Supplied By www.heating spares.co Tel. 0161 620 6677

Technical information

Remeha P 500

Remeha P500

• Pressurized boiler

• Heat output: 635 - 1900 kW

Supplied By www.heating spares.co Tel. 0161 620 6677

TABLE OF CONTENT

Remeha P 500

Preface 3

1 Description of the unit 3

1.1 General 3

1.2 Burners 3

2 Construction data 3

2.1 General 3

2.2 Sections 3

2.3 Casing 3

3 Technical data and dimensions 4

3.1 Dimensions 4

3.2 Technical data 4

3.3 Quotation specifi cations 5

4 Output data 5

4.1 Boiler effi ciency 5

4.2 Combustion effi ciency 5

5 Application data 5

5.1 L.P.H.W. version 5

5.1.1 Water temperature 5

5.1.2 Water pressure 5

5.1.3 Flow rate 5

5.1.4 Water treatment 6

5.2 Economisers 6

5.3 Flue gas discharge 6

5.4 Noise production 6

7 Assembly guidelines and installation

requirements 7

7.1 General 7

7.2 Water connections 7

7.3 Boiler assembly 7

8 Instrument panels 8

8.1 Equipment contents 8

8.2 Instrument panel High/Low with hours run

meters 8

8.3 Wiring diagram instrument panel High/Low

with hours run meters 1 9

9 Commissioning 10

9.1 Pressurized boiler with gas burner 10

9.1.1 Commissioning procedure 10

9.1.2 Putting out of operation 10

9.2 Pressurized boiler with oil burner 10

9.2.1 Commissioning procedure 10

9.2.2 Putting out of operation 10

10 Fault Finding 11

11 Maintenance recommendations 11

11.1 General 11

11.2 Maintenance instructions 11

6 Installation requirements 7

6.1 Installation recommendations in the boiler

house 7

2

Supplied By www.heating spares.co Tel. 0161 620 6677

PREFACE

These technical instructions contain useful and important information for the correct operation and maintenance of the Remeha boiler, model P200

Read these instructions carefully before putting the boiler into operation; familiarise yourself with its control

functions and operation, strictly observing the instructions given. Failure to do so may invalidate warranty or

prevent the boiler from operating.

A competent Engineer, with the relevant certifi cation (i.e.

CORGI, ACOPS, IEE regs. etc) must carry out the installation and commissioning of the boiler.

On completion a copy of the boiler log / commissioning

sheet should be returned to Broag Ltd for record purposes.

1 DESCRIPTION OF THE UNIT

1.1 General

High effi ciency pressurised boiler, suitable for use with

natural gas and light oil, by means of a pressure jet

burner. Also available with a condensing unit (ECO) (for

natural gas only).

The boiler meets the requirements of the CE regulations

in the following directives:

- Gas appliance directive no. 90/396/EEC

- Electrical low voltage directive no. 73/23/EEC

- E.M.C. directive no. 89/336/EEC

- Effi ciency directive no. 92/42/EEC.

Classifi cation type for evacuation of the combustion products: B23.

If you have any questions, or if you need more information about specifi c subjects relating to this boiler, or it’s

installation please do not hesitate to contact us.

The data published in these technical instructions is

based on the latest information (at date of publication)

and may be subject to revisions.

We reserve the right to continuous development in both

design and manufacture, therefore any changes to the

technology employed may not be retrospective nor may

we be obliged to adjust earlier supplies accordingly.

1.2 Burners

In principle all CE-approved pressure jet burners are suitable, subject to prior adjustment to the boiler capacity

and boiler construction. The individual boiler satisfi es

inspection requirement for central heating boilers.

2 CONSTRUCTION DATA

2.1 General

The boiler block consists of cast iron sections, which are

assembled by means of tapered nipples. The boiler is a

three-pass design. The boiler block is insulated with a

100-mm thick layer of glass wool.

2.2 Sections

The sections are made of pearlitic cast iron.

Weights and measures of the sections:

- Front section: 220 kg H x W = 1252 x 1130mm

- Intermediate section: 250 kg H x W = 1238 x 1130 mm

- Rear section: 250 kg H x W = 1238 x 1130 mm

2.3 Casing

Steel casing, fi nished with a high-quality insulation. The

front door is suitable for left or right opening as desired.

Fig. 01 Remeha P500

IL50

3

Supplied By www.heating spares.co Tel. 0161 620 6677

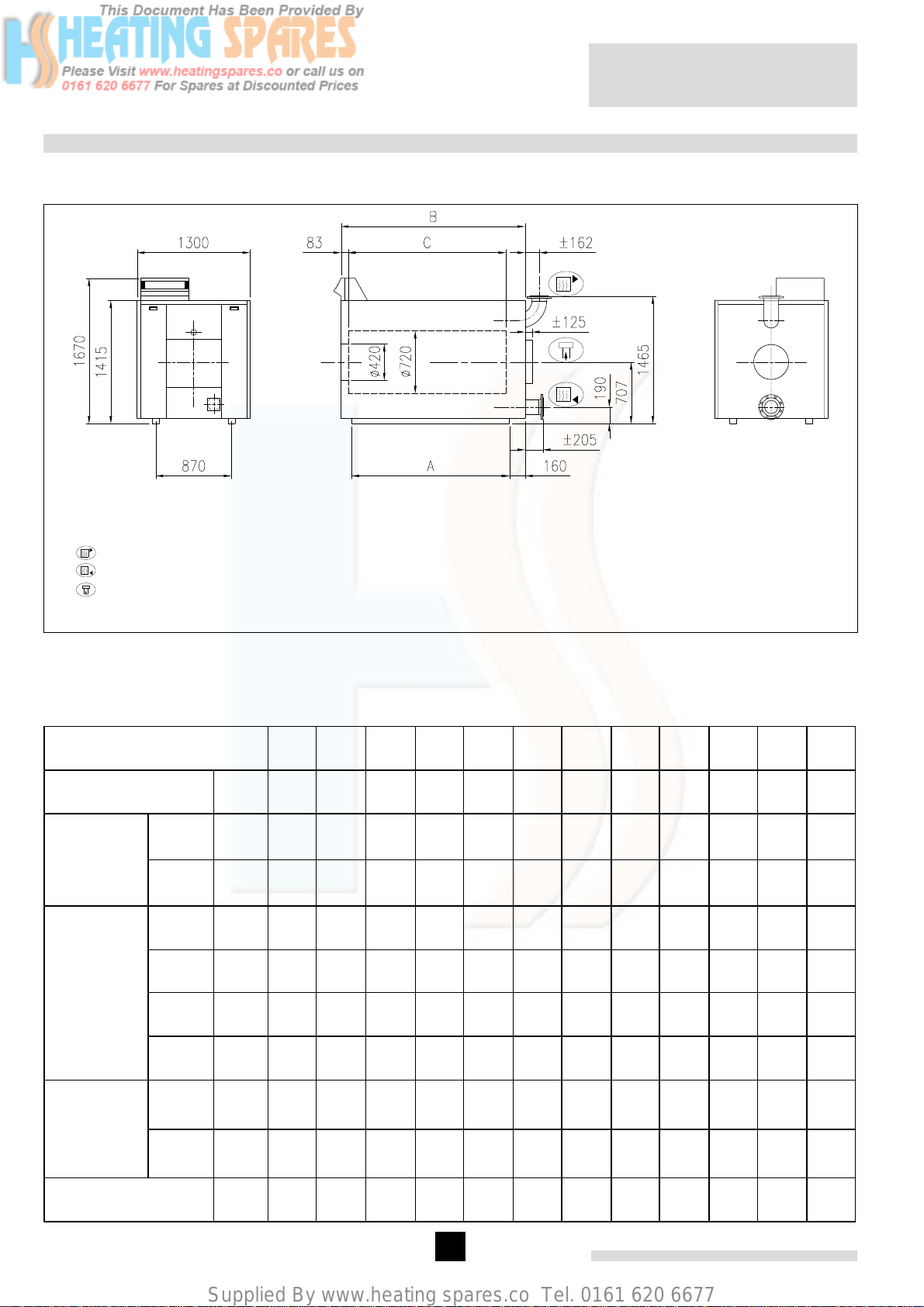

3 TECHNICAL DATA AND DIMENSIONS

3.1 Dimensions

Remeha P 500

Front view

Side view Rear view

Flow NG 150 - DIN2633

Return NG 150 - DIN2633

Flue ØD ext.

Flanges in accordance with BS 4505 PN 16

Fig. 02 Dimensions

00.15D.79.00006

3.2 Technical data

Number of sections 9 10 11 12 13 14 15 16 17 18 19 20

Nominal heat output kW 635 750 865 980 1095 1210 1325 1440 1555 1670 1785 1900

Nominal

heat input

Hi /

NCV

Hs /

GCV

A mm 1350 1500 1650 1800 1950 2100 2250 2400 2550 2700 2850 3000

kW 706 834 962 1090 1218 1341 1468 1592 1719 1846 1973 2100

kW 784 926 1068 1210 1352 1488 1630 1767 1908 2049 2190 2331

B mm 1660 1810 1965 2115 2265 2415 2565 2715 2870 3020 3170 3320

Dimensions

C mm 1270 1420 1570 1720 1870 2020 2170 2320 2470 2620 2770 2920

ØD mm 400 400 400 400 500 500 500 500 500 500 500 500

∆ t =

Water

resistance

Water contents litre 495 550 605 660 715 770 825 880 935 990 1045 1100

10°C

∆ t =

20°C

mbar 149 166 180 194 189 200 213 234 262 295 337 382

mbar 37 42 45 47 49 50 53 59 66 74 84 96

4

Supplied By www.heating spares.co Tel. 0161 620 6677

Boiler weight (dry) kg 2650 2910 3175 3435 3695 3955 4220 4480 4740 5005 5265 5525

Combustion chamber

resistance

Combustion gas side

content

Flue gas flow rate kg/h 1102 1302 1502 1702 1901 2081 2292 2485 2683 2882 3080 3278

1)

mbar 1.7 2.3 3.0 3.8 3.9 4.8 5.0 5.9 5.5 6.0 6.5 7.0

3

m

0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9

Table 01 Technical data

1)

Determined with 20 % excess air.

3.3 Quotation specifi cations

- Heat exchanger manufactured from corrosion resistant “pearlite” cast iron

- Maximum operating pressure of 6 bar

- Maximum operating temperature of 95°C

- Sectional design with three passes for max effi ciency

(gross 83%) and a generously sized combustion

chamber for minimising NOX production

- Water cooled base and rear sections

- Large insulated door (hinged left or right) allowing

easy access for service operations

- Powder coated enamel steel casing

- 80 - 100 mm thick glass wool insulation

- Suitable for use with a Natural gas, and/or 35 sec oil

fi red pressure jet burner (matched with most popular

burner manufacturers)

- Supplied as standard with on/off switch, temperature

indication, control and high limit thermostats

- Effi ciency 83% (Hs - GCV)

- Manufactured to ISO 9001

- CE approved.

- Supplied in broken down form for ease of delivery and

site access

4 OUTPUT DATA

4.1 Boiler effi ciency

Up to 90.2 % at Hi (81.3 % at Hs) at full load and up to

92.5 % at Hi (83.3 % at Hs) at part load.

Average water temperature 70°C (80/60°C).

5 APPLICATION DATA

5.1 L.P.H.W. version

5.1.1 Water temperature

Maximum water temperature is 110°C.

The minimum acceptable return water temperature is,

both for gas and oil fi red boilers 40°C, at a fl ow rate

corresponding to a ∆t of 20°C at nominal heat output.

5.1.2 Water pressure

Maximum pressure 6 bar.

The boiler is suitable for open and sealed systems up

to a maximum pressure of 6 bar and a minimum pressure of 0.8 bar. The boiler is suitable for installation in

basement or rooftop boiler houses.

4.2 Combustion effi ciency

Up to 91.2 % at Hi (82.2 % at Hs) at full load and up to

95.5 % at Hi (86.0 % at Hs) at part load.

Note: Hi = NCV; Hs = GCV

5.1.3 Flow rate

The minimum fl ow rate through the boiler is obtained

from the following formula:

Nominal heat output (kW) = m3/h

70

This minimum fl ow must be maintained for 5 minutes

after the burner stops fi ring to avoid high temperature

shutdown due to residual heat gain. Due to the design

and manufacture of the boiler no specifi c minimum water

fl ow requirement exists other than for over-temperature

protection.

5

Supplied By www.heating spares.co Tel. 0161 620 6677

Remeha P 500

5.1.4 Water treatment

The system should be fi lled with mains cold water (for

the UK this will usually have a pH of between 7 and 8).

Pressurised installations with a boiler/system content

ratio of 1:10 or less should not require water treatment,

provided that the following conditions apply:

1. The system is fl ushed thoroughly to remove all fl uxes

and debris and then fi lled completely once.

2. Make up water is limited to 5 % per annum.

3. The hardness of the water does not exceed 360 ppm

(20°D).

All scale deposits will reduce the effi ciency of the boiler

and should be prevented. However provided the above

is complied with any scale produced will not be too

detrimental to the boiler effi ciency and will not reduce

the anticipated life expectancy of the boiler.

NOTE: Scale deposits in excess of 3 to 5 mm will

reduce boiler effi ciency and greatly increase the risk of

premature casting failure.

As most systems contain a variety of metals which can

react with each other to cause corrosion. It is considered good practice to provide some form of water treatment (especially in open vented systems) in order to

prevent or reduce the following:

- Metallic corrosion;

- Formation of scale and sludge;

- Microbiological contamination;

- Chemical changes in the untreated system water.

Suitable chemicals and their use should be discussed

with a specialist water treatment company prior to carrying out any work. The specifi cation of the system

and manufacturers recommendations must be taken into

account, along with the age and condition of the system.

New systems should be fl ushed thoroughly to remove all

traces of fl ux, debris, grease and metal swarf generated

during installation. Care to be taken with old systems

to ensure any black metallic iron oxide sludge and other

corrosive residues are removed, again by thoroughly

fl ushing, ensuring that the system is drained completely

from all low points.

NOTE: Please ensure that the new boiler plant is not

in circuit when the fl ushing takes place, especially if

cleansing chemicals are used to assist the process.

Under no circumstances is the boiler to be operated

with cleaning chemicals in the system.

5.2 Economisers

ECO’s can be delivered upon request (for natural gas

only). For specifi cations please refer to Technical information ECO 13/14/15.

5.3 Flue gas discharge

For the discharge of the fl ue gases, chimney draught is

not required.

Tests have shown that very good combustion results are

obtained with zero draught at the boiler outlet.

5.4 Noise production

The noise level taken at a distance of 1 m around the

boiler is approximately 75 to 90 dBA. The noise level

at the chimney outlet will, depending on load, type of

burner and chimney situation, vary from 75 to 90 dBA,

measured at a distance of 1 m from the outlet. If

this noise production gives rise to problems in the immediate vicinity, then noise reducing or absorbing measures should be taken.

100

90

2

N/m

-5

80

dB re 2x10

70

60

50

31,5 63 125 250 500 1000 2000 4000 8000

frequency (Hz)

full load

9

part load

NR 90

NR 80

NR 70

NR 60

Fig. 03 Noise level readings without burner silencer

To summarise:

- Minimise water loss;

- Prevent pumping over in open vented systems;

- Provide adequate air venting at all high points;

The values that have been taken are averages obtained

from various measurements carried out at a distance of

approximately 1 m around the boiler and at a height of

approximately 1 m.

- Keep pH level between 7 - 9 when using additives;

- Maximum chlorine content of 200 mg/l;

- Take advice on the suitability of inhibitors.

6

Supplied By www.heating spares.co Tel. 0161 620 6677

6 INSTALLATION REQUIREMENTS

6.1 Installation recommendations in the boiler

house

The necessary minimum installation space of the boiler

can be seen from Fig. 04.

Fig. 04 Installation recommendations in the boiler

house

04.15D.79.00001

H = 80mm without vibration damper

H = 120mm with vibrationdamper

Fig. 05 Base details

00.15A.78.00001

Number

of

sections

9 1350

10 1500

11 1650

12 1800

13 1950

14 2100

15 2250

16 2400

17 2550

18 2700

19 2850

20 3000

A

mm

7 ASSEMBLY GUIDELINES AND INSTALLATION REQUIREMENTS

7.1 General

The Remeha boiler P 500 is delivered in individual parts.

The sizes of the boiler parts are such that they all can

At the front of the boiler a fl ange is provided with 2

x G ½” threaded holes for the fi tting of the thermostat

pockets.

enter the boiler house through a normal entrance.

The casing and equipment parts are delivered in packaged units. If necessary, the boiler can be put into

operation without casing. The casing can be added at a

later stage without dismantling the water connections.

7.3 Boiler assembly

Assembly and installation of a boiler delivered in indivi-

dual parts should only be undertaken by a recognised

and approved engineer and in accordance with the

assembly manual. Local regulations laid down by the

7.2 Water connections

relevant authorities must be adhered to.

The water connections are at the rear of the boiler.

The fl ow and return connections consist of a fl anged

fl ow elbow and a fl anged return connection in accordance with DIN 2633. The return connection is provided

with a G ¾” threaded hole in which a drain off cock is

fi tted.

7

Supplied By www.heating spares.co Tel. 0161 620 6677

8 INSTRUMENT PANELS

Remeha P 500

8.1 Equipment contents

The panels contain all the necessary control and measuring instruments required to control the boiler. The connections have to be made on a terminal strip. The capillaries and sensor wires, which come from the control

panel, are placed in the instrument pockets that are

fi tted at the front of the boiler.

12 3 6

9

Fig. 06 Layout of the instrument panel High/Low with hours run meters

00.03F.79.00004

See par. 8.2 for an instrument panel High/Low with hours

run meters. Several extra options can be built into the

panels.

Ask our technical department.

8.2 Instrument panel High/Low with hours run

meters

4 578

1. Operating switch (On/Off)

2. Control thermostat; setting between 35°C - 95°C

3. High/Low thermostat; setting between 35°C - 95°C

4. Hours run meter total running hours

5. Hours run meter full load running hours

6. Analoque thermometer water temperature

7. High limit thermostat 110°C (lock out)

8. Lock out warning lamp

9. Option for rematic® weather compensator

8

Supplied By www.heating spares.co Tel. 0161 620 6677

8.3 Wiring diagram instrument panel High/Low with hours run meters 1

3

1.) External control.

remove link; insert control pair (230 V)

2.) External control High/Low.

remove link; insert control pair (230 V).1

Fig. 07 Wiring diagram instrument panel High/Low with hours run meters

04.13C.SC.00001

9

Supplied By www.heating spares.co Tel. 0161 620 6677

9 COMMISSIONING

Remeha P 500

Note:

Commissioning to only be carried out by a qualifi ed

engineer with the relevant training and certifi cation i.e.

Acops-Corgi and a commissioning data sheet completed

on site for issue to owner.

9.1 Pressurized boiler with gas burner

9.1.1 Commissioning procedure

If the boiler is to be put into operation again following

a period of non-use, then the following procedure must

be carried out :

- Open the main gas cock.

- Switch the weather-compensator (if fi tted) over to

manual operation (h).

- Turn the thermostats to their highest setting.

- Switch on the circulation pump.

- Switch on the main switch.

- Switch on the operation switch in the instrument

panel.

- Consult burner manufacturers commissioning details.

Warning

If the instrument panel is fi tted with a weather compensator, set the program switch to ‘manual’ position (h).

The following will now take place:

- The gas burner fan will start running so that during

the purging time the combustion chamber will be ventilated with the air damper fully opened.

- The air damper will then go into start position.

- Ignition fl ame lights up and is checked.

- Then the control box gives the all clear signal for the

burner to switch over to full load.

9.1.2 Putting out of operation

It is suffi cient to switch off the operation switch on the

instrument panel. It is important that in the event of

work being carried out on the burner, the boiler/burner

unit must be completely electrically isolated and the

main gas cock must be shut.5

9.2 Pressurized boiler with oil burner

9.2.1 Commissioning procedure

If the boiler is to be put into operation again following

a period of non-use, then the following procedure must

be carried out :

- Open the main oil cock.

- Switch the weather-compensator (if fi tted) over to

manual operation (h).

- Turn the thermostat to their highest setting.

- Switch on the circulation pump.

- Switch on the main switch.

- Switch on the operation switch in the instrument

panel.

- Consult burner manufacturer commissioning details.

Warning

If the instrument panel is fi tted with a weather compensator, set the program switch to ‘manual’ position (h).

The following will now take place:

- The oil burner fan will start running so that during the

purging time the combustion chamber will be ventilated with the air damper fully opened.

- The air damper will then go into start position.

- Ignition fl ame lights up and is checked.

- Then the control box gives the all clear signal for the

burner to switch over to full load.

9.2.2 Putting out of operation

It is suffi cient to switch off the operation switch on the

instrument panel. It is important that in the event of

work being carried out on the burner, the boiler/burner

unit must be completely electrically isolated and the

main oil cock must be shut.

10

Supplied By www.heating spares.co Tel. 0161 620 6677

10 FAULT FINDING

High Limit thermostat lock out:

- Check the water circulation (circulation pump). Reset

the High Limit thermostat (Reset button is on the

instrument panel under the cover cap of the High

Limit thermostat).

- Advise the installer in the event of continued lockouts.

11 MAINTENANCE RECOMMENDATIONS

11.1 General

Depending on the operational conditions, the block and

the burner must be checked and cleaned at least once a

year for gas and at least twice a year for oil.

11.2 Maintenance instructions

Cleaning of the boiler:

- Put boiler out of operation.

- Open the front door, if necessary after dismantling the

burner.

- Remove the retarders (only for the 9 - 16 sections).

- Clean the combustion chamber and fl ue passes using

a suitable brush.

- Clean the removed retarders ( 9 - 16 sections).

- Remove the rear panel of the boiler and remove the

cleaning cover (underneath the smoke box).

- Vacuum clean the boiler and the combustion chamber.

- Renew the front door seals after cleaning the boiler.

- Re-assemble the removed parts and close the front

door.

- Re-assemble the burner (if dismantled).

- Check the boiler combustion side for leakage.

- Check the equipment for proper functioning and if

necessary re-adjust the control and safety equipment.

- Carry out combustion analysis.

- Check the water connections.

11

Supplied By www.heating spares.co Tel. 0161 620 6677

Remeha P500

Broag Ltd.

Head office

Remeha house

Molly Millars Lane

Wokingham,

Berkshire RG41 2QP

Tel.: 0118 978 3434

Fax: 0118 978 6977

E-mail address:

boilers@broag-remeha.com

© Copyright

All technical and technological information contained in these technical instructions,

as well as any drawings and technical descriptions furnished by us remain our

property and shall not be copied in part or whole without our prior consent in writing.

Subject to alterations

52881/1000/0202/Ips.

12

Branch office

Unit 3, Kestrel Close,

Quarry Hill ind. Estate,

Ilkeston

Derbyshire DE7 4RD

Tel.: 0115 944 0778

Fax: 0115 944 0588

Loading...

Loading...