Page 1

ST60 Tridata

Instrument

Owner’s

Handbook

Document number: 81040-4

Date:10 November 2002

Page 2

Raymarine, ST60and SeaTalk aretrademarks ofRaymarine Limited

© Handbook contents copyright Raymarine Limited 2002

Page 3

i

Important information

Safety notices

WARNING: Product installation & operation

This equipmentmust beinstalled and operated in accordance with

theRaymarine instructionsprovided.Failureto doso couldresultin

personal injury,damage toyour boat and/or poor product

performance.

WARNING: Electrical safety

Make sure you haveswitched offthe power supply before youstart

installing this product.

WARNING:

Although we have designedthis productto be accurate and reliable,

many factorscan affect its performance. Therefore, it shouldserve

only as anaid to navigation and should neverreplace commonsense

and navigational judgement. Always maintain apermanent watch

so you canrespond to situations as they develop.

EMC conformance

All Raymarineequipment and accessories are designed tothe best

industry standards foruse in the recreational marineenvironment.

The designand manufacture of Raymarineequipment and accessories

conform to the appropriate Electromagnetic Compatibility (EMC)

standards, but correctinstallation is required to ensure that performance

is notcompromised.

Handbook information

Tothe best of our knowledge,the information in this handbookwas

correct whenit went topress. However,Raymarine cannot accept

liability forany inaccuracies oromissions it maycontain.

In addition, our policy of continuous productimprovement may change

specifications withoutnotice. Therefore, Raymarine cannot accept

liability for anydifferences betweenthe product and the handbook.

Page 4

ii ST60 Tridata Instrument Owner’s Manual

Page 5

iii

Contents

Important information ..........................................................................................i

Safety notices ................................................................................. i

EMC conformance ........................................................................i

Handbook information .................................................................. i

Introduction ......................................................................................................... vii

Data inputs ..................................................................................vii

SeaTalk ....................................................................................... vii

Stand alone operation.................................................................viii

Remote control ..........................................................................viii

Mounting options.......................................................................viii

Parts supplied ............................................................................... ix

Chapter 1: Operation .........................................................................................1

1.1 Gettingstarted ...............................................................................1

Displayed information ..................................................................1

1.2 Normaloperation .......................................................................... 1

Depth ............................................................................................ 2

Current depth display ..............................................................2

Depth alarmthreshold displays ...............................................3

Speed ............................................................................................ 3

Boat speed ............................................................................... 3

Maximum speed .....................................................................4

Average speed ......................................................................... 4

Velocity made good (to windward) ......................................... 4

Trip ................................................................................................ 5

Log .......................................................................................... 5

Trip screen ............................................................................... 6

Water temperature ...................................................................6

Timers ..................................................................................... 6

1.3 Alarms ..........................................................................................7

1.4 Display settings ............................................................................. 7

Illumination .................................................................................. 7

Contrast .........................................................................................8

1.5 Remote control ............................................................................. 8

Chapter 2: Maintenance and Faultfinding ......................................................9

2.1 Maintenance .................................................................................9

Servicing andsafety ...................................................................... 9

Instrument ..................................................................................... 9

Transducers ................................................................................... 9

Cabling ........................................................................................ 10

Page 6

iv ST60 Tridata Instrument Owner’s Manual

2.2 Faultfinding ................................................................................ 10

Preliminary procedures ...............................................................10

Fixing faults ................................................................................ 10

Technical support ........................................................................11

World wide web .................................................................... 11

Telephone help line ............................................................... 11

Help usto help you ................................................................12

Chapter 3: Installation .....................................................................................13

3.1 Planningyour installation ........................................................... 13

Site requirements ........................................................................ 13

Transducers ...........................................................................13

Instrument ............................................................................. 15

EMC InstallationGuidelines ......................................................16

Suppression Ferrites ..............................................................17

Connections to Other Equipment ..........................................17

3.2 Procedures ..................................................................................18

Unpacking ...................................................................................18

Fitting theinstrument .................................................................. 18

Surface mounting .................................................................. 18

Flush mounting ..................................................................... 19

Bracket mounting ..................................................................22

Fitting transducer ........................................................................23

Running transducer cable ......................................................23

Connecting the instrument ..........................................................24

Types of connection ..............................................................24

Signal connections ................................................................24

Power supplyconnections ....................................................25

Chapter 4: Calibration .....................................................................................27

4.1 Introduction ................................................................................27

Speed readings ............................................................................27

EMC conformance...................................................................... 27

4.2 Usercalibration ...........................................................................27

Depth ........................................................................................... 29

Depth units ............................................................................29

Depth offset ...........................................................................29

Shallow alarmlock ............................................................... 30

Speed ........................................................................................... 31

Set speedunits ....................................................................... 31

Set speedresolution ..............................................................31

Set logunits ........................................................................... 31

Setting thecorrect speed .......................................................31

Adjust toSOG .......................................................................33

Page 7

v

Set temperatureunits ............................................................ 33

Temperature calibration ........................................................ 33

Timer alarm buzzer ...............................................................33

Leaving Usercalibration ............................................................. 33

4.3 Intermediate calibration ..............................................................34

Speed calibration ........................................................................35

Leaving Intermediatecalibration ................................................39

4.4 Dealer calibration ....................................................................... 39

User calibrationon/off ................................................................39

Response settings ........................................................................ 39

Boat showmode ..........................................................................41

Factory defaults ..........................................................................41

Leaving Dealercalibration ......................................................... 41

Page 8

vi ST60 Tridata Instrument Owner’s Manual

Page 9

vii

Introduction

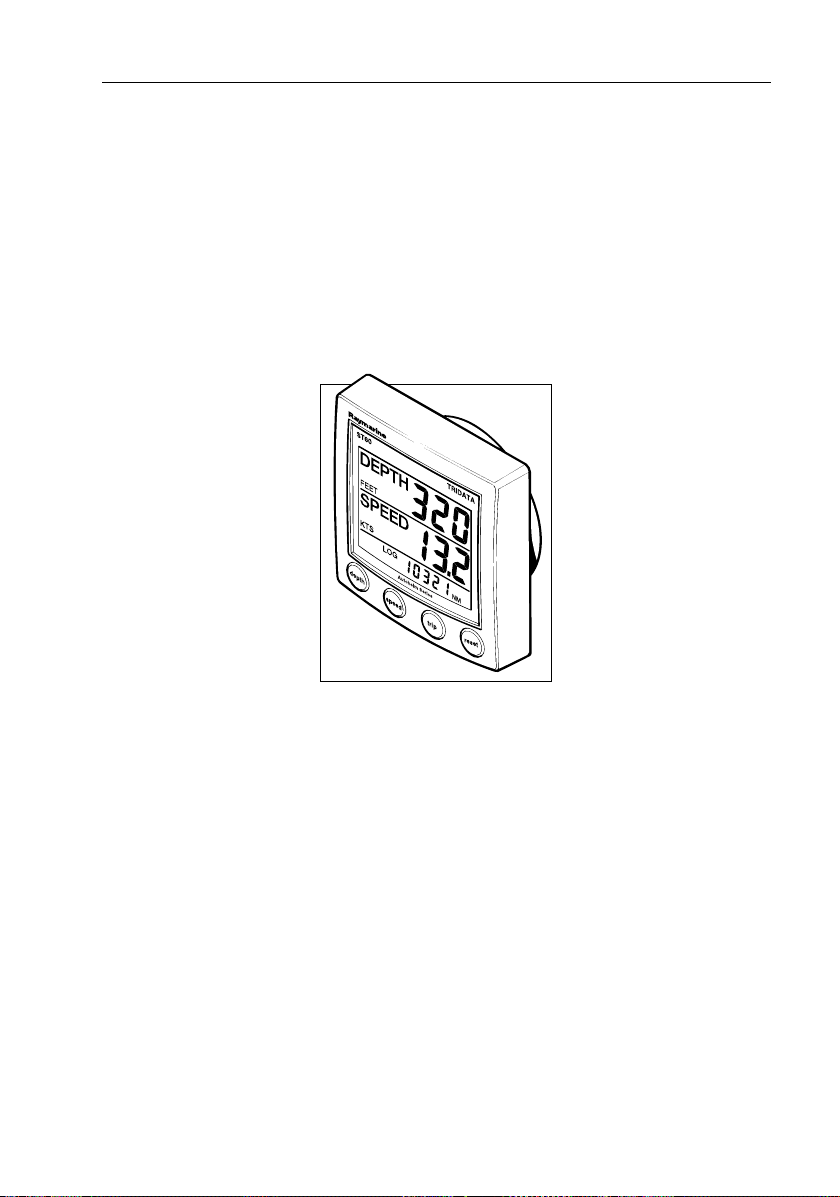

Thank youfor purchasing a Raymarine product.We are sure yourST60

instrument will giveyou many years oftrouble-free operation.

This handbook describeshow to install anduse the Raymarine ST60

Tridata instrument. Thisinstrument provides accuratedepth, speed, trip

and timer information, on ahigh quality Liquid Crystal Display (LCD).

The instrument is constructed in arugged weather-proofedcase to provide reliable performance,even under the most demanding conditions.

Data inputs

The ST60Tridata instrument can fulfil master and/orrepeater roles by

receiving data either from the appropriate transducers and/or from a

SeaTalk instrumentation system.

SeaTalk

SeaTalk enables a number of compatible instruments to operate asa

single, integrated navigationalsystem. Instrumentsin a SeaTalk system

are linkedby means ofa single cable, which feeds both power and data.

Instruments can thereforebe added to thesystem by plugging them into

the network.SeaTalk isflexible enough to adaptto any numberof

compatible instrumentswithout requiring acentral processor. SeaTalk

can alsocommunicate viaan interface, withnon-SeaTalk equipment

using theinternationally-accepted NationalMarine Electronics

Association (NMEA) protocol.

D4324-1

Page 10

viii ST60 Tridata Instrument Owner’s Manual

In a SeaTalk system,each instrument can be either a master ordedicated

repeater unit.A master instrumentis directly connectedto a transducer

(the device thatprovides the raw data),and provides data andcontrol for

the service itis providing,to allother equipment on the SeaTalk network.

A slave instrument is not directly connected to atransducer but repeats

information provided byother equipment in the SeaTalk network.

Stand alone operation

In Stand alone operation,the ST60 Tridatainstrument is connected only

to the relevant transducer and doesnot display information from, or

provide information to, anyother instruments.

Remote control

When connectedto SeaTalk,the ST60 Tridata instrument canbe

controlled remotelyby a SeaTalkRemote Keypad Unit,to provide

instant remoteaccess to the variousdisplay readouts.

Mounting options

If you donot want to surface mount your ST60 instrument, optionsare

available for:

• Flushmounting. If you have orderedthe flushmounting option alowprofile bezel and four fixing screwsare also provided.

• Bracket mounting.

Page 11

ix

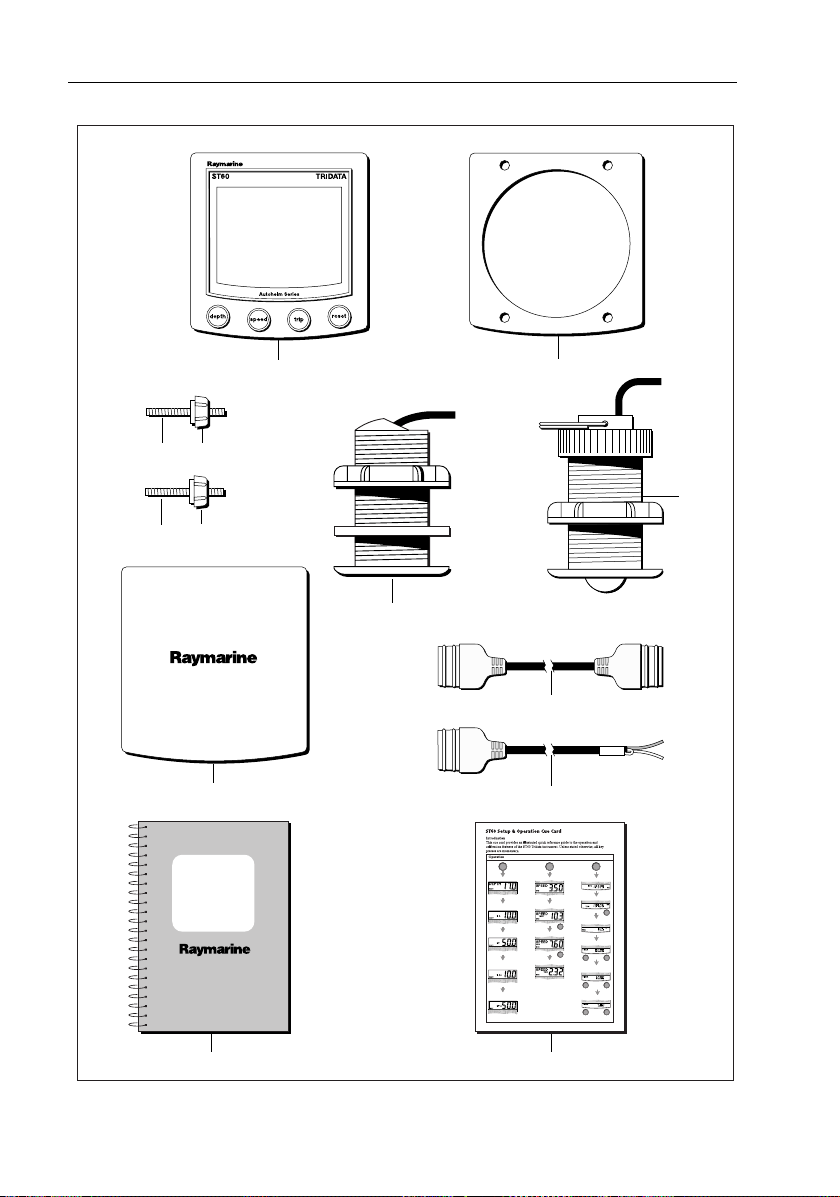

Parts supplied

Unpack your ST60instrument and check thatthe following items are

present:

• Item 1, ST60 Tridata instrument fitted with standard bezel for

surface mounting.

• Item2, Fixingstuds (2).

• Item 3, Thumb nuts(2).

•Item4,Gasket.

• Item 5, Depth transducer.

• Item 6, Speed transducer,plus bung (not illustrated).

• Item 7, SeaTalk interconnectioncable.

• Item 8, Power cable.

• Item 9, Instrument Cover.

• Item 10, Owner’sHandbook. A Warranty documentand fitting

templates are includedin this Handbook.

•Item11,CueCard.

Spare spadeterminals are alsoprovided, to re-terminate thetransducer

cable ifit hasto be cut to facilitate installation.

Note:The above packing list is for an ST60 Tridata system. Where an

instrument is purchased separately, Speed and D epth transducers are

not included.

Page 12

x ST60 Tridata Instrument Owner’s Manual

32

32

9

ST60

Tridata

Instrument

Owner's

Handbook

1

4

6

5

7

8

TRIDATA

trip

speed

depth

Current

Boat speed

Maximum

speed

Average speed

VMG to

windward

Log

Trip

reset

3s

to Reset

Water

temperature

reset

3s

to Reset

Count-up timer

reset

reset

reset

3s

to Reset

3s

to Reset

Start/Stop

10 minute

race start time

reset reset

3s

to Reset

Start/Stop

5 minute

race start timer

reset reset

3s

to Reset

Start/Stop

depth

Shallow Alarm

Threshold

Deep

alarm threshold

Anchor shallow

alarm threshold

Anchor deep

alarm threshold

1110

D4441-4

Page 13

Chapter 1: Operation 1

Chapter 1: Operation

1.1 Getting started

This handbook describeshow to operate, maintainand install the

Raymarine ST60 Tridata instrument.

CAUTION:Calibration requirement

The ST60Tridata instrument is calibrated to factory (default)

settings when firstinstalled and must therefore be calibrated before

use, inaccordance withthe procedures inChapter 4,Calibration,to

ensure optimum performance on your vessel.

Do NOT use theinstrument until the calibrationprocedures have

been satisfactorily completed.

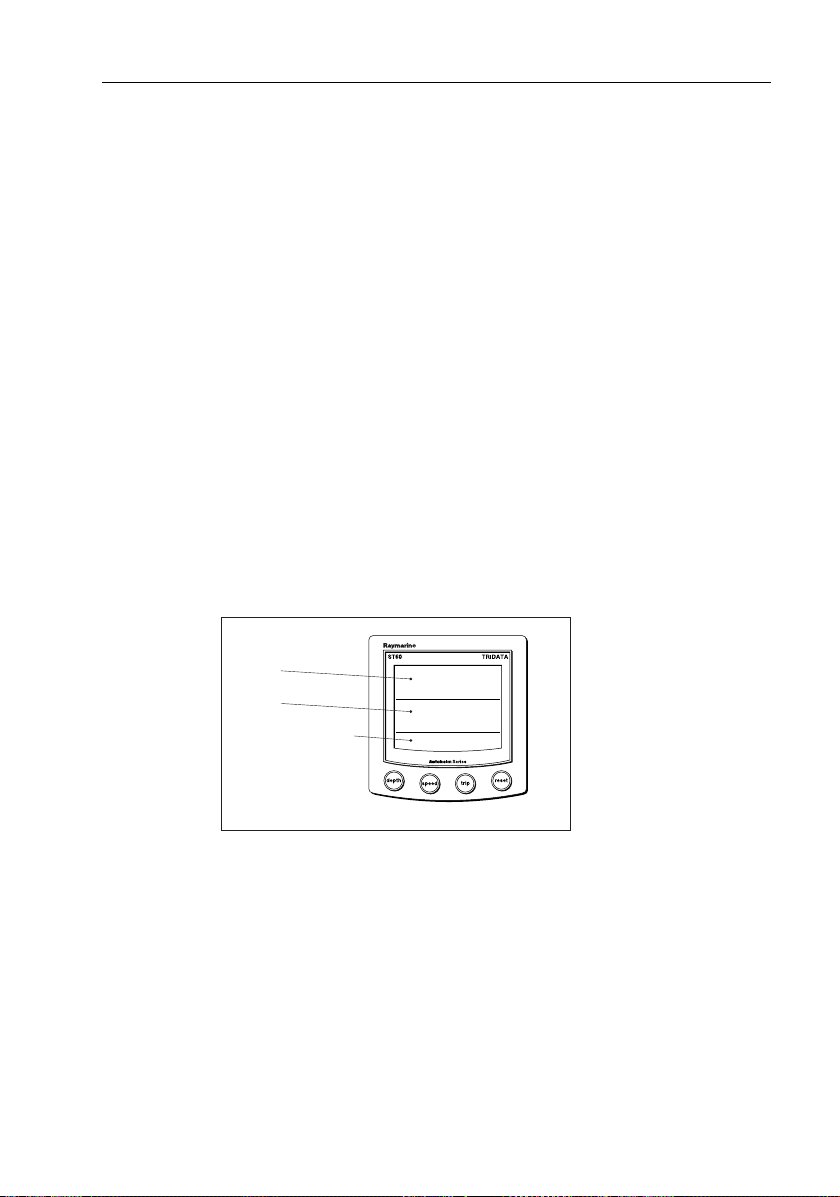

Displayed information

The ST60Tridata instrumentscreen is divided into three separate areas,

each of which displaysa separate type ofinformation,as shownin the

following illustration.

Depth

Speed

Trip, log, water

temperature & timer

Screen layout

1.2 Normal operation

Use theflow charts in this Chapterto operate your ST60 Tridata

instrument. Flow chartsare provided for:

•Usingthe

Onmaster instruments,this alsogives accessto depthalarm threshold

information, and allowsyou to set the alarmthresholds.

•Usingthe

speed andVelocityMade Good (VMG) to windward.

depth key. This gives accessto current depth information.

speed key. This givesaccess to maximumspeed, average

D4424-2

Page 14

2 ST60 Tridata Instrument Owner’s Manual

•Usingthetrip keyto gain accessto log, trip, water temperature and

timer information.

All keypresses are momentary unlessotherwise stated.

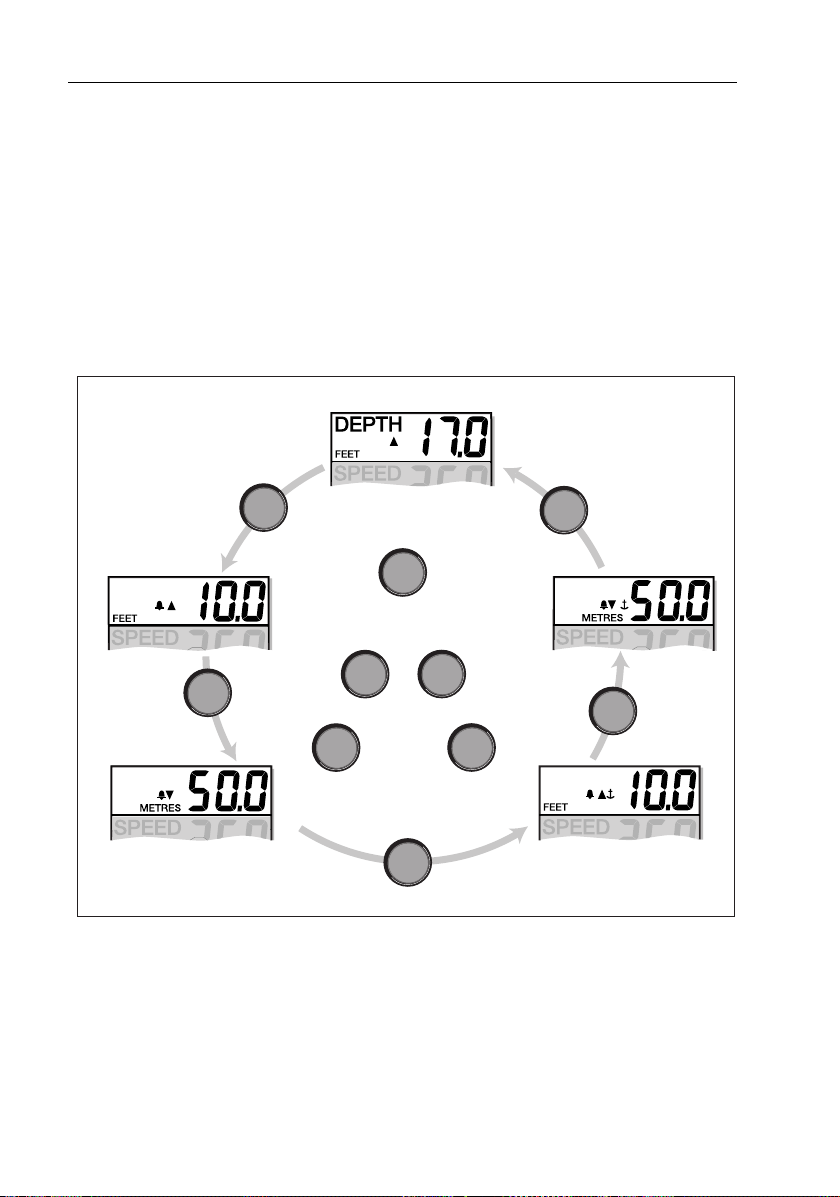

Depth

Use thedepth key to selectthe required information, asshown in the

Using the depth key illustration. The depth measurement units are either

feet ormetres, as selected during user calibration (see Chapter 4,

Calibration).

Current depth

Shallow

alarm threshold

depth

Deep

alarm threshold

Using the depth key

Current depth display

The current depth screen shows thetitle DEPTH, the selected depthunits

and the depthmeasurement. It also showsa depth trend indicator, which

is either an up arrowto show seabed rising or a down arrowto show

seabedfalling.

depth

To enable/disable any alarm

for 2 seconds

reset

Press

To enter and exit alarm adjust mode

Press

trip

In adjust mode, use

trip

to decrease or

(toggle action)

reset

and together

reset

depth

to increase

depth

Anchor deep

alarm threshold

depth

Anchor shallow

alarm threshold

D4413-1

Page 15

Chapter 1: Operation 3

If forany reason depth information is lost, the DEPTH title will flash once

per secondand the displayed depth valuewill be the lastgood reading.

Depth alarm threshold displays

The alarmthreshold displays areavailable if the instrument is operating

as a master.Each displayis identifiedby thepresence ofan alarmsymbol

( )and eitheran uparrow for ashallow alarm or a down arrow for a deep

alarm. The shallow anddeep anchoralarms areidentified by means of an

additional anchor icon.

You canenable and disableindividual alarmthresholds by pressing the

reset key for 2 seconds, whilethe relevant alarm threshold is displayed.

Each alarmthreshold is displayedfor a nominal 7seconds, and ifno

action is taken during that time, the display will timeout to the current

depth display.

Adjusting alarm thresholds

Toadjust the alarm threshold levels, press the

simultaneously to enteradjust mode, then use either the

decrease) orthe

have setthe requiredvalue,pressthe

alarm settingand exit theadjust mode.

reset key (to increase) the threshold value. When you

tripand reset keysagain, to savethe

trip andreset keys

trip key (to

Note:Adjustment of the shallow alarm threshold can be disabled duri ng

calibration. When adjustment is di sabled, you cannot enter adjust mode.

Speed

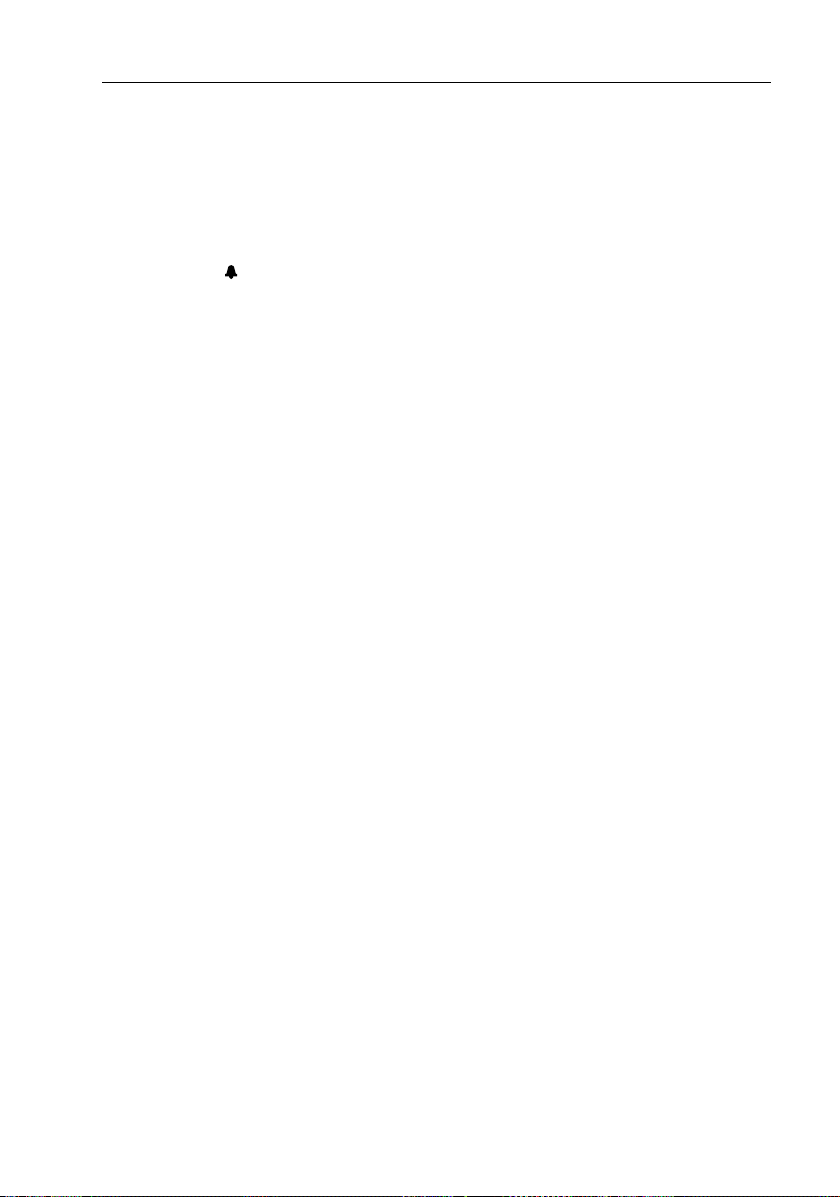

Use the speed keyto select the requiredinformation, as shown in the

Using the speed key illustration. The speed measurement units areeither

knots (KTS), milesper hour (MPH) orkilometres per hour (KMH),as

selected during usercalibration (see Chapter 4, Calibration).

The maximumspeed, average speed andVMG to windward are each

displayed for anominal 7 seconds, and if no action istaken during that

time, the display will timeout tothe Boat speed display.

Boat speed

Shows thecurrent speed and selected speed units.

Page 16

4 ST60 Tridata Instrument Owner’s Manual

Boat speed

speed

Maximum

speed

speed

Using the speed key

Average speed

speed

speed

VMG to

windward

D4414-1

Maximum speed

The screen shows the maximumspeed attained sincethe lastreset.

The maximum speed value is resetautomatically at power-up. If the

instrument is operating as a master, the maximum speed canalso bereset

manually by pressing the

reset key for 2 seconds.

Average speed

The screen shows the averagespeed since the last reset.

The averagespeed value is resetautomatically at power-up. If the

instrument isoperating as a master, the average speedcan also bereset

manually by pressing the

reset key for 2 seconds.

Velocity made good (to windward)

Velocity made good (VMG) information isavailable if your instrument is

partof aSeaTalksystemto whicha SeaTalk-compatiblewind instrument

is alsoconnected.

Page 17

Chapter 1: Operation 5

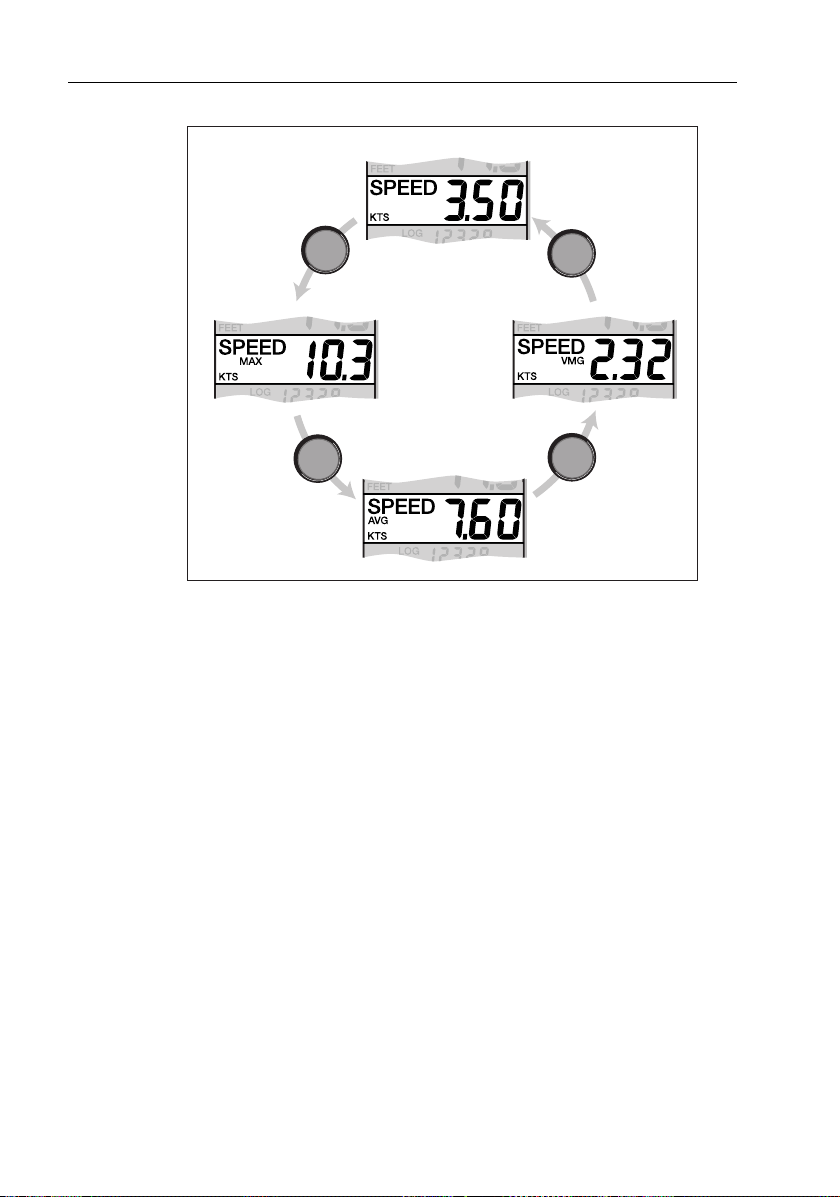

Trip

The trip key gives accessto log, trip,water temperature andtimer

displays, as shown inthe Using the trip key illustration.

trip

Water

temperature

Trip

Count-up

timer

Race start

timer 1

To enter/leave

adjust mode, press

trip

and

momentarily

Using the trip key

Log

trip

trip

reset

Press

reset

to start timer, or for lap time (when running)

To set a different race start timer value, press

to decrease the value

either momentarily

or for 1 s to reset timer to start value.

trip

trip

reset

to increase the value

trip

trip

To enter/leave

adjust mode, press

and

momentarily

reset

trip

Log

Race start

timer 2

D4415-2

The Log screen shows the total distance covered by the vessel since the

instrument was fitted.

Page 18

6 ST60 Tridata Instrument Owner’s Manual

Trip screen

The tripscreen shows the distancecovered sincethe trip valuewas last

reset.

The trip value is reset automatically at power-up, and if theinstrument is

operating as a master, the tripvalue canalso be reset manually by

pressing the

reset key for 3seconds.

Water temperature

The watertemperature is shownin either degreesCelsius (°C)or

Fahrenheit (°F), asset during calibration (see Chapter 4, Calibration).

Timers

The count-up timer and tothe two race-start timer times areeither in

seconds (S) or minutes (M), depending on thecounter values.

Refer tothe Using the trip keyflow diagram to display the required timer.

Once you havedone this, press the reset key to start thetimer running.

When atimer is running,the delimiter (i.e.‘.’or ‘:’) flashes.For lap

timing, press the reset key. To stop andreset a timerto the startvalue,

hold down the reset key for 1 second.

Once a timer is running, you can leave the timer pageand selectany other

display. Thecounter will continue torun in the background.

Race-start timers

You canset each race-start timerto any whole-minutevalue from 1 to 15

minutes.

Note: Whe n the instrument is first instal led, the race-st art timers are s et

to 4 and 5 minutes respectively.

To set a race-starttimer:

1. Use thetrip keyas shown inthe Using trip key flow diagramto select

the requiredrace-start timer.

2. Simultaneouslypress the trip andreset keys to enter the race-start

timeradjust mode.

3. Use either the tripor reset key to set the required value.

4. Simultaneouslypress the trip andreset keys to save the value and

leave the race-start timer adjust mode.

Page 19

Chapter 1: Operation 7

If youare using one ofthe race-start timers andthe timerbuzzer is

enabled, thebuzzer will:

• Double-beep every minute.

• Beep three timesat the startof the last30 seconds.

• Beep once for each of the last10 seconds.

• Beep for 2 seconds atzero.

The timerbuzzer is enabledor disabled aspart of thecalibration

procedure (see Chapter 4, Calibr ation).

Note:After a race-start timer has counted-down to zero, it will then start

counting up.

1.3 Alarms

An alarmcondition occurs if:

• The depth is less than the SHALLOWor SHALLOW anchorthreshold.

• The depth isgreater than theDEEP anchor threshold.

• The depth crosses the DEEPthreshold.

An alarmcondition is indicated by analarm buzzer anda flashing alarm

symbol ( ) on the display. SHALLOW or DEEP alarmsare indicated byup

and downarrows respectively,and for anchor alarmsan anchor symbol

( ) is displayed.

When theinstrument is operating as amaster, youcan check thealarm

thresholds and ifnecessary set them up,as detailed under Normal

operation - Depth.If an alarm isnot enabled, the associateddisplay

shows an OFF legend.

1.4 Display settings

Illumination

When theinstrument is first powered up, the display illumination is set to

its lowest (courtesy) level, to facilitate initial access to the keys.

To adjust thelevel of display illumination:

1. Hold down the

illumination-adjust mode.

2. There are four presetillumination levels. Use the

through theselevels until you reachthe level you want.

depth key for approximately one second, toenter the

depth keytocycle

Page 20

8 ST60 Tridata Instrument Owner’s Manual

3. Press any other keyto leave the illumination-adjust mode.

Note: The displ ay will also return to normal operation 7 seconds after

the last key press.

Contrast

To adjust the display contrast:

1. Holddown the

contrast-adjust mode.

2. There are fourpreset contrastsettings. Use the

through these settings until you achieve optimum display quality.

3. Press any other keyto leave the contrast-adjust mode.

Note: The displ ay will also return to normal operation 7 seconds after

the last key press.

1.5 Remote control

When itis connected toSeaTalk, the ST60 Tridata instrument canbe

controlled remotelywith a SeaTalk Remote Keypad Unit. Remote

control ofan instrument is indicated by a REMOTE legend on thedisplay,

to indicate that the keypad hascontrol.

Details on howto use the remote control facility can befound in the

SeaT alk Remote Keypad Owner’s Handbook.

depthkey forapproximately twoseconds, toenter the

depth keytocycle

Page 21

Chapter 2: Maintenance and Faultfinding 9

Chapter 2: Maintenance and Faultfinding

2.1 Maintenance

Servicing and safety

• Raymarine equipmentshould beserviced onlyby authorised Raymarine service technicians. They willensure thatservicing procedures

and replacementparts used will not affectperformance. There are no

user-serviceable parts inany Raymarine product.

• Some products generate highvoltages, and so never handlethe

cables/connectors when power is being applied tothe equipment.

• When powered up,all electrical equipmentproduces electromagnetic fields.These can cause adjacent pieces ofelectrical equipment

to interactwith oneanother,with aconsequent adverse effecton operation. In order to minimise theseeffects and enable youto getthe best

possible performance from your Raymarine equipment, guidelines

are given in theinstallation instructions, toenable you to ensureminimum interactionbetween different itemsof equipment, i.e. ensure

optimum Electromagnetic Compatibility (EMC).

• Always report any EMC-relatedproblem to your nearest Raymarine

dealer.We usesuch information toimprove ourquality standards.

• In someinstallations, it maynot bepossible to prevent theequipment

from beingaffected by external influences.In general thiswill not

damage the equipmentbut it can leadto spurious resetting action, or

momentarily may resultin faulty operation.

Instrument

Certain atmospheric conditionsmay cause condensation toform on the

instrument window. Thiswill not harmthe instrument andcan becleared

by increasing theillumination setting toLevel 3.

Periodically clean your ST60instrumentwitha softdamp cloth.Do NOT

use chemical and abrasive materials to clean the instrument.

Transducers

Refer tothe Installation and Maintenance instructions suppliedwith the

transducers.

Page 22

10 ST60 Tridata Instrument Owner’s Manual

Cabling

Examine all cables forchafing or other damage to theouter shield and,

where necessary, replaceand re-secure.

2.2 Fault finding

Preliminary procedures

Changes in the electronic environment mayadversely affect the operation ofyour ST60 equipment. Typical examplesof such changes are:

• Electrical equipmenthas recently beeninstalled or movedaboard

your vessel.

• Youare inthe vicinityofanother vessel or shorestation emitting radio

signals.

If you appearto have a problem,first ensure that theEMC requirements

(see Chapter3, Installation) are still being met before further

investigating the problem.

Fixing faults

All Raymarine products are subjected to comprehensive testand quality

assurance programmesprior topacking andshipping. However, if a fault

occurs, the followingtable may help toidentify and rectify the problem.

Fault Cause Remedy

Instrument display blan k. No power supply. Check power supply.

Check SeaTalk cabling and connector

security.

Check fuse/circuit breaker.

No speed or temp erature

information.

No speed information.

No exc han ge o f inf orm ation between SeaTalk

instruments

Speed transducer

cabling problem.

Speed transducer

paddle wheel fouled

SeaTalk cabling

problem.

Check cabling and security of

transducer connections.

Clean paddle wheel.

See CAUTION below.

Check the security of SeaTalk

connectors.

Disconnect instruments one by one, to

isolate faulty unit

Page 23

Chapter 2: Maintenance and Faultfinding 11

Fault Cause Remedy

Failure of group of

instruments in SeaTalk

chain.

LAST flashes or dashes

displayed continuously

(depth greater than 3 feet).

LAST flashes while under

way.

SeaTalk cabling or

connector problem.

Depth transducer or

connection problem.

Aerated water

Boat wake

Prop wash etc

Check the security of SeaTalk

connections between functioning and

non-functioning instruments.

Check depth transducer cable and

security of transducer connections.

Ensure readings stabilise when clear of

disturbed water.

CAUTION:

If youneed to remove the Speed transducer insert, havethe

transducer bung to hand and secure it in thetransducer body

immediately after the inserthas been removed, to prevent excessive

ingress of water.

Technical support

Raymarine provides acomprehensive customer support service, onthe

world wideweb and bytelephone help line. Please use either ofthese

facilities if you areunable to rectify a problem.

World wide web

Please visit the CustomerSupport area of our website at:

www.raymarine.com

As well as providing a comprehensive Frequently AskedQuestions

section and servicing information, it also givese-mail access to the

Raymarine Technical Support Departmentand a details of the locations

of Raymarine agents,worldwide.

Telephone help line

If youdo not have accessto the world wideweb, please call:

1-800-539-5539, extension 2444 or

(603) 881-5200 extension 2444

Page 24

12 ST60 Tridata Instrument Owner’s Manual

Help us to help you

When requesting service,please quote the following product

information:

• Equipment type.

• Model number.

• Serial number.

• Software issue number.

The Softwareissue number can beascertained by meansof the

Intermediate Calibration facility, see Chapter 4, Calibration.

Page 25

Chapter 3: Installation 13

Chapter 3: Installation

This chapterdescribes how toinstall the ST60Tridata instrument, and

associated Speedand Depthtransducers. Thetransducers arefitted in the

hull ofthe vessel and connected to the rearof the instrument.The actual

type oftransducers depends on the typeof hull in whichthey are to be

installed.

For advice, or further information regarding the installation of this

equipment, please contact the Raymarine Product Support Department

or your own National Distributor.

3.1 Planning your installation

Before starting the installation, spend some timeconsidering thebest

positions for bothtransducer and instrument, such thatthe Site

Requirements and the EMC Guidelines (below) aresatisfied.

Site requirements

Transducers

Speed

75 mm (2.94 in)

diameter

51 mm (2.0 in)

diameter

75 mm (2.94 in)

diameter

14 mm

(0.57 in)

100 mm

D4447-4

75 mm (2.94 in)

diameter

95 mm (3.75 in)

51 mm (2.0 in)

diameter

75 mm (2.94 in)

diameter

Depth

5 mm

(0.19 in)

The transducertypes required for the varioushull types are asfollows:

(3.95 in)

Page 26

14 ST60 Tridata Instrument Owner’s Manual

Hull material Speed transducer Depth transducer

Glass reinforced

plastic (GRP)

Steel M78712 Through hull plastic M78713 Through hull plastic or

Aluminium M78712 Through hull plastic M78713 Through hull plastic or

Wood M78716 Through hull bronze M78714 Through hull bronze or

M78712 Through hull plastic M78713 Through hull plastic or

M78718 Retractable through hull

M78718 Retractable through hull

M78718 Retractable through hull

M78719 Retractable through hull

bronze

Other transducer typesare also available for specificrequirements. For

further details, contact your local Raymarine dealer.

For accuratespeed and depth readingsthe transducers should be sited

within the clear water flow areas indicated by the shaded areas inthe

following diagram.

Sailing vessel

Planing power

vessel

Displacement power

vessel

Transducer siting

D4349-1

The transducers shouldalso:

• Be ahead ofthe propellers(by a minimum of 10% of thewater line

length).

• Be at least150 mm (6 in) awayfrom the keel (ideallyahead of the

keel ifa sailing yacht).

Page 27

Chapter 3: Installation 15

• Be as nearas possible tothe centre lineof the vessel.

• Be clear of otherthrough-hull fittingsor projections.

• Have sufficient clearance inside thehull to fit the nut.

• Have 100 mm (4 in) of headroom to allow for withdrawal.

In additionto the above requirements, thedepth transducer must be

mounted within 10

Maximum transducer angle

0

of thevertical, forward, aftand athwart ships.

10˚ maximum

D4350-3

Instrument

CAUTION:

The presenceof moistureat therear ofthe instrument could cause

damage either by entering the instrumentthrough the breathing

hole orby coming intocontact with theelectrical connectors.

ST60 instrumentscan be fittedeither above or belowdeck, provided the

rear ofthe instrument is sited whereit is protectedfrom contact with water.

Each instrumentmust also be positioned where:

• It is easilyread by thehelmsman

• It is protected against physical damage

• It is at least 230 mm (9 in) from a compass

• It is atleast 500 mm (20 in) from radio receiving equipment

• There is reasonablerear access forinstallation andservicing

Page 28

16 ST60 Tridata Instrument Owner’s Manual

With standard

bezel

diameter

90mm (3.54in)

115mm (4.53in)

With low

profile bezel

110mm (4.33in)

123mm (4.85in)

6.2mm

(0.25in)

24mm

(0.95in)

35mm

(1.4in)

15mm

(0.6in)

ST60 instrument dimensions

EMC Installation Guidelines

All Raymarineequipment and accessories are designed to the best

industry standards for usein the recreational marineenvironment.

Their design and manufacture conforms tothe appropriate

Electromagnetic Compatibility (EMC) standards,but correctinstallation

is required to ensure that performanceis not compromised. Although

every effort has been taken toensure that they will perform under all

conditions, it isimportant tounderstand what factors couldaffect the

operation of theproduct.

The guidelines given here describe theconditions foroptimum EMC

performance, but it is recognized that it may not be possibleto meetall of

these conditions in allsituations. To ensure the best possible conditions

for EMC performancewithin the constraints imposed by any location,

always ensure themaximum separationpossible betweendifferent items

of electricalequipment.

diameter

90mm (3.54in)

123mm (4.85in)

D5785-1

Page 29

Chapter 3: Installation 17

For optimum EMC performance, it isrecommended that wherever

possible:

• Raymarine equipment andcables connected toit are:

• At least 3ft (1 m) fromany equipment transmitting orcables carrying radio signals e.g. VHF radios, cables and antennas. Inthe

case of SSB radios, the distance shouldbe increased to 7 ft(2 m).

• More than 7 ft(2 m) from thepath of aradar beam. A radarbeam

can normally be assumed tospread 20 degreesabove and below

the radiatingelement.

• The equipment is supplied from a separate batteryfrom that used for

engine start. Voltage dropsbelow 10 V in thepower supply to our

products, and starter motor transients, can cause the equipment to

reset. This willnot damage the equipment, butmay cause the loss of

some information andmay change the operatingmode.

• Raymarine specified cablesare used. Cutting andrejoining these

cables cancompromise EMC performance andmust be avoided

unless doing so is detailed in the installation manual.

• If a suppression ferrite is attached to acable, thisferrite should notbe

removed. If theferrite needsto beremoved during installation it must

be reassembled inthe same position.

Suppression Ferrites

The following illustrationshows typical cable suppression ferritesused

with Raymarine equipment.Always use theferrites suppliedby

Raymarine.

D3548-2

Connections to Other Equipment

Ifyour Raymarineequipmentis tobeconnected tootherequipmentusing

a cablenot supplied by Raymarine, a suppression ferriteMUST always

be attachedto the cable near the Raymarineunit.

Page 30

18 ST60 Tridata Instrument Owner’s Manual

3.2 Procedures

As it is not possible to describeprocedures for all possible installation

scenarios, the procedures given heredescribe the broad requirements for

installing theSpeed and Depthtransducers and the ST60 Tridata

instrument. Adapt theseprocedures as appropriate, to suityour

individual requirement.

CAUTION:

Where itis necessary to cut holes (e.g.for cable routing and

instrument mounting), ensure thatthese will notcause ahazard by

weakening criticalparts of the vessel’s structure.

Unpacking

Unpack your ST60 equipment and checkthat the items describedin

Introductionare present.

Each ST60instrument is supplied witha standard bezelfor surface

mounting. Optional mounting kitsare available for flush mounting and

bracket mountingthe instrument.If you haveordered the flush mounting

option a low-profile bezel and four fixingscrews are also provided.

Fitting the instrument

The ST60 Tridata instrument can beinstalled usingone of a numberof

different mounting options:

• Surface mounting. Gives a profileof approximately 24 mm.

• Flush mounting. Gives a profile of approximately6 mm.

• Bracket mounting.

The ST60 instrumentscan also be mountedbehind a panel with just the

instrument dialand keys visible.

Surface mounting

To surface mount your ST60instrument (seethe S urface mounting

illustration):

1. Ensure that:

• The selected location is clean, smooth and flat.

• There is sufficientspace behind the selected location toaccommodate the rearof the instrument andconnectors.

Page 31

Chapter 3: Installation 19

11223455

Surface mounting

D4343-2

2. Apply the surface mounttemplate (suppliedat the rear ofthis handbook)to theselected location andmark thecentres forthe fixingstuds

(1) and the aperture (3) that will take the rear casing ofthe instrument.

3. Drill out the two5 mm fixing stud clearance holes(2).

4. Cut out the clearance hole (3)then remove the template.

5. Peel off the protective sheet fromthe self-adhesive gasket(4) then

stick the gasketinto position on the rearof the instrument.

6. Screwthe twofixing studs intothe threaded sockets on the rear ofthe

instrument.

7. Mount the assembled instrument, studs,bezel and gasketinto the

panel. Secure frombehind with the thumb nuts(5).

Flush mounting

The FlushMounting Kit usesa low-profile bezelto reduce thefitted

profile of the instrument, to approximately 6 mm above thepanel fascia.

Page 32

20 ST60 Tridata Instrument Owner’s Manual

Fitting the low-profile bezel

In order toflush-mount yourST60 instrument,you must first replace the

standard bezelwith the low-profilebezel as follows:

1. Hold theinstrument in both hands with the display towards you.

D4537-2

2. Using both thumbs, gently press an upper corner of the instrument

from the bezel, then remove the bezel from the instrument. Retain the

rubber keypadwhich is releasedwhen the bezelis removed.

3. Referring to the Fitting the low-pr ofile bezelillustration, place the

instrumentface upwardson aflat surfaceand placethe rubberkeypad

(7) in positionaround the display window (i.e.so that each key outline islocated over itsassociated keyon the instrument).

4. Snap the low-profile bezel (8) in positionover the instrument, so that

the rubber keys are correctlylocated in theholes on the bezel.

CAUTION:

Itisessentialthat onlyscrewsof thecorrect size areusedto securethe

instrument tothe bezel. Failure to observe this cautioncould result

in damageto both theinstrument and thebezel.

5. Using the four, self-tapping screws (9)provided, secure the instrument and bezeltogether.Fit thescrews from the rearof theinstrument

and tightenthem sufficiently tosecure the instrumentand bezel

together.DO NOT OVERTIGHTEN.

Page 33

Chapter 3: Installation 21

789

Fitting the low profile bezel

D4362-2

Flush mounting procedure

Flush mount yourinstrument (seethe Flush mountingillustration) as

follows:

1. Assemble the ST60instrument and low-profile bezel as described

under Fitting the low-profile bezel.

2. Ensure that:

• The panel on which you intend to mountthe instrumentis

between 3 mmand 20 mm thickness.

• The selected location isclean, smooth and flat.

• There is sufficient space behind theselected locationto accommodate the rearof the instrument andconnectors.

3. Apply the flush mount template(supplied atthe rear of thishandbook) to theselected location andmark out the apertureinto which

the assembledinstrument and bezel will sit.

4. Cut out the aperture(3) for the assembled instrument andbezel and

remove the template.

5. Peel off the protective sheet fromthe self-adhesive gasket(4) then

stick thegasket into position onthe rearof the bezel.

Page 34

22 ST60 Tridata Instrument Owner’s Manual

Flush mounting

113

4

556

D5462-1

6. Screw the two fixingstuds (1)into the threaded sockets onthe rearof

the instrument.

7. Mount the assembled instrument, studs,bezel and gasket intothe

panel.

8. Locate the flush mount bracket (6) ontothe fixing studs and secure

the assembly to thepanel with the thumb-nuts (5).

Bracket mounting

A Control UnitMounting Bracket (PartNo. E25009) enables you to

mount your ST60instrument inlocations where otherforms ofmounting

are impractical. Although this provides auseful alternative method for

securingyour instrument,it is onlysuitable for use in positionswhere the

instrument will notbe exposed to water.

To bracket mount your ST60instrument, do so inaccordance with the

Control Unit Mounting Bracket Instruction Sheet.

Page 35

Chapter 3: Installation 23

Fitting transducer

The ST60Tridata instrument issupplied, with appropriate through-hull

Speed and Depth transducers.

Each transduceris supplied with detailed instructions for installation and

maintenance. Before attempting to install a transducer, read these

instructions and theSite requirem entsfor transducers described inthis

Chapter.

Once youare satisfied youcan meet allthe installation requirements,

install thetransducer in accordancewith the accompanying installation

instructions.

Running transducer cable

Each transducertype has a14 m (45 ft) cable fitted with spadeterminals

for connection to the ST60Tridata instrument. The mannerin whichyou

run thecable will depend onthe locations ofthe transducers and

instrument. The followingguidelines are provided:

• If the cablehas to be fed through the deck,always use aproprietary

deck gland.

• Where cables are fed throughholes, alwaysuse grommets to prevent

chafing.

• Secure long cableruns so they donot present a hazard.

• Do not route thecable throughbilges.

• Wherever possible, route the cableaway from fluorescent lights,

engines, radiotransmitting equipment, asthese may causeinterference.

• The transducer cablesare fitted with spade connectors fordirect connection to therear ofthe instrument.However,it maybe necessary to

remove these to facilitate installation, e.g. if a cablehas tobe routed

through narrow apertures.Extra spade connectors are provided,to

replace any that are removed whenrunning transducer cables. When

fitting spade connectors, prepare thecable asat (a) in the following

illustration, then foldback thewire strands and insert into the spade

connector as at(b). Ensure the wire strands do not extendbeyond the

rear ofthe spadeconnector insulation,then crimpthe connector tothe

wire.

Page 36

24 ST60 Tridata Instrument Owner’s Manual

50 mm

(a)

3 mm

(b)

Observing the aboveguidelines, run the transducer cables tothe ST60

Tridata instrument.

Connecting the instrument

Types of connection

The ST60 Tridata instrument, can beconnected:

• As a stand-alone,master instrument connecteddirectly toa Speed

and/or Depth transducer.

• As a SeaTalk repeater.

• Tofulfil bothrepeater and masterroles bybeing connectedboth tothe

transducer andto SeaTalk.

If instruments are connected to SeaTalk, noseparate powerconnection is

necessary. Where a SeaTalksystem includes an autopilot, the power for

the system is provided by the autopilot.

A rangeof RaymarineSeaTalk extension cables is available to connect

separatedinstruments.These cables are supplied with aSeaTalk

connector fitted to each end. Ajunction box can beused to joincables.

6 mm

D4467-6

Signal connections

Make the necessary connections to yourST60 instrument (see the

Connection to ST60 T ridata instrumentillustration).

Page 37

Chapter 3: Installation 25

SeaTalk cable SeaTalk cable

D

E

P

T

H

D

E

E

P

S

Black

Blue

Cable from Depth transducer

Cable from Speed transducer

Connections to ST60 Tridata instrument

Screen

Brown

White

Screen

Green

Red

D4423-1

Power supply connections

SeaTalk systems

CAUTION:

When instruments are connected to SeaTalk, ensurethat the power

supply for the SeaTalk 12 V line is protected by a 5 Afuse.

Systems with alarge numberof instruments on theSeaTalk bus may

require connections tothe power supply from each end of thesystem

(‘ring-main’ style), tomaintain sufficientvoltage throughout the system.

This requirementdepends onthe total length ofthe cable run andthetotal

number ofinstruments inthe system, as follows:

Cable run No. of instruments Power connections

Up to 10 m 13 maximum

26 maximum

Up to 20 m 7 maximum

13 maximum

1

2

1

2

Page 38

26 ST60 Tridata Instrument Owner’s Manual

Red

5 A fused,

12 V dc supply

(typically provided

by autopilot)

Screen

Red

Screen

1234

Instruments

5 to 16

20

19

18

17

SeaTalk power connections

D4311-1

Stand alone instruments

Stand-aloneinstruments arenot connected to SeaTalk andtherefore need

to beconnected to analternative 12 V powersource. Power cablesare

available in 2 mand 9 m lengths.

To fit a powercable:

1. Ensure the intended powersource is switched off. Ifyou are using a

12 V battery, ensure the power cable is not connected to the battery.

2. Runthe power cable from the instrument toa suitable12 V dc power

source.

3. If the cablehas not already beentrimmed at the powersupply end:

• Cut thecable to length andtrimback anappropriate amount ofthe

outer sheath.

• Cut back andinsulate the yellow wire.

4. Connect the screen tothe power supply 0 V terminal.

5. Connect the redwire via a3 A over-current circuit breakerto the

power supply +12 Vterminal.

Page 39

Calibration 27

Chapter 4: Calibration

4.1 Introduction

The ST60Tridata instrumentis set up withfactory-programmed default

settings, so inorder to optimise the performanceof the instrument on

board aparticular vessel, theprocedures in this Chapter mustbe carried

out immediately afterthe completion of installation and before the

equipment is used for navigational purposes.

Where practicable, the calibrationprocedures are presented

diagrammatically to showthe sequence of keypresses and the resulting

displays. Adjustment instructions are givenas applicable.

Speed readings

One ofthe reasons for calibration is toensure thatthe speed readings

displayed at the instrumentare atrue indication of the actual speedof the

vessel.

In User calibration - Speed, you can:

• Automatically setthe displayed speedreading to bethe same asthe

Speed OverGround (SOG) (if SOGdata is available).

• Manually apply acalibration factor, toset the displayedspeed tothe

requiredvalue.

If neitherof the above methods are suitable, you cancarry out aspeed

calibration run overa measured distance, toenable the instrument to

calculate thecorrect calibration factor. Thisis described aspart of

Intermediate calibration.

EMC conformance

Always checkthe installation beforegoing to seato make sure that it is

not affected by radiotransmissions, enginestarting etc.

4.2 User calibration

The Usercalibration procedures enable you to:

• Set the requiredunits for depth readings.

• Set the offset fordepth readings,i.e. determine whether depth readings arefrom the keel ofthe vessel orfrom the waterline.

Page 40

28 ST60 Tridata Instrument Owner’s Manual

• Lock the shallow alarm.

• Set the requiredunits for speedreadings.

• Set the speed resolution.

• Select the logdistance units

• Either calibrate the speed reading to Speed Over Ground (SOG) or

manually apply acalibration factor, to obtain correctspeed through

the water.

• Select temperature units.

• Calibrate for correcttemperature readings.

• Set timer alarmbuzzer on or off.

Separate routines are provided for theUser calibration of thedepth and

speed functions. To carryout either of these routines:

1. Power up the ST60Tridata instrument.

To start User calibration

hold down

and

depth

for approximately 2 seconds

speed

User calibration

entry screen

User calibration - depth

see illustration

User calibration - speed

see illustration

D4416-1

Starting User calibration

2. Press the

depth and speed keys for approximately 2 seconds so that

press either

or

depth

speed

the User calibration entry screen is displayed.

3. Carry out the Usercalibration procedures for Depthand Speed.

Page 41

Calibration 29

Depth

Tocalibrate the depth functions:

1. With theUser calibrationentry screendisplayed, press the

2. Referringto theUser calibration - depthillustration, carry out thecal-

ibration procedure. Use the

and the

trip and reset keys toset the required valuesat each screen.

depth keytocyclefromscreentoscreen

Depth units

You canset either FEETor METRES.

From User calibration

start screen

Set depth

units

depth key.

depth

Set depth

offset

User calibration - depth

depth

Shallow

alarm lock

depth

D4417-1

Depth offset

WARNING:

The use ofincorrect offsetvalues could result in misleading

depth information being displayed with a consequent risk

of running aground.

Depths are measuredfrom the transducer tothe sea bed. However, you

can use thedepth offsetscreen to apply offsets to thisdistance, sothat the

displayed depth readingrepresents either the depthfrom the keel orthe

Page 42

30 ST60 Tridata Instrument Owner’s Manual

depth from thewater line. In order to do this, youneed to knowthe

vertical separation between the transducer position and:

• The bottom of thekeel.

• The waterline.

Use the

trip (decrement)and reset (increment)keys to set the required

offset value:

• If you want todisplay the depth readingfrom the transducer,set a

value of0.0.

• If youwant toapply awater line offset,adjust the displayed reading

until the appropriate positiveoffset valueis shown.

• If you want toapply a keel offset, adjustthe displayed reading until

the appropriate negativeoffset valueis shown.

+ve offset

values

Offset value

of 0.0

-ve offset

values

Depth offsets

D4352-2

Shallow alarm lock

When setto on, prevents alteration to theshallow depth alarm threshold.

Page 43

Calibration 31

Speed

Tocalibrate the speed functions:

1. With the User calibration entry screen displayed,press the speedkey.

2. Referring to the User calibrat ion - speedillustration, carry out the

calibration procedure. Use the speed key to cycle fromscreen to

screen andthe trip and resetkeys to setthe required valuesat each

screen (except Adjustto SOG display).

Set speed units

Select either KTS (knots), MPH (miles perhour) or KMH (kilometres per

hour), asrequired.

Set speed resolution

Select resolution ofeither 0.01 or 0.1 as required.

Set log units

Select either NM (nautical miles), SM(statute miles) or KM(kilometres),

as required.

Setting the correct speed

Set the displayed(current) speed using oneof the following methods:

• Use the Adjustto Speed Over Ground(SOG) screen toautomatically

set the currentspeed toSOG (ifavailable fromSeaTalk).Youmust be

running in slack tide conditions to successfully use this method.

• Manually apply a calibrationfactor by means of theCal factor adjust

screen, to setthe displayed speed valueto your best estimateof the

vessel’s speed.

Page 44

32 ST60 Tridata Instrument Owner’s Manual

From User calibration

start screen

Set speed

units

Set speed

resolution

Set log

units

speed

speed

speed

Setting the correct speed

Set timer alarm

Temperature

calibration

Set temperature

units

speed

speed

speed

User calibration - speed

Adjust

to SOG

If SOG

available

from

SeaTalk

If SOG

NOT

available

Cal

Factor

Adjust

trip

speed

reset

&

speed

D4418-1

Page 45

Calibration 33

Adjust to SOG

The Adjustto SOGscreen isdisplayed onlyif SOGdata is availablefrom

SeaTalk. The current SOG isdisplayed in the bottom section of the

display(SG12.8 inthe illustration),and the currentspeed registered bythe

instrument, as large figuresin the middlesection of the display(12.3 in

the illustration).

It isrecommended that, if you are running in slack tideconditions, you

press the

If youdo not wish toaccept SOG asthe current speed, pressthe

reset keys together to selectthe Cal factor adjust display.

Cal factor adjust

The Calfactor adjust screenenables you to manuallyadjust the

calibration factor. It shows the currentcalibration factor in thebottom

section of the display(CF 1.00 in the illustration), and thecurrent speedas

large figures (12.3in the illustration).

Usethe

speed is the speed through the water.

If SOG datais available from SeaTalk, youcan turnto the Adjust to SOG

screen bypressing the

Note:If neither of the above methods gives satisfactory results, carry o ut

the Speed calibration procedure (part of Intermediat e calibration).

reset key for 3 seconds, toaccept theSOG as the currentspeed.

trip and

trip or reset key to adjust the calibrationfactor sothat thecurrent

trip and reset keys.

Set temperature units

Select either °C or °F,as required.

Temperature calibration

Set the display to showthe current water temperature.

Timer alarm buzzer

Switches thecount-up and race-start timer audible alarmon the ST60

Tridata instrument beingcalibrated, on andoff.

Leaving User calibration

Holddown thedepth andspeed keysfor 2seconds, tosave yoursettings,

exit Usercalibration and resume normaloperation.

Page 46

34 ST60 Tridata Instrument Owner’s Manual

4.3 Intermediate calibration

Intermediate calibrationenables you to:

• Check the instrument software version.

• Check the instrument status- either YES(master)) or NO (repeater).

You canalso change the depthstatus, as required. Thisfeature is particularly useful inpreventing interference when using anotherproduct (e.g.a fishfinder)that operates at 200 kHz.

• Carry out acalibration run over a measured distance to ensure accurate speedreadings.

To start Intermediate calibration, holddown the

for approximately 4 seconds (seeIntermediate calibration flow chart).

To set the instrument status:

depth and speed keys

1. Press the

2. Press the

mode, then press either

either YES(for master operation) or NO(for repeater operation).

Note: You must not allocate more than one master d epth instrument in

any system.

3. Press the tripand reset keys simultaneouslyagain, to leave theadjust

mode.

depth key toselect the Instrument status screen.

trip andreset keys simultaneously to enter thedepth adjust

trip orreset to set therequired status, i.e.

Page 47

Calibration 35

depth

Software

version

Instrument

status

speed

depth

(or NO for repeater)

(or NO for repeater)

depth

Carry out speed calibration

as detailed in

Speed calibration - sheets 1 & 2

depth

Intermediate calibration

Speed calibration

The speedcalibration procedure involves carrying out two runs overa

measured distance,to enable acalibration factor tobe determined and

applied toyour ST60 Tridata instrument, to ensure optimum accuracy.

Each calibration run comprises outward and return legs,to minimise the

affect of tidaldrift when thecalibration factoris determined.

D4419-1

Page 48

36 ST60 Tridata Instrument Owner’s Manual

Note: It is recommended that the speed calibration procedure is carried

out in conditions of minimum ti dal drift.

To carry out aspeed calibration, start the Intermediatecalibration

procedure and use the

speed key to proceed to the Calibrationrun length

screen (seesheet 1 of theSpeed calibration flowchart). Proceed with the

speed calibrationas follows:

1. Withthe CalibrationRun Lengthscreen displayed, press the

reset keys together to enter adjust mode. Inthis mode, the displayed

trip and

run length flasheson and off.

2. Setthe lengthof the intended calibrationrun, usingeither the

to decrementor the

reset key to incrementthe run length value.You

trip key

can setany value between0.25 and 2.50.

3. Press trip and reset keystogether tocommence the speed calibration.

The Calstatus screenis displayed.The textat thebottom ofthe screen

alternates between Strt 1 and the calibration factor (CF) currently

applied.

4. Startfirst outward leg ofthe calibration run and asyou pass the start

point, press the

speed key, so that thetext out shows at the bottom of

the screen.As the calibration run proceeds, thedisplayed value will

increment.

5. At the end of the measured distance on the outward leg, pressthe

speed keyagain so that:

• The text rEtrn is flashing atthe bottom ofthe screen.

• The displayeddistance freezes.Note that thisvaluewill not bethe

same asthe measured distance dueto errors introducedby tidal

flow.

6. Turnthe vessel round, start thereturn leg and as you do so,press the

speed keyso the rEtrn legend stops flashing and thedisplayed value

increments.

7. At the endof the return leg,press the

speed key toend the calibration

run. At thispoint:

• The text Strt 2 alternating with thenew calibration factor is dis-

played atthe bottom ofthe screen.

• The displayeddistance freezes. Thisvalue shouldbe very closeto

the actual(measured) distance ofthe calibration run.

8. Press the

depth and speed keystogether, to storethe new calibration

factor.

Page 49

Calibration 37

from Intermediate calibration

(Instrument status display)

Calibration

run length

and

trip

and

trip

At the start of the

outward cal run

press

speed

Alternating

reset

reset

Press

Use

either

trip

to set length

of calibration run

Carry out the

outward leg of

the first cal run

speed

reset

At the end

of the

outward

cal run

Carry out the

return leg of

the first cal run

speed

At the end

of the return

cal run

Press

Speed calibration - sheet 1

To store the calibration factor, press

Alternating

depth

and

speed

At the start of

the return cal

run press

speed

speed

Carry out second cal run

as described on sheet 2

D4420-1

Page 50

38 ST60 Tridata Instrument Owner’s Manual

At the start of the

outward cal run

from Speed

calibration - sheet 1

press

speed

Carry out the

outward leg of

the second

cal run

Carry out the

return leg of

the second

cal run

At the end

of the return

cal run

speed

press

Speed calibration - sheet 2

Alternating

Press

and

depth

to store cal factor

At the end of the

outward cal run

At the start of

the return cal

run press

speed

speed

speed

press

Press

depth

to return to

Instrument status display

(Intermediate calibration)

D4421-1

9. Carry out a secondcalibration run (seesheet 2 of the Speed calibration flow chart),using the procedure described abovein steps 4 to8.

Note: At the end of this second run, the text End alternati ng with the new

calibration factor is displayed at the bottom of the screen.

10. Press the speed key to leave distance calibration and return to the

Instrument status screen.

Page 51

Calibration 39

Leaving Intermediate calibration

Holddown thedepth andspeed keysfor 2seconds, tosave yoursettings,

exit Intermediate calibration and resume normal operation.

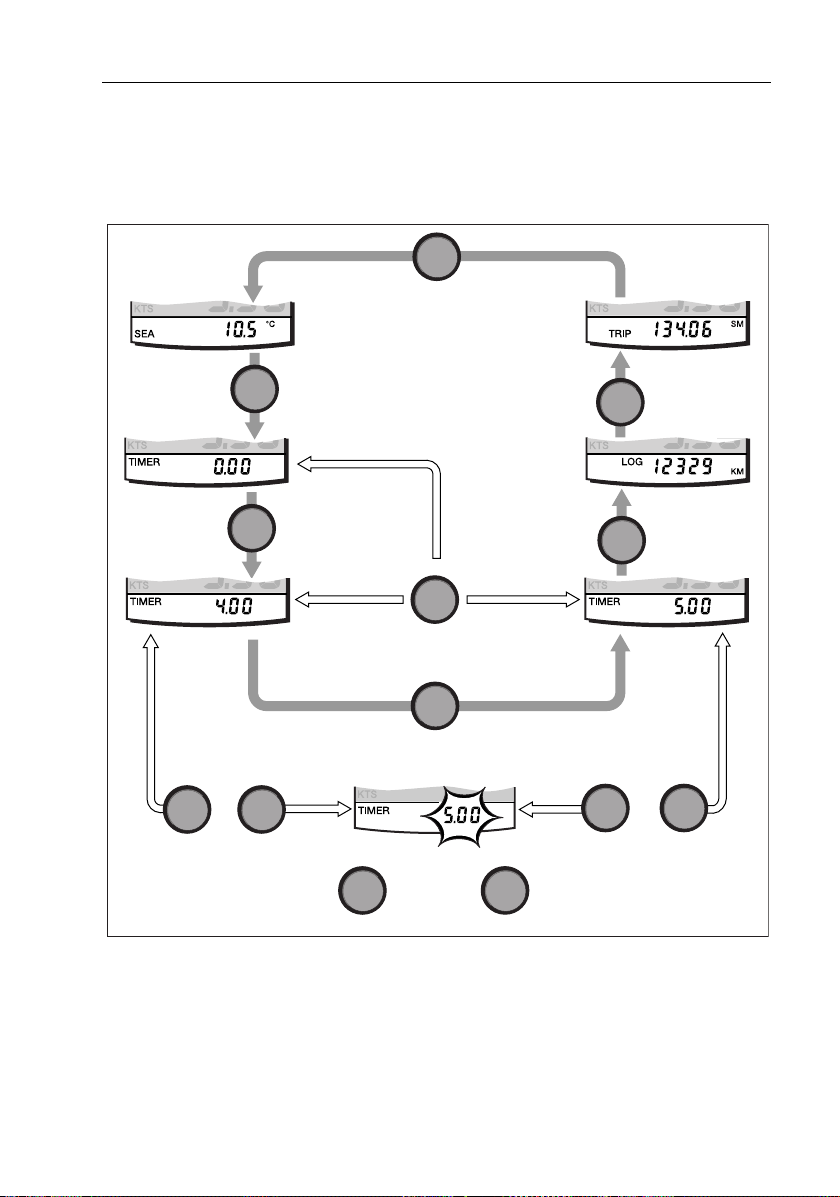

4.4 Dealer calibration

The Dealercalibration procedures enable thefollowing parameters to be

set:

• User calibration on/off.

• Speed response.

• Depth response.

• Boat show mode on/off.

Dealer calibration also givesaccess to theFactory defaults screen.This

enables you tore-apply the factory settingsif you want to resetthe

instrument to aknown operating condition.

Tocommence Dealer calibration, holddown the

together forapproximately 12 seconds, to select theDealer calibration

entrypage (seeDealer calibration diagram). Thenpress the

reset keys together,to enter thecalibration screen sequence.

Use thedepth key to movefrom screen to screen and the trip orthe rest

key toset the requiredvalues at each screen.

depth and speed keys

User calibration on/off

Press either thetrip orreset key to togglethe Usercalibration onor offas

required. Withoff selected, User calibration and Intermediate calibration

are both disabled.

Response settings

The response values for both SPEEDand DEPTH determinethe frequency

at which informationis updated. Alow number provides a smooth

response and ahigh number a muchlivelier update.

Use the

trip (decrement) andreset (increment) keys toset the required

value. Response values are from1 to 15.

trip and

Page 52

40 ST60 Tridata Instrument Owner’s Manual

Speed

response

Hold down and

for approximately 12 seconds

Calibration

on/off

depth

depth speed

trip

and

reset

At each screen use

depth

Factory

defaults

depth

Dealer calibration

Depth response

either

trip

to set the required values

depth

or

reset

depth

Boat show mode

D4422-1

Page 53

Calibration 41

Boat show mode

CAUTION:

Do NOTenable thismode. It mustonly beused for demonstration

purposes.

Ensure that the Boatshow Mode Useis set to OFF. If necessary, usethe

trip orreset key to achieve this.

Factory defaults

You canuse this screento reset theoperating parameters tothe factory

default values.If you want to applythe factory defaults, ensurethe

display shows YES, butif you want toretain the values you haveset up,

ensure thatthe display shows NO.Usethe

required selection.

The valuesyou have selected will be applied when youexit this screen.

trip andreset keys tomake the

Leaving Dealer calibration

Holddown thedepth andspeed keysfor 2seconds tosave yoursettings,

exit Dealercalibration and resume normaloperation.

Page 54

42 ST60 Tridata Instrument Owner’s Manual

Page 55

ST60 Surface Mount Template

TOP

Drill 5mm (3/16in) diameter

Machine hole

90mm (3.54in)

diameter

Shaded areas to be removed

Drill 5mm (3/16in) diameter

D4436-1

Page 56

Page 57

ST60 Flush Mount Template

114 mm

TOP

Shaded area to be removed

109 mm

4 holes

6 mm diameter

D4437-1

Page 58

Loading...

Loading...