Regency Trinity Installation Manual

TrinityMk II

WOODBURNING STOVE

SAFETY NOTICE

Please read this entire manual before you install and use your new room heater. Failure to follow instructions

may result in property damage, bodily injury or even death.

If this stove is not properly installed, a house fire may result. For your safety, follow the installation directions.

Contact local building or fire officials about restrictions and installation inspection requirements in your area.

This appliance is hot while in operation and retains its heat for a long period of time after use. Children, aged

or infirm persons should be supervised at all times and should not be allowed to touch the hot working surfaces

while in use or until the appliance has thoroughly cooled.

This stove must be connected to a UL/U.L.C. listed High Temperature residential chimney, Factory Built,

Residential Type and Building Heating Appliance, UL 103 or a code approved masonry chimney flue liner

constructed in accordance with NFPA 211 Chimney Vents and Solid Fuel Burning Appliances

Manufactured by Waterford Stanley (Marketing) Limited, Bilberry, Waterford, Ireland.

INSTALLATION & OPERATING INSTRUCTIONS

TABLE OF CONTENTS

PAGE NO.

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Pre-Installation Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Top Flue Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Rear Flue Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Blower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6. Blower Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7. Floor Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

8. Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

9. Outside Air Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

10. Mobile Home Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

11. Minimum Clearances to Combustible Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

12. Reduced Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

13. Double Wall Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

14. Wall Protectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

15. Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

16. Chimney Types: USA Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

17. Chimney Types: Canada Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

18. Chimney Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

19. Connecting to Masonry Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

20. Thimbles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

21. Chimney Connector Systems, Thimbles & Clearances from Combustible Walls. . . . . . 8

22. Masonry Fireplace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

23. Ventilation & Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

24. Spillage Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

25. Lighting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

26. Primary Air Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

27. Low or Overnight Burn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

28. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

29. De-Ashing (When Fire has Burned Out) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

30. Disposal of Ashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

31. Creosote (Formation & Need for Removal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

32. Glass Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

33. Glass Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

34. Vitreous Enamel Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

35. Fire Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

36. In the Event of a Chimney Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

37. Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1

WATERFORD TRINITY MKII WOODBURNING STOVE INSTALLATION AND OPERATING

INSTRUCTIONS

GENERAL

When installing, operating and maintaining your

Waterford Trinity MK II Stove respect basic

standards of fire safety. Read these instructions

carefully before commencing the installation. Failure

to do so may result in damage to persons and

property. Consult your local Municipal office, Fire

Department and your insurance representative to

determine what regulations are in force. Save these

instructions for further reference.

The complete installation must be done in

accordance with current Standards and Local

Codes. It should be noted that the requirements

and these publications may be superseded during

the life of this manual.

PRE-INSTALLATION ASSEMBL Y

(a) After removing the stove from its packing, open

the ashpit door (item 13 in exploded view) and

remove the contents

(b) Open the firedoor (item 8) and remove the

contents of the firebox, leaving the bricks in

place.

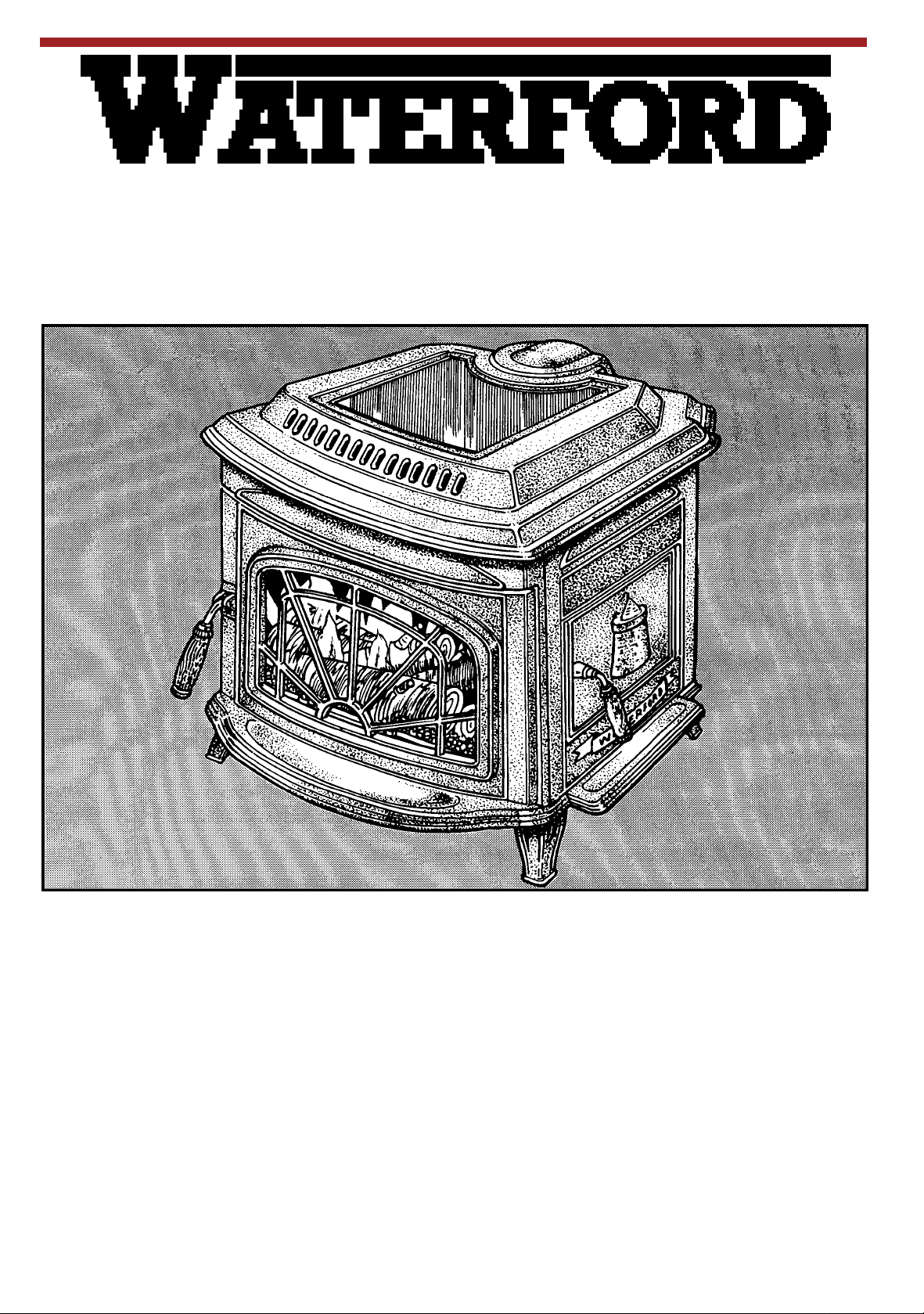

Fig.2

(f) Fit the front ashlip (item 12) using two of the

ashlip brackets (item 35) and screw together

using four 1/4” (6mm) x 1/2” (12mm) hex head

bolts provided. Stand the stove upright taking

care not to strain the back leg bolts.

Fig.3

(c) Remove the ashlip (item 12) from the rear of the

stove if you have not already done so. Remove

the loose fitting hob (item 3) and place on a nonabrasive surface.

Fig.1

(d) Place the plastic packing on the ground at the left

hand side of the stove.

NOTE: As the stove is very heavy take care when

laying the stove on its side on top of the packing.

(g) Fit the wooden handle (item 28) to the fuelling

door (item 8)

Fig.4

(e) Remove the wooden pallet by taking out the 4

retaining screws from the base of the legs (item

2). Discard brackets & woodscrews, replace

levelling screws.

h) If the side fuelling door (item 21) is to be used, fit

the side ash lip (item 24) using two ashlip

brackets (item 35) and screw together using four

2

1/4” (6mm) x 1/2” (12mm) hex head bolts provided.

Take out the chrome locking bolt and fit door latch

(item 73), the door latch spigot (item 40), and the

wooden handle (item 28) provided.

Fig.5

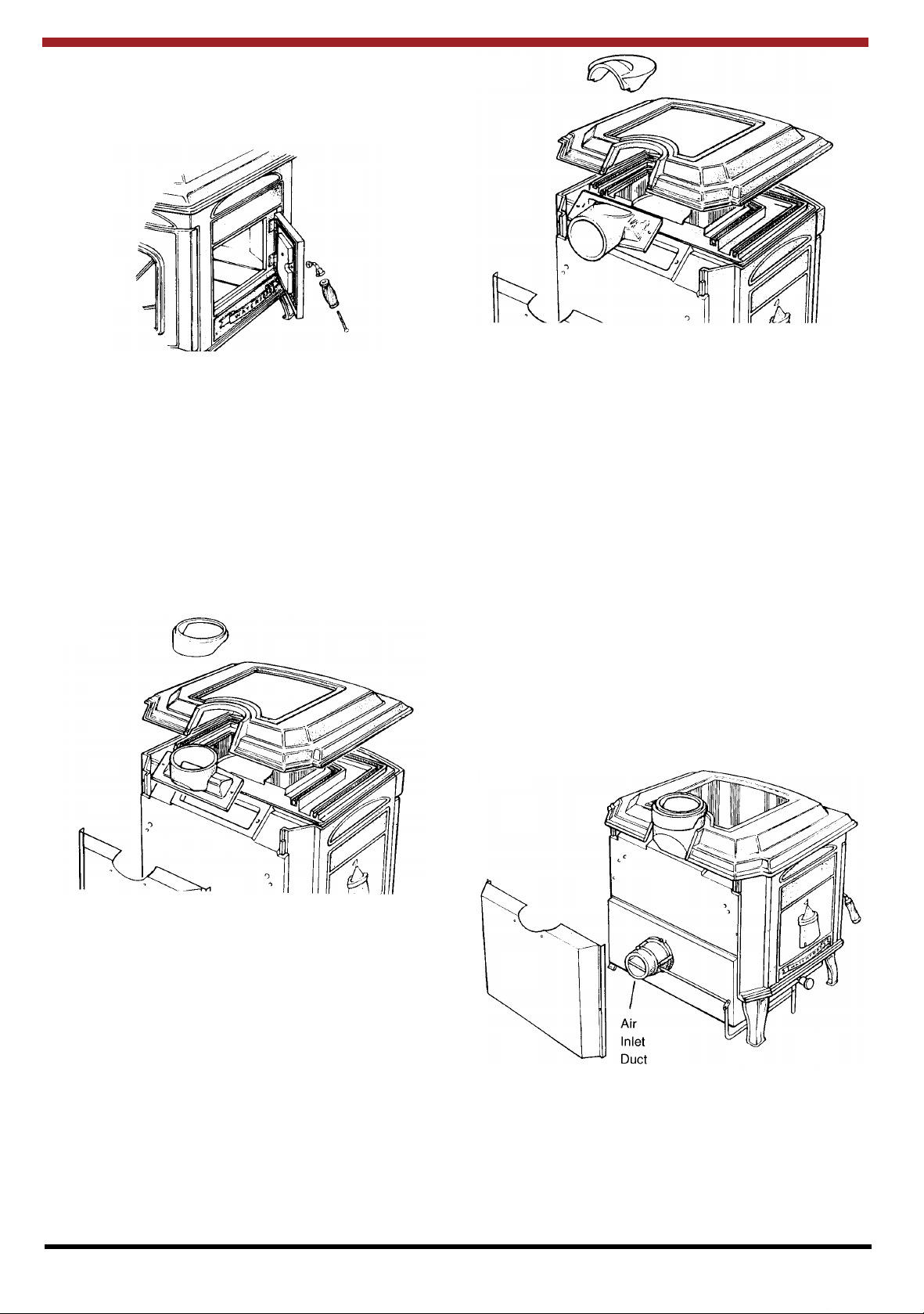

Fig. 7

BLOWER

This stove can be connected to either a top or rear

exit by simply reversing the orientation of the flue

spigot (item 5) on the flue spigot flange.

For either the top or the rear exit option place the

ceramic gasket onto the flue spigot flange – located

at the top of the back plate (item 31).

TOP FLUE EXIT

Screw the top outlet hob filler piece (item 6) onto the

hob (item 3), screw top outer blanking plate (item

29) onto the heat shield (item 30) using the two 1/4”

(6mm) x 3/4” (19mm) C/S screws provided.

Fig. 6

Caution: Moving parts may cause injury. Do not

operate unit with blower housing removed.

Danger: Risk of electric shock. Disconnect power

before servicing unit.

Hot parts: Do not operate unit with blower housing

removed.

The Listed Waterford Trinity Optional Blower comes

assembled, wired, and ready for use.

To fit the Listed Waterford Trinity MK II Optional

Blower take off rear heat shield (item 30) and fit

listed blower assembly (item 75) as per illustrations

below.

This unit must be connected to a grounded,

Standard 110 volt, 60 Hz electrical outlet, Never

route the power cord under or in front of the unit.

Do not, under any circumstances, cut or remove the

grounding prong from the power cord.

Do not use an adaptor plug.

Fig. 8

REAR FLUE EXIT

Screw the rear outlet hob filler piece (item 57) to the

hob (item 3) using the two screws provided.

Screw the rear outlet heat shield blanking plate (item

58) to the heat shield (item 30) using the two 1/4”

(6mm) x 3/4” (19mm) C/S screws provided.

BLOWER OPERATION INSTRUCTIONS

1. Press switch to ON position (see fig. 9).

2. Fan will power up when stove temperature

reaches snap switch operating temperature.

3. Fan operation will cease each time stove

temperature drops below snap switch operating

temperature.

3

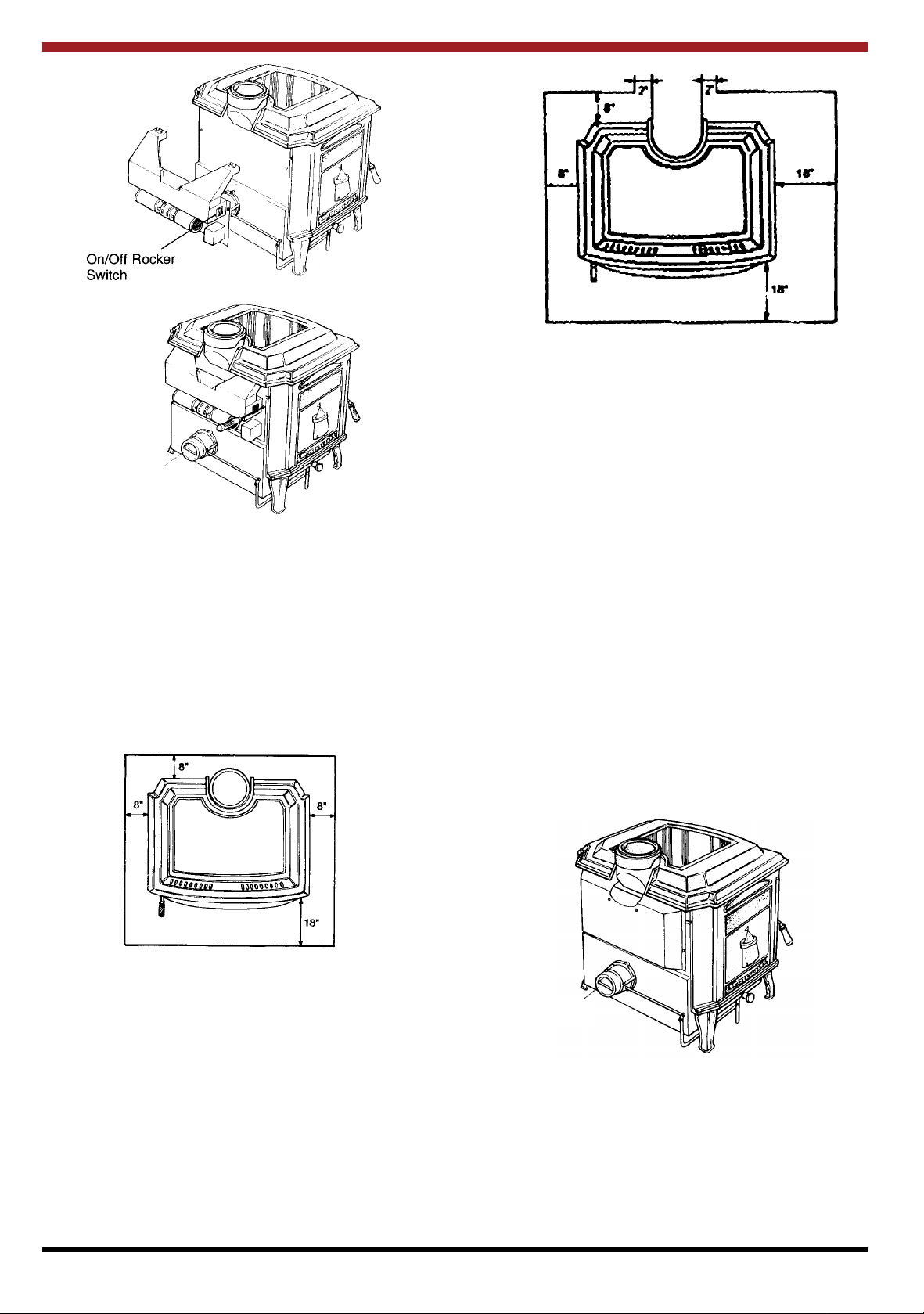

Fig. 9

Fig. 12

200mm

50mm

50mm

Fig. 10

Air inlet

duct

FLOOR PROTECTION

When installing this heater on a combustible floor, a

floor protector, consisting of a layer of noncombustible material at least 3/8” (9mm) thick or 1/4”

(6mm) thick covered with 1/8” (3mm) sheet metal is

required to cover the area under the heater and to

extend to at least 18” (450mm) at the front and 8”

(200mm) to the sides. This will provide protection

from sparks and embers which may fall out from the

door when stoking or fuelling.

200mm

450mm

450mm

LOCATION

There are several conditions to be considered when

selecting a location for your Waterford Trinity MK II

Wood Stove.

(a) Distance from a safe chimney.

(b) Position in the area to be heated - central

locations are usually best.

(c) Allowances for proper clearances to

combustibles.

(d) Obstruction in the ceiling, upper floor or roof, for

example, ducting, plumbing, electrical fittings

and wiring, overhead fixed furnishings etc.

WARNING:

DO NOT CONNECT TO OR USE IN

CONJUNCTION WITH ANY AIR DISTRIBUTION

DUCTWORK UNLESS SPECIFICALLY

APPROVED FOR SUCH INSTALLATION

Fig. 11

200mm

200mm

200mm

450mm

If the side door is to be used the floor protector must

extend at least 18” (450mm) from the right side of

the stove when looking from the front.

DO NOT OBSTRUCT FREE AIR SUPPLY TO THE

AIR INLET DUCT LOCATED AT THE BACK OF

THE STOVE.

Fig. 13

Air Inlet

Duct

OUTSIDE AIR CONNECTION

This stove may be connected direct to the outside of

the house for its combustion air supply.

The primary air inlet (item 55) located at the bottom

of the back panel (item 31) may be connected to

outside air.

4

Loading...

Loading...