Page 1

Wood Inserts

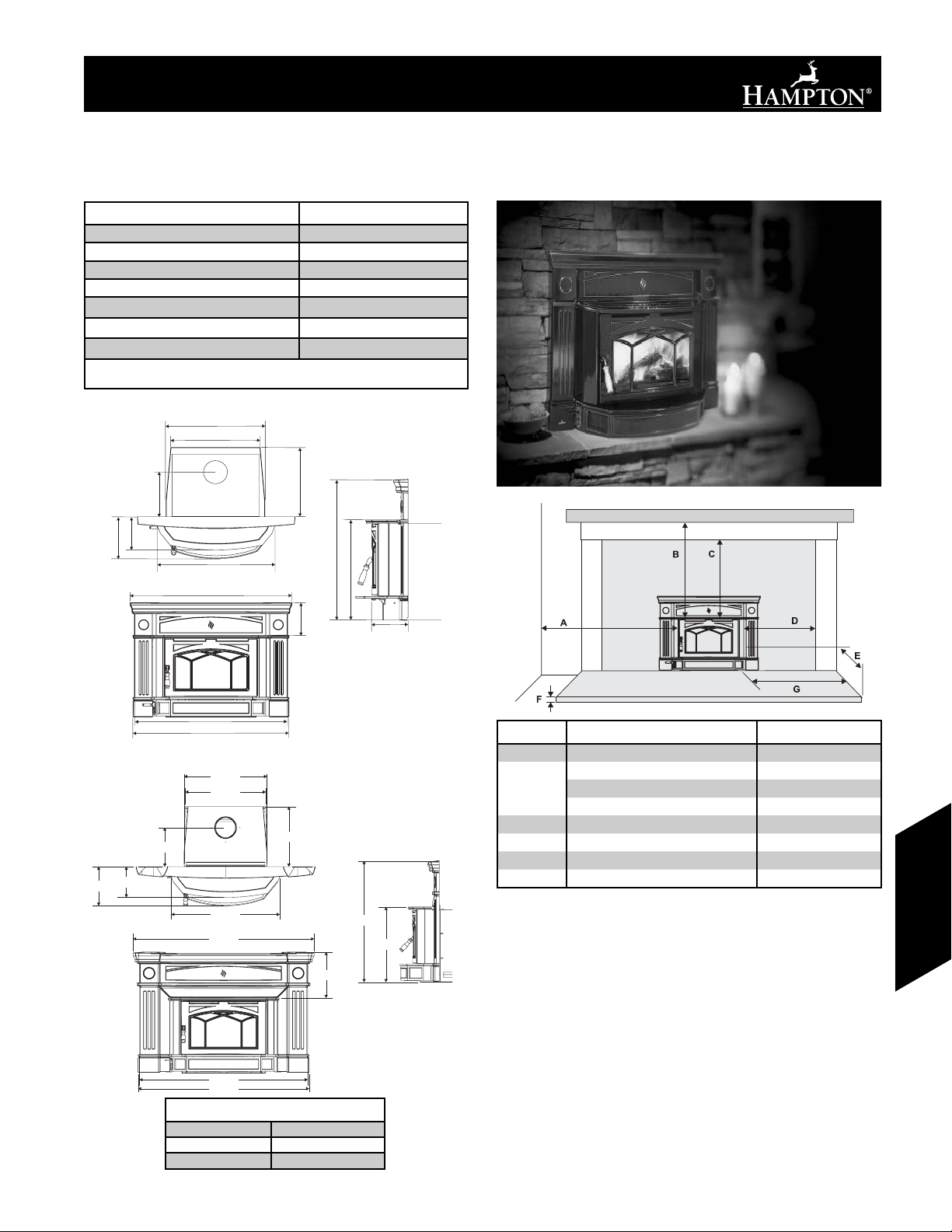

HI300 Medium Wood Insert

Model HI300

Optimum Effi ciency 77%

Emissions (grams/hr) EPA Certifi ed 3.8 grams/hr

Maximum BTU* 75,000 BTU

Maximum Log Size 18”

Firebox Size 2.3 cu. ft.

Flue Size 6”

Burn Time (typical)* up to 8 hrs.

* Length of burn time and BTU Range depends on type of wood, climate conditions and

installation.

HI300 Wood Insert

Unit With Cast Faceplate

23-3/4”

23-1/4”

11-1/8”

9”

11-3/8”

30-7/8"

42-1/2”

40”

41”

Unit With Oversize Cast Faceplate

23-3/4”

23-1/4”

17-1/4”

11-1/4”

7-7/8”

11-1/8”

31-1/4”

51-3/4”

48-1/8"

48-7/8"

Minimum Fireplace Opening

Height 21-1/2” (546mm)

Width 25” (635mm)

Depth 17-1/2” (445mm)

17-1/4”

8-1/2"

13-1/8”

30”

21-1/2”

7-3/4”

Dimension Description I2400

A Adjacent Side Wall (to side) 11” (280mm)

Mantle (to top)** 20” (508mm)

Mantle Depth (not shown) Maximum 10” (254mm)

Wood Inserts

34-5/8”

21-1/2”

B

C Top Facing (to top) 12” (305mm)

D Side Facing (to side) 8” (205mm)

E Minimum Hearth Extension* 18” (455mm)

F Minumim Heath Thickness* 0.5” (13mm)

G Minimum Hearth Side Extension 8” (205mm)

Side and Top facing is a maximum of 1.5" thick.

Floor protection must be non-combustible, insulating material with an R value of

1.1 or greater.

* Hearth thickness of 0.5" with k value = 0.84", R value = 6 or greater.

** A non-combustible mantel may be installed at a lower height if the framing

is made of metal studs covered with a non-combustible board.

Thermal fl oor protection is not required if the unit is raised 3.5" minimum (measured

from the bottom of the stove). However, standard ember fl oor protection is required.

It will need to be a non-combustible material that covers 16" (406 mm) in the US and

18" (450 mm) in Canada to the front of the unit and 8" (200 mm) to the sides.

If the unit is not raised, thermal fl oor protection required is 18" (450 mm) in the

US and Canada.

All fl oor protection must be non-combustible (i.e., metals, brick, stone, mineral

fi ber boards, etc.) Any organic materials (i.e. plastics, wood paper products, etc.)

are combustible and must not be used. The fl oor protection specifi ed includes

some form of thermal designation such as R-value (thermal resistance) or k-factor

(thermal conductivity).

83June 2007 Hampton Product Specifi cations Book

Loading...

Loading...