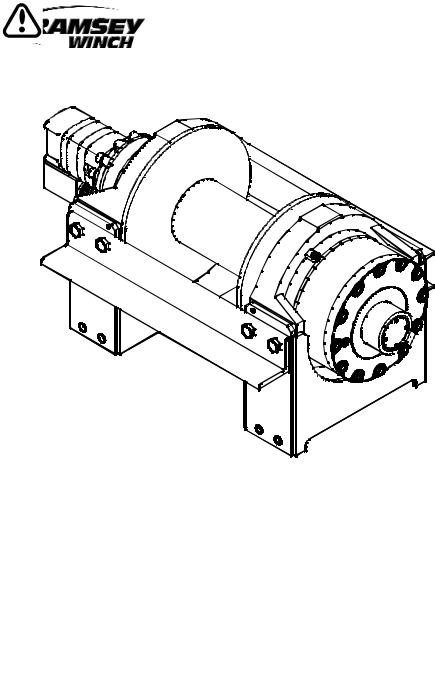

Ramsey RPH-35000 User Manual

OPERATING, SERVICE,

AND MAINTENANCE

MANUAL

MODEL RPH-35,000

INDUSTRIAL PLANETARY WINCH

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION AND OPERATION OF WINCH. SEE WARNINGS!

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 WINCH FRAME MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 CABLE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 HYDRAULIC SYSTEM REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 PERFORMANCE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 TYPICAL LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 CLUTCH OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 WINCH OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 INSTRUCTIONS FOR OVERHAUL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12 MOUNTING CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 DIMENSIONAL DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 PARTS LIST AND PART DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-15 LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BACK COVER

RAMSEY HYDRAULIC PLANETARY WINCH MODEL RPH 35,000

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most efficient operation from your Ramsey Winch, and safety procedures one needs to know before operating a Ramsey Winch. Do not operate this winch until you have carefully read and understand the "WARNINGS" and "OPERATION" sections of this manual.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great care and skill go into every winch we make. If the need should arise, warranty procedure is outlined on the back of your self-addressed postage paid warranty card. Please read and fill out the enclosed warranty card and send it to Ramsey Winch Company. If you have any problems with our winch, please follow instructions for prompt service on all warranty claims. Refer to back page for limited warranty.

SPECIFICATIONS*

NOTE: The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for wire rope ratings.

Rated Line Pull |

(lbs.) ………………………………………………… |

35,000 |

||||

|

(Kg.) ………………………………………………… |

15,909 |

||||

Gear Reduction |

………………………………………………………… |

31.89:1 |

||||

Weight (without cable) |

…………………………………………. 504 lbs. (229 Kg) |

|||||

|

|

|

|

|

|

|

LAYER OF CABLE |

1 |

2 |

3 |

4 |

5 |

|

|

|

|

|

|

|

|

*Rated line pull |

lbs. |

35,000 |

28,600 |

24,200 |

21,000 |

18,500 |

per layer |

Kg. |

15,909 |

13,000 |

11000 |

9,545 |

8,390 |

|

||||||

|

|

|

|

|

|

|

*Cable Capacity |

ft. |

25 |

60 |

105 |

155 |

200 |

|

|

|

|

|

|

|

|

m |

7.6 |

18.3 |

32 |

47.2 |

60 |

|

|

|

|

|

|

|

*Line Speed (at |

FPM |

15.4 |

18.6 |

21.1 |

23.5 |

28 |

15 GPM) |

MPM |

4.7 |

5.7 |

6.4 |

7.2 |

8.5 |

|

||||||

|

|

|

|

|

|

|

* These specifications are based on recommended wire rope of .75 inch dia. extra improved plow steel or equivalent

WARNINGS:

CLUTCH MUST BE TOTALLY ENGAGED BEFORE STARTING THE WINCHING OPERATION. DO NOT START WINCH MOTOR BEFORE ENGAGING CLUTCH

DO NOT DISENGAGE CLUTCH UNDER LOAD.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE. DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PEOPLE.

A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD.

CABLE ANCHOR IS NOT DESIGNED TO HOLD LOAD.

1

WINCH FRAME MOUNTING

Use (8) 5/8 inch diameter grade 5 or better bolts to attach mounting frame to wrecker.

CABLE INSTALLATION

1.Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of wire rope, opposite hook, with plastic or similar tape to prevent fraying.

2.Insert the end of the cable opposite the hook end into the hole in the drum barrel. Secure cable to drum barrel using setscrew furnished with winch. TIGHTEN SETSCREW

SECURELY.

3.Carefully run winch in the "reel-in" direction. Keeping tension on end of cable, spool all the cable onto the cable drum, taking care to form neatly wrapped layers.

The wire rope can easily be removed from the drum by loosening the setscrew.

HYDRAULIC SYSTEM REQUIREMENTS

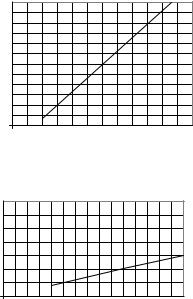

Refer to the performance charts, below, to properly match your hydraulic system to RPH 35000 winch performance. The charts consist of :

(1) Line pull (lb.) first layer vs. working pressure (PSI) and (2) Line speed, first layer (FPM) vs. Flow (GPM). Performance based on a motor displacement of 11.9 cubic inches with 15 GPM maximum flow rate. See page 13 for motor port size.

PERFORMANCE CHARTS

Line Pull (Lbs.)

35000

30000

25000

20000

15000

10000

5000

0500 1000 1500 2000 2500 3000

Pressure (PSI)

Line Speed (Ft/Min)

30

20

10

0

0 |

5 |

10 |

15 |

Flow (GPM)

2

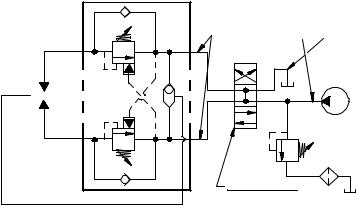

TYPICAL LAYOUT

DUAL-A & B PORT CONTROL

WITH BRAKE RELEASE SHUTTLE

HIGH PRESSURE LINE

LOW PRESSURE LINE

MOTOR |

A |

|

BRAKE |

PUMP |

|

|

|

|

PORT |

|

|

B

CONTROL VALVE

3 POSITION

4 WAY VALVE (MOTOR SPOOL)

CLUTCH OPERATION

To engage clutch:

1.Move the clutch control valve to the "clutch-engaged" position.

2.Anytime the temperature is below freezing, run motor in the "cable out" direction only until the drum starts to turn. In extreme cold temperatures (below 0° F/-18° C), pull out on the cable by hand only until the drum starts to turn.

3.Wait at least 3 seconds for the clutch to fully engage, after which the winch is ready to winch in the cable.

WARNING: Do not attempt to engage the clutch by first running the winch motor and then moving the clutch control valve to the "clutchengaged" position while the motor is running. Do not start picking up the load at the same time the clutch is being engaged.

To disengage clutch:

1.Run the winch in the "cable out" direction until the load is off the cable.

2.Move the clutch control valve to the "clutch-disengaged" position.

3.The cable may now be pulled off by hand

WINCH OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you actually use it. Plan your test in advance. Remember, you hear your winch as well as see it operate. Get to recognize the sounds of a light steady pull, a heavy pull, and sounds caused by load jerking or shifting. Gain confidence in operating your winch and its use will become second nature with you.

The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable pileup on one end of drum. If this happens reverse the winch to relieve the load and move your anchor point further to the center of the vehicle. After the job is done you can unspool and rewind for a neat lay of the cable.

3

MAINTENANCE

Adhering to the following maintenance schedule will keep your winch in top condition and performing as it should with a minimum of repair.

A. WEEKLY

1. Check the oil level and maintain it to the oil level plug. If oil is leaking out, determine location and repair.

2. Check the pressure relief plug in top of the gear housing. Be sure that it is not plugged. 3. Lubricate cable with light oil.

B. MONTHLY

1. Check the winch mounting bolts. If any are missing, replace them and securely tighten any that are loose. Use grade 5 or better bolts.

2. Inspect the cable. If the cable has become frayed with broken strands, replace immediately.

C. ANNUALLY

1.Drain the oil from the winch annually or more often if winch is used frequently.

2.Fill the winch to the oil level plug with clean kerosene. Run the winch a few seconds with no load in the reel in direction. Drain the kerosene from the winch.

3.Refill the winch to the oil level plug with all purpose SAE 80W-140 gear oil.

4.Inspect frame and surrounding structure for cracks or deformation.

TROUBLESHOOTING GUIDE

CONDITION |

POSSIBLE CAUSE |

CORRECTION |

|

|

|

|

|

|

Seals damaged or worn |

Replace seal. |

|

OIL LEAKS FROM WINCH |

Too much oil |

Drain excess oil. Refer to Operation. |

|

|

Damaged gasket |

Replace gasket. |

|

|

|

|

|

|

Low flow rate |

Check flow rate. Refer to Specifications |

|

WINCH RUNS TOO SLOW |

page 1. |

||

|

|||

|

|

||

|

Hydraulic motor worn out |

Replace motor. |

|

|

|

|

|

CABLE DRUM WILL NOT |

|

Check air pressure to clutch cylinder 90 |

|

Clutch not disengaged |

PSI minimum required. Refer to drawing |

||

FREESPOOL |

|||

|

page 13 for more information. |

||

|

|

||

|

|

|

|

BRAKE WILL NOT |

Air in hydraulic system |

Bleed air from brake. |

|

RELEASE |

|||

|

|

||

|

|

|

4

Loading...

Loading...