Page 1

Distributed by

Any reference to Raytheon or

RTN in this manual should be

interpreted as Raymarine.

The names Raytheon and RTN

are owned by the

Raytheon Company.

Page 2

ST40 Bidata

Instrument

Owner’s

Handbook

Document number: 81159_2

Date: 1st May 2001

Page 3

Copyright © Raymarine Limited 2001

Page 4

Preface

Important information

WARNING

Although your ST40 instrument is designed to give accurate and

reliable performance, it should serve only as an aid to navigation

and should never lead to the erosion of good seamanship. Always

maintain a permanent watch and be aware of situations as they

develop.

EMC conformance

All Raymarine equipment and accessories are designed to the best

industry standards for use in the leisure marine environment.

The design and manufacture of Raymarine equipment and accessories

conform to the appropriate Electromagnetic Compatibility (EMC)

standards, but correct installation is required to ensure that performance

is not compromised.

Handbook information

To the best of our knowledge, the information in this handbook was

correct when it went to press. However, the Raymarine policy of

continuous product improvement may change product specifications

without notice. Consequently, unavoidable differences may occur

between the product and the handbook from time to time, for which

Raymarine cannot accept liability.

i

Page 5

ii ST40 Bidata Instrument Owner’s Handbook

Page 6

Preface

Contents

iii

Important information .......................................................... i

WARNING......................................................................... i

EMC conformance ............................................................. i

Handbook information ....................................................... i

Preface.....................................................................................v

Parts supplied ................................................................... vi

Chapter 1: Operation .............................................................1

1.1 Introduction ................................................................. 1

Display ....................................................................... 1

1.2 Operating procedures .................................................. 2

Display action............................................................. 2

Silencing alarms ......................................................... 2

1.3 Alarms ......................................................................... 7

Alarm indications ....................................................... 7

Shallow alarm ........................................................ 7

Deep alarm ............................................................. 7

Anchor alarms ........................................................ 7

Enabling/disabling alarms .......................................... 8

Chapter 2: Maintenance and Fault Finding ........................ 9

2.1 Maintenance ................................................................ 9

Servicing and safety ................................................... 9

Instrument................................................................... 9

Transducer ................................................................ 10

Cabling ..................................................................... 10

2.2 Fault finding .............................................................. 10

Preliminary procedures ............................................ 10

Fixing faults .............................................................. 10

Assistance ................................................................. 13

Page 7

iv ST40 Bidata Instrument Owner’s Handbook

Chapter 3: Installation......................................................... 15

3.1 Planning your installation ......................................... 15

EMC installation guidelines ..................................... 15

Suppression Ferrites ........................................... 16

Connections to Other Equipment ......................... 16

Tools required .......................................................... 16

Site requirements ...................................................... 17

Transducers.......................................................... 17

Instrument ............................................................ 19

3.2 Procedures................................................................. 20

Fitting transducers .................................................... 20

Running transducer cable .................................... 20

Connections to the instrument .................................. 21

Stand-alone connections ...................................... 22

SeaTalk connections ............................................ 23

Fitting the instrument ............................................... 23

Desktop Mounting Bracket .................................. 25

3.3 Calibration requirement ............................................ 26

Chapter 4: Calibration ......................................................... 27

4.1 Introduction ............................................................... 27

EMC conformance ................................................... 27

4.2 User calibration ......................................................... 27

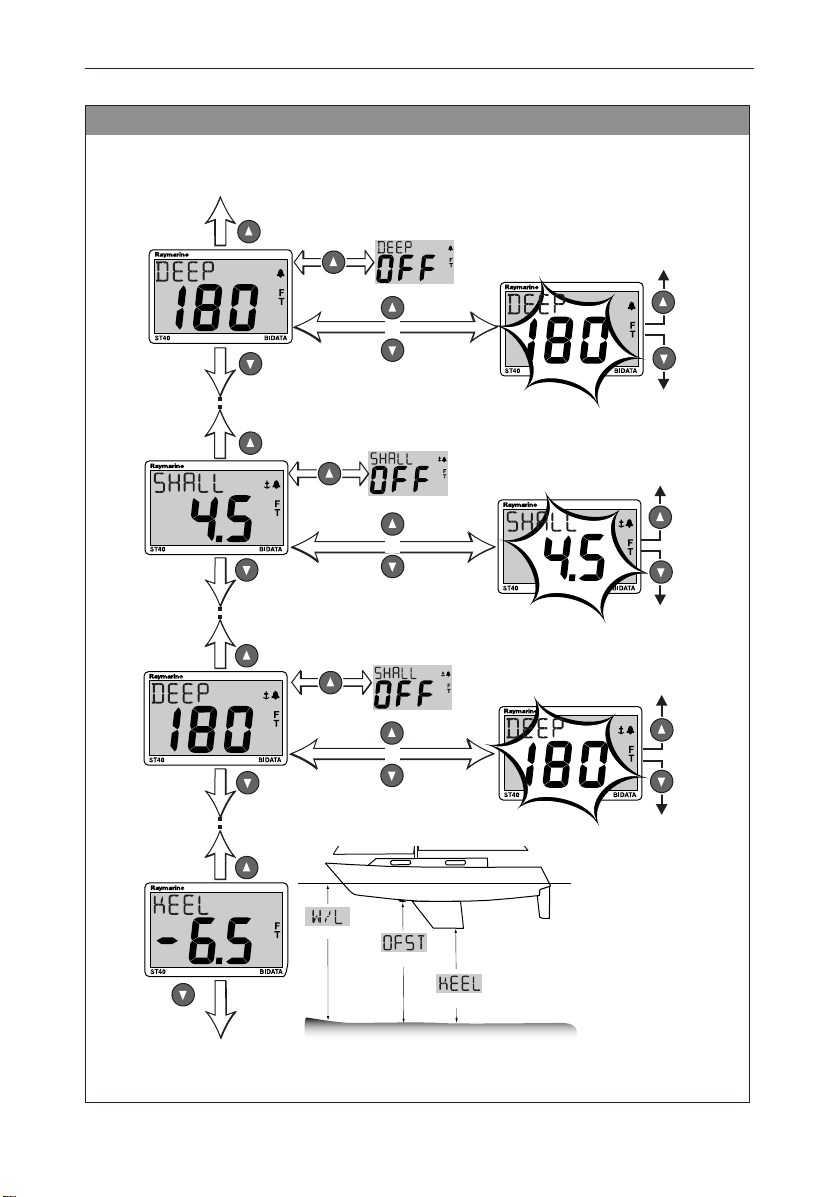

Depth offsets ............................................................ 31

4.3 Intermediate calibration ............................................ 31

4.4 Dealer calibration ...................................................... 32

Instrument Specification .................................................... 35

Glossary ................................................................................. 37

Index ...................................................................................... 39

Page 8

Preface

Preface

v

Thank you for purchasing a Raymarine product. We are sure your

ST40 instrument will give you many years of trouble-free operation.

This instrument is designed to provide reliable performance, even

under the most demanding conditions.

D4807-2

Page 9

vi ST40 Bidata Instrument Owner’s Handbook

Parts supplied

ST40

ST40 Bidata instrument

Gasket

Clamping bracket

ST40

Bidata

Instrument

Owner's

Handbook

Owner’s Handbook.

Warranty document and fitting

templates included in Handbook

BIDATA

Retractable speed transducer

Supplied with bung

(not illustrated)

1 m (3 ft) power cable

Worldwide

Distributors

Worldwide Service Centre

Handbook.

Instrument Cover

ST40 Bidata Instrument - quick reference guide

SPEED

Last permanent

screen is displayed

To enter adjust mode, press for 1 second to adjust BACKLIGHTING and a further 1 second to adjust CONTRAST

Depth transducer

Fixing

Thumb

stud

nut

Normal operation

SWITCH ON

DEPTH

Notes:

Depth

denotes temporary screens

*

which will time-out to the previous

permanent screen after 5 seconds.

Minimum

depth

Reset

Shallow

alarm

Deep

alarm

Shallow

anchor

alarm

Reset

Deep

anchor

alarm

Offset

Adjusting display backlighting/contrast

LEVEL 1

orTo exit adjust mode press or wait for 5 second timeout

On repeater instruments, on;ly the

Speed, Water temperature,

Depth and Minimum depth

screens are available.

Alarm on/off

3 seconds

Alarm on/off

3 seconds

Alarm on/off

3 seconds

Alarm on/off

3 seconds

With Set alarm level screen displayed,

press the

and keys simultaneously

to save the alarm level and return to

normal operation.

Current

speed

Maximum

speed

3 seconds

Reset

Average

speed

3 seconds

Log

Trip

3 seconds

Water

Temp.

OFF LEVEL 2LEVEL 3LEVEL 2

Quick Reference Guide

+

Set

alarm

level

-

LEVEL 1

Note:

The items shown here are supplied for an ST40 Bidata system. If an instrument is purchased separately, transducers

are not included. If any item is not present, contact your Raymarine Dealer.

D4730-2

Page 10

Chapter 1: Operation

Chapter 1: Operation

1.1 Introduction

Your ST40 Bidata instrument:

• Provides speed information (current, maximum and average), in

either knots (KTS), miles per hour (MPH) or kilometres per

hour (KPH).

• Provides log and trip information. These are given in either nautical

miles (NM), statute miles (M) or kilometres (KM).

• Provides water temperature information. This is given in either

degrees Celsius (°C) or degrees Fahrenheit (°F).

• Provides depth information in either feet (FT), metres (M) or

fathoms (FA).

• Records the minimum depth encountered during the period it is

switched on. You can reset this at any time.

• Enables you to define alarm thresholds for shallow water, deep

water, shallow anchor and deep anchor.

• Enables you to see what offset is applied to the depth reading.

1

Note: The required speed, distance, depth and water temperature units

are selected during User calibration (see Chapter 4, Calibration).

CAUTION

Your instrument is calibrated to factory (default) settings when

first supplied and must therefore be calibrated before use, to

ensure optimum performance on your vessel. Do NOT use the

instrument until the calibration procedures have been

satisfactorily completed, using the procedures in Chapter 4,

Calibration.

Coloured bezel and Desktop Mounting Bracket options are available

for your ST40 instrument. Contact your Raymarine dealer for further

information.

Display

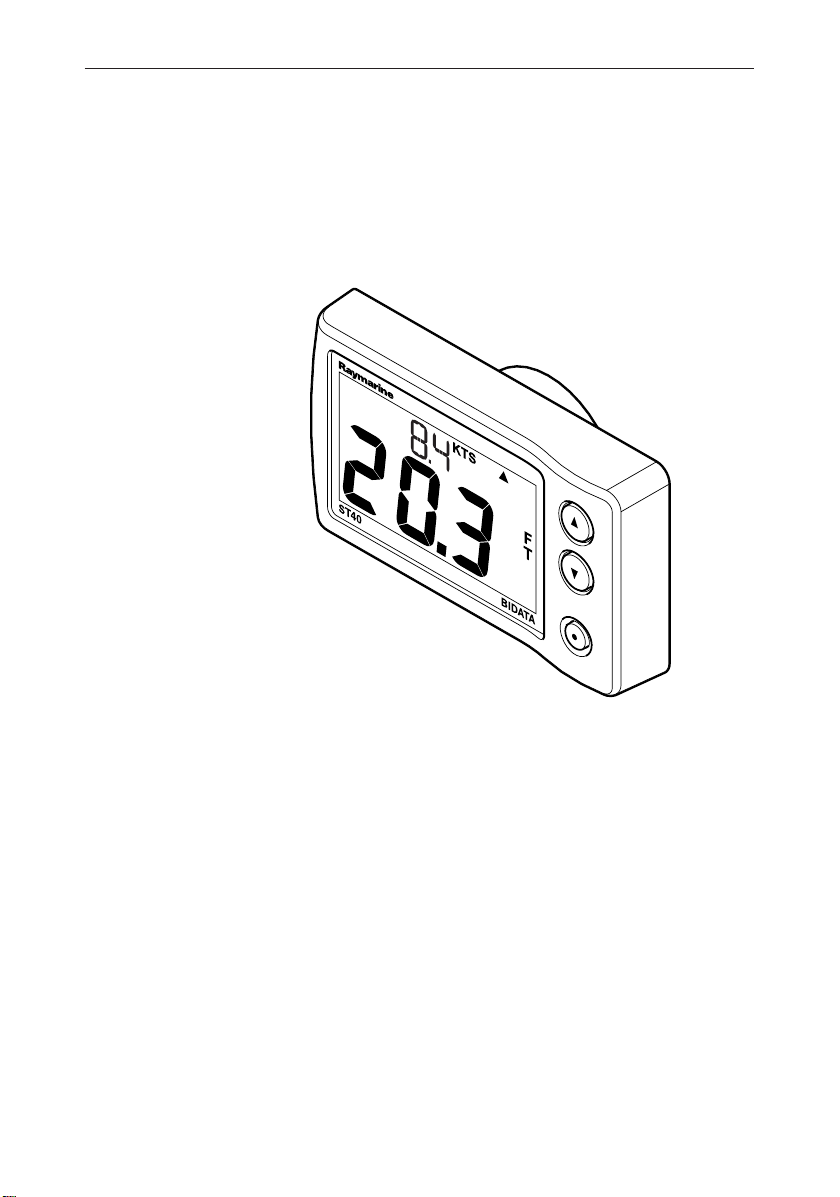

The ST40 Bidata display comprises upper and lower data areas, each of

which shows either depth or speed information, selected as shown in

the following illustration.

Page 11

2 ST40 Bidata Instrument Owner’s Handbook

DEPTH

SPEED

Selecting where speed and depth information is displayed

1.2 Operating procedures

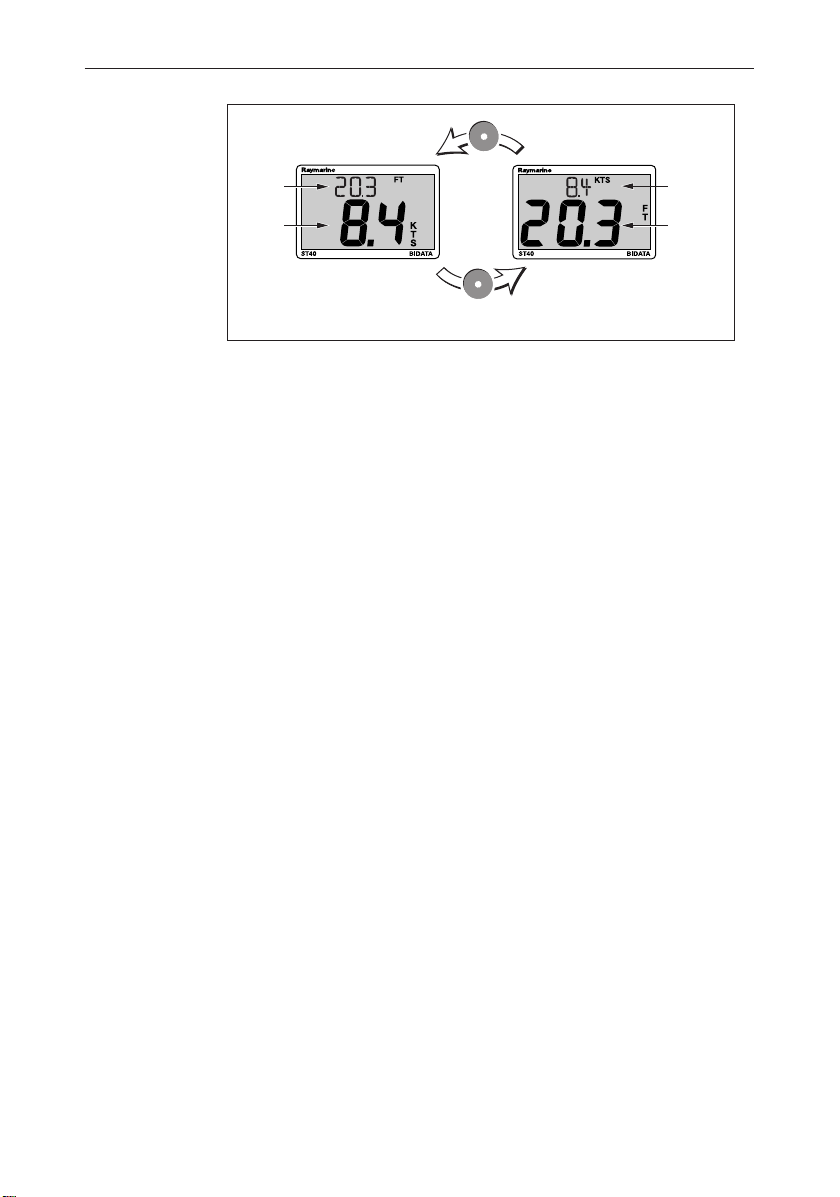

Operating information is presented in flow chart form. The flow charts

show the various operating screens and key presses necessary to carry

out the various instrument functions. Key presses are momentary unless

otherwise stated. Note that:

• Up/down depth-trend arrows are displayed, if the seabed is rising or

falling at a significant rate.

• The minimum depth reading is reset to zero at power up.

• The maximum speed reading is reset to zero at power up.

• The average speed reading is reset to zero at power up.

• The Log screen shows the total distance covered by the vessel since

the ST40 Bidata instrument was fitted.

• The trip reading is reset to zero at power up.

SPEED

DEPTH

D4733-2

Display action

During normal operation (see Normal operation flow charts), the

Speed, Depth and Water temperature screens are permanent

screens, i.e. once one of these is selected, it will remain until another

screen is manually selected. All other screens are temporary and after

5 seconds, will time out to the permanent screen which was last

displayed for 5 seconds or more.

Silencing alarms

To silence an alarm (see the Alarms section, later in this chapter),

momentarily press any one of the instrument keys.

Page 12

Chapter 1: Operation

3

NORMAL OPERATION (sheet 1)

Switch on

Current

speed

Maximum

speed

Average

speed

DEPTH

SPEED

Previous speed screen is displayed

Water temperature

To reset

3 seconds

To reset

Tri p

Log

SPEED

DEPTH

See

NORMAL OPERATION

(sheet 2)

To reset

3 seconds

Note:

The trip distance can be

reset only if the instrument

is a speed master,

i.e. connected to a speed

transducer.

3 seconds

Note: Screens annotated with * are temporary and will time-out

to the previous permanent screen after 5 seconds.

D4731-2

Page 13

4 ST40 Bidata Instrument Owner’s Handbook

NORMAL OPERATION (sheet 2)

Switch on

Minimum

depth

Shallow

alarm

SPEED

DEPTH

Depth

To reset

3 seconds

Alarm

on/off

3 seconds

DEPTH

SPEED

See NORMAL OPERATION (

To/from Offset screen (sheet 3)

Notes:

Note: Screens other than the Depth screen,

are temporary and will time-out to the previous

permanent screen after 5 seconds.

This diagram shows the operating sequence for

an ST40 Bidata master instrument. On a repeater

instrument, only the Depth, Minimum

depth, Speed and Water temperature

screens are available.

With any set alarm screen displayed, press the

and keys simultaneously

to save the alarm level and return to

normal operation.

Set Shallow alarm

sheet 1)

Increase

If the Shallow alarm

has been locked during User

calibration, you cannot switch it on

or off or change the threshold value.

To/from

Deep alarm screen

(sheet 3)

+

Momentary

Decrease

D4732-2

Page 14

Chapter 1: Operation

5

NORMAL OPERATION (sheet 3)

To/from Shallow alarm screen

Deep

alarm

Shallow anchor

alarm

Deep anchor

alarm

(sheet 2)

Alarm

on/off

3 seconds

Alarm

on/off

3 seconds

Alarm

on/off

3 seconds

+

Momentary

+

Momentary

Set Deep alarm

Set Shallow

anchor alarm

Set Deep

anchor alarm

Increase

Decrease

Increase

Decrease

Increase

Offset

To/from Depth screen

(sheet 2)

+

Momentary

(+ve values)

(offset = 0.0)

(-ve values)

Note: Screens other than the Depth screen, are temporary and

will time-out to the previous permanent screen after 5 seconds.

Decrease

D4734-2

Page 15

6 ST40 Bidata Instrument Owner’s Handbook

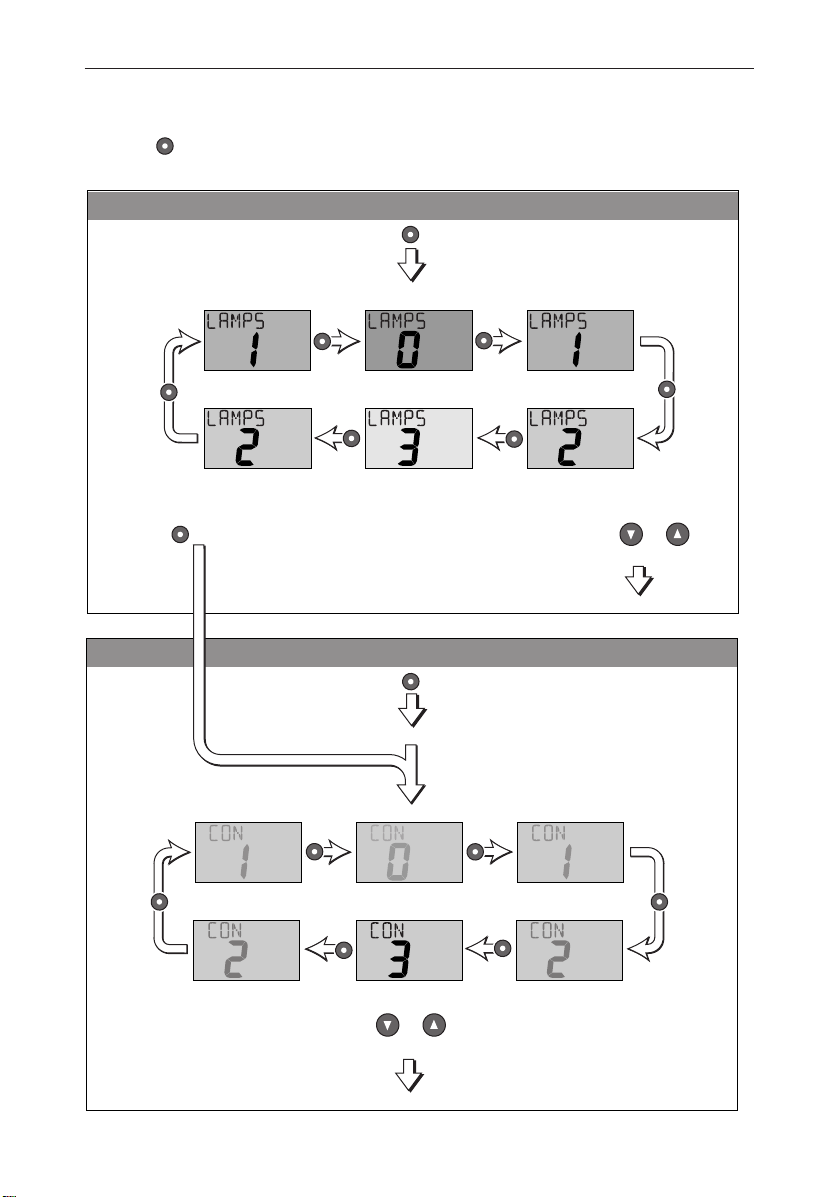

Adjusting display backlighting and contrast

Hold down for 1 second to enter Adjust Backlight mode

for 2 seconds to move through Adjust Backlight mode and enter Adjust Contrast mode

ADJUST BACKLIGHTING

to adjust contrast,

press

for 1 second

During normal operation, press

The current backlighting level is displayed.

Select the required backlighting level then:

for 1 second

to return to normal operation,

or wait for 5 second timeout

or

press

Normal operation

ADJUST CONTRAST

During normal operation, press

via Adjust Backlighting

The current contrast level is displayed.

Select the required contrast level then

or wait for 5 second timeout

Normal operation

for 2 seconds

orpress

D4845-1

Page 16

Chapter 1: Operation

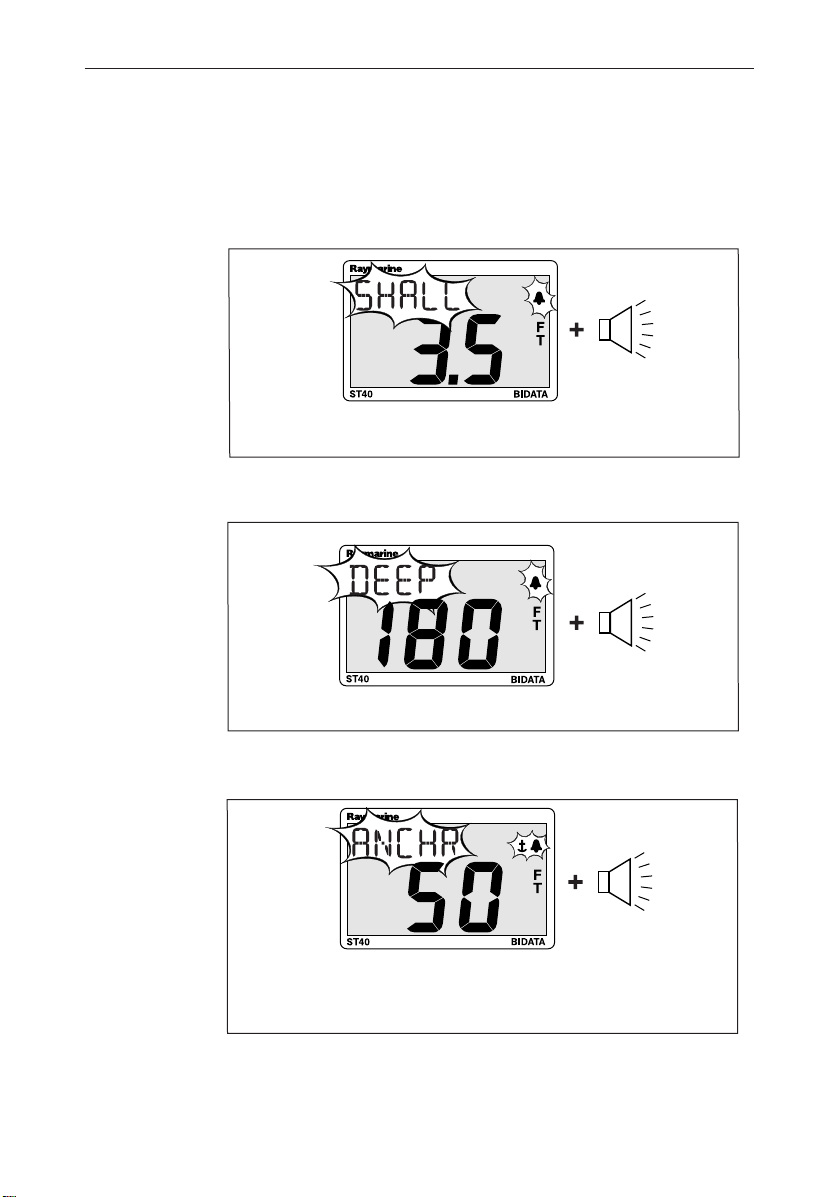

1.3 Alarms

Alarm indications

Shallow alarm

Depth is equal to or less than the shallow alarm threshold.

Alarm continues until cancelled manually.

Deep alarm

7

D4666-2

Triggered by depths equal to the deep alarm threshold. Continues until cancelled manually.

Anchor alarms

Depth is either:

equal to or less than the shallow anchor alarm threshold

or

equal to or more than the deep anchor alarm threshold

D4789_2

D4790-2

Page 17

8 ST40 Bidata Instrument Owner’s Handbook

Enabling/disabling alarms

You can enable or disable any alarm function (i.e. switch it on or off )

by selecting the relevant alarm screen (see Normal operation) and

holding down the key for 3 seconds (toggle action).

Page 18

Chapter 2: Maintenance and Fault Finding

Chapter 2: Maintenance and Fault Finding

2.1 Maintenance

Servicing and safety

• Raymarine equipment should be serviced only by authorised

Raymarine service technicians. They will ensure that service

procedures and replacement parts used will not affect performance.

There are no user-serviceable parts in any Raymarine product.

• Some products generate high voltages, so never handle the cables/

connectors when power is being supplied to the equipment.

• When powered up, all electrical equipment produces

electromagnetic fields. These can cause adjacent pieces of electrical

equipment to interact with one another, with a consequent adverse

affect on operation. In order to minimise these effects and enable

you to get the best possible performance from your Raymarine

equipment, guidelines are given in the installation instructions, to

enable you to ensure minimum interaction between different items

of equipment, i.e. ensure optimum Electromagnetic Compatibility

(EMC).

• Always report any EMC-related problem to your nearest Raymarine

dealer. We will use any such information to improve our quality

standards.

• In some installations, it may not be possible to prevent the

equipment from being affected by external influences. In general

this will not damage the equipment but it can lead to spurious

resetting action, or momentarily may result in faulty operation.

• Always switch off the power to Raymarine equipment before

working on it.

9

When requesting service, please quote equipment Type, Model

Number, Serial Number and, if possible, Software Release Issue. The

Software Release Issue can be ascertained by means of the

Intermediate Calibration facility, see Chapter 4, Calibration.

Instrument

Certain atmospheric conditions may cause a small amount of

condensation to form on the instrument window. This will not harm the

instrument and will clear after the instrument has been switched on for a

short period.

Page 19

10 ST40 Bidata Instrument Owner’s Handbook

Periodically clean your ST40 instrument with a soft damp cloth. Do

NOT use chemical or abrasive materials to clean the instrument.

Transducers

Refer to the Installation and Maintenance instructions supplied with the

transducers.

Cabling

Examine all cables for chafing or other damage to the outer shield and,

where necessary, replace and re-secure.

2.2 Fault finding

Preliminary procedures

If you appear to have a problem, first check the security of the

connections at the rear of the instrument and reconnect any that are

loose.

Changes in the electronic environment may adversely affect the

operation of your ST40 equipment. Typical examples of such changes

are:

• Electrical equipment has recently been installed or moved aboard

your vessel.

• You are in the vicinity of another vessel or shore station emitting

radio signals.

Fixing faults

Low battery

All Raymarine products are subjected to comprehensive test and

quality assurance programmes prior to packing and shipping. However,

if a fault occurs, the following guidelines may help to identify and

rectify the problem.

Action

Recharge your vessel’s battery as

soon as possible

BIDATA

D4737-2

Page 20

Chapter 2: Maintenance and Fault Finding

11

Display blank

ST40

DD

Depth reading

DD

flashes when

under way

No depth information

Action

Check fuse/circuit breaker.

Check power supply.

BIDATA

D4738-2

Check SeaTalk cabling and

connector security.

OR

BIDATAST40

BIDATAST40

D4739-2

Action

Ensure that reading stabilises when clear of disturbed water,

e.g. boat wakes, propeller wash etc.

OR

1 minute

BIDATAST40

1 minute

BIDATAST40

BIDATAST40

BIDATAST40

Action

Check the condition of the depth transducer cable and the

security of the connections.

Could also be due to weed growing on the transducer face.

D4740-2

Page 21

12 ST40 Bidata Instrument Owner’s Handbook

No speed or

temperature

information

OR

No speed

information but

temperature

information is

present

and

BIDATAST40

and

BIDATAST40

BIDATAST40

BIDATAST40

D4741-3

Action

Check the condition of the speed transducer cable and the

security of the connections.

OR

and

BIDATAST40

and

BIDATAST40

BIDATAST40

BIDATAST40

D4742-2

Action

CAUTION

If you need to remove the transducer insert, have the transducer

bung to hand and secure it in the transducer body immediately

after the insert has been removed, to prevent excessive ingress of

water.

The speed transducer paddle wheel may be fouled. Clean the paddle

wheel.

Page 22

Chapter 2: Maintenance and Fault Finding

13

SeaTalk

information

not being

transferred

For example, backlighting

level changes implemented

at one instrument do not

affect other instruments

between

instruments

A group of SeaTalk

instruments not

working

Assistance

ST40

ST40

ST40

D4747-2

Action

Check security of SeaTalk

connections between instruments.

Check condition of SeaTalk cables.

Isolate faulty instrument by

disconnecting instruments one by one.

Action

WIND

Check the security of SeaTalk

connectors between functioning and

non-functioning instruments.

DEPTH

BIDATA

If you are unable to rectify any problem, please contact your local

Raymarine Dealer for assistance.

Page 23

14 ST40 Bidata Instrument Owner’s Handbook

Page 24

Chapter 3: Installation

Chapter 3: Installation

This chapter describes how to install the ST40 Bidata instrument, and

associated transducers. The transducers are fitted in the hull of the

vessel and is connected to the rear of the instrument.

3.1 Planning your installation

Determine the best positions for both transducer and instrument, such

that the EMC installation guidelines and the Site requirements (below)

are satisfied.

EMC installation guidelines

All Raymarine equipment and accessories are designed to the best

industry standards for use in the leisure marine environment.

Their design and manufacture conform to the appropriate

Electromagnetic Compatibility (EMC) standards, but correct

installation is required to ensure that performance is not compromised.

Although every effort has been taken to ensure that they will perform

under all conditions, it is important to understand what factors could

affect the operation of the product.

15

The guidelines given here describe the conditions for optimum EMC

performance, but it is recognised that it may not be possible to meet all

of these conditions in all situations. To ensure the best possible

conditions for EMC performance within the constraints imposed by

any location, always ensure the maximum separation possible between

different items of electrical equipment.

For optimum EMC performance, it is recommended that wherever

possible:

• All Raymarine equipment and cables connected to it are:

• At least 1 m (3 feet) from any equipment transmitting or cables

carrying radio signals e.g. VHF radios, cables and antennas. In

the case of SSB radios, the distance should be increased to 2 m

(7 ft).

• More than 2 m (7 ft) from the path of a radar beam. A radar beam

can normally be assumed to spread 20 degrees above and below

the radiating element.

Page 25

16 ST40 Bidata Instrument Owner’s Handbook

D3548-2

• The equipment is supplied from a different battery from that used for

engine start. Voltage drops below 10 V in the power supply to our

products, and starter motor transients, can cause the equipment to

reset. This will not damage the equipment, but may cause the loss of

some information and may change the operating mode.

• Raymarine specified cables are used at all times. Cutting and

rejoining these cables can compromise EMC performance and so

must be avoided unless doing so is detailed in the installation

manual.

• If a suppression ferrite is attached to a cable, this ferrite should not

be removed. If the ferrite needs to be removed during installation it

must be reassembled in the same position.

Suppression Ferrites

The following illustration shows typical cable suppression ferrites fitted

to Raymarine equipment. Always use the ferrites supplied by

Raymarine.

Connections to Other Equipment

If your Raymarine equipment is going to be connected to other

equipment using a cable not supplied by Raymarine, a suppression

ferrite MUST always be fitted to the cable close to the Raymarine unit.

Tools required

The tools required for fitting the standard ST40 instrument system are

shown in the following illustration.

Page 26

Chapter 3: Installation

57 mm

(2.25 in)

51 mm

(2.0 in)

D4643-1

Note: If you intend fitting a nonstandard transducer, extra tools may

be required

Site requirements

Transducers

The transducer types required for the various hull types are as follows:

Hull material Speed transducer Depth transducer

GRP M78712 Through hull plastic M78713 through hull plastic

Steel (supplied as standard) (supplied as standard) or

Aluminium M78718 Retractable through hull

Wood M78716 Through hull bronze M78714 Through hull bronze

17

75 mm (2.94 in)

diameter

Depth

51 mm (2.0 in)

diameter

75 mm (2.94 in)

diameter

5 mm

(0.19 in)

89 mm (3.50 in)

Speed

Plastic through hull transducer dimensions

75 mm (2.94 in)

diameter

51 mm (2.0 in)

diameter

75 mm (2.94 in)

diameter

14 mm

(0.57 in)

100 mm

D4447-2

(3.95 in)

Page 27

18 ST40 Bidata Instrument Owner’s Handbook

Other transducer types are available for specific requirements. For

further details, contact your local Raymarine dealer.

The transducers should be sited within the clear water flow areas

indicated by the shaded areas below.

Sailing vessel

Planing power

vessel

Displacement power

vessel

Transducer siting

D4349-1

Each transducer should also:

• Be ahead of the propellers (by a minimum of 10% of the water line

length ).

• Be at least 150 mm (6 in) away from the keel (ideally ahead of the

keel if a sailing yacht).

• Be as near as possible to the centre line of the vessel.

• Be clear of other through-hull fittings or projections.

• Have sufficient clearance inside the hull to fit the nut.

• Have 100 mm (4 in) of headroom to allow for withdrawal.

In addition to the above requirements, the depth transducer must be

mounted within 100 of the vertical, forward, aft and athwart ships.

Page 28

Chapter 3: Installation

19

Depth transducer maximum angle

D4350-2

Instrument

55 mm

70 mm

(2.2 in)

(2.8 in)

ST40

126 mm (5.0 in)

Instrument dimensions

21 mm

(0.8 in)

30 mm (1.2 in)

minimum cable clearance

17 mm

(0.67 in)

D4644-2

CAUTION:

The presence of moisture at the rear of the instrument could cause

damage either by entering the instrument through the breathing

hole or by coming into contact with the electrical connectors.

Each instrument must be positioned where:

• It is easily read by the helmsman or navigator

• It is protected against physical damage

• It is at least 230 mm (9 in) from a compass

• There is reasonable rear access for installation and servicing

• The rear of the instrument is protected from water.

Page 29

20 ST40 Bidata Instrument Owner’s Handbook

3.2 Procedures

Adapt these procedures as appropriate, to suit your individual

requirement.

CAUTION:

Where it is necessary to cut holes (e.g. for cable routing and

instrument mounting), ensure that these will not cause a hazard by

weakening critical parts of the vessel’s structure. If in doubt, seek

the advice of a reputable boat builder.

Fitting transducers

Instructions for installing and maintaining the speed and depth

transducers are packed with them. Before attempting to install the

transducers, read these instructions and the Site requirements for

transducers described in this Chapter.

Running transducer cable

Each transducer type has a 9 m (30 ft) cable fitted with spade terminals

for connection to the ST40 Bidata instrument. Observing the following

guidelines, run the cable to the instrument:

• If the cable has to be fed through the deck, always use a good quality

deck gland.

• Where cables are fed through holes, always use grommets to prevent

chafing.

• Secure long cable runs so they do not present a hazard.

• Wherever possible, route the cable away from fluorescent lights,

engines, radio transmitting equipment, as these may cause

interference.

Important point: Do NOT shorten the cable from the depth transducer

as this will seriously degrade transducer performance.

Page 30

Chapter 3: Installation

Connections to the instrument

21

You can connect your instrument:

• Directly to the speed and depth transducers as a stand-alone master

instrument. When connected in this manner, the instrument must be

connected to a suitable power source using the 1 m (3 ft) power

cable provided.

• As part of a SeaTalk system either as a repeater or, with a transducer

also connected as a system master. To connect to SeaTalk, you will

need an additional SeaTalk Interconnection Kit (Part No. E25028).

When connected in this manner, power can be provided from the

SeaTalk bus (e.g. from the autopilot).

You can also connect the instrument to the speed and depth transducers

and to SeaTalk. When thus connected, the instrument will be the master

speed and depth instrument for the SeaTalk system.

If it is necessary to fit spade connectors to the transducer cable, do so as

shown in the following illustration. Prepare the cable, as at (a), and fit

the spade connectors, as at (b). When fitting each spade connector,

ensure that wire strands do not extend beyond the rear of the spade

connector insulation.

Preparing wires for connection

(a)

(b)

50 mm

4 mm

10 mm

3 mm

D4467-3

Page 31

22 ST40 Bidata Instrument Owner’s Handbook

3 A circuit breaker

Red +ve

Uninsulated wire (screen) -ve

+

_

D4791-2

Connections to a stand-alone instrument

Cable from

Depth transducer

Screen

Blue

Black

Cable from

Speed transducer

Screen

Brown

Green

White

Red

Power cable

Note:

A 3 A fuse can be used in place of

the circuit breaker, if preferred.

12 V dc supply

(e.g. battery)

Stand-alone connections

CAUTION

Ensure that the power supply for each stand-alone ST40

instrument is protected by a 3 A fuse or circuit breaker.

Page 32

Chapter 3: Installation

SeaTalk connections

CAUTION

When instruments are connected to SeaTalk, ensure that the

power supply for the SeaTalk 12 V line is protected by a 5 A fuse

or circuit breaker.

Note:

A 5 A fuse can be used in place of

the circuit breaker, if preferred.

12 V dc supply

(e.g. course

computer

or battery)

Red (+ve)

Uninsulated wire

(screen) -ve

Power cable

5 A circuit breaker

23

SeaTalk bus

Typical SeaTalk connections

Fitting the instrument

Fit your ST40 instrument as shown in the following illustrations.

1

SeaTalk bus

SeaTalk interface

kit

Remove template from handbook (immediately after index), apply to required location

and mark cutting centre.

ST40 Instrum

ent Tem

plate

TO

P

Cut out

shaded area only

Cutting centre

D4825-2

Cut out hole

57 m

m

diam

(2.25 in)

eter

D4759-1

Page 33

24 ST40 Bidata Instrument Owner’s Handbook

2

Cut hole

57 mm (2.25 in) cutter

D4760-1

Peel protective sheets from gasket

3

4

Stick gasket to rear of instrument

D4770-1

D4761-1

Page 34

Chapter 3: Installation

D4819-1

5

Screw stud into instrument

D4762-1

6

Feed cables through clamping bracket,

connect cables then secure instrument with

bracket and thumb nut

25

Desktop Mounting Bracket

An optional Desktop Mounting Bracket (Part No. E25024) enables you

to mount your ST40 instrument in locations where other forms of

mounting are impractical.

Page 35

26 ST40 Bidata Instrument Owner’s Handbook

D4646-1

To bracket mount your ST40 instrument, do so in accordance with the

Instruction Sheet, which is included with the Desktop Mounting

Bracket.

3.3 Calibration requirement

Once installation is complete and before you use your instrument, carry

out the calibration procedures detailed in Chapter 4, Calibration.

Page 36

Chapter 4: Calibration

Chapter 4: Calibration

4.1 Introduction

The procedures in this Chapter must be carried out before the

equipment is used operationally, to optimise the performance of the

instrument with the vessel.

Calibration information is presented in flow chart form. The flow charts

show the various calibration screens and key presses necessary to carry

out calibration. All key presses are momentary unless otherwise stated.

EMC conformance

• Always check the installation before going to sea to make sure that it

is not affected by radio transmissions, engine starting etc.

4.2 User calibration

User calibration enables you to:

• Set the required units for speed readings. Either KTS (knots), MPH

(miles per hour) or KPH (kilometres per hour).

• Select temperature units. Either °C or °F, as required.

• Set the speed display response. Use higher response values when

boating in conditions requiring rapid updates of the current speed

(e.g. competition sailing or on power boats). Use slower response

values when you require an average speed over a longer period of

time (e.g. when cruising, especially in heavy seas).

• Set the correct speed reading, either by using a Cal factor screen to

adjust the calibration factor, or by applying Speed Over Ground

(SOG) as the current speed. Your vessel must be moving at 0.5 KTS

or more and be receiving SeaTalk SOG data, to enable SOG to be

applied as the current speed. This should be done only in conditions

of zero tide and current.

• Set the depth display response. Use higher response values when

boating in conditions requiring rapid updates of depth information

(e.g. inshore, especially when travelling at high speed). Use slower

response values when you require an average depth over a longer

period of time (e.g. deep sea cruising).

• Set the required units for depth readings. Either FT (feet), M (metres)

or FA (fathoms).

27

Page 37

28 ST40 Bidata Instrument Owner’s Handbook

• Set the required depth offset.

• Lock the shallow alarm, to prevent unauthorised changes during

normal operation.

Power up the instrument then follow the procedure in the User

calibration flow diagram. This diagram shows the User calibration

sequence for an ST40 Bidata operating as a master instrument for both

speed and depth .

Page 38

Chapter 4: Calibration

hold down and

Depth

response

Speed

response

USER CALIBRATION (sheet 1)

During normal operation

Entry

screen

ST40

for approximately 2 seconds

Note:

If there is no key activity when the Entry screen

is displayed, calibration will time out to normal

operation after 5 seconds,

BIDATA

From Shallow alarm lock screen

(sheet 2)

CAL

BIDATAST40

15 (fast)

1 (slow)

CAL

15 (fast)

29

BIDATAST40

Depth

units

CAL

BIDATAST40

Speed

units

CAL

BIDATAST40

To Distance units screen

(sheet 2)

KPH

M

1 (slow)

FA

MPH

To save your settings and return to normal

operation from any screen, hold down

and

for approximately 2 seconds

D4743-2

Page 39

30 ST40 Bidata Instrument Owner’s Handbook

USER CALIBRATION (sheet 2)

From Speed units screen (sheet 1)

Distance

units

Temperature

units

2.5

(increase

speed)

0.25

(decrease

speed)

Cal

factor

CAL

BIDATAST40

CAL

BIDATA

CAL

To

Depth response

screen (sheet 1)

Shallow

alarm

KM

SM

F

Set to

SOG

lock

CAL

CAL

BIDATAST40

and

Displayed only if SOG available on

SeaTalk & vessel speed greater than

0.5 kt. To apply SOG value as speed

reading, press

BIDATAST40

for 3 seconds

in conditions of zero tide

and current

Depth

offset

WARNING:

CAL

BIDATAST40

Correct offset values are

essential to ensure the safe

operation of the vessel. If you

are not sure how to set the

correct values, refer to the

additional information given

in the text accompanying this

To save your settings and return to normal operation from any screen,

for approximately 2 secondshold down and

D4744-2

Page 40

Chapter 4: Calibration

Depth offsets

WARNING:

The use of incorrect offset values could result in misleading depth

information being displayed with a consequent risk of running

aground.

The depth offset screen enables you to determine the exact point on the

vessel from which depths are measured. This point can be:

• The transducer. Set offset to zero. With zero offset applied, the

screen header is OFST.

• The bottom of the keel. Set a negative offset equal to the vertical

distance between the transducer position and the bottom of the keel.

With a negative offset applied, the screen header is KEEL.

• The water line. Set a positive offset equal to the vertical distance

between the transducer position and the water line. With a positive

offset applied, the screen header is W/L.

4.3 Intermediate calibration

Intermediate calibration enables you to:

• Check the instrument software version.

• Check and if necessary set, the instrument status - either MASTR

(master) or REPTR (repeater), for both speed and depth.

31

Follow the procedure in the Intermediate calibration flow diagram.

Page 41

32 ST40 Bidata Instrument Owner’s Handbook

INTERMEDIATE CALIBRATION

During normal operation

for approximately 4 secondshold down and

Software

version

Depth

status

ST40

Note:

If there is no key activity when

the Software version screen

is displayed, calibration will

time out to normal operation

after 5 seconds,

BIDATA

CAL

Speed

status

To save your settings and return to normal operation from any screen,

hold down

4.4 Dealer calibration

Dealer calibration enables you to set:

• User calibration on/off.

• Boat show mode on/off.

Dealer calibration also gives access to the Factory defaults screen.

This enables you to reapply the factory settings if you want to reset the

instrument to a known operating condition.

Follow the procedure in the Dealer calibration flow diagram.

ST40

ST40

BIDATA

CAL

BIDATA

for approximately 2 secondsand

D4745-2

Page 42

Chapter 4: Calibration

DEALER CALIBRATION

During normal operation

for approximately 12 secondshold down and

Entry

screen

Note:

If there is no key activity when the Entry screen

is displayed, calibration will time out to normal

operation after 5 seconds,

33

Boat show

mode

ST40

Calibration

access

CAL

BIDATAST40

CAUTION:

Do NOT switch the Boat Show mode on.

This function must only be used for

demonstration purposes.

BIDATA

CAL

BIDATAST40

Factory

defaults

If

If

CAL

BIDATAST40

Return to

normal

operation

with factory

defaults set

To save your settings and return to normal operation from any screen,

hold down

and

for approximately 2 seconds

D4746-2

Page 43

34 ST40 Bidata Instrument Owner’s Handbook

Page 44

Instrument Specification

Instrument Specification

Supply voltage: 10 V to 16 V dc.

Current consumption (12 V supply): 35 mA typical.

70 mA with maximum backlighting.

Operating temperature: 0°C to +70°C.

Interfaces: SeaTalk.

Overall dimensions: 126 mm x 70 mm x 38 mm

(5.00 inches x 2.80 inches x 1.55 inches).

Boss diameter: 55 mm (2.20 inches).

Speed range: 0 to 99.9 knots.

Log range: 0 to 99999.

Trip reading range: 0 to 999 nautical miles.

35

Temperature reading range: -10°C to +40°C.

Depth range: 0 to 400 feet.

Shallow depth alarm: 0 to 29 feet.

Deep depth alarm: 30 to 400 feet.

Shallow anchor alarm: 1 to 250 feet.

Deep anchor alarm: 10 to 400 feet.

Approvals:

CE - conforms to

89/336/EC(EMC), EN60945.

94/25/EC(RCD), EN28846 (applies to

transducer only).

Page 45

36

ST40 Bidata Instrument Owner’s Handbook

Page 46

Glossary

Glossary

Cal factor Calibration factor. Used in the ST40 Speed and Bidata instruments to

ensure the current speed reading is the actual speed. Values are from 0.25

(reduce speed reading) to 2.5 (increase speed reading).

EMC Electromagnetic Compatibility.

FA Fathoms.

FT Feet.

KEEL When displayed on the Offset screen (during normal operation), or the

Depth offset screen (during User calibration), indicates that a negative

depth offset is set.

KPH Kilometres per hour.

KTS Knots.

M Metres.

MPH Miles per hour.

OFST When displayed on the Offset screen (during normal operation), or the

Depth offset screen (during User calibration), indicates that a depth

offset value of 0 is set.

37

Response The rate at which an instrument responds to changes in speed and depth.

Values are from 1 (slow response) to 15 (fast response).

SeaTalk SeaTalk is a proprietary Raymarine system which links different

compatible products, to provide a single, integrated navigational system.

SeaTalk can also communicate with non-SeaTalk equipment using the

internationally- accepted National Marine Electronics Association

(NMEA) protocol. Contact your Raymarine dealer for details.

W/L When displayed on the Offset screen (during normal operation), or the

Depth offset screen (during User calibration), indicates that a positive

depth offset is set.

Page 47

38

ST40 Bidata Instrument Owner’s Handbook

Page 48

Index

Index

39

A

Alarms 7–8

enable/disable 8

indications 7

ranges 35

setting thresholds 4–5

silencing 2

switching on and off 4–5

Average speed reset 2, 3

B

Backlighting 6

Boat show mode 32

C

Calibration 27–33

Dealer 32–33

Intermediate 31–32

setting appropriate response values 27

setting user access 33

User 27–31

User calibration screen sequences 31

Calibration requirement 1, 26

Cleaning the instrument 10

Condensation 9

Connecting the instrument 21

Contrast 6

Current consumption 35

D

Dealer calibration 32–33

Depth

alarms 4–5

appropriate response values 27

offset 5, 28, 30, 31

range 35

reading flashing 11

response 27, 29

units 27

Desktop Mounting Bracket 25–26

Dimensions 35

Display

backlighting 6

contrast 6

selecting speed or data display 2

E

EMC

conformance i, 27

installation guidelines 15–16

F

Factory defaults 32

Fault finding 10

assistance 13

blank display 11

depth reading flashing 11

low battery 10

no depth information 11

no speed information 12

no speed or temperature information 12

SeaTalk problems 13

I

Installation 15–26

connecting the instrument 21

EMC guidelines 15

fitting the instrument 23–26

planning 15–19

site requirements 17–20

tools required 16–17

transducers 20

Instrument

cleaning 10

condensation 9

connecting 21

current consumption 35

fitting 23–26

site requirements 19

status (master or repeater) 31

supply voltage 35

Intermediate calibration 31–32

Page 49

40 ST40 Bidata Instrument Owner’s Handbook

L

Log

range 35

Log distance 2

Low battery indication 10

M

Maintenance 9–10

Maximum speed reset 2, 3

Minimum depth reset 2, 4

N

Normal operation 3–6

O

Offset 5, 28, 30, 31

Operation 1–8

P

Panel lighting 6

Parts supplied vi

R

Reset

average speed 2, 3

maximum speed 2, 3

minimum depth 2, 4

trip distance 3

Response values

depth 27

speed 27

Site requirements 17–20

instrument 19

transducers 17–20

Software version 31

Specifications 35

Speed

appropriate response values 27

calibration factor 37

range 35

response 27

units 29

T

Temperature reading range 35

Transducers

fitting 20

site requirements 17–20

Trip distance

range 35

Trip distance reset 3

U

User calibration 27–31

screen sequences 31

V

Voltage 35

S

Servicing and safety 9

Setting

alarm thresholds 4–5

backlighting 6

calibration factor 30

contrast 6

correct speed 30

depth offset 30–31

depth response 29

depth units 29

shallow alarm lock 29

speed response 29

speed units 29

Shallow alarm lock 29

Page 50

D4800-1

Cut out hole

57 mm (2.25 in)

diameter

TOP

ST40 Instrument Template

Cut out

shaded area only

Page 51

Page 52

Limited Warranty Certificate

Raymarine warrants each new Light Marine/Dealer Distributor Product to be of good materials and

workmanship, and will repair or exchange any parts proven to be defective in material and

workmanship under normal use for a period of 2 years/24 months from date of sale to end user, except

as provided below.

Defects will be corrected by Raymarine or an authorized Raymarine dealer. Raymarine will, except

as provided below, accept labor cost for a period of 2 years/24 months from the date of sale to end user.

During this period, except for certain products, travel costs (auto mileage and tolls) up to 100 round

trip highway miles (160 kilometres) and travel time of 2 hours, will be assumed by Raymarine only

on products where proof of installation or commission by authorized service agents, can be shown.

Warranty Limitations

Raymarine Warranty policy does not apply to equipment which has been subjected to accident, abuse

or misuse, shipping damage, alterations, corrosion, incorrect and/or non-authorized service, or

equipment on which the serial number has been altered, mutilated or removed.

Except where Raymarine or its authorized dealer has performed the installation, it assumes no

responsibility for damage incurred during installation.

This Warranty does not cover routine system checkouts or alignment/calibration, unless required by

replacement of part(s) in the area being aligned.

A suitable proof of purchase, showing date, place, and serial number must be made available to

Raymarine or authorized service agent at the time of request for Warranty service.

Consumable items, (such as: Chart paper, lamps, fuses, batteries, styli, stylus/drive belts, radar mixer

crystals/diodes, snap-in impeller carriers, impellers, impeller bearings, and impeller shaft) are

specifically excluded from this Warranty.

Magnetrons, Cathode Ray Tubes (CRT), TFT Liquid Crystal Displays (LCD) and cold cathode

fluorescent lamps (CCFL), hailer horns and transducers are warranted for 1 year/12 months from date

of sale. These items must be returned to a Raymarine facility.

All costs associated with transducer replacement, other than the cost of the transducer itself, are

specifically excluded from this Warranty.

Overtime premium labor portion of services outside of normal working hours is not covered by this

Warranty.

Travel cost allowance on certain products with a suggested retail price below $2500.00 is not

authorized. When/or if repairs are necessary, these products must be forwarded to a Raymarine

facility or an authorized dealer at owner’s expense will be returned via surface carrier at no cost to the

owner.

Travel costs other than auto mileage, tolls and two (2) hours travel time, are specifically excluded on

all products. Travel costs which are excluded from the coverage of this Warranty include but are not

limited to: taxi, launch fees, aircraft rental, subsistence, customs, shipping and communication

charges etc. Travel costs, mileage and time, in excess to that allowed must have prior approval in

writing.

TO THE EXTENT CONSISTENT WITH STATE AND FEDERAL LAW:

(1) THIS WARRANTY IS STRICTLY LIMITED TO THE TERMS INDICATED HEREIN, AND

NO OTHER WARRANTIES OR REMEDIES SHALL BE BINDING ON RAYMARINE

INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABLE OR

FITNESS FOR A PARTICULAR PURPOSE.

(2) Raymarine shall not be liable for any incidental, consequential or special (including punitive or

multiple) damages.

All Raymarine products sold or provided hereunder are merely aids to navigation. It is the

responsibility of the user to exercise discretion and proper navigational skill independent of any

Raymarine equipment.

Document number: 84064-8

April 2001

Page 53

Factory Service Centers

United States of America UK, Europe, Middle East, Far East

Raymarine Inc

22 Cotton Road, Unit D

Nashua, NH 03063-4 219, USA

Telephone: +1 603 881 5200

Fax: +1 603 864 4756

www.raymarine.com

Sales & Order Services

Telephone: +1 800 539 5539 Ext. 2333 or

Technical Support

Telephone: +1 800 539 5539 Ext. 2444 or

Email: techsupport@raymarine.com

Product Repair Center

Telephone: +1 800 539 5539 Ext. 2118

+1 603 881 5200 Ext. 2333

+1 603 881 5200 Ext. 2444

Raymarin e Ltd

Anchorage Park, Portsmouth

PO3 5TD, England

Telephone: +44 (0) 23 9269 3611

Fax: +44 (0)23 9269 4642

www.raymarine.com

Customer Support

Telephone: +44 (0) 23 9271 4713

Fax: +44 (0)23 9266 1228

Email: techsupport@ raymarine.com

Stick barcode label here

Purchased f rom Purchase date

Dealer address

Installed by Installation date

Commissioned by

Commissioning date

Owner’s name

Mailing address

This portion should be completed and r etained by the owner.

Loading...

Loading...