GMS

Ground Monitoring System

Ransburg

PRODUCT MANUAL

LN-9265-09.2

MODEL: A12520-XXXX

IMPORTANT: Before using this equipment, carefully

read SAFETY PRECAUTIONS, starting on page 1,

and all instructions in this manual. Keep this Service

Manual for future reference.

Product Manual Price: $50.00

LN-9265-09.2

1

NOTES

LN-9265-09.2

2

CONTENTS

Section 1: SAFETY

5

Safety Precautions

Hazards / Safeguards

Section 2: INTRODUCTION 10

FM Conguration

Inputs

Outputs

Other Considerations

Theory of Operation

Features and Benets

Specications (Environmental / Physical)

Selection Guide

Section 3: INSTALLATION 16

Mounting the Control Unit

I/O Connections

PLC Interface

AC Input Connections

Interlocks

Relay Contact Outputs

Low Voltage Cable

Section 4: OPERATION 21

Powering Up the Control Unit

Lockouts

Set-up

Calibration

Operation Sequence

Section 5: MAINTENANCE 27

Suitable Solvents for Cleaning GMS Probe

LN-9265-09.2

3

CONTENTS

Section 6: TROUBLESHOOTING 28

Fault Descriptions

Section 7: APPENDIX 31

Probe Tool Center Point Drawings

Recommended Spare Parts List

Conguration Drawing w/ Parts List

Control Unit Electrical Schematic

Control Unit Parts List

Probe Parts List

Mounting Congurations

Warranty Policies

LN-9265-09.2

4

Section 1: SAFETY

Before operating, maintaining or servicing any Ransburg electrostatic coating system, read and understand all of the

technical and safety literature for your Ransburg products. This manual contains information that is important for you

to know and understand.

This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help

you recognize this information, we use the following

symbols:

CAUTION - states information that tells

how to prevent damage to equipment or

how to avoid a situation that might cause

minor injury.

WARNING - states information to alert you

to a situation that might cause serious injury if instructions are not followed.

WARNING

• The user MUST read and be familiar with the Safety Section in this manual and the Rans-

burg safety literature therein identied.

While this manual lists standard specications and ser-

vice procedures, some minor deviations may be found

between the literature and your equipment. Differences

in local codes and plant requirements, material delivery

requirements, etc., make such variations inevitable. Compare this manual with your system installation drawings

and appropriate Ransburg equipment manuals to reconcile such differences.

Careful study and continued use of this manual will provide a better understanding of the equipment and process,

resulting in more efcient operation, longer trouble-free

service and faster, easier troubleshooting. If you do not

have the manuals and safety literature for your Ransburg

system, contact your local Ransburg representative or

Ransburg.

• This manual MUST be read and thoroughly understood by ALL personnel who operate , clean or

maintain this equipment! Special care should be taken to ensure that the WARNINGS and safety requirements for operating and servicing the equipment are followed. The user should be aware of and

adhere to ALL local building and re codes and ordinances as well as NFPA 33 SAFETY STANDARD,

2009 EDITION, prior to installing, operating, and/or servicing this equipment.

• The hazards shown on the following pages may occur during normal use of this equipment. Please

read the hazard chart beginning on page 6.

LN-9265-09.2

5

AREA HAZARD SAFEGUARDS

Spray Area Fire Hazard

Improper or inadequate operation and main-

tenance procedures will cause a re hazard.

Protection against inadvertent arcing that is

capable of causing re or explosion is lost if

any safety interlocks are disabled during operation. Frequent power supply shutdown

indicates a problem in the system requiring

correction.

Follow These Guidelines

Fire extinguishing equipment must be present in the

spray area and test periodically.

Spray areas must be kept clean to prevent the accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

• Those used for equipment ushing should have

ash points equal to or higher than those of the

coating material.

• Those used for general cleaning must have ash

points above 1000F (37.80C).

Spray booth ventilation must be kept at the rates

required by NFPA 33, 2009 Edition, OSHA and local

codes. Ventilation must be maintained during cleaning

operations using ammable or combustible solvents.

Electrostatic arcing must be prevented.

Non-factory replacement parts or unauthorized equip-

ment modications may cause re or injury.

If used, a key switch bypass is intended for use only

during setup operations. Production should never be

done with safety interlocks disabled.

Never use equipment for use in waterborne installations

to spray solvent based materials.

LN-9265-09.2

6

AREA HAZARD SAFEGUARDS

Spray Area Explosion

Improper or inadequate operation and

maintenance procedures may cause an

explosion.

Protection against inadvertent arcing that is

capable of causing re or explosion is lost if

any safety interlocks are disabled during operation. Frequent power supply shutdown

indicates a problem in the system requiring

correction.

Follow These Guidelines

Electrostatic arcing MUST be prevented.

All electrical equipment must be located outside Class

I or II, Division 1 or 2 hazardous areas, in accordance

with NFPA 33, 2009 Edition.

Test only in areas free of ammable or combustible

materials.

The current overload sensitivity (if equipped) MUST

be set as described in corresponding section of the

equipment manual. Protection against inadvertent

arcing that is capable of causing re or explosion is lost

if the current overload sensitivity is not properly set.

Frequent power shutdown indicates a problem with the

system which requires correction.

Always turn the control panel off prior to ushing, cleaning, or working on spray system equipment.

Ensure that the control panel is interlocked with the

ventilation system and conveyor in accordance with

NFPA 33, 2009 Edition.

Have re extinguishing equipment readily available and

tested periodically.

Spray Area Follow These Guidelines

Explosion - Incompatible Materials

Halogenated hydrocarbon solvents for

example: methylene chloride and 1,1,1,-Trichloroethane are not chemically compatible

with the aluminum that might be used in

many system components. The chemical

reaction caused by these solvents reacting

with aluminum can become violent and lead

to an equipment explosion.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators, triggering valves, etc. Halogenated hydrocarbon solvents

must never be used with aluminum equipment during

spraying, ushing, or cleaning. Read the label or data

sheet for the material you intend to spray. If in doubt as

to whether or not a coating or cleaning material is compatible, contact your coating supplier. Any other type of

solvent may be used with aluminum equipment.

LN-9265-09.2

7

AREA HAZARD SAFEGUARDS

Spray Area / High Volt-

age Equipment

Electrical Equipment Follow These Guidelines

There is a high voltage device that can

induce an electrical charge on ungrounded

objects which is capable of igniting coating

materials.

Inadequate grounding will cause a spark

hazard. A spark can ignite many coating

materials and cause a re or explosion.

High voltage equipment is utilized. Arcing in

areas of ammable or combustible materials

may occur. Personnel are exposed to high

voltage during operation and maintenance.

Electrical Discharge

Electrical Discharge

Follow These Guidelines

Parts being sprayed must be supported on conveyors

or hangers and be grounded. The resistance between

the part and ground must not exceed 1 mega ohm.

All electrically conductive objects in the spray area, with

the exception of those objects required by the process

to be at high voltage, must be grounded.

Any person working in the spray area must be grounded.

Unless specically approved for use in hazardous

locations, the power supply and other electrical control

equipment must NOT be used in Class I, Division 1 or

2 locations.

All electrical equipment must be located outside Class

I or II, Division 1 or 2 hazardous areas. Refer to NFPA

33, 2009 Edition.

Protection against inadvertent arcing that

may cause a re or explosion is lost if safety

circuits are disabled during operation.

Frequent power supply shutdown indicates

a problem in the system which requires

correction.

An electrical arc can ignite coating materials

and cause a re or explosion.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of ammable or combustible

material.

Testing may require high voltage to be on, but only as

instructed.

Production should never be done with the safety circuits disabled.

Before turning the high voltage on, make sure no objects are within the sparking distance.

LN-9265-09.2

8

AREA HAZARD SAFEGUARDS

Toxic Substances Mechanical Hazard

Certain material may be harmful if inhaled,

or if there is contact with the skin.

Robot Work Area Mechanical Hazard

Improper use or maintenance can lead to

hazardous conditions, particularly from un-

expected robot manipulator movement.

Follow These Guidelines

Follow the requirements of the Material Safety Data

Sheet supplied by the coating manufacturer.

Adequate exhaust must be provided to keep the air free

of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of

inhaling sprayed materials. The mask must be compatible with the material being sprayed and its concentration. Equipment must be as prescribed by an industrial

hygienist or safety expert, and be NIOSH approved.

Follow These Guidelines

Applicator adjustments or maintenance should be done

after the robot is taken out of service. Do not adjust or

repair the applicator if the robot is operating or standing

ready to start.

Refer to robot operating instructions for the procedures

to take a robot out of service.

Follow all OSHA Lockout / Tagout procedures when

performing any maintenance.

All Areas Follow These Guidelines

Improper / Inadequate Training

Improper operation or maintenance may

create a hazard.

Personnel must be properly trained in the

use of this equipment.

Personnel must be given training in accordance with

the requirements of NFPA 33, 2009 Edition.

Instructions and safety precautions must understood

prior to using this equipment.

Comply with appropriate codes governing ventilation,

re protection, operation maintenance, and housekeeping. OSHA references are sections 1910.94 and

1910.107. Also refer to NFPA 33, 2009 Edition and

your insurance company requirements.

LN-9265-09.2

9

Section 2: INTRODUCTION

The Ransburg Ground Monitoring System (GMS) monitors the ground condition of non-metallic parts and provides

feedback, increasing the margin of safety. After scanning the part with an electrostatic charge, the GMS’s control unit

circuitry monitors several variables and compares the reading against a pre-determined standard. If the reading falls

outside of an acceptable range, the notication alarm will activate, allowing adjustments or corrections to be made, eliminating rework while increasing quality. Improper grounding can cause overspray, excess paint build-up, thin lm build,

ruined parts or a safety hazard.

The GMS consists of:

• Control Unit

• Probe Detector

• Cable

• Machine Mount Bracket

The device can be used in the spray area, FM testing is successfully complete and approval pending.

The control unit consists of an electrostatic generator, input-output signal circuitry, and is microprocessor/software based.

The probe detector contains a high voltage cascade, electrode assembly and an electrical circuit capable of providing

feedback to the control unit.

Probe Detector

Control Unit

LN-9265-09.2

10

FM CONFIGURATION

This device is FM approved when congured per the drawing shown below .

LN-9265-09.2

11

INPUTS

• 110 or 220VAC Main power input

• The control unit requires an input signal for part detection. A limit switch, photo-eye, PLC or robot signal input is

acceptable.

• The device will require eld calibration to the specic application.

OUTPUTS

• The control unit will provide a visual signal to alert the end user of the detection of an ungrounded part.

• Two contact closures (UNGROUNDED & HV ON) are provided to signal the application of HV and the detection of

an ungrounded part.

• These contacts may be hooked to a PLC, horn, or light (shown in the PLC INTERFACE section of this manual).

OTHER CONSIDERATIONS

• Designed for use on non-metallic substrates only.

• Accuracy of the system is dependent on part to probe detector distance staying consistent.

• The probe to part distance should be set to 4 inches and should not vary more than ± one (1) inch.

• Probe detector must stay clean.

• Inspect the probe detector electrode every two weeks.

LN-9265-09.2

12

THEORY OF OPERATION

• The part(s) to be detected are subjected to a high voltage electrostatic charge.

• The control unit circuitry measures the amount of energy required to charge the part during the charging time select-

ed, and compares that value with an installation specic pre-set “window”.

• If the reading falls within the end user determined pre-set setpoint, the part passes the ground test.

FEATURES AND BENEFITS

• Complete Monitoring System...consists of a control unit, ground probe, mounting bracket and low voltage cable.

• Meets Stringent Safety Requirements...FM approved for use in Class 1, Division 1 painting environments.

• Utilizes Various Input Signals for Part Detection...limit switch, photo-eye, PLC, robot signal or any 0 Volt ground

trigger detection process.

• Advanced Technology...allows user to adjust control unit for specic eld calibration..

• User-Friendly Control Unit Software...allows end user to control start timer, scan duration timer and alarm outputs.

• Easy to Read Visual Indicators...users receive simple, precise feedback regarding ground path strength.

• Versatile Model...compatible with electrostatic systems, plastic or other non-metallic surfaces.

• Versatile Ungrounded Part Alert Notication...unit provides two contact closures that may be interfaced to a PLC,

horn or light for ungrounded part alert. Contact closures included are:

1. One FAULT indicator

2. One HIGH VOLTAGE ON indicator

LN-9265-09.2

13

OPERATIONS:

• Probe distance from substrate for accurate monitoring: 4 inches +/- one inch

(100 mm +/- 25 mm)

• Minimum time for measurement and result output signal: 3.5 seconds

• Low voltage cable length: 10 meters standard

15, 20, 25 & 30 meters optional

CONTROL UNIT:

• Input voltage: 110/220 VAC

• Probe output: 85 kV maximum

• Current output: 100 µA maximum

• Height:: 5.5 inches (14.0 cm)

• Width: 8.5 inches (21.6 cm)

• Depth: 7.5 inches (19.1 cm)

SPECIFICATIONS - Environmental / Physical

PROBE:

• Weight: 7.5 lbs. (3.4 kg)

• Length: 12.1 inches (30.7 cm)

• Weight: 1 lb 10 oz (.75 kg)

• Mounting bracket weight: 1 lb 3 oz (.65 kg)

• Mounting bracket adjustment angles: 0, 30, 60 & 90°

LN-9265-09.2

14

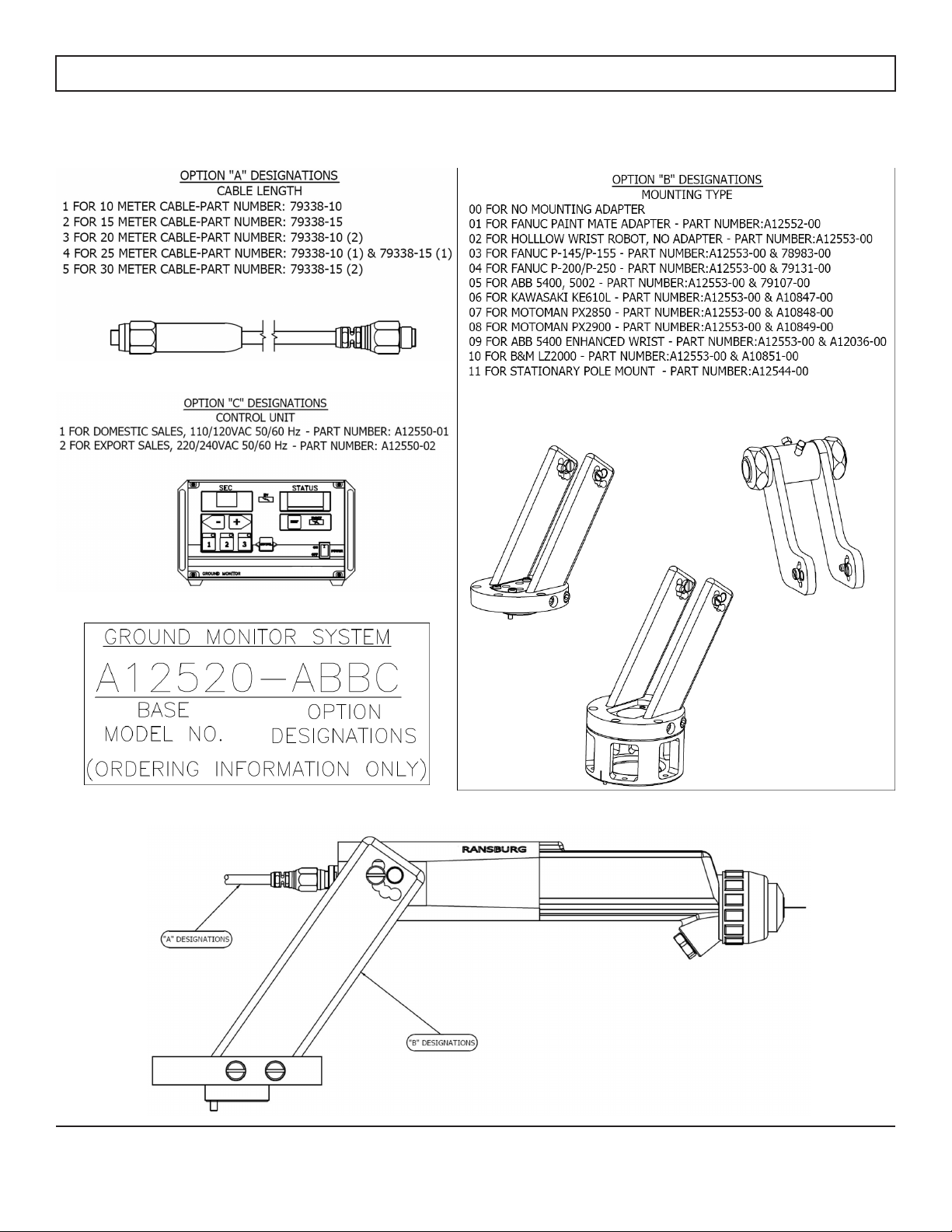

SELECTION GUIDE

A12520 - ABBC

TABLE A : LOW VOLTAGE CABLE LENGTH

1 = 10 meter

2 = 15 meter

3 = 20 meter

4 = 25 meter

5 = 30 meter

TABLE BB : MOUNTING CONFIGURATION

00 = no mounting adapter

01 = Fanuc Paint Mate

02 = hollow wrist robot (no adapter)

03 = Fanuc P-145 / P-155

04 = Fanuc P-200 / P-250

05 = ABB 5400 / 5002

06 = Kawasaki KE610L

07 = Motoman PX2850

08 = Motoman PX2900

09 = ABB 5400 enhanced wrist

10 = B&M LZ2000

11 = stationary or pole mount

TABLE C : INPUT VOLTAGE SELECTION

1 = 110/120 VAC, 50/60 Hz

2 = 220/240 VAC, 50/60 Hz

GMS Part Number Conguration

LN-9265-09.2

15

Section 3: INSTALLATION

Installation Prints:

Drawings and information contained in this section and the appendix of the manual are applicable to most installations.

However in some special cases, Ransburg may supply custom installation drawings for your specic site. It is highly

recommended that if your installation differs signicantly from the installation drawings supplied by Ransburg, you notify

your Ransburg representative to ensure that standard installation practices are not violated and to have your prints up-

dated to reect the installation accurately for future reference.

Equipment Locations:

The GMS control panel must be located outside of the hazardous area. If in doubt, contact your Ransburg representa-

tive for clarication.

MOUNTING THE CONTROL UNIT

The GMS control panel has an optional mounting kit available 79527-00. This kit allows either top mounting or back

mounting, with either swing-away or xed attachment. There are four convenient ways of mounting the enclosure assembly using the included hardware. See the Appendix section for the different mounting congurations available.

C A U T I O N

When mounting the control unit to a wall or ceiling, the 79527-00 Mounting Kit

should be used. If mounting to a non-metallic wall or ceiling, the mounting screws

must be secured to the wall or ceiling studs. If mounting to a metal wall or ceiling

(such as a spray booth) the wall or ceiling must be at least 0.050” (1.2mm) thick. In

both cases, the customer must supply the screws to attach the brackets to the wall

or ceiling. These screws should be at least 1/4” (6mm) in diameter.

I/O CONNECTIONS

For maximum noise immunity, I/O wiring should be run in conduit or cables having a foil shield with an overall braided

shield. The foil shield provides 100% shielding, while the braid provides a means of making proper 360° shield termina-

tions at the cable to cabinet connection points. To make I/O connections using shielded cable, perform the following:

1. Remove the cable grommet hardware from the I/O connector housing.

2. Route the desired length of I/O cable through the connector housing and mark 1” span of cable that passes

through connector housing to be stripped to braid.

3. Remove cable and strip marked 1” section to cable braid.

4. Slide the cable grommet hardware onto the cable.

5. Route the cable back through the connector housing and connect its wires to the desired I/O terminals inside

the GMS Control Unit or power supply.

6. Tighten the cable grommet ensuring the grommet spring makes 360° contact with the exposed braid of the

cable, for maximum noise immunity.

7. For maximum noise immunity, connect the braid of the cable to earth ground at the end opposite the control

unit or power supply.

LN-9265-09.2

16

PLC INTERFACE

The PLC interface for the Ground Monitor is very simple (Figure 1).

1. There is an input (2TB-5) to tell the process to initialize. This sinking input circuit needs a ground supplied to initialize the process.

2. The fault output is based on a non-grounded part detection. If a non-grounded part is detected a relay will close a

set of dry contacts (2TB-1 to 2TB-2) signaling a device of the users choice (light, horn, PLC, etc).

3. A “High Voltage On” output is also available to signal an external device (light, horn, PLC, etc). A set of dry contacts

(2TB-3 to 2TB-2) close when the high voltage is On. See page 20 for the maximum allowable electrical ratings for

the relay contacts.

NOTE: 2TB is common to both HV out and FAULT output

Figure 1

LN-9265-09.2

17

AC INPUT CONNECTIONS

For non-conduit installations, plug the detachable AC line cord into the receptacle on the rear of the control unit. Plug the

other end of the line cord into a properly grounded 120 volt AC outlet.

For installations where it is required to run the AC input wiring in conduit, perform the following.

1.Ensure the AC line cord is unplugged and remove the AC inlet receptacle wiring from TB1-N, TB1-L1, TB1-EARTH GROUND (see

gure 2)

2. Remove the mounting hardware from the AC inlet receptacle and remove it from the rear of the control unit.

3. Install the conduit adapter plate (supplied) in the hole where the AC inlet receptacle was removed. (see Figure 2)

4. Install the AC input wiring (0.8mm2 (18 AWG) minimum) through the conduit adapter plate using conduit and wire to TB1 as follows.

Hot/Line to TB1-L1

Neutral/Common to TB1-N

Ground to TB1-EARTH GROUND

NOTE

When using conduit to route the AC input wiring to the control unit, the last several feet of conduit attached to the control unit should be

of a exible type, such that the control unit chassis can be slid out of its enclosure for testing and set-up purposes.

Figure 2

LN-9265-09.2

18

INTERLOCKS

Interlocks required by code are as follows:

• Booth Fan Interlock - When the booth fan is on, a contact closure is made.

• Conveyor Interlock - when the conveyor is moving a contact closure is made.

W A R N I N G

Failure to connect interlocks could result in re or explosion.

W A R N I N G

ALWAYS ensure that high voltage is OFF before cleaning the applicator with solvent. NEVER clean the spray applicator with high voltage ON, as this is a severe

re hazard and risk to personnel safety.

To install the control unit interlocks perform the following:

1. Turn the control unit off and remove the fuses.

2. Loosen the front panel screws and slide the control unit chassis out.

3. Using a small blade screwdriver, remove the factory installed test jumper from TB1-L2 to TB1-L3 (Figure 3).

4. Using a shielded cable for the interlock wiring (supplied by user), route through the interlock connector on the

rear of the control unit and terminate to TB1-L2 and TB1-L3. The shielded cable must have a minimum rating of

300V and 105°C and its conductors should be 0.8mm2 (18 AWG) minimum. Secure the cable to the interlock

connector so that the shield of the cable is connected to the chassis of the enclosure.

5. Slide the chassis back in, secure the front panel screws, and replace the fuses.

NOTE:

Some codes may require the interlock wiring to be run in conduit. In this case shielded cable is not necessary, but

the conductors used should still meet the ratings specied above.

The interlock contacts (supplied by user) should be rated for at least 1-amp at 240 volts AC.

Figure 3

LN-9265-09.2

19

RELAY CONTACT OUTPUTS

A set of relay contacts for high voltage (CR1) and fault (CR2) conditions is provided at TB2-3 and TB2-1 (Figure 4). One

end of these relay contacts are connected together and also connected to a source input terminal at TB2-2 (Figure 4).

When a source voltage is present at TB2-2 and either the high voltage is on or a fault condition occurs, the source volt-

age will become available at the output end of the corresponding contact. Maximum contact ratings are as follows:

MAXIMUM CONTACT RATINGS ( RESISTIVE LOADS)

DESCRIPTION DC AC

MAX SWITCHING CAPACITY 60 W 62.5VA

MAX OPERATING CAPACITY 30 VDC 125 VAC

MAX OPERATING CURRENT 2A .5A

When wiring to TB2, use a shielded cable and route the wiring through the standard I/O connector.

An internal 24VDC source voltage is available at TB2-4. Using a jumper wire, this voltage may be connected to TB2-2

to be used as the source voltage for the relay contact outputs. In this case, the total current sourced should not exceed

1-amp (Figure 3).

Figure 4

LOW VOLTAGE CABLE

Connect the low voltage cable from the control unit to the applicator using a wrench to tighten.

CAUTION

DO NOT over tighten the low voltage connection at the applicator.

The plastic parts could be damaged.

With the GMS design, multiple cables may be connected together to create the length required,

up to a maximum of 30m (100 ft.). To connect the cables, insert the male end of one cable into the female end of the

other. Tighten both cable connectors against each other using two (2) 16mm (5/8”) open-end wrenches.

LN-9265-09.2

20

Section 4: OPERATION

POWERING UP CONTROL UNIT

When the AC power is turned on, the unit will display the set point number on the SEC display and the software revision

level in the STATUS display for 2-3 seconds.

LOCKOUTS

There are lockouts that may be done at the PC board (see Appendix section). These lockouts may be used individually

or in combination as required. If the jumpers are disconnected, the original functions are re-enabled. After changing any

jumpers, the AC power must be cycled for the new setting to take effect.

Front Panel Lockout

This feature locks out any changes to the timers from the front panel of the control unit. Default from the factory the front

panel lock out is disabled.

1. Set the timers to the desired value

2. Turn AC power off and access the interior of the control unit.

3. Place the jumper across the two (2) pins at location 16 on the main PC board (see Appendix section).

4. Close the control unit and turn AC power back on. Pressing the front panel +, -, or setpoint buttons will now

have no effect on the timers.

s using the front panel buttons. This must be set

LN-9265-09.2

21

prior to installing the jumper.

SET-UP

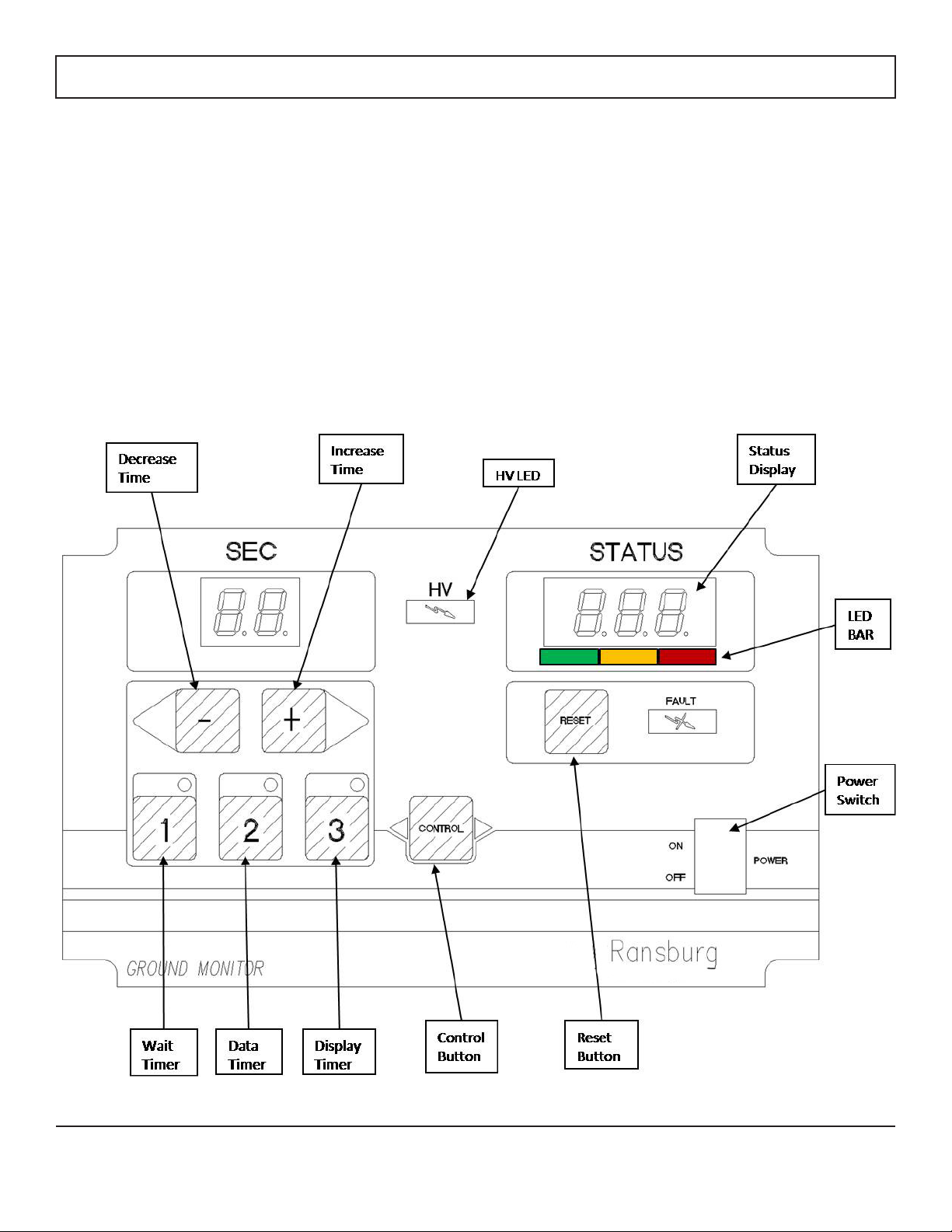

There are 3 timers to set before operating the Ground Monitor:

1. WAIT TIMER: The rst timer is the wait time. This will be the time to wait before turning on High Voltage

after a signal to start the process has been received. (default: 3 sec)

2. DATA TIMER: The second timer sets how long the sample will be. This is High Voltage on time. The mini-

mum settable time is 2 seconds, the average time necessary to get a good reading is 3.5 seconds. (default:

5 sec)

3. DISPLAY TIMER: The third timer sets the amount of time the result is shown for. Note: if another part input

is received during this countdown, the entire process will start over at step 1. (default: 5 sec)

LN-9265-09.2

22

CALIBRATION

1. Place the part to be checked in front of the Ground Monitor probe

2. Assure target distance is 4” (±1”)

3. Use a 1 KiloVolt (KV) megger to verify a good earth ground is present on part. The NFPA states a good ground as 1

Meg Ohm or less value.

4. Press the “Control” button on the controller. The entire LED bar (green yellow, and red) under status display will light

up to indicate the unit is in calibration mode.

5. Press the red “Override” button located on the back of the controller (you may need to hold the button in for a sec-

ond). This button manually begins a cycle.

6. When the high voltage comes on allow the numbers under “Status” to settle and then press the “Control” and “Reset”

buttons at the same time to store the calibration value. The value will typically be in the rang of 60 – 80. The default

value is 55.

7. When the calibration value is accepted the LED light bar will turn off.

8. You are now ready to operate the ground monitor.

LED Bar

Back of ControllerFront of Controller

Control Button Reset Button

Special Keys:

1 and Reset - Pressing these keys together will display the saved set point in the status window. The value will display

for 5 seconds, and then go back to regular mode

2 and Reset - Pressing these keys together will display the cumulative amount of hours the HV has been on.

Override Button

3 and Reset - Will reset the set point and timers to factory default values. The unit must be turned off and back on for

the default values to take effect.

Defaults:

Timer 1 = 3.0 seconds Timer 3 = 3.0 seconds

Timer 2 = 5.0 seconds Setpoint = 55

LN-9265-09.2

23

OPERATION SEQUENCE EXAMPLE

LN-9265-09.2

24

OPERATION SEQUENCE EXAMPLE (continued)

LN-9265-09.2

25

OPERATION SEQUENCE EXAMPLE (continued)

LN-9265-09.2

26

Section 5: MAINTENANCE

SUITABLE SOLVENTS FOR CLEANING GMS PROBE

When cleaning the probe, a suitable solvent for cleaning depends on the part(s) of the applicator to be cleaned and the

material that needs to be removed. Ransburg recommends that all exterior cleaning be done with non-polar solvents

to prevent a conductive residue on critical components. We also understand that some of these solvents do not always

meet the cleaning needs of some materials. If conductive polar solvents are used to clean the applicator components, all

residues must be removed using a non-conductive non-polar solvent (i.e. high ash Naphtha). If there are any questions

as to what solvents are best for cleaning, contact your local Ransburg distributor and/or your paint supplier. The GMS

probe and low voltage cable assemblies should not be submerged or soaked in solvent. However, the outer surfaces of

these items can be wiped with a suitable cleaning solvent. All electrical components cannot be cleaned or soaked in any

solvents.

WARNING

The user MUST read and be familiar with the safety instructions in this manual.

If compressed air is used in cleaning, REMEMBER that high pressure air can be dangerous and should

NEVER be used against the body. It can blind, deafen, and may even penetrate the

skin. If used for cleaning equipment, the user should wear safety glasses.

ALWAYS turn the control unit’s power off prior to cleaning and servicing the equipment.

Be SURE the power is OFF and the system is grounded before using solvent to clean ANY

equipment.

DO NOT operate a faulty applicator!

Use of ungrounded or plastic containers may cause re or explosion.

Cleaning of the exterior surface of the applicator should be done with non-polar solvents. If

cleaning requires the use of polar solvents, the applicator should be wiped down with non-polar

solvent prior to going back into use. Using polar solvents will leave a semi-conductive lm on

the surface of the applicator that will effect efciency of the applicator and cause damage to the

components.

LN-9265-09.2

27

Section 6: TROUBLESHOOTING

FAULT DESCRIPTIONS

When a fault occurs, the Fault Indicator on the front of the control unit will light, a fault code will be displayed on the status meter. Faults can be reset by pressing the Reset button on the front of the control unit .

Cable Fault (CF)

This fault will occur if high voltage is active and the microprocessor detects that no current is being supplied to the applicator. Typical causes include a broken or improperly connected low voltage cable. Other causes could include loose

wiring in the control unit or a faulty cascade circuit in the applicator. When this fault occurs, determine the cause of the

problem, then press the reset button.

Over Voltage Fault (OU)

This fault will occur if the microprocessor detects the unit is trying to output voltage above that

required for the application. If this occurs, reset the control unit. If this fault continues to occur, replace the main PC

board.

Safety Fault (SF)

If this fault occurs, the fault indicator at the control unit will illuminate, a SF indication will show in the status display. This

fault will occur if the microprocessor detects the unit is trying to output voltage to the applicator with no trigger. If this

occurs, reset the fault from the control unit. If this fault occurs repeatedly upon reset, replace the main PC board. Other

causes of this fault include a broken ground path between the applicator and control unit caused by a faulty cable or plug

assembly.

LN-9265-09.2

28

FAULT DESCRIPTIONS (continued)

Overload Fault (OL)

This fault will occur if the current output reaches 90uA.

Remove the condition causing excess microamps and reset the fault. Typically the target distance from the probe to the

part is too close. Back up target distance and re-calibrate.

Low Current Set point Fault (LC)

This fault will occur if the set point is set below a factory preset threshold. This is to prevent unacceptable calibration

values. If this occurs use an insulation test meter with at least 1KV output (Megger), to check that the target is properly

grounded, and verify the target distance is 4 inches, then re-calibrate the unit. To recover from a LC fault the calibration

must be set very quickly, then go back and allow the voltage to settle and reset the set point again.

Current Limit Fault (CL)

This fault will occur if the output current exceeds the maximum current by more than 20 uA for 2-3 seconds. If this oc-

curs, reset the fault from the applicator or control unit. If this fault occurs repeatedly, investigate the main PC board or

applicator barrel for the cause.

LN-9265-09.2

29

FAULT DESCRIPTIONS (continued)

Voltage Feedback Fault (UF)

This fault will occur if the microprocessor detects a loss of the voltage feedback signal. If this occurs, reset the fault from

the control unit. If this fault occurs repeatedly, replace the main PC board.

Feedback Fault (FF)

This fault will occur if the microprocessor detects a loss of the current feedback signal from the applicator. If this occurs,

reset the fault from the control unit. If this fault occurs repeatedly, investigate the main PC board, cable, plug assembly,

or cascade for the cause.

LN-9265-09.2

30

Section 7: APPENDIX

4.00

5.05

16.96

20.96

18.76

22.77

0 DEGREE TOOL CENTER POINT @ 4" TARGET DISTANCE

BRACKET

X

Y

PAINT MATE

5.05 in (128.3 mm)

20.96 in (532.4 mm)

HOLLOW WRIST

22.77 in (565.7mm)

5.05 in (128.3 mm)

XYX

Y

GMS PROBE 0° TOOL CENTER POINT DRAWING

LN-9265-09.2

31

GMS PROBE 30° TOOL CENTER POINT DRAWINGS

4.00

20.34

18.53

15.08

16.88

10.40

12.41

30 DEGREE TOOL CENTER POINT @ 4" TARGET DISTANCE

BRACKET X Y

PAINT MATE

12.41 in ( 315.2 mm)

18.53 in (470.7 mm)

HOLLOW WRIST

20.34 in (516.6 mm)

12.41 in ( 315.2 mm)

30°

X

Y

LN-9265-09.2

32

GMS PROBE 60° TOOL CENTER POINT DRAWINGS

4.00

12.56

10.72

12.71

14.55

14.12

12.72

10.88

17.56

60 DEGREE TOOL CENTER POINT @ 4" TARGET DISTANCE

BRACKET

X

Y

PAINT MATE

17.57 in (446.3 mm) 12.71 in (322.8 mm)

HOLLOW WRIST

17.57 in (446.3 mm) 14.55 in (369.6 mm)

X

Y

LN-9265-09.2

33

GMS PROBE 90° TOOL CENTER POINT DRAWINGS

6.96

8.72

5.15

6.96

15.16

4.00

19.14

90 DEGREE TOOL CENTER POINT @ 4" TARGET DISTANCE

BRACKET X Y

PAINT MATE

19.14 in (486.2 mm)

5.15 in (130.8 mm)

HOLLOW WRIST

6.96 in (176.8 mm)

19.14 in (486.2 mm)

X

Y

LN-9265-09.2

34

GMS PROBE 120° TOOL CENTER POINT DRAWINGS

1.60

4.00

.24

16.72

.40

2.2

9.36

7.52

120 DEGREE TOOL CENTER POINT @ 4" TARGET DISTANCE

BRACKET X Y

PAINT MATE

16.72 in (424.7 mm)

-2.22 in (-56.4 mm)

HOLLOW WRIST

-0.41 in (-10.4 mm)

16.72 in (424.7 mm)

X

Y

LN-9265-09.2

35

CONTROL UNIT ELECTRICAL SCHEMATIC

LN-9265-09.2

36

GMS CONTROL UNIT PARTS LIST

PARTS LIST

DESCRIPTION

PART NUMBER

QTY

ITEM

CHASSIS ASS'Y., MACH., 9050

79497

11

HOLDER, FUSE76469-0222

SWITCH76434-01

1

3

LINE FILTER ASS'Y., AC

79491-00

14

FUSE, SLOWBLOW, 250VAC 1A72771-06

15

ASS'Y., OUTLET

79495-00

1

6

POWER SUPPLY,24 V79428-00

1

7

CABLE GLAND,EMC SPRINGA113557-01

1

8

NUT, EMC GLANDA11358-01

1

9

CORD, LINE76449-02

1

10

MEMBRRANE, SWITCH ASSEMBLY79343-01

111

ASS'Y., PC BOARD, GMS

79390-26

1

12

BLOCK, TERMINAL76468-04213

LABEL, TERMINAL BLOCK76463-04

114

HOLE PLUG, 9/16 DIA

72596-01

115

HOLE PLUG, 7/16 DIA

72596-11216

RECEPTACLE, FEMALE CABLE76874-02

117

ENCLOSURE ASSY, 9050 CASCADE79512

1

18

PUSHBUTTON SWITCHA12569

1

19

PROTECTIVE GUARD, PUSHBUTTON SWITCHA12570

1

20

LABEL, TERMINAL BLOCK76463-05

1

21

HANDLE, ROUND, INSTRUMENTATIONLSMM0023-02

1

22

7

17

8

16

20

19

10

13

14

4

12

13

21

18

22

549

3

1

6

9

15

16

11

LN-9265-09.2

37

GMS PROBE PARTS LIST

PARTS LIST

DESCRIPTION

PART NUMBER

QTY

ITEM

ASS'Y, BARREL, SOLO

79736-0011

GROUND MONITOR BODYA12516-00

1

2

FLUID PASSAGE PLUG, SOLO BARRELA12513-00

1

3

CASCADE ASSY, SOLO79600-01

14

PLUG ASSY, L.V.A12517-00

15

AIR CAP SWIRL AIR NOZZLE79542-00

1

6

FLUID NOZZLE, SWIRL AIR79544-00

1

7

NUT, RETAINING, AIR NOZZLE79724-00

1

8

PRESSURE REDUCER, ATOMIZING AIR, VECTOR SOLO79809-00

1

9

SLOTTED SET SCREW, NYLON

79798-04

1

10

M5 x .8 x 40 mm MACHINE SCREW

A12540-00

3

11

NEEDLE SHROUDA12519-00

112

KIT, NEEDLE SHAFT ASSEMBLY79853-01113

REAR LABEL

A12568-00

1

14

16

CABLE W/ MOLDED CONNECTORS

79338-XX

1

16

GREASE, DI-ELECTRIC

LSCH0009-00

1

17

17

GASKET, BARREL79832-201

1

15

11

15

14

2

1

9

8

6

3

4

13

12

10

5

7

LN-9265-09.2

38

PANEL MOUNTING CONFIGURATIONS

79490-0025

79488-00

1

4

79489-001

3

79493-008

2

---

------

DESCRIPTION

PART NUMBER

QTY

ITEM

Parts List

5

2

4

5

2

5

3

2

5

2

2

5

2

3

5

2

5

2

4

5

--SCREW, PAN HEAD, 8-32 PHILLIPS, S.S.

BRACKET, MACH., 9050 CASCADE

HINGE, MACH., 9050 CASCADE ENCLOSURE

BRACKET, WALL MOUNT, 9050 CASCADE

LOCK WASHER,STD., HELICAL SPRING

SERVICE INSTRUCTION

SI-0222-06

7734-03

1

6

7

6

GMS ENCLOSURE

REF.

GMS ENCLOSURE

REF.

GMS ENCLOSURE

REF.

GMS ENCLOSURE

REF.

LN-9265-09.2

39

FRONT PANEL LOCKOUT

LN-9265-09.2

40

MANUAL CHANGE SUMMARY

This manual was published to supersede Service

manual LN-9265-09.1 Ground Monitor System to

make the following changes:

1. Update relay contact specications, page 20.

2. OL fault description updated. Cannot be disabled in

GMS revision 1.00 or 1.01 software. Page 29.

3. GMS cascade part number now 79600-01. page 38

4. Update appendix drawings.

5.

LN-9265-09.2

41

WARRANTY POLICIES

LIMITED WARRANTY

Ransburg will replace of repair without charge any part/or equipment that fails within the specied time (see below) because of faulty workmanship or material, provided that the equipment has been used and maintained in accordance with

Ransburg’s written safety and operating instructions, and has been used under normal operating conditions. Normal

wear items are excluded.

THE USE OF OTHER THAN RANSBURG APPROVED PARTS VOIDS ALL WARRANTIES.

SPARE PARTS: One hundred and eighty (180) days from date of purchase, except for rebuilt parts (any part number

ending in “R”) for which the warranty period is ninety (90) days.

EQUIPMENT: When purchased as a complete unit, (i.e. guns, power supplies, control units, etc.), is one (1) year from

date of purchase.

WRAPPING THE APPLICATOR IN PLASTIC WILL VOID THIS WARRANTY.

RANSBURG’S ONLY OBLIGATION UNDER THIS WARRANTY IS TO REPLACE PARTS THAT HAVE FAILED BECAUSE OF FAULTY WORKMANSHIP OR MATERIALS. THERE ARE NO IMPLIED WARRANTIES NOR WARRANTIES OF EITHER MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. RANSBURG ASSUMES NO

LIABILITY FOR INJURY, DAMAGE TO PROPERTY OR FOR CONSEQUENTIAL DAMAGES FOR LOSS OF GOODWILL OR PRODUCTION OR INCOME, WHICH RESULT FROM USE OR MISUSE OF THE EQUIPMENT BY PURCHASER OR OTHERS.

EXCLUSIONS:

If, in Ransburg’s opinion the warranty item in question, or other items damaged by this part was improperly installed,

operated or maintained, Ransburg will assume NO responsibility for repair or replacement of the item or items. The

purchaser, therefore will assume all responsibility for any cost of repair or replacement and service related costs if applicable.

LN-9265-09.2

42

NOTES

LN-9265-09.2

43

Product Manual Price: $50.00 (U.S.)

Manufacturing

1910 North Wayne Street

Angola, Indiana 46703-9100

Telephone: 260-665-8800

Fax: 260-665-8516

Technical Service - Assistance

320 Phillips Ave.

Toledo, Ohio 43612-1493

Telephone (toll free): 800-233-3366

Telephone: 419-470-2021

Fax: 419-470-2040

Technical Support Representatives can direct you to the appropriate telephone number for ordering spare parts.

© 2013 Ransburg. All rights reserved.

Models and specications subject to change without notice.

Form No. LN-9265-09.2

Litho in U.S.A.

06/12

LN-9265-09.2

44

Loading...

Loading...