Page 1

ST7000 Operation

Page 2

Page 3

Contents

1 . Introduction

- Basic Principles

2. Operator Controls

- Auto

- Course Changes

- Standby

- Track

- Response

- Illumination

3. Additional Displays

- Display

- Auto Mode

- Track Mode

- Navigation Displays

- Watch Alarm

- Warning Messages

4. Additional Information for Sailing Vessels

- Auto Tack

- Wind Trim

5. Operating Hints

- Response Level Adjustment

- Track

- Waypoint Advance

- Automatic Trim

- Rudder Gain

- Rudder Gain Adjustment (sail)

- Rudder Gain Adjustment (power)

- Rudder Gain/Speed Adjustment

(power craft)

- Unsatisfactory steering performance

- Failure to disengage

- Manual Override (sterndrive)

- Control Unit Display Adjustment

6. Maintenance

7. Safety

8. Fault Location Procedure

9. Warranty, After Sales Service

1

Page 4

1. Introduction

This Handbook describes how to operate your ST7000 and is intended for use after the autopilot has been set up.

Full details of setting up and initial sea trials procedures are described in the Installation Handbook.

Basic Principles

When switched on, the ST7000 will be in Standby mode. To select automatic steering simply steady the vessel on

the required heading and push Auto. At any time to return to manual steering push Standby.

Autopilot control has been simplified to a set of push button operations, all of which are confirmed with a beep tone.

In addition to the main 6 button course control keypad, the secondary 4 button keypad provides the following

functions:-

• Track

selects the built in track control to allow the autopilot to steer under the supervision of Radio Navigation

System.

• Response

selects 3 levels of course keeping response.

• Display

selects

1) waypoint information for display (when available).

2) the watch alarm.

3) illumination level.

Warning

Hand steering is not possible when 'Auto' is

selected. The 'Standby' button must be pressed to

disengage the Autopilot drive.

It is the skippers responsibility to brief

all crew members on this procedure.

When used with a Sterndrive Actuator a special

emergency manual override facility is provided. For

details see page 13.

2

Page 5

2. Operator Controls

Auto

Course Changes (-1, +1, -10, +10)

Push to engage automatic steering

and maintain current heading

OR

Push and hold down for 1 second to

return to previous automatic

heading (Display returns to Auto

after 10 seconds)

New Automatic Heading

Push to alter course to port (-) and

starboard (+) in increments of 1 and

10 degrees.

Automatic Heading

Previous Automatic Heading

Standby

Track (see operating hints)

Push to disengage the autopilot for

manual steering. (The previous

automatic heading is memorised).

Automatic Heading

Push to select track control from

Auto.

Push again to return to automatic

steering

OR

Push and hold down for 1 second to

select previous track control heading

from Auto or Track.

Current Heading

(Display returns to Track after 10 seconds).

3

Page 6

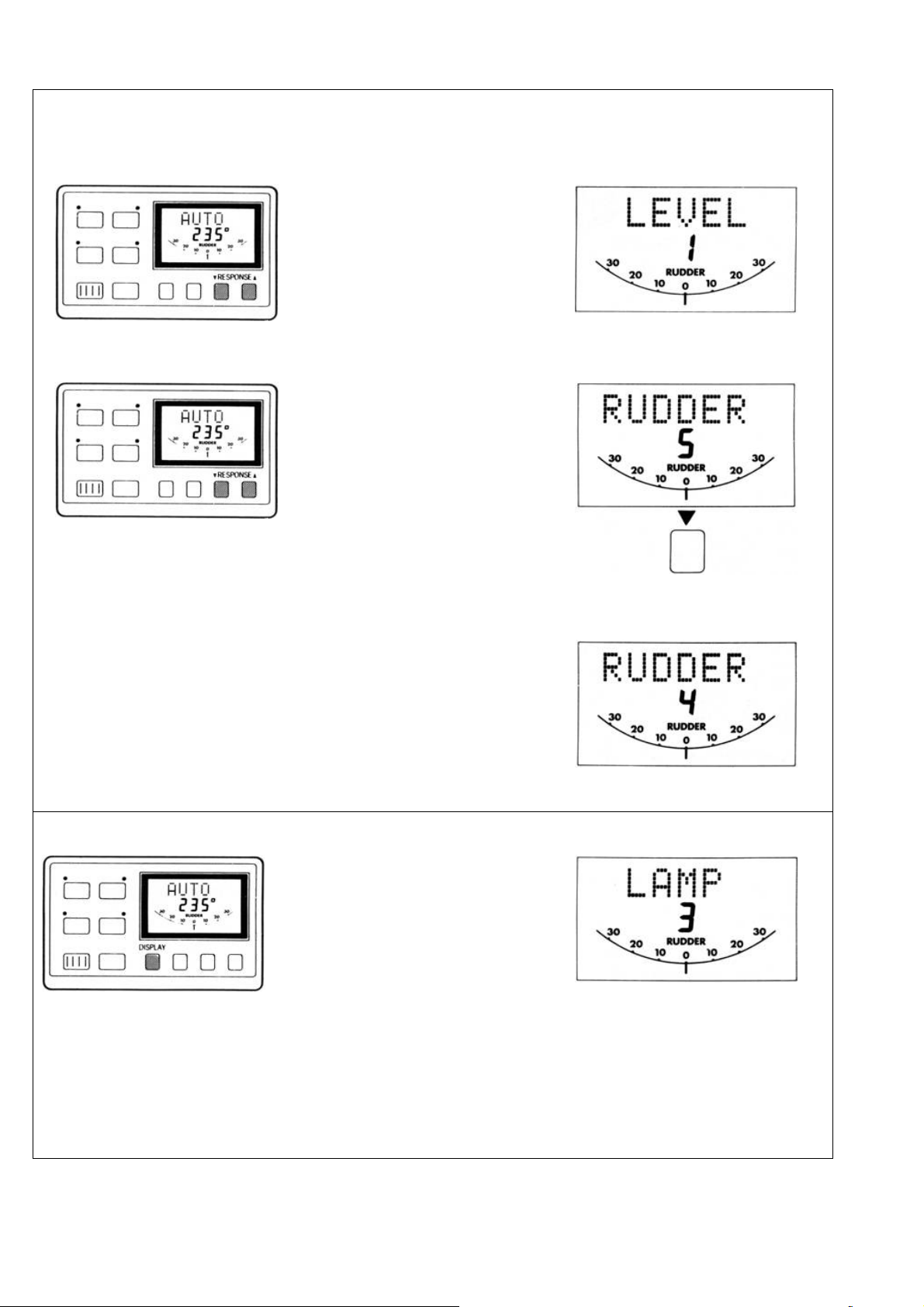

Response

Response Level Adjustment (see Operating Hints)

Push to increase (▲) or decrease

(▼) response level

To display response level without

changing it push both Response

keys together briefly.

Rudder Gain Adjustment (see Operating Hints)

Push and hold down for 1 second

both Response keys together to

display rudder gain level.

Response Level

Rudder Gain Level

Within 10 seconds push once to

increase (▲) or decrease (▼)

rudder gain.

(Response and Rudder levels are displayed for 10 seconds only)

Illumination

(illumination level is displayed for 10 seconds only)

4

Push and hold down Display for 1

second to switch on illumination.

Within 10 seconds push

Display to select illumination level.

Rudder Gain Level

Illumination Level

3 = High

2 = Medium

1 = Low

OFF = OFF

Page 7

3. Additional Displays

Display Auto Mode

The Display pushbutton is used to cycle through

additional information menus. These menus depend on

the autopilot mode and if navigation information is

available.

Standby Mode

• Main Display

• Main Display

• Navigation Displays

•

• Navigation Displays

•

See section on Navigation Displays.

See section on Navigation Displays

• Watch Alarm

5

Page 8

Track Mode Navigation Displays

• Main Display

• Navigation Displays

See section on Navigation Displays.

With the Navigation Receiver operating in waypoint

mode, the following information can be displayed

(provided that the Navigation Receiver transmits the

appropriate information - see Installation Handbook).

• Cross Track Error

The arrows show the direction to steer to rejoin the

desired Track:

► Starboard

◄ Port

• Bearing to Waypoint

• Watch Alarm

Magnetic

or

True

• Distance to Waypoint

6

Page 9

• Waypoint Number

Watch Alarm (not available in Standby)

• Engage the Autopilot in Auto/Track/Windvane mode.

• To select Watch alarm push Display repeatedly

until Watch appears.

The 4 minute timer is now running:-

- After 3 minutes 'Watch' flashes on all

control units.

- After 4 minutes the alarm sounds on all

control units.

• Push Auto at any time to reset the timer to 4

minutes and silence the alarm.

• To cancel the Watch alarm at any time push

Display.

7

Page 10

Warning Messages

• Off Course Alarm

- Sounds if the vessel deviates from the automatic

heading by more than the selected amount for over 20

seconds.

• Low Battery Alarm

- Sounds if the course computer supply voltage falls

below 11 volts for over 20 seconds.

• Track Mode Alarms

- Sounds if the cross track error exceeds 0.30nm

- Sounds when the target waypoint number

changes.The displayed bearing is to the new

waypoint. PORT or STBD indicates in which

direction the autopilot will turn onto the new

waypoint bearing

- Push Track to silence the alarm and automatically

steer onto the new bearing to waypoint.

• Manual Override Alarm

(Installations with stern drive actuators only).

- Sounds it no waypoint data is received from the

Radio Navigation System for over 20 seconds.

- Sounds if the data has the incorrect format or if an

invalid flag is set.

8

- Sounds for 10 seconds when the autopilot is

manually overridden at the steering wheel. After 10

seconds the autopilot will return to Standby

automatically.

Note: Push Standby to silence an alarm and select

Standby mode (unless indicated otherwise).

Page 11

4. Additional Information for Sailing Vessels

Autotack

The ST7000 has a built in Autotack function which will

turn the vessel through 100 deg. This operates in both

compass and vane modes as follows:-

Vane

Note: It is important that the rudder angle transducer is accurately aligned

as the Autotack function mirrors standing helm and any offset will change

the initial tack angle.

Wind Trim

Wind Trim allows the autopilot to be supervised by

apparent wind direction. The wind direction is read

either:-

- From the SeaTalk bus (requires Autohelm ST50 wind)

OR

Automatic Heading

Push +1 and +10 keys together to

initiate a tack turning to Starboard.

Push -1 and -10 keys together to

initiate a tack turning to Port.

Push both red keys together to

select Wind Trim and maintain the

current apparent wind angle.

- Directly from a Masthead Transducer (Z080)

OR

- From an NMEA 0183 input on the control unit.

Previous Automatic Heading

Push and hold down for 1 second

both red keys together to return to

the previous apparent wind angle.

9

Page 12

Wind Change Alarm

Wind Trim uses the fluxgate compass as the primary

heading reference and automatically adjusts the

compass heading to maintain the original apparent wind

angle. If changes in apparent wind angle adjust the

original automatic heading by more than 15 deg. the

wind change alarm will sound.

- The alarm is silenced by pushing both red keys

together briefly.

Display of Wind Angle

If the wind angle information is supplied using the NMEA

0183 input or SeaTalk bus, the apparent wind angle and

tack sense (P & S) is added to the display menu and

accessed via the Display button.

Using Wind Trim

It is important to understand that "Wind Trim" prevents

over-reaction to gusts or sudden wind shifts. One

minute is required to change the heading in response to

a permanent change in apparent wind angle. Do not

attempt to override the automatic sequence with the

course change buttons.

In gusty conditions sail a few degrees off the wind and

pay frequent attention to sail trim and helm balance

using the rudder angle indication.

Performance will normally be improved by reefing

headsail and mainsail a liftle early rather than too late.

Apparent Wind Angle

• Adjust Apparent Wind Angle

10

Use the +1 or +10 degree buttons to

change heading and hence adjust

the apparent wind

Page 13

5. Operating Hints

Response Level Adjustment

The ST7000 has three response levels which enable

tighter course keeping to be achieved in certain cases:Level 1 - Automatic Sea State Control

Level 2 - Automatic Sea State Inhibit Level 3 - Automatic

Sea State Inhibit and counter rudder.

When the autopilot is switched on, the response level

is set to 1. This provides the best compromise between

power consumption and course keeping accuracy and is

suitable for nearly all situations.

Increasing Response level provides tighter course

keeping at the expense of increased power

consumption and general wear and tear. It is advisable

to use the minimum response level necessary to

achieve the desired course keeping accuracy. On

larger power vessels level 3 can improve slow speed

steering where the natural yaw damping of the vessel is

reduced.

Note: Level 3 is not recommended for use at planing

speeds or in rough seas.

Track

To make full use of Track control the following simple

points should be observed:-

• Always steer the vessel to within 0.1 nm of track and

bring the heading to within 5 deg. of the bearing to

the next waypoint before selecting Track.

• Always check that there are no navigational hazards

either side of the intended track.

• Always maintain an accurate log with regular plots

to verify the computed position read from the Radio

Navigation Receiver. Maintain a proper lookout at

all times.

Waypoint Advance

if the navigation receiver is transmitting the waypoint

number to the ST7000 the waypoint alarm will sound

whenever a new target waypoint is selected (see Page

8). When the alarm is sounding the ST7000 will

maintain the current heading and automatic track control

is suspended. Check the displayed new bearing to

waypoint and when it is safe to turn onto it, resume

automatic track control by simply

pushing Track. This accepts the new target waypoint

and will steer the vessel onto the new bearing to

waypoint.

The tidal offset may be very different on the new

bearing, and it is good practise to check the cross track

error after a couple of minutes. If the cross track error

continues to increase make a course adjustment of say

10 degrees in the direction of the arrow. This will help

the Track control correct more quickly for the new tidal

vector.

Automatic Trim

If Automatic Trim has been selected during calibration

the ST7000 will correct for trim changes. This correction

can take up to one minute to apply the rudder offset

necessary to restore the set automatic heading. Large

course changes which change the apparent wind

direction can produce large trim changes. In these

cases the autopilot will not immediately assume the new

autoitiatic heading, and only seftle onto course when the

Automatic Trim has been fully established.

To minimise the inherent time delay the following

procedure may be adopted for large course changes.

• Note required new heading.

• Select Standby and steer manually.

• Bring vessel onto new heading.

• Select Auto and let vessel settle onto course.

• Bring to final course with 1 deg. Increments.

It is sound seamanship to make major course changes

only whilst steering manually. In this way any

obstructions or other vessels may be cleared properly

and due account taken of the changed wind and sea

conditions on the new heading prior to engaging the

autopilot.

Rudder Gain

The rudder gain level selected during initial sea trials will

normally provide excellent steering performance over a

wide range of conditions. However, it may be noticed

that the autopilot tends to be a little less stable on

northerly headings in the higher latitudes of the Northern

hemisphere (and conversely southerly headings in the

Southern hemisphere). This is caused by the increasing

angle of dip of the earth's

11

Page 14

magnetic field at higher latitudes which has the effect of

amplifying rudder response on northerly (southerly)

headings.

Rudder Gain Adjustment (Sail)

It is not normally necessary to adjust the autopilot gain

setting once the correct level has been established

during initial sea trials.

Depending on the yacht's individual steering

characteristics a change of one level may improve

course keeping accuracy when going from northerly to

southerly (increase) or southerly to northerly (decrease)

headings.

The effect may be judged by carrying out a sea trial in

smooth water conditions and observing the results.

Note: The effect is reversed for the Southern

hemisphere.

Rudder Gain Adjustment (Powercraft) The tendency

towards northerly (southerly) heading instability is more

obvious in high speed craft and can be corrected by a

reduction in the rudder gain sefting. At speeds in

excess of 30 knots a reduction of two levels can be

required on headings between 315 deg. and 045 deg

(Northern hemisphere) or 135 deg. and 230 deg.

(Southern hemisphere).

Two options are available to control this:-

• Manual (Low speed and displacement craft). The

rudder gain control may change by one level when

going from northerly to southerly (increase) or

southerly to northerly (decrease) headings. The

effect may be judged by carrying out a sea trial in

smooth water conditions and observing the results.

Note: The effect is reversed for the Southern

hemisphere.

• Autoadapt (High speed planing craft)

The ST7000 can be set automatically to reduce the

effects of northerly heading instability. This feature is

selected in calibration mode by entering the latitude (see

Installation Handbook, Calibration, section on 'Auto

Adapt'). When selected the ST7000 automatically

adjusts the Rudder Gain depending on the compass

heading, removing the need for manual adjustment.

12

Rudder Gain/Speed Adjustment (Powercraft) High

speed planing craft exhibit very different steering

characteristics when on and off the plane. As a result it

is generally necessary to adjust the Rudder Gain setting

when going from displacement speed to planing speed

or vice versa.

Two options are available to achieve this:

• Automatic

When the ST7000 is used with an Autohelm S150

Speed Instrument or Tridata, Rudder Gain is

adjusted automatically with boat speed. There

should be no geed for any manual adjustment.

• Manual (No ST50 Speed/-Fridata)

The Rudder Gain setting may be increased by one or

two levels when dropping from planing speed to cruise

speed and decreased by the same amount when

returning to planing speeds.

Note: It is important to make the gain adjustment after

dropping to displacement speed and before returning to

planing speed.

Note: The adjustment of Gain with boat speed is

normally only required for high speed planing

powercraft.

Unsatisfactory Steering Performance

If the ST7000 has been installed and set up in

accordance with the instructions in the Installation

Manual it will provide excellent steering performance

over a wide range of conditions.

It performance drops but the autopilot is still working

correctly, the following simple checks should find the

fault:-

• Has a magnetic influence been introduced near the

fluxgate compass? i.e. anchor, chain, radio

equipment, loudspeaker, tools, generator etc.

Check that the autopilot compass heading still

corresponds with the steering compass.

• Are all fuses intact, circuit breakers engaged?

• Are all screw connections tight and free of

corrosion?

Page 15

• If the autopilot fails to hold course check the Rudder

Gain level. Has it been changed from the initial sea

trials level (check in Installation Manual)?

• If the vessel wanders check that the Rudder

Reference Transducer linkage is secure with no free

play.

Hydraulic Drive Units only:-

• Check that all unions are tight and bleed system to

remove air.

Failure of Drive Unit to Disengage

The mechanical drive actuators of the ST7000 are

designed to 'Fail Safe' - When power is disconnected

the drive unit will disengage leaving the steering system

free for manual control.

When Standby is selected the actuator will disengage

leaving the steering free.

It is remotely possible that a fault could develop which

could cause the actuator to remain engaged even when

Standby is selected. If this happens:-

• DISCONNECT THE MAIN CIRCUIT BREAKER TO

THE AUTOPILOT - THE STEERING WILL

IMMEDIATELY BE FREE , or

• IN AN EMERGENCY THE ACTUATOR CLUTCH

CAN NORMALLY BE OVERRIDDEN BY TURNING

THE STEERING WHEEL HARD.

It is emphasised that this fault is extremely unlikely and

can be immediately corrected as described.

If preferred a separate Override switch can be fitted

close to the steering position which will break the

actuator clutch drive for

Emergency Use.

Stern Drive Actuator

Manual Override Option

When used with a stern drive actuator, the ST7000 can

be set up automatically to release the drive if the

steering wheel is turned in an emergency situation.

After releasing the drive unit the ST7000 will return to

Standby and sound the manual override alarm for 10

seconds.

This feature is selected during autopilot

calibration (see Installation Handbook).

Note: This feature is for use with a stern drive actuator

only.

Control Unit Display Adjustment

The control unit display is designed to provide good

legibility over a wide range of viewing angles. However,

it is recommended that wherever possible the control

unit is mounted so that the viewing angle is normal to

the lcd display when the helmsman is in the usual

steering position. If the control unit is mounted so that

the usual viewing position is at an angle to the lcd

display, the lcd contrast can be adjusted to improve

legibility.

• Push Display and Track together momentarily.

Push ▲ to increase, ▼ to decrease contrast level.

Continue until the display has optimum legibility when

viewed from the usual helming position. Push Display

and Track together momentarily to store the selected

contrast level.

Note: Increasing the contrast level will suit

installations where the instrument is normally viewed

from below.

13

Page 16

6. Maintenance

The autopilot is one of the most used and hardest

working items of equipment on board, and therefore

must receive its fair share of attention and routine

maintenance. The working parts of the drive system are

sealed and lubricated for life during manufacture and

therefore do not require servicing.

Regular inspection of the installation is recommended in

the following areas where applicable.

1. Check tension and alignment of the drive chain

(Rotary Drive) and lubricate with good quality

waterproof light grease.

2. Check that Hydraulic Steering systems are free

from leaks and trapped air. Bleed when necessary

to remove air from the system.

3. Check that all inter-connecting cable terminals are

fully tightened and corrosion free.

4. Check that external waterproof sockets are capped

when not in use and periodically spray with WD40

(or similar) to protect from corrosion.

5. Check that the heavy power supply cable

connections are tight and free from corrosion.

14

7. Safety

Passage making under autopilot can greatly

increase the pleasure of the voyage and ensure the

crew can relax. However, this can lead to a

dangerous lack of attention to basic seamanship.

The following rules should always be

observed:Maintain a permanent watch and check

regularly all round for other vessels and obstacles

to navigations. No matter how clear the sea may

appear a dangerous situation can develop rapidly.

• Maintain an accurate record of the vessel's

position either by use of a radio navigation receiver

or visual bearings.

• Maintain a continuous plot of position on a

current chart. Ensure the locked autopilot heading

steers you clear of all obstacles. Make proper

allowance for Tidal Set - the autopilot cannot!

• Even when your autopilot is locked to the

desired Track using a radio navigation receiver

maintain a log and a regular positional plot. Radio

navigation signals can produce significant errors

under some circumstances and the autopilot cannot

detect this situation.

• Ensure that all members of crew are familiar with

the procedures required to engage and disengage

the autopilot.

• When searoom is restricted a crew member

must be close to a control unit at all times if under

autopilot control.

• On Powercraft permanent watch should be

maintained at the steering station when at speed

with the autopilot engaged.

Your Autoheim ST7000 will add a new

dimension to your boating enjoyment. However, it is

the responsibility of the skipper to ensure the safety

of the vessel at all times by careful observance of

these basic rules.

Page 17

8. Fault Location Procedure

The ST7000 has been designed to achieve very high

standards of reliability combined with ease of servicing.

If a fault should appear, please double check that all

connections in the connector unit are sound and that the

heavy duty power connections are tight and free from

corrosion. If you are satisfied that all connections are

sound, the simple check procedure tabulated below will

assist you to locate the most likely fault area,

If the autopilot switches on but does not operate

correctly, check the rudder angle and heading displays

on the control unit. If these appear incorrect, double

check all connections from the course computer to the

compass and rudder reference transducers.

In the case of a sailing yacht fitted with a windvane

system, if a fault occurs only in vane mode then it is

likely that fault has developed

in the vane head or the interconnection system.

Since the course computer houses the majority of the

electronic control system there is a high probability that if

an electronic fault has occurred it will be located in this

area. The course computer unplugs easily from the

connector unit for servicing. (See Installation Manual).

Control Units are removed by undoing the two thumb

nuts (accessed from behind). Disconnect the cables by

rotating the locking rings anti-clockwise before

separating the connectors.

The faulty unit should be removed and returned to your

nearest service agent.

If ary difficulties arise, please consult Nautech's Product

Support Department in the UK or your own national

distributor who will also be able to provide expert

assistance.

15

Page 18

9. Warranty, After Sales Service

Limited Warranty

Nautech or its appointed Distributors or Service Centres

will, subject to the conditions below, rectify any failures in

this product due to faulty manufacture which become

apparent within twelve months of its purchase date.

Equipment used in the country of purchase should be

sent directly to the authorised Distributor for that country

or its appointed Service Centres. The product will then

be serviced free of charge and returned promptly direct

to the sender.

Equipment used outside the country of purchase can be

either:a. Returned to the Distributor or Dealer in whose

country the equipment was originally purchased - it

will then be serviced free of charge and promptly

returned direct to the sender,or

b. The product can be returned freight pre-paid to the

authorised Distributor or its appointed Service

Centres in the country in which the product is being

used. It will then be serviced and returned direct to

the sender on the basis that the Distributor or

Service Centre will supply any parts used free of

charge but the sender will be invoiced for the

necessary labour and return shipment at the local

rate.

Conditions

The warranty is invalid if:a. The product has been misused, installed or

operated not in accordance with the standards

defined in this manual.

b. Repairs have been attempted by persons other

than Nautech approved Service personnel.

Full International Warranty

Nautech or its appointed Distributors or Service Centres

will, subject to the conditions below, rectify any failures in

this product due to faulty manufacture which become

apparent within twelve months of its purchase date

wherever the vessel and the product may be operated.

Conditions

1. The product must be installed aboard the vessel in the

country of purchase.

2. The product must be installed in accordance with the

recommendations issued by Nautech Ltd.

3. The installation must be carried out by an installer

approved by Nautech: alternatively, the installation must

have been inspected and approved by Nautech or its

approved installer.

4. The Warranty Registration Card must be completed

by:-

- The owner or user.

- The dealer supplying the product.

- The installer.

5. The Full International Warranty is invalid if:-

(a) The product has been misused, or installed or

operated not in accordance with standards defined

in this handbook.

(b) Repairs have been attempted by persons

other than Nautech approved Service personnel.

(c) The warranty card has not been completed

correctly or is not accompanied by proof of

purchase.

Claim Procedure

1. The product should be sent direct to Nautech or its

appointed Distributor or Service Centre nearest to

the vessel. The completed Warranty Card and

proof of purchase must accompany the claim. The

product will then be serviced free of charge and

returned promptly direct to the sender.

2. Nautech, its Distributors and Service Centres, are

not liable for any charges arising from visits to the

vessel not to attend to the product, whether under

warranty or not, nor for sea trials or any other work

associated with the installation, The right is

reserved to charge for any such services at the

local rate.

After Sales Service

Your ST7000 is designed to give you long service and

reliable performance wherever you sail. To ensure that

you can always receive prompt and expert attention in

case of any difficulty, Nautech has established a

worldwide network of Autohelm Service Centres.

Please contact your nearest Service Centre for

assistance. Always have ready:-

- Your warranty card.

- Proof of purch

16

44318/5

Page 19

Page 20

Raymarine Ltd.

Anchorage Park, Portsmouth

Hampshire, P03 5TD, UK.

Telephone +44 (23) 92 693611

Fax +44 (23) 92 694642

www.raymarine.com

Loading...

Loading...