Page 1

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

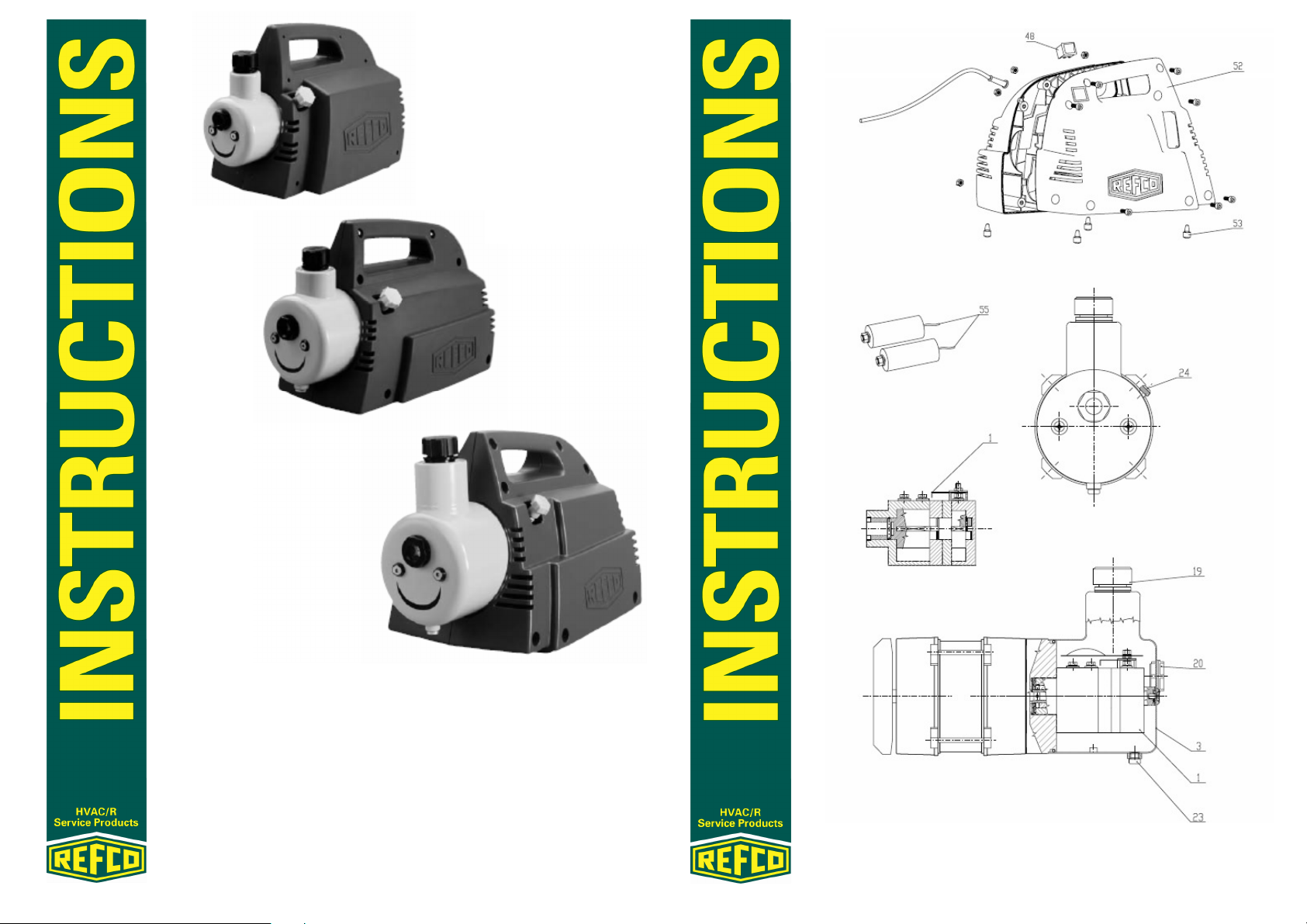

Instruction Manual

REFCO Rotary vane vacuum pumps

115V – 60 Hz

RL-2

RL-4

RL-8

Exploded view

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Page 2

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

RL vacuum pumps

Thank you for choosing a REFCO vacuum pump. We are proud of each

and every REFCO product and are dedicated to ensuring our products

always perform reliably.

The design of the vacuum pump ensures that the requirements of the

relevant CE directives and standards are fulfilled. Reading the following

operating instructions thoroughly and following our recommendations

will give you important information for the smooth operation and

maintenance of your pump and help to prolong its lifespan.

Please observe the warning signs!

They are indicated by this symbol: This international symbol warns

of hazards which could lead to serious injury or material damages.

Contents

Important safety notices …..………..………………………………………………3

Use of the pump ……..……………………..…………………………………………4

Set up operation/transport ..…………………..………………………………..4, 5

Electric data …..………………………………………………………………………..5

Technical description …………………………………………………………………5

Contents of delivery of standard execution RL-2, RL-4, RL-8 ……………5, 6

Other accessories ……………………………………………………………………..6

Note ….……………………………………………………………………………………6

Service/Oil change ………………………………………………………………….6, 7

Trouble shooting …………………………………………………………………….7, 8

Warranty …………………………………………………………………………………8

Technical data ………………………………………………………………………….9

Spare parts ………………………………………………………………………2, 9, 10

Environmental issues ………………………………………………………………10

Important safety notices

Before working with the vacuum pump, please read the

instruction manual carefully. This manual contains

important information regarding the smooth operation,

maintenance and disposal of the vacuum pump.

The vacuum pump should only be operated on a fused

power supply and must be correctly earthed. If the mains

cable is damaged or cut through during operation, do not touch the

cable and unplug the mains plug immediately. The device should

never be used with a damaged cable.

REFCO products have been specially designed and

manufactured for use by trained refrigeration installation

engineers. Because of the high pressures and the chemical

and physical gases used in refrigeration systems, REFCO

cannot be held responsible or liable for any accidents,

injuries or deaths arising from the use of their products.

REFCO explicitly states that their products must only be

sold to professionally-trained experts.

Use of the pump

The REFCO vacuum pumps have been especially designed and

manufactured for the evacuation of closed vessels and units in the

field of refrigeration and air-conditioning. The pump must always be

operated by a qualified professional technician!

This pump should only be operated by qualified personnel.

Suitable protective equipment like gloves, goggles and safety

footwear should be worn when working with refrigeration

systems.

The vacuum pump should not be exposed to rain, or used in wet

or damp conditions.

The vacuum pump must only be used in the field of

refrigeration and air-conditioning and must not be used, built in

or mounted into other appliances and applications.

The vacuum pump must not be used as a compressor or to

build up pressure with air or other gases.

The vacuum pump must not be operated in flammable

environments or places where explosive gas could be present.

The vacuum pump must not be used in connection with

aggressive liquids and gases such as i.e. ammonia or pure

oxygen which could cause damage to parts and components of

the pump.

Combustible refrigerants such as i.e. R600a, R600, R290, must

be vented through the exhaust to the outside of buildings by

means of a venting hose (see accessories).

The vacuum pump must not be used to pump liquids such as

i.e. water, fuels, oils, beverages, other liquid food, liquid refuse

or faeces.

Set up operation/transport

The vacuum pumps supplied without electrical plug must be equipped

with an electrical triple-pole plug according to the norms and

regulations of the country where the vacuum pump will be used. The

plug must be fitted by a trained professional. The electrical power

supply, with which the vacuum pump will be run, must be in

accordance with the voltage and frequency indicated on the rating

plate of the vacuum pump. The vacuum pump must only be connected

to a fused electric installation.

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Page 3

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

The vacuum pump is supplied without oil filling. Prior to the first

operation the vacuum pump must be filled to half level of the oil sight

glass (Pos. 20) with the oil provided (DV-44/DV-45). The oil is being filled

in through the port of the oil mist filter (Pos. 19).

Only fill oil up to half level of the oil sight glass. Refit the oil mist

filter (Pos. 19) after filling.

Remove the flare cap from the intake port to start the pump (with

model RL-8 also turn the ball valve to open position). Connect the

charging hose to the intake port as soon as the pump motor

reaches full speed.

Running the pump without being connected to a system and pulling

vacuum will result in extensive exhaust of oil mist through the oil

mist filter.

Carry the vacuum pump on the designated handle only.

Keep the pump levelled and secured during transport to avoid oil

spillage. Oil spillage could cause damage to the electric motor.

Electric data

The electric data is mentioned under „technical data“ on page 9 of this

manual.

Technical description

The REFCO vacuum pumps RL-2, RL-4, RL-8 are rotary vane type

vacuum pumps. The pump is cooled internally by a mechanical impeller

during operation. A fitted oil mist filter allows oil back flow into the oil

circulation system of the pump head. The gas ballast valve prevents the

build-up of condensation inside the oil box and the pump head. The

motor is protected by a thermocouple which turns the pump off

automatically if overheated.

Caution! The motor will restart automatically after a cooling period

of approximately 20 minutes.

Contents of delivery of standard execution RL-2, RL-4, RL-8

• Vacuum pump oil DV-44/DV-45

• Instructions of use

The RL-8 is in addition equipped with a ball valve to isolate the pump

from a system.

The pumps are supplied without oil filling. The must be filled with

the oil provided prior to the first operation.

Option: Intake port with anti-back flow to prevent oil sucks back in case

of an accidental shut off of the pump or power cut.

Intake port with back flow prevention:

For RL-2: RL-2-307-RS 4663786

For RL-4: RL-4-307-RS 4663336

For RL-8: RL-8-307-RS 4664244

Other accessories

Vacuum gauge with ball valve:

For vacuum pumps RL-2, RL-4, RL-8: RL-VAC 4663981

Special hose to vent combustible refrigerant from closed

environments:

Available for RL-2, RL-4: 10859-CL-197-Y-SP 9881865

Note

Please note the minimal operating temperatures for the vacuum

pumps are described under „technical data“ on page 8 of this

manual. If the environmental temperatures are below the minimal

rates the pump may take several seconds or minutes until the motor

runs on full speed and the pump can develop its full capacity.

Always turn off and disconnect power before moving or servicing

the REFCO vacuum pumps.

The vacuum pump and especially the front cover can reach

temperatures of up to 70°C/160°F during operation.

Check the appropriate oil level (half level of sight glass) and make

sure that there is enough oil. Should the oil be cloudy, dark or

contaminated, or should the oil level have increased without refilling,

change the oil immediately.

Ensure that the air intake of the impeller fan at the back of the pump

is not covered with any objects or cloths etc. Preventing the air flow

through the pump can lead to an automatic motor shut off by the

thermo couple.

Caution! Automatic restart after cooling time of approx.

20 minutes.

Service/Oil change

The main service point of a vacuum pump is the oil. Vacuum pump

oil must be changed at least after every 20 hours of service or

whenever the oil in the sight glass is cloudy or dark. The oil must be

changed immediately after an evacuation of a heavily contaminated

system. Residue of moist/water in the oil may cause corrosion and

damage to the vacuum pump.

Contaminated oil may damage the vacuum pump.

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Page 4

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

Change of oil

Condition

Possible problem

Solution

Pump does not

Oil temperature

Put the pump in warmer

Unsuitable oil

– too

Change with REFCO oil

Pump dirty

Change oil

Motor winding

Call customer service

The connection

Use a shorter

Supply voltage is

Pump is designed to

Motor does not

Defective capacitor

Change capacitor

Switch defective

Replace switch

Motor too hot

Let it cool down

Cable defective

Replace cable

Condition

Possible problem

Solution

Motor drones but

Oil heavily

Change pump head

Motor runs

⇒ no

Broken clutch pin

Call customer service

Oil spillage on oil

Pump overfilled with

Adjust oil to half level of

Extensive oil mist

Pump pressure =

Oil mist will disappear as

Oil not visible in

Not enough oil in

Top up with oil

Oil cloudy or dark

Contaminated oil

Change oil

Not enough

Gas ballast open

Close gas ballast valve

Loose cap on intake

Screw the cap on tightly

O-

ring in the intake

Replace O

-

ring

Oil level too low

Refill oil

Oil

is muddy (cloudy)

Change oil

Pipe leaking

Check pipe, seal it

Pump is worn out

Repair or replace pump

Motor noisy

Bearings worn out

Call customer service

Defective ventilator

Replace ventilator

Pump loses oil

Leaking gasket of oil

Change O

-

ring

Oil draining screw

Replace oil draining

Leaking gasket of

Change sight glass

Leaking gaskets box

Change gaskets of oil of

Leaking

shaft seals

Call customer service

• Run the pump until operating temperature has been reached. Turn the

pump of and disconnect from mains.

• Unscrew the oil mist filter (Pos. 19)

• Drain oil through drain plug (RL-4/RL-8 Pos. 23) or through opening for

oil mist filter (model RL-2 does not have an oil drainage plug and the

oil must be drained through opening of oil mist filter).

• Connect pump to the mains again and turn on. Let the pump run for

10-15 seconds with open intake port in order to drain oil residue in the

pump head.

• Turn the pump off and disconnect from the mains.

• Drain possible oil residue.

• Remount oil drain plug (Pos. 23).

• Refill with oil to half level of sight glass.

• Refit oil mist filter (Pos. 19). Let the pump run for a few seconds.

If the oil has been strongly contaminated the oil change procedure

must be repeated after a run time of 30 minutes in order to assure

that all waste particles inside the pump have been washed out with

the oil.

In order to achieve best performance with the REFCO vacuum pumps

only use REFCO oils DV-44, DV-45, DV-46, DV-48 or REFCO ester oil.

Waste oil must be disposed of according to the rules and

regulations which apply in the country of use of the pump.

Further service work than oil change has to be executed by a specialised

company.

Trouble shooting

does not run,

Pump locked up

performance

mist filter

from oil mist filter

sight glass

vacuum

contaminated

oil

atmospheric

pressure

pump

port

port cap is faulty

or contaminated

after lengthy use

Defective fan

impeller

Call customer service

sight glass, drain

additional oil

soon as a certain vacuum

has been reached

Call customer service

Change impeller

run on full speed

too low

environment/room

thick

defective

cable is too long

too low

connection cable

work at +/- 10% of the

supply voltage

start at all

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Call customer service

box

leaking

screw

sight glass

screws

screws

Warranty

REFCO grants a 24 month warranty period. Damage caused due to

improper use, lack of service as described in this manual, use of the

pump for other applications as the designated ones, use of unsuitable

vacuum pump oil or opening and dismantling the pump during warranty

period by the user will lead to loss of warranty. For repairs during the

warranty period the vacuum pump must be returned to the seller at

owners cost.

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Page 5

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

Technical data

RL-2 RL-4 RL-8

Capacity

l/min

(cfm) 40 (

1.35) 76 (2.7)

180

(6.4)

End vacuum with closed

gas ballast valve at 20°C

Minimal oil temperature

+5°C /

+5°C /

+2°C /

Intake port SAE

1/4" 1/4"+3/8"

1/4"+3/8"

Gas ballast

Yes Yes Yes

Oil mist filter

Yes Yes Yes

Oil back flow prevention

optional

optional

Yes

Oil capacity

ml (pt)

125 (

0.25)

250 (

0.5)

500 (

1

.0)

Sound pressure level

Power supply

115V

/ 60Hz

Motor

kW/Umin

0.16/2400

0.19/2400

0.37/2800

Measurements

mm

271x167x195

301x152x204

360x220x250

Weight

kg (

lbs)

3.8 (

8.4)

5.56 (

12.2)

11.8 (

26)

4509464

/ 1

5

1

4

68°F

for motor start up

emissions LpA

(LxWxH) inch

41°F

10.6x6.6x7.6

0.02 mbar (15 microns)

41°F

LpA ≤ 70dB (A)

11.8x6x8

36°F

14x8.6x9.8

Spare parts

Pos. Reference Description Part No.

Spare parts for RL-2

3........... RL-2-3000..... Oil box complete with gaskets................. 4661589

20......... RL-2-3011..... Oil sight glass complete........................... 4661597

19......... RL-4-303....... Oil mist filter complete............................. 4495471

24......... RL-2/4-3060.. Gas ballast valve complete...................... 4661423

53......... RL-8-4071..... Rubber pads (4 pcs)................................. 4507631

55……...RL-2-406 115V-60HZ........... Capacitor (2 pcs)................ 4661040

48......... RL-4-415....... On-Off switch............................................ 4496770

52......... RL-2-4000….. Housing complete (2 parts)...................... 4661538

1........... RL-2-2A......... Vacuum stage overhauled complete

with gasket in exchange…………………. 4661482

1........... RL-2-2A......... Vacuum stage overhauled complete

with gasket without exchange................. 4661482

............. RL-1-1000..... Gasket set................................................ 4668419

Spare parts for RL-4

3........... RL-4-3000..... Oil box complete with gaskets................. 4507674

20......... RL-4-3011..... Oil sight glass complete........................... 4507682

23......... RL-4-310....... Oil drain plug with gasket.........................4496761

19......... RL-4-303....... Oil mist filter complete............................. 4495471

24......... RL-2/4-3060.. Gas ballast valve complete...................... 4661423

53......... RL-8-4071..... Rubber pads (4 pcs)................................. 4507631

55......... RL-4-406-KS 115V-60HZ….. Capacitor (2 pcs)................ 4661058

48......... RL-4-415....... On-Off switch............................................ 4496770

52......... RL-4-4000..... Housing complete (2 parts)...................... 4661474

Pos. Reference Description Part No.

1........... RL-4-2A......... Vacuum stage overhauled complete

with gasket in exchange…………...….. 4661954

1………. RL-4-2A Vacuum stage overhauled complete

with gasket without exchange............. 4661954

............. RL-4-1000..... Gasket set........................................... 4668427

Spare Parts for RL-8

3........... RL-8-3000..... Oil box complete with gaskets............ 4507607

20......... RL-8-3011..... Oil sight glass complete……................ 4507615

23......... RL-4-310....... Oil drain plug with gasket.................... 4496761

19......... RL-8-303....... Oil mist filter complete........................ 4507445

24......... RL-8-3060..... Gas ballast valve complete................. 4507623

53......... RL-8-4071..... Rubber pads (4 pcs)............................ 4507631

55......... RL-8-406-60uF Capacitor (2 pcs)................................. 4660680

48......... RL-4-415....... On-Off switch.......................................4496770

52......... RL-8-4000..... Housing complete (2 parts)….............. 4507640

1........... RL-8-2A......... Vacuum stage overhauled complete

with gasket in exchange……………….. 4507658

1........... RL-8-2A......... Vacuum stage overhauled complete

with gasket without exchange……..... 4507658

............. RL-8-1000..... Gasket set........................................... 4668436

Spare Parts

⇒ To avoid damage or reduced pump performance, please make

sure to use the appropriate REFCO replacement parts and

components. Please indicate pump type and serial number (see

name-plate) when ordering spare parts.

Environmental issues

The vacuum pump has been developed for long term use. REFCO

takes energy saving and environmental impact into account when

procuring materials and manufacturing its products.

REFCO Manufacturing Ltd. feels responsible for all its products

throughout their entire lifespan and has therefore been certified in

accordance with DIN EN ISO 14001 : 2004.

When decommissioning the device, users should observe the disposal

regulations applicable in their country.

Oil and other components must be disposed of in an environmentallyfriendly manner.

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Industriestrasse 11 Telefax +41 41 919 72 83

6285 Hitzkirch - Switzerland info@refco.ch www.refco.ch

Loading...

Loading...