Ransburg A12148-XX User Manual

Ransburg

SERVICE MANUAL

LN-9902-00.3

(Replaces LN-9902-00.2)

February - 2013

AQUABLOCK

MODEL: A12148-XX

IMPORTANT: Before using this equipment,

carefully read SAFETY PRECAUTIONS, starting

on page 1, and all instructions in this manual.

Keep this Service Manual for future reference.

Service Manual Price: $30.00 (U.S.)

NOTE: This service manual has been superceded from service manual number

LN-9902-00.2 to service manual number LN-9902-00.3. Reasons for this change

are noted under “Manual Change Summary” inside the back cover of this manual.

Ransburg

LN-9902-00.3

Ransburg

CONTENTS

SAFETY:

AquaBlock 2- Contents

PAGE

1-4

SAFETY PRECAUTIONS...........................................................................................................

HAZARDS / SAFEGUARDS......................................................................................................

INTRODUCTION:

FEATURES..................................................................................................................................

SPECIFICATIONS......................................................................................................................

DESCRIPTIONS.........................................................................................................................

AQUABLOCK 2 MODEL IDENTIFICATION..............................................................................

STANDARD SYSTEM.................................................................................................................

INSTALLATION:

AQUABLOCK 2 LOCATION.......................................................................................................

MOUNTING.................................................................................................................................

PNEUMATIC CONNECTIONS...................................................................................................

PAINT SUPPLY...........................................................................................................................

AQUABLOCK 2 PNEUMATIC AND FLUID SCHEMATIC........................................................

AQUABLOCK 2 ELECTRICAL SCHEMATIC............................................................................

AQUABLOCK 2 SYSTEM W/GEAR PUMP...............................................................................

AQUABLOCK 2 SYSTEM W/FLOWMETER / REGULATOR...................................................

AQUABLOCK 2 INSTALLATION CHECKLIST..........................................................................

OPERATION:

1

2-4

5-10

5-6

6

7-8

9

9

11-18

11

11

11

11-12

13

14

15

16

17

19-20

START-UP...................................................................................................................................

MAINTENANCE:

PERIODIC MAINTENANCE.......................................................................................................

PREVENTIVE MAINTENANCE..................................................................................................

RE-ASSEMBLY...........................................................................................................................

LKIT0018-06 CERAMIC CYLINDER ASSEMBLY (200 CC )/PARTS LIST..............................

TOOLS TO REBUILD DISCONNECTS.....................................................................................

PROCEDURE FOR REBUILDING MALE AND FEMALE

AQUABLOCK 2 DISCONNECTS...............................................................................................

REMOVAL AND INSTALLATION OF MALE AND FEMALE

DISCONNECTS FROM AQUABLOCK 2 ASSEMBLY..............................................................

ALIGNMENT PROCEDURE FOR DISCONNECT COUPLINGS............................................

TROUBLESHOOTING GUIDE...................................................................................................

(Continued On Next Page)

LN-9902-00.3

19

21-36

21

22-23

23

24-25

26

26-31

31-32

33

35-36

AquaBlock 2 - Contents

CONTENTS (Cont.)

Ransburg

PAGE

PARTS IDENTIFICATION:

AQUABLOCK 2 ASSEMBLY PARTS IDENTIFICATION..........................................................

A12148-XX AQUABLOCK 2 PARTS LIST.................................................................................

FITTING SELECTION.................................................................................................................

A12140-01 FITTINGS (METRIC) AND

A12140-02 FITTINGS (FRACTIONAL) / PARTS LIST..............................................................

AQUABLOCK 2 RECOMMENDED SPARE PARTS.................................................................

A12101-00 MALE DISCONNECT ASSEMBLY PARTS............................................................

A12109-00 FEMALE DISCONNECT ASSEMBLY PARTS........................................................

ACCESSORIES..........................................................................................................................

WARRANTY POLICIES:

LIMITED WARRANTY.................................................................................................................

37-48

37-42

43-44

44

45-46

47

47

47

48

49

49

LN-9902-00.3

Ransburg

LN-9902-00.3

AquaBlock 2 - Safety

SAFETY

SAFETY PRECAUTIONS

Ransburg

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature

for your Ransburg products. This manual contains

information that is important for you to know and

understand. This information relates to USER

SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the following symbols. Please pay particular

attention to these sections.

A WARNING! states information to alert you

to a situation that might cause serious injury

if instructions are not followed.

A CAUTION! states information that tells how

to prevent damage to equipment or how to

avoid a situation that might cause minor injury.

A NOTE is information relevant to the procedure in progress.

While this manual lists standard specications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements,

etc., make such variations inevitable. Compare

this manual with your system installation drawings

and appropriate Ransburg equipment manuals to

reconcile such differences.

W A R N I N G

!

The user MUST read and be familiar

with the Safety Section in this manual and the

Ransburg safety literature therein identied.

This manual MUST be reaed and thor-

oughly understood by ALL personnel who

operate, clean or maintain this equipment!

Special care should be taken to ensure that

the WARNINGS and safety requirements for

operating and servicing the equipment are

followed. The user should be aware of and

adhere to ALL local building and re codes

and ordinances as well as NFPA-33 SAFETY

STANDARD, prior to installing, operating,

and/or servicing this equipment.

W A R N I N G

!

The hazards shown on the following

page may occur during the normal use of

this equipment. Please read the hazard

chart beginning on page 2.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efcient operation,

longer trouble-free service and faster, easier troubleshooting. If you do not have the manuals and

safety literature for your Ransburg system, contact

your local Ransburg representative or Ransburg.

1

LN-9902-00.3

Ransburg

AquaBlock 2 - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate oper-ation and maintenance

pro-cedures will cause a re

hazard.

Protection against inadvertent arcing that is capable of

causing re or explosion is

lost if any safety interlocks

are disabled during operation. Frequent power supply

shut-down indicates a problem in the system requiring

correc-tion.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in the

spray area and tested periodically.

Spray areas must be kept clean to prevent the accumulation of combustible residues.

Smoking must never be allowed in the spray area.

The high voltage supplied to the atomizer must be

turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

Those used for equipment ushing should have ash

points equal to or higher than those of the

coating material.

Those used for general cleaning must have ash

points above 100oF (37.8oC).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, and local codes. In addition, ventilation must be maintained during cleaning

operations using ammable or combustible solvents.

Electrostatic arcing must be prevented.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but only

as instructed.

Non-factory replacement parts or unauthorized equip-

ment modications may cause re or injury.

If used, the key switch bypass is intended for use only

during set-up operations. Production should never

be done with safety interlocks disabled.

Never use equipment intended for use in waterborne

installations to spray solvent based materials.

The paint process and equipment should be set up

and operated in accordance with NFPA-33, NEC, and

OSHA requirements.

LN-9902-00.3

2

AquaBlock 2 Safety

Ransburg

AREA

Tells where hazards

may occur.

General Use and

Maintenance

Electrical

Equipment

HAZARD

Tells what the hazard is.

Improper operation or maintenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

High voltage equipment is utilized. Arcing in areas of ammable or combustible mater-ials

may occur. Personnel are

exposed to high voltage during

operation and maintenance.

Protection against inadvertent

arcing that may cause a re or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shutdown indicates a problem in

the system which requires

correction.

SAFEGUARDS

Tells how to avoid the hazard.

Personnel must be given training in accordance

with the requirements of NFPA-33.

Instructions and safety precautions must be read

and understood prior to using this equipment.

Comply with appropriate local, state, and national

codes governing ventilation, re protection, operation maintenance, and housekeeping. Reference

OSHA, NFPA-33, and your insurance company

require-ments.

The power supply, optional remote control cabinet,

and all other electrical equipment must be located

outside Class I or II, Division 1 and 2 hazardous

areas. Refer to NFPA-33.

Turn the power supply OFF before working on the

equipment.

Test only in areas free of ammable or combustible

material.

Testing may require high voltage to be on, but only

as instructed.

Production should never be done with the safety

circuits disabled.

Explosion Hazard/

Incompatible

Materials

3

An electrical arc can ignite coat-

ing materials and cause a re or

explosion.

Halogenated hydrocarbon solvents for example: methylene

chloride and 1,1,1,-Trichloroethane are not chemically compatible with the aluminum that

might be used in many system

components. The chemical reaction caused by these solvents

reacting with aluminum can become violent and lead to an

equipment explosion.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum equip-

ment during spraying, ushing, or cleaning. Read

the label or data sheet for the material you intend

to spray. If in doubt as to whether or not a coating

or cleaning material is compatible, contact your

material supplier. Any other type of solvent may

be used with aluminum equipment.

LN-9902-00.3

Ransburg

AquaBlock 2- Safety

AREA

Tells where hazards

may occur.

Toxic Substances

Intended Use

HAZARD

Tells what the hazard is.

Certain material may be harmful if inhaled, or if there is contact with the skin.

Using coating materials and/or

cleaning and ushing solvents

which fave ash points below

100°F (37.8°C) may cause a

re hazard.

SAFEGUARDS

Tells how to avoid the hazard.

Follow the requirements of the Material Safety Data

Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a chance

of inhaling sprayed materials. The mask must be

compatible with the material being sprayed and its

concentration. Equipment must be as prescribed

by an industrial hygienist or safety expert, and be

NIOSH approved.

This system is intended for use with waterborne

coating formulations only.

LN-9902-00.3

4

AquaBlock 2- Introduction

INTRODUCTION

FEATURES

Ransburg

Over the past several years, the nishing industry

has experienced increasing pressure to meet the

requirements of environmental legislation aimed

at reducing the amount of air pollution being generated by the painting process. This has brought

about increased use of conforming coatings such

as water based paints which contain less solvent.

Another obvious answer to reducing the use of

solvents is to reduce the amount of coating being

applied. This can be accomplished by the use of

electrostatic applicators. Therefore, it appeared

logical to combine these two solutions to achieve

the best of both worlds.

However, water based coatings contain water

which is electrically conductive. This means

that in an electrostatic spray system, the supply

of water based coatings must be isolated from

ground to prevent the high voltage from shorting

out through the conductive water based coating.

For many years, isolated paint supply systems

have been used in electrostatic spray systems

when highly conductive coatings were applied.

This was a necessary condition if you were using

electrostatics and conductive coatings.

As the use of water based coatings increased, the

need for other methods to avoid the use of isolated coating supplies became obvious. Isolated

coating supplies require a lot of oor space, the

use of protective fencing around the isolation area,

and in many cases, long delays in production are

experienced to accomplish color change.

pressure drop across the system depending on

the viscosity and volume of paint going through

the system.

The voltage block system is comprised of the

AquaBlock 2 cabinet. The AquaBlock 2 cabinet

contains the 4-way shuttle assembly, the cylinder

and pneumatic sensing / switching valves. Because it is pneumatically controlled the AquaBlock

2 can be located inside or outside of hazardous

areas.

The paint enters one port of the 4-way shuttle assembly and is connected alternately to one of two

outlets at each end of the cylinder. The cylinder is

a double ended piston assembly, having a 220cc

capacity. The physical disconnect of the 4-way

shuttle assembly in conjunction with the cylinder

provides electrical isolation between the paint

connections. The 4-way shuttle is moved by a

pneumatic actuator which is actuated by the end

of stroke sensors built-in to the cylinder assembly.

Thus, the system operates with minimal interrup-

tion or delay, providing a smooth, continuous ow

of paint to the spray applicator(s).

The AquaBlock 2 system is a modular design

which can be integrated into any existing paint

feed system, handle single or multiple automatic

applicators and requires little maintenance. Color

change through the AquaBlock 2 can be accomp-lished in as little as 60 seconds, depending

on the system conguration.

To respond to this need, Ransburg has developed the AquaBlock 2 which is a high vol-tage

blocking device used to prevent the high voltage

from following the conductive path from the spray

applicator, through the paint line, to the grounded

water based coating supply. The AquaBlock 2 is

inserted between the grounded paint supply line

entering the spray booth and the spray applicator(s). One AquaBlock 2 can be used for one or

more automatic spray applicators. There is a

5

LN-9902-00.3

Ransburg

AquaBlock 2 - Introduction

NOTE

Most power supplies manufactured by

Ransburg can be used with the AquaBlock

2 System. However, in existing installations where older models are in use, the

high voltage system should be pre-tested

using the recommended test procedure to

determine if a newer, more suitable model

should be installed for best performance.

Where competitive models are in use, the

same test procedure should be applied.

Our service representatives can assist

you in conducting this test.

W A R N I N G

!

The AquaBlock 2 is intended for use

with non-ammable coating materials. The

ash point of all coating materials, cleaning

solvents, etc., must be greater than 100°F.

SPECIFICATIONS

Physical

Dimensions: 30" Wide X 36" High X 13"

Deep

(76.2 cm Wide X 91.4 cm High

X 33.0 cm Deep)

Weight: 110 lbs. (Approx.) (50 Kg)

Electrical

High Voltage: 90kV Maximum

Mechanical

Air

Air Supply: 90 psi +/- 5 psi

(6.2 bar +/- 0.3 bar)

10 SCFM Maximum

(Air required for cylinder

sensing curcuit) (283 slpm)

NOTE

The AquaBlock 2 is not intended for use

with emulsion type materials. If concerned,

test material thoroughly.

C A U T I O N

!

DO NOT USE TAP WATER FOR

FLUSHING OR CLEANING. Deionized

water is the acceptable material.

Air Filtration: 25-50 Micron

Paint Supply

Pressure: 100 psi Maximum (6.9 bar)

20 psi Minimum (1.4 bar)

Volume: See Maximum Pressure

(Depending on viscosity)

Temperature: 120°F Maximum (49°C)

Filtration is required for paint, water, and/or solvent

supplies connected to the system.

LN-9902-00.3

6

AquaBlock 2 - Introduction

DESCRIPTIONS

Ransburg

4-Way Shuttle Assembly

The 4-Way Shuttle Assembly consists of a series

of quick-disconnects and their respective mounting

blocks, and a pneumatic actuator. The AquaBlock

2 has four (4) Female Quick-Disconnects that are

located on two (2) stationary End Blocks. One

End Block is mounted on the left side of the shuttle

assembly and one is mounted on the right side.

Four (4) Male Quick-Disconnects are located on a

moving Center Block with two on each side. The

movement of the Center Block / Male Quick Disconnects is controlled by the pneumatic actuator.

As the AquaBlock 2 operates the Center Block is

shuttled, back and forth, to create a connection

to alternating sides of the cylinder and the paint

inlet and outlet.

The 4-way shuttle assembly receives grounded

paint from the paint supply system and directs it

to one end of the cylinder assembly. The paint

being forced into the cylinder forces paint out of

the other side (using incoming paint pressure).

The paint being forced out of the cylinder assem-

bly then ows through another port of the 4-way

shuttle assembly and out to the atomizer. When

the lling side of the cylinder is full, a pneumatic

signal is sent to the actuator that moves the 4-way

shuttle. The ow of paint in the 4-way shuttle is

now switched and the emptied side of the cylinder

is now lling with paint from the grounded paint

supply. The full side of the cylinder is now connected to the atomizer.

Actuator

The pneumatic actuator is a part of the 4-way

shuttle assembly. It is located in the back portion

of the assembly and is shielded from high voltage

by a series of shields, covers, and mounting blocks.

When a pneumatic signal is received from the

4-way valve of the pneumatic control assembly,

the actuator moves the center block from one end

of the shuttle assembly to the other. Once the

4-way shuttle assembly is switched, the air signal

is maintained to overcome the spring force of the

quick disconnects and hold the connection.

Pneumatic Control Assembly

This assembly includes a 4-way pneumatic valve

which controls the operation of the actuator in

response to pneumatic signals received from the

end-of-stroke sensors in the cylinder assembly.

There are specially sized orices built-in to the

90 degree cross tting at the inlet of the 4-way

pneumatic valve which are connected to each of

the pilots. These restricted orices supply a low

volume of air to the pneumatic sensor circuit in

the cylinder assembly.

The 4-way valve is normally maintained in an

open position to one of the specied outlet ports.

When it receives an end of stroke signal from the

cylinder assembly, it switches to the other port.

The valve supplies air to move the actuator and

the 4-way shuttle assembly to the opposite side.

Cylinder

The cylinder is a double-ended piston reservoir

with a port located at each end. The pistons are

moved by uid pressure entering one end of the

cylinder from the paint supply system while it

is evacuated from the other end and fed to the

applicator(s).

High Voltage / 4-Way Shuttle

Interlock

A pneumatic 3-way valve is located in the top

of the AquaBlock cabinet and is activated when

the cabinet door is opened. This 3-way valve is

a normally closed type that supplies air to the

bulkhead tting located in the top of the cabinet

and also to a high volume 3-way valve inside of

the cabinet when the door is fully closed. The

pneumatic signal at the bulkhead is intended for

an interlock for the high voltage power supply.

This interlock can be accomplished through a

pressure switch to shut down high voltage when

the cabinet door is opened. The air pilot supplied

to the high volume 3-way valve is to interlock the

motion of the 4-way shuttle assembly. When the

door is opened the pilot is removed and the air

supply to the actuator is closed off.

7

LN-9902-00.3

Ransburg

AquaBlock 2 - Introduction

NOTE

If the high voltage power supply does

not have a pneumatic pressure switch,

contact your local Ransburg representative

about adding it to your power supply.

System Electrical Current Monitor

The electrical circuit that monitors the electrostatic current that bleeds through the AquaBlock

2 is composed primarily of a microampere meter

located on the face of the cabinet. The electrical

circuit is completed by one wire connected from

the paint supply tting to the meter and another

wire from the meter to earth ground. The meter

provides an indication of the level of current that

is passing through the AquaBlock 2 from the

electrostatic applicator. This current measurement provides useful information as to the level of

contamination inside the quick disconnect shields,

contamination inside the cabinet, and abnormal

system operation such as quick disconnect (or

uid seal) leakage, etc.

Current Range

(Microamperes)

0-20

20-50

50+

* Possible Damage

Current Meter

Activity

Normal Operation Range

Clean Quick-Disconnect Shields

Shut System Down *

The scale on the microampere meter is divided

into three zones (refer to "Current Meter" chart).

Each time the 4-way shuttle assembly switches

there is a possibility that the current meter will

show a current reading momentarily. If the needle

on the meter returns slowly to the steady state

current or stays high, this could be an indication

of a problem situation that requires immediate

attention and potential system damage.

LN-9902-00.3

8

AquaBlock 2 - Introduction

Ransburg

AQUABLOCK 2 MODEL IDENTIFICATION *

When ordering, use A12148-AA as indicated by Table A (see "Table A" in the "Parts Identication"

section). Two digits must follow the basic part number, for example:

A12148 - XX

Basic Part Number

* Model number and serial number are located on the face of the rear plate assembly.

(Table A)

Fitting Selection

Figure 1: Standard System

TABLE A - Fitting Selection (Figure 8)

Dash

#

01

02

9

Assembly, AquaBlock 2, Metric

Assembly, AquaBlock 2, Fractional

"A"Description

A12140-01

A12140-02

LN-9902-00.3

Ransburg

AquaBlock 2 - Introduction

NOTES

LN-9902-00.3

10

AquaBlock 2 - Installation

INSTALLATION

Ransburg

W A R N I N G

!

This manual MUST be read and thor-

oughly understood by ALL personnel who

operate, clean, or maintain this equipment.

Special care should be taken to ensure

that the WARNINGS and requirements for

operating and servicing are safely followed.

W A R N I N G

!

All AquaBlock 2 installations must com-

ply with appropriate local, state, and national

codes governing ventilation, re protection,

operation, maintenance, and housekeeping.

Refer to OSHA, NFPA-30, NFPA-33,

and customer's insurance requirements.

AQUABLOCK 2 LOCATION

MOUNTING

1. Mount the unit onto an appropriate structure

in or near the spray booth using four bolts (7/16"

minimum diameter).

2. Ground the unit by attaching the grounding

cable provided to a suitable earth ground.

PNEUMATIC

CONNECTIONS

1. From a ltered and regulated air supply, connect 3/8" or 10mm OD tubing to the tting labeled

NOTE

The air supply pressure to the Aqua-

Block 2 system must be between 85 and

95 psi (90 psi nominal).

“AIR SUPPLY” on the top of the cabinet.

The AquaBlock 2 cabinet is installed between the

grounded coating supply and the electrostatic

spray applicator(s). This system provides a “voltage block” to prevent high voltage from following

the conductive path through the water based paint

line connected from the spray applicator(s), which

are at high voltage, and the grounded paint supply.

The unit should be installed near the spray

equipment to minimize the length of uid line to

be ushed and also minimize the amount of uid

hose that will be charged at high voltage potential.

2. Connect 1/4" or 6mm OD tubing from the tting

labeled “HIGH VOLTAGE INTERLOCK” to the

appropriate pressure switch connection on the

power supply. When the cabinet door is open,

the high voltage power supply is de-energized.

PAINT SUPPLY

1. Connect 3/8" or 8mm OD tubing from the

water based coating supply to the tting labeled

“FLUID INLET” on the top of the cabinet.

C A U T I O N

!

This connection uses a metal tting

which is grounded through the current me-

ter. No other metal ttings should be used

to replace plastic connections located on or

in this cabinet.

11

LN-9902-00.3

Ransburg

AquaBlock 2 - Installation

C A U T I O N

The last 18-24-inches of the paint

supply hose connected to the uid inlet of

the enclosure must be made of a non-con-

ductive material. This isolated uid hose is

required to ensure proper operation of the

current meter.

2. Feed the 3/8-inch or 8mm OD paint line going to

the spray applicator(s) through the slotted opening

in the bottom of the cabinet. The tubing should be

shielded tubing, such as Ransburg part number

74178-01, or if other tubing is used it should be

covered with 1-inch (or equivalent) Polyurethane

tubing from the connection inside of the AquaBlock

2 cabinet to the applicator(s). Connect the tubing

to the tting on the bottom of the 4-way shuttle

assembly and the other end to the applicator(s).

C A U T I O N

!!

Systems utilizing positive displacement

pumps for the regulation of the uid ow to

the applicator(s) must be located after the

AquaBlock 2 in the charged uid stream. This

is to avoid over-pressurization of the AquaBlock 2 system, or the paint tubing feeding

the system, during the switching operation.

This location requires that the pump and

any other conductive objects attached to the

pump be isolated from ground.

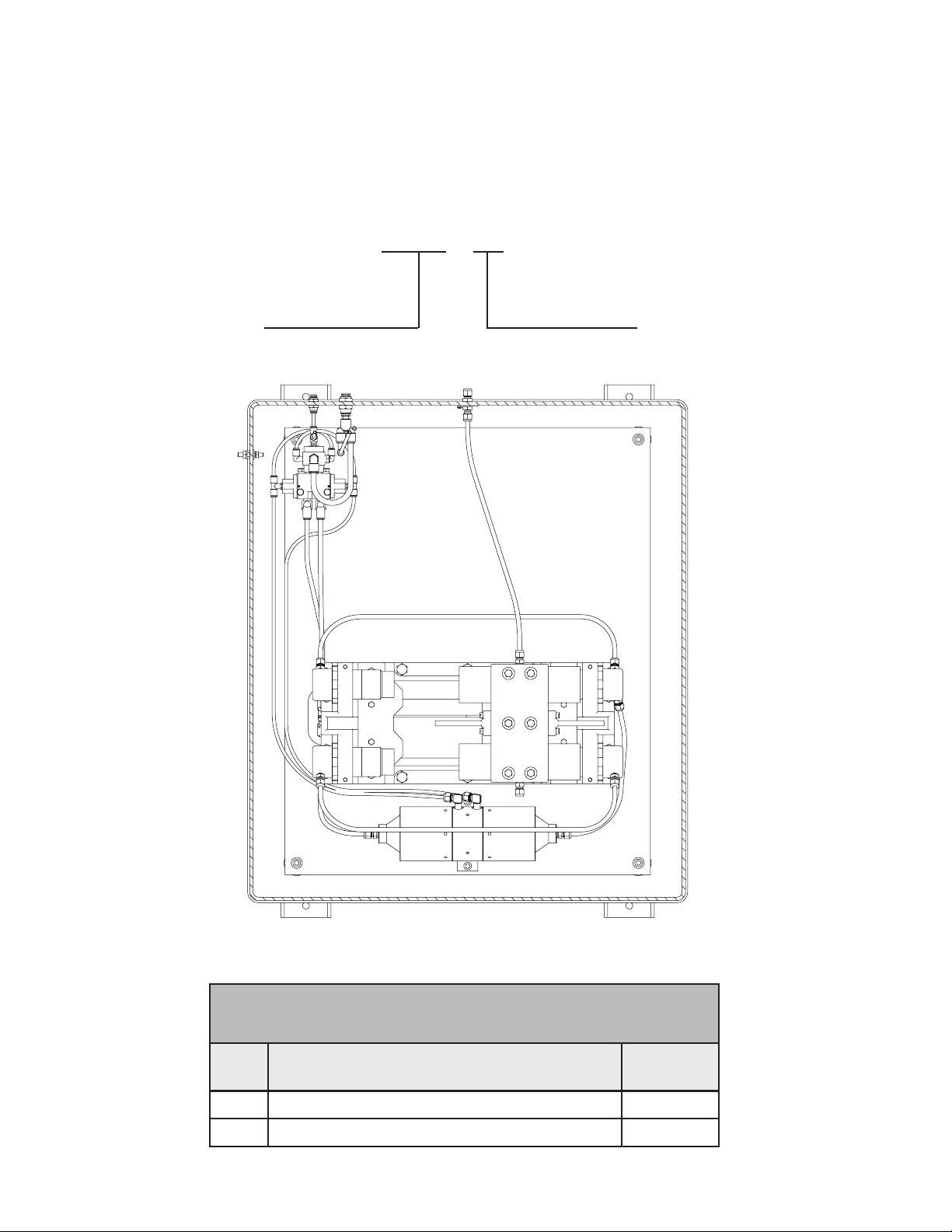

Figures 4 and 5 illustrate basic examples of typical

installations for the AquaBlock 2 system. Figure

4 shows a typical system with an isolated gear

pump ow control system, and Figure 5 shows a

typical system with an isolated owmeter and uid

regulator ow control system.

C A U T I O N

!

The paint line exiting the AquaBlock 2

cabinet should not be broken, or contain additional connections, from the connection at the

4-way shuttle assembly to the applicator(s).

If additional connections are required, for the

addition of ow control system components,

etc., special care must be taken to ensure

that the connections do not pass close to

ground sources that could cause current

leakage or electrical arcing. Additionally

the use of conductive com-ponents, such

as metal owmeters or regulators, should

be limited as much as possible to decrease

system capacitance as much as possible.

LN-9902-00.3

12

Loading...

Loading...