Ransburg

EVOLVER 303TM SOLVENTBORNE

SERVICE MANUAL

AA-07-03.2

March - 2013

ROBOTIC ATOMIZERS

MODEL: A11976-XXX

IMPORTANT: Before using this equipment, carefully read SAFETY PRECAUTIONS, starting on

page 1, and all instructions in this manual. Keep

this Service Manual for future reference.

With

Technology

Service Manual Price: €40.00 (Euro)

$50.00 (U.S.)

Ransburg

CONTENTS

SAFETY:

Evolver 303 Robotic Atomizers - Safety

PAGE

1-5

SAFETY PRECAUTIONS............................................................................................................

HAZARDS / SAFEGUARDS.......................................................................................................

INTRODUCTION:

RANSBURG ELECTROSTATIC PROCESS...............................................................................

EVOLVER 303 SOLVENTBORNE SPRAY APPLICATORS......................................................

SPECIFICATIONS.......................................................................................................................

EVOLVER 303 APPLICATOR ASSEMBLY................................................................................

EVOLVER 303 TUBING BUNDLE ASSEMBLY (ENGLISH).....................................................

EVOLVER 303 TUBING BUNDLE ASSEMBLY (METRIC).......................................................

EVOLVER 303 SOLVENTBORNE ROBOTIC APPLICATORS................................................

FEATURES..................................................................................................................................

A11976-XXX EVOLVER SPRAY APPLICATOR ASSEMBLY..................................................

TOOL CENTER-POINT COMPARISONS TABLE.....................................................................

INSTALLATION:

EVOLVER 303 ROBOTIC ATOMIZER INSTALLATION............................................................

POWER SUPPLY ASSEMBLY...................................................................................................

MOUNTING..................................................................................................................................

ELECTRICAL AND FIBER OPTIC CONNECTIONS.................................................................

FLUID CONNECTIONS...............................................................................................................

TYPICAL INSTALLATION...........................................................................................................

LOW VOLTAGE CABLE CONNECTIONS.................................................................................

EVOLVER SPRAY APPLICATOR AIR AND FLUID LAYOUT..................................................

APPLICATOR AND MANIFOLD ASSEMBLY............................................................................

LOW VOLTAGE CABLE INSTALLATIONS................................................................................

SIGNAL IDENTIFICATION TABLES (ENGLISH/METRIC).......................................................

APPLICATOR AND MANIFOLD ASSEMBLY / PARTS LIST....................................................

SPRAY / BELL APPLICATOR TRIGGERING............................................................................

TUBING BUNDLE INSTALLATION............................................................................................

BUNDLE LUBRICATION.............................................................................................................

1

2-5

6-14

6

6-7

8

9

10

11

12

13

14

14

15-24

15

15

15

15

15

15

16

17

18-19

19-20

20

21

22

23

23-24

OPERATION:

SPRAY APPLICATOR CONTROLS...........................................................................................

HVLP SPRAY...............................................................................................................................

FLUID VALVE CONTROLS.........................................................................................................

SINGLE PURGE SPRAYING......................................................................................................

(Continued On Next Page)

AA-07-03.2

25-27

25

25-26

26

26-27

Evolver 303 Robotic Atomizers - Safety

MAINTENANCE:

Ransburg

PAGE

28-50

ROUTINE MAINTENANCE SCHEDULE....................................................................................

PROCEDURES............................................................................................................................

SPRAY HEAD REMOVAL / ASSEMBLY / PARTS LIST............................................................

SERVICE......................................................................................................................................

SPRAY HEAD ASSEMBLY..........................................................................................................

79138 EVOLVER APPLICATOR HEAD ASSEMBLY / PARTS LIST........................................

REMOVING SPRAY APPLICATOR FROM THE

REAR MANIFOLD ASSEMBLY...................................................................................................

EVOLVER 303 60° SINGLE HEAD APPLICATOR

ASSEMBLY / PARTS LIST...........................................................................................................

DISASSEMBLY OF A11981 SPRAY APPLICATOR

ASSEMBLY / PARTS LIST...........................................................................................................

CASCADE WIRE PLUG ASSEMBLY..........................................................................................

LOW VOLTAGE CABLE REMOVAL / PARTS LIST...................................................................

A11241-01 SINGLE PURGE VALVE MANIFOLD

DISASSEMBLY / PARTS LIST.....................................................................................................

TROUBLESHOOTING GUIDE....................................................................................................

PARTS IDENTIFICATION:

A11976 SPRAY APPLICATOR ASSEMBLY / PARTS LIST..........................................................

79138-01 SPRAY HEAD ASSEMBLY / PARTS LIST...................................................................

79138-02 HVLP SPRAY HEAD ASSEMBLY PARTS LIST...........................................................

79179-00 SINGLE HEAD 60° / PARTS LIST...............................................................................

79243-00 DUAL HEAD 60° / PARTS LIST...................................................................................

79180-00 SINGLE HEAD 90° / PARTS LIST...............................................................................

79224-00 DUAL HEAD 90° / PARTS LIST...................................................................................

A11981 MANIFOLD ASSEMBLY / PARTS LIST.........................................................................

A11206-01 REAR PLATE ASSEMBLY (SINGLE PURGE) /

PARTS LIST.................................................................................................................................

A12000-XXXXX TUBING BUNDLE ASSEMBLY (ENGLISH) / PARTS LIST...............................

A12000-XXXXX TUBING BUNDLE ASSEMBLY MODEL

IDENTIFICATION (ENGLISH).....................................................................................................

A11061-XXXXX TUBING BUNDLE ASSEMBLY (METRIC) / PARTS LIST.................................

A11061-XXXXX TUBING BUNDLE ASSEMBLY MODEL

IDENTIFICATION (METRIC).......................................................................................................

A10406 OR LECU5004 MICROPAK CONTROL UNIT...............................................................

ACCESSORIES AND SERVICE KITS........................................................................................

REPAIR KITS..............................................................................................................................

SERVICE PARTS........................................................................................................................

LUBRICANTS AND SEALERS...................................................................................................

RECOMMENDED SPARE PARTS.............................................................................................

28-29

29-30

31-32

33

33-35

36-37

38

39

40-41

42

43-45

46

47-50

51-80

51-52

53-54

55

56

56

57

57

58-59

60

61-63

64-66

67-69

70-72

73

73-75

76

77

77

78-80

WARRANTY POLICIES:

LIMITED WARRANTY..................................................................................................................

81

81

AA-07-03.2

Evolver 303 Robotic Atomizers - Safety

SAFETY

Ransburg

SAFETY PRECAUTIONS

Before operating, maintaining or servicing any

Ransburg electrostatic coating system, read and

understand all of the technical and safety literature for your Ransburg products. This manual

contains information that is important for you to

know and understand. This information relates to

USER SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this information, we use the following symbols. Please pay

particular attention to these sections.

A WARNING! states information to alert you

to a situation that might cause serious injury

if instructions are not followed.

A CAUTION! states information that tells how

to prevent damage to equipment or how to

avoid a situation that might cause minor injury.

A NOTE is information relevant to the procedure in progress.

W A R N I N G

!

The user MUST read and be familiar with

the Safety Section in this manual and the

Ransburg safety literature therein identied.

This manual MUST be read and thor-

oughly understood by ALL personnel who

operate, clean or maintain this equipment!

Special care should be taken to ensure that

the WARNINGS and safety requirements for

operating and servicing the equipment are

followed. The user should be aware of and

adhere to ALL local building and re codes

and ordinances as well as NFPA-33 SAFETY STANDARD, LATEST EDITION, prior

to installing, operating, and/or servicing this

equipment.

W A R N I N G

!

While this manual lists standard specications

and service procedures, some minor deviations

may be found between this literature and your

equipment. Differences in local codes and plant

requirements, material delivery requirements,

etc., make such variations inevitable. Compare

this manual with your system installation drawings and appropriate Ransburg equipment manuals to reconcile such differences.

Careful study and continued use of this manual will

provide a better understanding of the equipment

and process, resulting in more efcient operation,

longer trouble-free service and faster, easier

troubleshooting. If you do not have the manuals

and safety literature for your Ransburg system,

contact your local Ransburg representative or

Ransburg.

The hazards shown on the following pag-

es may occur during the normal use of this

equipment. Please read the hazard chart beginning on page 2.

1

AA-07-03.2

Ransburg

Evolver 303 Robotic Atomizers - Safety

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Fire Hazard

Improper or inadequate

operation and maintenance

procedures will cause a re

hazard.

Protection against inadvertent arcing that is capable of

causing re or explosion is

lost if any safety interlocks

are disabled during operation. Frequent Power Supply

or Controller shutdown indicates a problem in the system

requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Fire extinguishing equipment must be present in

the spray area and tested periodically.

Spray areas must be kept clean to prevent the

accumulation of combustible residues.

Smoking must never be allowed in the spray

area.

The high voltage supplied to the atomizer must

be turned off prior to cleaning, ushing or maintenance.

When using solvents for cleaning:

• Those used for equipment ushing should

have ash points equal to or higher than

those of the coating material.

• Those used for general cleaning must have

ash points above 100°F (37.8°C).

Spray booth ventilation must be kept at the rates

required by NFPA-33, OSHA, country, and local

codes. In addition, ventilation must be maintained during cleaning operations using ammable or combustible solvents.

Electrostatic arcing must be prevented. Safe

sparking distance must be maintained between

the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage

is required at all times.

Test only in areas free of combustible material.

Testing may require high voltage to be on, but

only as instructed.

Non-factory replacement parts or unautho-

rized equipment modications may cause re or

injury.

If used, the key switch bypass is intended for

use only during setup operations. Production

should never be done with safety interlocks disabled.

Never use equipment intended for use in waterborne installations to spray solvent based materials.

The paint process and equipment should be

set up and operated in accordance with NFPA33, NEC, OSHA, local, country, and European

Health and Safety Norms.

AA-07-03.2

2

Evolver 303 Robotic Atomizers - Safety

Ransburg

AREA

Tells where hazards

may occur.

Spray Area

HAZARD

Tells what the hazard is.

Explosion Hazard

Improper or inadequate operation and maintenance proce-

dures will cause a re hazard.

Protection against inadvertent

arcing that is capable of caus-

ing re or explosion is lost if

any safety interlocks are disabled during operation.

Frequent Power Supply or

Controller shutdown indicates

a problem in the system requiring correction.

SAFEGUARDS

Tells how to avoid the hazard.

Electrostatic arcing must be prevented. Safe

sparking distance must be maintained between

the parts being coated and the applicator. A distance of 1 inch for every 10KV of output voltage

is required at all times.

Unless specically approved for use in hazardous locations, all electrical equipment must be

located outside Class I or II, Division 1 or 2

hazardous areas, in accordance with NFPA-33.

Test only in areas free of ammable or combustible materials.

The current overload sensitivity (if equipped)

MUST be set as described in the corresponding section of the equipment manual. Protection against inadvertent arcing that is capable

of causing re or explosion is lost if the current

overload sensitivity is not properly set. Frequent power supply shutdown indicates a problem in the system which requires correction.

General Use and

Maintenance

Improper operation or maintenance may create a hazard.

Personnel must be properly

trained in the use of this equipment.

Always turn the control panel power off prior to

ushing, cleaning, or working on spray system

equipment.

Before turning high voltage on, make sure no

objects are within the safe sparking distance.

Ensure that the control panel is interlocked with

the ventilation system and conveyor in accordance with NFPA-33, EN 50176.

Have re extinguishing equipment readily available and tested periodically.

Personnel must be given training in accordance

with the requirements of NFPA-33, EN 60079-0.

Instructions and safety precautions must be

read and understood prior to using this equipment.

Comply with appropriate local, state, and national codes governing ventilation, re protection, operation maintenance, and housekeeping. Reference OSHA, NFPA-33, EN Norms

and your insurance company requirements.

3

AA-07-03.2

Ransburg

Evolver 303 Robotic Atomizers - Safety

AREA

Tells where hazards

may occur.

Spray Area /

High Voltage

Equipment

HAZARD

Tells what the hazard is.

Electrical Discharge

There is a high voltage device

that can induce an electrical

charge on ungrounded objects

which is capable of igniting

coating materials.

Inadequate grounding will

cause a spark hazard. A

spark can ignite many coating

materials and cause a re or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Parts being sprayed and operators in the spray

area must be properly grounded.

Parts being sprayed must be supported on conveyors or hangers that are properly grounded. The resistance between the part and earth

ground must not exceed 1 meg ohm. (Refer to

NFPA-33.)

Operators must be grounded. Rubber soled insulating shoes should not be worn. Grounding

straps on wrists or legs may be used to assure

adequate ground contact.

Operators must not be wearing or carrying any

ungrounded metal objects.

When using an electrostatic handgun, operators

must assure contact with the handle of the applicator via conductive gloves or gloves with the

palm section cut out.

NOTE: REFER TO NFPA-33 OR SPECIFIC

COUNTRY SAFETY CODES REGARDING

PROPER OPERATOR GROUNDING.

All electrically conductive objects in the spray

area, with the exception of those objects required by the process to be at high voltage, must

be grounded. Grounded conductive ooring

must be provided in the spray area.

Always turn off the power supply prior to ushing, cleaning, or working on spray system equipment.

Unless specically approved for use in hazardous locations, all electrical equipment must be

located outside Class I or II, Division 1 or 2 hazardous areas, in accordance with NFPA-33.

AA-07-03.2

4

Evolver 303 Robotic Atomizers - Safety

Ransburg

AREA

Tells where hazards

may occur.

Electrical

Equipment

HAZARD

Tells what the hazard is.

Electrical Discharge

High voltage equipment is utilized in the process. Arcing

in the vicinity of ammable or

combustible materials may oc-

cur. Personnel are exposed to

high voltage during operation

and maintenance.

Protection against inadvertent

arcing that may cause a re or

explosion is lost if safety circuits

are disabled during operation.

Frequent power supply shutdown indicates a problem in the

system which requires correction.

An electrical arc can ignite coat-

ing materials and cause a re or

explosion.

SAFEGUARDS

Tells how to avoid the hazard.

Unless specically approved for use in hazardous locations, the power supply, control cabinet,

and all other electrical equipment must be located outside Class I or II, Division 1 and 2 hazardous areas in accordance with NFPA-33 and EN

50176.

Turn the power supply OFF before working on

the equipment.

Test only in areas free of ammable or combustible material.

Testing may require high voltage to be on, but

only as instructed.

Production should never be done with the safety

circuits disabled.

Before turning the high voltage on, make sure no

objects are within the sparking distance.

Toxic Substances

Spray Area

Certain material may be harmful

if inhaled, or if there is contact

with the skin.

Explosion Hazard –

Incompatible Materials

Halogenated hydrocarbon sol-

vents for example: methylene

chloride and 1,1,1,-Trichloroethane are not chemically

compatible with the aluminum

that might be used in many system components. The chemical

reaction caused by these solvents reacting with aluminum

can become violent and lead to

an equipment explosion.

Follow the requirements of the Material Safety

Data Sheet supplied by coating material manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being

sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienist or

safety expert, and be NIOSH approved.

Aluminum is widely used in other spray application equipment - such as material pumps,

regulators, triggering valves, etc. Halogenated

hydrocarbon solvents must never be used with

aluminum equipment during spraying, ushing,

or cleaning. Read the label or data sheet for the

material you intend to spray. If in doubt as to

whether or not a coating or cleaning material is

compatible, contact your coating supplier. Any

other type of solvent may be used with aluminum

equipment.

5

AA-07-03.2

Ransburg

INTRODUCTION

Evolver 303 Robotic Atomizers - Introduction

THE RANSBURG

ELECTROSTATIC

PROCESS

This process is a method for electrostatically applying coatings to objects. A power supply produces

a high voltage charge which is supplied to the

applicator, creating an electrostatic eld between

the applicator and the target object. The target

is electrostatically grounded through its support

which may be either stationary or moving.

A regulated uid system delivers coating material

to the applicator, where it is atomized forming

a spray mist. There, under the inuence of the

electrostatic eld, the atomized coating becomes

electrostatically charged. The charged particles

are attracted to and deposited on the grounded

target object. The forces between the charged

particles and the target are sufcient to turn overspray around and deposit it on the back surface

of the target. Therefore, a higher percentage of

the spray is deposited.

EVOLVER 303™

SOLVENTBORNE SPRAY

APPLICATORS

The Evolver 303 Spray Applicators System

will allow for the use of spray applicators or bell

applicators with minimal required down-time

during the switching process. This system can

also operate as a spray applicator system only

that later can be upgraded to allow for bell applicators to be used. Lastly, this system can

allow a user currently possessing an RMA-303

bell system to use spray applicators as well, with

minimal conver-sion required. The Evolver 303

Solventborne Applicator line consists of both

60° and 90° single and dual-headed 100 kV automatic electrostatic applicators. Developed for

use on robots, the Evolver 303 spray applicator

incorporates a unique 1/3 turn quick-disconnect

spray head and a one piece slide over manifold

cover, providing the user an efcient tool for the

electrostatic application of coatings.

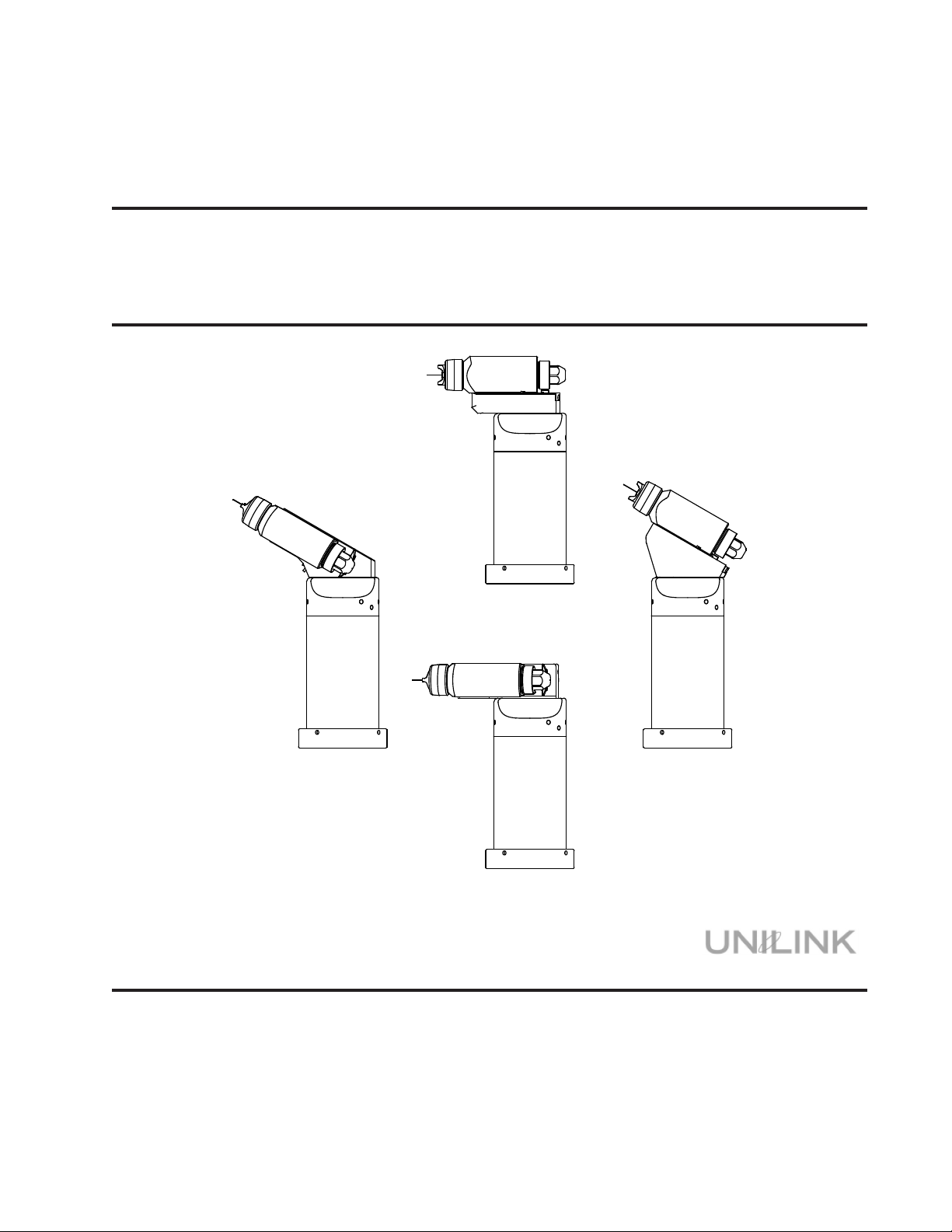

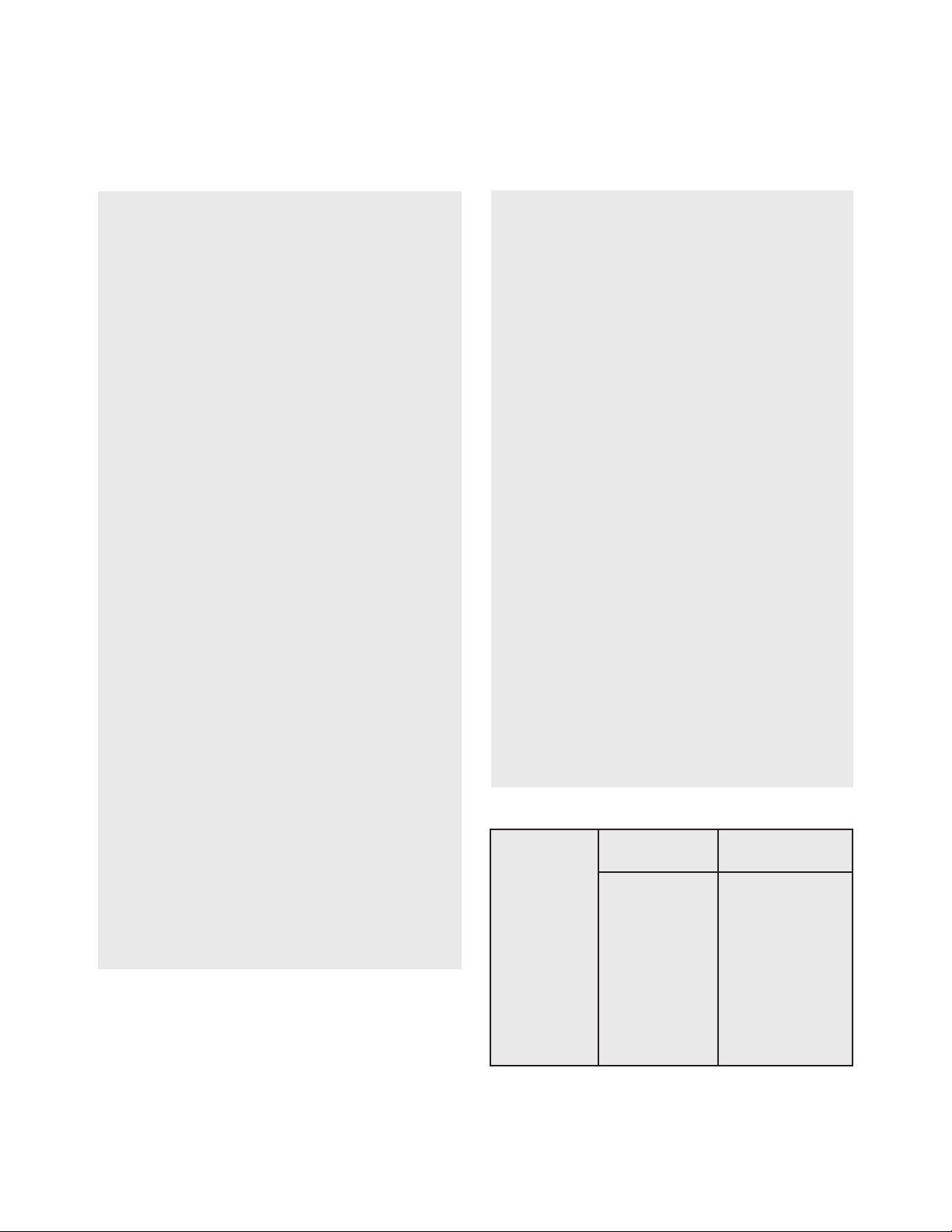

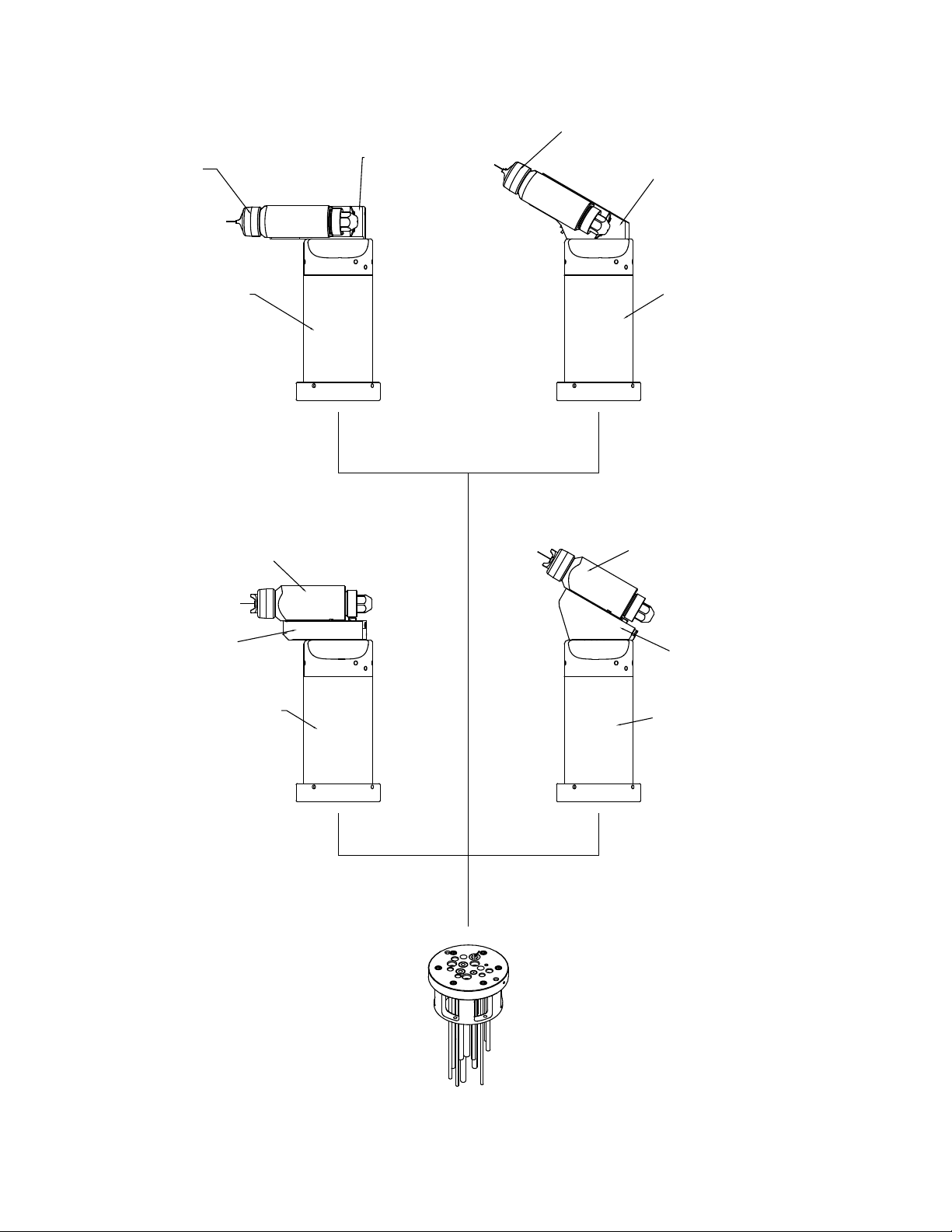

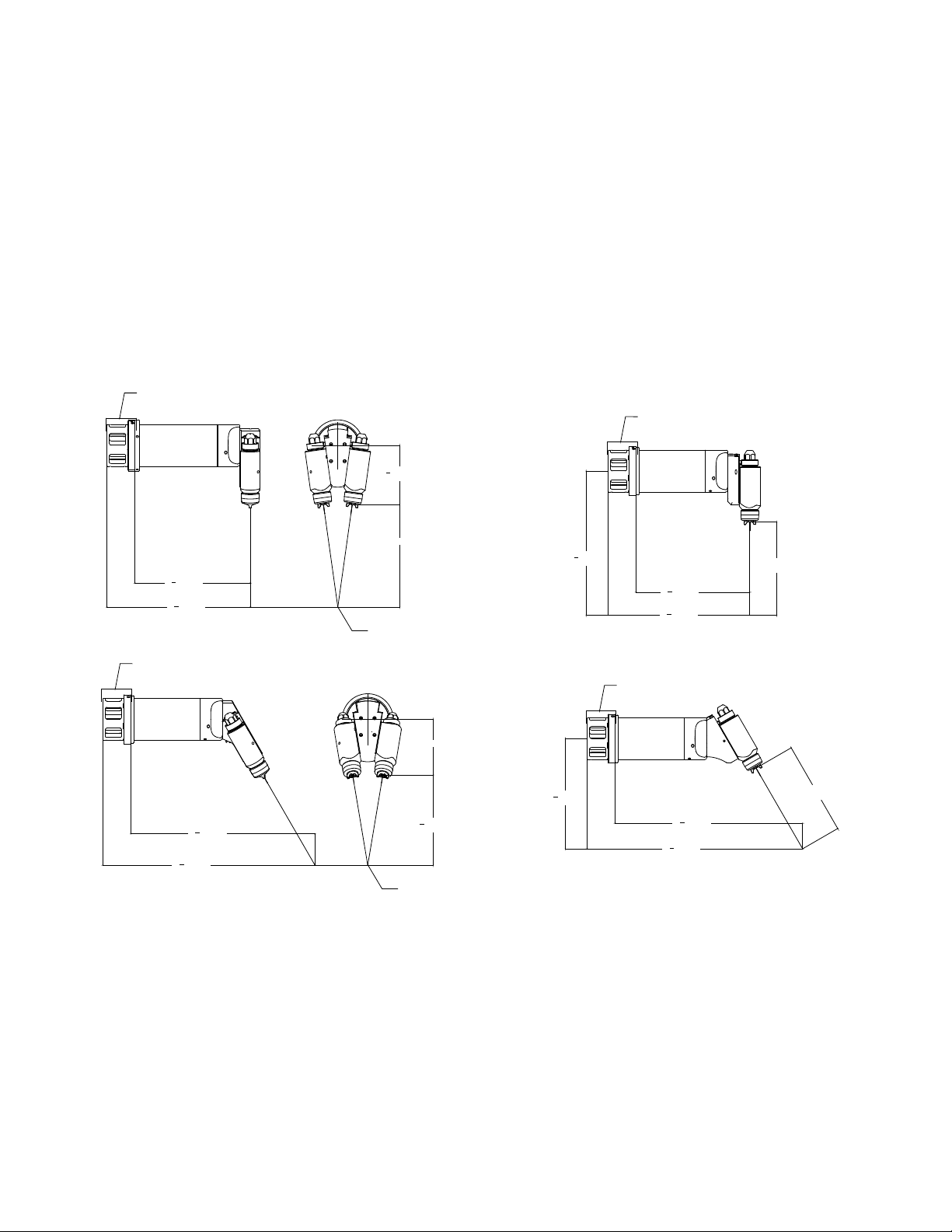

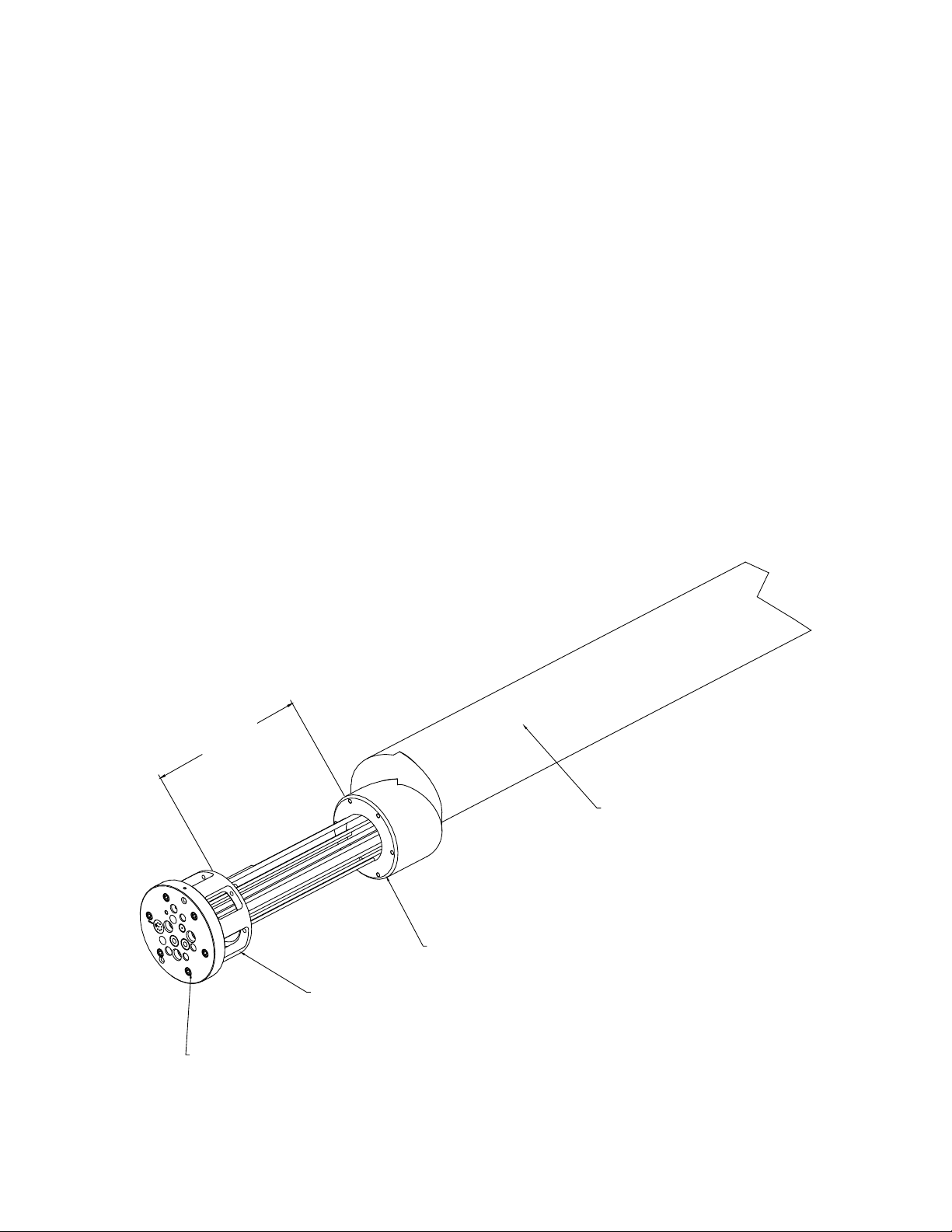

There are two single head models of the Evolver

303 Applicator (see Figure 1). Each model differs

in the applicator to axis orientation of the spray

head. These models are:

A11976-0XX 60° Single Head

A11976-1XX 90° Single Head

Two dual-head versions of the Evolver 303 Applicator are also available (see Figure 1). The

dual headed applicators are primarily used where

high volume uid delivery is required. The dual

headed applicator is available in two different

congurations as follows:

A11976-2XX 60° Dual Head

A11976-3XX 90° Dual Head

AA-07-03.2

6

Evolver 303 Robotic Atomizers - Introduction

Ransburg

The Evolver 303 Spray Applicator System consists

of four major components:

1. Quick-Disconnect Spray Head

2. Gun Head Mounting Block Assembly

3. Valve Manifold Assembly (Includes the High

Voltage Cascade with a Quick-Disconnect

Ring)

4. Rear Tubing Manifold Assembly (both English

and Metric)

The spray head(s) and valve manifold contain

the uid, air, and high voltage passages. All uid

passages contain stainless steel and/or nylon

ttings, compatible with halogenated hydrocarbon solvents. The robot manifold incorporates

stainless steel uid connections.

The high voltage cascade is entirely encapsulat-

ed with a solvent resistant epoxy. This cascade

generates voltages up to 100 kV fed by a low

voltage cable.

NOTES

There are three sources for the high voltage

supply to the Evolver 303 Applicators:

• MicroPak™ Control Unit (LECU5004)

• Stand-alone control/power supply unit

(A10406)

• MicroPakTM Control Unit (LECU5004-31)

The MicroPak Power Supply Control unit provides

a low voltage signal through the robot manifold to

the spray applicator. The high voltage cascade

located within the applicator converts the low

voltage DC signal to a high voltage electrostatic

output.

7

AA-07-03.2

Ransburg

SPECIFICATIONS

Evolver 303 Robotic Atomizers - Introduction

Environmental/Physical

Robot/Mounting Compatibility:

All hollow wrist robots

Applicator Control Unit:

MicroPak Control Unit - LECU5004-31

Stand-Alone Control Unit - A10406

Operating Temperature

Range: 55°F (12.8°C) - 131°F (55°C)

Weight

Single-Headed:

60° 7.44 lbs. (3.37 Kg)

90° 7.13 lbs. (3.23 Kg)

Dual-Headed:

60° 9.33 lbs. (4.23 Kg)

90° 9.18 lbs. (4.16 Kg)

Manifold:

A11981-XX 5.24 lbs. (2.38 Kg)

(No tubing or cable)

Length

Single-Headed:

60° 15.1 in. (38.4cm)

90° 12.2 in. (36.0cm)

Dual-Headed:

60° 14.2 in. (36.1cm)

90° 11.0 in. (27.9cm)

Tubing Manifolds (English):

A12000-0XXXXXX Air Tubing not

included

A12000-1XXXXXX 15 ft.

A12000-2XXXXXX 30 ft.

Tubing Manifolds (Metric):

A11061-0XXXXXX Air Tubing not

included

A11061-1XXXXXX 4 1/2m (15 ft.)

A11061-2XXXXXX 9m (30 ft.)

Electrical Requirements

Output Voltage: 30-100 kV

Output Range: 0-85 µA

Paint Flow Rate: Variable to 1500 cc/min.

(Depending on viscosity & conguration)

Trigger Response

Time: 134ms Open

318ms Closed

Operating Air Pressures

Atomizing Air: 100 psig (6.9 bar) max.

Fan Air: 100 psig (6.9 bar) max.

Trigger Pilot: 70 psig min./100 psig

(4.8 - 6.9 bar) max.

Dump Pilot: 70 psig min./

100 psig max.

(4.8 - 6.9 bar)

Operating Fluid

Pressure: 200 psig

(13.8 bar) max.

100 psig

(6.9 bar) max.

Regulated (with

on-board regulator)

Robot Manifold Tubing Requirements

Atomizing Air

Fan Air

Trigger Air

Dump Pilot

Fluid:

PTFE

Dump:

PTFE

Tubing Bundle

English

5/16" OD Nylon

5/16" OD Nylon

1/4" OD Nylon

5/32" OD Nylon

3/8" OD

(Non-Shielded)

1/4" ID

Tubing Bundle

Metric

8mm OD Nylon

8mm OD Nylon

6mm OD Nylon

4mm OD Nylon

8mm OD

(Non-Shielded)

8mm ID

AA-07-03.2

8

Evolver 303 Robotic Atomizers - Introduction

EVOLVER 303 APPLICATOR ASSEMBLY

A11976 - A B C

Head Conguration

0 = 60° Single Head

1 = 90° Single Head

2 = 60° Dual Head

3 = 90° Dual Head

Body Style

0 = For Highly Resistive Materials (Clear Coat)

1 = For Conductive Materials (Base/Clear)

2 = For Highly Conductive Materials (Base/Clear)

Atomization Technology

0 = Conventional Spray

1 = HVLP Spray

Ransburg

9

AA-07-03.2

Ransburg

Evolver 303 Robotic Atomizers - Introduction

EVOLVER 303 TUBING BUNDLE ASSEMBLY (ENGLISH)

A12000 - A BB C D

Tubing Bundle Length

0 = Air Tubing (Not Included)

1 = 15 Ft. Long Tubing Assembly

2 = 30 Ft. Long Tubing Assembly

Low Voltage Cable Length

00 = No Cable

01 = 25 Ft. Low Voltage, Non-Junction

02 = 40 Ft. Low Voltage, Non-Junction

03 = 50 Ft. Low Voltage, Non-Junction

04 = 75 Ft. Low Voltage, Non-Junction

05 = 100 Ft. Low Voltage, Non-Junction

06 = 15 Ft. Robot to JB / 15 Ft. JB to MicroPak

07 = 15 Ft. Robot to JB / 40 Ft. JB to MicroPak

08 = 15 Ft. Robot to JB / 60 Ft. JB to MicroPak

09 = 15 Ft. Robot to JB / 75 Ft. JB to MicroPak

10 = 25 Ft. Robot to JB / 25 Ft. JB to MicroPak

11 = 25 Ft. Robot to JB / 50 Ft. JB to MicroPak

12 = 25 Ft. Robot to JB / 75 Ft. JB to MicroPak

13 = 40 Ft. Robot to JB / 15 Ft. JB to MicroPak

14 = 40 Ft. Robot to JB / 25 Ft. JB to MicroPak

15 = 40 Ft. Robot to JB / 40 Ft. JB to MicroPak

16 = 40 Ft. Robot to JB / 60 Ft. JB to MicroPak

17 = 50 Ft. Robot to JB / 40 Ft. JB to MicroPak

31 = 25 Ft. Low Voltage, Non-Junction,

Evolver MicroPak

32 = 50 Ft. Low Voltage, Non-Junction,

Evolver MicroPak

33 = 75 Ft. Low Voltage, Non-Junction,

Evolver MicroPak

34 = 100 Ft. Low Voltage, Non-Junction,

Evolver MicroPak

35 = 15 Ft. Robot to JB / 15 Ft. JB to Evolver MicroPak

36 = 15 Ft. Robot to JB / 40 Ft. JB to Evolver MicroPak

37 = 15 Ft. Robot to JB / 60 Ft. JB to Evolver MicroPak

38 = 15 Ft. Robot to JB / 75 Ft. JB to Evolver MicroPak

39 = 25 Ft. Robot to JB / 25 Ft. JB to Evolver MicroPak

40 = 25 Ft. Robot to JB / 50 Ft. JB to Evolver MicroPak

41 = 25 Ft. Robot to JB / 75 Ft. JB to Evolver MicroPak

Robot Adapter

0 = Adapter (Not Included)

1 = Adapter (Fanuc)

2 = Adapter (ABB)

3 = Adapter (Fanuc-P200)

4 = Adapter (KAWASAKI-KE610L)

5 = Adapter (MOTOMAN-PX2850)

6 = Adapter (MOTOMAN-PX2900)

7 = Adapter (B & M LZ2000)

Fiber Optic Cable Length

0 = Fiber Optic Cable Not Included

1 = 15 Ft. Long Fiber Optic Cable

2 = 25 Ft. Long Fiber Optic Cable

3 = 50 Ft. Long Fiber Optic Cable

4 = 75 Ft. Long Fiber Optic Cable

5 = 100 Ft. Long Fiber Optic Cable

6 = 40 Ft. Long Fiber Optic Cable

AA-07-03.2

10

Evolver 303 Robotic Atomizers - Introduction

Ransburg

EVOLVER 303 TUBING BUNDLE ASSEMBLY (METRIC)

NOTES

A11061 - A BB C D

Tubing Bundle Length

0 = Air Tubing (Not Included)

1 = 4 /12m (15 Ft.) Long Tubing Assembly

2 = 9m (30 Ft.) Long Tubing Assembly

Low Voltage Cable Length

0 0 = No Cable

01 = 25 Ft. Low Voltage, Non-Junction

02 = 40 Ft. Low Voltage, Non-Junction

03 = 50 Ft. Low Voltage, Non-Junction

04 = 75 Ft. Low Voltage, Non-Junction

05 = 100 Ft. Low Voltage, Non-Junction

06 = 15 Ft. Robot to JB / 15 Ft. JB to MicroPak

07 = 15 Ft. Robot to JB / 40 Ft. JB to MicroPak

08 = 15 Ft. Robot to JB / 60 Ft. JB to MicroPak

09 = 15 Ft. Robot to JB / 75 Ft. JB to MicroPak

10 = 25 Ft. Robot to JB / 25 Ft. JB to MicroPak

11 = 25 Ft. Robot to JB / 50 Ft. JB to MicroPak

12 = 25 Ft. Robot to JB / 75 Ft. JB to MicroPak

13 = 40 Ft. Robot to JB / 15 Ft. JB to MicroPak

14 = 40 Ft. Robot to JB / 25 Ft. JB to MicroPak

15 = 40 Ft. Robot to JB / 40 Ft. JB to MicroPak

16 = 40 Ft. Robot to JB / 60 Ft. JB to MicroPak

17 = 50 Ft. Robot to JB / 40 Ft. JB to MicroPak

31 = 25 Ft. Low Voltage, Non-Junction,

Evolver MicroPak

32 = 50 Ft. Low Voltage, Non-Junction,

Evolver MicroPak

33 = 75 Ft. Low Voltage, Non-Junction,

Evolver MicroPak

34 = 100 Ft. Low Voltage, Non-Junction,

Evolver MicroPak

35 = 15 Ft. Robot to JB /

15 Ft. JB to Evolver MicroPak

36 = 15 Ft. Robot to JB /

40 Ft. JB to Evolver MicroPak

37 = 15 Ft. Robot to JB /

60 Ft. JB to Evolver MicroPak

38 = 15 Ft. Robot to JB /

75 Ft. JB to Evolver MicroPak

39 = 25 Ft. Robot to JB /

25 Ft. JB to Evolver MicroPak

40 = 25 Ft. Robot to JB /

50 Ft. JB to Evolver MicroPak

41 = 25 Ft. Robot to JB /

75 Ft. JB to Evolver MicroPak

Robot Adapter

0 = Adapter (Not Included)

1 = Adapter (Fanuc)

2 = Adapter (ABB)

3 = Adapter (Fanuc-P200)

4 = Adapter (KAWASAKI-KE610L)

5 = Adapter (MOTOMAN-PX2850)

6 = Adapter (MOTOMAN-PX2900)

7 = Adapter (B & M LZ2000)

Fiber Optic Cable Length

0 = Fiber Optic Cable Not Included

1 = 15 Ft. Long Fiber Optic Cable

2 = 25 Ft. Long Fiber Optic Cable

3 = 50 Ft. Long Fiber Optic Cable

4 = 75 Ft. Long Fiber Optic Cable

5 = 100 Ft. Long Fiber Optic Cable

6 = 40 Ft. Long Fiber Optic Cable

11

AA-07-03.2

Ransburg

SPRAY HEAD

ASSY.

MOUNTING

BLOCK ASSY.

Evolver 303 Robotic Atomizers - Introduction

SPRAY HEAD

ASSY.

MOUNTING

BLOCK ASSY.

VALVE MANIFOLD

ASSY.

SPRAY HEAD

MOUNTING

BLOCK ASSY.

VALVE MANIFOLD

A11976-3XX

90° DUAL HEAD

ASSY.

ASSY.

VALVE MANIFOLD

ASSY.

A11976-2XX

60° DUAL HEAD

SPRAY HEAD

ASSY.

MOUNTING

BLOCK ASSY.

VALVE MANIFOLD

ASSY.

AA-07-03.2

A11976-1XX

90° SINGLE HEAD

A12000-XXXXX REAR MANIFOLD TUBING ASSY. - ENGLIGH

A11061-XXXXX REAR MANIFOLD TUBING ASSY. - METRIC

A11976-0XX

60° SINGLE HEAD

Figure 1: Evolver 303 Solventborne Robotic Applicators

12

ROBOT MANIFOLD

QUICK DISCONNECT

ROBOT SPACER PLATE

ROBOT MANIFOLD QUICK

DISCONNECT RING

ROBOT SPACER PLATE

Evolver 303 Robotic Atomizers - Introduction

Ransburg

FEATURES

The features of the Evolver 303 Series Applicators

include:

!Quick disconnect spray head

!High quality Ransburg air cap and uid

nozzle

!Various adapter plates available to match

most robotic mounting congurations

! No external high voltage Cable. The intern-

ally mounted high voltage cascade requires

only low voltage control wiring

!Less waste to the spray booth with the dump

valve located internally next to the feed tube

!Assembly components made of durable

engineered resin material for optimum

mechanical strength and solvent resistance

!Small, light weight package allows for better

maneuverability in tight areas

!Negligible maintenance down time with the

quick disconnect feature. An atomizer can

be exchanged in less than two minutes for

off-line maintenance

!Field proven high voltage system

!Dual start, dual pitch air cap retaining ring

!Quick color change capability

!Clean interior design with slip-on shroud

!Internal fan and atomization air control valve,

with a mechanically timed trigger sequence

!Color coded air and trigger actuation lines

!Quick Change to a RMA-303 bell applicator

!Heavy duty design ensures excellent service

life even when subjected to the quick mo

tions

of robotic applicators

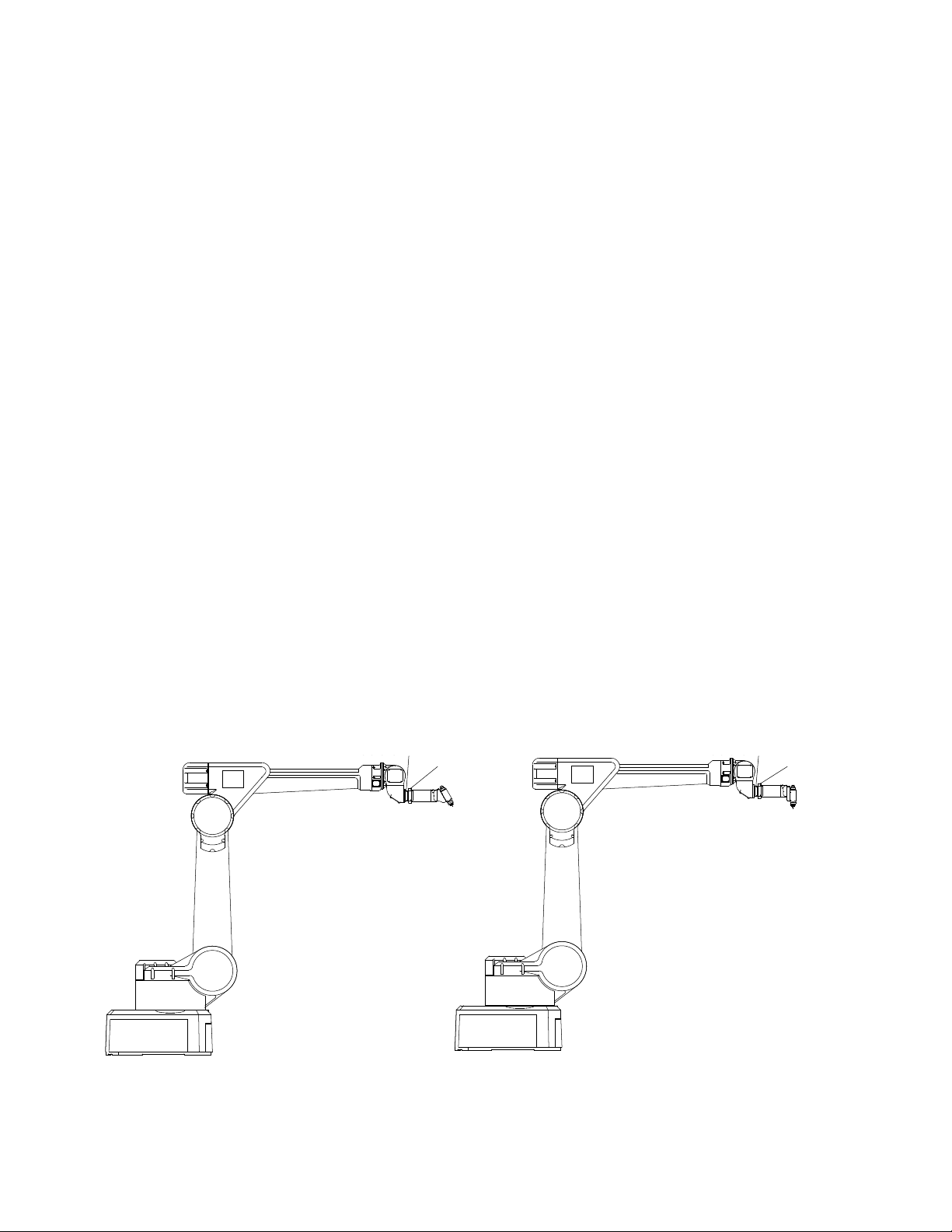

-0XX

A11976

60° SINGLE HEAD

MOUNTED ON ROBOT

RING

-1XX

A11976

90° SINGLE HEAD

MOUNTED ON ROBOT

13

Figure 2: Typical Robotic Applicator Mounting

AA-07-03.2

Ransburg

Evolver 303 Robotic Atomizers - Introduction

A11976-XXX EVOLVER

SPRAY APPLICATOR

ASSEMBLY

The spray applicator assembly is designed to connect to hollow wrist robots. A low voltage control

cable is supplied with the tubing bundle to connect

the cascade to the MicroPak power supply.

ROBOT ADAPTER AND

MOUNTING PLATE

3

6

[161.4]

8

11 [279.1]

3

12

[314.5]

8

3

15

[390.6]

8

CONVERGENCE POINT

ROBOT ADAPTER AND

MOUNTING PLATE

DUAL HEAD 90°

Tool Center-Point

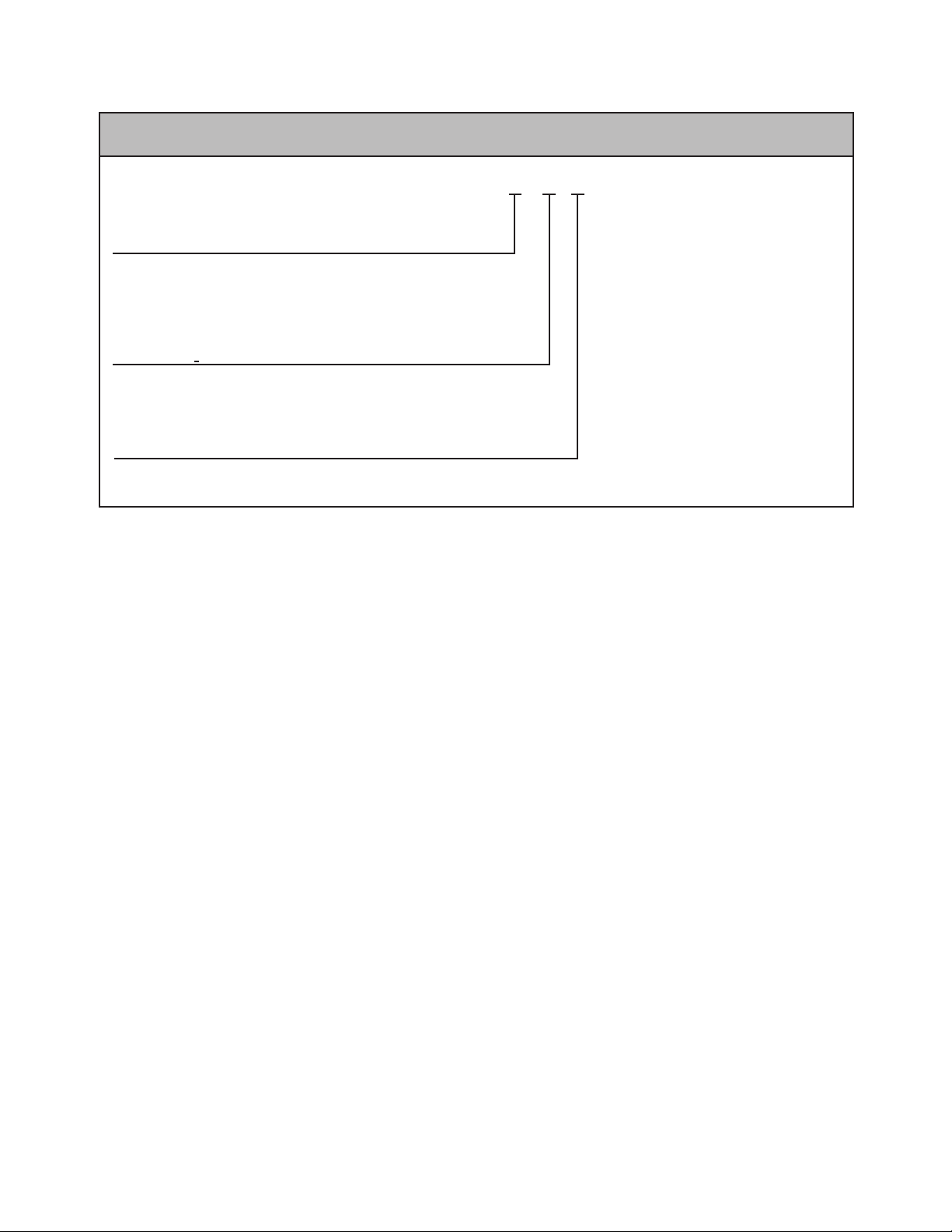

Figure 3 shows the tool center-point information

for the four applicators. For dual head applicators,

the tool center-point is based upon the convergence point. For the single head applicators it

is based upon a 10" target distance. The "Tool

Center-Point Comparisons Table" compares the

tool center-point of several automatic spray applicators.

ROBOT ADAPTER AND

MOUNTING PLATE

1

[392.8]

15

2

1

12

[310.2]

4

1

15

[386.3]

4

SINGLE HEAD 90°

ROBOT ADAPTER AND

MOUNTING PLATE

10 [254.0]

TARGET DISTANCE

AA-07-03.2

22

19

3

[578.4]

4

3

[502.4]

4

DUAL HEAD 60°

6 [151.9]

3

11

[299.9]

4

5

9

[245.6]

8

CONVERGENCE POINT

Figure 3: Tool Center-Point

1

20

[511.4]

8

1

23

[587.5]

8

SINGLE HEAD 60°

10 [254.0]

TARGET DISTANCE

14

Evolver 303 Robotic Atomizers - Installation

INSTALLATION

Ransburg

EVOLVER 303 ROBOTIC

ATOMIZER

INSTALLATION

This information is intended ONLY to indicate the

general installation parameters of this product and,

where applicable, its working relationship to other

Ransburg system components in typical use. Each

installation is unique and should be directed by an

authorized Ransburg representative or conducted

from the Ransburg installation drawings provided

for your particular installation.

POWER SUPPLY

ASSEMBLY

Refer to the most current Power Supply Unit

manuals for complete information regarding power

supply installation.

• MicroPak Control Unit (LECU5004)

(for non-FM installations)

ELECTRICAL AND FIBER

OPTIC CONNECTIONS

The ber optic cable is included in the Evolver 303

tubing bundle, but not used. It is there, ready to

use, in case a user is using or chooses to use in

the future, a bell applicator, which requires the ber

optic cable. The ber optic connection is made on

the back of the applicator's robot plate. The ber

optic cable comes preassembled with connectors

that are secured in place by set screws tightened

from the side of the robot plate. An adequate

ground must be provided to the mounting plate to

ensure that uid ttings, etc. are at ground potential.

FLUID CONNECTIONS

The paint, solvent, and dump uid tubing are connected on the back of the robot plate with stainless

steel compression ttings and PFA tubing. Fluid

tubing requirements are shown in the "Signal

Identication Tables" in the "Installation" section.

• Stand-alone control/power supply unit

(A10406) (for FM installations)

• MicroPak Control Unit (LECU5004-31)

(for FM installations)

MOUNTING

The Evolver 303 is equipped with a quick disconnect assembly. The quick disconnect feature

consists of a robot plate which is permanently

attached to the robot through a wrist adapter plate

and a mating rear plate which is part of the Evolver

303 Spray Applicator assembly. The applicator

is secured to the robot plate with a threaded retaining ring.

15

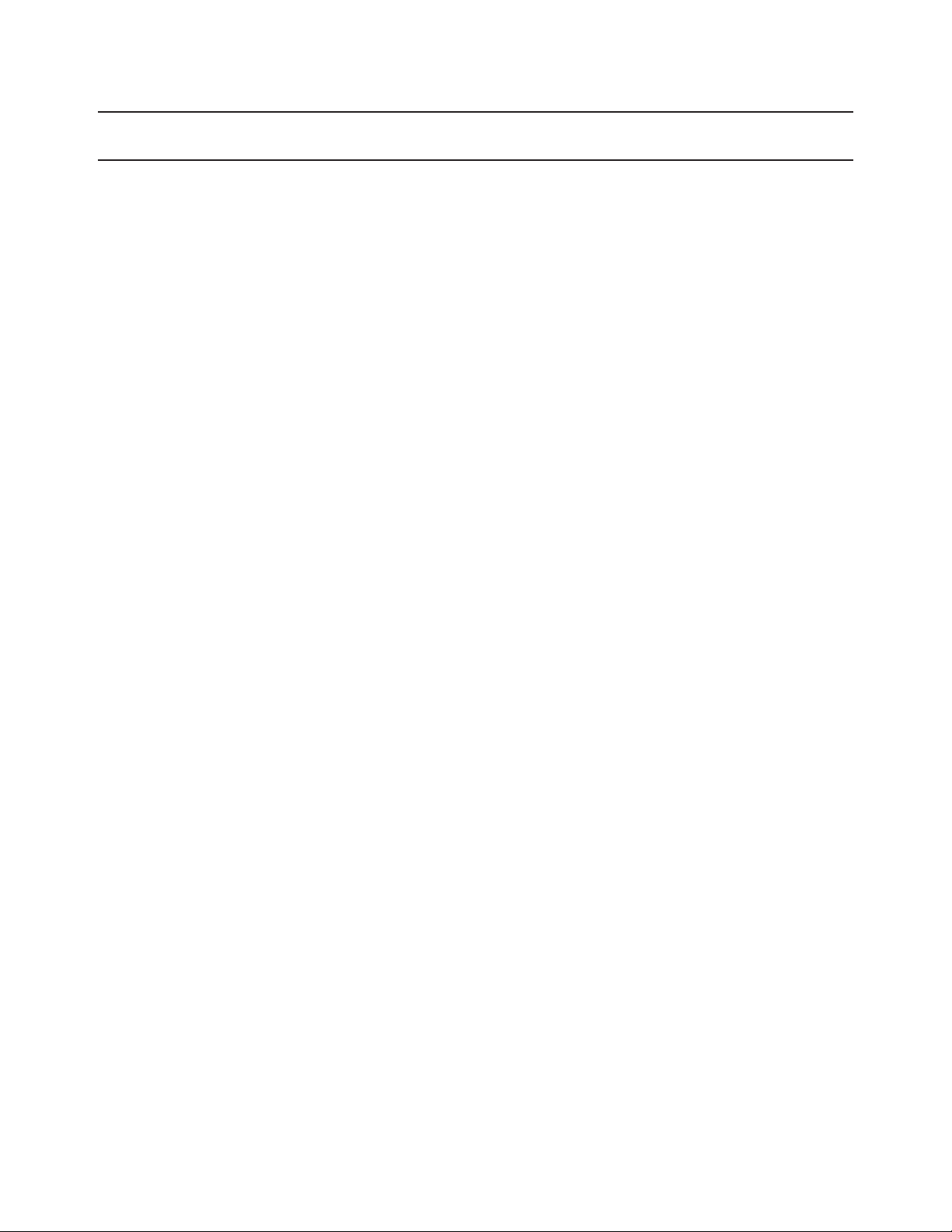

TYPICAL INSTALLATION

Figure 4 shows a typical installation of the Evolver

303 and the wiring installation of the applicator

with the MicroPak.

AA-07-03.2

HV GND. BUS

3

2

J6

1

J10

J2

+24 VDC

24 VRET

1

2

FACT. GND

+24 VDC

24 VRET 3

2

1

MICROPAK

BARE (DRAIN)

BARE (DRAIN)

YELLOW

ORANGE

N/C

N/C

N/C

N/C

GRAY

BLACK

N/C

N/C

GREEN

BLUE

N/C

J3

WHITE

RED

3/4" BRAID CABLE EARTH GROUND

Ransburg

Evolver 303 Robotic Atomizers - Installation

!

W A R N I N G

> The power supply MUST be located outside

the HAZARDOUS area (Reference OSHA,

NFPA-33, and your insurance company requirements.)

> User should be aware of, and adhere to,

all local re codes and ordinances.

> The user MUST provide a properly fused

disconnect between the power source and the

power supply which complies with appropriate

codes.

> Fluid supply must be grounded per NFPA-33.

AA-07-03.2

Figure 4: Low Voltage Cable Connections

16

Evolver 303 Robotic Atomizers - Installation

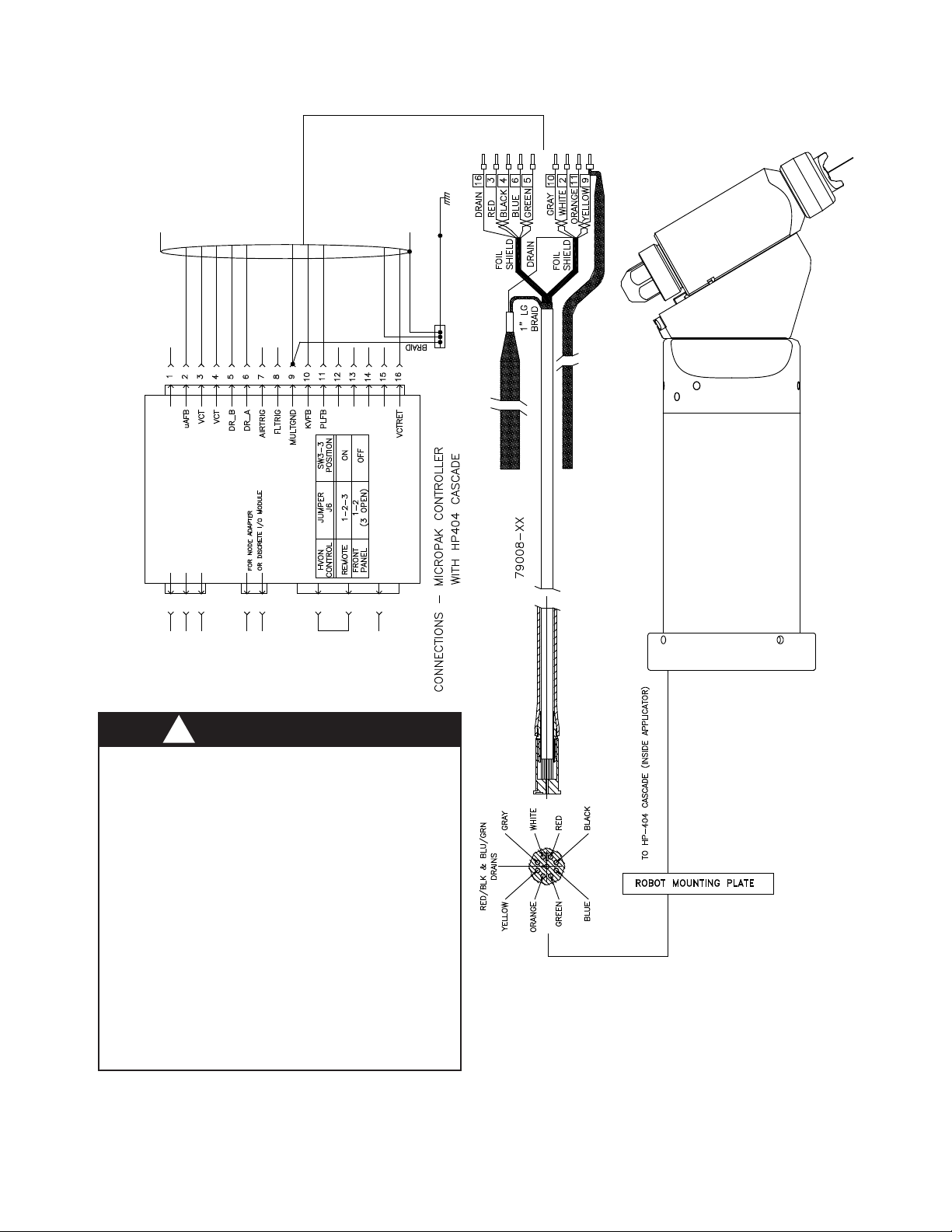

(IF USED)

TRIGGER SOLENOID

SUPPLIED BY OTHERS

DUMP

PAINT SUPPLY 1

Ransburg

IF A CAP CLEANER IS USED IT MUST BE

VENTED TO ATMOSPHERE WITHOUT PRESSURE

IF USING A CAP CLEANER THE

DIRECTLY INTO THE AIR CAP.

SOLVENT/AIR SHOULD NOT BE SPRAYED

BUILD UP.

AREA TO REDUCE ROTATION STRESS .

LEAVE TUBING SLACK IN THE WRIST AND ELBOW

SOLVENT SUPPLY

LUBRICATE THE TUBING BUNDLE

EXCESSIVELY TO EASE INSTALLATIO N

WITH THE ITW EQUIPMENT PURCHASE.

FOR REFERENCE ONLY AND IS NOT INCLUDED

THE ROBOT IS SHOWN

SOLVENT INBOUND

PAINT 1 INBOUND

AND EXTEND TUBING LIFE.

DUMP LINE OUT

(BLUE)

(ORANGE)

(GRAY)

(GREEN)

L.V. CABLE

(BLUE)

SEAL AIR/FAN AIR

SHAPING AIR/ATOMIZATION AIR

PAINT 1 TRIGGER VALVE SIGNAL

PAINT 1 DUMP VALVE TRIGGER SIGNAL

ANALOG SIGNAL AND

TRANSDUCER REQUIRED

(NATURAL)

(YELLOW)

(MAIN AIR IF EXTERNAL TR IGGER USED)

SOLVENT VALVE TRIGGER SIGNAL

BEARING AIR/PAINT TRIGGER

(USED FOR DUAL PURGE AND REGULATED AP PLICATIONS)

PAINT 2 TRIGGER/PEGULATOR P ILOT

CONTROLS BY OTHERS

CONTROL PANEL

17

INSIDE ENCLOSURE

ATTACH TO ISOLATED H.V. GND (FOR MICROPAK)

3/4" HV GND BRAID (DEARBORN #91234 OR EQUIVALANT)

120VAC

GROUND

ATTACH TO PANEL

AC NEUTRAL

BUILDING STEEL/GROUND ROD

Figure 5: Evolver Spray Applicator Air And Fluid Layout

AA-07-03.2

Ransburg

Evolver 303 Robotic Atomizers - Installation

APPLICATOR AND

MANIFOLD ASSEMBLY

(See Figures 4, 5, and 6)

The tubing, hose, and low voltage cable come

bundled from the factory. Pull the bundle through

the robot spacer plate and robot wrist carefully

to prevent any cuts on the cable or hoses. Use

the six (6) socket head cap screws (76566-24C)

included with the rear manifold tubing assembly

to attach the rear manifold assembly (A12000 or

A11061) to the robot spacer plate (see Table 1).

Connect each signal line as required per "Signal

Identication Tables (English and Metric) Tubing

Bundles" in the "Installation" section.

Rear Plate Assembly

The rear plate assembly is designed to be at

ground potential when mounted to the robot plate

component within the tubing bundle assembly.

The air and uid ports are compactly oriented

for use in robotic applications. The interior air

supplies are ported through the ve (5) support

rods and also directly tubed to the upper manifold

assembly. On the exterior side of the rear plate,

the ports are provided with o-ring seals so that

the applicator can be quickly mated and secured

to the robot plate

Robot Plate

The robot plate is a component of the tubing bundle

assembly and intended to be permanently mounted

to the robot. A wrist adapter is also available, which

matches the robot's mounting conguration. The

incoming air lines, uid lines, low voltage cable,

and ber optic cable are connected to the ttings

provided on the back of the robot plate. The rear

plate of the applicator assembly is secured to the

robot plate with a threaded retaining ring.

screws fail and the applicator will break free. This

will leave the break-away ring and the mounting

ring attached to the robot.

Power Supply and Controls

The high voltage cascade located inside the Evolver 303 is controlled by the MicroPak control unit.

The low voltage ouput of the MicroPak is multiplied

by the internal cascade to the high voltage level

required. This eliminates the need for a high voltage cable. A low voltage cable interconnects the

cascade and the MicroPak control. The MicroPak

Eurocard format is designed to t in a conventional

19-inch or 1- inch rack and requires a 24V power

input at a maximum 3 amps. The MicroPak and

the internal cascade will produce voltages up to

100,000VDC.

The MicroPak is designed to electronically limit

current to provide safe operation in a spray booth.

The voltage and current draw of the applicator are

continuously displayed on the MicroPak control

panel. Voltage and over-current limits are adjust-able on the front of the MicroPak. MicroPak

internal safety circuits will shut down the system

on over-current and cable faults.

With additional control modules, all of the functions

of the Evolver 303 and MicroPak can be controlled

by a programmable controller. A Serial Digital

Module pneumatically controls the paint and

dump valves located on the applicator. An I/O

module provides communication between these

modules and the PLC.

The above modules are mounted in one 19-inch

rack and interconnected through a common

mother board.

Break-Away Feature (Optional)

The Evolver 303 can be converted to have a break-

away feature, by replacing the ve (5) stainless

steel screws with ve (5) special designed plastic

screws (77524-00). This feature is meant to reduce the damage to the applicator, robot, etc. If

a collision occurs, the ve (5) plastic break-away

AA-07-03.2

18

Evolver 303 Robotic Atomizers - Installation

Ransburg

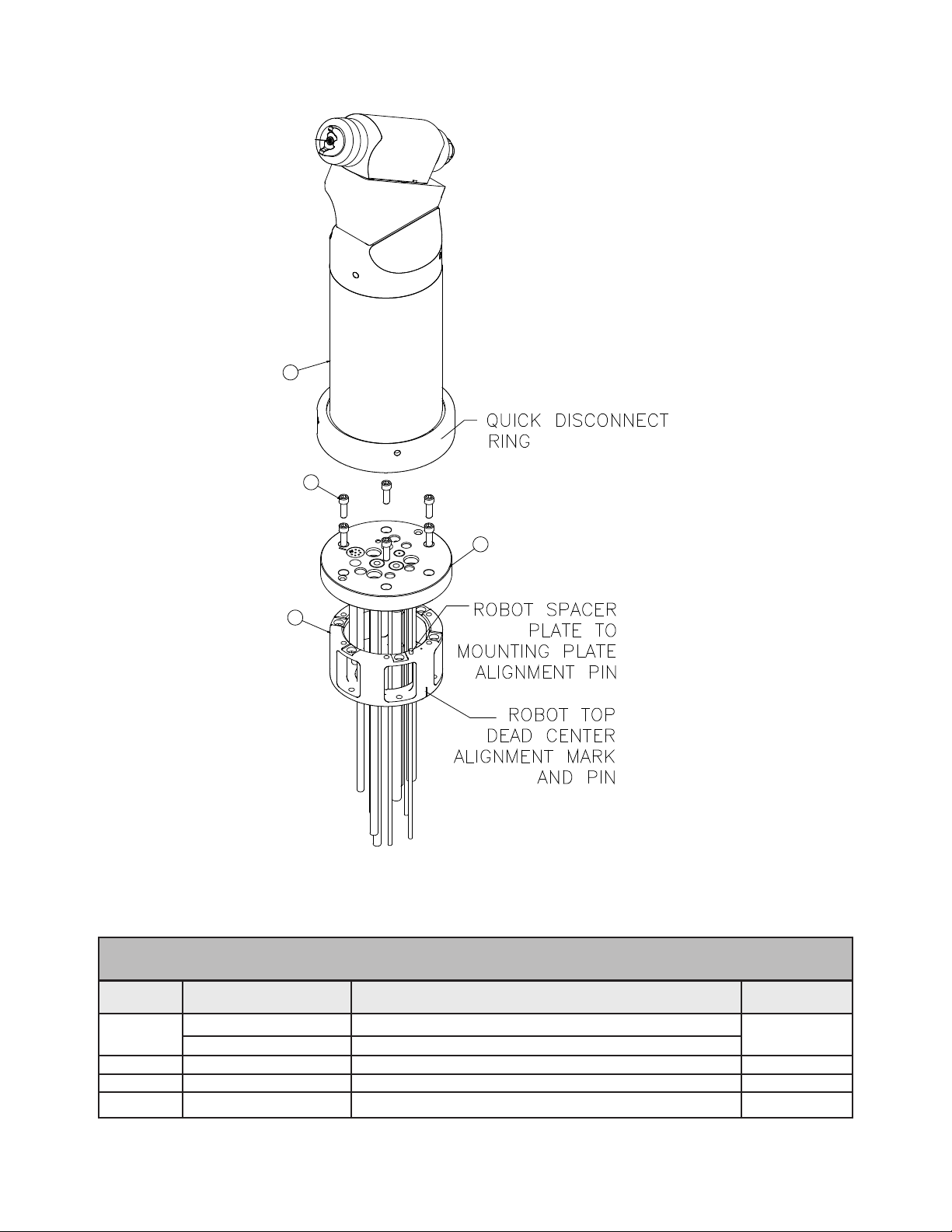

Robot Spacer Plate

The robot spacer plate is included with the robot

manifold assembly to increase life of the tubing

bundle. The extra spacing it provides increases

the bend radius of the tubes and decreases the

hose or cable stress at the connector.

There is only one way the spacer plate may be

assembled to the mounting plate. The spacer

plate has an alignment pin that may only engage

in one hole position in the robot mount plate. This

provides the nal position to top dead center of

the robot.

Six (6) robot spacer plates shown in Table 1 are

available for this product.

TABLE 1 - SPACER PLATES

Part # Description

79107-00 ABB Robots

78983-00 Fanuc P155, 145 Robots

79131-00 Fanuc P200 Robot

A10847-00 Adapter (Kawasaki-KE610L)

A10848-00 Adapter (Motoman-PX2850)

A10849-00 Adapter (Motoman-PX2900)

A10851-00 Adapter (B & M LZ 2000)

maintain FM Approval, this cable must be secured

to the stress relief bar on the rear of the power

supply. (See "A10406-XX Evolver MicroPak

Power Supply" manual for further information on

connecting the low voltage cable.)

NOTE

> With the exception of uid, dump, and

bearing air/paint trigger, all other pilot and

air supply lines should be bulkheaded

and their diameters increased one nom-

inal size. For example: atomization air

should be increased to a 1/2" ID (8mm)

from bulkhead plate to the volume booster.

NOTE

> If the length of the fan or atomization

air lines exceeds 30 ft. (10m), the lines

must be upsized to 1/2" ID (12mm for

metric).

NOTE

LOW VOLTAGE CABLE

INSTALLATIONS

For installations utilizing the LECU5004-XX MicroPak power supply, connect the low voltage cable

(79008-XX) from the robot manifold assembly to

the LECU5004-XX MicroPak controller or junction

box. If connecting to a junction box, use a junction

cable (77062-XX) to make the con-nection from

the junction box to the LECU5004-XX MicroPak.

Make connections as shown in Figure 4.

For installations utilizing the A10406-XX Evolver

MicroPak power supply, connect the low voltage

cable (A11353-XX or A11356-XX) from the robot

manifold assembly or junction box to the receptacle

on the rear of the A10406-XX power supply. To

19

> For the dipswitch settings for the

Evolver 303, reference the current MicroPak service manual.

NOTE

> Leave 12-24 inches (.30m-.61m) of

extra length on all lines to prevent extreme

tension being applied to these lines during

robot movement. This increases tubing

bundle life.

AA-07-03.2

Ransburg

Evolver 303 Robotic Atomizers - Installation

!

C A U T I O N

> Do not exceed 100' combined length of the

low voltage cables.

W A R N I N G

!

> If a non-explosion proof junction box/terminal

strip is used, it must be located outside the

hazardous area.

> Install and route the hoses and cable so

that they are NOT exposed to temperatures

in excess of 120° F. Ensure that all hose and

cable bends are NOT LESS THAN a 6-inch

(15cm) radius and are not subjected to more

than 360° of torsional twist. Failure to comply

with these parameters could cause equipment

malfunctions that might create HAZARDOUS

CONDITIONS!

W A R N I N G

!

SIGNAL IDENTIFICATION TABLE (ENGLISH)

Abbr.

B.A/P.T Bearing Air (Paint Trigger) Yellow Nylon 1/4" OD X .170" ID

B.A RTN Bearing Air Return Yellow Nylon 5/32" OD X .106" ID

BRK Brake Air Orange Nylon 1/4" OD X .170" ID

DL Dump Line Natural PTFE 5/16" OD X .250" ID

F.O Fiber Optic Cable Natural Polyethylene 1/4" OD (jacket)

LV Low Voltage Cable Black N/A N/A

P Paint In Natural PTFE 3/8" OD X .250" ID

PT Paint Trigger Green Nylon 5/32" OD X .106" ID

DT Dump Trigger Silver Nylon 5/32" OD X .106" ID

SA.I/A.A Inner Shaping Air (Atom, Air) Blue Nylon 5/16" OD X .250" ID

SOL Solvent In Natural Nylon 1/4" OD X .170" ID

SA.O/F.A Outer Shaping (Fan Air) Gray Nylon 5/16" OD X .250" ID

ST/RP Solvent Trigger Signal Blue Nylon 5/32" OD X .106" ID

T.A Turbine Air Green Nylon 3/8" OD X .275" ID

Description Color

Tubing Material

Tubing Size

AA-07-03.2

SIGNAL IDENTIFICATION TABLE (METRIC)

Abbr.

B.A/P.T Bearing Air (Paint Trigger) Yellow Nylon 6mm OD X 4mm ID

B.A RTN Bearing Air Return Yellow Nylon 4mm OD X 2.7mm ID

BRK Brake Air Orange Nylon 6mm OD X 4mm ID

DL Dump Line Natural PTFE 10mm OD X 8mm ID

F.O Fiber Optic Cable Natural Polyethylene 1/4" OD (jacket)

LV Low Voltage Cable Black N/A N/A

P Paint In Natural PTFE 8mm OD X 6mm ID

PT Paint Trigger Green Nylon 4mm OD X 2.7mm ID

DT Dump Trigger Silver Nylon 4mm OD X 2.7mm ID

SA.I/A.A Inner Shaping Air (Atom, Air) Blue Nylon 8mm OD X 6mm ID

SOL Solvent In Natural PTFE 6mm OD X 4mm ID

SA.O/F.A Outer Shaping (Fan Air) Gray Nylon 8mm OD X 6mm ID

ST/RP Solvent Trigger Signal Blue Nylon 4mm OD X 2.7mm ID

T.A Turbine Air Green Nylon 10mm OD X 8mm ID

Description Color

Tubing Material

Tubing Size

20

Evolver 303 Robotic Atomizers - Installation

2

3

Ransburg

1

4

Figure 6: Applicator and Manifold Assembly

APPLICATOR AND MANIFOLD ASSEMBLY - PARTS LIST (Figure 6)

Item #

Part # Description Qty

1 A11061-XXXXXXX Tubing Bundle Assembly (Metric) 1

A12000-XXXXXXX Tubing Bundle Assembly (English)

2 A11976-XXX Evolver 303 Spray Applicator Assembly 1

3 76566-24C Screw, 1/4-20 X 3/4" Lg., SHCS 6

4 See Table 1 Robot Adapter 1

21

AA-07-03.2

Ransburg

Evolver 303 Robotic Atomizers - Installation

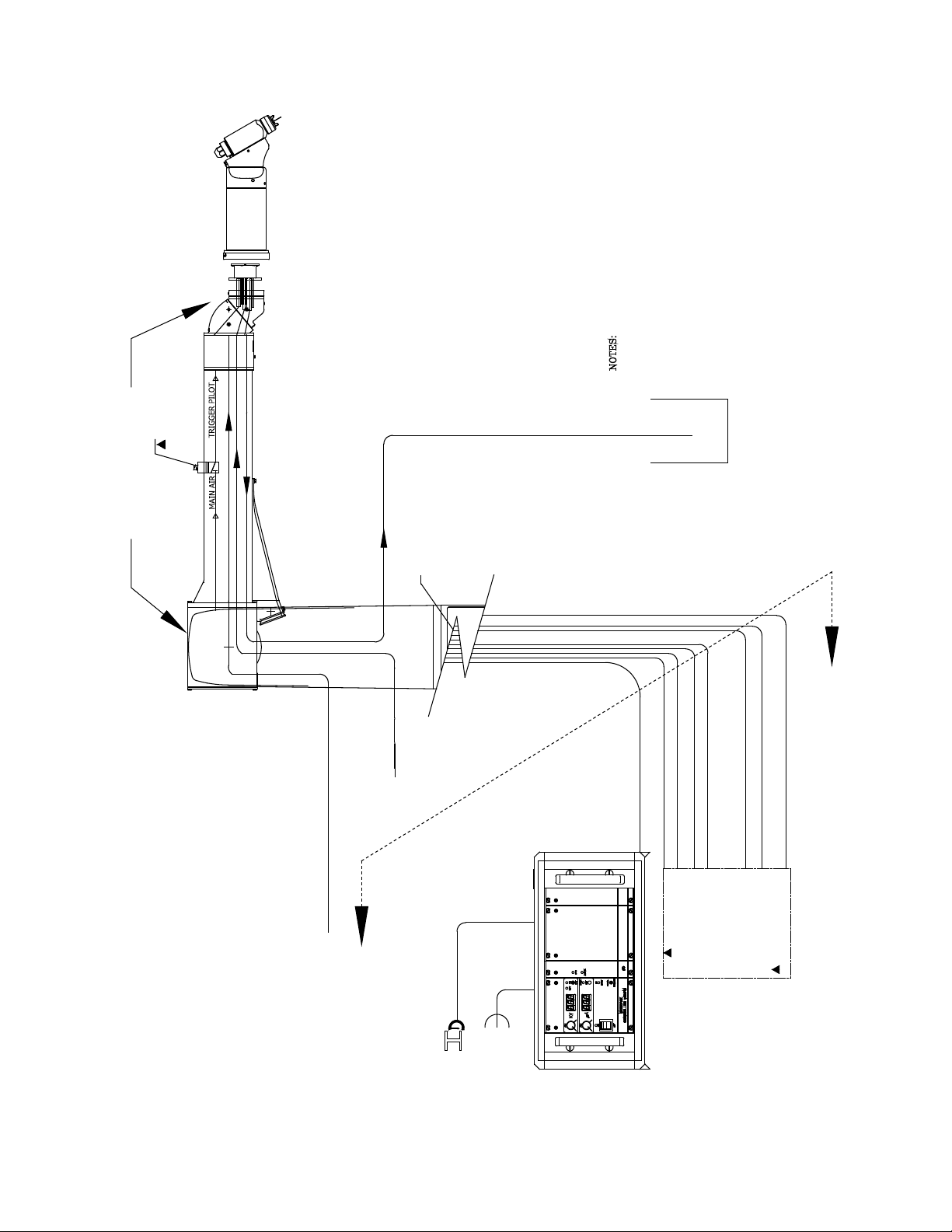

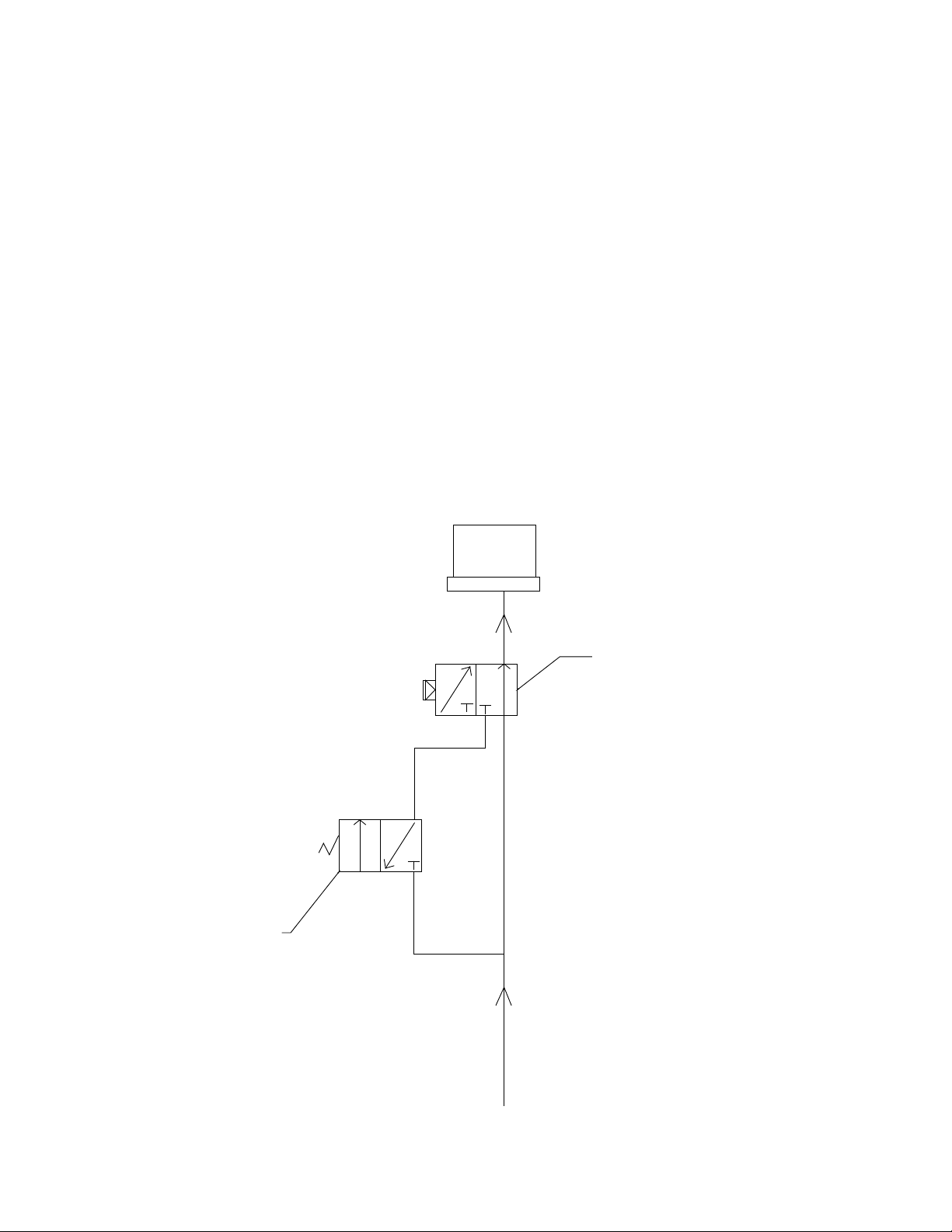

SPRAY / BELL

APPLICATOR

TRIGGERING

If you are currently using an RMA-303 bell applicator system and want to add the Evolver 303

spray applicator system to spray using the same

tubing bundle, a simple conversion must be made

in order to allow for switching between spray and

bell applicators. Figure 7 shows the recommended system that should be placed in the bearing

air line between the main air input and the robot

manifold plate. It is suggested that this circuit

be placed on the robot arm. This system should

also be used when the user is implementing the

Evolver 303 spray applicator system and plans to

use RMA-303 bell applicators as well.

In Figure 7, the trigger solenoid must be an electronically activated, normally closed valve with

exhaust, or a 3-way valve, with 100 psi max.,

24VDC. Typically this solenoid already exists in

the robot arm and can be used in this circuit. The

spray applicator trigger/bearing air select valve

must be a pneumatically activated, normally open

solenoid. A suggested solenoid is P/N 11678-01.

An additional solenoid must be used to activate the

PT (Paint Trigger) valve. If any of these solenoids

are located inside a hazardous area, they must

be explosion proof.

SPRAY APPLICATOR SIDE

TRIGGER

SOLENOID

BEARING AIR LINE

SPRAY APPLICATOR TRIGGER/

BEARING AIR SELECT

BELL APPLICATOR SIDE

MAIN AIR LINE

AA-07-03.2

Figure 7: Conversion Schematic

22

Evolver 303 Robotic Atomizers - Installation

Ransburg

TUBING BUNDLE

INSTALLATION

Typically, the tubing bundle is pulled through the

robot arm from the robot wrist side. Keep the

bundle taped except for the portion of the bundle

that will be inside the arm. Pull the tubing through

the wrist and arm, leaving about 250mm (10") of

tubing sticking out of the front of the wrist plate

(see Figure 8).

Fasten the cable bundle in the robot at the rear

exit of the arm. Push the robot spacer plate and

applicator mounting plate to the robot wrist plate

aligning the top dead center marks of the spacer

plate and robot wrist plate. Fasten using appropriate screws. Installing the tubing bundle in this

fashion will increase tubing bundle life signicantly.

BUNDLE LUBRICATION

When the tubing bundle is installed, it should be

lubricated with a generous amount of lubricant to

increase the service life of the tubes. A recommended lubricant is Shell Alvania EP #02. There

are other lubricants that are available for use.

Prior to using a lubricant, ensure it is silicone free,

resists heat breakdown, and is compatible with

the materials being applied.

23

250 MM

(10")

APPROX.

TYPICAL

ROBOT

ARM

ROBOT WRIST PLATE

ROBOT

SPACER

PLATE

APPLICATOR

MOUNTING

PLATE

Figure 8: Tubing Bundle Installation

AA-07-03.2

Ransburg

Evolver 303 Robotic Atomizers - Installation

If you currently have an A12000 or A11061 Tubing

Bundle for either a RMA-303 or an Evolver 303

and the number engraved on your tubing bundle

plate is A11062-REV.A through A11062-REV.G,

this plate will not allow you to switch between

RMA-303 applicators and Evolver 303 applicators.

If you have Rev. H or greater, the online switching

capability is provided in the plate.

If you desire to switch between RMA-303 and

Evolver 303 applicators, you must contact your

local authorized Ransburg distributor for the plate

to be reworked. Once the rework is complete, the

plate can be re-installed just as before, and both

applicator types used interchangeably.

NOTES

AA-07-03.2

24

Evolver 303 Robotic Atomizers - Operation

OPERATION

Ransburg

W A R N I N G

!

> Operators must be fully trained in safe

operation of electrostatic equipment. Operators must read all instructions and safety

precautions prior to using this equipment

(see NFPA-33).

As with any spray nishing system, operation

of the Evolver 303 involves properly setting the

operating parameters to obtain the best nish

quality for the coating material being sprayed,

while maintaining correct operation and reliability

of the equipment used. Adjustments to operating

parameters, which cover spraying, cleaning, and

on/off control, include the following:

• Coating Materials

• Fluid Flow Rate Control

• Fluid Valve / Trigger Control

• Atomization Air (Paint Atomization

Control)

• Fan Air (Pattern Control)

• Electrostatic Voltage

• Target Distance

SPRAY APPLICATOR

CONTROLS

Atomization Air (SAI/AA) /

Fan Air (SAO/F.A)

The atomization and fan air are turned on by the

trigger line and are controlled by an internal air

valve located in the applicator head. During normal

operation with applicator triggered off, there is a

slight bleed of air through the atomization port.

Atomizing Air

Adjustments are made through the robot PLC or

a manually adjustable air regulator. The lowest

air pressure required to break up the paint should

be used. Lower atomizing air pressures result in

less overspray and increased transfer efciency.

Fan Air

Adjusting the fan air increases or decreases the

size of the spray pattern. Increasing pressure

increases pattern size. Pattern adjustment should

be made to suit the size and shape of the object

being painted. This adjustment is made through the

robot PLC or a manually adjustable air regulator.

25

W A R N I N G

!

> Electrical discharge of a high electrical

capacitance uid/paint system can cause re

or explosion with some materials. If arcing

occurs when a specic coating material is

used, turn the system off and verify that the

uid is non-ammable. In these conditions,

the system is capable of releasing sufcient

electrical and thermal energy to cause igni-

tion of specic hazardous materials in the air.

Air cap atomization and fan pressures should be

set and recorded using an air cap test kit. This

provides a consistent measurement, so initial

settings may be duplicated at any time. (See

"Accessories" in the "Parts Identication" section.)

HVLP SPRAY

The Evolver 303 HVLP models, when properly

set-up, are designed to provide maximum transfer efciency by limiting air cap pressures to 10

psi (0.7 bar) (in the U.S., this complies with rules

issued by SCAQMD and other air quality authorities). Air cap pressures should be measured with

an optional air cap test kit. (See "Accessories" in

the "Parts Identication" section.)

AA-07-03.2

Ransburg

Evolver 303 Robotic Atomizers - Operation

NOTE

> For HVLP operation (max. 10 psi, 0.7

bar cap pressure), DO NOT exceed the

air inlet pressure, which was read at the

gun base before the tubing manifolds,

given as follows:

PSI (Bar) CAP #

42 (2.9) 48-1

42 (2.9) 481-1

FLUID VALVE CONTROLS

Trigger and Dump

(See Figure 9)

The uid valves in the Evolver 303 are actuated

by an air signal. The air pressure must exceed

70 psi (4.8 bar) to assure proper actuation of the

valve. Applying air to the valve actuator turns on

the uid ow for the valve.

The paint trigger valve controls the paint ow

to the applicator. When actuated, paint ows

through the valve to the coiled uid tube and into

the spray head.

The dump valve controls the paint ow through the

dump line. When actuated, paint ow is directed

to the dump return line. This provides a method

of rapidly removing paint from the incoming line

for cleaning and/or color change. Normally, the

dump valve is not actuated at the same time as

the paint valve since the paint valve is intended

to cause the uid to ow to the applicator head

at the prescribed input pressure.

SINGLE PURGE

SPRAYING

When the target part is nished and a color change

is desired, ensure voltage is turned off.

W A R N I N G

!

> Failure to turn voltage OFF during color

change sequence when solvent is owing

through the uid nozzle, could cause a re

or explosion.

When the cleaning cycle with solvent is complete,

an air purge for several seconds is recommended

to clean and dry the ID of the dump line hose.

Paint Viscosity

The applicator is capable of atomizing paint of

most any desired viscosity. It is recommended

to keep the material viscosity as low as possible.

This allows spraying at lower fan and atomization

air pressures which result in less overspray and

higher transfer efciency.

W A R N I N G

!

> Most paints and solvents, including those

listed in "Polar & Non-Polar Solvents Chart"

in the "Maintenance" section, are toxic to a

certain degree and ammable or combustible.

Use them only in a well ventilated atmosphere.

Use protective equipment as required in the

Material Safety Data Sheet supplied with the

substance.

Fluid Flow Rate

Fluid ow is adjusted through the robot PLC by

varying the pilot pressure to an exterior uid regu-

lator. Fluid pressures from the circulating system

may exceed the maximum uid pressure rating

of the Evolver 303 applicator. Because of these

high uid pressures, a manual step-down uid

regulator must be used.

Applicator Trigger Control Air

The Evolver applicators require a minimum of 70

psig trigger control air pressure to ensure proper

operation of the applicator piston.

AA-07-03.2

26

Evolver 303 Robotic Atomizers - Operation

Ransburg

Electrostatic Voltage

Under no load conditions, the maximum voltage

limit for these spray applicatorss is 100 kV. Some

painting operations may require different voltage

settings to obtain optimum transfer efciencies. If

Faraday cage areas are predominant on the item

being painted, a lower voltage setting would aid

in coating these areas.

NOTE

> If a 0 kV command is sent to the Mi-

croPak, a feedback fault will occur.

When not spraying, it is recommended to set back

voltage to 30-40 kV or off between target parts.

Sometimes, depending upon target carrier spacing, higher setback voltages may be required. The

ramp-up time for the HP-404 cascade (0-100 kV)

is approximately 3 seconds.

W A R N I N G

!

> If a bell applicator is being used, and

needs to be switched to a spray applicator,

the bell applicator must have all voltage,

uids, and air turned off, and the bell cup

completely spun-down before the changeout can occur.

The MicroPak voltage ramp-down works at a rate

of 33 kV/sec.

Target Distance

The distance between the applicator tip and the

article being painted should be 10-14 inches

(.25m-.36m) for a single head applicator and at

or near the convergence point for a dual head

applicator. Excessive distance causes a waste

of coating material and wrap back (paint particles

being deposited on the applicator body or the robot

arm). At close distances the voltage at the tip of

the applicator will be reduced, which decreases

the charging effect of the applicator.

W A R N I N G

!

> If target distance is less than 8-inches

(.20m), an arc could occur.

Applicator Head

Fluid Tube to

Dump Valve

To Paint Waste Tank

Paint Valve

Solvent In

Cup Wash

Solvent Valve (Plugged)

Paint Supply

27

Figure 9: Single Purge Air and Fluid Passage

Schematic

AA-07-03.2

Ransburg

MAINTENANCE

Evolver 303 Robotic Atomizers - Maintenance

Good maintenance is essential to safe and productive operation. Schedules should be established

by the user, based on the following general information and observations of the initial production

requirements. The Ransburg maintenance and

safety information should be made available to

each operator.

Normal re protection measures are necessary,

including proper storage of paints and solvents

and the proper disposal of waste. Ready access

to appropriate re extinguishing equipment is

required. For details, consult the appropriate

NFPA safety information and/or applicable country

safety standard.

W A R N I N G

!

> An electrical discharge or spark may create

an electrical and/or re hazard during maintenance. Do not clean or service the spray

applicator with the power supply on. Verify

that the power supply has been locked out and

tagged out per OSHA and/or your applicable

country safety codes.

> Unexpected robot movement can be haz-

ardous. Do not adjust or repair the spray applicator when the robot is operating or waiting

to start. The robot must be locked out and

tagged out per OSHA and/or your applicable

country safety codes.

ROUTINE MAINTENANCE

SCHEDULE

Follow these maintenance steps to extend the

life of the spray applicator and ensure efcient

operation:

Several Times Daily

1. Turn the MicroPak control unit OFF! Follow

"Lockout/Tagout Procedures".

2. Inspect the uid nozzle, air cap, and elec-

trode wire for paint accumulation. Clean as frequently as necessary. See "Procedures" in the

"Maintenance" section.

W A R N I N G

!

> Take precautions to see that skin is not

punctured by sharp electrode.

C A U T I O N

!

> Do not bend the applicator electrode while

wiping. Never immerse the applicator in solvents. This will cause damage to the electrical

components.

Daily (Or at Shift Start)

1. Turn the MicroPak control unit OFF and:

AA-07-03.2

> Solvents used for equipment ushing must

have ash point ratings equal to or greater than

the ash point rating of the coating material.

Solvents used for general cleaning must have

ash point ratings higher than 100°F (37.8°C).

>Never remove spray applicator head from

assembly while under pressure.

•

Check within 20 ft. (6.1 meters) of the point

operation (of the applicator) and remove or

ground ALL loose or ungrounded containers.

• Inspect workholders for accumulated coating

materials (remove such accumulations if

present). Ensure resistance to ground from

work holder is less than 1 megohm.

• Check that the nozzle assembly is clean and

undamaged. Ensure air caps are clean and

undamaged.

of

28

Evolver 303 Robotic Atomizers - Maintenance

Ransburg

2. Turn the MicroPak control unit ON! Energize

high voltage.

Shut-Down (Or at Shift End)

1. Turn the MicroPak control unit OFF.

2. Flush the lines and allow the solvent to remain

in the lines. See "Procedures" in the "Maintenance" section.

3. Wipe the applicator (including the air cap)

and robot wrist with a cloth and a suitable, clean

non-polar solvent.

Weekly

1. Check the entire system for damage, leaks,

and paint accumulation.

2. Clean the atomizer assembly.

3. Conduct a current output test. See "Procedures" in the "Maintenance" section.

C A U T I O N

!

> Failure to use a non-polar solvent may

cause a decrease in voltage at the tip of the

applicator. This will signicantly decrease

transfer efciency.

4. Remove end cap [1]. Removing the end cap

releases tension on all internal spray head components. Remove needle spring [2] and valve spring

[3], which are loose after removing the end cap.

C A U T I O N

!

> Never attempt to clean the air cap holes

with a wire or other metal object. Doing so

may damage the air cap, resulting in distortion of the spray pattern.

PROCEDURES

Applicator Cleaning/Service

(See Figure 10a and 10b)

1. Flush the paint supply line and the applicator

paint passages using a solvent which is compatible

with the material being sprayed. Continue to ush

until all traces of paint are gone.

2. Turn off the solvent supply, actuate paint pushout air at color changer, and trigger the applicator

and PT. Allow all of the uid to drain from the

spray applicator uid passages.

3. Clean the exterior surfaces of the spray appli-

cator with a solvent soaked rag. As long as the

applicator is intact, a polar solvent may be used

for all cleaning, however, after cleaning, wipe off

all surfaces with a non-polar solvent to reduce

conductive residue on the applicator's surface.

(See "Polar & Non-Polar Solvents Chart" in the

"Maintenance" section regarding proper solvent

selection.)

5. Remove the air cap retainer [36] and air cap

[35]. Soak in a non-polar solvent if necessary. If

paint remains in the air cap holes, clean with a

toothpick or similar soft wood object. Air caps are

best cleaned in an ultrasonic cleaner.

6. Remove the air cap locator [33] and uid tip

[34]. Clean using a non-polar solvent.

7. Tightly grip the plastic needle [6] and unscrew

counter-clockwise to remove the front electrode

needle assembly. A short piece of H-2339 tub-

ing (1/4" OD x 0.175" ID) pressed over the front

needle will assist in unscrewing the assembly.

If required, use needle nose pliers with masking

tape or duct tape. Carefully clean with a non-polar

solvent. Replace any parts that show signs of

wear or damage.

C A U T I O N

!

> If using needle nose pliers to unscrew the

front needle, be very careful. Do not grip on

the tapered sealing surface. If the pliers slip,

they could damage the tapered sealing surface

of the needle.

29

AA-07-03.2

Ransburg

POLAR AND NON-POLAR SOLVENTS

Evolver 303 Robotic Atomizers - Maintenance

Non-Conductive (Non-Polar)

Amyl Acetate

Methyl Amyl Acetate

Toluene

Xylene

High Flash Naptha

Mineral Spirits

8. Remove uid nozzle [32] by unscrewing

counter-clockwise. Inspect o-ring [30] and all passages for build up or damage. Clean or replace

as necessary. Lubricate and reinsert o-ring into

applicator barrel and reinstall uid nozzle. Torque

uid nozzle to 25 lbs•in (2.82 Nm).

Moderately Conductive

Methyl Isobutyl Ketone

Ethyl Acetate

Methyl Ethyl Ketone

Butyl Carbitol

NOTE

> There should be a small gap between

the uid nozzle and the applicator barrel

after tightening.

Extremely Conductive (Polar)

Methanol

Carbitol

Diacetone

Butyl Alcohol

Acetone

Butyl Cellosolve

10. Screw uid tip [34] back into place. Hand

tighten rst, then with a small wrench, tighten an

additional 30 degrees.

11. Replace air cap locator [33], air cap [35], and

air cap retainer [36].

12. Apply a thin lm of petroleum jelly to valve and

needle springs [2] and [3]. Install the springs

back into the end cap and the spray head

assembly.

13. Screw end cap [1] back on.

9. After cleaning, insert the electrode assembly

[31] back into the spray head assembly. Apply

Adhesive #222, low strength (purple) thread-locker,

to the threads of the electrode assembly before

reassembly.

NOTE

> The uid tip [34] should always be

installed and tightened before installing

the needle and valve springs.

C A U T I O N

!

> After tightening the uid tip, always check

to see if the proper gap (1/16") between the

needle nuts and air valve stem occur, before

installng the needle and valve springs back

into the head.

Current Output Test

1. Clean and blow out all uid passages with

non-conductive solvent.

2. Remove from robot and perform bench test

using a spare tubing bundle.

3. Turn the control unit power ON.

4. Activate high voltage and slowly approach the

applicator electrode with ground hook or wire.

5. Monitor the current output on MicroPak. Current should rise as ground approaches. At ap-

proximately 85 microamperes, the MicroPak will

shut off. The OVERCURRENT indicator should

come on.

The spray head can be removed from assembly

as shown in Figure 10a for cleaning and service.

AA-07-03.2

30

Evolver 303 Robotic Atomizers - Maintenance

ROTATE HEAD APPROX.

45° CCW TO REMOVE

Ransburg

3

INSERT A

THROUGH THE HOLE TO LOOSEN

THE LOCKING SCREW (3), TURN

THE SCREW CLOCKWISE, WHICH IN

TURN WILL DISENGAGE THE

LOCKING TAB (2), TURN UNTIL THE

TAB COMES IN CONTACT WITH THE

INSIDE WALL. AS ILLUSTRATED IN

FIGS. 24 THRU 27.

THEN ROTATE THE HEAD AS

SHOWN BY HAND AND PULL UP TO

REMOVE.

" ALLEN WRENCH

16

35

31

34

36

33

32

30

Figure 10a: Spray Head Removal

27

28

29

1/16" (1.59 MM)

1

3

6

4

2

5

31

Figure 10b: Spray Head Assembly

AA-07-03.2

Ransburg

SPRAY HEAD ASSEMBLY - PARTS LIST (Figure 10b)

Evolver 303 Robotic Atomizers - Maintenance

Item #

1 79148-00 End Cap, Spray Head 1

2 17615-00 Spring, Compression 1

3 9334-00 Spring, Valve Return 1

4 7733-07 Jam Nut 1

5 76199-00 Rear Adjusting Nut 1

6 79151-00 Assembly, Needle Shaft 1

27 RME-38 Return Spring, Piston 1

28 EMF-7 Seal, Washer 1

29 RME-32 Seal 1

30 79001-01 O-Ring, Solvent Proof 1

31 70430-01 Electrode, High Wear 1

32 EMF-195 Nozzle, Fluid Hole 1

33 EMF-192 Locator, Air Cap 1

34 79140-02 Fluid Tip, .055" (1.4mm) Diameter 1

35 79153-65R-1 Air Cap, Pined 1

36 79154-00 Retaining Ring, Tapered 1

Part # Description Qty

NOTE

> Ensure that the fan and atomization air

are on and owing prior to triggering the

uid. Ensure air before uid adjustment

is correct. Failure to follow this sequence

will cause spits and defects on the part

being painted.

AA-07-03.2

32

Evolver 303 Robotic Atomizers - Maintenance

Ransburg

SERVICE

Because we want to provide our users with the

most up-to-date technology possible, we are constantly seeking to improve products. If a change

in product conguration occurs after it is on the

market, we will implement that technology in future

production and, if practical, make it available to

current users. The following service information is

based on standard specications and procedures

for this product. If you nd some minor deviations

between this information and your equipment

because of design or manufacturing changes,

contact your Ransburg representative to resolve

the difference.

W A R N I N G

!

> An electrical discharge or spark may create

an electrical and/or re hazard during maintenance. Do not service the spray applicator

with the power supply on. Verify that the power

supply on/off switch has been turned off.

> Unexpected robot movement can be hazard-

ous. Do not adjust or repair the spray applicator

when the robot is operating or waiting to start.

The robot must be locked out and tagged out

per OSHA prior to removing the applicator

from the robot manifold assembly.

Before performing any work on the spray applica-

tor, always ush the uid passages, blow dry with