Page 1

ENVIRO- D UO

46 86 3 53

Instruction Manual

Two – Piston Recovery Station

Bedienungsanleitung

Zwei-Kolben-Absauggerät

Mode d'emploi

Station de récupération à double piston

Istruzioni per l'uso

Unità di recupero a due pistoni

Manual de instrucciones

Estación de recuperación de dos pistones

Page 2

Page 3

Instructi on Manual ENVIRO-DUO English

OPERATING INSTRUCTIONS

ENVIR O-DUO

Table of Contents

1. General Information……………… …………………1…

2. Safety………………………………………………………3

2.1 Personnel Qualifications…………………………3

2.2 Special Hazards……………………………………4

2.3 Labels / Safety Markings…………………………7

3. Technical Specifications………………………………8

4. Parts Description…………………………………………9

5. Instruction of Operation Panel………………………10

6. Electrical Diagram……………………………………11

7. Operation………………………… ……………………12

8. Recovery Method………………………………………15

9. Self-Purge Method…………………………………… 17

10. Liquid Push / Pull Mode………………………………18

11. FAQ and Trouble Shooting……………………………20

12. Maintenance……………………………………………22

13. Service……………………………………………………23

14. Recycling…………………………………………………23

Page 4

English Ins truction Manual ENVIRO-DUO

1. General Information

Thank y ou for purcha sing the EN VIRO-DUO Refr igerant

Recovery Machine!

ENV I RO-DU O co m bine s an inn o v ativ e r efr iger ant ga s

comp ression s ystem with a ru gged, mould ed case that is

designed to offer maximum protection from damage during

transit and normal handling.

With normal use and with care as prescribed in this Manual,

your ENVIRO-DUO will give you yea rs of trouble-free

operation.

Safety First!

When found on the machine, this international symbol

is intended to alert the user to the prese nce of impor tant

operating, safety and maintenance (servicing) instructions

in this Manual. As used in the Manual, it is draw

your attention to critical items.

It is important to read this entire Manual and be familiar with

its contents before using the machin e!

The ENVIRO-DUO is a Recovery Machine for a broad range

of ref rigerants. Recovering refrigerants into a separa te

storage cylinder involves a proces s of gas compression,

resulting in high pressures within the machine, the connecting

hoses and the storage cylinder. High-pressure systems must

always be treated with care and respect to prevent careless

accidents.

intended to

1

Page 5

Instructi on Manual ENVIRO-DUO English

Product Saf ety:

The ENVIRO- DUO has been designed to me et the

requirements of the Stan dard for Refrigerant Re covery

Machines, ARI and certification.

If an approved cylinder with overfill is not available always

use an approved scale to monitor the cylinders capacity.

Additionally, approved refrigerant hoses must be used which

have shut-off devices within 300 mm of the ends to reduce

the likelihood of refrigerant leakage to the atmosphere when

changing cyli nders or setups.

Responsib ility:

A qualified technician who has been properly trained in the

care and use of such equipment and in the recovery process

itself must only operate the ENVIRO- DUO.

The operating instructions are part of the prod uct and

must be store d in close proximity to the E NVIRO-DUO

where they should be readily accessi ble to qualified

personnel at all times.

The qualified personnel must have carefully read and

understood the operating instructions prior to operating

the d evice.

The manufacturer shall not be liable for any damage

whatsoever arising through improper use, failure to comply

with these operating instructions, assignment of inadequately

qualified personnel, or unauthorised modification of the

ENVIRO-DUO.

The General Terms and Conditions as set out in the sales

documentation shall apply.

Subject to te chnical modificatio ns.

2

Page 6

English Ins truction Manual ENVIRO-DUO

Key to symbols

WARNING!

… indicates a potentially hazardous situation that

could result in serious injury or death if not avoided.

DANGER!

… in dicates el ectrical hazard. F ailure to comply

with these safety instructions may result in serious

injury or death.

2. Safety

WARNING!

Before setup and operation of the device, ensure

that it is not damaged in any way. Failure to comply

could result in serious physical injury and/or material

damage.

DANGER!

Risk of death by electrocution.

2.1 Personnel Qualifications

WARNING!

Risk of injury through use by unqualified personnel!

Improper handling of the device can lead to serious

personal and ma terial damage.

3

Page 7

Instructi on Manual ENVIRO-DUO English

The activities de scribed in these operating in structions

should only be ca rried out by skilled pe rsonnel in

possession of the qualifications o utlined below.

Keep unqualified personnel away from hazardous areas.

Skilled per sonnel

Skilled personnel are workers who, through their specialist

training and operational knowledge of the recovery machine,

are capable of carrying out the described work and

independ ently identifying p otential hazards.

ONLY QUALIFIED SERVICE PERSONNEL SHOULD

OPERATE THIS UNIT. MOST STATES AN D

COUNTRIES, MAY REQUIR E THE USER TO BE

LICENSED. PLEASE CHECK WITH YOUR LOCAL

GOVERNMEN T AGENCY.

2.2 Special Hazards

Before starting the Equipment assu re that it is

well grounded .

Risk of serious injury and death!

While using th e electrical wire, the wire mus t be

well connected and grounded.

Risk of serious injury and death!

Only a qualified electrician should perform wire

connection according to the t echnical stan dard

and circuit diagram.

Risk of serious injury and death!

4

Page 8

English Ins truction Manual ENVIRO-DUO

Be sure the power is off before exam ining or

repairing the recovery unit. Risk of s erious

injury and death!

Use only authorized refi llable refrigerant tanks.

The Unit r equires the use of recovery tanks with

a minimum working p re ssure of 40 bar (580psi).

Do not overfill the recovery tank. Tan k is full at

80% capacity. There should be enough space for

liquid expans ion.

Overfilling of the tank may cause a viol ent

explosion.

A charging scale is required to prevent overfilling.

It is compulsory to wear safety goggles, and protective

gloves while working with re frigerants to protect

skin and eyes from refrigerant gas and liquid. Avoid

any contact with caustic gas or liquid.

Risk of serious injury!

Be sure that any room where work is being

conducted is thoroughly ventilat ed.

When using an ext ension cord, t he cord should

be a minimum of 1.5 mm (15 awg) and no longer

2

than 7.5 m. Otherwise Voltage may drop and damage

the compressor! The cable must be completely

unrolled.

5

Page 9

Instructi on Manual ENVIRO-DUO English

Input pressure of the unit should not exce ed 26

bar (377 psi).

Only keep unit in a horizontal position, otherwise

unexpected vibrations, noise or a brasions may

occur.

Avoid exposing the equipmment to the sun or rain.

USE CAUTION WHEN OPERATION OUTDOORS.

Be certain that the power cord, the cylinder overfill

safety cord and th e unit itself are n ot plac ed in

water or other potentially dangerous locations.

While the EN VIRO-DUO is very safe to op erate,

using in environments such as hard rain or sand

and dust storms must be avoided.

FLAMMABLE ENVIRONMENTS ARE

DANGEROUS

when any machine is used because motors and

switches can generate sparks. This equipment should

be used in locations with mechan ical ventilation

providing at least four air changes per hour, or the

equipment should be located at least 50 cm above

the floor.

DO NOT US E THIS EQUIPMEN T IN THE

VICINITY OF SPILLED OR OPEN CONTAINERS

OF GASOLINE OR ANY OTHER FLAMMABLE

6

Page 10

English Ins truction Manual ENVIRO-DUO

Do not block the ventilation opening o f the unit.

If the overlo ad protector pops, repo sition it after

5 minutes.

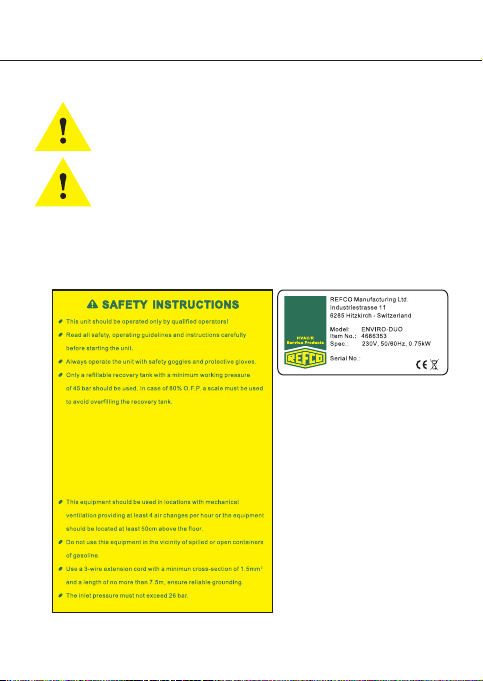

2.3 Labels / Safety Markings on Machin e

Identification plate

7

Page 11

Instructi on Manual ENVIRO-DUO English

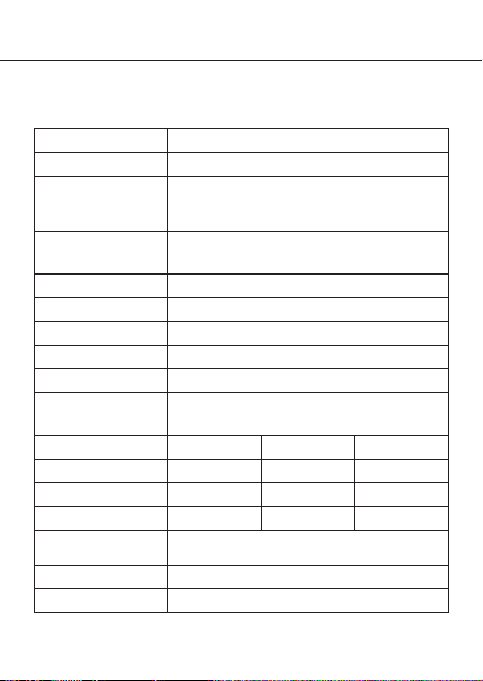

3. Technical Specifications

Refrigerant

Category Ⅲ

Category Ⅳ

Category Ⅴ

Power

Motor

Motor Speed

Current

Compressor

High Pressure

Protection

Recovery Speed

Gas

Liquid

Push/Pull Mode

Ambient

Temperature

Dimensions

Net Weight

R-12, R-134a, R-40 1C, R-406A, R-500

R-22, R-401A, R-40 1B, R-402B,

R-407C, R-407D, R- 408A, R-409A,

R-411A, R-411B , R-412A, R -502, R-509

R-402A, R-404A, R- 407A, R-407B,

R-410A , R-507

220-240V CA 50-60 Hz

0.75 kW

1450rpm@50Hz

5A@50Hz

Oil-less, Air-coo l, Piston

38.5bar/3850kP a (558psi)

Category Ⅲ

0.40 Kg/min

3.00 Kg/min

7.50 Kg/min

0°C-40°C/32-10 4°F

400mm(L)×250(W )mm×345mm(H)

15.8kg

Category Ⅳ

0.60 Kg/min

3.50 Kg/min

8.50 Kg/min

Category Ⅴ

0.80 Kg/min

3.50 Kg/min

9.50 Kg/min

8

Page 12

English Ins truction Manual ENVIRO-DUO

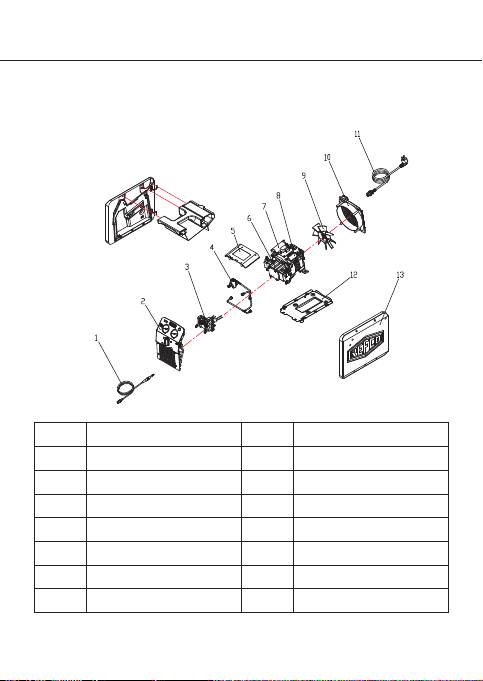

4. Parts Description

Component

No.

O.F.P. Cabl e

1

Front Panel

2

3

Control Valve

4

Copper Pipes

Junction Box Cover

5

6

Compressor

Running Capac itor

7

9

Component

No.

Starting Capacitor

8

Fan

9

10

Fan Cover

Power Supply Cord

11

Base

12

13

Cover

Page 13

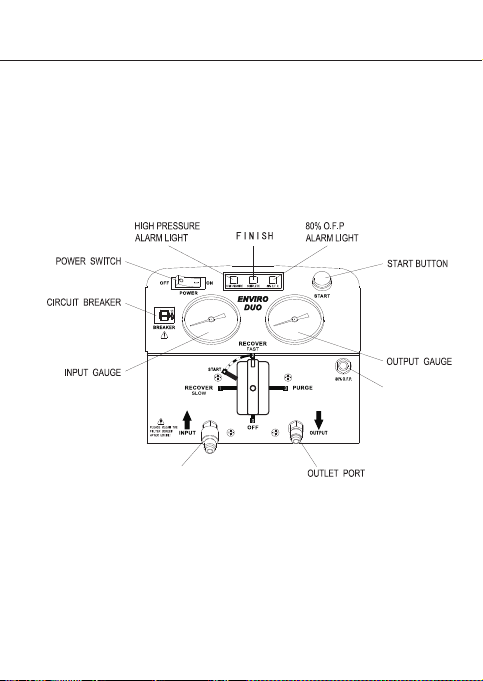

Instructi on Manual ENVIRO-DUO English

5. Instruction of Operation Panel

OVE RFILL

CAB LE SOCK ET

INTA KE PORT

INL ET FILTER I NCL. O- RING

FILT ER THRED AD APTER

10

Page 14

English Ins truction Manual ENVIRO-DUO

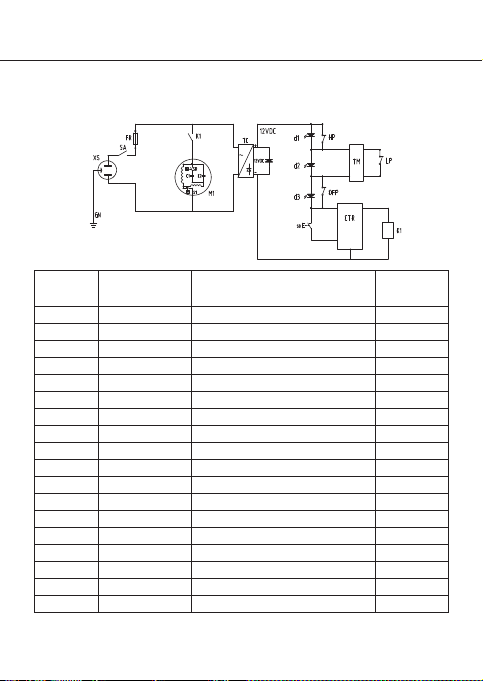

6. Electrical Diagram

11

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Graphics

Code

XS

SA

FR

M1

SR

C1

C2

ST

TC

HP

LP

OFP

d1,d3

d2

SC

SB

CTR

K1

Description

Power Outlet

Power Switches

Overload Protection Device

Compressor Motor

Centrifugal Switch

Start Capacitor

Running Capac itor

Motor Thermal Protectors

Electronic Transformer

High Pressure Switch

Low Pressure Switch

80% O.F.P. Switch

Red Indicator

Green Indicator

Option Switch

Start Butto n

Control Module

Relay

Remarks

Page 15

Instructi on Manual ENVIRO-DUO English

7. Operation

1.

Do not mix diffe rent refrigeran ts together i n one tank,

otherwise they cannot be separated o r used.

2.

The switch should be at“Position 0”before operation. All

the valves m ust be closed, the input and output fittings

should be covered with protective caps when the unit is

not in operation. Air humidity is harmful to the recovery

result and will shorten the life span of t he unit.

3.

A filter drier should always be used and should be replaced

frequently. Each type of refrigerant must have its own

filter. For the sake of ensuring the proper operationof the

unit, please use the filter specified by our company.

High quality filter drier will bring h igh quality services.

4.

Special caution is needed when recovering from a burnt

system. In th is case two dry filters are r equired.

5.

The unit has an Internal High Pressure Shut-Off Switch.

If the pressure inside the system is above 38.5 bar, th e

compressor will automatically sh ut off the power.

To restart the compressor, please lower the internal pressure,

then push on the start button to restart the compressor.

When High Pressure Protection is initiated, please find out

the cause and deal with it before restar ting the unit.

Cause of High Pressure Protection an d Trouble Shooting:

a.

The input value o f the refrigerant tank is c losed — open

the valve to solve the problem.

12

Page 16

English Ins truction Manual ENVIRO-DUO

b.

The connecting hose between the reco very unit and

refrigerant tank is stuck — close all the valves and replace

the connecting hose.

c.

The temperature of the refrigerant t ank is too high,

therefore, pressure s is too high — give it some time to

cool down and the pressure will come back t o normal.

d.

The unit has an I nternal Lo w Pressure Shut-Off Swit ch

and delay circuit. If the pressure inside the system is below

-2.5 ~ -6.8 psi for 20 seconds, the unit will auto-matically

shut off and the Green Alarm Light wi ll switch on.

When the unit completes recovery and purge oper-ation,

there is no pressure in the intake port. Therefore the unit

can only run for 20 seconds after restar t.

When the input pressure is above 0.8 bar (11 psi), the

unit will run continuously.

e.

This unit can be used together with a overfill level sensor.

Please connect the recovery uni t and the tank with the

80% O.F.P. Cable (Item 1 in the PARTS DIAGRAM).

If the liquid refrigerant reaches 80% capacity of the tank,

the recovery unit will auto matically shut off and the Red

Alarm Light wil l s witch on (80% O.F.P. ALARM). Before

restart please replace tank.

f.

If the refr igerant tank has no f loat level sensor, pl ease

take the 80% O.F.P Cable off. Otherwise the recov ery

unit can not start. In this case, an electric scale is required

to monitor the recovered refrigera nt amount.

13

Page 17

Instructi on Manual ENVIRO-DUO English

g.

In order to gain maxim um recovery s peed, a hose with

inner diameter bigger than 4 mm and shorter than 1.5 m

is recommended.

h.

While recovering large amounts of li quid, use the

Push/Pull Mode.

I.

After recove ring, make sure there is no r efrigerant left

in the unit. Read the Pu rge Operation careful ly. Liquid

refrigerant remaining in the unit may be expanded and

damage the components.

j.

If the unit is to be stored or not used for any length of time,

we recommend that it be comple tely evacuated of any

residual refrigerant and purged wi th dry nitrogen.

k.

A connection hose with check valve is recommended, it

can prevent refrigerant loss.

l.

The intake port is equipped with filte r screen;

please wash it frequently to keep it cle an.

m.

If it is difficult to start the unit, please turn the Sw itch

two rounds to balance the inte rnal pressure and make

it easier to start the unit.

n.

The Low Pressure Gauge shows the press ure of the

intake port of the compress or and the High Pressure

Gauge shows the pressure of the outlet p ort.

o.

After Using, please turn the knob to "0" p osition.

14

Page 18

English Ins truction Manual ENVIRO-DUO

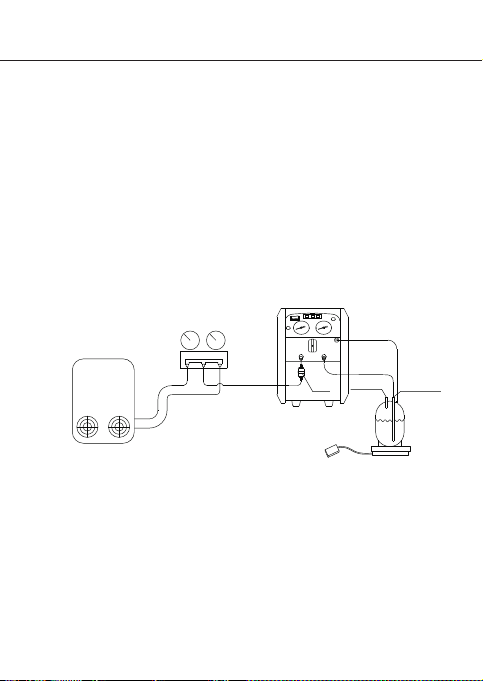

8. Recovery Method

1.

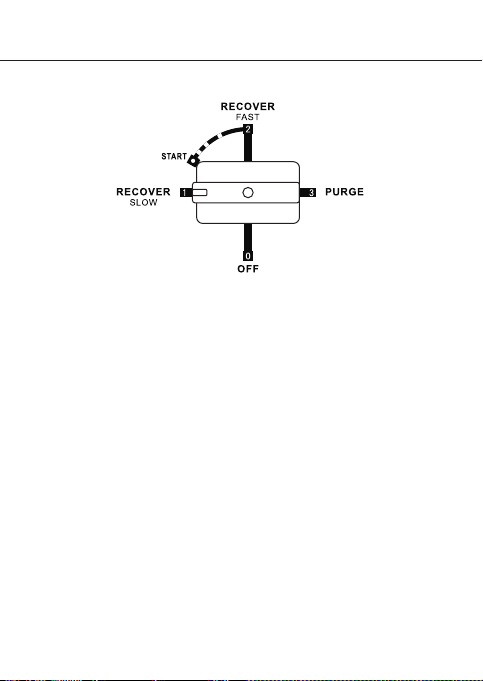

Turn the Switch to posit ion "1".

2.

Correctly and firmly connect the hos es.

(See Connection Drawing)

3.

Connect the unit to the ri ght po wer su pply (as shown

on the Name Plate), tur n the p ower on to start the uni t.

4.

Push the START button to turn on the unit.

Mani fold

gaug e set

Outp ut

Vapo r valve

80% O .F.P.

floa t cable

Liqu id valv e

Tank

HVAC Sy stem

Vapo r

Liqu id

5.

Open the valve of the refrigerant tank .

6.

Open the liquid valve on the manifold ga uge.

7.

Slowly turn the Switch to position "2" for faster recovery.

Inpu t

Filt er

Sca le

15

Page 19

Instructi on Manual ENVIRO-DUO English

Notice:

a.

If liquid impacting occurs i n the compressor when at

position “2”, pl ease turn the knob to pos ition “star t”

slowly. The reading of low pressure gauge will decrease

until the impacting stops, but the pressure should be

above“0”, because the intake port cannot intake when

the pressure is “0”.

If it is difficult to start or restart after power off , please

turn the knob to pos ition “START”, then turn on the

power and hit the RESET button.

b.

If the knob is turned to position “1” and the unit it running,

a stable recovery of liquid refrigerant can o ccur, but

at a lower recovery rate. If liquid impacting o ccurs in

the co mpressor whe n at posi tion “1”, slowly turn the

knob clockwise to position “start”. The reading of low

pressure gauge will decrease until the impacting stops.

The pressure should be above “0”, because it cannot

intake if the pressure is “0”.

8.

When liquid recovery is finished, tu rn the Switch to

position "2" for faster recovery.

9.

The unit will automatically stop when recovery is finished,

please start the Purge operation now.

16

Page 20

English Ins truction Manual ENVIRO-DUO

9. Self-Purge Method

1.

①Do not turn off the power when the "co mplete" light

turns green and unit stops running, pl ease hit the reset

button first, then turn the switch to po sition "3" to start

purge.

② If the ultimate vacu um meets your request but the

unit is still running, please turn the swit ch to position

"3" to start pu rge directly.

2.

When the required vacuum is reached, p urging ends.

a.

Close the valve on the refrigerant tan k.

b.

Close the check valves on the connecti ng hoses.

c.

Close the liqui d valve and gas valve on th e manifold

gauge.

d.

Close the connecting valve between the refrigeration

system and the manifold valve.

e.

Turn the power off, and disconnect all th e external

hoses.

f.

Cap the intake port and the outlet port.

17

Page 21

Instructi on Manual ENVIRO-DUO English

WARNING!

After each use the unit must be purged, to m ake

sure there is no refrigerant left in the u nit.

Remaining liquid refrigerant may expand and

damage the components.

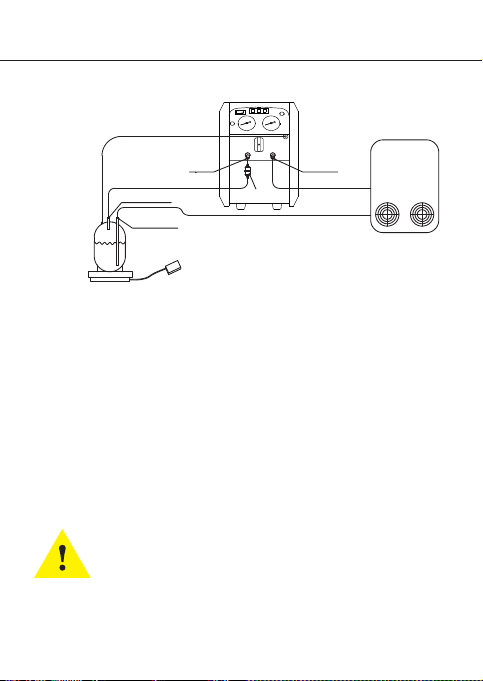

10. Liquid Push / Pull Mode

When recove ring more than 10 kgs of liqu id

refrigerant, Push/Pull is recomm ended.

WARNING!

An electric scale needs to be used together with

the recovery unit to monitor the recover process.

Once the siphon is started, it can overfill the recovery

tank even if the tank is equipped with a float lev el

sensor. The siphon can continue even if the machine

is t urned off. You must m anually close the valves

on the tank and the unit to prevent overfilling.

1.

Turn the Switch to posit ion "1".

2.

Correctly and firmly connect the hos es

(See Connection Diagram).

3.

Turn the power on and hit th e start button.

4.

Open the gas valve and liquid valve of the r efrigerant

tank.

5.

Turn the Switch to posit ion "2" to start Push/Pull Mode

operation recovery.

18

Page 22

English Ins truction Manual ENVIRO-DUO

80% O .F.P.

floa t cable

HVAC Sy stem

Filt er

Outp ut

Vapo r

Liqu id

Inpu t

Vapo r valve

Liqu id valv e

Tank

Sca le

6.

When the reading on the electr ic scale is not changing

or changing very slowly, it means that the liquid recovery

is finished, it's time f or gas recovery. (The hoses

to be re-connected and please follow the Purge Operation

to purge the gas refrigerant.)

7.

Close the gas valve on the refrigerant tank and then turn

the power off.

8.

Close all the valves and disconnect all the external hoses.

Connect the hoses according to the Recovery Operation

to do the gas refrigerant recovery.

9.

PURGE

WARNING!

When the reading on th e electric scal e shows

that the refrigerant in the tank reaches 80%

capacity, please turn the po wer off and close

the valves on the tank.

19

need

Page 23

Instructi on Manual ENVIRO-DUO English

11. FAQ and Trouble Shooting

Fault

Fan is not

revolving

Compressor

doesn't work

Compressor

can't start

(blocked)

Compressor

starts but

stops within

a few

minutes

Cause Solution

Mechanical da mage

1. Shut off by High

Pressure

Protectio n, red

light ON

2. Low Pressure

Protectio n, green

light ON (rec overy

not finishe d)

3. 80% O.F.P cable

not well co nnected

1. External pressure

is too high

2. Motor fail ure or

other compo nent

damage

1. High Pressure

Protectio n caused

by mis-operation

shuts the uni t off,

ie: Outlet va lve

closed, ref rigerant

tank valve cl oesd

1. Replace the fan

2. Factory se rvice is

needed

1. Lower the pressure

of the unit

2. Check to see if the

hoses are well

connected

3. Check the

connectio n

4. Turn the switch two

rounds and stop at

position “1”

1. Turn the Switch

two rounds and

point to posi tion "1",

and then rest art

2. Factory se rvice is

needed

1. Read carefully the

Operation M anual

and follow th e

instructi ons while

operating

20

Page 24

English Ins truction Manual ENVIRO-DUO

Fault

Compressor

starts but

stops within

a few

minutes

Low

recovery

speed

Not enough

vacuum

21

Cause Solution

2. Motor Over load

Protectio n shuts

the motor off

3. 80% Over Filling

Protectio n, red

light ON

4. Recovery finished,

green light ON

5. Overload during

liquid recovery

process, li ght

flashes on an d off

6. Circuit breaker

shuts off

1. The pr essure of

the refrige rant

tank is too hig h

2. Piston ring on the

compresso r is

damaged

1. Hose connection

loosened

2. Leakage of the

unit

2. Give the mot or

some time to re start

3. Follow the purge

Operation t o do the

Purging

4. Turn the Switch two

rounds and point to

position "1", and

then restar t the unit

5. Turn the switch two

rounds and stop at

position “1” while

recovering liquid

refrigera nt

6. Cool the circuit

breaker down and

restart aft er 5

minutes

1. Cooling the tank

down can help to

bring down the

pressure

2. Factory se rvice is

needed

1. Tighten the

connecting hoses

2. Factory se rvice is

needed

Page 25

Instructi on Manual ENVIRO-DUO English

12. Maintenance

1.

Your ENVIRO-DUO will provide many seasons of reliable

service if it is properly maintained. The actual maintenance

requirements are minimal but impor tant.

2.

Keep the unit cle an by wiping it down with a damp cloth

to remove dirt, oils, etc. prior to stor age for the day.

Standard household detergent or isopropyl alcohol may

be used if the unit is particularly dirt y; in all cases,

exercisecare to prevent liquids from entering the unit.

Gasoline and other solvents are to be avoided as they

can damage the ENVIRO-DUO's plastic enclosure and

they are hazardous.

3.

Clean inlet particle filter regularly. Discard internal filter

screen if it is heavily contami nated and replac e with a

new screen. Replace screen as per sketch for efficiency.

4.

Ensure that the Inlet and Discharge ports are protected

and kept clean by replacing the plastic caps after every

use. For best results, keep a FILTER permanently

connected to the INLET port and ch ange it regularly.

5.

Change HOSES periodically as they develop leaks and

a build-up of contamina nts over time. Change hoses at

least once per season.

6.

When performance declines it is likely that the compressor

seals require replacing. This is normal with use and may

occur after a year or two or more often, depending upon

the conditions th at are prevalent during there covery

operations. Co ntact your Wholesaler for assis tance in

selecting the proper maintenance k it.

22

Page 26

English Ins truction Manual ENVIRO-DUO

13. Service

DO NOT CHANGE any of the original components as the

safety of the machine could be compromised. All service

work must be perform ed at a R EFCO approved facility

in o rder to maintain the safety rating and the Warranty,

if applicable.

14. Recycling

For disposal, please bring your reco very machine to an

offic ial recycling locatio n.

23

Page 27

Bedienungsa nleitung ENVIRO-D UO Deutsch

BEDIENUNGSANLEITUNG

ENVIR O-DUO

Inhaltsverzeichnis

1. Allgemeines……………………………… …… 1………… ……

2. Sicherheit……………………………………………………3

2.1 Personalqualifikation…………………………………4

2.2 Bes ondere Gefahren…………… …………………4

2.3 Sicherheitsmarkierungen………………………… 8

3. Technische Daten …………………………………………9

4. Teilbezeichnung …………………………………………10

5. Anleitung zur Betriebskonsole…………………………11

6. Elektrischer Schaltplan…………………………………12

7. Betrieb………………………………………………………13

8. Absaugvorgehen…………………………………………16

Selbstreinigungsverfahren

9.

10. Push-/Pull-Modus für Flüssigkeiten …………………20

11. Häufig gestellte Fragen und Problemlösungen …… 23

12. Unterhalt …………………………………………………26

13. Service ……………………………………………………27

14. Recycling …………………………………………………27

………………………………19

Page 28

Deutsch Bed ienungsanleitung EN VIRO-DUO

1.Allgemeines

Viele n Dank für den Erwerb des ENV IRO-DUO

Kältemittelabsauggeräts!

ENVIRO-DUO kombinie rt innovative Absaugtechno logie

mit einem ergonomischen, robusten Design für maximalen

Schutz bei Transport und Gebrauch.

Be i o rdn ung sge mäs sem Ge bra uch u nd ric hti ger Pf leg e

en tspre chend der Be die nungs anlei tung, könn en Sie Ihr

EN VIRO- DUO Ab saugg erä t jahre lang störu ngsfr ei

ei nsetz en.

Sicherheit geht vor!

Die ses in ter nati ona le Sym bol , d as auf de m Gerä t

vorzufinden ist, weist den Benutzer auf wichtige Betriebs-,

Sicherheits- und Wartung sanweisungen hin, die in dieser

Bedienungsanleitung zu finden sind. Wenn dieses Symbol

in der Anleitun g ver wen det wir d, we ist e s auf k ritische

As pekt e hin.

Bitte lesen Sie diese Anleitung vor Verwendung des Geräts

vollständig du rch und machen Sie sich mit allen Inhalten

vertraut!

ENVIRO-DUO ist ein Absa uggerät, das für zahlreiche

Kältemittel eingesetzt we rden kann. Das Ab saugen von

Kältemitteln in ei nen separate n Zylinder erfolgt du rch

Gasverdichtung, wodurch ein hohe r Druck im Gerät, in

den Verbindungssc hläuchen und im separaten Zylinder

entsteht. Hochdr ucksysteme müssen stets vorsicht ig

behandelt werden, um Unfä lle durch Unachtsamkeit zu

vermeiden.

1

Page 29

Bedienungsa nleitung ENVIRO-D UO Deutsch

Produktsi cherheit:

ENVIRO-DUO wurde so konzipiert, dass die Anforderungen

der Norm für Kältemittelabsauggeräte, , erfülltARI und

werden.

Ve rw e n d e n S i e immer e in e zugel a s s e n e Wa ag e zu r

Überwa c h ung der Zy l inder f ü llme n g e, sofe r n k e in

zugelassener Zylinder mit Überfüllsicherung zur Verfügung

steht. Darüber hi nau s müss en die K ält emi ttelsch läu che

mi t m ehr al s 300 mm Länge mit ei ner Absp err sich eru ng

ve rse hen se in, u m b ei Zylinderwechse l o der

Aufbauver än d e r ung d i e Wa hrsche i n lichk e it e ines

Kältemittelaustritts in die Atmosphäre z u verringern.

Haftung:

Da s E NVI RO- DUO Absa ugg erä t d arf nur dur ch

au sge bildetes Fac hperson al verwen det werden, d as mit

der Pflege und de m G ebra u ch des Ge r äts un d m i t d em

Absaugprozess ver traut ist .

Die Betriebsanleitung ist Produk tbestandteil und muss

in unmi ttelb arer Nähe des E NVIRO -DUO für das

Fachpersonal jederzeit zugängl ich aufbewahrt werden .

Das Fachpersonal muss die Betriebsanleitung vor Beginn

alle r Arbeite n sorgfä ltig durch gelesen und versta nden

haben.

Die Haft ung des Herstel lers erlischt bei Schäden durch

bestimmungswidrige Verwendung, Nichtbeachten dieser

Betriebsanleitung, Einsatz ungenügend qualif izierten

Fachpersonals sowie eigenmächtig en Veränderungen

am ENVIRO-DUO.

2

Page 30

Deutsch Bed ienungsanleitung EN VIRO-DUO

Es gelten die Allgemeinen Geschäftsbedingungen, w ie

sie in den Verkauf sunterlagen darge legt sind.

Technische Verän derungen vorbehalten.

Symbolerklärung

WARNUNG!

… weist a uf ein e mög licherweise gef ähr lic he

Si tua tio n h in, die zum Tod ode r z u schweren

Verl etz ung en führen k ann , w enn sie nic ht

ge mie den wi rd.

GEFAHR!

… kennzeichnet Gefährdung durch el ektrischen

Strom. Bei Nichtbeachtung der Sicherheitshinweise

besteht die Gefahr schwerer oder töd licher

Verletzungen .

2. Sicherheit

WARNUNG!

Vor Einrichtung und Betrieb sichers tellen, dass

das Gerät keine Schäden aufweist. Be i

Nichtbeachten können schwere

Körperverletzungen und/oder Sa chschäden

auftreten.

GEFAHR!

Lebensgefah r durch elektrische n Strom.

3

Page 31

Bedienungsa nleitung ENVIRO-D UO Deutsch

2.1 Personalqualifikation

WARNUNG!

Verletzungsgefahr bei Betrieb durch unzureichend

qualifiziertes Personal!

Unsachgemässer Umgang kann zu erheblichen

Personen- und Sachschäden führen .

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten

nur durch Fach personal m it nachfol gend beschriebener

Qualifikation durchführen lass en.

Unqualifizi ertes Personal von den Gefa hrenbereichen

fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung

und seiner Bedienungsken ntnisse des Absa uggeräts in

der Lage, die beschriebenen Arbeit en auszu führen und

mögliche Gefahren selbstständi g zu erkennen.

DIESE S GERÄT DAR F AUSSCHLI ESSLICH DUR CH

FACHPERSONAL VERWE NDET WE RDEN.

IN DEN ME ISTEN LÄNDE RN MUSS DER BENUTZER ÜBE R

EINE EN TSPRECHEN DE FACHAUSBILDUNG VER FÜGEN.

BITTE KLÄREN SIE DIES MIT DER ZUSTÄNDIGEN LOKALEN

BEHÖR DE AB.

2.2 Besondere Gefahren

Vor jed em Einsatz ist die ordnungsg emässe

Erdung des Geräts zu prüfen!

Gefahr von schwere n Körperverl etzungen mit

möglicher Todesfolg e!

4

Page 32

Deutsch Bed ienungsanleitung EN VIRO-DUO

Währ end der Verwen dung des Elektr okabels

muss di ese s o rdn ung sge mäs s

an ges chl oss en und geerdet se in.

Ge fahr vo n schw ere n K örp erve rle tzun gen mi t

möglicher Todesfolg e!

Die Verkabelun g muss entsprechend d er

technischen Spezifikationen und dem Schaltplan

durch einen ausge bildeten Elektrik er

vorgenommen werden.

Gefahr von schweren Körperverlet zungen mit

möglicher Todesfolg e!

Vor Inspektion oder Reparatur des Absauggeräts

muss sichergestellt werden, dass die Stromzufuhr

abgestellt ist.

Gefahr von schw eren Körperverletzu ngen mit

möglicher Todesfolg e!

Ausschliesslich zugelassene, wiederauffüllbare

Kältemitteltanks verwenden. Das Gerät erfordert

die Verwendung von Absaugtanks mit einem

Min destarbeitsdruc k von 40 bar (580 psi). Der

Absaugtank darf nicht überfüllt we rden. Der

Tank ist bei einer Füllmenge von 80% voll befüllt.

Es muss ausreichend Platz zur

Flüssigkeitsausdehnung vorhanden sein. Bei

Überfüllen des Tanks besteht Explosio nsgefahr.

Zu r Ver m eid ung ein es Über füll ens is t e i ne

Fü l lWaage er ford erl i ch.

5

Page 33

Bedienungsa nleitung ENVIRO-D UO Deutsch

Das Tragen von Sch utzbrille und

Sch utzh a ndsc huhe n i s t b eim Ar beit e n m it

Käl t emit teln zum Sch utz von Haut un d Auge n

vo r K ühl gas en und Käl teflüssig keit Pfli ch t. Der

Kontakt mit ätzenden Flü ss igkeite n oder Ga sen

is t z u v erme ide n. Gef a hr von sc hwe ren

Körperverletzungen!

Vor dem Einsatz muss sichergestellt werden, dass

der Raum, in welchem Arbeiten vorg enommen

werden, gut belüftet ist.

Bei Verwendung eines Verlängerungskabels muss

dieses einen Mi ndestquerschnit t von 1,5 mm²

(15 awg) aufwei sen und darf nicht läng er als 7,5

m sein.

Das Kabel soll ganz abgerollt sein. And ernfalls

kann es zu einem Spannungsabfall und e iner

Beschädigun g des Kompressors kom men!

Der Eingangsd ruck des Geräts darf 26 b ar

(377 psi) nicht überschreiten.

Das Gerät darf nur in horizontaler Position

verwendet werden, da sonst Vibr ationen,

Geräusche und Ab schleifungen auft reten

önnen.

Das Gerät sollte weder Sonne noch Rege n

ausgesetzt werden.

6

Page 34

Deutsch Bed ienungsanleitung EN VIRO-DUO

BEIM EINSATZ IM FREIEN IST BESONDERE

VORSICHT GEBOTEN. Es ist sic herzustellen,

dass das Netzkabel, das Überfüllsicherungskabel

und das Gerät selbst nicht in Wasser oder an

and eren potentiell gefährlichen Orten

eingesetzt werden. Trotz des äusserst sicheren

Betriebs von ENVIRO-DUO darf das Gerät bei

Regenfall oder Sandstürmen im Freien nicht

verwendet werden.

ENT ZÜND L ICH E U M GEBU NGEN si n d beim

Betrieb aller Geräte GEFÄHRLICH, da Motoren

un d S cha l ter Fun kenb ildu ng veru rsac hen

kö nnen . Diese s Ge rät dar f nur an Orte n mit

mechanischer Bel üftun g mit m indes tens vier

Lu ftw ech sel n pro Stun de oder mit einem

Bodenabstand von mindestens 50 cm eingesetzt

werden.

DI ESES GE RÄT DAR F NICHT I N DER

UMGEBUNG VON AUSGELAUFENEM BENZIN

ODER JEDWEDEN ANDEREN ENTZÜNDLICHEN

FLÜSSIGKEITEN ODER IN DER NÄHE OFFENER

BEHÄLTER VERWENDET WERDEN, WELCHE

SOLCHE FLÜSSIGKEITEN ENTHALTEN.

Die Be lüftu ngsöffnun g des Gerät s darf nich t

bloc kier t werd en.

Bei Aktivierung der Überlastsicherung kann diese

nach 5 Minuten zurückgesetzt werde n.

7

Page 35

Bedienungsa nleitung ENVIRO-D UO Deutsch

2.3 Sicherheitsmarkierungen

8

Page 36

Deutsch Bed ienungsanleitung EN VIRO-DUO

3. Technische Daten

Kältemittel

Kategorie Ⅲ

Kategorie Ⅳ

Kategorie Ⅴ

versorgung:

Motor

Motorgeschwindigkei t

Strom aufnahme

Kompressor-

ausführung

Hochdruckabschaltung

Absauggeschwindigkei t

Gas

Flüssigkeit

Push-/Pull-Mod us

Umgebungs-

temperatur

Abmessungen

Netto gewicht

R-12, R-134a, R-40 1C, R-406A, R-500

R-22, R-401A, R-40 1B, R-402B,

R-407C, R-407D, R- 408A, R-409A,

R-411A, R-411B , R-412A, R -502, R-509

R-402A, R-404A, R- 407A, R-407B,

R-410A , R-507

220-240V CA 50-60 HzSpannungs-

0.75 kW

1450rpm@50Hz

5A@50Hz

Ölfre i, luftgekü hlt, 2 Kolben-Ausfüh rung

38.5bar/3850kP a (558psi)

Kategorie Ⅲ Kategorie Ⅳ Kategorie Ⅴ

0.40 Kg/min

3.00 Kg/min

7.50 Kg/min

0°C-40°C/32-10 4°F

400mm(L)×250(B )mm×345mm(H)

15.8kg

0.60 Kg/min

3.50 Kg/min

8.50 Kg/min

0.80 Kg/min

3.50 Kg/min

9.50 Kg/min

9

Page 37

Bedienungsa nleitung ENVIRO-D UO Deutsch

4. Teilbezeichnung

Komponente

Nr.

Überfüllsicher ungskabel

1

Frontkonsole

2

3

Kontrollventil

Kupferrohre

4

Abdeckung

5

Abzweigdose

Kompressor

6

Betri ebskonden sator

7

Komponente

Nr.

8

Startkondensat or

Ventilator

9

Ventilatorabdec kung

10

Netzanschlussk abel

11

Grundplatte

12

Plastikabdecku ng

13

10

Page 38

Deutsch Bed ienungsanleitung EN VIRO-DUO

5. Anleitung zur Betriebskonsole

STR OMSCH ALTER

LEI TUNGS SCHUT ZSCHA LTER

EIN LASSMAN OMETE R

11

HOC HDRUC K

WARN LEUCH TE

ANS AUGÖF FNUNG

FILT ERSCH EIBE/ O-RIN G

NIP PELVER SCHRA UBUNG

KOM PLETT

80% Ü BERFÜ LLSIC HERUN G

WARN LEUCH TE

AUS LASSÖ FFNUN G

START SCHALT ER

AUS LASSMAN OMETE R

STE CKÖFF NUNG

ÜBE RFÜLL SICHE RUNG

Page 39

Bedienungsa nleitung ENVIRO-D UO Deutsch

6. Elektrischer Schaltplan

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Symbol in

der Gra phik

XS

SA

FR

M1

SR

C1

C2

ST

TC

HP

LP

OFP

d1,d3

d2

SC

SB

CTR

K1

BESCHREIBUNG

Steck dose

Strom schalter

Überlastschutz

Kompressormoto r

Zentr ifugalsch alter

Start kondensat or

Betri ebskonden sator

Motor-Thermosc hutz

Elektronischer

Transformator

Hochdruckschal ter

Niederdrucksch alter

80%

Überlastschutz schalter

Rote Anzeige

Grüne Anzeige

Optio nsschalte r

Start schalter

Kontrollmodul

Relais

Anmerkungen

12

Page 40

Deutsch Bed ienungsanleitung EN VIRO-DUO

7. Betrieb

1.

Keine unterschiedlichen Kältemittel in ein und demselben

Tan k m isc h en. Ih re Tr ennu ng und Verwe ndun g i st

ansonsten nicht mehr möglich.

2.

De r D reh schalte r muss vor In betr ieb nah me auf

„Position 0“ stehen. Wenn das Gerät nicht in Betrieb ist,

müssen alle Ventile geschlossen und die Einl ass- und

Auslass anschlüsse mit Schutzkappen versehen sein.

L u f t fe u ch ti gk ei t k a n n d i e R üc kg ew i n n u n g

beeinträchtigen und zu einer verkürzten Lebensdauer

des Geräts fü hren.

3.

Es soll te ein Trock enf ilter ve rwend et werde n, der

reg elmässi g au sgetausch t we rden muss. Für jedes

Kältemittel muss ein eigener F ilter vor ha nden sein . Es

so llt en vo n uns ere m Unt ern ehmen em pfohlene Filter

verwendet werden, um einen ordnungsgemässen Betrieb

des Geräts zu gewährleisten. Mit Qualitäts-Trockenfiltern

können die be sten Ergebnisse e rzielt werden.

4.

Vorsicht beim Absaugen aus „durchgebrannten“ Anlagen.

In diesem Fall müssen zwei in Reihe gesc haltete Filter

verwendet werden.

5.

Das Gerät verfügt über eine interne Hochdruckabschaltung.

Übersteigt der interne Systemdru ck 38,5 bar, schaltet

der Kompressor automatisch die Str omzufuhr ab. Zum

Neu s t art d es K ompre s s ors m uss der i ntern e Dr u c k

abgelassen und die Hochdruckabschaltung zurückgesetzt

werd en. Anschl iessend kann d i e S t r o m zufuhr zum

Neustart des Kompressors wieder eingeschaltet werden.

13

Page 41

Bedienungsa nleitung ENVIRO-D UO Deutsch

Schaltet sich das Gerät durch die Hochdruckabschaltung

aus, zunächst eine Fehlersuche dur chführen und

anschliessend neu starten.

Hauptgründe u nd Problemlösunge n für die

Druckabschaltung:

a.

Das Einlassventil des Kältemitteltanks ist verschlossen

– zur Problembehebung das Ventil öffnen.

b.

Der Verbindungsschlauch zwischen Absauggerät und

Kältemitteltank ist blockiert – alle Ventile schlie ssen

und den Verbindu ngsschlauch erset zen.

c.

Die Tempe ratur im Kältemittelt ank ist zu hoch,

wodurch der Druck zu hoch ist – zum Abkühlen etwas

Zeit verstreiche n lassen, wodurch sich de r Druck

normalisiert.

d.

Das Gerät verfügt über eine interne

Niederdruckabschaltung und ein e

Verzögerungs schaltung. We nn der interne

Systemdruck 20 Sekunden unter -5 inHg~ -14 inHg

(-2.5 ~ -6.8 psi) liegt, schaltet sich das Gerät automatisch

ab und die grü n e W arnl e ucht e le u chtet au f . N a ch

Abschluss des Absaug- und Reinigungsvorgangs steht

die Ansaugöffnung nicht unter Druck. Sie ist daher bei

einem Neustart des Geräts nur für einen Zeitraum von

20 Sekunden funktionsfähig.

Wenn der Eingangsd ruck über 0,8 bar (11 psi) liegt,

kann das Gerät kontinuierlich arbe iten.

e.

Dieses Gerät kann mit einem Schwimme rFüllstan dssensor verwendet werd en. Bitte das

14

Page 42

Deutsch Bed ienungsanleitung EN VIRO-DUO

Absauggerätund den Tank mit dem 80 %

Überfüllsicherungskabel verb inden (Teil 1 in der

TEILEÜBER SICHT). Wenn ein flüssiges Kältemittel

80% der Füllmenge des Tanks ausf üllt, schaltet sich

das Absauggerä t automatisch ab und di e rote

Warnleuchte leucht et auf (80% ÜBERFÜLLALA RM)

Vor dem Neustart muss der Tank ausgetauscht werden.

f.

Das 80% Überfüllsicheru ngskabel entfernen, wenn

der Kältemitteltank über keinen Sc hwimmerFüllstandssensor verfügt. Ansonsten kann das

Absauggerät nicht gestar tet werden. In diesem Fal l

muss die abgesaugte Kältemittelm enge durch eine

Füll-Waage überwac ht werden.

g.

Zum Erreichen der maximalen Absauggeschwindigkeit

wird ein Sch lauchinnendurchme sser von über 4 mm

empfohlen, wobei der Schlauch kürzer als 1,5 m sein

sollte.

h.

Bei m Abs a uge n gr osse r F l üss i gkei tsme ngen de n

Pus h-/P ull- M odu s ve rwen den.

i.

Vergewissern Sie sich nach dem Absaugen, dass die

Anlage frei von Kältemittel ist. Lesen Sie die Hinweise

zur Selbstreinigun g sorgfältig durch. Rückstände

flüssigen Kältemittels können sich ausde hnen und

die Bauteile beschädigen.

j.

Wir empfehlen, das Kältemittel vol lständig aus der

Anlage abzula ssen und sie mit trocke nem Stickstoff

zu spülen, wenn diese über einen belie bigen

Zeitraum gelagert oder nicht verwe ndet wird.

15

Page 43

Bedienungsa nleitung ENVIRO-D UO Deutsch

k.

Zur Vermeidung von Kältemittelverlust wird empfohlen,

Verbindungss chläuche mit Absperr ventil zu

verwenden.

l.

Die Ansaugöffnung ist mit einer Filterscheibe versehen.

Diese muss regelmässig gesäubert w erden.

m.

Lässt sich das Gerät nur schwer starte n, den

Drehschalter zweimal herumdrehen, damit sich der

Innendru ck normalisiert und d as Gerät leichter

gestartet werden kann.

n.

Die Niederdru ckanzeige gibt den Dr uck der

Ansaugöffnung des K ompressors an, während die

Hochdruckanzeige den Druck der Auslassöffnung

anzeigt.

o.

Den Schalter nach Verwendung auf Posi tion „0“

drehen.

8. Absaugvorgehen

1.

Den Schalter auf Position „1“ drehen .

2.

Alle Anschlüsse korrekt und fest anzi ehen

(siehe Anschlu ssübersicht).

3.

Das Absauggerät an die richtige Stomzufuhr anschliessen

(siehe Typenschild). D ie Stro mzufuhr einschalten, um

das Gerät zu st arten.

4.

Zum Starten d es Geräts den STARTSCHALTE R

betätigen.

16

Page 44

Deutsch Bed ienungsanleitung EN VIRO-DUO

Vert eiler m it

Hei zungs- ,

Lüft ungs- u nd

Klim aanla genSys tem

5.

Das Ventil des Käl temitteltanks öffnen.

6.

Das Flüssigkeitsventil des Vertei lers mit

Mes seinri chtun gen

Gas

Flüs sigke it

EINL ASS

Waag e

AUS LASS

Gas ventil

Schw immer kabel

der 8 0% Über füllsic herung

Flüs sigke itsven til

Messeinrichtungen öffnen .

7.

Drehen Sie den Schalter zum schnelleren Absaugen

langsam auf Position „2“.

Hinweis:

a.

Falls der Kompressor auf Position „2" klopft , langsam

den Schalter auf Position „START” drehen. Die

Niederdruckanzeige beginnt ab zu fa ll en bis es

schliesslich zu keinem Klopfen mehr kommt. Der Druck

muss über “0” liegen , da die Ansaugöffnung sonst kein

Kältemittel aufnehm en ka nn.

Falls die Maschine nach dem Ausschalten nicht startet,

de n S cha lter au f Posi tio n „ START” dre hen, d ann

einschalten und „RESET” drücken.

17

Page 45

Bedienungsa nleitung ENVIRO-D UO Deutsch

b.

Be i lau fen dem Ger t, auf Posi tio n „1" , k ann e ine ä

konstante, jedoch langsamere Absauggeschwindigkeit

beibehalten w erden. Falls es auf Pos ition „1" klopft ,

de n Sch lter langs am im Uhrz eiger sinn auf P ositi on

„START” drehen. Die Niederdruckanzeige fällt ab, bis

es zu keinem Klopfen mehr kommt. Der Dru ck muss

üb er „0 " ble iben, da sonst ke in Kä ltemitte l

aufgenommen werden kann.

8.

Drehen Sie den Schalter nach erfolgtem Absauge n der

Flüssigkeit zum schnelleren Absaugen des Gases auf

Position „2“.

9.

Das Gerät stellt sich nach erfolgtem Absaugen

automatisch ab. Bitte anschliessend Reinigungsvorgang

starten.

ABSAU GEN

SCH NELL

ABSAU GEN

LAN GSAM

REINI GUNG

AUS

18

Page 46

Deutsch Bed ienungsanleitung EN VIRO-DUO

9. Selbstreinigungsverfahren

1.

①Die Stromzufuhr nicht abschalten , wenn die

„Komplett"-Leuchte grün wird und d as Gerät aufhört

zu arbeiten. Betätigen Sie zunächs t den Resetschalter

und bringenSi e den Drehschalter au f Position „3", um

die Reinigung z u starten.

②Wenn da s Endvakuum bereits err eicht ist, das Gerät

aber weiterhin arbeitet, den Drehs chalter auf Position

„3" bringen, um die Reinigung direkt z u starten.

2.

Bei Erreichen des benötigten Vakuums wird der

Reinigungsv organg beendet.

a.

Das Ventil des Käl temitteltanks sch liessen.

b.

Das Absperrven til der Verbindungss chläuche

schliessen.

c.

Das Flüssigkeits- und Gasventil de s Verteilers mit

Messeinrichtungen schliessen .

d.

Das Verbindung sventil zwischen de m

Kältemittelsystem und dem Ventilb lock schliessen.

e.

Die Stromzufuhr abstellen und alle e xternen

Schläuche entfernen.

f .

Die Ansaug- und Aus lassöffnung j eweils mit einer

Verschlusskappe versehen.

WARNUNG!

Nach jeder Verwe ndung muss eine Reini gung

vorgenommen werden. Vergewisser n Sie sich,

dass die Anlage fr ei von Kältemittel is t.

Rückstände von flüssigem Kältemi ttel können

sich ausdehne n und Bauteile beschä digen.

19

Page 47

Bedienungsa nleitung ENVIRO-D UO Deutsch

10. Push-/Pull-Modus für Flüssigkeiten

Beim Absaugen grosse r Kälteflüssigkeitsmengen

von über 10 kg wi rd der Push-/Pull-Modus

empfohlen .

WARNUNG!

Zur Überwachung des Absaugprozess es muss

das Absauggerät mit einer Füll-Waage verwendet

werden. Sobald der Absaugprozess beginnt, kann

es zu einem Überfüllen des Kältemitt eltanks

kommen, selbst wenn der Tank mit einem

Schwimmer-Füllstandssensor ausgestattet i st.

Selbst durch Abschalten des Geräts ka nn das

Absaugen mögl icherweise nicht ge stoppt

werden. Die Vent ile des Tanks und Geräts

müssen in diesem Fall manuell verschlossen

werden, um ein Überfüllen zu vermeiden.

1.

Den Drehschal ter auf Position „1“ st ellen.

2.

Alle Anschlüss e korrekt und fest anzi ehen

(siehe Anschlu ssübersicht).

3.

Die Stromzufuhr anstellen und den St artschalter

betätigen.

20

Page 48

Deutsch Bed ienungsanleitung EN VIRO-DUO

Schw immer kabel d er

80% Ü berfül lsich erung

EINL ASS

Gas ventil

Flüs sigke itsve ntil

Waag e

4.

Das Gas- und Flü ssigkeitsventil des Käl temitteltanks

AUS LASS

Gas

Flüs sigke it

Hei zungs- , Lüftu ngsund Kl imaan lagen -Syst em

öffne n.

5.

Den Drehschal ter auf Position „2“ br ingen, um den

Absaugprozess im Push-/Pull-Mo dus zu starten.

6.

Wenn si ch die Anzeige der elektri schen Waage nicht

oder nur sehr langsam verändert, ist d as Absaugen der

Flüssigkeit beendet und es kann mit de r

Gasrückgewinnung fortgefahre n werden.

7.

Das Gasventil des Kältemitteltan ks schliessen und

anschliessend die Stromzufuhr ab stellen.

8.

Alle Ventile schliessen und externe Schläuche abnehmen.

Alle Schläuche zur Rückgewinnung des gasförmige n

Kältemittels anschliessen.

9.

REINIGUNG

21

Page 49

Bedienungsa nleitung ENVIRO-D UO Deutsch

WARNUNG!

Wenn die Anzeige der elektrischen Waage angibt,

dass das Kältemittel 80% der Füllmenge des Tanks

ausfüllt, die Stromzufuhr abstel len und die

Tankventile schliessen.

22

Page 50

Deutsch Bed ienungsanleitung EN VIRO-DUO

11. Häufig gestellte Fragen und Problemlösungen

Fehler

Ventilator

dreht sich

nicht

Kompressor

arbeitet

nicht.

Kompressor

kann nicht

gestartet

werden

(blockiert)

Ursache

Mechanischer

Schaden

1. Abschalten des

Gerät s durch

Hochd ruck absch altung, rot e

Warnleuchte

Niede rdruck absch altung,

grüne s Licht

(Absa ugen nicht

abgeschlossen)

2. 80%

Überf üllsi cheru ngs-

kabel nicht rich tig

angeschlossen

1. Exte rner Druck

ist zu ho ch

Lösung

1. Ventilator erset zen

2. We nden Sie sich a n

den

Wer kskundend ienst.

1. Gerä tedruck sen ken

2. Prüf en Sie, ob die

Schlä uche richti g

anges chlossen si nd.

3. Prüf en Sie den

Anschl uss.

4. Drehen Sie den

Drehs chalter zwe imal

herum u nd bringen

Sie ihn d ann auf

Posit ion „1“.

1. Drehen Sie den

Drehs chalter

zweim al herum,

stell en Sie ihn dann

auf Pos ition „1“ und

nehme n Sie

ansch liessend

einen N eustart vor.

23

Page 51

Bedienungsa nleitung ENVIRO-D UO Deutsch

Fehler

Kompressor

kann nicht

gestartet

werden

(blockiert)

Kompressor

läuft an,

schaltet sich

jedoch

innerhalb

weniger

Minuten

wieder ab.

Ursache

2. Moto rversagen

oder

Besch ädigung

eines anderen

Baute ils

1. Hochdruck absch altung

durch

unsac hgemässen

Gebra uch wie:

Auslassventil

versc hlossen,

Kältemitteltankventil

versc hlossen

2. Abschalten des

Motor s durch

Motorüberlastschutz

3. 80%

Überf üllsi cheru ng,

rote Le uchte

4. Absaugen

abgeschlossen,

grüne Leuchte

Lösung

2. We nden Sie sich a n

den

Wer kskundend ienst.

1. Lesen Sie die

Bedie nungsanle itung

sorgf ältig durch u nd

befol gen Sie bei

Anwendung sämtlic he

Anweisungen.

2. Lassen Sie etwas Ze it

verst reichen, bi s Sie

den Mot or neu star ten.

3. Befo lgen Sie bei

Durch führung des

Reini gungsvorg angs

die ent sprechend en

Anweisungen.

4. Drehen Sie den

Drehs chalter zwe imal

herum u nd bringen

Sie ihn d ann auf

Posit ion „1“. Nehm en

Sie ans chliessen d

einen N eustart des

Gerät s vor.

24

Page 52

Deutsch Bed ienungsanleitung EN VIRO-DUO

Fehler

Kompressor

läuft an,

schaltet sich

jedoch

innerhalb

weniger

Minuten

wieder ab.

Niedrige

Absauggeschwindigkeit

Kein ausreichendes

Vaku um

25

Ursache

5. Überlast währen d

des Absaug-

prozesses von

Flüssigkeiten,

Leuchte blinkt

6. Abschaltung

durch

Leistungsschal ter

1. Der Druck des

Kälte mitteltan ks

ist zu ho ch.

2. Die

Kolbe nmans chett e

des Kom pressors

ist bes chädigt.

1. Schl aucha nschl uss

gelockert

2. Gerä t undicht

Lösung

5. Drehen Sie den

Drehs chalter zwe imal

herum u nd bringen

Sie ihn d ann auf

Posit ion „1“, währ end

flüss iges Kältem ittel

abges augt wird.

6. Lassen Sie den

Leist ungsschal ter

abküh len und führe n

Sie nac h 5 Minuten

einen N eustart dur ch.

1. Durch Abkühlen des

Tanks k ann der Druck

gesen kt werden.

2. We nden Sie sich a n

den

Wer kskundend ienst.

1. Verbindungsschläuche

fest an ziehen

2. We nden Sie sich a n

den

Wer kskundend ienst.

Page 53

Bedienungsa nleitung ENVIRO-D UO Deutsch

12. Unterhalt

1.

Die Massnahmen zum Unterhalt der ENVIRO-DUO sind

minimal aber sehr wichtig.

2.

Halten Sie das Ge häuse stets sauber und reinigen Sie

dieses mit einem feuchten Lappen um Staub und Ölreste

zu entfernen. Falls das Gerät äusserlich stark verschmutzt

ist, benützen Sie normales Haushaltreinigungsmittel oder

Reinigungsa lkohol. Stellen Sie beim Reinigen sich er,

dass kein Wasser ins Innere des Gerätes kommen kann.

Lösungsmittel dürfen nicht benützt werden, da diese das

Gehäuse beschädigen könnten.

3.

Reinigen Sie de n Einlasspartikel filter regelmässig.

4.

Stellen Sie nach jedem Gebrauch d es Gerä tes siche r,

dass die Plastikverschlusskappen wieder aufgesetzt wird.

5.

Die Schläu che sollten von Ze it zu Zeit ersetzt werden,

jedoch mindes tens einmal pro Jahr.

6.

Wenn die Leistung der ENVIRO- DUO nachlässt ist es

möglich, dass die Dichtungen im Kompressor ersetzt

werden müssen. Dies ist normal und m uss je nach

Gebrauch und G ebrauchskonditi onen nach 1-2 J ahren

vorgenommen werden. Kontakt ieren Sie in diesem Fall

Ihren Händler.

26

Page 54

Deutsch Bed ienungsanleitung EN VIRO-DUO

13. Service

ERSETZEN SI E KEINE DIESER

KOMPONENN TEN DURCH ANDERE,

sonst kann das Funktionieren und die Sicherheit

ENVIRO-DUO

der nicht mehr gewährleistet werden.

Reparaturen dürfen nur durch REFCO oder von

REFCO anerkannte Betriebe ausgeführt werden.

14. Recycling

Zur Entsorg ung, bringen Sie die ENVI RO-DUO zu einem

offiz iellen Recycling Plat z.

27

Page 55

Mode d'emploi ENVIRO-DUO Franç ais

MODE D'EMPLOI

ENVIR O-DUO

Sommaire

1. Généralités………………………………… … 1………… ……

2. Sécurité……………………………………………………… 3

2. 1 Quali fi cations du per sonnel… ………………… 4

2.2 Dangers spécifiq ues…………………… ………… 5

2.3 Sig nal isati on / Marqu ages de sé curit é………8

3. Caractéristiques techniques…………………………… 9

4. Désignation des pièces……………………………………10

5. Consignes du panneau de commande ………………11

6. Schéma électrique…………………………………………12

7. Fonctionnement……………………………………………13

8. Processus de récupération …………………………… 16

9. Processus de purge automatique………………………19

10. Réfrigérant liquide : mode Push / Pull (surpression)…20

11. FAQ et dépan na ge ………………………………… …22

12. Maintenance ……………………………………………24

13. Servi ce ………………… ………………… ……………25

14. Recyclage…………………………………………………25

Page 56

Français Mo de d'emploi ENVIRO- DUO

1. Généralités

Félicitations pour l'achat de la station de récupération pour

réfrigérants ENVIRO-DUO! ENVIR O-DUO associe un

système novateur de com pression à gaz pour réfrigér ant

et un solide carter moulé offrant un maximum de protection

en cours de transport et d'utilisation normale. Dans le cadre

de l'usage normal e t du s oin recommandés dans ce mode

d'emploi, votre ENVIRO-D UO fonctionnera parfaitement

pendant des ann ées.

Priorité à la s écurité !

Apposé sur l'appareil, ce symbole international vise à

alerter l'utilisateur du fait que ce mode d'emploi contient des

consignes importantes en matière d'utilisation, de sécurité

et de ma intenance (entretien). Comme employé dans ce

document, il doit attirer l'attention de l'utilisateur sur certains

points cruciaux. Il est donc essenti el d'avoir lu et compris

ce mode d'emploi dans son intégralité avant d'engager tout

travail!

L'ENVIRO-DUO est une station de récupération convenant

à toute une série de réfrigérants. La ré cupération de

réfrigérants dans un cylindre accumulateur dissocié implique

un processus de compression à gaz. Ce processus provoque

de fortes pressions dans l'apparei l, les tuyaux de

raccordement e t le cylin dre accumulateur. Les systèmes

à haute pression doivent toujours être manipulés avec soin

et précaution pour éviter tous accid ents par négligence.

1

Page 57

Mode d'emploi ENVIRO-DUO Franç ais

Sécurité du p roduit :

L'ENVIRO-DUO a été conçu conformément aux exigences

de la norme applicable aux dispositifs de récupération pour

réfrigérants, ARI et . En cas d'indisponibilité d'un cylindre

à trop-plein homologué, se servir systématiquement d'une

balance homologuée pour surveiller la capacité du cylindre.

En outre, il est indisp ensable de recourir à des tuyaux d e

réfrigérant homologués, munis de dispositifs d'arrêt de

300 mm pouces aux extrémités. Ceux-ci permettent de limiter

les fuites potentielles de réfrigérant dans l'atmosphère

lors du remplacement du cyli ndre ou des changements

d'installation.

Responsabilité :

Seul un technicien qualifié – ayant été correctement formé

au maniement précautionneux et à l'usage de cet appareil

et du processus de récupération en tant que tel – peut faire

fonctionner l'ENVIRO-DUO.

Les consignes d'utilisation font partie intégrante du

produit et doivent être conservées à proxim ité directe

de ENVIRO-DUO pour être acc essibles à tout mome nt

au personnel qu alifié.

Le personnel qualifié doit avoir lu attentivement et compris

ces consignes avant de faire fonctio nner l'appareil.

Le f abric ant e st déga gé de t oute respo nsabili té en cas

de dommages découlant d'une utilisation non-conforme,

de l'inobservation des présentes consignes, de l'intervention

de personnel in suffisammen t qualifié, voire de la

2

Page 58

Français Mo de d'emploi ENVIRO- DUO

réalisation d e modifications sur l 'ENVIRO-DUO sans

l'accord du fabricant.

Les condition s générales de vente figu rant dans les

documents commerciaux s'appliq uent.

Sous réserve de modifications tech niques.

Explicati on des symboles

AVERTI SSEMENT !

… indique une situation potentiellement dangereuse

qui peut entraîner la mort ou des blessures graves

si elle n'est pas évitée.

DANGER !

… indique un danger lié au courant électrique.

L'inobservation de ces recommandations de

sécurité peut provoquer des blessures graves,

voire la mort.

2. Sécurité

AVERTI SSEMENT !

S'assurer que le dispositif ne prése nte aucun

dommage avant sa mise en service et son

utilisation.

L'inobservation de cette recomma ndation peut

provoquer des blessures graves et/ ou des

dommages matériels.

3

Page 59

Mode d'emploi ENVIRO-DUO Franç ais

DANGER !

Danger de mort par électrocution.

2.1 Qualifications du personnel

AVERTI SSEMENT !

Risque de bless ures dû à un manque de

qualification du personnel !

Une manipulat ion non conforme de l'a ppareil

peut entraîner de graves dommages ma tériels

et corporels.

Les travaux décr its dans ce mode d'emploi doivent être

réalisés exc lusivement par un personnel com pétent

possédant les qualifications req uises ci-dessous.

Interdire l'accès des zo nes dangereuses au personnel

non qualifié.

Personnel qualifié

Du fait de sa formation spécialisée et de ses connaissances

du fonctionnement de la station de récupération, le personnel

qualifié est en mesure d'exécuter les travaux décrits et de

détecter lui-même d'éventuels da ngers.

SEUL UN PERSONNEL TECHNIQUE QUALIFIÉ DOIT

FAIRE FONCTIO NNER CET AP PAREIL ; LA PLUPART

DES ÉTATS, PAYS, ETC… SONT EN DROIT D 'EXIGER

QUE L'UT ILISATEUR DISPOSE D'UNE FORMATIO N

ADEQUATE. VEUILLEZ VOUS RENSE IGNER AUPRÈS

DES AUTO RITÉS LOCALES.

4

Page 60

Français Mo de d'emploi ENVIRO- DUO

2.2 Dangers spécifiques

S'assurer que l' appareil est bien raccordé à la

terre avant de le mettre en marche.

Danger de bless ures graves et de mort !

Le cordon électrique doit être parfaitement branché

et raccordé à la terre pendant son utilisation.

Danger de blessures graves et de mort !

Seul un électricien qualifié peut brancher le cordon

conformément à la norme technique et au schéma

de connexion.

Danger de bless ures graves et de mort !

S'assurer que l'électricité est coupée avant

d'examiner ou de réparer la station de récupération.

Danger de bless ures graves et de mort !

Se servir exclusivement de réservoirs réutilisables

homologués pour contenir le réfrigérant. La station

requiert l'usage de réservoirs de récupération d'une

pression de service minimale de 40 bars (580 psi).

Ne pas remplir excess ivement ce réservoir car

celui-ci est plein l orsque 8 0% de sa capacité est

atteinte. On doit laisser suffisammen t d'espac e

pour l'expansion du liquide ; un réser voir

excessivement remp li peut causer une violente

explosion.

5

Page 61

Mode d'emploi ENVIRO-DUO Franç ais

Une balance électrique est nécessaire pour éviter

tout trop-plein.

obligatoire lorsqu'on travaille avec des réfrigérants ;

le but est de protéger la peau et les yeux des

réfrigérants liquides et gazeux. Éviter tout contact

avec des gaz ou liquides caustiques.

Risque de blessures graves !

Veiller à ce que le lo cal de travail soit

entièrement aéré.

En cas d'us age d'une rallonge, le cordon doit

mesurer au moins 1,5 mm² (15 awg) et ne pas

dépasser 7,5 m de longueur. Sinon, la tension

peut chuter et endommager le compres seur !

La pression d'aspiration de l'appareil ne doit

pas dépasser 26 bars (377 psi).

Laisser l'appareil en position horizontale. Sinon,

on peut voir apparaître des vibratio ns

intempestives, du bruit et des abras ions.

Éviter d'exposer le matériel au soleil ou à la pluie.

6

Page 62

Français Mo de d'emploi ENVIRO- DUO

PRENDRE DES PRÉCAUTIONS EN CAS

D'USAGE DU DISPOSITIF À L'EXTÉRIEU R.

S'assurer que le cordon électrique , le cordon de

sécurité du cylindre et la station en tant que telle

ne se t rouvent pas dans l'eau ou d'autres li eux

potentiellement dangereux. Bie n que le

fonctionnement de l' ENVIRO-DUO s oit très sû r,

il faut éviter de s' en servir dans des milieux tels

que des pluies très fortes ou des tempêtes de sable.

IL EST DANGEREUX D'UTILISER tout appa reil

dans des ENVIRONNEMENTS INFLAMMABLES,

car les moteurs et interrupteurs peuvent produire

des étin ce lles. Ce matériel d oi t être utilisé dans

des locaux équi pés d'une ventilati on mécanique

effectuant au moins quatre changements d 'a ir à

l' heu re ; sinon, i l doi t être p lac é à 1 8" mi nim um

au-dessus du sol.

Ne pas bloquer l'orifice de ventilation de l'appareil.

Si le système de protection de surchar ge saute,

le repositionner au bout de 5 minutes.

7

Page 63

Mode d'emploi ENVIRO-DUO Franç ais

2.3 Signalisation / Marquages de séc urité

Plaque signal étique

8

Page 64

Français Mo de d'emploi ENVIRO- DUO

3. Caractéristiques techniques

Réfrigérants

Catégorie Ⅲ

Catégorie Ⅳ

Catégorie Ⅴ

Alimentation

Moteur

Vit esse moteur

Puissance

Compresseur

Coupe-circuit

haute pression

(coupure

automatique)

Vit esse de

récupération

Vape ur

Liquide

Mode Push/Pull

Température de

fonctionnement

Dimensions

Poids net

R-12, R-134a, R-40 1C, R-406A, R-500

R-22, R-401A, R-40 1B, R-402B,

R-407C, R-407D, R- 408A, R-409A,

R-411A, R-411B , R-412A, R -502, R-509

R-402A, R-404A, R- 407A, R-407B,

R-410A , R-507

220-240V CA 50-60 Hz

0.75 kW

1450rpm@50Hz

5A@50Hz

Sans huile, à refroi dissement à air, piston

38.5bar/3850kP a (558psi)

Category Ⅲ

0.40 Kg/min

3.00 Kg/min

7.50 Kg/min

0°C-40°C/32-10 4°F

400mm(L)×250(I )mm×345mm(H)

15.8kg

Category Ⅳ

0.60 Kg/min

3.50 Kg/min

8.50 Kg/min

Category Ⅴ

0.80 Kg/min

3.50 Kg/min

9.50 Kg/min

9

Page 65

Mode d'emploi ENVIRO-DUO Franç ais

4. Désignation des pièces

Composant

N°

Câble de flottaiso n

1

Panneau avant

2

Valv e de contrôle

3

Tuyaux en cuivre

4

Couvercle boîte de

5

dérivation

Compresseur

6

Condensateur de

7

marche

Composant

N°

Condensateur de

8

démarrage

Ventilateur

9

Capot de protectio n

10

du ventilateur

Cordon d'aliment ation

11

électrique

Base

12

Couvercle en

13

plastique

10

Page 66

Français Mo de d'emploi ENVIRO- DUO

5. Consignes du panneau de commande

INT ERRUP TEUR

PRI NCIPAL

COU PE-CI RCUIT

MAN OMETR E

D'A SPIRAT ION

11

VOYA NT LUMIN EUX

HAU TE PRES SION

PRI SE D'AS PIRATI ON

FILT RE

TEN DEUR DE F ILTRE

FIN

VOYA NT LUMIN EUX

80% O FP

PRI SE DE REF OULEM ENT

MAN OMETR E DE

REF OULEM ENT

CON NECTE UR

CÂB LE DE

FLO TTAISO N

Page 67

Mode d'emploi ENVIRO-DUO Franç ais

6. Schéma électrique

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Code du

schéma

XS

SA

FR

M1

SR

C1

C2

ST

TC

HP

LP

OFP

d1,d3

d2

SC

SB

CTR

K1

DESIGNATION

Prise de courant

Inter rupteur

Dispositif de prot ection

contre la surcharg e

Moteur du compress eur

Inter rupteur cen trifuge

Conde nsate ur de dém arrag e

Condensateur de ma rche

Therm o-pro tecti ons du mo teur

Transformateu r élect roniq ue

Inter rupte ur haut e press ion

Inter rupte ur bass e press ion

Inter rupteur 80% O FP

Voyant rouge

Voyant vert

Inter rupteur en op tion

Touche de démarrage

Module de contrôle

Relais

Remarques

12

Page 68

Français Mo de d'emploi ENVIRO- DUO

7. Fonctionnement

1.

S'abstenir de mélanger divers réfrigérants dans un seul

réservoir c ar ils n e pourr a i e n t pas ê t r e séparés n i

utilisés.

2.

Avant t oute utilisation, l'i nterrupteur doit êt re en

"position 0". Toutes les valves doivent être fer mées, et

les pr ises d'aspiration et de re foulement do ivent être

munies de bouc hons protec teurs lor sque l'appa reil ne

fonctionne pas. L'humidit é de l'air nuit au ré sultat de la

récupération e t lim ite par ailleurs la durée de vie de la

station.

3.

Il faut toujours utiliser un déshydr ateur-filtre et le

remplacer fréquemment. Chaque type de réfrigérant doit

par ailleurs po sséder son propre filtre. P rière d'utiliser

le filtre indiqué par notre socié té afin de gar antir le b on

fonctionnement de l'appareil. Un déshydrateur-filtre de

grande qualité fournira des services de qualité équivalente.

4.

Des précautions particulières s'imposen t lorsqu'o n

récupère un ré frigérant à partir d'un système br ûlé ; il

faut alors deux filtres

5.

L'appareil est équipé d'un coupe-circuit pour la haute

pression interne. Si l a pression à l'intérieur du système

dépasse 38,5 bars, le compresseur coupe automatiquement

l'alimentati on. Pour relancer le compresseur, prière de

faire chuter la pression interne et d'appuyer sur le bouton

"Haute Pression (HP)", puis enclencher l'alimentat ion

électrique pour redémarrer le compresseur.

13

Page 69

Mode d'emploi ENVIRO-DUO Franç ais

En cas d'amorçage du système de protec tion haute

pression, prière d'en découvrir la cau se et de régle r le

problème avan t de relancer l'appar eil. Cause(s) du

problème de protection de haute pression et dépannage:

a.

La valve d'aspiration du réserv oir d e réf rigérant est

fermée : son ouverture permet de résoudre le problème.

b.

Le tuyau raccordant la station de récupération au

réservoir de réfrigér ant est coincé : fermer toutes

les valves et changer ce tuyau.

c.

La température du réservo ir de réfrigérant est trop

élevée, ce qui entraîne une pression trop forte –laisser

refroidir quelque s inst ants e t la pression revien t à la

normale.

d.

L'appareil com prend un coupe-circuit pour la basse

pression interne et un circuit de retard. Si la pression

à l'intérieur de l'appareil est inférieure à -2.5 psi ~ 6.8

psi pendant 20 secondes, la station s' arrête

automatiquement et le voyant lumineux vert s'allume.

En cas d'absence de pression dans la prise d'aspiration

lorsque la station termine l'opération de récupération

et de purge, elle ne peut f onctionner que pendan t 20

secondes si vous redémarrez l'appa reil.

Si la pression d' aspiration est supérieure à 0,8 bar

(11 psi) , la station travaille en c ontinu.

14

Page 70

Français Mo de d'emploi ENVIRO- DUO

e.

La station peut être utilisée uniquement avec un capteur

de niveau à flotteur. Prière de raccorder la station et

le réservoir à l'aide d'un câble 80% OFP (pos te 1,

TABLEAU DES PIÈCES). Si le réfrigérant atteint 80%

de ca pacité du réservoir, la station de récupération

s'arrête automatiquement et le voyant lumineux rouge

s'allume (VOYANT LUMINEUX 80% OFP ). Installer

un réservoir neuf avant de redémarre r.

f.

Si le réservoir de réfrigérant ne poss ède pas de

capteur de niveau à flotteur, prière de r etirer le

câble 80% OFP. Sinon, la st ation de récupération ne

peut pas être lancée. Dans ce cas, une bal ance

électrique est indispensable pou r surveiller le

volume de réfrigérant récupéré.

g.

Pour atteindre une vitesse de récupération maximale,

il est recommandé d'user d'un tuyau fl exible d'un

diamètre interne supérieur à 4 mm et d'une longueur

inférieure à 1,5 m.

h.

Utiliser le mode Push/Pull (surpression) pour récupérer

de grandes quan tités de liquide.

i.

Une fois l'opération de récupération terminée, s'assurer

qu'il ne reste plus de réfrigérant dans l'appareil. Lire

attentivement le paragraphe Opération de purge. Le

réfrigérant liquide restant dans l'appareil peut fuir et

endommager les éléments.

j.

En cas d'entreposage ou de non-utilisation de la station

pendant un certain temps, nous recom mandons.

15

Page 71

Mode d'emploi ENVIRO-DUO Franç ais

k.

de la vider entièrement de tout réfrigérant résiduel

et de la purger à l'azote sec.

l.

Il est recommandé de r accorder le tuy au à la valve

de contrôle pour prévenir toute pert e de réfrigérant.

m.

La prise d'aspiration est équipée d'un filtre à nettoyer

fréquemment pour qu'il reste propr e.

n.

En cas de diffic ultés à fai re démarrer l'appareil,

prière d'orienter l'inte rrupteur sur la p osition 2 pour

équilibrer la pr ession inter ne et faire en sorte que le

démarrage soit plus facile.

o.

Le manomètre basse press ion indiqu e la pression

de la prise d'asp iration du com presseur, tandis que

le m anomètre haute pre ssion indi que la pression de

la prise de refoulement.

p.

Après utilisation, prière de met tre l'interrupte ur en

position "0".

8. Processus de récupération

1.

Tourner l'interrupteur en position " 1".

2.

Raccorder les tuyaux correctemen t et solidement

(cf. schéma d e connexion).

3.

Brancher correctement la station à l'alimentation électrique

(comme indiqué sur la plaque signalétique), mettre sous

tension pour démarrer l'appareil .

4.

Appuyer sur la touche Démarrage pour la mise en service.

16

Page 72

Français Mo de d'emploi ENVIRO- DUO

Mano mètre s

(ens emble d e jauge s)

Sys tème HVAC ( CVC)

Vape ur

Liqu ide

5.

Ouvrir le robinet du réservoir de réfr igérant.

6.

Ouvrir le robinet Liquide de la jauge.

7.

Tourner lentem ent l'interrupteur en position "2" pour

ASPI RATION

Câb le de flot taiso n

80% OF P

REFO ULEME NT

Robi net

Vape ur

Bala nce

une récupération plus rapide. N.B. :

N.B. :

a.

Si du liquid e passe dans l e compres seur lors que le

commutateur est en posi tion 2, basculer lent ement

sur la position START. La pre ssion affiché e sur le

manomètre BP va diminuer jusqu 'à ce que les

àcoups cessent mais la pression devr a rester

supérieure à "0" afin que l'aspirati on ait lieu. Si le

démarrage ou redémarrage est difficil e après que la

machine ait été arrêtée, mett re le commutateur sur

la position "START", mett re l a machine sous tension

et appuyer sur le bouton RESET.

17

Robi net Liq uide

Rés ervoi r

Page 73

Mode d'emploi ENVIRO-DUO Franç ais

b.

Lorsque le commutateur est en positi on 1 et que la

machine est en marche, la récupérati on de fluide

frigorigène liquide peut avoir lie u à vitesse lente.

Si des à-coups se produisent dans le com presseur

lorsque le commutateur est en positi on 1, tourner

lentement en position "START". La pression BP va

diminuer jusq u'à ce que les à-coups ce ssent. La

pression doit être maintenue supér ieure à "0" afin

que l'aspiration ait lieu.

8.

Lorsque la récupération du liquide e st finie, mettre

l'interrupteur en position "2" pour une récupération plus

rapide.

9.

La station s'arrête automatiquem ent lorsque la

récupération est terminée ; prière de procéder à présent

à la purge.

RÉCUPÉRATION

RAPID E

RÉCUPÉRATION

LENTE

PURGE

ARRÊT

18

Page 74

Français Mo de d'emploi ENVIRO- DUO

9. Processus de purge automatique

1.