Page 1

Distributed by

Any reference to Raytheon or

RTN in this manual should be

interpreted as Raymarine.

The names Raytheon and RTN

are owned by the

Raytheon Company.

Page 2

ST4000+ Wheel & Tiller Autopilots

Owner’s Handbook

Document number: 81131-6

Date: August 2001

Page 3

ii ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot

are registered trademarks of Raymarine Ltd.

Raymarine, AST (Advanced Steering T echnology), AutoAdapt,

AutoLearn, AutoRelease, AutoSeastate, AutoTack, AutoTrim,

FastTrim, GyroPl us, RayGyro, RayPilot and W indTrim are

trademarks of Raymarine Ltd.

Handbook contents © Raymarine Ltd 2001.

Page 4

Preface iii

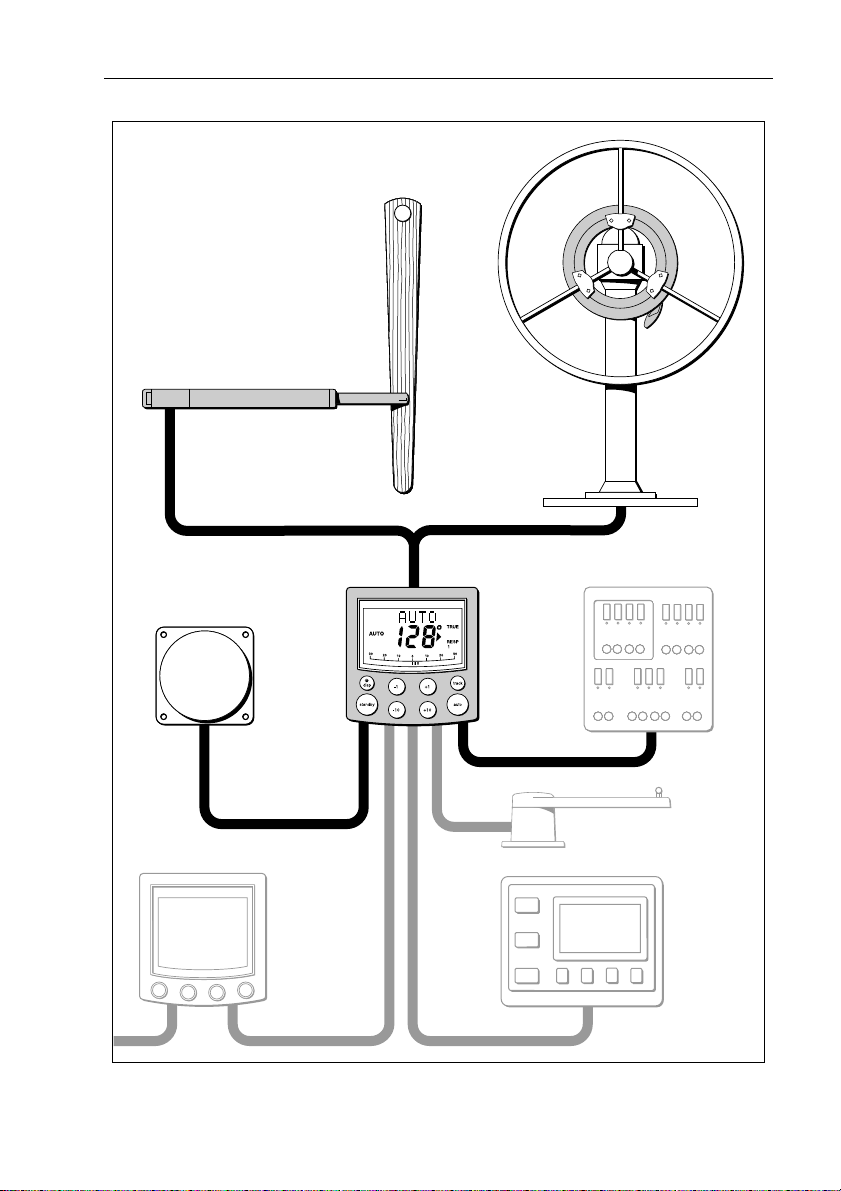

ST4000+ autopilot system layout

Wheel drive

OR

Tiller drive

Boat's electrical

distribution panel

Fluxgate compass

ST4000+

control unit

SeaTalk instrument

Rudder position sensor

(optional fit for wheel pilot only)

NMEA

instrument

or navigator

D5332-1

Page 5

iv ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Page 6

Preface v

Contents

About this handbook ...........................................................ix

Important Information .........................................................x

Warranty ......................................................................................x

Safety notices ..............................................................................x

EMC conformance .....................................................................xi

Handbook information ...............................................................xi

Chapter 1: Introduction ............................................................1

1.1 Features .....................................................................................1

1.2 Extended systems ......................................................................2

Chapter 2: Basic Operation .......................................................3

2.1 Using the control unit ................................................................4

Key functions ............................................................................ 4

Display layout ...........................................................................5

2.2 Using Auto mode ......................................................................6

Engaging the autopilot (Auto mode) .........................................6

Disengaging the autopilot (Standby mode) ..............................7

Changing course in Auto mode .................................................8

Dodging obstacles in Auto mode ..............................................8

Returning to the previous locked heading (LAST HDG) ......... 9

Automatic tack (AutoT ack) .................................................... 10

Making major course changes ................................................ 10

Gusting conditions .................................................................. 11

2.3 Adjusting autopilot performance ............................................12

Changing the response lev el (AutoSeastate) ..........................12

Changing the rudder gain ........................................................13

2.4 Autopilot alarms .....................................................................14

Responding to alarms ..............................................................14

2.5 Adjusting display and keypad lighting ...................................18

Chapter 3: Advanced Operation ............................................19

3.1 Using Track mode ...................................................................20

Selecting Track mode .............................................................20

Exiting Track mode ............................................................. ....22

Cross track error ......................................................................22

Tidal stream compensation .....................................................23

W aypoint arrival and advanc e .................................................24

Dodges in Track m ode ............................................................ 25

Safety in Track mode .............................................................. 25

Page 7

vi ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

3.2 Using Wind Vane mode .......................................................... 27

Selecting Wind Vane mode ..................................................... 27

Exiting Wind Vane mode ........................................................28

Adjusting the locked wind angle .............................................28

Returning to the previous apparent wind angle

(LAST WND) .........................................................................28

Dodges in Wind Vane mode .................................................... 29

Wind shift alarm ......................................................................29

Using AutoT ack in W ind Vane mode ......................................30

Operating hints for Wind Vane mode ...................................... 30

3.3 Displaying data pages ............................................................. 31

Chapter 4: Maintenance & Fault Finding ..............................33

4.1 Fault finding ............................................................................34

4.2 General maintenance .............................................................. 36

Wheel drive ............................................................................. 36

Control unit .............................................................................38

EMC advice ............................................................................ 39

4.3 Product support ....................................................................... 40

Software version ..................................................................... 40

Chapter 5: Installing the ST4000+ ..........................................43

5.1 Planning the installation .........................................................44

Too ls required .........................................................................44

EMC installation guidelines ................................................... 46

5.2 Control unit .............................................................................48

Location ..................................................................................48

Mounting procedure ...............................................................49

Cable connectors .....................................................................51

Power supply connection ........................................................ 51

SeaTa lk connections ............................................................... 52

NMEA connections ................................................................ 53

5.3 Fluxgate compass ...................................................................55

Location ..................................................................................55

Mounting ................................................................................ 57

Connecting to the control unit ................................................. 58

5.4 Tiller drive (tiller pilots only) ..................................................59

Critical dimensions .................................................................59

Basic installation ..................................................................... 60

Installation accessories ........................................................... 61

Connecting to the control unit ................................................. 68

Page 8

Preface vii

5.5 Wheel drive (wheel pilots only) ..............................................70

Installation stages ....................................................................70

Drilling the spoke clamp holes ................................................71

Securing the wheel drive to the wheel .....................................74

Attaching the pedestal bracket ................................................ 75

Connecting to the control unit .................................................79

5.6 Rudder position sensor (wheel pilot option) ...........................81

Ensuring correct alignment .....................................................81

Securing the sensor to the boat ................................................83

Attaching the sensor to the tiller arm .......................................83

Checking alignment ................................................................84

Connecting to the control unit .................................................84

Chapter 6: Setting-up the ST4000+ ........................................85

6.1 Functional test ......................................................................... 86

Switch on ................................................................................86

Autopilot steering direction ....................................................86

Checking connections .............................................................88

6.2 Check rudder sensor operation (if fitted) ................................90

6.3 Initial sea trial .......................................................................... 91

Overview ................................................................................ 91

Correcting the compass deviation ..........................................92

Adjusting the heading alignment ............................................95

Checking autopilot operation ..................................................95

Checking the rudder gain ........................................................ 96

6.4 Autopilot calibration techniques .............................................98

Step 1 - Switch on ancillary equipment ...................................98

Step 2 - Apply initial settings ..................................................98

Step 3 - Adjust the rudder damping .........................................99

Step 4 - Adjust the rudder gain ................................................99

Step 5 - Adjust the AutoTrim setting .......................................99

Step 6 - Further adjustments ....................................................99

Chapter 7: Customizing the ST4000+ ..................................101

7.1 User setup ..............................................................................102

Compass deviation correction (SWING COMPASS) .......... 102

Deviation display (DEVIA TION) ........................................102

Heading alignment (ALIGN HDG) ......................................102

Heading mode (HDG MAG/TRU) .......................................102

Bar selection (RUDD BAR/STEER BAR/NO BAR) .......... 104

Data pages 1-7 (DA T A P AGE) ..............................................104

Page 9

viii ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

7.2 Dealer setup ..........................................................................106

Calibration lock (CAL LOCK) ............................................. 108

Pilot type (4000 WHL/TILL) ............................................... 108

Rudder gain (RUDD GAIN) .................................................108

Response level (RESPONSE) .............................................. 108

Turn limit (TURN RATE) ..................................................... 108

Rudder alignment (ALIGN RUD) ........................................ 108

Rudder limit (RUD LIMIT) .................................................. 109

Off course alarm (OFF COURSE) ........................................109

AutoTa ck angle (AUTOT AC K) ........................................... 109

AutoTrim (AUTOTRIM) ..................................................... 110

Drive type (DRIVE TYP) ..................................................... 110

Magnetic variation (VARIA TION) ....................................... 110

AutoAdapt (AUTOADAP T) .................................................111

Latitude (LA TITUDE) ...........................................................111

Rudder damping (RUDD DAMP) ........................................ 112

Cruise speed (CRUISE SP) .................................................. 112

Specifications .................................................................... 113

Glossary .............................................................................. 115

Index ................................................................................... 117

Page 10

Preface ix

About this handbook

W elcome to the handbook for the ST4000+ wheel and tiller

autopilot systems. Thi s handbook contains two main parts:

Part 1: Using the ST4000+ Autopilot

Chapter 1: Introduction

1

Introduces the autopilot, its features and its use.

Chapter 2: Basic Operation

Covers basic autopilot operation: using Auto mode,

2

interpreting alarms, adjusting autopilot performance and

changing the control unit lighting.

Chapter 3: Advanced Operation

Explains how to use Track and Wind Vane modes, and

3

display data pages.

Chapter 4: Maintenance & Fault Finding

Provides general maintenance procedures and

4

information to help you resolve problems you may

encounter with the autopilot

page 1

page 3

page 19

page 33

Part 2: Installing the ST4000+ Autopilot

Chapter 5: Installing the ST4000+

5

Explains how to install your autopilot and its components.

Chapter 6: Setting-up the ST4000+

Covers functional testing and dockside procedures after

6

installation, and initial sea trials.

Chapter 7: Customizing the ST4000+

Provides details on adjusting the autopilot settings to suit

7

your boat.

page 43

page 85

page 101

At the end of this h andbook we have included product

specifications, a glossary and index, and templates for installing

different part s of the syst em.

Note: T his handbook contains important information about

installing, using and maintainin g your new Raymarine product. To

get the best from the product, please read this h andbook thoroughly.

Page 11

x ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Important Information

Warranty

T o register your new Raymarine product, please take a few minutes to

fill out the warranty card. It is important that you complete the owner

information and return the card to us to receive full warranty benefits.

Safety notices

WARNING: Product installation

This equipment must be installed and operated in accordance

with the instructions contained in this handbook. Failure to do so

could result in poor pr oduct performance, personal injury

and/or damage to your boat.

WARNING: Electrical safety

Make sure the power supply is switched off befor e you make any

electrical connections.

WARNING: Calibration

We supply th is product calibrated to default settings tha t should

provide stable performance for most boats. T o ensure op timum

performance on your boat, you mu st complete Chapter 6:

Setting-up the ST4000+ befor e use.

WARNING: Navigation aid

Although we have designed this pr oduct to be accurate and

reliable, many factors can affect its performance. As a result, it

should only be used as an aid to n avigation and should never

replace common s ense and navigational judgement. A lways

maintain a permanent watch so you can respond t o situations as

they develop.

Y our Raymarine autopilot will add a new dim ension to your boating

enjoyment. However, it is the skipper’s responsibility to ensure the

safety of the boat at all times by following these basic rules:

• Ensure that someone is present at the helm A T ALL TIMES, to

take manual control in an emergency .

Page 12

Preface xi

• Make sure that all members of crew know how to disengage the

autopilot.

• Regularly check for other boats and any obstacles to navigation –

no matter how clear the sea may appear, a dangerous situation can

develop rapidly.

• Maintain an accurate record of the boat’s position by using either

a navigation aid or visual bearings.

• Maintain a continuous plot of your boat’s position on a current

chart. Ensure that the locked autopilot heading will steer the boat

clear of all obstacles. Make proper allowance for tidal set – the

autopilot cannot.

• Even when your autopilot is locked onto the desired track using a

navigation aid, always maintain a log and make regular positional

plots. Navigation signals can produce signifi cant errors under

some circumstances and the autopilot will not be able to detect

these errors.

EMC conformance

All Raymarine equipment and accessories are designed to the best

industry standards for use in the recreational marine environment.

The design and manufacture of Raymarine equipment and

accessories conform to the appropriate Electromagnetic

Compatibility (EMC) standards, but correct installation is required to

ensure that performance is not compromised.

Handbook information

T o the best of our knowledge, the information in this handbook was

correct when it went to press. However, Raymarine cannot accept

liability for any inaccuracies or omissions it may contain. In addition,

our policy of continuous product improv ement may change

specifications without notice. As a result, Raymarine cannot accept

liability for any differences between the product and th e handbook.

Page 13

xii ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Page 14

Part 1: Using the ST4000+

Part 1: Using the ST4000+

Page 15

Part 1: Using the ST4000+

Page 16

Chapter 1: Introduction 1

Chapter 1: Introduction

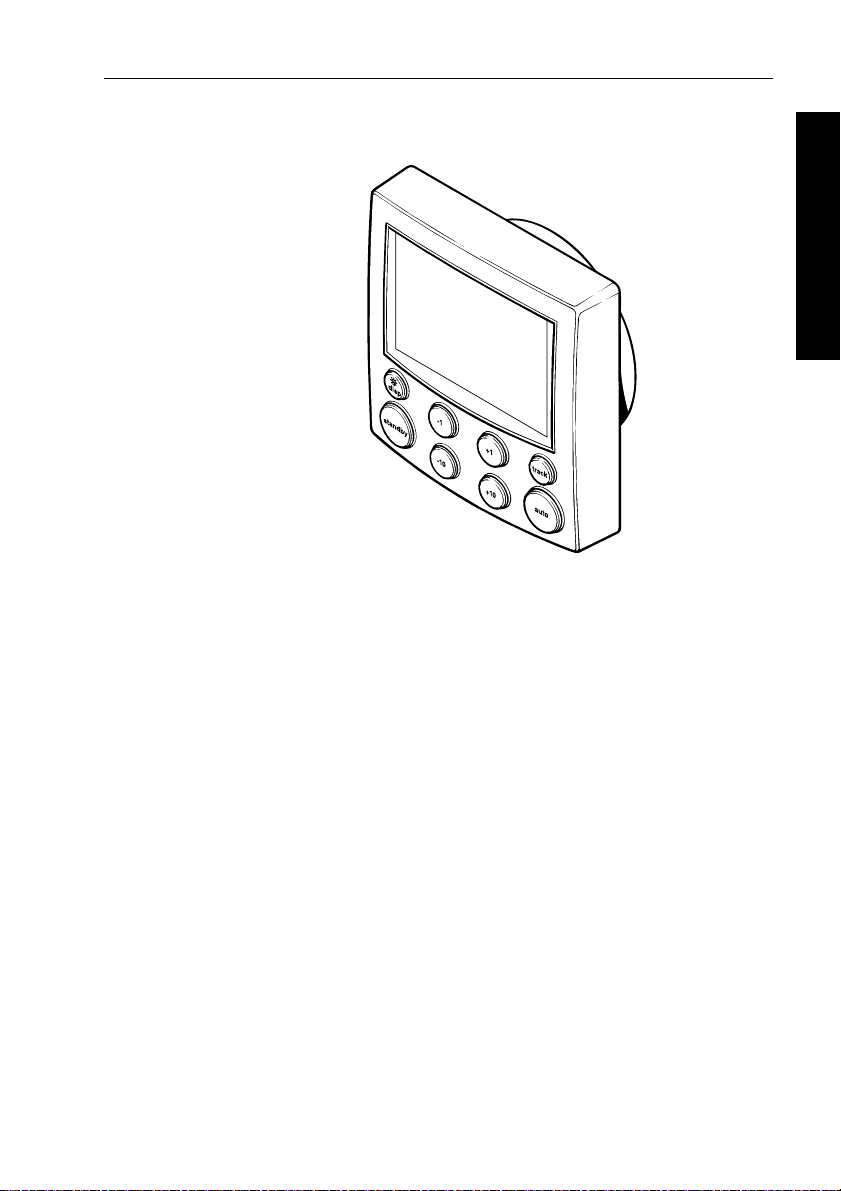

D5460-1

1.1 Features

The Raymarine ST4000 Plus (ST4000+) is a SeaT alk® compatible

autopilot available in versions suitable for boats with either tiller or

wheel steering systems. This autopilot system will st eer your boat to

a heading automatically, accurately and reliably .

The ST4000+ has four main operating modes:

1 Introduction

1.

Standby: autopilot off (see page 7)

2.

Auto: autopilot engaged and locked onto a heading (see page 6)

Track: autopilot engaged and maintaining a track between two

3.

waypoints created using a navigation sy stem (see page 20)

4.

Wind Vane: autopilot engaged and maintaining a course relative

to an apparent wind angle (see page 27)

The ST4000+ also provides the following features:

• automatic tack facility (AutoTack) in Auto and Wind V a ne modes

• automatic compass deviation correction

• Northerly/So utherly heading compens ation

• automatic heading deadband – seastate control

• waypoint advance feature

• setup and calibration options to optimize performance on your boat

Page 17

2 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

1.2 Extended systems

The ST4000+ is compatible with all other SeaT alk instruments.

Y ou can connect it to additional fixed or handheld SeaTalk autopil ot

control units located at secondary steering and control positi ons

(see page 52).

1 Introduction

Y ou can also use the ST4 000+ autopilot with any navigator

(GPS, Decca, Loran) or wind instrument that transmits data in the

internationally-accepted National Marine Electronics Association

(NMEA) 0183 format.

The ST4000+ can display SeaT alk and NMEA instrument data in a

user-defined selection of data pages. When you are usin g the

ST4000+ to repeat instrument data, i t shows a ‘pop-up’ pilot page for

5 seconds whenever you make a change in autopilot control.

The ST4000+ can share all data transmitted from SeaT alk

instruments:

• it can use wind information from a SeaT alk wind instrument for

wind trim steering in Wind Vane mode without the need for a

separate vane

• it can use track information from a SeaT alk navigation instrument

to provide waypoint control in T rack mode

• it can use boat speed from a SeaTalk speed instrument to optimize

track-keeping performance

Rudder position sensor (wheel drives only)

On wheel drive systems you can fit a rudder position sensor to

improve the wheel pilot’s performance (see page 81). This is

particularly advisable if your boat’s steering system has significant

backlash, or you require optimum performance from a mechanical or

cable steering system. By using the information from the rudder angle

sensor, the ST4000+ will also be able to show the true rudd er angle in

Standby and Auto modes.

Note: Y ou MUST add a rudder positi on sensor if fitting the ST4000+

to a hydraulic steering system.

Page 18

Chapter 2: Basic Operation 3

Chapter 2: Basic Operation

The sections in this chapter explain how to use the basic functions on

your autopilot:

Using the control unit

2.1

2.2

2.3

2.4

2.5

Summarizes the key functions and screen layout on the

ST4000+ control unit.

Using Auto mode

Provides instructions for engaging/disengaging the

autopilot and using Auto mode.

Adjusting autopilot performance

Making temporary adjustments to response level and

rudder gain to enhance autopilot performance.

Autopilot alarms

Describes how to recognize and respond to the

autopilot alarms.

Adjusting display and keypad lighting

Explains how to change the lighting on the control unit

display and keypad.

page 4

page 6

page 12

page 14

page 18

2 Basic Operation

CAUTION: Important note for wheel drive systems

After each trip, flush inside the drive unit by inserting a hose pipe

in the free slot on the back cover . This will prevent any build-up of

salt on the drive ring and bearings.

Page 19

4 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

2.1 Using the control unit

Key functions

• The autopilot always powers up in Stan dby mode.

• Y ou control the autopil ot by pressing the buttons on the control

unit. The control unit confirms each button press with a short

beep.

• Y ou access the main functions by pressing a sing le key:

• for example, when the autopilot is operating you can make

course changes using the

• T o access other functions you need to press two keys together:

• for example, when the autopilot is operating you make an

AutoTack to po rt by pressing the

• Y ou can return to manual steering at any t ime by pressing

standby and disengaging the autopilot (see page7).

2 Basic Operation

Press for Response level

-1 plus -10

Press together

for AutoTack

to port

-1, +1, -10 and +10 keys

-1 and -10 keys together

-1 plus +1

Press for 1 second

for Rudder Gain

+1 plus +10

Press together

for AutoTack

to starboard

DISP

Press for

Data Page

Press for 1 second

for lamp control

STANDBY

Press for

Standby mode

Press and hold for

User and Dealer

setup modes

Course change keys

Port 1˚ Starboard 1˚

Port 10˚ Starboard 10˚

STANDBY plus AUTO

Press for Wind Vane mode

Press for 1 second for Last Wind

Press again to accept Last Wind

TRACK

Press for Track

mode from Auto

Press to accept

waypoint advance

Press for 1 second

to skip waypoint

AUTO

Press for Auto mode

Press for 1 second

for Last Heading

Press again to

accept Last Heading

D3447-2

Page 20

Chapter 2: Basic Operation 5

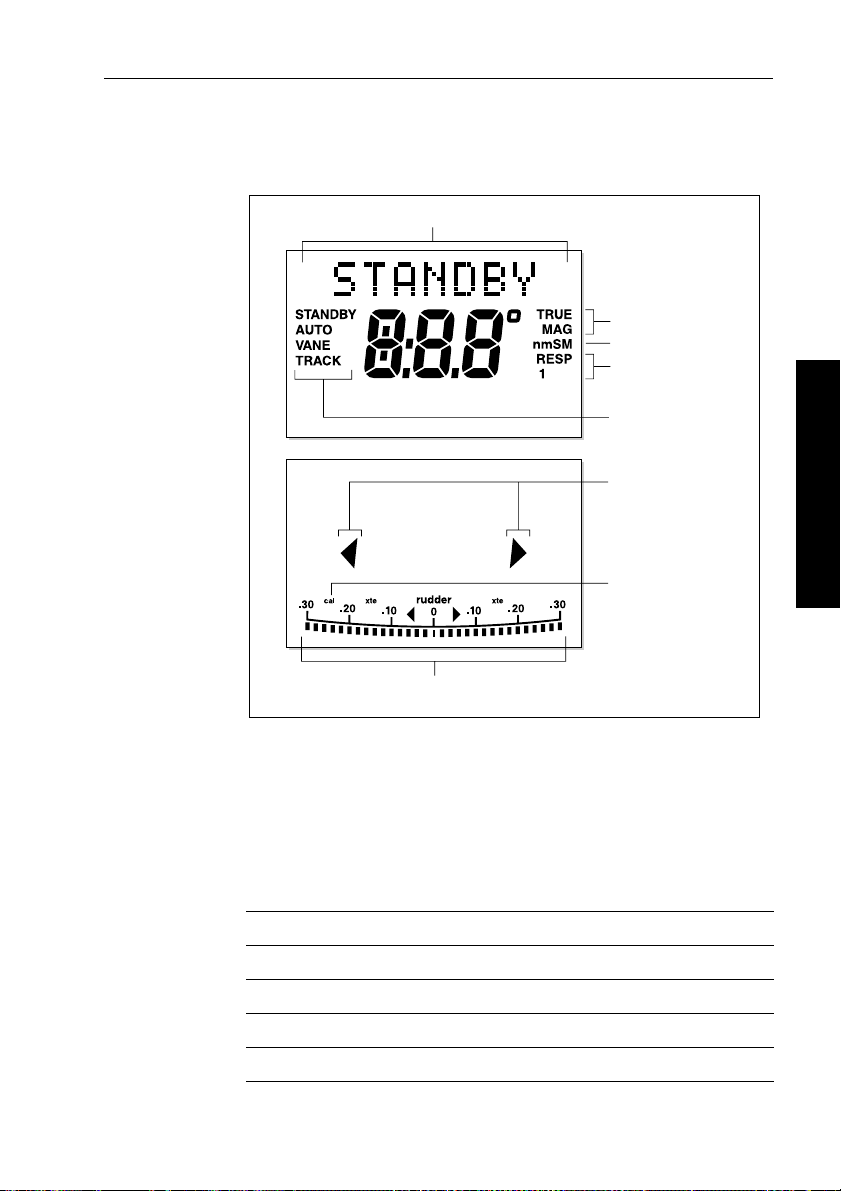

Display layout

The ST4000+ autopilot display provides t he following information:

Variable text region (up to 9 characters/digits)

Heading indicators

Distance units

Response level indicator

Autopilot mode

indicators

Port and Starboard

direction-to-steer

indicators

Calibration mode

indicator

Rudder or Steer direction indicator

(bar graph in 2˚ increments)

• If the display shows no distance unit all distances are in

kilometres (Km), otherwise distances are in nautical miles (nm

or statute/land miles (SM).

• The bar graph at the bottom of the screen is normally a

direction-to-steer indicator (you can change this in User setup,

see page 104). The information displayed on the bar graph varies

according to the autopilot mode:

Autopilot mode Information displayed on bar graph

Standby Rudder bar (only if a rudder position sensor is fitted)

2 Basic Operation

D3316-2

)

Auto Heading error bar

Track Cross track error (XTE) bar, in 0.02 nm increments

Wind Vane Wind angle error bar

Page 21

6 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

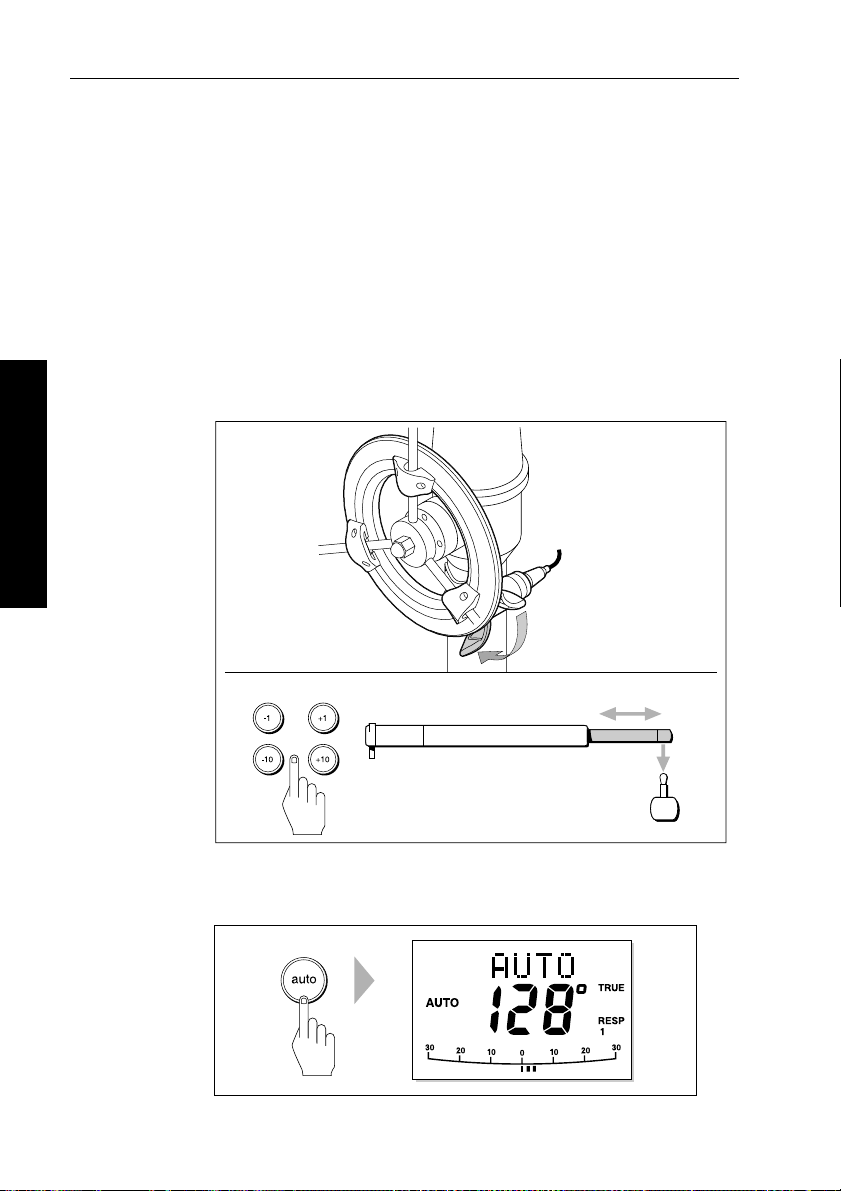

2.2 Using Auto mode

Engaging the autopilot (Auto mode)

1. Steady the boat on the required headi ng.

2. Wheel Pilot: Engage the wheel drive clutch by rotating the clutch

lever clockwise (so the lever engages full y onto the locating pip).

Tiller Pilot: Place the pushrod end over the tiller pin. If necessary,

extend or retract the pushrod using the

WARNING: Wheel drive clutch

Always reach AROUND (not through) the wheel to operate the

wheel drive clutch lever.

.

Wheel pilot

2 Basic Operation

-1, +1, -10 and +10 keys.

Engage the clutch

on the wheel pilot

Tiller pilot

Use these keys to

extend or retract the pushrod

a

3. Press auto:

• in Auto mode, the display shows the locked autopilot heading

b

D5341-1

D3560-2

Page 22

Chapter 2: Basic Operation 7

CAUTION:

Autopilot course control makes it easier to sail a boat, but it is

NOT a substitute for good seamanship. ALW A YS maintain a

permanent watch, no matter how clear the sea appears to be.

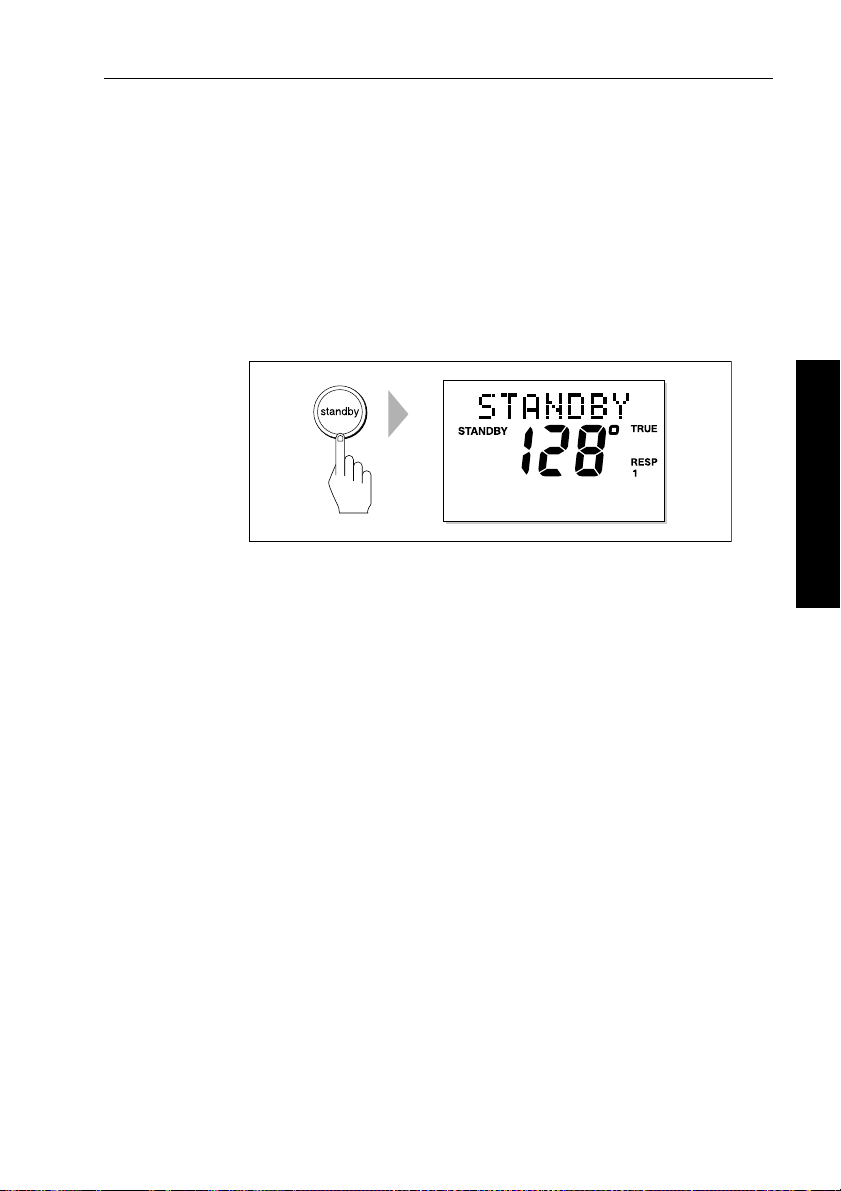

Disengaging the autopilot (Standby mode)

1. Press standby.

• in Standby mode, the display shows the boat’s c urrent

compass heading.

D3561-2

2. Disengage the autopilot to return to hand steering:

• Wheel Pilot: Disengage the wheel drive clutch by rotating the

clutch lever anti-clockwise (so the lever engages fully onto

the locating pip).

• Tiller Pilot: Remove the drive unit from the tiller pin. If

required, retract the push rod using

3. The last heading is memorized and can be recalled (see page 9).

-1, +1, -10 and +10 keys.

2 Basic Operation

CAUTION: Wheel drive systems

On wheel drive systems, always make sure that the clutch is

FULL Y DISENGAGED befor e you leave the boat.

Page 23

8 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

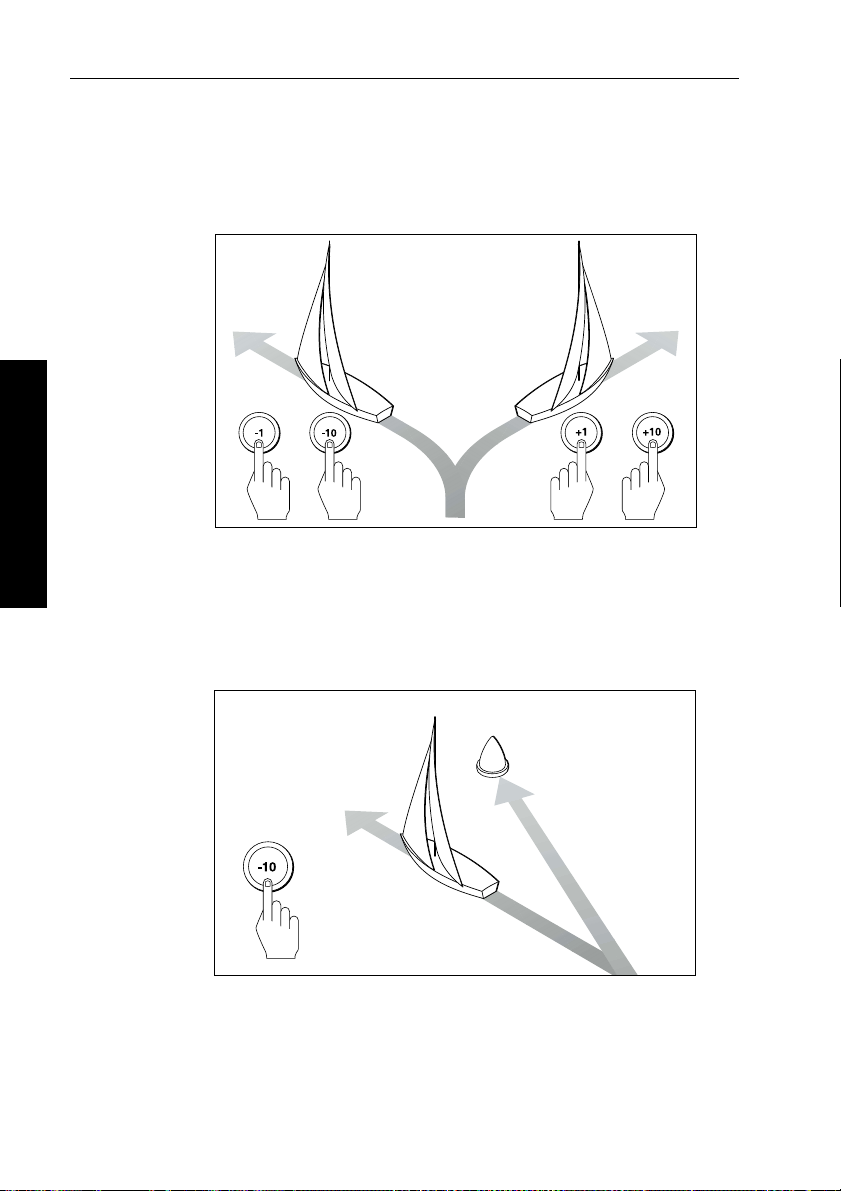

Changing course in Auto mode

In Auto mode, use the -1 and -10 (port) and +1 and +10 (starboard)

keys to change the locked heading in steps of 1° or 10°. For example:

press

-10 three times for a 30° course change to port.

Port Starboard

oror

2 Basic Operation

Dodging obstacles in Auto mode

T o avoid an obstacle when your boat is under autopilot control:

1. Select a course change in the appropriate direction. For exampl e,

press

-10 three times for a 30° dodge to port.

D3320-2

Obstacle

Original

course

Dodge

2. When safely clear of the obstacle, you can either:

• reverse the previous course change (for example, press

three times), or

• return to the previous locked heading (

LAST HDG)

D3303-2

+10

Page 24

Chapter 2: Basic Operation 9

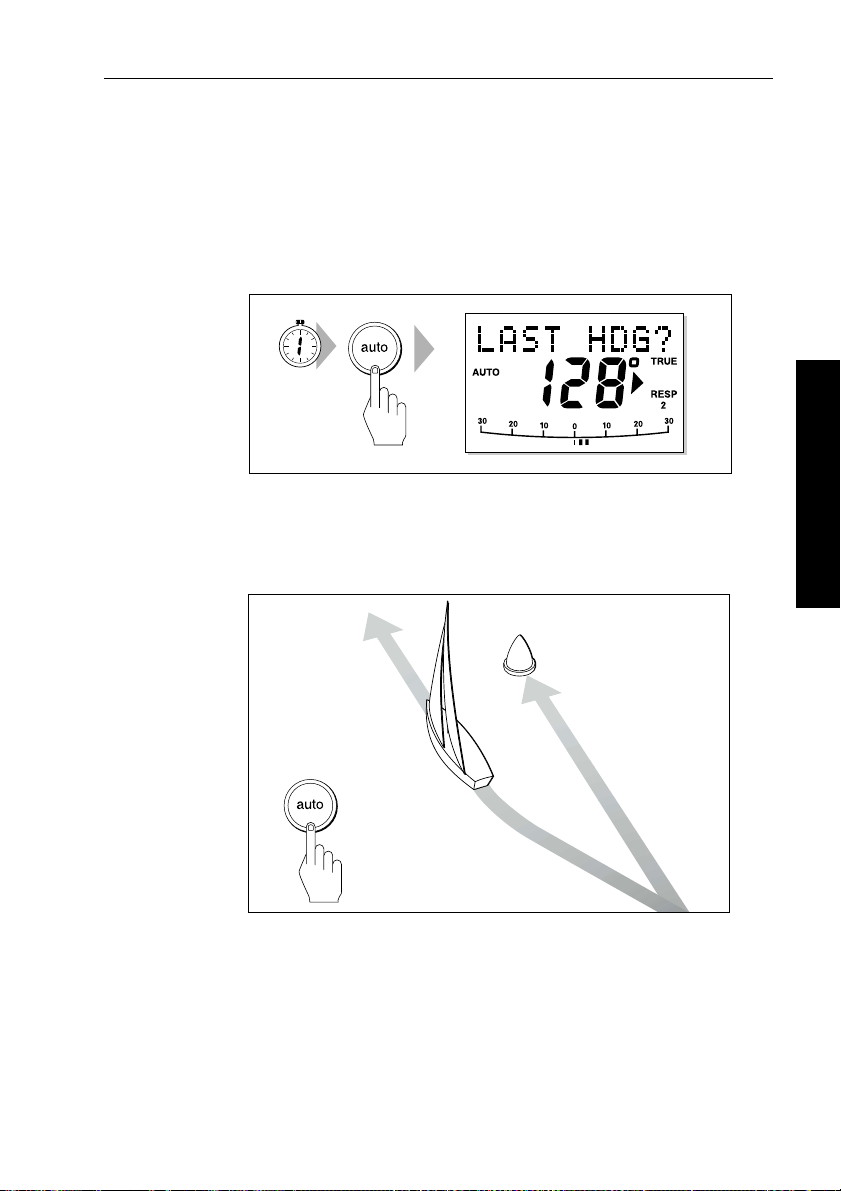

Returning to the previous locked heading (LAST HDG)

If you have steered the boat away from the selected locked heading

for any reason (for example, executing a dodge maneuver or selecting

Standby), you can return to the previous l ocked heading as follows:

1. Press

Note: T he direction-to-steer indicator shows the direction t he boat

will turn.

2. T o accept the previous heading, and resume this course, press

auto for 1 second. The display shows the prev ious locked

heading (

SECOND

LAST HDG?) for 7 seconds.

auto within this 7 second period.

D3562-2

2 Basic Operation

Obstacle

Resumed

course

Dodge

Note: If you do not press

auto while the display is flashing, the

autopilot will maintain the current heading.

Original

course

D5431-1

Page 25

10 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

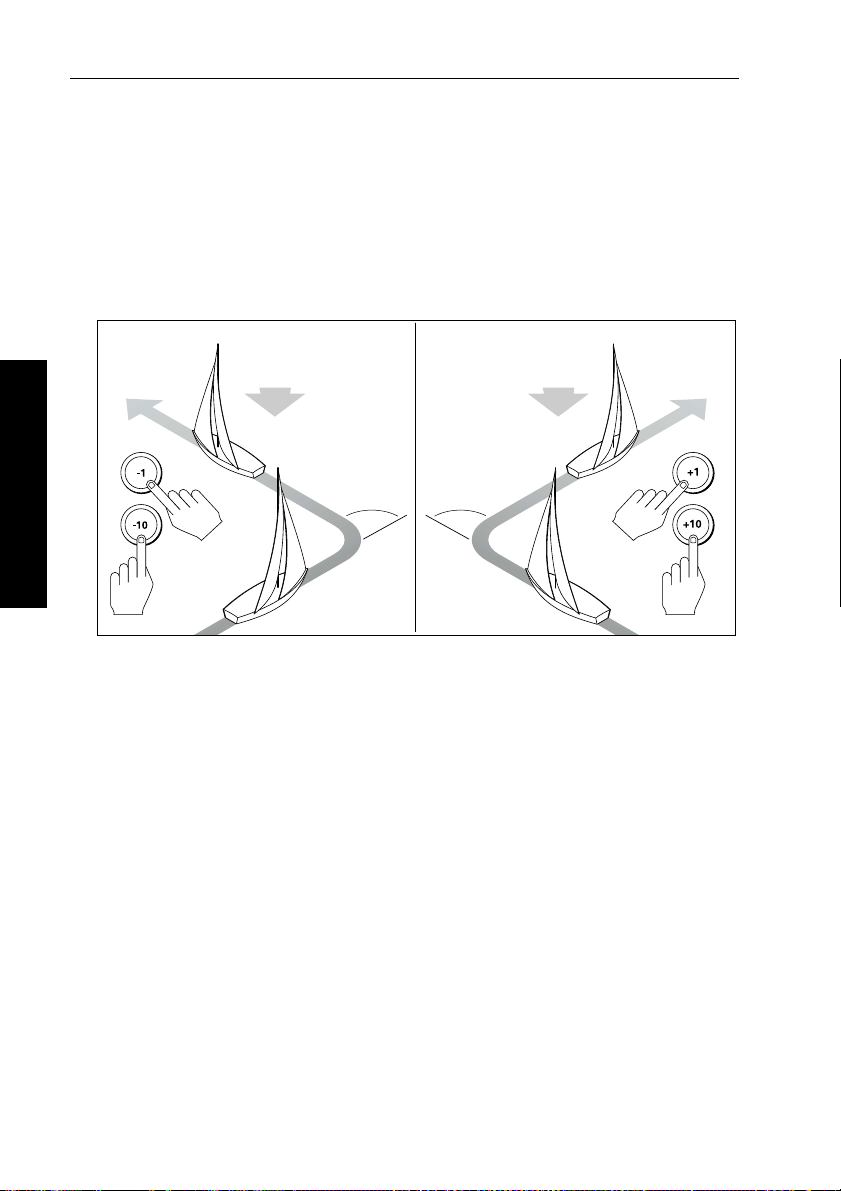

Automatic tack (AutoTack)

The ST4000+ has a built in automatic tack facility (AutoT ack) that

turns the boat through a pre-determined angle in the required

direction. The default AutoTack angle is 100°, but you can adjust this

in Dealer setup (see page 109).

• to AutoTack to port: press the

• to AutoTack to starboard: press the

AutoTack - Port

-1 and -10 keys together

+1 and +10 keys together

AutoTack - Starboard

Wind

AutoTack

angle

AutoTack

angle

Wind

2 Basic Operation

D5399-1

Making major course changes

CAUTION:

Only make major course changes when steering MANUALL Y .

This ensures that the boat wil l safely clear any obstructions or

other boats, and you can take into account the changed wind and

sea conditions on the new heading before engaging the autopilot.

Large course changes which change the apparent wind direction can

produce large trim changes. When a sudden trim change occurs (for

example due to weather helm or sail imbalance) there will be a delay

of up to one minute before the automatic trim applies rudder to restore

the locked heading.

In these situations, the autopilot will not immediately assume the new

automatic heading, and will only settle onto course when the

automatic trim has been fully established. To eliminate this problem,

use the following procedure to make major course changes:

Page 26

Chapter 2: Basic Operation 11

1. Note the required new heading.

2. Select

3. Select

standby for manual steering, so you can bring th e boat to

the new heading MANUALLY.

auto: allow the boat to settle onto course, then bring the

boat to the final course in 1° steps using the

-1 or +1 keys

Gusting conditions

In gusting conditions, the course may tend to wan der slightly ,

particularly if the sails are badly balanced. If you take the following

precautions, the autopilot will be able to maintain competent control

even in gale force conditions:

• Y ou can signifi cantly improve course keeping by improving the

sail balance:

• do not allow the boat to heel over excessively

• ease the mainsheet traveller to leeward to reduce heeling and

weather helm

• if necessary, reef the mainsail a little early

• In very strong winds and lar ge seas, you should avoid sailing with

the wind dead astern:

• ideally, bring the wind at least 30° away from a dead run

• in severe conditions, you may also need to r emove the

mainsail and sail under headsail only

2 Basic Operation

Page 27

12 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

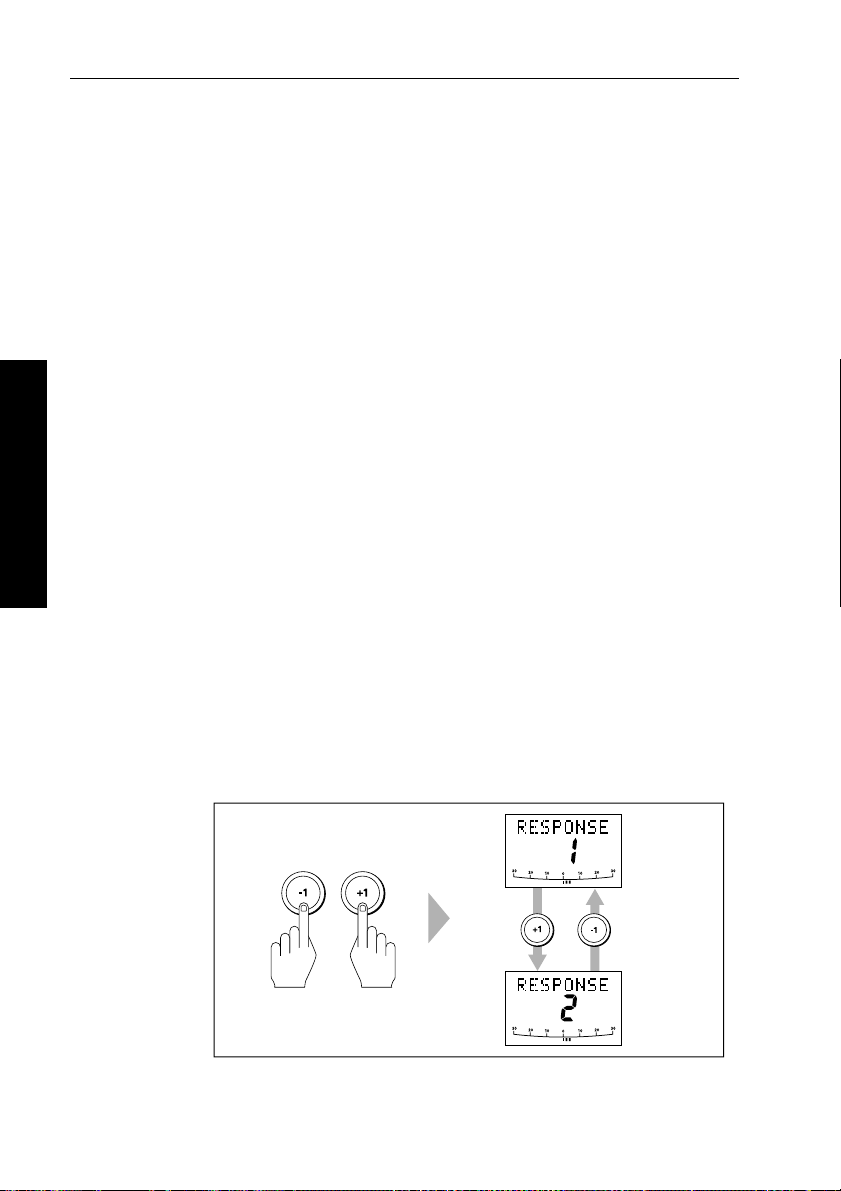

2.3 Adjusting autopilot performance

During normal autopilot operation in any mode you can make

temporary adjustments to:

• response level

• rudder gain

Note: Y ou will lose these temporary changes to response level and

rudder gain whenever the system is powered off then on again. You

can make permanent adjustments in Dealer setup ( see page 108).

Changing the response level (AutoSeastate)

The response level controls the relationship between the autopilot’s

course keeping accuracy and the amount of helm/drive activity .

• Response Level 1: AutoSeastate on ( Automatic deadband)

This setting causes the autopilot to gradually ignore repetitive

2 Basic Operation

boat movements and only react to true variations in course. This

provides the best compromise between power consumption an d

course keeping accuracy , and is the default calibration setting.

• Response Level 2: AutoSeastate off (Minimum deadband)

This setting provides the tightest course keep ing possible.

However, tighter course keeping results in increased power

consumption and drive unit activity .

To make a temporary change to the response setting:

1. Display the

RESPONSE screen by pressing the -1 and +1 keys

together momentarily .

D3310-4

Page 28

Chapter 2: Basic Operation 13

Note: If you h ave set up the RESPONSE screen as a default data page

(see page 104) you can also access it by pressing

disp and then

scrolling through the data pages .

2. Press

3. Press

-1 or +1 to change the response level.

disp or wait for 5 seconds to return to the pr evious display .

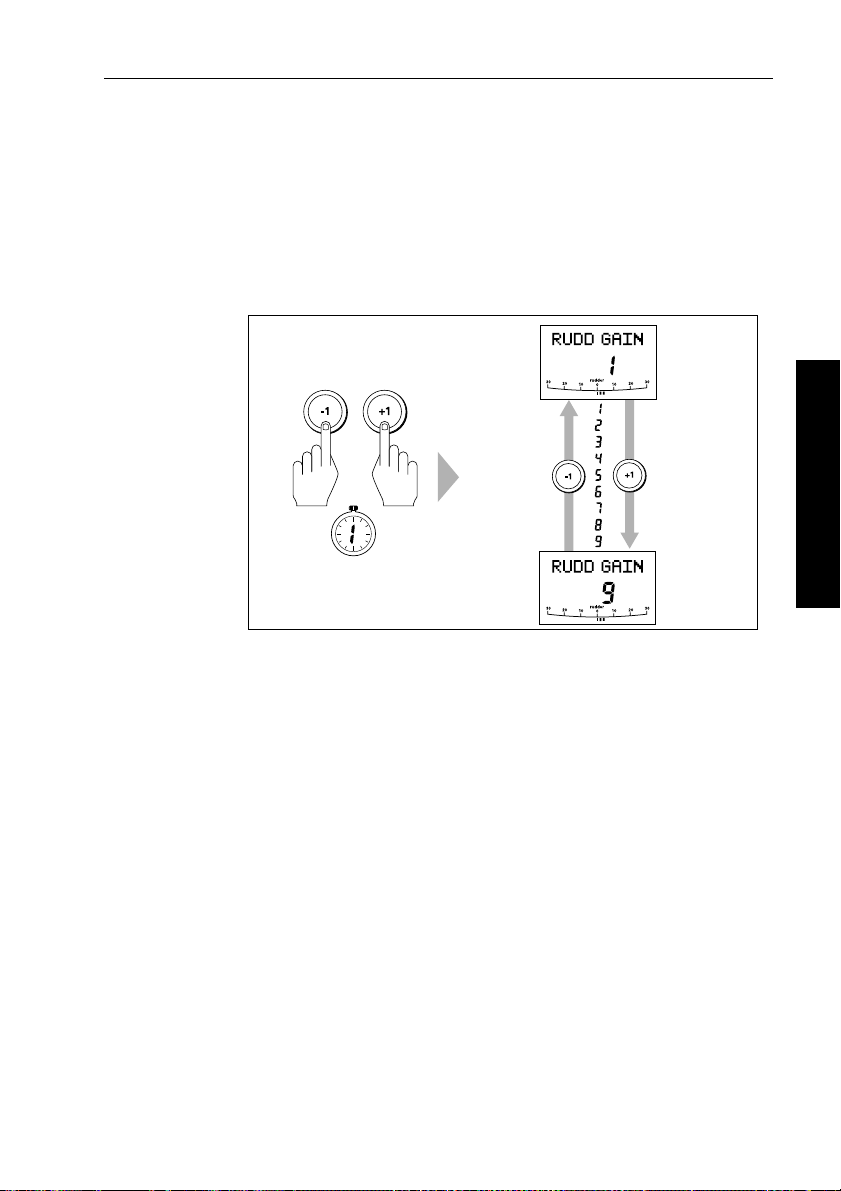

Changing the rudder gain

SECOND

To make a temporary change to the rudder gain:

1. Press the

rudder gain (

Note: If you have set up the

(see page 104) you can also access it by pressing

scrolling through the data pages .

2. Press

3. Press

Note: S ee page 96 for instructions on how to check that the rudder

gain is set correctly.

-1 and +1 keys together for 1 second to display the

RUDD GAIN) screen

-1 or +1 to change the rudder gain.

disp or wait for 5 seconds to return to the pr evious display .

Decrease

rudder gain

Increase

rudder gain

D5400-1

RUDD GAIN screen as a default data page

disp and then

2 Basic Operation

Page 29

14 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

2.4 Autopilot alarms

Responding to alarms

The ST4000+ activates the alarms listed on the following pages:

• Unless otherwise stated, you should deal with alarms by pressing

standby to clear the alarm and return to hand steering.

• In some situations, the autopilot will raise more than one alarm.

When you have dealt with the first alarm, the autopilot will

display the next alarm.

SeaTalk Failure alarm (STLK FAIL)

The ST4000+ displays the SeaT alk failure message if there is a wiring

fault in the SeaTalk connection.

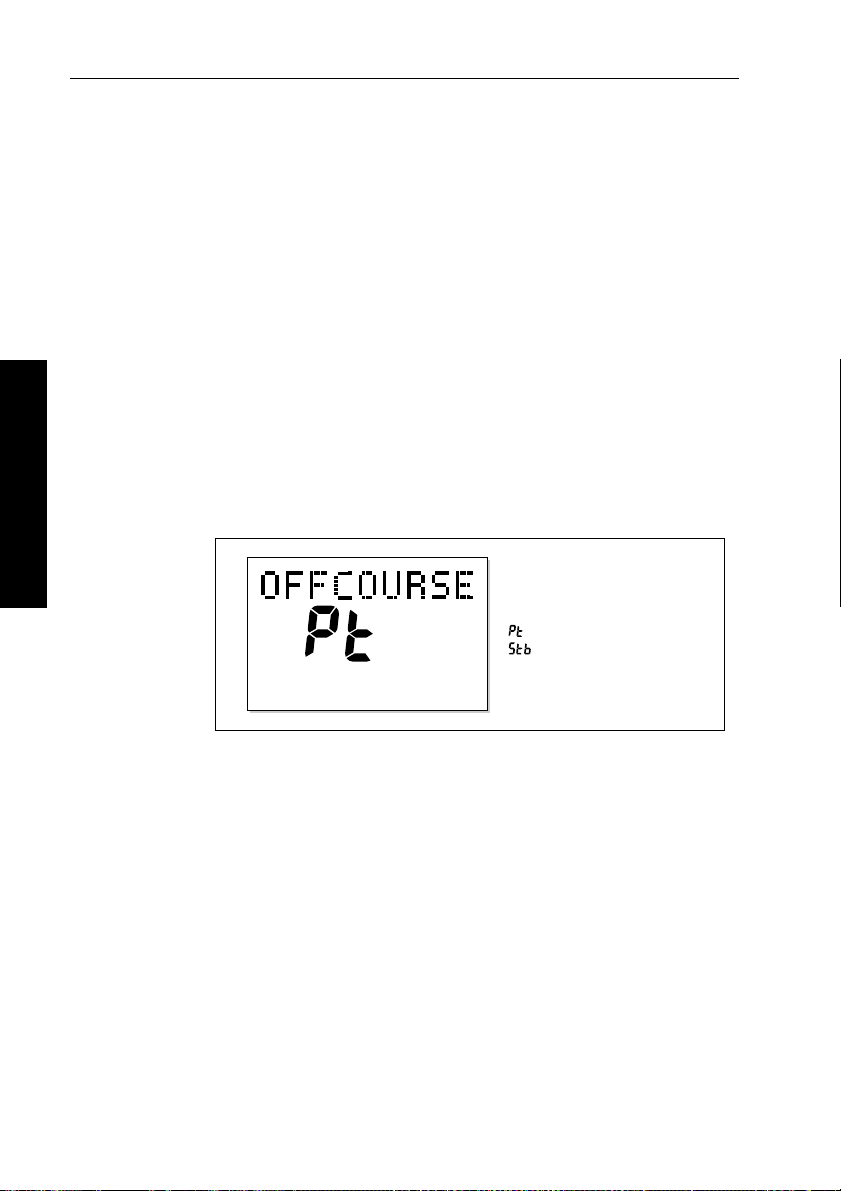

Off Course alarm (OFFCOURSE)

2 Basic Operation

= deviation to port

= deviation to starboard

D3315-2

The ST4000+ activates this alarm when the boat has been off course

from the locked heading by more than the specified angle* for longer

than 20seconds. It shows whether the deviation is to port or starboard.

Note: * Y ou can adjust this specified alarm angle in Deal er setup

(see page 109).

1. T o cancel the off course alarm, press

standby to return to hand

steering.

2. Check whether your boat is carrying too much sail, or whether the

sails are badly balanced. Y ou can usually signif icantly improve

course keeping by improving the sail balance.

Note: T he ST4000+ also clears the alarm if the heading recover s, if

you change the course, or if you change the operating mode.

Page 30

Chapter 2: Basic Operation 15

Wind Shift alarm (WINDSHIFT)

The ST4000+ activates the W indshift alarm when it detects a change

in the apparent wind angle of more than 15° (see page 29).

Large Cross Track Error alarm (LARGE XTE)

The ST4000+ activates this alarm when the cross track error exceeds

0.3 nm (see page 22).The alarm clears if the heading recovers, if you

change the course, or if you change the operating mode.

Drive Stopped alarm (DRIVESTOP)

The ST4000+ activates this alarm if:

• the rudder position sensor fails, or

• the autopilot is unable to turn the rudder (this occurs if the weather

load on helm is too high, or if the rudder position s ensor has

passed beyond the preset rudder limits or rudder end-st ops)

Data Not Received alarm (NO DATA)

The ST4000+ activates this alarm in any of the following situations:

• the compass is not connected

• the autopilot is in Wind Vane mode and it has not received wind

angle data for 30 seconds

• the autopilot is in Track mode and:

• the boat has arrived at the last waypoint in the track, or

• the autopilot is not receiving SeaT alk navigation data, or

• the position sensor (GPS, Loran, Decca) is receiving a low

strength signal – this will clear as soon as the sign al strength

improves

The autopilot stops adjusting the heading as soon as it loses data.

2 Basic Operation

Waypoint Advance alarm (NEXT WPT?)

The ST4000+ activates the W aypoint Advance alarm whenever the

target waypoint number changes. Thi s occurs when:

• you select automatic acquisition by pressing

• you request waypoint advance by pressing

Track mode (with SeaT alk navigators onl y)

track from Auto

track f or 1 second in

Page 31

16 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

• the boat arrives at the target waypoint and the navigator accepts

the next waypoint

• you activate the Man Overboard (MOB) function in Track mode

When the alarm sounds, the pilot continues on its current heading but

displays:

• the bearing to the next waypoint

• the direction the boat will turn to take up that bearing

Responding to a Waypoint Advance alarm

T o respond to a W aypoint Advance alarm:

• check that it is safe to turn onto the new track, then press

accept the waypoint advance

• alternatively, you can cancel the alarm without accepting the

waypoint advance by pressing:

steering, or

2 Basic Operation

Note: W aypoint advance only operates if the ST4000+ is receiving

valid bearing to waypoint and waypoint n umber information.

auto to return to Au to mode.

standby to return to hand

track to

Low Battery alarm (LOW BATT)

The ST4000+ activates the Low Battery alarm when the supply

voltage drops below 10 V (±0.5 V).

Responding to a Low Battery alarm:

T o respond to a Low Battery alarm:

• press

• start the engine to recharge the battery

standby to clear the alarm and return to hand steering

Watch alarm (WATCH)

The ST4000+ activates the W atch alarm when the autopilot is in

W atch mode and the timer has reached 4 minutes.

Setting the Watch timer

T o set the Watch timer:

1. First, you must configure the

pages for display (see page 104).

2. When you have done this select Auto, T rack or Wind Vane mode.

WATCH screen as one of the data

Page 32

Chapter 2: Basic Operation 17

3. Press the disp key until you see the WATCH data page:

• the watch timer will start counting

• when the timer reaches 3 minutes, the

flashing to indicate that the timer is in the last minute

• when the timer reaches 4 minutes, the ST4000+ activates the

audible W atch alarm

Responding to a Watch alarm

T o respond to a W atch alarm:

WATCH text star ts

• press

• press any other key to silence the alarm, reset the timer and

Note: Y ou cannot engage Auto mode directly from Watch mode –

pressing

Auto mode, you must first exit Watch mode (see below).

Exiting Watch mode

T o exit Watch mode:

• press

• press

auto to silence the alarm and reset the timer to 4 minutes

or

perform that key’s normal function

auto will onl y reset the Watch timer. If you want to enter

disp to displa y a different data page

or

standby

Shallow alarm (SHALLOW)

The ST4000+ activates the Shallow alarm if it receives a shallow

depth alarm via SeaT alk:

• press

standby or disp to cancel the alarm

Man Overboard alarm (MOB)

The ST4000+ activates the Man Overboard alarm if it receives a man

overboard (MOB) message from another instrument on the SeaT alk

system. It displays the text

the

XTE, DTW and BTW data pages.

If the autopilot is in T rack mode, it will sound the W aypoint Advance

alarm to notify you of the change in waypoint.

MOB instead of the waypoint number for

2 Basic Operation

Page 33

18 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

2.5 Adjusting display and keypad lighting

Note: When the display lighting is off, the control unit still illuminates

the keys at a courtesy level.

T o adjust the display and keypad lighting:

1. Press

2. Press the

Note:

.

2 Basic Operation

disp for 1 second from any mode to access the LAMP screen

and turn on the lights.

disp key to cycle through the poss ible illumination

settings:

LAMP 3, LAMP 2, LAMP 1, OFF, LAMP 1, LAMP 2, LAMP 3

and so on.

LAMP 3 is the brightest setting.

SECOND

D3313-3

3. The display automatically returns to the previ ous mode if you do

not press a key for 7 seconds:

• if you press another mode key within 7 seconds you will select

the mode assigned to that key (for example:

mode,

standby selects St andby mode)

auto selects Auto

Note: You can als o adjust the lighting level from any other SeaTalk

instrument or control unit connected to SeaTalk.

Note: W hen you switch off the unit you lose any changes you have

made to the lighting.

Page 34

Chapter 3: Advanced Operation 19

Chapter 3: Advanced Operation

The sections in this chapter explain how to use the more advanced

functions on your autopilot:

Using Track mode

3.1

3.2

3.3

Tracking between waypoints created on navigation

equipment connected to the autopilot system.

Using Wind Vane mode

Using the autopilot to maintain a course relative to the

apparent wind angle.

Displaying data pages

Describes how to use d ata pages to display SeaTalk and

NMEA information on the control unit.

page 20

page 27

page 31

3 Advanced Operation

Page 35

20 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

3.1 Using Track mode

Note: Y ou can only use Track mode if you have connected the

ST4000+ to a suitable navigation sy stem providing SeaTalk or

NMEA navigation information.

The ST4000+ can receive track and cross track error information

from either:

• a SeaT alk navigation instrument or chartplotter (see page 52 for

information on connecting to SeaT alk)

or

• a non-SeaT alk navigation system transmitti ng data in the

NMEA 0183 format – you can connect this directly to the

ST4000+ NMEA input (see page 53 for information on

connecting to NMEA equipment)

In Track mode, the ST4000+ maintains a track between two

waypoints created on the navigation system. The autopilot computes

any course changes to keep your boat on track, automatically

compensating for tidal streams and leeway.

Selecting Track mode

3 Advanced Operation

T o select Track mode, press the track key with the autopilot in Auto

mode.

When you select Track mode, the autopilot can acquire a track

through either:

• automatic acquisition (see below), when both cross track error

(XTE) and bearing to waypoint (BTW) data are available

or

• manual acquisition (see page 21), when only cross track error

information is available

Automatic track acquisition

If cross track error and bearing to waypoint information are both

available (via SeaTalk or NMEA), the autopilot can acquire a track

automatically:

1. Bring the boat within 0.1 nm of track.

2. Press

3. Press

auto. The autopilot will display the current locked heading.

track to enter Track mode.

Page 36

Chapter 3: Advanced Operation 21

4. W ait for the W aypoi nt Advance alarm to sound. The display will

show the bearing to the next planned waypoint and the direction

the boat will turn to reach this waypoint.

Note: If the boat is more than 0.3 nm from the track, the Larg e Cross

Track Error alarm will sound (see page22). Press

cancel the alarm, hand steer closer to the track, press

press

track.

standby to

auto and then

5. Check that it is safe to turn the boat onto th e new course.

6. Press the

track key:

• the boat will turn onto the new course

• the display shows the new bearing to waypo int

Automatic track acquisition

From auto mode, press track to enter Track mode: Then press track again to turn boat to waypoint:

Waypoint

at 270˚

Waypoint

at 270˚

Current

heading

Previous

heading

D5414-1

Manual track acquisition

If your navigation system only prov ides cross track error information,

you must acquire the track manually:

1. Steer the boat to within 0.1 nm of track.

2. Brin g the heading to within 5° of the bearing to the next wa ypoint.

3. Press

4. Press

auto.

track to enter T rack mo de. The d isplay then shows the

locked pilot heading.

3 Advanced Operation

Page 37

22 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Note: Tidal streams have a far more significant effect at lower sp eeds

than at higher speeds. If the tidal flow is less than 35% of the boat’s

speed, you will not notice any difference in the autopilot’s

performance in Track mode. However, you should take extra care

during manual acquisition, as fo llows:

• Before you select T rack mode, make sure t he boat is as close as

possible to track, and the dir ection made good over the gr ound is

as close as possible to the dir ection of the next waypoint.

• Make positive checks of the boat’s position at regular intervals,

especially if you are close to pot ential navigational hazard s.

Exiting Track mode

Y ou can return to either Auto or S tandby mode from T rack mode by:

• pressing

• pressing

auto to ret urn to Auto mode

standby to return to manual steering

Cross track error

Cross track error (XTE) is the distance between the current position

and a planned route. The autopilot receives the cross track error

information from the navigation equipment, and displays the XTE in

nautical miles (

nm), statute miles (SM) or kilometres.

3 Advanced Operation

Actual route

Waypoint 1

Planned route

Cross track error (XTE)

more than 0.3 nm

Waypoint 2

D5415-1

Page 38

Chapter 3: Advanced Operation 23

If the cross track error is greater than 0.3 nm, the ST4000+ will sound

the Large Cross T rack Error alarm and shows whether you are to the

port

(Pt) or starboard (Stb) of the planned track.

T o cancel the Large Cross Track Error alarm:

• press

• press

standby to return to hand st eering, or

auto to return to Au to mode a nd retain t he current heading

Note: W hen the Large Cross Track Error alar m sounds, it usually

means that the cross tide is too great for your boat’s current speed.

Tidal stream compensation

Under most conditions, Track mode will hold the selected track to

within ±0.05 nm (300 ft) or better.The autopilot takes account of the

boat’s speed when computing course changes t o ensure optimum

performance over a wide range of boat speeds. In order o f preference,

the ST4000+ uses:

• measured boat speed (speed through water)

• if this is not available, it uses the speed over ground (SOG)

• if this is not available, it uses the cruise speed specified in Dealer

setup (see page 112)

Waypoint 2

3 Advanced Operation

Boat's speed over ground

Waypoint 1

Tidal component

Boat's speed through water

D3261-2

Page 39

24 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Waypoint arrival and advance

Arrival

As the boat arrives at the target waypoint the navigation ai d should

manually or automatically select the next target waypoint. The

ST4000+ will then detect the new target waypoint number, sound the

W aypoint Advance alarm and display the W aypoint Advance screen.

This shows the new bearing to the next waypoint and the direction the

boat will turn to acquire the new track.

Advance

When the ST4000+ sounds the W aypoint Advance alarm, it suspends

Track mode and maintains the current boat heading.T o advance to the

next waypoint:

1. Check that it is safe to turn onto the new track.

2. Press the

alarm and turn the boat towards the next waypoint.

track key . This wi ll cancel the W aypoint Advance

3 Advanced Operation

Target

waypoint

Note: If you do not press

track to accept the Waypoint Advance, the

ST4000+ will maintain the current heading and co ntinue sounding

the alarm.

Waypoint arrival and advance

Waypoint arrival Waypoint advance

Next target

waypoint at 270˚

Old target

waypoint

New target

waypoint at 270˚

D5416-1

Page 40

Chapter 3: Advanced Operation 25

Note: W hen you reach the last waypoint in the track, the NO DATA

alarm will sound to indicate t hat there is no further waypoint

information. Press

standby to r eturn to hand steering.

auto to conti nue on the same heading, or

Skipping a waypoint – SeaTalk navigators only

If you want to advance to the next waypoint before you have arrived

at the target waypoint, you can skip a waypoin t by pressing

1 second. The display will then show the W aypoint Advance screen

for the next waypoint.

track for

Dodges in Track mode

When the autopilot is in Track mode you still have full control from

the keypad.

Initiating a dodge maneuver

In Track mode, you can make a dodge maneuver by u sing the course

change keys (

Cancelling a dodge maneuver

After you have avoided the hazard, you can cancel the dodge course

change by making an equal course change in the opposite direction.

Note: Pr ovided the boat remains within 0.1 nm of track, you do not

need to steer back towards the track.

-1, +1, -10 or +10) to select the desired course change.

3 Advanced Operation

Safety in Track mode

WARNING:

T rack mode provides accurate track keeping even in complex

navigational situations. However, it is still the skipper’s

responsibility to ensur e the safety of their boat at all times

through care ful navigation and fr equent position checks.

Sailing in Track mode assi sts precise navigation and removes the

tasks of compensating for wind and tid al drift. However , you MUST

still maintain an accurate log with regular plots.

Page 41

26 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Confirming position at the start of a journey

At the start of a journey you must always use an easily identifiable

fixed object to confirm the fix given by the navigation system. Check

for fixed positional errors and compensate for them.

Verifying computed positions

Always verify the computed position with a dead reckoned positio n,

calculated from the average course steered and the distance logged.

Plot frequency

• In open water, y ou should make plots at least every hour .

• In confined waters or when near to potential hazards, you should

make plots more frequently .

Setting waypoints

• Local variations in radio signal quality and changes in the tidal

stream can produce deviations from the desired track. When

setting waypoints, remember that deviations can occur.

• Thoroughly check along each track. Check up to 0.5 nm each side

of the track to ensure that there are no hazards within this zone.

3 Advanced Operation

Note: For the waypoint advance function to work, the last four

characters of adjacent waypoint names must be different.

Page 42

Chapter 3: Advanced Operation 27

3.2 Using Wind Vane mode

Note: Y ou can only use Wind Vane mode if you have connected the

ST4000+ to a suitable wind inst rument/vane providing SeaTalk or

NMEA wind direction informati on.

T o use Wind Vane mode (also known as V ane mode), t he ST4000+

must receive wind information from one of the followi ng sources:

• SeaT alk wind instrument, connected to the ST4000+ via SeaT alk

• NMEA wind instrument

• Raymarine wind vane connected through a SeaTalk interface box

In Wind Vane mode the ST4000+ maintains a course relative to an

apparent wind angle. It uses wind trim to eliminate the effects of

turbulence and short term wind variati ons. This provides smooth and

precise performance with minimal power consumption.

When the ST4000+ is in Wi nd V ane mode it uses the fluxgate

compass as the primary heading reference. As changes in the

apparent wind angle occur, the ST4000+ adj usts the locked compass

heading to maintain the orig inal appar ent wind an gle.

Selecting Wind Vane mode

Y ou can select W ind Vane mode from either Standby or Auto mode:

1. Steady the boat onto the requi red apparent wind angle.

2. Press

standby and auto together to select Wind V ane mode and

lock the current apparent wind angle:

• the display shows the locked heading (e.g.

the apparent wind angle (e.g.

WIND 145P indicates an apparent

128°) along with

wind angle of 145° to port)

3 Advanced Operation

The ST4000+ will then adjust the boat’s heading to maintain the

locked apparent wind angle.

D3565-2

Page 43

28 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Exiting Wind Vane mode

Y ou can return to Auto or Standby mode from W ind V ane mode by:

• pressing

• pressing

auto to ret urn to Auto mode

standby to steer manually in S tandby mode

Adjusting the locked wind angle

Y ou can adjust the locked wind angle by using the -1, +1, -10 and +10

keys to change course. For example, to bear away by 10° when th e

boat is o n a star board ta ck:

3 Advanced Operation

• press

-10 to turn the boat 10° to port – the locked apparent wind

angle and locked heading will both change by 10°

• the autopilot will then adjust the locked heading as required to

maintain the new apparent wind angle

Note: Becaus e turning the boat affects the relationship between the

true and apparent wind angles, you shoul d only use this method to

make minor adj ustments to the apparent wind angle. For maj or

changes, return to Standby mode, steer onto the new heading, t hen

reselect Wind Vane mode.

Returning to the previous apparent wind angle (LAST WND)

If you have steered the boat away from the selected apparent wind

angle for any reason (such as a dodge maneuver or selecting Standby

mode), you can return to the previous locked wind angle:

1. Press

standby and auto tog ether for 1 second to display the

previous apparent wind angle (

• the

LAST WND? text alternates with the previous wind angle

LAST WND?):

and direction. The display shows the previo us locked heading

and indicates which direction the boat will turn

SECOND

D3566-2

Page 44

Chapter 3: Advanced Operation 29

2. Check that it is safe to turn onto this course.

3. T o accept this apparent wind angle, press

together within 7 seconds.

Note: If you d o not accept the previous wind within 7 seconds, the

autopilot will lock onto the current apparent wind angle.

standby and auto

Dodges in Wind Vane mode

When the autopilot is in Wi nd V ane mode you s till have full control

from the keypad.

Initiating a dodge maneuver

In Wind Vane mode, you can make a dodge maneuver by using the

course change keys (

change. The autopilot will adjust both the locked heading and locked

apparent wind angle.

Cancelling a dodge maneuver

After you have avoided the hazard, you can reverse the previous

course change, or return to the previous wind angle (

-1, +1, -10 or +10) to select the desired course

LAST WND?).

Wind shift alarm

If the autopilot detects a wind shift of more than 15° it will sound the

wind shift alarm and display the

page 15).

• T o cancel the alarm and retain the existing wind angle and new

heading:

• press

• Alternatively, to cancel the alarm and return to the previous

heading, either:

• adjust the locked wind angle using the

+10 keys

or

• press

required heading, and press

return to Wind Vane mode with the new apparent wind angle

3 Advanced Operation

WINDSHIFT alarm message (see

standby and auto together.

-1, +1, -10 and

standby to return to hand steering, steer onto the

standby and auto to gether to

Page 45

30 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Using AutoTack in Wind Vane mode

After using the AutoT ack function (see page 10) to tack in Wind V ane

mode, you may need to adjust the locked heading until you achieve

the required apparent wind angle.

Note: Bef ore you use the AutoTack function in Wind Vane mode, you

must make sure that the wind vane was centered accurately at

installation.

Apparent wind angle

After tacking, you may need to make

minor course changes to achieve the

desired apparent wind angle

AutoTack

angle

3 Advanced Operation

AutoTack to Port

Operating hints for Wind Vane mode

• Always trim your sails carefully to minimize the amount of

standing helm.

• Reef the headsail and mainsail a little early rather than too late.

• In Wind Vane mode the pilot will react to long-term wind shifts,

but will not correct for short-term changes such as gusts.

• In gusty and unsteady inshore condi tions, it is best to sail a few

degrees further off the wind so that changes in apparent wind

direction can be tolerated.

D4373-2

Page 46

Chapter 3: Advanced Operation 31

3.3 Displaying data pages

Use the disp key to show ‘data pages’ of SeaT alk or NMEA data:

1. Press

2. Select the data page you want to use as the principle display o n the

Three data pages are set in the factory as a default (see diagram).

Within User setu p you can select up to seven pages and control the

information they display (see page 104):

• if the autopilot system cannot obtain the required information for

• the ‘direction-to-steer’ arrows relate to the data page information

• most data pages show repeated data so you cannot adjust them:

Default data pages

disp to access the first data page, and press it again to cycle

through each data page in turn:

• to return to a previous data page, press

disp for 1 second

within 2 seconds of displaying a page

• when you cycle past the last data page, the display returns to

the current autopilot mode screen (for example, Auto)

control un it:

• the current autopilot mode is shown at the left of the displ ay

and the autopilot bar graph remains in use

• if you then select a new mode or make a course change, the

autopilot mode screen appears as a ‘pop-up’ for 5 seconds

a data page, the display will show dashes instead of a value

the exceptions are the

RESPONSE and RUDDER GAIN data pages

(if you have selected them for display) which you can adjust

using the

-1 and +1 keys

3 Advanced Operation

Autopilot mode

Data page 2

Data page 1Data page 3

D3314-2

Page 47

32 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

3 Advanced Operation

Page 48

Chapter 4: Maintenance & Fault Finding 33

Chapter 4: Maintenance & Fault Finding

This chapter provides information about identif ying common

problems, maintaining your autopilot syst em and obtaining product

support:

Fault finding

4.1

4.2

4.3

This section provides a checklist to help you identify

and resolve common autopilot problems.

General maintenance

This section explains how to maintain your autopilot

system.

Product support

This section outlines the product support available

from Raymarine worldwide.

page 34

page 36

page 40

4 Maintenance & Fault Finding

Page 49

34 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

4.1 Fault finding

All Raymarine products are designed to provide many years of

trouble-free operation. W e also put them through comprehensive

testing and quality assurance procedures befo re shipping.

In the unlikely event that a fault does occur with your autopilot, use

the following table to help identify the problem and provide a

solution.

If you cannot resolve the problem yourself, refer to the product

support information on page 40.

SYMPTOM SOLUTION

The control unit display is

blank

The displayed compass

heading does not agree with

the boat’s compass

Boat turns slowly and takes a

long time to come onto course

Boat overshoots when

turning onto a new course

The autopilot appears to be

unstable in Track mode, or

track-holding is slow

The autopilot appears to be

unstable on Northerly

headings in the Northern

hemisphere and Southerly

headings in the Southern

hemisphere

Display shows CAL LOCK when

entering calibration

No power – check the fuse/circuit

breaker.

You have not corrected the compass

for deviation – carry out the

deviation and alignment procedures

(see page 92 and page 95).

Rudder gain too low (see page 96).

Rudder gain too high (see page 96).

If tide speed exceeds 35% of boat

speed, and boat speed is not

available via SeaTalk, change the

Cruise Speed setting in Dealer Setup

to the boat’s cruising speed (see

page 112).

Northerly/Southerly heading

correction (AutoAdapt) is not set up

(see page 111).

Calibration lock is on – turn off the

calibration protection feature is in

Dealer setup (see page 108).

4 Maintenance & Fault Finding

Page 50

Chapter 4: Maintenance & Fault Finding 35

SYMPTOM SOLUTION

The autopilot will not ‘talk’ to

other SeaTalk instruments

Position information not

received

The autopilot will not auto

advance to the next waypoint

The control unit dis play shows

a series of rotating dashes

The control unit dis play shows

a series of stationary dashes

The control unit dis play shows

NO DATA

Wheel drive: drive belt slips in

Auto mode (motor operates

but drive does not turn wheel)

Wheel drive: drive belt drags

in Standby mode

Cabling problem – make s ure all th e

cables are connected properly.

Navigator not transmitting the

correct position data.

No bearing to waypoint information

received from the navigator.

Compass deviation correction is

running (see page 92).

The control unit is not receiving

data – check the cabling.

The signals received by the navigator

are too weak for r eliable navigation –

refer to the navigator handbook for

further action.

OR

Wind trim data is not available –

check the connection to the wind

instrument.

Tighten the clutch – see page 37.

Loosen the clutch – see page 37.

4 Maintenance & Fault Finding

Page 51

36 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

4.2 General maintenance

CAUTION:

The control unit, fluxgat e compass, tiller drive and rudder

position sensor do not contain any user serviceable parts. These

products should be serviced on ly by authorized Raymarine

service technicians.

Wheel drive

Routine maintenance

After each trip, flush inside the drive unit by inserting a hose pipe

in the free slot on the back cover .

Cleaning the wheel drive

CAUTION:

Do not use mineral-based solvents (such as WD40) to lubricate or

clean the wheel drive as they will damage the material.

W e recommend that you complete the following steps each season to

prevent the build-up of salt on the wheel drive b earings and drive belt:

1. Remove the wheel drive from the wheel:

• remove the wheel from the pedestal

• remove the spoke clamp screws

• remove the wheel drive front cover

2. Check inside the drive unit for any signs of damage.

3. Thoroughly flush the wheel drive in terior with fresh water to

remove any salt build-up on the bearings and drive belt.

Do not lubricate any part of the wheel drive. It is des igned to

run without lubrication.

4. Replace the front cover then fit wheel drive back onto the wheel.

5. Fit the wheel and wheel drive back onto the pedestal.

6. Clean the wheel drive case (using mild detergent if necessary),

then flush thoroughly with fresh wat er.

4 Maintenance & Fault Finding

Page 52

Chapter 4: Maintenance & Fault Finding 37

Adjusting the clutch

Y ou need to adjust the clutch if the drive belt slips in Auto mode or

drags in Standby mode. In normal use, you can tell if the clutch is

slipping if the motor operates but the drive does not turn the wheel.

T o adjust the clutch, first make sure that the autopilot is in Standby

mode and the clutch is disengaged. Then:

1. Use a 3 mm allen key (supplied) to loos en the clutch knob screw

about 2 turns anti-clockwise.

2. Turn th e clutch knob either 4 clicks clockwise to tighten the

clutch, or 4 clicks anti-clockwise to loosen the clutch.

3. Use the allen key to re-tighten the clutch knob screw.

4. Check that the wheel still moves freely with the clutch off.

Note: If the wheel does not move freely, reduce the clutch tension by

turning the clutch knob 2 clicks anti-clockwise and check again

5. Check the drive’s operation with the clutch engaged.

This procedure is usually sufficient to correct a slipping or dragging

drive belt. In some cases, however , you may need to repeat the steps

to adjust the clutch further.

Clutch knob

screw

Clutch knob

Adjusting the clutch

Loosen the screw

1

(2 turns)

To loosen

the clutch

(4 clicks)

To tighten

the clutch

(4 clicks)

2

4 Maintenance & Fault Finding

D5349-2

Tighten the screw

(2 turns)

3

Page 53

38 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Replacing the belt

The drive belt is designed to be user serviceable. If there is

insufficient adjustment to cure a slipping clutch, or if the drive belt is

damaged in any way (if it is broken, frayed or stretched), you s hould

replace the drive belt. Y ou can obtain a replacement belt from any

Raymarine dealer (part number A18083). Fitting instructions are

supplied with the belt.

User serviceable parts

Y ou can obtain th e following 4000 mk2 wheel drive spare parts from

your Raymarine dealer:

Part description Part number

Front cover A18074

Clutch lever A18077

Clutch knob A18078

Pedestal bracket (torque restraint) A18080

Drive belt A18083

Clutch kit (clutch eccentric and clutch roller) A18084

Single spoke clamp, screws and inserts A18089

Control unit

Routine checks

The control unit is a sealed unit. As a result, user maintenance is

limited to the following routine checks:

• make sure all cable connectors are firmly attached

• examine the cables for signs of wear or damage – replace any

damaged cables

4 Maintenance & Fault Finding

Page 54

Chapter 4: Maintenance & Fault Finding 39

Cleaning the display

CAUTION:

T ake care when cleaning the display. Do not wipe the display

screen with a dry cloth as this could scratch the screen coating.

Do not use acid, ammonia based or abrasive products.

• Never use chemical or abrasive materials to clean the control unit.

If the control unit is dirty, wipe it with a clean, damp cloth.

• In certain conditions, condensation may appear inside the display

screen. This will not harm the unit, and you can clear it by

switching on the illumination for a short time.

EMC advice

• When powered up, all electrical equipment produces

electromagnetic fields. These can cause adjacent pieces of

electrical equipment to interact with one another, with a

consequent adverse effect on operation.

• T o minimize these effects and enable you to get th e best possible

performance from your Raymarine equipment, guidelines are

given in the installation instructions, to enable you to ensure

minimum interaction between different items of equipment, i.e.

ensure optimum Electromagnetic Compatibility (EMC).

• Always report any EMC-related problems to your nearest

Raymarine dealer. W e use such information to improve our

quality standards.

• In some installations, it may not be pos sible to prevent the

equipment from being affected by external influences. In general

this will not damage the equipment but it can lead to spurious

resetting action, or momentarily may result in faulty operation.

4 Maintenance & Fault Finding

Page 55

40 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

4.3 Product support

Raymarine products are supported by a worldwide network of

distributors and Authorized Service Representa tives. If you

encounter any difficulties with thi s product, please contact either

your national distributor , service representative, or the Raymarine

T echnical Services Call Center. Refer to the back cover or the

W orldwide Distributor List for contact details.

Software version

If you cannot trace or rectify the fault, contact your nearest

Raymarine distributor or Service Representative, specifying:

• the product serial number , which is printed on the rear cover of the

autopilot

• the software version number:

• press

SECONDS

standby for 4 seconds to display the software version

ST4000+

software

version

D5334-1

4 Maintenance & Fault Finding

Page 56

Part 2: Installing the ST4000+

Part 2: Installing the ST4000+

Page 57

Part 2: Installing the ST4000+

Page 58

Chapter 5: Installing the ST4000+ 43

Chapter 5: Installing the ST4000+

The sections in this chapter explain how to install and connect the

components of your autopilot system:

Planning the installation

5.1

5.2

5.3

5.4

5.5

5.6

Preparation steps, tools required and EMC installation

guidelines.

Control unit

How to install the surface mount and flush mount

control units, and connect power, SeaTalk and NMEA.

Fluxgate compass

How to install the fluxgate compass.

Tiller drive (tiller pilots only)

How to install the 4000 tiller drive.

Wheel drive (wheel pilots only)

How to install the wheel drive.

Rudder position sensor (wheel pilot option)

How to install the optional rudder position sensor for

wheel pilots.

5 Installing the ST4000+

page 44

page 48

page 55

page 59

page 70

page 81

Page 59

44 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

5.1 Planning the installation

Before you start installing the autopilot system, read through the

relevant installation sections in this chapter .

After reading through the following EMC installation guidelines,

identify suitable locations for each part of the system:

• consider how you will run cables to and from each component

5 Installing the ST4000+

Tools required

• avoid running cables through bilges where possi ble

• avoid running cables close to fluorescent lights, engi nes, radio

transmitting equipment etc.

T o install this autopilot system you will need the following items:

• tape measure (metric/imperial)

• pliers and cross-head/pozi-drive screwdriver

• drill and drill bits:

• 5 mm (

• 3 mm (

• pencil, masking tape and center punch

• sandpaper/file to smooth cut edges

• for the control unit:

• jigsaw or 90 mm hole cutter (for the control unit aperture)

• SeaT alk cables (if required – see page 52)

• extra power cable (if required - see page 52)

• for the tiller drive only:

• two-part epoxy adhesive for tiller pin and mounting so cket

• installation accessories (if required – see page 61)

• drill bits as required

• appropriate power cable (see page 68) for the tiller socket

• for the wheel drive only:

• spanner for the wheel nut

• washing-up liquid (to lubricate the sp okes)

• hacksaw to cut the pedestal bracket

• 4 mm + 6 mm drill bits and 3 mm allen key (supplie d)

5

/32 in) for surface mount control unit

1

/8 in) for compass and rudder position sens or

Parts supplied

Use the following illustrations to check the parts supplied with your

ST4000+ autopilot system.

Page 60

Chapter 5: Installing the ST4000+ 45

Control unit and compass (all systems)

Control unit

No8 x 3/4 in

screw (x4)

Fluxgate compass

with 8 m (26 ft) cable

Gasket

!

COMPASSAREA

Stud (x2)

Control unit

power cable

1 m (3 ft 3 in)

Compass

warning

label

Thumb screw (x2)

Spade

connector (x12)

Control unit terminal cover

(if desired, attach to rear of control unit

after connecting all cables)

M4 x

25 mm

screw

Sun cover

5 Installing the ST4000+

Also packed: Handbook, Quick Reference Card, Worldwide Distributor List

Tiller drive parts

Plug

Cable clip

and screw,

No 6 x 1/2 in

Optional: installation accessories if required

Mounting

socket (D002)

Tiller drive

Tiller

pin (D001)

Socket screw

No 4 x 3/4 in (x2)

D5438-1

Socket

D5437-1

Page 61

46 ST4000+ Wheel & Tiller Autopilots: Owner’s Handbook

Wheel drive parts

Wheel drive parts

Wheel drive

Wheel drive

Pedestal bracket

Pedestal bracket

Spoke clamp (x3)

Spoke clamp (x3)

16 mm spoke

16 mm spoke

clamp insert (x3)

clamp insert (x3)

Clamp screw,

Clamp screw,

M5 x 16 mm (x6)

M5 x 16 mm (x6)

12 mm spoke

12 mm spoke

clamp insert (x3)

clamp insert (x3)

Bracket screw,

Bracket screw,

No 10 x 3/4 in (x4)

No 10 x 3/4 in (x4)

5 Installing the ST4000+

4 mm

4mm

drill bit

drill bit

3 mm

3mm

allen key

allen key

Cable clip

Cable clip

and screw,

and screw,

No 6 x 1/2 in

No 6 x 1/2 in