Page 1

DIGIMON-SE

DIGIMON4

Installation and operating guide

Digital Manifold

Guide d’installation et d‘utilisation

By-pass électronique

Guía de instalación y funcionamiento

Analizador digital

1

Page 2

Page 3

Instruction Manual DIGIMON-SE / DIGIMON4 English

Instruction manual

2-way and 4-way digital manifolds

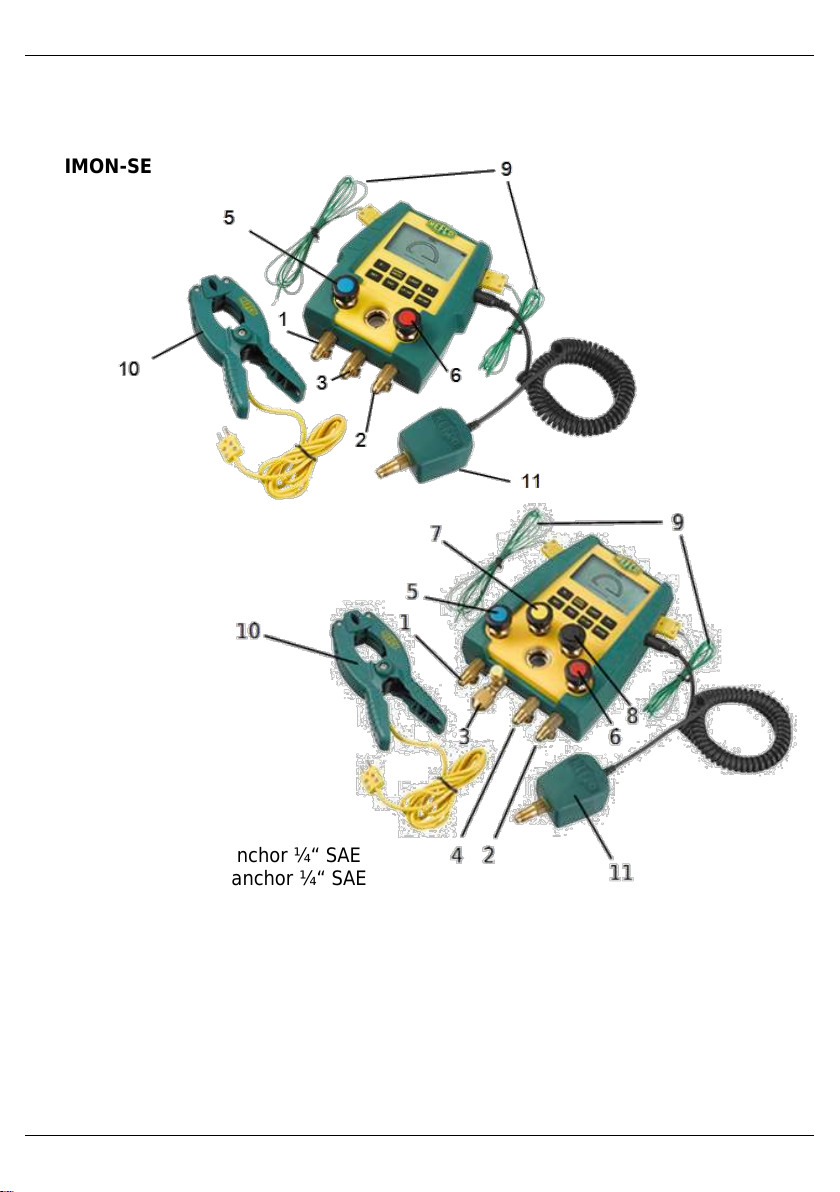

DIGIMON-SE

DIGIMON4

1. Low pressure anchor ¼“ SAE

2. High pressure anchor ¼“ SAE

3. Vacuum anchor ¼“ SAE or 3/8“

4. Refrigerants anchor ¼“ SAE

5. Low pressure valve (blue)

6. High pressure valve (red)

7. Vacuum valve (yellow)

8. Refrigerants valve (black)

9. 2 external K-type thermocouples

10. Clamp thermocouple K-type (optional) P/N 4681466

11. External vacuum sensor DIGIMON-VAC (optional) P/N 4686713

1

Page 4

English Instruction Manual DIGIMON-SE / DIGIMON4

Contents

Important safety notice ............................................................................. 3

Purpose and use ........................................................................................ 3

Scope of delivery ...................................................................................... 4

Transport .................................................................................................. 4

Important note .......................................................................................... 4

Technical description ................................................................................. 4

Key functions ............................................................................................. 6

Battery charge level indicator .................................................................... 6

Application ................................................................................................ 7

Connecting the manifold .......................................................................... 12

Evacuating the system ............................................................................. 12

Filling the system .................................................................................... 13

Measuring using the Superheat / Subcool modes ...................................... 14

Maintenance work on the manifold ........................................................... 14

Guarantee ............................................................................................... 14

Environmental issues ............................................................................... 15

Replacement parts and accessories .......................................................... 15

Resetting pressure sensors ...................................................................... 16

Factory settings ....................................................................................... 16

Resetting the external vacuum sensor ...................................................... 16

Calibrating pressure sensors .................................................................... 17

Calibrating the temperature display ......................................................... 18

2

Page 5

Instruction Manual DIGIMON-SE / DIGIMON4 English

Important safety notice

Before working with the manifold, please read the instruction manual

carefully. This manual provides important information regarding the smooth

operation, maintenance and disposal of the manifold.

Purpose and use

The manifold has been developed for measuring and adjusting pressure and

temperature in both mobile and stationary refrigeration equipment.

The manifold must not be used for anything other than the above-stated

purposes.

The manifold must not be used with pressures higher than 60bar / 870psi /

6000kPa / 6MPa.

Under no circumstances should the manifold be used as a pressure regulator,

especially not when using nitrogen N2.

The manifold must not be used with the refrigerant ammonia (NH3 / R717).

The manifold should not be exposed to rain or used in damp or wet

environments.

Protective goggles and gloves must always be worn when using the manifold.

REFCO products have been specially designed and manufactured for use by

trained refrigeration and air-conditioning service engineers only. Due to the high

pressures and the physical and chemical gases used in refrigeration systems, REFCO

cannot be held liable or responsible for any accidents, injuries or deaths arising during

use of the manifold. REFCO explicitly states that their products must only be sold to

professionally trained experts.

3

Page 6

English Instruction Manual DIGIMON-SE / DIGIMON4

Scope of delivery

Information about the various models and variations of our products can be found in

the REFCO catalogue or at www.refcoswiss.com

Transport

The manifolds are delivered from the factory in a plastic box, with or without filling

hoses. Manifolds are high-grade instruments and should always be transported and

stored in a box.

Important note:

Remove refrigerants from the manifold and the hoses after use.

The hose connectors hanging freely from the manifold (screw joints / system side) can

be screwed onto the Y-connectors and to the central T-piece, when not in use. This

serves to protect the thread from contamination and damage.

Technical description

The DIGIMON can be used with the following refrigerants:

R11, R113, R114, R12, R123, R124, R13, R134a, R13B1, R22, R227, R23, R290, R32

R401A(Liq), R401A(Vap), R401B(Liq), R401B(Vap), R402A(Liq), R402A(Vap),

R402B(Liq), R402B(Vap), R403B(Liq), R403B(Vap), R404A, R406A (Liq), R406A(Vap),

R407A(Liq), R407A(Vap), R407C(Liq), R407C(Vap), R407F(Liq), R407F(Vap),

R408A(Liq), R408A(Vap), R409A(Liq), R409A(Vap), R410A, R413A(Liq), R413A(Vap),

R414B(Liq), R414B(Vap), R416A, R417A(Liq), R417A(Vap), R420A, R422A(Liq),

R422A(Vap), R422B(Liq), R422B(Vap), R422C(Liq), R422C(Vap), R422D(Liq),

R422D(Vap), R427A(Liq), R427A(Vap), R437A, R438A(Liq), R438A(Vap), R500,

R502, R503, R507, R508A, R508B, R600A, R744, R1234yf

(Liq) = liquid / bubble point, (Vap) = vapour / dew point

4

Page 7

Instruction Manual DIGIMON-SE / DIGIMON4 English

Property

Value

Maximum working

pressure:

Low pressure: 60bar / 870psi / 6000kPa / 6MPa

High pressure : 60bar / 870psi / 6000kPa / 6MPa

Pressure

resolution:

0.01 bar / 0.5psi / 1kPa / 0.001MPa

Pressure units:

bar / psi / kPa / MPa

Positive pressure

display:

0 to 60bar, up to 870psi, up to 6000kPa, up to 6MPa

Negative pressure

display:

0 to -0.95bar, 0 to -13.7psi, 0 to -95kPa, 0 to -0.095MPa

Accuracy class:

Class 1.0

External

thermocouple:

Temperature range:

-40°C to +125°C / -40°F to +257°F

Plug:

K-type

Accuracy of

measurement:

+/- 1.8°F

Resolution:

0.5°C / 0.5°F

Optional clamp

thermocouple Ktype

Temperature range:

-40°C to +125°C / -40°F to +257°F

For pipe diameters of:

6mm to 38mm / ¼“ to 1 ½“

Plug:

K-type

Accuracy of

measurement:

+/- 1.8°F

Resolution:

0.5°C / 0.5°F

Ambient

temperature:

0°C to +50°C / +32°F to +122°

Power supply:

4 x 1.5 V AA / Mignon / LR6 batteries

Service life of approx. 50 hours when used continuously.

Storage

temperature:

- 20°C to + 60°C / -4°F to 140°F

Property

Value

Vacuum display:

Bar diagram display

1 bar ca. 0 to -300mbar

2 bars ca. -300 to -380mbar

3 bars ca. -380 to -460mbar

4 bars ca. -460 to -540mbar

5 bars ca. -540 to -620mbar

6 bars ca. -620 to -700mbar

7 bars ca. -700 to -780mbar

8 bars ca. -780 to -860mbar

9 bars ca. -860 to -920mbar

10 bars ca. -920 to ultimate vacuum

Vacuum display without vacuum sensor

5

Page 8

English Instruction Manual DIGIMON-SE / DIGIMON4

Property

Value

Range:

0 to 10000 Microns

Resolution:

0.1Pa / 1Micron / 0.001mbar / 0.001Torr / 1mTorr /

0.0001psi / 0.0001inHg

Units:

Pa / Micron / mbar / Torr / mTorr / psi / inHg

Accuracy of

measurement:

up to 100 Microns +/- 10 Microns

up to 101 - 750 Microns +/- 45 Microns

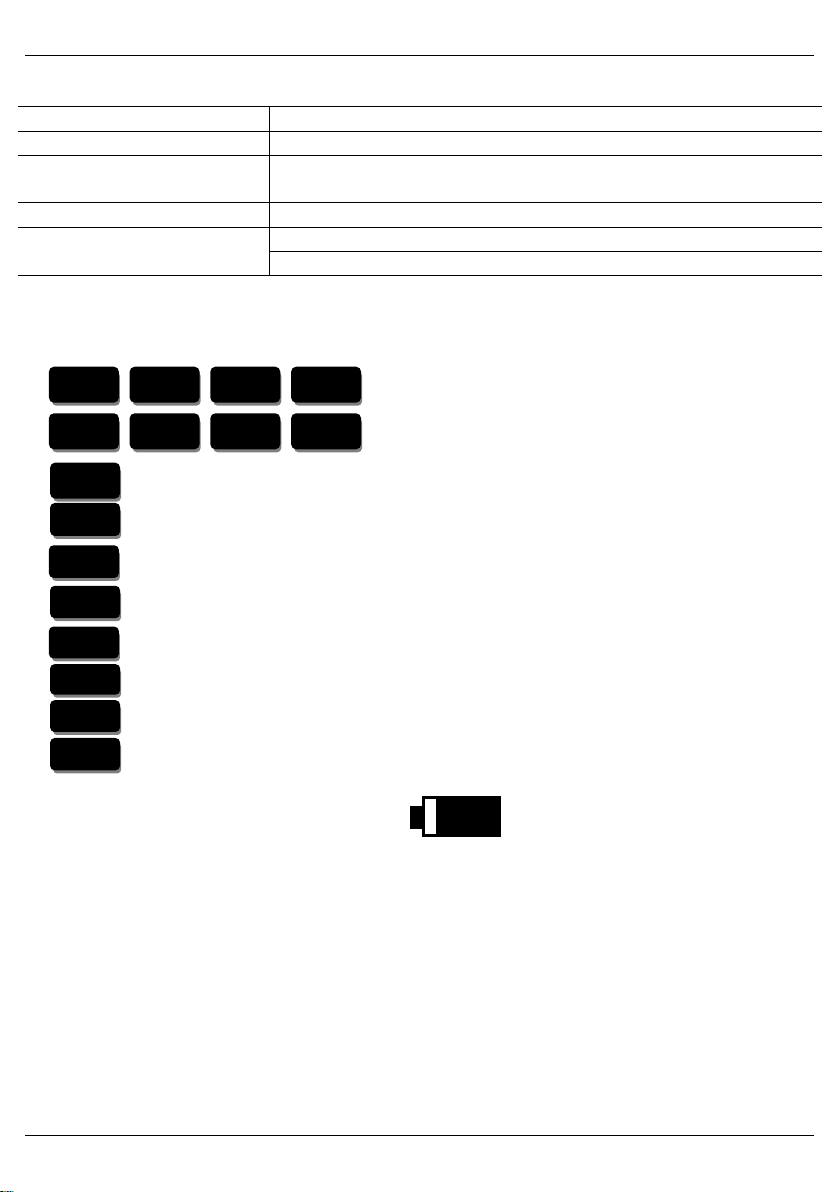

LIGHT

VAC

SET

LP/HP

SUPERH

SUBC00L

R +

R -

ON/OFF

ON/OFF

LP/HP

VAC

SET

R +

SUPERH

SUBC00L

LIGHT

R -

Vacuum display with external vacuum sensor

Key functions

Power supply ON/OFF

Switch pressure display function

Switch vacuum display function

Switch LCD light on/off (switches off automatically after 1 minute)

Select refrigerant, search forwards (select pressure unit)

Select refrigerant, search backwards (select temperature unit)

Switch function ON or OFF

Confirm function / selection

Battery charge level indicator

If the battery is empty, the indicator will display an entirely white battery symbol. The

batteries must then be replaced in order to guarantee full function.

6

Page 9

Instruction Manual DIGIMON-SE / DIGIMON4 English

LIGHT

SET

LIGHT

ON/OFF

Application

Set-up

Insert 4 batteries in the battery compartment at the back of the device.

Caution: Ensure the batteries are inserted observing the correct

polarities. Do not leave empty batteries in the battery

compartment. If you will not be using the DIGIMON for a

longer period of time, remove the batteries from the battery

compartment.

Press the button, the device is now switched on.

Check battery charge level indicator.

Illuminating the display

Press the button to switch the display light on or off. The light switches off

automatically after 1 minute.

Automatic shut-off

The DIGIMON switches off automatically approximately 15 minutes after the last

measurement or after the last button has been pressed.

Resetting pressure sensors

By pressing the and buttons the DIGIMON pressure displays are

reset to zero, in order to avoid incorrect measurement values.

Important note:

Depressurise the DIGIMON (remove hoses).

Open the blue and red valves.

To obtain a correct measurement value on the display, the DIGIMON

should not be reset when pressurised or under a vacuum.

7

Page 10

English Instruction Manual DIGIMON-SE / DIGIMON4

SET

SET

R -

R +

PSI

°F

PSI

PSI

PSI

°F °F

°F

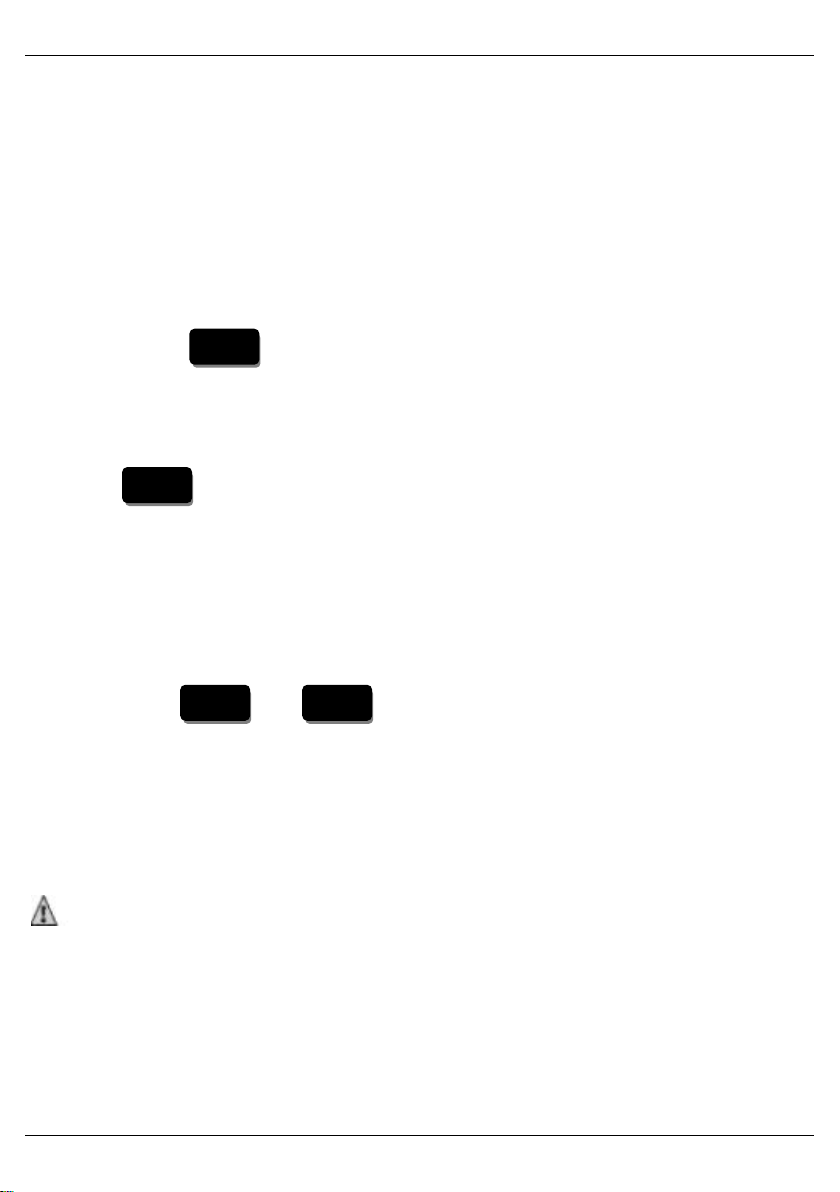

Digital display

Analogue display with memory function

Select refrigerant

Press the or buttons to select the desired refrigerant from the list.

During selection, you will see a flashing "R" on the display.

Press the button to confirm selection of the desired refrigerant. The "R" no

longer flashes on the display.

Important note:

If the refrigerant selection is not confirmed with , the previously selected

refrigerant will remain active.

8

Page 11

Instruction Manual DIGIMON-SE / DIGIMON4 English

LIGHT

SET

LP/HP

LP/HP

LP/HP

SET

R -

SET

R +

SET

PSI

PSI

°F

°F

°F

°F

°F

°F

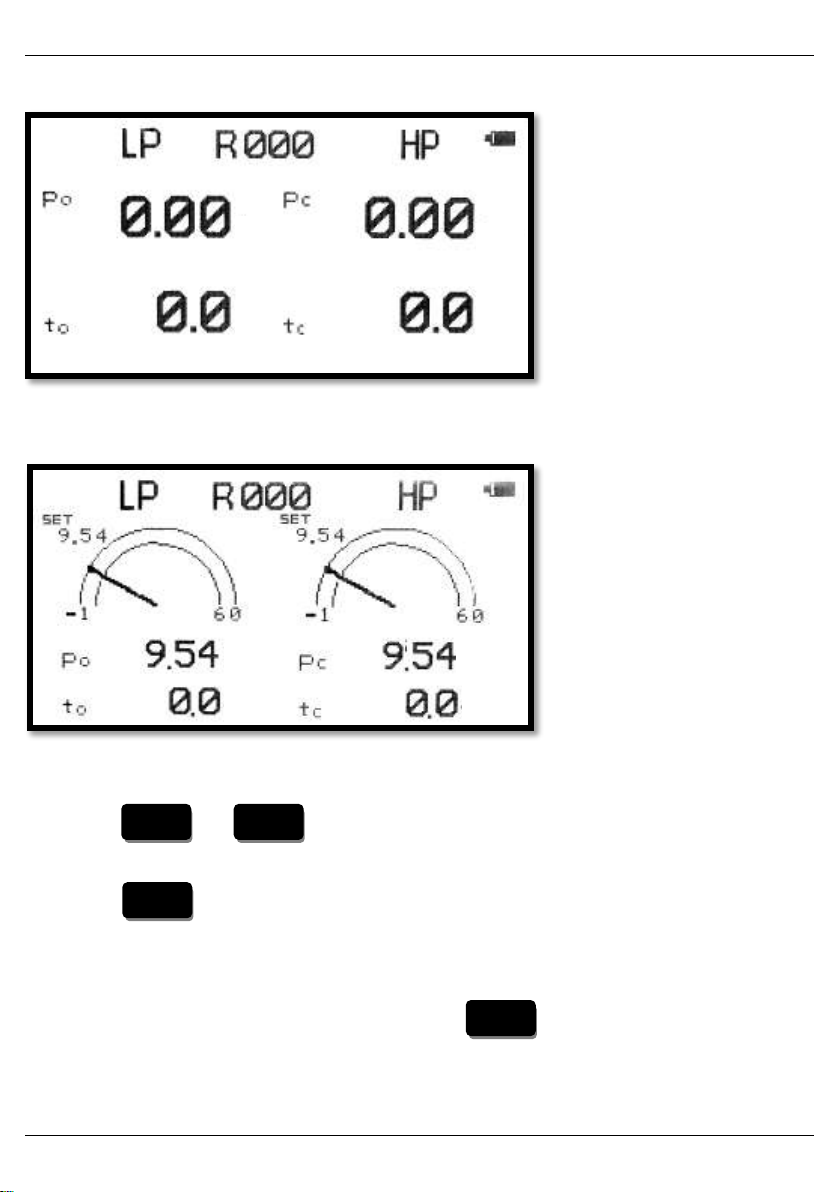

Select pressure unit

Hold down the button. Use to select the desired unit. Release both

buttons.

Select temperature unit

Hold down the button. Use to choose between °C and °F. Release

both buttons.

Important note:

The device will save the last pressure and temperature units selected.

Memory function of the analogue pressure display:

Save value (current measurement value): press the and buttons at

the same time

Retrieve memory value: press the button for 3 seconds (display freezes)

Clear display: press the button for 3 seconds saved value is no longer

visible

Delete memory value: press the and buttons at the same time

Superheat/Subcool mode

9

Page 12

English Instruction Manual DIGIMON-SE / DIGIMON4

VAC

SUPERH

SUBC00L

PSI

PSI

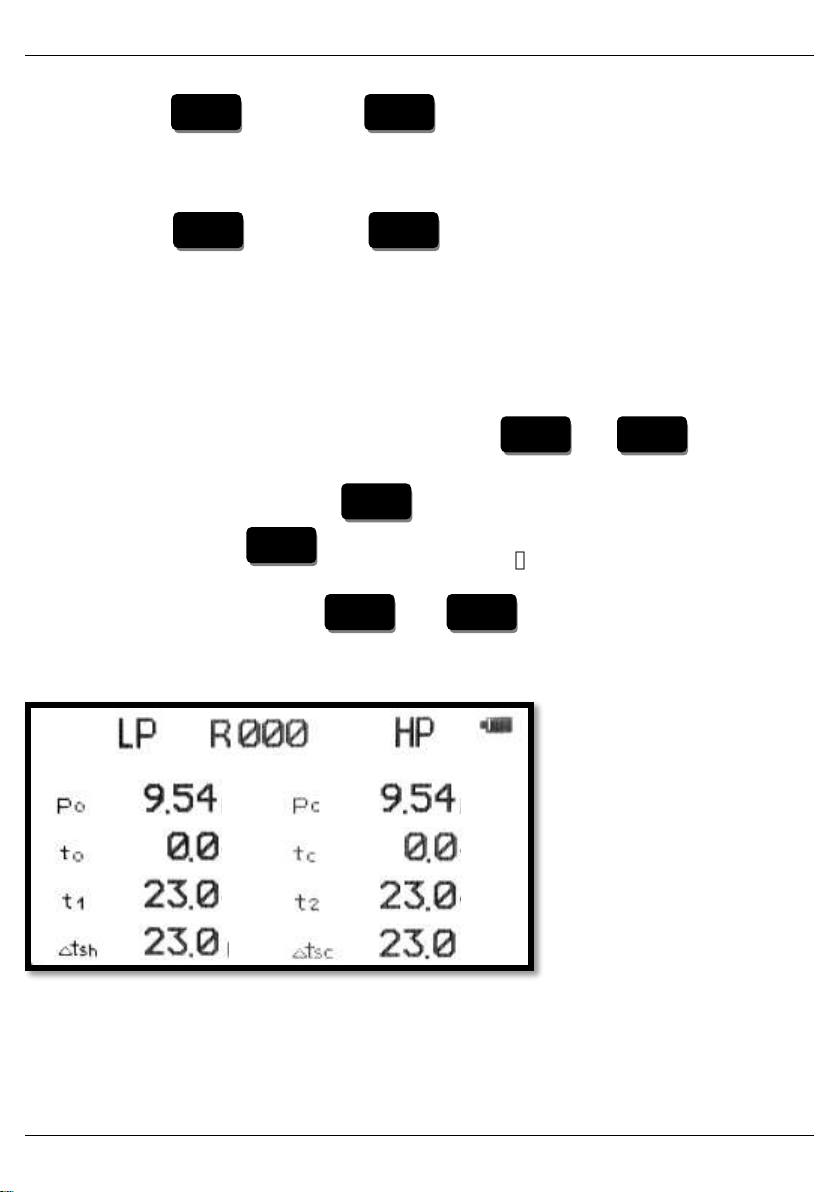

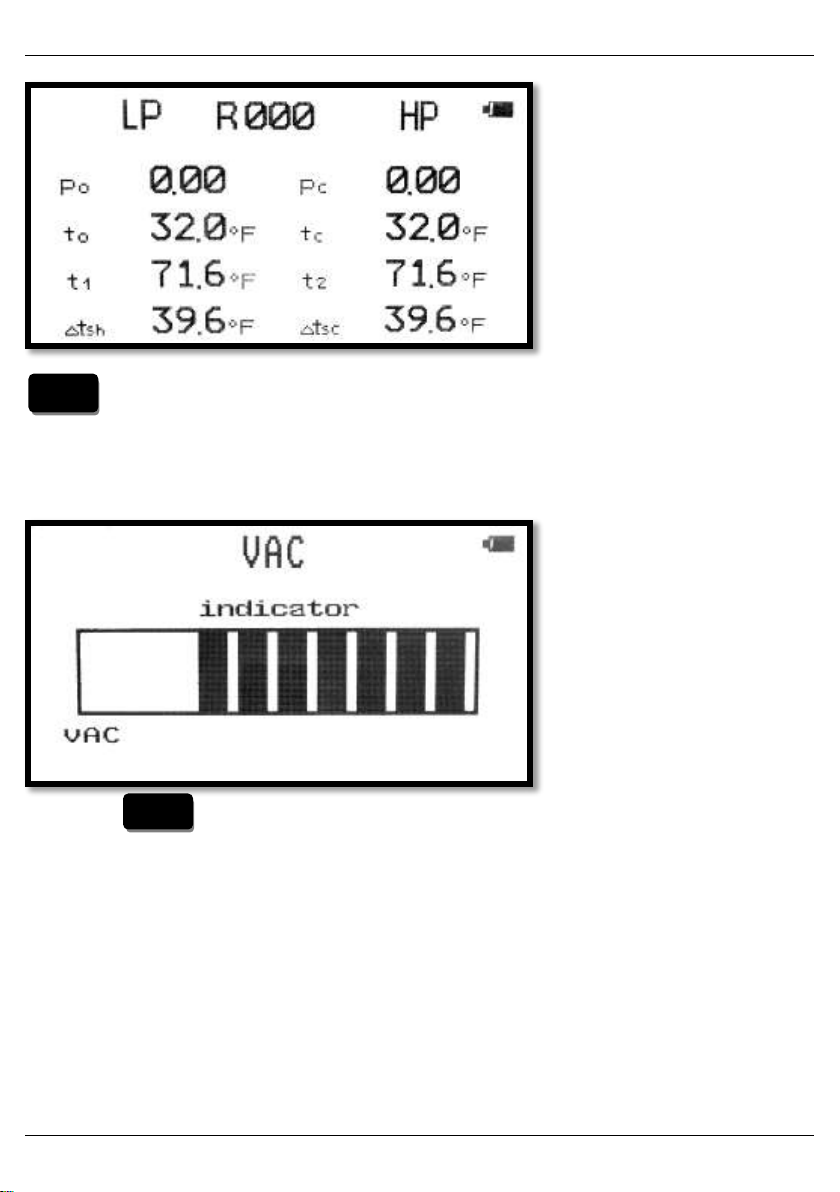

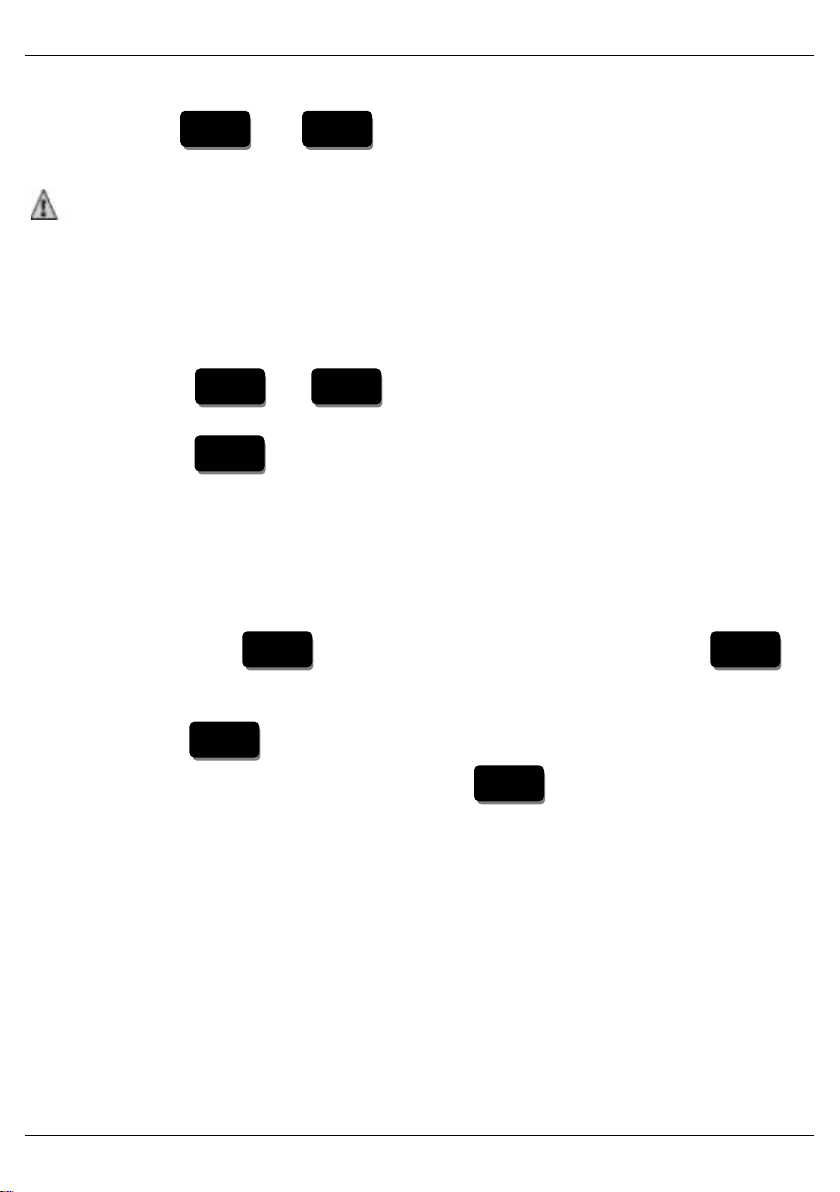

displays the difference "K" (F) between the temperature according to the

vapour pressure table (to, tc) and the measured temperature (t1, t2) of the external

thermocouples (9) or the clamp thermocouples (10).

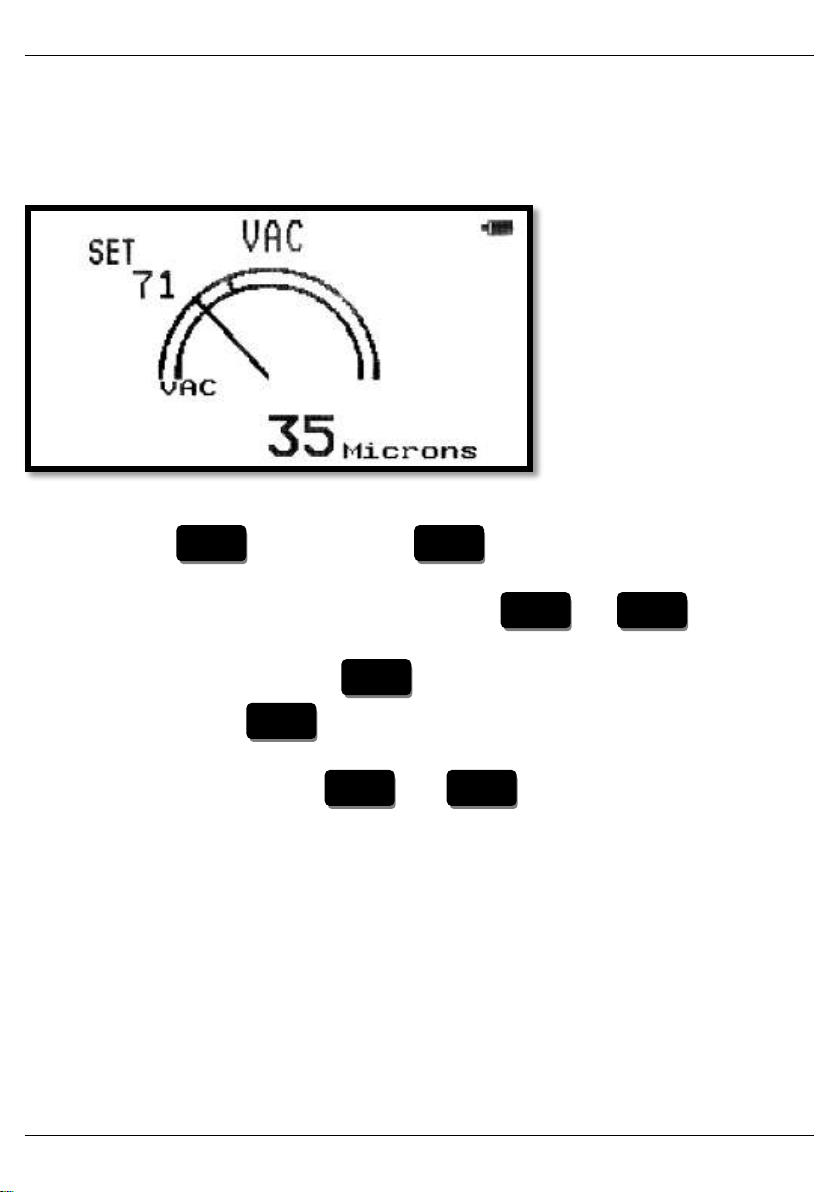

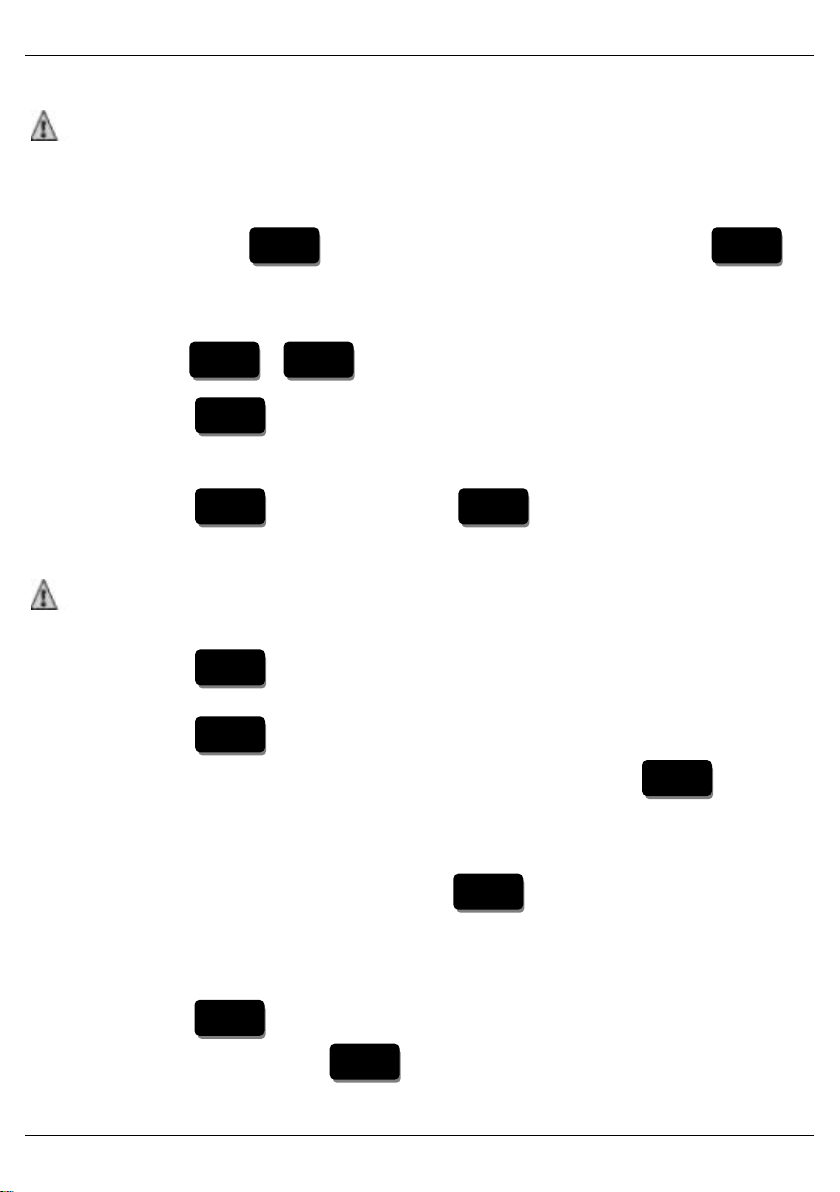

Vacuum display

Press the button to bring up the vacuum display.

Vacuum display values

When evacuating the device, a maximum of 10 bars will be displayed. When the

display remains stable, the ultimate vacuum has been reached and the evacuation

time begins. The display of the ultimate vacuum (10 bars) depends on the vacuum

pump's performance and the atmospheric pressure.

Important note:

The DIGIMON manifold must be switched on before commissioning the attached

vacuum pump. The manifold must be switched on during evacuation.

10

Page 13

Instruction Manual DIGIMON-SE / DIGIMON4 English

LIGHT

SET

VAC

VAC

VAC

SET

R +

SET

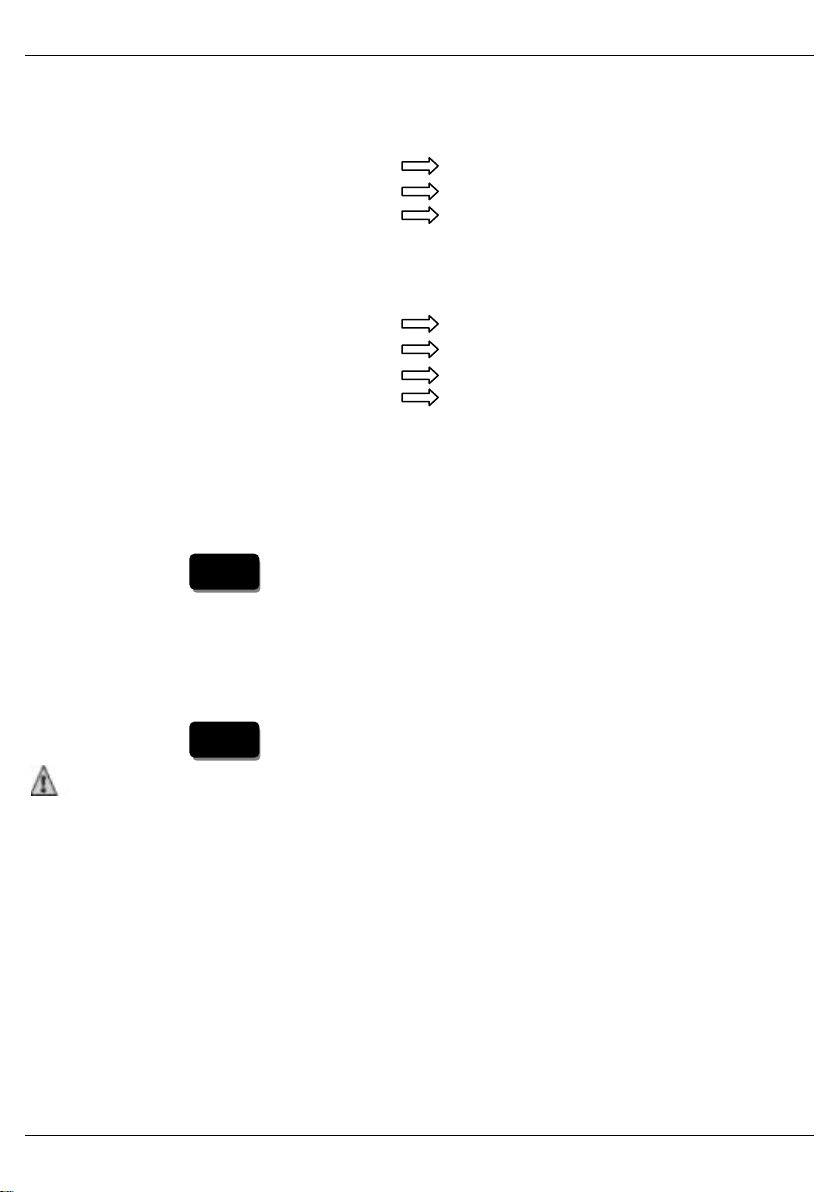

External vacuum sensor (optional)

The external vacuum sensor should be used to measure exact vacuum values. The

sensor should be connected to the system.

Vacuum display

Select pressure unit

Hold down the button. Use the button to select the desired unit.

Release both buttons.

Save value (current measurement value): press the and buttons at

the same time

Retrieve memory value: press the button for 3 seconds (display freezes)

Clear display: press the button for 3 seconds saved value is no longer

visible

Delete memory value: press the and buttons at the same time.

11

Page 14

English Instruction Manual DIGIMON-SE / DIGIMON4

LP/HP

VAC

Connecting the manifold

a) with DIGIMON-SE

Connect blue hose (1) to suction pressure side of system

Connect red hose (2) to high pressure side of system

Connect yellow hose (3) to vacuum pump

Close both valves (5+6)

b) with DIGIMON4

Connect blue hose (1) to suction pressure side of system

Connect red hose (2) to high pressure side of system

Connect yellow hose 3/8“ (3) to vacuum pump

Connect yellow hose 1/4“ (4) to refrigerant cylinder

Close both valves (5+6)

Evacuating the system

Switch on the manifold

Press the button

Connect the hoses

Switch on vacuum pump

Open all valves

Check vacuum display

When the ultimate vacuum is achieved, close all valves.

Press the button to exit vacuum mode.

Evacuation time varies depending on the size of the system. A small to

medium-sized system requires a minimum evacuation time of 20 minutes.

12

Page 15

Instruction Manual DIGIMON-SE / DIGIMON4 English

Filling the system

a) with DIGIMON-SE manifold

Disconnect the yellow hose from the vacuum pump and screw it onto the

refrigerant bottle or cylinder.

Open the valve on the refrigerant bottle or cylinder.

Open the blue valve (5) (low pressure side) and let the required amount of

refrigerant to flow in. If the required amount of refrigerant does not flow into

the system, the compressor must be switched on.

After the system has been filled with the desired amount, close the valve on

the refrigerant bottle or cylinder.

Close the blue valve (5).

Check the system's pressure and temperature!

Remove the hoses from the system.

Open valves (5+6).

b) with DIGIMON4 manifold

Disconnect the yellow hose (3/8“) from the vacuum pump and the DIGIMON4

(3) and screw the caps onto the 3/8“ SAE thread.

Open the black valve (8).

Open the valve on the refrigerant bottle or cylinder. Then open the blue valve

(5) and allow the required amount of refrigerant to flow in. If the required

amount of refrigerant does not flow into the system, the compressor must be

switched on.

After the system has been filled with the desired amount, close the black

valve (8).

Close the valve on the refrigerant bottle or cylinder.

Open the red valve (6). Check the pressure and temperature on the high and

low pressure sides of the system! If all pressures are in order, close all valves.

Remove the hoses from the system.

Open all valves.

13

Page 16

English Instruction Manual DIGIMON-SE / DIGIMON4

Measuring using the Superheat / Subcool modes

See section "Connecting the DIGIMON manifold".

Plug the K-Type plug of the external thermocouples (9) or the clamp

thermocouple (10) into the DIGIMON (sockets on the right (t1) and left (t2)

side of the housing).

Fix the external thermocouple (9) or the clamp thermocouple (10) with

adhesive tape to the required measuring point on the high pressure or suction

pressure side of the system.

Set the appropriate refrigerant (see section "Select refrigerant").

Switch on the temperature difference display: press SUPERHEAT/ SUBCOOL.

Maintenance work on the manifold

A visual inspection of the connections and filling hoses must be carried out

before each use, to check for mechanical damage.

Do not use aggressive cleaning agents or solvents to clean the device. Gentle

household cleaners and soapy water should be used instead.

Manifold seals are subject to mechanical and age-related wear. Therefore, the

manifold should be regularly tested by the user for leaks.

In case of leaky valves, the piston should be replaced (M4-6-04-R/10).

The special REFCO M4-6-11-T tool should be used to change the sight glass on

the manifold.

The manifold should be checked after the replacement of seals to

ensure there are no leaks.

Guarantee

Your new DIGIMON has been developed in accordance with the latest occupational

health and ergonomic requirements and reflects the latest state-of-the-art

technology. REFCO Manufacturing Ltd has been certified in accordance with DIN EN

ISO 9001: 2008. Regular quality control checks as well as an accurate manufacturing

process guarantee reliable functionality and are the basis for the REFCO guarantee, in

accordance with the General Terms and Conditions of Sale and Delivery applicable on

the day of delivery. Damages arising from obvious maltreatment or wear are

excluded from the guarantee.

14

Page 17

Instruction Manual DIGIMON-SE / DIGIMON4 English

Description

Identifier

P/N

Control knob red

M4-7-SET-R

4677842

Control knob blue

M4-7-SET-B

4677850

Control knob black

M4-7-SET-N

4677868

Control knob yellow

M4-7-SET-Y

4687876

Complete valve set

M2-10-95-R/10

4662607

Valve piston

M4-6-04-R/10

4662624

Sight glass set MS

M4-6-11

4491018

Battery compartment cover 2-way

DIGIMON-SE-BATTERY-COVER

4686772

Battery compartment cover 4-way

DIGIMON4-BATTERY-COVER

4686749

Tool for sight glass assembly

M4-6-11-T

4493169

Plastic case

DIGIMON-SE-CASE

4676730

External K-type thermocouple

DIGIMON-SENSOR-K-TYPE

4681394

Clamp thermocouple K-type

DIGIMON CLAMP

4681466

External vacuum sensor

DIGIMON-VAC

4686713

Environmental issues

The DIGIMON manifold has been developed for long term use. REFCO takes energy

saving and environmental impact into consideration when procuring materials and

manufacturing its products. REFCO Manufacturing Ltd feels responsible for all of its

products throughout their entire lifespan and has therefore been certified in

accordance with DIN EN ISO 14001 : 2004. When decommissioning the device,

users should observe the disposal regulations applicable in their country.

Replacement parts and accessories

15

Page 18

English Instruction Manual DIGIMON-SE / DIGIMON4

ON/OFF

SET

ON/OFF

VAC

SET

VAC

LIGHT

LIGHT

SET

Resetting pressure sensors

By pressing the and buttons the DIGIMON pressure displays are

reset to zero, in order to avoid incorrect measurement values.

To obtain a correct measurement value on the display, the DIGIMON

should not be reset when pressurised or under a vacuum.

Factory settings

Set the DIGIMON to the "Digital display" screen.

Press the and buttons at the same time for 5 seconds.

Display shows - - - - - - - -

Press the button to exit.

Resetting the external vacuum sensor

Switch off the DIGIMON

Connect vacuum sensor

Hold down the button and switch on the device using the

button.

Display shows VAC-ZERO

Press the button to exit display shows End.

The device can be switched on using the button and is ready for

operation once again.

16

Page 19

Instruction Manual DIGIMON-SE / DIGIMON4 English

ON/OFF

R -

SET

SET

SET

R +

SET

R -

SET

R -

R +

ON/OFF

LIGHT

Calibrating pressure sensors

A correct calibration requires a certified monitor.

(e.g. REF-CLASS-GAUGE P/N 4682293)

1. Switch off the DIGIMON

2. Press down the button and switch on the device using the

button.

The display shows "Password" 000

3. Press the / button to select Code 009.

4. Press the button to exit.

The display shows "P-call"

5. Press the button and then the button to calibrate.

400 psi should be displayed on the LP side display

For a correct calibration, there should be no pressure or vacuum in the

DIGIMON.

6. Press the button to select the low pressure side's calibration

pressure (400psi).

7. Press the button to exit.

8. Wait 3-5 seconds until the pressure is stable and press the button

again.

The display shows "0000"

9. Pressurise the DIGIMON with a calibration pressure of 400psi (27.58 bar).

When the pressure is stable, press the button to confirm.

The display shows "LP End"

10. The calibration of the low pressure side has been completed.

11. Press the button to calibrate the high pressure side (HP). Repeat

from Point 6 or press the button to end the calibration.

17

Page 20

English Instruction Manual DIGIMON-SE / DIGIMON4

SET

SET

R -

SET

R -

R +

ON/OFF

LIGHT

LP

00xxx

27.0°C

Temperature code

Current temperature

LP

End

00xxx

27.0°C

Calibrating the temperature display

1. Switch off the DIGIMON

2. Plug in the thermocouples (K-type).

Room and measurement temperatures must remain constant at 77°F +/-7°F

and be stable for at least 20 minutes. The thermocouple cables must be

straight (unwound).

During calibration, you should neither touch the cables nor the plugs.

3. Hold down the button and switch on the device using the

button.

The display shows "Password" 000

4. Press the / button to select code 018.

5. Press the button to exit.

Display shows “T-call”

6. Press the button and then the button to calibrate.

7. During calibration, ensure that both thermocouples are connected to the

DIGIMON.

The display shows (low pressure side)

The current temperature displayed on the DIGIMON should not deviate

by more than +/-0.5°C from the room temperature.

8. Press the button to confirm.

The display shows:

18

Page 21

Instruction Manual DIGIMON-SE / DIGIMON4 English

ON/OFF

R -

9. Press the button to calibrate the high pressure side (HP) Repeat

from Point 6 or press to end the calibration.

19

Page 22

English Instruction Manual DIGIMON-SE / DIGIMON4

20

Page 23

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

Manuel d’utilisation et d’entretien

pour by-pass électronique à 2 et 4 voies

DIGIMON-SE

DIGIMON4

1. Raccord basse pression ¼“ SAE

2. Raccord haute pression ¼“ SAE

3. Raccord pour vide ¼“ SAE ou 3/8“

4. Raccord pour réfrigérant ¼“ SAE

5. Vanne basse pression (bleue)

6. Vanne haute pression (rouge)

7. Vanne pour vide (jaune)

8. Vanne pour réfrigérant (noire)

9. 2 sondes de température externes de type K

10. Sonde de température à pince de type K (en option) Réf. 4681466

11. Capteur pour vide externe DIGIMON-VAC (en option) Réf. 4686713

21

Page 24

Français Mode d'emploi DIGIMON-SE / DIGIMON4

Sommaire

Recommandations de sécurité importantes ............................................. 23

Utilisation / mise en œuvre ..................................................................... 23

Contenu de la livraison ........................................................................... 24

Transport ................................................................................................ 24

Remarques .............................................................................................. 24

Description technique .............................................................................. 24

Fonction des touches ............................................................................... 26

Affichage du niveau de la batterie ............................................................ 26

Utilisation ................................................................................................ 27

Raccordement du by-pass ........................................................................ 32

Tirage au vide de l’installation ................................................................. 32

Remplissage de l’installation.................................................................... 33

Mesure en modes surchauffe (superheat) et sous-refroidissement

(subcool)…………………………… .................................................................... 34

Entretien du by-pass ................................................................................ 34

Garantie .................................................................................................. 34

Environnement ........................................................................................ 35

Pièces de rechange et accessoires ........................................................... 35

Remise à zéro des capteurs de pression ................................................... 35

Configuration usine .................................................................................. 36

Remise à zéro du capteur pour vide externe ............................................. 36

Calibrage des capteurs de pression .......................................................... 37

Calibrage de l’affichage de la température ............................................... 38

22

Page 25

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

Recommandations de sécurité importantes

Avant d’utiliser le by-pass, veuillez lire attentivement le manuel

d’utilisation. Il contient des informations importantes sur l’utilisation

correcte, l’entretien et le recyclage du by-pass.

Utilisation / mise en œuvre

Le by-pass a été conçu afin d'effectuer la mesure et le réglage des pressions et des

températures des installations de réfrigération mobiles et fixes.

Le by-pass ne doit pas être utilisé dans d'autres domaines que la réfrigération

ou la climatisation.

Le by-pass ne doit pas être utilisé pour des pressions supérieures à 60 bar / 870

psi / 6000 kPa / 6 MPa.

Le by-pass ne doit en aucune circonstance être utilisé comme réducteur de

pression, notamment avec l’azote (N2).

Le by-pass ne doit pas être utilisé avec l’ammoniaque en tant que réfrigérant

(NH3 / R717).

Le by-pass ne doit pas être exposé à la pluie ou être utilisé dans un

environnement humide ou mouillé.

Lors de l'utilisation du by-pass, il est nécessaire de toujours porter des lunettes

de protection et des gants.

Les produits REFCO ont été spécialement conçus et fabriqués pour les

spécialistes de la réfrigération et de la climatisation. En raison des pressions élevées

et des gaz physicochimiques utilisés dans les systèmes de réfrigération, REFCO

décline toute responsabilité en cas d'accidents mortels ou moins graves et de

blessures. REFCO incite expressément à réserver la vente de ses produits uniquement

à des spécialistes disposant d'une formation professionnelle adéquate.

23

Page 26

Français Mode d'emploi DIGIMON-SE / DIGIMON4

Contenu de la livraison

Le contenu de la livraison des différents types et versions est disponible dans le

catalogue REFCO ou sur www.refcoswiss.com

Transport

Les by-pass sont livrés à partir de l’usine dans une valise en plastique avec ou sans

les tuyaux de charge. Les by-pass sont des instruments de mesure de haute qualité et

doivent toujours être transportés et conservés dans cette valise.

Remarques:

Après utilisation, les réfrigérants doivent être éliminés du by-pass et des tuyaux.

En cas d’inutilisation, les raccords de tuyau libres (raccords filetés / côté installation)

peuvent être vissés aux raccords en Y et à la pièce en T centrale. Cela permet d’éviter

de salir et d’endommager les raccords filetés.

Description technique

Le by-pass DIGIMON peut être utilisé avec les réfrigérants suivants :

R11, R113, R114, R12, R123, R124, R13, R134a, R13B1, R22, R227, R23, R290, R32

R401A(Liq), R401A(Vap), R401B(Liq), R401B(Vap), R402A(Liq), R402A(Vap),

R402B(Liq), R402B(Vap), R403B(Liq), R403B(Vap), R404A, R406A (Liq), R406A(Vap),

R407A(Liq), R407A(Vap), R407C(Liq), R407C(Vap), R407F(Liq), R407F(Vap),

R408A(Liq), R408A(Vap), R409A(Liq), R409A(Vap), R410A, R413A(Liq), R413A(Vap),

R414B(Liq), R414B(Vap), R416A, R417A(Liq), R417A(Vap), R420A, R422A(Liq),

R422A(Vap), R422B(Liq), R422B(Vap), R422C(Liq), R422C(Vap), R422D(Liq),

R422D(Vap), R427A(Liq), R427A(Vap), R437A, R438A(Liq), R438A(Vap), R500,

R502, R503, R507, R508A, R508B, R600A, R744, R1234yf

(Liq) = Liquide / point d’ébullition, (Vap) = Vapeur / point de rosée

24

Page 27

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

Propriété

Valeurs

Pression de travail

maximale :

Basse pression

60 bar / 870 psi / 6000 kPa / 6 MPa

Haute pression

60 bar / 870 psi / 6000 kPa / 6 MPa

Résolution en pression :

0.01 bar / 0.5 psi / 1 kPa / 0.001 MPa

Unités de mesure de la

pression :

bar / psi / kPa / MPa

Affichage pression

positive :

0 à 60 bar, jusqu’à 870 psi, jusqu’à 6000 kPa, jusqu’à 6

MPa

Affichage pression

négative :

0 à -0.95 bar, 0 à -13.7 psi, 0 à -95 kPa, 0 à -0.095 MPa

Précision :

Classe 1.0

Sonde de température

externe :

Plage de température :

-40°C à +125°C / -40°F à +257°F

Connecteur :

Type K

Précision :

+/- 1°K (+/- 1.8°F)

Résolution :

0.5°C / 0.5°F

Sonde à pince en option

de type K

Plage de température :

-40°C à +125°C / -40°F à +257°F

Pour tubes de

diamètres :

6 mm à 38 mm / ¼“ à 1 ½“

Connecteur :

Type K

Précision :

+/- 1°K (+/- 1.8°F)

Résolution :

0.5°C / 0.5°F

Température ambiante :

0°C à +50°C / +32°F à +122°F

Alimentation :

4 piles x 1.5 V de type AA / Mignon / LR6

Durée de vie en utilisation continue : env. 50 heures.

Température de

stockage :

- 20°C à + 60°C / -4°F à 140°F

Propriété

Valeurs

Affichage du vide :

Affichage indicatif

par barres

1 barre env. 0 à -300 mbar

2 barres env. -300 à -380 mbar

3 barres env. -380 à -460 mbar

4 barres env. -460 à -540 mbar

5 barres env. -540 à -620 mbar

6 barres env. -620 à -700 mbar

7 barres env. -700 à -780 mbar

8 barres env. -780 à -860 mbar

9 barres env. -860 à -920 mbar

10 barres env. -920 mbar jusqu’au vide final

Affichage du vide sans capteur pour vide

25

Page 28

Français Mode d'emploi DIGIMON-SE / DIGIMON4

Propriété

Valeurs

Plage :

0 à 10 000 microns

Résolution :

0.1Pa / 1 micron / 0.001 mbar / 0.001 torr / 1mtorr /

0.0001psi / 0.0001 inHg

Unités :

Pa / micron / mbar / torr / mtorr / psi / inHg

Précision :

jusqu’à 100 microns +/- 10 microns

jusqu’à 101 - 750 microns +/- 45 microns

ON/Off

LP/HP

VAC

SET

R +

SUPERH

LIGHT

R -

LP/HP

ON/Off

LIGHT

VAC

R +

R -

SUPERH

SET

Affichage du vide avec capteur pour vide externe

Fonction des touches

MARCHE/ARRET alimentation

Commutation de la pression affichée

Affichage/masquage du vide

Marche/arrêt du rétro-éclairage de l’écran (arrêt automatique après 1

minute)

Sélection du réfrigérant, recherche par ordre croissant (sélectionner

l’unité de pression)

Sélection du réfrigérant, recherche par ordre décroissant (sélectionner

l’unité de température)

Marche/arrêt de la fonction

Confirmer la fonction / la saisie

Affichage du niveau de la batterie

Lorsque la batterie est vide, la partie noire du symbole disparaît complètement. Les

piles doivent être remplacées afin d’assurer le fonctionnement correct de l’appareil.

26

Page 29

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

LIGHT

SET

LIGHT

ON/Off

Utilisation

Préparation

Installer quatre piles dans le compartiment prévu à cet effet à l’arrière de

l’appareil.

Attention : Veiller à bien respecter la polarité des piles. Ne pas laisser de

piles déchargées dans le compartiment. En cas d’inutilisation

prolongée du by-pass DIGIMON, retirer les piles du

compartiment.

Appuyer sur la touche pour mettre en marche l’appareil.

Contrôler le niveau de charge des piles.

Eclairage de l’écran

Appuyer sur pour mettre en marche ou arrêter l’éclairage de l’écran.

L’éclairage s’arrête automatiquement après 1 minute.

Arrêt automatique

Le by-pass DIGIMON s’arrête automatiquement env. 15 minutes après la dernière

mesure ou le dernier appui sur une touche.

Remise à zéro des capteurs de pression

Les touches et permettent de remettre à zéro les indicateurs de

pression du DIGIMON afin d’éviter les erreurs d’indication de mesure.

Remarques :

Dépressuriser le DIGIMON (débrancher les tuyaux).

Ouvrir les vannes bleue et rouge.

Pour un affichage correct des valeurs de mesure, la remise à zéro ne

doit pas être effectuée lorsque l’appareil est sous pression ou sous vide.

27

Page 30

Français Mode d'emploi DIGIMON-SE / DIGIMON4

SET

SET

R -

SET

Affichage numérique

Affichage analogique avec fonction

d’enregistrement

Sélection du réfrigérant

Les touches ou permettent de sélectionner le réfrigérant souhaité

dans la liste. Pendant la sélection, le symbole « R » clignote sur l’écran.

La touche permet d’enregistrer la sélection. Le symbole « R » arrête de

clignoter.

Remarque:

Si le choix du réfrigérant n’est pas confirmé en appuyant sur , le réfrigérant

choisi précédemment reste actif.

28

Page 31

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

LIGHT

SET

LP/HP

LP/HP

LP/HP

SET

R -

SET

R +

SET

Sélection de l’unité de mesure de la pression

Maintenir la touche appuyée. Sélectionner l’unité souhaitée avec la touche

. Relâcher les deux touches.

Sélection de l’unité de mesure de la température

Maintenir la touche appuyée. Choisir l’unité °C ou °F en appuyant sur

. Relâcher les deux touches.

Remarque :

Les dernières unités de mesure de pression et de température restent en mémoire.

Fonction d’enregistrement de l’affichage analogique de la pression:

Enregistrer une valeur (valeur de mesure actuelle): appuyer en même temps sur les

touches et .

Consulter une valeur enregistrée: maintenir la touche enfoncée pendant 3

secondes (affichage figé).

Déverrouillage de l’affichage: maintenir la touche enfoncée pendant 3

secondes la valeur enregistrée disparaît.

Supprimer la valeur enregistrée: appuyer en même temps sur les touches et

.

Mode surchauffe/sous-refroidissement

29

Page 32

Français Mode d'emploi DIGIMON-SE / DIGIMON4

VAC

SUPERH

SUBC00L

indique la différence „K“ (F) entre la température théorique du tableau de

pression de vapeur (to, tc) et la température mesurée (t1, t2) au niveau des sondes

de température externes (9) ou à pince (10).

Affichage du vide

Appuyer sur la touche pour accéder à l’affichage du vide.

Valeurs d’affichage du vide

Lors du tirage au vide, 10 barres s’affichent au maximum. Lorsque l’affichage reste

stable, le niveau de vide final est atteint et le temps de tirage débute. L’affichage du

niveau de vide final (10 barres) dépend de la capacité de la pompe à vide et de la

pression atmosphérique.

30

Page 33

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

LIGHT

SET

VAC

VAC

VAC

SET

R +

SET

Remarque :

Le by-pass DIGIMON doit être mis en marche avant de faire fonctionner la pompe à

vide. Il doit être allumé pendant l’opération de tirage au vide.

Capteur pour vide externe (en option)

Pour obtenir des valeurs de mesure du vide précises, il est nécessaire d’utiliser le

capteur pour vide externe. Ce dernier doit être raccordé à l’installation.

Affichage du vide

Sélectionner l’unité de mesure

Maintenir la touche appuyée. Sélectionner l’unité souhaitée avec la touche

. Relâcher les deux touches.

Enregistrer une valeur

(valeur de mesure actuelle): appuyer en même temps sur les touches

et .

Consulter une valeur enregistrée: maintenir la touche enfoncée pendant 3

secondes (affichage figé).

Déverrouillage de l’affichage: maintenir la touche enfoncée pendant 3

secondes la valeur enregistrée disparaît.

Supprimer la valeur enregistrée: appuyer en même temps sur les touches et

.

31

Page 34

Français Mode d'emploi DIGIMON-SE / DIGIMON4

LP/HP

VAC

Raccordement du by-pass

a) avec DIGIMON-SE

Raccorder le tuyau bleu (1) côté basse pression de l’installation

Raccorder le tuyau rouge (2) côté haute pression de l’installation

Raccorder le tuyau jaune (3) à la pompe à vide

Fermer les deux vannes (5+6)

b) avec DIGIMON4

Raccorder le tuyau bleu (1) côté basse pression de

l’installation

Raccorder le tuyau rouge (2) côté haute pression de

l’installation

Raccorder le tuyau jaune 3/8“ (3) à la pompe à vide

Raccorder le tuyau jaune 1/4“ (4) au cylindre de réfrigérant

Fermer les deux vannes (5+6)

Tirage au vide de l’installation

Mettre en marche le by-pass

Appuyer sur la touche

Raccorder les tuyaux

Mettre en marche la pompe à vide

Ouvrir toutes les vannes

Contrôler l’affichage du vide

Lorsque le niveau de vide final est atteint, fermer toutes les vannes.

Appuyer sur la touche pour quitter le mode de tirage au vide.

Le temps de tirage au vide varie en fonction de la taille de l’installation.

Un temps de tirage au vide d’au moins 20 minutes est nécessaire pour les

installations de moyenne ou petite taille.

32

Page 35

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

Remplissage de l’installation

a) avec le by-pass DIGIMON-SE

Débrancher le tuyau jaune de la pompe à vide et le raccorder à la bouteille ou

au cylindre de réfrigérant.

Ouvrir la vanne de la bouteille ou du cylindre du réfrigérant.

Ouvrir la vanne bleue (5) (côté basse pression) et laisser affluer la quantité de

réfrigérant souhaitée. Si la quantité de réfrigérant nécessaire ne s’écoule pas

dans l’installation, le compresseur doit alors être mis en marche.

Après avoir obtenu la quantité nécessaire, fermer la vanne de la bouteille ou

du cylindre de réfrigérant.

Fermer la vanne bleue (5).

Contrôler la pression et la température de l’installation !

Débrancher les tuyaux de l’installation.

Ouvrir les vannes (5+6).

b) avec le by-pass DIGIMON4

Débrancher le tuyau jaune (3/8“) de la pompe à vide et du DIGIMON4 (3)

et visser les capuchons de protection sur les raccords filetés SAE 3/8“.

Ouvrir la vanne noire (8).

Ouvrir la vanne de la bouteille ou du cylindre de réfrigérant, ouvrir la vanne

bleue (5) et laisser affluer la quantité de réfrigérant souhaitée. Si la quantité

de réfrigérant nécessaire ne s’écoule pas dans l’installation, le compresseur

doit alors être mis en marche.

Après avoir obtenu la quantité nécessaire, fermer la vanne noire (8).

Fermer la vanne de la bouteille ou du cylindre de réfrigérant.

Ouvrir la vanne rouge (6). Contrôler la pression et la température de

l’installation côtés haute et basse pression ! Lorsque les pressions sont

correctes, fermer toutes les vannes.

Débrancher les tuyaux de l’installation.

Ouvrir toutes les vannes.

33

Page 36

Français Mode d'emploi DIGIMON-SE / DIGIMON4

Mesure en modes surchauffe (superheat) et sousrefroidissement (subcool)

Voir « Raccordement du by-pass DIGIMON ».

Raccorder le connecteur de type K des sondes de température externes (9) ou

à pince (10) au DIGIMON (raccords des côtés gauche (t1) et droit (t2) du

boîtier).

Fixer la sonde de température externe (9) à l’aide d’adhésif ou la sonde à

pince (10) à l’endroit désiré du côté haute ou basse pression de l’installation.

Paramétrer le réfrigérant souhaité (voir « Sélection du réfrigérant »).

Mettre en marche l’affichage de la différence de température : appuyer sur

SUPERHEAT/ SUBCOOL.

Entretien du by-pass

Avant toute utilisation, les raccords et tuyaux de remplissage doivent être

soumis à un contrôle visuel afin de s’assurer de l’absence de tout dommage

mécanique.

Aucun détergent ou solvant puissant ne doit être utilisé pour nettoyer

l’appareil. Il est nécessaire d’utiliser des produits ménagers et des savons

doux.

Les joints du by-pass subissent naturellement une usure mécanique et due au

vieillissement. L’utilisateur doit donc vérifier régulièrement l’étanchéité du by-

pass.

En présence de fuites au niveau des vannes, il est nécessaire de remplacer le

piston (M4-6-04-R/10).

Pour changer le voyant du by-pass, il est nécessaire d’utiliser l’outil spécial

M4-6-11-T de REFCO.

Après avoir remplacé les joints, l’étanchéité du by-pass doit être

contrôlée.

Garantie

Votre nouveau by-pass DIGIMON a été développé dans le respect des dernières

avancées ergonomiques, technologiques et en matière de physiologie du travail.

L’entreprise REFCO Manufacturing a obtenu la certification DIN EN ISO 9001 : 2008.

Des contrôles de qualité permanents et un traitement minutieux garantissent de

solides capacités de fonctionnement et permettent l’application de la garantie REFCO

valable selon les conditions de vente et de livraison applicables au jour de la livraison.

Sont cependant exclus les dommages dus à l’usure ou à une négligence manifeste.

34

Page 37

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

Description

Désignation

Réf.

Bouton de réglage rouge

M4-7-SET-R

4677842

Bouton de réglage bleu

M4-7-SET-B

4677850

Bouton de réglage noir

M4-7-SET-N

4677868

Bouton de réglage jaune

M4-7-SET-Y

4687876

Kit garniture de vanne

M2-10-95-R/10

4662607

Piston de vanne

M4-6-04-R/10

4662624

Kit voyant complet

M4-6-11

4491018

Couvercle du compartiment des

piles 2 voies

DIGIMON-SE-BATTERY-COVER

4686772

Couvercle du compartiment des

piles 4 voies

DIGIMON4-BATTERY-COVER

4686749

Outil pour le montage du voyant

M4-6-11-T

4493169

Valise en plastique

DIGIMON-SE-CASE

4676730

Sonde de température externe de

type K

DIGIMON-SENSOR-K-TYPE

4681394

Sonde de température à pince de

type K

DIGIMON CLAMP

4681466

Capteur pour vide externe

DIGIMON-VAC

4686713

LIGHT

SET

Environnement

Le by-pass DIGIMON a été développé pour une utilisation à long terme. Lors de

l’approvisionnement en matériaux et de la production, les économies d’énergie et

le respect de l’environnement ont été pris en compte. REFCO Manufacturing Ltd se

considère responsable pendant toute la durée de vie de ses produits. C’est pour

cette raison que REFCO Manufacturing a souhaité obtenir la certification DIN EN

ISO 14001 : 2004. Lors de la mise au rebut de l’appareil, l’utilisateur doit

respecter les directives de recyclage applicables à son pays.

Pièces de rechange et accessoires

Remise à zéro des capteurs de pression

Les touches et permettent de remettre à zéro les indicateurs de

pression du DIGIMON afin d’éviter les erreurs d’indication de mesure.

Pour un affichage correct des valeurs de mesure, la remise à zéro ne

doit pas être effectuée lorsque l’appareil est sous pression ou sous vide.

35

Page 38

Français Mode d'emploi DIGIMON-SE / DIGIMON4

ON/Off

SET

ON/Off

VAC

SET

VAC

LIGHT

Configuration usine

Choisir « Affichage numérique » sur le DIGIMON.

Appuyer en même temps sur les touches et pendant 5

secondes.

L’écran indique - - - - - - - -

Appuyer sur la touche pour terminer.

Remise à zéro du capteur pour vide externe

Arrêter le DIGIMON

Raccorder le capteur à vide

Maintenir la touche enfoncée et mettre l’appareil en marche en

appuyant sur .

L’écran indique VAC-ZERO

Appuyer sur la touche pour terminer l’écran indique End.

L’appareil peut être mis en marche en appuyant sur et est de

nouveau opérationnel.

36

Page 39

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

ON/Off

R -

SET

SET

SET

R +

SET

R -

SET

R -

R +

ON/Off

LIGHT

Calibrage des capteurs de pression

Un calibrage correct nécessite un appareil de contrôle certifié.

(par ex. REF-CLASS-GAUGE Réf. 4682293)

1. Arrêter le DIGIMON

2. Maintenir la touche enfoncée et mettre l’appareil en marche en

appuyant sur .

L’écran indique « Password » 000

3. Appuyer sur / pour sélectionner le code 009.

4. Appuyer sur la touche pour valider.

L’écran indique « P-call »

5. Appuyer sur la touche puis pour procéder au calibrage.

L’écran doit indiquer 400 psi du côté basse pression

Afin d’assurer un calibrage correct, le DIGIMON ne doit être ni sous

pression, ni sous vide.

6. Appuyer sur la touche pour sélectionner la pression de calibrage

(400psi) du côté basse pression (LP).

7. Appuyer sur la touche pour valider.

8. Attendre 3-5 secondes jusqu’à ce que la pression soit stable et appuyer à

nouveau sur la touche .

L’écran indique « 0000 »

9. Mettre le DIGIMON sous pression avec une pression de calibrage de 400 psi

(27.58 bar). Lorsque la pression est stable, confirmer en appuyant sur

.

L’écran indique « LP End »

10. Le calibrage du côté basse pression est terminé.

11. Appuyer sur la touche pour procéder au calibrage du côté haute

pression (HP) répéter la procédure à partir du point 6 ou appuyer sur

pour terminer le calibrage.

37

Page 40

Français Mode d'emploi DIGIMON-SE / DIGIMON4

SET

R -

SET

R -

R +

ON/Off

LIGHT

Code de température

Température actuelle

LP

00xxx

27.0°C

Calibrage de l’affichage de la température

1. Arrêter le DIGIMON

2. Raccorder les capteurs de température (type K).

Les températures ambiante et de mesure doivent en permanence s’élever à

25 +/-3°C et être stables pendant au moins 20 minutes. Les câbles des

capteurs doivent être droits (déroulés).

Aucun câble ou connecteur ne doit être touché pendant le calibrage.

3. Maintenir la touche enfoncée et mettre l’appareil en marche en

appuyant sur .

L’écran indique « Password » 000

4. Appuyer sur / pour sélectionner le code 018.

5. Appuyer sur la touche pour valider.

L’écran indique « T-call »

6. Appuyer sur la touche puis pour procéder au calibrage.

7. Pendant le calibrage, s’assurer que les deux capteurs de température sont

bien reliés au DIGIMON.

L’écran indique (côté basse pression)

La température actuelle affichée sur le DIGIMON ne doit pas diverger de

+/-0.5°C de la température ambiante.

38

Page 41

Mode d'emploi DIGIMON-SE / DIGIMON4 Français

ON/Off

R -

SET

LP

End

00xxx

27.0°C

8. Appuyer sur la touche pour confirmer.

L’écran indique

9. Appuyer sur la touche pour procéder au calibrage du côté haute

pression (HP) répéter la procédure à partir du point 6 ou appuyer sur

pour terminer le calibrage.

39

Page 42

Español Manual de instrucciones DIGIMON-SE / DIGIMON4

Instrucciones de uso y mantenimiento

Analizador digital de 2 y 4 vías

DIGIMON-SE

DIGIMON4

1. Conexión de baja presión ¼“ SAE

2. Conexión de alta presión ¼“ SAE

3. Conexión para vacío ¼“ SAE, resp. 3/8“

4. Conexión para refrigerantes ¼“ SAE

5. Válvula de baja presión (azul)

6. Válvula de alta presión (roja)

7. Válvula de vacío (amarilla)

8. Válvula para refrigerantes (negra)

9. 2 sensores de temperatura externos de tipo K

10. Sensor de temperatura de pinza de tipo K (opcional), art. n.º 4681466

11. Sensor externo de vacío DIGIMON-VAC (opcional), art. n.º 4686713

40

Page 43

Manual de instrucciones DIGIMON-SE / DIGIMON4 Español

Índice

Advertencias de seguridad ....................................................................... 42

Especificaciones de uso ............................................................................ 42

Contenido del suministro ......................................................................... 43

Transporte .............................................................................................. 43

Información importante ........................................................................... 43

Descripción técnica ................................................................................. 43

Funciones de los botones ........................................................................ 45

Indicación del nivel de carga de las pilas ................................................. 45

Funcionamiento ....................................................................................... 46

Conexión del analizador digital ............................................................... 51

Vaciado del equipo................................................................................... 51

Llenado del equipo ................................................................................... 52

Mediciones en el modo “Superheat (sobrecalentamiento)/Subcool

(subenfriamiento)” .................................................................................. 53

Mantenimiento del analizador digital ....................................................... 53

Garantía .................................................................................................. 54

Información medioambiental ................................................................... 54

Accesorios y recambios ............................................................................ 54

Puesta a cero de los sensores de presión ................................................ 55

Ajustes de fábrica ................................................................................... 55

Puesta a cero del sensor externo de vacío ............................................... 55

Calibración de los sensores de presión .................................................... 56

Calibración de la indicación de temperatura ............................................ 57

41

Page 44

Español Manual de instrucciones DIGIMON-SE / DIGIMON4

Advertencias de seguridad

Antes de utilizar el analizador digital, lea atentamente estas

instrucciones de uso, ya que contienen información importante para el uso

correcto, el mantenimiento y la eliminación del aparato.

Especificaciones de uso

El analizador digital DIGIMON ha sido diseñado para medir y regular las condiciones

de presión y temperatura en equipos fijos y móviles de refrigeración y aire

acondicionado.

El analizador digital no debe utilizarse para otros usos distintos a los propios

del ámbito de los sistemas de aire acondicionado y refrigeración.

El analizador digital no debe utilizarse a presiones superiores a 60 bar / 870 psi

/ 6000 kPa / 6 MPa.

El analizador digital no debe utilizarse en ningún caso como válvula de

reducción de presión, sobre todo, si se emplea nitrógeno N2.

El analizador digital no debe utilizarse en combinación con el refrigerante

amoniaco (NH3 / R717).

El analizador digital no debe exponerse a la lluvia, ni utilizarse en ambientes

húmedos o mojados.

Cuando trabaje con el analizador digital DIGIMON, lleve siempre gafas y guantes

de protección.

Los productos REFCO han sido diseñados y fabricados específicamente para ser

utilizados por técnicos frigoristas cualificados. Debido a las altas presiones y a los

gases físicos y químicos que se utilizan en los sistemas de frío, REFCO descarta

cualquier responsabilidad o indemnización en caso de accidente, lesiones o

fallecimiento. REFCO advierte expresamente de que este tipo de productos solo debe

venderse exclusivamente a profesionales debidamente cualificados.

42

Page 45

Manual de instrucciones DIGIMON-SE / DIGIMON4 Español

Contenido del suministro

El contenido incluido en el suministro de los distintos modelos y variantes se puede

consultar en el catálogo de REFCO o en la página web www.refcoswiss.com

Transporte

Los analizadores digitales se suministran de fábrica en un maletín de plástico con o

sin mangueras de llenado y son instrumentos de medición de alta calidad que deben

transportarse y guardarse siempre en el maletín.

Información importante

Después de cada uso, vacíe siempre el refrigerante que quede en el analizador y en

las mangueras.

Si no utiliza las conexiones para mangueras (roscas) que sobresalen en el lateral del

analizador, conéctelas a las conexiones en Y o a la pieza en T situada en el centro del

aparato para protegerlas así de la suciedad o de posibles daños.

Descripción técnica

El analizador digital DIGIMON puede utilizarse con los siguientes refrigerantes:

R11, R113, R114, R12, R123, R124, R13, R134a, R13B1, R22, R227, R23, R290, R32

R401A(Liq), R401A(Vap), R401B(Liq), R401B(Vap), R402A(Liq), R402A(Vap),

R402B(Liq), R402B(Vap), R403B(Liq), R403B(Vap), R404A, R406A (Liq), R406A(Vap),

R407A(Liq), R407A(Vap), R407C(Liq), R407C(Vap), R407F(Liq), R407F(Vap),

R408A(Liq), R408A(Vap), R409A(Liq), R409A(Vap), R410A, R413A(Liq), R413A(Vap),

R414B(Liq), R414B(Vap), R416A, R417A(Liq), R417A(Vap), R420A, R422A(Liq),

R422A(Vap), R422B(Liq), R422B(Vap), R422C(Liq), R422C(Vap), R422D(Liq),

R422D(Vap), R427A(Liq), R427A(Vap), R437A, R438A(Liq), R438A(Vap), R500,

R502, R503, R507, R508A, R508B, R600A, R744, R1234yf

(Líq) = líquido / punto de burbujeo (Vap) = vapor / punto de rocío

43

Page 46

Español Manual de instrucciones DIGIMON-SE / DIGIMON4

Características

Valores

Presión máx. de

servicio:

baja presión 60 bar / 870 psi / 6000 kPa / 6 MPa

alta presión 60 bar / 870 psi / 6000 kPa / 6 MPa

Resolución de la

indicación de presión:

0.01 bar / 0.5 psi / 1 kPa / 0.001 MPa

Unidades de medición

de la presión:

bar / psi / kPa / MPa

Indicación de la

presión positiva:

entre 0 y 60 bar, 870 psi, 6000 kPa, 6 MPa

Indicación de la

presión negativa:

entre 0 y -0.95 bar, -13,7 psi, -95 kPa, -0.095 MPa

Clase de precisión:

Clase 1.0

Sensor de temperatura

externo:

Rango de

temperatura:

entre -40 °C y +125 °C / entre -40 °F y

+257 °F

Conexión:

tipo K

Precisión:

+/- 1 °K (+/- 1.8°F)

Resolución:

0,5 °C / 0,5 °F

Sensor de

temperatura de pinza

opcional de tipo K

Rango de

temperatura:

entre -40 °C y +125 °C / entre -40 °F y

+257 °F

Para tubos de

diámetro:

entre 6 mm y 38 mm / entre ¼“ y 1 ½“

Conexión:

tipo K

Precisión:

+/- 1 °K (+/- 1.8°F)

Resolución:

0,5 °C / 0,5 °F

Temperatura

ambiental:

entre 0 °C y +50 °C / entre +32 °F y +122 °F

Alimentación:

baterías / pilas: 4 pilas AA / Mignon / LR6 de 1,5 V

duración de uso continuado: aprox. 50 horas

Temperatura de

almacenamiento:

entre -20 °C y + 60 °C / entre -4 °F y 140 °F

Características

Valores

Indicación del

vacío:

Diagrama de

barras

1 barra: aprox. entre 0 y -300 mbar

2 barras: aprox. entre. -300 y -380 mbar

3 barras: aprox. entre -380 y -460 mbar

4 barras: aprox. entre -460 y -540 mbar

5 barras: aprox. entre -540 y -620 mbar

6 barras: aprox. entre -620 y -700 mbar

7 barras: aprox. entre -700 y -780 mbar

8 barras: aprox. entre. -780 y -860 mbar

9 barras: aprox. entre -860 y -920 mbar

10 barras: aprox. entre -920 y vacío final

Indicación del vacío sin sensor de vacío

44

Page 47

Manual de instrucciones DIGIMON-SE / DIGIMON4 Español

Características

Valores

Rango de medición:

entre 0 y 10.000 micrones

Resolución:

0.1 Pa / 1 micrón / 0.001 mbar / 0.001 Torr / 1m Torr /

0.0001 psi / 0.0001 inHg

Unidades de medición:

Pa / micrón / mbar / Torr / mTorr / psi / inHg

Precisión de medición:

hasta 100 micrones +/- 10 micrones

entre 101 y 750 micrones +/- 45 micrones

LIGHT

VAC

SET

LP/HP

SUPERH

R +

R -

ON/Off

ON/Off

LP/HP

VAC

SET

R +

SUPERH

LIGHT

R -

Indicación del vacío con sensor externo de vacío

Funciones de los botones

Encender/apagar la alimentación

Conmutar entre las opciones de indicación de presión

Conmutar entre las opciones de indicación de vacío

Encender/apagar la iluminación de la pantalla LCD (apagado

automático tras 1 minuto)

Seleccionar refrigerante, buscar hacia adelante (seleccionar unidad de

presión)

Seleccionar refrigerante, buscar hacia atrás (seleccionar unidad de

temperatura)

Activar o desactivar modo “Superheat (sobrecalentamiento)/Subcool

(subenfriamiento)”

Confirmar acción o función seleccionada

Indicación del nivel de carga de las pilas

Si el símbolo del nivel de carga de las pilas se queda sin superficie negra, significa

que las pilas apenas tienen carga y deben cambiarse para poder garantizar la plena

funcionalidad del aparato.

45

Page 48

Español Manual de instrucciones DIGIMON-SE / DIGIMON4

LIGHT

SET

LIGHT

ON/Off

Funcionamiento

Preparativos

Inserte 4 pilas en el compartimento situado en la parte trasera.

Atención: Cerciórese de que la polaridad de las pilas es la correcta. No

deje nunca pilas gastadas en el compartimento y, si no va a

utilizar el analizador digital durante un largo periodo de

tiempo, saque las pilas del compartimento,

independientemente de su nivel de carga.

Pulse este botón para encender el analizador digital.

Controle el nivel de carga de las pilas.

Iluminación de la pantalla

Pulsando el botón se enciende o se apaga la iluminación de la pantalla. La

iluminación se apaga automáticamente después de 1 minuto.

Apagado automático

El analizador digital se apaga automáticamente aprox. 15 minutos después de la

última medición o de la última vez que se ha pulsado un botón.

Puesta a cero de los sensores de presión

Pulsando los botones y , se pone a cero la indicación de presión de

DIGIMON para evitar que se obtengan valores incorrectos.

Importante:

Deje sin presión al analizador DIGIMON (quite las mangueras).

Abra las válvulas azul y roja.

Para que la indicación de la medición sea correcta, la puesta a cero no

se puede efectuar bajo presión o en vacío.

46

Page 49

Manual de instrucciones DIGIMON-SE / DIGIMON4 Español

SET

SET

R -

R +

Indicación digital

Indicación analógica con función de memoria

Seleccionar el refrigerante

Con los botones de búsqueda y se puede seleccionar el refrigerante

deseado de la lista disponible. Durante la búsqueda, la letra “R” parpadea en la

pantalla.

Pulsando el botón se confirma el refrigerante seleccionado y la letra “R” deja

de parpadear.

Importante:

Si el refrigerante seleccionado no se confirma con el botón , sigue activado el

último refrigerante confirmado.

47

Page 50

Español Manual de instrucciones DIGIMON-SE / DIGIMON4

LIGHT

SET

LP/HP

LP/HP

LP/HP

SET

R -

SET

R +

SET

Seleccionar la unidad de presión

Mantenga pulsado el botón y seleccione la unidad de presión deseada con el

botón . A continuación, deje de pulsar los dos botones.

Seleccionar la unidad de temperatura

Mantenga pulsado el botón y con el botón seleccione entre grados

°C o °F. A continuación, deje de pulsar los dos botones.

Importante:

Las últimas unidades de presión y temperatura seleccionadas quedan guardadas en

la memoria.

Función de memoria en la indicación analógica de la presión:

Guardar valor (valor actual): pulse a la vez los botones y .

Mostrar valor guardado: mantenga pulsado el botón durante 3 segundos (el

valor se queda “congelado” en la pantalla).

Ocultar valor guardado: mantenga pulsado el botón durante 3 segundos

el valor deja de verse en la pantalla.

Borrar valor guardado: pulse a la vez los botones y .

Modo “Superheat (sobrecalentamiento)/Subcool (subenfriamiento)”

Superheat/Subcool

48

Page 51

Manual de instrucciones DIGIMON-SE / DIGIMON4 Español

VAC

SUPERH

SUBC00L

El botón muestra la diferencia de temperatura “K” (F) que existe entre la

tabla de presión del vapor (to, tc) y la temperatura medida (t1, t2) por los sensores

externos de temperatura (9) o los sensores de temperatura de pinza (10).

Indicación del vacío

Pulse el botón para activar la indicación del vacío.

Indicación del vacío

Durante el proceso de vaciado se muestran como máximo 10 barras. Si la indicación

de los valores de vacío se mantiene estable, se ha llegado al vacío final y comienza el

tiempo de vaciado. La indicación del vacío final (10 barras) depende de la potencia de

la bomba de vacío y de la presión atmosférica.

Importante:

El analizador DIGIMON debe estar encendido antes de poner en marcha la bomba de

vacío conectada y permanecer encendido durante todo el proceso de vaciado.

49

Page 52

Español Manual de instrucciones DIGIMON-SE / DIGIMON4

LIGHT

SET

VAC

VAC

VAC

SET

R +

SET

Sensor externo de vacío (opcional)

Para obtener resultados más precisos en la medición del vacío, se recomienda

trabajar con el sensor externo de vacío. Este sensor debe conectarse al equipo.

Indicación del vacío

Seleccionar la unidad de medición

Mantenga el botón pulsado y con el botón seleccione la unidad de

medición deseada. A continuación, deje de pulsar los dos botones.

Guardar valor (valor actual): Pulse a la vez los botones y .

Mostrar valor guardado: Mantenga pulsado el botón durante 3 segundos (el

valor se queda “congelado” en la pantalla).

Ocultar valor guardado: Mantenga pulsado el botón durante 3 segundos

el valor deja de verse en la pantalla.

Borrar valor guardado: Pulse a la vez los botones y .

50

Page 53

Manual de instrucciones DIGIMON-SE / DIGIMON4 Español

LP/HP

VAC

Conexión del analizador digital

a) Con DIGIMON-SE

Conecte la manguera azul (1) al lado de la presión de

succión del equipo

Conecte la manguera roja (2) al lado de la alta presión

del equipo

Conecte la manguera amarilla (3) a la bomba de vacío

Cierre las dos válvulas (5+6)

b) Con DIGIMON4

Conecte la manguera azul (1) al lado de la presión de succión

del equipo

Conecte la manguera roja (2) al lado de la alta presión del

equipo

Conecte la manguera amarilla 3/8“ (3) a la bomba de vacío

Conecte la manguera amarilla 1/4“ (4) al cilindro de refrigerante

Cierre las dos válvulas (5+6)

Vaciado del equipo

Encienda el analizador digital.

Pulse el botón .

Conecte las mangueras.

Encienda la bomba de vacío.

Abra todas las válvulas.

Controle la indicación de vacío.

En cuanto se llegue al vacío final, cierre todas las válvulas.

Pulse el botón para salir del modo de vacío.

El tiempo de vaciado depende del tamaño del equipo. Para un equipo de

tamaño pequeño o mediano se necesita un tiempo mínimo de vaciado de al

menos 20 minutos.

51

Page 54

Español Manual de instrucciones DIGIMON-SE / DIGIMON4

Llenado del equipo

a) Con DIGIMON-SE

Desconecte la manguera amarilla de la bomba de vacío y conéctela a la

botella o al cilindro de refrigerante.

Abra la válvula de la botella o del cilindro de refrigerante.

Abra la válvula azul (5) (lado de baja presión) y deje que entre la cantidad

deseada de refrigerante. Si en el equipo no entra la cantidad necesaria de

refrigerante, debe conectarse también el compresor.

Una vez alcanzada la cantidad de llenado deseada, cierre la válvula de la

botella o del cilindro de refrigerante.

Cierre la válvula azul (5).

Controle la presión y la temperatura del equipo.

Desenrosque las mangueras del equipo.

Abra las válvulas (5+6).

c) Con DIGIMON4

Desconecte la manguera amarilla (3/8“) de la bomba de vacío y del analizador

DIGIMON4 (3)

y enrosque las tapas protectoras en la rosca 3/8“ SAE.

Abra la válvula negra (8).

Abra la válvula de la botella o del cilindro de refrigerante y la válvula azul (5),

y deje que entre la cantidad deseada de refrigerante en el equipo. Si en el

equipo no entra la cantidad necesaria de refrigerante, debe conectarse

también el compresor.

Una vez alcanzada la cantidad de llenado deseada, cierre la válvula negra (8).

Cierre la válvula de la botella o del cilindro de refrigerante.

Abra la válvula roja (6) y controle la presión y la temperatura del equipo en

los lados de alta y baja presión. Si los valores de presión son adecuados,

cierre todas las válvulas.

Desenrosque las mangueras del equipo.

Abra todas las válvulas.

52

Page 55

Manual de instrucciones DIGIMON-SE / DIGIMON4 Español

Mediciones en el modo “Superheat

(sobrecalentamiento)/Subcool (subenfriamiento)”

Vea el epígrafe “Conexión del analizador digital”.

Conecte el enchufe de tipo K del sensor de temperatura externo (9) o del

sensor de temperatura de pinza (10) al analizador DIGIMON (en las tomas

situadas a los lados derecho (t1) e izquierdo (t2) de la carcasa).

Fije el sensor de temperatura externo (9) con cinta adhesiva o el sensor de

temperatura de pinza (10) a la posición de medición deseada en el lado de

alta presión o de succión del equipo.

Seleccione el refrigerante adecuado (vea el epígrafe “Seleccionar el

refrigerante”).

Active la indicación de la diferencia de temperatura pulsando el botón

SUPERHEAT/SUBCOOL.

Mantenimiento del analizador digital

Antes de cada uso, compruebe visualmente que las conexiones y las

mangueras no presentan ningún daño mecánico.

No limpie nunca el aparato con productos de limpieza o disolventes abrasivos,

sino solo con productos de limpieza del hogar suaves.

Las juntas de un analizador están expuestas por naturaleza a un desgaste

mecánico provocado por el paso del tiempo. Por eso, es imprescindible

comprobar periódicamente la hermeticidad de las juntas.

En las válvulas que hayan perdido hermeticidad, debe cambiarse el pistón

(M4-6-04-R/10).

Para cambiar el visor del analizador, debe utilizarse la herramienta especial

de REFCO M4-6-11-T.

Después de cambiar las juntas, compruebe siempre que el analizador es

hermético.

53

Page 56

Español Manual de instrucciones DIGIMON-SE / DIGIMON4

Descripción

Nombre

Art. n.º

Botón giratorio rojo

M4-7-SET-R

4677842

Botón giratorio azul

M4-7-SET-B

4677850

Botón giratorio negro

M4-7-SET-N

4677868

Botón giratorio amarillo

M4-7-SET-Y

4687876

Juego de válvulas

M2-10-95-R/10

4662607

Válvula de pistón

M4-6-04-R/10

4662624

Juego de visor MS

M4-6-11

4491018

Tapa del compartimento de pilas, 2 vías

DIGIMON-SE-BATTERY-COVER

4686772

Tapa del compartimento de pilas, 4 vías

DIGIMON4-BATTERY-COVER

4686749

Herramienta para instalar el visor

M4-6-11-T

4493169

Maletín de plástico

DIGIMON-SE-CASE

4676730

Sensor de temperatura externo de tipo K

DIGIMON-SENSOR-K-TYPE

4681394

Sensor de temperatura de pinza de tipo K

DIGIMON CLAMP

4681466

Sensor externo de vacío

DIGIMON-VAC

4686713

Garantía

Su nuevo DIGIMON ha sido diseñado de acuerdo a los últimos avances en ergonomía

y fisiología del trabajo y cumple con los estándares tecnológicos actuales. La empresa

REFCO Manufacturing Ltd. ha sido certificada según la norma DIN EN ISO 9001 : 2008.

El cuidadoso proceso de fabricación y los continuos controles de calidad a los que se

ha sometido el aparato garantizan su correcto funcionamiento. La garantía REFCO se

rige por las condiciones generales de venta y envío vigentes en el día de la entrega

del producto. De la garantía queda excluido cualquier daño provocado por un uso

indebido o por el desgaste natural del equipo.

Información medioambiental

El analizador digital DIGIMON ha sido diseñado para que pueda ser utilizado

durante mucho tiempo y, tanto en su fabricación como en la selección de sus

materiales, se ha prestado especial atención para que consuma poca energía y

sea lo más sostenible posible con el medio ambiente. REFCO Manufacturing Ltd. se

considera responsable de sus productos “durante toda la vida”. Por eso, REFCO

Manufacturing ha sido certificado según la norma DIN EN ISO 14001 : 2004. A la

hora de desechar el aparato, el usuario deberá seguir la normativa vigente en su

país.

Accesorios y recambios

54

Page 57

Manual de instrucciones DIGIMON-SE / DIGIMON4 Español

ON/Off

SET

ON/Off

VAC

SET

VAC

LIGHT

LIGHT

SET

Puesta a cero de los sensores de presión

Pulsando los botones y se pone a cero la indicación de presión de

DIGIMON para evitar que se obtengan valores de medición incorrectos.

Para que la indicación de los valores sea correcta, la puesta a cero no

debe ser efectuada bajo presión o en vacío.

Ajustes de fábrica

Coloque el analizador DIGIMON en el modo “Indicación digital”.

Mantenga pulsados a la vez los botones y durante 5

segundos.

En la pantalla aparece - - - - - - - - .

Pulse el botón para confirmar la acción.

Puesta a cero del sensor externo de vacío

Apague el analizador digital DIGIMON.

Conecte el sensor de vacío.

Mantenga el botón pulsado y encienda el aparato pulsando el botón

.

En la pantalla aparece VAC-ZERO.

Pulse el botón para confirmar la acción en la pantalla aparece

End.

Pulse el botón para encender el aparato y volver a ponerlo en estado

operativo.

55

Page 58

Español Manual de instrucciones DIGIMON-SE / DIGIMON4

ON/Off

R -

SET

SET

SET

R +

SET

R -

SET

R -

R +

ON/Off

LIGHT

Calibración de los sensores de presión

Para efectuar una calibración correcta se precisa un aparato de control

Certificado (p. ej. REF-CLASS-GAUGE, n.º art. 4682293).

1. Apague el analizador DIGIMON.

2. Mantenga pulsado el botón y encienda el aparato .

En la pantalla aparece “Password” 000.

3. Seleccione el código 009 con los botones de búsqueda / .

4. Pulse el botón para confirmar el código.

En la pantalla aparece “P-call”.

5. Pulse el botón y confirme la calibración pulsando el botón .

En el lado LP de la pantalla debe aparecer 400 psi.

Para que la calibración sea correcta, no debe haber presión ni vacío en

el analizador DIGIMON.

6. Pulse el botón y seleccione la presión de calibración (400 psi) del lado

de baja presión.

7. Pulse el botón para confirmar la acción.

8. Espere entre 3 y 5 segundos a que la presión sea estable y vuelva a pulsar el

botón .

En la pantalla aparece “0000”.

9. Ponga el analizador digital DIGIMON a una presión de 400 psi (27.58 bar) y,

cuando la presión sea estable, confirme la acción con el botón .

En la pantalla aparece “LP End”.

10. Se ha completado la calibración del lado de baja presión.

11. Pulse el botón para calibrar el lado de alta presión (HP) siga el

proceso descrito a partir del punto 6 o pulse el botón para finalizar la

calibración.

56

Page 59

Manual de instrucciones DIGIMON-SE / DIGIMON4 Español

SET

R -

SET

R -

R +

ON/Off

LIGHT

LP

00xxx

27.0°C

Código de temperatura

Temperatura actual

Calibración de la indicación de temperatura

1. Apague el analizador digital DIGIMON.

2. Conecte los sensores de temperatura externos (tipo K).

La temperatura ambiental y de medición deben estar a unos valores

constantes de 77°F +/-7°F y mantenerse estables al menos durante 20

minutos. Los cables de los sensores deben encontrarse en posición recta

(extendidos).

Durante la calibración no se deben tocar cables ni enchufes.

3. Mantenga pulsado el botón y encienda el aparato pulsando el botón

.

En la pantalla aparece “Password” 000.

4. Pulse los botones / y seleccione el código 018.

5. Pulse el botón para confirmar la acción.

En la pantalla aparece “T-call”.

6. Pulse el botón y luego el botón para calibrar la indicación de

la temperatura.

7. Durante la calibración, cerciórese de que los dos sensores de temperatura

están conectados con el analizador digital DIGIMON.

En la pantalla aparece (lado de baja presión)

La temperatura indicada ahora en el analizador no puede variar más de

+/-0.5 °C de la temperatura ambiental.

57

Page 60