Randell RAN FRA-2, RAN SCA-2, RAN SCA-3, RAN SCA-4, RAN SCA-5 Service Manual

...

OPERATORS MANUAL

This manual provides information on

Installation, operating, maintenance,

trouble shooting & replacement parts for

RANSERVE

MOBILE SYSTEMS

SERVING LINES

NOTIFY CARRIER OF DAMAGE AT ONCE.

It is the responsibility of the consignee to inspect the container upon

receipt of same and to determine the possibility of any damage, including concealed damage. Randell suggests that if you are suspicious

of damage to make a notation on the delivery receipt. It will be the

responsibility of the consignee to file a claim with the carrier. We recommend that you do so at once.

Information contained in this document is known to be current and accurate

at the time of printing/creation. Unified Brands recommends referencing

our product line websites, unifiedbrands.net, for the most updated product

information and specifications.

P/N OMANUAL_MS-2/27/07

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

randell.com

Table of Contents

page 2 ...................................................................................................... Congratulations

page 3 ......................................................................................... Factory Correspondence

page 3 ......................................................................................... Serial Number Location

pages 4-5 .................................................................................. Randell Limited Warranty

page 6 .................................................................................. Frequently Asked Questions

page 7 ................................................................................. Section 1 Refrigerated Units

pages 7-10 ........................................................................................... Unit Specications

pages 11-12. .............................................................................................Unit Installation

page 13 ..................................................................................................... Unit Operation

page 13-14 ............................................................................... Preventative Maintenance

page 15 ................................................................................................... Troubleshooting

page 16 ................................................................................................ Replacement Parts

page 17 .................................................................................... Section 2 Hot Food Units

page 17-18 .......................................................................................... Unit Specications

page 19 ................................................................................................... Unit Installation

page 20 ..................................................................................................... Unit Operation

page 20 .................................................................................... Preventative Maintenance

page 21 ................................................................................................... Troubleshooting

page 22 ................................................................................................ Replacement Parts

page 23 .............................................................................. Section 3 Serving Equipment

page 23 ............................................................................................... Unit Specications

page 24 ............................................................................................................. Unit Parts

Congratulations on your recent purchase of Randell food service equipment, and

welcome to the growing family of satised Randell customers.

Our reputation for superior products is the result of consistent quality craftsmanship. From the earliest stages of product design to successive steps in fabrication and assembly, rigid standards of excellence are maintained by our staff of

designers, engineers, and skilled employees.

2

888-994-7636

Only the nest heavy-duty materials and parts are used in the production of

Randell brand equipment. This means that each unit, given proper maintenance,

will provide years of trouble free service to its owner.

In addition, all Randell food service equipment is backed by some of the best warranties in the food service industry and by

our professional staff of service technicians.

Retain this manual for future reference.

NOTICE: Due to a continuous program of product improvement, Randell Man-

ufacturing reserves the right to make changes in design and specications without prior notice.

NOTICE: Please read the entire manual carefully before installation.

If certain recommended procedures are not followed, warranty claims will be denied.

MODEL NUMBER

SERIAL NUMBER

INSTALLATION DATE

888-994-7636

MODEL NUMBER

SERIAL NUMBER

INSTALLATION DATE

MODEL NUMBER

SERIAL NUMBER

INSTALLATION DATE

Randell Manufacturing Service

and Parts Hotline

Randell Manufacturing

Serial Number Location For RanServe Equipment

1. The serial number tag on Randell refrigerated equipment is located in the

mechanical housing.

2. The serial number tag on Randell hot food and silverware stand are located on

the far left front side of the unit.

3. The serial number tag on Randell cashier stands and cold pans are located on

the far left side.

randell.com

3

Warranty Policies

PARTS WARRANTY

LABOR COVERAGE

Randell warrants all component parts of manufactured new equipment to be free of defects in material or workmanship, and that the equipment meets or exceeds reasonable

industry standards of performance for a period of one year from the date of shipment

from any Randell factory, assembly plant or warehouse facility.

NOTE: Warranties are effective from date of shipment, with a thirty day window

to allow for shipment, installation and set up. In the event equipment was shipped

to a site other than the nal installation site, Randell will warranty for a period of

three months following installation, with proof of starting date, up to a maximum of

eighteen months from date of purchase.

Component part warranty does not cover glass breakage or gasket replacement. Randell

covers all shipping cost related to component part warranty sent at regular ground rates

(UPS, USPS). Freight or postage incurred for any express or specialty methods of

shipping are responsibility of the customer.

In the unlikely event a Randell manufactured unit fails due to defects in materials or

workmanship within the rst ninety days, Randell agrees to pay reasonable labor

incurred. During the rst ninety days work authorizations are not required for in warranty

repairs. However, repair times are limited to certain ex rate schedules and hours will be

deducted from service invoices if they exceed allowed times without prior approval and

a work authorization number. Warranties are effective from date of shipment, with a 30

day window to allow for shipment, installation and setup. Where equipment is shipped to

any site other than nal installation Randell will honor the labor warranty for a period of

ninety days following installation with proof of starting date, up to a maximum of nine

months from date of purchase. Travel time is limited to one hour each direction or two

hours per invoice. Any travel time exceeding two hours will be the responsibility of

the customer.

FIVE YEAR EXTENDED

COMPRESSOR WARRANTY

4

888-994-7636

NOTE: Temperature adjustments are not covered under warranty, due to the wide

range of ambient conditions.

United States Installations only

Randell will pay for the replacement compressor only. Freight, labor, refrigerant, handling and all other miscellaneous charges are the responsibility of the customer. Randell

will fulll its warranty obligation by using one of the four methods provided below,

which will be selected by the Randell in-house service technician:

1. Provide reimbursement to servicing customer for the cost of the locally obtained replacement compressor in exchange for the return of the defective compressor returned

to Randell freight prepaid. Randell does limit the amount of reimbursement allowed and

does require a copy of the local supply house bill for replacement compressor.

Customer should not pay servicing agent up front for compressor.

2. Provide repair at the manufacturing facility by requiring that the defective unit be sent

back to Randell freight prepaid. Perform repair at the expense of Randell and ship the

item back to job location freight collect.

3. Furnish a replacement compressor freight collect in exchange for the return of the

defective compressor sent back freight prepaid.

4. Furnish complete condensing unit or replacement package freight collect in exchange

for the return of the defective compressor sent back freight prepaid. (decisions based

on whether or not to send complete condensing unit will be made by Randell in-house

service technician)

Warranty Policies (continued)

EXPORT WARRANTY

FREIGHT DAMAGE

GASKET COVERAGE

Our export warranties will cover all non electrical parts for the period of one year from

the date of shipment to be free of defects in material or workmanship. Electrical parts are

also covered if ordered and operated on 60 Hz. Electrical components, ordered and operated on 50 Hz, are warranted for the rst 90 days from shipment only. Service labor is

covered for the rst 90 days with authorization from factory prior to service. Warranty is

automatically 60 days from ship date. Inbound costs on any factory supplied items would

be the responsibility of the customer. Adherence to recommended equipment maintenance procedures, according to the owners manual provided with each unit, is required

for this warranty to remain in effect, and can have a substantial effect on extending the

service life of your equipment. Equipment abuse voids and warranty. Extended warranties are not available for parts labor or compressors on units shipped outside the United

States.

Any and all freight damage that occurs to a Randell piece of equipment as a result of

carrier handling is not considered warranty, and is not covered under warranty guidelines.

Any freight damage incurred during shipping needs to have a freight claim led by the receiver with the shipping carrier (note all damages on freight bill at time of delivery).

Randell does not cover gaskets under warranty. Gaskets are a maintenance type component that are subject to daily wear and tear and are the responsibility of the owner of the

equipment. Because of the unlimited number of customer related circumstances that can

cause gasket failure all gasket replacement issues are considered non-warranty. Randell

recommends thorough cleaning of gaskets on a weekly basis with a mild dish soap and

warm water. With proper care Randell gaskets can last up to two years, at which time we

recommend replacement of all gaskets on the equipment for the best possible performance.

NOTICE: FOOD LOSS IS NOT COVERED UNDER WARRANTY

randell.com

5

Frequently Asked Questions:

1. Do you offer 14 G SS Models?

ANSWER: Yes

2. Is it possible to plug in one unit to run my entire line?

ANSWER: Yes, we offer an electrical distribution system vs a duct system. With the

Randell Electrical Distribution System (EDS), you can bank several units together so a

common electrical connection point is possible.

3. Are the Randell casters non-skid type?

ANSWER: Yes,

5. Why is my unit leaking all over the oor?

ANSWER: Your units drain valve is open and needs to be shut.

6. Why is there tape on my brand new units casters?

ANSWER: At the factory the tape is applied to the casters to protect them. Please remove

any tape that you see on your casters.

6

888-994-7636

SECTION 1

Randell Refrigerated Equipment

UNIT SPECIFICATIONS FOR: THE RANDELL FRA RanServe SERIES

RANFG FRA SHOWN

FRA SERIES

Storage Gallon

Model L D H Cu. Ft. Capacity H.P. Volts Amps NEMA Ship Wt.

RAN FRA-1 24" 27" 35" 1.8 6 1/3 115/60/1 6.3 5-15P 200

RAN FRA-2 36" 27" 35" 3.6 12 1/3 115/60/1 6.3 5-15P 230

RANFG FRA-1 26" 30" 35" - - - - - 5-15P 200

RANFG FRA-2 36" 30" 35" - - - - - 5-15P 230

*14G models available with 14Gauge SS tops

randell.com

7

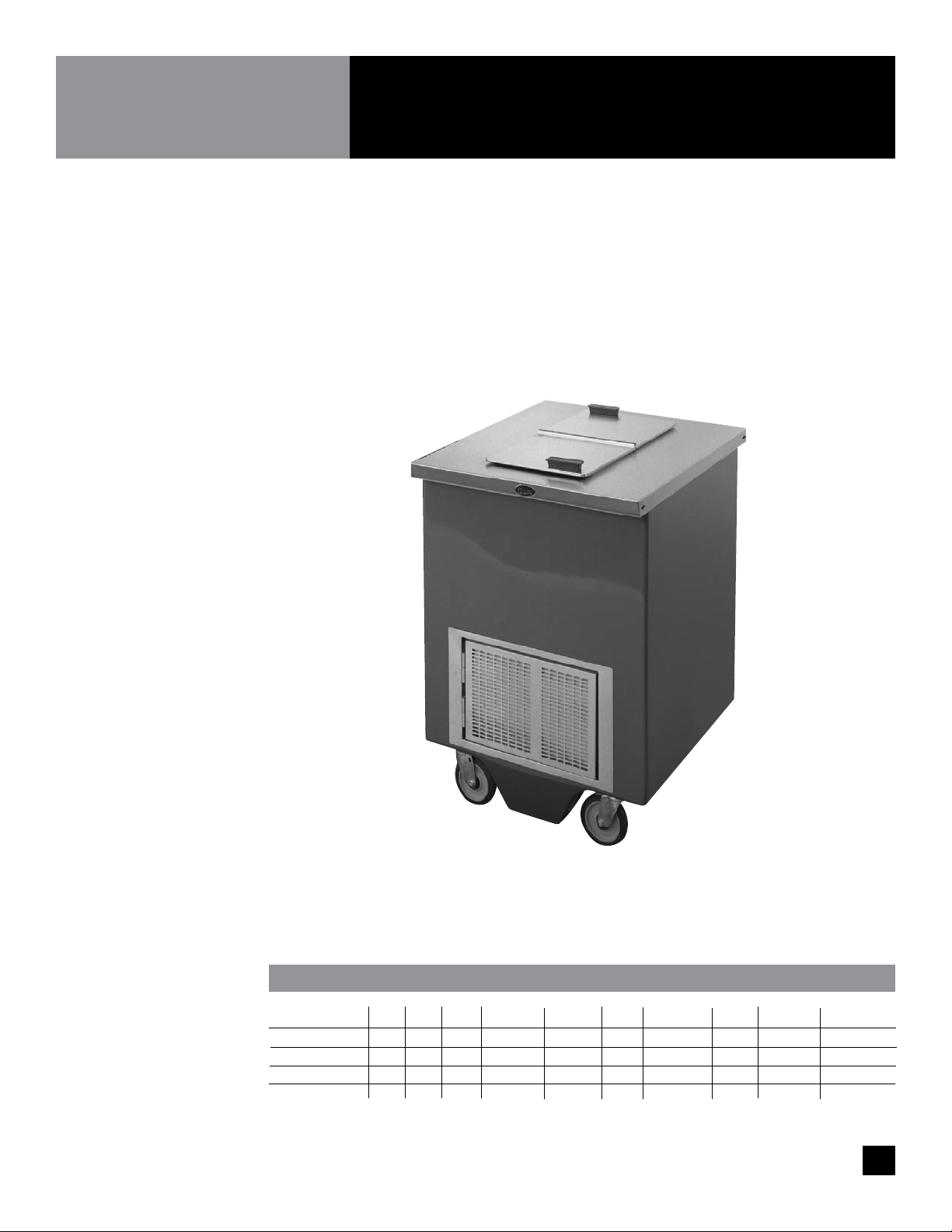

UNIT SPECIFICATIONS FOR: THE RANDELL SCA SERIES

RANFG SCA SHOWN

RAN SCA SERIES

12" x 20" Pan Coldpan

Model L D H Capacity Interior Dimensions HP Volts Amps NEMA Ship Wt.

RAN SCA-2 36" 30" 35" 2

RAN SCA-3 48" 30" 35" 3

RAN SCA-4 60" 30" 35" 4

RAN SCA-5 72" 30" 35" 5

RAN SCA-6 84" 30" 35" 6

Open Base

RAN SCA-2S 36" 30" 35" 2

RAN SCA-3S 48" 30" 35" 3

RAN SCA-4S 60" 30" 35" 4

RAN SCA-5S 72" 30" 35" 5

COMMON DATA FOR SCA SERIES (INCLUDES THE STANDARD SCA SERIES AND THE “S” STORGAE BASE SERIES)

RANFG SCA-2 36" 30" 35" 2

RANFG SCA-3 48" 30" 35" 3

RANFG SCA-4(S) 60.25" 30" 35" 4

RANFG SCA-5(S) 72" 30" 35" 5

RANFG SCA-6(S) 86" 30" 35" 6

STORAGE SHELF INFORMATION FOR SCA “S” SERIES

2 & 3 pan not abailable with storage shelf (too small)

Model L(A) W(B) H(C) Ship Wt

RANFG SCA-4S 60.25" 25.5" 14.5" 375

RANFG SCA-5S 72" 37.5" 14.5" 425

RANFG SCA-6S 86" 51.5" 14.5" 475

Amp loads may change when adding incandescent light options.

8

888-994-7636

*14G models available with 14Gauge SS tops

26 1/4" x 21" x 8 3/4"

39 1/8" x 21" x 8 3/4"

52 1/16" x 21" x 8 3/4"

64 15/16" x 21" x 8 3/4"

77 7/8" x 21" x 8 3/4"

28 1/8" x 21" x 8 3/4"

39 1/8" x 21" x 8 3/4"

52 1/16" x 21 7/8" x 8 3/4"

64 15/16" x 21 7/8" x 8 3/4" 1/4 115/60/1 5 5-15P 425

26 1/4" x 21" x 8 3/4"

39 1/8" x 21" x 8 3/4"

52 1/16" x 21" x 8 3/4"

64 15/16" x 21" x 8 3/4"

77 7/8" x 21" x 8 3/4"

1/4 115/60/1 5 5-15P 250

1/4 115/60/1 5 5-15P 300

1/4 115/60/1 5 5-15P 350

1/4 115/60/1 5 5-15P 400

1/4 115/60/1 5 5-15P 400

1/4 115/60/1 5 5-15P 275

1/4 115/60/1 5 5-15P 325

1/4 115/60/1 5 5-15P 375

1/4 115V 5 5-15P 230

1/4 115V 5 5-15P 300

1/4 115V 5 5-15P 350

1/4 115V 5 5-15P 400

1/4 115V 5 5-15P 450

Loading...

Loading...