Remeha P420 Installation and Service Manual

Remeha

Fuel oil/gas boilers

P 420

EN

Installation and

Service Manual

300016839-001-C

63190

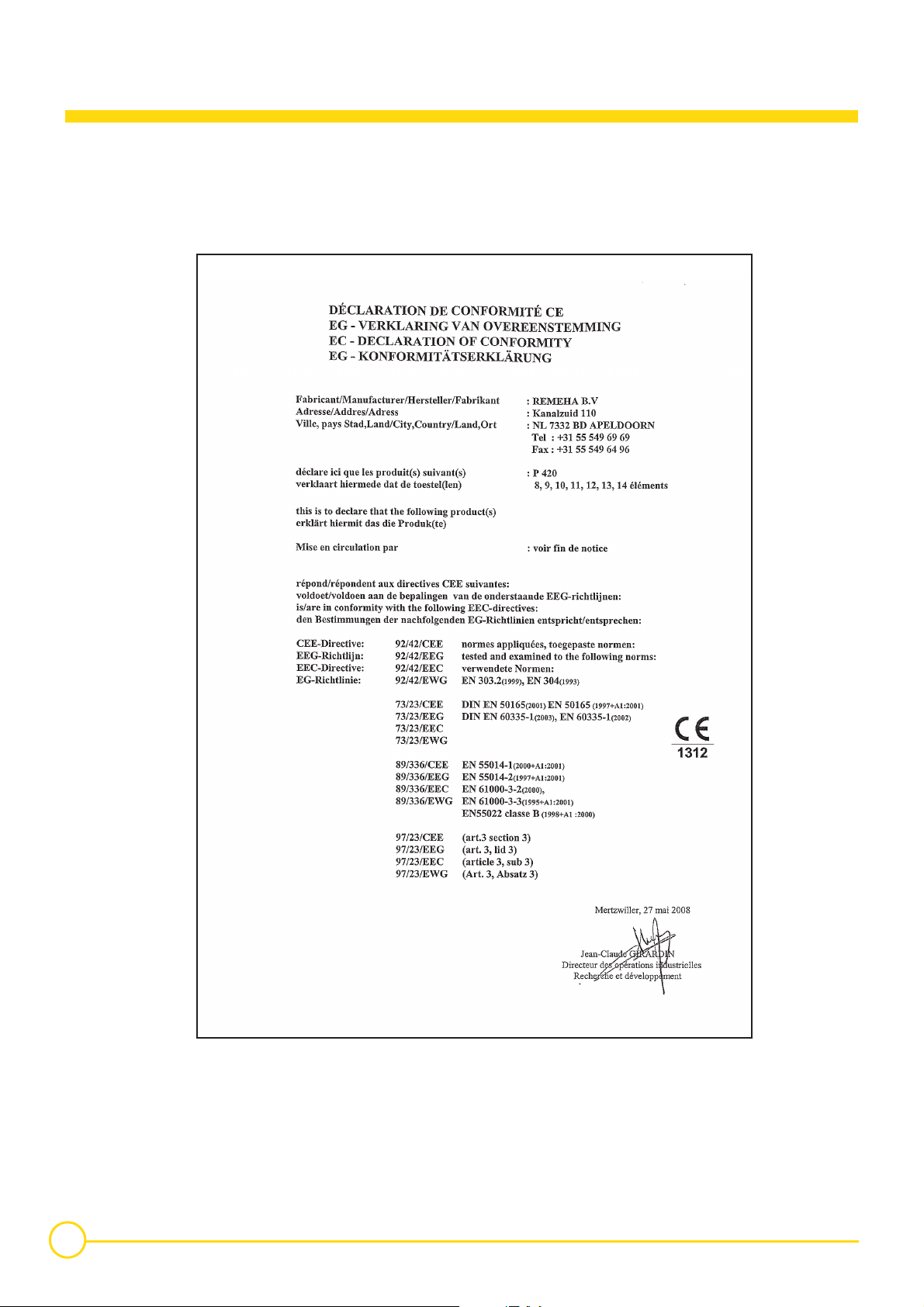

Declaration of conformity 1

The appliance complies with the standard model described in

declaration of compliance 1. It is manufactured and distributed

pursuant to the requirements of european directives. The original of

the declaration of compliance is available from the manufacturer.

C001880

2

P 420 20/09/2011 - 300016839-001-C

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Symbols and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.3.1 Directive 97/23/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 Safety instructions and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.1 Fire hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.2 Risk of intoxication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.3 Risk of being burnt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.4 Risk of damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.1 Regulations governing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.2 Package list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.3 Choice of the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.3.1 Main dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.3.2 Position of the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.3.3 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.4 Example of an installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.5 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.5.1 Flushing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.5.2 Sludge removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5.3 Hydraulic connection of the heating circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.5.4 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.5.5 Hydraulic connection of the water circuit for domestic use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.6 Chimney connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.6.1 Flue size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.6.2 Connection to the flue gas pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.7 Fuel-oil or gas connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.8 Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.9 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

6 Switching off the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

6.1 Precautions required in the case of long boiler stops (one or more years) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

6.2 Precautions required if the heating is stopped when there is a risk of freezing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

7 Checking and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.1 System maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.1.1 Water level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.1.2 Draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.2 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

7.3.1 Cleaning the flue gas circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

20/09/2011 - 300016839-001-C P 420

3

7.3.2 Cleaning the combustion chamber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

7.3.3 Positioning of the baffle plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

7.3.4 Cleaning the flue gas box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

7.3.5 Ramonage chimique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7.4 Cleaning the casing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7.5 Entretien du brûleur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

8 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4

P 420 20/09/2011 - 300016839-001-C

1Introduction

1.1 Symbols and abbreviations

Caution danger

Risk of injury and damage to equipment. Attention must be

paid to the warnings on safety of persons and equipment.

Specific information

Information must be kept in mind to maintain comfort.

1.2 General

1.2.1 Manufacturer's liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with 1 marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

1.2.2 Installer's liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

` Read and follow the instructions given in the manuals provided

with the appliance.

Reference

Z

Refer to another manual or other pages in this instruction

manual.

DHW: Domestic hot water

Our liability as the manufacturer may not be invoked in the following

cases

:

` Failure to abide by the instructions on using the appliance.

` Faulty or insufficient maintenance of the appliance.

` Failure to abide by the instructions on installing the appliance.

` Carry out installation in compliance with the prevailing

legislation and standards.

` Perform the initial start up and carry out any checks necessary.

` Explain the installation to the user.

1.2.3 User's liability

To ensure the optimum operation of your appliance, we strongly

recommend that you abide by the following instructions:

` Read and follow the instructions given in the manuals provided

with the appliance.

` Call on qualified professionals to carry out installation and initial

start up.

` Get your fitter to explain your installation to you.

` Have the required checks and services done.

` Keep the instruction manuals in good condition close to the

appliance.

This appliance is not intended to be used by persons (including

children) whose physcial, sensory or mental capacity is impaired or

persons with no experience or knowledge, unless they have the

benefit, through the intermediary of a person responsible for their

safety, of supervision or prior instructions regarding use of the

appliance. Care should be taken to ensure that children do not play

with the appliance.

` If a maintenance is necessary, warn the user of the obligation

to check the appliance and maintain it in good working order.

` Give all the instruction manuals to the user.

20/09/2011 - 300016839-001-C P 420

5

1.3 Homologations

This product will be marketed in the following European Union

member states:

NL - BE - ES - GB - HU - SE

with a gas or oil-burner of the associated category.

1.3.1 Directive 97/23/EC

Gas and oil boilers with a maximum operating temperature of 110°C

and hot water tanks with a maximum operating pressure of 10 bar

pertain to article 3.3 of the directive, and therefore, cannot be CEmarked to certify compliance with the directive 97/23 EC.

The boilers and hot water tanks are designed and manufactured in

accordance with the sound engineering practice, as requested in

article 3.3 of the directive 97/23/EC, it is certified by compliance with

the directives 90/396/EC, 92/42/EC, 2006/95/EC and 2004/108/EC.

6

P 420 20/09/2011 - 300016839-001-C

2 Safety instructions and recommendations

2.1 Safety instructions

For a proper operating of the boiler, follow carefully the

instructions.

Only qualified professionals are authorised to work on the

appliance and the installation.

Incorrect use or unauthorised modifications to the

installation or the equipment itself invalidate any right to

claim.

2.1.1 Fire hazard

It is forbidden to store inflammable products and materials

in the boiler room or close to the boiler, even temporarily.

If you smell gas, do not use a naked flame, do not smoke,

do not operate electrical contacts or switches (doorbell,

lights, motor, lift, etc.):

2.1.2 Risk of intoxication

Do not obstruct the air inlets in the room (even partially).

If you smell flue gases:

Before any work, switch off the mains supply to the

appliance.

Keep to the polarity shown on the terminals: phase (L),

neutral (N) and earth

Keep children away from the boiler.

1. Shut off the gas supply

2. Open the windows

3.

Extinguish all flames.

4.

Evacuate the premises.

5.

Contact a qualified professional.

6.

Inform the gas supplier.

1. Switch the appliance off.

2. Open the windows.

3. Evacuate the premises.

4. Contact a qualified professional.

.

4

.

.

2.1.3 Risk of being burnt

Depending on the settings of the appliance:

- The temperature of the flue gas conduits may exceed 60°C.

- The temperature of the radiators may reach 95°C.

- The temperature of the domestic hot water may reach 65°C.

2.1.4 Risk of damage

Do not stock chloride or fluoride compounds close to the

appliance.

Install the appliance in frost-free premises.

2.2 Recommendations

` Check regularly that the installation contains water and is

pressurised.

` Keep the appliance accessible at all times.

` Avoid draining the installation.

` The appliance should be on Summer or Antrifreeze mode rather

than switched off to guarantee the following functions:

Do not neglect to service the appliance: Contact a qualified

professional or take out a maintenance contract for the

annual servicing of the appliance.

- Anti blocking of pumps

- Frost protection

- Protection against corrosion on domestic hot water tanks fitted

with a titanium anode

20/09/2011 - 300016839-001-C P 420

.

.

.

7

3 Technical description

3.1 General description

The boilers of the P 420 range are pressurised hot water boilers

designed for connecting to a flue pipe which require a separate

automatic fuel-oil or gas burner.

The useful power of P 420 boilers is between 250 and 700 kW.

Models available

Boiler with control panel, which may be fitted with an optional

Rematic 2945 C3 control unit for heating only or heating and

domestic hot water production.

8

P 420 20/09/2011 - 300016839-001-C

3.2 Technical specifications

Maximum operating pressure: 6 bar

Boiler thermostat setting: 30 to 90°C

Maximum operating temperature: 100°C

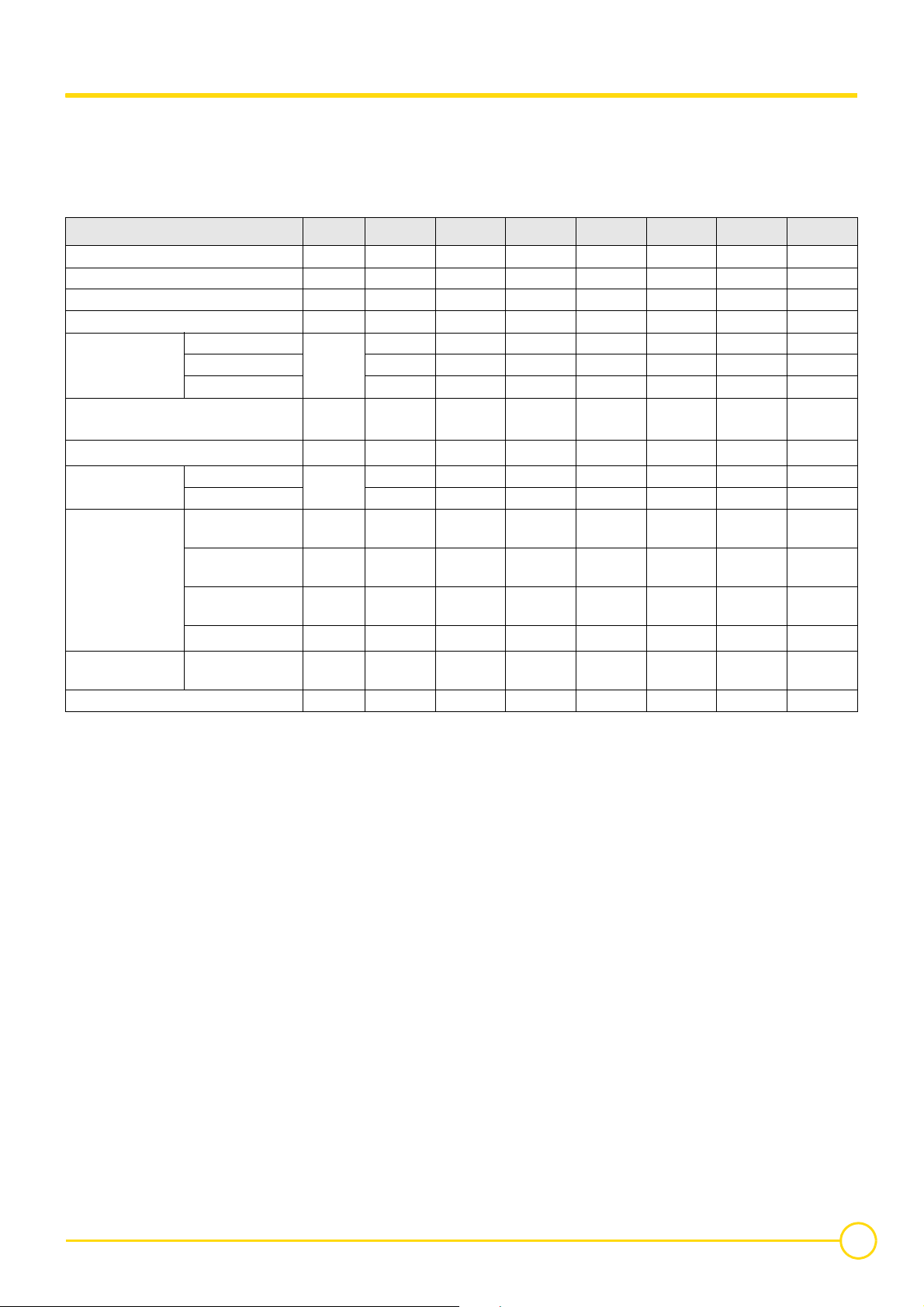

Boiler P 420-8 P 420-9 P 420-10 P 420-11 P 420-12 P 420-13 P 420-14

Useful output kW 300-390 390-450 450-540 540-600 600-670 670-720 720-780

Power input kW 329-434 429-502 495-599 594-670 661-751 737-804 789-871

Number of sections 8 9 10 11 12 13 14

Water content l 366 409 452 495 538 581 624

∆ T = 10K

Water resistance

Pressure in the furnace for nozzle pressure =

(1) (3) (2))

0

Smoke temperature

Mass flue gas flow

(1) (2)

rate

Combustion chamber

Maintenance consumption*

Shipping weight kg 1470 1650 1830 2010 2190 2370 2550

∆ T = 15K 14213645587087

∆ T = 20K 8 12 20 25 33 40 49

(1) (3) (2)*

Fuel oil

Gas 700 810 972 1080 1207 1297 1405

Diameter, combustion chamber

Width, combustion

chamber

Depth, combustion

chamber

Volume

à 50°C W 315 358 413 451 494 505 555

mbar

mbar 1.1 1.5 2.0 2.5 2.5 2.5 3.5

°C < 220 < 220 < 220 < 220 < 220 < 220 < 220

Kg/h

mm 530 530 530 530 530 530 530

mm 638 638 638 638 638 638 638

mm 1183 1343 1503 1663 1823 1983 2143

m

31 48 80 101 130 158 194

650 750 900 1000 1116 1200 1450

3

0.310 0.354 0.396 0.439 0.481 0.523 0.565

*Maintenance consumption: total heat emission when the burner is

off as a percentage of the nominal input power when the difference

between the mean boiler temperature and the room temperature is

30 K.

(1)

Nominal operation (top boiler power)

)

(2

CO2 = 13.1 to 13.5% with fuel oil and 9.5% with natural gas.

(3)

Boiler temperature: 80 °C - Ambient temperature: 20 °C

20/09/2011 - 300016839-001-C P 420

9

4 Installation

4.1 Regulations governing installation

Installation must be carried out in accordance with the

prevailing regulations, the codes of practice and the

recommendations in these instructions.

4.2 Package list

See assembly instructions.

Z

4.3 Choice of the location

4.3.1 Main dimensions

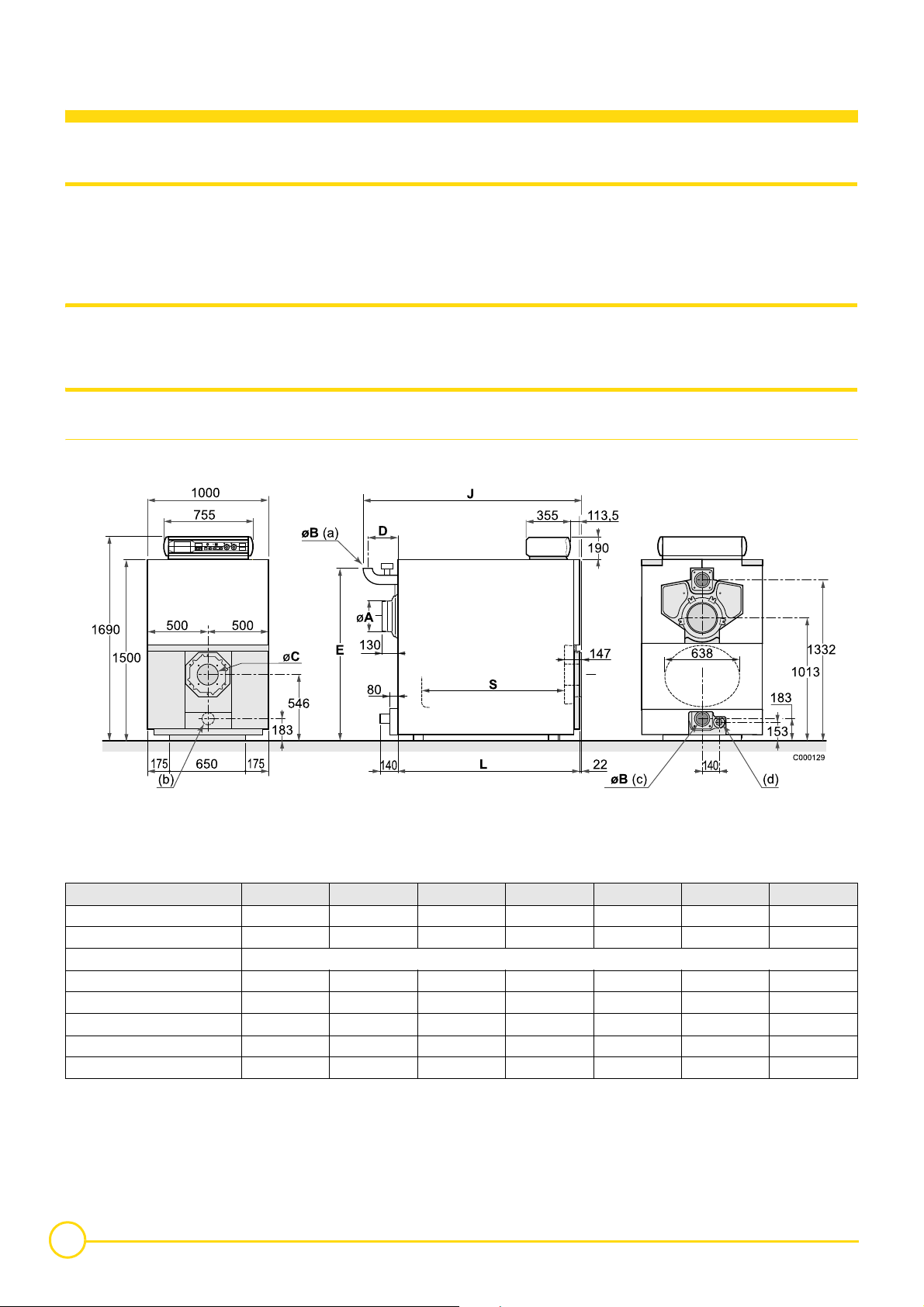

(a) Boiler flow - weld

(b) Sludge removal hole Ø Rp 2 1/2 - plugged

Boiler type P 420-8 P 420-9 P 420-10 P 420-11 P 420-12 P 420-13 P 420-14

ø A 250 250 250 300 300 300 300

ø B 2" 1/2 2" 1/2 2" 1/2 3" 3" 3" 3"

ø C plate intact or pre-drilled to the diameter specified on order

D 235 235 235 254 254 254 254

E 1427142714271447144714471447

J 1800195021202305246526252785

L 1505166518251985214523052465

S 1183134315031663182319832143

10

(c) Boiler return - weld

(d) Rp 2 draining outlet - plugged

P 420 20/09/2011 - 300016839-001-C

Loading...

Loading...