Remeha P320 Installation and Service Manual

Remeha

Fuel oil/gas boilers

P 320

EN

Installation and

Service Manual

300016243-001-D

63184

Declaration of conformity 1

The appliance complies with the standard model described in

declaration of compliance 1. It is manufactured and distributed

pursuant to the requirements of european directives. The original of

the declaration of compliance is available from the manufacturer.

C001879-B

2

P 320 20/09/2011 - 300016243-001-D

Contents

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.2 Main dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3 Installing the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 Boiler location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2 Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.1 Important recommendations on connecting the heating circuit to the boiler and the drinking water system . . . . . . . . . . . . . . . . . . 10

5.2 Important recommendations for connecting the boiler to the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.3 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.4 Sludge removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6 Chimney connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.1 Flue size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.2 Chimney connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7 Fuel-oil or gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

8 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

9 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9.1 Sweeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9.2 Cleaning the casing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

9.3 Precautions required in the case of long boiler stops (one or more years) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

9.4 Precautions required if the heating is stopped when there is a risk of freezing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

10 Burner maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

11 System maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

11.1 Water level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

11.2 Draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

13 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

20/09/2011 - 300016243-001-D P 320

3

1 General

This product will be marketed in the following European Union

member states:

NL - BE - ES - GB - HU - SE

with a gas or oil-burner of the associated category.

Directive 97/23/EC

Gas and oil boilers with a maximum operating temperature of 110°C

and hot water tanks with a maximum operating pressure of 10 bar

pertain to article 3.3 of the directive, and therefore, cannot be CEmarked to certify compliance with the directive 97/23 EC.

Symbols used

Caution danger

Specific information Information must be kept in mind to maintain comfort

Reference Refer to another manual or other pages in this instruction manual

Z

The boilers and hot water tanks are designed and manufactured in

accordance with the sound engineering practice, as requested in

article 3.3 of the directive 97/23/EC, it is certified by compliance with

the directives 90/396/EC, 92/42/EC, 2006/95/EC and 2004/108/EC.

Warning

The boiler shall be assembled and installed by a qualified

professional only.

For a proper operating of the boiler, follow carefully the instructions.

Risk of injury and damage to equipment. Attention must be paid to the

warnings on safety of persons and equipment

4

P 320 20/09/2011 - 300016243-001-D

2 Description

The boilers of the P 320 range are pressurised hot water boilers

designed for connecting to a flue pipe which require a separate

automatic fuel-oil or gas burner.

The useful power of P 320 boilers is between 55 and 280 kW.

Models available

Boiler with control panel, which may be fitted with an optional

Rematic 2945 C3K control unit for heating only or heating and

domestic hot water production.

20/09/2011 - 300016243-001-D P 320

5

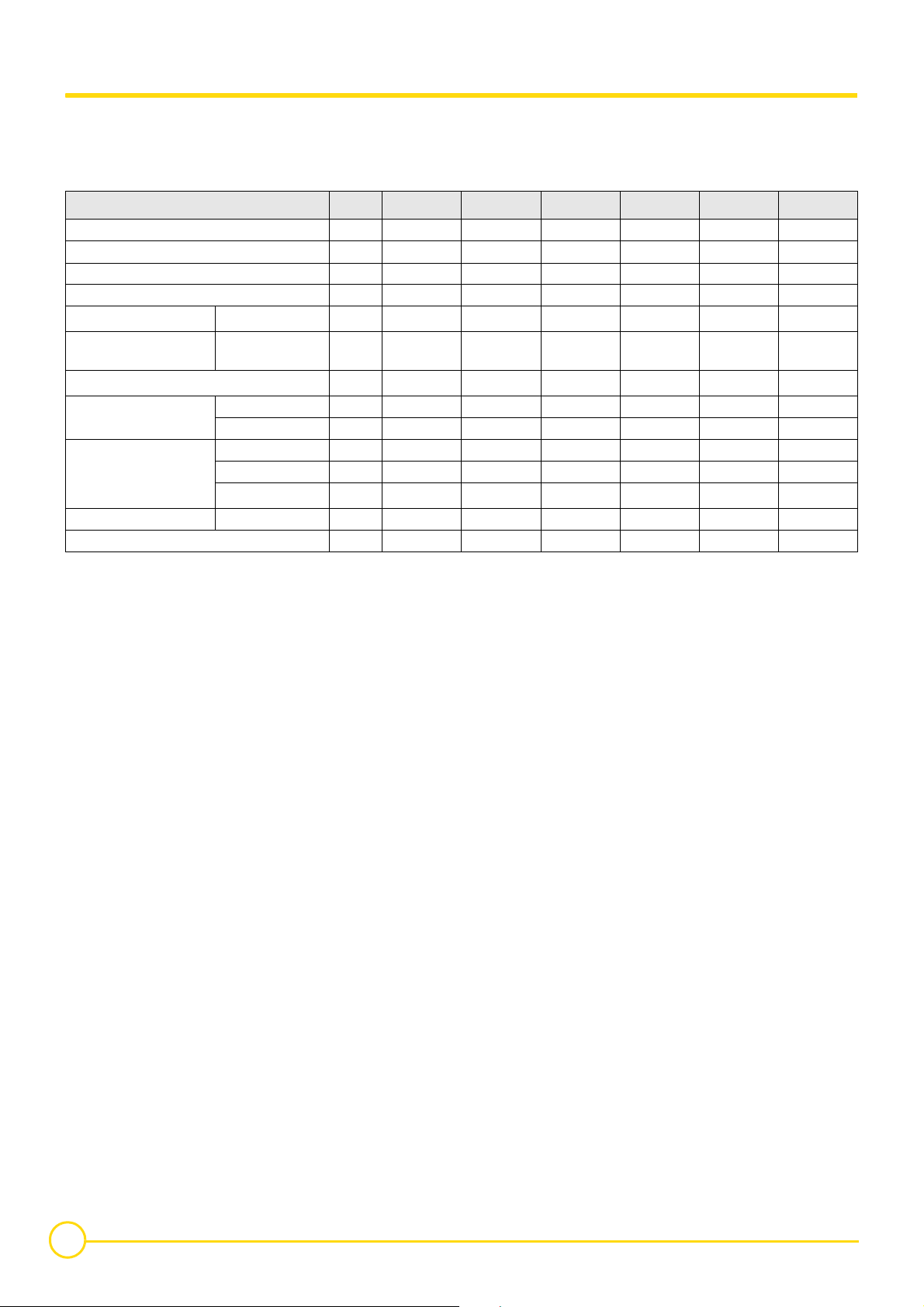

2.1 Technical specifications

Maximum operating pressure: 6 bar

Safety thermostat setting: 110 °C

Boiler thermostat setting: 30 to 90°C

Boiler P 320-4 P 320-5 P 320-6 P 320-7 P 320-8 P 320-9

Useful output kW 70-105 105-140 140-180 180-230 230-280 280-330

Power input kW 76-117 115-156 153-199 197-253 252-309 305-361

Number of sections 4 5 6 7 8 9

Water content l 96 116 136 156 176 196

Water resistance

Pressure in the furnace for

nozzle pressure = 0

Flue gas temperature

Mass flue gas flow rate

Combustion chamber

Maintenance consumption by 50°C % 0.17 0.14 0.13 0.11 0.10 0.09

Shipping weight kg 610 739 845 980 1101 1228

(1)

Nominal operation (top boiler power)

(2)

CO2 = 13.1 to 13% with fuel oil and 9.5% with natural gas.

(3)

Boiler temperature: 80 °C, Ambient temperature: 20 °C

1 mbar = 10 mmWG = 10 daPa

In order for the boiler to operate correctly, it is imperative

to respect the draught at the nozzle: 0 at the nozzle.

∆ T = 15K

(1) (3)

Fuel oil Kg/h 178 238 306 391 475 560

(1)

Gas Kg/h 187 250 321 410 499 588

Inscribed diameter mm 377 377 377 377 377 377

Depth mm 621 781 941 1101 1261 1369

Volume

(1)

mbar 6.2 10.9 20.4 30 44.5 63.8

mbar +0.3 +0.6 +1.1 +1.6 +2.2 +2.5

°C < 210 < 210 < 210 < 210 < 210 < 210

3

0.096 0.122 0.148 0.174 0.200 0.226

m

6

P 320 20/09/2011 - 300016243-001-D

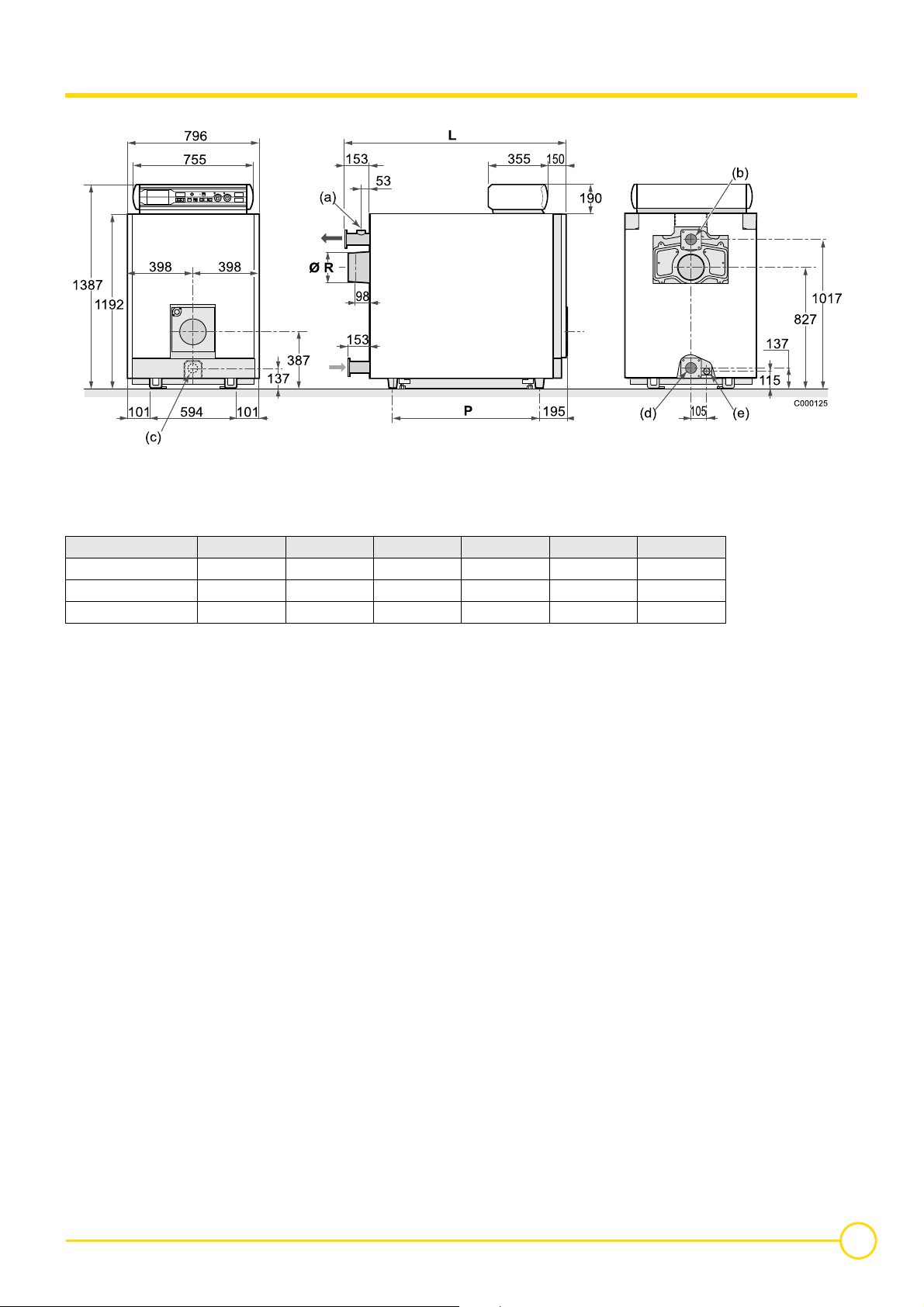

2.2 Main dimensions

(a) Rp 1 1/2 socket for the safety control unit

(b) 2 1/2 heating outlet (flange + counter flange)

(c) Sludge removal hole Ø Rp 2 1/2

P 320-4 P 320-5 P 320-6 P 320-7 P 320-8 P 320-9

L (mm) 991 1151 1311 1471 1631 1791

P (mm) 490 650 810 970 1130 1290

R (mm) 180 180 180 200 200 200

(d) 2 1/2 heating return (flange + counter flange)

(e) Rp 1 1/2 draining outlet (supplied with plug)

20/09/2011 - 300016243-001-D P 320

7

3 Installing the boiler

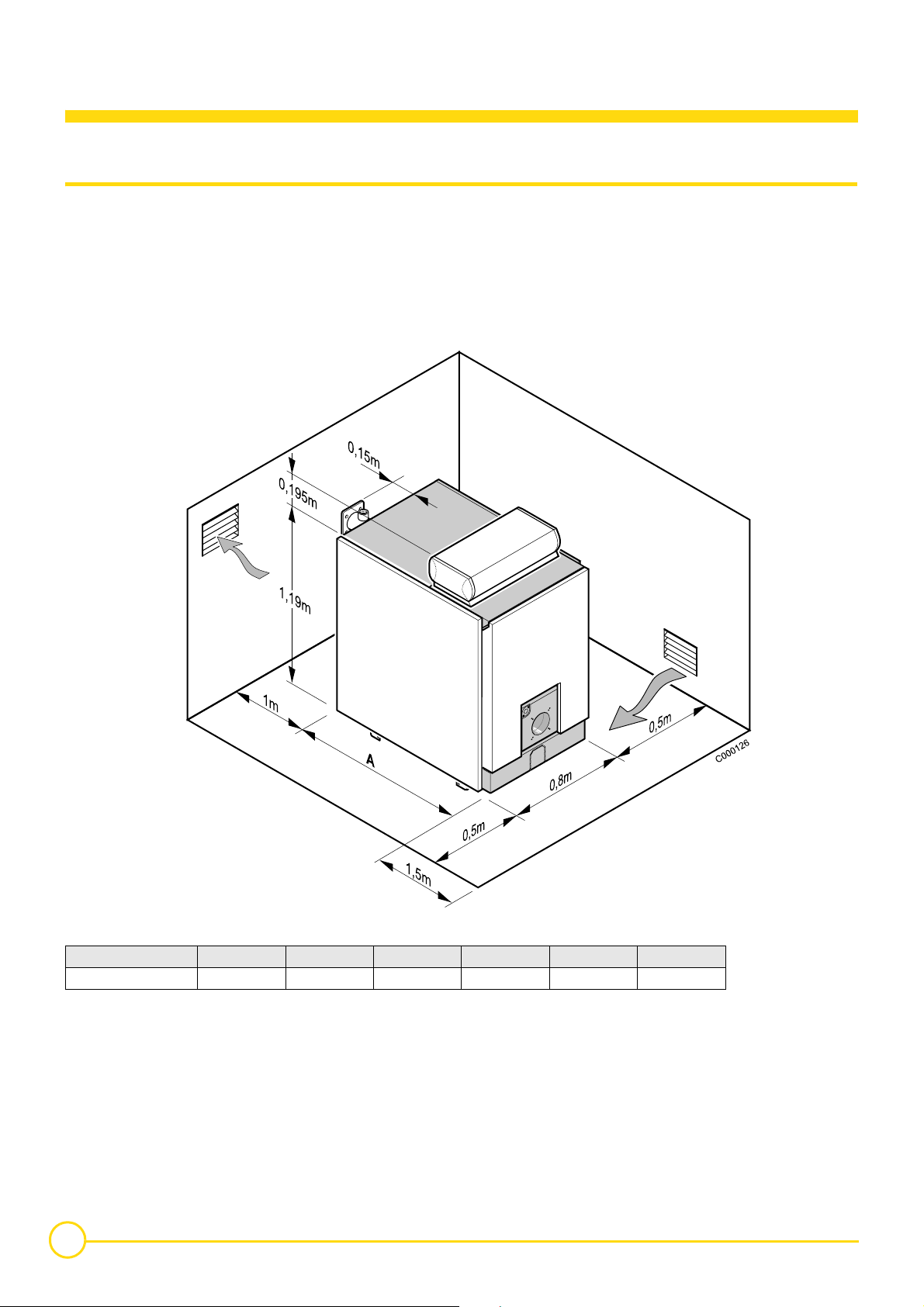

3.1 Boiler location

The P320 boiler does not require a special base for its assembly.

Their closed furnace system means that the floor need not have

refractory properties. All you have to ensure is that the floor can

support the weight of the boiler when it is fitted for operation. If the

boiler location is not determined precisely, leave enough space

around the boiler to facilitate monitoring and maintenance

operations.

Boiler P 320-4 P 320-5 P 320-6 P 320-7 P 320-8 P 320-9

A 838 998 1158 1318 1478 1638

Pay attention to the overall volume of the burner when the

door is open. To install several boilers in cascade, these

dimensions should be adapted accordingly.

8

P 320 20/09/2011 - 300016243-001-D

3.2 Ventilation

The location of air inlets in relation to the high ventilation openings

shall ensure that the air is renewed in the entire volume of the boiler

room.

It is in any case imperative to conform to the local regulations in force.

4 Mounting

Caution:

In order to avoid damage to the boiler, it is necessary to prevent the

contamination of combustion air by chlorine and/or fluoride

compounds, which are particularly corrosive.

These compounds are present, for example, in aerosol sprays,

paints, solvents, cleaning products, washing products, detergents,

glues, snow clearing salts, etc.

Therefore:

• Do not pull in air evacuated from premises using such products:

hairdressing salons, dry cleaners, industrial premises (solvents),

premises containing refrigeration systems (risk of refrigerant

leakage), etc.

• Do not stock such products close to the boilers.

If the boiler and/or peripheral equipment are corroded by such

chloride or fluoride compounds, the contractual guarantee

cannot be applied.

For mounting instructions, see installation instructions.

Z

20/09/2011 - 300016243-001-D P 320

9

Loading...

Loading...