Remeha Gas-110 Installation and Service Manual

Remeha Gas 110 Eco

Gas fired condensing boiler

Gas 110 Eco 115 / 65

EN

Remeh a

Installation, User and

Service Manual

300014883-001-K

Declaration of conformity 1

The appliance complies with the standard model described in

declaration of compliance 1. It is manufactured and distributed

pursuant to the requirements of european directives. The original of

the declaration of compliance is available from the manufacturer.

C002718-B

2

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

Contents

1 Used symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 Important recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2.2 Gas categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.3 Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.4 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4.1 Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4.2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.5 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

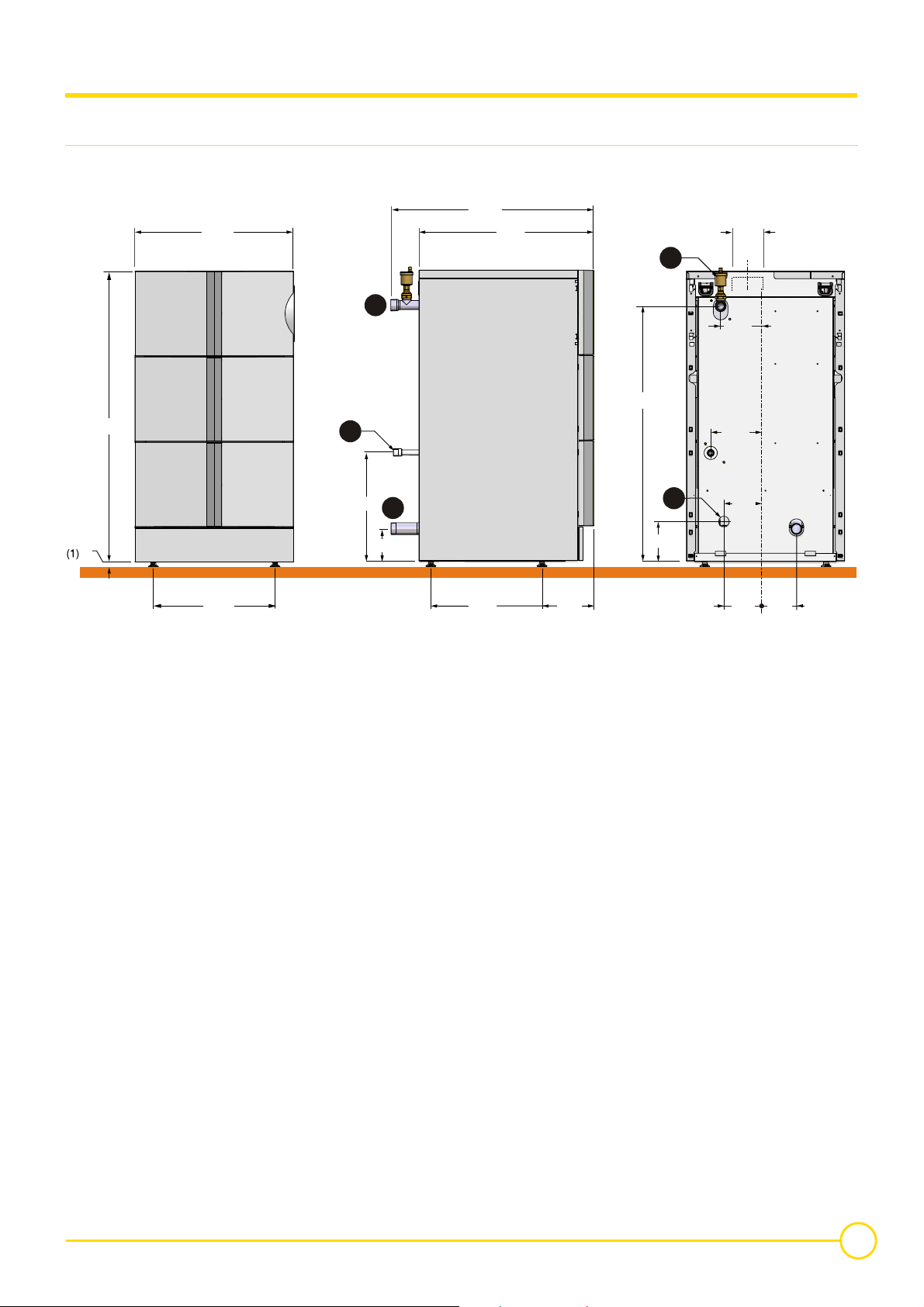

3.6 Main dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.6.1 Boiler self-standing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

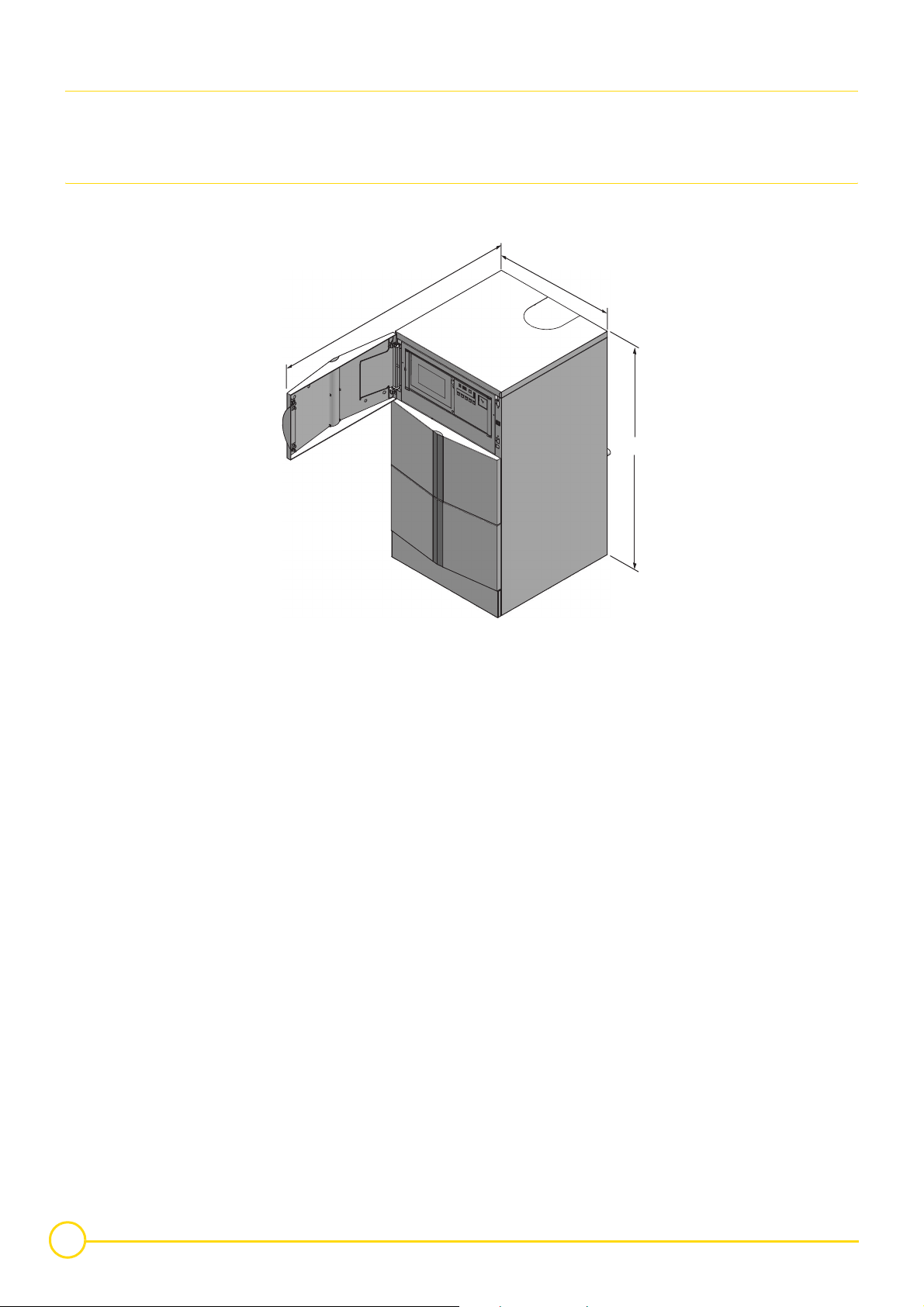

3.6.2 Boiler installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

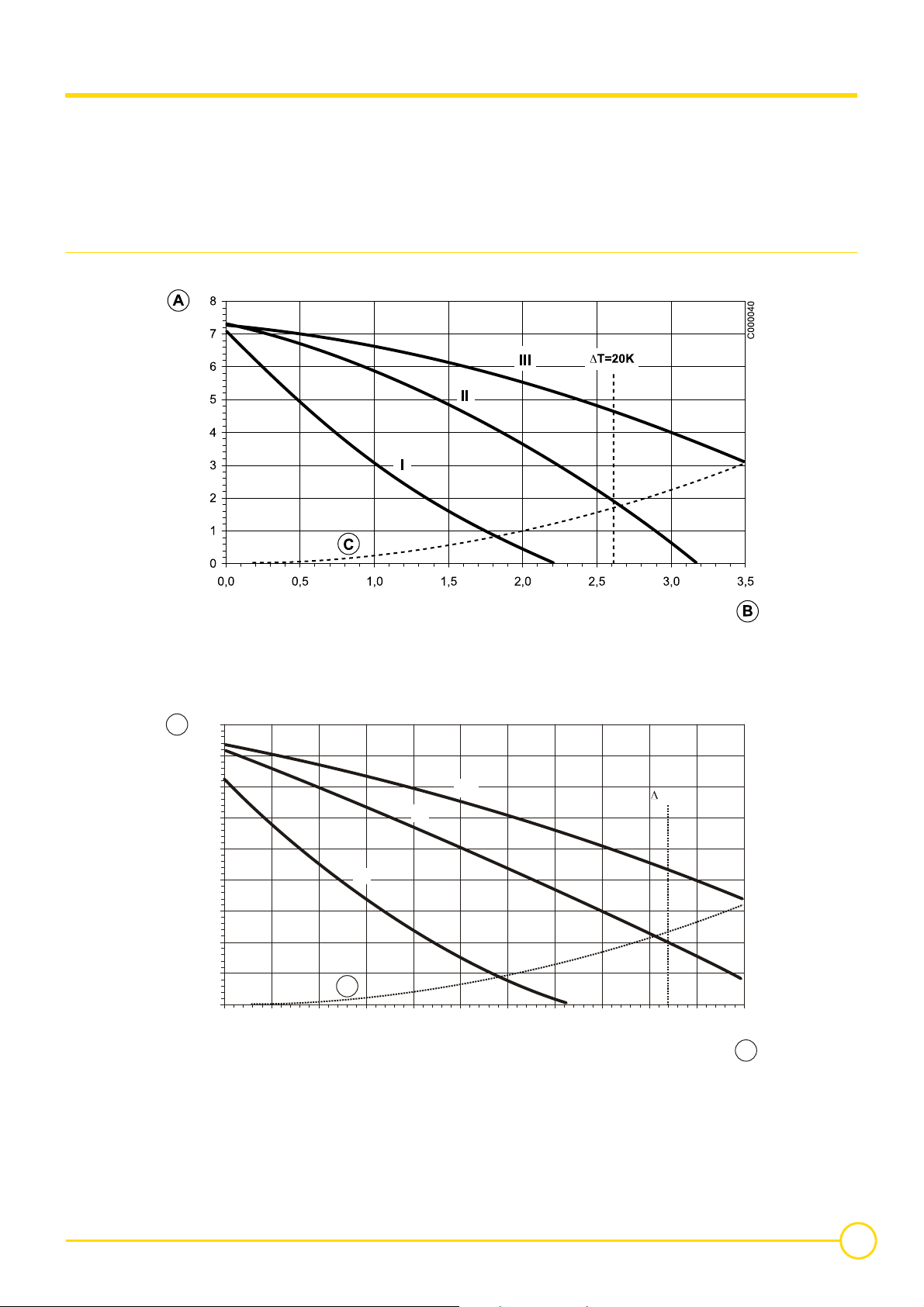

3.7 Hydraulic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4 Control and safety equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

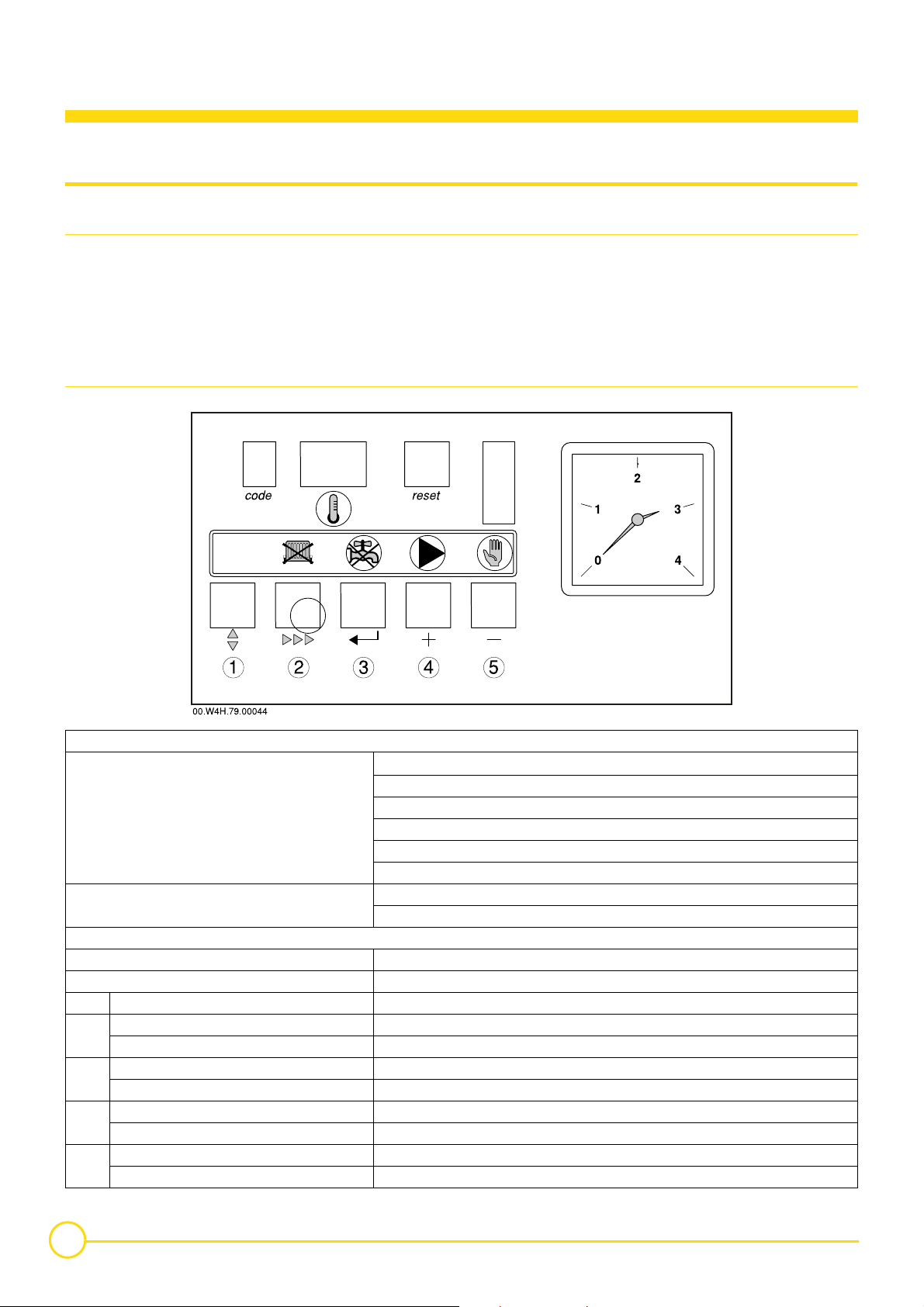

4.1.2 Layout of the control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.3 Combined key functions (in operating mode only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1.4 Display of values with more than two digits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2 Flow diagram control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3 Operating mode (N>>) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.4 Shut-off mode (B<<) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.5 Setting mode user level (<>>). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.5.1 Flow temperature set point (). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.5.2 Pump run on time HTG ()) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.5.3 DHW temperature set-point ( ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.5.4 Boiler control setting (*). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.6 Setting mode service level (<) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.6.1 Flow temperature set point during forced part load () . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.6.2 High limit thermostat () . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.6.3 Fan speed at full load HTG (?) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.6.4 Fan speed at part load (HTG and DHW - ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.6.5 Starting point modulation () . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.6.6 Interface selection () . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.6.7 DHW cut-in temperature (+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.6.8 Fan Speed at DHW full load (0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.6.9 Forced part load time after start (HTG only - /). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.6.10 DHW control stop set point (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.6.11 DHW control option (3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.6.12 HTG cut in temp (5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.6.13 Boiler type (7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.6.14 Maximum delay time (;) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.6.15 Start and end point analog signal ( and =

4.7 Read-out mode (<) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.8 Fan speed mode (') . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.9 Failure mode (N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.1 Statutory terms and conditions of installation and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

25/01/2011 - 300014883-001-K Gas 110 Eco 115 / 65

3

5.2 Important comments on the treatment of the heating circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.3 Water discharge connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.4 Room sealed installations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.5 Checking the gas inlet (Boiler only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.6 Reversal of the direction the control panel access door opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.7 Levelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

5.8 Handling the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6 Connecting the flue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.1 Flue pipe connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.1.1 Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.1.2 Lengths of the air/flue gas pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.2 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

7 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.1 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.2 Check points before commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.2.1 Checking the gas supply pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.3 Putting the appliance into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7.3.1 Gas 110 Eco 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

7.3.2 Gas 110 Eco 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

7.4 Programming boiler control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

7.5 Instruct the user of the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

7.6 Shut-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

8 Fault finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

8.1 General (all installations) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

8.2 Fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

9 Adapting to another gas type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

9.1 Switching from Natural Gas to Propane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

9.2 Gas type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

10 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

10.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

10.2 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

10.2.1 Checking the combustion in the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

10.2.2 Setting the ignition electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

10.2.3 Checking the hydraulic pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

10.2.4 Checking the ionization current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

10.3 Cleaning and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

10.4 Maintenance of the air/flue gas drain connection flues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

10.5 Temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

11 Schematic diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

12 Spare parts - Gas 110 Eco 115 / 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

1 Used symbols

Caution danger

Risk of injury and damage to equipment. Attention must be

paid to the warnings on safety of persons and equipment

Important information

Information must be kept in mind to maintain comfort

Reference

Z

Refer to another manual or other pages in this instruction

manual

DHW: Domestic hot water

Hi: Lower heating value LHV (Nett)

Hs: Higher heating value HHV (Gross)

2 Important recommendations

For a proper operating of the boiler, follow carefully the

instructions.

Any intervention on the appliance and heating equipment

must be carried out by a qualified engineer.

The manufacturer is not liable for any improper use of the

appliance or failure to maintain or install the unit correctly

(the user shall take care to ensure that the system is

installed by a qualified engineer).

Work on electrical equipment must be carried out by a

qualified professional in compliance with the prevailing

regulations.

Check that the appliance is properly set for the type of gas

used.

Keep to the polarity shown on the terminals: phase (L),

neutral (N) and earth

Check the seal on the gas and water pipe connections.

We shall not accept any responsibility for any damage and

disturbance arising from not following these instructions.

4

.

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions with the relevant certification ie: ACS, IEE regulations,

etc.

The first start-up is to be performed by your installation/

commissioning engineer.

Only original spare parts must be used.

Any work on the boiler unit is authorised only if carried out by a

qualified engineer.

Before commissioning, the factory settings of the appliance must be

compared with the local energy supply conditions. If the settings have

to be modified, this must be carried out by a qualified professional.

Condensing boilers require a flue gas discharge system or a fresh air

inlet specially adapted to the method of operation. Its execution

depends on the place of installation and the building.

Compliance with a minimum distance between the flue gas

evacuation system in forced flue mode or the boiler with combustible

substances must comply with current regulations. At nominal output,

the temperature of the components does not exceed 85 °C.

Work on electrical equipment must be carried out by a

qualified professional in compliance with the prevailing

regulations.

Installation and maintenance of the boiler must be carried out by a

qualified professional in compliance with prevailing local and national

regulations.

25/01/2011 - 300014883-001-K Gas 110 Eco 115 / 65

5

3 Description

3.1 General

Gas 100 Eco 115 / 65 boilers are floor standing gas-fired condensing

boilers fitted with an "Open Therm" control interface which enable

direct weather compensation using Remeha single and multi boilers

controls or the customer can choose to use external control options

supplied by others without affecting boiler performance.

They are designed for closed circuit hot water boiler rooms with a

maximum operating temperature of 90°C. However, open vented

systems can be accommodated.

3.2 Homologations

3.2.1 General instructions

Boiler Gas 110 Eco 65 / Gas 110 Eco 115

No. CE CE-0063BS3826

Type

Flue gas discharge Chimney / Flue gas outlet

Ignition Automatic

Gas Natural gas / Propane

3.2.2 Gas categories

See chapter 5.2 "Important comments on the treatment of the

Z

heating circuit".

Installation is recommended on low temperature heating installations

(Underfloor heating, radiators, ...).

B

- C

- C33 - C43 - C53 - C63 - C

23

13

83

- C

93

Gas 110 Eco 65

Gas 110 Eco 115

Gas 110 Eco 65

Gas 110 Eco 115

Category Type of gas used

II

2H3P

Category Type of gas used

II

2H3P

Natural gas 40 mbar

Propane 60 mbar

Natural gas 17 mbar 25 mbar

Propane 25 mbar 57.5 mbar

Supply pressure (Gas pressure when the boiler

is not operating)

Maximum allowed on the gas valve

Working pressure

Minimum Maximum

6

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

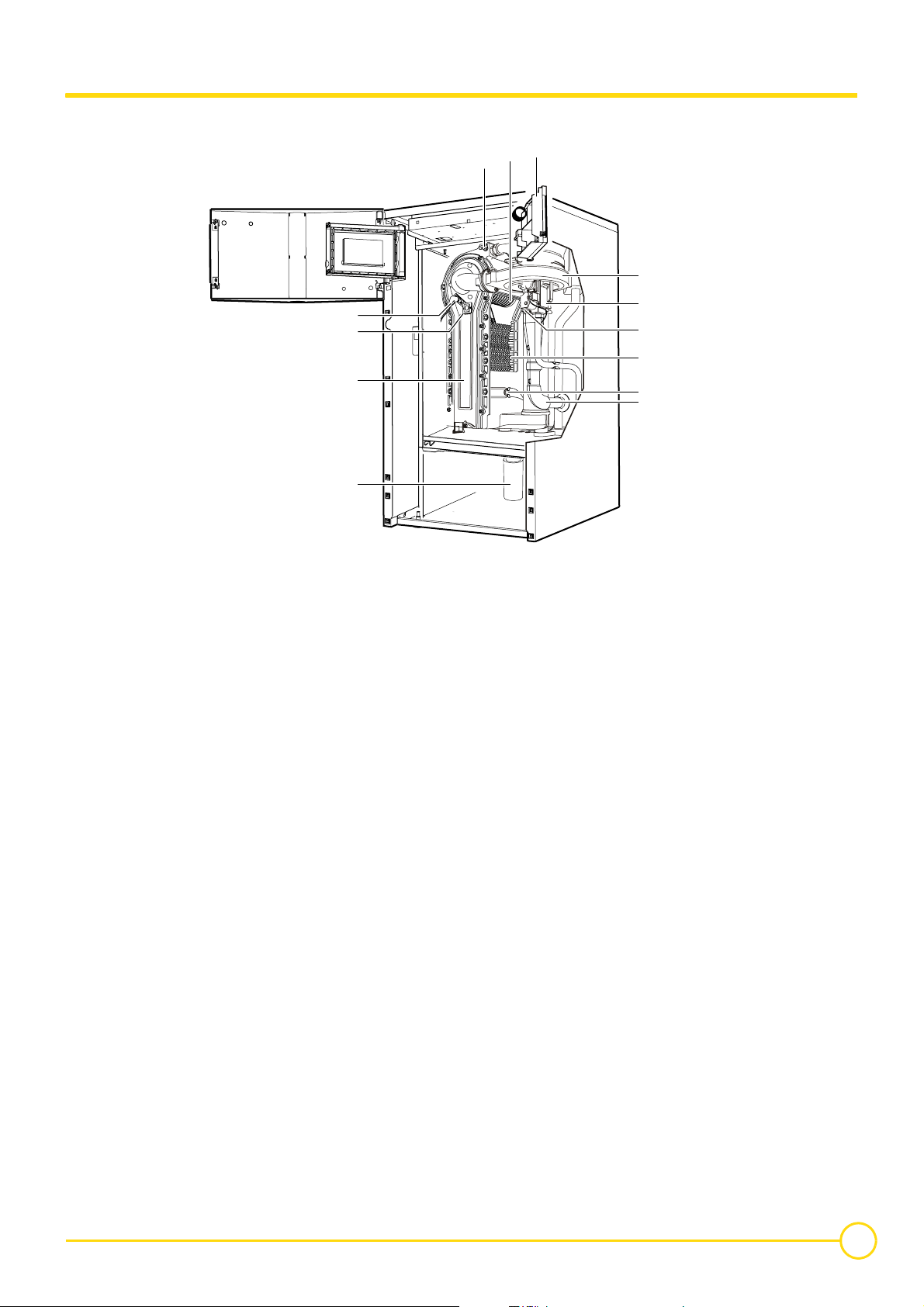

3.3 Main parts

• Gas 110 Eco 65

7

8

9

6

1 Fan air inlet

2 Return sensor

3 Heating body

4 Heat exchanger

5 Combined venturi and gas valve unit

6 Fan

7 Control panel

8 Burner

9 Flow temperature sensor

10 Ignition electrode + Ionization electrode

11 Sight glass

12 Front plate exchanger

13 Siphon

10

11

12

13

5

4

3

2

1

C001484

25/01/2011 - 300014883-001-K Gas 110 Eco 115 / 65

7

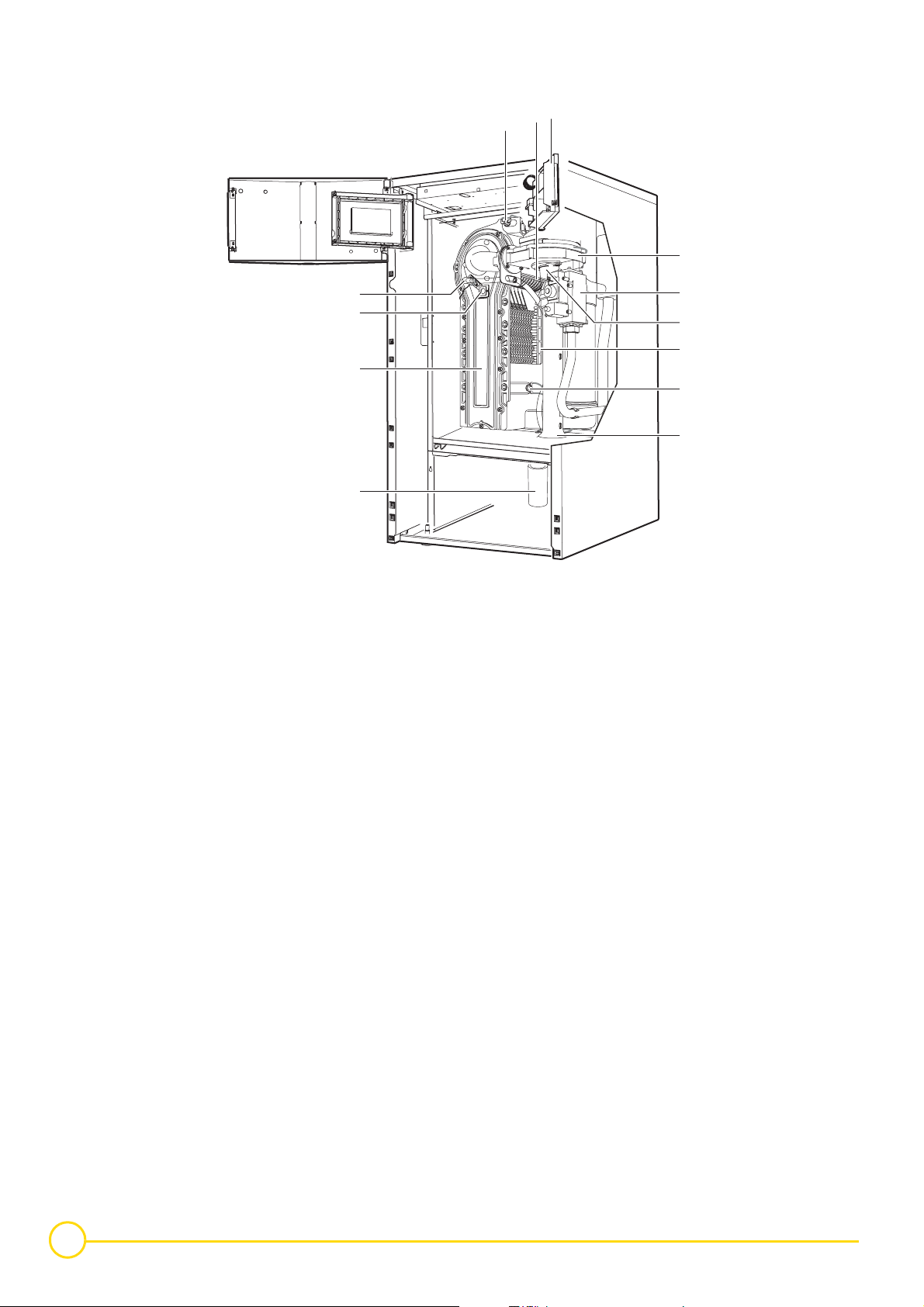

• Gas 110 Eco 115

7

8

9

6

1 Fan air inlet

2 Return sensor

3 Heating body

4 Heat exchanger

5 Combined venturi and gas valve unit

6 Fan

7 Control panel

8 Burner

9 Flow temperature sensor

10 Ignition electrode + Ionization electrode

11 Sight glass

12 Front plate exchanger

13 Siphon

10

11

12

13

5

4

3

2

1

C001485

8

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

3.4 Technical characteristics

3.4.1 Boiler

- For operation on Natural Gas or Propane (See "Switching from

Natural Gas to Propane")

- The boiler is preset in the factory to operate on natural gas G20,

20 mbar (minimum 17 mbar)

- The boiler is suitable for room sealed or open flue applications

- Single-unit heat exchanger in aluminium/silicium alloy

- Cylindrical premix burner covered in metal fibres

3.4.2 Control panel

Please read the following installation and commissioning

instructions carefully before operating your equipment. The

manufacturer shall not be liable for damage caused by the

failure to comply with these instructions and the warranty shall

no longer apply.

If work is carried out on the heating installation: assembly,

commissioning, maintenance and repair work on the

appliance and on the heating installation must be carried

out only by a qualified heating professional.

Before installation: Ensure that the mains power supply is

isolated.

Before commissioning: Check the seal on the gas and

water pipe connections.

- Centrifugal fan with combustive air intake silencer for a low noise

level

- Compact gas line with zero pressure regulator, two valves and filter

- Water condensation siphon with run-off pipe

- Automatic air vent

- Mechanical manometer

- Soundproofed boiler body

- A documentation pack.

The connection of the control panel must be carried out by

a qualified professional. For a proper operating of the

boiler, follow carefully the instructions.

- Power supply: 230 V (±10%) - 50 Hz

25/01/2011 - 300014883-001-K Gas 110 Eco 115 / 65

9

3.5 Technical data

Gas 110 Eco 65 115

CE identification no **** CE-0063BS3826

Boiler specifications

Power input (Hi) - minimum/maximum G20 kW 12.2 - 62.0 17.2 - 110.2

Power input (Hs) - minimum/maximum G20 kW 13.5 - 68.8 19.1 - 122.3

Nominal output 50/30 °C - minimum/maximum G20 kW 13.3 - 65.0 18.4 - 114.0

Nominal output 80/60 °C - minimum/maximum G20 kW 12.0 - 61.0 16.6 - 107.0

Gas flow rate at nominal output (15 °C - 1013 mbar)

Natural gas G20

Propane

Efficiency 75/60 °C (DIN 4702 T8) (Hi) % 106 106

Efficiency 75/60 °C (DIN 4702 T8) (Hs) % 95.5 95.5

Efficiency 40/30 °C (DIN 4702 T8) (Hi) % 111 102.5

Efficiency 40/30 °C (DIN 4702 T8) (Hs) % 100 92.4

Load and water temperature efficiency

(-100% Pn-Average temperature 70 °C) (Hi)

Load and water temperature efficiency

(-100% Pn-Average temperature 70 °C) (Hs)

Load and water temperature efficiency

(-30% Pn-Return temperature 30 °C) (Hi)

Load and water temperature efficiency

(-30% Pn-Return temperature 30 °C) (Hs)

Stand-by losses ∆T = 30K W 125 131

Mass flue gas flow rate - minimum/maximum Kg/h 20.5/104 28.9/186

level in flue gases

CO

2

- Natural gas G20

- Propane

Available pressure at boiler outlet Pa 100 250

Average flue gas temperature (75/60 °C) °C 65 67.9

Connection to a chimney (internal diameter) mm 100/150 100/150

Emission NOx (Natural gas G20) - dry 0% O

2

Emission CO (Natural gas G20) - DIN 4702 Teil 8 mg/kWh 21 31 (EN297A3)

NOx classification 55

Maximum operating temperature °C 90 90

Maximum operating pressure bar 4 4

Water resistance (∆T = 20K) mbar 175 230

Water resistance (∆T = 11K) mbar 580 830

Nominal water flow Pn to ∆T = 20K

Nominal water flow Pn to ∆T = 11K

Water content

Flow and return connection (diameter) 1" 1/4 Male 1" 1/4 Male

Condensation water pH 3-5 3-5

Condensation water run-off (diameter) mm 25 25

Electrical specifications

Electrical connection V/Hz 230/50 230/50

Power consumption W 88 213

Degree of protection DIN40050 IP 21 IP 21

Dimensions

Height mm 1100 1322

Width mm 600 600

Depth mm 663 663

Shipping weight kg 116 133

3

m

Kg/h

/h

6.56

4.82

11.66

8.56

%98.3 97.1

%88.6 87.5

% 108.9 107.1

%98.1 96.5

%

%

9.0

10.7

9.5

10.0

mg/kWh 32 35

3

m

/h

3

/h

m

l

2.62 4.6

4.76 8.36

6.5 7.5

10

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

3.6 Main dimensions

3.6.1 Boiler self-standing

• Gas 110 Eco 115 / 65

600

A

770

663

ØF

8

1

170

D

9

208

21

C001272

460

1 Heating outlet R 1 1/4 m

6 Heating return R 1 1/4 m

7 Condensates discharge (Ø 25 mm external)

8 Automatic air vent

9 Gas inlet R 3/4

Gas 110 Eco 65: 1100 mm

A

Gas 110 Eco 115: 1322 mm

Gas 110 Eco 65: 410 mm

B

Gas 110 Eco 115: 632 mm

Gas 110 Eco 65: 124 mm

C

Gas 110 Eco 115: 346 mm

Gas 110 Eco 65: 968 mm

D

Gas 110 Eco 115: 1190 mm

Gas 110 Eco 65: 152 mm

E

Gas 110 Eco 115: 374 mm

ØF Forced flue connection Ø 100/150 mm

B

6

C

7

E

198420

173

158

118

R = Thread

G = Exterior cylindrical threading, sealed by sheet gasket

(1) Basic dimension 21 mm

adjustment possible: 21 to 40 mm

25/01/2011 - 300014883-001-K Gas 110 Eco 115 / 65

11

3.6.2 Boiler installed

Clear space should be left around the boiler:

- 70 cm in front of the boiler

- 40 cm above the boiler

• Gas 110 Eco 115 / 65

- 2.5 cm each side of the boiler

(Facilitates removal of the casing)

600

1263

A

C001486

A. Gas 110 Eco 65 = 1100

Gas 110 Eco 115 = 1322

12

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

3.7 Hydraulic specifications

Depending on the flow, the following diagrams represent:

- the manometric heights of the heating

- loss of load in the boiler.

For a fixed flow, the manometric height available at the boiler outlet

is obtained by taking the difference between the manometric height

of the circulator pump and the loss of load in the boiler.

Optional 3-speed circulator pump for Gas 110 Eco 65 - UPS 25-70 130

For example: Gas 110 Eco 65 with UPS 25-70 130 pump:

manometric height available at 2.61 m

3

/h = 4.6 mWG - 1.6 mWG = 3

mWG (i.e. 3 mbar)

3

2.61 m

/h corresponds to a load of 61 kW and a ∆t of 20 K

A. Rated net head (mWG)

B. Flow rate (m

3

/h)

C. Loss of load Gas 110 Eco 65

Optional 3-speed circulator pump for Gas 110 Eco 115 - UPS 25-80 130

9

A

8

7

6

5

4

3

2

1

I

III

II

C

0

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0 4,5 5,0 5,5

A. Rated net head (mWG)

3

B. Flow rate (m

/h)

C. Loss of load Gas 110 Eco 115

C001242

T=20K

B

25/01/2011 - 300014883-001-K Gas 110 Eco 115 / 65

13

4 Control and safety equipment

4.1 Control panel

4.1.1 General

The boiler is supplied with a standard set of defaults pre-programmed

for normal operation but can be tailored by the Engineer to suit most

site conditions. These values are set and read using the built in

control panel or with a notebook computer (with an interface and

software available on request).

4.1.2 Layout of the control panel

For security the control has three levels of access:

- User level - free access

- Service level - access with service code by qualified personnel

- Factory level - access by PC with factory code (Remeha only).

"code"-display

Indicates on user level:

Additional indication on service level: Fan speed mode: alternate half digit '

x-display

Indicates: Temperatures, settings, fault codes (flashing digits), shut-off codes (flashing dots)

reset-key: To reset after a lockout condition

Key "r": Program function: key to select the required mode

Key "w": Program function: key to select the required program within the selected mode

Key w + Symbol v: Switch function: burner switch HTG (manual override)

Key "l": Program function: key to save the settings

Key "l" + Symbol q Switch function: burner switch DHW (manual override)

Key [+]: Program function: to select a higher setting

Key [+] + Symbol u Switch function: pump manual override

Key [-]: Program function: to select a lower setting

Key [-] + Symbol n: Switch function: manual override (hand/auto)

Operating mode: only one digit

Setting mode: digit with dot

Read-out mode: digit with flashing dot

Shut-off mode: letter B

Forced full load: letter G

Forced part load: letter H

Failure mode: flashing digit

14

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

4.1.3 Combined key functions (in operating mode only)

When the boiler is in the operating mode, keys with the illuminated

symbols above have a double function (Program and Switch).

To use them for a Program function press the key once - and for a

Switch function (either on or off) press the key and hold for

5 seconds.

The status of the switch function will be confirmed by the illuminated

symbol as follows:

• Key

"w" and symbol v:

- (symbol) not illuminated: HTG under normal control

- red (symbol) on: HTG off (manual override)

• Key

"l" and symbol q:

- (symbol) not illuminated: DHW under normal control

- red (symbol) on: DHW off (manual override)

• Key

[+] and symbol u:

- green (symbol) on: continuous pump operation

- (symbol) not illuminated: pump under boiler control

• Key

[-] and symbol n:

- green (symbol) on: HTG on (manual override)

4.1.4 Display of values with more than two digits

- (symbol) not illuminated: HTG under normal control.

Manual override will stay active until deactivated, even if power is

switched off and then restored.

NOTE: In the Switch function, (in order to protect the boiler and the

installation) the flow temperature cannot exceed it’s pre-set

maximum. It is also not possible to change any parameters.

• Forced mode "high" (G>>)

By pressing the keys

"r" and [+] simultaneously in operating mode,

the boiler will burn at maximum power. The letter G will now appear

on the display.

By pressing the keys

[+] and [-] simultaneously, the boiler will return

to operating mode. Following a manual override the boiler will return

to normal (auto control) if no keys are used within a 15 minute period.

• Forced mode "low" (H>>)

By pressing the keys

"r" and [-] simultaneously in operating mode,

the boiler will burn at minimum power. The letter H will now appear

on the display. By pressing the keys

[+] and [-] simultaneously, the

boiler will return to operating mode. Following a manual override the

boiler will return to normal (auto control) if no keys are used within a

15 minute period.

The display has only two digits available therefore values over this

are displayed as follows:

- negative values will be indicated by a dot behind the last digit e.g.

= -10

- values from 00 to 99 will be indicated without any punctuation

marks

- values from 100 to 199 will be indicated by a dot between both

digits e.g. = 100, = 110, & = 199.

- values from 200 to 299 will be indicated by a dot behind every digit

e.g. = for 200, = 210, = 299.

25/01/2011 - 300014883-001-K Gas 110 Eco 115 / 65

15

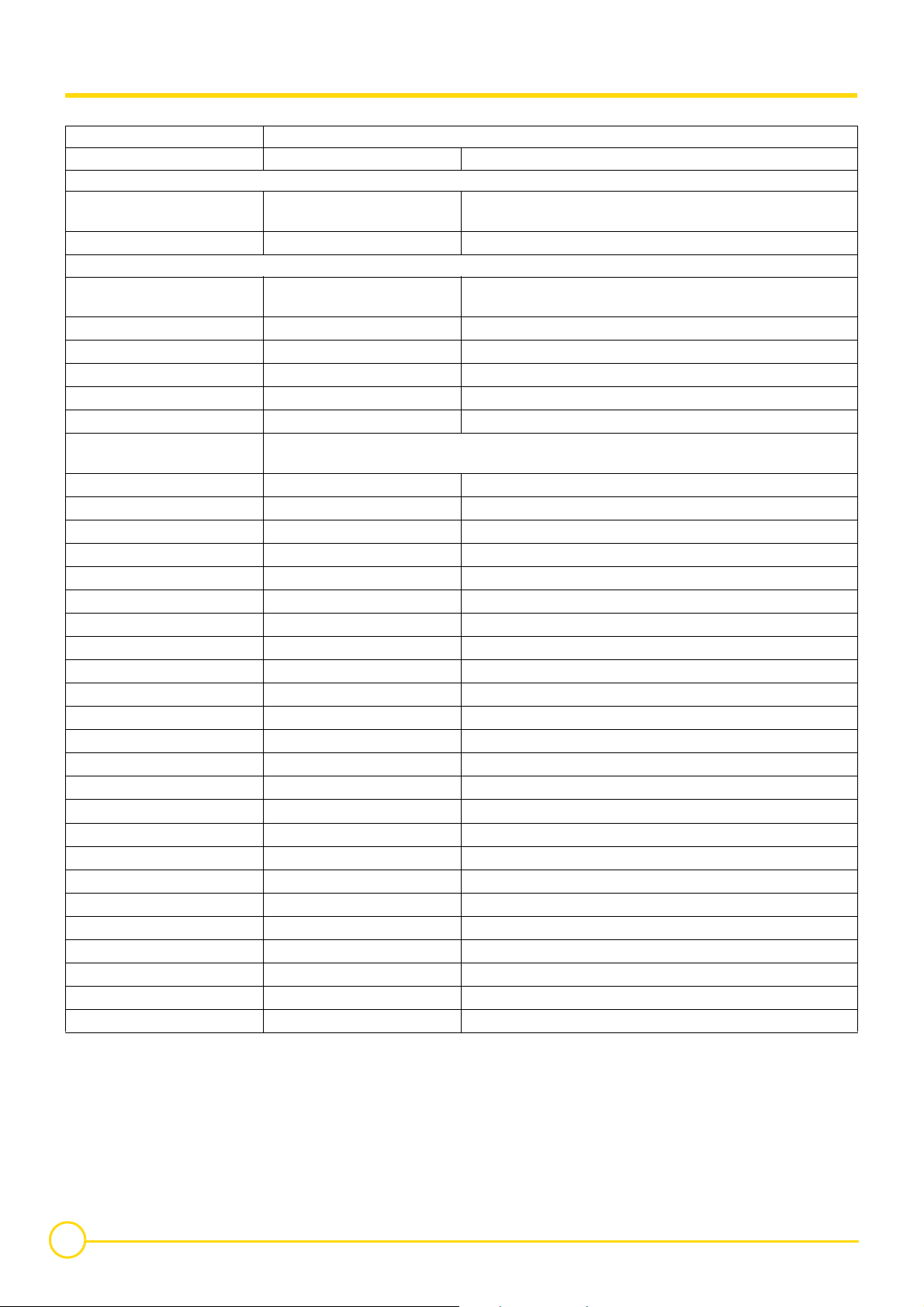

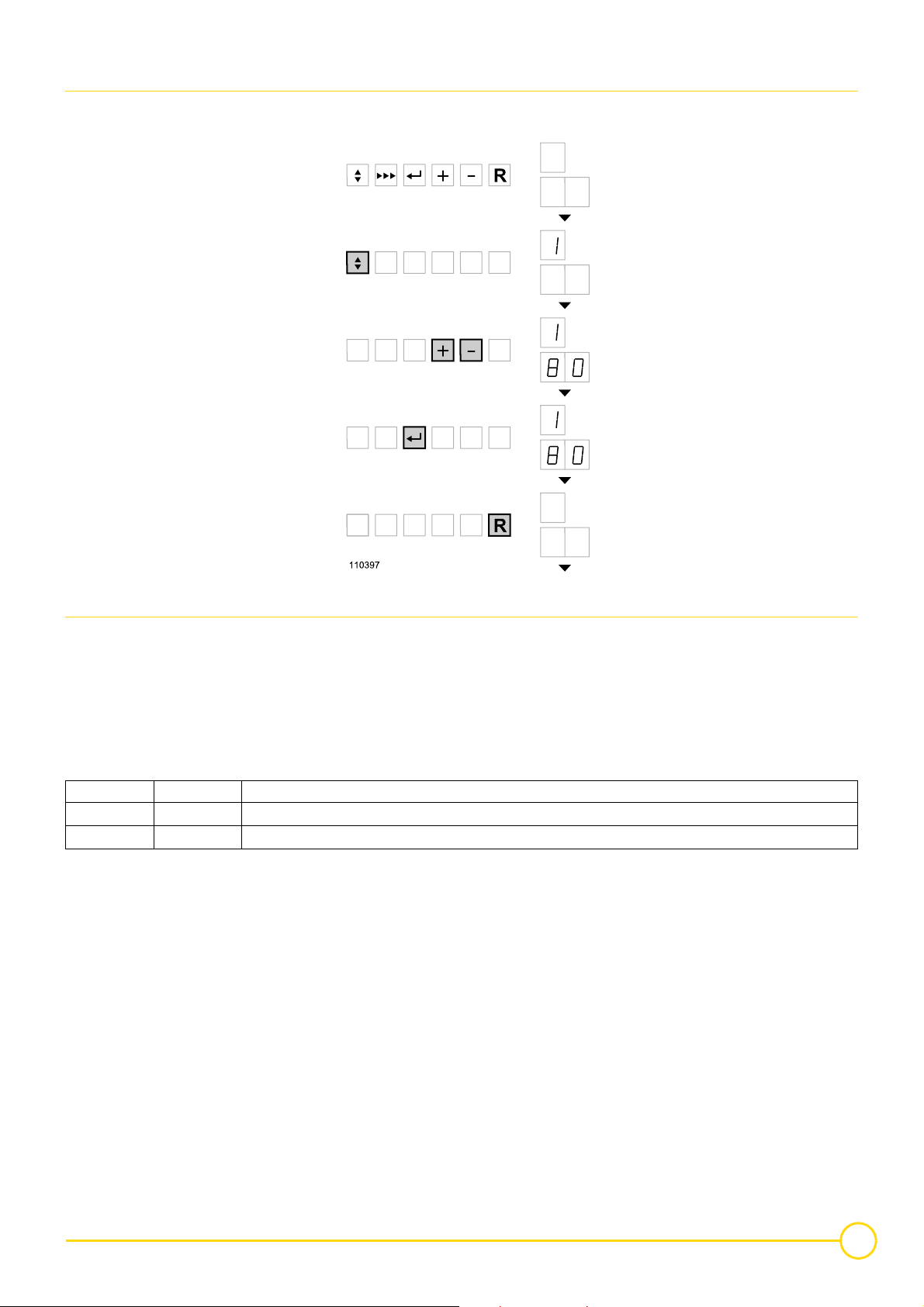

4.2 Flow diagram control system

Press the "r"-key for the menu Press the "w"-key for the menu

"code"-display x-display

Operating mode

§ 4.3

Z

Setting mode, user level

§ 4.5

Z

Setting mode, service level

§ 4.6

Z

Only digit or letter

- &,G,H,B

Digit or letter with fixed dot

)

*

M

Flow temperature or shut-off code

Flow temperature set-point

Pump run on time HTG

DHW temperature set-point

Boiler control setting

Base point internal compensation slope

Service engineer level only:

?

+

0

.

/

1

Flow temperature set-point during forced part load

High limit temperature set-point

Fan speed at full load (HTG)

Fan speed at part load (HTG and DHW)

Modulation start point ∆T (F/R)

Interface selection (control option)

DHW cut-in ∆T

Fan speed at full load (DHW)

Intern

N/a

N/a

Forced part load time after start (HTG)

Fan speed at start

2 DHW control stop or boiler modulation set point (based on parameter )

3

4

5

6

7

;

8

=

@

DHW control mode

N/a

HTG cut-in ∆T (based on return)

N/a

Boiler type

Intern

Maximum delay time

Start point for 0 V analog signal

End point for 10 V analog signal

Intern

16

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

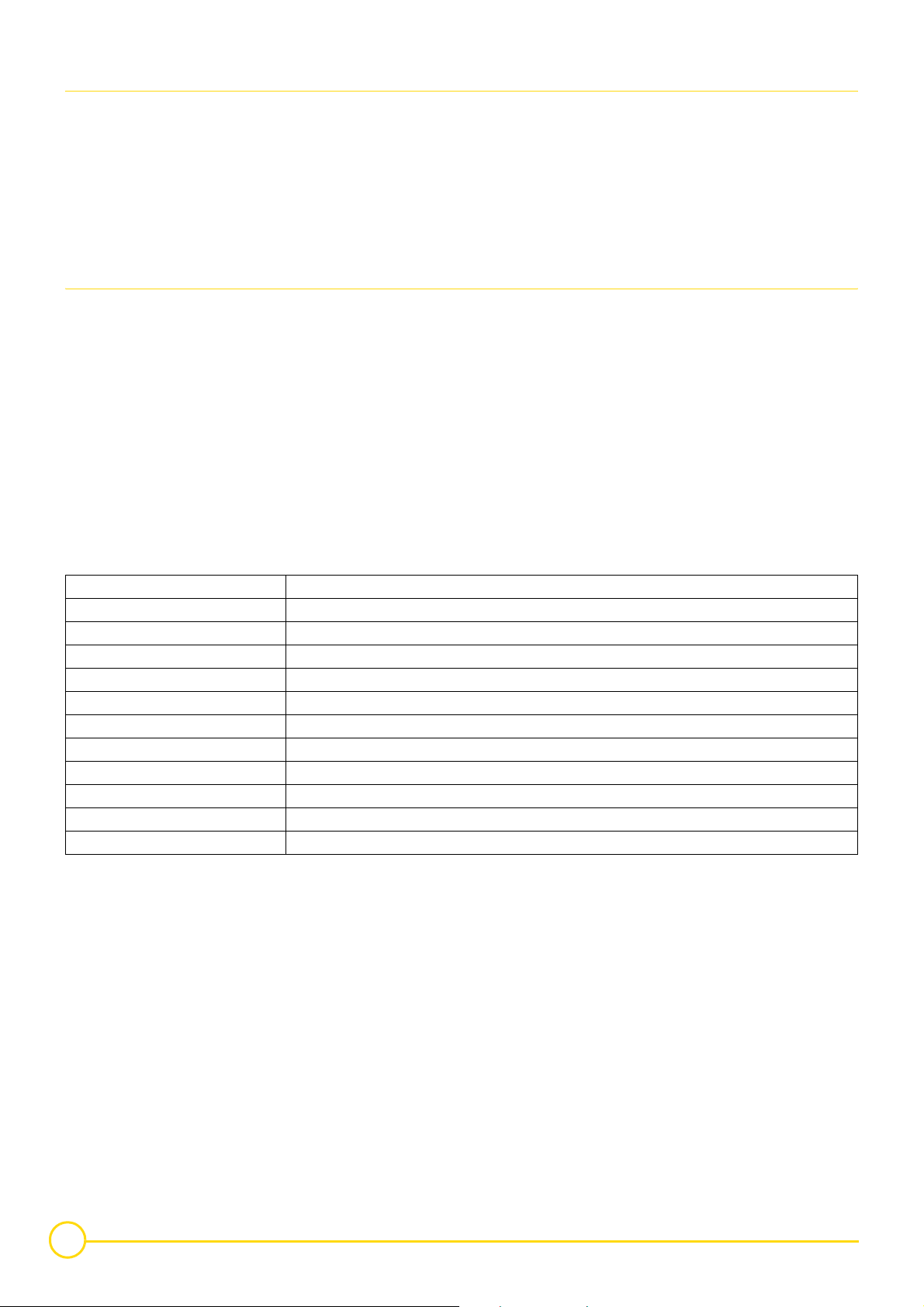

Read-out mode

§ 4.7

Z

Service engineer level only:

Speed mode

§ 4.8

Z

Digit or letter with flashing dot

)

?

8

*

Alternate half digit ' Fan speed

Actual flow temperature

Actual return temperature

Actual DHW temperature (with sensor)

Actual outdoor temperature (only if outdoor sensor fitted)

N/a

Flow temperature (set point)

Actual heat demand status

Calculated HTG cut-in temperature

Actual flow temperature rise

N/a

Failure mode

§ 4.9

Z

Flashing digit

!

"

#

Failure code

Operating code during failure

Flow temperature during failure

Return temperature during failure

DHW temperature during failure

N/a

4.3 Operating mode (N>>)

During operation the "code"-display shows the status (position in

cycle) of the boiler, whilst the

temperature.

Code Description

Standby: there is no heat demand from control system

Ignition: ignition is activated for 2.4 seconds while the gas valve is opened

HTG mode: the boiler operates in the HTG mode

! DHW mode: the three way valve or DHW pump activated

" Internal check

# Normal control stop during HTG (flow temperature > set-point + 5 °C)

$ HTG pump run on

% DHW pump run on or for three way valve option, HTG pump run on with valve open to DHW (max. 5 minutes)

& Normal control stop during DHW (flow temperature > set point DHW + DHW control stop set point + 5 °C)

B Shut-off mode

G Forced full load

H Forced part load

Pre-purge: before start-up, the boiler is purged for 4.2 seconds

Post-purge: when the heat demand has been met, the fan continues to operate for another 10 seconds

x-display indicates the actual flow

The digits or letters in the code-display have the following meaning:

25/01/2011 - 300014883-001-K Gas 110 Eco 115 / 65

17

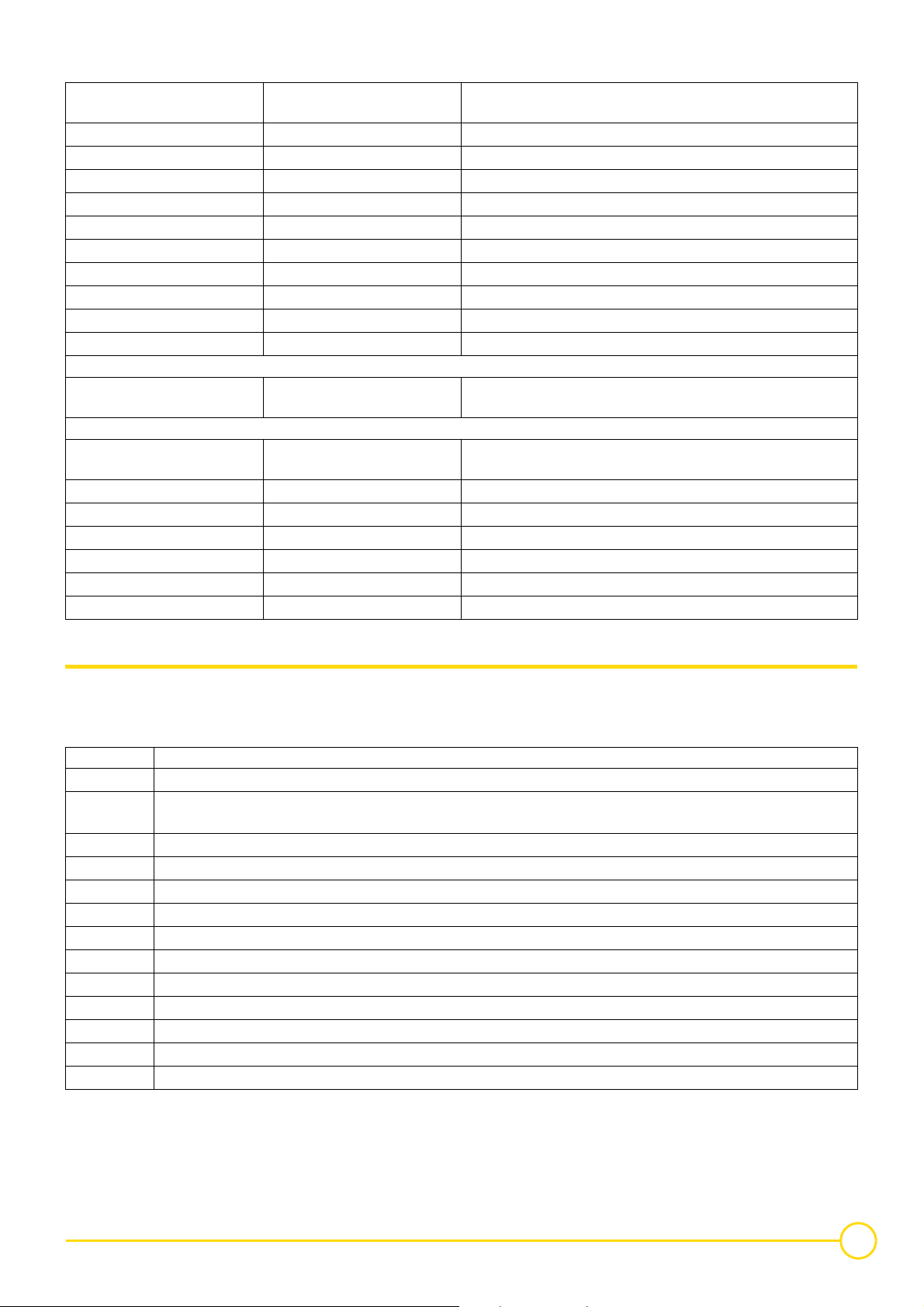

4.4 Shut-off mode (B<<)

During shut-off mode condition the "code"-display will show a B,

whilst the

Code Description

B)

x-display indicates the cause with two flashing dots.

Maximum acceptable flow temperature rise exceeded. The boiler will shut off for ten minutes, then restart. Should the flow

Table below details cause of shut-off mode.

temperature conditions remain the same after 5 attempts, this code will be recorded as a shutdown failure. Boiler will not

lockout.

B)+

Contacts of the external interlock have opened during heat demand. The boiler will shut off for 120 seconds. Should the contacts close again during heat demand, the boiler will wait the remaining time from the 120 seconds before attempting a

restart.

B) Internal check on fan speed. After 5 attemps, the boiler will lockout. This code will be recorded.

B) Internal check on fan speed. After 5 attemps, the boiler will lockout. This code will be recorded.

B Maximum temperature difference between flow and return exceeded. The boiler will shut off for 150 seconds, then restart.

Should the temperature difference conditions remain the same after 10 attemps, this code will be recorded as a shut-down

failure. Boiler will not lockout.

B One or several adjusted parameters out of range including some factory defaults which should not have been changed.

Check and reset parameters:

- Press the "reset"-key immediately followed by pressing the "r"-key for about 12 seconds,

-"code"-display shows 7,

-use [+] and [-] -keys to enter correct boiler parameter

(7=! for Gas 110 Eco 115, 7=#! for Gas 110 Eco 65)

-press "l"-key to confirm settings,

- check parameter settings and change were needed or desired.

NOTE: Shut-off mode is a normal boiler operating function and does

not represent a boiler failure.

However, this may indicate a system problem, an internal boiler

check or an incorrect parameter setting.

4.5 Setting mode user level (<>>)

Code Description Setting range Preset

) Pump run on time HTG

*

;

NOTE: Changing code ) and code * should only be on design

engineers advice.

Flow temperature set point

-& °C %

= pump run on 10 seconds

-"= pump run on in minutes

DHW temperature set point

Boiler control setting Control mode (modulating-on/off etc.)

Base point internal compensation slope N/a

-$" °C (only with sensor) ""

18

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

4.5.1 Flow temperature set point ()

The required flow temperature is adjustable from 20 to 90 °C.

4.5.2 Pump run on time HTG ())

Pump run on time can be adjusted (Please refer to installation

contractor)

- Press the "r" -key until the digit (with dot) appears in the

"code"-display.

- Press the "w"-key until the digit ) (with dot) appears in the

"code"-display.

- Set the required value, using the [+] and [-] -keys.

Code x Description

)Pump runs on for 10 seconds

)<NPump runs on for 1 to 15 minutes (NN= to ")

- Press the "l"-key to store the new value (value will flash twice).

- Press the "reset"-key to return to operating mode.

NOTE: For continuous pump operation use manual override,

See chapter 4.1.3.

Z

25/01/2011 - 300014883-001-K Gas 110 Eco 115 / 65

19

4.5.3 DHW temperature set-point ( )

The DHW temperature is adjustable from 20 to 75 °C (factory

default 55 °C). Only with DHW priority sensor.

- Press the "r" -key until the digit (with dot) appears in the

"code"-display.

- Press the "w"-key until the digit (with dot) appears in the

"code"-display.

- Set the required value, using the [+] and [-] -keys.

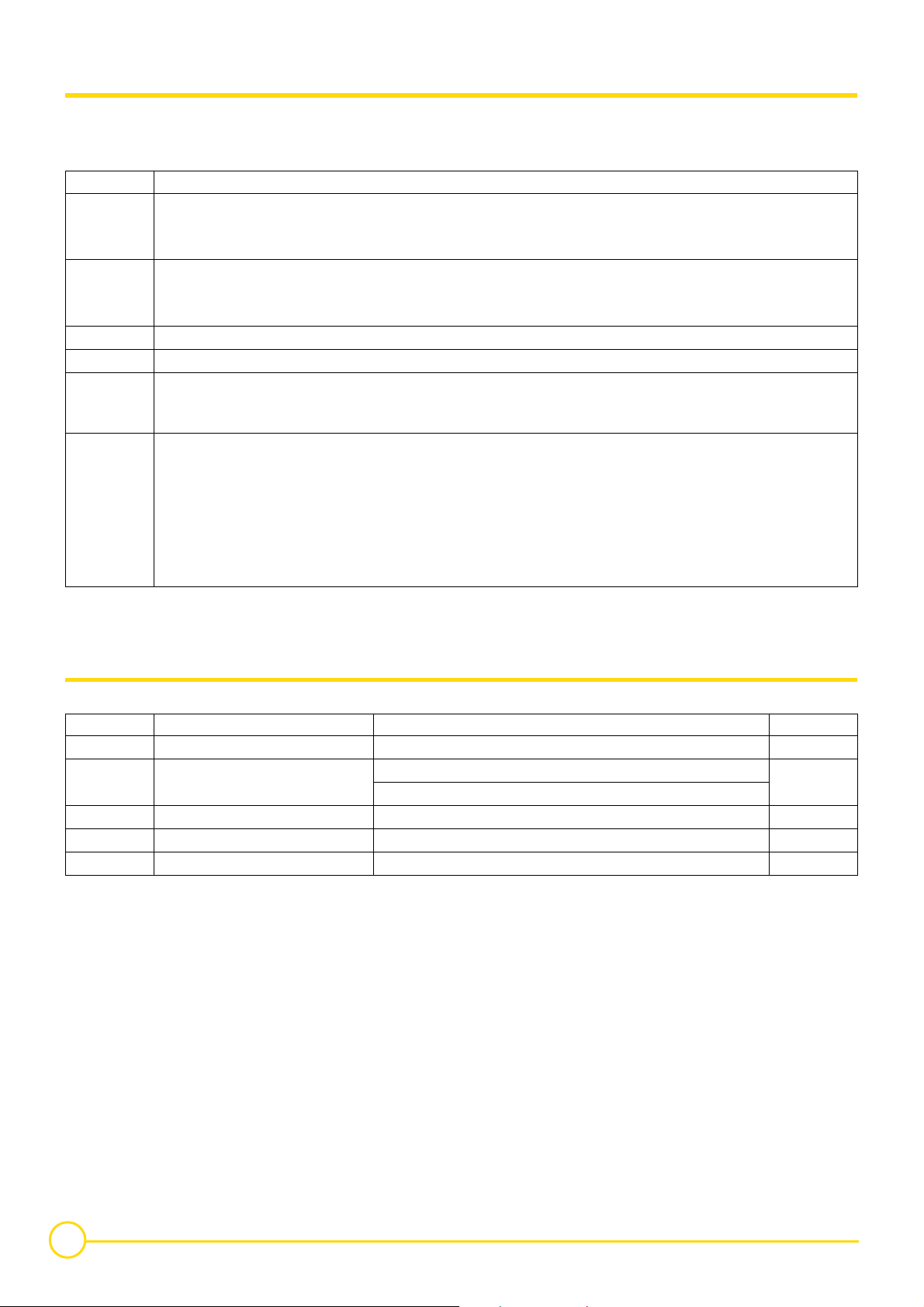

4.5.4 Boiler control setting (*)

The boiler is factory set to option (HTG modulating or on/off

with DHW on).

To change the control option:

- Press the "r" -key until the digit (with dot) appears in the

"code"-display.

- Press the "w"-key until the digit * (with dot) appears in the

"code"-display.

- Set the required X and Y values as listed below in using the

[+] and [-] -keys.

- Press the "l"-key to store the new value (value will flash twice).

- Press the "reset"-key to return to operating mode.

- Press the "l"-key to store the new value (value will flash twice).

- Press the "reset"-key to return to operating mode.

NOTE: there are further adjustments available on service level.

Please refer to your service engineer or contractor.

See chapter 4.6.7.

Z

"With the ""code""- display showing * - the

the method of boiler control in the first segment N> and the option

to turn the HTG and DHW on or off in the second segment >O". By

using codes from the table below a series of control options are

available.

Example: NO

- Boiler enabled internal modulation with booster on * - HTG

and DHW on (as default)

! - Analog signal 0 -10 V on temperature - HTG on and DHW

off

- Boiler high/low - HTG off and DHW on

x-display will indicate

x-display

First segment N> Boiler control option

Boiler enabled internal modulation with booster on *

Boiler high/low

Boiler enabled internal modulation with booster off *

! Analog signal 0 - 10 V on temperature

" Analog signal 0 - 10 V on output %

Second segment >O Operation mode

HTG and DHW off

HTG and DHW on

HTG on and DHW off

HTG off and DHW on

* NOTE: boiler setting * and have the same function

Description

20

Gas 110 Eco 115 / 65 25/01/2011 - 300014883-001-K

Loading...

Loading...