Ransburg A12374-XXX User Manual

SERVICE MANUAL

AA-08-01.1

January - 2013

EVOLVER 303TM DUAL PURGE SOLVENTBORNE

ROBOTIC ATOMIZERS

MODEL: A12374-XXX

IMPORTANT: Before using this equipment, carefully

read SAFETY PRECAUTIONS, starting on page 1, and all

instructions in this manual. Keep this Service Manual

for future reference.

With

Technology

Service Manual Price: $50.00 (U.S.)

CONTENTS

SAFETY:

Evolver 303 Dual Purge Robotic Atomizers - Contents

PAGE

1-4

SAFETY PRECAUTIONS.............................................................................................................

HAZARDS / SAFEGUARDS.........................................................................................................

INTRODUCTION:

RANSBURG ELECTROSTATIC PROCESS......................................................................

EVOLVER 303 DUAL PURGE SOLVENTBORNE

SPRAY APPLICATORS..............................................................................................................

SPECIFICATIONS.......................................................................................................................

EVOLVER 303 DUAL PURGE APPLICATOR ASSEMBLY.....................................................

EVOLVER 303 DUAL PURGE TUBING BUNDLE ASSEMBLY (METRIC)..............................

EVOLVER 303 DUAL PURGE SOLVENTBORNE

ROBOTIC APPLICATORS..........................................................................................................

FEATURES..................................................................................................................................

A12374-XXX EVOLVER DUAL PURGE SPRAY

APPLICATOR ASSEMBLY..........................................................................................................

TOOL CENTER-POINT COMPARISONS TABLE.....................................................................

INSTALLATION:

EVOLVER 303 DUAL PURGE ROBOTIC ATOMIZER

INSTALLATION............................................................................................................................

POWER SUPPLY ASSEMBLY...................................................................................................

MOUNTING..................................................................................................................................

ELECTRICAL AND FIBER OPTIC CONNECTIONS.................................................................

FLUID CONNECTIONS...............................................................................................................

TYPICAL INSTALLATION...........................................................................................................

LOW VOLTAGE CABLE CONNECTIONS.................................................................................

EVOLVER 303 DUAL PURGE SPRAY APPLICATOR

AIR AND FLUID LAYOUT...........................................................................................................

APPLICATOR AND MANIFOLD ASSEMBLY............................................................................

LOW VOLTAGE CABLE INSTALLATIONS................................................................................

LOW VOLTAGE CABLE ON ROBOT.........................................................................................

BULKHEAD CUT-OUT DIAGRAM..............................................................................................

ROBOT PLATE............................................................................................................................

QUICK-DISCONNECT CABLES................................................................................................

SIGNAL IDENTIFICATION TABLE BELLS (APPLICATORS)...................................................

APPLICATOR AND MANIFOLD ASSEMBLY / PARTS LIST....................................................

SPRAY / BELL APPLICATOR TRIGGERING............................................................................

CONVERSION SCHEMATIC.....................................................................................................

TUBING BUNDLE INSTALLATION............................................................................................

BUNDLE LUBRICATION.............................................................................................................

1

2-4

5-12

5

5-6

7

8

8

9

10

11

12

13-24

13

13

13

13

13

13

14

15

16-17

17-18

19

20

20

20

21

22

23

23

24

24

(Continued On Next Page)

Evolver 303 Dual Purge Robotic Atomizers- Contents

CONTENTS (Cont.)

PAGE

OPERATION:

SPRAY APPLICATOR CONTROLS...........................................................................................

HVLP SPRAY...............................................................................................................................

FLUID VALVE CONTROLS.........................................................................................................

DUAL PURGE SPRAYING.........................................................................................................

DUAL PURGE AIR AND FLUID PASSAGE SCHEMATIC........................................................

MAINTENANCE:

ROUTINE MAINTENANCE SCHEDULE....................................................................................

PROCEDURES............................................................................................................................

SPRAY HEAD REMOVAL / ASSEMBLY / PARTS LIST............................................................

SERVICE......................................................................................................................................

SPRAY HEAD ASSEMBLY..........................................................................................................

79138 EVOLVER 303 DUAL PURGE APPLICATOR HEAD

ASSEMBLY / PARTS LIST...........................................................................................................

REMOVING SPRAY APPLICATOR FROM THE

REAR MANIFOLD ASSEMBLY...................................................................................................

EVOLVER 303 DUAL PURGE 60° SINGLE HEAD

APPLICATOR ASSEMBLY / PARTS LIST..................................................................................

DISASSEMBLY OF A12373 SPRAY APPLICATOR

ASSEMBLY / PARTS LIST...........................................................................................................

CASCADE WIRE PLUG ASSEMBLY..........................................................................................

LOW VOLTAGE CABLE REMOVAL / PARTS LIST...................................................................

A12376-00 DUAL PURGE VALVE MANIFOLD

DISASSEMBLY / PARTS LIST.....................................................................................................

TROUBLESHOOTING GUIDE....................................................................................................

25-28

25

25-26

26

26-27

28

29-52

29-30

30-32

33-34

35

35-38

39-40

41

42

43-44

45

45-47

48

49-52

PARTS IDENTIFICATION:

A12374 SPRAY APPLICATOR ASSEMBLY W/A12283

TUBING BUNDLE ASSEMBLY/ PARTS LIST............................................................................

79138-01/-04 CONVENTIONAL AND 79138-02/-05 HVLP

SPRAY HEAD ASSEMBLY / PARTS LIST..................................................................................

79179-00 SINGLE HEAD 60° / PARTS LIST...............................................................................

79243-00 DUAL HEAD 60° / PARTS LIST...................................................................................

79180-00 SINGLE HEAD 90° / PARTS LIST...............................................................................

79224-00 DUAL HEAD 90° / PARTS LIST...................................................................................

A12373 MANIFOLD ASSEMBLY / PARTS LIST.........................................................................

A12375-01 REAR PLATE ASSEMBLY (SINGLE PURGE) /

PARTS LIST..................................................................................................................................

A12283-XXXXXXX TUBING BUNDLE ASSEMBLY (METRIC) /

PARTS LIST..................................................................................................................................

SIGNAL IDENTIFICATION TABLE BELLS (APPLICATORS)....................................................

(Continued On Next Page)

53-78

53-54

55-57

58

58

59

59-60

61-62

63-64

65-66

67

Evolver 303 Dual Purge Robotic Atomizers - Contents

CONTENTS (Cont.)

PARTS IDENTIFICATION (Cont.):

A12283-XXXXXXX TUBING BUNDLE ASSEMBLY MODEL

IDENTIFICATION (METRIC).......................................................................................................

A10406 OR LECU5004 MICROPAK CONTROL UNIT...............................................................

ACCESSORIES AND SERVICE KITS........................................................................................

REPAIR KITS................................................................................................................................

SERVICE PARTS.........................................................................................................................

LUBRICANTS AND SEALERS....................................................................................................

EVOLVER 303 DUAL PURGE RECOMMENDED SPARE PARTS..........................................

PAGE

53-78

68-69

70

70-73

74

75

75

76-77

WARRANTY POLICIES:

LIMITED WARRANTY..................................................................................................................

79

79

Evolver 303 Dual Purge Robotic Atomizers - Safety

SAFETY

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any Ransburg electrostatic coating system, read and understand all of the technical and safety literature for your

Ransburg products. This manual contains information

that is important for you to know and understand. This

information relates to USER SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this

information, we use the following symbols. Please

pay particular attention to these sections.

A WARNING! states information to alert you to a situ-

ation that might cause serious injury if instructions

are not followed.

A CAUTION! states information that tells how to

prevent damage to equipment or how to avoid a

situation that might cause minor injury.

A NOTE is information relevant to the procedure in

progress.

While this manual lists standard specications and

service procedures, some minor deviations may be

found between this literature and your equipment.

Dierences in local codes and plant requirements,

material delivery requirements, etc., make such

variations inevitable. Compare this manual with

your system installation drawings and appropriate

Ransburg equipment manuals to reconcile such

dierences.

W A R N I N G

!

> The user MUST read and be familiar with the

Safety Section in this manual and the Ransburg

safety literature therein identied.

> This manual MUST be read and thoroughly

understood by ALL personnel who operate, clean

or maintain this equipment! Special care should

be taken to ensure that the WARNINGS and safety

requirements for operating and servicing the

equipment are followed. The user should be

aware of and adhere to ALL local building and

re codes and ordinances as well as NFPA-33

SAFETY STANDARD or applicable country safety

standards prior to installing, operating, and/or

servicing this equipment.

W A R N I N G

!

> The hazards shown on the following page

may occur during the normal use of this equipment. Please read the hazard chart beginning

on page 2.

Careful study and continued use of this manual will

provide a better understanding of the equipment and

process, resulting in more ecient operation, longer

trouble-free service and faster, easier troubleshooting.

If you do not have the manuals and safety literature

for your Ransburg system, contact your local Ransburg

representative or Ransburg.

1

AA-08-01.1

Evolver 303 Dual Purge Robotic Atomizers - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate operation and maintenance procedures will cause a re hazard.

Protection against inadvertent

arcing that is capable of causing

re or explosion is lost if any

safety interlocks are disabled

during operation. Frequent

power supply shut-down indicates a problem in the system

requiring correc-tion.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the spray

area and tested periodically.

Spray areas must be kept clean to prevent the accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be turned

o prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

Those used for equipment ushing should have ash points

equal to or higher than those of the coating material.

Those used for general cleaning must have ash points

above 100°F (37.8°C).

Spray booth ventilation must be kept at the rates required

by local and/or country codes. In addition, ventilation

must be maintained during cleaning operations using

ammable or combustible solvents.

General Use and

Maintenance

1

Improper operation or maintenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only as

instructed.

Non-factory replacement parts or unauthorized equipment

modications may cause re or injury.

If used, the key switch bypass is intended for use only

during set-up operations. Production should never be

done with safety interlocks disabled.

The paint process and equipment should be set up and

operated in accordance with local and/or country safety

codes.

Personnel must be given training in accordance with the

requirements of NFPA-33.

Instructions and safety precautions must be read and

understood prior to using this equipment.

Comply with appropriate local, state, and national codes

governing ventilation, re protection, operation maintenance, and housekeeping. Reference OSHA, NFPA-33, and

your insurance company requirements.

AA-08-01.1

2

Evolver 303 Dual Purge Robotic Atomizers - Safety

AREA

Tells where hazards

may occur.

Toxic Substances

Explosion Hazard/

Incompatible

Materials

HAZARD

Tells what the hazard is.

Certain material may be harmful if

inhaled, or if there is contact with

the skin.

Halogenated hydrocarbon solvents

for example: methylene chloride

and 1,1,1,-Trichloroethane are not

chemically compatible with the

aluminum that might be used in

many system components. The

chemical reaction caused by these

solvents reacting with aluminum

can become violent and lead to an

equipment explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air

free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance of

inhaling sprayed materials. The mask must be compatible with the material being sprayed and its concentration. Equipment must be as prescribed by an industrial

hygienist or safety expert, and be NIOSH approved.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators, triggering valves, etc. Halogenated hydrocarbon solvents

must never be used with aluminum equipment during

spraying, ushing, or cleaning. Read the label or data

sheet for the material you intend to spray. If in doubt as

to whether or not a coating or cleaning material is compatible, contact your material supplier. Any other type

of solvent may be used with aluminum equipment.

Electrical

Equipment

High voltage equipment is utilized.

Arcing in areas of ammable or

combustible materials may occur.

Personnel are exposed to high

voltage during operation and

maintenance.

Protection against inadvertent arcing that may cause a re or explosion

is lost if safety circuits are disabled

during operation.

Frequent power supply shutdown

indicates a problem in the system

which requires correction.

An electrical arc can ignite coating

materials and cause a re or explosion.

The power supply, optional remote control cabinet, and

all other electrical equipment must be located outside

Class I or II, Division 1 and 2 hazardous areas. Refer to

applicable code for specic area and/or country.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of ammable or combustible

material.

Testing may require high voltage to be on, but only as

instructed.

Production should never be done with the safety circuits disabled.

Before turning the high voltage on, make sure no objects

are within the sparking distance.

3

AA-08-01.1

Evolver 303 Dual Purge Robotic Atomizers - Safety

AREA

Tells where hazards

may occur.

Robot Work AreaGeneral Use and

Maintenance

Personnel Safety

HAZARD

Tells what the hazard is.

Improper use or maintenance can

lead to hazardous conditions, particularly from unexpected robot

manipulator movement.

Skin puncturing by sharp electrode.

SAFEGUARDS

Tells how to avoid the hazard.

Applicator adjustments or maintenance should be done

after the robot is taken out of service. Do not adjust or

repair the applicator if the robot is operating or standing ready to start.

Refer to robot operating instructions for the procedures

to take the robot out of service.

Take precautions to see that esh is not punctured by

sharp electrode.

AA-08-01.1

4

Evolver 303 Dual Purge Robotic Atomizers - Introduction

INTRODUCTION

THE RANSBURG ELECTROSTATIC

PROCESS

This process is a method for electrostatically applying

coatings to objects. A power supply produces a high

voltage charge which is supplied to the applicator,

creating an electrostatic eld between the applicator

and the target object. The target is electrostatically

grounded through its support which may be either

stationary or moving.

A regulated uid system delivers coating material to

the applicator, where it is atomized forming a spray

mist. There, under the inuence of the electrostatic

eld, the atomized coating becomes electrostatically charged. The charged particles are attracted to

and deposited on the grounded target object. The

forces between the charged particles and the target

are sucient to turn overspray around and deposit it

on the back surface of the target. Therefore, a higher

percentage of the spray is deposited.

EVOLVER™ 303 DUAL PURGE

SOLVENTBORNE SPRAY

APPLICATORS

The Evolver™ 303 Dual Purge Spray Appli-cators System

will allow for the use of spray applicators or bell applicators with minimal required down-time during

the switching process. This system can also operate

as a spray applicator system only that later can be

upgraded to allow for bell applicators having "Unilink

Technology"to be used. This system can allow a user

currently possessing an RMA-303 bell system to use

spray applicators as well, with minimal conversion

required. Lastly, this system is a true dual purge

system in that paint can be sprayed with full voltage

on, while simultaneously color changing the second

paint line. The Evolver 303 Dual Purge Solventborne

Applicator line consists of both 60° and 90° single

and dual-headed 100kV automatic electrostatic applicators. Developed for use on robot, the Evolver

303 Dual Purge spray applicator incorporates a

unique 1/3 turn quick-disconnect spray head and a

one piece slide over manifold cover, providing the

user an ecient tool for the electrostatic application

of coatings.

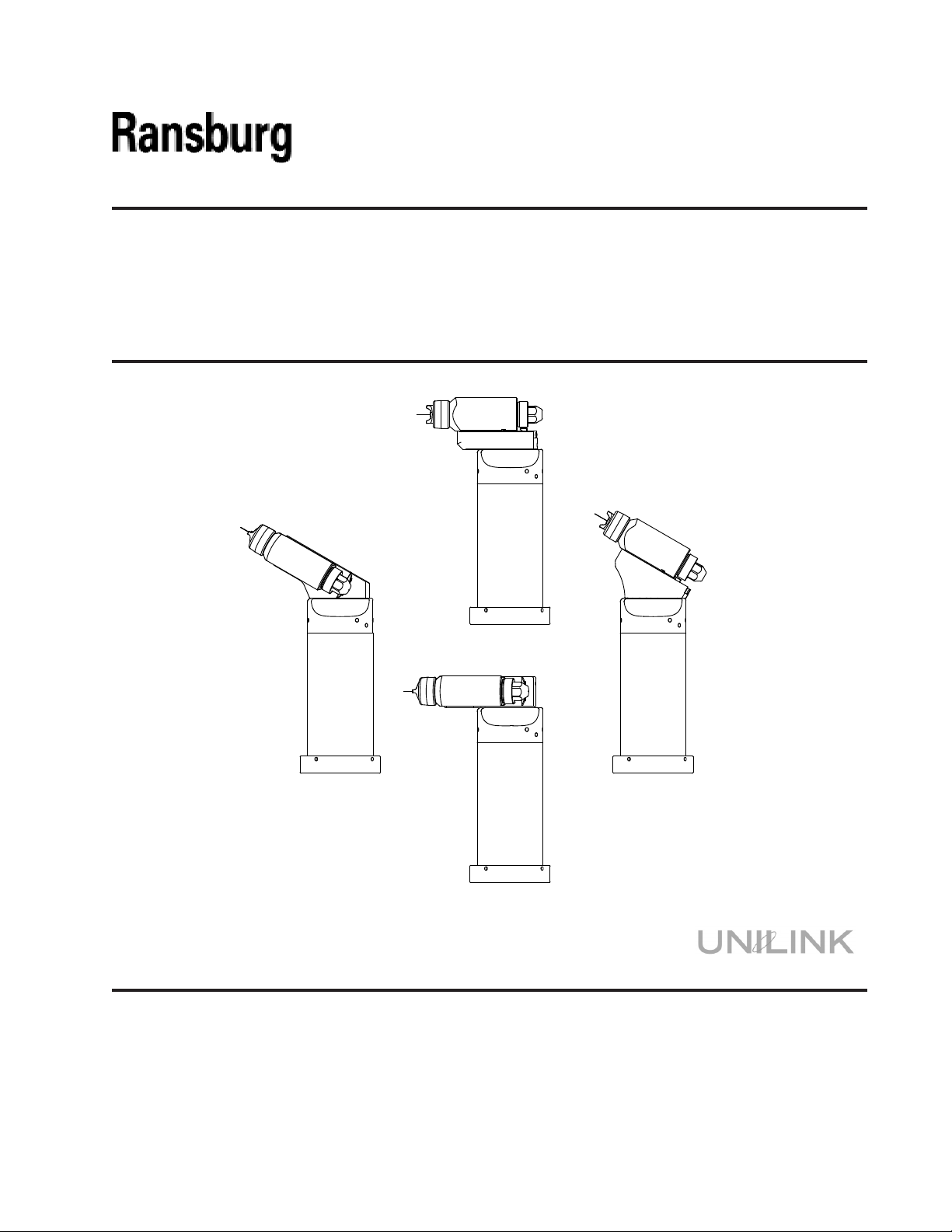

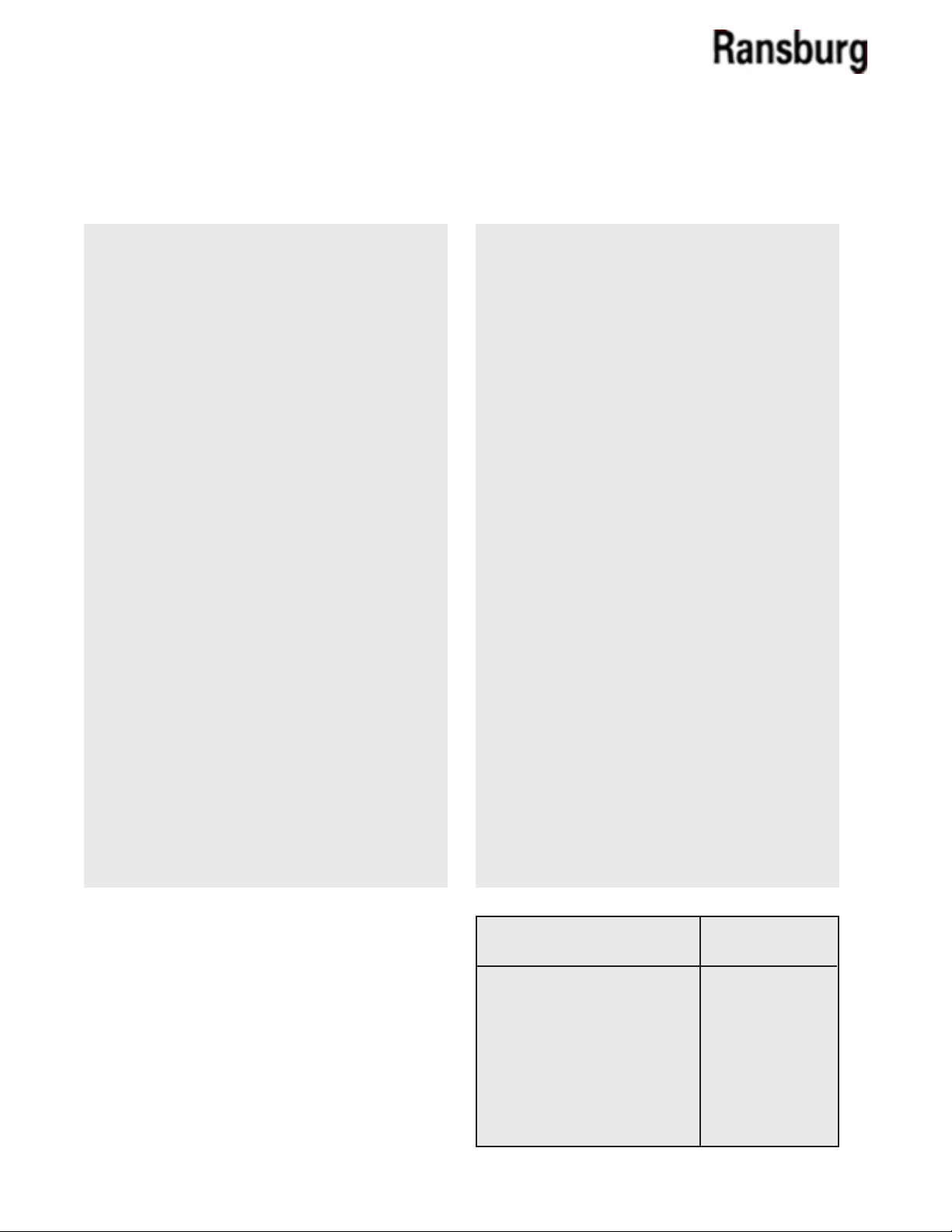

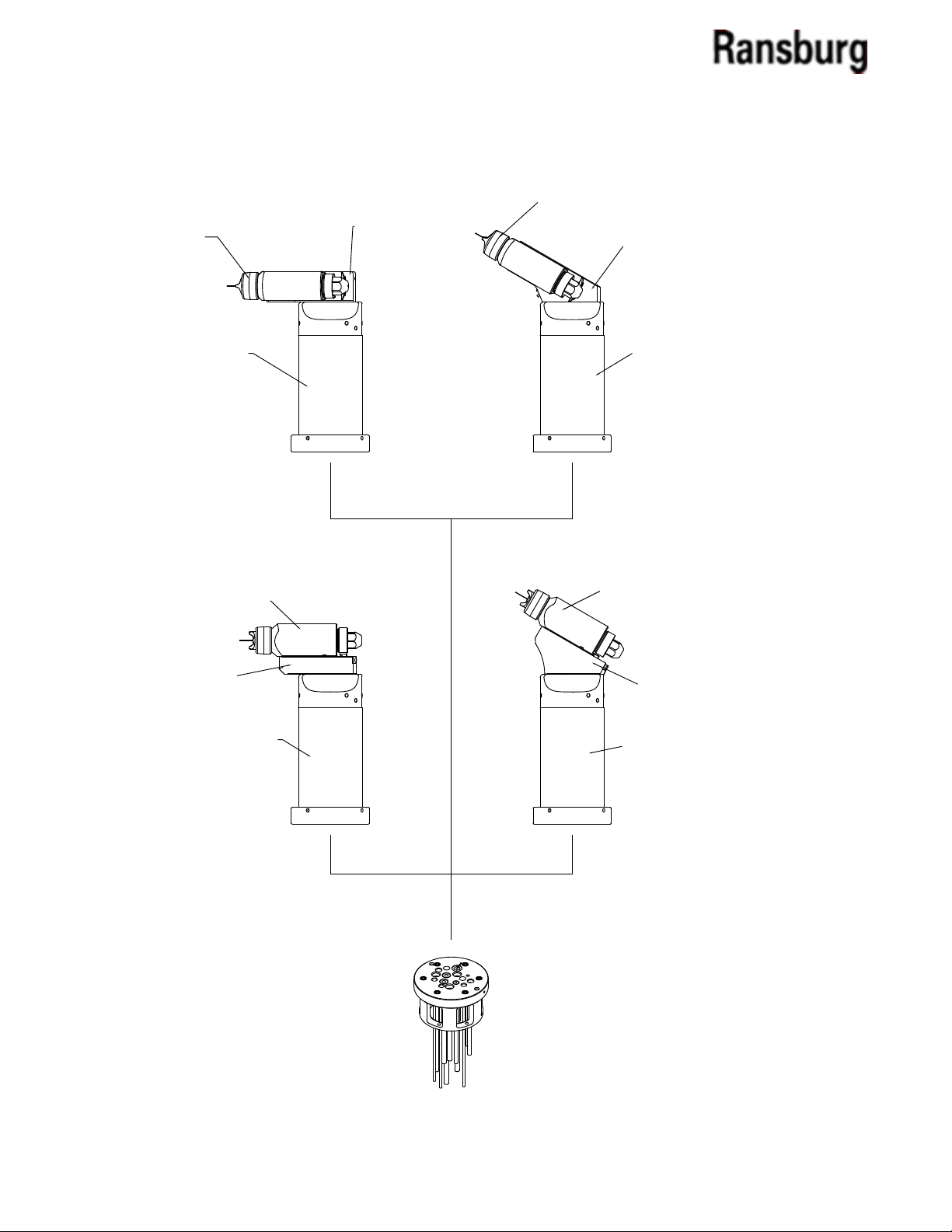

There are two single-head models of the Evolver 303

Dual Purge Applicators (see Figure 1). Each model

diers in the applicator to axis orientation of the spray

head. These models are:

A12374-0XX 60° Single-Head

A12374-1XX 90° Single-Head

Two dual-head versions of the Evolver 303 Dual Purge

Applicator are also available (see Figure 1). The dualheaded applicators are primarily used where high

volume uid delivery is required. The dual-headed

applicator is available in two dierent congurations

as follows:

A12374-2XX 60° Dual-Head

A12374-3XX 90° Dual-Head

5

AA-08-01.1

Evolver 303 Dual Purge Robotic Atomizers - Introduction

The Evolver 303 Dual Purge Spray Applicator System

consists of four major components:

1. Quick-Disconnect Spray Head

2. Applicator Head Mounting Block Assembly

3. Valve Manifold Assembly (Includes the High

Voltage Cascade with a Quick-Disconnect

Ring)

4. Rear Tubing Manifold Assembly (both English

and Metric)

The spray head(s) and valve manifold contain the

uid, air, and high voltage passages. All uid

passages contain stainless steel and/or nylon ttings,

compatible with halogenated hydrocarbon solvents.

The robot manifold incorporates stainless steel uid

connections.

The high voltage cascade is entirely encapsulated

with a solvent resistant epoxy. This cascade generates

voltages up to 100kV fed by a low voltage cable.

NOTES

There are three sources for the high voltage supply

to the Evolver 303 Dual Purge Applicators:

• MicroPak™ Control Unit (LECU5004)

• Stand-alone control/power supply unit

(A10406)

• MicroPakTM Control Unit (LECU5004-31)

The MicroPak Power Supply control unit provides a

low voltage signal through the robot manifold to the

spray applicator. The high voltage cascade located

within the applicator converts the low voltage DC

signal to a high voltage electrostatic output.

For applications that have the ability to control fan

and atomization air remotely, the bleed style head

is available.

AA-08-01.1

6

Evolver 303 Dual Purge Robotic Atomizers - Introduction

SPECIFICATIONS

Environmental/Physical Electrical Requirements

Robot/Mounting Compatibility:

All hollow wrist robots

Applicator Control Unit:

MicroPak Control Unit - LECU5004-31

Stand-Alone Control Unit - A10406

Operating Temperature

Range: 55°F (12.8°C) - 131°F (55°C)

Approximate Weight

Single-Headed:

60° 9.02 lb. (4.1 Kg)

90° 8.71 lb. (3.9 Kg)

Dual-Headed:

60° 10.91 lb. (4.9 Kg)

90° 10.76 lb. (4.9 Kg)

Manifold:

A12373-XX 6.82 lb. (3.1 Kg)

(No tubing or cable)

Length

Single-Headed:

60° 16.5-inch (41.9 cm)

90° 13.6-inch (34.5 cm)

Dual-Headed:

60° 15.8-inch (40.1 cm)

90° 12.4-inch (31.5 cm)

Tubing Manifolds (Metric):

A12283-0XXXXXX Air Tubing not

included

A12283-1XXXXXX 4 1/2m (15-ft.)

A12283-2XXXXXX 9m (30-ft.)

Output Voltage: 30-100kV

Output Range: 0-85 µA

Paint Flow Rate: Variable to 1500 cc/min.

(Depending on viscosity and conguration)

Trigger Response

Time: 134ms Open

318ms Closed

Operating Air Pressures

Atomizing Air: 100 psig (6.9 bar)

max.

Fan Air: 100 psig (6.9 bar)

max.

Trigger Pilot: 70 psig min./100

psig

(4.8 - 6.9 bar) max.

Dump Pilot: 70 psig min./

100 psig max.

(4.8 - 6.9 bar)

Operating Fluid

Pressure: 200 psig

(13.8 bar) max.

100 psig

(6.9 bar) max.

Regulated (with

on-board regulator)

Robot Manifold Tubing

Requirements

Atomizing Air

Fan Air

Trigger Air

Dump Pilot

Fluid:

Dump:

7

Tubing Bundle

Metric

8mm OD Nylon

8mm OD Nylon

6mm OD Nylon

4mm OD Nylon

8mm OD

(Non-Shielded)

7mm ID

AA-08-01.1

Evolver 303 Dual Purge Robotic Atomizers - Introduction

EVOLVER 303 DUAL PURGE APPLICATOR ASSEMBLY

A12374 - A B C

Head Conguration

0 = 60° Single-Head

1 = 90° Single-Head

2 = 60° Dual-Head

3 = 90° Dual-Head

Body Style

0 = For Highly Resistive Materials (Clear Coat)

1 = For Conductive Materials (Base / Clear)

2 = For Highly Conductive Materials (Base / Clear)

Atomization Technology

0 = Conventional Spray / Non-Bleed

1 = HVLP Spray / Non-Bleed

4 = Conventional Spray / Bleed

5 = HVLP Spray / Bleed

EVOLVER 303 DUAL PURGE TUBING BUNDLE ASSEMBLY METRIC

A12283 - A BB CC DD

Tubing Bundle Length

0 = Air Tubing (Not Included)

1 = 4.5m (15-ft.) Long Tubing Assembly

2 = 9m (30-ft.) Long Tubing Assembly

Low Voltage Cable Length

0 0 = Low Voltage Cable Not Included

01 = 15-ft. Low Voltage - Quick Connect to MicroPak

02 = 25-ft. Low Voltage - Quick Connect to MicroPak

03 = 40-ft. Low Voltage - Quick Connect to MicroPak

04 = 50-ft. Low Voltage - Quick Connect to MicroPak

05 = 75-ft. Low Voltage - Quick Connect to MicroPak

Robot Adapter

00 = Adapter Not Included

01 = Adapter (Fanuc P-155) 78983-00

02 = Adapter (ABB 5400, 5002) 79107-00

03 = Adapter (Fanuc-P200/P-250) 79131-00

04 = Adapter (KAWASAKI-KE610L) A10847-00

05 = Adapter (MOTOMAN-PX2850) A10848-00

06 = Adapter (MOTOMAN-PX2900) A10849-00

07 = Adapter (B & M LZ2000) A10851-00

08 = Adapter (ABB 5400 Enhanced Wrist) A12036-00

Fiber Optic Cable Length

00 = Fiber Optic Cable Not Included

01 = 15-ft. Long Fiber Optic Cable

02 = 25-ft. Long Fiber Optic Cable

03 = 40-ft. Long Fiber Optic Cable

04 = 50-ft. Long Fiber Optic Cable

05 = 75-ft. Long Fiber Optic Cable

06 = 100-ft. Long Fiber Optic Cable

AA-08-01.1

8

SPRAY HEAD

ASSY.

MOUNTING

BLOCK ASSY.

VALVE MANIFOLD

ASSY.

A12374-3XX

90° DUAL HEAD

SPRAY HEAD

ASSY.

MOUNTING

BLOCK ASSY.

VALVE MANIFOLD

ASSY.

A12374-2XX

60° DUAL HEAD

SPRAY HEAD

ASSY.

MOUNTING

BLOCK ASSY.

VALVE MANIFOLD

ASSY.

A12374-1XX

90° SINGLE HEAD

SPRAY HEAD

ASSY.

MOUNTING

BLOCK ASSY.

VALVE MANIFOLD

ASSY.

A12374-0XX

60° SINGLE HEAD

A12283-XXXXXXX REAR MANIFOLD TUBING ASSY. - METRIC

Evolver 303 Dual Purge Robotic Atomizers - Introduction

Figure 1: Evolver 303 Dual Purge Solventborne Robotic Applicators

9

AA-08-01.1

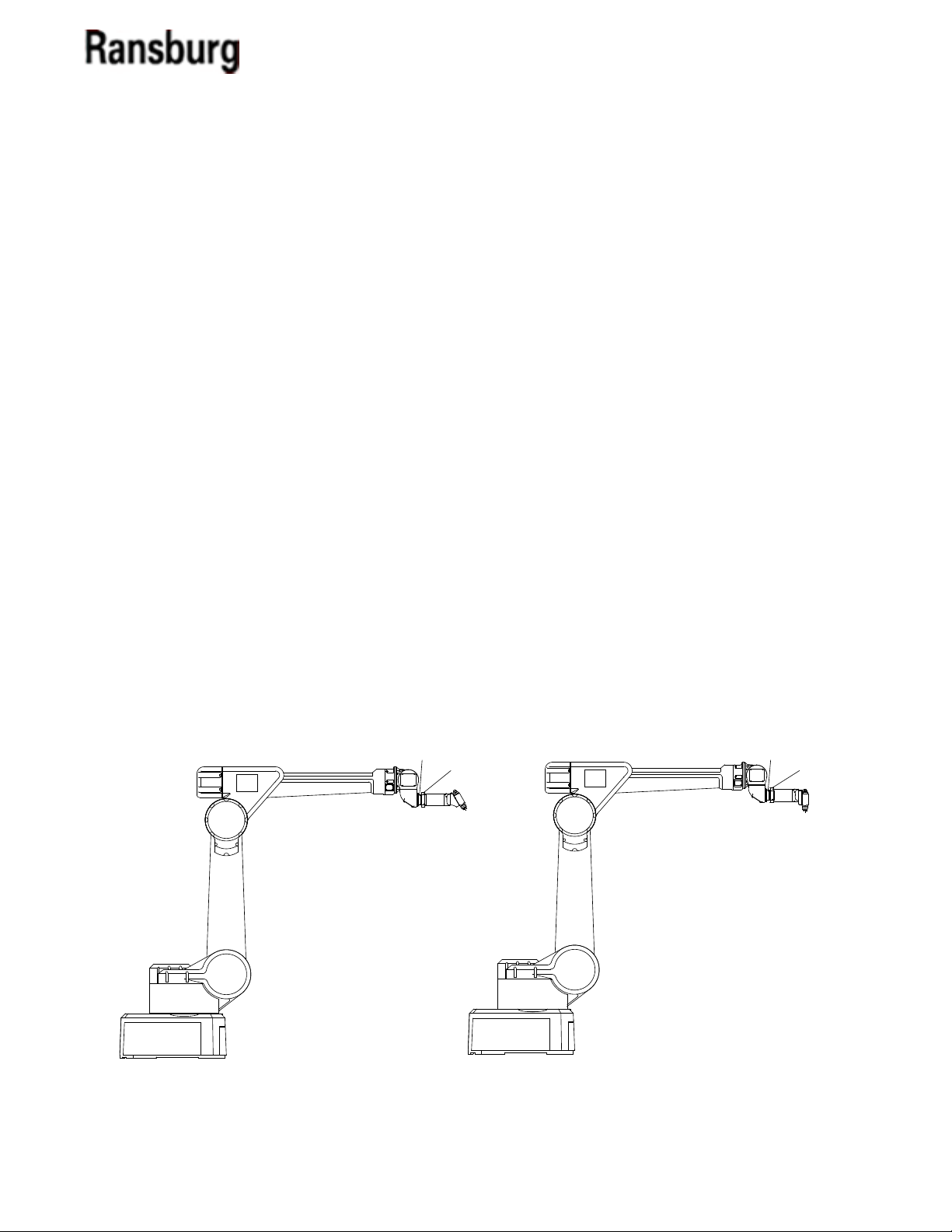

FEATURES

ROBOT MANIFOLD QUICK

DISCONNECT RING

ROBOT SPACER PLATE

A12374

-0XX

60° SINGLE HEAD

MOUNTED ON ROBOT

ROBOT MANIFOLD QUICK

DISCONNECT RING

ROBOT SPACER PLATE

A12374

-1XX

90° SINGLE HEAD

MOUNTED ON ROBOT

Evolver 303 Dual Purge Robotic Atomizers - Introduction

The features of the Evolver 303 Dual Purge Series

Applicators include:

! Quick-disconnect spray head

! High quality Ransburg air cap and uid

nozzle

! Various adapter plates available to match

most robotic mounting congurations

! No external high voltage cable. The intern ally mounted high voltage cascade requires

only low voltage control wiring

! Less waste to the spray booth with the dump

valve located internally next to the feed tube

! Assembly components made of durable

engineered resin material for optimum

mechanical strength and solvent resistance

! Heavy duty design ensures excellent service

life even when subjected to the quick motions

of robotic applicators

! Small, light weight package allows for better

maneuverability in tight areas

! Negligible maintenance down time with the

quick-disconnect feature. An atomizer can

be exchanged in less than two minutes for

o-line maintenance

! Field proven high voltage system

! Dual start, dual pitch air cap retaining ring

! Quick color change capability

! Clean interior design with slip-on shroud

! Internal fan and atomization air control valve,

with a mechanically timed trigger sequence

! Color coded air and trigger actuation lines

! Quick change to a RMA-303 bell applicator

! True dual purge technology, allowing the user

to spray one color at voltage, while simul-

taneously purging the second color

AA-08-01.1

Figure 2: Typical Robotic Applicator Mounting

10

Evolver 303 Dual Purge Robotic Atomizers - Introduction

A12374XXX EVOLVER DUAL

PURGE SPRAY APPLICATOR

ASSEMBLY

The spray applicator assembly is designed to connect

to hollow wrist robots. A low voltage control cable

is supplied with the tubing bundle to connect the

cascade to the MicroPak power supply.

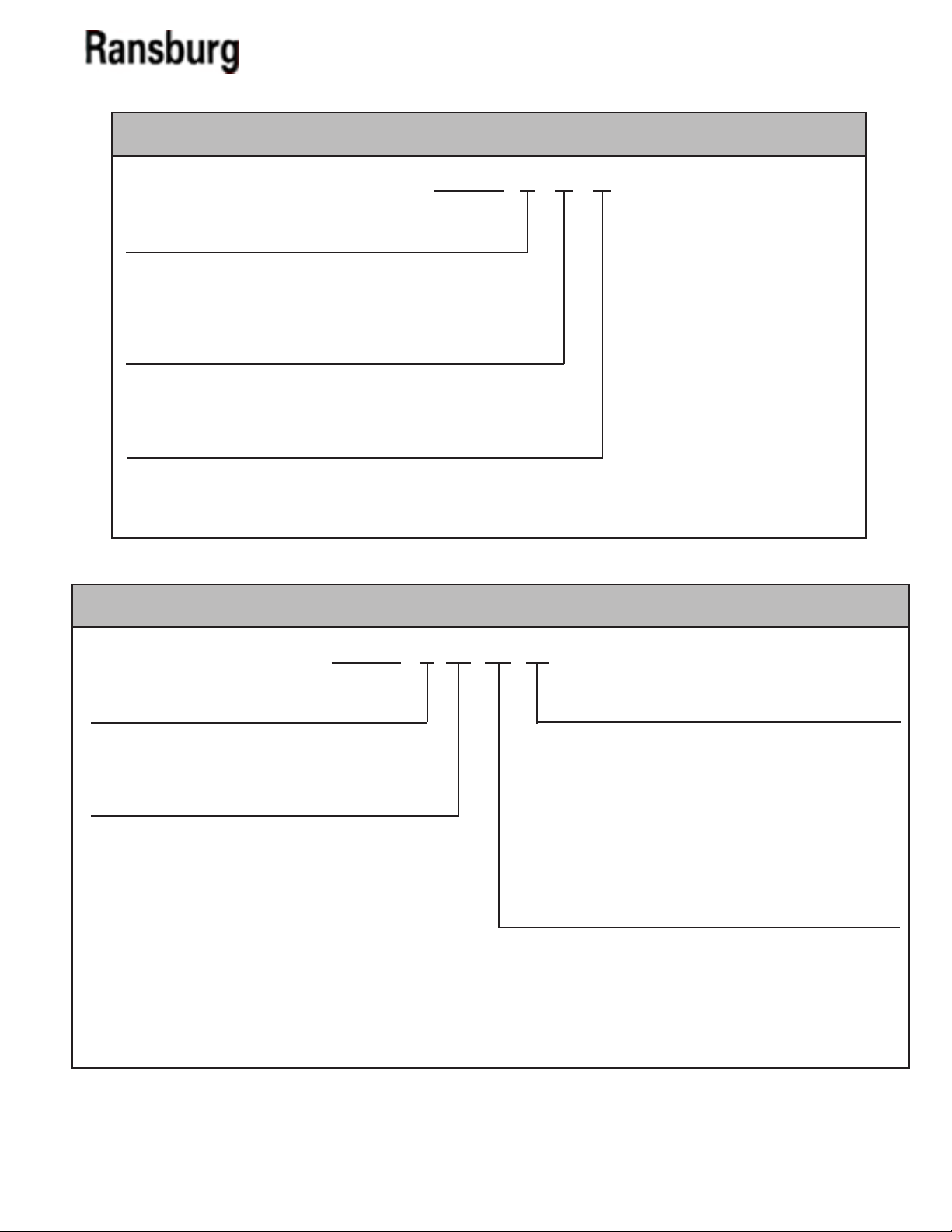

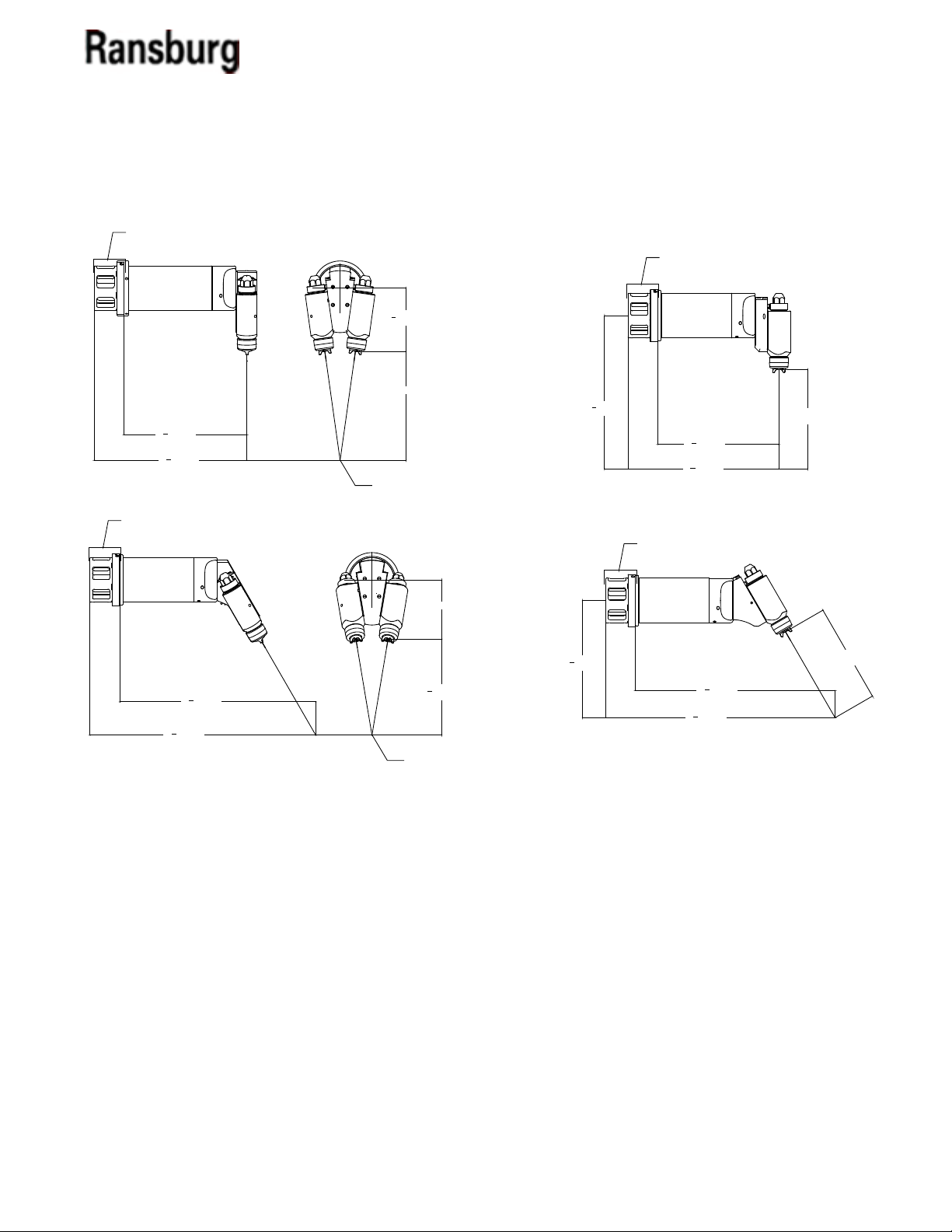

Tool Center-Point

Figure 3 shows the tool center-point information for

the four applicators. For dual head applicators, the

tool center-point is based upon the convergence

point. For the single head applicators it is based

upon a 10" target distance. The "Tool Center-Point

Comparisons Table" compares the tool center-point

of several automatic spray applicators.

11

AA-08-01.1

Evolver 303 Dual Purge Robotic Atomizers - Introduction

6 [151.9]

DUAL HEAD 90°

SINGLE HEAD 90°

SINGLE HEAD 60°

DUAL HEAD 60°

CONVERGENCE POINT

CONVERGENCE POINT

ROBOT ADAPTER AND

MOUNTING PLATE

ROBOT ADAPTER AND

MOUNTING PLATE

ROBOT ADAPTER AND

MOUNTING PLATE

ROBOT ADAPTER AND

MOUNTING PLATE

23

1

8

[587.5]

15

1

4

[386.3]

15

1

2

[392.8]

22

3

4

[578.4]

11

3

4

[299.9]

6

3

8

[161.4]

11 [279.1]

15

3

8

[390.6]

10 [254.0]

TARGET DISTANCE

10 [254.0]

TARGET DISTANCE

12

1

4

[310.2]

20

1

8

[511.4]

12

3

8

[314.5]

9

5

8

[245.6]

19

3

4

[502.4]

AA-08-01.1

Figure 3: Tool Center-Point

12

Evolver 303 Dual Purge Robotic Atomizers - Installation

INSTALLATION

EVOLVER 303 DUAL PURGE

ROBOTIC ATOMIZER

INSTALLATION

This information is intended ONLY to indicate the

general installation parameters of this product and,

where applicable, its working relationship to other

Ransburg system components in typical use. Each

installation is unique and should be directed by an

authorized Ransburg representative or conducted

from the Ransburg installation drawings provided

for your particular installation.

POWER SUPPLY ASSEMBLY

Refer to the most current Power Supply Unit

manuals for complete information regarding power

supply installation.

• MicroPak Control Unit (LECU5004)

• Stand-alone control/power supply unit

(A10406)

ELECTRICAL AND FIBER OPTIC

CONNECTIONS

The ber optic cable is included in the Evolver 303

dual purge tubing bundle, but not used. It is there,

ready to use, in case a user is using or chooses to use

in the future, a bell applicator, which requires the

ber optic cable. The ber optic connection is made

on the back of the applicator's robot plate. The ber

optic cable comes preassembled with connectors that

are secured in place by set screws tightened from the

side of the robot plate. An adequate ground must be

provided to the mounting plate to ensure that uid

ttings, etc. are at ground potential.

FLUID CONNECTIONS

The paint, solvent, and dump uid tubing are connected on the back of the robot plate with stainless

steel compression ttings and PFA tubing. Fluid

tubing requirements are shown in the "Signal Identication Tables" in the "Installation" section.

• MicroPak Control Unit (LECU5004-31)

MOUNTING

The Evolver 303 dual purge is equipped with a quick

disconnect assembly. The quick disconnect feature

consists of a robot plate which is permanently attached to the robot through a wrist adapter plate

and a mating rear plate which is part of the Evolver

303 Dual Purge Spray Applicator assembly. The applicator is secured to the robot plate with a threaded

retaining ring.

13

TYPICAL INSTALLATION

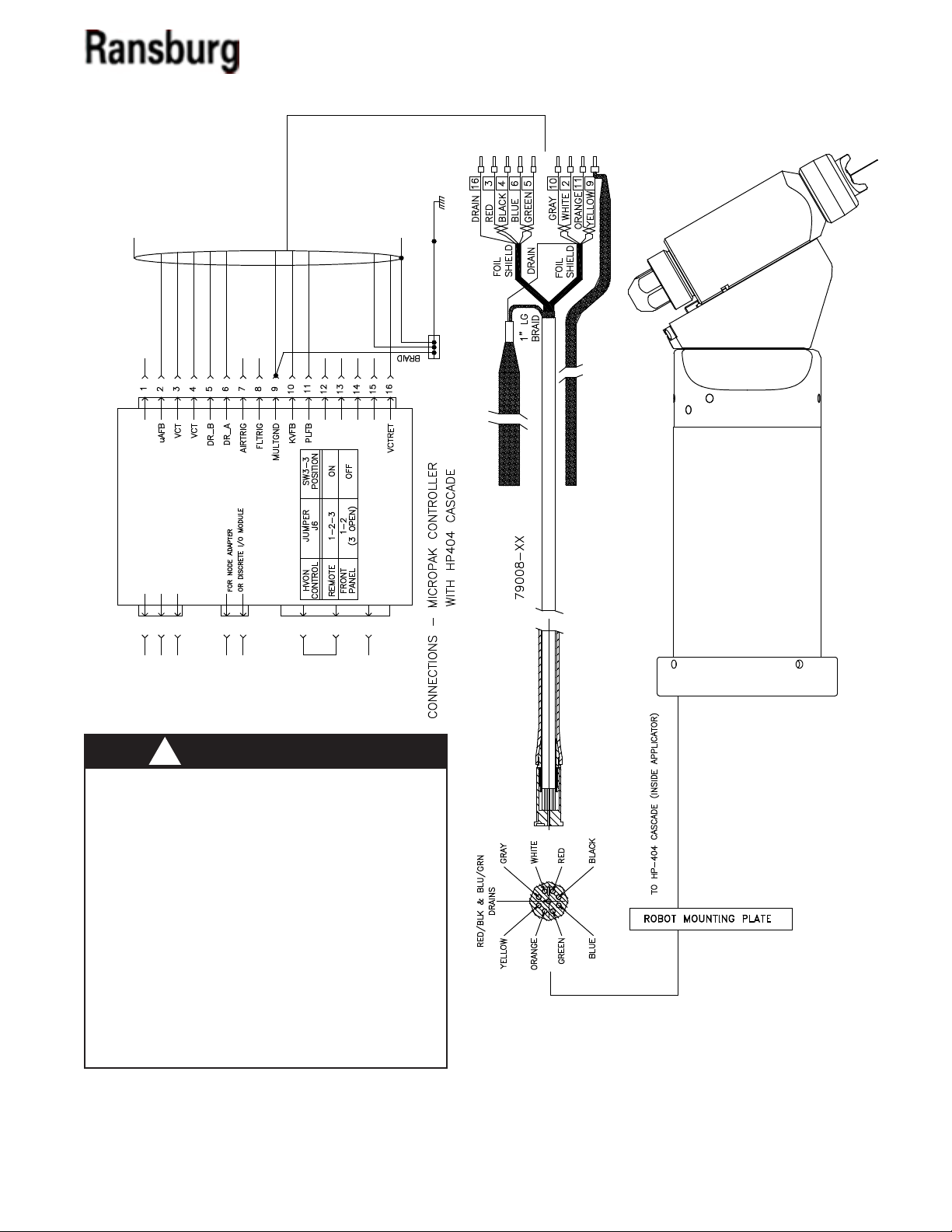

Figure 4 shows a typical installation of the Evolver

303 dual purge and the wiring installation of the

applicator with the MicroPak.

AA-08-01.1

HV GND. BUS

3

2

J6

1

J10

J2

+24 VDC

24 VRET

1

2

FACT. GND

+24 VDC

24 VRET 3

2

1

MICROPAK

BARE (DRAIN)

BARE (DRAIN)

YELLOW

ORANGE

N/C

N/C

N/C

N/C

GRAY

BLACK

N/C

N/C

GREEN

BLUE

N/C

J3

WHITE

RED

3/4" BRAID CABLE EARTH GROUND

Evolver 303 Dual Purge Robotic Atomizers - Installation

!

W A R N I N G

> The power supply MUST be located outside

the HAZARDOUS area (Reference OSHA, NFPA-33,

and your insurance company requirements.)

> User should be aware of, and adhere to, all

local re codes and ordinances.

> The user MUST provide a properly fused

disconnect between the power source and the

power supply which complies with appropriate

codes.

> Fluid supply must be grounded per NFPA-33.

Figure 4: Low Voltage Cable Connections

AA-08-01.1

14

Evolver 303 Dual Purge Robotic Atomizers - Installation

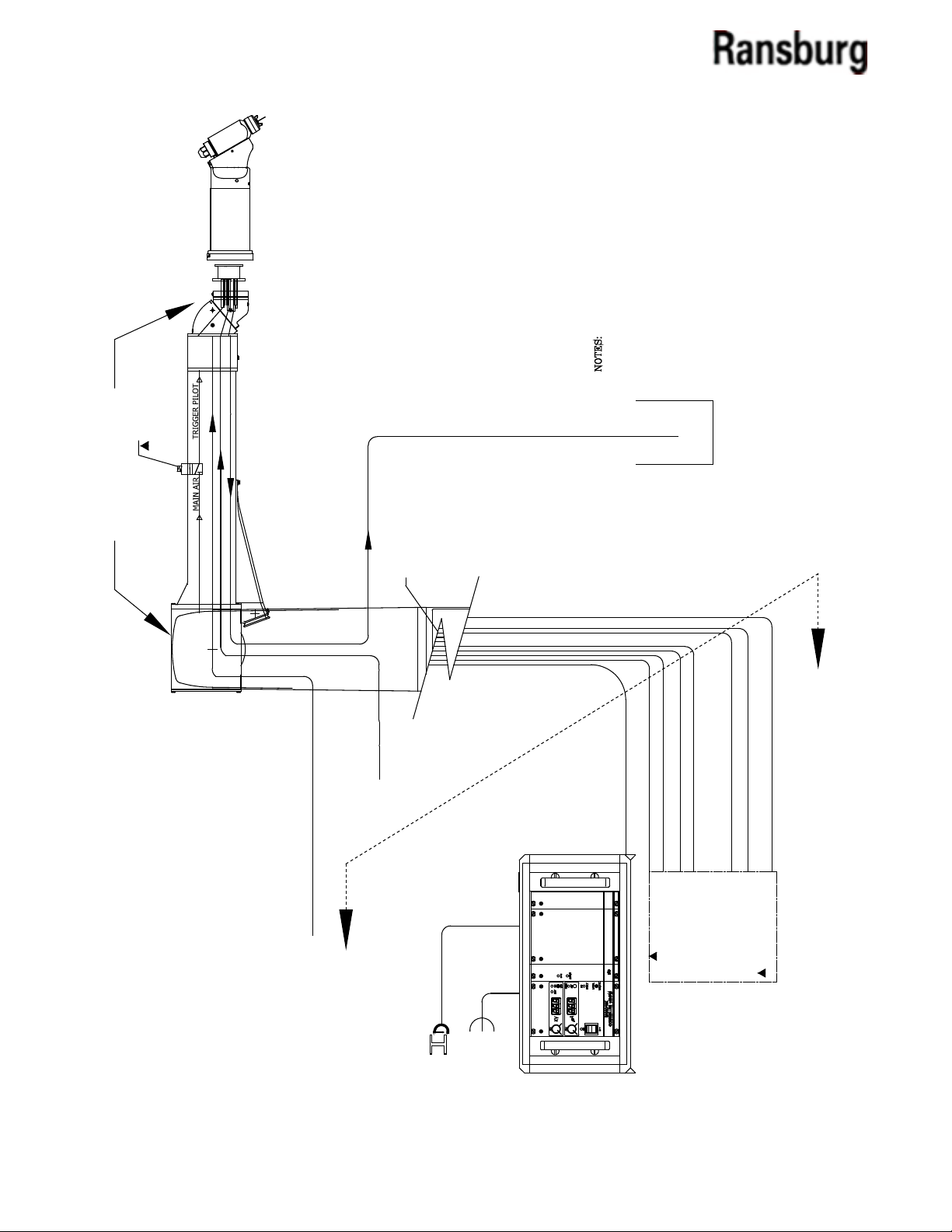

SHAPING AIR/ATOMIZATION AIR

SEAL AIR/FAN AIR

BEARING AIR/PAINT TRIGGER

SOLVENT VALVE TRIGGER SIGNAL

LEAVE TUBING SLACK IN THE WRIST AND ELBOW

AREA TO REDUCE ROTATION STRESS.

TRIGGER SOLENOID

(IF USED)

SUPPLIED BY OTHERS

(MAIN AIR IF EXTERNAL TRIGGER USED)

INSIDE ENCLOSURE

3/4" HV GND BRAID (DEARBORN #91234 OR EQUIVALANT)

ATTACH TO ISOLATED H.V. GND (FOR MICROPAK)

ATTACH TO PANEL

GROUND

AC NEUTRAL

120VAC

BUILDING STEEL/GROUND ROD

L.V. CABLE

CONTROL PANEL

CONTROLS BY OTHERS

ANALOG SIGNAL AND

TRANSDUCER REQUIRED

IF USING A CAP CLEANER THE

IF A CAP CLEANER IS USED IT MUST BE

VENTED TO ATMOSPHERE WITHOUT PRESSURE

DIRECTLY INTO THE AIR CAP.

SOLVENT/AIR SHOULD NOT BE SPRAYED

BUILD UP.

LUBRICATE THE TUBING BUNDLE

EXCESSIVELY TO EASE INSTALLATION

AND EXTEND TUBING LIFE.

(BLUE)

(GRAY)

(YELLOW)

(BLUE)

PAINT 1 TRIGGER VALVE SIGNAL

PAINT 1 DUMP VALVE TRIGGER SIGNAL

(GREEN)

(ORANGE)

SOLVENT SUPPLY

WITH THE ITW EQUIPMENT PURCHASE.

FOR REFERENCE ONLY AND IS NOT INCLUDED

THE ROBOT IS SHOWN

DUMP

SOLVENT INBOUND

DUMP LINE OUT

PAINT SUPPLY 1

PAINT 1 INBOUND

PAINT 2 TRIGGER/PEGULATOR PILOT

(USED FOR DUAL PURGE AND REGULATED APPLICATIONS)

(NATURAL)

15

Figure 5: Evolver 303 Dual Purge Spray Applicator Air and Fluid Layout

AA-08-01.1

Evolver 303 Dual Purge Robotic Atomizers - Installation

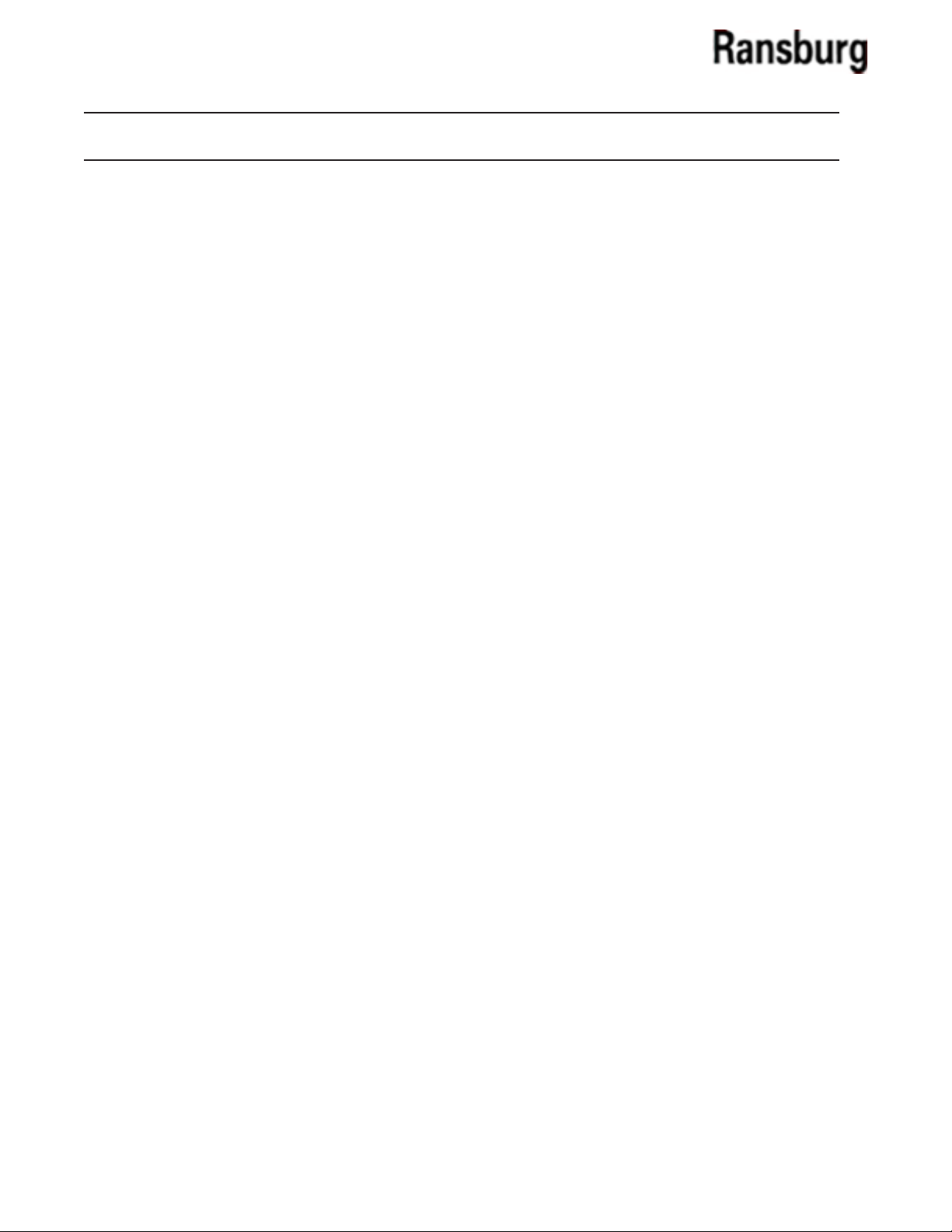

APPLICATOR AND MANIFOLD

ASSEMBLY

(See Figures 4 and 5)

The tubing, hose, and low voltage cable come

bundled from the factory. Pull the bundle through

the robot spacer plate and robot wrist carefully to

prevent any cuts on the cable or hoses. Use the six

(6) socket head cap screws (76566-24C) included

with the rear manifold tubing assembly to attach

the rear manifold assembly ( A12283) to the robot

spacer plate (see Table 1).

Connect each signal line as required per "Signal

Identication Tables (Metric) Tubing Bundles" in the

"Installation" section.

Rear Plate Assembly

The rear plate assembly is designed to be at ground

potential when mounted to the robot plate component within the tubing bundle assembly. The air and

uid ports are compactly oriented for use in robotic

applications. The interior air supplies are ported

through the ve (5) support rods and also directly

tubed to the upper manifold assembly. On the exterior side of the rear plate, the ports are provided

with o-ring seals so that the applicator can be quickly

mated and secured to the robot plate

Robot Plate

The robot plate is a component of the tubing bundle

assembly and intended to be permanently mounted

to the robot. A wrist adapter is also available, which

matches the robot's mounting conguration. The

incoming air lines, uid lines, low voltage cable, and

ber optic cable are connected to the ttings provided

on the back of the robot plate. The rear plate of the

applicator assembly is secured to the robot plate with

a threaded retaining ring.

Break-Away Feature (Optional)

The Evolver 303 dual purge can be converted to

have a break-away feature, by replacing the ve (5)

stainless steel screws with ve (5) special designed

plastic screws (77524-00). This feature is meant to

reduce the damage to the applicator, robot, etc. If a

collision occurs, the ve (5) plastic break-away screws

fail and the applicator will break free. This will leave

the break-away ring and the mounting ring attached

to the robot.

Power Supply and Controls

The high voltage cascade located inside the Evolver

303 dual purge is controlled by the MicroPak control

unit. The low voltage ouput of the MicroPak is multiplied by the internal cascade to the high voltage level

required. This eliminates the need for a high voltage

cable. A low voltage cable interconnects the cascade

and the MicroPak control. The MicroPak Eurocard

format is designed to t in a conventional 19-inch

or 1-inch rack and requires a 24V power input at a

maximum 3 amps. The MicroPak and the internal

cascade will produce voltages up to 100,000VDC.

The MicroPak is designed to electronically limit current to provide safe operation in a spray booth. The

voltage and current draw of the applicator are continuously displayed on the MicroPak control panel.

Voltage and over-current limits are adjust-able on

the front of the MicroPak. MicroPak internal safety

circuits will shut down the system on over-current

and cable faults.

With additional control modules, all of the functions

of the Evolver 303 dual purge and MicroPak can be

controlled by a programmable controller. A Serial

Digital Module pneumatically controls the paint and

dump valves located on the applicator. An I/O module

provides communication between these modules

and the PLC.

The above modules are mounted in one 19-inch rack

and interconnected through a common motherboard.

AA-08-01.1

16

Evolver 303 Dual Purge Robotic Atomizers - Installation

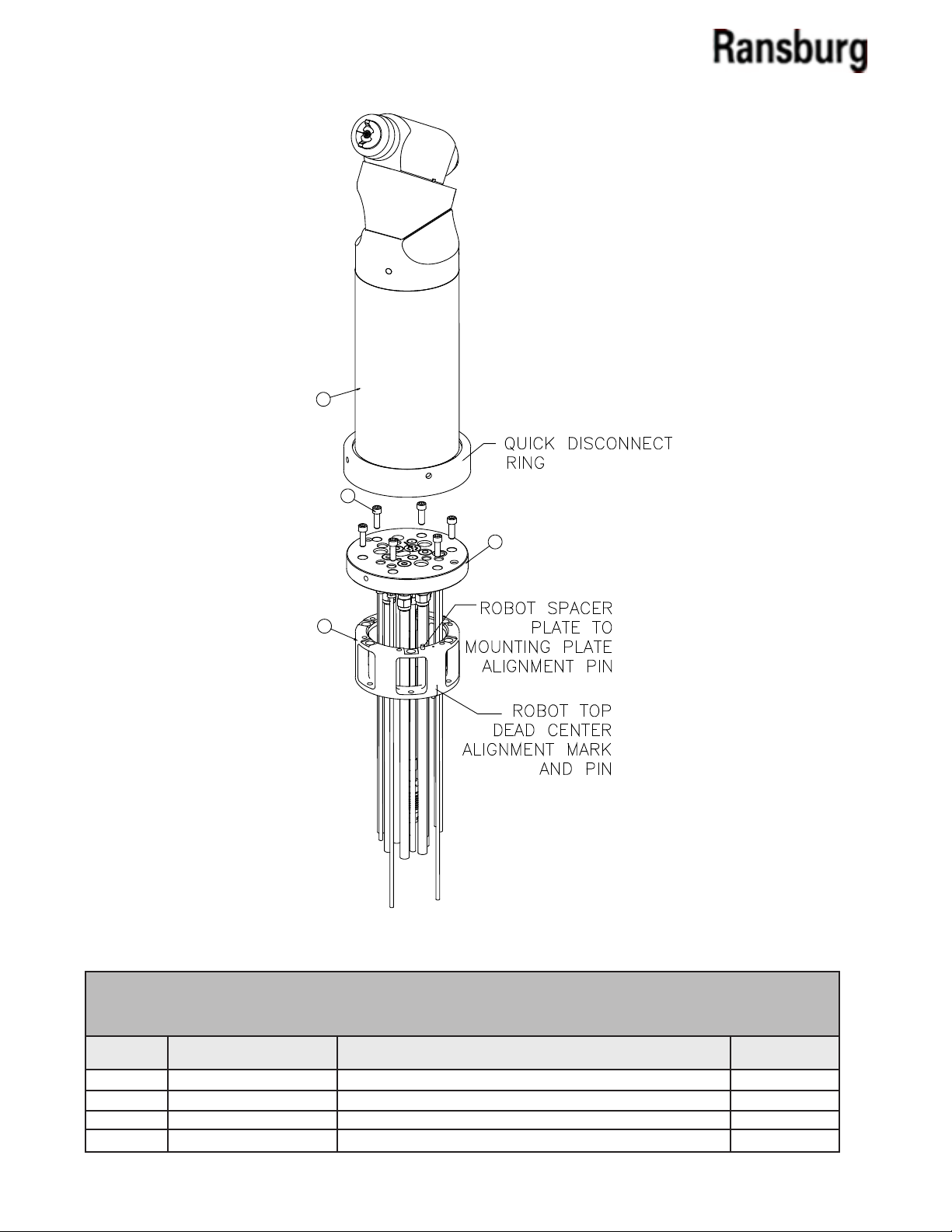

Robot Spacer Plate

The robot spacer plate is included with the robot

manifold assembly to increase life of the tubing

bundle. The extra spacing it provides increases the

bend radius of the tubes and decreases the hose or

cable stress at the connector.

There is only one way the spacer plate may be assembled to the mounting plate. The spacer plate has

an alignment pin that may only engage in one hole

position in the robot mount plate. This provides the

nal position to top dead center of the robot.

Six (6) robot spacer plates shown in Table 1 are available for this product.

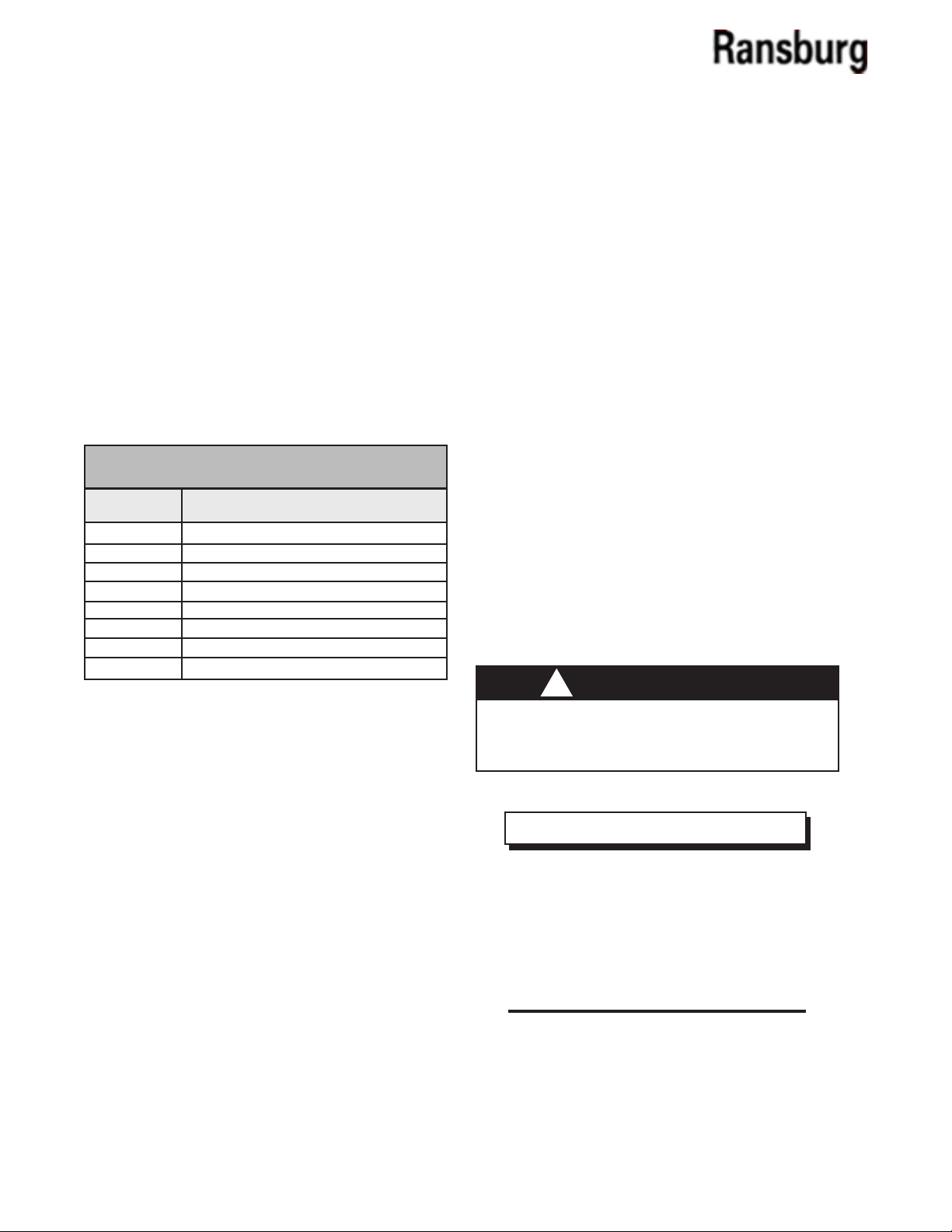

TABLE 1 - SPACER PLATES

Part # Description

79107-00 ABB 5400, 5002 Robots

78983-00 Fanuc P155, 145 Robots

79131-00 Fanuc P200/P-250 Robots

A10847-00 Adapter (Kawasaki-KE610L)

A10848-00 Adapter (Motoman-PX2850)

A10849-00 Adapter (Motoman-PX2900)

A10851-00 Adapter (B & M LZ2000)

A12036-00 Adapter (ABB 5400 Enhanced Wrist)

LOW VOLTAGE CABLE

It is important that the quick disconnect tting be

secured to a good ground source. The A12241-XX

cable is supplied with a ground cable which can be

secured to the bulkhead connector and the other

end to a known ground source. The cable can also

be grounded by attaching the bulkhead connector

to a grounded bulkhead plate. The bulkhead plate

can be no more than 1/8-inch (3.18mm) in thickness.

The bracket should be made as in Figure 7 to hold

the connector from turning. To mate the connectors, align the raised key section of the cable on the

applicator end with the key groove of the cable that

goes to the MicroPak. Push the male end into the

mating connector until an audible click is heard. Tug

on cable to ensure that it is locked in place. To remove

or disconnect the cable, pull back on the male connector shell and pull cable back at the same time. To

remove this section from the robot plate, remove the

applicator. Locate the set screw holding the anged

plastic 9 pin connector. Loosen with a 3/32" hex key

wrench. Pull the cable out from the robot plate end.

Install new cable in reverse direction, align the 9 pin

connector with the alignment mark on the robot

plate face and tighten set screw. Torque 5-10 lbs•in

(0.56-1.13 Nm).

W A R N I N G

!

> Cable connector shell must be electrically

grounded. Electrical noise or other interference

may result.

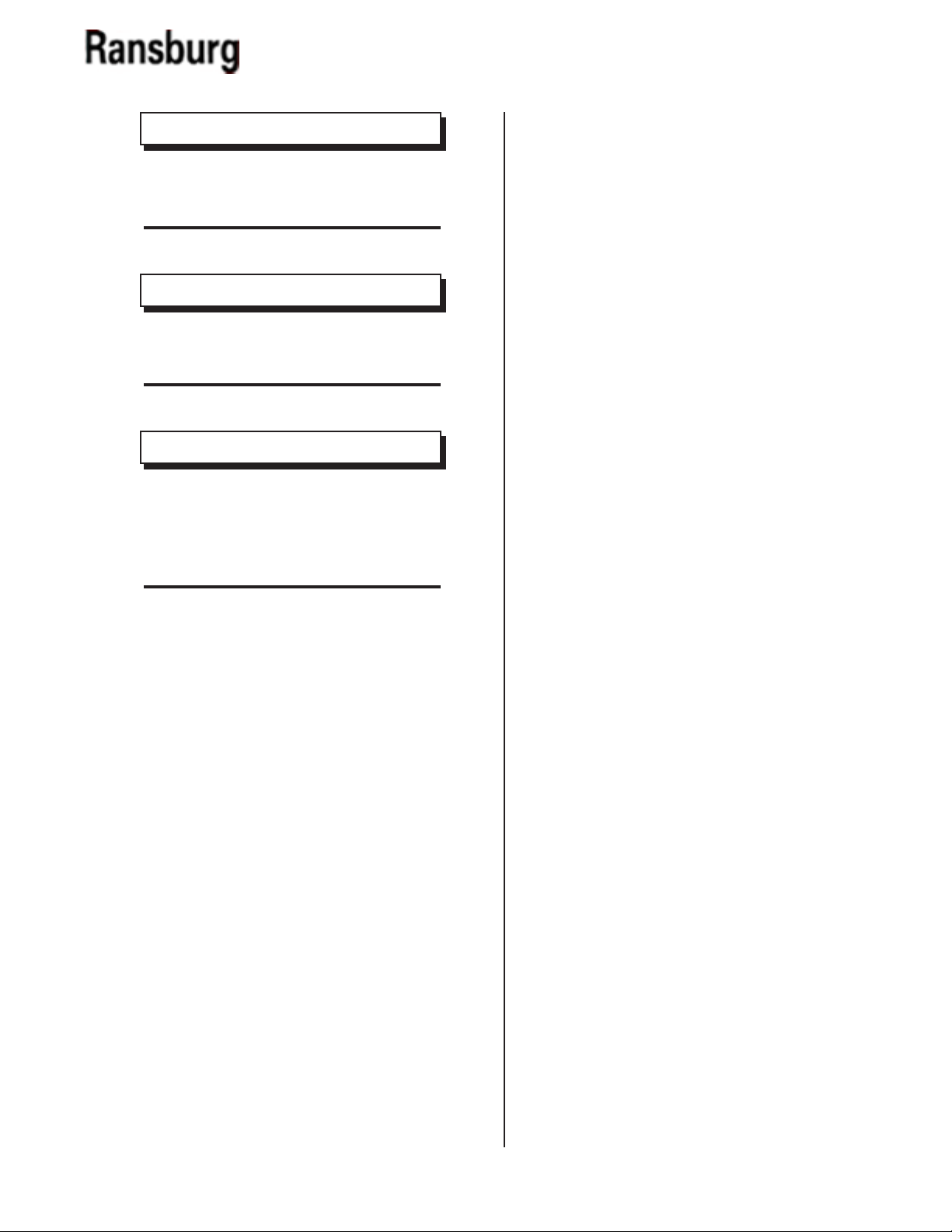

INSTALLATIONS

(See Figures 6, 7, and 8)

A low voltage cable is provided to send power to

the high voltage cascade in the applicator as well

as sending important information during operation

back to the MicroPak controls. One piece of the cable

is a permanent length of approximately

72-inches (1.8 meters) from the robot plate end. The

connecting cable can be ordered in various lengths

depending on the distance required to reach from

the robot arm to the MicroPak controller. The ends of

the cables have a male and female quick disconnect

end. This provides for a quick and easy removal of

the cable at the robot plate if servicing or replacement is required.

17

NOTE

> With the exception of uid, dump, and

bearing air/paint trigger, all other pilot and

air supply lines should be bulkheaded and

their diameters increased one nominal size.

For example: atomization air should be increased to an 1/2" ID (8mm) from bulkhead

plate to the volume booster.

AA-08-01.1

Evolver 303 Dual Purge Robotic Atomizers - Installation

NOTE

> If the length of the fan or atomization air

lines exceeds 30-ft. (10m), the lines must be

upsized to 1/2" ID (12mm for metric).

NOTE

> For the dipswitch settings for the

Evolver 303 dual purge, reference the current

microPak service manual

NOTE

> Leave 12-24-inches (.30-.61m) of

extra length on all lines to prevent extreme

tension being applied to these lines during

robot movement. This increases tubing

bundle life.

NOTES

AA-08-01.1

18

Evolver 303 Dual Purge Robotic Atomizers - Installation

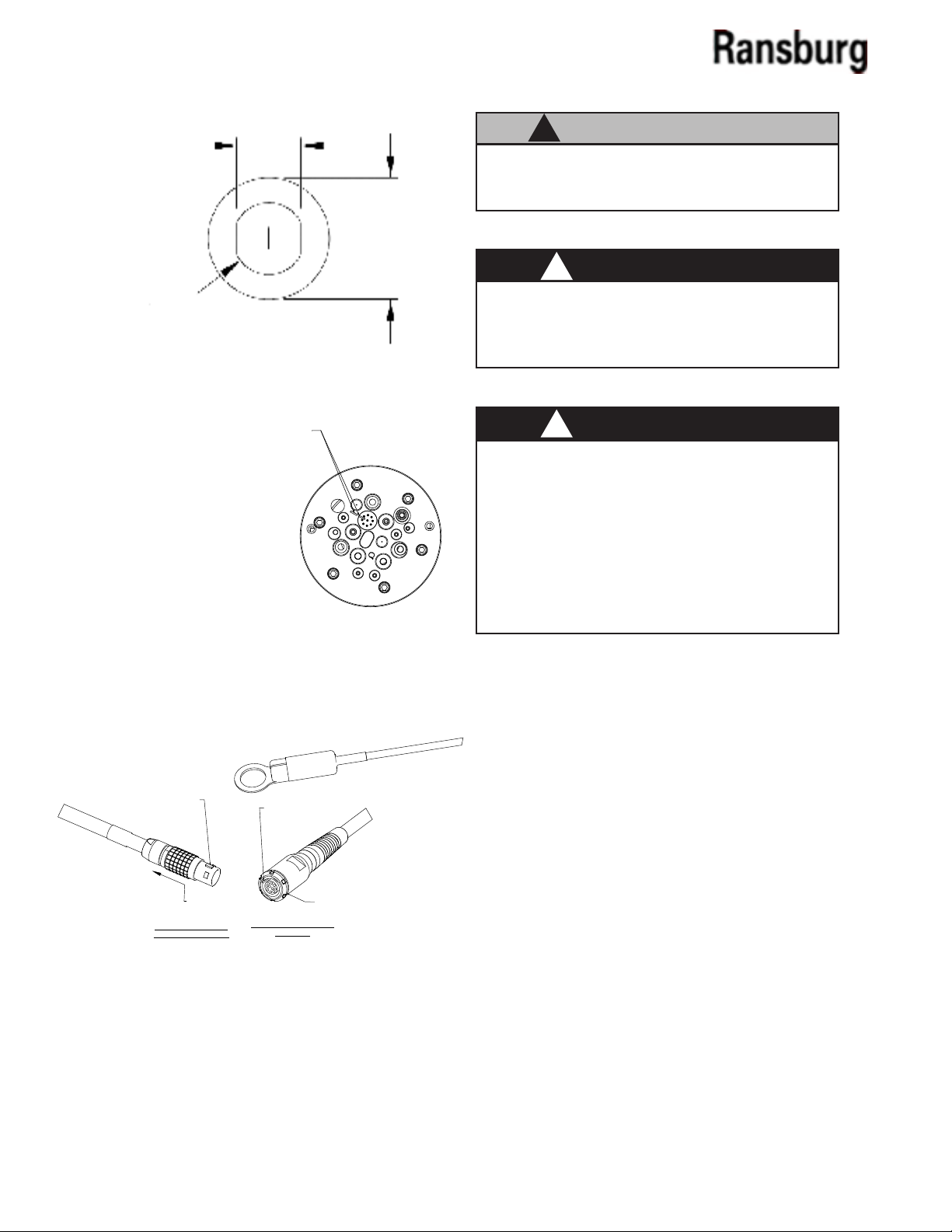

ALIGN TIMING MARKS ON ROBOT PLATE

AND LOW VOLTAGE CABLE CONNECTOR AS SHOWN.

TIGHTEN SET SCREW TO 5-10 LBS./IN (0.56-1.13 Nm) TORQUE

ROBOT PLATE

(ATOMIZER SIDE)

FEMALE KEY SLOT

RAISED MALE KEY

PUSH TO RELEASE

BULKHEAD AND MICROPAK

CABLE END

MALE CONNECTOR AND

APPLICATOR CABLE END

CONNECT HERE TO BULKHEAD OR

ATTACH GROUND CABLE HERE

OPTIONAL GROUND CABLE

0.53"

(13.49mm)

0.59"

(15.00mm)

Figure 6: Bulkhead Cut-Out Diagram

1.00"

(25.40mm)

!

C A U T I O N

> Do not exceed 100-ft. combined length of

the low voltage cables.

W A R N I N G

!

> If a non-explosion proof junction box/termi-

nal strip is used, it must be located outside the

hazardous area.

W A R N I N G

!

> Install and route the hoses and cable so that

they are NOT exposed to temperatures in excess

of 120° F. Ensure that all hose and cable bends

are NOT LESS THAN a 6-inch (15cm) radius and

are not subjected to more than 360° of torsional

twist. Failure to comply with these parameters

could cause equipment malfunctions that might

create HAZARDOUS CONDITIONS!

Figure 7: Robot Plate

Figure 8: Quick-Disconnect Cables

19

AA-08-01.1

Evolver 303 Dual Purge Robotic Atomizers - Installation

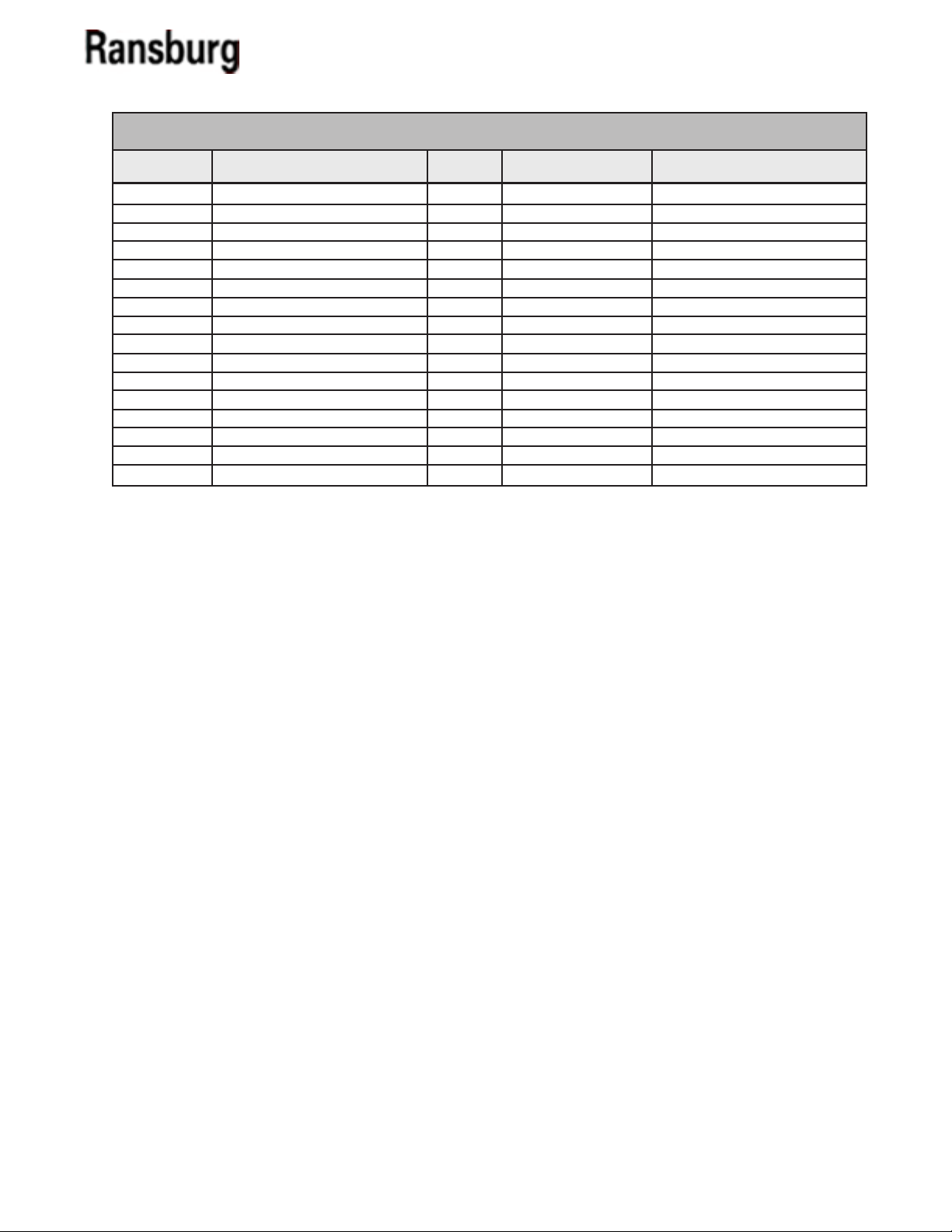

SIGNAL IDENTIFICATION TABLE BELLS APPLICATORS

Abbr.

B.A/P.T Bearing Air (Paint Trigger) Yellow Nylon 6mm OD X 4mm ID

B.A RTN Bearing Air Return Yellow Nylon 4mm OD X 2.7mm ID

BRK Brake Air Orange Nylon 6mm OD X 4mm ID

DL1/DL2 Dump Line Natural 10mm OD X 7mm ID

F.O Fiber Optic Cable Natural Polyethylene 1/4" OD (jacket)

LV Low Voltage Cable Black N/A N/A

P1.IN/P2.IN Paint In Natural 5/16" OD X 3/16" ID

P1T Paint 1 Trigger Green Nylon 4mm OD X 2.7mm ID

P2T Paint 2 Trigger Natural Nylon 4mm OD X 2.7mm ID

P1D Paint 1 Dump Trigger Silver Nylon 4mm OD X 2.7mm ID

P2D Paint 2 Dump Trigger Black Nylon 4mm OD X 2.7mm ID

SA.I/A.A Inner Shaping Air (Atom. Air) Blue Nylon 8mm OD X 6mm ID

SOL Solvent In Natural 6mm OD X 4mm ID

SA.O/F.A Outer Shape Air (Fan Air) Gray Nylon 8mm OD X 6mm ID

ST/RP Solvent Trigger Signal Blue Nylon 4mm OD X 2.7mm ID

T.A Turbine Air Natural Nylon 10mm OD X 7mm ID

Description Color

Tubing Material

Tubing Size

AA-08-01.1

20

Evolver 303 Dual Purge Robotic Atomizers - Installation

3

1

2

4

Figure 9: Applicator and Manifold Assembly

APPLICATOR AND MANIFOLD ASSEMBLY - PARTS LIST

(Figure 9)

Item #

1 A12283-XXXXXXX Tubing Bundle Assembly (Metric) 1

2 A12374-XXX Evolver 303 Dual Purge Spray Applicator Assembly 1

3 76566-24C Screw, 1/4-20 X 3/4" Lg., SHCS 6

4 See Table 1 Robot Adapter 1

Part # Description Qty

21

AA-08-01.1

Loading...

Loading...