Ransburg LECU5004 User Manual

SERVICE MANUAL

LN-9218-00.13

(REPLACES: LN-9218-00.12)

February - 2013

Ransburg

TM

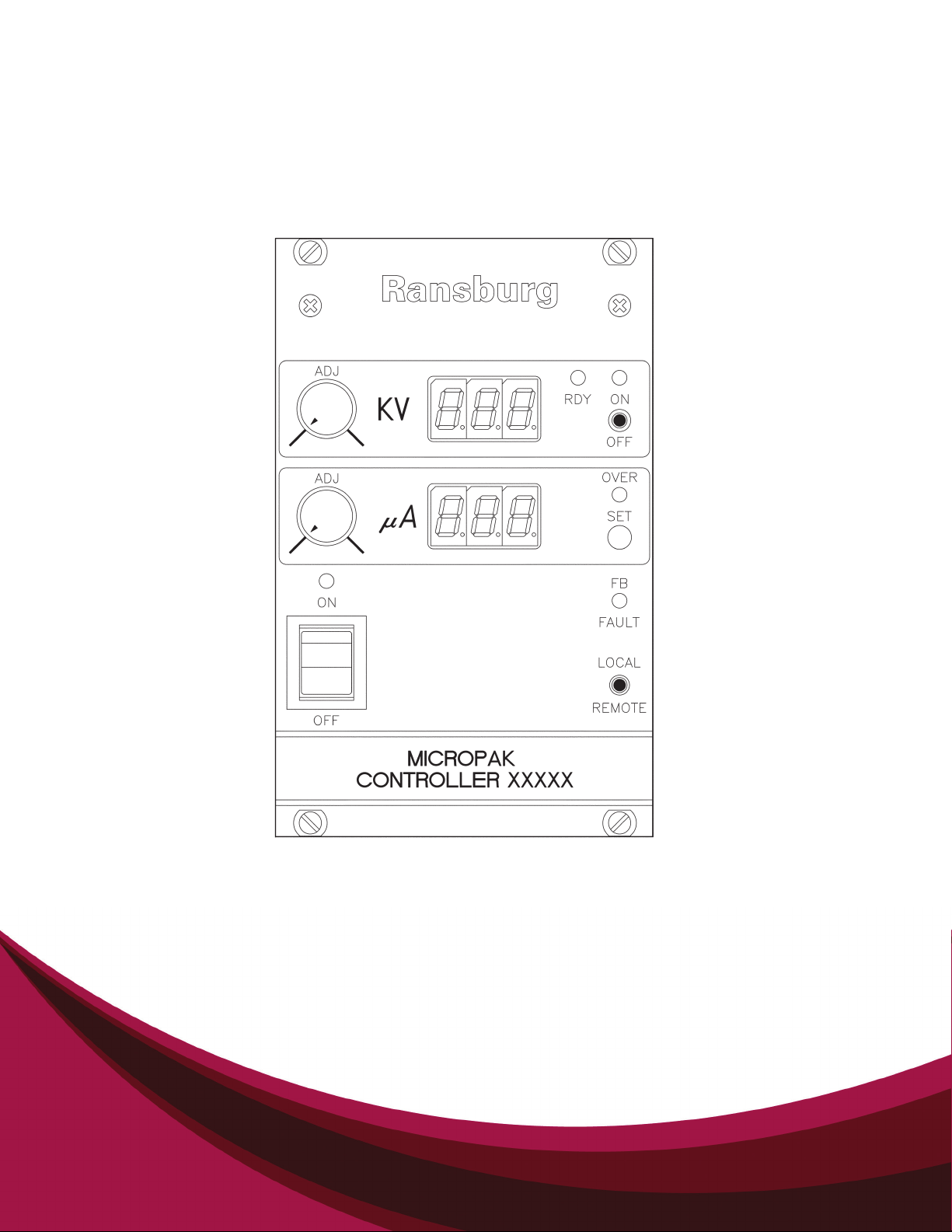

MICROPAK

MODEL: LECU5004

IMPORTANT: Before using this equipment,

carefully read SAFETY PRECAUTIONS, starting

on page 1, and all instructions in this manual.

Keep this Service Manual for future reference.

Service Manual Price: $50.00 (U.S.)

MicroPak

NOTE: This manual has been changed from revision LN-9218-00.12 to revision LN-9218-00.13.

Reasons for this change are noted under “Manual Change Summary” inside the back cover

of this manual.

Ransburg

LN-9218-00.13

Ransburg

MicroPak - Contents

CONTENTS

SAFETY: 1-5

SAFETY PRECAUTIONS ......................................................................................................1

HAZARDS / SAFEGUARDS ..................................................................................................2-5

INTRODUCTION: 6-7

GENERAL DESCRIPTION ....................................................................................................6

SAFETY FEATURES .............................................................................................................6

DISPLAYS .............................................................................................................................6

SPECIFICATIONS .................................................................................................................6-7

INSTALLATION: 8-12

CONNECTIONS ....................................................................................................................8-12

OPERATION: 13-28

PAGE

OPERATOR CONTROL ........................................................................................................13

MODES OF OPERATION / CONFIGURATION ....................................................................13-17

VERSION 3.8 SOFTWARE ...................................................................................................17

VERSION 3.9 SOFTWARE ...................................................................................................17

SWITCH SETTINGS .............................................................................................................18

SWITCH CONFIGURATION .................................................................................................19

INPUT / OUTPUT SIGNALS .................................................................................................20-23

MICROPAK NODE ADAPTER PLC I/O .................................................................................23-27

DIAGNOSTICS ......................................................................................................................28

MAINTENANCE: 29-31

TROUBLESHOOTING ..........................................................................................................29

OHM METER MEASUREMENTS / CASCADE .....................................................................30

OHM METER MEASUREMENTS FOR RANSPAK 1000 CASCADE ...................................31

PARTS IDENTIFICATION: 32-33

MICROPAK APPLICATION TABLE ...................................................................................... 32

MICROPAK PARTS LIST ..................................................................................................... 33

WARRANTY POLICIES: 34

LIMITED WARRANTY ...........................................................................................................34

LN-9218-00.13

MicroPak - Safety

SAFETY

Ransburg

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature for your Ransburg products. This manual

contains information that is important for you to

know and understand. This information relates to

USER SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the following symbols. Please pay

particular attention to these sections.

A WARNING! states information to alert you

to a situation that might cause serious injury

if instructions are not followed.

A CAUTION! states information that tells how

to prevent damage to equipment or how to

avoid a situation that might cause minor injury.

A NOTE is information relevant to the procedure in progress.

W A R N I N G

!

The user MUST read and be familiar with

the Safety Section in this manual and the

Ransburg safety literature therein identied.

This manual MUST be read and thor-

oughly understood by ALL personnel who

operate, clean or maintain this equipment!

Special care should be taken to ensure that

the WARNINGS and safety requirements for

operating and servicing the equipment are

followed. The user should be aware of and

adhere to ALL local building and re codes

and ordinances as well as NFPA-33 SAFETY STANDARD, LATEST EDITION, prior

to installing, operating, and/or servicing this

equipment.

W A R N I N G

!

While this manual lists standard specications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements,

etc., make such variations inevitable. Compare

this manual with your system installation drawings and appropriate Ransburg equipment manuals to reconcile such differences.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efcient operation,

longer trouble-free service and faster, easier

troubleshooting. If you do not have the manuals

and safety literature for your Ransburg system,

contact your local Ransburg representative or

Ransburg.

The hazards shown on the following pag-

es may occur during the normal use of this

equipment. Please read the hazard chart beginning on page 2.

1

LN-9218-00.13

Ransburg

MicroPak - Safety

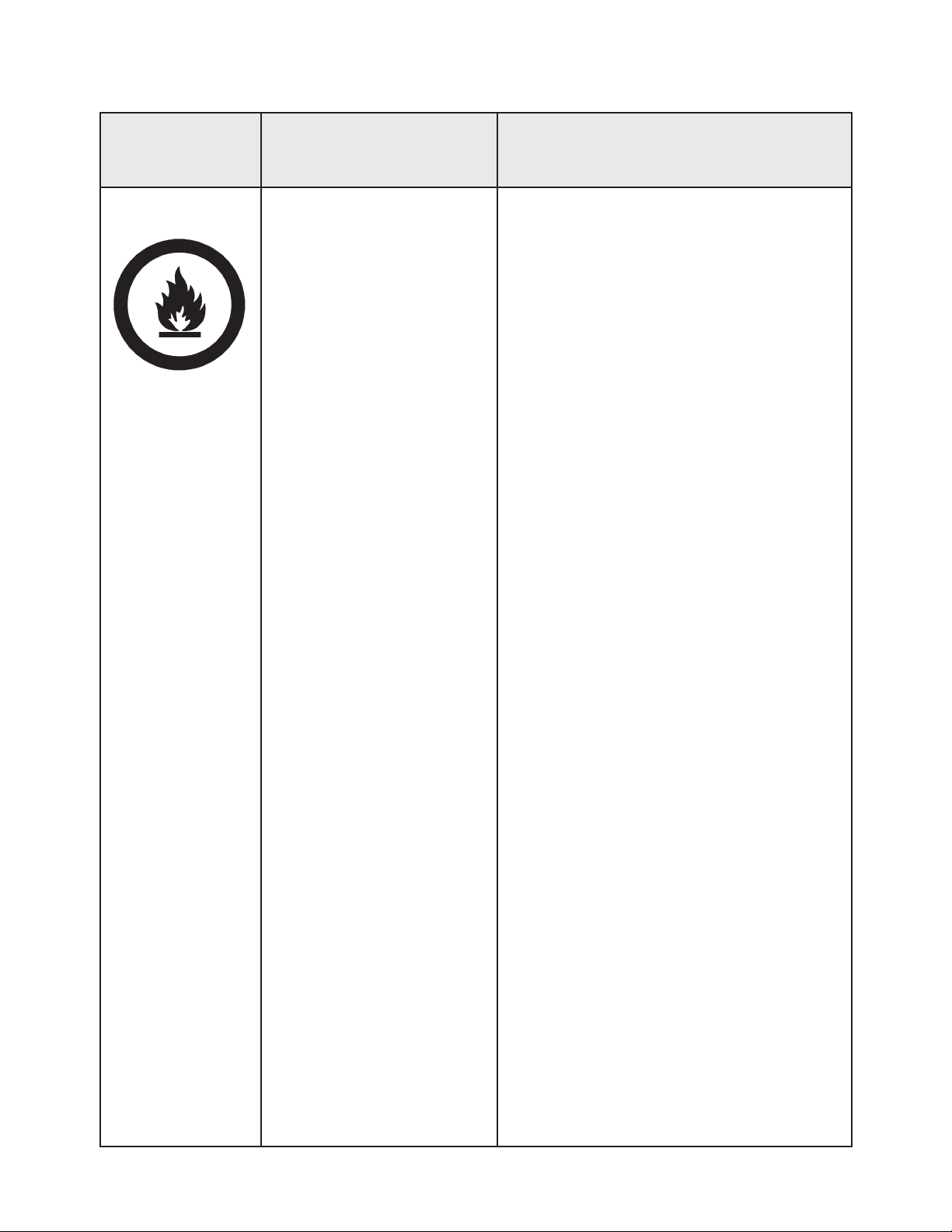

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate

operation and maintenance

procedures will cause a re

hazard.

Protection against inadvertent arcing that is capable of

causing re or explosion is

lost if any safety interlocks

are disabled during operation. Frequent Power Supply

or Controller shutdown indicates a problem in the system

requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in

the spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray

area.

The high voltage supplied to the atomizer must

be turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

• Those used for equipment ushing should

have ash points equal to or higher than

those of the coating material.

• Those used for general cleaning must have

ash points above 100°F (37.8°C).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, country, and local

codes. In addition, ventilation must be maintained during cleaning operations using ammable or combustible solvents.

Electrostatic arcing must be prevented. Safe

sparking distance must be maintained between

the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage

is required at all times.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but

only as instructed.

Non-factory replacement parts or unautho-

rized equipment modications may cause re or

injury.

If used, the key switch bypass is intended for

use only during setup operations. Production

should never be done with safety interlocks disabled.

Never use equipment intended for use in waterborne installations to spray solvent based materials.

The paint process and equipment should be

set up and operated in accordance with NFPA33, NEC, OSHA, local, country, and European

Health and Safety Norms.

LN-9218-00.13

2

MicroPak - Safety

Ransburg

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Explosion Hazard

Improper or inadequate operation and maintenance proce-

dures will cause a re hazard.

Protection against inadvertent

arcing that is capable of caus-

ing re or explosion is lost if

any safety interlocks are disabled during operation.

Frequent Power Supply or

Controller shutdown indicates

a problem in the system requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Electrostatic arcing must be prevented. Safe

sparking distance must be maintained between

the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage

is required at all times.

Unless specically approved for use in hazardous locations, all electrical equipment must be

located outside Class I or II, Division 1 or 2

hazardous areas, in accordance with NFPA-33.

Test only in areas free of ammable or combustible materials.

The current overload sensitivity (if equipped)

MUST be set as described in the corresponding section of the equipment manual. Protection against inadvertent arcing that is capable

of causing re or explosion is lost if the current

overload sensitivity is not properly set. Frequent power supply shutdown indicates a problem in the system which requires correction.

General Use and

Maintenance

Improper operation or maintenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

Always turn the control panel power off prior to

ushing, cleaning, or working on spray system

equipment.

Before turning high voltage on, make sure no

objects are within the safe sparking distance.

Ensure that the control panel is interlocked with

the ventilation system and conveyor in accordance with NFPA-33, EN 50176.

Have re extinguishing equipment readily available and tested periodically.

Personnel must be given training in accordance

with the requirements of NFPA-33, EN 60079-0.

Instructions and safety precautions must be

read and understood prior to using this equipment.

Comply with appropriate local, state, and national codes governing ventilation, re protection, operation maintenance, and housekeeping. Reference OSHA, NFPA-33, EN Norms

and your insurance company requirements.

3

LN-9218-00.13

Ransburg

MicroPak - Safety

AREA

Tells where hazards

may occur.

Spray Area /

High Voltage

Equipment

HAZARD

Tells what the hazard is.

Electrical Discharge

There is a high voltage device

that can induce an electrical

charge on ungrounded objects

which is capable of igniting

coating materials.

Inadequate grounding will

cause a spark hazard. A

spark can ignite many coating

materials and cause a re or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Parts being sprayed and operators in the spray

area must be properly grounded.

Parts being sprayed must be supported on conveyors or hangers that are properly grounded. The resistance between the part and earth

ground must not exceed 1 meg ohm. (Refer to

NFPA-33.)

Operators must be grounded. Rubber soled insulating shoes should not be worn. Grounding

straps on wrists or legs may be used to assure

adequate ground contact.

Operators must not be wearing or carrying any

ungrounded metal objects.

When using an electrostatic handgun, operators

must assure contact with the handle of the applicator via conductive gloves or gloves with the

palm section cut out.

NOTE: REFER TO NFPA-33 OR SPECIFIC

COUNTRY SAFETY CODES REGARDING

PROPER OPERATOR GROUNDING.

All electrically conductive objects in the spray

area, with the exception of those objects required by the process to be at high voltage, must

be grounded. Grounded conductive ooring

must be provided in the spray area.

Always turn off the power supply prior to ushing, cleaning, or working on spray system equipment.

Unless specically approved for use in hazardous locations, all electrical equipment must be

located outside Class I or II, Division 1 or 2 hazardous areas, in accordance with NFPA-33.

LN-9218-00.13

4

MicroPak - Safety

Ransburg

AREA

Tells where hazards

may occur.

Electrical

Equipment

HAZARD

Tells what the hazard is.

Electrical Discharge

High voltage equipment is utilized in the process. Arcing

in the vicinity of ammable or

combustible materials may oc-

cur. Personnel are exposed to

high voltage during operation

and maintenance.

Protection against inadvertent

arcing that may cause a re or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shutdown indicates a problem in the

system which requires correction.

An electrical arc can ignite coat-

ing materials and cause a re or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Unless specically approved for use in hazardous locations, the power supply, control cabinet,

and all other electrical equipment must be located outside Class I or II, Division 1 and 2 hazardous areas in accordance with NFPA-33 and EN

50176.

Turn the power supply OFF before working on

the equipment.

Test only in areas free of ammable or combustible material.

Testing may require high voltage to be on, but

only as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Toxic Substances

Spray Area

Certain material may be harmful

if inhaled, or if there is contact

with the skin.

Explosion Hazard –

Incompatible Materials

Halogenated hydrocarbon sol-

vents for example: methylene

chloride and 1,1,1,-Trichloroethane are not chemically

compatible with the aluminum

that might be used in many system components. The chemical

reaction caused by these solvents reacting with aluminum

can become violent and lead to

an equipment explosion.

Follow the requirements of the Material Safety

Data Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being

sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienist or

safety expert, and be NIOSH approved.

Aluminum is widely used in other spray application equipment - such as material pumps,

regulators, triggering valves, etc. Halogenated

hydrocarbon solvents must never be used with

aluminum equipment during spraying, ushing,

or cleaning. Read the label or data sheet for the

material you intend to spray. If in doubt as to

whether or not a coating or cleaning material is

compatible, contact your coating supplier. Any

other type of solvent may be used with aluminum

equipment.

5

LN-9218-00.13

Ransburg

INTRODUCTION

GENERAL DESCRIPTION

MicroPak - Introduction

The MicroPakTM Controller, in conjunction with

an appropriate cascade, is used to provide high

voltage for electrostatic application equipment.

The controller is packaged in a single, 3.2 inch

wide Eurocard module, and thus consumes less

than 1/4 of the available space in a 19 inch rack.

The MicroPak uses a combination of proven high

voltage generation technology including microprocessor-based control with diagnostic and communication functions. The processor circuitry provides

the maximum in applicator transfer efciency, while

maintaining the maximum safety when used in

conjunction with FM listed applicators.

SAFETY FEATURES

When used with FM listed applicators, the MicroPak provides the ultimate in operational safety.

The microprocessor circuits allow the use of output

load curve control, which limits the high voltage

output to safe levels, even with the controls set at

maximum levels, and does so without a hard shut

down. The Over current set point, which can be

monitored on the µa Display by pressing the SET

push-button and holding for one second, does pro-

vide a hard shutdown if the output current exceeds

the set point. The kV set point is also displayed

on the kV display when the SET push-button is

pressed for one second.

DISPLAYS

The front panel displays for output voltage and

current indicate the outputs from the cascade of

direct charge applicators or the probe tip voltage

in the case of indirect charge applicators. They are

derived from feedback signals in the low voltage

cable between the controller and the cascade.

In RansPakTM 1000 mode, beginning with software

version 3.2, the signal used for the current (µA)

display is conditioned to subtract out the internal

cascade “bleeder” current and thus display the

actual output current.

SPECIFICATIONS

(At Sea-Level Conditions)

Environmental / Physical

Temp. Operating: (0

Storage: (-40

Humidity: (95% Non-Condensing)

Size: 100 X 160mm

Eurocard module,

total width 3.2 in.

(one module)

Electrical Requirements

Power Required:

(per MicroPak) 24 VDC at 2.5A

(fully loaded output),

HP404, RP404, and

HP505 Cascades

28 VDC at 6A

(fully loaded output),

RansPak 1000 (RP1000)

Cascade

Note: 24 VDC and 28 VDC power supplies must

be regulated and have overcurrent (40%) and

overvoltage (20%) protection.

o

to 55o C)

o

C to 85o C)

LN-9218-00.13

6

MicroPak - Introduction

Ransburg

Electrical

Controls:

1. All communication to Controller by CANBus

2. Direct A-B RIO communication via additional

Node Adapter Module (Part# LECU4012) or

Serial Node Adapter + Module (Part #78553)

(One Node Adapter per rack)

3. Discrete signals available via additional I/O

Module (Part# 76037) in place of Node

Adapter with levels as shown below

Analog In: (0-10 VDC or 4-20 mA DC)

kV Set

Current Set

(Overcurrent Setpoint)

(Di/dt Sensitivity)

Analog Out: (0-10 VDC)

OUTPUT kV

OUTPUT CURRENT

Discrete Out: (Dry Contact)

HV ON

FB FAULT

HV READY

OVER CURRENT FAULT

LOCAL

HV RESET

Discrete In: (24 VDC Source or Sink)

HV OFF

HV ON

FLUID TRIGGER

START

Trigger Out: (24 VDC, 150 mA Maximum)

(For EFM Gun) AIR TRIGGER

AIR TRIGGER / SEQUENCER

MicroPak with HP404 / RP404 Cascades

Output: 100 kV @ 0 µA

125 µA @ 0 kV

Cascade Size: HP404 1.50” X 1.56” x 7.0”

RP404 4” X 4” X 12”

MicroPak With RP1000 Cascade

Output: 100 kV, 1000 µA

(75% Duty Cycle)

Cascade Size: 4” X 4” X 12”

MicroPak With LEPS5002 Cascade

Output: 100 kV, 1000 µA

(75% Duty Cycle)

Cascade Size: 14” X 12” X 12”

MicroPak With HP404 FM Cascade

Output: 100 kV, 0 µA

(85 µA Max.)

Cascade Size: 1.50” X 1.56” X 7.0”

MicroPak With HP505 Cascade

Output: 100 kV @ 0 µA

240 µA @ 0 kV

Cascade Size: 1.50” X 1.56” X 7.0”

7

LN-9218-00.13

Ransburg

INSTALLATION

MicroPak - Installation

CONNECTIONS

- For MicroPak with HP404, RP404

& HP505-+24 VDC

- For MicroPak with RP1000 - +28 VDC

Input Power

This must be supplied from a regulated power

supply. Connection is made at J2 for +24/28 V,

24/28 VRET, and Factory Ground. The 24/28

VDC supply is protected against excessive current

draw by an automatically resetting fuse internal to

the MicroPak. In case of a current draw over 6 A,

the fuse will open circuit and automatically reset

when 24/28 VDC power is removed.

C A U T I O N

!

The 24VRET must be connected to Fac-

tory Ground at the +24 VDC power supply

(see Figures 1 and 2).

Node Adapter / Discrete I/O Power

When a Node Adapter or Discrete I/O Module is

used, power must be supplied to it via J10. Connect +24 VDC to J10-1, and 24 VRET to J10-2

(see Figures 1 and 2).

The two wire braids must be connected to a dedicated HV power supply ground bus. This bus must

be isolated from the system ground bus except at

the termination point to earth ground.

W A R N I N G

!

If these connections are not made in this

manner, damage will result to system electronic components, and system safety may

be compromised.

Remote I/O

If applicable, connect Remote I/O Blue to J5-B,

Shield to J5-S, and Clear to J5-C.

CANBus

Provide a jumper from the MicroPak mother board

connector J8 (CAN) to pneumatic mother board

connector J4. This should be done with a short

section of shielded pair cable while observing the

(+) and to (+) convention. See Figure 3.

In Node Adapter applications, provide additional

jumper wires from pneumatic mother board to the

next pneumatic mother board, up to a maximum

of four (4) mother boards.

.

Output To Cascade

HP404, HP505 & RP404

Make connections to J3 per Figure 1. Use the

appropriate cable assemblies for HP404 / HP505

(see MicroPak parts list at back of this manual).

Use only the A12971 cable assembly for RP404.

RP1000

Make connections to J3 per Figure 2. Use only

the 74947 cable assembly.

LN-9218-00.13

Interlock

Terminal strip J6 provides a connection point for

system interlock to prevent generation of high

voltage. Terminal J6-1 must be connected to J6-2

by jumper or voltage free contact in order to make

the High Voltage Ready (HVRDY) mode. If this

connection is momentarily broken, HVRDY must

be reset. Make no connection to J6-3 before

reading “HV On Control” in the “Operation” section

of this manual.

8

MicroPak - Installation

Ransburg

MicroPak Grounding

1. The Power Supply must be referenced to true

earth ground at only one point. (Refer to Figures

1, 2, and 3 for Grounding Connections.)

C A U T I O N

!

Separate ground connections MUST be

used for grounding the part and the Power

Supply.

2. Shields from the low voltage cable must be

connected to a bus isolated from panel ground,

then by a 3/4” braid to the building steel or ground

grid if available.

3. The 24 or 28 VDC power supply common should

be connected to the factory ground input for safety,

even though they are connected to the isolated

bus via the MicroPak motherboard.

2. The feedback signals for kV and µA are developed with respect to the cascade ground. If the

cascade ground were routed only to earth ground

via the above mentioned shields, the feedback

conditioning circuitry would have to depend on

the panel ground or power supply common to

get a ground reference for the feedback signals.

This means the low level return current for these

signals would have to ow to earth ground and

back to the controller via factory ground or power

supply common. This adds large amounts of noise

to these low voltage signals.

3. A great deal of testing under high voltage corona

conditions has conrmed that this cascade ground

should be connected directly at a single point to the

signal ground plane of the MicroPak power supply

controller. This single point method maintains a

“clean” feedback signal while limiting the amount

of high frequency noise that is dumped onto the

signal ground and therefore other grounds in the

overall system, such as the PLC.

MicroPak Grounding Theory

1. The low voltage cable has a large amount of high

frequency noise on the shields and grounds from

being in proximity to the high voltage generator.

Taking these grounds directly to earth ground or a

ground grid through good high frequency conductors (braid) keeps this high frequency noise from

interfering with the low voltage control circuitry.

This is why they are isolated from panel ground.

This is consistent with standard practice for lightning protection. (See NFPA-70 and NFPA -780.)

9

LN-9218-00.13

Loading...

Loading...