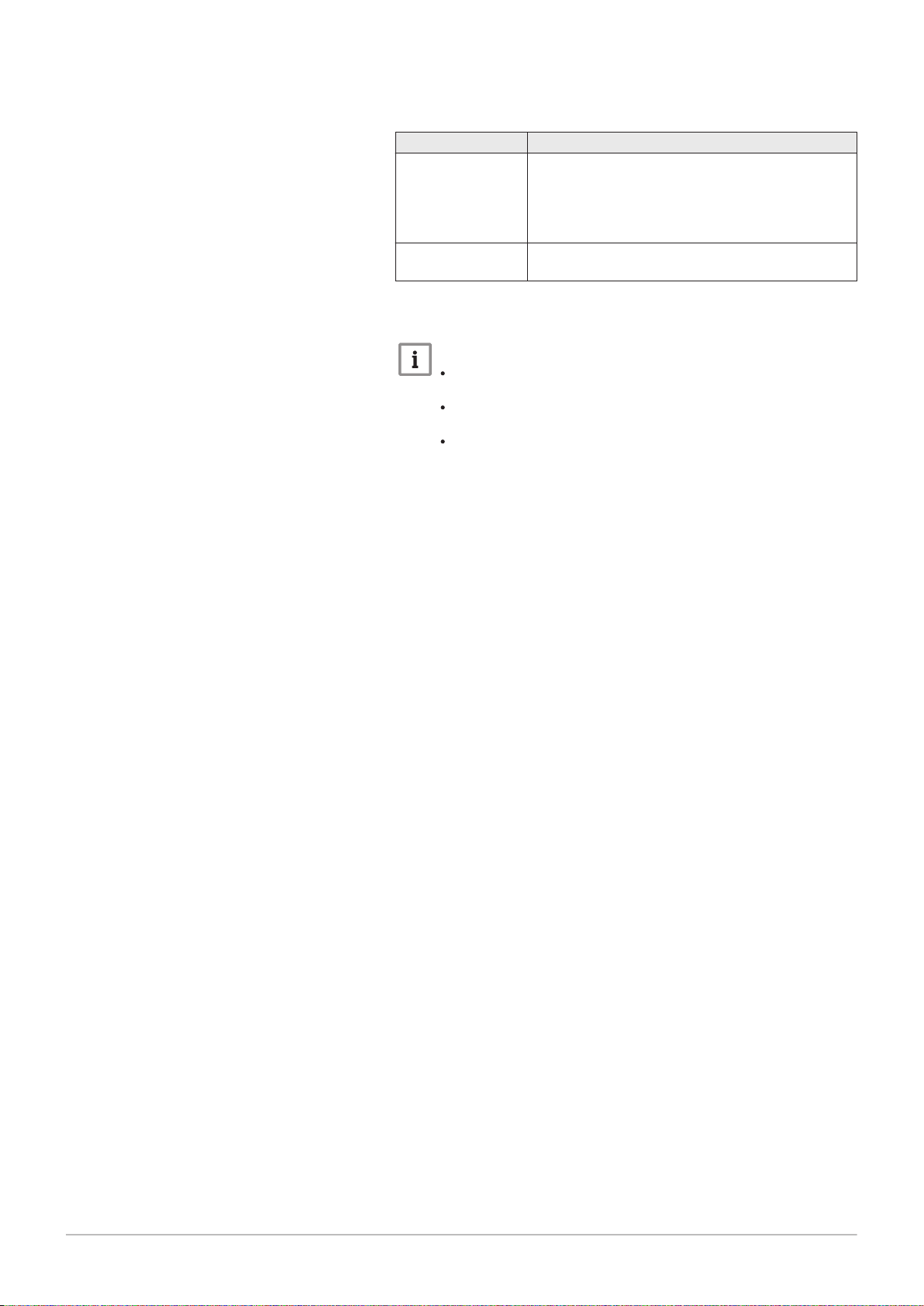

Tab.17 Increasing standard ΔT setting

Boiler type ΔT setting

Quinta Ace 30

Quinta Ace 45

The standard ΔT setting of 25K can be increased to

a maximum of 40K.

Quinta Ace 55

Quinta Ace 65

Quinta Ace 90

Quinta Ace 115 The standard ΔT setting of 20K can be increased to

a maximum of 35K.

Increase the ΔT setting using parameter GP021. When increasing the ΔT,

the control unit limits the flow temperature to a maximum of 80 °C.

Important

With the increased ΔT setting, the Service Tool will use a substatus to indicate that the limited flow temperature is active.

Prevent the boiler from locking out and ensure a minimal water

circulation by using a bypass or low-loss header.

If a PWM-controlled central heating-pump is controlled by the

boiler control unit, set parameter PP014 to 2.

AD-0000018-02

2

1

5

4

3

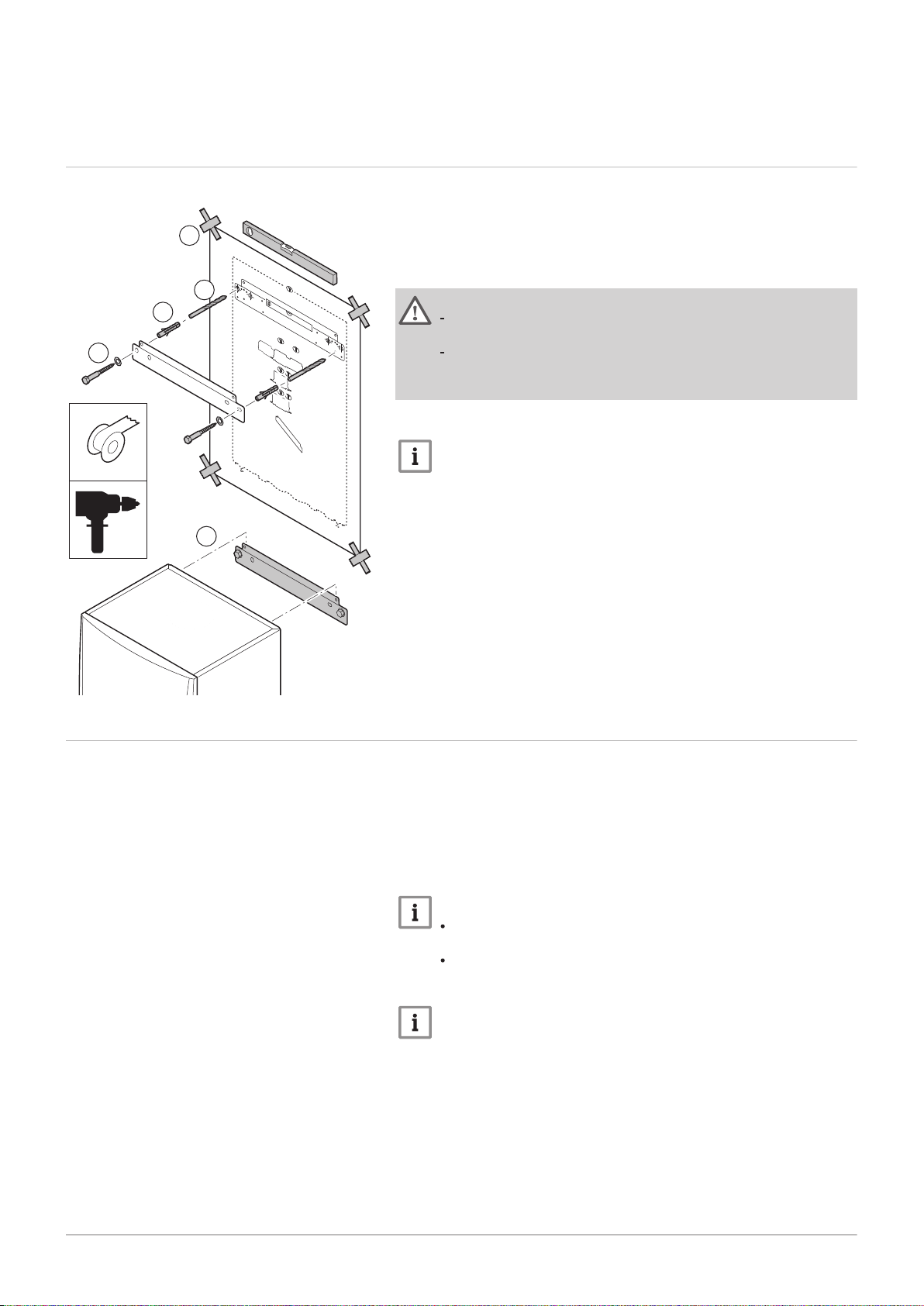

5 Installation

22 7684359 - v.06 - 10012019

5 Installation

5.1 Positioning the boiler

Fig.10 Mounting the boiler

The fitting bracket on the back of the casing can be used to mount the

boiler directly on the suspension bracket.

The boiler is supplied with a mounting template.

1. Attach the mounting template of the boiler to the wall using adhesive

tape.

Warning

Use a level to check whether the mounting template is hanging

perfectly horizontally.

Protect the boiler against building dust and cover the connection

points for the flue gas outlet and air supply. Only remove this

cover to assemble the relevant connections.

2. Drill 2 holes of Ø 10 mm.

Important

The extra fixing holes in the suspension bracket are intended for

use in the event that one of the two holes is not suitable for the

correct fastening of the plug.

3. Fit the Ø 10 mm plugs.

4. Remove the mounting template.

5. Attach the suspension bracket to the wall with the Ø 10 mm bolts

supplied.

6. Mount the boiler on the suspension bracket.

5.2 Rinsing the system

The installation must be cleaned and flushed in accordance with BS 7593

(2006) and BSRIA BG 33/2014.

Before a new boiler can be connected to an existing or new system, the

entire system must be thoroughly cleaned and flushed. This step is

absolutely crucial. The flushing helps to remove residue from the

installation process (weld slag, fixing products etc.) and accumulations of

dirt (silt, mud etc.)

Important

Flush the system with a volume of water equivalent to at least

three times the volume of the system.

Flush the DHW pipes with at least 20 times the volume of the

pipes.

Important

Due to the presence of an aluminium heat exchanger, suitable

chemicals and the correct use of these chemicals should be

discussed with specialist water treatment companies.

5.3 Connecting the heating circuit

AD-4100110-01

1

2

4

5

4

3

AD-0000024-02

4

1

2

3

7684359 - v.06 - 10012019 23

5 Installation

Fig.11 Connecting the CH flow and CH

return

1. Remove the dust cap from the CH flow connection at the bottom

of the boiler.

2. Fit the outlet pipe for CH water to the CH flow connection.

3. Remove the dust cap from the CH return connection at the

bottom of the boiler.

4. Fit the inlet pipe for CH water to the CH return connection.

5. Install the pump in the CH return pipe (if applicable).

For more information, see

Connecting the PWM pump, page 29

Connecting the standard pump, page 30

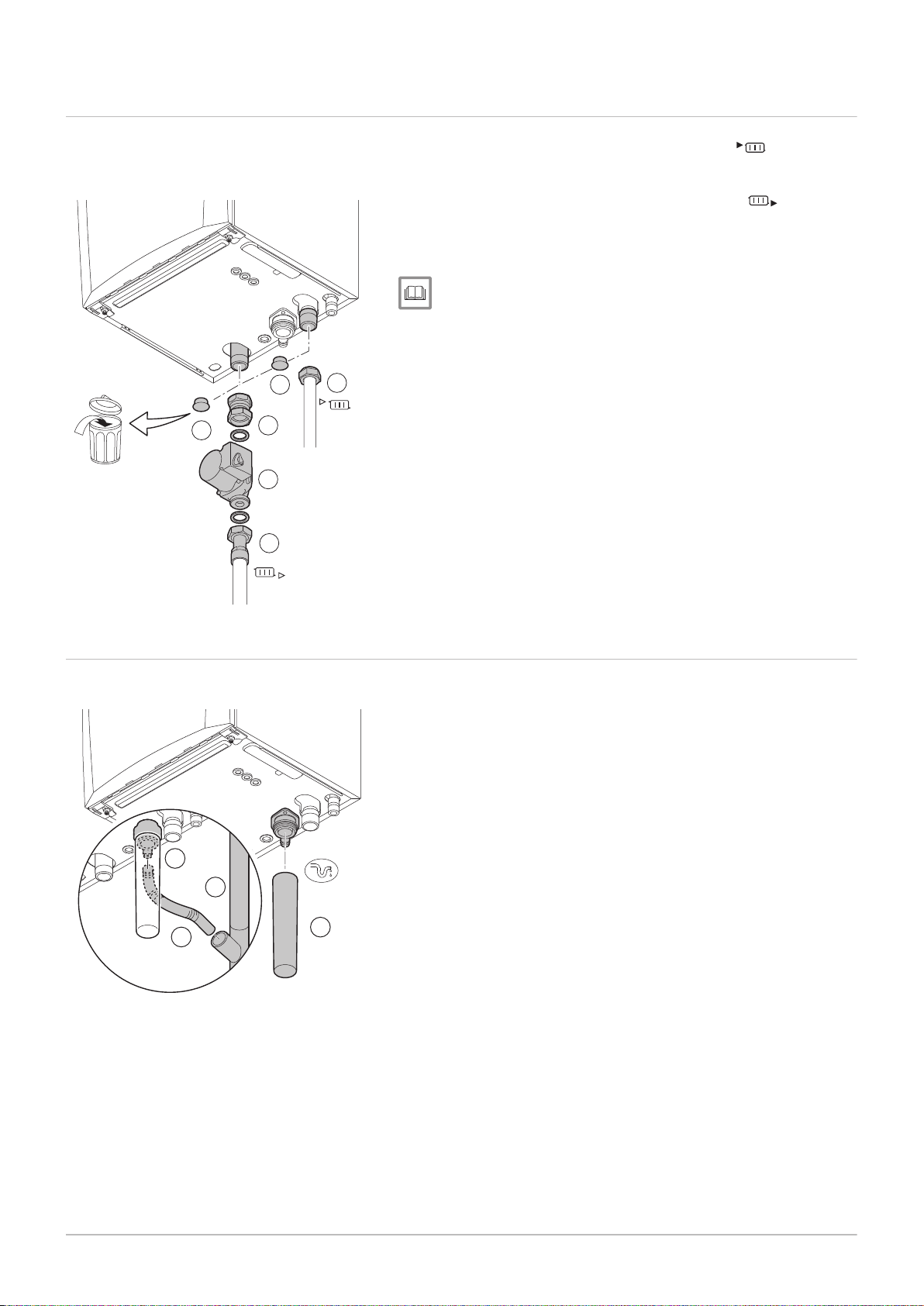

5.4 Connecting the condensate discharge pipe

Fig.12 Connecting the condensate

discharge pipe

1. Fit a plastic drain pipe of Ø 32 mm or larger, terminating in the drain.

2. Insert the flexible condensate drain hose into the pipe.

3. Fit a stench-trap or siphon in the drain pipe.

4. Fit the siphon.

Loading...

Loading...