Page 1

TAP-CLAMP

TEMPERATURE AND

Installation and operating guide

Temperature And Pressure Gauge

Installations- und Bedienungsanleitung

Temperatur und Druckprüfgerät

Guide d’installation et d‘utilisation

Istruzioni per l’installzione e l’uso

Guía de instalación y funcionamiento

PRESSURE GAUGE

4687787

4687785

TAP

1

Page 2

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

Contents

Introduction ..................................................................................................................... 2

General information ........................................................................................................ 4

Important safety notice................................................................................................... 5

Technical Data ................................................................................................................. 6

Parts description ............................................................................................................. 8

Transport, packaging and storage .............................................................................. 15

Setup, operation ............................................................................................................ 16

Maintenance .................................................................................................................. 22

Guarantee ...................................................................................................................... 27

Replacement parts and accessories ........................................................................... 27

1

Page 3

English Instruction Manual TAP / Temperature And Pressure Gauge

Introduction

Thank you for your purchase of the REFCO TAP, Temperature And Pressure gauge.

The REFCO TAP wireless digital pressure and temperature gauge is an user friendly

instrument to measure temperature and pressure form the low and high sides of air

conditioning and refrigeration systems.

Features:

- Quick and easy connection to pressure source and temperature measuring point.

- The wireless K-type temperature clamp, equipped with digital display, is applicable for

pipe diameters 6 mm to 41 mm (1/4" to 1-5/8").

- Measurements and calculation of superheat or subcooling can be shown on pressure

gauge display and / or on your mobile device.

- Up to 6 TAP devices can be monitored on your mobile device.

- Create report and send by e-mail to your office.

- Uses common AAA batteries.

- TAP is available in a suitable case either as single or double set.

FCC Part 15.19 Warning Statement

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION

IS SUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY

NOT CAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST

ACCEPT ANY INTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT

MAY CAUSE UNDESIRED OPERATION.

2

Page 4

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

FCC Part 15.21 Warning Statement

NOTE: THE GRANTEE IS NOT RESPONSIBLE FOR ANY CHANGES OR

MODIFICATIONS NOT EXPRESSLY APPROVED BY THE PARTY RESPONSIBLE

FOR COMPLIANCE. SUCH MODIFICATIONS COULD VOID THE USER’S

AUTHORITY TO OPERATE THE EQUIPMENT.

FCC Part 15.105 Warning Statement

Note: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

RF warning statement:

The device has been evaluated to meet general RF exposure requirement. The device

can be used in portable exposure condition without restrict ion.

3

Page 5

English Instruction Manual TAP / Temperature And Pressure Gauge

General information

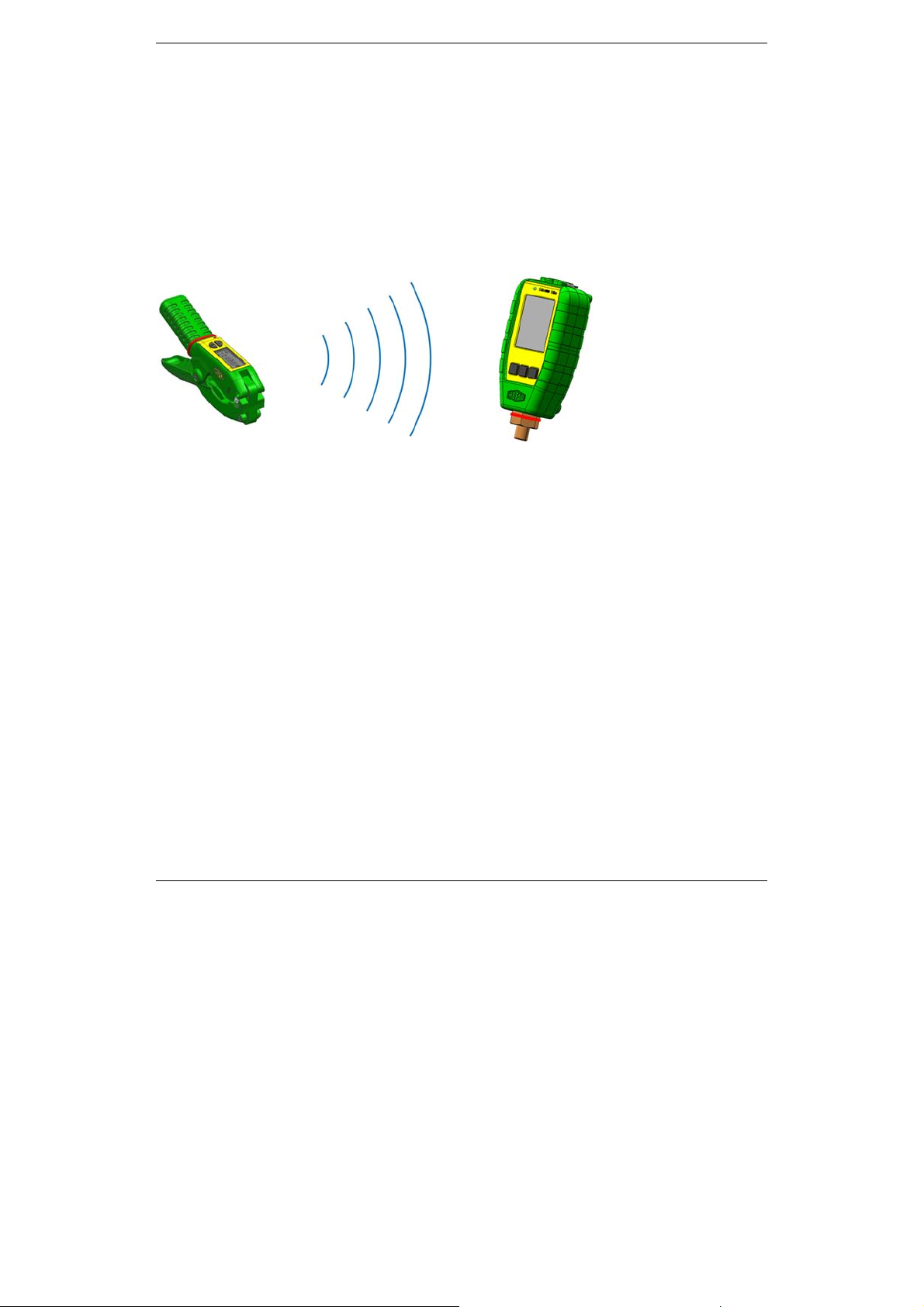

The TAP product consists of:

- A wireless temperature clamp with display to monitor sensible temperature.

- A pressure gauge with display to monitor current pressure and temperatures.

- Up to 6 paired devices can be connected to a smartphone or tablet to observe and

calculate measurements by using the REFCO App.

TAP

Wireless temperature clamp Pressure gauge

The TAP referred to in these operating instructions has been manufactured using stateof-the-art technology. All components are subjected to rigorous quality assurance

criteria during the manufacturing process. Our management systems are certified in

accordance with ISO 9001.

The TAP has been developed for long term use. REFCO takes energy saving and

environmental impact into consideration when procuring materials and manufacturing its

products. REFCO Manufacturing Ltd feels responsible for all of its prod ucts throughout

their entire lifespan and has therefore been certified in accordance with DIN EN ISO

14001 : 2004. When decommissioning the device, users should observe the disposal

regulations applicable in their country.

REFCO products have been specially designed and manufactured for use by trained

refrigeration and air-conditioning service engineers only. Due to the high pressures and

chemical gases used in refrigeration systems, REFCO cannot be held liable or

responsible for any accidents, injuries or deaths arising during use of the TAP. REFCO

explicitly states that their products must only be sold to professionally trained service

engineers.

These operating instructions contain important information about handling the TAP. Safe

operation of the device requires adherence to all safety instructions and operating

guidelines.

4

Page 6

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

- The local accident prevention regulations applicable to the area in which the TA P

is being used should also be adhered to, along with general safety guidelines.

- The operating instructions are part of the product and must be stored in close

proximity to the TAP where they should be readily accessible to qualified

personnel at all times.

- The qualified personnel must have carefully read and understood the operating

instructions prior to operating the device.

- The manufacturer shall not be liable for any damage whatsoever arising through

improper use, failure to comply with these operating instructions, assignment of

inadequately qualified personnel, or unauthorised modification of the TAP.

- The General Terms and Conditions as set out in the sales documentation shall apply.

Symbols and writing standards

Illustration Explanation

Warning: Seriuos physical injury can

occur

Caution: Slight physical injury can occur

Damage to the equipment may occur

TAP Temperature and Pressure measuring

device (Temperature clamp + pressure

gauge)

[OK] Control key of the instrument

"OK" Expressions and readouts

Important safety notice

Before working with the TAP, please read the instruction manual carefully. This

manual provides important information regarding the smooth operation, maintenance

and disposal of the TAP.

The TAP must not be used with pressures higher than 60 bar / 870 psi / 6000 kPa.

Protective goggles and gloves should always be worn when using the TAP.

The TAP must not be used with the refrigerant (NH

/ R-717) ammonia.

3

5

Page 7

English Instruction Manual TAP / Temperature And Pressure Gauge

The TAP must not be used for anything other than the below-stated purposes.

The TAP should not be exposed to moisture or used in damp or wet environments.

Remove refrigerants from the TAP and the hoses after use.

Purpose and use

The TAP has been developed for measuring pressure and temperature in both mobile

and stationary refrigeration equipment.

TAP is only designed for temporary measurement, don`t use it as a stationary long term

measurement unit.

Scope of delivery

Information about the various models and variations of our products can be found in the

REFCO catalogue or at www.refco.ch. The REFCO App is available on App Store and

Play Store.

Technical Data

Temperature clamp

Property Value

Thermocouple: K-type

Temperature range: -40 °C to +125 °C / -40 °F to +257 °F

Accuracy of

measurement:

Resolution: 0.1°C / 0.1°F

Temperature units: °C / °F

Pipe diameters of: 6 mm to 41 mm / ¼" to 1-5/8"

Ambient temperature: 0 °C to +50 °C / +32 °F to +122 °F

Storage temperature: - 20 °C to + 60 °C / -4 °F to 140 °F

Power supply: 3 x 1.5 V AAA / batteries

Backlight LCD display: 35 mm x 15 mm

Automatic power save

mode:

Size: 160 mm x 80 mm x 40 mm

Weight: 180 gr / 6.4 oz

6

+/- 1°C / +/- 1.8°F

Service life of approx. 50 hours when used continuously.

Battery life varies with the brand or age of battery.

Settable to: 10 min / 20 min / Off

Page 8

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

Pressure gauge

Property Value

Maximum working

pressure:

Pressure resolution: 0.07 bar / 0.1 psi / 7 kPa / 0.007 MPa

Pressure units: bar / psi / kPa / MPa

Positive pressure

display:

Accuracy:

Power supply: 4 x 1.5 V AAA / batteries

Storage temperature: - 20 °C to + 60 °C / -4 °F to 140 °F

Backlit LCD display: 40 mm x 30 mm

Automatic power save

mode:

Interface: Micro USB

Connection fitting: ¼" SAE

Size: 125 mm x 57 mm x 34 mm

Weight: 200 gr / 7.0 oz

The TAP can be used with the following refrigerants:

R11, R113, R114, R12, R123, R124, R13, R134a, R13B1, R22, R227, R23, R290, R32

R401A(Liq), R401A(Vap), R401B(Liq), R401B(Vap), R402A(Liq), R402A(Vap),

R402B(Liq), R402B(Vap), R403B(Liq), R403B(Vap), R404A, R406A (Liq), R406A(Vap),

R407A(Liq), R407A(Vap), R407B, R407C(Liq), R407C(Vap), R407F(Liq), R407F(Vap),

R408A(Liq), R408A(Vap), R409A(Liq), R409A(Vap), R410A, R413A(Liq), R413A(Vap),

R414B(Liq), R414B(Vap), R416A(Liq), R416A(Vap), R417A(Liq), R417A(Vap), R420A,

R422A(Liq), R422A(Vap), R422B(Liq), R422B(Vap), R422C(Liq), R422C(Vap),

R422D(Liq), R422D(Vap), R427A(Liq), R427A(Vap), R437A, R438A(Liq), R438A(Vap),

R448A(Liq), R448A(Vap), R449A(Liq), R449A(Vap), R450A(Liq), R450A(Vap),

R452A(Liq), R452A(Vap), R500, R502, R503, R507, R508A, R508B, R513A, R600a,

R744, R1233zd, R1234yf, R1234ze

(Liq) = liquid / bubble point, (Vap) = vapour / dew point

60 bar / 870 psi / 6000 kPa / 6 MPa

0.95 to 60 bar, up to 870 psi, up to 6000 kPa, up to 6 MPa

1.0% FS

Service life of approx. 35 hours when used continuously.

Battery life varies with the brand or age of battery.

Settable 10 min / 20 min / Off

7

Page 9

English Instruction Manual TAP / Temperature And Pressure Gauge

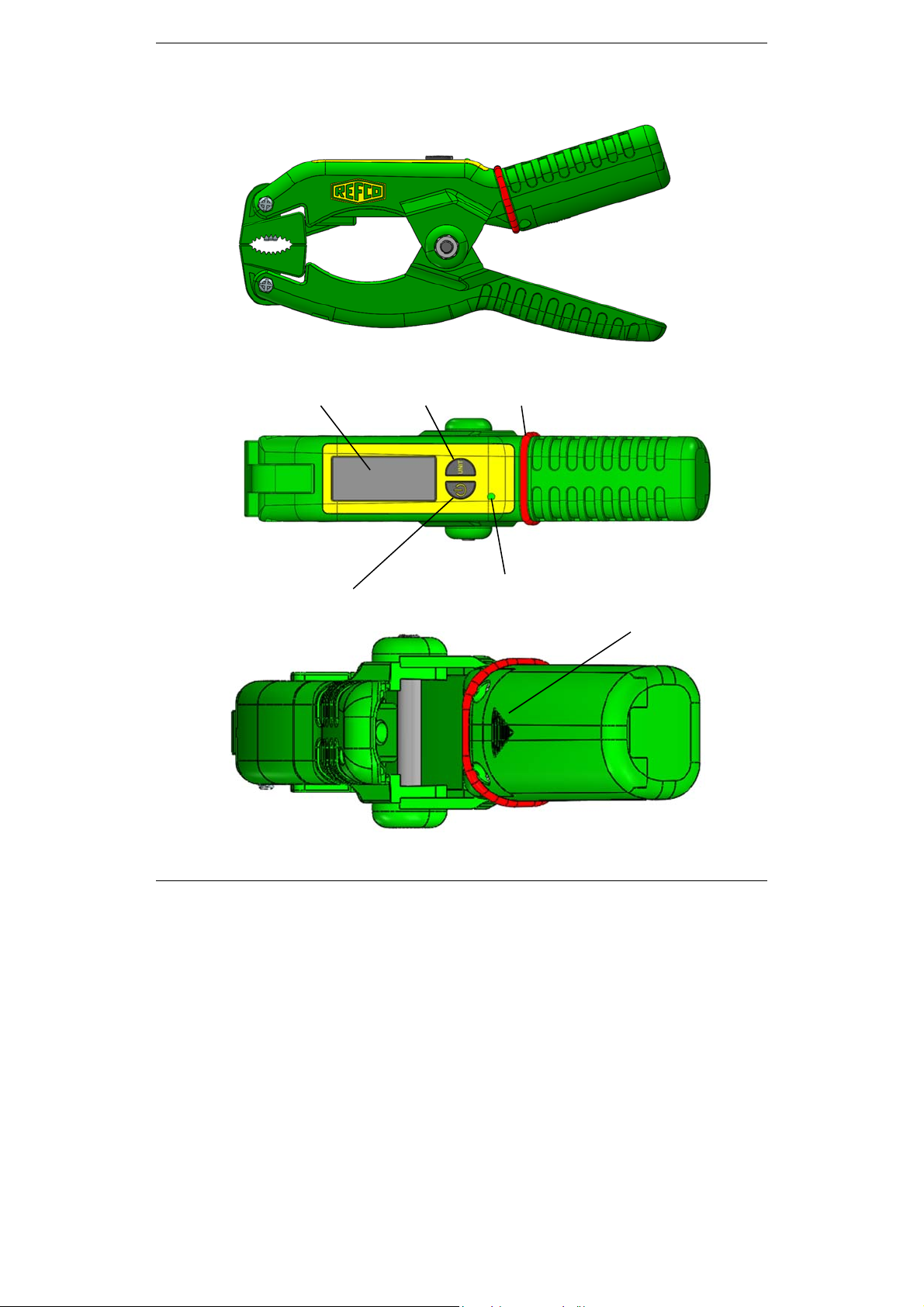

Parts description

Temperature Clamp

Display

UNIT button

Marking band blue or red

8

ON / OFF button

Indicator LED

light

Battery case cover

3 x 1.5 V AAA

Page 10

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

A

Pressure Gauge

LED Indicator light

Slider switch

Online / Offline

Battery case cover

4 x 1.5 V AA

Display

ON / OFF

UP

MENU

DOWN

SET

Connection fitting ¼" SAE

Marking band

blue or red

Connection

Micro USB

Mounting ring

9

Page 11

English Instruction Manual TAP / Temperature And Pressure Gauge

Buttons and functions of TAP CLAMP

ON / OFF UNIT

ON / OFF

UNIT

ON / OFF

+

UNIT

ON by short pressing < 1 sec.

- Backlight on

- Start image on

(Backlight shuts off after 1 min.)

Backlight ON/OFF Only in system On-mode by pressing

[ON] < 1 sec. (Backlight shuts off after 1 min.)

Auto Off

- Factory default auto off time = 20 min (configurable)

UNIT by short pressing < 1 sec.

- °C appears

- °F appears

(Once set, setting remains)

By pressing [ON/OFF] + [UNIT] button same time <1 sec. the

following mode is activated:

- Set number of temperature clamp. Scroll from T1 to T6 by pressing

[UNIT] button < 1 sec. (once set, setting remains)

By pressing [ON/OFF] + [UNIT] button same time >1 sec. the

following mode is activated:

- Set Auto Off as required. 10 min / 20 min / OFF.

(Factory default value is 20 min.)

Scroll from 10 / 20 / OFF by pressing [UNIT] button < 1 sec.

(once set, the setting remains)

OFF by pressing 1 sec.

- Display shows "OFF"

- Backlight off

- Display off

UNIT by pressing 1 sec.

- No function

- To escape from last set menu

10

Page 12

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

Indicator

LED light

Display

Green LED light flashing No LED light

- Power on

- Wireless transmission to

pressure gauge on.

- Power off

- Wirless transmission to

pressure gauge off.

T1.…T6

°C

°F

Number of TAP CLAMP

T1 to T6

Temperature units

Transmiting symbol

Flashing during connection setup.

Constant after connection.

11

Auto Off

10 min. / 20 min. / OFF

Low battery indication

If the battery charge level < 30%, the battery empty

symbol will appear on display. The batteries must then

be replaced within two hours in order to guarantee full

function.

Page 13

English Instruction Manual TAP / Temperature And Pressure Gauge

Buttons and functions on TAP Pressure Gauge

ON / OFF

ON / OFF

ON by short pressing < 1 sec.

- Backlight on

- Start image on

(Backlight shuts off after 1 min.)

Backlight ON/OFF

- Only in system On-modus by short pressing [ O N] < 1 sec.

(Backlight shuts off after 1 min.)

Auto Off

- Factory default auto off time = 20 min.

UP / MENU

UP by short pressing < 1 sec.

- To scroll up

DOWN / SET

DOWN by pressing < 1 sec.

Scroll UP

MENU

OFF by pressing 1 sec.

- Display shows "OFF"

- Backlight off

- Display off

MENU by pressing 1 sec.

- To enter menu mode

- To escape from last set menu

SET by pressing 1 sec.

Scroll DOWN

SET

- To scroll down - To confirm selection

12

Page 14

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

Indicator LED light

green

Slider

switch

Online Offline

- Wireless transmission to

smart device on

Measurements transmitting

continuous to smart device.

- LED light on.

- Wireless connection to smart

device is active.

- To use TAP with smart device.

Online

- Wireless transmission to

smart device off

No measurements transmitting

to smart device.

- LED light off.

No wirless connection to smart

device.

- To use TAP without smart

device.

- To safe battery life.

Note:

Wirless transmission between temperature clamp and pressure

gauge remains always on. Pressure gauge always receives signal

from temperature clamp if within 10 m / 33 ft of each other.

Offline

13

Page 15

English Instruction Manual TAP / Temperature And Pressure Gauge

Display

P1…P6

To/c

T1..T6

TAP1…TAP6

R000

T

ID of TAP pressure gauge

TAP1 to TAP6

Refrigerants menu

Menu with stored refrigerant charts

bar, psi

kPa, MPa

°C

°F

°C

°F

K

°F

Settings

Transmiting symbol

Flashing during connection setup.

Constant after connection.

Low battery indication of TAP pressure gauge

If the battery charge level < 30%, the battery

empty symbol will appear on display. The

batteries must then be replaced within two hours

in order to guarantee full function.

Pressure units

(P) = Pressure

Temperature units

(To = Evaporating temperature )

(Tc = Condensing temperature)

Temperature units

(T) = Temperature from temp. clamp

Temperature difference

(T) = Temperature difference

14

Low battery indication of connected TAP

CLAMP

Page 16

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

Transport, packaging and storage

Transport

The TAP is delivered from the factory in a plastic box, with or without different

accessories as ordered. Inspect the TAP for any potential transportation damage. Any

obvious damage should be reported to the vendor immediately.TAP is a high-grade

instrument and should be transported and stored in a box, for long term protection.

Packaging

Retain the original packaging as it provides optimum protection for transportation of the

device (e.g. onward dispatch of the device, sending it for repair etc.).

Storage

- Storage temperature: -20 °C to +60 °C

- Humidity: 0 to 90% relative humidity (no condensation)

15

Page 17

English Instruction Manual TAP / Temperature And Pressure Gauge

Setup and operation

TAP CLAMP

Set-up

TAP CLAMP

Insert 3 x 1.5 V (AAA) batteries in the battery compartment

of the TAP CLAMP.

Switch on

Set

TAP CLAMP

ID

Ensure the batteries are inserted observing the correct polarities. Do

not leave dead batteries in the battery compartment. If you will not be

using the TAP CLAMP for a long period of time, remove the batteries

from the battery compartment.

- Press [ON/OFF] button, to switch on device.

After start image, display appears

- Press [ON/OFF] + [UNIT] button same time < 1 sec. to enter set

mode.

- Scroll from T1 to T6 by pressing [UNIT] button < 1 sec.

- Press [ON/OFF] button 1 sec. to confirm and return to main

display.

Note:

Chosen ID will be transmitting to pressure gauge and is

shown on display.

16

Page 18

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

Set Auto Off

Note:

Set unit

TAP Pressure Gauge

Set-up TAP

- Press [ON/OFF] + [UNIT] button same time >1 sec. to enter set

mode.

- When Auto Off mode is activated timer symbol appears.

- Scroll from 10 / 20 / OFF by pressing [UNIT] button <1 sec.

- Press [ON/OFF] button 1 sec. to confirm and return to main menu.

Factory default Auto Off is set to 20 min.

Subsequent the symbol and the auto off time disappear from display.

- Press [UNIT] button < 1sec.

- Switch between °C and °F by using [UNIT] button <1 sec.

Insert 4 x 1.5 V (AAA) batteries in the battery compartment on the

back side of the TAP.

Ensure the batteries are inserted observing the correct polarities. Do

Switch on

17

not leave dead batteries in the battery compartment. If you will not be

using the TAP pressure gauge for a long period of time, remove the

batteries from the battery compartment.

- Press [ON] button to switch on device.

After start, REFCO-logo appears on display.

Page 19

English Instruction Manual TAP / Temperature And Pressure Gauge

Set TAP ID

Note:

Set

refrigerant

- Press [MENU] button

TAP ID menu is selected.

- Press [SET] button

- Choose a TAP ID number by pressing [UP] or [DOWN] button

< 1 sec.

- Press [SET] button

- Press [MENU] button

Number for P1 to P6 is always concurrent with the TAP number.

To change current refrigerant setting:

- Press [MENU] button

- Press [DOWN] button

menu.

- Press [SET] button

- Press [UP] or [DOWN] button

refrigerant type entry.

- Press [SET] button

- Press [MENU] button

1 sec. to activate selection mode.

1 sec. to enter TAP ID menu.

1 sec. to confirm selected ID.

1 sec. to return to main display.

1 sec. to activate selection mode.

1 sec. to scroll down to the refrigerant

1 sec. to enter refrigerant menu.

1 sec. to scroll to the desired field

1 sec. to confirm.

1 sec. to return to main display.

Note:

The first 6 refrigerants can be favorites.

Following are all known refrigerants from library.

18

Page 20

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

Note on R000:

Additional function to select from table of refrigerant: If use entry

„R000“ it means „Pressure only“. No readouts from chart. It gives the

possibility to measure only pressure and temperature without any

refrigerant chart temperatures shown.

Set favorites

Note:

Set pressure

unit

- Press [MENU] button

- Press [DOWN] button

menu.

- Press [SET] button

- Press [UP] or [DOWN] button

refrigerant.

- Press [ON/OFF] button < 1 sec. to add refrigerant to favorites.

New favorite is placed at first of column.

Last of the 6 entries drops out.

- Press [MENU] button

- Press [DOWN] button

menu.

- Press [SET] button

- Press [UP] or [DOWN] button

- Press [SET] button

- Press [MENU] button

1 sec. to activate selection mode.

1 sec. to scroll down to the refrigerant

1 sec. to enter refrigerant menu.

1 sec. to scroll to the desired

1 sec. to activate selection mode.

1 sec. to scroll down to the pressure unit

1 sec. unit field will flash.

1 sec. to select pressure unit.

1 sec. to confirm.

1 sec. to return to main display.

19

Page 21

English Instruction Manual TAP / Temperature And Pressure Gauge

Set

temperature

unit

Pairing

- Press [MENU] button

- Press [DOWN] button

unit menu.

- Press [SET] button

- Press [UP] or [DOWN] button

- Press [SET] button

- Press [MENU] button

-Ensure the distance between the devices is less than 5 meters.

- Ensure TAP CLAMP(S) which shall be paired with TAP pressure

gauge are switched on.

- Ensure TAP pressures gauge is on.

- Press [MENU] button

selection mode.

- Press [DOWN] button

down to the field "T".

- Press [SET] button

Display of TAP pressure gauge shows "Scan…"

Note:

If no device can be found, "No Signal" appears on display before

return to menu.

- If device be found, display shows a list of found TAP CLAMP ID(s).

- Select desired TAP CLAMP ID by pressing [UP] or [DOWN] button

1 sec. to activate selection mode.

1 sec. to scroll down to the temperature

1 sec. unit field will flash.

1 sec. to select temperature unit.

1 sec. to confirm.

1 sec. to return to main display.

1 sec. on TAP pressure gauge to activate

1 sec. of TAP pressure gauge to scroll

1 sec. to start scanning.

1 sec.

- Press [SET] button

During pairing procedure, display shows " Connect…".

1 sec. to start pairing.

20

Page 22

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

If pairing was successful, display shows "END".

Paired TAP CLAMP is recognised on TAP display with T and relevant

number (1 to 6).

- If pairing was not successful, display shows "ERROR“. If this

happens, repeat steps above and try again.

Change

Settings

- Press [MENU] button

- Press [UP] button

- Press [SET] button

- Press [UP] or [DOWN] button

Available fields:

Auto Off

Update

Version

SD Mode

P-Zero

- Press [SET] button

1 sec. to activate selection mode.

1 sec. to scroll up to the setting field .

1 sec. to enter settings menu.

1 sec. to confirm.

1 sec. to scroll to the desired field.

Update

Version

21

Auto Off

- Press [UP] or [DOWN] button

option. (10 min. / 20 min. / Off)

- Press [SET] button

Updating refrigerants.

See in chapter maintenance.

Current version of refrigerant chart is shown.

1 sec. to confirm.

1 sec. to choose the auto shutoff

Page 23

English Instruction Manual TAP / Temperature And Pressure Gauge

SD Mode

P-Zero

This function is used in combination for update.

See in chapter maintenance.

Resetting pressure sensor.

See in chapter maintenance / Resetting pressure sensor

Maintenance

A visual inspection of the connections and hoses must be carried out before

each use to check for mechanical damage.

Do not use aggressive cleaning agents or solvents to clean the device. Gentle

household cleaners and soapy water should be used instead.

TAP seals are subject to mechanical and age-related wear. Therefore, the TAP

should be regularly tested by the user for leaks.

Resetting pressure sensore on TAP pressure gauge

The TAP pressure sensor can be reset in order to avoid incorrect measurement values.

P-Zero

To obtain a correct measurement value on the display, the TAP should not

be reset when pressurised.

1. Ensure TAP pressure gauge is switched on.

2.

Press [MENU] button

1 sec. to activate selection mode.

3.

Press [UP] button

4.

Press [SET] button

5.

Press [UP] or [DOWN] button

6.

Enter "P-Zero" by pressing [SET] button

7. Display shows 0.0psi

8.

Press [SET] button

9. Display shows setting menu.

10.

Press [MENU] button

22

1 sec. to scroll up to the setting field .

1 sec. to enter settings menu.

1 sec. to scroll to the "P-Zero" field.

1 sec. for confirmation.

1 sec. to quit.

1 sec.

Page 24

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

Updating of refrigerants on TAP pressure gauge via Micro USB

The TAP pressure gauge supports updates of refrigerant data via Micro USB.

The latest refrigerant charts can be found at www.refco.ch

Updating refrigerants

1. Ensure TAP pressure gauge is switched on.

2.

Press [MENU] button

3.

Press [UP] button

4.

Press [SET] button

1 sec. to activate selection mode.

1 sec. to scroll up to the setting field .

1 sec. to enter settings menu.

5.

Press [UP] or [DOWN] button

6. Enter "SD Mode" , select "USB MSC".

7. Connect TAP to computer by USB connection; the device shown on computer.

8. Copy the file "Refriger .bin" to the folder "Refriger" which is under the device.

9. Disconnect the TAP from computer.

10. Enter "SD Mode" , select "SD FAFS"

11. Enter "Update" (MENU) to update the refrigerant data.

1 sec. to scroll to the "SD Mode" field.

23

Page 25

English Instruction Manual TAP / Temperature And Pressure Gauge

Calibration

The accuracy of all measuring devices will degrade over time. Calibration improv es the

accuracy of the TAP. On this device temperature and pressure can be re-calibrated.

Temperature calibration can be done using two procedures: calibrat ion using ice water

as reference or by using room temperature as reference.

Calibration of temperature clamp

Risk of short circuit. If the electronic components come into contact with

water, short circuits are possible. Don`t dunk the temperature clamp below

max. water level. (See figure below)

Ice water calibration (0 °C / 32 °F)

Risk of short circuit. If the electronic components come into contact with

water, short circuits are possible. Dunk the temperature clamp below max.

water level as shown.

1. Prepare ice water:

Take your time, use lots of ice and stir water often. It can take

up to 15 minutes for the ice water temperature to settle exactly

at 0.0 °C / 32.0 °F Use separate accurate thermometer to

verify water temp.

For best results use an insulated cup, do not let the sensor

tips touch any ice cubes, only the ice water in the top 2-3 cm

of the ice bath after +/- 15 min. Do not touch or hold the

sensor wires.

24

Page 26

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

2. Turn off the clamp.

3. While holding [UNIT], press [ON / OFF] until display shows "CALL"

4. Release both buttons, the display shows "00"

5. Press [UNIT] button < 1 sec. to adjust the number to "06"

6. Press [ON / OFF] button < 1 sec., the display shows "00 °C"

7. Press [UNIT] button < 1 sec. to show a code of temperature

8. Put the K – thermocouple (plate) into 0 °C ice water.

9. Wait the temperature code reading to be steady, press [UNIT] button < 1 sec.

10. The display shows the ambient temperature.

11. Press [UNIT] button < 1 sec. to quit the temperature calibration.

Room temperature calibration

1. Turn off the clamp.

2.

Place the clamp at constant temperature at 25

3 °C condition for 2 hrs. to ensure

the temperature of the K – thermocouple to be even.

3. While holding [UNIT], press [ON / OFF] until display shows „CALL“

4. Release both buttons, the display shows „00“

5. Press [UNIT] button < 1 sec. to adjust the number to „09“

6. Press [ON / OFF] button < 1 sec. to show a code of temperature.

7. Wait the temperature code reading to be steady, press [ON / OFF] button < 1 sec.

8. The display shows the ambient temperature.

9. Press [ON / OFF] button < 1 sec. to quit the temperature calibration.

25

Page 27

English Instruction Manual TAP / Temperature And Pressure Gauge

Calibration of pressure gauge

Pressure calibration

1. Turn off the TAP.

2. While holding [UP / MENU] button, press [ON / OFF] button, the display shows

„P-CALL“

3. Press [DOWN / SET] button until the display shows „Password 00“

4. Press [UP / MENU] button shortly to adjust the number to „Password 8“

5. Press [DOWN / SET] button until the display shows a reading which is presenting the

unload pressure. (i.e. 0.0 psi)

6. Press [DOWN / SET] awhile to enter calibration

Ensure all the refrigerant is exhausted from TAP valve or connected hoses

before performing calibration. The accuracy will be affected due to the

remaining refrigerant.

7. While entering calibration, the display shows „400.0 psi“. The default pressure of

calibration standard is 400 psi.

8. Press [UP / MENU] button shortly to select the calibration standard. The inlet

pressure must be equal to the calibration standard pressure.

9. Press [DOWN / SET] awhile for calibration standard confirmation; the display shows

the reading of unloaded pressure.

10. Wait until the reading of unload pressure ist stable, pressuirze 400 psi (the inlet

pressure must be equal to the calibration standard pressure). The display shows the

corresponding pressure value (i.e. 400.0 psi)

11. When the reading is stable, press [DOWN / SET] for confirmation. Now the display

shows „END“

12. Press [DOWN / SET] awhile to quit the pressure calibration.

26

Page 28

Instruction Manual TAP, TAP-CLAMP / Temperature And Pressure Gauge English

Guarantee

Your new TAP has been developed in accordance with the latest occupational health

and ergonomic requirements and reflects the latest state-of-the-art technology. REFCO

Manufacturing Ltd has been certified in accordance with DIN EN ISO 9001: 2008.

Regular quality control checks as well as an accurate manufacturing process guarante e

reliable functionality and are the basis for the REFCO guarantee, in accordance with the

General Terms and Conditions of Sale and Delivery applicable on the day of delivery.

Damages arising from obvious maltreatment or wear are excluded from the guarantee.

Return and disposal

Dispose of faulty rechargeable batteries/spent batteries in accordance with the valid

legal specifications. At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local regulations).

Replacement parts and accessories

Description Identifier P/N

TAP pressure gauge TAP 4687787

TAP clamp TAP-CLAMP 4687785

¼“ SAE hose red CL-6-R 9881265

¼“ SAE hose blue CL-6-B 9881256

¼“ SAE hose yellow CL-6-Y 9881274

Quick coupler straight ¼“ SAE QC-S4A-1/4"SAE 4687736

Quick coupler straight ½“-20UNF QC-S4A-1/2"-20UNF 4687737

Swivel Arm ¼“ SAE-N SWIVEL-ARM-1/4"SAE-N 4687631

Threaded T-style SAE ¼“

female with swivel nut

Adapter ¼“ SAE x ½“-20UNF QC-S410A/2 4687095

Swivel adapter

3/8“ SAE male x ¼“ SAE female

A-31851/10 9884841

QC-S4-3/8"x1/4"/2 4687406

27

Page 29

Page 30

Deutsch Bedienungsanleitung DIGIMON / DIGIMON4

REFCO Manufacturing Ltd.

Industriestrasse 11

6285 Hitzkirch - Switzerland

Telefon +41 41 919 72 82

Telefax +41 41 919 72 83

info@refco.ch

www.refco.ch

4687790

1

Loading...

Loading...