Ransburg A12300 User Manual

Ransburg

SERVICE MANUAL

LN-9263-08.5

(Replaces LN-9263-08.4)

February - 2013

RMA

TM

-303 DUAL PURGE

DIRECT CHARGE ROBOT MOUNTED

ROTARY ATOMIZER

MODEL: A12300

With

Technology

IMPORTANT: Before using this equipment,

carefully read SAFETY PRECAUTIONS, starting on page 1, and all instructions in this

manual. Keep this Service Manual for future

reference.

Service Manual Price: $50.00 (U.S.)

Ransburg

NOTE: This service manual has been superceded from service manual number LN-9263-08.4 to

service manual number LN-9263-08.5 Reasons for this change are noted under “Manual

Change Summary” inside the back cover of this manual.

LN-9263-08.5

Ransburg

CONTENTS

SAFETY:

RMA-303 Dual Purge/Direct Charge - Contents

PAGE

1-4

SAFETY PRECAUTIONS...........................................................................................................

HAZARDS / SAFEGUARDS......................................................................................................

INTRODUCTION:

FEATURES..................................................................................................................................

GENERAL DESCRIPTION.........................................................................................................

SPECIFICATIONS......................................................................................................................

IMPORTANT NUMBERS............................................................................................................

GRAPHICAL INFORMATION.....................................................................................................

65MM DUAL FLEX WITH AND WITHOUT REPULSION RING...............................................

30MM WITH AND WITHOUT REPULSION RING....................................................................

55MM WITH AND WITHOUT REPULSION RING....................................................................

65MM MONO FLEX WITH AND WITHOUT REPULSION RING.............................................

CIRCUIT SCHEMATICS.............................................................................................................

INSTALLATION:

AIR FILTER INSTALLATION......................................................................................................

AIR PRESSURE REQUIREMENTS..........................................................................................

EQUIPMENT GROUNDING AND SAFETY

RECOMMENDATIONS...............................................................................................................

AIR HEATER REQUIREMENTS................................................................................................

AIR FILTRATION REQUIREMENTS.........................................................................................

MOUNTING.................................................................................................................................

ELECTRICAL AND FIBER OPTIC CONNECTIONS................................................................

FLUID CONNECTIONS..............................................................................................................

TYPICAL INSTALLATION...........................................................................................................

AIR HEATER...............................................................................................................................

TYPICAL INSTALLATION RMA-303..........................................................................................

TUBING BUNDLE INSTALLATION............................................................................................

BUNDLE LUBRICATION............................................................................................................

RMA-303 WIRING INSTALLATION............................................................................................

INTERLOCKS..............................................................................................................................

1

2-4

5-30

5

6-7

8

9

10-23

24

25

26

27

28-30

31-40

31

31

32-33

34

35

36

36

36

36

36

37

38

38

39

40

OPERATION:

FLUID FLOW RATE CONTROL.................................................................................................

FLUID VALVE CONTROL..........................................................................................................

DUAL PURGE SPRAYING........................................................................................................

TURBINE SPEED.......................................................................................................................

BEARING AIR ADJUSTMENT...................................................................................................

SHAPING AIR KIT #1..................................................................................................................

SHAPING AIR KIT #2..................................................................................................................

SHAPING AIR KIT #3..................................................................................................................

SHAPING AIR KIT #4..................................................................................................................

BRAKE AIR..................................................................................................................................

(Continued On Next Page)

LN-9263-08.5

41-52

41

42

42

42

43

43-44

44

45

45

46

RMA-303 Dual Purge/Direct Charge - Contents

Ransburg

CONTENTS (Cont.)

OPERATION (Cont.):

ELECTROSTATIC VOLTAGE....................................................................................................

TARGET DISTANCE..................................................................................................................

GENERAL OPERATING SEQUENCE......................................................................................

LOW VOLTAGE CABLE INSTALLATION AND REMOVAL.....................................................

LOW VOLTAGE CABLE ON ROBOT........................................................................................

BULKHEAD CUT-OUT DIAGRAM.............................................................................................

ROBOT PLATE...........................................................................................................................

QUICK-DISCONNECT CABLES................................................................................................

MAINTENANCE:

O-RINGS.....................................................................................................................................

CLEANING PROCEDURES.......................................................................................................

VIBRATION NOISE.....................................................................................................................

TURBINE MAINTENANCE.........................................................................................................

AIR FILTERS / ELEMENTS REPLACEMENT...........................................................................

GENERAL MAINTENANCE.......................................................................................................

PREVENTIVE MAINTENANCE..................................................................................................

BELL CUP PREVENTIVE MAINTENANCE...............................................................................

BELL CUP CLEANING...............................................................................................................

CLEANING SHAPING AIR HOLES...........................................................................................

RMA-303 PREVENTIVE MAINTENANCE SCHEDULE...........................................................

DISASSEMBLY PROCEDURE..................................................................................................

TROUBLESHOOTING GUIDE...................................................................................................

PAGE

41-52

46

46

46-48

49

50

51

51

52

53-80

53

53-55

55

55

55

56

56-58

58-59

60

61

62-63

63-76

77-80

PARTS IDENTIFICATION:

RMA-303 ROTARY ATOMIZER DUAL PURGE /

DIRECT CHARGE MODEL IDENTIFICATION / PARTS LIST.................................................

RMA-303 ASSEMBLY / PARTS LIST.........................................................................................

A12288-00 REAR PLATE ASSEMBLY / PARTS LIST..............................................................

A11289-00 VALVE MANIFOLD ASSEMBLY / PARTS LIST.....................................................

A12290-01/02 CUP WASH LINE ASSEMBLIES........................................................................

SHAPING AIR KITS / PARTS LIST............................................................................................

A12398-XXXXXXX TUBING BUNDLE ASSEMBLY MODEL

IDENTIFICATION (FRACTIONAL TUBING).............................................................................

ROBOT PLATES (FRACTIONAL OR METRIC)........................................................................

A12398-XXXXXXX TUBING BUNDLE ASSEMBLY (FRACTIONAL) /

PARTS LIST................................................................................................................................

A12283-XXXXXXX TUBING BUNDLE ASSEMBLY MODEL

IDENTIFICATION (METRIC TUBING).......................................................................................

A12283-XXXXXXX TUBING BUNDLE ASSEMBLY (METRIC) /

PARTS LIST................................................................................................................................

RMA-303 RECOMMENDED SPARE PARTS...........................................................................

SERVICE KITS............................................................................................................................

LUBRICANTS AND SEALERS...................................................................................................

AIR FILTER / ELEMENT REPLACEMENT................................................................................

ASSEMBLY TOOLS....................................................................................................................

ACCESSORIES..........................................................................................................................

81-108

81-84

85-86

87

88

88

89-90

91-92

93

94-95

96-98

99-100

101-105

105

105

106

106

107

WARRANTY POLICIES:

LIMITED WARRANTY.................................................................................................................

109

109

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Contents

LN-9263-08.5

RMA-303 Dual Purge/Direct Charge - Safety

SAFETY

SAFETY PRECAUTIONS

Ransburg

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature

for your Ransburg products. This manual contains

information that is important for you to know and

understand. This information relates to USER

SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the following symbols. Please pay particular

attention to these sections.

A WARNING! states information to alert you

to a situation that might cause serious injury

if instructions are not followed.

A CAUTION! states information that tells how

to prevent damage to equipment or how to

avoid a situation that might cause minor injury.

A NOTE is information relevant to the procedure in progress.

While this manual lists standard specications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements,

etc., make such variations inevitable. Compare

this manual with your system installation drawings

and appropriate Ransburg equipment manuals to

reconcile such differences.

W A R N I N G

!

The user MUST read and be familiar

with the Safety Section in this manual and the

Ransburg safety literature therein identied.

This manual MUST be read and thor-

oughly understood by ALL personnel who

operate, clean or maintain this equipment!

Special care should be taken to ensure that

the WARNINGS and safety requirements for

operating and servicing the equipment are

followed. The user should be aware of and

adhere to ALL local building and re codes

and ordinances as well as NFPA-33 SAFETY

STANDARD, prior to installing, operating,

and/or servicing this equipment.

W A R N I N G

!

The hazards shown on the following

page may occur during the normal use of

this equipment. Please read the hazard

chart beginning on page 2.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efcient operation,

longer trouble-free service and faster, easier troubleshooting. If you do not have the manuals and

safety literature for your Ransburg system, contact

your local Ransburg representative or Ransburg.

1

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate oper-ation and maintenance

pro-cedures will cause a re

hazard.

Protection against inadvertent arcing that is capable of

causing re or explosion is

lost if any safety interlocks

are disabled during operation. Frequent power supply

shut-down indicates a problem in the system requiring

correc-tion.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

spray area and tested periodically.

Spray areas must be kept clean to prevent the accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

Those used for equipment ushing should have ash

points equal to or higher than those of the

coating material.

Those used for general cleaning must have ash

points above 100oF (37.8oC).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, and local codes. In addition, ventilation must be maintained during cleaning

operations using ammable or combustible solvents.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only

as instructed.

Non-factory replacement parts or unauthorized equip-

ment modications may cause re or injury.

If used, the key switch bypass is intended for use only

during set-up operations. Production should never

be done with safety interlocks disabled.

Never use equipment intended for use in waterborne

installations to spray solvent based materials.

The paint process and equipment should be set up

and operated in accordance with NFPA-33, NEC, and

OSHA requirements.

LN-9263-08.5

2

RMA-303 Dual Purge/Direct Charge - Safety

Ransburg

AREA

Tells where hazards

may occur.

General Use and

Maintenance

Electrical

Equipment

HAZARD

Tells what the hazard is.

Improper operation or maintenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

High voltage equipment is utilized. Arcing in areas of ammable or combustible mater-ials may

occur. Personnel are exposed to

high voltage during operation and

maintenance.

Protection against inadvertent

arcing that may cause a re or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shutdown indicates a problem in the

system which requires correction.

An electrical arc can ignite coat-

ing materials and cause a re or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Personnel must be given training in accordance

with the requirements of NFPA-33.

Instructions and safety precautions must be read

and understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, re protection, operation maintenance, and housekeeping. Reference

OSHA, NFPA-33, and your insurance company

require-ments.

The power supply, optional remote control cabinet,

and all other electrical equipment must be located

outside Class I or II, Division 1 and 2 hazardous

areas. Refer to NFPA-33.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of ammable or combustible

material.

Testing may require high voltage to be on, but only

as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Explosion Hazard/

Incompatible

Materials

3

Halogenated hydrocarbon solvents for example: methylene

chloride and 1,1,1,-Trichloroethane are not chemically compatible with the aluminum that

might be used in many system

components. The chemical reaction caused by these solvents

reacting with aluminum can become violent and lead to an

equipment explosion.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum equip-

ment during spraying, ushing, or cleaning. Read

the label or data sheet for the material you intend

to spray. If in doubt as to whether or not a coating

or cleaning material is compatible, contact your

material supplier. Any other type of solvent may

be used with aluminum equipment.

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Safety

AREA

Tells where hazards

may occur.

Toxic Substances

Spray Area/High

Voltage Equipment

HAZARD

Tells what the hazard is.

Certain material may be harmful if inhaled, or if there is contact with the skin.

There is a high voltage device

that can induce an electrical

charge on objects which is capable of igniting coating materials.

Inadequate grounding will cause

a spark hazard. A spark can ignite many coating materials and

cause a re or explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the air

free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance

of inhaling sprayed materials. The mask must be

compatible with the material being sprayed and its

concentration. Equipment must be as prescribed by

an industrial hygienist or safety expert, and be

NIOSH approved.

Parts being sprayed must be supported on convey-ors or hangers and be grounded. The resistance

between the part and ground must not exceed 1

megohm.

All electrically conductive objects in the spray area,

with the exception of those objects required by the

process to be at high voltage, must be grounded.

Any person working in the spray area must be

grounded.

Personnel Safety/

Mechanical

Hazards

Robot Work Area General Use and

Maintenance

The bell atomizer can rotate at

speeds up to 70,000 rpm. At

these speeds, the edge of the

applicator can easily cut into skin.

Loose articles of clothing can also

be caught by the rotating bell.

Improper use or maintenance

can lead to hazardous conditions, particularly from unexpected robot manipulator movement.

Unless specically approved for use in hazardous

locations, the power supply and other electrical control equipment must not be used in Class 1, Division

1 or 2 locations.

Personnel must stay clear of the bell whenever it

is rotating.

Before touching the bell, the turbine air must be

shut off.

If the bell has been rotating, allow at least two

minutes for it to come to a complete stop before

touching it.

Applicator adjustments or maintenance should be

done after the robot is taken out of service. Do not

adjust or repair the applicator if the robot is operating

or standing ready to start.

Refer to robot operating instructions for the procedures to take the robot out of service.

LN-9263-08.5

4

RMA-303 Dual Purge/Direct Charge - Introduction

Ransburg

INTRODUCTION

FEATURES

Features which make the RMATM-303 Dual Purge Direct Charge Robot Mounted Rotary Atomizer

advantageous for use in electrostatic applications include:

ut

• True dual purge capability. Spray one color

while cleaning the other paint line with no

loss of tip voltage.

• Assembly components made of durable engineered resin material for optimum nmechanical

strength and solvent resistance.

• Heavy duty design ensures excellent service

life even when subjected to the quick motions

of robotic applications.

• Proven long life turbine motor capable of

speeds up to 70 krpm. (See "Specications" in

the "Introduction" section of this manual for bell

cup speed ratings.)

• Serrated and non-serrated bell cups are avail-

able for application exability and colo match.

All bell cups are made using Titanium material.

The 55mm bell cup is also available in aluminum.

• Aerodynamic design for ease of cleaning

external surfaces.

• 60o angled body provides more maneuverability

and facilitates robotic programming.

• Small light weight package allows better maneuverability in tight areas.

uid valves, make off-line maintenance more

efcient and economical.

• Fast color changes are achieved using center

feed uid delivery and the uid valves provide

for simultaneous paint push out while solvent

washes the feed tube and bell cup.

• Internal and external bell wash is quick and

efcient. Externally mounted regulators control

the ow.

• Less waste to the spray booth, with the dump

valve located internally next to the feed tube.

• No external high voltage cable. The internally

mounted high voltage cascade requires only

low voltage control wiring.

• Compact high voltage control system. The

MicroPak cascade control takes only 1/4 of the

space in a 19-inch Euro rack, leaving room for

additional control modules.

• Various adapter plates available to match most

robotic mounting congurations.

• Direct charging of uid (solventborne paint)

promotes high transfer efciency.

• Large range of uid tip sizes available.

• Speed control uses reliable magnetic pickup for

ber optic transmission of rotational speed data.

• Negligible maintenance down time. With the

quick disconnect feature, an atomizer can be

exchanged in less than 2 minutes for off-line

maintenance.

• The easily removable front and rear shrouds,

turbine assembly and the internally mounted

5

• Optional repulsion ring and shroud for tighter

pattern control and less overspray.

LN-9263-08.5

Ransburg

GENERAL DESCRIPTION

RMA-303 Dual Purge/Direct Charge - Introduction

Bell Cup Assembly

All bell cups are made of high strength Titanium.

They are available in 65mm serrated, non-serrated

for base coat applications and 55mm or 65mm

serrated for clear coat and primer applications. A

30mm and 55mm aluminum bell cup is available

Air Bearing Turbine Assembly

The air bearing turbine assembly with bell cup

is mounted to the air manifold assembly with a

turbine retaining ring.

Air Manifold Assembly

The atomizer extension is angled at 60° for robot

applications. The uid feed tube and ber optic

turbine speed emitter are threaded into the front of

the manifold. The turbine, uid, and air manifold

are separated from the bell plate assembly by ve

sup-port rods. Nested between the manifolds and

the bell plate is the high voltage cascade.

Bell Plate Assembly

The bell plate assembly is designed to be at ground

potential when mounted to the robot plate component within the tubing bundle assembly. The

air and uid ports are compactly oriented for use

in robotic applications. The interior air supplies

are ported through the ve support rods and also

directly tubed to the air manifold assembly. On

the exterior side of the bell plate, the ports are

provided with o-ring seals so that the atomizer can

be quickly mated and secured to the robot plate.

Robot Plate

The robot plate is a component of the tubing bundle

assembly and intended to be permanently mounted

to the robot. A wrist adapter is also available, which

matches the robot's mounting conguration. The

incoming air lines, uid lines, low voltage cable,

and ber optic cable are connected to the ttings

provided on the back of the robot plate. The bell

plate of the atomizer assembly is secured to the

robot plate with a threaded retaining ring.

Valve Manifold

Congured to allow two colors to be loaded at one

time. The manifold can be converted for single

paint supply by installing valve port plugs (7762000 Valve Plug Kit).

Break-Away Feature (Optional)

The RMA-303 can be converted to have a break-

away feature, by replacing the ve (5) stainless

steel screws with ve (5) special designed plastic

screws (77524-00). This feature is meant to reduce the damage to the atomizer, robot, etc. If a

collision occurs, the ve (5) plastic break-away

screws fail and the atomizer will break free. This

will leave the break-away ring and the mounting

ring attached to the robot.

LN-9263-08.5

6

RMA-303 Dual Purge/Direct Charge - Introduction

Power Supply and Controls

The high voltage cascade located inside the RMA303 is controlled by the MicroPakTM control unit.

The low voltage output of the MicroPak is multiplied by the internal cascade to the high voltage

level required. This eliminates the need for a high

voltage cable. A low voltage cable interconnects

the cascade and MicroPak control. The MicroPak

Eurocard format is designed to t in a conventional

19-inch or 10 inch rack and requires a 24V power

input at a maximum 3 amps. The MicroPak and

the internal cascade will produce voltages up to

100,000 VDC.

The MicroPak is designed to electronically limit

current to provide safe operation in a spray booth.

The voltage and current draw of the atomizer are

continuously displayed on the MicroPak control

panel. Voltage and overcurrent limits are ad-

justable on the front of the MicroPak. MicroPak

internal safety circuits will shut down the system

on over-current and cable faults.

Ransburg

NOTES

With additional control modules, all of the functions

of RMA-303 and MicroPak can be controlled by

a programmable controller. A Serial Atomizer

module pneumatically controls the speed of the

rotary atomizer with dynamic feedback through a

ber optic transmitter located on the applicator.

An AirTronic module pneumatically controls the

atomizer’s inner (pattern control) and outer (cutin control) shaping air. A Serial Digital module

pneumatically controls the paint, solvent, and

dump valves located on the atomizer. An I/O

module provides communication between these

modules and the PLC.

The above modules are mounted in one 19-inch

rack and interconnected through a common

mother board.

7

LN-9263-08.5

Ransburg

SPECIFICATIONS

RMA-303 Dual Purge/Direct Charge - Introduction

Electrical

Power Supply

Type: MicroPak™

Charging Method: Direct

Output Voltage: 30-100kV Variable

Output Current: 125 µA Max

Turbine Speed

Control: Eurocard Atomizer

Module

Inner/Outer Shaping

Air Control: Eurocard AirTronic

Module

Part Sprayability: Determine sprayability of

part to be coated using Test Equipment (76652)

Paint Conductivity Meter)

Mechanical (Cont.)

Bearing Air Supply: 90 psig (±10 psi)

(Nominal): (621 kPa ±69 kPa)

2.9 SCFM (82 slpm)

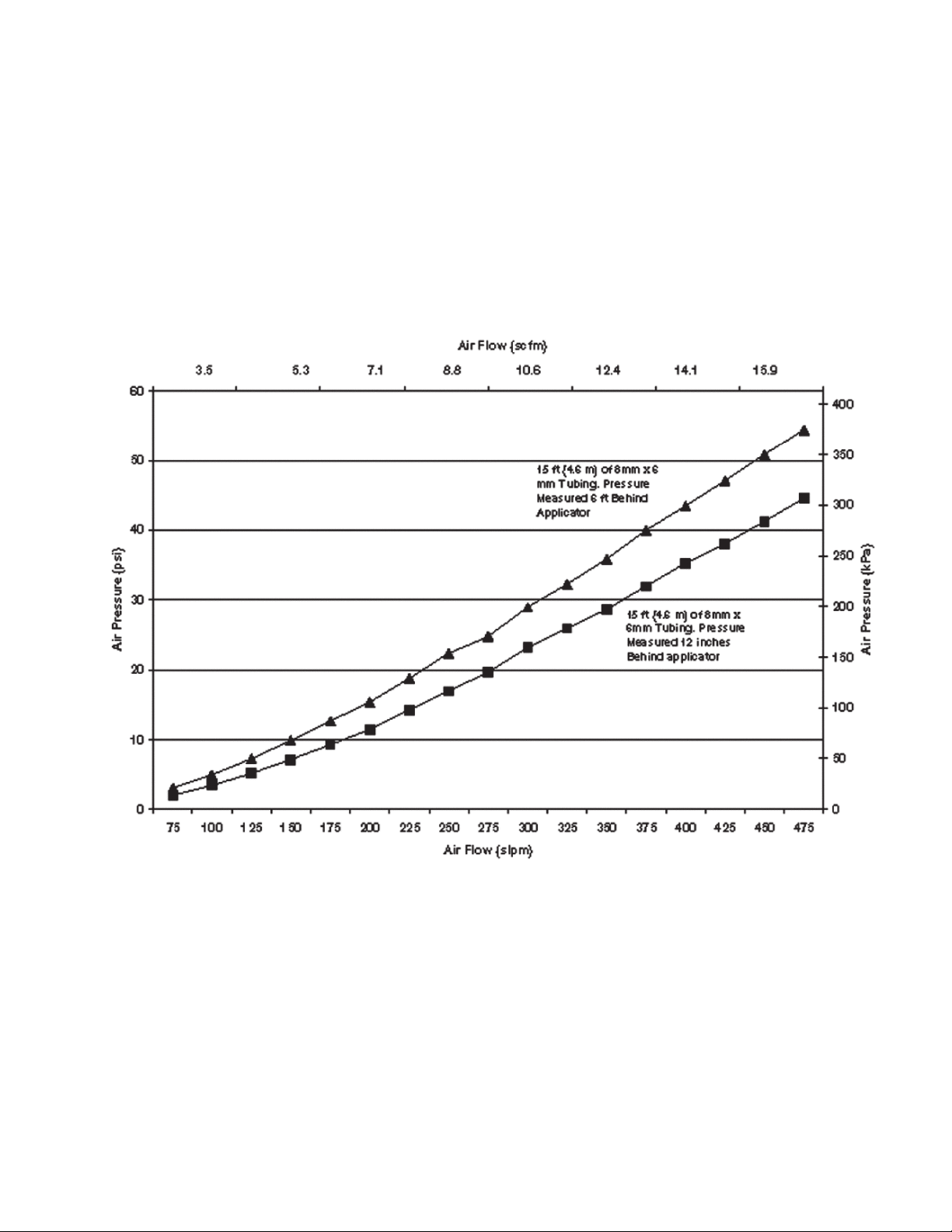

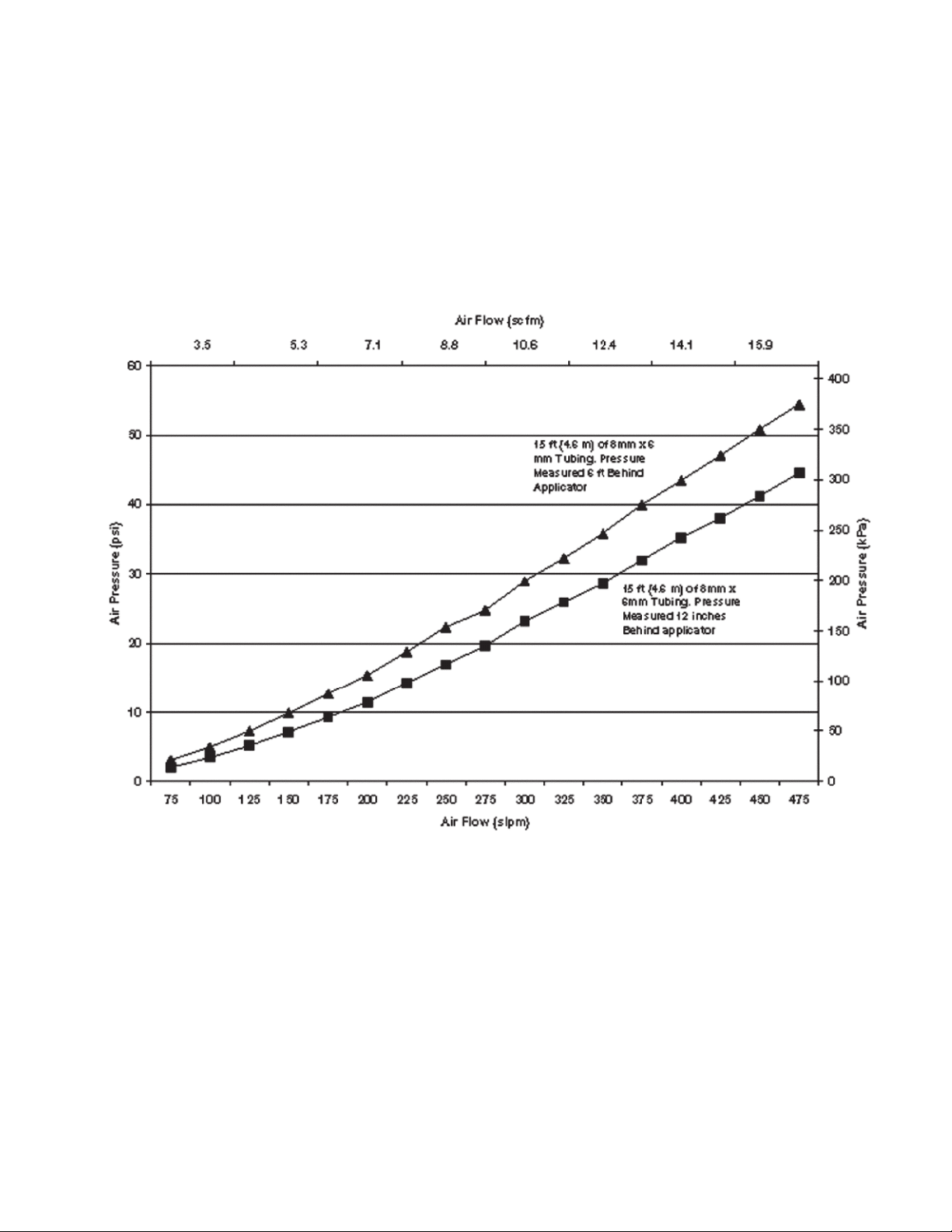

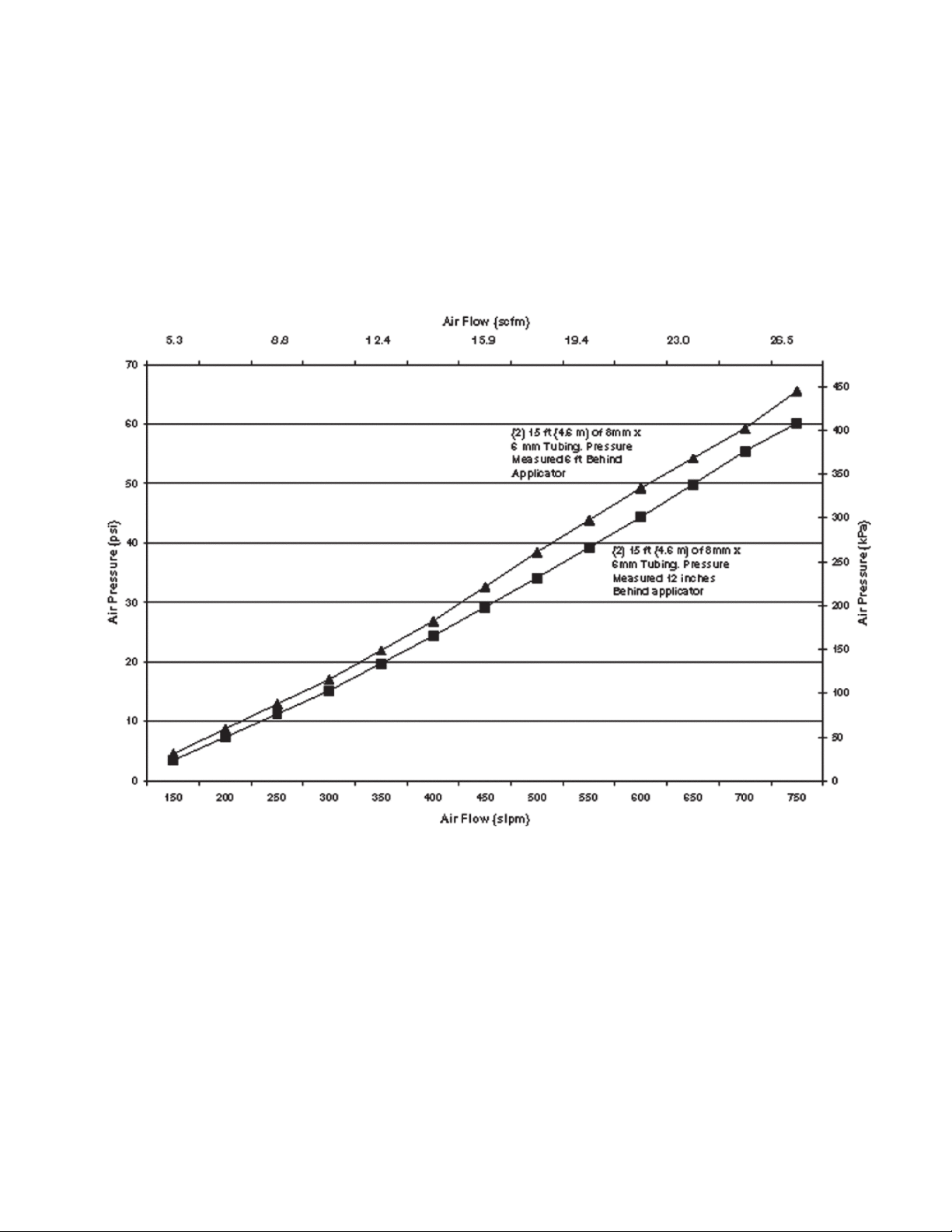

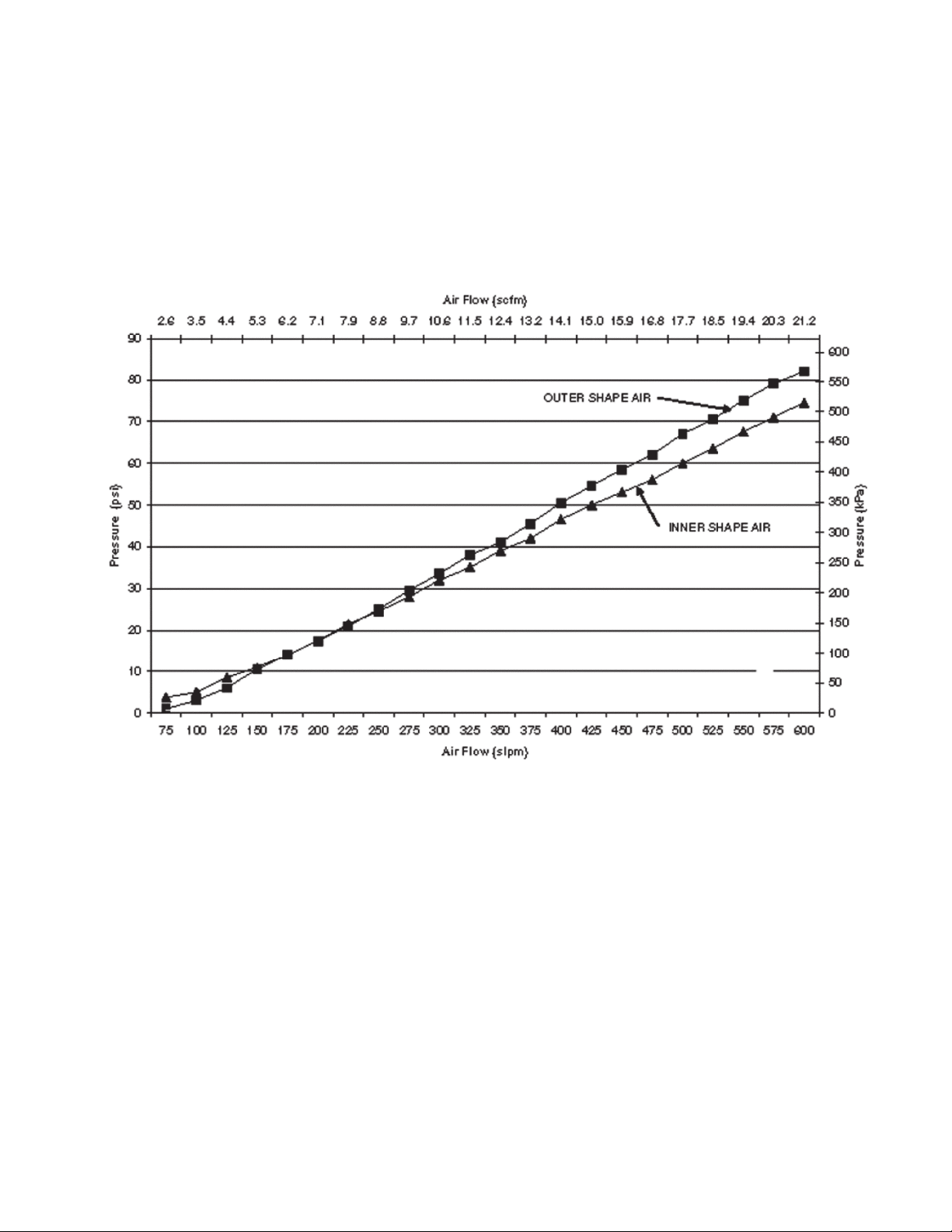

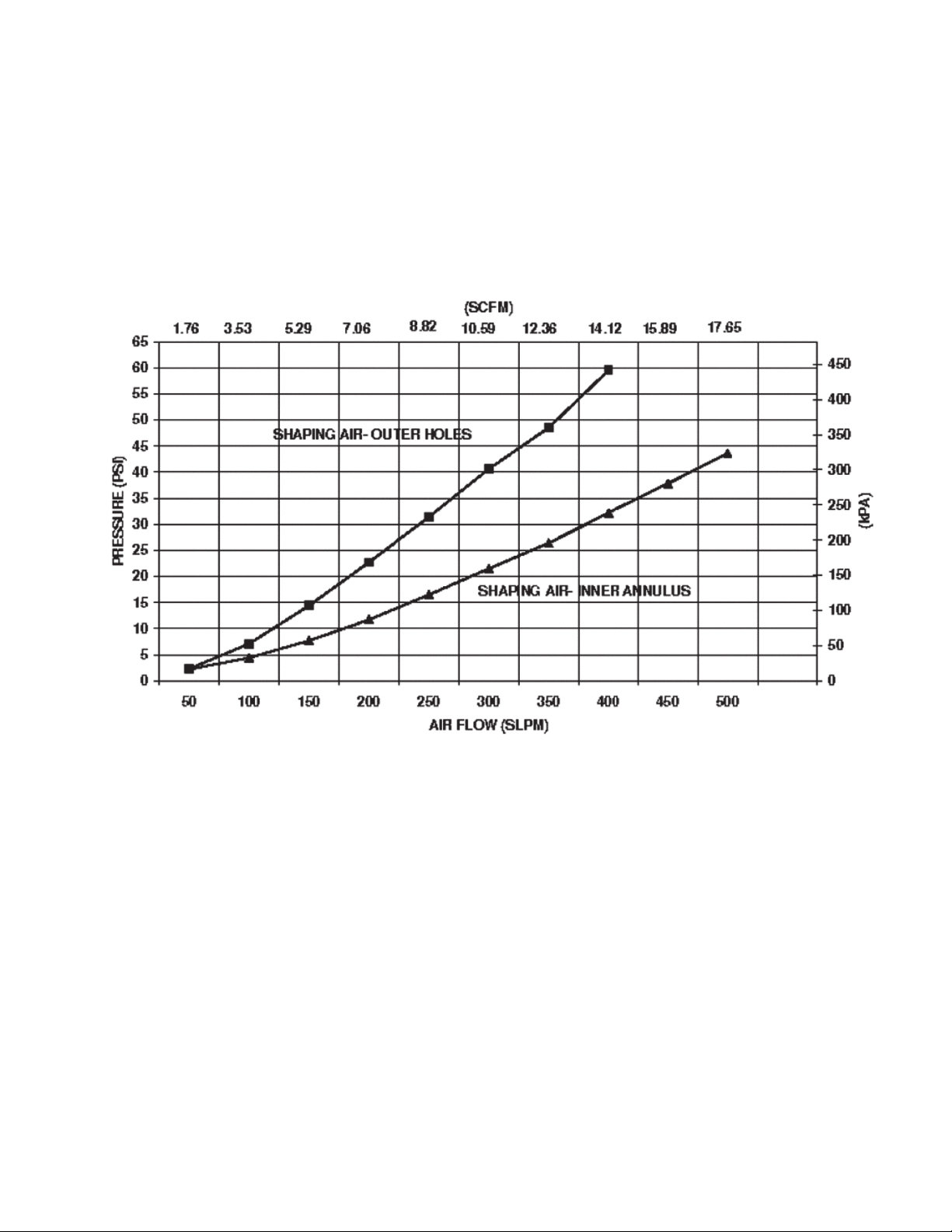

Shaping Air #1 (SAI): Variable

(See "Pressure Flow Data Charts" in this section)

Shaping Air #2 (SAO): Variable

(See "Pressure Flow Data Charts" in this section)

Brake Air Supply: 60-100 psig

(Nominal): (414-689 kPa)

Maximum Fluid Pressure Supply:

Paint: 200 psi (1379 kPa)

Solvent: 150 psi (1035 kPa)

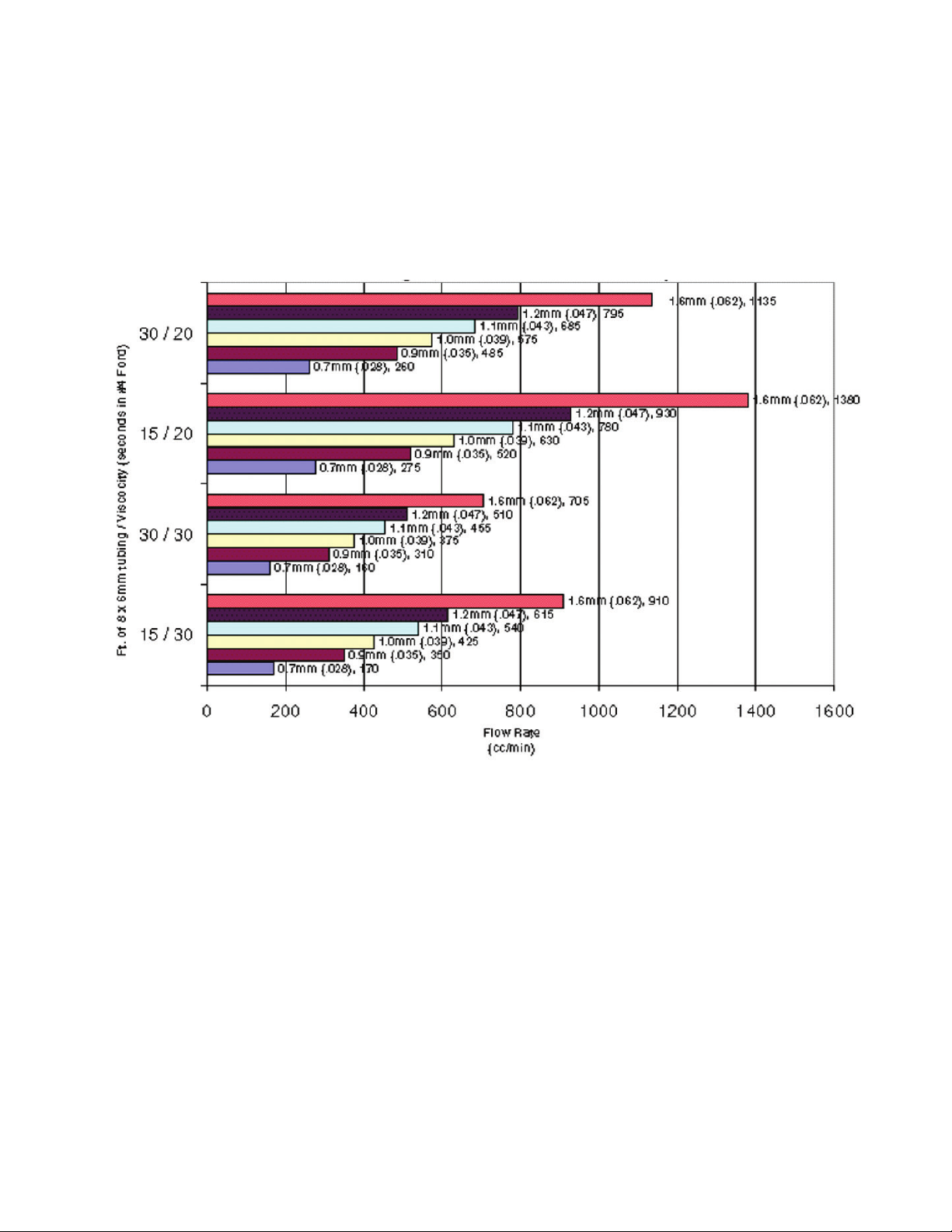

Fluid Flow Rate: 25-700 cc/minute

Bell Cup Cleaning Time

(Internal/External): 2-7 sec. (Approx.)

Mechanical

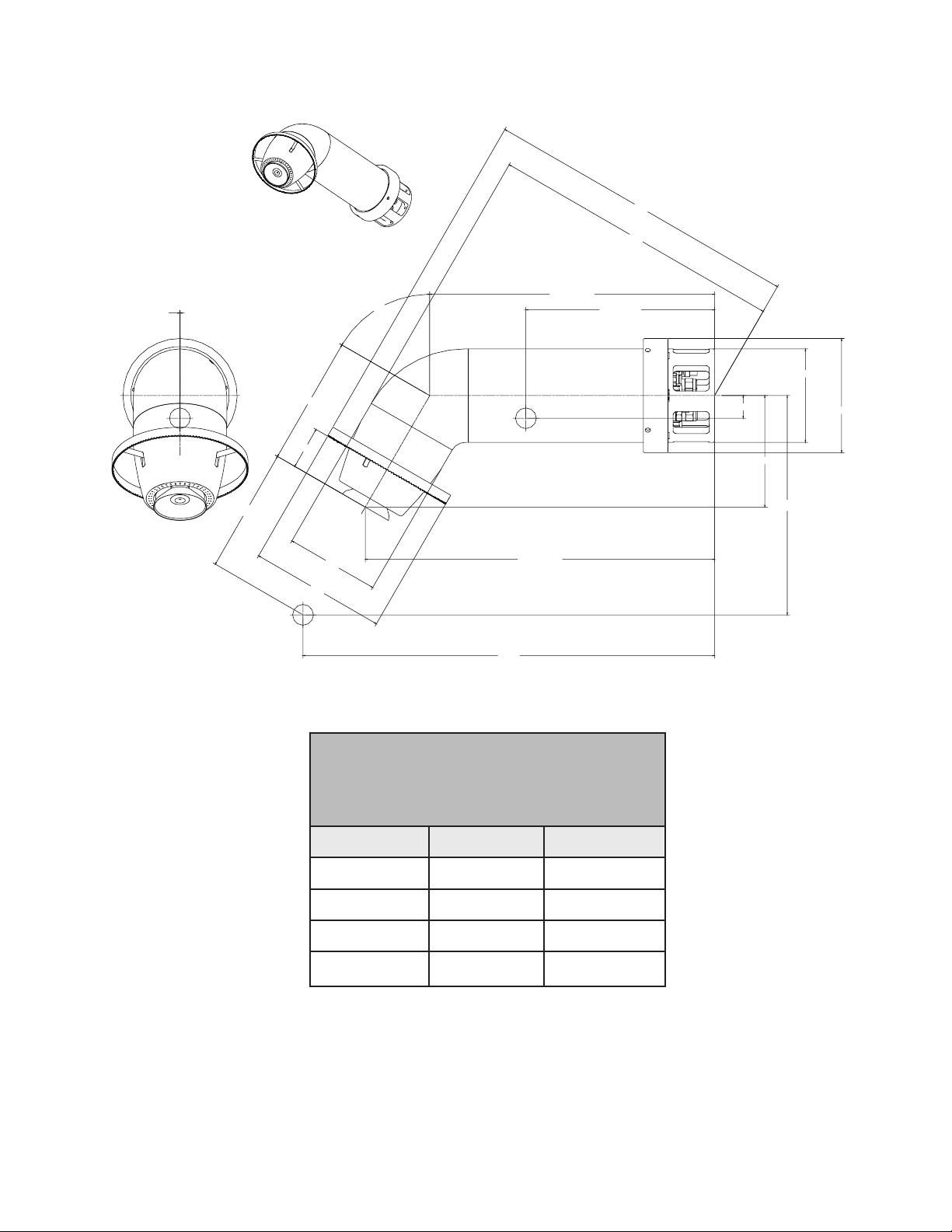

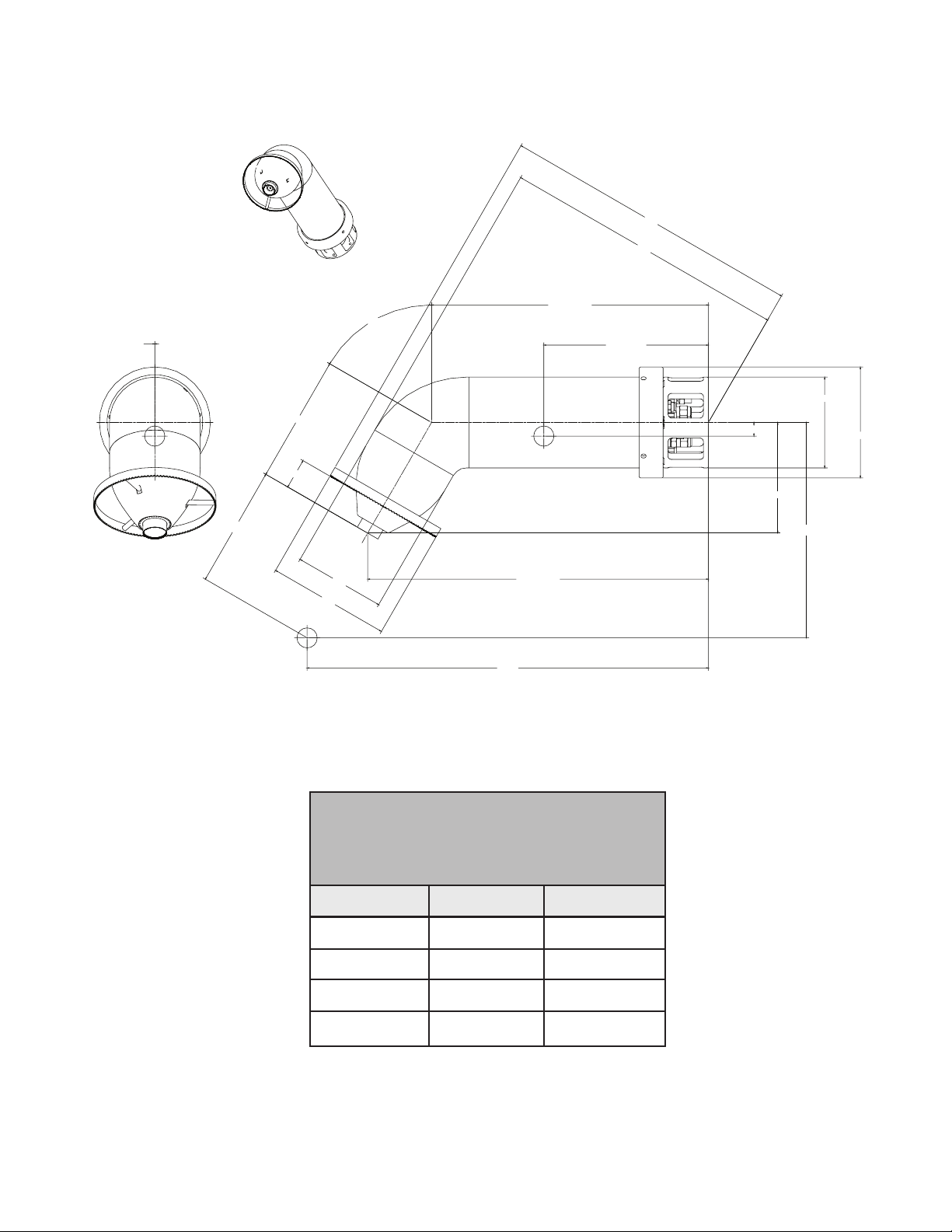

Length: (See Figures 1- 4)

Diameter: (See Figures 1-4)

Approximate Weight:

Total Payload: (See Figures 1-4)

(Robot Plate & Adapter)

Turbine Type: Air Bearing Impulse

Drive

Turbine Air Supply: Variable

(See "Pressure Flow Data Charts" in this section.)

Maximum/Minimum

Turbine Speed: Continuous

30mm, 55mm, 65m

Bell Cup:

Maximum Angular

Velocity for Turbine

(robot motion) 250°/sec.

70K rpm max./20K rpm min.

Color Change Time: Dependent on system con-

guration, uid pressures, uid viscosity, uid line

lengths, etc.

Speed Readout: Magnetic pick-up,

unidi-rectional ber optic

transmission

Atomizer Replacement

Time: Less than 2 minutes

Bell Cup Replacement

Time: Less than 2 minutes

Minimum Control Equipment

Requirements: (Versions listed or

higher)

MicroPak LECU5004-11 (V3.83)

Atomizer Module 76011-00 (V3.42)

I/O Module A11345-00

(V1.4) (4-20 mA)

76037-03 (V3.44)

(0-10V)

* Specications and ratings based on testing

at sea level standard conditions.

LN-9263-08.5

8

RMA-303 Dual Purge/Direct Charge - Introduction

Ransburg

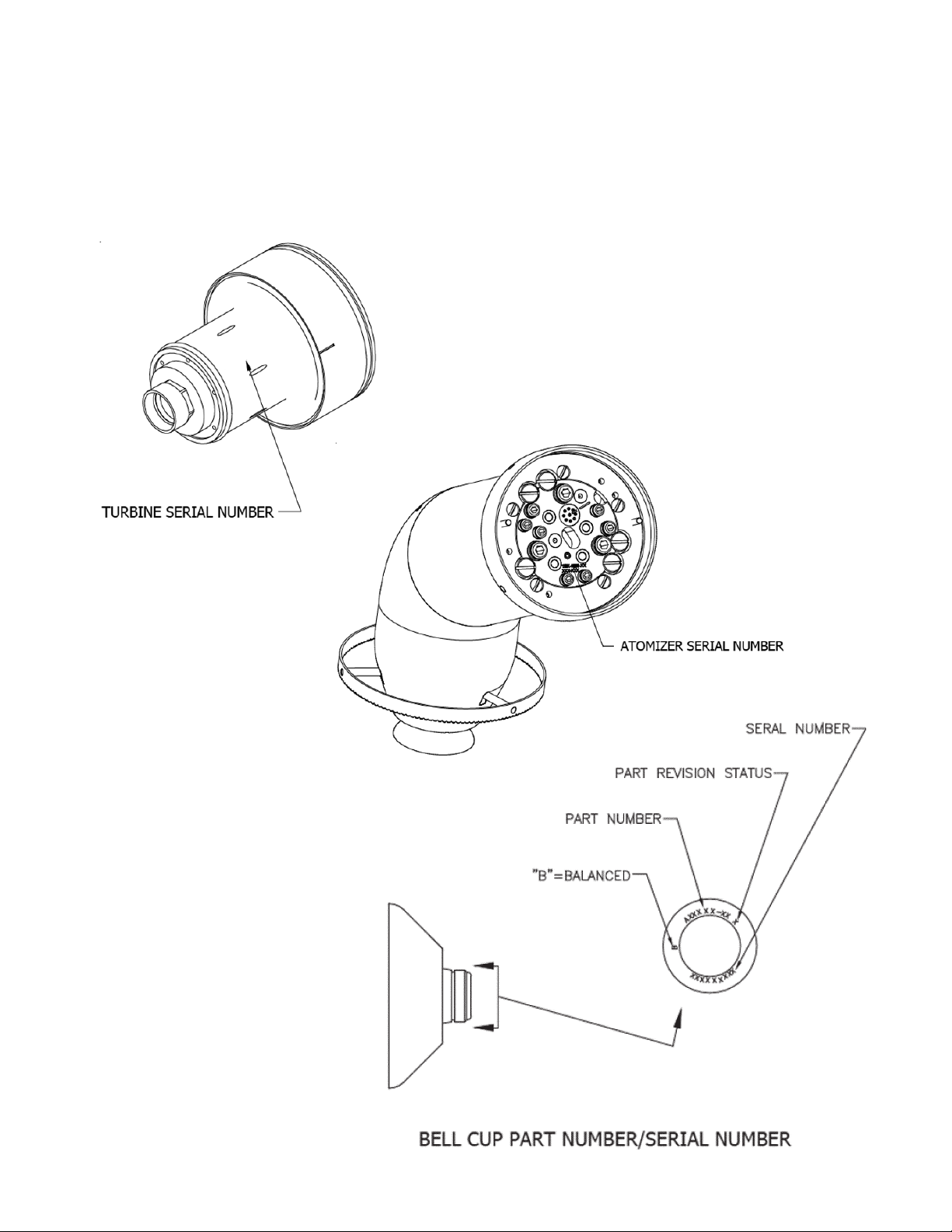

IMPORTANT NUMBERS

Record these numbers in a log book for future reference. The last digits of the Atomizer serial number

are also the Turbine serial numbers.

9

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Introduction

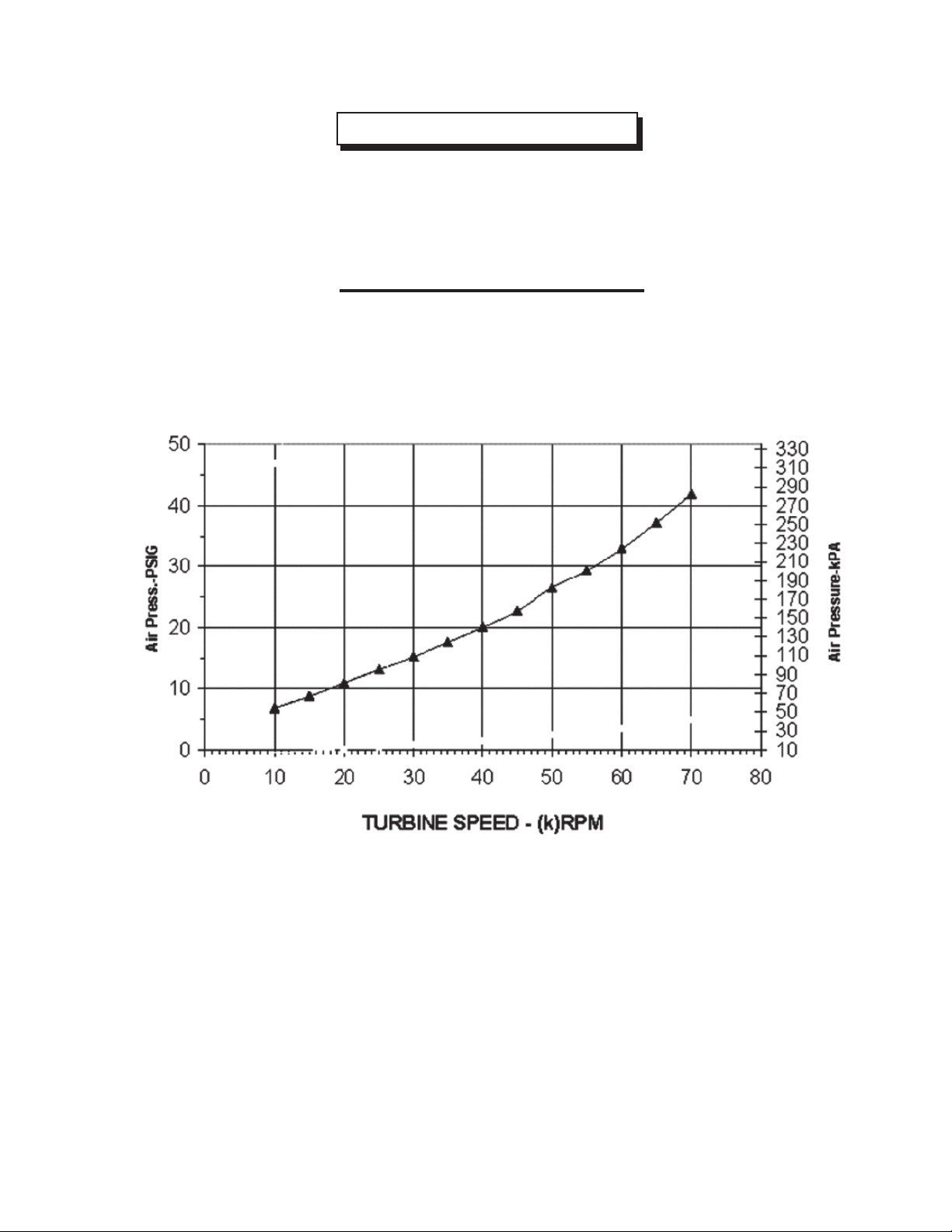

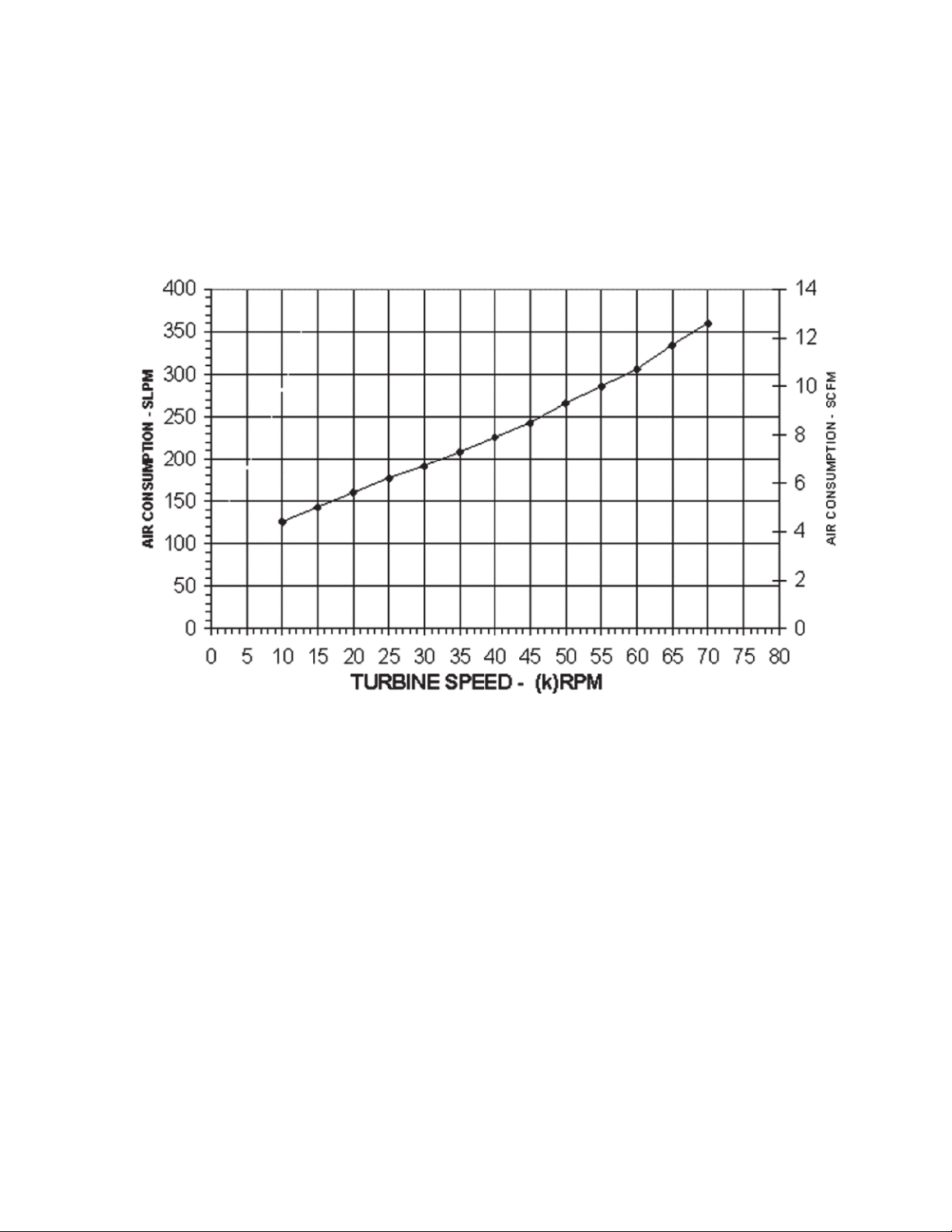

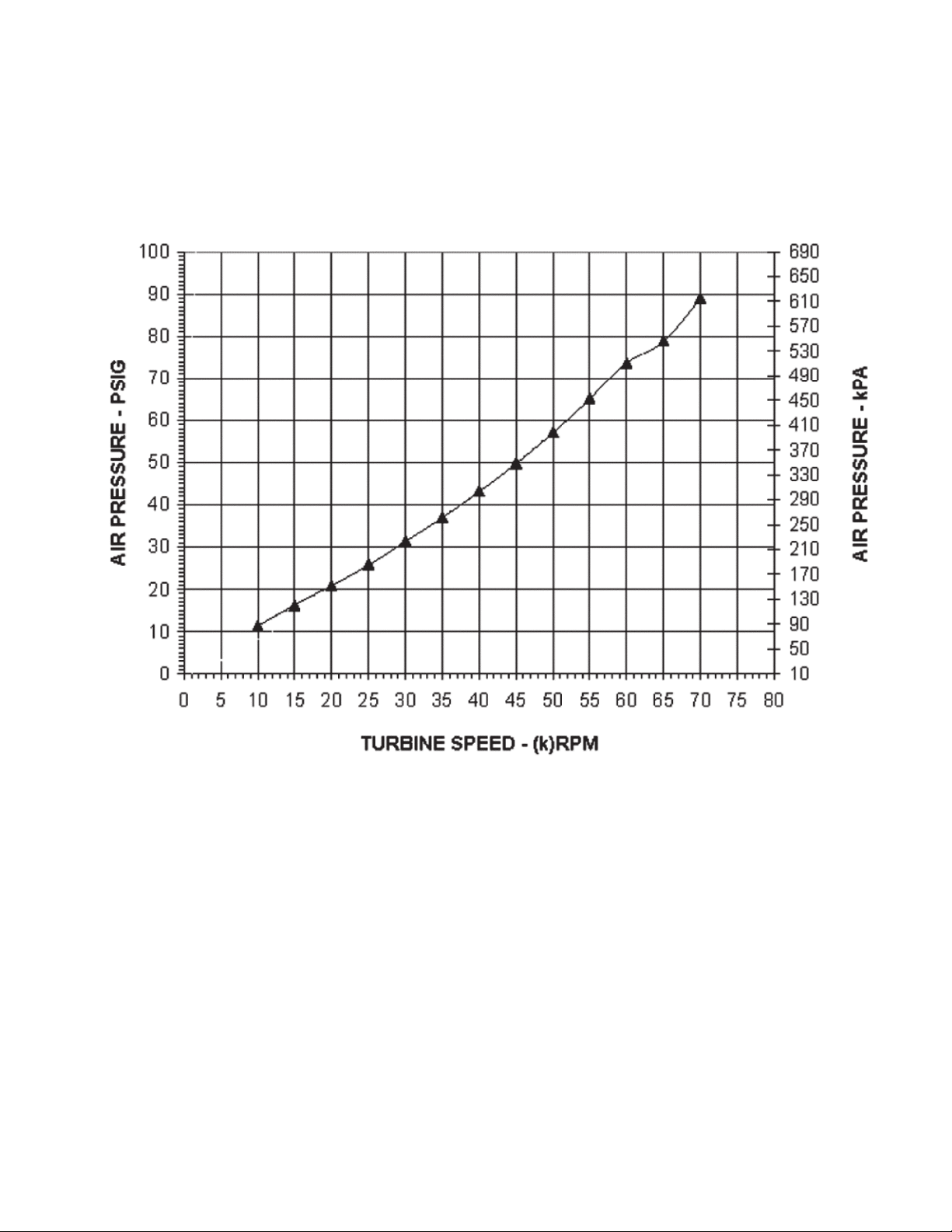

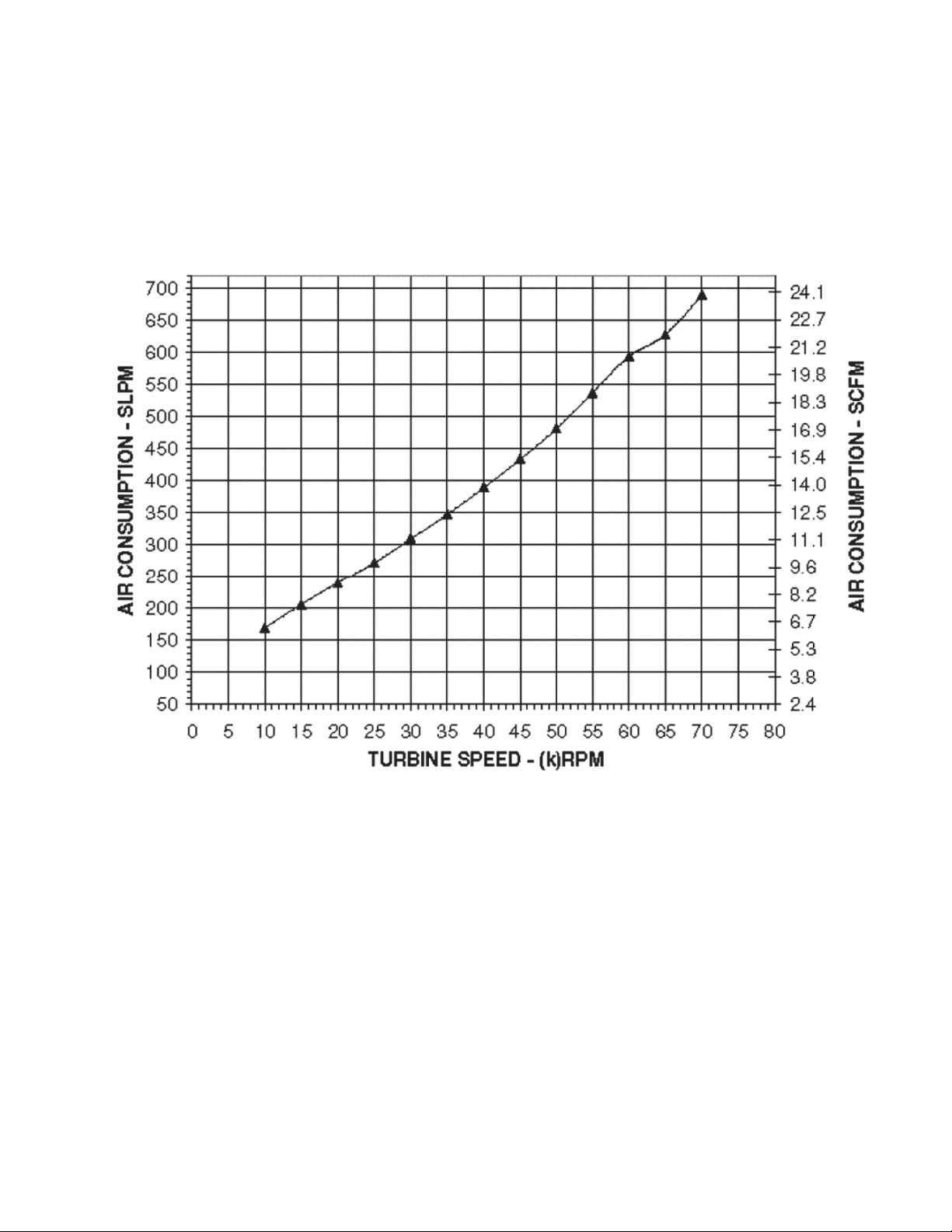

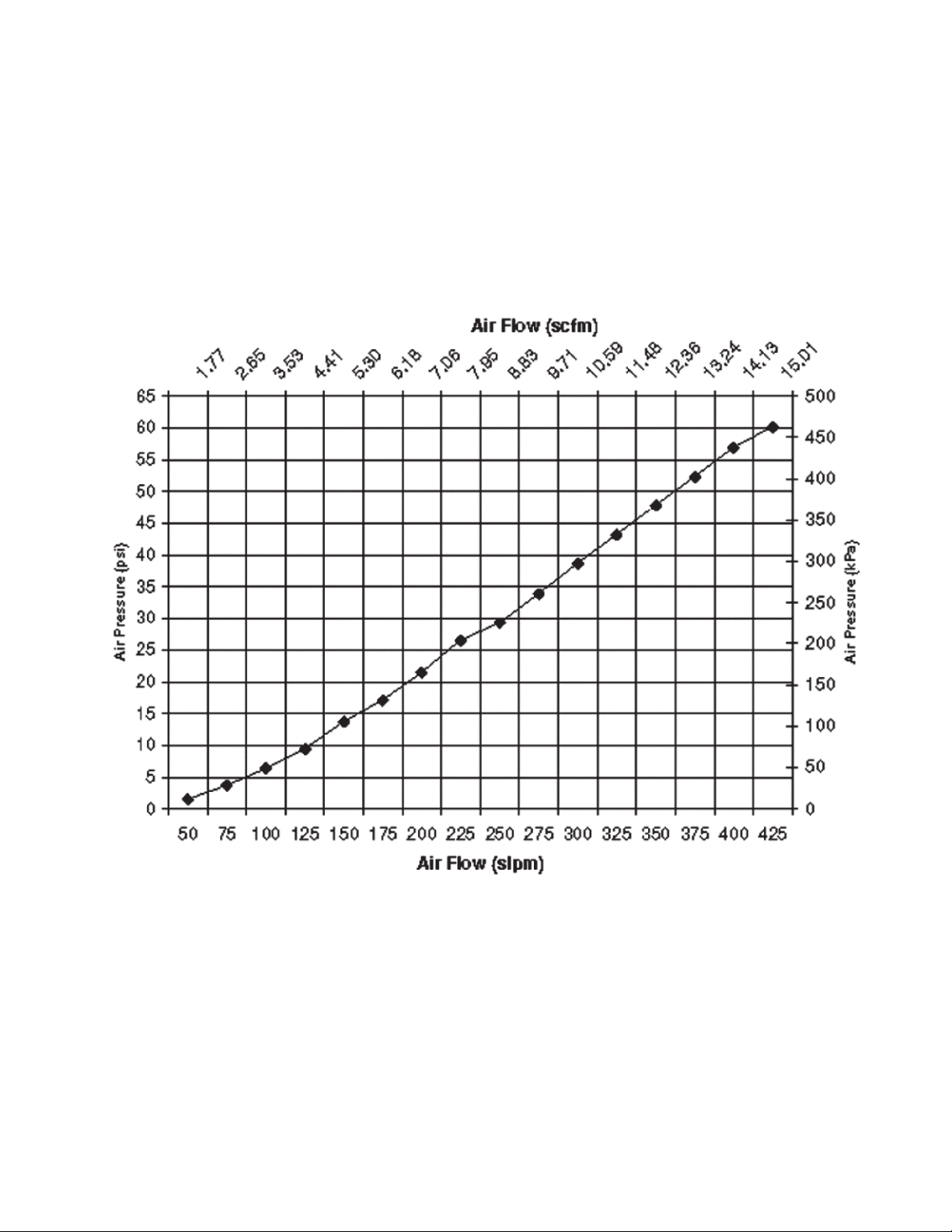

NOTE

Graphical information provided for

reference only. Performance will vary

depending on coating material viscosity

and ow rate, supply tubing lengths, etc.

(Pressure data shown was measured

12-inches (305mm) behind the applicator.)

TURBIME SPEED VS. PRESSURE - NO LOAD

LN-9263-08.5

10

RMA-303 Dual Purge/Direct Charge - Introduction

TURBIME SPEED VS. AIR CONSUMPTION - NO LOAD

Ransburg

11

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Introduction

TURBIME SPEED VS. PRESSURE

LOAD @ 700cc Water

LN-9263-08.5

12

RMA-303 Dual Purge/Direct Charge - Introduction

TURBIME SPEED VS. AIR CONSUMPTION

LOAD @ 700cc Water

Ransburg

13

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Introduction

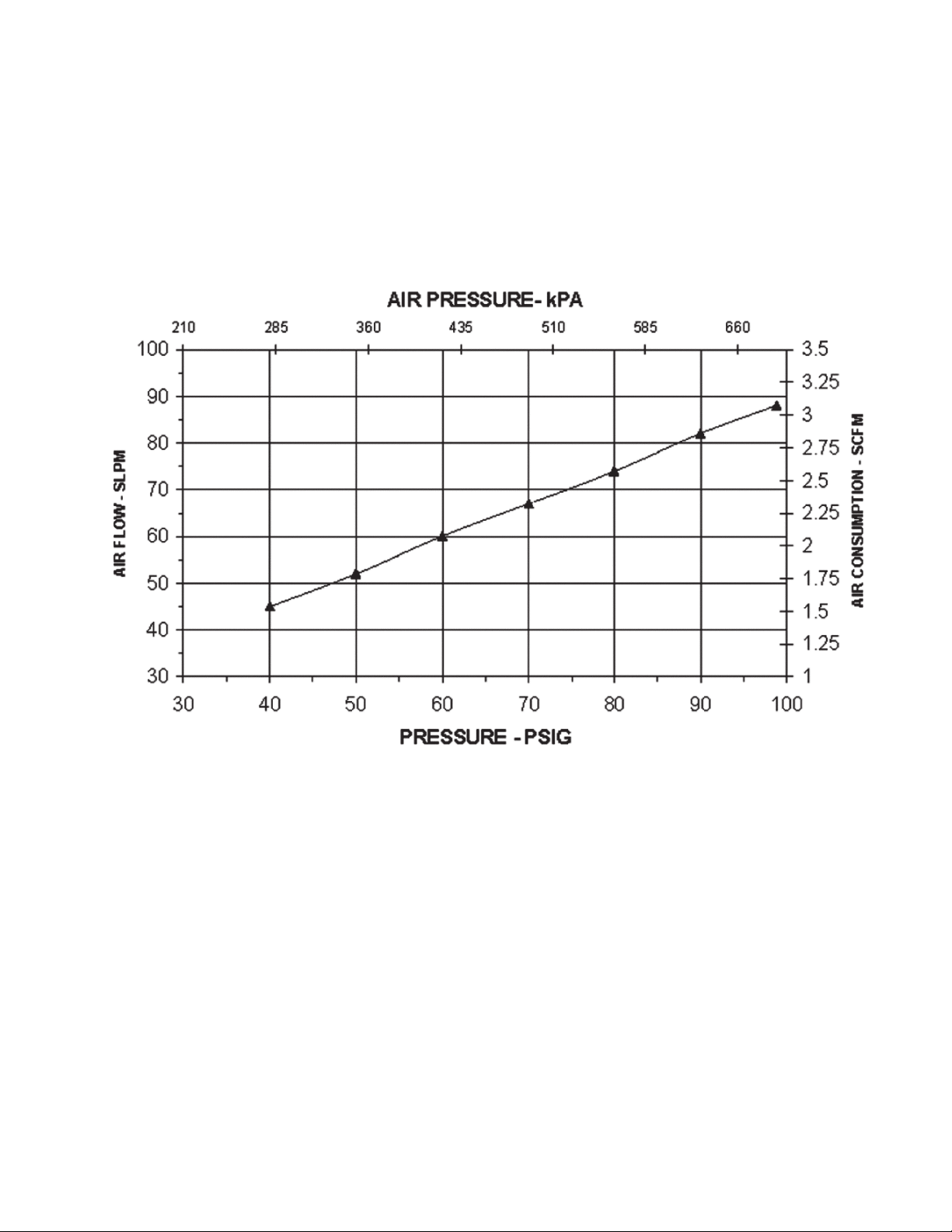

BEARING AIR FLOW VS. SUPPLY PRESSURE

(1 psig = 6.89 kPA)

LN-9263-08.5

14

RMA-303 Dual Purge/Direct Charge - Introduction

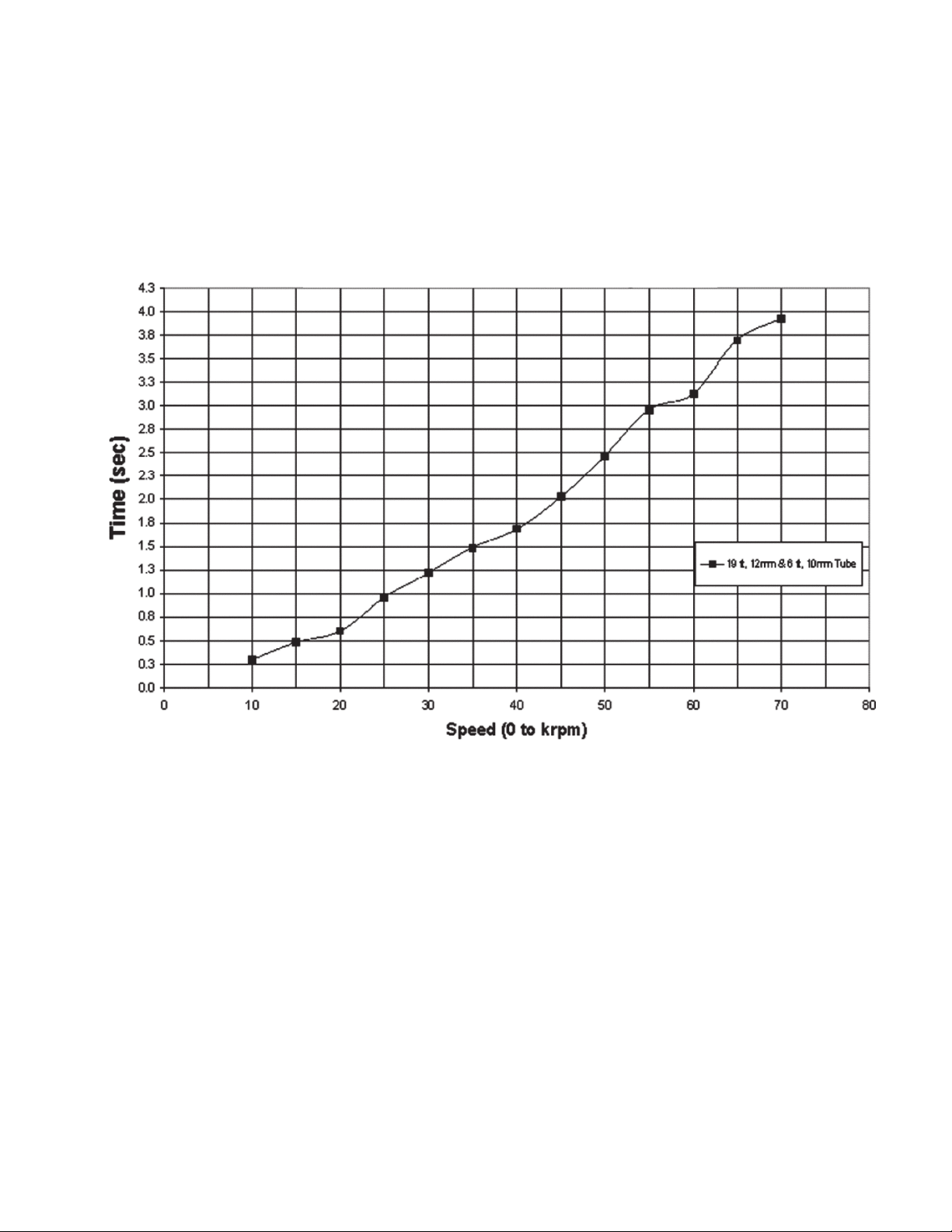

RMA-303 Average Acceleration

Unloaded 65mm Bell Cup

Ransburg

15

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Introduction

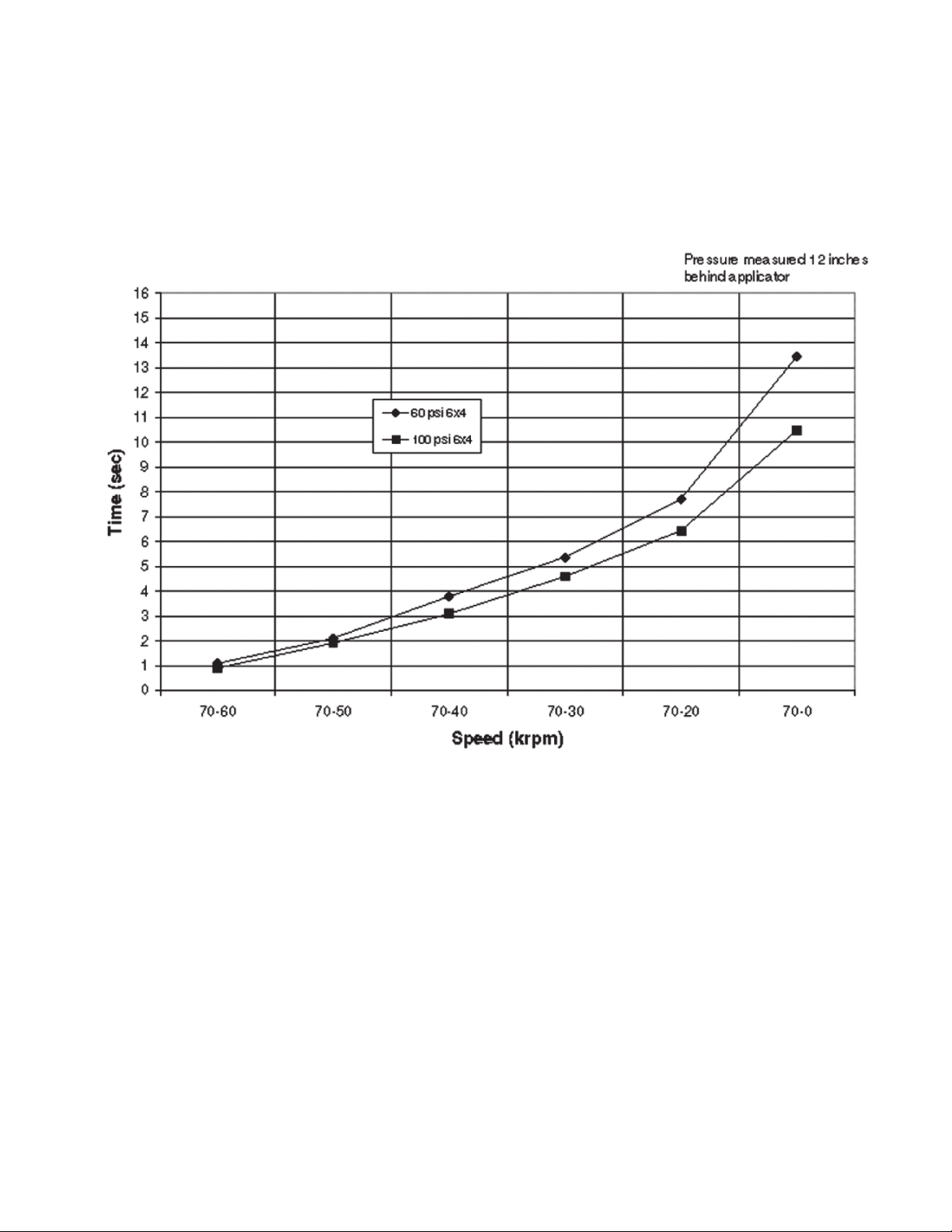

RMA-303 Spindle Deceleration Times

(Unloaded 65mm Bell Cup)

LN-9263-08.5

16

RMA-303 Dual Purge/Direct Charge - Introduction

RMA-303 Direct

SHAPING AIR FLOW VS. PRESSURE

A12089-01/02 SHAPE AIR KIT

Ransburg

17

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Introduction

Flow vs. Pressure

Single Shape Air - Single Supply Source

A12089-01/02 SHAPING AIR KIT

LN-9263-08.5

18

RMA-303 Dual Purge/Direct Charge - Introduction

Flow vs. Pressure

Mono Flex Shape Air - Single Supply Source

A12089-06/-07/-08 SHAPING AIR KIT

Ransburg

19

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Introduction

Flow vs. Pressure

Mono Flex Shape Air - Dual Supply Source

A12089-06/-07/-08 SHAPING AIR KIT

LN-9263-08.5

20

RMA-303 Dual Purge/Direct Charge - Introduction

RMA-303 Dual Flex Air

A12089-09/-10/-11 Series Shape Air

Flow vs. Pressure

Ransburg

21

LN-9263-08.5

Ransburg

RMA-303 Dual Purge/Direct Charge - Introduction

SHAPING AIR FLOW VS. SUPPLY PRESSURE

30MM SHROUD STYLE

A12089-04/-05 SHAPING AIR KIT

LN-9263-08.5

22

RMA-303 Dual Purge/Direct Charge - Introduction

Maximum Flow Rate by Tip Size,

Hose Length, and Material Viscocity

Ransburg

23

LN-9263-08.5

Ransburg

"X"

RMA-303 Dual Purge/Direct Charge - Introduction

15.16 [385.16]

14.13 [358.93]

.007 [.18]

COG

60°

6.21 [157.66]

2.06 [52.22]

13.72 [348.54]

9.09 [230.84]

COG

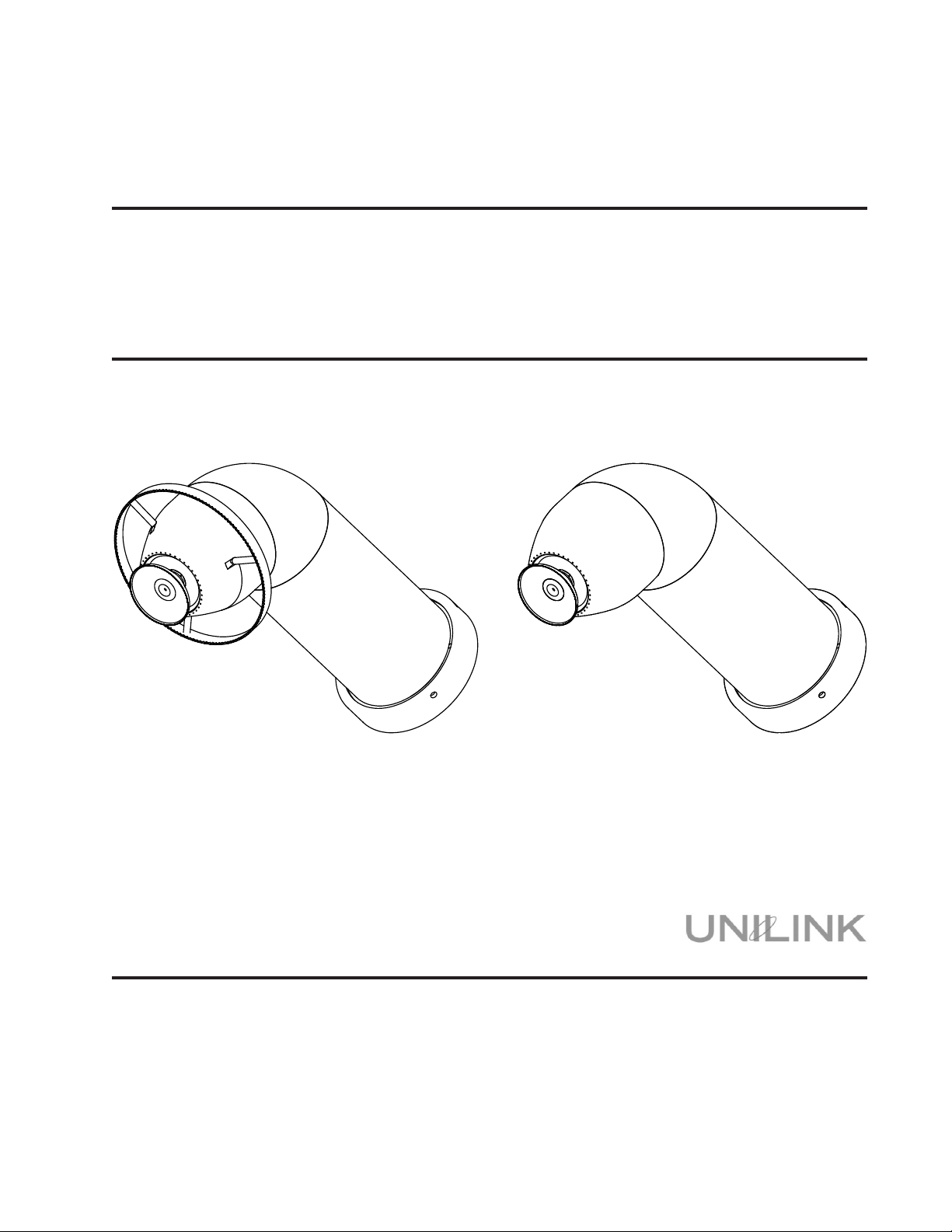

65MM DUAL FLEX WITH

AND

WITHOUT REPULSION RING

T.D.

Ø4.50 [114.17]

Ø6.56 [166.62]

16.83 [427.37]

Figure 1: 65mm Dual Flex With and Without Repulsion Ring

1.09 [27.71]

5.38 [136.54]

Ø4.50 [114.30]

"Y"

Ø5.50 [139.70]

LN-9263-08.5

65MM DUAL FLEX WITH & WITHOUT REPULSION RING

TD

6-Inches

(152mm)

8-Inches

(203mm)

10-Inches

(254mm)

12-Inches

(305mm)

Weight: With Repulsion Ring 17.2 lbs. (7.8 Kg) total

Without Repulsion Ring 16.8 lbs. (7.6 Kg) total

X

19.83-Inches

(503.6mm)

20.83-Inches

(529mm)

21.83-Inches

(554.4mm)

22.83-Inches

(579.8mm)

Y

10.58-Inches

(268.6mm)

12.31-Inches

(312.6mm)

14.04-Inches

(356.6mm)

15.77-Inches

(400.6mm)

24

RMA-303 Dual Purge/Direct Charge - Introduction

"X"

13.72 [348.54]

60°

.007 [.18]

COG

6.33 [160.87]

COG

1.51 [38.32]

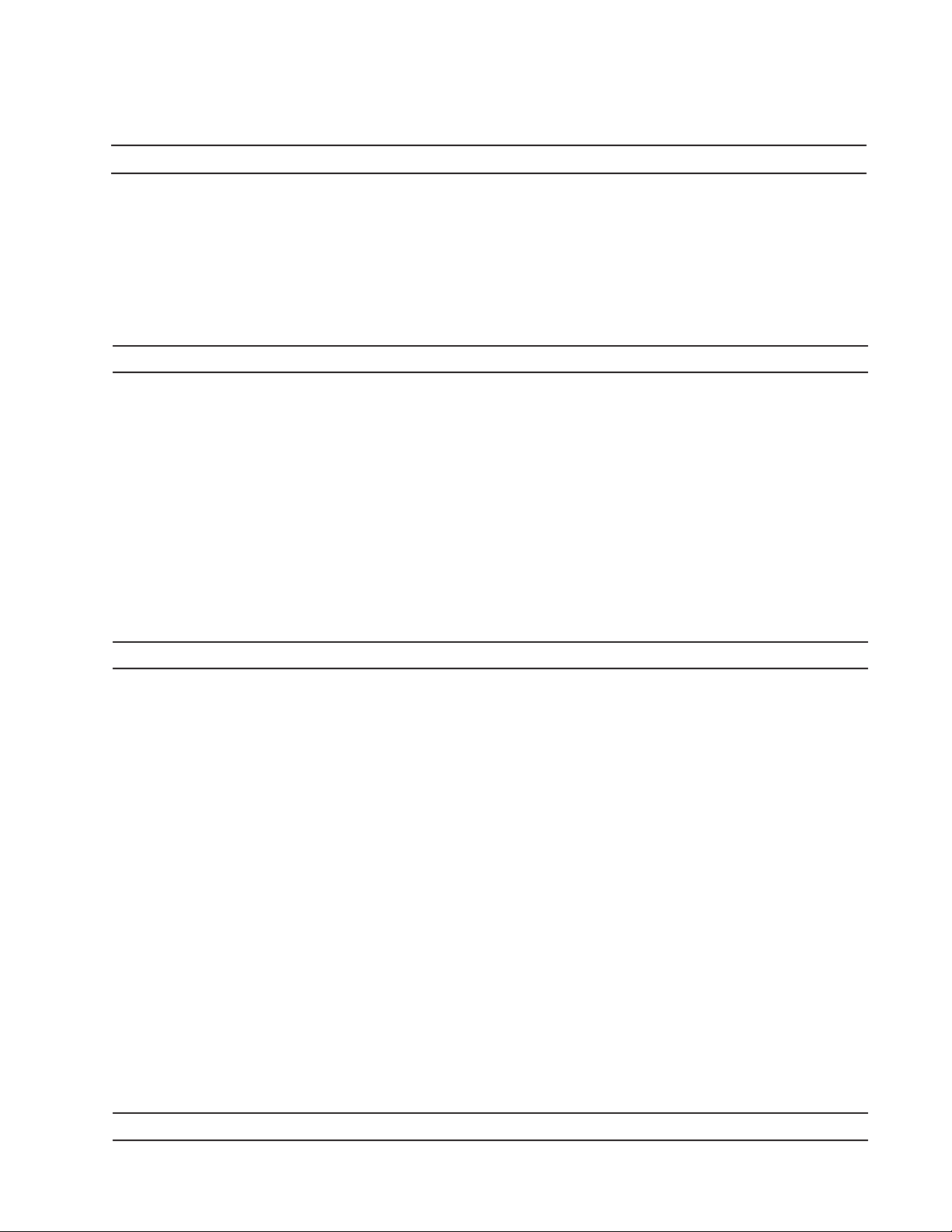

30MM WITH AND

T.D.

WITHOUT REPULSION RING

14.91 [378.81]

14.13 [358.93]

8.16 [207.21]

Ransburg

Ø4.50 [114.30]

.67 [17.07]

5.49 [139.32]

"Y"

Ø5.50 [139.70]

Ø4.50 [114.17]

Ø6.06 [153.92]

16.89 [428.98]

Figure 2: 30mm With and Without Repulsion Ring

30MM WITH AND WITHOUT

REPULSION RING

TD

6-Inches

(152mm)

8-Inches

(203mm)

10-Inches

(254mm)

12-Inches

(305mm)

X

19.89-Inches

(505.2mm)

20.80-Inches

(530.6mm)

21.89-Inches

(556.4mm)

22.89-Inches

(581.4mm)

Y

10.68-Inches

(271.3mm)

12.41-Inches

(315.2mm)

14.14-Inches

(359.2mm)

15.88-Inches

(403.4mm)

25

Weight: With Repulsion Ring 15.4 lbs. (7.0 Kg) total

Without Repulsion Ring 15.2 lbs. (6.9 Kg) total

LN-9263-08.5

Loading...

Loading...