GAS 110 ECO

CONDENSING

High efficiency floor standing

fully condensing boiler with

ultra low NOx emission

for single and modular/

cascade applications

Outputs: Gas 110 Eco

- 65 13.3 - 65 kW

- 115 18.4 - 113.8 kW

REMEHA GAS 110 ECO

Tr eadLightly

ON THE PLANET

Gas

110 Eco

Modular / Cascade

Gas Fired Condensing Boiler

Boiler description

The Remeha Gas 110 Eco 115 / 65 are floor standing, condensing

boilers. The one piece, cast aluminium heat exchanger and other

major components are contained within a sealed air box. This forms

the main boiler casing with a removable front section for

maintenance purposes. All electrical and electronic controls are

contained within the boiler casing.

The combined flue gas outlet and combustion air inlet are mounted

on the top of the boiler, with the flow, return, gas and condensate

connections located at the rear of the boiler. The boiler is suitable

for room-sealed or open flue applications. It has been designed for

central heating and indirect hot water production. It must be

installed on a fully pumped system and is suitable for use on both

sealed and open vented installations (minimum operating pressure

of 0.5 bar open vented and 0.8 bar pressurised).

The pre-mix, down-firing gas burner (NG or LPG) with its gas/air

ratio control system, ensures clean, trouble free operation with

higher than average efficiencies (of up to 110% NCV) in the

condensing mode, combined with ultra low NOx and minimum CO

emissions. The standard control package allows actual and set

values to be read and adjusted on the built-in digital display which

also provides normal operating and fault code indication. An

intelligent, advanced boiler control (abc) continuously monitors the

boiler conditions, varying the heat output to suit the system load.

The control is able to react to external “negative” influences in the

rest of the system (flow rates and air/gas supply problems)

maintaining boiler output for as long as possible without resorting

to a lock out condition. At worst the boiler will reduce its output

and/or shut down (shut-off mode); awaiting the “negative”

conditions to return to normal before re-starting. The ‘abc’ control

cannot override the standard flame safety controls.

Declaration of compliance

We hereby certify that the series of appliances specified hereinafter

is in compliance with the standard model described in the EC

declaration of compliance, and that it is manufactured and

marketed in compliance with the requirements and standards of the

following European Directives.

Manufacturer: Broag-Remeha Ltd, Remeha House,

Molly Millars Lane RG41 2QP WOKINGHAM, Berks

Product type: Gas fired condensing boiler

Formats: Remeha Gas 110 Eco 115 / 65

Standards & rules: - 90/396/EEC Gas Appliance Directive

Reference Standards: EN 437; EN 483;

EN 625; EN 677

- 2006/95/EC Low Voltage Directive

Reference Standard: EN 60.335.1

- 2004/108/EC Electromagnetic Compatibility Directive

Generic standards: EN1000-6-3 ; EN 61000-6-1

- 92/42/EEC Efficiency Directive ****

Inspecting

organisation: Gastec

Values: NOx (mg/kWh) dry @ 0% O2

Gas 110 Eco 65 25 21 - DIN 4702 Teil 8

Gas 110 Eco 115 30 31 - EN 297A3

CE-0063BS3826

Contents

page

Introduction/Boiler description 2

Typical boiler construction 3

Efficiency/Application information 3

Advantages at a glance/Operating principle 4

Dimensions 5

Maintenance and Service clearances 5

Technical data 6

Modular/cascade boiler options 7

Smart Connection Technology 8

Typical installations 9

Typical flue options 10

Flue systems 11

Modular flue systems 12

Flue dilution systems 12

Electrical installations and controls 13

Electrical connections and controls 14

Optional controls and accessories 15

Introduction

Remeha Gas 110 Eco boilers are floor

standing gas-fired condensing boilers

fitted with an "Open Therm" control

interface which enable

direct weather

compensation using Remeha single

and multi boilers controls or the

customer can choose to use external

control options supplied by others

without affecting boiler performance.

The Remeha Gas 110 Eco has been

developed specifically to fit directly

into the same floor area as a

traditional boiler of equal output.

This will promote the benefit of

higher energy efficiency and lower

carbon emissions. They are designed

for sealed and open vented heating

systems, with a maximum operating

temperature of 90°C. Installation is

recommended where possible on low

temperature heating installations.

2

REMEHA GAS 110 ECO

3

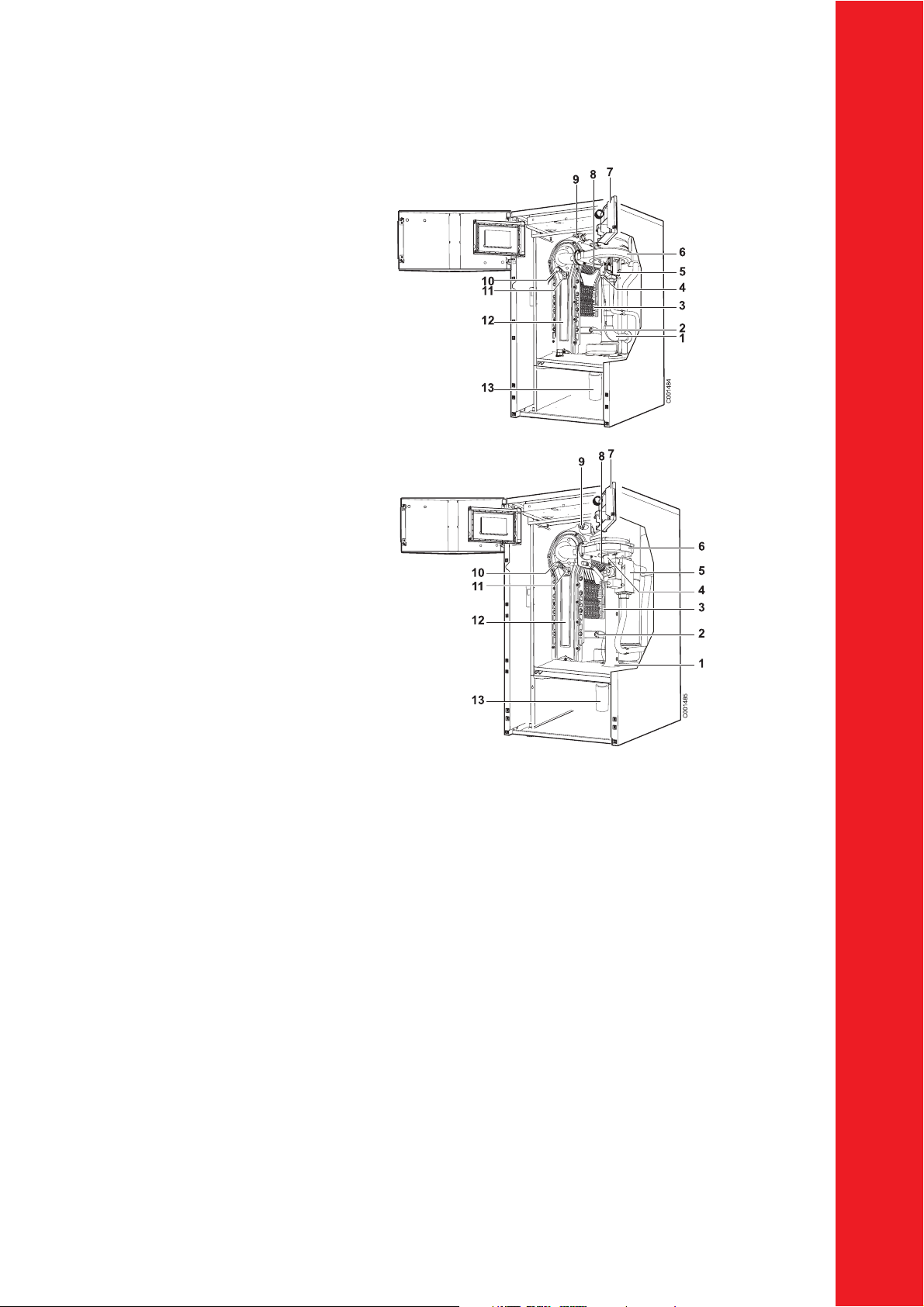

Typical boiler construction

Gas 110 Eco 65

1. Fan air inlet

2. Return sensor

3. Heat exchanger

4. Venturi

5. Gas valve

6. Fan

7. Control panel

8. Burner

9. Flow temperature sensor

10. Ignition electrode + Ionisation electrode

11. Flame inspection window

12. Heat exchanger inspection cover

13. Siphon

Gas 110 Eco 115

1. Fan air inlet

2. Return sensor

3. Heat exchanger

4. Venturi

5. Gas valve

6. Fan

7. Control panel

8. Burner

9. Flow temperature sensor

10. Ignition electrode + Ionisation electrode

11. Flame inspection window

12. Heat exchanger inspection cover

13. Siphon

Efficiency information

SBEM efficiency

65–97.57% 115–96.45% – The SBEM ‘heat generator seasonal efficiency’ figures are based upon GCV

using formula (30% *0.81) + (100%*0.19)

Annual efficiency

Up to 109% at Hi (98% at Hs) at an input of 30% and a return temperature of 30°C.

Heat to water efficiency

a. Up to 99% at Hi (89% at Hs) at an average water temperature of 70°C (80/60ºC) - Gas 110 Eco 65 only.

b. Up to 98% at Hi at an average water temperature of 70°C (80/60ºC) - Gas 110 Eco 115 only, also 88% at Hs.

c. Up to 110% at Hi (99% at Hs) at an average water temperature of 35°C (40/30ºC) - Gas 110 Eco 65 only.

d. Up to 106% at Hi at an average water temperature of 35°C (40/30ºC) - Gas 110 Eco 115 only, also 95% at Hs.

Note: NCV = Hi, GCV = Hs

Application information

The Remeha Gas 110 Eco can be used on all new and refurbishment projects in both single and multiple

(modular/cascade) configurations. Conventional and room-sealed flue system capability means that the

boiler can be sited almost anywhere within a building. The Remeha weather compensators options are able

to communicate directly with the boiler controls (two wire) to make full use of its fully modulating feature,

ensuring that the boiler closely matches the system demand at all times. External control systems (BMS)

can be interfaced with the boiler to provide on/off, high/low or modulating (0-10v) control options.

Operating principle

Combustion air is drawn into the closed air box, by a variable speed

fan, through the air inlet connection from the plant room (open

flued) or from outside via the concentric flue system (room-sealed).

On the inlet side of the fan is a specially designed venturi which is

connected to the outlet side of the gas valve.

Depending on the demand (under the dictates of flow/return sensor

and other external/internal control inputs) the electronic control

unit directly monitors the volume of gas and air being delivered to

the premix burner. This mixture is initially ignited by the combined

ignition/ionisation probe which then monitors the state of the

flame. Should the flame not ignite or be unstable, within the preset safety time cycle, the controls will shut the boiler down (after 5

attempts) requiring manual intervention to reset the boiler. The

digital display will also indicate a flashing fault code confirming

the reason for the failure.

The products of combustion in the form of hot flue gases are forced

through the heat exchanger, transferring their heat to the system

water (the flue gas temperature is reduced to approximately 5°C

above the temperature of the system return water) then discharged

via the condensate collector, vertically through the flue connection

to atmosphere. Because of the low flue gas exit temperature there

will be a vapour cloud formed at the flue gas terminal – this is not

smoke, simply water vapour formed during the combustion process.

If the controls allow the flow and therefore return temperature to

fall below dew point (55°C) this water vapour will begin to

condense out in the boiler transferring it’s latent heat into the

system water, increasing the output of the boiler without

increasing gas consumption. Condensation formed within the boiler

and flue system is discharged from the boiler to an external drain

via the drain pan/siphon supplied.

4

Advantages

at a glance

•

High efficiency: 110% NCV at

40/30ºC (99% GCV)

•

Boiler control:

a) Modulating (18-100%)

b) High/low (18-100%)

c) On/off

•

Conventional or “room

sealed” flue options

• The boiler is particularly suitable

for retro-fit applications,

having a small footprint

•

Premix burner for

clean combustion

•

Low NO

x <35mg/kWh

(02=0%, dry)

•

Quiet operation <48 dBA

•

Cascade / Modular packages for

up to 6 boilers

•

Quick and easy installation

•

Advanced boiler control, Remeha’s

‘abc’, for reliable heat delivery

•

Digital display

•

Data file for storing information

•

Remote signalling options

•

Cast aluminium heat exchanger

•

Easy maintenance

•

Built-in calorifier control

•

Options for modular control and/

or weather compensator

•

Control 0-10V signal or volt free

•

PC connection

•

For use with natural gas and

L.P.G. (Some models require a

conversion kit)

REMEHA GAS 110 ECO

5

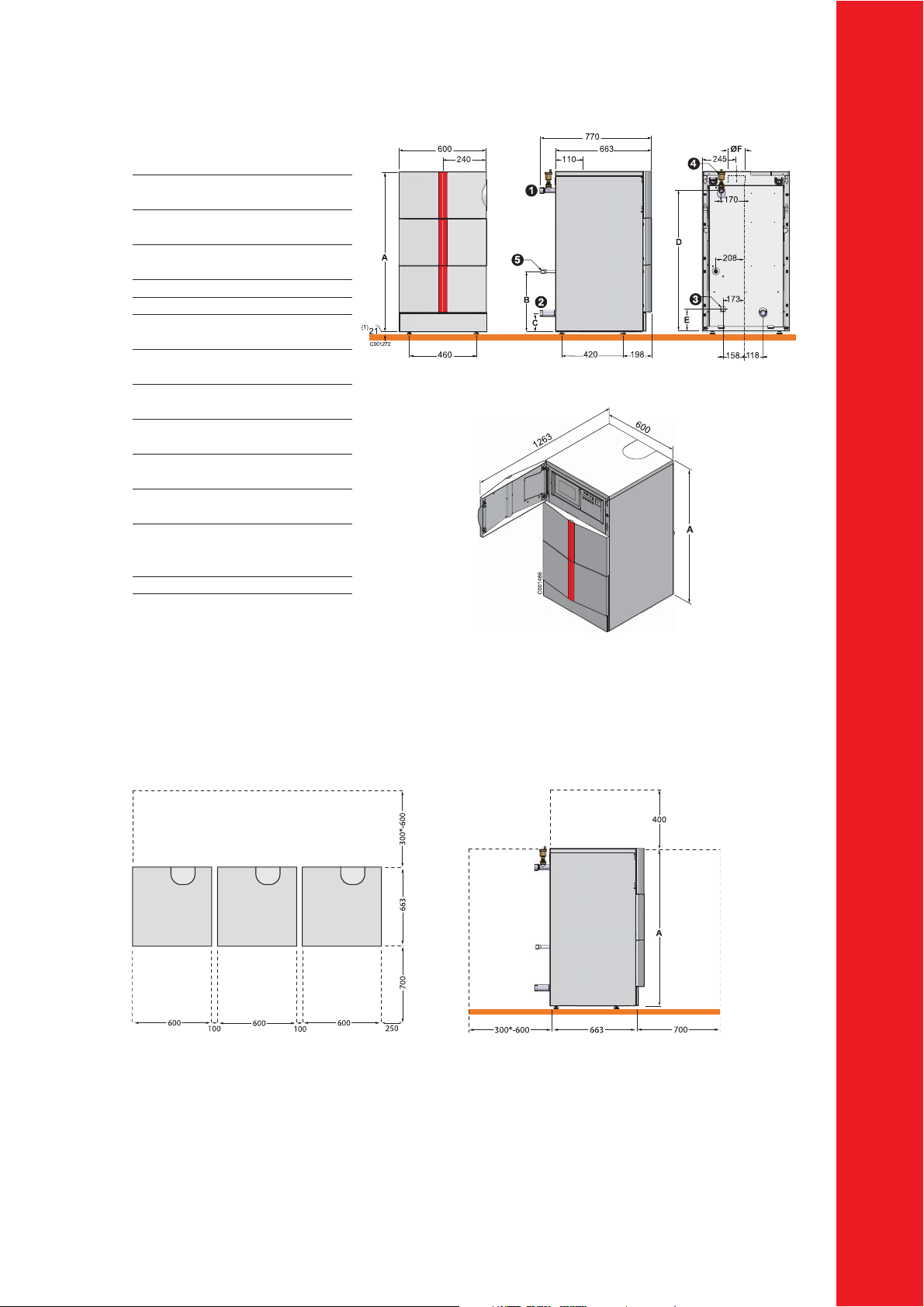

Dimensions

1 Heating outlet

R 1 1/4

2 Heating return

R 1 1/4

3 Condensates discharge

(Ø 25 mm external)

4 Automatic air vent

5 Gas inlet R 3/4

A Remeha Gas 110 Eco 65: 1100 mm

Remeha Gas 110 Eco 115: 1322 mm

B Remeha Gas 110 Eco 65: 410 mm

Remeha Gas 110 Eco 115: 632 mm

C Remeha Gas 110 Eco 65: 124 mm

Remeha Gas 110 Eco 115: 346 mm

D Remeha Gas 110 Eco 65: 968 mm

Remeha Gas 110 Eco 115: 1190 mm

E Remeha Gas 110 Eco 65: 152 mm

Remeha Gas 110 Eco 115: 374 mm

ØF Forced flue connection

Remeha Gas 110 Eco 65: Ø 100/150 mm

Remeha Gas 110 Eco 115: Ø 100/150 mm

R Thread

(1) Basic dimension 21 mm

adjustment possible: 21 to 40 mm

Maintenance and Service clearances

View from above View from the side

Clear space should be left around the boiler :

- 700mm in front of the boiler

- 400mm above the boiler

- 100mm each side of the boiler

(Facilitates removal of the casing)

Note: 300mm refers to singular boiler installations,

600mm refers to modular boiler applications.

Loading...

Loading...