Page 1

Instructions of use

HVAC/R

Service Products

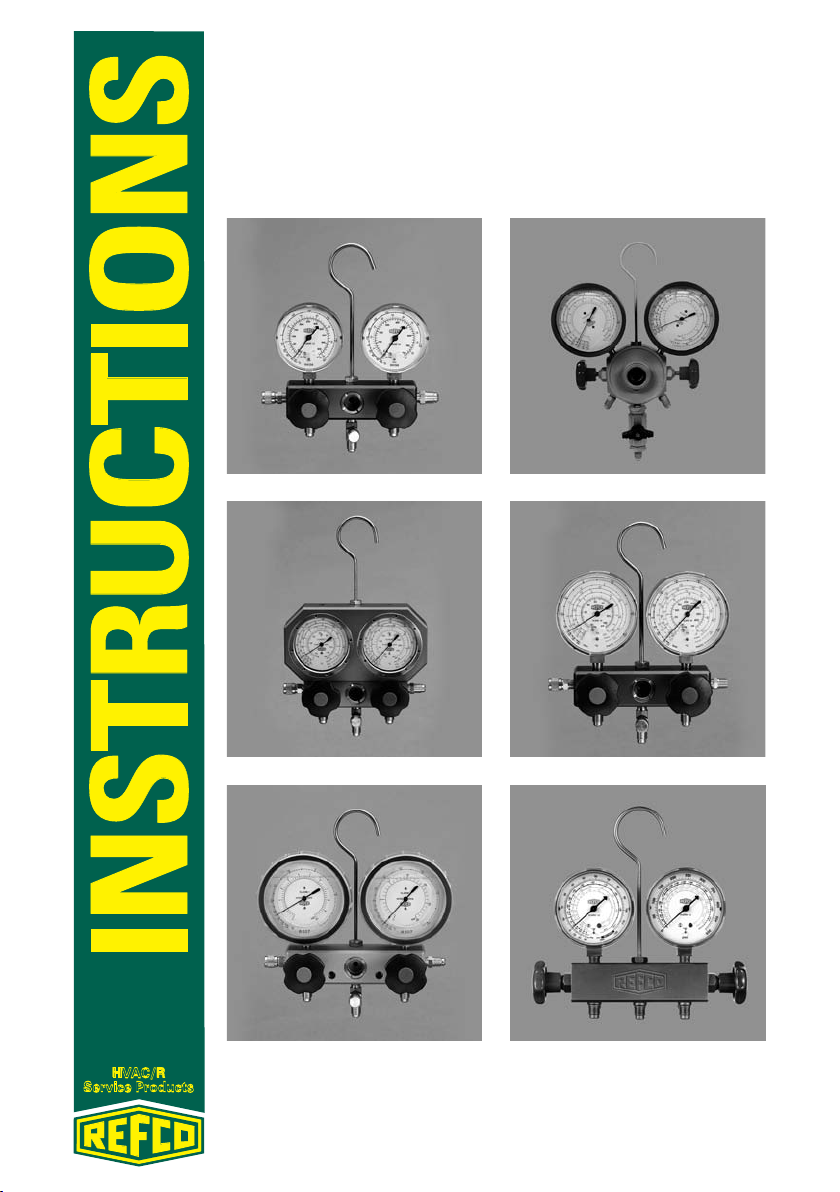

for REFCO 2-way manifolds:

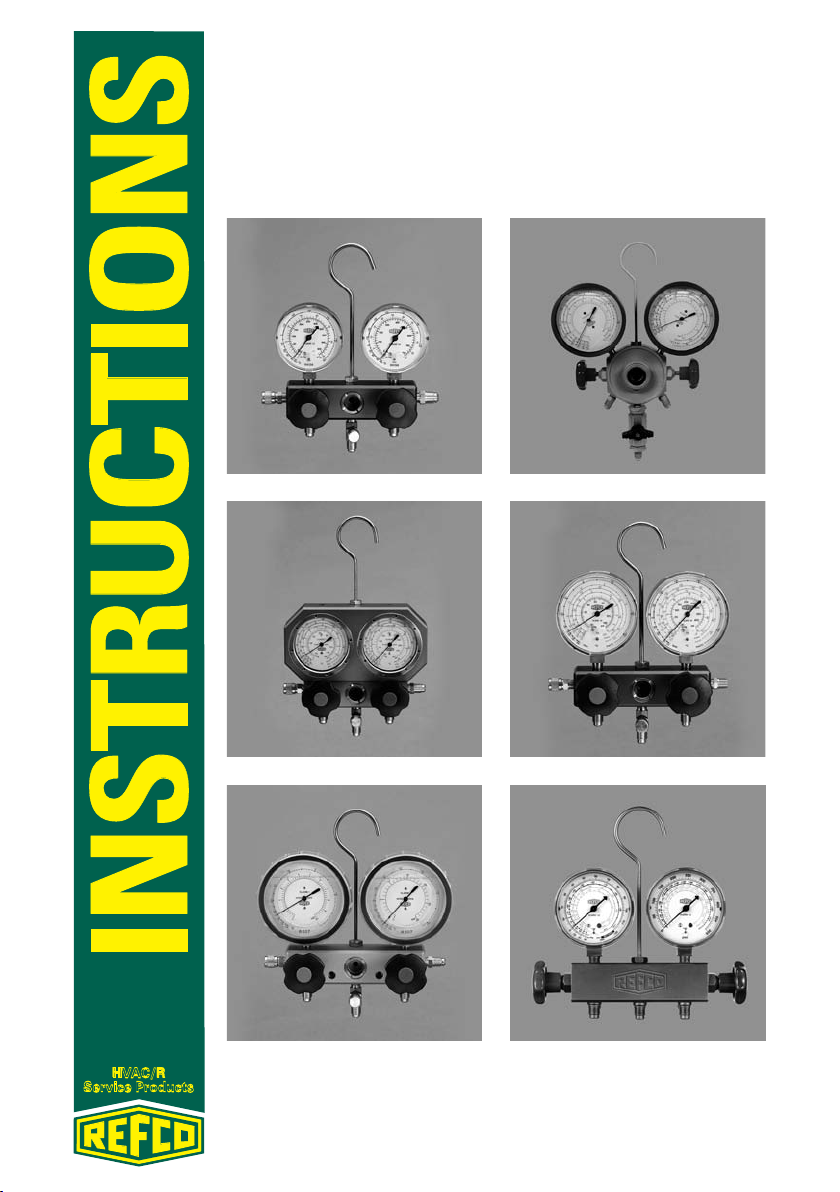

Apex M2 SM2

BM2 MK-2 Star

Jumbo-Star

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 2

HVAC/R

Service Products

Important

Read this manual and become familiar with the spe-

!

cifications and operation of REFCO manifolds prior to

use. The instructions of use will give you important

information in regards to the operation, service and the

disposal of the manifold.

Purpose and use:

The manifolds have been designed especially to measure pressure in

refrigeration equipment. The manifold may only be used by trained

technicians.

!

The manifold must not be used for other than refrigeration applications in connection with refrigerants. The manifold is not suitable for

other liquids or gases than those indicated on the gauge.

!

The manifold must not be used with pressures higher than the pres-

sure scale indicated on the high pressure gauge of the manifold.

!

The manifold can in no case be used as a pressure regulator.

!

The manifold must not be used with ammonia (NH-3).

!

Safety goggles and gloves must be worn at all time during the use

of the manifold.

First use / Transport:

The manifolds are supplied from the factory either in a plastic carrying

case or cardboard box with, or without charging hoses.

Manifolds are high precision measuring instruments. After use, store

the manifold always in the carrying case or the cardboard box provided. Plastic carrying cases can be purchased optionally. Please refer to

the manifold accessory section in the REFCO catalogue.

Technical description:

The 2-way manifold is a high precision instrument. Both gauges, high

and low pressure can be readjusted to the zero point. The manifold

gauges are marked with temperature and pressure scales or are

equipped with interchangeable refrigerant scales.

Changeable piston type valves ensure perfect sealing. Glycerine-oil

filled gauges are equipped with a safety pressure relief in case of a

pressure build up inside the gauge due to a defect. The hoses can be

hooked up to the hose anchors on the side and at the front of the t-style

for storage during non use. This protects the hoses against contamination or damage.

Delivery content:

The content of delivery for each manifold varies depending on the type.

Please refer to the REFCO catalogue for further information about executions and accessories.

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 3

HVAC/R

Service Products

Use of manifold:

Preparing

Before use ensure that the temperature scales on the manifold gauges

match the refrigerants used in the system.

Adjust the gauge with the zero adjusting screw to zero. Position of the

hand may vary and might not point to zero depending on the atmospheric pressure. Readjusting the gauge might therefore be necessary

before each use of the manifold. The zero adjusting screw is positioned

either at the top or through the front lens depending on the type of

manifold.

Below the different types available:

BM2, STAR, JUMBO-STAR, SM2 ➞ lift plastic plug on lens

➞ screw on dial.

STAR, MK-2, M2 ➞ screw on top of gauge (outside –"12-o-clock")

After adjusting replace the lens or the plastic plug.

Connecting the manifold to a system

• Connect blue hose (4) ➞ compound side of system.

• Connect red hose (5) ➞ pressure side of system.

• Connect yellow hose (8) ➞ vacuum pump.

• Close both valves (6+7).

Evacuation of a system

• Turn on the vacuum pump

• Open both valves (6+7)

• Check pressure on compound gauge

• If vacuum reached close both valves (6+7)

Please note: The evacuation time may vary depending on the size of a

system. A minimal time span of 20 minutes must be observed to evacuate a small to middle size system.

Filling of a system after evacuation

• Keep all valves closed. Disconnect the yellow hose from the vacuum

pump and connect this hose to a refrigerant container.

• Open blue valve (compound side)

• Open valve on refrigerant container. The system is now being filled

with refrigerant. Check the correct quantity of refrigerant with a charging scale for example the REFCO REF-METER and observe the pressure

on the compound gauge. If the flow of refrigerant is too slow or insufficient the compressor of the unit can be turned on to speed up the

process. Ensure that you fill vapour refrigerant only. Filling with full liquid may lead to damage of components of the system.

• If the correct filling quantity has been reached close all valves.

• After the filling process check the pressure on the pressure and compound side of the unit. You may use the flare cap provided.

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 4

HVAC/R

Service Products

Finishing

• Disconnect all hoses from the system.

• Open valves (6+7)

Service of manifold

• The charging hoses must be checked and clean of oil residue before

each use. A visible control is also necessary to ensure that the hoses

and the connection are undamaged und tight.

• The seals and gaskets of the manifold are parts of use and must therefore be replaced from time to time. The manifold is to be tested regularly to ensure the valves are still tight.

• If a manifold shows to be leaking the pistons of the valves can easily

be changed and are available as a spare part. Please refer to the manifold accessory section of the REFCO catalogue.

• If the sight glass is leaking a replacement kit is also available. To

change the sight glass a special tool is necessary (M4-6-11-T, Part No.

4493169) which is also available from REFCO. Replace and tighten the

new sight glass carefully in order to prevent damage of the glass.

• To change the valve core on models with t-style or vacuum gauge

connection, use a valve core screw driver A-32000 from REFCO.

• After change of spare parts of the manifold it is absolutely necessary

to test the manifold for tightness before the next use.

Further accessories and charging hoses for REFCO manifolds can be

found in the REFCO catalogue or on the web www.refco.ch.

Disposal of manifold

• Dispose of the manifold according to the rules and regulations of the

country of use.

Spare Parts for manifolds

Knob blue M2-6-09-B Part No 4490950

Knob red M2-6-09-R Part No 4490968

Complete valve set M2-10-95/10 Part No 9884818

Piston including gaskets M4-6-04/10 Part No 9884161

Sight glass set M4-6-11 Part No 4491018

Key for manifold

Sight glass M4-6-11-T Part No 4493169

Multi Case M4-6-15 Part No 4666106

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 5

HVAC/R

Service Products

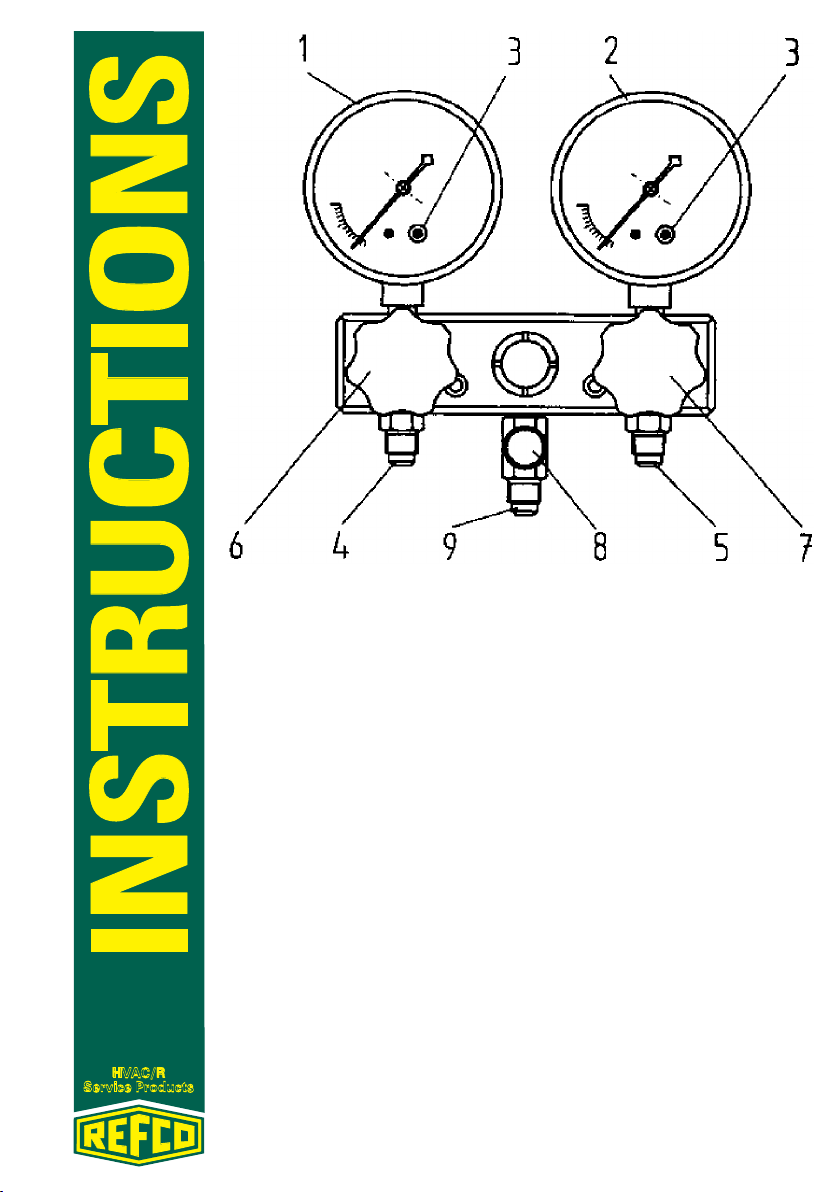

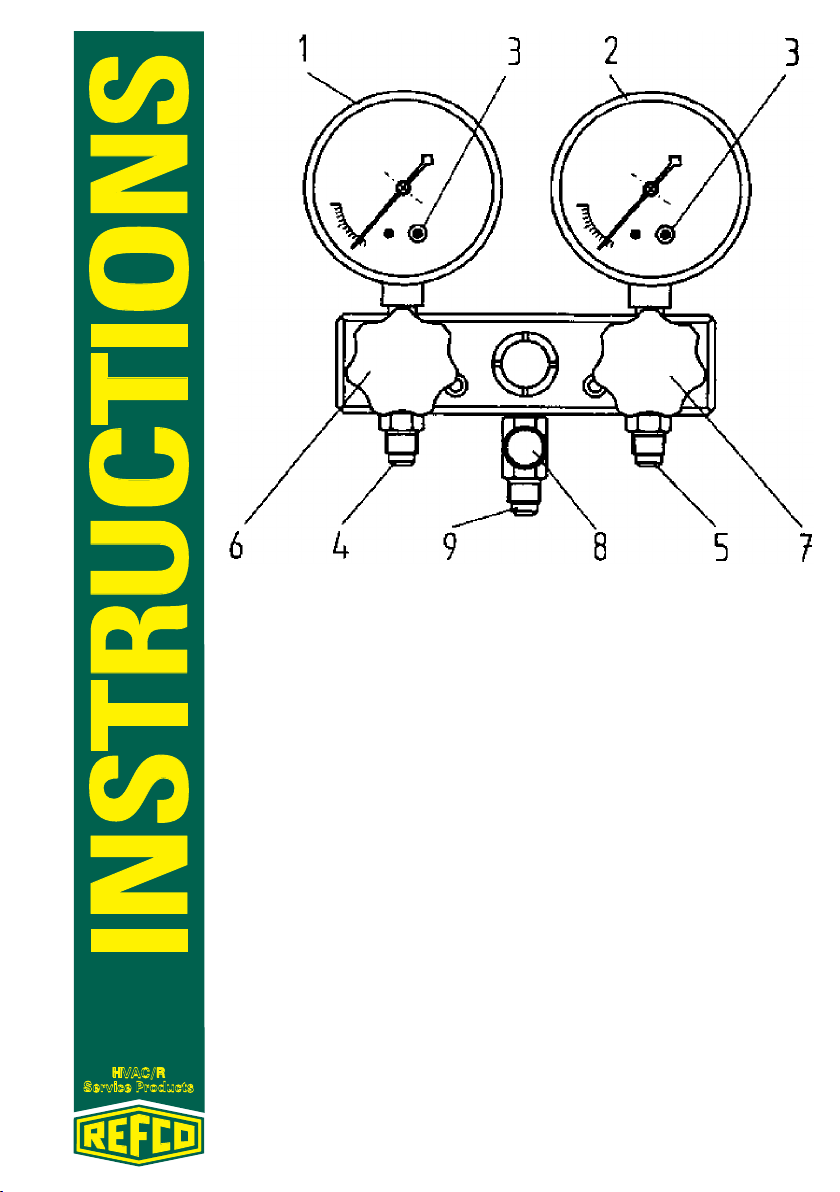

Index

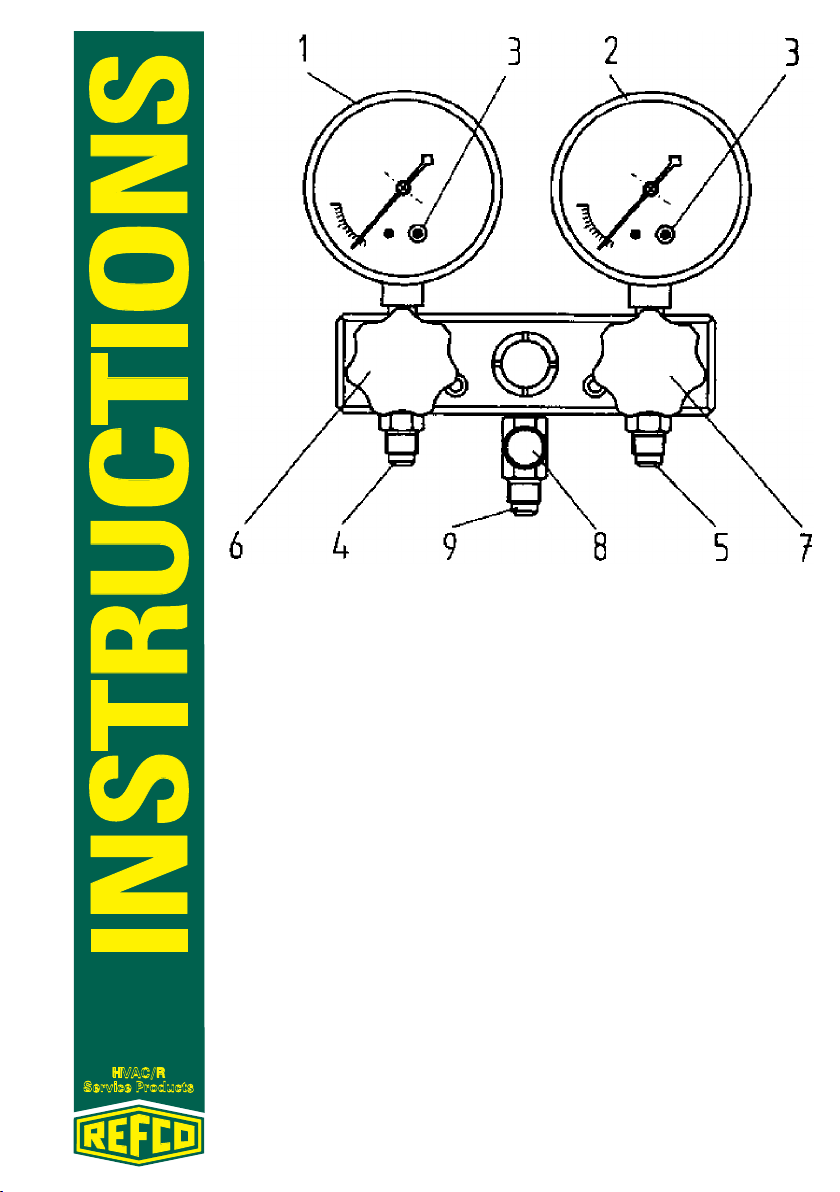

1 compound gauge

2 pressure gauge

3 adjusting screw

4 compound connection

5 pressure connection

6 compound valve

7 pressure valve

8 vacuum connection

9 refrigerant connection

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 6

HVAC/R

Service Products

Bedienungs- und Wartungsanleitung

für 2-Weg Monteurhilfen

Apex M2 SM2

BM2 MK-2 Star

Jumbo-Star

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 7

HVAC/R

Service Products

Wichtiger Hinweis

Bevor Sie die Arbeit mit der Monteurhilfe aufnehmen,

!

lesen Sie aufmerksam die Bedienungsanleitung. Sie gibt

Ihnen wichtige Hinweise für den reibungslosen Betrieb,

den Unterhalt, und die Entsorgung der Monteurhilfe.

Verwendung/Einsatz:

Die Monteurhilfe ist entwickelt worden zum Messen und Einstellen der

Druckverhältnisse in mobilen und stationären Kälte-Erzeugungsanlagen. Sie ist für die Bedienung durch ausgebildete Fachleute ausgelegt.

!

Die Monteurhilfe darf nicht für andere Zwecke ausserhalb des Klima-

Kältebereichs eingesetzt werden.

!

Die Monteurhilfe darf nicht für Drücke, welche höher sind als der

vorgegebene Höchstdruck auf dem Hochdruck-Manometer (Rot),

eingesetzt werden.

!

Die Monteurhilfe darf unter keinen Umständen als Druckreduzier-

ventil eingesetzt werden.

!

Die Monteurhilfe darf nicht mit dem Kältemittel Ammoniak (NH3)

eingesetzt werden.

!

Beim Arbeiten mit der Monteurhilfe sind immer Schutzbrille und

Handschuhe zu tragen.

Inbetriebnahme/Transport:

Die Monteurhilfen werden ab Werk in einem Kunststoff-Koffer inklusive

Füllschläuche oder in einer Kartonschachtel, mit oder ohne Füllschläuche, geliefert.

Monteurhilfen sind hochwertige Messinstrumente. Wir empfehlen

daher alle im Karton gelieferten Monteurhilfen für den Transport in ein

stabiles Behältnis zu packen.

Als Zubehör bietet REFCO dazu einen Kunststoffkoffer an.

Technische Beschreibung:

Die 2-Weg-Monteurhilfe ist ein hochwertiges Messinstrument. Die beiden Manometer, Hochdruckseite (Rot) und Niederdruckseite (Blau) sind

auf den Nullpunkt justierbar. Die Monteurhilfen sind mit fixen

Kältemittel-Temperaturskalen auf den Zifferblättern, oder mit auswechselbaren Temperaturskalen auf Glasscheiben und Skalenringen ausgestattet.

Auswechselbare Kolbenventile garantieren eine perfekte Abdichtung.

Flüssigkeitsgedämpfte Manometer verfügen über eine rückseitige

Membransicherung gegen Innenüberdruck. Die frei von der

Monteurhilfe hängenden Schlauchanschlüsse (Verschraubungen

Anlagenseite) können bei Nichtgebrauch an den seitlichen

Anschlüssen und am mittigen T-Stück angeschraubt werden.

Dies dient dem Schutz der Gewinde vor Verschmutzung und

Beschädigung.

Lieferumfang:

Der Lieferumfang für die verschiedenen Ausführungen und Variationen

ist dem REFCO-Katalog zu entnehmen.

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 8

Gebrauch:

HVAC/R

Service Products

Vorbereitung

Vor der Anwendung der Monteurhilfe muss sich der Kältemonteur

vergewissern, dass die Temperaturskala auf den Manometern mit dem

Kältemittel der zu messenden Anlage übereinstimmt. Bei

Abweichungen ist die Monteurhilfe zu wechseln, oder man muss die

Temperaturskalen-Gläser oder –Ringe auf den Manometern auswechseln, damit eine Übereinstimmung mit dem Kältemittel in der Anlage

gegeben ist.

Die Nullpunktstellung des Zeigers ist zu kontrollieren. Die

Zeigerstellung verändert sich mit der Entwicklung des atmosphärischen Luftdrucks. Eine Nachjustierung über eine

Korrekturschraube ist möglich. Die Korrekturschraube ist je nach

Manometertyp unterschiedlich platziert. Um die Korrekturschraube

bedienen zu können ist folgendes vorzukehren:

BM2, STAR, JUMBO-STAR, SM2 ➞ Stopfen am Sichtglas entfernen

➞ Schraube auf Zifferblatt

STAR, MK-2, M2 ➞ Schraube auf Manometergehäuse

(aussen –"12-Uhr")

Zur Korrektur des Zeigers auf den Nullpunkt kann die Schraube mit

einem Schraubenzieher leicht nach links oder rechts gedreht werden,

bis die genaue Position eingestellt ist. Nach erfolgter Korrektur Stopfen

oder Glas wieder montieren.

Monteurhilfe an Anlage anschliessen

• Blauen Schlauch anschliessen (4) ➞ Anlage Saugdruckseite anschliessen

• Roten Schlauch anschliessen (5) ➞ Anlage Hochdruckseite anschliessen

• Gelben Schlauch anschliessen (8) ➞ Vakuumpumpe anschliessen

• Beide Ventile (6+7) schliessen

Evakuieren der Anlage

• Vakuumpumpe einschalten

• Beide Ventile öffnen (6+7)

• Negativen Druck an Niederdruckmanometer kontrollieren

• Wenn Endvakuum erreicht, beide Ventile (6+7) schliessen

Beachten: Die Evakuierzeit variiert je nach Grösse der Anlage. Eine

minimale Evakuierzeit von 20 Minuten benötigt man mindestens für

eine kleine bis mittelgrosse Anlage.

Füllen der Anlage

• Gelben Schlauch von Vakuumpumpe lösen und an Kältemittelflasche

oder Kältemittelzylinder anschrauben.

• Blaues Ventil (Niederdruckseite) öffnen

• Ventil an Kältemittelflasche oder Kältemittelzylinder öffnen und gewünschte Menge Kältemittel einströmen lassen. Falls nicht die

erforderliche Menge Kältemittel in die Anlage strömt, muss der

Kompressor zugeschaltet werden.

• Nach Erreichen der Füllmenge, blaues Ventil schliessen.

• Ventil der Kältemittelflasche oder des Kältemittelzylinders schliessen.

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 9

• Druck und Temperatur der Anlage überprüfen!

HVAC/R

Service Products

• Schläuche von der Anlage abschrauben

• Ventile (6+7)öffnen

Unterhaltsarbeiten an der Monteurhilfe

• Die Füllschläuche sind vor jedem Einsatz einer Sichtprüfung auf

mechanische Beschädigungen zu unterziehen. Die Schläuche müssen

ölfrei sein.

• Die Dichtungen einer Monteurhilfe unterliegen naturgemäss einem

mechanischen und alterungsbedingtem Verschleiss. Daher ist die

Monteurhilfe regelmässig vom Anwender auf Undichtheiten zu prüfen.

• Bei undichten Ventilen ist der Kolben komplett (mit O-Ring und

Teflondichtung) zu ersetzen.

• Zum Wechseln des Schauglases an der Monteurhilfe ist das REFCOSpezialwerkzeug M4-6-11-T, Art.Nr. 4493169 zu verwenden. Die

Verwendung anderer Werkzeuge kann den Schraubring und das

Schauglas beschädigen, oder das richtige Eindrehen des

Schraubringes verhindern.

• Zum Wechseln von undicht gewordenen Ventilkernen ist ebenfalls ein

Ventilkernschlüssel (A-32000 von REFCO) zu verwenden.

• Nach dem Ersetzen von einer oder mehreren Dichtungen ist vor einer

erneuten Inbetriebnahme eine Dichtheits-Kontrolle vorzunehmen.

Weitere Möglichkeiten an Zubehör, Schläuchen und Ventilen sind im

REFCO-Katalog ersichtlich.

Entsorgung der Monteurhilfe

• Bei Ausserbetriebsetzung einer Monteurhilfe hat der Anwender die

einschlägigen Entsorgungsvorschriften seines Landes zu beachten.

Ersatzteile zu Monteurhilfen

Sterngriff Blau M2-6-09-B Best.-Nr. 4490950

Sterngriff Rot M2-6-09-R Best.-Nr. 4490968

Ventileinsatz-Set M2-10-95/10 Best.-Nr. 9884818

Ventil-Kolben M4-6-04/10 Best.-Nr. 9884161

Schauglas-Set M4-6-11 Best.-Nr. 4491018

Werkzeug für

Schauglas M4-6-11-T Best.-Nr. 4493169

Kunststoff-Koffer M4-6-15 Best.-Nr. 4666106

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 10

HVAC/R

Service Products

Index

1 Saugmanometer

2 Druckmanometer

3 Einstellschraube

4 Niederdruckanschluss

5 Hochdruckanschluss

6 Saugventil

7 Druckventil

8 Vakuumanschluss

9 Kältemittelanschluss

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 11

Mode d’emploi

HVAC/R

Service Products

pour by-pass REFCO 2 voies:

Apex M2 SM2

BM2 MK-2 Star

Jumbo-Star

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 12

HVAC/R

Service Products

Important

Lire ce manuel et se familiariser avec les caractéris-

!

tiques et le fonctionnement des by-pass REFCO avant

utilisation. Les instructions d’utilisation vous donneront

des informations importantes sur l’usage et l’entretien

des by-pass.

Utilisation des by-pass:

Les by-pass ont été spécialement conçus pour mesurer la pression

dans un système de réfrigération. Le by-pass doit toujours être utilisé

par des professionnels qualifiés.

!

Le by-pass ne doit pas être utilise dans d’autre domaines que la

réfrigération en rapport avec les réfrigérants. Le by-pass n’est pas utilisable avec d’autres liquides ou gaz que ceux indiqués sur le cadran

des manomètres.

!

Le by-pass ne doit pas être utilisé à des pressions supérieures à la

pression maximum du manomètre haute pression.

!

Le by-pass ne doit en aucun cas être utilisé comme détendeur de

pression.

!

Le by-pass ne doit pas être utilisé avec de l’ammoniac (NH-3).

!

Pendant l’utilisation du by-pass, il est impératif de porter des lu-

nettes de sécurité et des gants de protection

Préparatifs / Transport:

Les by-pass sont livrés d’usine dans une valise plastique ou dans une

boîte carton avec ou sans tuyaux de charge.

Les by-pass sont des instruments de mesure de grande précision.

Après usage, ranger le by-pass dans sa valise ou sa boîte carton. La

valise plastique peut être achetée séparément ; voir la section des

accessoires de by-pass dans le catalogue REFCO.

Description technique:

Le by-pass 2 voies est un instrument de mesure de haute précision. Les

deux manomètres, basse et haute pression possèdent une vis de

remise à zéro. Le manomètres possèdent des échelles de pression et

de température ou sont équipés d’échelles de température interchangeables. Les vannes à piston remplaçables assurent une parfaite

étanchéité. Les manomètres à bain d’huile sont équipés d’une pastille

de sécurité au cas où, par suite d’un défaut, la pression passe dans le

boîtier du manomètre. L’extrémité libre des tuyaux peut être fixée sur

les raccords de coté ou sur le raccord en Té du by-pass après usage.

Dans ce cas les tuyaux seront protégés contre tout type

d’ agression.

Composition:

La composition de chaque by-pass varie selon le type. Se référer au

catalogue REFCO pour connaître la composition et la liste des accessoires.

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 13

Utilisation du by-pass:

HVAC/R

Service Products

Préparation

Avant utilisation, s’assurer que les échelles de températures correspondent aux réfrigérants dans l’unité.

Procéder à la remise à zéro des manomètres. La position de l’aiguille

peut varier en fonction de la pression atmosphérique. C’est pourquoi il

est nécessaire de régler le zéro avant chaque utilisation. La vis de

réglage est située sur le dessus du manomètre ou sur le cadran derrière le verre selon le type de by-pass.

Différents modèles existants:

BM2, STAR, JUMBO-STAR, SM2 ➞ bouchon plastique sur le verre

➞ vis sur le cadran

STAR, MK-2, M2 ➞ vis au-dessus du manomètre (à l’extérieur – "à

midi")

Après réglage remettre en place le verre ou le bouchon plastique.

Raccordement du by-pass à l’unité

• Raccorder le tuyau bleu (4) ➞ coté basse pression de l’unité.

• Raccorder le tuyau rouge (5) ➞ coté haute pression de l’unité.

• Raccorder le tuyau jaune (8) ➞ pompe à vide.

• Fermer les deux vannes (6+7).

Tirage au vide d’une unité

• Mettre en route la pompe à vide

• Ouvrir les deux vannes (6+7)

• Vérifier la pression indiquée sur le manomètre basse pression

• Lorsque le vide est atteint, fermer les deux vannes (6+7)

Note: Le temps de tirage au vide dépend de la taille de l’unité. Une

durée minimale de 20 minutes est nécessaire pour tirer au vide une

unité petite ou moyenne.

Remplissage d’une unité après triage au vide

• Laisser les deux vannes fermées. Débrancher le tuyau jaune de la

pompe à vide et le raccorder à la bouteille de réfrigérant.

• Ouvrir la vanne bleue (basse pression)

• Ouvrir la vanne de la bouteille de réfrigérant. Contrôler la charge de

réfrigérant à l’aide d’une balance de charge, le modèle REFCO REFMETER par exemple et vérifier la pression indiquée sur le manomètre

basse pression. Si le flux du réfrigérant est trop bas ou insuffisant, le

compresseur de l’unité peut être mis en route pour accélérer la procédure. Vérifier que la charge est effectuée en réfrigérant sous forme

gazeuse seulement. Charger en liquide peut endommager les composants de l’unité.

• Une fois la charge correcte effectuée, fermer toutes les vannes.

• Contrôler les pressions et températures de fonctionnement sur les

manomètres.

Travail final

• Débrancher les tuyaux de l’unité.

• Ouvrir les vannes (6+7)

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 14

Maintenance du by-pass

HVAC/R

Service Products

• Les tuyaux de charge doivent être vérifiés et nettoyés (résidus d’huile)

avant chaque usage. Un contrôle visuel est également nécessaire pour

vérifier l’état du tuyau et des raccords.

• Les vannes et joints du by-pass sont des pièces d’usure et pour cela

doivent être remplacés de temps en temps. Le by-pass doit être

régulièrement vérifié pour s’assurer que les vannes sont toujours

étanches.

• S’il apparaît des fuites, les pistons des vannes existant en pièces

détachés peuvent être changés aisément. Se référer à la section accessoire de by-pass du catalogue REFCO.

• Si le voyant est également fuyant, il peut être remplacé. Pour cela l’utilisation d’un outil spécial est nécessaire (M4-6-11-T, Réf. No. 4493169).

Remonter le nouveau voyant avec précautions pour éviter d’endommager le verre.

• Pour changer la valve du raccord en Té ou sur le raccord pour vacuomètre, utiliser l’outil A-32000 de REFCO.

• Après tout changement de composant il est absolument nécessaire

de contrôler l’étanchéité du by-pass.

D’autres accessoires et tuyaux de charge pour by-pass REFCO peuvent

être trouvés dans le catalogue REFCO ou sur le site www.refco.ch.

Mise au rebut du by-pass

• Mettre au rebut le by-pass selon les règles et les réglementations en

vigueur dans le pays d’utilisation.

Pièces de rechange pour by-pass

bouton bleu M2-6-09-B Référence 4490950

bouton rouge M2-6-09-R Référence 4490968

vanne complète M2-10-95/10 Référence 9884818

piston avec joints M4-6-04/10 Référence 9884161

voyant avec joint et

écrou M4-6-11 Référence 4491018

outil de montage

du voyant M4-6-11-T Référence 4493169

valise plastique M4-6-15 Référence 4666106

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 15

HVAC/R

Service Products

Index

1 manomètre basse pression

2 manomètre haute pression

3 vis de règlage

4 raccord basse pression

5 raccord haute pression

6 vanne basse pression

7 vanne haute pression

8 raccord pour vide

9 raccord pour réfrigèrant

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 16

Istruzioni d’uso

HVAC/R

Service Products

Per i gruppi manometrici REFCO a 2 vie:

Apex M2 SM2

BM2 MK-2 Star

Jumbo-Star

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 17

Importante

HVAC/R

Service Products

Prima di iniziare il lavoro con i gruppi manometrici

!

REFCO, leggere attentamente il manuale d’uso. Le

istruzioni d’uso vi danno le informazioni utili, importanti sull’uso esatto, é maneggiamento dei gruppi manometrici.

Utilizzo dei gruppi manometrici:

I gruppi manometrici sono stati specialmente progettati per misurare le

pressioni in un sistema di refrigerazione. I gruppi devono essere sempre usati da persone professionalmente qualificate.

!

I gruppi devono essere utilizzati solo nella refrigerazione e in rapporto con il gas refrigerante. I gruppi manometrici vanno usati solo per

i gas refrigeranti indicati sul quadrante dei manometri, non usare altri

liquidi o gas che indicati!

!

I gruppi manometrici non devono essere usati con pressioni superiori alla pressione indicata sul manometro d’alta pressione.

!

Non usare mai il gruppo manometrico come riduttore di pressione.

!

I gruppi manometrici non vanno usati con l’ammoniaca (NH-3).

!

Durante l’uso dei gruppi manometrici è importante di usare gli

occhiali di sicurezza e i guanti protettivi.

Preparativi / Trasporto:

I gruppi manometrici sono forniti dalla fabbrica in una valigetta di plastica o in una scatola di cartone con o senza i tubi di carica.

I gruppi manometrici REFCO sono degli strumenti d’alta precisione.

Dopo averli usati, posare il gruppo manometrico nell’apposita valigetta o scatola di cartone. La valigetta di plastica può essere acquistata

separatamente; vedere il catalogo REFCO nel capitolo "gruppi manometrici”.

Descrizioni tecniche:

Il gruppo manometrico a due vie è uno strumento di misura d’alta precisione. I due manometri, di bassa e d’alta pressione so equipaggiate

con una vite d’azzeramento. Sull’ quadrante del manometro e stampato sia la scala con temperatura con la pressione o sono equipaggiate

con delle scale intercambiabili con la temperatura.

Le valvole a pistone si possono sostituire facilmente e assicurano una

tenuta perfetta. In caso di un malfunzionamento del gruppo o soprapressioni all’interno del manometro, i manometri a bagno d’olio sono

equipaggiati con una membrana di sicurezza.

Le estremità dei tubi di carica liberi possono essere fissate dopo il

lavoro ai raccordi sui fianchi o il raccordo a T del gruppo manometrico.

In questo caso i tubi sono protetti contro tutti i tipi d’impurità.

Accessori e tipi:

Gli accessori di tutti i gruppi manometrici sono differenti da tipo a tipo.

Contattare il catalogo REFCO per trovare il modello e gli accessori da

voi richiesto.

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 18

Come utilizzare il gruppo manometrico

HVAC/R

Service Products

Preparazione

Prima dell’utilizzo, assicurarsi che le scale della temperatura corrispondano al gas utilizzato dentro l’unità.

Azzerare i manometri prima di usare il gruppo manometrico. La

posizione della lancetta può variare à secondo la pressione atmosferica. Per questa ragione è sempre nécessario di azzerare il manometro,

prima d’ogni utilizzo. La vite di regolazione è situata sopra il

manometro o sul quadrante dietro il vetrino del manometro, à secondo il tipo del gruppo manometrico

I modelli sono:

BM2, STAR, JUMBO-STAR, SM2 ➞ tappo in plastica sul vetrino ➞

vite di azzeramento sul quadrante

STAR, MK-2, M2 ➞ vite d’azzeramento sul manometro (al esteriore)

Dopo la regolazione rimettere il tappo o rimontare il vetrino.

Raccordo tra il gruppo manometrico e l’unità.

• Raccordare il tubo blu (4) con la parte di bassa pressione dell’unità.

• Raccordare il tubo rosso (5) con la parte d’alta pressione dell’unità.

• Raccordare il tubo giallo (8) con la pompa a vuoto.

• Chiudere le due valvole (6+7).

Tirare il vuoto da un impianto

• Metter in moto la pompa per vuoto.

• Aprire le due valvole (6+7).

• Verificare la pressione negativa indicata sul manometro di bassa pressione.

• Quando il vuoto e raggiunto, chiudere le due valvole (6+7).

Nota: Il tempo per tirare il vuoto da un impianto, dipende dalla taglia

dell’unità. Una durata minima per un impianto piccolo o medio é di

minimo 20 minuti.

Carica di un impianto dopo il vuoto

• Lasciare chiuse le valvole chiuse. Staccare il tubo giallo dalla pompa

per vuoto, è raccordarla con la bombola per gas refrigerante.

• Aprire la valvola Blu (bassa pressione)

• Aprire la valvola della bombola di gas refrigerante. Controllare la carica con l’aiuto di una bilancia, per esempio, con il modello REFCO REFMETER, è verificare la pressione sul manometro di bassa pressione. In

caso ché il flusso del gas refrigerante é basso o insufficiente, può

essere messo in moto il compressore dell’unità per accelerare la procedura. Si consiglia ché la carica sia effettuata gasiforme. La carica liquida può danneggiare gli elementi dell’unità

• Una volta effettuata la carica corretta, chiudere tutte le valvole

• Controllare le pressioni e temperature di funzionamento sui manometri.

Lavori finali

• Svitare i tubi dall’unità.

• Aprire le valvole (6+7)

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 19

HVAC/R

Service Products

Manutenzione del gruppo manometrico

• Dopo il lavoro, i tubi di carica devono essere controllati e puliti

(residui d’olio). Un controllo visivo è necessario per verificare lo stato

dei raccordi é della gomma.

• Le valvole e le guarnizioni del gruppo manometrico sono pezzi di

usura é devono essere sostituiti di tempo in tempo. Il gruppo manometrico deve essere controllato regolarmente per assicurarsi che le

valvole hanno tenuta.

• In caso di perdite sul gruppo, controllare i pistoni. I pistoni vanno

cambiati completamente (teflon é O-ring insieme). Contattare il catalogo REFCO per trovare i pezzi di ricambi e gli accessori.

• In caso che la spia ha delle fughe, anch’essi si possono sostituire. In

questo caso si deve utilizzare la chiave speciale (M4-6-11-T, No. ordine

4493169). Per evitare di danneggiare il vetrino, montare la nuova spia

con precauzione!

• Per cambiare le valvole di servizio in caso di perdite, è consigliabile di

usare la chiave A-32000 della REFCO.

• Dopo ogni sostituzione é necessario di controllare il gruppo mano-

metrico sulla funzionalità è tenuta.

Altri accessori e tubi di carica per i gruppi manometrici REFCO possono

essere trovati sul catalogo REFCO o sul sito WEB www.refco.ch.

Smaltimento dei gruppi manometrici

• Lo smaltimento dei gruppi manometrici è sottomesso à secondo le

leggi in vigore del paese d’utilizzo.

Manòpola blu M2-6-09-B No. d’ordine 4490950

Manòpola rossa M2-6-09-R No. d’ordine 4490968

Rubinetto completo M2-10-95/10 No. d’ordine 9884818

Pistone con guarnizione M4-6-04/10 No. d’ordine 9884161

Indicatore completo M4-6-11 No. d’ordine 4491018

Chiave per

Indicatore M4-6-11-T No. d’ordine 4493169

Valigetta in plastica M4-6-15 No. d’ordine 4666106

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

Page 20

HVAC/R

Service Products

Index

1 manometro bassa pressione

2 manometro alta pressione

3 vita di azzeramento

4 raccordo bassa pressione

5 raccordo alta pressione

6 valvola bassa pressione

7 valvola alta pressione

8 valvola di vuoto

9 raccordo per refrigerante

REFCO Manufacturing Ltd. Telefon +41 41 919 72 82

Industriestrasse 11 Telefax +41 41 919 72 83

CH-6285 Hitzkirch (Switzerland) Info@refco.ch www.refco.ch

9884793/2609

Loading...

Loading...