Remeha

Fuel oil/gas boilers

P 420

EN

Assembly

Instructions

300016854-001-A

63193

1 Package list

Package list : Before starting to assemble the boiler, refer to the table below to check if you have received all the packages required.

1. Boiler body + Accessories

Boilers supplied with an assembled body

Number of sections 8 9 10 11 12 13 14

Assembled boiler body - (contents depend upon model) 1111111

For boiler supplied with the boiler body in bulk

Number of sections 8 9 10 11 12 13 14

Front section 1111111

Special intermediate section 1111111

Normal intermediate section 567891011

Rear section 1111111

Common accessories 1 PackageCS20CS20CS20CS20CS20CS20CS20

Lower insulation, boiler body 1 PackageCS51CS53CS53CS55CS55CS57CS57

Base frame - dimensions depend upon

model

1111111

2. Baffle plates

Number of sections 8 9 10 11 12 13 14

Baffle plates 1 Package CS 30 CS 31 CS 31 CS 32 CS 32 CS 33 CS 33

3. Casing

Number of sections 8 9 10 11 12 13 14

Casing (common parts) Package RB21111111

Casing, variable parts Package MP2 - - 1 - - 1 -

Package MP3 1 - - 1 - - 1

Package MP4- 111222

Package MP5 - 1 - - 1 - -

4. Cable channel

Number of sections 8 9 10 11 12 13 14

Cable channel 1 Package CS 41 CS 42 CS 43 CS 44 CS 45 CS 46 CS 47

5. Control panel RC 1

6. Technical documents

Number of sections 8 9 10 11 12 13 14

Technical documents

(Content depends upon country)

2

1 Package1111111

P 420 02/04/08 - 300016854-001-A

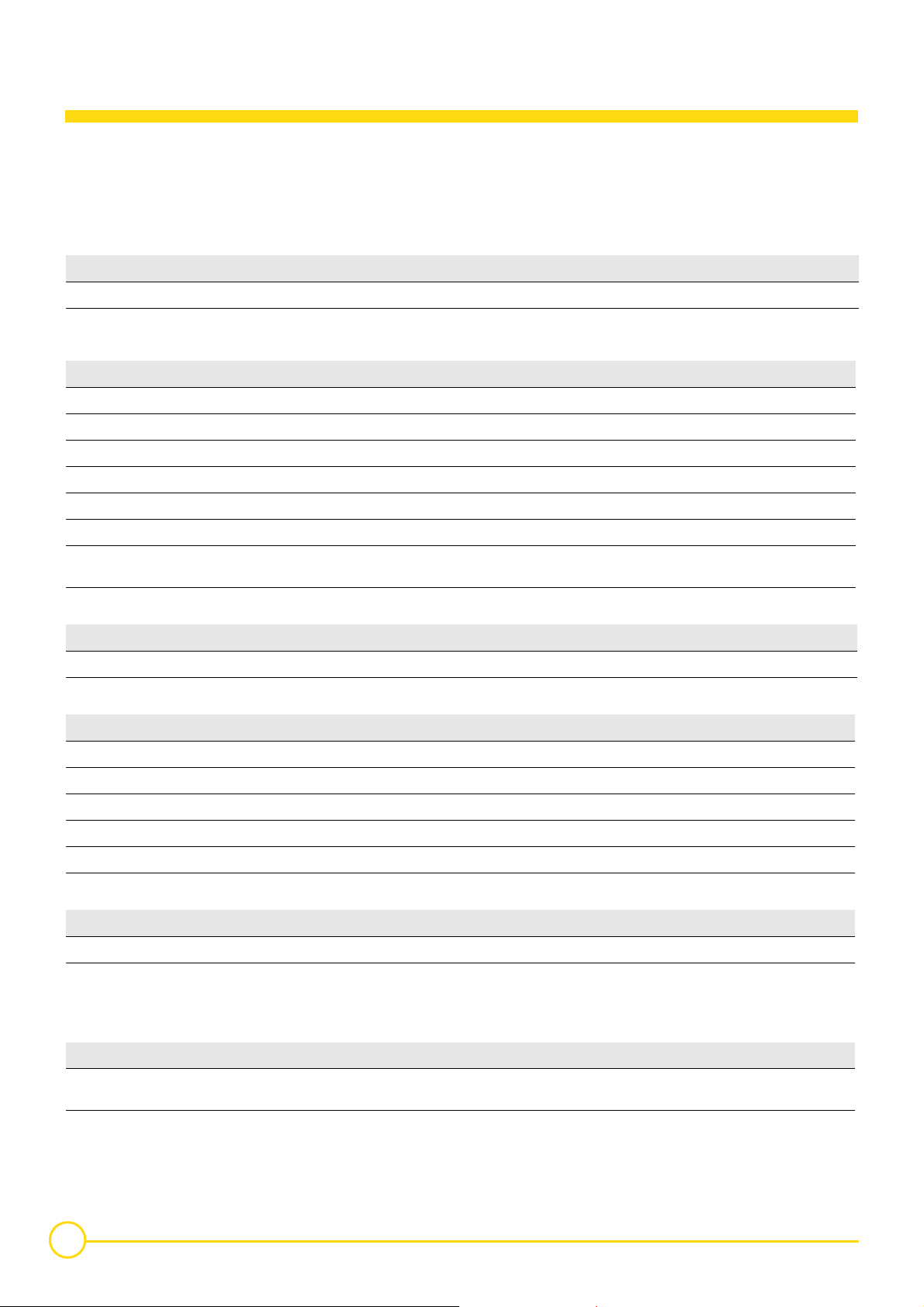

2 Boilers supplied with an assembled body

Manoeuvring the assembled boiler body

To manoeuvre the assembled body, it is possible to use the four

lifting rings located on the frame.

Hydraulic test:

Refer to view 10

Certain parts will have to be removed to carry out the hydraulic test.

3 Mounting

Warning : Assemble the boiler in the order given by the

numbers of each figure, in compliance with all the

instructions.

Tools required

- 1 22 box spanner

- 1 Phillips screwdriver

- 1 hammer

- 1 putty gun

- 1 stanley knife

- 13 - 19 - 24 spanners

- 1 Allen key

- JDTE or JDTE Plus assembly tool

Mounting:

For boilers with assembled boiler body, start assembly from figure 16

Refer to the applicable price list for any optional features used.

02/04/08 - 300016854-001-A P 420

3

Boilers supplied with an assembled body

• Hydraulic test:

Refer to view 10

Certain parts will have to be removed to carry out the hydraulic test.

For boiler supplied with the boiler body in bulk

Hydraulic test: Refer to view 10

Mounting: Assembly of the sections is done from back to front

as shown below, beginning with assembly view 1

Front - Rear

Boiler type Rear section

P 420-8

P 420-9

P 420-10

P 420-11

P 420-12

P 420-13

P 420-14

1151

1161

1171

1181

1191

11101

11111

Special intermediate

section

• Mounting:

For boilers with assembled boiler body, start assembly from figure 16

Normal intermediate

section

Front section

4

P 420 02/04/08 - 300016854-001-A

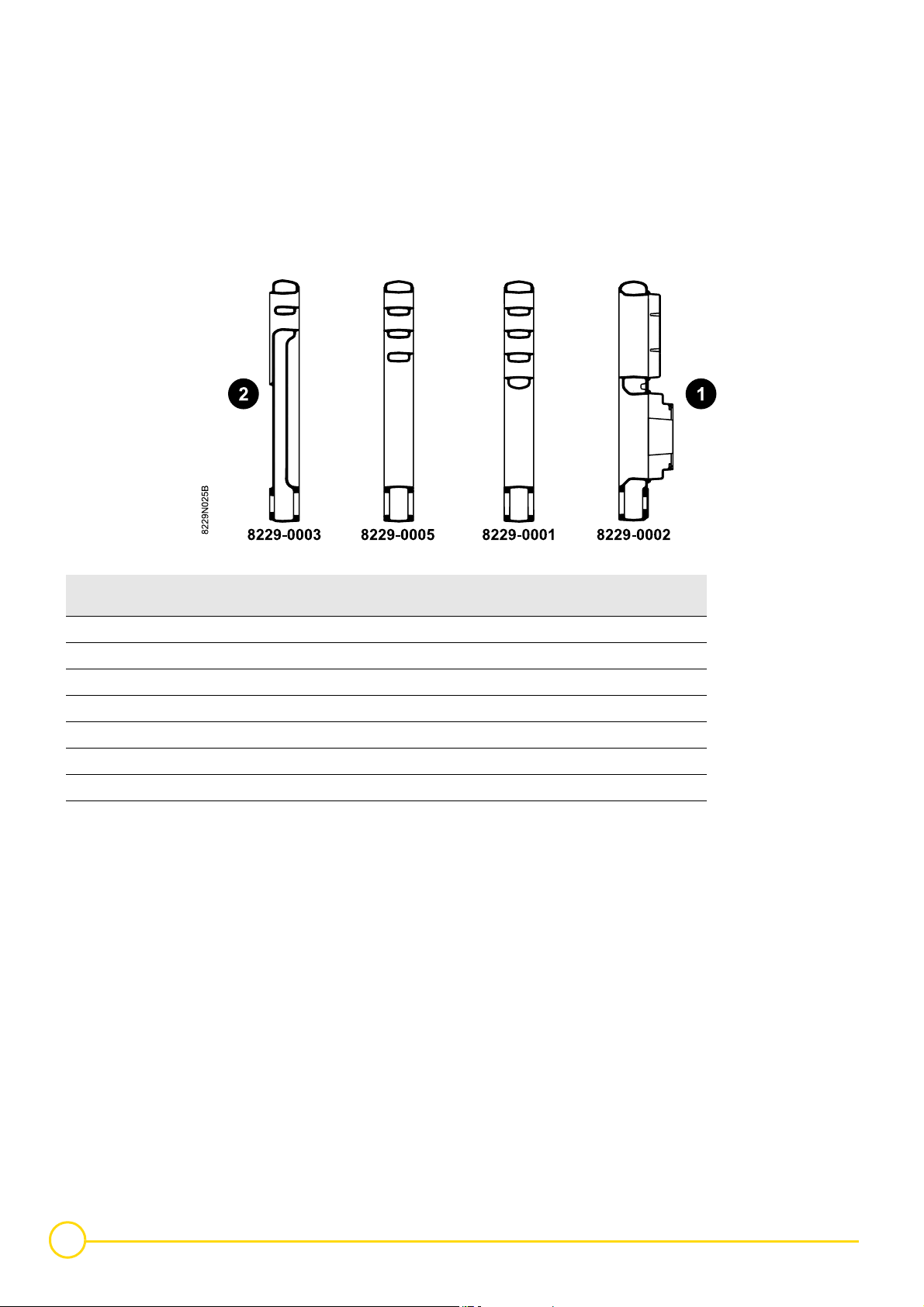

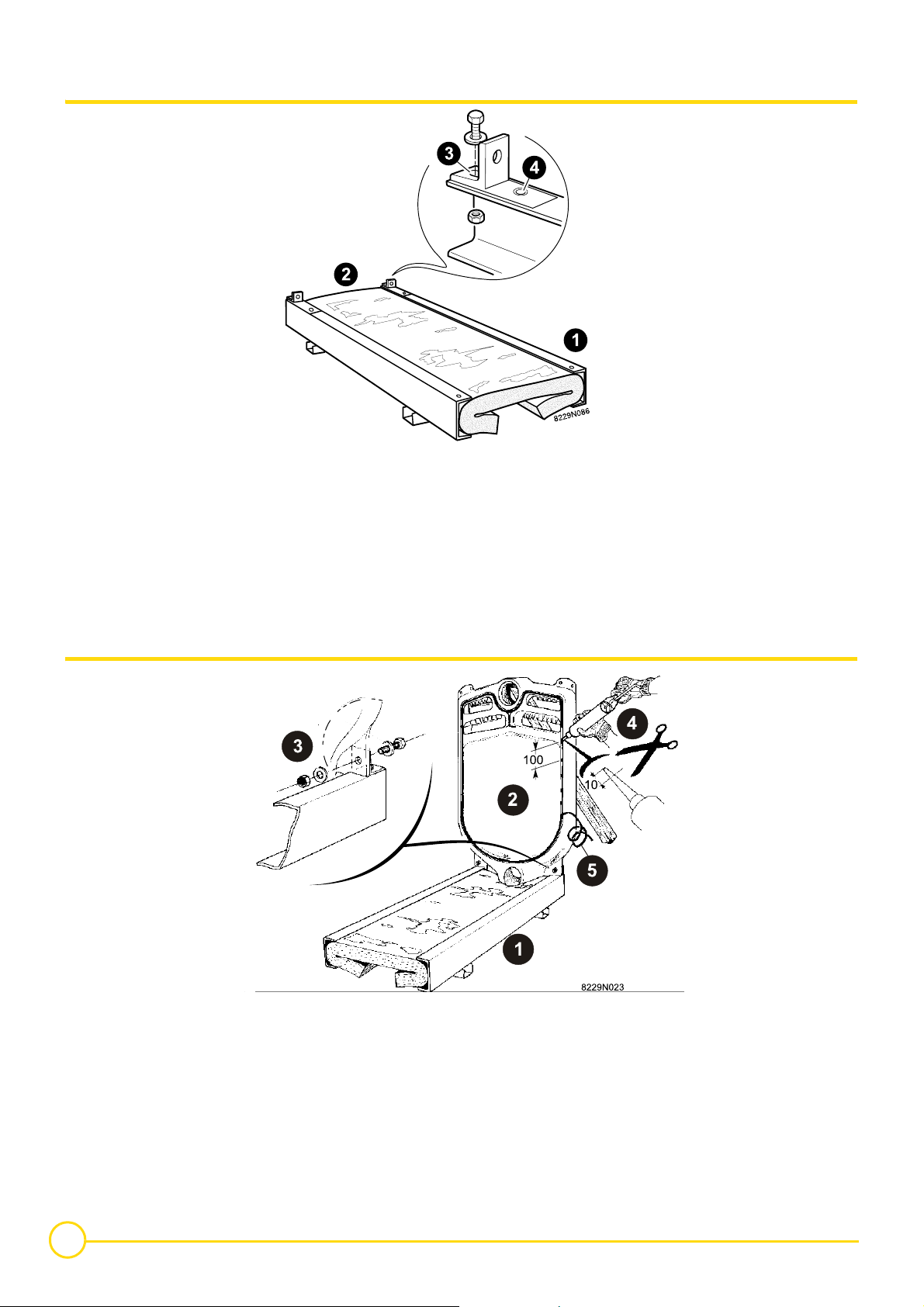

1 Assembly of the base frame, delivered unassembled

1

M001233

2

3

2

3

M001234

02/04/08 - 300016854-001-A P 420

5

2 Fitting the brackets

Front - Rear

P 420-8 - P 420-10 - P 420-12 - P 420-14

` Fit the 2 rear holding brackets and secure them to the frame.

Use the corresponding holes following the indication on the frame.

` Position the lower insulation (fabric to the top) package CS 51 to CS 57. If necessary, adapt the length of or fold the lower insulation after

completing assembly of the casing.

P 420-9 - P 420-11 - P 420-13

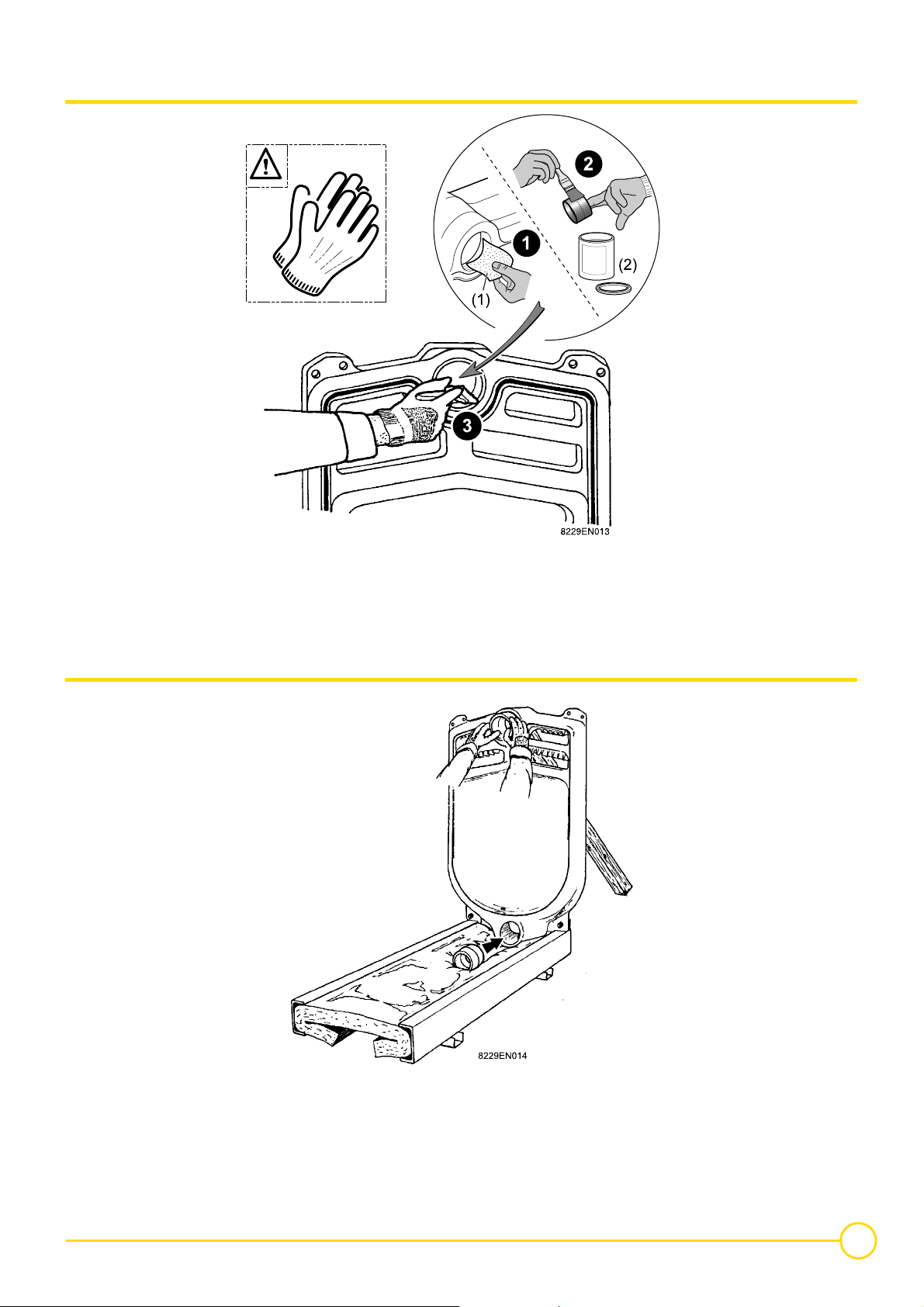

3 Positioning the frame and the rear section

Establish the location of the frame on the basis of the opening direction of the furnace door and the length of the burner.

Position the rear section on the frame and prop it up.

Affix it to the brackets (2 screws HM 12x40/40 + 4 washers L12 + 2 nuts HM12).

Around every 100 mm, place points of silicon mastic (1 tube delivered with the accessories package CS 20) in the leak proofing groove in

the section using a gun.

Carefully introduce the leak proof thermocord into the leak proofing groove.

do not pull on the seal while inserting it. Otherwise, you may stretch it and reduce its thickness. You must not make the junction

point with the thermocord in the lower part of the section.

6

P 420 02/04/08 - 300016854-001-A

4

Handle the nipples with gloves, there might be sharp

edges.

- Clean the bores and nipples. Coat with the lubricant supplied with

the sections.

5

(1) Sandpaper

(2) Lubricant (Supplied)

- Gently push in the 2 nipples.

02/04/08 - 300016854-001-A P 420

7

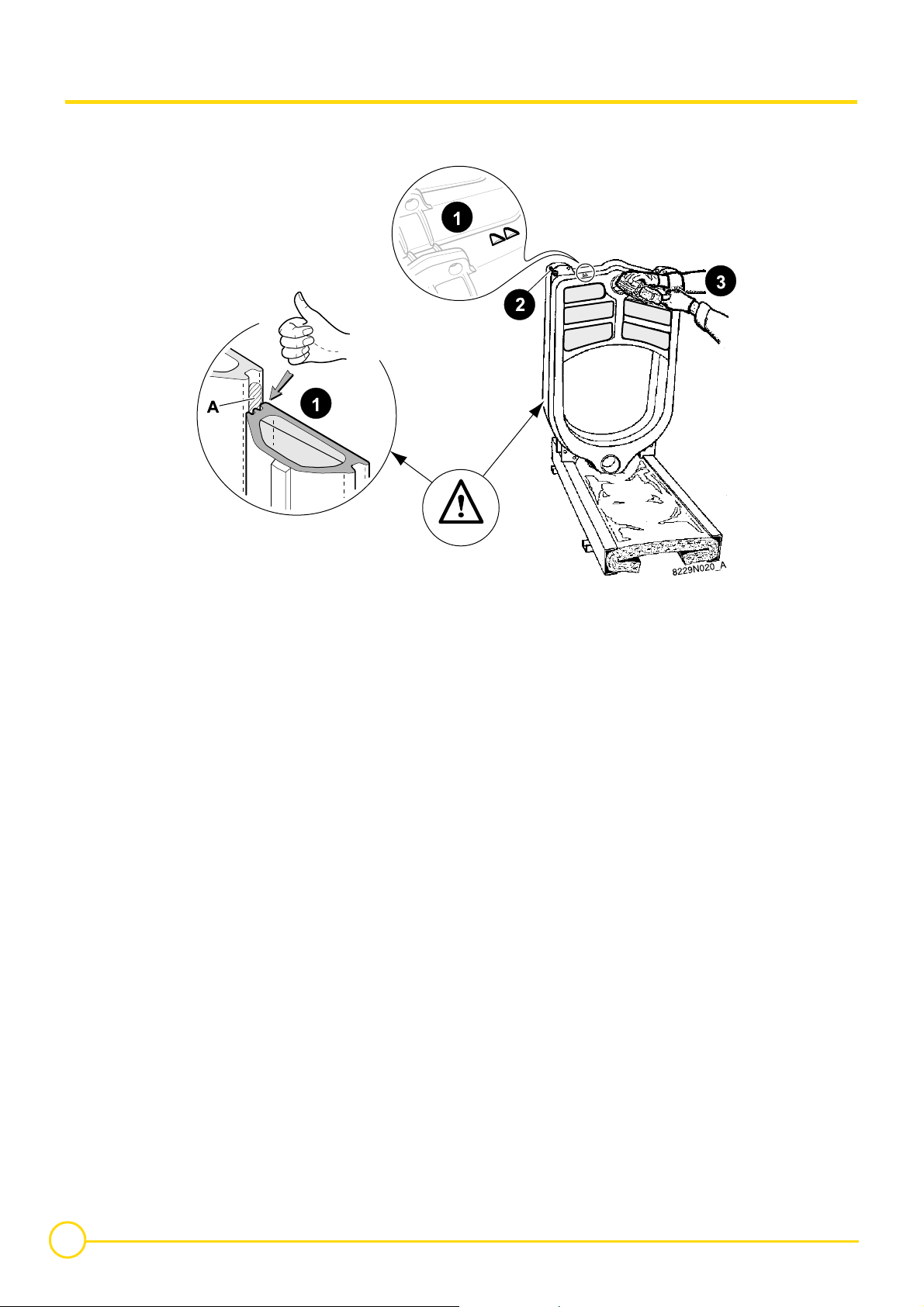

6 Assembling the sections

A : Thermocord

Special intermediate section in front of rear section.

Place the first special intermediate section, making sure that it is turned in the right direction, i.e. with the flattening groove against the

thermocord.

For safety reasons, insert an upper assembly rod (loose boiler body accessories package) into the holes in the 2 sections.

Push the section gently and simultaneously on the 2 nipples of the rear section with a hammer and a piece of wood positioned in line with

the bores.

8

P 420 02/04/08 - 300016854-001-A

7

- Put the assembly tool in position.

- Tighten gradually so as to bring together the upper and lower connections evenly and simultaneously.

8

- Fit the remaining sections one by one in the order shown, proceeding as per the views 3-4-5-6.

- Leave the assembly tool in place.

02/04/08 - 300016854-001-A P 420

9

9 Fitting the upper and lower assembly rods and the upper casing

supports

(1) Front - (2) Rear

- Fit the upper assembly rods (boiler body accessories) in the order

shown in the diagram above. Place the expansion spring and its

washer on each rod at the rear. Stop tightening the nuts when

the free space between the threads is around 2 mm.

- Fit the upper casing supports (package CS13) and the upper

cross-bars (package CS10-11-12-14) with the assembly rods

(boiler body accessories package) as per the details A-B-C-D.

- Fit the lower assembly rods in the order shown in the diagram.

- Remove the assembly tool.

10

P 420 02/04/08 - 300016854-001-A

10 Hydraulic test

After assembling the boiler body, the installer must carry out a water tightness test at a pressure equal to 1.3 times the operating

pressure (that is 7.8 bar mini) for 10 minutes at least.

Ensure that all the air in the boiler is vented to avoid any

bursting of the body.

After the tightness test, drain the boiler and remove all the parts used

for the test.

02/04/08 - 300016854-001-A P 420

11

11

- Secure the flue gas nozzle (boiler body accessories) to the flue gas

box (package CS 20) using 4 screws HM 12 x40 + 4 nuts H 12 + 4

washers.

12

P 420 02/04/08 - 300016854-001-A

12

Fit the 2 threaded rods using multiple slip joint pliers (body

accessories package) M12x175 for the flue gas outlet.

Secure the outlet and return pipes (boiler body accessories

package) using 4 nuts H16 for each pipe (24 mm spanner),

remembering to insert the leak proof seal.

A : P420-8 to P420-10.

B : For P420-11 to P420-14, the return collector is replaced by

a collector with water distributor (marked "INJ")

Fit the flue gas outlet to the heating body (6 nuts H12 + 6 flat

washers L12 - 19 mm spanner).

Fit 2 screws HM 12x60 + 2 nuts to the flue gas outlet for the

sweeping hatch (see detail).

Affix the sweeping hatches (package CS 20) using 4 nuts H12 +

2 washers L12 + 2 washers M12.

Assembling the flow switch:

Fasten the flow switch on the sleeve tube. The direction of the arrow

head on the collet must be the same as the flowing out of the water

in the tube.

The table opposite is used to check that the flow controller delivered

corresponds to the boiler being assembled.

Boiler Flow controller no.

P 420-8 8802-4706

P 420-9 8802-4710

P 420-10 8802-4712

P 420-11 8802-4722

P 420-12 8802-4725

P 420-13 8802-4727

P 420-14 8802-4729

02/04/08 - 300016854-001-A P 420

13

13

Put in place the lower plug and the upper plug with the sensor

tube (boiler body accessories package).

Do not forget the hemp.

Put the 8 M12x50 pins in place in the holes provided for this

purpose.

Put the 2 M12x85 pins in place in the holes provided for this

purpose.

Fit the hinges to the sweeping doors (package CS20) using 2

screws HM 12 x 25 + 2 nuts M 12 + 4 washers DE 12

-

Fit the hinge on the door of the combustion chamber (boiler

body accessories package) to the left or right depending on which

way you wish to open it and secure using 3 screws HM12x30 +

washers CL14.

14

Boiler body accessories package

Assemble the door of the combustion chamber (4 nuts M12 + 4

thick washers)

Put in place the added hinge with its hinge pin.

14

P 420 02/04/08 - 300016854-001-A

15

Affix the added hinge (boiler body accessories package) to the

door of the combustion chamber using the 3 screws HM12x30 + 3

washers L 12 (previously dismantled).

Leave the 3 screws HM12x30 and the 3 washers L12 in

place on the combustion chamber door on the side

opposite to the added hinge.

-

Put in place the left and right sweeping doors with their hinge

pin (package CS 20).

02/04/08 - 300016854-001-A P 420

15

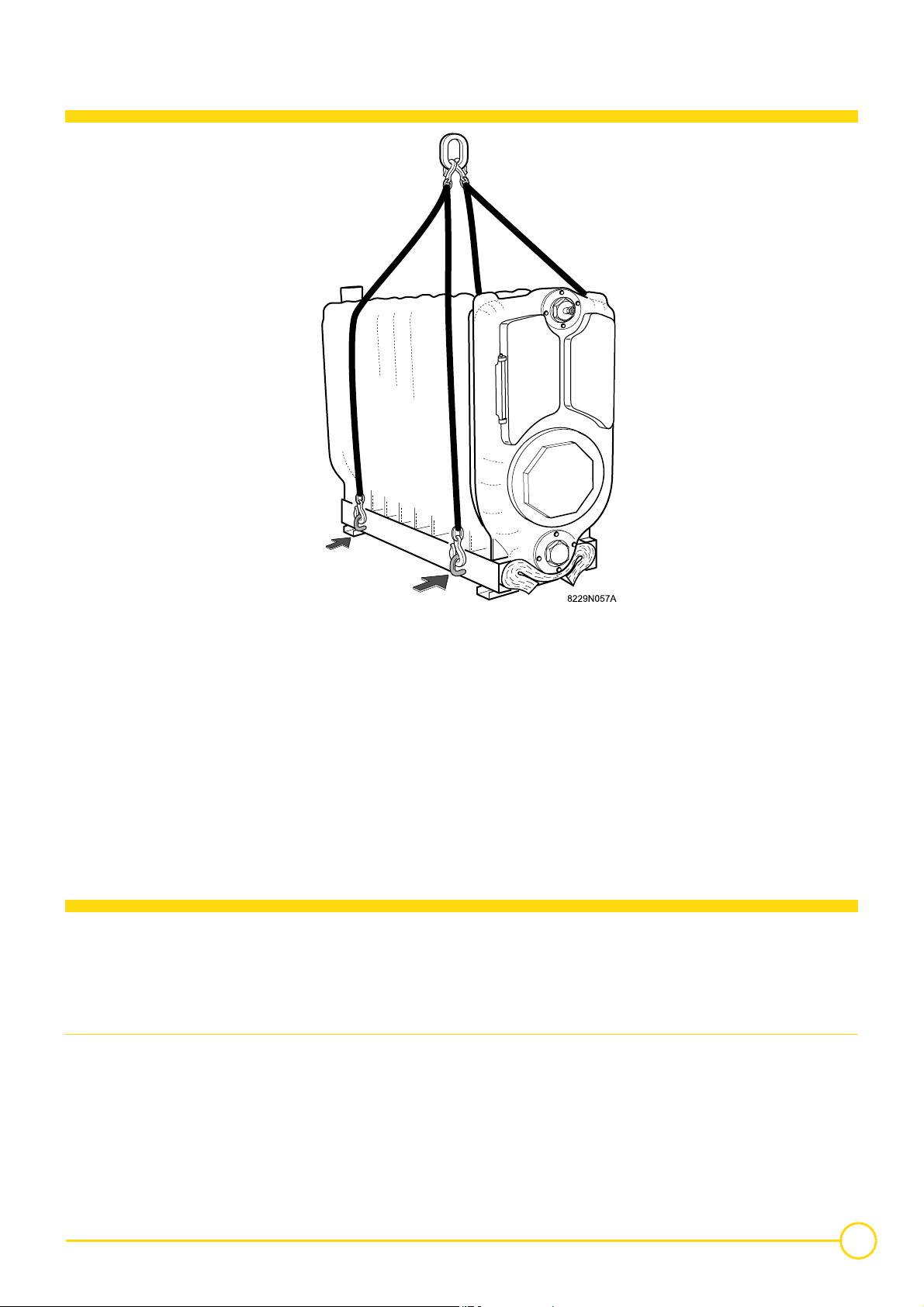

16 Assembling the baffle plates

Boilers for following countries: NL - BE - ES

Flue ways P 420-8 P 420-9 - P 420-10 P 420-11 - P 420-12 P 420-13 - P 420-14

Upper

Central

Lower

8229-0010 and 8229-0022 2 x 8229-0010

8229-0011 and 8229-0023 2 x 8229-0011

8229-0012 and 8229-0024 2 x 8229-0012

2 x 8229-0010 and

1 x 8229-0022

2 x 8229-0011 and

1 x 8229-0023

2 x 8229-0012 and

1 x 8229-0024

3 x 8229-0010

3 x 8229-0011

3 x 8229-0012

Boilers for following countries: GB - HU - SE

Flue ways P 420-8 P 420-9 - P 420-10 P 420-11 P 420-12 P 420-13 - P 420-14

Upper

Central

Lower

The 8-figure part number of the baffle plate is moulded into the

metal.

- Put the upper, central and lower baffle plates in place, following the

order of assembly shown in the diagram.

Follow the order of assembly shown in the diagram.

Hook the baffle plates into one another before fitting them

into the flue ways.

- Close the sweeping doors and secure using 3 nuts HM12 + 3 thick

washers L12x32x5.

8229-0010 and 8229-

8229-0011 and 8229-

8229-0012 and 8229-

0022

0023

0024

2 x 8229-0010

2 x 8229-0011

2 x 8229-0012

2 x 8229-0010 and

1 x 8229-0022

2 x 8229-0011 and

1 x 8229-0023

2 x 8229-0012 and

1 x 8229-0024

2 x 8229-0010 and

1 x 8229-0022

2 x 8229-0011 and

1 x 8229-0023

2 x 8229-0012 2 x 8229-0012

3 x 8229-0010

3 x 8229-0011

16

P 420 02/04/08 - 300016854-001-A

17 Boilers supplied with an assembled body

. (1) Rear

- Unscrew the screw A on the bracket.

To fit the flow controller, refer to stage no. 11.

Z

18

Affix the lower casing supports (packages RB2, MP2 and MP5)

to the frame using 1 screws HM8x25 + serrated washer for each

support.

Insert the boiler body insulation panels. Hold the insulation in

place by knotting each strap to the lower casing support on either

side of the boiler

Insulation width, boiler body

Boiler

P 420-8 1 - - - 1

P 420-9 1 1 1 - -

P 420-10 1 1 - 1 -

P 420-11 1 1 - - 1

P 420-12 1 2 1 - -

P 420-13 1 2 - 1 -

P 420-14 1 2 - - 1

package RB2 MP4 MP5 MP2 MP3

500 500 600 800 900

Front Rear

02/04/08 - 300016854-001-A P 420

17

19

` Insert the rear insulation - Package R B2.

20

Boilers supplied with an assembled body: Fit the upper crosspieces (See step 9), then:

Put the left and right cable ways in place, respecting the assembly sequence.

Secure the cable ways (3 screws HM5x25 + serrated washers).

Secure the front top panel (package RB2) with 4 screws HM5x25 + serrated washers.

18

P 420 02/04/08 - 300016854-001-A

21 Control panel assembly

22

(1) Front - (2) Rear

Position the control panel in the rear bushes.

Open the control panel by unscrewing the 2 screws on the front

of the panel.

*

*

* except NL (see instructions delivered with the water low safety

pressure-sensitive switch)

- Carefully unroll and take out the various bulbs from the control

panel, passing them through the opening in the front cover.

- Then, insert the bulbs inside the pocket and maintain them with the

spring.

- At the front, screw the control panel to the cover using 2 selftapping screws Ø 3.9x12.7 + serrated washers (Phillips

screwdriver).

23 Electrical connection

All connections are made with the terminal boxes designed for that

purpose on the back of the boiler's command board.

Connections must be made by a qualified technician.

02/04/08 - 300016854-001-A P 420

19

24 Casing assembly

Position the front side panels (length 520 - Package RB2) in the

lower casing supports and hook them into the cable ways.

Position the front side panels with the bushes pointing to

the front of the boiler.

Fix to the front on the lower casing brackets using 2 screws

HM5x25 + serrated washers.

25

Fit to the front (2 screws Ø 3.94x12.7 + serrated washers).

Position the burner cable as shown in the diagram and on the

opposite side to the hinges on the door of the combustion chamber.

-

Position the rear side panels with the bushes pointing to

the rear of the boiler.

Boiler

P 420-8 520(RB2) 930(MP3)

P 420-9 520(RB2) 480(MP4) 610(MP5)

P 420-10 520(RB2) 480(MP4) 770(MP2)

P 420-11 520(RB2) 480(MP4) 930(MP3)

P 420-12 520(RB2) 480(MP4) 480(MP4) 610(MP5)

P 420-13 520(RB2) 480(MP4) 480(MP4) 770(MP2)

P 420-14 520(RB2) 480(MP4) 480(MP4) 930(MP3)

Front Rear

Insulation width, boiler body

` Position the remaining side panels in the order shown in the

diagram: position each panel in the lower casing supports and

hook it into the cable way.

20

P 420 02/04/08 - 300016854-001-A

26

Position the front and rear covers in the order shown in the

diagram.

The intermediate and rear covers are narrower than the front

cover.

Affix the first intermediate cover (length 480) to the cable ways

using 4 screws HM5x25 + serrated washers.

-

Affix the remaining covers to the cable ways using 2 screws

HM5x25 + serrated washers.

Boiler type

P 420-8 480 (RB 1) 480 490 MP3

P 420-9 480 (RB 1) 480 480 170 MP4+MP5

P 420-10 480 (RB 1 480 480 330 MP2+MP4

P 420-11 480 (RB 1) 480 480 490 MP3+MP4

P 420-12 480 (RB 1) 480 480 480 170 MP5+MP4

P 420-13 480 (RB 1) 480 480 480 330 MP2+MP4

P 420-14 480 (RB 1) 480 480 480 490 MP3+MP4

Length of the

front cover

Length of the intermediate cover

Length of the

rear cover

Pack no.

02/04/08 - 300016854-001-A P 420

21

27 Assembly of the rear panels Package RB2

Hook the lower rear panel to the 2 bushes on the side panels.

Put in place the 2 self-tapping screws Ø 3.9 x 12.7 + serrated washers without tightening them.

Hook the left and right upper rear panels to the 2 bushes on the side panels and secure each one to the lower rear panel using 2 self-

tapping screws Ø 3.9x12.7 + serrated washers.

Fix to the rear top panel (2 self-tapping screws Ø 3.9x12.7 + serrated washers).

Hook the additional lower rear panel onto the 2 screws on panel and tighten these 2 screws to secure the panel to .

Fit the lower rear panel (2 screws + Serrated washers).

28 Mounting of the front casing panels

Affix the lower front panel to the cross-bar (2 screws ø 3.94x12.7

+ serrated washers).

Position the lower cross-bar and affix to the side panels using 2

self-tapping screws ø 3.94x12.7 + serrated washers.

Position the panel for combustion chamber door and secure

using 2 screws HM12x25 + flat washers.

22

P 420 02/04/08 - 300016854-001-A

29

Hook the lower left and right front panels to the bush on the side panel.

Hook on the front casing support (2 bushes).

Position the top front panel in the front casing support and hook it into the front cover.

30 Rating plate

3

` Affix the rating plate supplied with the instructions, which

corresponds to the country of destination.

M000048

1: Boiler type

2: Power ranges

3: Thermic output

02/04/08 - 300016854-001-A P 420

23

© Copyright

All technical and technological information contained in these technical instructions, as well as any

drawings and technical descriptions supplied, remain our property and shall not be multiplied

without our prior consent in writing.

Subject to alterations.

02/04/08

Loading...

Loading...