Page 1

Installation

and

Operating Guide

Scalar 218FC Library

Page 2

Copyright Notice

© Copyright ADIC 1998, 1999

The information contained in this document is subject to change without notice.

This document contains proprietary information which is protected by copyright. All rights are reserved. No

part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of ADIC.

ADIC shall not be liable for errors contained herein or for incidental or consequential damages (including

lost profits) in connection with the furnishing, performance or use of this material whether based on

warranty, contract, or other legal theory.

Printed in the USA

Document Number 62-0134-01 Rev B

Corporate Headquarters:

Advanced Digital Information Corporation

Shipping Address: 11431 Willows Road NE

Redmond, WA 98052

Mailing Address: P.O. Box 97057

Redmond, WA 98073-9757

Telephone: (425) 881-8004

Fax: (425) 881-2296

ADIC Technical Assistance Center: (800) 827-2822

Worldwide Web: http://www.adic.com

BBS: (425) 883-3211

ADIC Europe

ZAC des Basses Auges

1, rue Alfred de Vigny

78112 - Fourqueux, FRANCE

33 1(0) 30 87 53 00

Fax: 33 1(0) 30 87 53 01

Scalar, ADIC and ADIC Europe are trademarks of Advanced Digital Information Corporation. Exabyte

registered trademark and EXB-480

trademark and DLT™ is a trademark of Quantum Corporation.

™

is a trademark of Exabyte Corporation. Quantum® is a registered

August 1999

®

is a

ii

Page 3

Copyright Notice (Europe)

© Copyright ADIC Europe 1998, 1999

All rights reserved. No part of this document may be copied or reproduced in any form or by any means,

without prior written permission of ADIC Europe ZAC des Basses Auges, 1, rue Alfred de Vigny, 78112 Fourqueux, FRANCE.

ADIC Europe assumes no responsibility for any errors that may appear in this document, and retains the right

to make changes to these specifications and descriptions at any time, without notice.

This publication may describe designs for which patents are pending, or have been granted. By publishing

this information, ADIC Europe conveys no license under any patent or any other right.

ADIC Europe makes no representation or warranty with respect to the contents of this document and

specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

Further, ADIC Europe reserves the right to revise or change this publication without obligation on the part of

ADIC Europe to notify any person or organization of such revision of change.

Every effort has been made to acknowledge trademarks and their owners. Trademarked names are used

solely for identification or exemplary purposes, any omissions are made unintentionally.

iii

Page 4

EMI/RFI Compliance

United States – FCC

WARNING: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception

(which can be determined by turning the equipment off and on) the user is encouraged to try to correct the

interference by one or more of the following measures:

Re-orient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced radio/TV technician for help.

You may find the following booklet prepared by the Federal Communications Commission helpful: How to

Identify and Resolve Radio-TV Interference Problems. This booklet is available from the US Government

Printing Office, Washington, DC 20402, Stock No. 004-000-00354-04.

Any changes or modifications not expressly approved by ADIC could void the user's authority to operate this

equipment.

Canada – Department of Communications

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus as

set out in the interference-causing equipment standard entitled "Digital Apparatus", ICES-003 of the

Department of Communications.

Cet appareil numérique respecte les limites de bruits radioélectriques applicables aux appareils numériques

de Class A prescriptes dans la norme sur le matériel brouilleur: "Appareils Numériques", NMB-003 édictée

par le ministre des Communications.

iv

Page 5

DECLARATION OF CONFORMITY

according to EN 45014

Manufacturer’s Name:

Manufacturer’s Address:

declares, that the product:

Product

(Produit, Erzeugnis):

conforms to the following international specifications, as required by 89/336/EEC & 92/31/EEC:

Supplementary Information:

Model Number

(Marque Commercial,

Warenbezeichnung):

EMI:

EMC:

Safety:

Advanced Digital Information Corporation

11431 Willows Road

Redmond, Washington 98052

USA

SCALAR 218FC

SCALAR 218FC

EN 50081-1, EN-55022 Class B

EN 50082-1, IEC 801-2, IEC 801-3, IEC 801-4

EN 60950

ZAC des Basses Auges

1, rue Alfred de Vigny

78112 - Fourqueux

FRANCE

Redmond, Washington USA 12/10/96

Location Date Signature/Title

63-1095-01 rev A

v

Product Engineering Mgr.

Page 6

Blank Page

vi

Page 7

Table of Contents

Copyright Notice ................................................................................................................................................i

Copyright Notice (Europe) .............................................................................................................................. iii

EMI/RFI Compliance........................................................................................................................................iv

Safety Warnings................................................................................................................................................ix

Precautions.........................................................................................................................................................x

Chapter 1 Introduction...............................................................................................................................................1

Features..............................................................................................................................................................3

Chapter 2 Getting Started ..........................................................................................................................................5

Requirements .....................................................................................................................................................6

Unpacking and Inspecting..................................................................................................................................6

Checking the Accessories ..........................................................................................................................7

Preparing the Library for Installation.................................................................................................................7

Removing the Shipping Bracket ................................................................................................................7

Prepare and Install the Data Cartridges......................................................................................................9

Preparing the Host Computer System..............................................................................................................11

Power Off the Computer..........................................................................................................................11

Confirm and/or Install the Fibre Channel Host Interface.........................................................................11

Backup Software......................................................................................................................................12

Chapter 3 Connecting the Scalar 218FC Library.....................................................................................................13

Installing the Interface Cables .........................................................................................................................14

Fibre Channel Connection .......................................................................................................................14

Fibre Channel Interface Serial Port.......................................................................................................... 14

10Base-T Ethernet Connection ................................................................................................................14

Setting the SCSI IDs........................................................................................................................................14

Powering on the System...................................................................................................................................16

Chapter 4 Configuring the Fibre Channel Subsystem..............................................................................................17

Configuring Your Communications Terminal .................................................................................................18

Configuring the Fibre Channel Interface .........................................................................................................21

Introduction..............................................................................................................................................21

Configuration ........................................................................................................................................... 22

Trace Settings Configuration ...................................................................................................................31

Trace Dumps............................................................................................................................................ 37

New Firmware Revisions......................................................................................................................... 38

Rebooting the Scalar 218FC ....................................................................................................................40

Installing the Backup Software........................................................................................................................40

Chapter 5 Equipment Description............................................................................................................................41

Front Panel Switches and Indicators................................................................................................................42

Rear Panel Indicators, Switches and Connectors.............................................................................................44

How the Scalar 218FC Processes SCSI Commands ........................................................................................45

Off-Line Mode Menus .....................................................................................................................................47

Configuration Menu.................................................................................................................................48

Diagnostics Menu ....................................................................................................................................54

vii

Page 8

Write Flash Memory................................................................................................................................ 54

Serial Dnld Flash ..................................................................................................................................... 55

Chapter 6 Operation and Maintenance .................................................................................................................... 56

Normal Operations ..........................................................................................................................................57

General Guidelines .................................................................................................................................. 57

Power-Up Checks .................................................................................................................................... 57

Drive Power-on Self-Test ........................................................................................................................ 57

Drive Operating Conditions..................................................................................................................... 59

DLT Media .............................................................................................................................................. 61

Opening the Sliding Access Panel........................................................................................................... 62

Using the Mailbox ................................................................................................................................... 63

Manually Loading/Unloading Cartridges to/from the Storage Slots (Bulk Loading) .............................. 64

Normal Maintenance .......................................................................................................................................64

Cleaning the Drive Head ......................................................................................................................... 64

Cleaning the Enclosure ............................................................................................................................ 67

Chapter 7 Troubleshooting and Diagnostics............................................................................................................ 68

Appendix A FC to SCSI Mapping........................................................................................................................... 73

Appendix B Diagnostics Menu................................................................................................................................ 80

Appendix C Error Codes .........................................................................................................................................92

Appendix D Scalar 218FC Rack-Mount Installation............................................................................................... 96

Appendix E Glossary............................................................................................................................................. 104

Appendix F Specifications.....................................................................................................................................111

viii Table of Contents

Page 9

Safety

Warnings

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

This symbol should alert the

user to the presence of

“dangerous voltage” inside the

product that might cause harm

or electric shock.

All safety and operating instructions should be read before this product is

operated, and should be retained for future reference. This unit has been

engineered and manufactured to assure your personal safety. Improper use

can result in potential electrical shock or fire hazards. In order not to defeat

the safeguards, observe the following basic rules for its installation, use and

servicing.

The Scalar 218 weighs over 60 lbs. when equipped with two drives. Do Not

attempt to lift the Scalar out of the packing box, or off of a work surface, by

yourself. To avoid personal injury and possible damage to the equipment,

two people are required when unpacking, lifting and moving the unit.

Heed Warnings - All warnings on the product and in the operating instructions should be adhered

to.

CAUTION:

THE RISK OF ELECTRIC

SHOCK, DO NOT REMOVE

COVER (OR BACK).

NO USER-SERVICEABLE

PARTS INSIDE. REFER

SERVICING TO QUALIFIED

SERVICE PERSONNEL.

Caution

Warning

TO REDUCE

Follow Instructions - All operating and use instructions should be followed.

Ventilation - The product should be situated so that its location or position does not interfere with

proper ventilation.

Heat - The product should be situated away from heat sources such as radiators, heat registers,

furnaces, or other heat producing appliances.

ix

Page 10

Power Sources - The product should be connected to a power source only of the type directed in

the operating instructions or as marked on the product.

Power Cord Protection - The AC line cord should be routed so that it is not likely to be walked on

or pinched by items placed upon or against it, paying particular attention to the cord at the wall

receptacle, and the point where the cord exits from the product.

Object and Liquid Entry - Care should be taken to insure that objects do not fall and liquids are not

spilled into the product’s enclosure through openings.

Servicing - The user should not attempt to service the product beyond that described in the

operating instructions. All other servicing should be referred to qualified service personnel.

Precautions

Do not use oil, solvents, gasoline, paint thinners or insecticides on the unit.

Do not expose the unit to moisture, to temperatures higher than 140ºF (60ºC) or to extreme low

temperatures.

Keep the unit away from direct sunlight, strong magnetic fields, excessive dust, humidity and

electronic/electrical equipment, which generates electrical noise.

Hold the AC power plug by the head when removing it from the AC source outlet; pulling the cord

can damage the internal wires.

Use the unit on a firm level surface free from vibration, and do not place anything on top of unit.

Handle optical cables with care. Do not bend at 90º, as cable is made of optical (glass) fibers and

they may break. Take care not to touch or otherwise contaminate ends of optical cables as it may

degrade signal integrity. The optical contacts can be cleaned using a piece of silk cloth.

x

Page 11

Chapter

Introduction

This Chapter …

❐ provides a brief overview of the Scalar 218FC Library features. For detailed

specifications, see Appendix F.

1

Page 12

With ever changing technology, enterprise storage managers must deal with applications that are increasingly

information intensive. At the same time, they are faced with increasing storage demands and shrinking

backup windows. To meet these demands, the paradigm of storage routing is being introduced into the Data

Center. The need for faster access, distributed resources, greater bandwidth and high availability is creating a

convergence of networking and storage media. Fibre Channel technology is one of the most important

technological paradigms currently being brought to these problems.

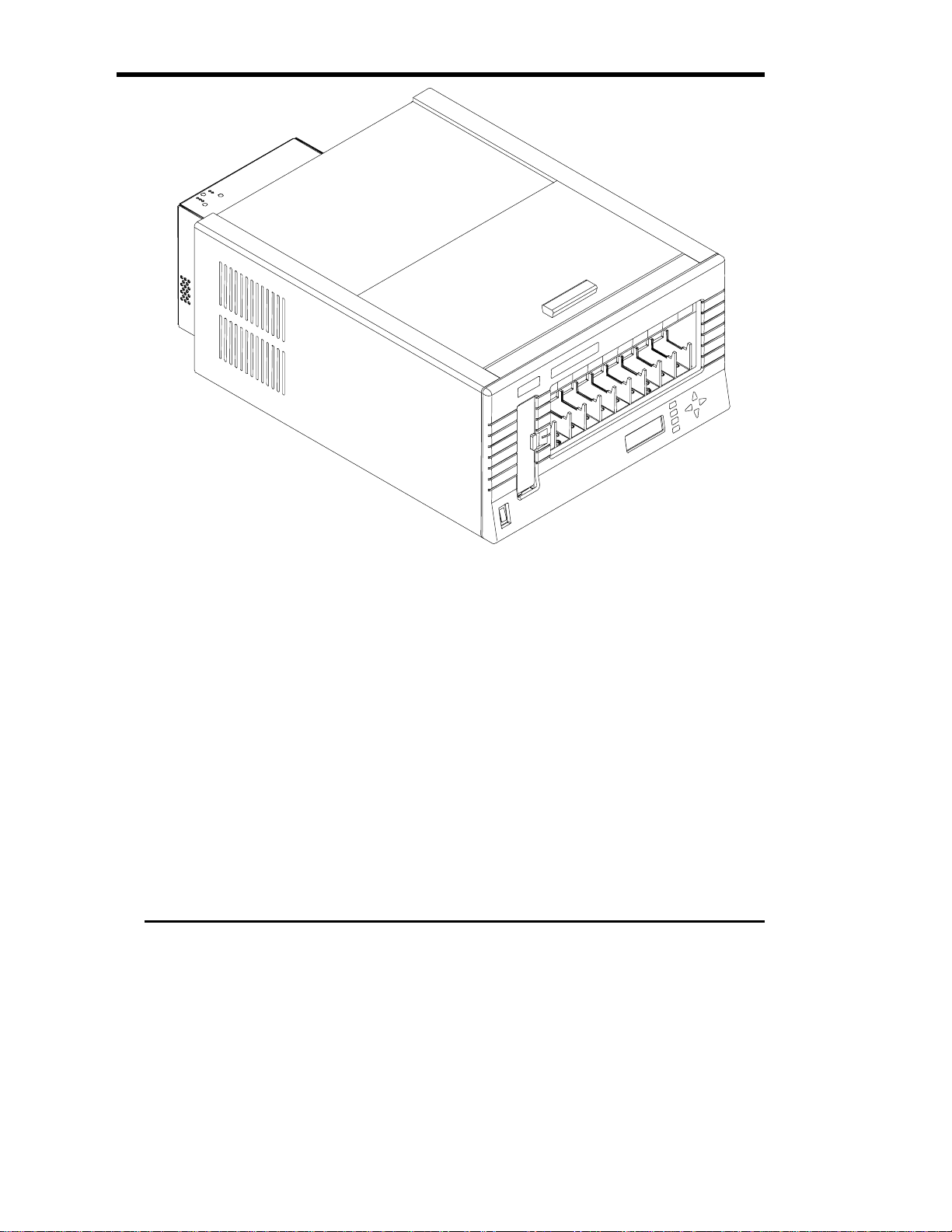

Your ADIC Scalar 218FC Library is a fully automated, high-performance, high-capacity, mass storage

system. The Scalar 218FC provides you with unattended, near-line and off-line data storage, archiving,

backup, hierarchical storage management (HSM), and retrieval for mid-range and high-end servers and

networks.

Your Scalar 218FC Library allows direct inter-connect to the Fibre Channel network. The maximum two

DLT™ drives and library can be controlled through a single server, and can also be connected to a FC-AL

(Fibre-Channel Arbitrated Loop) interface to allow for independent control of the drives from various

workstations. Your Scalar library supports the non-OFC (multi-mode) standard for transmission lengths of up

to 500 meters. Your 218FC continues to operate using SCSI-2 compliant protocol over the Fibre Channel

interface to achieve high capacity, high throughput, and data compression by incorporating streaming tape

drives. Your library can contain up to 18 data cartridges providing a maximum formatted capacity of 1.44 TB

and a sustained data transfer rate as high as 1440 MB per minute at an average compression of 2:1 (when

equipped with two drives). The tape media, rated at up to 1,000,000 passes and a shelf life of 30 years

provides superior media durability and data reliability.

2 Introduction

Page 13

Features

Direct connection to Fibre Channel networks. Your Scalar 218FC is designed to provide high-speed

data storage and retrieval using SCSI-2 compliant protocol over Fibre Channel networks.

Desktop and Rack-Mounted units. Your Scalar 218FC is the first desktop unit to offer over 1 TB of

data storage. Its attractive case looks great in any office environment. The more utilitarian rack-mounted

unit includes all of the features of the desktop unit, but comes equipped with built-in hardware to allow

simple installation into standard 19-inch racks.

Multi-function Operator Panel. The Operator Panel, located at the bottom-right corner of the front

panel, employs a 4-line by 20-character liquid crystal display (LCD) and an eight-key keypad to permit

you to monitor and control the operations of your library.

Media Picker. The uniquely designed Media Picker is the media cartridge handling mechanism and

normally responds to commands from the application software to move the cartridges between the

storage slots and the drives. The Media Picker employs a bi-directional, pass-through gripper that will

pick a cartridge from both the front of the picker, or the rear.

Mailbox. The firmware-configurable single-slot mailbox, mounted on the front panel, allows you to

insert and remove cartridges from your library without opening the sliding access panel. When

configured with a mailbox slot, there are 17 storage slots available for data cartridges in the Scalar

218FC. This reduces the maximum data capacity to 1.36 TB.

DLT drives. Your Scalar 218FC library is equipped with one or two fourth-generation DLT7000 or

DLT8000 drives. The DLT8000 provides a maximum data cartridge capacity of 80 GB (avg. 2:1

compression) with the DLTtape IV cartridge. The DLT7000 can read and write 2.6 GB, 6.0 GB, and

10.0 GB tape formats, while the DLT8000 can read and write 10.0 GB, 15.0 GB, 20.0 GB, and 35.0 GB

tape formats, providing 100% interchange compatibility with earlier DLT drives. You may select tape

density through the application software or by pressing a button on the drive.

Barcode Scanner. The Barcode Scanner reads cartridge information contained in a barcode label

attached to each of the data cartridges. This information becomes part of the application software’s

library cartridge inventory.

Exabyte® Emulation. To maximize application software compatibility, your ADIC library provides

functional emulation of the Exabyte EXB-480

EXB-480.

System Integrity. A physically lockable sliding access panel on the top of the Scalar 218FC protects

the cartridge slots, drives, and robotics. The application software can enable or disable system security.

Additionally, the application software can set a logical system lock.

Maintainability. The transparent window on the front panel allows you to view the full operation of

your library. If a problem occurs, it is both visible and readily correctable. Your library will report any

condition that causes a cartridge load or unload to fail, by displaying an appropriate message on the

Operator Panel LCD.

Cleaning Cartridge. Although the cleaning cartridge can occupy a cartridge storage slot in the Scalar

218FC (facilitating automated cleaning cycles), you may manually insert a cleaning cartridge through

the Mailbox or the sliding access panel.

Manual Cartridge Use. You may easily transport individual cartridges to the drives using the Mailbox

slot, or through the sliding access panel.

Introduction 3

™

library and can appear as either a Scalar or an Exabyte

Page 14

Cartridge Pre-Check. Whenever you power up, your Scalar 218FC maps all cartridge locations. With

barcode scan enabled, the barcode scanner will scan the barcode label on each cartridge and build a log

of valid cartridge locations.

Downloadable Firmware. Your Scalar 218FC and the DLT drives employ Flash EEPROM technology.

The library firmware is easily updated using any computer and an associated serial communications

application. The drive firmware is updated on-site by loading a firmware update tape (“FUP” tape).

Built-in Diagnostics. Diagnostic firmware tells you when it is time to clean the drive. It also reports

diagnostic results, and drive operating status. Embedded data logging of operational and drive errors can

aid you in failure analysis.

4 Introduction

Page 15

Chapter

Getting Started

This Chapter …

❐ covers what you need (and what you need to know) to install your Scalar

218FC. Read this chapter before you begin installation.

5

Page 16

Installation of the Scalar 218FC desktop unit requires checking all necessary Fibre Channel interface

connections, loading application software on the host computer, and applying power. Installation of the rackmount unit begins by mounting slide rails, a cable channel, and channel stop to your rack before continuing

the installation.

Requirements

The footprint of your Scalar 218FC Library is 19.0 inches wide, 27.6 inches deep, and 11.0 inches high.

You must allow clearance at the rear and sides of the desktop unit for airflow and enough room at the

top to permit you to bulk load and unload data cartridges through the sliding access panel. To bulk load

and unload cartridges from the rack-mount unit, you must slide the library out from the rack to the stop

limits of the rails. There must be adequate clearance above it, to perform the bulk load/unload

procedure.

You must integrate your Scalar 218FC into your host computer system. Backup software and a Fibre-

Channel Host Bus Adapter interface card must be purchased separately.

Necessary tools: to install the rack-mount unit, you will need the following tools.

#1 philips screwdriver.

11/32-inch hex nut-driver.

Unpacking and Inspecting

Warning

The Scalar 218FC weighs more than 60 pounds. Do Not attempt to lift the

Library out of the packing box by yourself. See the Scalar 218FC Unpacking

Instructions, taped to the outside of the poly bag surrounding the Scalar, for

complete unpacking instructions.

1. Following the procedures in the document mentioned in the above warning, unpack all items from the

carton. Save the packing materials in case you need to move or ship the system in the future.

Caution

You must use the original or equivalent packing materials when shipping the

Scalar 218FC. Failure to use the original or equivalent materials may

invalidate your warranty.

6 Getting Started

Page 17

Checking the Accessories

Check to make certain that the following items are included with your Scalar 218FC:

Power cord

One DLTtape IV data cartridge

One cleaning cartridge, or a coupon for a free DLT cleaning cartridge

One 3-meter, 50-micron, Non-OFC cable

This Installation and Operating Guide

A Warranty Registration card

Two keys for the sliding access panel lock (desktop unit only), or the slam-lock (rack-mount unit only)

One cable channel (rack-mount unit only)

One channel stop (rack-mount unit only)

Two outer rails (rack-mount unit only)

Mounting hardware (rack-mount unit only)

✔ None of the items should show signs of damage.

Preparing the Library for Installation

Caution

If the operating environment differs from the storage environment by 15° C

(30° F) or more, let the unit acclimate to the surrounding environment for at

least 12 hours.

Rack-mount Scalar 218FC

Complete instructions for installing the rack-mount Scalar 218FC are in Appendix D of this manual. After

mounting the unit in your rack, return to this section to complete the installation process.

Removing the Shipping Bracket

A shipping bracket holds the Media Picker in place. Remove this bracket before powering-on the unit.

Follow the instructions below to remove the shipping bracket.

Desktop Scalar 218FC

1. Remove the keys taped to the rear panel of your library, and unlock the sliding access panel. The lock is

located in the top-right corner of the front panel.

2. Using the handle, open the access cover fully by pushing it towards the rear of the Scalar.

Getting Started 7

Page 18

Rack-mount Scalar 218FC

1. Remove the keys taped to the rear panel of your library, and unlock the front panel. Slide it towards you

until the slide stops engage.

All Scalar 218FC Units

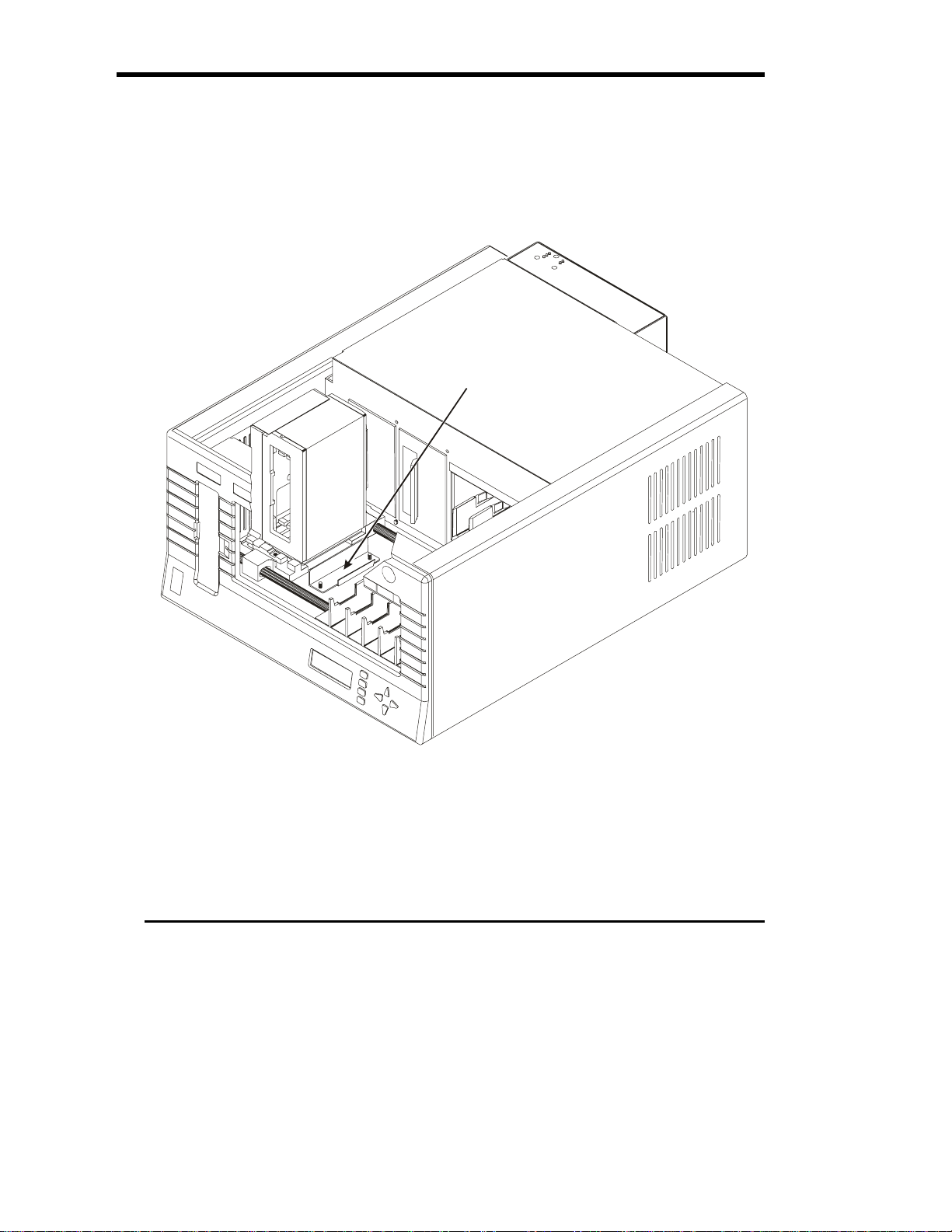

1. Inside the Scalar 218FC cartridge storage bay, locate the red shipping bracket mounted on the floor.

2. Remove the wing nuts that secure the shipping bracket to the floor.

Remove this bracket

Removing the Shipping Bracket (Desktop Scalar 218FC shown)

3. Pull the shipping bracket off the studs and remove it from the Scalar 218FC.

4. Remove the packing foam located between the left chassis wall and the Media Picker.

8 Getting Started

Page 19

r

Prepare and Install the Data Cartridges

Barcode Labels

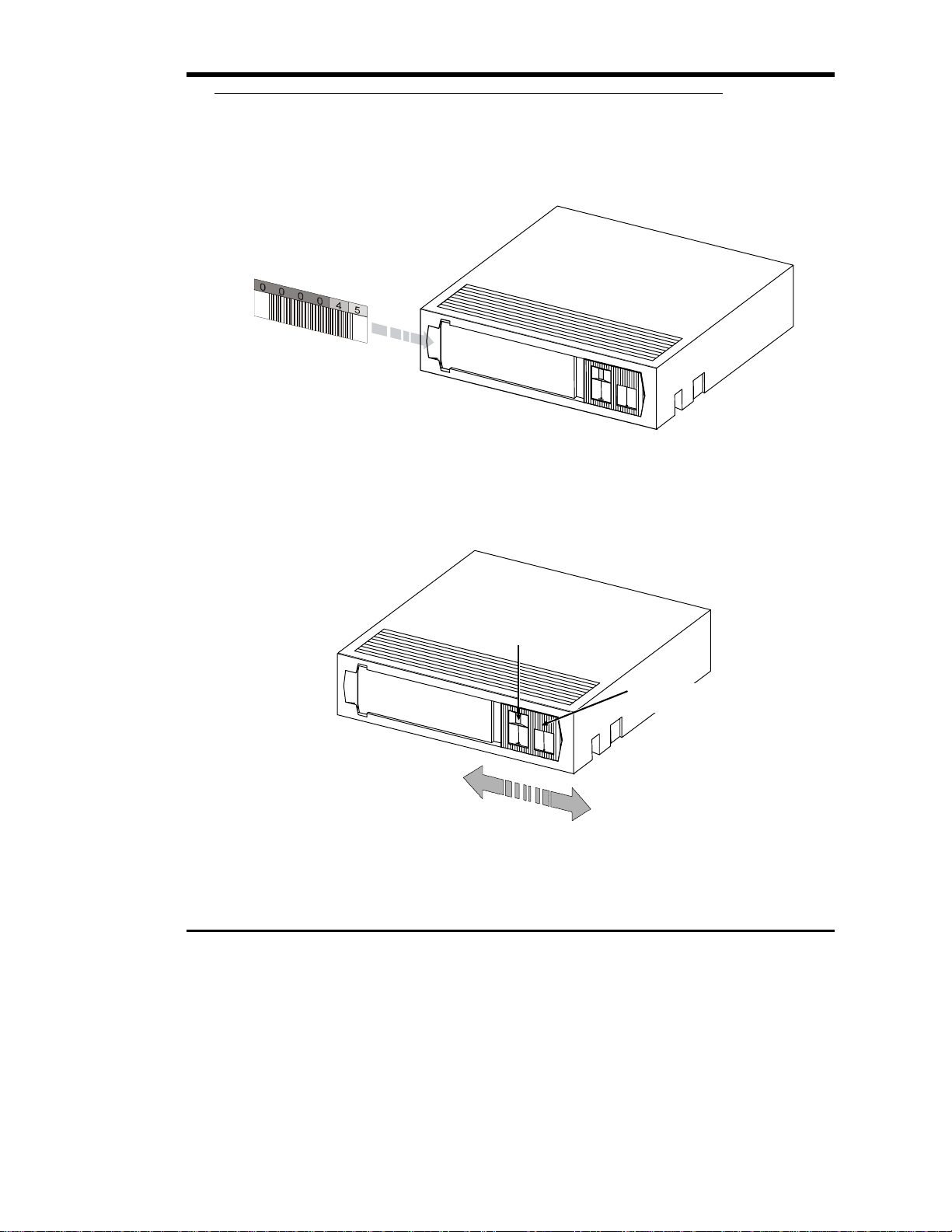

To install the barcode labels, position the label with the numbers upright, as shown in the illustration below,

sliding the label under the ridges on the sides of the cartridge recess.

Barcode Labels

Write-Protect Switch

1. Set the write-protect switch (see illustration below) on each cartridge to the appropriate position. Use

your finger to push the switch in one of the directions shown in the following illustration.

Orange

Indicato

Write-protect

Switch

Write-protected

Write-enabled

DLT Cartridge Write-Protect Switch

Getting Started 9

Page 20

Install Data Cartridges

Desktop Scalar 218FC

1. If necessary, unlock the sliding access panel by placing the key in the lock, and turning it one-half turn

ccw (left) to unlock.

2. Open the sliding access panel by sliding it to the rear of the Scalar 218FC.

Rack-mount Scalar 218FC

1. If necessary, unlock the front panel and slide it towards you until the slide stops engage.

All Scalar 218FC Units

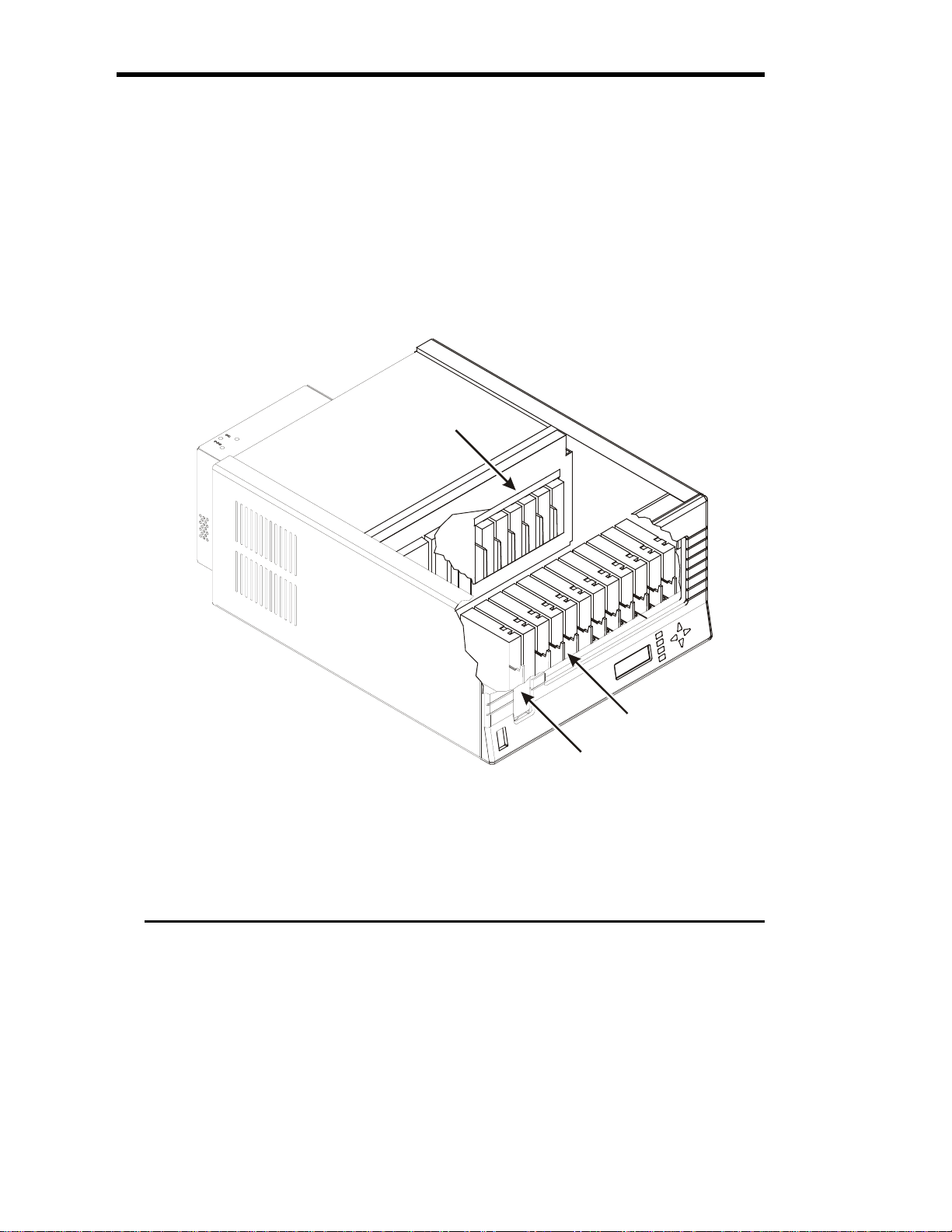

1. Place each of the cartridges into the library storage slots. Install all cartridges with the barcode label

facing forward and the write-protect switch at the top.

Cartridges 12-17

10 Getting Started

Cartridge Locations

Cartridges 2-11

Mailbox or cartridge 1

Page 21

Note

The design of the six rear slots and the Mailbox slot prevents

you from incorrectly installing the cartridges. When powered-on,

the Scalar 218FC senses the orientation of each cartridge

installed in the 11 front slots. The library will sound the error

alarm and display a message on the LCD warning of any

incorrectly installed cartridges in these slots.

Install Cleaning Cartridge (Optional)

If your backup software is capable of scheduling and performing a drive cleaning cycle automatically, you

may want to dedicate a cartridge storage slot to a cleaning cartridge. After using all cleaning cycles, remove

the cleaning cartridge and install a new one. Refer to Chapter 5: Operations and Maintenance, section

Cleaning the Drive Head, for information on determining when a new cleaning cartridge is needed.

Close and Lock the Sliding Access Panel or

Scalar

1. On the desktop Scalar 218FC, close the sliding access panel by sliding it forward.

2. Insert the key into the front panel lock and turn ½-turn clockwise to lock the sliding access panel in

place.

3. Remove the key from the lock.

4. On the rack-mount Scalar 218FC, slide the Scalar back into the rack until the slam-lock engages.

5. Insert the key into the slam-lock and turn ½-turn clockwise to lock the Scalar into the rack.

6. Remove the key from the lock.

Preparing the Host Computer System

Power Off the Computer

1. Turn off the power switch.

Confirm and/or Install the Fibre Channel Host

Interface

Your Scalar 218FC must be connected directly to a fibre channel host bus adapter card installed in the

computer or through a fibre channel hub. Install the fibre channel interface (card or hub) before connecting

your Scalar library. Refer to the instructions supplied with your selected fibre channel interface.

Getting Started 11

Page 22

Backup Software

A variety of backup and data storage software is available for use with your Scalar 218FC. Special backup

software should not be required to operate with the fibre channel interface since the same SCSI commands

are simply sent over the fibre channel interface to the target device. Please check with ADIC Sales or

Customer Assistance if you have a question on the compatibility of a particular software package.

Now you are ready to connect your Scalar 218FC to your host computer. Follow the instructions provided in

the next chapter.

12 Getting Started

Page 23

Chapter

Connecting the Scalar 218FC Library

This Chapter …

❐ provides instructions for physically connecting your Scalar 218FC to your host

system.

❐ steps you through the final phase of the installation process.

13

Page 24

Installing the Interface Cables

Follow the steps on the following pages to connect your Scalar 218FC to your host computer and the Fibre

Channel bus. This involves installing cables onto the connectors at the rear of the Scalar 218FC. See the

section titled: Rear Panel Indicators, Switches and Connectors in Chapter 4 Equipment Description for an

illustration showing the positions of the connectors on the rear panel of the Scalar 218FC.

Fibre Channel Connection

Your Scalar 218FC provides support for Multi-Mode Fibre at 1.0625 Gbaud using dual SC connectors:

1. Connect the 3-meter, 50-micron, non-OFC cable (supplied with your Scalar 218FC) between the SC

connectors on the Host Bus Adapter (HBA) installed in your host computer or to a fibre channel hub,

and the SC connectors on the rear of the Scalar 218FC. The connectors are keyed to prevent improper

installation of the cable.

Fibre Channel Interface Serial Port

The modular jack on the rear panel of your Scalar 218FC provides an RS-232 connection that can be used to

configure the fibre channel subsystem, monitor diagnostic status, or update the firmware. To connect the

serial cable:

1. Make sure that power is off to the Scalar 218FC.

2. Connect the serial cable plug into the serial connector of the host computer and the modular plug to the

serial port connector of the Scalar 218FC.

10Base-T Ethernet Connection

Your Scalar 218FC supports Ethernet connectivity to provide enhanced configuration capabilities. All

functions available through the Fibre Channel Interface Serial Port are available through Ethernet. For

example, if you are going to download upgraded firmware using the serial port, you will need to have a copy

of the firmware on the host computer hard drive or on a diskette before beginning the procedure. Using

Ethernet, however, you can log into a BBS or a world-wide web site and download firmware directly to the

Scalar 218FC. If you plan to use the Ethernet capability:

1. Connect an Ethernet cable between your network and the Ethernet connector on the rear panel of the

Scalar 218FC.

Setting the SCSI IDs

Your Scalar 218FC consists of three SCSI devices; the two DLT drives and the library robotics. Each SCSI

device in your Scalar 218FC must be set to a unique ID. The ID for the robotics is set by selecting it through

the Operator Panel, Off-Line Mode, Configuration Menu, Set SCSI ID option (see sub-subsection titled: Set

SCSI ID, subsection Configuration Menu, section Off-Line Mode Menus in Chapter 4 Equipment

Description). Set each drive ID by selecting the appropriate ID number on the switch located on the back of

14 Connecting the Scalar 218FC Library

Page 25

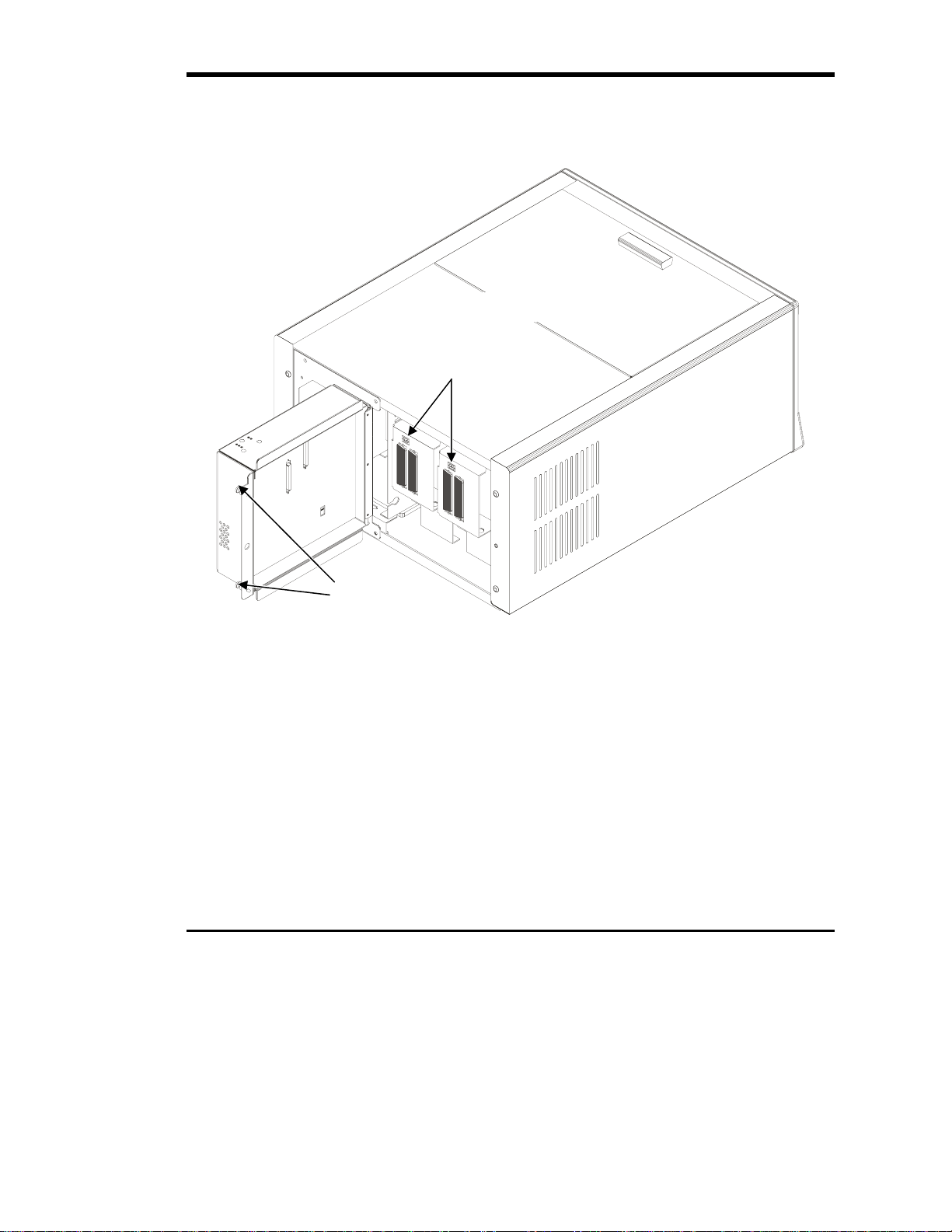

the drive assembly. Access the switches by opening the Scalar 218FC fibre channel subsystem cover on the

rear panel as shown in the following illustration:

1. Loosen the two thumbscrews that secure the right side of the cover to the rear panel by turning each of

them counter-clock-wise until the internal spring pushes the screw away from the mounting hole.

Some details not shown for clarity

Drive SCSI ID Switches

Thumbscrews

Drive SCSI ID Switches

Connecting the Scalar 218FC Library 15

Page 26

Powering on the System

❐ Plug the power cord into the back of your Scalar 218FC.

❐ Plug the power cord from the Scalar 218FC into a grounded electrical outlet.

Use caution when plugging the power cord into an electrical outlet.

Hazardous voltages are present in the sockets of the outlet.

❐ Plug the power cord from your host computer into a grounded electrical outlet.

❐ Turn on power to your Scalar 218FC.

❐ Turn on power to the host computer.

The following illustration shows the Operator Panel LCD message displayed when your Scalar 218FC has

completed the boot and initialization process.

Notes

With the factory default conditions unchanged, your Scalar

218FC will sign-on as a Scalar 218.

Your Scalar 218FC displays its current internal temperature

(in degrees centigrade). Whenever the internal temperature

meets or exceeds 40º C, an alarm will sound and the

“**HIGH TEMP ALARM**” message will appear on the LCD.

The alarm will quit and the message will be removed from the

LCD when the temperature falls below 40º C.

16 Connecting the Scalar 218FC Library

Page 27

Chapter

Configuring the Fibre Channel

Subsystem

This Chapter …

❐ provides instructions for configuring the fibre channel subsystem of your

Scalar 218FC.

❐ steps you through the final phase of the installation process.

17

Page 28

Configuring Your Communications Terminal

The fibre channel subsystem of your Scalar 218FC includes an embedded high-performance 32-bit

microprocessor with its own firmware located in Flash EEPROM. The Configuration Program, part of this

firmware, allows you to configure the subsystem, monitor subsystem diagnostic results, and download new

subsystem firmware. For information on configuring the robotics subsystem of your Scalar 218FC, refer to

section titled: Off-Line Mode Menus in Chapter 4 Equipment Description.

This manual and the Configuration Program make references to the “FCR 100” in discussions on fibre

channel configuration, monitoring of diagnostic results, and firmware downloading procedures. In these

instances, “Scalar 218FC fibre channel subsystem” and “FCR 100” are interchangeable.

To configure the fibre channel subsystem of your Scalar 218FC, to monitor diagnostic results or to download

new subsystem firmware, you need to use a host computer application that supports the X-modem data

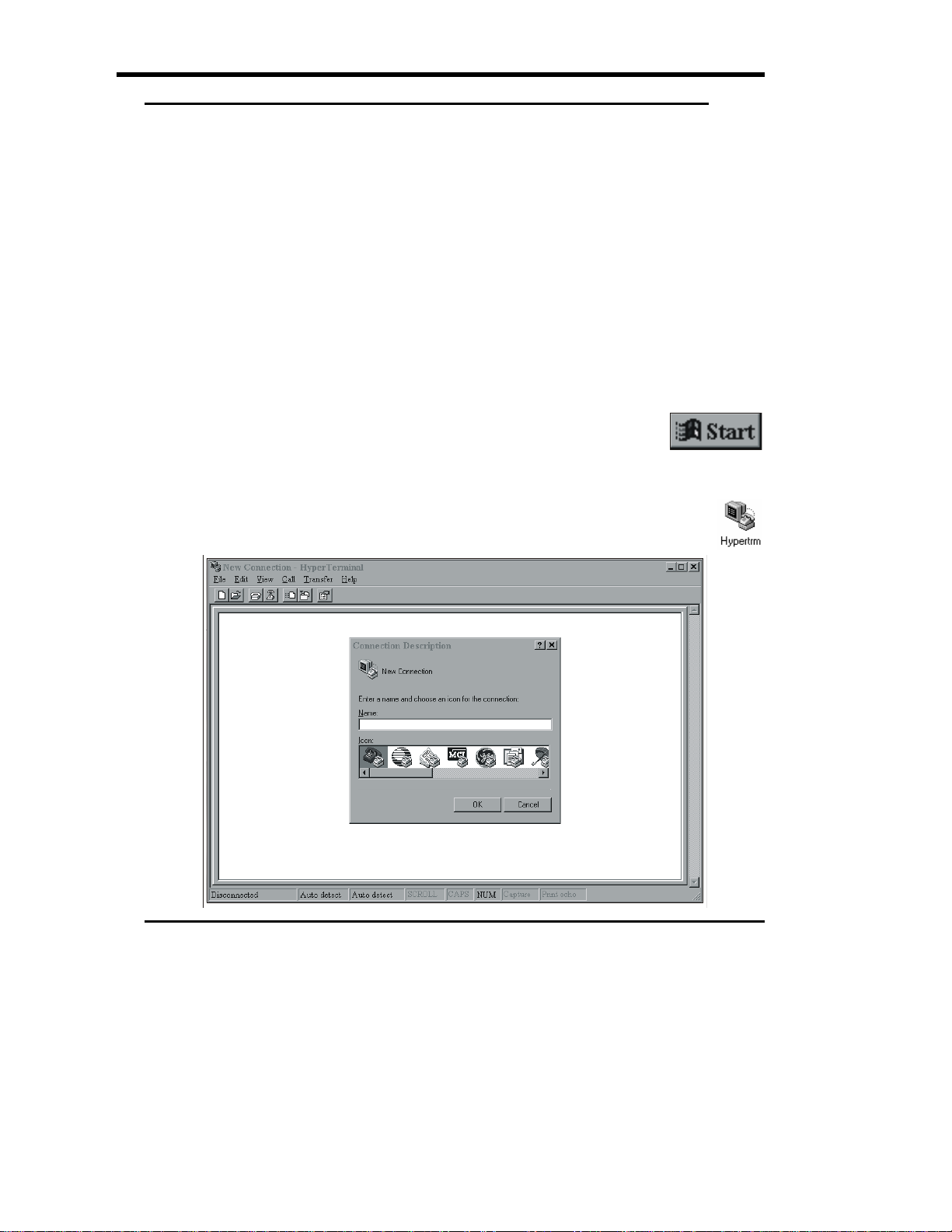

transfer protocol. The following example uses the HyperTerminal application included in Windows NT 4.0.

Other applications may use different procedures and com ports, but notice that the baud rate, number of data

bits, number of stop bits, whether parity is enabled and what type of flow control to use must be set for your

serial communications port as given in this example.

1. Select Programs from the Start Menu by clicking on the Start Button.

2. Select Accessories from the Programs menu.

3. Select HyperTerminal from the Accessories menu.

4. Click on the Hypertrm icon in the HyperTerminal program group.

5. A new HyperTerminal window appears with a dialog box for you to enter

a name for your hyperterminal and to select an icon to represent the

Hyperterminal in future sessions.

18 Configuring the Fibre Channel Subsystem

Page 29

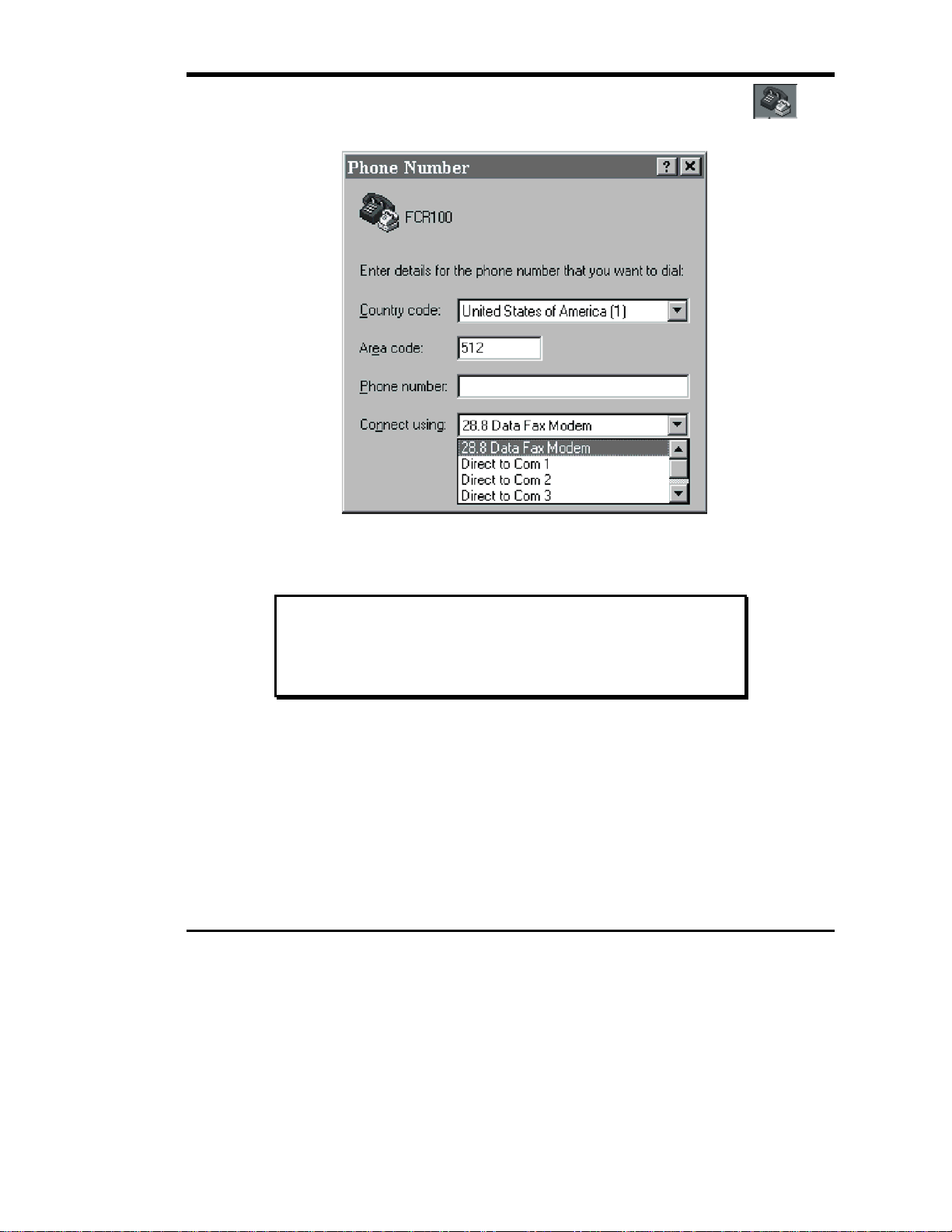

6. For this example we will name our Hyperterminal FCR 100 and select the Dial-in icon:

7. Click on OK. Now the Phone Number dialog box appears.

You do not have to enter a phone number, since you will be connecting directly through your serial port.

8. From the Connect using: pull-down menu, select the communications port assigned to your serial

port.

Note

This example uses COM2 for the serial port. You may use any

serial port that supports baud rates of at least 9600 bits per

second.

Configuring the Fibre Channel Subsystem 19

Page 30

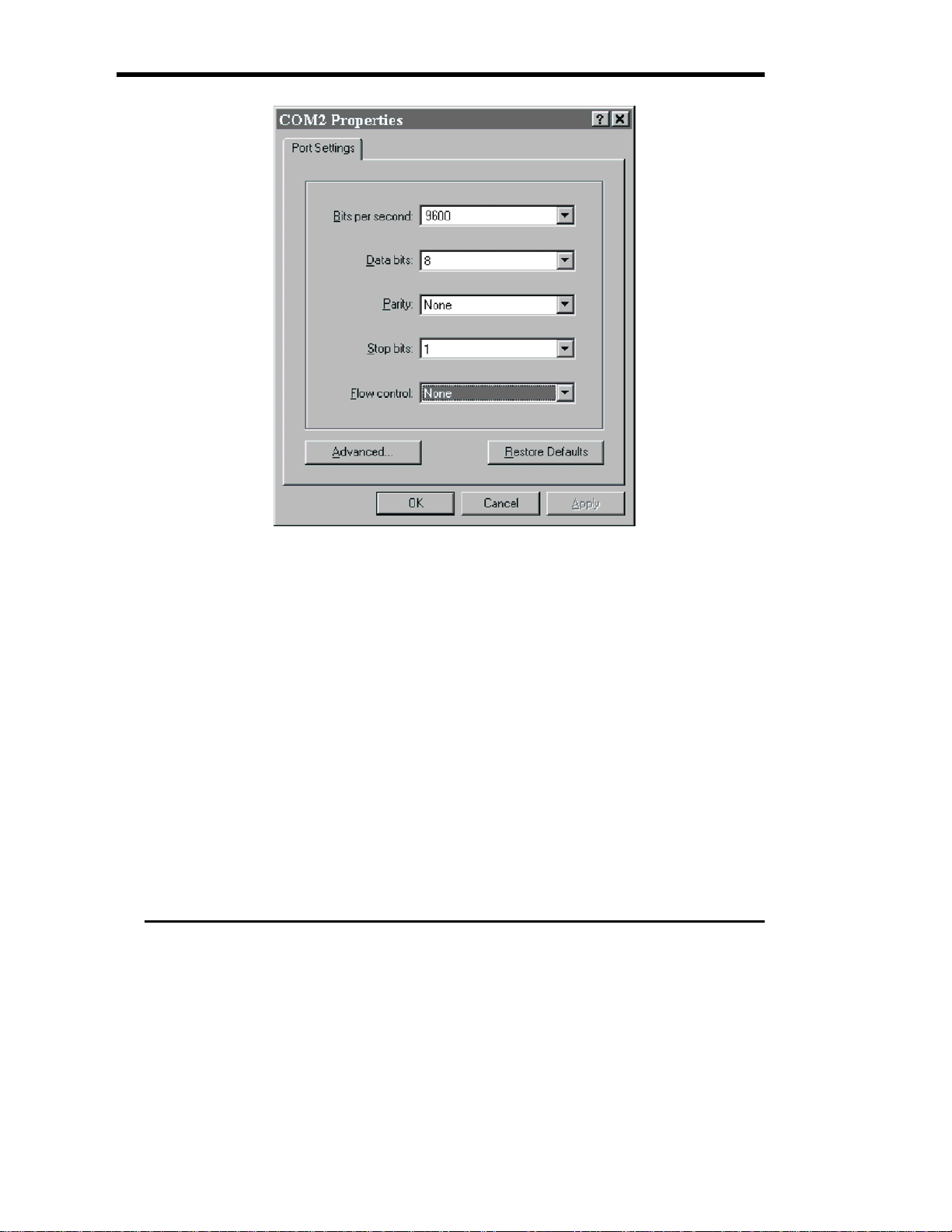

9. Click on OK. The Com PORT Properties dialog box appears:

Set your port settings to those shown in this dialog box:

Bits per second (baud rate)

Data bits

Parity

Stop bits

Flow control

9600 (default), 19200, 38400, 57600, or 115200

8

None

1

None

10. Click on OK.

11. Repeatedly press ENTER on the host computer until the Configuration Program main menu appears in

the command prompt area of HyperTerminal; The Build Level is the firmware level of the fibre channel

subsystem:

ADIC FCR100/CP4100 Fibre Channel/SCSI Router Configuration

Build Level: a9802

1) Perform Configuration

2) Do a Trace Dump

3) Reboot

4) Download a New Revision of the Firmware

Command >

20 Configuring the Fibre Channel Subsystem

Page 31

Notes

You may have to set the Bits per second (baud rate) in the

COM2 Properties dialog box to a higher value to establish

serial communications between your Scalar 218FC and your

computer. If the Configuration Program main menu does not

appear after pressing ENTER several times, change the baud

rate to the next higher value and repeat step 11. Continue

increasing the baud rate until the menu appears.

The Build Level: a9802 in the main menu is the current

version of fibre channel subsystem firmware installed in your

Scalar 218FC.

Configuring the Fibre Channel Interface

Introduction

The Scalar 218FC Configuration Program allows you to control many configuration settings through the

fibre channel serial interface or through the Ethernet connectivity capability. Among these are:

Baud rate of the serial port

Fibre Channel configuration

SCSI configuration

Ethernet configuration

Fibre Channel-to-SCSI mapping

Trace level settings

The default configuration settings of the Scalar 218FC are adequate for most applications. Configuration

settings may be changed and saved. They become the new default settings the next time you start your Scalar

218FC.

Repeatedly press ENTER on the host computer until the Configuration Program main menu appears on the

monitor:

ADIC FCR100/CP4100 Fibre Channel/SCSI Router Configuration

Build Level: a9802

1) Perform Configuration

2) Do a Trace Dump

3) Reboot

4) Download a New Revision of the Firmware

Command >

Configuring the Fibre Channel Subsystem 21

Page 32

Configuration

To configure the Scalar 218FC fibre channel interface, press 1 under the Configuration Program menu. This

displays the Configuration Menu:

Configuration Menu

Build Level: a9802

1) Baud Rate Configuration

2) Fibre Channel Configuration

3) SCSI Configuration

4) Ethernet Configuration

5) Fibre Channel to SCSI Mapping Configuration

6) SCSI to Fibre Channel Mapping Configuration

7) Trace Settings Configuration

8) SNMP Configuration*

A) Save Configuration

B) Restore Last Saved Configuration

C) Reset Configuration to Factory Defaults

X) Return to main menu

Notes

Most of the factory default settings within this section

should not have to be modified. The following descriptions

of each menu choice are provided so that you will have a

better understanding of how the fibre channel subsystem

functions.

Menu choice 6) SCSI to Fibre Channel Mapping

Configuration is not supported by your Scalar 218FC.

Call the ADIC Technical Assistance Center at (800) 827-2822

if any default settings do not meet the desired requirements.

Baud Rate Configuration

The baud rate is the rate of speed used by the Scalar 218FC Fibre Channel serial port to communicate with

another serial device. To configure the baud rate, press 1. This displays the following menu of choices:

Baud Rate Configuration Menu

Build Level: a9802

1) * 9600 2) 19200

3) 38400 4) 57600

5) 115200

22 Configuring the Fibre Channel Subsystem

Page 33

X) Return to previous menu:

The Baud Rate Configuration Menu displays a list of possible baud rates accepted by the Scalar 218FC fibre

channel interface. The default baud rate is 9600.

To select a different baud rate than the default:

1. Press the number corresponding to the desired baud rate in the listing.

To abort baud rate configuration, press X to return to the Scalar 218FC Fibre Channel Configuration Menu.

Note

Alphabetical menu and list choices in the Configuration Program

are

not

case sensitive. Uppercase and lowercase characters may

be used interchangeably.

2. Press X on the Baud Rate Configuration menu to return to the Configuration Menu.

3. Press A on the Configuration Menu to save the new baud rate setting.

Fibre Channel Configuration

Each Fibre Channel node is assigned a unique world wide name based on a unique vendor identifier that is

registered with IEEE. The World Wide Name is a 64 bit value. This value is broken into a 32-bit high-order

word and a 32-bit low-order word for configuration. An ADIC World Wide Name has the following format:

High-order

Low-order

To perform fibre channel configuration, press 2 in the Configuration Menu. This displays the following

menu of choices:

Fibre Channel Configuration Menu

Build Level: a9802

Current Fibre Channel Configuration:

World Wide Name High: 0x10000011

World Wide Name Low: 0x10000001

Use Hard ALPA: No

This menu displays:

The current value of the high-order word of the Fibre Channel World Wide Name

The current value of the low-order word of the Fibre Channel World Wide Name

The current value of the Hard Source ID (Use Hard ALPA) flag

You can change any of these three values.

10 00 00 E0

02

1) Change World Wide Name High

2) Change World Wide Name Low

3) Toggle Hard ALPA Usage

X) Return to previous menu

xx xx xx

Configuring the Fibre Channel Subsystem 23

Page 34

Note

Certain Host Bus Adapters (HBA’s) may require that you change

the Use Hard ALPA: No (default) to Use Hard ALPA: Yes. Call

ADIC Technical Support at (425) 883-HELP (4357) for additional

information.

World Wide Name High

This is the high-order word of the World Wide Name associated with a Fibre Channel entity.

To change the high-order word of the World Wide Name:

1. Press 1 in the Fibre Channel Configuration Menu. The Scalar 218FC Fibre Channel Serial Interface

displays the following prompt:

Enter new World Wide Name High value >

2. Enter the high-order word of your new World Wide Name.

If the value you specify is not a valid World Wide Name, the system will display the following warning:

ERROR:

Invalid World Wide Name Value!

Press Any Key to Continue...

World Wide Name Low

This is the low-order word of the World Wide Name associated with the Fibre Channel entity.

To change the low-order word of the World Wide Name:

3. Press 2 in the Fibre Channel Configuration Menu. The Scalar 218FC Fibre Channel Serial Interface will

display the following prompt:

Enter new World Wide Name Low value >

4. Enter the low-order word of your new World Wide Name.

If the value you specify is not a valid World Wide Name, the system will display the following

warning:

ERROR:

Invalid World Wide Name Value!

Press Any Key to Continue...

Hard ALPA Usage. This setting allows you to specify whether you can change the Fibre Channel Source

ID. If Use Hard ALPA is set to Yes (TRUE), then the Source ID may be changed. If Use Hard ALPA is

set to No (FALSE), then the Source ID may not be changed.

To change the Use Hard ALPA:

5. Press 3 in the Fibre Channel Configuration Menu.

This toggles the setting of Use Hard ALPA between Yes and No. If you toggle to yes, the menu adds a

selector to allow a hard address value and an address value of 0x1 is set.

6. Press X to return to the Configuration Menu.

24 Configuring the Fibre Channel Subsystem

Page 35

7. Press A on the Configuration Menu to save the new Fibre Channel configuration.

Configuring the Fibre Channel Subsystem 25

Page 36

SCSI Configuration

The SCSI configuration selection allows you to change the Initiator SCSI ID as well as to add or remove a

target SCSI ID.

SCSI Configuration Menu

Build Level: a9802

Current SCSI Configuration:

Initiator SCSI ID: 7

Target SCSI ID(s):

Reset SCSI Bus on Boot: Yes

SCSI Initial Discovery Delay: 15000 ms

1) Change Initiator SCSI ID

2) Add Target SCSI ID

3) Remove Target SCSI ID

4) Toggle SCSI Reset Operation

5) Change Discovery Delay Time

X) Return to previous menu

This menu displays:

the current SCSI Initiator ID

a list of the current SCSI Target IDs

the current value of the SCSI bus reset flag

a menu of valid SCSI configuration operations.

The operations to change these values are described below.

Change Initiator SCSI ID. The Initiator SCSI ID is the ID of the SCSI device that requests an operation to

be performed. To change the initiator SCSI ID:

Note

In any case

, do not enter Target SCSI IDs. It should not be

necessary to change the Initiator SCSI ID setting.

1. Press 1 while in the SCSI Configuration Menu. The Configuration Menu displays the following prompt:

Enter new Initiator SCSI ID >

2. Enter the new SCSI Initiator ID. The Configuration Menu accepts values between 0 and 15. The Scalar

218FC allows a target to have more than one ID.

3. After specifying your new SCSI Initiator, press Enter.

If you specify an invalid value, the Configuration Menu displays the following message:

ERROR:

26 Configuring the Fibre Channel Subsystem

Page 37

Invalid SCSI ID. Valid values are 0 - 15.

Press Any Key to Continue...

If the new initiator is in the list of Target SCSI ID(s), you must remove it. See Remove Target SCSI

ID, below. This prevents a SCSI device from being both initiator and target.

4. Press X to return to the Configuration Menu.

5. Press A to save the new SCSI configuration.

Add Target SCSI ID. The target SCSI ID is the ID of the SCSI device receiving a request. You may have

more than one ID as a SCSI target on the Scalar 218FC. To add a Target SCSI ID:

1. Press 2 while in the SCSI Configuration Menu. The Configuration Menu displays the following prompt:

Add new Target SCSI ID >

2. Enter a new SCSI Target ID. The Scalar 218FC accepts values between 0 and 15.

The new Target ID is added to the list of Target SCSI IDs under the SCSI Configuration Menu.

If you specify an ID that is already on the list of Target SCSI IDs, no change to the current list is made.

If you specify a number that is out of range, the Configuration Menu displays the following error:

ERROR:

Invalid SCSI ID. Valid values are 0 - 15.

Press Any Key to Continue...

3. Press X to return to the Configuration Menu.

4. Press A to save the new SCSI configuration.

Toggle SCSI Reset Operation. You can set the Scalar 218FC fibre channel subsystem to reset the SCSI

bus on boot. By default, this setting is Yes. To toggle the SCSI reset setting:

1. Press 4 under the SCSI Configuration Menu. The resulting display will reflect the setting change.

Change Discovery Delay Time. You can set the Scalar 218FC fibre channel subsystem to reset the SCSI

bus on boot. By default, this setting is Yes. To toggle the SCSI reset setting:

Ethernet Configuration

To select Ethernet Configuration, press 4 while in the Configuration Menu.

Ethernet Configuration Menu

Build Level: a9802

Current Ethernet Configuration:

Ethernet Physical Address : Unique value (set at factory)

IP Address : 001.001.001.001 (default value)

Subnet Mask : 255.255.255.0 (default value)

1) Change Ethernet Physical Address

2) Change IP Address

3) Change IP Subnet Mask

X) Return to previous menu

The Ethernet Configuration Menu displays:

the current Ethernet Physical Address

Configuring the Fibre Channel Subsystem 27

Page 38

the current Scalar 218FC Fibre Channel IP Address

the current Scalar 218FC Fibre Channel IP Subnet Mask.

The operations to change these values are described below.

Ethernet Physical Address. The Ethernet Physical Address is sometimes referred to as the MAC

address. It is a unique 48-bit value that is based on a vendor ID assigned by the IEEE. To change the Scalar

218FC’s physical Ethernet address:

1. Press 1 while in the Ethernet Configuration Menu. The Configuration Menu displays the following

prompt:

Enter new Ethernet Physical Address >

2. Enter your new Ethernet physical address and press Return.

If you enter an invalid Ethernet address, the Serial Interface displays the following error:

ERROR:

Invalid Ethernet Address!

Press Any Key to Continue...

3. Press X to return to the Configuration Menu.

4. Press A to save the new Ethernet Address.

IP Address. The IP address is used by the TCP/IP protocol to route information in a TCP/IP network. A

systems administrator usually assigns the IP address. To change the Scalar 218FC Internet (IP) address:

1. Press 2 while in the Ethernet Configuration Menu. The interface displays the following prompt:

Enter new IP Address >

2. Enter the new IP address and press Return.

If the IP address you specify is invalid, the following error message is displayed:

ERROR:

Invalid input!

Press Any Key to Continue...

3. Press X to return to the Configuration Menu.

4. Press A to save the new IP Address.

IP Subnet Mask

The IP subnet mask is used by TCP/IP protocol to establish a path to a default TCP/IP gateway. A systems

administrator usually assigns this value. To change the IP subnet mask:

1. Press 3 while in the Ethernet Configuration Menu. The following prompt is displayed:

Enter new Subnet Mask >

2. Enter the new IP subnet mask and press Return.

If you enter an invalid IP subnet mask, the following message is displayed:

ERROR:

Invalid input!

Press Any Key to Continue...

3. Press X to return to the Configuration Menu.

4. Press A to save the new IP subnet mask.

28 Configuring the Fibre Channel Subsystem

Page 39

Fibre Channel-to-SCSI Mapping Configuration

For a discussion of Fibre Channel-to-SCSI mapping, see Appendix A. To configure Fibre Channel-to-SCSI

mapping, select item 5 from the Configuration Menu. This presents the following display:

Fibre Channel to SCSI Configuration Menu

Build Level: a9802

Current Fibre Channel to SCSI Mapping Mode is Auto-assigned

1) Display Attached SCSI Devices, LUN Priority

2) Display Attached SCSI Devices, Target ID Priority

3) Display Attached SCSI Devices, Bus Number Priority

4) Change the Fibre Channel to SCSI Mapping Mode

X) Return to Previous Menu

LUN Priority Display. To view LUN priorities of attached SCSI devices:

1. Press 1 while in the Fibre Channel-to-SCSI Configuration Menu.

The Configuration Menu displays a screen similar to the following:

Querying SCSI devices, please be patient ...

Currently Attached Devices

Build Level: userLevel

BUS TGT LUN DEVICE DESCRIPTION

0 1 0 Scalar 448

0 2 0 Quantum DLT 7000

0 3 0 Quantum DLT 7000

X to return, <enter> for more >

Target ID Priority Display. To display the target ID priorities of SCSI devices, select 2. This results in a

display similar to the one shown above.

Bus Priority. Item 3 has no significance on the Scalar 218FC, since it only has one SCSI bus. Selecting this

choice results in the following error:

ERROR:

There is only one bus on this device

Press Any Key to Continue...

Fibre Channel-to-SCSI Mapping Mode. This allows you to select the way in which Fibre Channel

addresses are mapped to SCSI addresses.

Pressing 4 on the Fibre Channel-to-SCSI Mapping Mode Configuration Menu displays the following menu of

selections:

Fibre Channel to SCSI Mapping Mode Configuration Menu

Build Level: a9802

Current Fibre Channel to SCSI Mapping Mode is Auto-assigned

1) Set to SCC

2) Set to Indexed

3) Set to Auto-assigned, LUN priority

Configuring the Fibre Channel Subsystem 29

Page 40

4) Set to Auto-assigned, target ID priority

5) Set to Auto-assigned, bus number priority

X) Return to Previous Menu

Notes

If your selected HBA supports SCC Mode set the SCSI

Mapping Mode to SCC.

The factory default setting is: 5) Set to Auto-assigned, bus

number priority.

At the head of the display is the current value of the Fibre Channel-to-SCSI Mapping Mode. The default

value is SCSI Controller Command (SCC). There are five possible mapping modes:

SCC— Use the SCSI-3 Controller Command Set (SCC) Logical Unit Addressing method. This mode

requires that the host device driver is capable of addressing a controller device. In this mode, the

controller will respond directly to commands issued using the Peripheral Device Addressing Method.

Commands addressed using the Logical Unit Addressing Method will be routed to the appropriate SCSI

device as specified by the host.

Indexed—provides a user-configurable table that maps FCP LUN values to SCSI devices directly. In

this mode, the controller is not addressable by the host. Configuration allows for sequential FCP LUN

values (0, 1,

saved in FLASH memory and will persist across power cycles. Various editing assists are provided for

creating and modifying this table.

Auto-assigned, LUN priority—Auto assigned mode is similar to indexed mode: a table is used to map

FCP LUN values to SCSI addresses. However, this table is created at power up and does not persist

across reboots or power cycles. Discovery is performed on the SCSI bus, and each device is added to the

table in the order in which it is discovered.

In LUN priority, as discovery is performed, the LUN value is incremented after the Target value. Therefore,

as discovery is performed, all SCSI targets are identified before subsequent LUNs are identified.

Auto-assigned, target ID priority—As discovery is performed, the Target value is incremented after the

LUN. Therefore, all LUNs appear adjacent to the target device in the table.

Auto-assigned bus number priority—This option is not relevant to the configuration of the FCR100,

which has only one bus.

To change the Fibre Channel-to-SCSI mapping mode:

1. Press the number corresponding to the desired mapping mode.

2. Press X to return to the Configuration Menu.

3. Press A on the Configuration Menu to save the new mapping configuration.

2,...) to be mapped to arbitrary SCSI BUS:TARGET:LUN addresses. This table can then be

SCSI-to-Fibre Channel Mapping

The SCSI-to-Fibre Channel Mapping option is not supported by your Scalar 218FC.

30 Configuring the Fibre Channel Subsystem

Page 41

Trace Settings Configuration

Trace Settings Configuration allows you to set the trace level for diagnostics. For performance reasons, trace

settings should all be turned off, except in cases where a problem might be detected by a trace. The default

configuration has all levels set to ON. Pressing 7 on the Configuration Menu results in the following display:

Trace Settings

Build Level: a9802

Level 0 : ON Level 1 : OFF

Level 2 : OFF Level 3 : OFF

Level 4 : OFF Level 5 : OFF

Level 6 : OFF Level 7 : OFF

U) Update Current Operating Trace Levels

X) Return to previous menu

Enter trace level to change >

Note

The Trace capability is provided for diagnostic purposes only.

You should only change the Trace Level settings when

instructed to do so by ADIC Technical Support. Call ADIC

Technical Support at (425) 883-HELP (4357) for additional

information.

To change the trace level:

1. Enter a trace level number corresponding to the trace level you wish to change. This toggles the current

value between ON and OFF.

2. After all settings have been toggled to the value you desire, you can make them permanent by selecting

U to update the current operating trace level. (Note that Step 4, below, is still necessary, however.

3. Press X to return to the Configuration Menu.

4. Press A to save the your configuration settings.

Save Configuration

Pressing A on the Configuration Menu saves all currently changed values. See the previous examples for the

use of this option.

Restore Last Saved Configuration

Pressing B on the Configuration Menu restores all values from the previously saved configuration.

Reset Configuration to Factory Defaults

Pressing C on the Configuration Menu restores the factory default configuration. The following table

summarizes the default settings:

Setting Value

Baud Rate

World Wide Name High

Configuring the Fibre Channel Subsystem 31

Unique value (set at factory)

9600

Page 42

World Wide Name Low

Hard Address Usage

Initiator SCSI ID

Target SCSI ID(s):

Reset SCSI Bus on Boot

Ethernet Physical Address

IP Address

Subnet Mask

Fibre Channel-to-SCSI Mapping Mode

Unique value (set at factory)

No

7

Yes

Unique value (set at factory)

001.001.001.001

255.255.255.0

Auto-assigned Bus Number Priority

Return to main menu

Pressing X on the Configuration Menu returns to the main configuration program. If you have made changes

to the configuration, the program will display the following message:

The configuration has changed and you have not saved the new configuration to

flash. The configuration must be saved to flash for it to take effect on the

next reboot!

Save the configuration now (Y/N)? n

SNMP Configuration

The following section describes the ADIC SNMP Management Information Base (MIB). Many of these

definitions are specific to ADIC products and are not currently publicly defined by the IETF (Internet

Engineering Task Force) or other public body. General parameters are described for SNMP gets and sets for

various functional areas of the Scalar 218FC, and appropriate standards are described.

Several Fibre Channel draft MIB definitions are available for review from:

ftp://ftp.isi.edu/internet-drafts/

ftp.dpt.com/t11/pub/fc/misc./

Your Scalar 218FC currently supports the ADIC private MIB, whose details follow.

Description

The fibre channel subsystem of your Scalar 218FC provides several interfaces, each of which sends and

receives data. Management functions are accessible out-of-band via the Ethernet port (10BaseT) that serves

as the initial access point for MIB data. The MIB is used to track statistics regarding the flow of data (from

Fibre Channel-to-SCSI and vice versa), as well as to allow for configuration changes to be made to the fibre

channel subsystem. Possible configuration changes are mostly concerned with the need to change addressing

modes depending upon customer needs.

The ADIC private MIB includes all information accessible from the serial user interface. This MIB is

included in the fibre channel subsystem firmware installed on your Scalar 218FC.

Interfaces

There are a total of four types of interfaces to the FCR100:

Fibre Channel

SCSI

Ethernet

32 Configuring the Fibre Channel Subsystem

Page 43

RS-232 (serial port)

The fibre channel subsystem of your Scalar 218FC is configured as follows:

1 SCSI F/W interface

1 Gigabit Fibre Channel interface (optical)

1 10BaseT Ethernet Port

1 RS-232 Serial Port

The serial and Ethernet ports are used primarily for fibre channel subsystem configuration and management.

(TCP/IP requests may also be serviced over the Fibre Channel ports (in-band) in future releases.) A

discussion of each of these ports and its associated MIB data follows. Configuration information for each

interface is contained in the following section as well.

Fibre Channel

Fibre Channel data reported includes frame and packet information, upper layer protocol (ULP) type (FCP or

IP), and other Fibre Channel-specific information. Draft MIBs for Fibre Channel N_Ports and F_Ports are in

the public realm.

ADIC proposes to support portions of two standard Fibre Channel MIBs as well as an ADIC private MIB.

The ADIC private MIB includes:

Groups for Fibre Channel Configuration

FC N_Port Physical Table

FC N_Port Statistics

SCSI-to-FC Mapping

FC-to-SCSI Mapping

SCSI

SCSI is not generally an SNMP managed protocol. The ADIC MIB, however, gathers SCSI information for

management purposes. This ADIC specific MIB provides information about the following:

number of I/O operations per bus

number of disconnects

abort count

total data counts in bytes

bus resets

vital product data from Inquiry command for each SCSI device

This information can be found in the SCSIStatisticsTable and the SCSIProductData Groups of the ADIC

private MIB.

Ethernet and Serial Interfaces

The Ethernet interface is used for configuration and management, so total traffic flow is relatively low. The

basic Ethernet configuration items are found in the Management Interfaces Table.

The serial port is provided for user configuration. The serial port baud rate will be kept in the Management

Interfaces Table.

Configuring the Fibre Channel Subsystem 33

Page 44

ADIC Private MIB

The following chart lists all attributes that can be specified using the ADIC private SNMP MIB. Included

with each attribute are the attribute’s read/write property and a brief description of the meaning of values

read or written.

Parameter Read/Write Description

fcConfigNodeName

Read/Write Worldwide name of a collection of N_Ports that

comprise a Node.

fcConfigNodeNumNPorts

fcConfigEnableReset

Read Only Number of N_Ports that comprise the named Node.

Read/Write Toggle for software reset. True indicates that resetting

the product via SNMP is allowed. NOTE: each time

the product is initialized this object is set to FALSE

(i.e. it is not sticky).

fcConfigUseHardAddress

Read/Write Toggle for address configuration. True indicates that

configuration of the source ID is allowed. False

indicates that the source ID may not be changed.

fcConfigSourceID

Read/Write 3 byte Source address. For arbitrated loop, this will be

the Hard Assigned AL_PA (preceded by 20 bytes).

fcConfigSCSIMode

fcConfigTraceMask

fcConfigReset

Read/Write Fibre Channel-to-SCSI mapping mode.

Read/Write Trace Level.

Read/Write Reset the product. Setting this object to TRUE will re-

start all the software (similar to powering the product

off, then on). The reset will only take place if

fcConfigResetEnable is also TRUE. NOTE: resetting

the product will disconnect all current Fibre Channel

connections.

fcConfigCommit

miSerialBaudRate

miMACAddress

miethernetIPAddr

miethernetIPNetmask

miCommunitySet

miCommunityGet

scsiConfigTable

scsiConfigEntry

scsiConfigIndex

scsiConfigInitID

scsiConfigTargetIDAdd

Read/Write Commit the configuration values to the flash memory.

Read/Write The baud rate for the serial interface.

Read/Write Physical address (MAC address).

Read/Write The IP address for this device.

Read/Write Ethernet Net Mask.

Read/Write SNMP Community name for Sets. Not supported.

Read/Write SNMP Community name for Gets. Not supported.

Read/Write A Table containing SCSI Configuration parameters.

Read/Write An entry in the SCSI Configuration Table.

Read Only Index into the SCSI Configuration Table.

Read/Write Initiator SCSI ID.

Read/Write Set this SCSI target ID.

Parameter Read/Write Description

scsiConfigTargetIDRemove

Read/Write Remove this SCSI target ID. The SCSI ID you specify

will no longer be a target.

34 Configuring the Fibre Channel Subsystem

Page 45

scsiConfigResetFlag

Read/Write Toggle SCSI Reset Operation. TRUE indicates that

the SCSI bus will be reset on boot.

fctoSCSIMapTable

fctoSCSIMapEntry

fctoSCSIMapIndex

A Table containing the Fibre Channel-to-SCSI Map.

An entry in the Fibre Channel-to-SCSI Map Table.

Read Only Index into the Fibre Channel-to-SCSI Map (SCSI

LUN).

fctoSCSIbus

fctoSCSItarget

fctoSCSILUN

scsitoFCMappingTable

Read/Write SCSI bus number.

Read/Write SCSI ID.

Read/Write SCSI LUN.

A Table containing information describing how SCSI

channels are mapped to the Fibre Channel.

scsitoFCMapEntry

scsitoFCMapIndexBus

scsitoFCMapIndexSCSIID

scsitoFCMapIndexLUN

scsitoFCMapDestID

scsitoFCMapLUNlo

scsitoFCMapLUNhi

fcNPortPhysTable

fcNPortPhysEntry

fcNPortPhysNPortIndex

An entry in the SCSI-to-FC Mapping Table.

Read Only Index into the SCSI-to-FC Map. SCSI bus number

Read Only Index into the SCSI-to-FC Map. SCSI ID.

Read Only Index into the SCSI-to-FC Map. SCSI LUN.

Read/Write The Fibre Channel Node number.

Read/Write SCSI LUN low bytes.

Read/Write SCSI LUN high bytes.

A Table containing N_Port Physical Characteristics.

An entry in the N_Port Physical Characteristics Table.

Read Only A unique number that identifies an N_Port/NL_Port.

This number ranges from 1 to the value of

fcNodeNumNPorts and its value remains constant for

the identified N_Port/NL_Port until the management

agent of the Node is re-initialized.

FcNPortSpeed

fcNPortMedia

fcNPortTransmitterType

fcNPortDistance

Read Only The transmission rate, an FC-0 physical characteristic.

Read Only Type of media, an FC-0 physical characteristic.

Read Only Type of transmitter, an FC-0 physical characteristic.

Read Only The maximum distance, an FC-0 physical

characteristic.

fcNPortLinkState

Read Only The state of the FC link. Pending indicates that the

initialization is still pending. Failed indicates that link

initialization has failed. Successful indicates that the

FC Link has initialized successfully.

fcNPortRTTOV

Read Only Receiver_Transmitter timeout value, used by the

receiver logic to detect Loss of Synchronization.

Parameter Read/Write Description

fcNPortTopologyModel

Read Only The topology model on the Link. The N_Port/NL_Port

may be attached to a Fabric, or attached to another

N_Port or to FC-AL (Arbitrated Loop). This value is

only meaningful if the FC Link has initialized

successfully. (i.e. fcNportLinkState = Successful)

Configuring the Fibre Channel Subsystem 35

Page 46

scsiStatisticsTable

scsiStatsEntry

scsiStatsIndex

scsiStatsIOs

scsiStatsDisconnects

scsiStatsAbortCount

A Table containing SCSI Statistics.

An entry in the SCSI Statistics Table.

Read Only Index into the SCSI Statistics Table.

Read Only The number of IO operations on the SCSI bus.

Read Only The number of Disconnects on the SCSI bus.

Read Only The of SCSI bus termination messages (i.e. ABORT,

ABORT TAG, CLEAR QUEUE, BUS DEVICE

RESET) which have terminated I/O processes.

scsiStatsBusResets

scsiProductDataTable

scsiPDEntry

Read Only The count of SCSI bus resets

Read Only A Table containing SCSI Product Data.

Read Only An entry in the SCSI Product Data Table.

(scsiPDIndex.)

scsiPDIndex

Read Only The Index into the SCSI Product Data Table. (The

SCSI LUN.)

scsiPDDeviceCode

scsiPDQualifier

scsiPDRemoveable

scsiPDANSIVersion

scsiPDECMAVersion

scsiPDISOVersion

ScsiPDRespFormat

ScsiPDLength

ScsiPDSoftReset

ScsiPDCommandQing

ScsiPDLinkedCommands

ScsiPDSyncTransfer

scsiPD16Bit

scsiPD32Bit

ScsiPDRelativeAddr

ScsiPDVendorID

ScsiPDProductID

ScsiPDRevLevel

FcNPortStatisticsTable

Read Only Device type code.

Read Only Device type qualifier.

Read Only Removable media.

Read Only Device type version.

Read Only Device type version.

Read Only Device type version.

Read Only Response Format.

Read Only Additional data length.

Read Only Support for Soft reset.

Read Only Support for Command Queuing.

Read Only Support for Linked Commands.

Read Only Support for sync transfer.

Read Only 16-bit wide SCSI support.

Read Only 32-bit wide SCSI support.

Read Only Support for Relative address.

Read Only Vendor ID.

Read Only Product ID.

Read Only Revision Level.

Read Only A table of NPort statistics.

Parameter Read/Write Description

FcNPSEntry

Read Only An entry in the NPort statistics table.

36 Configuring the Fibre Channel Subsystem

Page 47

FcNPSIndex

FcNPSInDeviceDataFrames

FcNPSOutDeviceDataFrames

FcNPSInLinkDataFrames

FcNPSOutLinkDataFrames

FcNPSInLCRFrames

FcNPSOutLCRFrames

FcNPSInPBSYFrames

FcNPSOutPBSYFrames

FcNPSInPRJTFrames

FcNPSOutPRJTFrames

FcNPSAborts

FcNPSLaserFaults

FcNPSLOS

FcNPSBadRXChar

FcNPSClearRegisters

Read Only A unique number that identifies an N_Port. This

number ranges from 1 to the value of

fcNodeNumNPorts and its value remains constant for

the identified N_Port until the management agent of

the Node is re-initialized.

Read Only The number of Device Data frames received by this

N_Port/NL_Port.

Read Only The number of Device Data frames transmitted by this

N_Port/NL_Port.

Read Only The number of Link Data frames received by this

N_Port/NL_Port.

Read Only The number of Link Data frames transmitted by this

N_Port/NL_Port.

Read Only Counter not implemented.

Read Only Counter not implemented.

Read Only The number of P_BSY frames received by this

N_Port/NL_Port.

Read Only The number of P_BSY frames transmitted by this

N_Port/NL_Port.

Read Only The number of P_RJT frames received by this

N_Port/NL_Port.

Read Only The number of P_RJT frames transmitted by this

N_Port.