SERVICE MANUAL

LN-9400-00.9

(Replaced LN-9400-00.8)

December 2012

DYNAFLOW

TM

USER MANUAL

MODEL: 77376 and A12233

IMPORTANT: Before using this equipment,

carefully read SAFETY PRECAUTIONS, starting on page 1, and all instructions in this

manual. Keep this Service Manual for future

reference.

Service Manual Price: $50.00 (U.S.)

NOTE: This manual has been changed from revision LN-9400-00.8 to revision LN-9400-00.9

Reasons for this change are noted under “Manual Change Summary” inside the back

cover of this manual.

LN-9400-00.9

DynaFlowTM User Manual - Contents

CONTENTS

SAFETY:

SAFETY PRECAUTIONS.........................................................................................

HAZARDS / SAFEGUARDS..............................................................................................

PAGE

1-5

1

2-5

INTRODUCTION:

FEATURES........................................................................................................................

DESCRIPTION.................................................................................................................

BLOCK DIAGRAM.............................................................................................................

DYNAFLOW SPECIFICATIONS...................................................................................

INSTALLATION:

SYSTEM GUIDELINES, EQUIPMENT GROUNDING, LOCATIONS, MOUNTING.............

BLOCK DIAGRAM FOR A SINGLE-COMPONENT GUN................................................

BLOCK DIAGRAM FOR A TWO-COMPONENT GUN.............................................................

BLOCK DIAGRAM FOR A THREE-COMPONENT GUN.........................................................

INPUT POWER.............................................................................................................

INTERFACING TO THE FLOW CONTROLLER........................................................

MOTHER BOARD TERMINALS, HARDWARECONFIGURATION, TRANSDUCERS.........

OPERATION:

OVERVIEW.....................................................................................................................

PARAMETER DESCRIPTIONS.........................................................................................

AUTOMATIC GUN APPLICATIONS.................................................................................

MANUAL HAND GUN APPLICATIONS.............................................................................

GENERAL........................................................................................................................

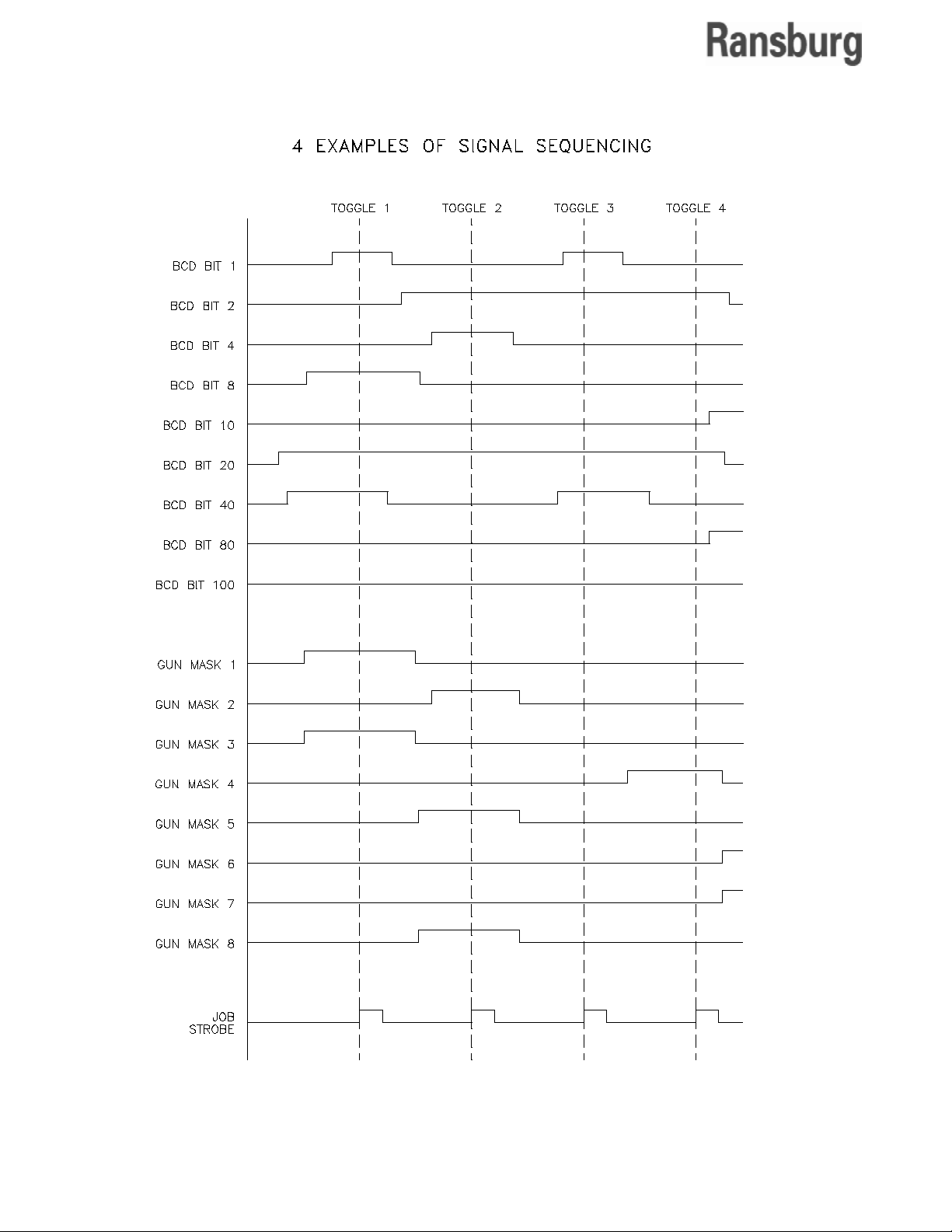

JOB SELECT TIMING DIAGRAM..................................................................................

JOB SELECT TIMING DIAGRAM SAMPLE, JOB QUEUE, REVERSE FLOW.................

PROCEDURES, FIRST TIME STARTUP, NORMAL STARTUP..........................

PID CONTROL........................................................................................................

6-13

6

6-9

10

11-13

14-27

14-15

16

17

18

19

20-23

24-26

28-61

28-29

30-43

44-45

45-46

46-47

48-49

50-54

54-56

56-61

MAINTENANCE:

TROUBLESHOOTING......................................................................................................

SYSTEM PREVENTIVE MAINTENANCE INSTRUCTIONS............................................

SYSTEM COMPONENTS AND PARTS IDENTIFICATION...........................................

RECOMMENDED SPARE PARTS................................................................................

HARDWARE SETTINGS................................................................................................

NEW CHANNEL CARD JUMPERS...........................................................................

INTERFACE MODULE DIP SETTINGS.................................................................

CONTROL RACK TERMINAL IDENTIFICATION......................................................

SERIAL COMMUNICATION PROTOCOLS................................................................

RATIO CONVERSION......................................................................................

WARRANTY POLICIES:

LIMITED WARRANTY..............................................................................................

(Continued Next Page)

LN-9400-00.9

62-87

62-71

71

72

73-74

75-78

79-80

81

82-85

86

87

88

88

DynaFlowTM User Manual - Contents

CONTENTS (Cont.)

PAGE

APPENDIX:

ADDENDUM A....................................................................................................................

ADDENDUM B..................................................................................................................

ADDENDUM C................................................................................................................

89-93

89-90

91-92

93

LN-9400-00.9

SAFETY

DynaFlowTM User Manual - Safety

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature for your Ransburg products. This manual

contains information that is important for you to

know and understand. This information relates to

USER SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the following symbols. Please pay

particular attention to these sections.

A WARNING! states information to alert you

to a situation that might cause serious injury

if instructions are not followed.

A CAUTION! states information that tells how

to prevent damage to equipment or how to

avoid a situation that might cause minor injury.

A NOTE is information relevant to the procedure in progress.

W A R N I N G

!

The user MUST read and be familiar with

the Safety Section in this manual and the

Ransburg safety literature therein identied.

This manual MUST be read and thoroughly understood by ALL personnel

who operate, clean or maintain this

equipment! Special care should be

taken to ensure that the WARNINGS and

safety requirements for operating and

servicing the equipment are followed.

The user should be aware of and adhere

to ALL local building and re codes and

ordinances as well as NFPA-33 SAFETY

STANDARD, LATEST EDITION, prior to

installing, operating, and/or servicing

this equipment.

W A R N I N G

!

While this manual lists standard specications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements,

etc., make such variations inevitable. Compare

this manual with your system installation drawings

and appropriate Ransburg equipment manuals to

reconcile such differences.

Careful study and continued use of this manual

will provide a better understanding of the equip-

ment and process, resulting in more efcient

operation, longer trouble-free service and faster,

easier troubleshooting. If you do not have the

manuals and safety literature for your Ransburg

system, contact your local Ransburg representative or Ransburg.

The hazards shown on the following

page may occur during the normal use of

this equipment. Please read the hazard

chart beginning on page 2.

LN-9400-00.9

1

DynaFlowTM User Manual - Safety

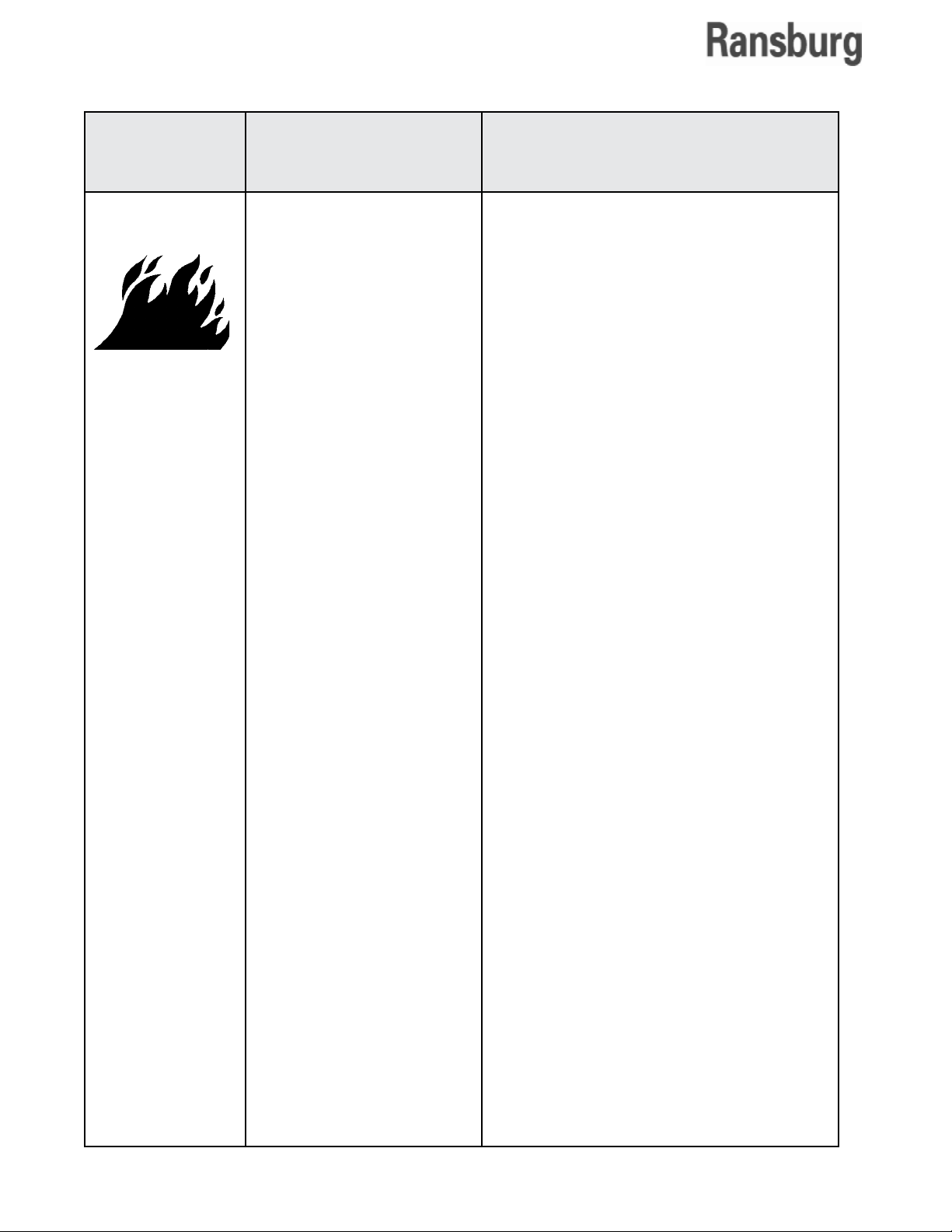

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate opera-tion

and maintenance procedures will

cause a re hazard.

Protection against inadvertent

arcing that is capable of causing

re or explosion is lost if any safety

interlocks are disabled during operation. Frequent power supply

shutdown indicates a problem in

the system requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

spray area and tested periodically.

Spray areas must be kept clean to prevent the accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

Those used for equipment ushing should have ash

points equal to or higher than those of the coating

material.

Those used for general cleaning must have ash

points above 100

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, and local codes. In addition, ventilation must be maintained during cleaning

operations using ammable or combustible solvents.

o

F (37.8oC).

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only

as instructed.

Non-factory replacement parts or unauthorized

equipment modications may cause re or injury.

If used, the key switch bypass is intended for use

only during setup operations. Production should

never be done with safety interlocks disabled.

Never use equipment intended for use in waterborne

installations to spray solvent based materials.

The paint process and equipment should be set up

and operated in accordance with NFPA-33, NEC,

and OSHA requirements.

2

LN-9400-00.9

DynaFlowTM User Manual - Safety

AREA

Tells where hazards

may occur.

General Use and

Maintenance

Electrical

Equipment

HAZARD

Tells what the hazard is.

Improper operation or maintenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

High voltage equipment is utilized.

Arcing in areas of ammable or

combustible materials may oc-

cur. Personnel are exposed to

high voltage during operation and

maintenance.

Protection against inadvertent

arcing that may cause a re or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shut-down

indicates a problem in the system

which requires correction.

An electrical arc can ignite coat-

ing materials and cause a re or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Personnel must be given training in accordance with

the requirements of NFPA-33.

Instructions and safety precautions must be read

and understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, re protection, operation maintenance, and housekeeping. Reference

OSHA, NFPA- 33, and your insurance company

requirements.

The power supply, optional remote control cabinet,

and all other electrical equipment must be located

outside Class I or II, Division 1 and 2 hazardous

areas refer to NFPA-33.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of ammable or combustible

material.

Testing may require high voltage to be on, but only

as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Explosion Hazard/

Incompatible

Materials

LN-9400-00.9

Halogenated hydrocarbon solvents for example: methylene

chloride and 1,1,1,-Trichloroethane are not chemically compatible

with the aluminum that might be

used in many system components.

The chemical reaction caused by

these solvents reacting with aluminum can become violent and

lead to an equipment explosion.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum equip-

ment during spraying, ushing, or cleaning. Read

the label or data sheet for the material you intend to

spray. If in doubt as to whether or not a coating or

cleaning material is compatible, contact your material supplier. Any other type of solvent may be used

with aluminum equipment.

3

DynaFlowTM User Manual - Safety

AREA

Tells where hazards

may occur.

Toxic Substances

Toxic Substances

HAZARD

Tells what the hazard is.

Certain material may be harmful

if inhaled, or if there is contact

with the skin.

SAFEGUARDS

Tells how to avoid the hazard.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air

free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance

of inhaling sprayed materials. The mask must be

compatible with the material being sprayed and its

concentration. Equipment must be as prescribed

by an industrial hygienist or safety expert, and be

NIOSH approved.

4

LN-9400-00.9

NOTES

DynaFlowTM User Manual - Safety

LN-9400-00.9

5

DynaFlowTM User Manual - Introduction

INTRODUCTION

FEATURES

• Congurable operating parameters (JOBs)

which can be saved and recalled on demand.

• Graphic diagnostics for troubleshooting and

for achieving maximum system performance.

• Comprehensive help information easily view-

ed on the OPERATOR INTERFACE.

• Congurable manual and/or automatic GUN

applications.

• Dynamic analog uid control – the control of

ow rate while running a JOB.

• Reverse uid ow detection provides added

protection for system components.

NOTE

DESCRIPTION

The ability to control the delivery of material greatly

increases the overall efciency of the spray operating system and results directly in more uniform

and consistent paint nish quality and reduces the

amount of material waste. The ability of the uid

ow controller to respond with quick, concise, and

repeatable control maximizes nish quality and

minimizes material waste.

The DynaFlowTM Flow Controller design utilizes

a form of distributed processing similar to many

of the industrial network architectures available

today. The entire task of uid ow control is broken

up into parts. Each portion of the system is de-

signed for a specic purpose. Since each element

of the system is performing specialized functions,

and all elements are operating at the same time,

overall performance of the system is enhanced.

Functionality of the control system components

is as follows:

This feature requires ow meters that

provide reverse ow output.

• Pot-life timer alarms.

• Local and remote monitoring and control.

• Discrete PLC interface capability for remote

control.

• Remote I/O (RIO) communications link for

direct connection to Allen-Bradley PLCs.

• Process and conguration error and fault de-

tection and reporting.

• USB memory stick, backup of conguration

and operational data.

• Versatile system integration.

• Easy to use.

Channel Module

The Channel Module represents the core of the

system. Each Channel Module is responsible for:

• Monitoring the CHANNEL specic inputs and

supplying the necessary CHANNEL specic

outputs for control and status.

• Receiving and processing the ow meter

feedback pulses.

• Determining the analog PID output control

signal by performing high-speed oating-

point math.

• Receiving and interpreting commands from

the Interface Module through high speed

Ransburg CAN Bus communication.

• Supplying data and status upon request to

and from the Interface Module.

• Help text and troubleshooting guide available

on screens.

6

LN-9400-00.9

DynaFlowTM User Manual - Introduction

Located on the front panel of the Channel Module are several status indicator lights (LEDs).

These are:

1. CPU - Is ON when the microprocessor is operating normally.

2. ACTIVE - Is ON when communication is taking

place to the Interface Module.

3. FAULT - Is ON when there is a problem with

the module.

Interface Module

The Interface Module performs the following:

• Stores system conguration and data

tables.

• Acts as an interpreter for communication

with an external Host computer, PLC and/

or the local Operator Interface. Communi cates through a high speed Ransburg CAN

Bus data link to each Channel Module.

• Responsible for system specic inputs and

supplying the necessary system specic

outputs for control and status.

Located on the front panel of the Interface Module are several status indicator lights (LEDs).

These are:

1. CPU - Is ON when the microprocessor is operating normally.

2. ACTIVE - Is ON when RIO communication

is taking place to an Allen-Bradley PLC.

3. FAULT - Is ON when there is a problem with

the module.

Local Operator Interface

Supplied as part of the DynaFlow Stand-Alone

Control Cabinet, Model# 77376 and A12233.

• Permits total control of the system.

• Displays system conguration and data to

the operator.

• Computes and displays text and graphic di-

agnostic information.

• Organizes, formats, and reports all data

and conguration tables.

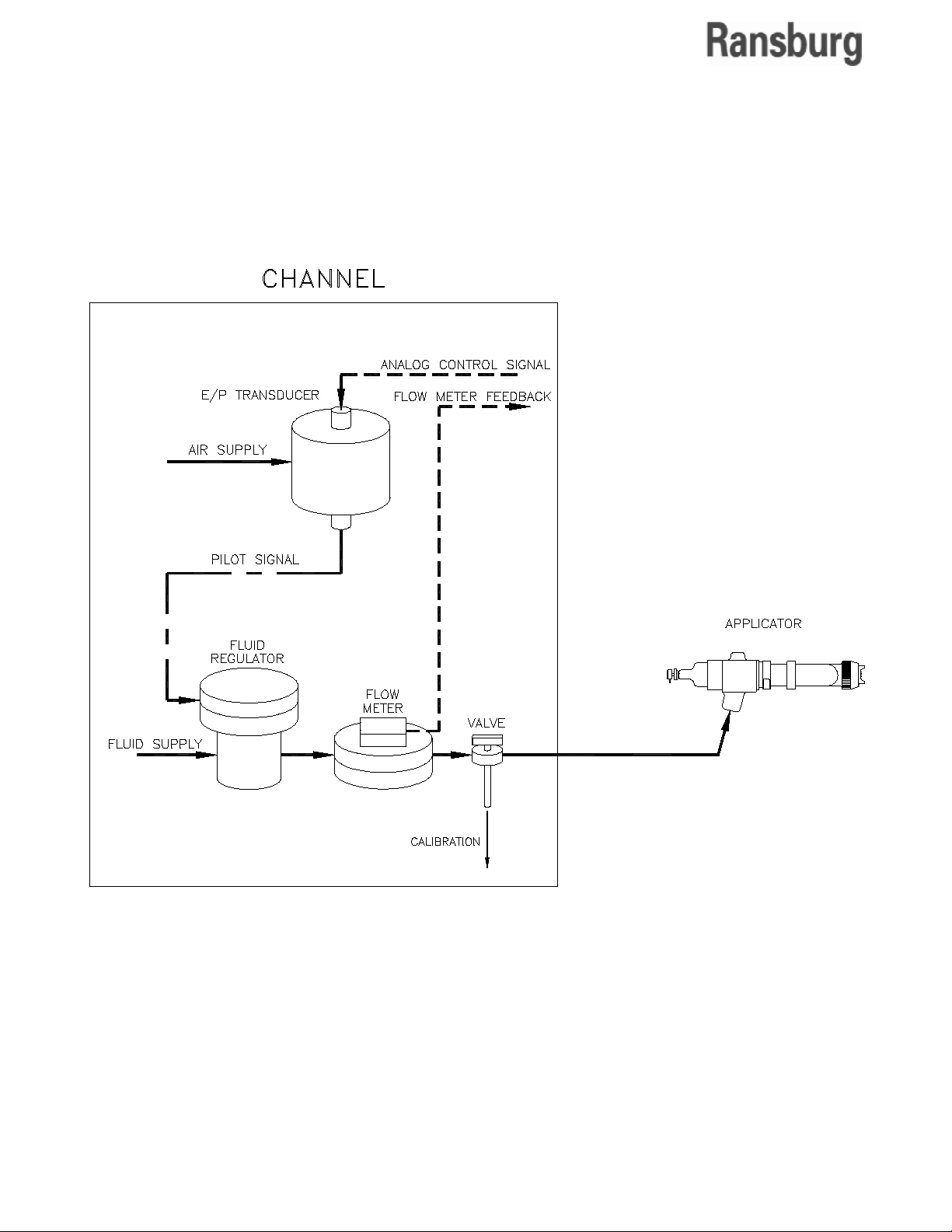

The DynaFlow uid ow control system achieves

real-time closed loop control through the use of

CHANNELs and GUNs. A CHANNEL consists

of an electrical-to-pneumatic (E/P) transducer,

material regulator and uid ow meter combination through which a single material is controlled.

A GUN represents a single applicator through

which one or more materials are delivered. One

or more CHANNELs are congured for each GUN.

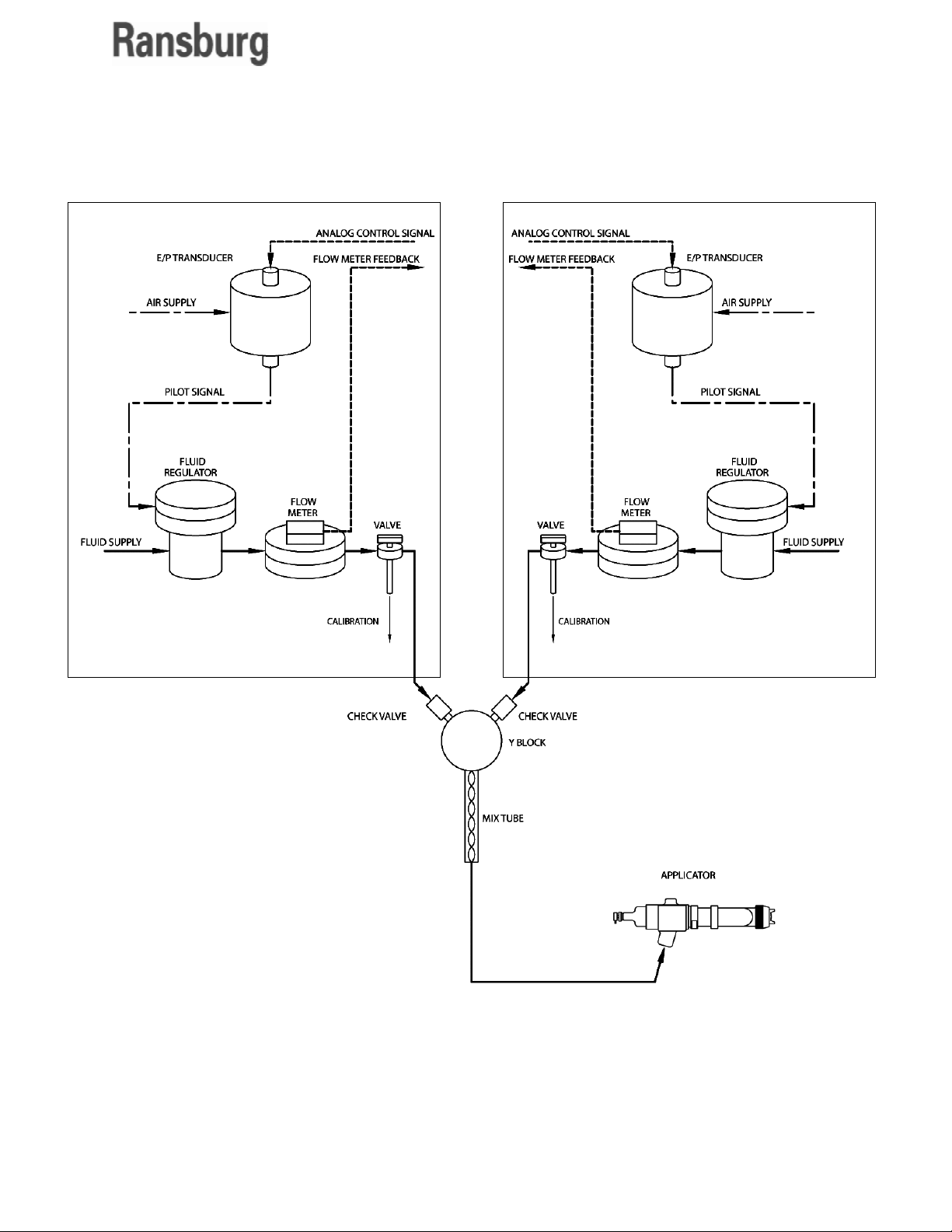

Two-component delivery systems (referred to as

2K systems) have two CHANNELs assigned to

a single GUN. The materials are statically mixed

before being delivered to the GUN.

Each CHANNEL operates independently of, and

simultaneously with all the other CHANNELs. This

lets the DynaFlow controller provide accurate dynamic regulation for each CHANNEL, regard-less

of minor system wear or changes in system variables. With a single-component coating material,

the DynaFlow controller detects changes from the

programmed ow rate and adjusts the output to

correct it. With two-component coatings (where

both the resin and catalyst are regulated and

monitored), the DynaFlow controller detects any

change in the total ow and makes the required

adjustments to maintain the programmed ow

and ratio. This holds the ow rates of the coating

components constant. Deviations from the desired

mix ratio are also immediately corrected using this

same closed loop process.

A detailed guide on PID control is supplied in this

manual to assist you should you want to adjust

the control parameters. There are many additional

features included in the DynaFlow Fluid Flow Con-

trol which reect on the many years of experience

accumulated by Ransburg.

The control rack and OPERATOR INTERFACE

panels are consistent with and easily integrated

with other Ransburg control products into larger

custom system control panels. This optimizes

costs, space and functionality for control of multiple

applicator spray stations. Spray stations may also

LN-9400-00.9

7

DynaFlowTM User Manual - Introduction

incorporate rotary atomizer speed control, shaping

air, high voltage power supplies and more.

The standard stand-alone control cabinet includes

control of up to 8 CHANNELs. It incorporates an

integrated 15" color LCD touch screen, PC based

display/interface sub-panel.

Congurable Operating

Parameters

The design of the DynaFlow system allows it to

be congured to meet the specic requirements

of each application. The 8 available CHANNELs

can be linked together, using 1 of 8 GUNs, to

control the ow and mixing regulation of two-

component materials. The installed channels can

be congured to suit the application. If you are

using single-component coatings, the DynaFlow

controller can support 8 separate single CHANNEL GUNs operating simultaneously. If you are

using two-component materials, then 4 separate

2-CHANNEL GUNs operating simultaneously

can be supported. For example, you can use 4

CHANNELs assigned to 2 GUNs to spray 2 dual

component paints on automatic machines, and 2

CHANNELs assigned to 1 GUN to spray one dual

component paint with a manual hand spray GUN.

In addition to the above, a GUN congured for

two-component operation can be dynamically

changed to operate in a single-component mode

by simply setting the ratio JOB parameter to

100. This allows a GUN to operate in either dual

or single-component modes by simply changing

JOB numbers.

The controlling parameters for each GUN and the

CHANNEL(S) assigned to that GUN, are called

JOBs. The JOB values dene ow characteristics

such as Target Flow Rate, Mix Ratio, Flow Toler-

ance, etc. JOBs include all of the parameters that

may be dependent on the material used. This offers

the ability to optimize system control as needed

per material and then recall the settings each

time that material is requested. There are up to

100 JOB #s for each GUN. By saving frequently

used JOB #s to memory you can later recall them

by loading the number representing that JOB #.

All of the JOB #s can be backed-up to, and restored

from a USB memory device. Reference the "Opera-

tor Interface Users Manual" and "Program-mers

Manual" for details on data transfer operation and

available formats.

The ow control unit includes one Interface Module

and up to 8 hardware PID control CHANNELs,

2 CHANNELs located on each of the 4 possible

Channel Modules. The Interface Module will communicate to a host controller. The host is one of

the following:

• PLC using discrete I/O

• Allen-Bradley PLC using RIO

• Local Operator Interface using an RS-

232C communication port

3-K Operation

DynaFlow was designed for either single or twocomponent operation. Three-component operation

is possible by conguring two, two-component,

guns. The rst Gun is set up as follows:

Gun 1 =

Master Channel =

Material = Resin

Flow Controller = Color Change

Value (CCV)

Flow Meter = Standard Gear-Type

Slave Channel =

Material = 2nd Component

Flow Controller = MVR, with appropriate size

needle

Flow Meter = Piston or Gear, depending on

min/max ow rates

(see Notes 4 and 5)

Operating Mode = Manual

8

LN-9400-00.9

DynaFlowTM User Manual - Introduction

The output of the rst Gun is then fed into the

Master Channel input of the second Gun. The

second Gun is setup as follows:

Gun 2 =

Master Channel =

Material = Output of Gun 1 (Resin + 2

nd

Component)

Flow Controller = Color Change Value

(CCV)

(see Notes 1, 2, and 3)

Flow Meter = Gear-Type

Slave Channel =

Material = 3rd Component

Flow Controller = MVR, with appropriate

size needle

Flow Meter = Piston or Gear, depending on

min/max ow rates

(see Notes 4 and 5)

Operating Mode = Manual or Auto

(see Notes 1, 2, and 3)

NOTE

Refer to Addendum C for complete

information regarding the ow limitations of

the DynaFlow Channel cards.

NOTES:

1. If the output of Gun 2 supplies one or more

hand guns, then Gun 2 should be operated in

Manual mode using a CCV for the Master

Channel ow controller.

2. If the output of Gun 2 supplies a single applicator, then an MVR should be used for the

Master Channel ow controller and Gun 2

should be operated in Auto mode.

3. If the output of Gun 2 supplies multiple applicators other then hand guns, then Gun 2 should

be operated in Manual mode using a CCV for the

Master Channel ow controller. Additional Guns

should be congured for each applicator as shown

below to provide automatic ow control for each

applicator.

Gun 3 through 6 =

Master Channel =

Material = Output of Gun 2 (Resin + 2

nd

+

3rd Components)

Flow Controller = DR1

Flow Meter = Gear-Type

Operating Mode = Auto

LN-9400-00.9

9

DynaFlowTM User Manual - Introduction

10

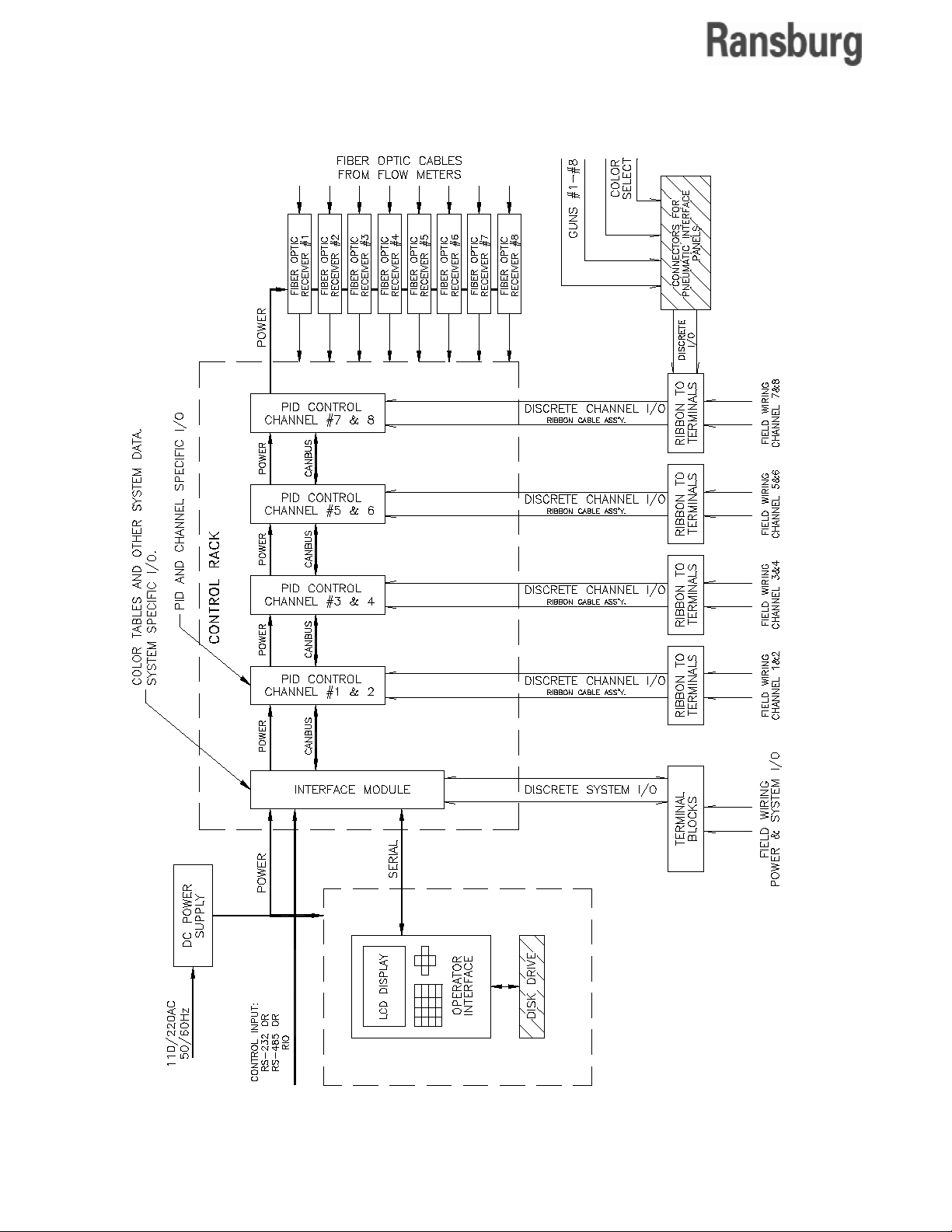

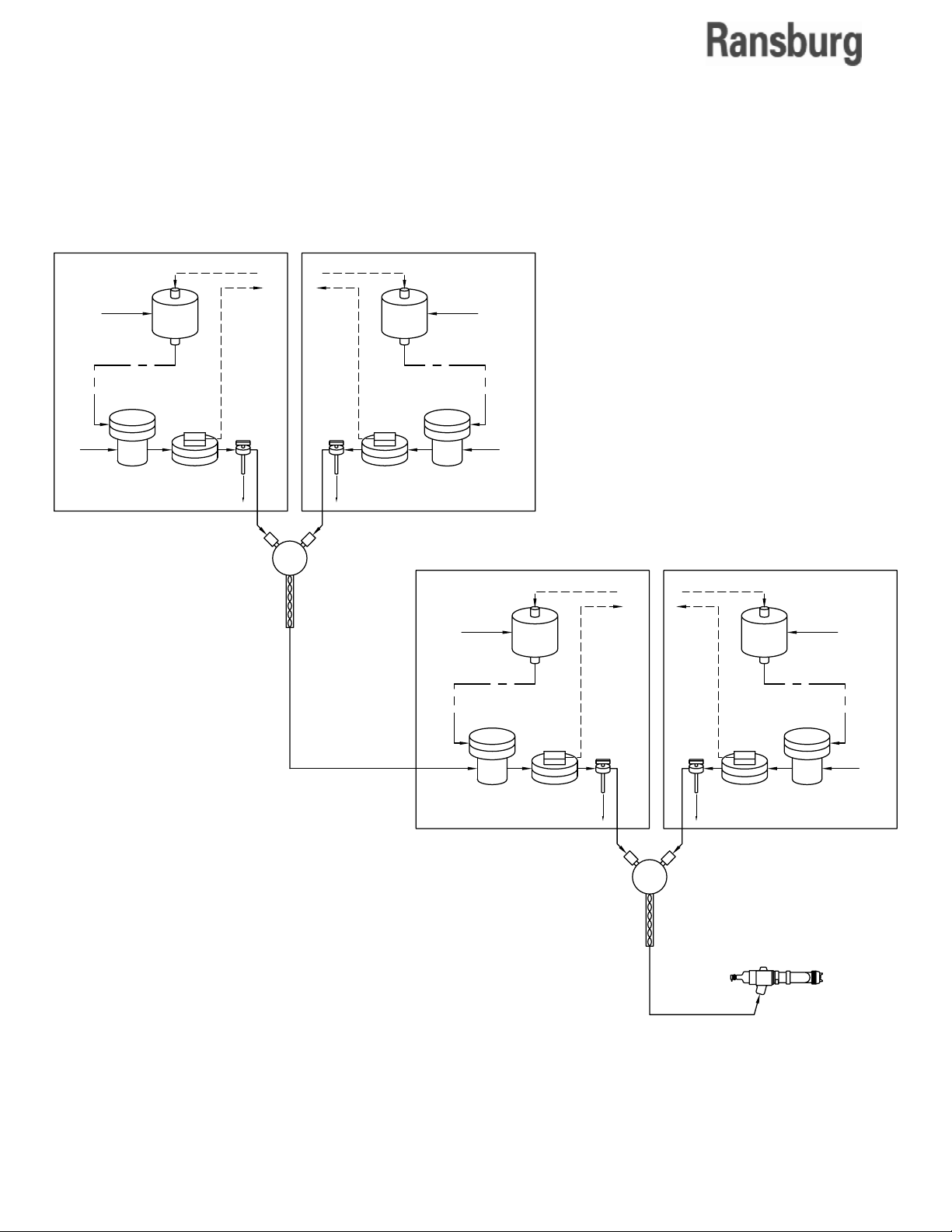

Figure 1: Block Diagram

LN-9400-00.9

DynaFlowTM User Manual - Introduction

DYNAFLOW SPECIFICATIONS

Pneumatic Requirements

Transducers: The air supplied to the trans-

ducers must be clean and dry

and meet the following general

specications:

Filtration: 20 Micron

Supply Pressure: 90 PSIG min. to 150 PSIG

max.

Volume: 0.04 to 0.13 Cv

Operating Temperature:

32o to 150o F (0o to 65.5o C)

Control Rack (Up to 8 Channels Per

1/2 of 19" Rack)

Dimensions: 83mm H X 250mm W X

184mm D standard half rack

Power Requirements:

24 VDC at 1 Amp typical, all 8

CHANNELs installed

The following must be followed if the ow control

rack and/or Operator Interface is to be integrated

into a larger system control panel:

- The 24 VDC Power Supply must be located in the

same control panel as the uid ow control.

- DO NOT use a central power supply located else

where. The power supplies may be sized for and

used for other controls within the same cabinet

WITH THE EXCEPTION OF HIGH VOLT-

AGE POWER SUPPLY CONTROLLERS.

High voltage power supply controllers MUST have

a dedicated power supply.

Interface Module Hardware

General: This Module is responsible for

local display/keyboard control and

communication to the Host control ler. Responsible also for non-vola tile storage of all JOB data tables

and system conguration param-

eters.

Dimensions: 3U (130.5 mm) H x 7H

(35.2 m) W standard 19" rack module

Interface Module Hardware (Cont.)

Digital Inputs: 24 VDC at 2.3 ma typical per input

(optically isolated, source by de fault, sink selectable)

- JOB Select Strobe

- JOB Select 1 (lower signicant

BCD digit)

- JOB Select 2

- JOB Select 4

- JOB Select 8

- JOB Select 10 (middle signicant

BCD digit)

- JOB Select 20

- JOB Select 40

- JOB Select 80

BCD digit)

- System Ready/Halt

- Global Gun Enable

Digital Outputs: 24 VDC sourced at 300 ma maxi-

mum per output (Solid state relay

contacts)

System Pulse: Used as watchdog timer by an

external supervisory PLC or com-

puter.

System Fault: Used to activate an alarm and to

supply a signal remotely that a

System, GUN, or other fault has

occurred.

Communications

RS-232C Port: Communication with local

Opperator Interface unit.

Allen-Bradley

RIO Port: For direct high-speed communi-

cation with Allen-Bradley PLC's.

CAN: Control Area Network (CAN) high

speed communication with all

channel Modules and with other

racks.

Power Requirement: 24 VDC at 100 ma typical

Operating Temperature: 0

JOB Select 100 (upper signi

o

to 55o C

cant

LN-9400-00.9

11

DynaFlowTM User Manual - Introduction

Channel Module Hardware

Specications

General: Each Channel Module is responsible

for processing channel specic dis-

crete I/O and performing all of the

necessary PID closed loop control

functions. Data and control I/O other

than discrete is communicated

through Ransburg CAN Bus located

on the Motherboard.

Dimensions: 3U (130.5mm) H x 7H (35.2mm) W

standard 19" rack module

24 Digital Inputs

(2 Channels):

(optically isolated, source by default,

sink selectable)

Trigger (level): Automatic mode only - For

manual mode, uid starts with uid

ow on master channel.

Halt (edge): Stops current JOB # (no effect on

next JOB # in queue)

Clean (edge): Forces regulator full on for

cleaning

Run (edge): Gets next JOB # - used in conjunc-

tion with JOB # and Toggle select

bits

Gun Mask (edge): Used in conjunction with

JOB # select bits

Total Reset (edge): Resets all totals

Total Hold (level): Holds present total value

regardless of uid ow

Transparent/PID (level): When active directs

the external analog input directly to

the transducer output

Analog Hold (level):

Freezes PID and holds cur-

rent analog control output

Load (edge): Loads uid with controlled mix ratio

for GUNs operating in MANUAL

Mode

External Fault/

Enable (level): Enable signal input. Must

be active for uid to be delivered by

GUN regardless of the operating

mode.

Spare: Not used presently

24 VDC at 2.3 ma typical per input

Channel Module Hardware

Specications (Cont.)

12 Digital Outputs

(2 Channels): 24 VDC sourced at 300 ma max-

imum per output (Solid state relay

contacts)

Ready: Everything is ready for operation,

congured correctly and I/O logic

OK

Active: CHANNEL is active and controlling

Fault: Fault has occurred

Pot Life Timer: Pot life timer expired

Clean/Load/Calibrate: Indicates Clean, Load, or

Calibrate mode is active

MVR Enable: Used to control trigger valve for

CHANNEL in fast trigger applica-

tions with Analog Hold enabled

4 Analog Inputs

(2 Channels): Jumper selectable 0-10 VDC (de-

10-bit A/D.

Set Point Control #1: Used for external analog

control. When used, offset and full

scale need to be set. This is

accomplished through the

MAXIMUM FLOW RATE and

MINI MUM FLOW RATE JOB

parameters.

Set Point Control #2: Used for external analog

10-bit A/D control. When used, off set and full scale need to be set.

This is accomplished through the

MAXIMUM FLOW RATE and

MINIMUM FLOW RATE JOB

parameters.

Spare #1: Not used presently

Spare #2: Not used presently

4 Analog Outputs

(2 Channels): Jumper selectable 0-10 VDC (de-

12-bit D/A.

Transducer Control #1: Output to proportional

E/P 12-bit D/A controller

Transducer Control #2: Output to proportional

E/P controller

Flow Rate #1: Flow Rate (scaled between MINI MUM FLOW RATE and MAXI MUM FLOW RATE JOB param-

eters)

Flow Rate #2: Flow Rate (scaled between MINI

MUM FLOW RATE and MAXIMUM

fault) or 4-20 ma, op-amp buff

fault) or 4-20 ma, op-amp buff

ered,

ered,

12

LN-9400-00.9

DynaFlowTM User Manual - Introduction

Channel Module Hardware Specications (Cont.)

FLOW RATE JOB parameters)

4 Frequency Inputs: From ow meters (reverse

ow capable)

Source Signal #1 & #2:

Frequency used to determine

ow rate (pulses per volume or

weight).

Maximum Frequency = 435 Hz

Minimum Frequency = 1 Hz

(Refer to Addendum C for ow limitations.)

Phase Signal #1 & #2: State used to determine

direction of ow rate, forward or

reverse.

PID Control: Closed loop control based on

the Kp, Ki, Kd and deadband

JOB parameters. 30ms PID up

date time (default), each chan-

nel.

Control Enclosure (A12233)

Dimensions: 610mm H X 610mm W X 410mm D

Weight: 45.5 Kg (100 lbs)

AC Power: 115/230 VAC, 3A

50/60 HZ

1 Phase

Temperature: 5°C - 40° C

Humidity: 80% to 31° C decreasing to 50% at

40° C non-condensing

Interface Enclosure (A12182)

Dimensions: 610mm H X 610mm W X 410mm D

Weight: 22.7 Kg (50 lbs)

Temperature: 5°C - 40° C

Communications

CAN: Controller Area Network (CAN) High-

speed serial communications to In terface Module.

RS-232C Port:

Spare auxiliary communication port.

Power Requirements: 24 VDC at 100 ma

typical – each Channel Module

Operating

Temperature: 0

o

to 55o C

Humidity: 80% to 31° C decreasing to 50% at

40° C non-condensing

LN-9400-00.9

13

DynaFlowTM User Manual - Installation

INSTALLATION

SYSTEM GUIDELINES

Prints Specic per Installation

Often times, installation prints are custom drawn

for each site. You should check those prints for

information that is specic to your installation.

Any deviations from those prints made during or

after installation should be recorded for further

reference.

Cable Assemblies

Most electrical interconnections between the DynaFlow controller and other system components

are made through cable assemblies.

NOTE

Any unused conduit holes must be blanked off

to prevent solid objects from entering the interior of the enclosure.

Equipment Locations

With the exception of the following restrictions,

the installation of the Transducers or Transducer

Panel, the Remote Operators Station and Regulator/Flow meter assemblies are application and

site dependant. Specic instructions for location

and mounting of these assemblies are covered

on the site installation drawings.

1. The maximum recommended distance from

the Control Panel to each ow meter is 100-ft.

as determined by the maximum standard available length of the ber-optic cable assemblies or

intrinsic electrical cable assemblies.

2. The maximum recommended length of air pi-

lot tubing between the electrical-to-pneumatic

(E/P) transducer and the material regulator is

largely determined by the application. In general,

the pilot lines should be kept as short as pos-

sible to achieve the best uid ow response and

regulation. See "Pilot Signal Guidelines" chart in

this section.

Equipment Grounding

C A U T I O N

!

The control panel should be grounded

in accordance with national and local

electrical codes.

The protective ground conductor must be

terminated directly to the protective conductor ground terminal located inside the Control

Enclosure which is marked with symbol -

3. The maximum distance between the optional

LBAL5001-XX Pneumatic Interface Panel to the

Control Console is 40-ft., as determined by the

interconnecting electrical cable assembly.

4. The maximum recommended 1/4-inch OD

hose length from the LBAL5003, Remote Operator Panel, and the LBAL5001, Pneumatic Interface Panel, is 50-ft., however this can be longer

depending on the application. The maximum

distance between the A12182 interface panel and

the A12233 console is 100-ft.

5. The maximum recommended length for the

E/P transducer electrical control cable is 95 ft.

However, in some cases 175-ft. has been used.

Generally, if a GUN number (not atomizers) controls a complete zone of 6 or more atomizers, do

not exceed 95-ft. of cable.

Consult Ransburg if longer distances than those

shown above are desired.

14

LN-9400-00.9

DynaFlowTM User Manual - Installation

C A U T I O N

!

Do not locate the Control Panel

near or adjacent to heat producing equipment such as ovens, high wattage lamps,

steam pipes, etc.

Equipment Mounting

Use the mounting ears supplied to mount the

control or interface enclosure on a wall or building structure. The anchor system used must be

rated to support the specied weight of the enclosure being mounted (see specications, page

13). When properly mounted, the anchor system

shall be capable of withstanding 4 times the rated

weight without causing a hazardous condition.

W A R N I N G

!

If improperly located, certain electrical

equipment can become a source of ignition

and create a risk of re or explosion.

W A R N I N G

!

The Control Enclosure must be lo-

cated in such a way that access to the On/

Off power switch and Stop switch is not

blocked.

The On/Off switch turns off AC power to the

PC and 24 VDC supply.

The Stop switch interrupts only the 24

VDC.

The AC power input FUSED DISCONNECT

must be located in an accessible area near

the Control Enclosure

The Control and Interface Enclosures must

be located outside of the Class 1, Division

1 and 2 hazardous locations which are de-

ned for spray nishing of ammable and/

or combustible materials. Denitions and

requirements for classied areas are found

in the National Electrical Code, NFPA-70,

Article 516 and the National Fire Protection

Association (NFPA-33).

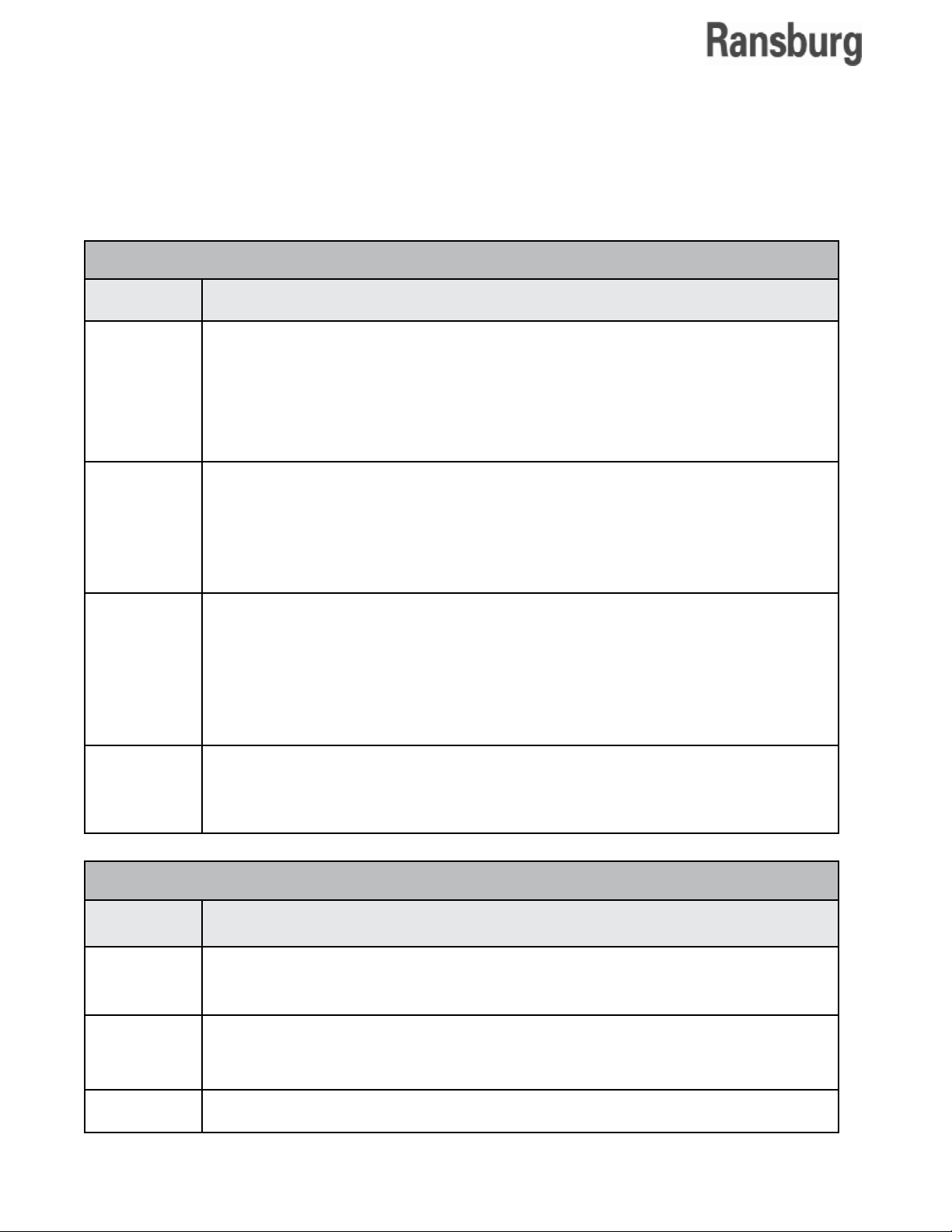

PILOT SIGNAL GUIDELINES

Tubing Size ODFluid Regulator

Application

Two-component

Single-Component

1/4"

1/4"

Type

MVR

DR1

Typical

Minimum

Length

Feet Meters

15

15

4.6

4.6

Maximum

Length

Feet

50

100

Meters

15.3

30.5

LN-9400-00.9

15

DynaFlowTM User Manual - Installation

16

Figure 2: Block Diagram for a Single-Component Gun

LN-9400-00.9

DynaFlowTM User Manual - Installation

CHANNEL 1

CHANNEL 2

LN-9400-00.9

Figure 3a: Block Diagram for a Two-Component Gun

17

CHANNEL 1

CHANNEL 2

DynaFlowTM User Manual - Installation

E/P TRANSDUCER

AIR SUPPLY

FLUID SUPPLY

PILOT SIGNAL

FLUID

REGULATOR

ANALOG CONTROL SIGNAL

FLOW METER FEEDBACK

FLOW

METER

VALVE

FLOW METER FEEDBACK

CALIBRATION CALIBRATION

CHECK VALVE

Y BLOCK

MIX TUBE

ANALOG CONTROL SIGNAL

VALVE

CHECK VALVE

FLOW

METER

E/P TRANSDUCER

AIR SUPPLY

PILOT SIGNAL

FLUID

REGULATOR

FLUID SUPPLY

FLUID SUPPLY

E/P TRANSDUCER

AIR SUPPLY

PILOT SIGNAL

FLUID

REGULATOR

CHANNEL 3

FLOW

METER

ANALOG CONTROL SIGNAL

FLOW METER FEEDBACK

VALVE

CHANNEL 4

ANALOG CONTROL SIGNAL

FLOW METER FEEDBACK

VALVE

FLOW

METER

E/P TRANSDUCER

AIR SUPPLY

PILOT SIGNAL

FLUID

REGULATOR

FLUID SUPPLY

18

CHECK VALVE

Figure 3b: Block Diagram for a Three-Component Gun

CALIBRATIONCALIBRATION

CHECK VALVE

Y BLOCK

MIX TUBE

APPLICATOR

LN-9400-00.9

DynaFlow

TM

User Manual - Installation

INPUT POWER

Input supply voltage connections should be made

from a FUSED DISCONNECT that is located in

an accessible area near the Control Enclosure.

Electrical conduit is recommended for the input

power wiring. Use 3 cond. 14 ga. wire for incoming AC power supply.

If using SO type portable cord, a strain relief rated

for the diameter of cord being used is required for

protection against cord abrasion and damage.

The protective ground conductor must be terminated directly to the protective conductor ground

terminal located inside the Control Enclosure which

is marked with symbol -

If there are large AC line voltage uctuations or

voltage transients such as those typically produced

by heavy electric machinery or welding equipment,

then a constant voltage transformer (CVT) or an

uninterruptedly power supply (UPS) should be

used between the FUSED DISCONNECT and

the Control Panel.

C A U T I O N

!

Before applying power to the control

panel, verify that it is set to match the

source voltage. There may sometimes be

a voltage selection switch (usually located

on the DC power supplies) to select between 120 VAC and 240 VAC or different

indicator bulbs may be required.

W A R N I N G

!

Do not install or service this equip-

ment or perform installation or adjustment

procedures unless you are properly trained

and qualied.

Installing and servicing this equipment

requires access to parts which could cause

electric shock or serious injury if work is not

performed properly.

C A U T I O N

!

If a CVT or UPS is to be used on the

input to the Control Panel, use a CVT with

a Volt-Amp (VA) output rating equal to

or greater than the output voltage multiplied by the control panel fuse rating (see

specication section). Also make sure that

the device input ratings correspond with

the voltage and frequency of the source

supplied by the FUSED DISCONNECT.

The device output should be rated for 240

VAC maximum.

All work must comply with applicable local

and national regulations and codes.

LN-9400-00.9

19

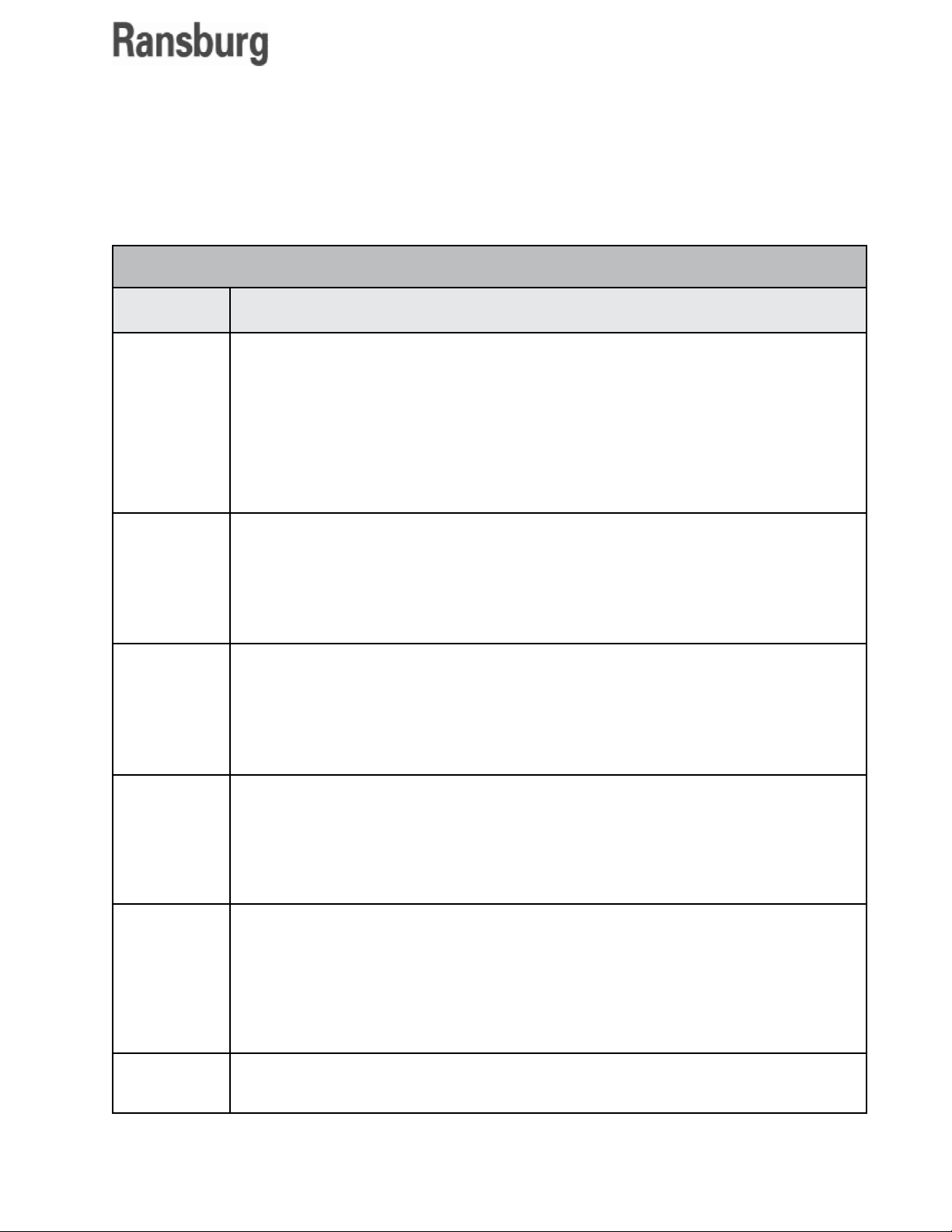

DynaFlowTM User Manual - Installation

INTERFACING TO THE

FLOW CONTROLLER

System I/O

SYSTEM INPUTS

Input

Signals

JOB Select

Inputs

JOB Strobe

Input

System Ready/

Halt Input

Description

These inputs are used to select a JOB number from the external PLC or other host controller.

These inputs represent Binary Coded Decimal (BCD) that translates to 3 digits, each digit

represented as a 4-bit binary code. The JOB Select inputs are used in conjunction with the

GUN Mask inputs to determine which GUNs will accept the JOB number represented by the

total of the active JOB Select Bits. See "Operation" section of this manual for details. These

signals must be asserted prior to the JOB Strobe Input and held on slightly after the strobe

signal goes low.

JOB Strobe requires a pulsed signal of at least 0.25 seconds duration. This signal is used in

conjunction with the GUN MASK inputs and program select inputs to activate a new JOB # for

any or all GUNs. When the controller detects this input, the program select inputs and GUN

MASK inputs are read and action taken to load the new JOB # in the JOB # QUEUE. The new

program select and GUN MASK inputs must be present before the PROGRAM SET STROBE

is activated. Reference "Job Selection Timing Diagram Sample" in the "Operation" section.

System Ready/Halt is a maintained signal that permits activation of any or all GUNs. For the

controller to operate, this signal must be maintained in the high state (24 VDC). When this

signal is active, the system Ready/Halt output will be held ON.

If the signal is lost, ALL GUNs will stop and the READY output is turned OFF. The GUNs must

be restarted in the normal manner when this signal is again activated. The JOB # QUEUE for

any GUN is not effected by the state of this input.

Global GUN

Enable

The Global GUN Enable is a maintained signal that overrides all of the individual External

Fault/Enable GUN inputs. Reference "GUN INPUTS". This is most useful when using RIO,

RS-485, or RS-232C control and the discrete GUN I/O is not used through J3, J4, J5, or J6

of the mother board.

SYSTEM OUTPUTS

Output

Signals

System Pulse

Output

System Fault

System Spare

20

Description

The System Pulse output can be used as a watchdog function by a PLC or other external

controller to determine if the ow controller is operating normally. The output is a 50% duty

cycle, 0.5 HZ signal (2 pulses per second).

A high signal on this output indicates that a system, GUN or other fault has occurred. The

type of fault that causes this output to activate is selectable by the Horn Code located in the

System Conguration table.

Not used presently.

LN-9400-00.9

DynaFlow

TM

User Manual - Installation

Gun I/O

Discrete GUN I/O provides the input control and output status signals required to interface each GUN

with a PLC or similar controller, or other system control components. All GUN I/O can also be controlled

or monitored through an external host controller operating through a serial data communications link

or the state of each forced active through the local OPERATOR INTERFACE/host controller.

GUN INPUTS

Input

Signals

Trigger

Description

For automatic applicators: Starts uid ow when supplied a 24 VDC signal assuming that the

GUN has been put in run mode, is congured properly, and all other conditions are satised.

For manual GUNs: A Trigger signal is required for the LOAD mode. The Trigger signal can

be generated from an atomizing air ow switch. If a Trigger signal is received from the ow

switch but no uid ow is recorded from the catalyst (slaved) CHANNEL, then a FLOW TOO

LOW fault is generated. This ensures that both material components are present to the GUN.

If the dip switch, Pos #1 on the Channel Card is on, then this input is not used. Fluid ow

through the master channel is used to indicate a TRIGGER ON condition.

Halt/Reset

Clean

Run

Gun Mask

Halt requires a pulsed signal of at least 0.25 seconds duration. It is used to stop the JOB #

currently being executed or to stop a CLEAN/PURGE operation. GUN faults are also reset.

While in HALT mode, any new JOB # selection using the JOB # Strobe will be entered into

the Queue. The GUN will run the JOB # located in the Queue when a RUN signal is again

supplied. The faults can still be viewed in the ERROR LOG data table. Halt has no effect on

the JOB # in the Queue (Next JOB # to be run).

Clean requires a pulsed signal of at least 0.25 seconds duration. It forces the material regula-

tors controlled by the GUN parameters to the full open position. This permits the uid system

to be cleaned. The removal of the GUN Enable signal or a HALT input signal is required to

end the CLEAN operation. Actual cleaning sequencing (PURGE) such as soft air push-out is

performed by the PLC, or other external controller. For details, refer to "Clean Mode" in the

"Operation" section of this manual.

This input will activate the GUN and will allow material ow if all other requirements are met.

This is identical to pushing the GUN ON switch on the OPERATOR INTERFACE PANELS.

Run requires a pulsed signal of at least 0.25 seconds duration. If this signal is reapplied once

the JOB # has been started, then it is ignored. When this signal is supplied following a HALT,

the JOB # stored in the queue will be activated. If no new JOB # was entered during the

previous HALT, then the JOB # located in the queue will not change and will be used again.

The Gun Mask input species whether a JOB # or toggled into GUN #n queue. This signal

is used in conjunction with the system PROGRAM SELECT and PROGRAM STROBE inputs.

A 24 VDC signal selects the GUN, a 0 VDC signal masks the GUN as ‘not used for the JOB

# selected’. Multiple gun masks can be asserted simultaneously if it is desired to load more

than one gun with the same JOB #.

Total Reset

LN-9400-00.9

Total Reset requires a pulsed signal of at least 0.25 seconds duration. This signal will reset

the daily and JOB totals for the GUN. The non-resettable total will not be effected.

21

DynaFlowTM User Manual - Installation

GUN INPUTS (Continued)

Input

Signals

Total Hold

Transparent/

PID

Analog Hold

Load

Description

This signal will stop all totals for the CHANNEL as long as the signal is supplied, even if the

GUN is running and there is uid ow. The non-resettable total will not be effected. This is

most often used during ush or soft air push cycles. It can also be used to account for only

that material which is delivered onto parts.

For GUNs congured as single-component, automatic mode only. This input is only acknowledged for run and load modes. This input must be supplied before the clean input or the trigger input if in run mode. This signal will place the CHANNEL in single-component, open loop

mode and redirect the Analog Set Point Input directly to the E/P transducer control output.

MAXIMUM FLOW RATE, MINIMUM FLOW RATE, MVR HIGH and MVR LOW parameters

have no effect while in the transparent mode. The Out of Tolerance, FLOW TOO LOW and

FLOW TOO HIGH faults will also be disabled while in the Transparent condition.

This signal applies only to GUNs congured for single-component automatic mode. This

signal will suspend PID control and freeze the analog control output to the E/P transducer to

the current value. Normal PID operation will resume when this signal is removed. This would

typically be used during ushing operations or for control stability in situations where there

are extremely quick trigger cycles or equipment limitations. The Out of Tolerance, Flow Too

Low and Flow Too High faults will also be disabled while in the Analog Hold condition.

Load requires a pulsed signal of at least 0.25 seconds duration. The LOAD input places a

manual, two-component GUN into LOAD MODE. LOAD MODE is a special way to meter

both resin and catalyst to the applicator after the system has been through a CLEAN operation while assuring accurate ratios. A GUN can be placed into the LOAD MODE directly from

the RUN MODE. For details, refer to LOAD MODE in the "Operation" section of this manual.

External Fault/

Enable

Spare Digital

Input

Analog Set

Point

Spare Analog

Input

External Fault will detect a low signal of at least 0.25 seconds duration. This signal must be

maintained high for normal operation. No uid ow will occur regardless of the operat-

ing mode if the Enable input is not active. This input is supplied as an interlock for other

equipment to automatically shut down the uid ow controller. The system must be reset after

the External Fault is returned to the high state. Reference "Recovering From Faults" in the

"Operation" section of this manual. A Global Gun Enable system input will override this input.

Not used presently.

This is a 0-10 VDC or 4-20 ma input signal (hardware selectable on the Channel Card) which

can be used to command ow rate when the applicator is in AUTOMATIC mode. The scaling

for input signal vs. ow rate is determined by the GUN JOB # parameters, MAXIMUM FLOW

RATE and MINIMUM FLOW RATE. An Analog Set Point signal less than 0.25 VDC will cause

the controller to use the SET POINT parameter located in the JOB table instead.

Not used presently.

22

LN-9400-00.9

GUN OUTPUTS

DynaFlowTM User Manual - Installation

Output

Signal

Ready

Active

Fault

Pot Life Timer

Clean/Load/

Calibrate

MVR Enable

Analog Control

Output

Description

This output is 24 VDC when the GUN is congured properly, a valid JOB is loaded.

This output is 24 VDC when the GUN is RUN mode and owing uid or prepared to ow uid.

This output is 24 VDC if a GUN fault condition occurs.

This output is 24 VDC if the Pot-Life Timer has expired. This may also initiate a horn if set to

do so in the Horn Code Conguration, set in the System Conguration.

This output is 24 VDC when the GUN is placed in Clean, Load, or Calibrate Mode.

This output is 24 VDC anytime material should be owing for the GUN. It is used to control

trigger valve(s) installed at the inlet of the MVR valve(s) on fast-trigger JOBs.

This is a 0-10 VDC or 4-20 ma output signal (selectable on the Channel Module) which is

connected to the transducer for control of the material regulator for the CHANNEL. The

output signal is limited through the use of the JOB parameters, MVR HIGH and MVR LOW.

Scaling is assumed to be 0 VDC (4 ma) equals 0 PSIG at the output of the E/P transducer

and 10 VDC (20 ma) equals 100 PSIG at the output of the transducer. The MVR HIGH and

MVR LOW JOB parameters are based on a percentage of the span of 0 to 100 PSIG. This

an MVR LOW value of 10% equals 10 PSIG.

Analog Flow

Rate Output

Fluid Line

Flushed Output

User Interface

Revision

Language

This is a 0-10 VDC or 4-20 ma output signal (selectable on the Channel Module) indicating

the actual ow rate for the CHANNEL. Scaling of the output signal is accomplished through

the use of the JOB parameters MAXIMUM FLOW RATE and MINIMUM FLOW RATE, where

0 VDC (4 ma) equals the MINIMUM FLOW RATE value and 10 VDC (20 ma) equals the

MAXIMUM FLOW RATE value.

For the Master Channel, if DIP switch 2/2 on the Interface Module is off, the total ow rate for

the gun is output and if the switch is on only the ow rate for the Master Channel is output.

For the Slave Channel, only the ow rate for the Slave Channel is output.

On guns congured for dual component operation, the pot-life expired output on the slave

(B) channel indicates when the uid line has been completely ushed. Once mixed material

has entered the uid line, this output is energized and it remains energized until the unit is

completely ushed. That is, in order to turn this bit off, the amount of material programmed

in for mixed volume must be expended from the applicator while the gun is in clean mode.

Displays the current version of the user-interface software running on the user-interface PC.

This allows users to select between English and one Alternate Language. The alternate

language text is stored on the ash drive or hard drive of the PC in les named: TEXTMESS_ALT.TXT, PARAMHLP_ALT.TXT, LABELS_ALT.TXT, SOLENOIDVALVES_ALT.TXT,

and HELP_ALT.TXT.

LN-9400-00.9

23

DynaFlowTM User Manual - Installation

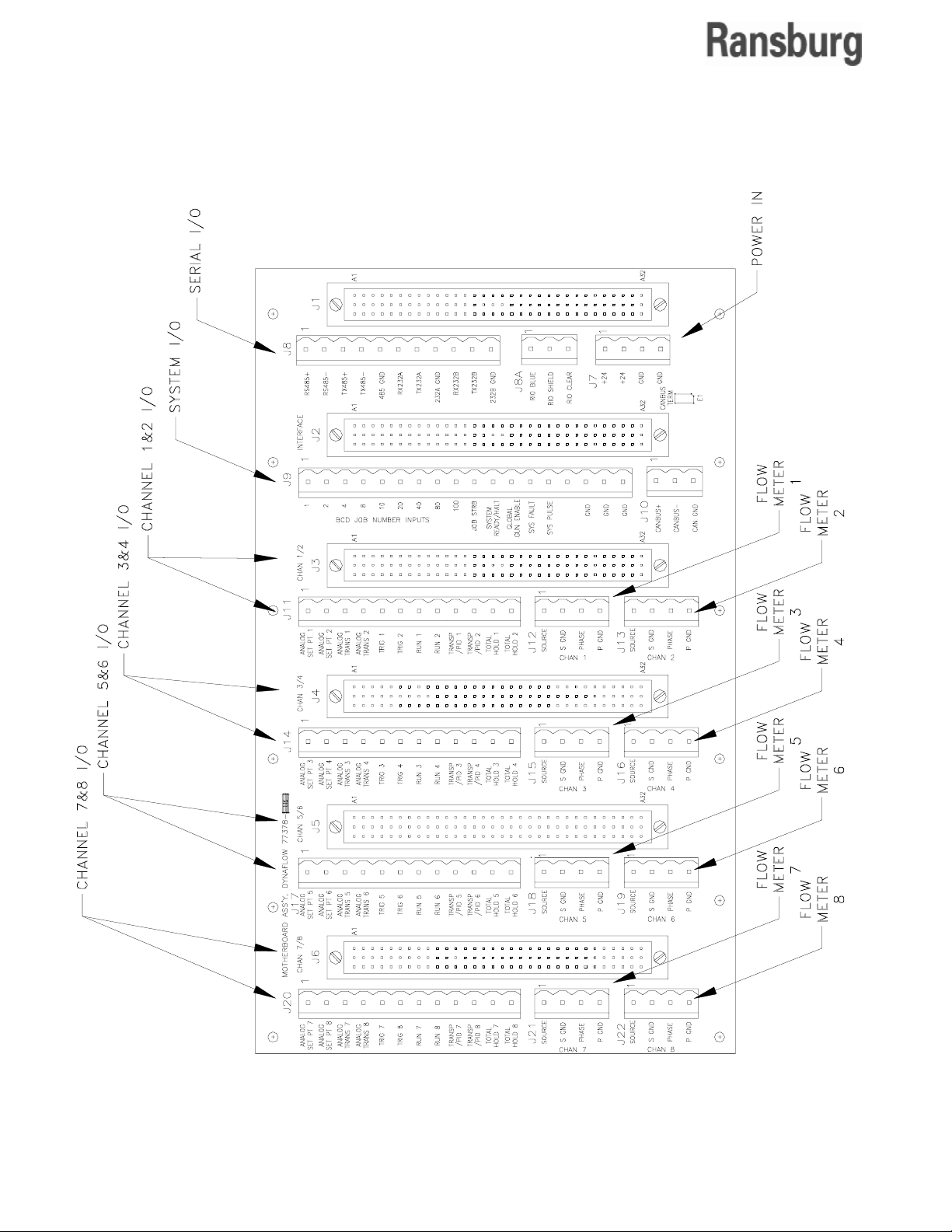

Control Rack Wiring

(Reference page 82 for terminal identication.)

24

Figure 4: Mother Board Terminals

LN-9400-00.9

DynaFlowTM User Manual - Installation

Hardware Conguration

Reference "Addendum A" in the "Appendix" section for board level hardware settings. For new

system installations, all hardware settings should

already be in the correct positions. However, if

replacing any electronic board assembly, verify

that the settings of the new board are identical to

those of the board being replaced. In the event

that the replacement board is a newer revision

and does not appear identical, refer to any documentation that was supplied with the board, or

contact your Ransburg representative or contact

Ransburg service.

Transducers

The transducers convert electrical control signals

from the uid ow controller to the air pressure

signals used to operate the material regulators.

The transducers can be either current controlled

(4-20 ma) or voltage controlled (0-10 VDC). The

transducers can be mounted separately or collectively depending on the installation requirements.

Make sure that the Channel Module jumper settings match the type of transducer being used

(refer to "Channel Module Mother Board Jumper

Settings Channel 1 I/O and Channel 2 I/O" in the

"Appendix" section).

The electrical-to-pneumatic (E/P) transducers are

supplied as separate sub-assemblies or as part

of a standard transducer panel. The transducer

panel offers a convenient way to mount transducers for 2K applications. There are typically two

transducers located in each panel with electrical

terminals and an air supply input.

The transducers may also be mounted individually

on any air drop outside of the Class 1, Division 1

hazardous location if:

1. Tubing and cable lengths do not violate the

minimum and maximum lengths specied in the

"Installation" section of this manual under

Equipment Locations".

2. The air supply meets the specications as

listed in the "Introduction" section of this manual

under "Pneumatic Specications" or those pub-

lished with the transducer.

A 1:1 volume booster may also be connected

directly to the transducer output when; operating

a DR-1

longer than recommended, or of a larger tubing

diameter is used other than that recommended.

Keep the distance between the transducer to the

material regulator as short as possible, without

violating the minimum lengths specied, to avoid

system response delays and to achieve the op-

timum uid ow characteristics for the system.

TM

Fluid Regulator, if pilot line lengths are

Material Regulators and

Flow Meters

The location and mounting of the material regulators and ow meters is specic to each installation. The information presented here is intended

as a guideline only. Reference should be made

to the supplied documentation specic to your

installation.

Fluid Supply Requirements

• The uid supply must be free of pulsation

and surges.

• A uid strainer/lter must be installed im-

mediately before the material regulators. The

elment size of the strainer should be 100

mesh or per the recommendation of your

Ransburg representative.

• For Two-Component (2K) Systems: Selector

valves are required for calibration or verify-

ing of the ow meters and should be mount ed close to the mixing block. These are sup plied as part of the standard uid panel.

Drawings created specically for your sys-

tem will provide detailed information about

valve type and location. Mount the calibra tion valves in an easily accessible area close

to the mixing block. For most applications

the ow meter and material regulator are

mounted as an assembly as close as possible

to the mixing block and calibration valves.

• For systems with fast trigger cycles that

utilize weepless MVR valves, or where

dynamic control of uid ow rates (different

ow rate during a JOB), consider installing

trigger valves (typically color control valves)

immediately upstream of the MVR valves so

that the CHANNELs may be placed in

LN-9400-00.9

25

DynaFlowTM User Manual - Installation

Analog Hold mode without causing the uid

tubes to pressurize to the material supply

pressure while the GUN is not triggered.

• For systems with fast trigger cycles or where

dynamic control of uid ow rates (different

ow rates during a JOB), mount the E/P

transducer as close to the material regulator

as possible. Remember that the transducers

MUST be mounted outside of the hazardous

location (refer to NFPA-70, NEC). For appli-

cations where the requested uid ow is for

the most part consistent, and transitional re sponse time of the system is not as critical,

then the E/P transducers may be located in

the main control panel.

• Be sure that stainless steel tubing or piping

and stainless steel ttings are used for all

uid lines and connections where metal is

desired.

• Always mount the ow meter and regula-

tor as close as feasible to the applicator. This

reduces paint line pulsation due to applicator

reciprocators and reduces the possibility of a

paint leak effecting paint delivered to the

part.

NOTES

26

LN-9400-00.9

NOTES

DynaFlowTM User Manual - Installation

LN-9400-00.9

27

DynaFlowTM User Manual - Operation

OPERATION

OVERVIEW

This section will acquaint you with the general

operation of the DynaFlow Fluid Flow Controller.

The following information describing CHANNELs,

GUNs and PARAMETERS summarize the three

main features that form the basis of the uid ow

controller.

CHANNELs

A CHANNEL consists of an electrical-to-pneumatic

(E/P) transducer, a material regulator and a uid

ow meter combination through which a single

material is controlled. One or two CHANNELs

may be congured for each GUN. Two-component

systems (sometimes referred to as 2K systems)

have two CHANNELs assigned to a single GUN.

Single-component systems (sometimes referred

to as 1K systems) have only one CHANNEL assigned to a single GUN.

Each DynaFlow control system has up to 8

CHANNELs available that can be congured to

suit the application. For example, you can use 4

CHANNELs assigned to 2 GUNs to spray 2 dual

component paints on automatic machines, and 2

CHANNELs assigned to 1 GUN to spray one dual

component paint with a manual hand spray GUN.

Please note that most GUN parameters also

apply to single-component control as well. The

CHANNEL that has the greatest ow rate in two-

component systems is typically called the Master

CHANNEL. A CHANNEL cannot be assigned to

more than one GUN.

GUNs

A GUN represents a single applicator through

which one or two materials are delivered.

If you are using single-component coatings, the

DynaFlow controller can support 8 separate single

CHANNEL GUNs operating simultaneously. If

you are using two-component materials, then 4

separate 2-CHANNEL GUNs operating

simultaneously can be supported. Adjacent

CHANNELs (1 & 2, 3 & 4, 5 & 6, and 7 & 8) can

be linked together, using 1 of 8 GUNs, to control

the ow and mixing regulation of two-component

materials. A GUN congured for two-component

operation can also operate in single-component

control mode by setting the ratio to 99, or higher.

Three Component (3-K) Operation

DynaFlow was designed for either single or twocomponent operation. Three-component operation

is possible by conguring two, two-component,

guns. The rst Gun is set up as follows:

Gun 1 =

Master Channel =

Material = Resin

Flow Controller = Color Change Value

(CCV)

Flow Meter = Standard Gear-Type

Slave Channel =

Material = 2nd Component

Flow Controller = MVR, with appropriate

size needle

Flow Meter = Piston or Gear-Type,

depending on min/max

ow rates (see Notes 4 and 5)

Operating Mode = Manual

The output of the rst Gun is then fed into the

Master Channel input of the second Gun. The

second Gun is setup as follows:

Gun 2 =

Master Channel =

Material = Output of Gun 1 (Resin + 2nd

Component)

Flow Controller = Color Change Value (CCV)

(see Notes 1, 2, and 3)

Flow Meter = Gear-Type

28

LN-9400-00.9

DynaFlowTM User Manual - Operation

Slave Channel =

Material = 3

Flow Controller = MVR, with appropriate

size needle

Flow Meter = Piston or Gear-Type,

depending on

min/max ow rates

(see Notes 4 and 5)

Operating Mode = Manual or Auto

(see Notes 1, 2, and 3)

NOTES:

1. If the output of Gun 2 supplies one or more

hand guns, then Gun 2 should be operated in

Manual mode using a CCV for the Master Chan-

nel ow controller.

2. If the output of Gun 2 supplies a single applicator, then an MVR should be used for the Mas-

ter Channel ow controller and Gun 2 should be

operated in Auto mode.

3. If the output of Gun 2 supplies multiple applicators other then hand guns, then Gun 2 should

be operated in Manual mode using a CCV for

the Master Channel ow controller. Additional

Guns should be congured for each applicator

as shown below to provide automatic ow

control for each applicator.

rd

Component

Parameters

The controlling parameters for each GUN, and for

the CHANNELs assigned to that GUN, are called

JOBs (also commonly referred to as PSETs, Color

Tables or Recipes). The JOB values dene ow

characteristics such as TARGET FLOW RATE,

MIX RATIO, FLOW TOLERANCE, etc. JOBs

include all of the parameters that may be dependent on the material used. This offers the ability

to optimize system control as needed per material

and then recall the settings each time that material is requested. There are up to 100 JOB #s for

each GUN. By saving frequently used JOB #s to

memory you can later recall them by loading the

number representing that JOB #. The parameters

are viewed and edited through the local Operator

Interface or through a remote host computer.

A set of initial parameter values is included in the

controller. The initial (default) values determine the

operating conditions of the controller when started

for the rst time. Some of these will need to be

edited during initial setup based on the installation.

Gun 3 through 6 =

Master Channel =

Material = Output of Gun 2 (Resin + 2nd + 3rd

Components)

Flow Controller = DR1

Flow Meter = Gear-Type

Operating Mode = Auto

4. Minimum ow rate for the DynaFlow is deter-

mined for each channel based on the number

of pulses/liter for the ow meter for the channel.

(Refer to "Addendum C" for ow limitations.)

LN-9400-00.9

29

DynaFlowTM User Manual - Operation

PARAMETER DESCRIPTIONS

CONFIG SYSTEM (F1)

All system parameters are password protected,

unless disabled by setting the password to zero

(0). Any time an operator wishes to change any

of these parameters, they are prompted for the

password. The password only needs to be entered

once as long as the time between keystrokes does

not exceed the Password Timer as described

below. System parameters may be edited at any

time regardless of the operating mode if no sys-

tem errors exist. Any active system errors must

be cleared.

NOTE

Any modications to the System Pa-

rameters screen data are saved only when

the operator presses the "Store Data" key

(F5), otherwise the modications will be

lost when the screen is exited with the es-

cape (ESC) key.

applications, painters will only trigger the spray

GUN enough to get atomization air to ow without

material. They use this air to blow off or feather

the part. The software would normally sense this

air ow without material ow and then fault the

GUN. This parameter allows the painter a preset

number of seconds of blow off time before faulting.

This parameter is specied in seconds, and the

default is 5 seconds. A setting of zero (0) disables

the no master ow fault.

Change Password (F3)

Used in conjunction with the Password Timer parameter. The operator can change the password

if the previous password is known. The password

is required for editing or setting all data tables and

conguration parameters. A password of '0' will

disable password operation.

Password Timeout

Once a valid password has been entered, this

parameter sets the amount of time (in min) which

is allowed from the last keystroke until password

operation is stopped. Once the timer has expired,

the user will be prompted for the password again

if password protected settings are to be edited.

Horn Code

This is a coded number that represents when the

supervisor would like the System Fault output relay

to energize. This output is normally connected to

a horn. The options desired are selected.

0 = No horn

1 = Horn when controller faults

2 = Horn when pot-life timer has expired

4 = Horn when external fault is detected

Blow Off Time

This parameter is used only if the GUN is congured as a manual GUN. The software monitors

the trigger signal to identify when the spray GUN

is triggered. (Typically this signal comes from an

air ow switch located in the atomization air line.)

If the software ever detects a GUN trigger signal

without pulses from the master channel ow meter

after the ‘Blow Off’ time has elapsed, a No Master

Flow fault is issued. This prevents a painter from

painting if the ow meter sticks. In some manual

RIO Rack Address, Rack Size,

Starting Quarter, and Baud Rate

Displays the RIO communication parameters,

as decoded from the Interface Module DIP SW1

and SW2 settings.

SIO Baud Rate and COM Port

Displays the SIO communication baud rate, as

decoded from the Interface Module DIP SW1

and SW2 settings, and the COM port (COM1 or

COM2), as dened in the GO.INI le.

Channel Module Firmware Revision(s)

Displays the rmware revision for the installed

Channel Modules.

Interface Module Firmware Revision

Displays the rmware revision for the Interface

Module.

User Interface Revision

Displays the current version of the user-interface

software running on the user-interface PC.

30

LN-9400-00.9

DynaFlowTM User Manual - Operation

System Time and Date

Displays the current date and time and permits

changing the same.

Language

This allows users to select between English and

one Alternate Language. The alternate language

text is stored on the ash drive or hard drive of

the PC in les named: TEXTMESS_ALT.TXT,

PARAMHLP_ALT.TXT, LABELS_ALT.TXT, SOLENOIDVALVES_ALT.TXT, and

HELP_ALT.TXT.

Channel Module DIP SW1 Settings

Displays the DIP SW1 settings for each installed

Channel Module.

Interface Module DIP SW1 and SW2 Settings

Displays the DIP SW1 and SW2 settings for the

Interface Module.

MANUAL - This setting is used when the user

wishes only to control the ratio of the material.

Users can 'demand' as much material as they wish

and the controller will deliver as much as possible

while keeping the ratio on target.

- Number of Channels

This parameter has three possible settings: 0,

1, and 2.

0 - This, effectively, disables the gun.

1 - This indicates that the gun is to be a single

channel, ow control only applicator.

2 - This indicates that the gun is to be congured

as a dual-channel, ratio controlled applicator.

- Master Channel

This parameter has eight possible settings: 1-8.

For single channel guns, it simply indicates which

channel will be controlling the ow control valve

and reading the owmeter for this applicator.

CONFIG GUN (F2)

GUN Conguration Parameters should not be

edited while the GUN is running. This includes

all operational modes.

NOTE

Any modications to the GUN Cong-

uration Parameters screen data are saved

only when the operator presses the "Store

Data" key (F5), otherwise the modications will be lost when the screen is exited

with the escape (ESC) key.

- Mode

This parameter has three possible settings: OFF,

AUTO, and MANUAL.

OFF - This setting completely disables the gun,

removes its data from the main screen, and places

the channels tied to the gun available for use by

another gun.

For dual-channel guns, this indicates (normally)

which channel will be controlling the resin part of

the mixed material. It is always desirable for the

master channel to have the higher ow rate of the

two materials.

- Slave Channel

This parameter has four possible values: 2, 4,

6, or 8.

It indicates which channel will be the slave (typically the catalyst) to the master channel (selected

above) for ratio control.

- Clean Channels

This parameter has four possible values: NONE,

MASTER, SLAVE, or BOTH.

This setting determines which of the uid regulators (or MVR valves) are opened to full when the

unit is put in 'Clean Mode' for ushing and lling

operations.

Default JOB#

Sets the JOB# which is loaded at power ON.

AUTO - This setting is used when the user wants

to control both the ow rate and the ratio (if it is

a plural component material) of the applicator.

LN-9400-00.9

31

Flow Tolerance Percentage

This is a number (in percent) that indicates how

much deviation above and below the set point is

acceptable. Increasing this number will reduce

nuisance faults, but may lead to inaccurate uid

metering if set too high.

3.

Measure total hose length and inside diameter.

4. Use the following formula to calculate hose

volume.

5. Add 10% to calculated value.

This number is a percent of the specied mix ratio

for each of the 2 materials that is allowed to occur

before the system faults with an OUT OF TOLERANCE fault. This is only updated after the volume

of material, as set by the Tolerance Volume, has

passed through the GUN. The accumulated ow

volume is reset to 0 upon the application of each

RUN command.

Tolerance Volume

This parameter has no effect on single-component

GUNs and only effects GUNs congured for two-

component operation.

This is the volume over which the ratio accuracy

is checked. Every time the volume of Master

CHANNEL uid specied in this parameter has

owed, the ratio is checked. The default value is

150 cc’s of the Master CHANNEL. This parameter should never be set so low that less than 10

cc’s of the slave channel has owed. If this value

is set too low, nuisance OUT OF TOLERANCE

faults will occur.

The rst time a gun is triggered after being placed

in Run mode, the Tolerance Volume is 150% of

the value entered in the job.

Mixed Volume

The amount of mixed material present in the mix

tube, uid lines, and spray GUN combined. The

uid in the spray GUN is always the material

that has been mixed the longest. The processor

keeps track of how long this material has been

mixed (Pot-Life Timer), and therefore needs to

know the volume from the mix tube to the spray

GUN. To determine the amount of mixed material

in the system:

Volume = d2 x L x 12.87

Volume = Volume in cc’s

d = Inside diameter of hose

L = Length of the uid line from the ow

meter to the spray GUN in inches

It is best to over-estimate the amount of mixed

material rather than to under-estimate it!

T

he DynaFlow system uses the Mixed Volume and

the Pot-Life Time when it monitors the ow rate of

the Gun. Pot-Life is monitored by dividing the Mixed

Volume into 40 equal sized 'buckets' of material.

When an amount of material has owed that equals

the 'bucket' volume, the 40 'buckets' are time-shifted

so the oldest 'bucket' is eliminated, representing

the material that has vacated the Mixed Volume

tubing at the GUN, and a new 'bucket' is added.

If the GUN is in either Run or Load mode, a time

value of 1 second is placed in the new 'bucket' to

represent mixed material. If the GUN is in Clean

mode, a time value of zero is placed in the new

'bucket' representing solvent. Every second, the

time values stored in the 'buckets' are incremented

if they are non-zero (i.e. contain mixed material vs.

solvent). A Pot-Life alarm condition

exists if any of the 40 'buckets' contains a time

value greater than the Pot-Life Time (see JOB

parameters). A Pot-Life alarm may be cleared by

entering a Pot-Life Time of zero seconds.

Flush Volume

This parameter is programmed in cc's. It is the

volume of ush solvent or ush solvent/air mixture

required to give an adequate ush of the uid lines

for the gun. It is used by the software to determine

when an adequate ush has occurred.