Page 1

Distributed by

Any reference to Raytheon or

RTN in this manual should be

interpreted as Raymarine.

The names Raytheon and RTN

are owned by the

Raytheon Company.

Page 2

ST600R

Autopilot

Control Unit

Owner’s

Handbook

Document number: 81134-3

Date: May 2001

Page 3

Page 4

Preface

stdby

i

-- 1

-- 10

track

+1

+10

auto

Raymarine, as part of its commitment to continuous improvement and updating, reserves

the right to make changes, without prior notice, to the equipment, equipment specifications, and the

instructions contained within this handbook.

To the best of our knowledge, the information contained within this handbook was correct

as it went to press.

A great deal of care has been taken to ensure that this handbook is as accurate as possible. However,

liability cannot be accepted for inaccuracies or omissions.

Autohelm and SeaTalk are registered trademarks of Raymarine Ltd.

WindTrim, AutoTack, AutoTrim, AutoSeastate, AutoAdapt, AutoRelease and CodeLock are

trademarks of Raymarine Ltd.

Copyright © Raymarine Ltd 2001.

Page 5

ST600R Autopilot Control Unitii

Page 6

Preface

Preface

iii

This handbook contains information on the operation and

installation of your new equipment. In order to obtain the best

performance from your autopilot, please read this handbook

thoroughly.

How this Handbook is Organised

This handbook is divided into the following chapters:

Chapter 1: Introduces the autopilot, its features and its use.

Chapter 2: Covers basic autopilot operation.

Chapter 3: Explains how to use Track and Vane (WindTrim)

modes and adjust autopilot performance, and summarises the

ST600R alarms.

Chapter 4: Explains how to use the CodeLock security feature.

Chapter 5: Provides details on how to make adjustments to

customise the autopilot to your particular vessel.

Chapter 6: Explains how to install the ST600R.

Chapter 7: Covers functional testing and initial calibration

procedures after installation, and intial sea trials.

Chapter 8: Provides general maintenance procedures.

Chapter 9: Provides information to help you resolve any problems

you may encounter with your autopilot.

An index is included at the end of this handbook, followed by the

necessary template(s).

Warranty

To verify the ownership of your new autopilot, please take a few

minutes to complete the warranty card. It is important that you

complete the owner information and return the card to the factory to

receive full warranty benefits.

Page 7

ST600R Autopilot Control Unitiv

Safety Information

Passage making under autopilot control is an enjoyable experience

that can, if you are not careful, lead to the relaxation of the

permanent watch. A permanent watch MUST be maintained no

matter how clear the sea may appear to be.

Remember, a large ship can travel two miles in five minutes – just

the time it takes to make a cup of coffee.

The following rules should always be observed:

•Maintain a permanent watch and regularly check all around for

other vessels and obstacles to navigation – no matter how clear the

sea may appear a dangerous situation can develop rapidly.

•Maintain an accurate record of the vessel’s position either by use of

a radio navigation receiver or visual bearings.

•Maintain a continuous plot of position on a current chart. Ensure the

locked autopilot heading steers you clear of all obstacles. Make

proper allowance for Tidal Set – the autopilot cannot!

•Even when your autopilot is locked onto the desired Track using a

radio navigation receiver, always maintain a log and make regular

positional plots. Radio navigation signals can produce significant

errors under some circumstances and the autopilot cannot detect this

situation.

•Make sure that all members of crew are familiar with the procedures

to disengage the autopilot.

Your Raymarine autopilot will add a new dimension to your boating

enjoyment. However, it is the responsibility of the skipper to ensure

the safety of the vessel at all times by careful observance of these

basic rules.

EMC Conformance

All Raymarine equipment and accessories are designed to the best

industry standards for use in the leisure marine environment.

Their design and manufacture conforms to the appropriate

Electromagnetic Compatibility (EMC) standards, but good

installation is required to ensure that performance is not

compromised.

Page 8

Preface

Contents

v

Chapter 1: Introduction .............................................................. 1

1.1 Overview.................................................................................1

1.2 Specification ............................................................................2

Chapter 2: Basic Operation........................................................ 3

2.1 Key Functions.......................................................................... 3

2.2 Display Layout ........................................................................4

2.3 Using Auto Mode ....................................................................5

Engaging the Autopilot (Auto)................................................5

Disengaging the Autopilot to Return to Hand Steering .............5

Changing Course in Auto Mode.............................................. 6

Dodging Obstacles in Auto Mode ........................................... 6

Returning to the Previous Locked Heading

(LAST HDG) ........................................................................7

Automatic Tack (AutoTack) ...................................................8

Off Course Alarm ..................................................................9

Operating Hints...................................................................... 9

2.4 Manual Mode ........................................................................10

2.5 Display and Keypad Illumination ............................................11

2.6 SeaTalk Data Pages ................................................................12

Changing Chapters...............................................................12

Cycling Pages ......................................................................12

SeaTalk Data Chart ..............................................................13

Chapter 3: Advanced Operation .............................................. 14

3.1 Operation in Track Mode........................................................14

Initiating Track Mode...........................................................14

Automatic Acquisition ..................................................15

Manual Acquisition ......................................................16

Cross Track Error .................................................................17

Tidal Stream Compensation..................................................18

Waypoint Arrival and Advance............................................. 18

Arrival ......................................................................... 18

Skipping a Waypoint – SeaTalk Navigators Only ...........19

Advance ...................................................................... 19

Dodges ................................................................................19

Initiating a Dodge Manoeuvre .......................................19

Cancelling a Dodge Manoeuvre ....................................19

Safety ..................................................................................19

Position Confirmation at the Start of a Passage ...............19

Verifying Computed Positions ...................................... 20

Plot Frequency ............................................................. 20

Setting Waypoints ........................................................ 20

General ........................................................................ 20

Page 9

ST600R Autopilot Control Unitvi

3.2 Operation in Vane Mode (WindTrim) ..................................... 20

Selecting Vane Mode ...........................................................21

Adjusting the Locked Wind Angle ........................................21

Returning to Previous Apparent Wind Angle (LAST WND) .. 22

Dodges ................................................................................22

Wind Shift Alarm................................................................. 23

Using AutoTack in Vane Mode ............................................23

Operating Hints.................................................................... 24

3.3 Adjusting Autopilot Performance ...........................................25

Changing the Response Level (Auto Seastate) ....................... 25

Changing the Rudder Gain ...................................................26

3.4 Alarms .................................................................................. 26

SeaTalk Failure ....................................................................27

No Link ...............................................................................27

Auto Release........................................................................ 27

Off Course ...........................................................................27

Wind Shift ...........................................................................27

Large Cross Track Error .......................................................27

Drive Stopped ......................................................................28

Data Not Received ...............................................................28

Waypoint Advance ..............................................................28

Low Battery.........................................................................29

Watch Alarm .......................................................................29

Man Overboard (MOB)........................................................ 29

Chapter 4: CodeLock ............................................................... 31

4.1 CodeLock Modes................................................................... 31

4.2 Setting Up CodeLock .............................................................31

Initial Setup .........................................................................32

Changing the Code or Master Unit ........................................ 33

4.3 Entering Your Code (Manual Mode Only) ..............................3 3

4.4 Code Number Problems .........................................................34

Chapter 5: Customising the System ........................................ 35

5.1 User Setup ............................................................................. 35

Compass Deviation Correction (SWING COMPASS)...........37

Deviation Display (DEVIATION) ........................................3 7

Heading Alignment (ALIGN HDG)......................................37

Pilot Type* ..........................................................................37

Heading Mode (HDG) .........................................................37

Bar Selection (RUDD BAR).................................................38

Rudder Calibration (DOCKSIDE RUDD CAL)* ..................38

Quitting User Setup ..............................................................38

5.2 Dealer Setup: Type 100/300 Course Computer ........................ 39

Recommended Settings ........................................................41

Pilot Type (ST6000 Plus & Type 100/300) ............................42

Pilot Type (ST4000 Plus and ST5000 Plus) ...........................4 2

Page 10

Preface

vii

Calibration Lock .................................................................. 42

Rudder Gain ........................................................................43

Rate Level ...........................................................................4 3

Rudder Offset ......................................................................43

Rudder Limit .......................................................................44

Turn Limit ........................................................................... 44

Cruise Speed ........................................................................44

Off Course Alarm ................................................................45

AutoTrim ............................................................................45

Power Steer .........................................................................4 6

Drive Type ..........................................................................4 6

Rudder Damping .................................................................4 7

Variation .............................................................................47

AutoAdapt...........................................................................48

Latitude ...............................................................................48

Auto Tack* ..........................................................................49

Wind Trim* .........................................................................49

Auto Release........................................................................ 49

Response .............................................................................49

Recording Calibration Settings .............................................50

Chapter 6: Installation .............................................................. 51

6.1 Planning the Installation .........................................................52

Choosing the Correct Connection Cable ................................52

Cabling Guidelines .............................................................. 52

EMC Installation Guidelines.................................................53

6.2 Connections...........................................................................54

ST1000 and ST2000 Plus Autopilot Connections ..................54

ST4000/5000/6000 Plus Connections ................................... 55

ST6000 & ST7000 Autopilot Connections ............................56

6.3 Mounting the Bulkhead Socket ...............................................56

6.4 Bulkhead Bracket Installation ................................................. 58

6.5 Functional Test (Repeater Unit) ..............................................58

Switch On............................................................................59

SeaTalk Interface .................................................................59

Chapter 7: Post Installation Procedures .................................. 61

7.1 Functional Test and Initial Calibration .....................................61

Switch On............................................................................61

Operating Sense ...................................................................62

Navigation Interface (GPS, Decca, Loran) .............................62

Wind Transducer Interface ...................................................6 3

EMC Conformance ..............................................................63

7.2 Initial Sea Trial.......................................................................64

Automatic Compass Deviation Correction ............................64

Further Heading Alignment Adjustment................................ 67

Checking Autopilot Operation ..............................................6 7

Checking the Rudder Gain....................................................68

Page 11

ST600R Autopilot Control Unitviii

Chapter 8: Maintenance ........................................................... 71

General................................................................................71

Servicing and Safety............................................................. 71

Advice.................................................................................71

Chapter 9: Fault Finding........................................................... 72

Index ........................................................................................ 74

Page 12

Chapter 1: Introduction

Chapter 1: Introduction

1.1 Overview

The ST600R is a SeaTalk® compatible autopilot control unit. It is

designed for use as a repeater in an autopilot system, allowing

autopilot control from a secondary location, or as the control unit for

a Type 100/300 Course Computer. It can also repeat instrument

data in an extensive set of Data Pages.

There are five operating modes:

Standby:Autopilot off

Auto:Autopilot engaged and locked onto a heading

Track:Autopilot maintains a track between two waypoints

created using a navigation system

Vane:Autopilot maintains a courserelative to an apparent

wind angle

Manual:Autopilot off during joystick control of steering

When the ST600R is being used to repeat instrument data, “pop-up

pilot” pages are displayed for 5 seconds whenever a change in

autopilot control is made.

The ST600R also provides the following:

•Setup and calibration options to suit each installation, giving

maximum performance with many types of boat and three

calibration menus (user, intermediate and dealer)

•Dockside rudder calibration feature that automatically determines

the characteristics of your installation, and adjusts for them, before

you set sail

•CodeLock security support

• Automatic tack facility that can be in used in Auto and Vane modes

• Automatic compass deviation correction

• Northerly/Southerly heading compensation

• Automatic heading deadband - seastate control

• Waypoint advance feature

1

Page 13

2

ST600R Autopilot Control Unit

1.2 Specification

• Power Supply: 8.5 to 16.5V DC

• Current consumption:

Standby: 60mA (less than 200mA with full lighting)

• Operating temperature: 0°C to +70°C (32°F to 158°F)

• Nine button illuminated digital keypad

• LCD display of heading, locked course and navigational data, with

three levels of illumination

Page 14

Chapter 2: Basic Operation

Chapter 2: Basic Operation

This chapter provides summary diagrams of the screen layout and

key functions. It also provides instructions for engaging the

autopilot and using Auto mode, changing the lighting and

displaying Data Pages.

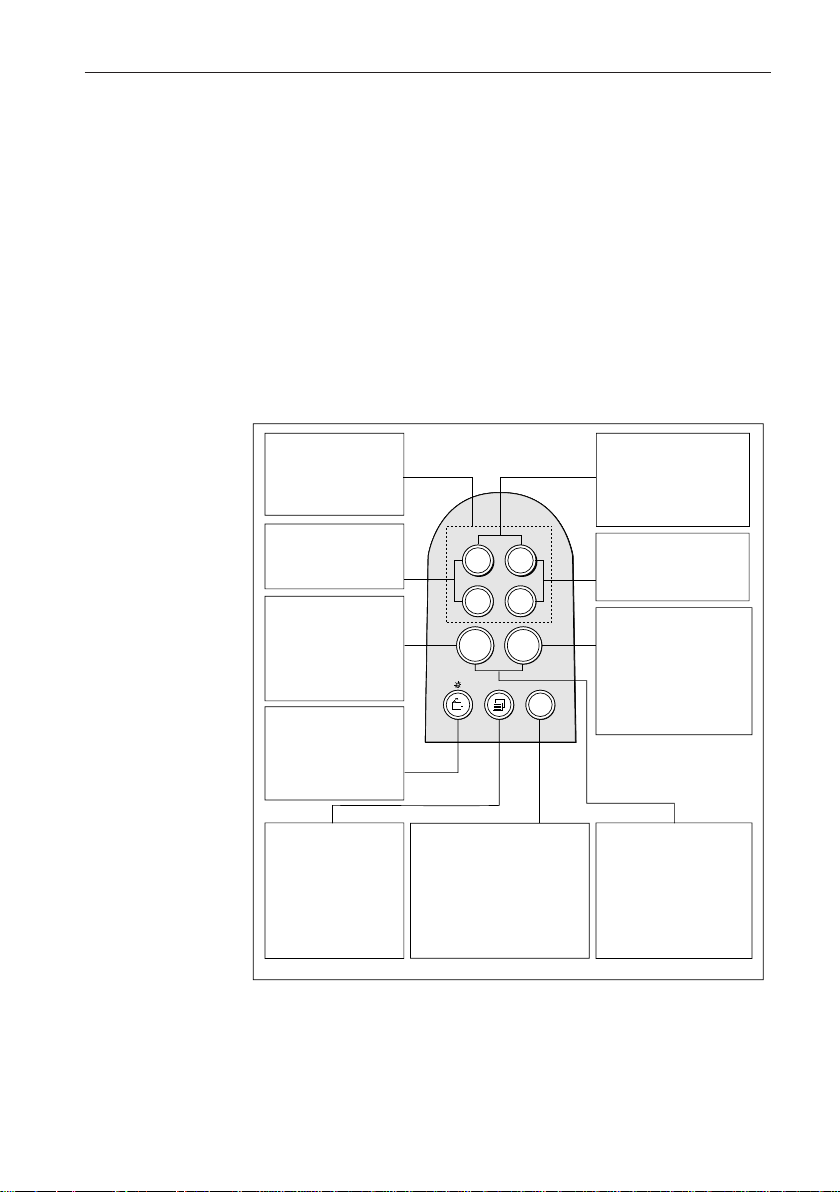

2.1 Key Functions

The autopilot is controlled using simple push-button operations, all

of which are confirmed with a beep. In addition to the main single

key functions, there are several dual key functions.

3

Port and Starboard

Course Change

Keys -1 & -10 (port)

+1 & +10 (starb'd)

-1 plus -10

Press together for

AutoTack to port

STANDBY

Press for Standby

mode

Press and hold for

Setup modes

CHAPTER

Press for

Data Chapter

Press for 1 second

for lamp control

PAGE

Press to cycle

through the

SeaTalk pages.

Press for 1 second

to return to the

previous page.

--1

+1

+10

-

-10

auto

stdby

track

TRACK

Press for Track mode

from Auto

Press to accept waypoint

advance

Press for 1 second to skip

waypoint

-1 plus +1

Press together for

Response level

Press together for 1

second for Rudder Gain

+1 plus +10

Press together for

AutoTack to starboard

AUTO

Press for Auto mode

Press for 1 second

for Last Heading

Press again to

accept Last Heading

STANDBY + AUTO

Press for Vane mode

Press for 1 second

for Last Wind

Press again to accept

Last Wind

• The autopilot always powers up in Standby mode. (If the words

CODE LOCK are displayed, enter your code as described in

Chapter 4.)

• Course changes are made using the -1, +1, -10 and +10 keys.

• Return to manual steering at any time by pressing STANDBY.

D3447-1

Page 15

4 ST600R Autopilot Control Unit

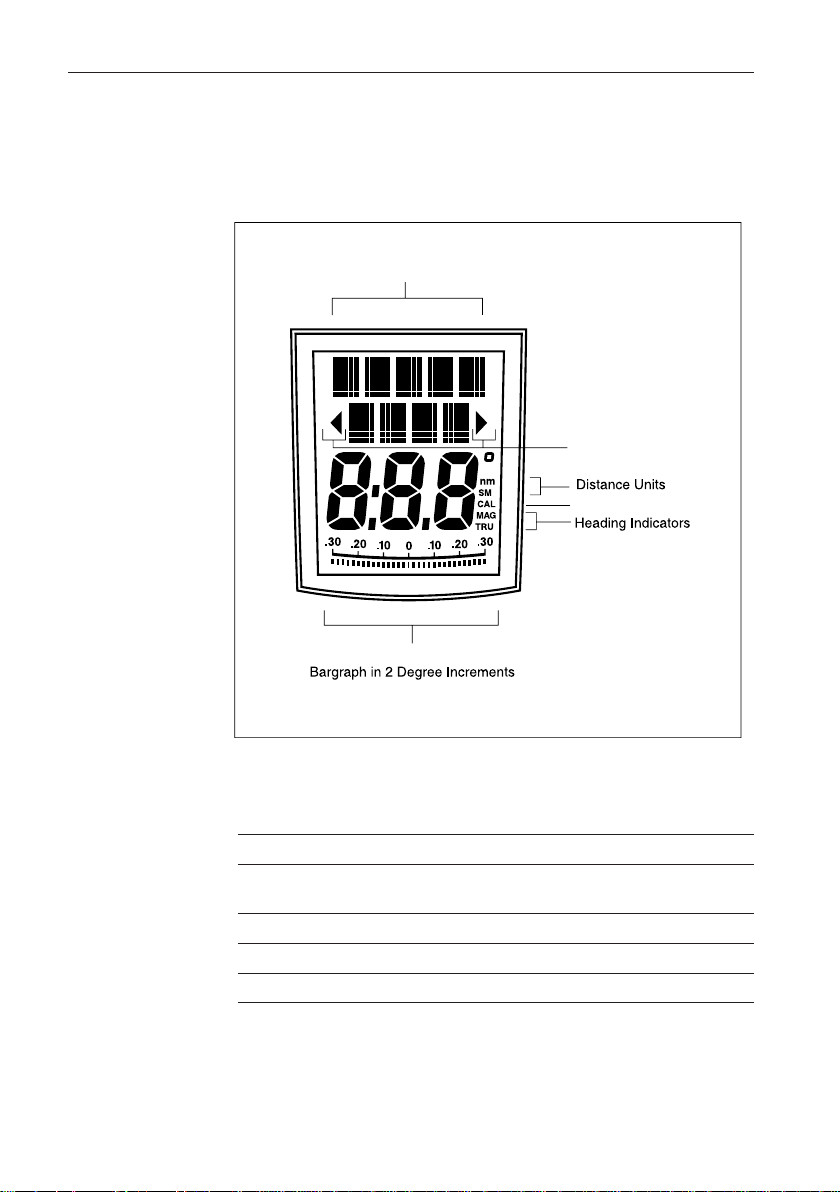

2.2 Display Layout

The following illustration shows all the elements, together with a

brief description, that make up the ST600R autopilot LCD display.

Variable Text Region

(5+4 Characters/Digits Maximum)

Port and Starboard

Direction to Steer

Indicators

Calibration Indicator

Rudder or Steer Direction Indicator

D3682-1

• The bar graph at the bottom of the display is normally the rudder bar.

If it has been set as a direction-to-steer indicator (refer to User

Setup), the display depends on the current mode (see below).

Mode Bar

Standby Not used (rudder angle if feedback transducer is

connected to autopilot)

Auto Heading error bar

Track Cross track error (XTE) bar, in 0.02nm increments

Vane Wind angle error bar

• If neither distance units (nm or SM) is displayed, the distance is in

Km.

Page 16

Chapter 2: Basic Operation

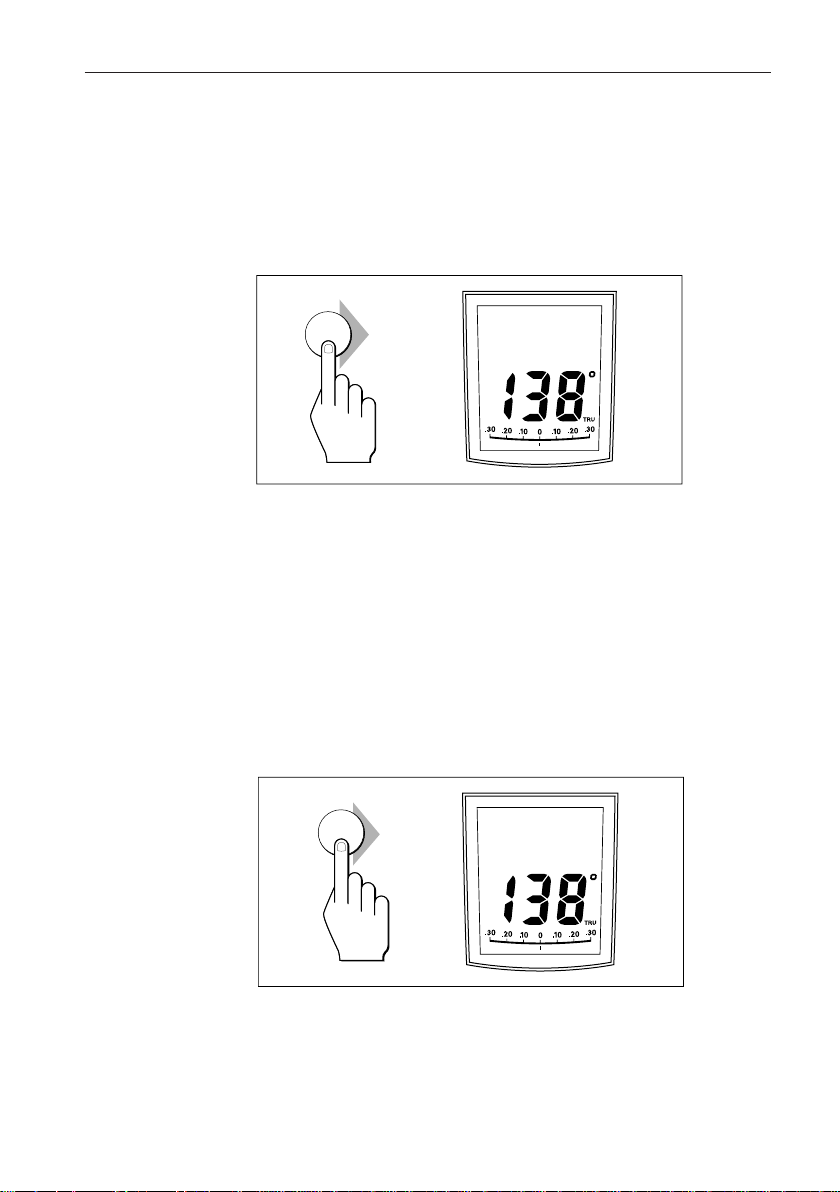

1. Steady the vessel on the required heading.

2. Press AUTO.

5

2.3 Using Auto Mode

Engaging the Autopilot (Auto)

auto

AUTO

DXXXX-1

• In Auto mode, the display shows the locked autopilot heading.

Caution: Passage making under autopilot control is an enjoyable

experience that can, if you are not careful, lead to the relaxation

of the permanent watch. A permanent watch MUST be

maintained no matter how clear the sea may appear to be.

Remember, a large ship can travel two miles in five minutes –

just the time it takes to make a cup of coffee.

Disengaging the Autopilot (Standby) to Return to

Hand Steering

• Press STANDBY.

stdby

STDBY

DXXXX-1

• In Standby mode, the display shows the vessel’s current compass

heading.

• The previous autopilot heading is memorised and can be recalled

(see opposite).

Page 17

6 ST600R Autopilot Control Unit

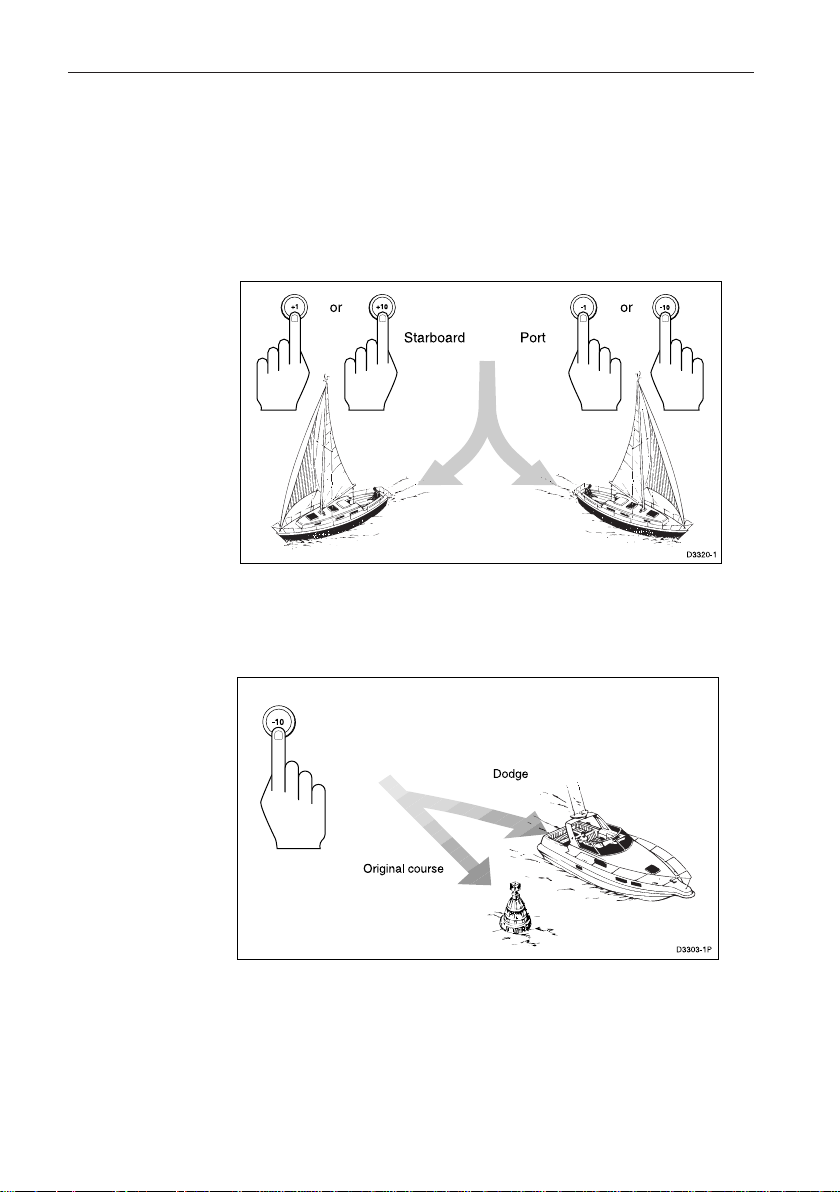

Changing Course in Auto Mode

• The +1 and +10 (starboard) and –1 and –10 (port) keys are used to

change the locked heading, in increments of 1° and 10°, when the

autopilot has control.

Example: a 30° course change to port = press –10 three times.

Dodging Obstacles in Auto Mode

Select a course change in the appropriate direction, for example,

port 30° = -10 three times.

• When safely clear of the obstacle, you can reverse the previous

course change (for example, press +10 three times), or return to the

previous locked heading (LAST HDG).

Page 18

Chapter 2: Basic Operation

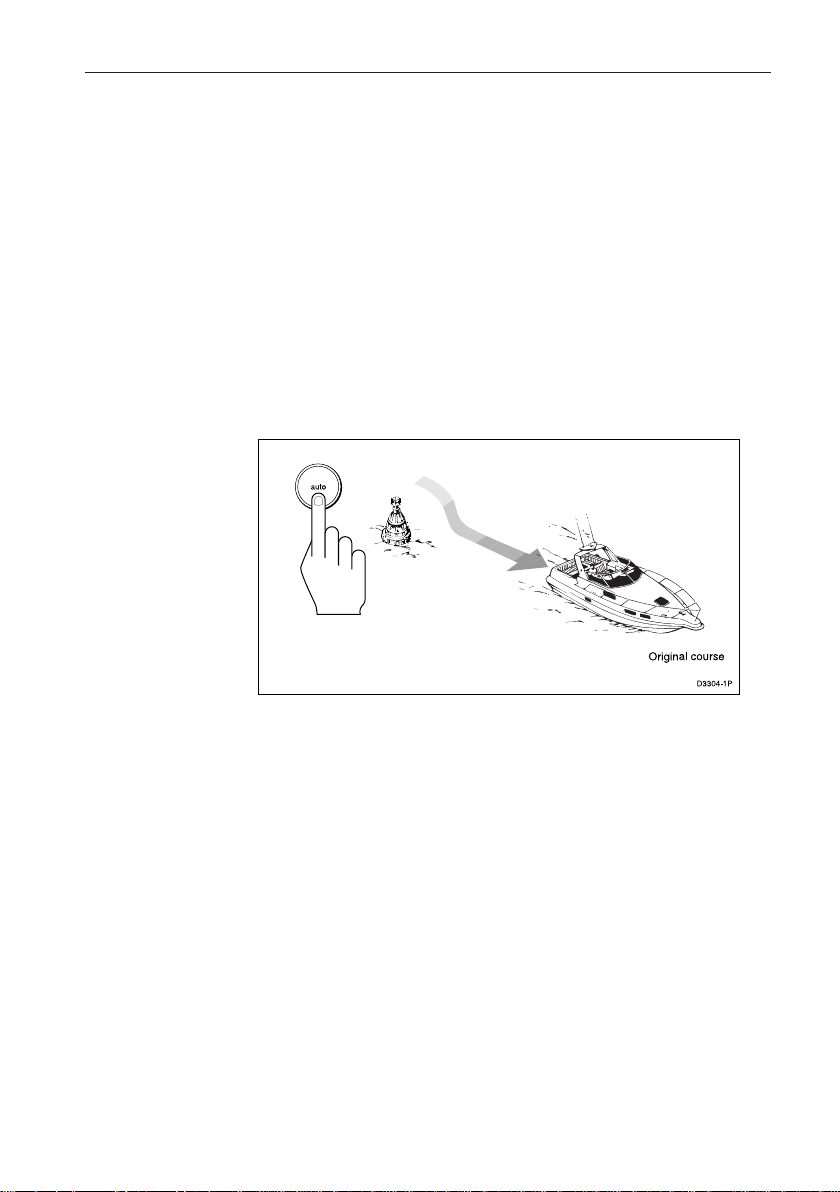

1. Press AUTO for 1 second. The previous locked heading (LAST

Note: A direction-to-steer indicator is displayed to show you the direction

2. To accept this heading, and resume the original course, press AUTO

7

Returning to the Previous Locked Heading

(LAST HDG)

If you steer your vessel away from the selected locked heading (for

example, executing a dodge manoeuvre or selecting Standby) you

can return to the previous locked heading as follows:

HDG) is displayed for 7 seconds and the display flashes.

the vessel will turn.

once within this 7 second period.

If you do not press AUTO while the display is flashing, the current

heading will be maintained.

Page 19

8 ST600R Autopilot Control Unit

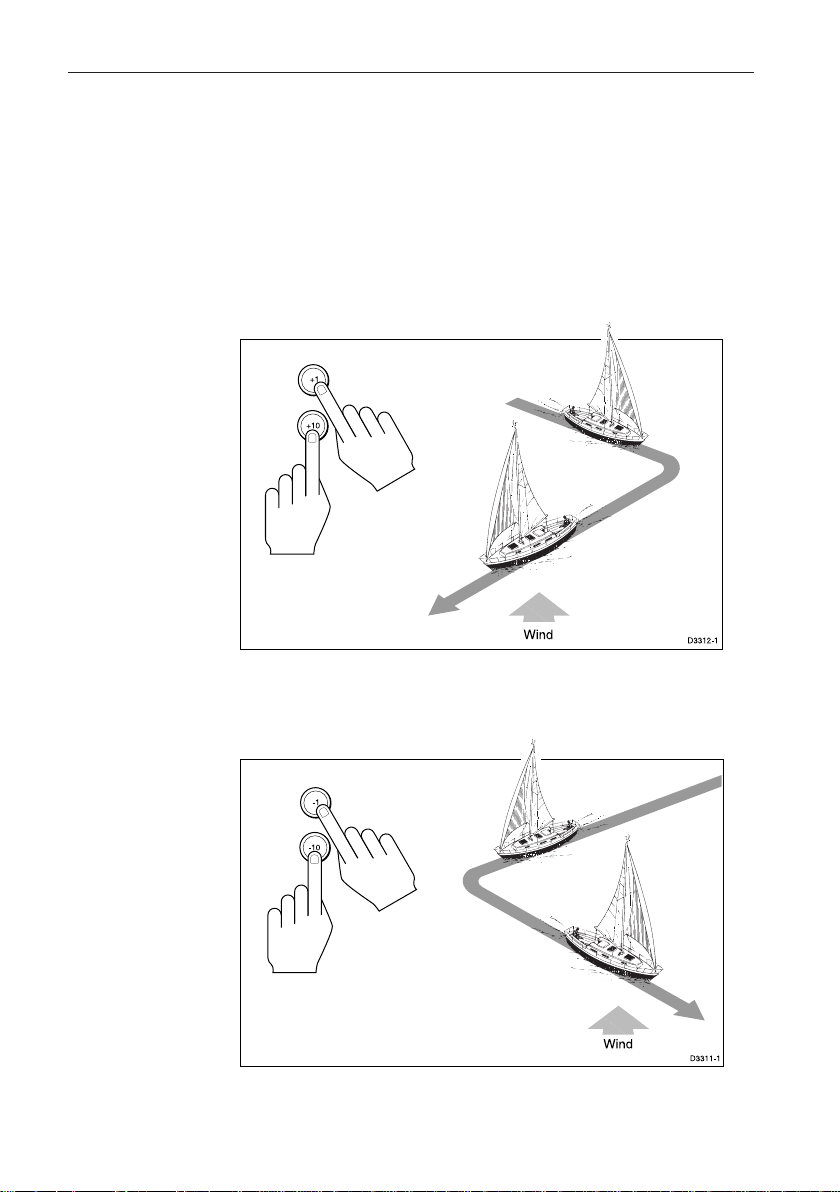

Automatic Tack (AutoTack)

The autopilot has a built in automatic tack facility that turns the

vessel through a predetermined angle (the factory default, set in

Dealer calibration, is 100°) in the required direction.

AutoTack to Starboard

• Press the +1 and +10 keys together to tack to starboard.

AutoTack to Port

• Press the -1 and -10 keys together to tack to port .

Page 20

Chapter 2: Basic Operation

1. To cancel the off course alarm, press STANDBY to return to hand

2. Make sure your vessel is not carrying too much sail or the sails are

9

Off Course Alarm

The off course alarm sounds if the locked autopilot heading and the

vessel’s current heading differ for more than 20 seconds, and by

more than the alarm angle set in calibration (the factory default

is 20°).

steering.

badly balanced. Significant improvements in course keeping can

usually be obtained by improving sail balance.

Operating Hints

Making Major Course Changes

• It is sound seamanship to make major course changes only when

steering manually.

• Manual course changes ensure that obstructions or other vessels are

cleared properly, and due account taken of the changed wind and sea

conditions on the new heading prior to engaging the autopilot.

Course Changes Under Autopilot Control

It is important to understand the effect of sudden trim changes on

steering performance. When a sudden trim change occurs, due, for

example, to weather helm or sail imbalance, there will be a delay

before the automatic trim applies rudder to restore the locked

heading. This correction can take up to one minute.

Large course changes, which change the apparent wind direction,

can produce large trim changes. In these situations, the autopilot will

not immediately assume the new automatic heading, and will only

settle onto course when the automatic trim has been fully

established.

Page 21

10 ST600R Autopilot Control Unit

To eliminate this problem, the following procedure can be adopted

for large course changes:

1. Note the required new heading.

2. Select STANDBY and steer manually.

3. Bring the vessel onto the new heading.

4. Select AUTO and let the vessel settle onto course.

5. Bring the vessel to the final course with 1° increments.

Gusty Conditions

In gusty conditions, the course may tend to wander slightly,

particularly if the sails are badly balanced. Significant

improvements in course keeping can always be obtained by

improving sail balance. Bear in mind the following important

points:

• Do not allow the yacht to heel over excessively

• Ease the mainsheet traveller to leeward to reduce heeling and

weather helm

• If necessary, reef the mainsail a little early

It is also advisable, whenever possible, to avoid sailing with the

wind dead astern in very strong winds and large seas.

Ideally, the wind should be brought at least 30° away from a dead

run and, in severe conditions, it may be advisable to remove the

mainsail altogether and sail under headsail only.

Provided these simple precautions are taken, the autopilot will be

able to maintain competent control in gale force conditions.

2.4 Manual Mode

If your system is fitted with a joystick, the ST600R will enter

Manual mode when the joystick is in use.

The ST600R will return to Standby mode when the joystick button

is released, or if you press the STANDBY key on the ST600R.

Page 22

Chapter 2: Basic Operation

LAMP

DXXXX-1

LAMP

LAMP LAMP

LAMP

STBY

• Press for 1 second, from any mode, to enter illumination

• Subsequent presses of the key cycles the possible illumination

Notes: If other SeaTalk instruments or autopilot control units are connected

11

2.5 Display and Keypad Illumination

adjustment mode and turn the lights on.

settings: L3, L2, L1, OFF, L1, L2, L3 etc. where L3 is the brightest

setting.

The display times out to normal operation after 7 seconds of keypad

inactivity.

Pressing any other key before the 7 second time-out will select the

mode assigned to that key (for example, AUTO selects Auto mode,

STANDBY selects Standby mode).

to SeaTalk, the illumination can be adjusted from these units.

Any adjustments to the illumination are lost when the unit is

switched off.

The keys are still lit at a courtesy level when the display lighting is off.

If the illumination is initially OFF, upon entry to illumination adjustment

mode the illumination is set to level 3.

Page 23

12 ST600R Autopilot Control Unit

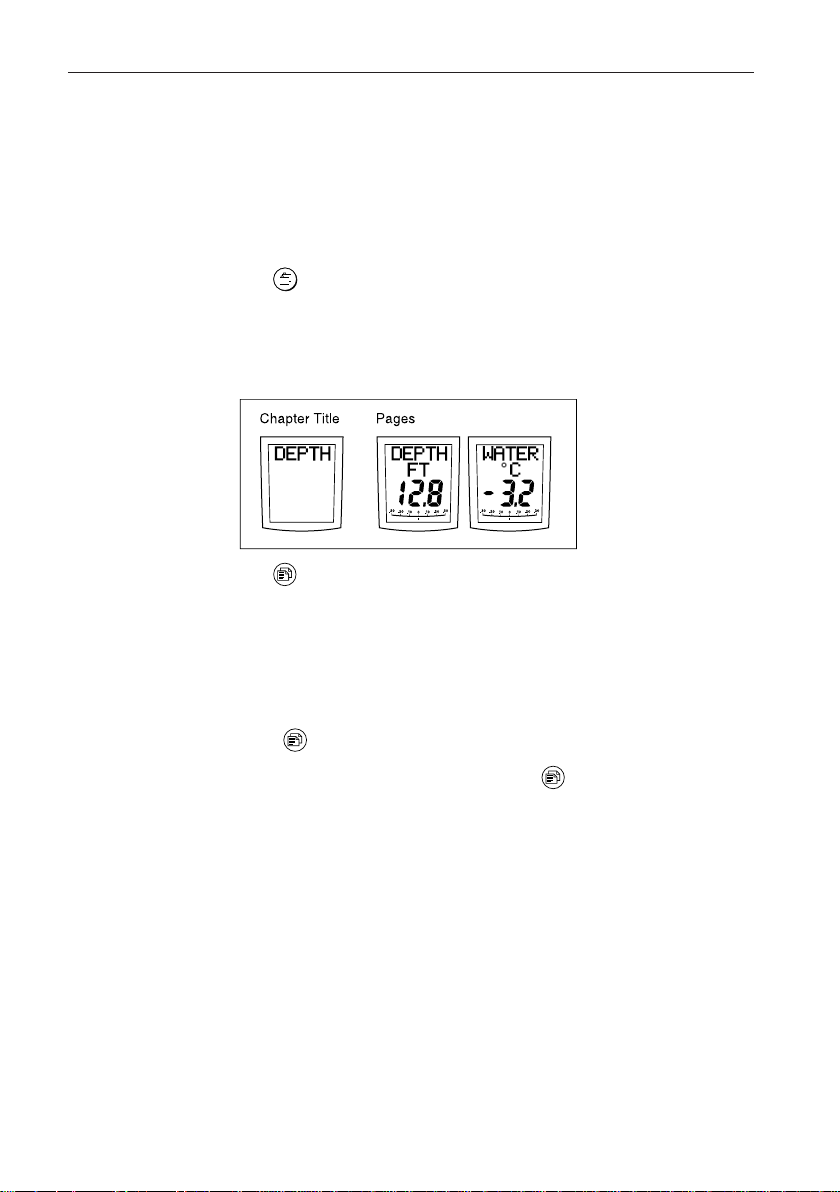

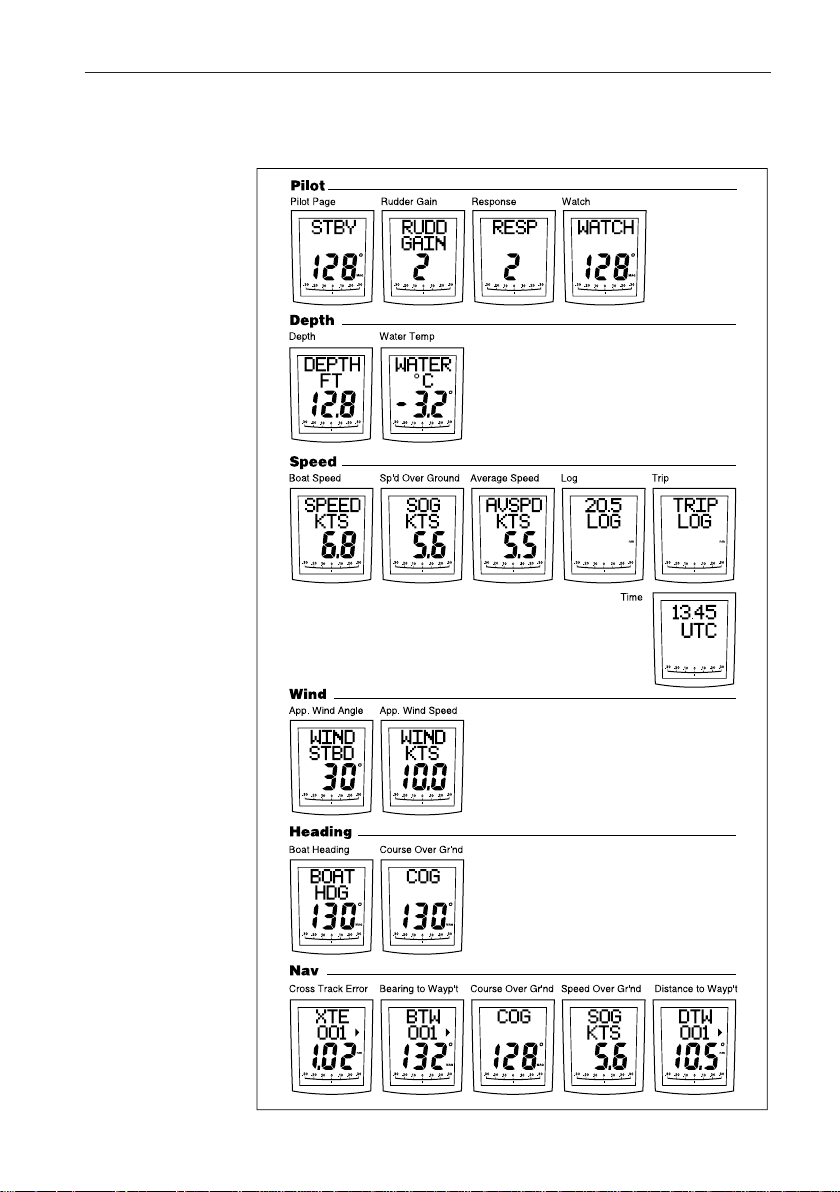

2.6 SeaTalk Data Pages

The ST600R can display 21 “pages” of SeaTalk data, grouped into 6

“chapters” (see opposite page).

Changing Chapters

The key is used to cycle through the chapters. The chapter title

(for example, SPEED) is displayed for 2 seconds, then the first page

in the chapter is displayed.

Cycling Pages

The key is used to cycle through the pages in the current chapter.

Once a Data Page is selected, this page becomes the principle

autopilot display. The autopilot mode displays (Standby, Auto,

Track, Vane and Manual) then become “pop-ups”, and are

displayed for 5 seconds when the autopilot mode is changed or a

course change is made.

• Press to display each Data Page in turn.

• To return to a previous Data Page, press for 1 second. You can

continue to move backwards through the Data Page sequence in this

way.

• If the required data for a page is not available, dashes are displayed

instead of a value.

• Most displays are repeated data and cannot be adjusted. The

exceptions are the Response and Rudder Gain pages, which can be

adjusted using the +1 and -1 keys (refer to section 3.3 for the

alternative method of adjusting the Response/Gain).

• The autopilot bar graph remains in use.

• The “direction-to-steer” arrows relate to the Data Page information.

Page 24

Chapter 2: Basic Operation

13

SeaTalk Data Chart

Page 25

14 ST600R Autopilot Control Unit

Chapter 3: Advanced Opera tion

This chapter provides information on:

• Operation in Track mode

• Operation in Vane mode (WindTrim)

• Adjusting response and rudder gain

• Alarms

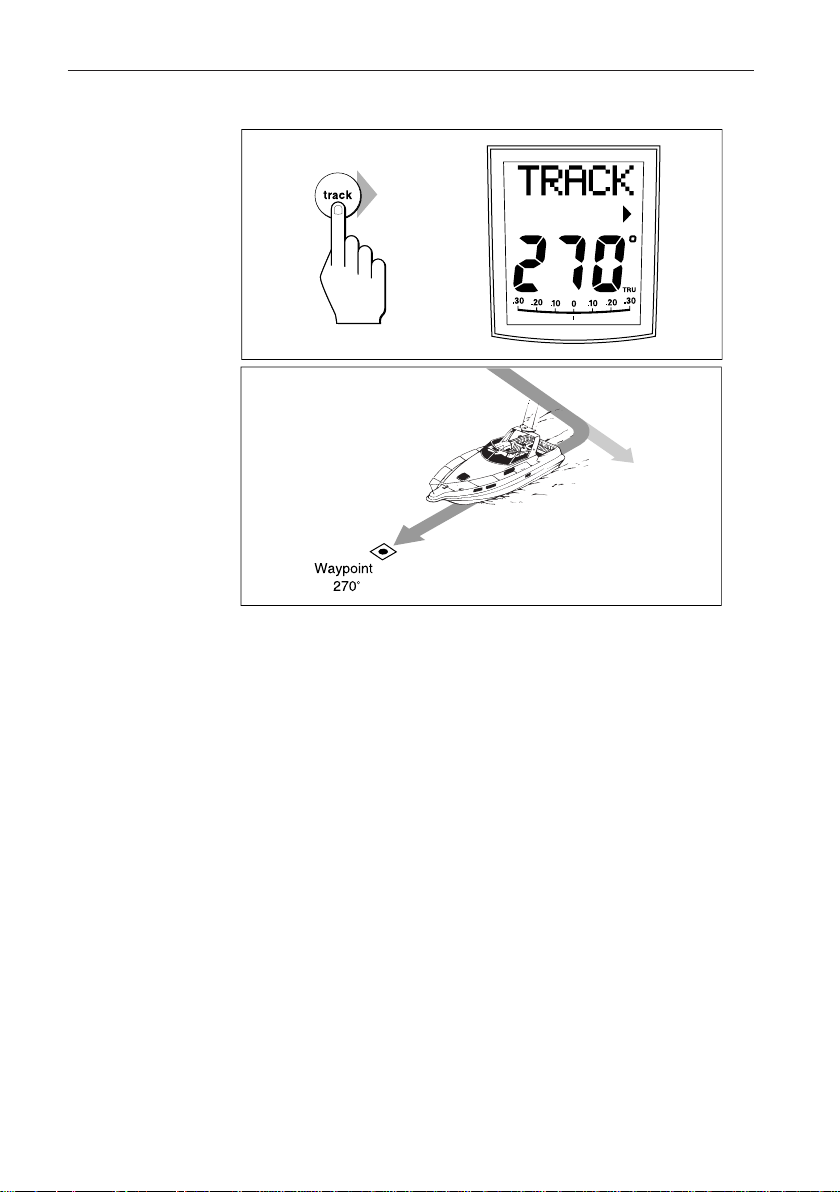

3.1 Operation in Track Mode

Track mode is used to maintain a track between two waypoints

created on a GPS, Decca, or Loran navigation system. The autopilot

will then compute any course changes to keep your boat on track,

automatically compensating for tidal streams and leeway.

The autopilot can receive cross track error (the distance your vessel

is from a planned track) from a SeaTalk navigation instrument or

chartplotter

Track mode is selected by pressing the TRACK key, but can only be

selected in Auto mode. You can return to either Auto or Standby

from Track as follows:

• Press AUTO to leave Track mode and return to Auto mode.

• Press STANDBY to leave Track mode and return to manual

steering.

Initiating Track Mode

When initiating Track mode, the track can be acquired in one of two

ways:

• Automatic acquisition – when cross track error and bearing to

waypoint data are available

• Manual acquisition – when cross track error is the only available

data

Page 26

Chapter 3: Advanced Operation

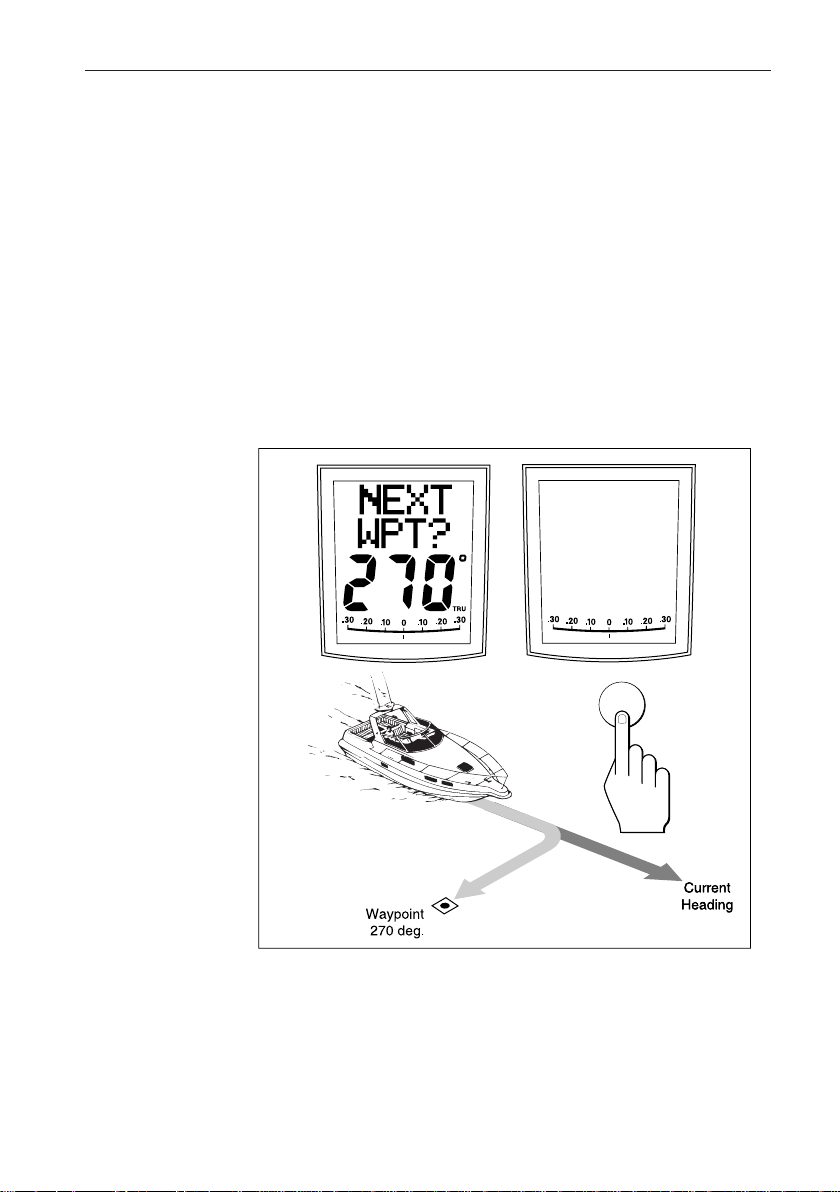

Automatic Acquisition

Automatic acquisition can only be achieved if the pilot is receiving

cross track error and bearing to waypoint information (via SeaTalk

or NMEA 0183). It is initiated as follows:

1. Bring the vessel to within 0.1nm of track

2. Press AUTO.

3. Press TRACK to enter Track mode, with the current locked heading

displayed.

After a short delay for data acquisition, the Waypoint Advance

alarm will sound, and the display will show the planned bearing to

waypoint alternating with the direction in which the boat will turn.

15

STBD

track

Note: If the vessel is further than 0.3nm from the track, the Large Cross

Track Error alarm will sound. Press STANDBY to cancel the alarm,

hand steer closer to the track, and press AUTO and TRACK again.

4. Check that it is safe to turn onto the new course.

5. Press the TRACK key. The boat will turn on to the new course and

the alarm will be cancelled.

Page 27

16 ST600R Autopilot Control Unit

Previous

Heading

D3505-1

• The display shows the new bearing to waypoint.

Manual Acquisition

For manual track acquisition when cross track error is the only data

available:

1. Steer the vessel to within 0.1nm of track.

2. Bring the heading to within 5° of the bearing to the next waypoint.

3. Press AUTO.

4. Press TRACK to enter Track mode.

• The display shows the cross track error and the locked pilot heading.

Note: At low speeds, the effect of tidal streams is far more significant than it

is at higher speeds. Providing the tidal flow is less than 35% of the

vessel’s speed, no noticeable difference should occur in the

performance of Track mode. However, extra care should be taken

during manual acquisition, as follows:

• Ensure that the vessel is as close as possible to track, and the

direction made good over the ground is as close as possible to the

direction of the next waypoint, before selecting Track mode.

• Make positive positional checks at regular intervals, especially if

navigational hazards are close by.

Page 28

Chapter 3: Advanced Operation

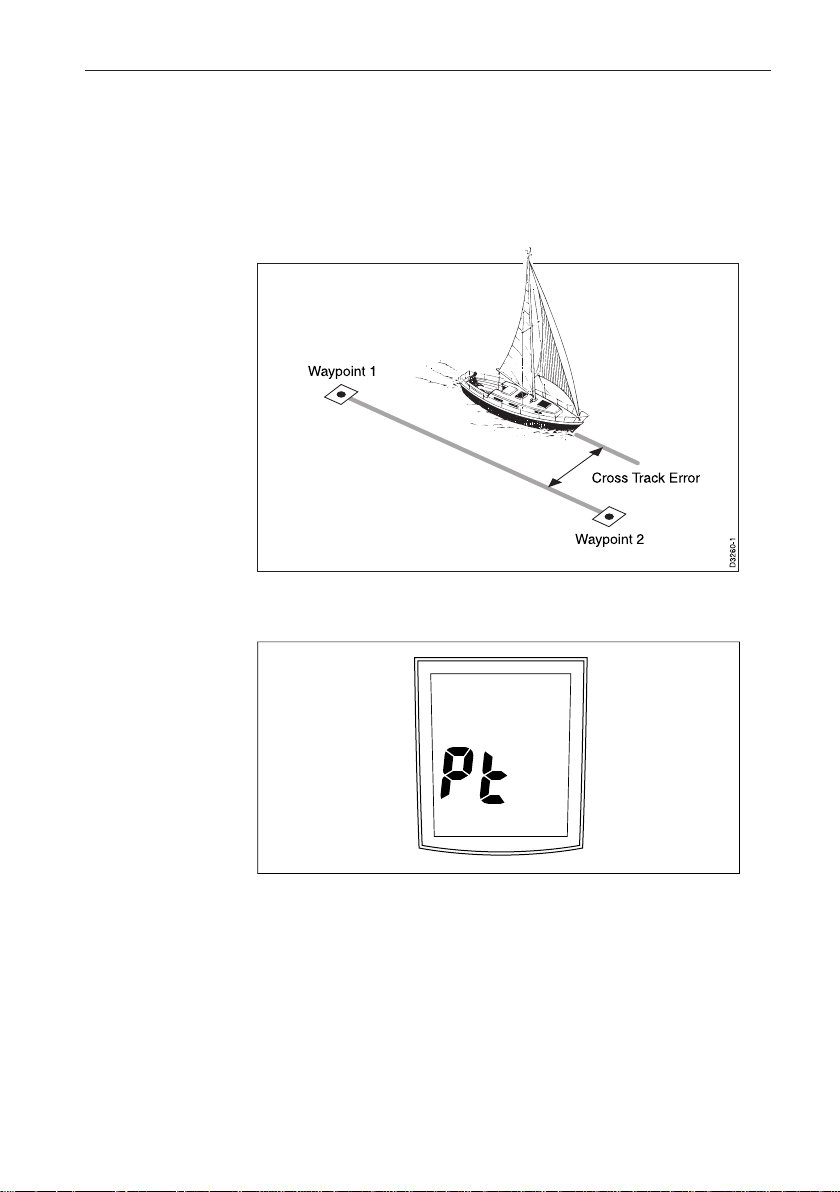

Cross Track Error

Cross track error (XTE) is the distance between the current position

and a planned route. This is displayed in nautical miles (nm), statute

miles (SM) or kilometres, and is taken directly from your navigator.

The Large Cross Track Error alarm sounds if the cross track exceeds

0.3nm.

17

LARGE

XTE

DXXXX-1

• The direction of the error is identified as “Pt” port or “Stb”

starboard.

• To cancel the alarm, press STANDBY to return to hand steering, or

AUTO to return to Auto mode.

Note: If the Large Cross Track Error alarm sounds, it is usually an indication

that the cross tide is too great for the vessel’s current speed.

Page 29

18 ST600R Autopilot Control Unit

Tidal Stream Compensation

Under most conditions, Track mode will hold the selected track to

within ±0.05nm (300ft) or better.

The autopilot takes account of vessel speed when computing course

changes to ensure optimum performance over a wide range of vessel

speeds. If speed data is available, the autopilot uses the measured

vessel speed. Otherwise, the Speed Over Ground (SOG) or specified

cruise speed is used, depending on the calibration setting (see

“Dealer Setup” in Chapter 5).

Vessel's speed

Vessel's

Waypoint Arrival and Advance

If your navigation receiver transmits valid NMEA waypoint number

and bearing to waypoint data, it is possible to advance from one

waypoint to the next by simply pressing TRACK.

Arrival

As the vessel passes the target waypoint, the navigation receiver

should select (manually or automatically) the next target waypoint.

The autopilot detects the new target waypoint number, sounds the

Waypoint Advance alarm and displays the Waypoint Advance

information. This display shows the new bearing to waypoint and

the direction the boat will turn to acquire the new track.

To accept the new target waypoint, press TRACK.

Page 30

Chapter 3: Advanced Operation

Skipping a Waypoint – SeaTalk Navigators Only

If you wish to advance to the next waypoint before you have arrived

at the target waypoint, press TRACK for 1 second. The Waypoint

Advance information for the next waypoint is displayed.

Advance

While the waypoint advance alarm is sounding, Track mode is

suspended and the autopilot maintains the current boat heading.

1. Check that it is safe to turn onto the new track.

2. Press the TRACK key. This will cancel the waypoint arrival alarm

and turn the boat towards the next waypoint.

Unless the Waypoint Advance is accepted in the above manner, the

alarm will continue to sound and the current heading will be

maintained.

Dodges

Full control is still available from the keypad when the autopilot is in

Track mode.

Initiating a Dodge Manoeuvre

In track mode, dodge manoeuvres are accomplished by simply

selecting the desired course change using the course change keys

(-1, +1, -10 or +10).

19

Cancelling a Dodge Manoeuvre

Once the hazard has been avoided, the course change selected for

the dodge manoeuvre should be cancelled by selecting an equal

course change in the opposite direction.

Note: Provided the vessel remains within 0.1nm of track, there is no need to

steer back towards the track.

Safety

Passage making in Track mode removes the chores of compensating

for wind and tidal drift, and will aid precise navigation. However, it

is important to maintain an accurate log with regular plots.

Position Confirmation at the Start of a Passage

At the start of a passage you must always confirm the fix given by

the position transducer, using an easily identifiable fixed object.

Check for fixed positional errors and compensate for them.

Page 31

20ST600R Autopilot Control Unit

Verifying Computed Positions

•Verify the computed position with a dead reckoned position,

calculated from the average course steered and the distance logged.

Plot Frequency

•In open water, plots should be at least hourly.

•In confined waters, or when potential hazards are near, plots should

be more frequent.

•Local variations in radio signal quality, and changes in the tidal

stream, will produce deviations from the desired track.

Setting Waypoints

•When setting waypoints, remember that deviations will occur.

•Thoroughly check along each track.

•Check up to 0.5nm each side of the track to ensure that there are no

hazards within the zone.

General

The use of track mode will enable accurate track keeping even in

complex navigational situations. However, it cannot remove the

responsibility of the skipper to ensure the safety of his vessel at all

times by careful navigation and frequent position checks.

3.2 Operation in Vane Mode (WindTrim)

Vane mode, also known as WindTrim, allows the autopilot to

maintain a course relative to an apparent wind angle. It uses wind

trim to eliminate the effects of turbulence and short term wind

variations, and provides smooth precise performance under Vane

mode operation with minimal power consumption.

Vane mode uses the fluxgate compass as the primary heading

reference and, as changes in the apparent wind angle occur, the

locked compass heading is adjusted to maintain the original

apparent wind angle.

To use Vane mode, the autopilot must receive wind information

from one of the following sources:

•

SeaTalk Wind instrument, connected to the autopilot via SeaTalk

•NMEA wind information

•Raymarine wind vane connected to a SeaTalk interface box

Page 32

Chapter 3: Advanced Operation

DXXXX-1

WIND

145P

autostdby

Selecting Vane Mode

Vane mode can be selected from either Standby or Auto modes, as

follows:

1. Steady the vessel onto a heading at which the apparent wind angle is

close to angle you require.

2. Press STANDBY and AUTO together to select Vane mode and

lock the current apparent wind angle.

• The locked heading is displayed in large characters. The locked

apparent wind angle is displayed above the heading, with an P (port)

or S (starboard) direction indicator.

• The boat heading is adjusted by the autopilot to maintain the locked

apparent wind angle.

21

Adjusting the Locked Wind Angle

The locked wind angle can be adjusted by changing course using the

-1, +1, -10 and +10 keys.

For example, to bear away by 10° when the vessel is on starboard

tack, press -10 to turn the vessel 10° to port. The locked apparent

wind angle and locked heading both change by 10°. The new

apparent wind angle is maintained, and the locked heading adjusted

by the autopilot as required.

Note: This method does not apply to systems using the Type 100/300

Course Computer. Also, this method should only be used for minor

adjustments to the apparent wind angle, since turning the boat

affects the relationship between the true and apparent wind angles.

For major changes, return to Standby mode, steer onto the new

heading, and reselect Vane mode.

Page 33

22 ST600R Autopilot Control Unit

DXXXX-1

LAST

autostdby

Returning to the Previous Apparent Wind Angle

(LAST WND)

If for any reason the vessel is steered away from the selected

apparent wind angle (for example, a dodge manoeuvre or selecting

Standby) you can return to the previous locked wind angle:

1. Press STANDBY and AUTO together for 1 second to display the

previous apparent wind angle (LAST WND).

The LAST WND? text alternates with the previous wind angle and

direction. The previous locked heading is displayed, with an

indicator to show you the direction in which the vessel will turn.

2. Check that it is safe to turn on to this course.

3. To accept this apparent wind angle, press STANDBY and AUTO

together within 7 seconds.

If you do not accept the previous wind within this time, the autopilot

will lock on to the current apparent wind angle.

Dodges

Full control is still available from the keypad when the autopilot is in

Vane mode.

• Dodge manoeuvres are accomplished by simply selecting the

desired course change using the course change keys

(-1, +1, -10 or +10). Both the locked heading and locked apparent

wind angle are adjusted.

• Once the hazard has been avoided, you can reverse the previous

course change, or return to the previous apparent wind angle

(LAST WND).

Page 34

Chapter 3: Advanced Operation

Wind Shift Alarm

The wind shift alarm sounds, and the text “WINDSHIFT” is

displayed, if a wind shift of more than 15° is detected.

1. Press STANDBY to cancel the alarm and return to hand steering,

and steer onto the required heading.

2. Press STANDBY and AUTO together to return to Vane mode with

the new apparent wind angle.

Using AutoTack in Vane Mode

The automatic tack function, when used in Vane mode, turns the

vessel so that the locked apparent wind angle is changed to an equal

angle on the opposite bow.

Initially, the autopilot turns the vessel through the specified tack

angle (the factory default is 100°). Then the locked heading is

adjusted until the required apparent wind angle is achieved.

• To tack to starboard, press the +1 and +10 keys together.

• To tack to port, press the -1 and -10 keys together.

Note: If you use the Autotack function in Vane mode, it is important to check

that the wind vane has been centred accurately when it was installed.

Also, the AutoTack feature cannot be adjusted if you are using a

Type 100/300 Course Computer.

23

Page 35

24 ST600R Autopilot Control Unit

AutoTack

Angle

Automatic Course

Ajustment (If Required)

to Mirror the Previous

Apparent Wind Angle

Apparent Wind Angle

D3391-1

Operating Hints

• Major changes to the selected apparent wind angle should be made

by returning to Standby mode, changing course manually, then

reselecting Vane Mode.

• Vane mode filters the windvane output. This provides the optimum

response for off-shore conditions where genuine shifts in wind

direction occur gradually.

• In gusty and unsteady inshore conditions, it is best to sail a few

degrees further off the wind so that changes in apparent wind

direction can be tolerated.

• It is important to ensure that the amount of standing helm is

minimised by careful sail trimming and positioning of the mainsheet

traveller.

• The headsail and mainsail should be reefed a little early rather than

too late.

Page 36

Chapter 3: Advanced Operation

3.3 Adjusting Autopilot Performance

The response level and rudder gain can be adjusted during normal

operation using a combined key-press.

The default calibration settings for response and rudder gain (refer to

Dealer Setup) are restored when the system is powered on.

Changing the Response Level (Auto Seastate)

The response level controls the relationship between the autopilot’s

course keeping accuracy and the amount of helm/drive activity.

• Response Level 1, Auto Seastate (Automatic Deadband), causes the

autopilot to gradually ignore repetitive movements of the vessel and

only react to true variations in course. This provides the best

compromise between power consumption and course keeping

accuracy, and is the default calibration setting.

• Response Level 2 (Minimum Deadband) provides the tightest

course keeping possible. However, tighter course keeping results in

increased power consumption and drive unit activity.

• Response Level 3 (also Minimum Deadband) provides the tightest

course keeping possible by introducing yaw damping (requires a

rate gyro and is only available with course computer systems).

The response can be changed at any time. To do so:

1. Press the +1 and -1 keys together momentarily to display the

Response screen.

2. Press +1 or -1 to change the response level.

25

3. Wait for 5 seconds, or press , to return to the previous display.

Normal Operation

BOAT

HDG

RESP

RESP

DXXXX-1

Page 37

26 ST600R Autopilot Control Unit

Changing the Rudder Gain

Press the +1 and -1 keys together for 1 second to display the Rudder

Gain screen, and adjust the setting in the same way as for the

response level. Refer to Chapter 7, “Post Installation Procedures”,

for instructions on how to check that the rudder gain is set correctly.

Warning: It is important that the rudder gain is correctly set on planing

craft. Incorrect adjustment will lead to poor steering

performance and is dangerous at high speeds.

3.4 Alarms

This section summarises the alarms (in order of priority) that are

reported by the ST600R.

Press STANDBY to clear an alarm and return to hand steering,

unless indicated otherwise.

ST

FAIL

WIND

SHFT

NEXT LOW

NO

LINK

LARGE

XTE

BATT

AUTO

RELSE

DRIVE

STOP

WATCH WATCH

OFF

CRS

NO

DATA

Page 38

Chapter 3: Advanced Operation

SeaTalk Failure

This silent alarm indicates that there is a wiring fault in the SeaTalk

connection.

No Link

This silent alarm indicates that there is no link between the ST600R

and the course computer.

Auto Release

The Auto Release alarm is activated when an Raymarine stern drive

actuator is returned to manual steering.

Off Course

This alarm is activated when the vessel has been off course from the

locked heading by more than the specified angle for more than 20

seconds (see Section 2.3, “Using Auto Mode”).

The alarm is cleared if the heading recovers or the course is

changed, or if the operating mode is changed.

Wind Shift

This alarm is activated when the apparent wind angle requires an

adjustment of the locked heading by more than 15° (see Section 3.2,

“Operation in Vane Mode”).

27

Large Cross Track Error

This alarm is activated when the cross track error exceeds 0.3nm

(see Section 3.1, “Operation in Track Mode”).

The autopilot stops controlling the locked heading as soon as this

condition occurs.

The alarm is cleared if the heading recovers or the course is

changed, or if the operating mode is changed.

Page 39

28 ST600R Autopilot Control Unit

Drive Stopped

This alarm is activated if the autopilot is unable to turn the rudder.

This occurs if the weather load on helm is too high, or if the

requested rudder position is past the preset rudder limits or the

rudder end-stops.

Data Not Received

This alarm is displayed in the following circumstances:

• Track mode is engaged and the autopilot is not receiving SeaTalk

navigation data.

• Track mode is engaged and the position transducer (GPS, Loran,

Decca) is receiving a low strength signal – this will clear as soon as

the signal strength improves.

• Vane mode is engaged and the autopilot has not received wind angle

data for 30 seconds.

The autopilot stops adjusting the locked heading as soon as data is

lost.

Waypoint Advance

The waypoint advance alarm sounds whenever the target waypoint

number changes, which occurs in the following circumstances:

• Automatic acquisition is selected by pressing TRACK from Auto

mode

• Waypoint advance is requested by pressing TRACK for 1 second in

Track mode (SeaTalk Navigators only).

When the alarm sounds, the pilot continues on its current heading,

but displays the bearing to the next waypoint and the direction in

which the boat will turn to take up that bearing.

Check that it is safe to turn onto the new track, and press TRACK to

accept the waypoint advance.

To cancel the alarm without accepting the waypoint advance, press

STANDBY to return to hand steering, or AUTO to return to Auto.

Note: The waypoint advance will only operate on pilots receiving valid

bearing to waypoint and waypoint number information.

Page 40

Chapter 3: Advanced Operation

Low Battery

The Low Battery alarm sounds when the supply voltage drops

below 10V (±0.5V).

Press STANDBY to clear the alarm and return to hand steering.

Start the engine to recharge the battery.

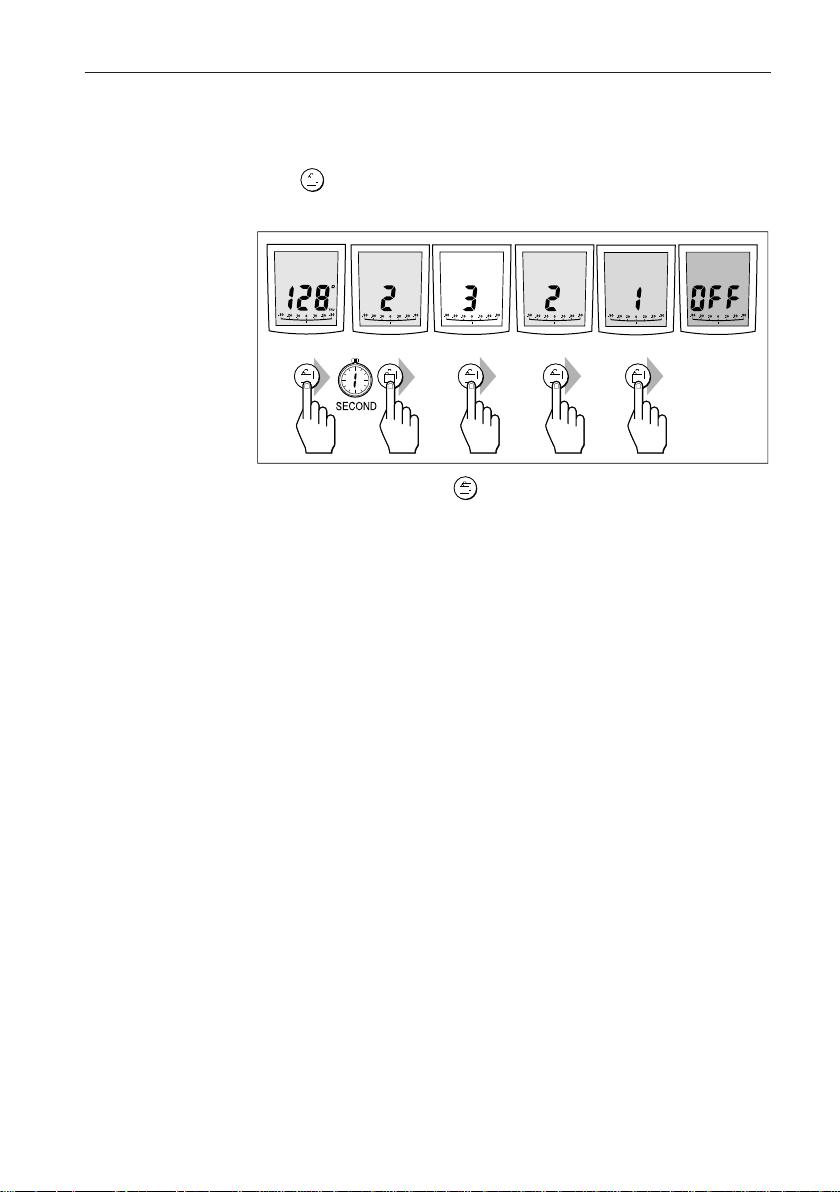

Watch Alarm

The Watch alarm is activated in Watch mode when the timer Page is

displayed.

• The watch timer starts counting.

• When the timer reaches 3 minutes, the text on the display starts

flashing to indicate the last minute of Watch alarm.

• When the timer reaches 4 minutes, the audible Watch alarm is

activated.

3. Press AUTO at any time to silence the alarm and reset the timer to

4 minutes (Pressing any other key resets the timer and performs the

key’s normal function).

4. To clear Watch mode, press to display the PILOT page.

Note: Watch mode is also cleared if the chapter is changed or a pilot mode

change occurs.

29

Man Overboard (MOB)

If a man overboard (MOB) message is received from another

instrument on the SeaTalk system, the text “MOB” is shown instead

of the waypoint number for the XTE, DTW and BTW Data Pages.

If the autopilot is operating in Track mode, the Waypoint Advance

alarm will sound to notify the change in waypoint.

Page 41

30 ST600R Autopilot Control Unit

Page 42

Chapter 4: CodeLock

Chapter 4: CodeLock

CodeLock is a personal four-digit security feature designed to

protect your valuable instruments against theft. You don’t have to

activate the system, but it’s there if you need to. You can activate it

using any CodeLock-compatible control unit on your SeaTalk

system.

When you first enter a code and activate CodeLock, the code is sent

to all the CodeLock-compatible units on the system. After this,

whenever you power on the system, the units will only start up if

they receive the correct code.

Remember to fix a CodeLock sticker by each instrument, to deter

potential thieves.

4.1 CodeLock Modes

When you set up CodeLock, you can choose whether the code will

be sent automatically or must be entered manually at power on, as

follows:

• Auto mode is used when there is a display unit situated in a secure

location, ideally below deck, or one which can be unplugged and

removed to a secure location. You enter your chosen code on this

“master” unit when you first activate CodeLock. This code is then

automatically sent to all CodeLock-compatible display heads on

SeaTalk, without further intervention, every time the system is

powered on.

• Manual mode is used to provide a higher degree of security,

perhaps when all your instruments are mounted in exposed

locations. In this case, you must enter your personal code every time

the system is switched on. The code can be entered into any

convenient CodeLock-compatible control unit, and is then sent to all

the other compatible units via SeaTalk.

31

4.2 Setting Up CodeLock

CodeLock is set on the ST600R using the Intermediate Setup

options.

Page 43

32 ST600R Autopilot Control Unit

Initial Setup

When you first install your ST600R, CodeLock is set OFF. To

activate CodeLock, refer to the following flow diagram.

Setting CodeLock

Normal Operation

Software Version CodeLock Screen

Software Version

STBY

VERS

ION

stdby

Enter a Four Digit Code Number

Enter a number at the flashing cursor:

+1

--1

+10

--10

auto

stdby

Code Complete Auto Mode or...

CODE

0345

Code Set Normal Operation

CODE

SET

-1 cycles: 0 9 8 7 6 5 4 3 2 1

+1 cycles: 0 1 2 3 4 5 6 7 8 9

Move the cursor to the next position

track

CODE

AUTO

STBY

stdby

+1

OR

--1

4

Manual Mode

CODE

MAN

9 10

• Make sure that the autopilot is in Standby mode before accessing

Intermediate Setup.

• If the CAL LOCK screen is displayed instead of the VERSION

screen, you need to turn off the lock feature in Dealer Setup.

The Intermediate Setup displays have the following functions:

Page 44

Chapter 4: CodeLock

Note: If you set up CodeLock in Auto mode, the unit on which you enter the

33

• Manual/Auto modes are explained in section 4.1

• Version numbers: Displays the current ST600R version number,

alternating with the ST60 pilot version number (if applicable). You

cannot adjust these displays.

• CodeLock status: Reports the current status, which can be OFF or

SET. You cannot adjust this display directly.

• CodeLock entry: Used to enter a new code if CodeLock is OFF, or

to turn CodeLock off if it is already set.

• CodeLock mode: Used to select Auto or Manual CodeLock mode,

when a new code has been entered.

Changing the Code or Master Unit

You can change the code from any CodeLock compatible control

unit on your SeaTalk system, provided you know the current code.

new code becomes the new master unit.

To change the code:

1. Display the CodeLock entry screen and enter your current code, as

shown in the flowchart.

The code is checked. If it is incorrect, the four dashes are redisplayed

and you must enter the code again. If it is correct, the CodeLock

status screen is displayed, with the status set to OFF.

2. Press to display the CodeLock entry screen again.

3. Enter the new code (as described in Initial Setup) and move on to the

CodeLock mode selection screen.

4. Set the mode to Auto or Manual, as required.

5. Press and hold STANDBY for 2 seconds to exit Intermediate Setup

and save the new settings.

4.3 Entering Your Code (Manual Mode Only)

If CodeLock has been set up in Manual mode, the correct code must

be entered on one of the control units every time the system is

switched on. The code number created on the master is entered via

the keypad from any CodeLock-compatible instrument, and this

code is then sent to all compatible instruments on the same SeaTalk

bus. Once this code has been received the instruments operate in the

normal way.

Page 45

34 ST600R Autopilot Control Unit

To enter your chosen code number on the ST600R control unit, use

the keys as shown.

CodeLock Manual

Decrease the number at the flashing cursor:

--1

+1

+10

--10

stdby

auto

track

0 9 8 7 6 5 4 3 2 1

Increase the number at the flashing cursor:

0 1 2 3 4 5 6 7 8 9

Move the cursor to the next position

CODE

Press this key to accept code, after the

last number has been entered, and go

to normal operation

Code Complete Normal Operation

CODE

STBY

0345

To enter the code on any other master display unit, refer to the

handbook for that unit for details of the code entry procedure.

4.4 Code Number Problems

• If an incorrect code number has been entered, the four dashes are

redisplayed, with the prompt “code”. Repeat the procedures

illustrated above entering the correct four digit number.

• If you forget your code number, you must take your master unit to an

authorised dealer, together with appropriate proof of ownership such

as the original invoice. The dealer will be able to reset the unit so

that you can enter a new code.

Page 46

Chapter 5: Customising the System

Chapter 5: Customising the System

The ST600R provides setup and configuration options that are used

to adjust the settings for the ST600R itself, the compass, and the

autopilot.

Note: You should perform the post installation procedures described in

Chapter 7 before adjusting any other calibration features.

There are three setup levels:

• User Setup, which controls compass setup, rudder calibration and the

ST600R display features

• Intermediate Setup, which controls the CodeLock security feature

and displays status and version number information (see Chapter 4)

• Dealer Setup, which controls the autopilot settings, and also the

calibration lock which can be used to prevent accidental access to

User and Intermediate Setup

The Dealer Setup options described in this chapter only apply if you

have installed the ST600R as the control unit for a Type 100/300

course computer. If you have installed the ST600R as a repeater unit

on an autopilot system, please refer to the Dealer Setup instructions

in the handbook for the main control unit.

35

5.1 User Setup

The flow chart on the following page shows the User Setup control

procedure, and the setup screens with their default settings.

Information on the functions of the different settings is given in the

remainder of this section.

The following points should be considered:

• Make sure that the autopilot is in Standby mode before you access

User Setup

• If the CAL LOCK screen is displayed instead of the initial page, you

need to turn off the lock feature in Dealer Setup

• Setup options are always saved on exit

Page 47

36

ST600R Autopilot Control Unit

stdby

stdby

* Not applicable to pre version 11 Type 100/300 Course Computer software

Page 48

Chapter 5: Customising the System

Compass Deviation Correction (SWING COMPASS)

The compass deviation correction option allows you to correct the

compass for deviating magnetic fields. The procedure must be

performed as the first item in your initial sea trial, and is described in

detail in Chapter 7, “Post Installation Procedures”.

Deviation Display (DEVIATION)

This screen shows the current deviation value, calculated from the

correction procedure (Swing Compass). You cannot edit this value.

Heading Alignment (ALIGN HDG)

The heading alignment screen shows the current reported heading.

Note: You should always check the compass alignment after performing a

compass deviation correction (see “Post Installation Procedures”).

However, once the initial correction procedure has been performed,

you can make adjustments to the alignment as often as you wish,

without re-correcting your compass.

• Steer onto a known heading, and check the heading displayed.

• If required, adjust the heading value to match the known value, using

the +1, -1, +10 and -10 keys.

37

Pilot Type*

Displays the Pilot Type: sterndrive, displacement, semidisplacement or planing.

Heading Mode (HDG)

Select either magnetic or true heading mode, using the +1 or -1 key.

When heading data is displayed in normal operation, the screen

indicates whether true or magnetic mode has been selected.

* Not applicable to pre version 11 Type 100/300 Course Computer software

Page 49

38

ST600R Autopilot Control Unit

Bar Selection (RUDD BAR)

Select the type of bar graph, using the +1 or -1 key, to be shown at the

bottom of the SeaTalk displays.

The options are as follows:

RUDD BAR: This shows the rudder position, and is the default

setting. Note that a rudder reference transducer is required for

accurate rudder position information.

STEER BAR: The bar graph is used as follows:

Mode Bar

Standby Not used (shows rudder angle if a feedback transducer

connected to the autopilot

Auto Heading error bar

Track XTE bar

Vane Wind angle error bar

Rudder Calibration (DOCKSIDE RUDD CAL)*

Dockside Rudder Calibration is used to automatically calibrate the

rudder range (for systems with a rudder reference unit) and optimise

autopilot performance by matching the autopilot to its installation.

Warning: This procedure moves the helm, and should only be used when

the vessel is at the dockside. For sterndrive systems, the

engines must be running before you start the procedure.

• The auto dockside procedure is not available if the ST600R is used

with a Type 100/300 Course Computer.

• The Dock Side calibration feature is started using the +1 or -1 key.

• If you start the procedure by mistake, press any key to cancel it.

• If the autopilot does not respond, the display shows “AUTO N/A”.

• Activation and completion of Auto Dockside are displayed as:

“AUTO WAIT” and “AUTO END” respectively.

• The “ALIGN RUD” screen follows “AUTO END” if you have a

rudder feedback transducer. The helm should be centred by hand and

the rudder bar adjusted to zero using the -1 and +1 keys.

Quitting User Setup

To quit User Setup at any time, press STANDBY for 2 seconds.

* Not applicable to pre version 11 Type 100/300 Course Computer software

Page 50

Chapter 5: Customising the System

5.2 Dealer Setup: Type 100/300 Course

Computer

This section describes the Dealer Setup options if you have installed

the ST600R as the control unit for a Type 100/300 Course Computer.

If you have installed the ST600R as a repeater unit on another

autopilot system, please refer to the Dealer Setup instructions in the

handbook for the main control unit.

Dealer Setup allows you to customise the autopilot to suit your boat.

However, once you have set the Pilot Type, the factory default

settings will provide safe performance for the initial sea trial, and fine

tuning is not normally required.

The flow chart on below shows you how to enter Dealer Setup, scroll

through the setup displays, adjust the values and exit.

39

Page 51

40

ST600R Autopilot Control Unit

ST600R Dealer ST600R Calibration Screens when

used with the ST6000 Plus and Type 100/300 Course

Computer

Dealer Calibration

stdby

1234

5678

9101112

13 14 15 16

--1

+1

17 18 19 20

--1

Adjusting

Dealer

Calibration

Features

* Not available on pre version 11 Type 100/300 Course Computers

+1

Quitting

Dealer

Calibration

stdby

Page 52

Chapter 5: Customising the System

ST600R Dealer Calibration Screens when used with

the ST4000 Plus and ST5000 Plus Autopilots

The ST600R screen cycle for the ST4000 Plus and ST5000 Plus is as

follows:

• Pilot Type (eg, 4000 WHL)

• Calibration Lock (CAL LOCK)

• Rudder Gain (RUDD GAIN)

• Response (RESP)

• Turn Rate (TURN RATE)

• Rudder Offset (ALIGN RUDD)

• Off Course (OFF CRS)

• Auto Tack (AUTO TACK)

• Cruise Speed (SPEED CRS)

• Rudder Damping (RUDD DAMP)

• Latitude (LAT ADAP)

• Variation (VAR EAST/WEST)

• Drive Type (DRIVE TYPE)

• Automatic Trim (AUTO TRIM)

41

Recommended Settings

The following pages list the default calibration settings for sailing/

power displacement and planing power vessels. Once you have set

the Pilot Type, these will provide good performance for initial sea

trials and can be fine tuned later to optimise performance.

After initial calibration has been carried out, further adjustment can

be made at any time.

The features that can be adjusted are listed in the table at the end of

this chapter, where you can record your settings for future reference.

Information on the functions of the different settings is given in the

remainder of this section.

The following points should be noted:

• Make sure that the autopilot is in Standby mode before you access

Dealer Setup

• Setup options are always saved on exit

Page 53

42

ST600R Autopilot Control Unit

Pilot Type (ST6000 Plus & Type 100/300)

This should be set when the system is first switched on. The default

settings for other Dealer Setup options depend on the pilot type you

select here.

Setting Description

DISPL MNT Displacement

SEMI DIS Semi-displacement

PLANING Planing

SOLENOID Constant running solenoid system

STERN DRV Sterndrive

Default: PLANING

Pilot Type (ST4000 Plus and ST5000 Plus)

When the ST600R is used with the ST4000 Plus and ST5000 Plus

autopilots, the following ‘pilot types’ may be selected.

Setting Description

4000 WHL ST4000 Plus Wheeldrive

4000 TILL ST4000 Plus Tiller Pilot

5000 SAIL ST5000 Plus SailPilot

5000 STRN ST5000 Plus Sterndrive

5000 HYD ST5000 Plus Hydraulic

Calibration Lock

Calibration lock controls whether User Setup and Intermediate Setup

are available, and is intended for charter boat users.

Setting Description

ON Setup ON

OFF Setup OFF

Default: OFF

Page 54

Chapter 5: Customising the System

Rudder Gain

This must be set while under way, as described in Chapter 7, “Post

Installation Procedures”.

Range: 1 to 9

Default: 5 (Displacement)

Rate Level

Rate Level monitors the speed at which rudder is applied when

changing course. Rate level will, if the rate at which the vessel is

turning is too fast, counter this turn with opposite rudder.

The settings available are as follows:

Range: 1 to 9

Defaults: 7 Displacement

43

5 (Semi-displacement)

4 (Planing)

3 (Sterndrive)

7 Semi-displacement

7 Planing

5 Sterndrive

Rudder Offset

You only need to set this option if your system includes a rudder

reference unit.

• Manually place the helm in a central position. The reported rudder

angle is indicated on the rudder bar graphic at the bottom of the

screen.

• Adjust the offset value, using the +1 and -1 keys, until the rudder

position is shown as central on the rudder bar. The offset must be

within the range -7° to +7°.

Range: –7° to +7°

Default: 0

Page 55

44

ST600R Autopilot Control Unit

Rudder Limit

Rudder Limit restricts autopilot rudder movement to just less than

the steering systems mechanical stops. This avoids putting the

steering system under unnecessary load.

The range available is as follows:

Range: 15° to 40°

Defaults: 30° Displacement, semi-displacement, planing

20° Sterndrive

Turn Limit

This limits the rate of turn of your vessel when under autopilot

control. The value must be within the range 5 to 20°. For sailboat

applications it should be set to 20°.

Range: 5° to 20° per second

Default: 20° (Displacement)

15° (Semi-displacement)

08° (Sterndrive)

Cruise Speed

The Cruise Speed value is used by the autopilot during Track mode

operation, when it calculates compensation for tidal streams and

leeway.

Set the value to the boat’s normal cruising speed.

Alternatively, set Cruise Speed to Auto mode (A) (not available when

using a Type 100/300 Course Computer) so that Speed Over Ground

(SOG) data is used, if available. SOG will normally give better coursekeeping than a fixed value. However, using SOG could cause

problems at low boat speeds where the tide exceeds 35% of the boat

speed.

Note: If boat speed data is available via SeaTalk or NMEA, the Cruise

Speed setting is ignored and the actual boat speed is used.

Range: 4 to 60 knots

Defaults: 6 (Displacement)

8 (Semi-displacement)

20 (Planing)

20 (Sterndrive)

Page 56

Chapter 5: Customising the System

Off Course Alarm

This is the off course alarm angle. It controls the alarm that warns you

if the autopilot is unable to maintain its set course.

The alarm operates if the autopilot strays off course by more than the

alarm angle limit for more than 20 seconds.

The value must be within the range 15 to 40°, and can be adjusted in

1° steps.

45

Range: 15 to 40°

Default: 20°

AutoTrim

The AutoTrim level setting determines the rate at which the autopilot

applies “standing helm” to correct for trim changes caused by

varying wind loads on the sails or superstructure. The settings are:

Setting Effect Recommended for:

1 Slow trim correction Heavy displacement vessels,

2 Medium trim correction Heavy displacement vessels.

3 Fast trim correction Moderate to light displacement

4 Super fast correction Planing power vessels

Default: 3

The default setting (Level 3) should provide optimum performance

with the ST600R autopilot. However, depending on the vessel’s

dynamic stability, an incorrect rate of trim application may result in

poor course keeping due to autopilot instability.

with full keel or transom rudder.

vessels.

Page 57

46

ST600R Autopilot Control Unit

After gaining experience with the ST600R, you may wish to change

the setting. The effect of the setting must be evaluated while under

sail.

• Decrease the AutoTrim level if the autopilot gives unstable course

keeping or excessive drive activity with a change in the heel angle.

• Increase the AutoTrim level if the autopilot reacts slowly to a

heading change due to a change in the heel angle.

• For systems without a rudder reference unit, these settings have no

effect and trim is set to level 3.

Power Steer

Power steer selects the Joystick mode of operation: Proportional or

‘Bang-Bang’.

Proportional applies rudder in proportion to Joystick movement –

the further the Joystick is held over the greater the applied rudder.

Bang-Bang applies continuous rudder drive in the direction of lever

movement. To improve control the speed of rudder movement

changes with the angle of the lever. For maximum speed push the

lever hardover. If the lever is returned to the centre position the rudder

will remain in its current position.

The settings available are as follows:

Range: 1 = Proportional

2 = Bang-bang

Default: 1

Drive Type

The drive type controls the way which the autopilot drives the

steering system. The default setting should be retained for

mechanically driven vessels.

Range: 1 = Mechanically driven vessels without a rudder reference unit

2 = Hydraulic, no rudder reference unit

3 = Linear, rotary and sterndrive with a rudder reference unit

4 = Hydraulic with rudder reference unit

Default: 1

Page 58

Chapter 5: Customising the System

Rudder Damping

You only need to set this option if your system includes a rudder

reference unit, and the drive “hunts” when trying to position the

rudder. Test for this when your vessel is moored dockside, by

pressing AUTO and then +10. If the helm overshoots and has to drive

back or starts to hunt back and forth, you need to increase the

damping level.

In auto mode (A), the autopilot applies damping compensation

automatically – not available if using a Type 100/300 Course

Computer.

Alternatively, you can set a value in the range 1 to 9. Adjust the

damping one level at a time, and always use the lowest acceptable

value.

Range: 1 to 9

Default: 1

Variation

If required, set this value to the level of magnetic variation present at

your vessel’s current position. +ve variation = East, -ve variation =

West. The variation setting is sent to other instruments on the

SeaTalk system, and can be updated by other SeaTalk instruments.

47

Range: -30° to +30°

Default: Off

Page 59

48

ST600R Autopilot Control Unit

AutoAdapt

The patented AutoAdapt feature allows the autopilot to compensate

for heading errors at higher latitudes, which are caused by the

increasing dip of the earth’s magnetic field. The increased dip has the

effect of amplifying rudder response on northerly headings in the

northern hemisphere, and on southerly headings in the southern

hemisphere.

Set AutoAdapt to “nth” in the northern hemisphere, or “sth” in the

southern hemisphere. You then need to enter your current latitude in

the next setup screen, so that the autopilot can provide accurate

course keeping by automatically adjusting the rudder gain

depending on the heading.

Range: 0ff = Off

nth = North

Sth = South

Default: Off

Latitude

This screen is only used if AutoAdapt is set to North or South.

Use the +1, -1, +10, and -10 keys to set the value to your vessel’s

current latitude, to the nearest degree.

Range: 0 to 80°

Default: Off

Note: If valid latitude data is available via SeaTalk, it will be used instead of

this calibration value.

Page 60

Chapter 5: Customising the System

Auto Tack*

The AutoTack angle is the angle through which the vessel will turn

when the automatic tack feature is selected. The value must be within

the range 40 ~ 125° and can be adjusted in 1° steps.

Wind Trim*

This varies the response of the autopilot when in wind mode.

The settings available are as follows:

Range: 1 Normal setting

Default: 1

Auto Release

Auto Release provides emergency manual override, should it be

necessary, to avoid an obstacle at the last moment. This option only

applies to sterndrive actuators – for all other systems this option

should be set to off.

Range: Off

Defaults: 0 for Displacement, Semi-displacement &

49

2 Faster response for wind shifts

On

Planing

1 for Sterndrives

Response

This is the power-on response setting. The response level can be

changed during normal operation (see Section 3.3) or via the

Response Data Page, if this is set for display (see Section 2.6).

Range: Level 1 (Auto Seastate)

Level 2 (Auto sea state inhibit)

Level 3 (Auto sea state inhibit counter rudder)

Default: Level 1

*Not available on th ST4000 Plus and ST5000 Plus

Page 61

50

ST600R Autopilot Control Unit

Recording Calibration Settings