Ransburg

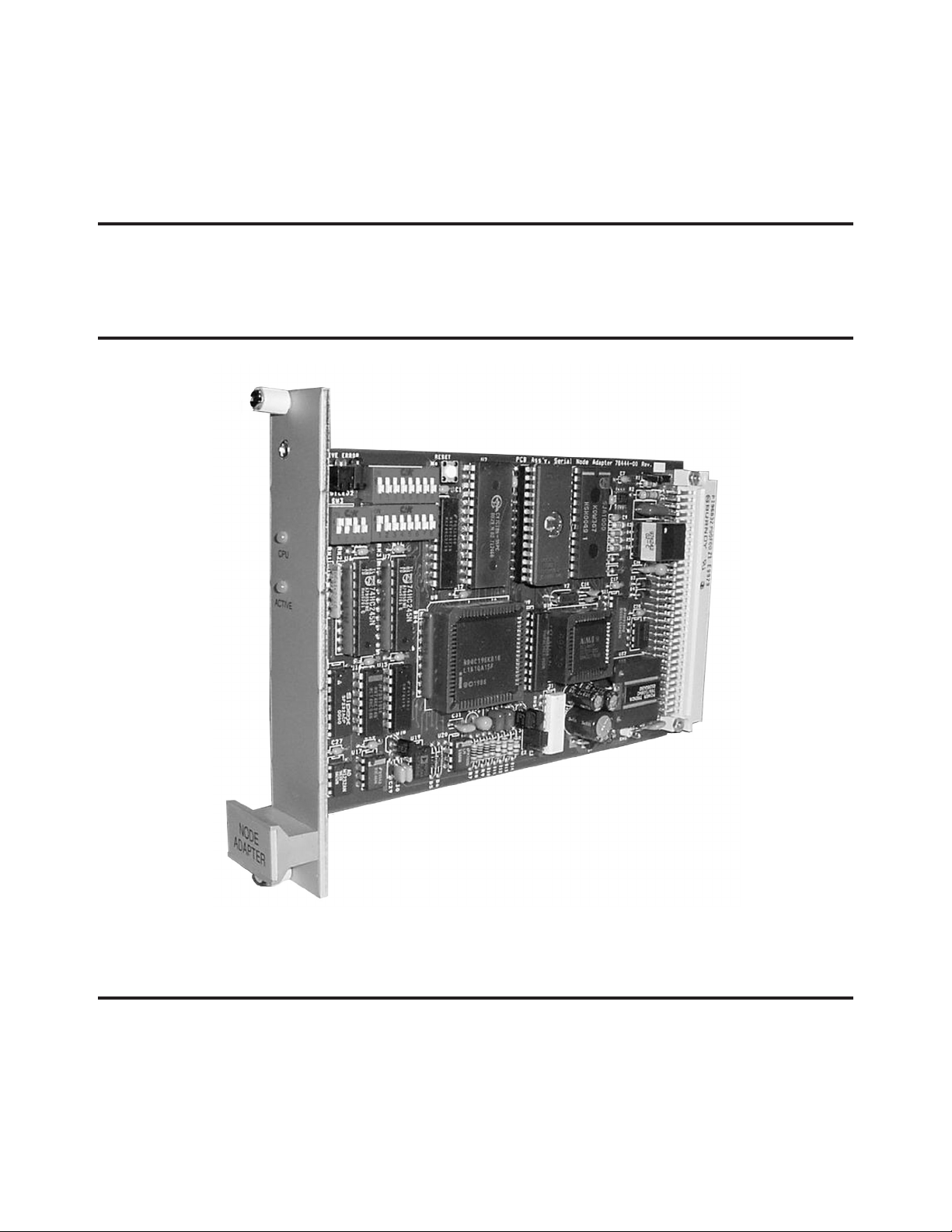

SERIAL NODE ADAPTER /

SERVICE MANUAL

LN-9238-02.3

(Replaces LN-9238-02.2)

April - 2013

SERIAL NODE ADAPTER

+

MODEL: LECU4012-00 & 78553-00

IMPORTANT: Before using this equipment, carefully read SAFETY PRECAUTIONS, starting on

page 1, and all instructions in this manual. Keep

this Service Bulletin for future reference.

Service Manual Price: $ 20.00 (U.S.)

Ransburg

NOTE: This manual has been changed from LN-9238-02.2 to revision LN-9238-02.3. Reasons for

this change are noted under "Manual Change Summary" inside the back cover.

Serial Node Adapter/Serial Node Adapter +

LN-9238-02.3

Serial Node Adapter/Serial Node Adapter + - Contents

CONTENTS

SAFETY:

Ransburg

PAGE

1-5

SAFETY PRECAUTIONS............................................................................................................

HAZARDS / SAFEGUARDS.......................................................................................................

INTRODUCTION:

GENERAL DESCRIPTION.........................................................................................................

SPECIFICATIONS......................................................................................................................

MODES OF OPERATION..........................................................................................................

INSTALLATION:

CONNECTIONS AND CONFIGURATIONS...............................................................................

PRINTED CIRCUIT BOARD......................................................................................................

SW1, SW2, SW3 SWITCHES....................................................................................................

OPERATION:

TABLE 1 - MICROPAK MODE

BLOCK TRANSFER WRITES................................................................................................

BLOCK TRANSFER READS..................................................................................................

BLOCK TRANSFER READS STATUS WORD DEFINITION.................................................

DISCRETE OUTPUT CONFIGURATION...............................................................................

TABLE 2 - NPB MODE (DIPSWITCH SW2-1 ON)

BLOCK TRANSFER WRITES................................................................................................

BLOCK TRANSFER READS...................................................................................................

MICROPAK STATUS WORD DEFINITION............................................................................

ATOMIZER STATUS WORD DEFINITION.............................................................................

DISCRETE OUTPUT CONFIGURATION...............................................................................

TABLE 3 - FLEX MODE (DIPSWITCH SW2-1 & SW2-5 ON)

BLOCK TRANSFER WRITES.................................................................................................

BLOCK TRANSFER READS...................................................................................................

AIRTRONICS FLOW TOLERANCE WORD DEFINITION......................................................

BLOCK TRANSFER READ - MOTHERBOARD 0 CONFIGURATION..................................

BLOCK TRANSFER READ - MOTHERBOARD 1 CONFIGUARTION..................................

BLOCK TRANSFER READ - MOTHERBOARD 2 CONFIGURATION..................................

BLOCK TRANSFER READ - MOTHERBOARD 3 CONFIGURATION..................................

BLOCK TRANSFER READ MICROPAK WORD DEFINITION.............................................

BLOCK TRANSFER READ ATOMIZER MODULE WORD DEFINITION.............................

BLOCK TRANSFER READ AIRTRONIC MODULE WORD DEFINITION............................

BLOCK TRANSFER READ ANALOG MODULE STATUS WORD DEFINITION....

DISCRETE OUTPUT CONFIGURATION..............................................................................

DISCRETE INPUT CONFIGURATION..................................................................................

1

2-5

6-8

6

6

7-8

9-11

9-10

10

11

12-34

12

13

14

15

16

16

17

17

17

18

19

20

20

20

21

21

22

22

23

23

24-25

26

LN-9238-02.3

Ransburg

OPERATION (CONT.):

Serial Node Adapter/Serial Node Adapter + - Contents

PAGE

12-34

APPENDIX 1 - FLEXIBLE 1/4 RACK MOTHERBOARD SYSTEM............................................

ASSEMBLY 78145-00..................................................................................................................

ASSEMBLY 78147-00..................................................................................................................

COMMUNICATION - DISCRETE WIRING.................................................................................

COMMUNICATION - REMOTE I/O.............................................................................................

FLEXIBLE 1/4 RACK RACK MOTHERBOARD SYSTEM.........................................................

CONFIGURATION WORD CONSTRUCTION..........................................................................

MAINTENANCE

TROUBLESHOOTING GUIDE...................................................................................................

PARTS IDENTIFICATION:

PARTS LIST................................................................................................................................

WARRANTY POLICIES:

LIMITED WARRANTY.................................................................................................................

27

27

28-30

30

30

31

32-34

35

35

36

36

37

37

LN-9238-02.3

Serial Node Adapter/Serial Node Adapter + - Safety

SAFETY

Ransburg

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature

for your Ransburg products. This manual contains

information that is important for you to know and

understand. This information relates to USER

SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the following symbols. Please pay particular

attention to these sections.

A WARNING! states information to alert you

to a situation that might cause serious injury

if instructions are not followed.

A CAUTION! states information that tells how

to prevent damage to equipment or how to

avoid a situation that might cause minor injury.

A NOTE is information relevant to the procedure in progress.

W A R N I N G

!

The user MUST read and be familiar with the

Safety Secon in this manual and the Ransburg

safety literature therein idened.

This manual MUST be read and thoroughly

understood by ALL personnel who operate, clean

or maintain this equipment! Special care should

be taken to ensure that the WARNINGS and

safety requirements for operang and servicing

the equipment are followed. The user should be

aware of and adhere to ALL local building and re

codes and ordinances as well as NFPA-33 SAFETY

STANDARD, LATEST EDITION, prior to installing,

operang, and/or servicing this equipment.

W A R N I N G

!

While this manual lists standard specications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements,

etc., make such variations inevitable. Compare

this manual with your system installation drawings and appropriate Ransburg equipment manuals to reconcile such differences.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efcient operation, longer trouble-free service and faster, easier

troubleshooting. If you do not have the manuals

and safety literature for your Ransburg system,

contact your local Ransburg representative or

Ransburg.

The hazards shown on the following pages

may occur during the normal use of this equipment. Please read the hazard chart beginning on

page 2.

1

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate

operation and maintenance

procedures will cause a re

hazard.

Protection against inadvertent arcing that is capable of

causing re or explosion is

lost if any safety interlocks

are disabled during operation. Frequent Power Supply

or Controller shutdown indicates a problem in the system

requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in

the spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray

area.

The high voltage supplied to the atomizer must

be turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

• Those used for equipment ushing should

have ash points equal to or higher than

those of the coating material.

• Those used for general cleaning must have

ash points above 100°F (37.8°C).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, country, and local

codes. In addition, ventilation must be maintained during cleaning operations using ammable or combustible solvents.

Electrostatic arcing must be prevented. Safe

sparking distance must be maintained between

the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage

is required at all times.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but

only as instructed.

Non-factory replacement parts or unauthor-

ized equipment modications may cause re or

injury.

If used, the key switch bypass is intended for

use only during setup operations. Production

should never be done with safety interlocks disabled.

Never use equipment intended for use in waterborne installations to spray solvent based materials.

The paint process and equipment should be

set up and operated in accordance with NFPA33, NEC, OSHA, local, country, and European

Health and Safety Norms.

LN-9238-02.3

2

Serial Node Adapter/Serial Node Adapter + - Safety

Ransburg

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Explosion Hazard

Improper or inadequate operation and maintenance proce-

dures will cause a re hazard.

Protection against inadvertent

arcing that is capable of caus-

ing re or explosion is lost if

any safety interlocks are disabled during operation.

Frequent Power Supply or

Controller shutdown indicates

a problem in the system requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Electrostatic arcing must be prevented. Safe

sparking distance must be maintained between

the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage

is required at all times.

Unless specically approved for use in hazardous locations, all electrical equipment must be

located outside Class I or II, Division 1 or 2

hazardous areas, in accordance with NFPA-33.

Test only in areas free of ammable or combustible materials.

The current overload sensitivity (if equipped)

MUST be set as described in the corresponding section of the equipment manual. Protection against inadvertent arcing that is capable

of causing re or explosion is lost if the current

overload sensitivity is not properly set. Frequent power supply shutdown indicates a problem in the system which requires correction.

General Use and

Maintenance

Improper operation or maintenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

Always turn the control panel power off prior to

ushing, cleaning, or working on spray system

equipment.

Before turning high voltage on, make sure no

objects are within the safe sparking distance.

Ensure that the control panel is interlocked with

the ventilation system and conveyor in accordance with NFPA-33, EN 50176.

Have re extinguishing equipment readily available and tested periodically.

Personnel must be given training in accordance

with the requirements of NFPA-33, EN 60079-0.

Instructions and safety precautions must be

read and understood prior to using this equipment.

Comply with appropriate local, state, and national codes governing ventilation, re protection, operation maintenance, and housekeeping. Reference OSHA, NFPA-33, EN Norms

and your insurance company requirements.

3

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Safety

AREA

Tells where hazards

may occur.

Spray Area /

High Voltage

Equipment

HAZARD

Tells what the hazard is.

Electrical Discharge

There is a high voltage device

that can induce an electrical

charge on ungrounded objects

which is capable of igniting

coating materials.

Inadequate grounding will

cause a spark hazard. A spark

can ignite many coating materials and cause a re or explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Parts being sprayed and operators in the spray

area must be properly grounded.

Parts being sprayed must be supported on conveyors or hangers that are properly grounded.

The resistance between the part and earth

ground must not exceed 1 meg ohm. (Refer to

NFPA-33.)

Operators must be grounded. Rubber soled insulating shoes should not be worn. Grounding

straps on wrists or legs may be used to assure

adequate ground contact.

Operators must not be wearing or carrying any

ungrounded metal objects.

When using an electrostatic handgun, operators

must assure contact with the handle of the applicator via conductive gloves or gloves with the

palm section cut out.

NOTE: REFER TO NFPA-33 OR SPECIFIC

COUNTRY SAFETY CODES REGARDING

PROPER OPERATOR GROUNDING.

All electrically conductive objects in the spray

area, with the exception of those objects required by the process to be at high voltage, must

be grounded. Grounded conductive ooring

must be provided in the spray area.

Always turn off the power supply prior to ushing, cleaning, or working on spray system equipment.

Unless specically approved for use in hazardous locations, all electrical equipment must be

located outside Class I or II, Division 1 or 2 hazardous areas, in accordance with NFPA-33.

LN-9238-02.3

4

Serial Node Adapter/Serial Node Adapter + - Safety

Ransburg

AREA

Tells where hazards

may occur.

Electrical

Equipment

HAZARD

Tells what the hazard is.

Electrical Discharge

High voltage equipment is utilized in the process. Arcing

in the vicinity of ammable or

combustible materials may oc-

cur. Personnel are exposed to

high voltage during operation

and maintenance.

Protection against inadvertent

arcing that may cause a re or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shutdown indicates a problem in the

system which requires correction.

An electrical arc can ignite coat-

ing materials and cause a re or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Unless specically approved for use in hazardous locations, the power supply, control cabinet,

and all other electrical equipment must be located outside Class I or II, Division 1 and 2 hazardous areas in accordance with NFPA-33 and EN

50176.

Turn the power supply OFF before working on

the equipment.

Test only in areas free of ammable or combustible material.

Testing may require high voltage to be on, but

only as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Toxic Substances

Spray Area

Certain material may be

harmful if inhaled, or if there is

contact with the skin.

Explosion Hazard –

Incompatible Materials

Halogenated hydrocarbon sol-

vents for example: methylene

chloride and 1,1,1,-Trichloroethane are not chemically compatible with the aluminum that

might be used in many system

components. The chemical

reaction caused by these solvents reacting with aluminum

can become violent and lead to

an equipment explosion.

Follow the requirements of the Material Safety

Data Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being

sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienist or

safety expert, and be NIOSH approved.

Aluminum is widely used in other spray application equipment - such as material pumps,

regulators, triggering valves, etc. Halogenated

hydrocarbon solvents must never be used with

aluminum equipment during spraying, ushing,

or cleaning. Read the label or data sheet for the

material you intend to spray. If in doubt as to

whether or not a coating or cleaning material is

compatible, contact your coating supplier. Any

other type of solvent may be used with aluminum

equipment.

5

LN-9238-02.3

Ransburg

INTRODUCTION

Serial Node Adapter/Serial Node Adapter + - Introduction

GENERAL DESCRIPTION

This service manual covers both the Serial Node

Adapter and Serial Node Adapter Plus. The

Plus version does everything the original Node

Adapter does and has added capabilities such as

certain I/O signals may be handled either via A-B

Remote I/O or discretely. In general, this manual

will address the two as one module and point out

the additional capabilities of the Node Adapter

Plus where applicable.

The Serial Node Adapter / Serial Node Adapter

+ Modules have three parts: 1) Allen Bradley

remote I/O (RIO) interface, 2) central processor,

and 3) serial input/output circuits.

The RIO interface contains some Allen-Bradley

(A-B) components which are licensed to Ransburg.

These are designed specically to communicate

with the proprietary protocol of the RIO serial

link. The central component of this block is an

application specic IC (ASIC) which is capable

of formatting the RIO information for use by the

central processor. The termination of the RIO

cable is made to the motherboard at the rear of

the Serial Node Adapter + Module location.

SPECIFICATIONS

Environmental / Physical

Operating Temperature: 0° to 55°C

Storage Temperature: -40°C to 75°C

Humidity: 95% Non-Condensing

Size: 100 x 160mm

Eurocard module,

25mm wide

Electrical

Power Required: 24 Vdc at 150 mA Max.

The core of the central processor is an 8032

microprocessor which communicates with the

Allen-Bradley ASIC. The 8032 provides an RS232 port from which diagnostic functions are

accomplished via internal “debugger” software.

The main software program, which includes the

“debugger” functions, is contained in an Erasable

Programmable Read-Only Memory (EPROM).

The serial I/O circuits are the interface to the other

Eurocard modules in the control rack or racks.

The Serial Node Adapter + uses two-wire serial

(CANBus) bus communication for this, and all

associated modules are equipped to receive and

send information on this bus.

LN-9238-02.3

6

Serial Node Adapter/Serial Node Adapter + - Introduction

Ransburg

MODES OF OPERATION

The Serial Node Adapter/Serial Node Adapter +

has three modes of operation, determined by what

modules need to be operated. The three modes

are: 1) MicroPak, 2) NPB (1 MicroPak, 1 Serial

Atomizer), and 3) Flex mode.

MicroPak Mode

MicroPak mode is for communication with the

MicroPak only, up to four units. This mode is

selected by setting SerNA dipswitch SW2-1 to

OFF. SW2, positions 5, 6, 7, and 8 must be set

to OFF. PLC data mapping information is shown

in Table 1 of the PLC I/O section.

NPB Mode

Node Per Bell mode communicates with one

MicroPak and one Serial Atomizer module and

is selected by setting SerNA dipswitch SW2-1 to

ON. SW2, positions 5, 6, 7, and 8 must be set to

OFF. PLC data mapping information is shown in

Table 2 of the PLC I/O section.

Flex Mode

Beginning with Serial Node Adapter/Serial Node

Adapter + version 2.02 software, this module has

the capability of communicating with one MicroPak

and any combination of Serial Atomizer (SerAT),

and Serial Digital (SerDG) modules, up to a total

of 12 modules. Note: Serial Atomizer must

have version 3.0 or higher Eprom (77118-05)

and it's SW2-4 in ON position. Space is also

reserved for Serial Analog (SerAN) modules, presently under development. This is the FLEX mode

of operation. The new version 2.02 software is

completely compatible with the old MicroPak and

Node Per Bell modes as long as the Serial Node

Adapter/ Serial Node Adapter + dipswitch SW2

is set correctly. For these older modes, SW2,

position 5, 6, 7, and 8 must be set OFF, as is currently done on Serial Node Adapter modules with

software earlier than 2.02. With these settings,

the Serial Node Adapter/Serial Node Adapter +

looks the same to the PLC and other modules as

the older versions.

determine what module is in what location. It will

then read a group of three conguration words,

which are programmed into Block Transfer Writes

from the PLC. (The instructions for making up

these conguration words are given in Appendix

1). While making this comparison, the module will

ash its "CPU" indicator. If these two congurations are the same, the Serial Node Adapter/Serial

Node Adapter + will begin communication with the

local modules, and the "CPU" indicator will stay

on solid. This method of redundant conguration

checking will prevent data from being sent to the

wrong module in case of a faulty module or one

having been removed. (PLC data mapping information is shown in Table 3 of the PLC I/O Section.)

Flex Mode Settings

The setting of the four dipswitches, SW2, 5-8 is

critical to proper operation. (See Figure 6 entitled

"SW1, SW2, and SW3 Switches". ) In order to enable FLEX mode, SW2-1 must be ON. If SW2 - 1

is ON, the positions 5-8 mean:

Position 5:

OFF means the mode is determined by SW2-1,

either MicroPak only or NPB (one MicroPak and

one Serial Atomizer). In this mode the Serial

Node Adapter version 2.02 is backward compat-

ible with existing applications.

ON (with position 1 ON) means the new FLEX

mode. This means the PLC programmer must

include the conguration information in the rst

three words of BTW.

Position 6 and 7:

These are used, as shown in Figure 1, to set the

logical rack size of the node adapter as it appears

to the PLC. The number of SerDG modules on

the bus determines the size.

Again, the Serial Node Adapter could do this

function automatically, but a faulty module or

modules removed could create an erroneous

reading.

In the FLEX mode, on power up, before sending

data to modules, the Serial Node Adapter/Serial

Node Adapter + will read the local serial bus and

7

LN-9238-02.3

Ransburg

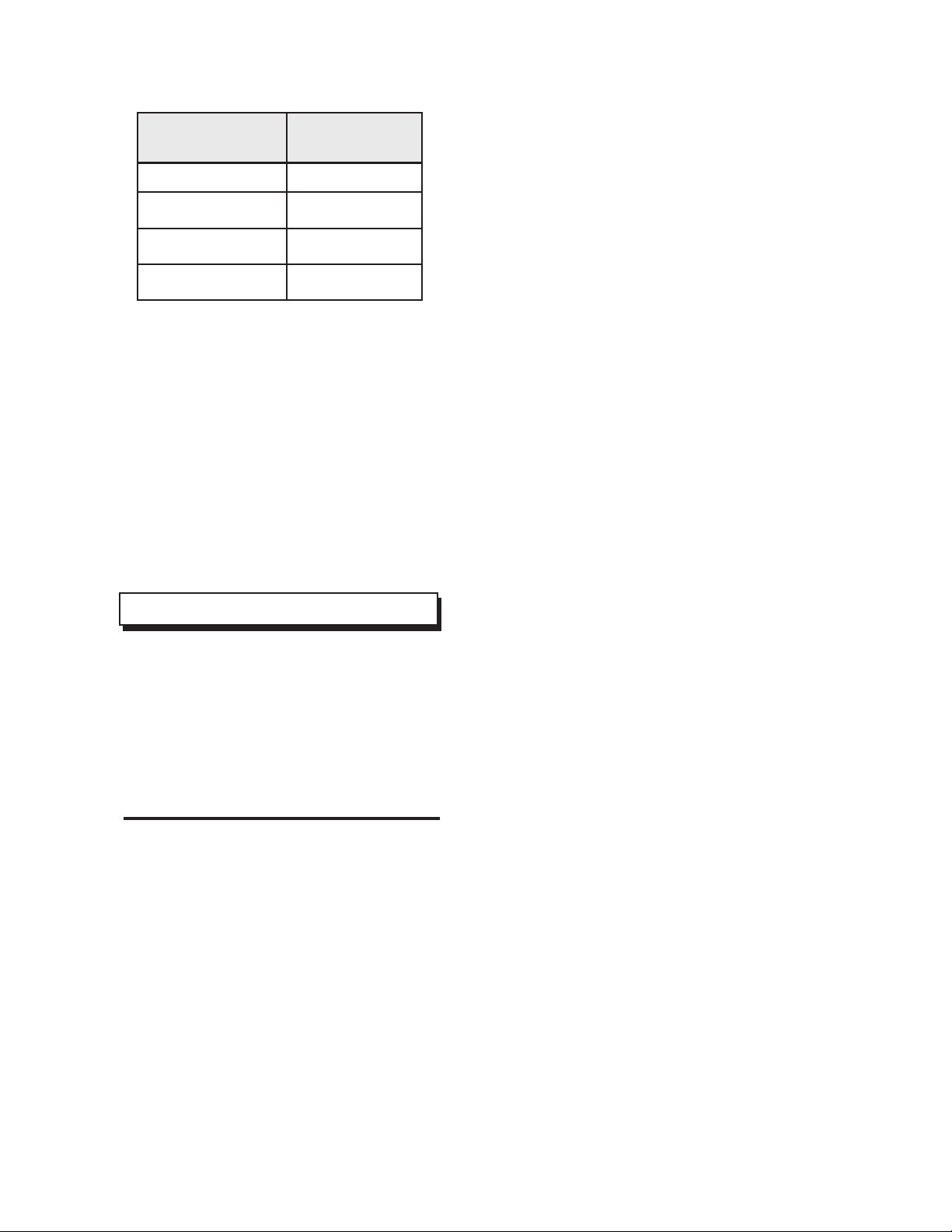

# SerDG

Modules

Serial Node Adapter/Serial Node Adapter + - Introduction

Rack Size

0 - 2

3 - 6

7 - 10

11 - 12

Figure 1: Position 6 & 7 Rack Size Settings

Position 8:

This position enables a Bus Agreement Override

mode that allows the Serial Node Adapter/Serial

Node Adapter + to communicate between the

internal bus and the PLC when the two congurations do not agree. In this mode the Serial Node

Adapter/Serial Node Adapter + will use the bus

conguration specied in the BTW conguration

word.

1/4

1/2

3/4

Full

NOTE

> This mode should only be used for

troubleshooting. It is possible for data to

be communicated to the wrong module.

For this reason, bit 14 is set in the BTR

words 0, 1, and 2, indicating this

mode has been entered. The "CPU" indicator on the Serial Node Adapter/Serial

Node Adapter + will ash also.

LN-9238-02.3

Figure 1: AdaptaFlow System Rack

8

Serial Node Adapter/Serial Node Adapter + - Installation

INSTALLATION

Ransburg

CONNECTIONS AND

CONFIGURATIONS

Input Power

Required input power is regulated 24 Vdc which

is supplied by the motherboard of the rack which

contains the Serial Node Adapter. An on-board

dc-dc converter makes 5 Vdc for the module's logic

level circuits. The Serial Node Adapter + may be

installed in any one of three motherboards. The

power connections for each are shown in Figure 2.

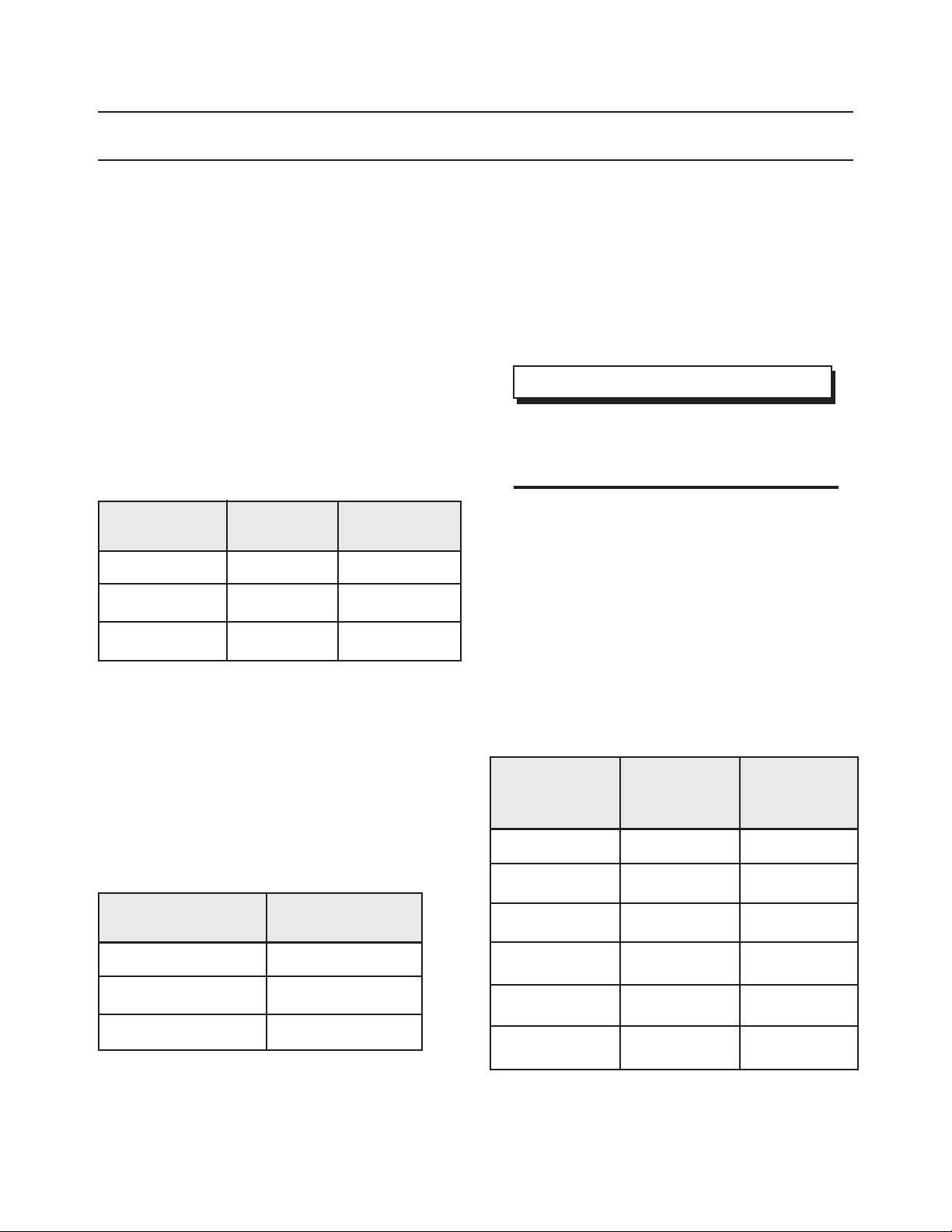

Motherboard

LECU4014-02

78145-00

78149-00

Figure 2: Input Power Connections

+24 Vdc

J10 - 1

J7 - 3 (+24)

J16 - 3 (+24)

24 Vdc com

J10 - 2

J7 - 4 (GND)

J16 - 4 (GND)

The RIO cable may be "daisy-chained" from

one node to another per Allen-Bradley installa-

tion specications. Where a termination resistor

is specied, usually the last termination point in

a chain, install the appropriate resistor directly

across ""BLU" and "CLR" on the RIO connector.

NOTE

> Switch SW3, positions 1 and 2 must

be in the OFF position for full RIO communication.

Remote I/O With Certain

Discrete Inputs (Serial Node

Adapter + Only)

Certain inputs may be controlled independent of

the Remote I/O communication in this mode set

by switch SW3, positions 1 and 2. (See Figure 6)

These inputs are KV Set and Speed Set (analogs)

and HV ON, Fluid Trigger and Di-dt inhibit (24V

digital). The pin connections for these signals are:

Remote I/O

The connection of the Allen-Bradley Remote

I/O (RIO) is made to the connector labeled RIO.

This connector is located at the top of each of the

above motherboards. The RIO cable wires are

connected as shown below.

RIO Wire

Blue

Bare

Clear

Figure 3: RIO Cable Wire Connections

9

RIO

Terminal

BLU

SHLD

CLR

Inputs

KV Setpoint

Speed Setpoint

HV On

Fluid Trigger

Di/dt Inhibit

Spare

Figure 4: RIO Discrete Inputs

Pin

Connections

5A

4C

20C

17C

15C

18C

76111-XX Ca-

ble Assy. Wire

Color

YEL

BRN

BLU/BLA

RED/BLA

ORG

----

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Installation

A 76111-XX I/O cable may be used to access the

pins in Figure 4.

The analog signal scaling may be either 0-10

Vdc or 4-20 mAdc as selected by switch SW3-3.

Digital inputs may be either 24 Vdc source (set

Jumper E2 in 2-3 position) or sink to ground (set

Jumper E2 in 1-2 position).

NOTE

> SW3 installed only in the Serial Node

Adapter + version.

Serial Bus Connection To Other

Motherboards

The Serial Node Adapter/Serial Node Adapter +

communicates to other modules in the rack via the

local Serial Bus. If more than one motherboard

is communicating with the Serial Node Adapter/

Serial Node Adapter +, the Serial Bus must be

jumpered to motherboards not having a Serial

Node Adapter. This is done by a short section

of shielded twisted pair cable between connectors labeled “Serial” or “CAN”, and being sure to

observe the (+) to (+) convention.

A bus termination resistor (120 ohms, 1/2w) must

be connected across the (+) and (-) terminals of

the nal cable termination.

Serial Node Adapter/Serial

Node Adapter + Addressing/

Conguration

The Serial Node Adapter/Serial Node Adapter +

must be set for the appropriate RIO address. The

rack address and starting quarter are set by switch

SW1 as shown in Figure 6. The Operating Mode,

Last State, Baud Rate, and Rack Size are set by

positions 1-8 on switch SW2 as shown in Figure 6.

LN-9238-02.3

Figure 5: Printed Circuit Board

10

Serial Node Adapter/Serial Node Adapter + - Installation

Ransburg

11

Figure 6: SW1, SW2, and SW3 Switches

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Operation

OPERATION

TABLE 1 - SERIAL NODE ADAPTER + LECU4012-00

PLC I/O - MICROPAK MODE

BLOCK TRANSFER WRITES

BTW

WORD

MODULE

CONFIGURATION

0

1

2

3

4

5

6

7

8

9

MicroPak #1

MicroPak #1

MicroPak #1

----

MicroPak #2

MicroPak #2

MicroPak #2

----

MicroPak #3

MicroPak #3

High Voltage Setpoint (Value of 0-100 corresponds to 0-100 KV)

Current Limit Setpoint

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Ccascade: 0-1000 corresponds to 0-1000 µA

Di/dt Setpoint (Value of 0-9 corresponds to max. to min. sensitivity)

(Not Used)

High Voltage Setpoint (Value of 0-100 corresponds to 0-100 KV)

Current Limit Setpoint

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

Di/dt Setpoint (Value of 0-9 corresponds to max. to min. sensitivity)

(Not Used)

High Voltage Setpoint (Value of 0-100 corresponds to 0-100 KV)

Current Limit Setpoint

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

LN-9238-02.3

10

11

12

13

14

15

MicroPak #3

----

MicroPak #4

MicroPak #4

MicroPak #4

----

Di/dt Setpoint (Value of 0-9 corresponds to max. to min. sensitivity)

(Not Used)

High Voltage Setpoint (Value of 0-100 corresponds to 0-100 KV)

Current Limit Setpoint

HP404 Ccascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

Di/dt Setpoint (Value of 0-9 corresponds to max. to min. sensitivity)

(Not Used)

12

Serial Node Adapter/Serial Node Adapter + - Operation

Table 1 - Serial Node Adapter + LECU4012-00

PLC I/O - MicroPak Mode (Cont.)

BLOCK TRANSFER READS

BTR

WORD

MODULE CONFIGURATION

Ransburg

0

1

2

3

4

5

6

7

8

9

MicroPak #1

MicroPak #1

MicroPak #1

MicroPak #2

MicroPak #2

MicroPak #2

MicroPak #3

MicroPak #3

MicroPak #3

MicroPak #4

High Voltage Feedback (Value of 0-100 corresponds to 0-100 KV)

Current Feedback

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

Status Word *

High Voltage Feedback (Value of 0-100 corresponds to 0-100 KV)

Current Feedback

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

Status Word *

High Voltage Feedback (Value of 0-100 corresponds to 0-100 KV)

Current Feedback

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

Status Word *

High Voltage Feedback (Value of 0-100 corresponds to 0-100 KV)

10

11

* See "Status Word Denition" on next page.

13

MicroPak #4

MicroPak #4

Current Feedback

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-100 corresponds to 0-1000 µA

Status Word *

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Operation

Table 1 - Serial Node Adapter + LECU4012-00

PLC I/O - MicroPak Mode (Cont.)

BLOCK TRANSFER READS STATUS WORD DEFINITION

BIT

00

01

02

03

04

05

06

07

08

09

10

STATUS

High Voltage Held In Reset

High Voltage Ready

High Voltage On

Di/dt Fault

High Voltage Overload

Feedback Fault

Sequence

Local

Fluid Trigger Active

Air Trigger Active

Di/dt Enabled

13-15

LN-9238-02.3

11

12

KV Out of Tolerance

Low Output Current

(Not Used)

14

Serial Node Adapter/Serial Node Adapter + - Operation

Table 1 - Serial Node Adapter + LECU4012-00

PLC I/O MicroPak Mode (Cont.)

DISCRETE OUTPUT CONFIGURATION

WORD/

BIT

MODULE

OUTPUT

Ransburg

0/00-07

0/10

0/11

0/12

0/13

0/14-17

1/00

1/01

1/02

1/03

1/04

05

06

----

MicroPak #1

MicroPak #2

MicroPak #3

MicroPak #4

----

MicroPak #1

MicroPak #1

MicroPak #1

MicroPak #1

MicroPak #2

MicroPak #2

MicroPak #2

(Not Used)

Di/dt Inhibit

Di/dt Inhibit

Di/dt Inhibit

Di/dt Inhibit

(Not Used)

High Voltage On Command

High Voltage Reset

Fluid Trigger

Air Trigger

High Voltage On Command

High Voltage Reset

Fluid Trigger

15

07

10

11

12

13

14

15

16

17

MicroPak #2

MicroPak #3

MicroPak #3

MicroPak #3

MicroPak #3

MicroPak #4

MicroPak #4

MicroPak #4

MicroPak #4

Air Trigger

High Voltage On Command

High Voltage Reset

Fluid Trigger

Air Trigger

High Voltage On Command

High Voltage Reset

Fluid Trigger

Air Trigger

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Operation

Table 2 - SERIAL NODE ADAPTER + LECU4012-00

PLC I/O - NPB MODE (DIPSWITCH SW2-1 ON)

BLOCK TRANSFER WRITES

BTW

WORD

MODULE

CONFIGURATION

0

1

2

3

4

5

MicroPak #1

MicroPak #1

MicroPak #1

----

Atomizer 1

----

High Voltage Setpoint (Value of 0-100 corresponds to 0-100 KV)

Current Limit Setpoint:

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

Di/dt Setpoint (Value of 0-9 corresponds to max. to min. sensitivity)

(Not Used)

Speed Setpoint:

Liquid: 0-50 corresponds to 0-50 krpm

Powder: 0-250 corresponds to 0-25 krpm

(Not Used)

BLOCK TRANSFER READS

BTW

WORD

0

MODULE

MicroPak

CONFIGURATION

High Voltage Feedback (Value of 0-100 corresponds to 0-100 KV)

LN-9238-02.3

1

2

3

4

5

6

MicroPak

MicroPak

Atomizer 1

Atomizer 1

Atomizer 1

----

Current Feedback:

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

MicroPak Status Word *

Atomizer Status Word **

Atomizer Drive Pressure (Value of 0-60 corresponds to 0-60 psi)

Speed Feedback:

Liquid: (Value of 0-50 corresponds to 0-50 krpm)

Powder: (Value of 0-250 corresponds to 0-25 krpm)

(Not Used)

16

Serial Node Adapter/Serial Node Adapter + - Operation

Table 2 - Node Adapter + LECU4012-00

PLC I/O - NPB Mode (Dipswitch SW2-1 On) (Cont.)

Ransburg

* MICROPAK STATUS

WORD DEFINITION

BIT

00

01

02

03

04

05

06

07

08

09

10

11

12

STATUS

HV Held In Reset

HV Ready

HV On

Di/dt Fault

HV Overload

Feedback Fault

Sequence

Local

Fluid Trigger Active

Air Trigger Active

Di/dt Enabled

KV Out of Tolerance

Low Output Current

** ATOMIZER STATUS WORD

DEFINITION

BIT

00-07

08

09

10

11

12

13

14

15

STATUS

Bearing Air (8-bits)

Overspeed

Underspeed

Loss of Feedback

Invalid Data Input

Low Bearing Air

Bell Running

Out of Tolerance

(Not Used)

DISCRETE OUTPUT

CONFIGURATION

WORD/

BIT

MODULE

OUTPUT

13-15

* See "Conguration Word Construction" in Appendix 1.

** If no SerAT Modules Installed, next module type moves to this position.

*** See following "Tolerance Word Construction."

17

(Not Used)

0

1/00

1/01

1/02

1/03

1/04

1/05-07

Not Used

MicroPak

MicroPak

MicroPak

MicroPak

MicroPak

Not Used

------

High Voltage On

Command

High Voltage Reset

Fluid Trigger

Air Trigger

Di/dt Inhibit

------

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Operation

Table 3 - Serial Node Adapter + LECU4012-00

PLC I/O - Flex Mode (Dipswitch SW2-1 and SW2-5 On)

BLOCK TRANSFER WRITES

BTW

WORD

MODULE

BTW BLOCK CONFIGURATION

0

1

2

3

4

5

6

7

8

9

X

Motherboard 0

Motherboard 1

Motherboard 2

Motherboard 3

MicroPak

MicroPak

MicroPak

----

SerAT 1**

----

SerAN 1

Conguration word dening Motherboard 0 Modules *

Conguration word dening Motherboard 1 Modules *

Conguration word dening Motherboard 2 Modules *

Conguration word dening Motherboard 3 Modules *

High Voltage Setpoint: (Value of 0-100 corresponds to 0-100 KV)

Current Limit Setpoint:

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

Di/dt Setpoint (Value of 0-9 corresponds to max. to min. sensitivity)

(Not Used)

Speed Setpoint:

Liquid: 0-50 corresponds to 0-50 krpm

(Additional Serial Atomizer(s) with higher slot addresses)

Channel 1 Setpoint (Value of 10-100 corresponds to 0-90 psi)

X

X

X

X

X

X

* See "Conguration Word Construction" in Appendix 1.

** If no SerAT Modules Installed, next module type moves to this position.

*** See following "Tolerance Word Construction."

LN-9238-02.3

SerAN 1

----

AirTronic 1

AirTronic 1

AirTronic 1

----

Channel 2 Setpoint (Value of 10-100 corresponds to 0-90 psi)

(Additional Serial Analog(s) with higher slot addresses)

Channel 1 Setpoint (Enter in slpm, e.g. to set 85 slpm, enter 85)

Channel 2 Setpoint (Enter in slpm, e.g. to set 85 slpm, enter 85)

High / Low Flow Tolerance (0-15 equals 0-30% of setpoint) ***

(Additional AirTronic modules(s) with higher slot addresses)

18

Serial Node Adapter/Serial Node Adapter + - Operation

Table 3 - Node Adapter + LECU4012-00

PLC I/O - Flex Mode (Dipswitch SW2-1 and SW2-5 On) (Cont.)

BLOCK TRANSFER READS

BTW

WORD

0

MODULE

Motherboard 0

BTR BLOCK CONFIGURATION

Hardware Conguration and Status Bits

Ransburg

1

2

3

4

5

Motherboard 1

Motherboard 2

Motherboard 3

MicroPak

MicroPak

Hardware Conguration and Status Bits

Hardware Conguration and Status Bits

Hardware Conguration and Status Bits

High Voltage Feedback (Value of 0-100 corresponds to 0-100 KV)

Current Feedback:

HP404 Cascade: 0-250 corresponds to 0-250 µA

RP1000 Cascade: 0-1000 corresponds to 0-1000 µA

6

7

8

9

MicroPak

SerAT1 **

SerAT 1

SerAT 1

MicroPak Status Word

Atomizer Status Word

Atomizer Drive Pressure (Value of 0-60 corresponds to 0-60 psi)

Speed Feedback:

Liquid: (Value of 0-50 corresponds to 0-50 krpm)

Powder: (Value of 0-250 corresponds to 0-25 krpm)

X

X

----

SerAN 1

(Additional Serial Atomizer Modules)

Channel 1 Pressure Out

19

X

X

X

X

X

X

X

SerAN 1

----

SerAN (All)

AirTronic 1

AirTronic 1

AirTronic 1

----

Channel 2 Pressure Out

(Additional Serial Analog Modules

Analog Status Word

Channel 1 Actual Flow

Channel 2 Actual Flow

Input Air Line Pressure and Status

(Additional AirTronic Modules)

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Operation

Table 3 - Node Adapter + LECU4012-00

PLC I/O - Flex Mode (Dipswitch SW2-1 and SW2-5 On) (Cont.)

AIRTRONICS FLOW TOLERANCE WORD DEFINITION

BIT

00-03

04-07

08-11

12-15

DEFINITION

CH 1 Low Flow Tolerance, (0-15 equals 0-30% of setpoint)

CH 1 High Flow Tolerance, (0-15 equals 0-30% of setpoint)

CH 2 Low Flow Tolerance, (0-15 equals 0-30% of setpoint)

CH 2 High Flow Tolerance, (0-15 equals 0-30% of setpoint)

BLOCK TRANSFER READ - MOTHERBOARD 0 CONFIGURATION

BIT

00

01

02-03

04-07

DEFINITION

BTW word 0 does not agree with Motherboard 0 Hardware Conguration

Serial Node Adapter is in Override Mode

(Not Used)

Motherboard 0, Slot 2 Module Type

BLOCK TRANSFER READ - MOTHERBOARD 1 CONFIGURATION

LN-9238-02.3

08-11

12-15

BIT

00

01

02-03

04-07

08-11

12-15

Motherboard 0, Slot 1 Module Type

Motherboard 0, Slot 0 Module Type

DEFINITION

BTW word 1 does not agree with Motherboard 1 hardware conguration

Serial Node Adapter is in Override Mode.

(Not Used)

Motherboard 1, Slot 2 Module Type

Motherboard 1, Slot 1 Module Type

Motherboard 1, Slot 0 Module Type

20

Serial Node Adapter/Serial Node Adapter + - Operation

Table 3 - Node Adapter + LECU4012-00

PLC I/O - Flex Mode (Dipswitch SW2-1 and SW2-5 On) (Cont.)

BLOCK TRANSFER READ - MOTHERBOARD 2 CONFIGURATION

Ransburg

BIT

00

01

02-03

04-07

08-11

12-15

DEFINITION

BTW word 2 does not agree with Motherboard 2 hardware conguration

Serial Node Adapter is in Override Mode.

(Not Used)

Motherboard 2, Slot 2 Module Type

Motherboard 2, Slot 1 Module Type

Motherboard 2, Slot 0 Module Type

BLOCK TRANSFER READ - MOTHERBOARD 3 CONFIGURATION

BIT

00

01

DEFINITION

BTW word 3 does not agree with Motherboard 3 hardware conguration

Serial Node Adapter is in Override Mode.

21

02-03

04-07

08-11

12-15

(Not Used)

Motherboard 3, Slot 2 Module Type

Motherboard 3, Slot 1 Module Type

Motherboard 3, Slot 0 Module Type

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Operation

Table 3 - Node Adapter + LECU4012-00

PLC I/O - Flex Mode (Dipswitch SW2-1 and SW2-5 On) (Cont.)

BLOCK TRANSFER READ

MICROPAK WORD

DEFINITION

BIT STATUS

00

01

02

03

04

05

06

07

08

High Voltage In Reset

High Voltage Ready

High Voltage On

Di/dt Fault

High Voltage Overload

Feedback Fault

Seqence Mode

Local Mode

Fluid Trigger On

BLOCK TRANSFER READ

ATOMIZER MODULE WORD

DEFINITION

BIT

00-07

08

09

10

11

12

13

14

15

STATUS

Bearing Air (8-Bit)

Overspeed

Underspeed

Loss of Feedback

Invalid Data Input

Low Bearing Air

Bell Running

Out of Tolerance

(Not Used)

09

10

11

12

13-15

Air Trigger On

Di/dt Enabled

KV Out of Tolerance

Low Output Current

(Not Used)

LN-9238-02.3

22

Serial Node Adapter/Serial Node Adapter + - Operation

Table 3 - Node Adapter + LECU4012-00

PLC I/O - Flex Mode (Dipswitch SW2-1 and SW2-5 On)

Digital Modules, No AirTronic Modules (Cont.)

Ransburg

BLOCK TRANSFER READ

8

AIRTRONIC MODULE WORD

DEFINITION

BIT

00-07

08

09

10

11-15

STATUS

Input Pressure (8 Bit)

Channel 1 in Local

Channel 2 in Local

Slave Mode

(Not Used)

BLOCK TRANSFER READ

ANALOG MODULE WORD

DEFINITION

BIT

00-07

08

09

10

11

12-15

STATUS

Error Check (All 1)

1/4 Rack 0 In Local

1/4 Rack 1 In Local

1/4 Rack 2 In Local

1/4 Rack 3 In Local

(Not Used)

23

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Operation

Table 3 - Node Adapter + LECU4012-00

PLC I/O - Flex Mode (Dipswitch SW2-1 and S2-5 On)

Digital Modules, No AirTronic Modules (Cont.)

DISCRETE OUTPUT CONFIGURATION

WORD/

BIT

MODULE OUTPUT

0/00-07

0/10

11

12

13

14

15

16

17

1/00

01

02

03

----

MicroPak

MicroPak

MicroPak

MicroPak

MicroPak

----

----

Digital

Digital (1)

Digital (1)

Digital (1)

Digital (1)

(Not Used)

High Voltage On Command

High Voltage Reset

Fluid Trigger

Air Trigger

Di/dt Inhibit

(Not Used)

(Not Used)

Manual Lock-out

Valve 1

Valve 2

Valve 3

Valve 4

04

05

06

07

Add additional outputs to Digital Module as required.

If AirTronic Modules are present, see the following.

LN-9238-02.3

Digital (1)

Digital (1)

Digital (1)

Digital (1)

Valve 5

Valve 6

Valve 7

Valve 8

24

Serial Node Adapter/Serial Node Adapter + - Operation

Table 3 - Node Adapter + LECU4012-00

PLC I/O - Flex Mode (Dipswitch SW2-1 and SW2-5 On)

AirTronic Modules, No Digital Modules (Cont.)

DISCRETE OUTPUT CONFIGURATION

WORD/

BIT

MODULE

OUTPUT

Ransburg

00/07

0/10

11

12

13

14

15

16

17

1/00

01

02

03

----

MicroPak

MicroPak

MicroPak

MicroPak

MicroPak

All AirTronic

All AirTronic

----

AirTronic (1)

AirTronic (1)

AirTronic (1)

AirTronic (1)

(Not Used)

High Voltage on Command

High Voltage Reset

Fluid Trigger

Air Trigger

Di/dt Inhibit

Channel 1 Fault Inhibit

Channel 2 Fault Inhibit

(Not Used)

Trigger Channel 1

Hold Channel 1

Trigger Channel 2

Hold Channel 2

25

04

05

06

07

1/10-17

If Digital Modules and AirTronic Modules are together on the same Node Adapter bus,

data for all Digital Modules is addressed before the data for the AirTronic Modules.

AirTronic (2)

AirTronic (2)

AirTronic (2)

AirTronic (2)

AirTronic

Trigger Channel 1

Hold Channel 1

Trigger Channel 2

Hold Channel 2

(Additional AirTronic Modules)

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Operation

Table 3 - Node Adapter + LECU4012-00

PLC I/O - Flex Mode (Dipswitch SW2-1 and SW2-5 On) (Cont.)

DISCRETE INPUT CONFIGURATION

WORD/

BIT

MODULE INPUT

0/00-07

0/10

11

12

13

14

15

16

17

1/00

01

02

03

----

AirTronic 1

AirTronic 1

AirTronic 1

AirTronic 1

AirTronic 1

AirTronic 1

AirTronic 1

AirTronic 1

AirTronic 2

AirTronic 2

AirTronic 2

AirTronic 2

(Not Used)

Channel 1 Low Tolerance Alarm

Channel 1 High Tolerance Alarm

Channel 2 Low Tolerance Alarm

Channel 2 High Tolerance Alarm

Input Pressure Low Alarm (<75 psi)

Input Pressure High Alarm (>95 psi)

Internal Communication Fault

Hose Fault

Channel 1 Low Tolerance Alarm

Channel 1 High Tolerance Alarm

Channel 2 Low Tolerance Alarm

Channel 2 High Tolerance Alarm

04

05

06

07

1/10-17

Add additional inputs from AirTronics Module as required.

* See "Conguration Word Construction" in Appendix 1.

** If no SerAT Modules Installed, next module type moves to this position.

*** See following "Tolerance Word Construction."

LN-9238-02.3

AirTronic 2

AirTronic 2

AirTronic 2

AirTronic 2

AirTronic 3

Input Pressure Low Alarm (<75 psi)

Input Pressure High Alarm (>95 psi)

Internal Communication Fault

Hose Fault

(Additional AirTronic Modules)

26

Serial Node Adapter/Serial Node Adapter + - Operation

Ransburg

APPENDIX 1

FLEXIBLE 1/4 RACK

MOTHERBOARD SYSTEM

The 1/4 rack motherboards, 78145-00, 78147-00,

and 78149-00 will allow for exible application of

Serial Pneumatic Modules including Serial Atomizer (SerAT), AirTronic, Serial Digital (SerDG),

Cascading Digital (CCDG), and when available,

Serial Analog (SerAN) modules. Each motherboard has three slots, which will be referred to as

slots 0, 1, and 2, when viewed left to right, from

the module insertion side.

Specic Applications

1. Assembly 78145-00:

Slot 0 is reserved for Serial Node Adapter,

LECU4012-00 or Discrete I/O module,

76037-03 or -04. Note that a blank cover,

PNA10211-02 is required to cover an empty

space (module is 1" wide and the slot width is

1.4" wide). Slots 1 and 2 will accept any

combination of SerAT, AirTronic, SerDG, and

SerAN modules.

2. Assembly 78147-00:

For use when Serial Node Adapter is located

in another motherboard or for discretely wired

applications. Slots 0, 1, and 2 are identical and

will accept any combination of SerAT, Air-Tronic,

SerDG, and SerAN modules. If I/O communication is by internal serial bus, a jumper cable

must be connected to the serial bus source.

27

Figure 7: Assembly 78145-00

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Operation

LN-9238-02.3

Figure 8: Assembly 78147-00

28

Serial Node Adapter/Serial Node Adapter + - Operation

Ransburg

29

Figure 9: Assembly 78147-00

LN-9238-02.3

Ransburg

3. Assembly 78149-00:

This is reserved for the Cascading Digital

module (CCDG). The pneumatic connector is

unique to this module. Slots 0, 1, and 2 are

identical. I/O communication is via internal serial

bus (use cable to jumper to serial bus source)

or by discrete wiring to the module's terminal

strip on the rear.

Serial Node Adapter/Serial Node Adapter + - Operation

COMMUNICATION DISCRETE WIRING

1. Serial Atomizer (SerAT) - must be paired with

Discrete I/O module (one DIO per SerAT). Connections are made via the Discrete I/O cable.

2. Serial Digital (SerDG), Cascading Digital

(CCDG) - will accept 24 Vdc signals to 8 pin

terminal strips on rear of motherboard, behind

each slot. Module must be set via dipswitch for

this I/O conguration. The I/O for both Serial and

Cascading Digital is identical.

3. Serial Analog (SerAN) - will accept 0-10 Vdc or

4-20 mA signals to 8 pin terminal strips on rear of

motherboard, behind each slot. Module must be

set via dipswitch for this I/O conguration.

COMMUNICATION REMOTE I/O

The Allen-Bradley RIO via the Serial Node Adapter

can talk to any combination of up to 12 SerAT,

SerDG, CCDG, and SerAN modules via its local

CANBus. This requires Serial Node Adapter

Eprom Part #77128-04 (Version 2.02 or higher).

The local CANBus can consist of up to 4, 1/4 rack

motherboards connected together. Each motherboard has an addressing switch, which must be

set to from 0 to 3, so that each slot has a unique

bus address. The PLC data mapping for the FLEX

mode is shown in the following gures.

LN-9238-02.3

30

Serial Node Adapter/Serial Node Adapter + - Operation

FLEXIBLE 1/4 RACK

MOTHERBOARD SYSTEM

Conguration Word Construction

Ransburg

The above shows a group of any four of the

78145, 147, or 149 motherboards. The rotary

address switch sets an address number 0, 1, 2,

or 3 for that motherboard. Each motherboard

communicating with a given Serial Node Adapter

must have a different address number. This address number is completely independent of the

physical location of the motherboard. Each slot

in these motherboards has a number assigned

to it which is determined by which slot and which

mother-board.

The conguration words entered in the BTW's

dene what modules are located in each motherboard. Word 0 denes what modules are located

in the motherboard with address 0, word 1 denes

motherboard 1, etc. The modules are assigned an

ID number that is used to identify it and its position

in the motherboard. These ID's are:

MODULE IDENTIFICATION

NUMBERS

MODULE

MODULE

MicroPak

Serial Atomizer

Serial Digital

Serial Analog

AirTronic

TYPE ID#

0001

0010

0011

0100

0101

31

LN-9238-02.3

Ransburg

The BTW's used for conguration words would

look like this:

Serial Node Adapter/Serial Node Adapter + - Operation

BTW'S USED FOR CONFIGURATION WORDS

WORD/BIT

0 - Motherboard 0

1 - Motherboard 1

2 - Motherboard 2

3 - Motherboard 3

15 14 13 12

Slot 0

Slot 0

Slot 0

Slot 0

11 10 9 8

Slot 1

Slot 1

Slot 1

Slot 1

7 6 5 4

Slot 2

Slot 2

Slot 2

Slot 2

3 2 1 0

N/A

N/A

N/A

N/A

For Example:

For the above example the conguration words are:

BTW'S USED FOR CONFIGURATION WORDS

WORD/BIT

0 - Motherboard 0

1 - Motherboard 1

2 - Motherboard 2

3 - Motherboard 3

LN-9238-02.3

15 14 13 12

0 0 1 0

0 1 0 1

0 0 1 1

0 0 1 1

11 10 9 8

0 0 1 0

0 1 0 0

0 0 1 1

0 0 1 1

7 6 5 4

0 1 0 1

0 1 0 0

0 0 1 1

0 0 1 1

3 2 1 0

N/A

N/A

N/A

N/A

32

Serial Node Adapter/Serial Node Adapter + - Operation

If the address 0 motherboard is a 78145-00, having a Serial Node Adapter in the leftmost slot,

the procedure is the same. There is simply no

contribution to a conguration word from this slot

(Word 0, bits 12-15 are zero).

If any of the slots are empty, simply enter zero

for that slot.

With MicroPak

When a MicroPak is used, there is no change to

the conguration system. There is no conguration word used for the MicroPak, but MicroPak

switch SW7 must be set at the default, address

1 (positions 1, 2, and 3 ON, position 4 OFF). In

the following example, a MicroPak motherboard

has been added to this combination.

Ransburg

The conguration words are identical to that above.

Note that at least one of the motherboards in this

example must be located in another physical rack.

The above examples show a maximum number

of modules communicating with one Serial Node

Adapter. A more practical system (single bell)

might be:

33

LN-9238-02.3

Ransburg

The conguration words for this example are:

BTW'S USED FOR CONFIGURATION WORDS

Serial Node Adapter/Serial Node Adapter + - Operation

WORD/BIT

0 - Motherboard 0

1 - Motherboard 1

2 - Motherboard 2

3 - Motherboard 3

15 14 13 12

0 0 1 0

0 0 0 0

0 0 0 0

0 0 0 0

11 10 9 8

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

7 6 5 4

0 1 0 1

0 0 0 0

0 0 0 0

0 0 0 0

3 2 1 0

N/A

N/A

N/A

N/A

LN-9238-02.3

34

Serial Node Adapter/Serial Node Adapter + - Maintenance

MAINTENANCE

TROUBLESHOOTING GUIDE

SERIAL NODE ADAPTER + LED INDICATORS

Ransburg

ACTIVE

LED

ON

OFF

BLINK

ON

OFF

CPU

LED

ON

ON

ON

BLINK

OFF

FAULT DESCRIPTION POSSIBLE CAUSE

Normal Operation

Serial Node Adapter not

communicating with Remote I/O

Serial Node Adapter is not

controlling I/O

Checking Conguration

No Serial Node Adapter activity

----

1. RIO cable not connected

2. Incorrect dipswitch settings on Serial

Node Adapter for Baud rate, Address or

Starting Quarter

1. PLC in program mode

2. Another Node with same address on

RIO

1. Normal during power-up

2. Flex Mode - after power-up, indicates

conguration word does not match

installed hardware.

1. No power to Serial Node Adapter

2. Hardware failure

35

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Parts Identication

PARTS IDENTIFICATION

FLEXIBLE 1/4 RACK MOTHERBOARD SYSTEM - PARTS LIST

PART #

78145-00

78147-00

78149-00

LECU4014-02

76913-01-05

LECU4012-00

78553-00

A10211-02

76037-03

76037-04

76011-00

DESCRIPTION

1/4 Rack Motherboard, Type 0, Serial Node Adapter + Ser. Pneum.

1/4 Rack Motherboard, Type 1, Serial Pneum.

1/4 Rack Motherboard, Type 2, SerCCDG

1/4 Rack Motherboard, Type 3, MicroPak

1/2 Rack Motherboard, Serial Pneum.

Serial Node Adapter

Serial Node Adapter +

Blank Plate, 0.4"

Discrete I/O Module, 0-10V

Discrete I/O Module, 4-20mA

Serial Atomizer Module

LN-9238-02.3

76911-01

76911-02

78499-XX

78497-XX

76111-XX

Cascading Output Serial Digital Module

Serial Digital Module

Rack Assembly, 19" (With Modules)

Rack Assembly, 10" (With Modules)

I/O Cable (for Node Adapter + functions)

36

Serial Node Adapter/Serial Node Adapter + - Warranty Policies

WARRANTY POLICIES

Ransburg

LIMITED WARRANTY

The Ransburg Serial Node Adapter/Serial Node

Adapter + is warranted to be free of defects in

workmanship and material. The terms of this war-

ranty, except as hereinafter provided, extend from

one year from the date of rst installation. This

excludes equipment failures which are the result

of misapplication, misuse, incorrect maintenance,

or normal wear. If, after inspection by Ransburg

a defect is conrmed, we will at our option repair,

replace or issue credit, minus allowance for usage received.

This Warranty Does NOT Cover:

1. Labor or incidental costs occasioned by

removal, replacement or repair of the moule

by an unauthorized entity.

2. Modules inspected and determined by

Ransburg not to have been installed and

maintained in accordance with Rans burg service instruction LN-9217-00.1 (latest

edition).

3. Cost of repair/replacement and return trans portation from Ransburg of merchadise

determined not to be defective.

There is no other express warranty, implied

warranties,including those of merchantability

and tness for a particular purpose are limited

to one year from purchase and to the extent

permitted by law any and all implied warranties

are excluded. This is the exclusive remedy,

and liability for conse-quential or incidental

damages under any and all warranties are

exluded to the extent exclusion is permitted

by law. Some states do not allow limitations

on how long an implied warranty lasts, or the

limitation or exclusion of consequential or

incidental damages, so the above limitation

or exclusion may not apply to you.

This warranty gives you specic legal rights and

you may also have other rights which vary from

state to state.

In the event of malfunction, rst ensure that the

equipment is the correct equipment to do the job

required, is properly installed and adjusted, and

is correctly maintained and operated. Then, if a

claim is made that Ransburg equipment or a part

thereof does not operate properly, contact your

Ransburg distributor through which the equipment

was purchased or your Ransburg representative.

37

LN-9238-02.3

Ransburg

Serial Node Adapter/Serial Node Adapter + - Manual Change

MANUAL CHANGE SUMMARY

This manual was published to supercede Service

Manual LN-9238-02.2, Serial Node Adapter/Serial

Node Adapter + to make the following changes:

1. Revise Figure 4: RIO Discrete Inputs in the

"Installation" section, page 7.

2. Revised "Serial Bus Connection to Other

Motherboards" in the "Installation" section, page 8.

3. Updated "Table 1 - Serial Node Adapter +

LECU4012-00, PLC I/O MicroPak Mode, Discrete

Output Conguration" in the "Operation" section,

page 13.

4. Updated "Table 3 0- Node Adapter + LECU4012-

00, PLC I/O - Flex Mode (Dipswitch SW2-1

and SW2-5 On, Block Transfer Reads" in the

"Operation" section, page 17.

5. Updated "Table 3 - Node Adapter + LECU-

4012-00, PLC I/O - Flex Mode (Dipswitch SW2-1

and SW2-5 On), Digital Modules, No AirTronic

Modules, Block Transfer Read 8AirTronic Module

Word Denition" in the "Operation" section, page

21.

6. Updated "Table 3 - Node Adapter + LECU4012-

00, PLC I/) - Flex Mode (Dipswitch SW2-1 and

SW2-5 On), airTronic Modules, No Digital Modules,

Discrete Output Conguration" in the "Operation

" section, page 23.

7. Revised "Module Identication Numbers" chart

in the "Operation" section, page 29.

8. Revised "BTW's Used for Conguartion Words"

chart in the "Operation" section, page 30.

9. Revised "BTW's Used for Conguartion Words"

chart in the "Operation" section, page 32.

10. Revised "Serial Node Adapter + LED Indicators

in the "Maintenance" section, page 33.

11. Revised "Flexible 1/4 Rack Motherboard

System Part Numbers" in the Operation" section,

page 34.

LN-9238-02.3

38

Service Manual Price: $ 20.00 (U.S.)

Manufacturing

1910 North Wayne Street

Angola, Indiana 46703-9100

Telephone: 260/665-8800

Fax: 260/665-8516

Technical/Service Assistance

Telephone: 800/ 233-3366

Fax: 419/ 470-2071

Technical Support Representative will direct you to the appropriate

telephone number for ordering Spare Parts.

© 2013 Ransburg. All rights reserved.

Models and specications subject to change without notice.

Form No. LN-9238-02.3

Litho in U.S.A.

04/13

Loading...

Loading...