Page 1

North Americas Best

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2100-I & 3100-I2100-I & 3100-I

2100-I & 3100-I

2100-I & 3100-I2100-I & 3100-I

Installation, Operation &Installation, Operation &

Installation, Operation &

Installation, Operation &Installation, Operation &

Maintenance InstructionsMaintenance Instructions

Maintenance Instructions

Maintenance InstructionsMaintenance Instructions

PLEASE READ THIS ENTIRE OPLEASE READ THIS ENTIRE O

PLEASE READ THIS ENTIRE O

PLEASE READ THIS ENTIRE OPLEASE READ THIS ENTIRE O

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

Close attention to fire protection is required when installing your insert. If this unit is not properly

installed a house fire may result. For your safety, follow the installation instructions and contact local

building or fire officials about restrictions and installation inspection requirements in your area.

Never use gasoline or similar liquids to start a fire in this unit. Keep all such liquids well away from stove.

If any part of the stove starts to glow during operation, the stove is in an overfired condition. Close

the air controls completely until the glowing has stopped. OVERFIRING VOIDS WARRANTY.

Cool ashes should be disposed of carefully- using a metal container.

Do not burn wet or green wood. Store wood in a dry location.

Do not burn garbage, treated wood, or wood with salt (driftwood, etc.).

Do not permit creosote or soot to accumulate excessively in the chimney or inside the firebox.

Check your chimney system thoroughly when installing into an existing metal or masonry chimney. Seek

professional advice if in doubt about its condition.

Do not connect this unit to a chimney flue already serving another appliance.

Comply with all minimum clearances to combustibles as shown in this manual.

Build fire on brick firebox floor - Do not use grates and irons or other methods to support the fuel.

Install insert so it can be removed for cleaning and inspection.

Hot while in operation. Keep children, clothing and furniture away. Contact can cause skin burns.

for purchasing one of the finest sto for purchasing one of the finest sto

for purchasing one of the finest sto

for purchasing one of the finest sto for purchasing one of the finest sto

Before proceeding, please record the stoBefore proceeding, please record the sto

Before proceeding, please record the sto

Before proceeding, please record the stoBefore proceeding, please record the sto

401 N. Wynne Street

Colville, WA 99114

WNER’S MANUWNER’S MANU

WNER’S MANU

WNER’S MANUWNER’S MANU

AL AND SAL AND S

AL AND S

AL AND SAL AND S

Important Safety Notes...

Thank yThank y

Thank y

Thank yThank y

vv

e serial number on the enclosed We serial number on the enclosed W

v

e serial number on the enclosed W

vv

e serial number on the enclosed We serial number on the enclosed W

ou,ou,

ou,

ou,ou,

vv

es in the wes in the w

v

es in the w

vv

es in the wes in the w

orld for yorld for y

orld for y

orld for yorld for y

SAVE THESE INSTRUCTIONS

#832-0520 Revised 03/1999

AFETY NOAFETY NO

AFETY NO

AFETY NOAFETY NO

our homeour home

our home

our homeour home

..

.

..

arranty Card.arranty Card.

arranty Card.

arranty Card.arranty Card.

www.aladdinhearth.com

aladdin@aladdinhearth.com

TES.TES.

TES.

TES.TES.

Page 2

2100-I & 3100-I FIREPLACE INSERT

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

NOTES

MODEL PURCHASED:

SERIAL NUMBER:

DATE PURCHASED:

DEALERSHIP WHERE PURCHASED:

DEALER PHONE NUMBER

________________________________________________________________

________________________________________________________________

________________________________________________________________

ATTACH YOUR SALES RECEIPT AND WARRANTY STUB HERE:

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

NOTES & SYMBOLS

Page 2

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678

ADDITIONAL INFORMATION :

Quick Reference Symbols

OPERATING TIPS & PROCEDURES

CAUTION AND WARNING !

INSTALLATION INSTRUCTIONS

CLEANING & MAINTENANCE TIPS

IMPORTANT REMINDERS

March 1999

Page 3

2100-I & 3100-I FIREPLACE INSERT

TABLE OF CONTENTS

Welcome ........................................................................................... 4

Dimensions ........................................................................................... 5

Safety Labels ......................................................................................... 6

Component Parts Diagram .................................................................... 8

Clearances to Combustibles .................................................................. 9

Hearth Requirements ............................................................................. 9

INSTALLATION

Recommendations ............................................................. 10

Canadian ........................................................................... 10

General Procedures Listing ............................................... 11

Unpacking/Use of Leveling Bolts..................................... 11

Blower Assembly .............................................................. 12

Panel Set............................................................................ 13

Face Trim .......................................................................... 13

Door Handle ...................................................................... 13

Chimney Requirements..................................................... 14

MASONRY FIREPLACE ................................................ 16

METAL HEAT EXCHANGER ........................................ 18

FACTORY BUILT FIREPLACE (Zero Clearance) ......... 18

OPERATION

Wood Selection ................................................................. 20

Overfiring.......................................................................... 20

Building a fire ................................................................... 20

Obtaining Burn Rates........................................................ 21

Fan Operation.................................................................... 22

MAINTENANCE

Gold Plated Surfaces ......................................................... 22

Glass.................................................................................. 22

Glass Replacement ............................................................ 22

Chimney ............................................................................ 23

Ash Removal..................................................................... 23

Firebrick ............................................................................ 23

Baffle Removal & Installation............................................................... 24

Air Quality and the Quadra-Fire Insert.................................................. 26

Warranty ........................................................................................... 27

CONTENTS

Page 3 March 1999

Page 4

2100-I & 3100-I FIREPLACE INSERT

WELCOME !

Aladdin Hearth Products welcomes you to our tradition of excellence! In choosing a Quadra-Fire

appliance, you have our assurance of commitment to quality, durability, and performance.

This commitment begins with our research of the market, including ‘Voice of the Customer’

contacts, ensuring we make products that will satisfy your needs. Our Research and Development

facility then employs the world’s most advanced technology to achieve the optimum operation of

our stoves, inserts and fireplaces. And yet we are old-fashioned when it comes to craftsmanship.

During manufacturing each unit is meticulously fabricated and gold surfaces are hand-finished for

lasting beauty and enjoyment. Our pledge to quality is completed as each model undergoes a

quality control inspection. Additionally, we feel it is important to offer you several finishing options and accessories to compliment your home’s décor, individualize the use of your appliance, and

provide financial options in acquiring a quality hearth appliance. Ask your Quadra-Fire Dealer for

information on these options. From design, to fabrication, to shipping: Our guarantee of quality is

more than a word, it’s Quadra-Fire tradition, and we proudly back this tradition with a Lifetime

Warranty.

Prior to installation, we ask you to take a few moments to read this manual. It has been our experience that your overall enjoyment of your new appliance will be greatly enhanced by becoming

familiar with its’ installation, operation and maintenance requirements. We wish you and your

family many years of enjoyment in the warmth and comfort of your hearth appliance. Thank you

for choosing Quadra-Fire.

With warm regards,

President V.P. Research & Development

Controller Operations Manager V.P. Sales & Marketing

Western Sales Manager Central Sales Manager Eastern Sales Manager

WELCOME

Manufacturing Eng. Manager Sr. Purchasing Agent Technical Support Manager

Customer Support Manager Human Resources Supervisor

Manager

Page 4

3100-I, shown with optional gold accent door and gold accent louvered sides

March 1999

Page 5

2100-I & 3100-I FIREPLACE INSERT

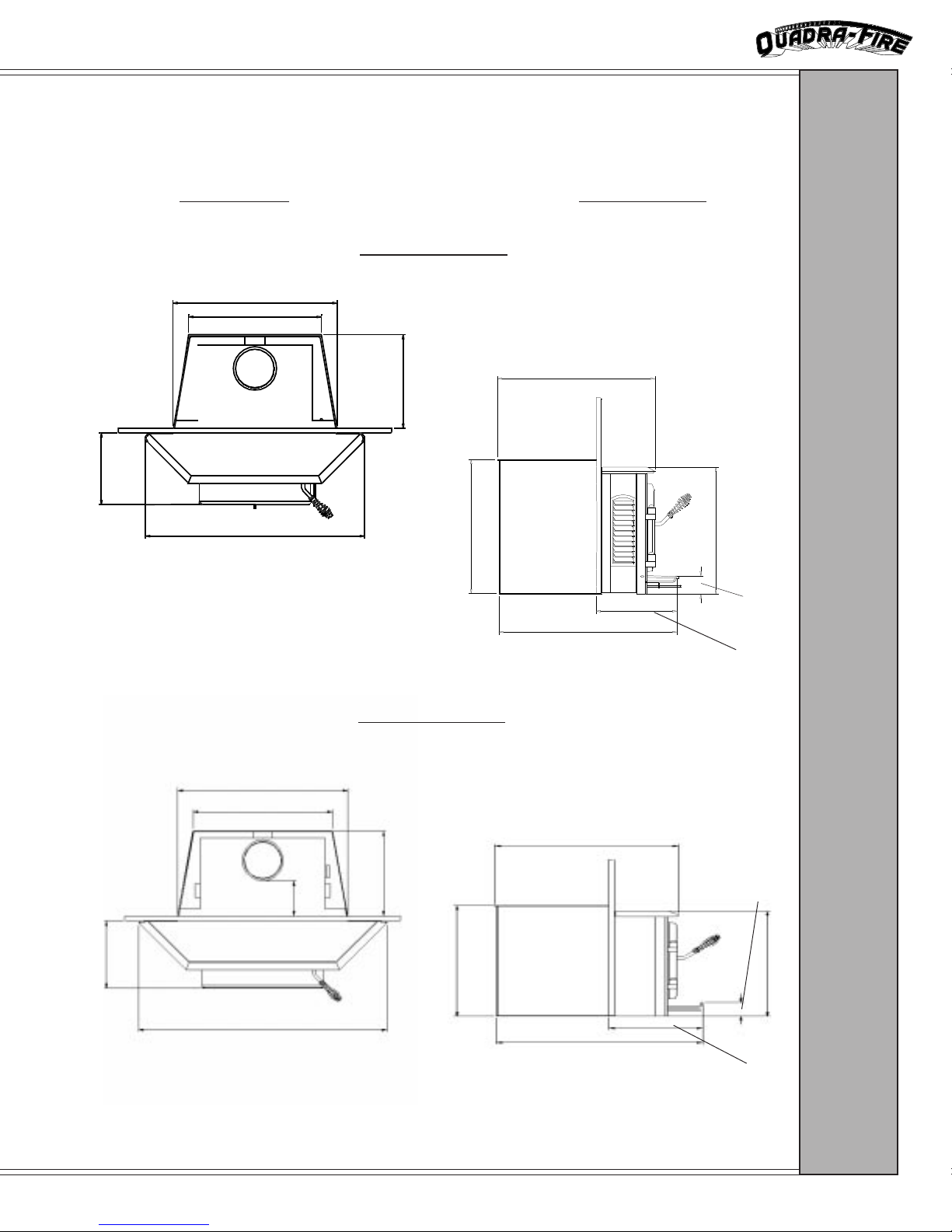

DIMENSIONS

MODEL 2100-I

SIDE VIEWTOP VIEW

10 15/16 (279 mm)

25 1/16 (637 mm)

20 1/4 (514 mm)

33 7/16 (850 mm)

14 1/14 (362 mm)

19 7/16 (495 mm)

MODEL 3100-I

DIMENSIONS

22 3/4 (578 mm)

18 3/8 (468 mm)

2 11/16 (69 mm)

25 3/4 (654 mm)

11 11/16 (297 mm)

27 1/4 (698 mm)

22 3/8 (583 mm)

5 3/4

10 15/16 (279 mm)

39 7/8 (1012 mm)

22 3/4 (576 mm)

2 11/16 (43 mm)

(152 mm)

13 13/16 (354 mm)

21 7/16 (546 mm)

25 9/16 (650 mm)

11 11/16 (295 mm)

20 7/16 (519 mm)

Page 5 March 1999

Page 6

2100-I & 3100-I FIREPLACE INSERT

2

2

2

2

2

2

2

2

2

2

2

2

2

2

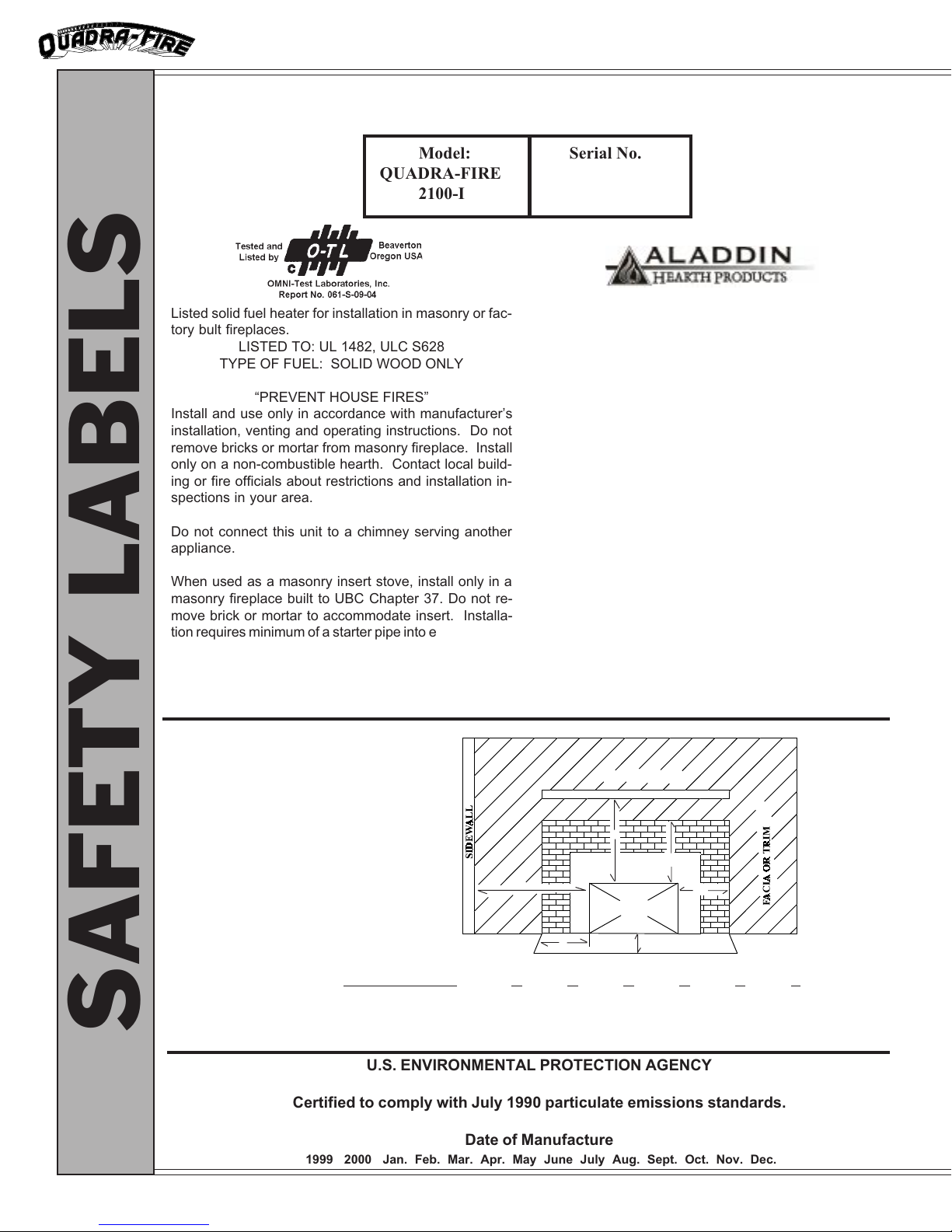

CONTACT YOUR LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION INSPECTION IN YOUR AREA

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

Model: Serial No.

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

QUADRA-FIRE

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

2100-I

23456789012345678901234567890121234567890123456789012345678901

23456789012345678901234567890121234567890123456789012345678901

MANUFACTURED BY:

Listed solid fuel heater for installation in masonry or factory bult fireplaces.

LISTED TO: UL 1482, ULC S628

TYPE OF FUEL: SOLID WOOD ONLY

PREVENT HOUSE FIRES

Install and use only in accordance with manufacturers

installation, venting and operating instructions. Do not

remove bricks or mortar from masonry fireplace. Install

only on a non-combustible hearth. Contact local building or fire officials about restrictions and installation inspections in your area.

Do not connect this unit to a chimney serving another

appliance.

When used as a masonry insert stove, install only in a

masonry fireplace built to UBC Chapter 37. Do not remove brick or mortar to accommodate insert. Installation requires minimum of a starter pipe into existing chimney with an airtight face seal.

Operate only with doors closed. Replace glass only

with 5mm ceramic available from your dealer.

Minimum Clearances to Combustible Materials (in inches)

Approved for installation and use in factory built zeroclearance fireplaces conforming to minimum fire

chamber specifications.

Components required for installation: positive or direct

flue connection assembly or listed vent liner. Inspect

and clean vent system frequently in accordance with

manufacturers instructions.

In Canada a full length S635 flue liner is required.

For use with solid wood fuel only. Do not use grate or

elevate fire. Build wood fire directly on hearth.

Route power cord away from unit. Do not route cord

over or under appliance.

DANGER: Risk of electrical shock. Disconnect power

supply before servicing.

Optional component:

Blower Assembly: Part #831-0911

Electrical Rating:

115 VAC, .6 Amps, 60 Hz.

MANTEL

Install insert with a mimimum of

26 clearance to combustible

sidewall, 10 to side and 14 to top

trim, 22 from top of insert to mantel. Floor protector must be 3/8

mimimum non-combustible material or equivalent, extending 16 in

front and 8 to both sides.

SAFETY LABELS

Certified to comply with July 1990 particulate emissions standards.

1999 2000 Jan. Feb. Mar. Apr. May June July Aug. Sept. Oct. Nov. Dec.

Page 6

B

C

A

D

INSERT

F

HEARTH EXTENSION

E

INSTALLATION A B C D E F

UNITED STATES 26 22 14 10 16 8

CANADA 32 27 14 12 16 8

815mm 685mm 355mm 305mm 405mm 200mm

U.S. ENVIRONMENTAL PROTECTION AGENCY

Date of Manufacture

March 1999

Page 7

2100-I & 3100-I FIREPLACE INSERT

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

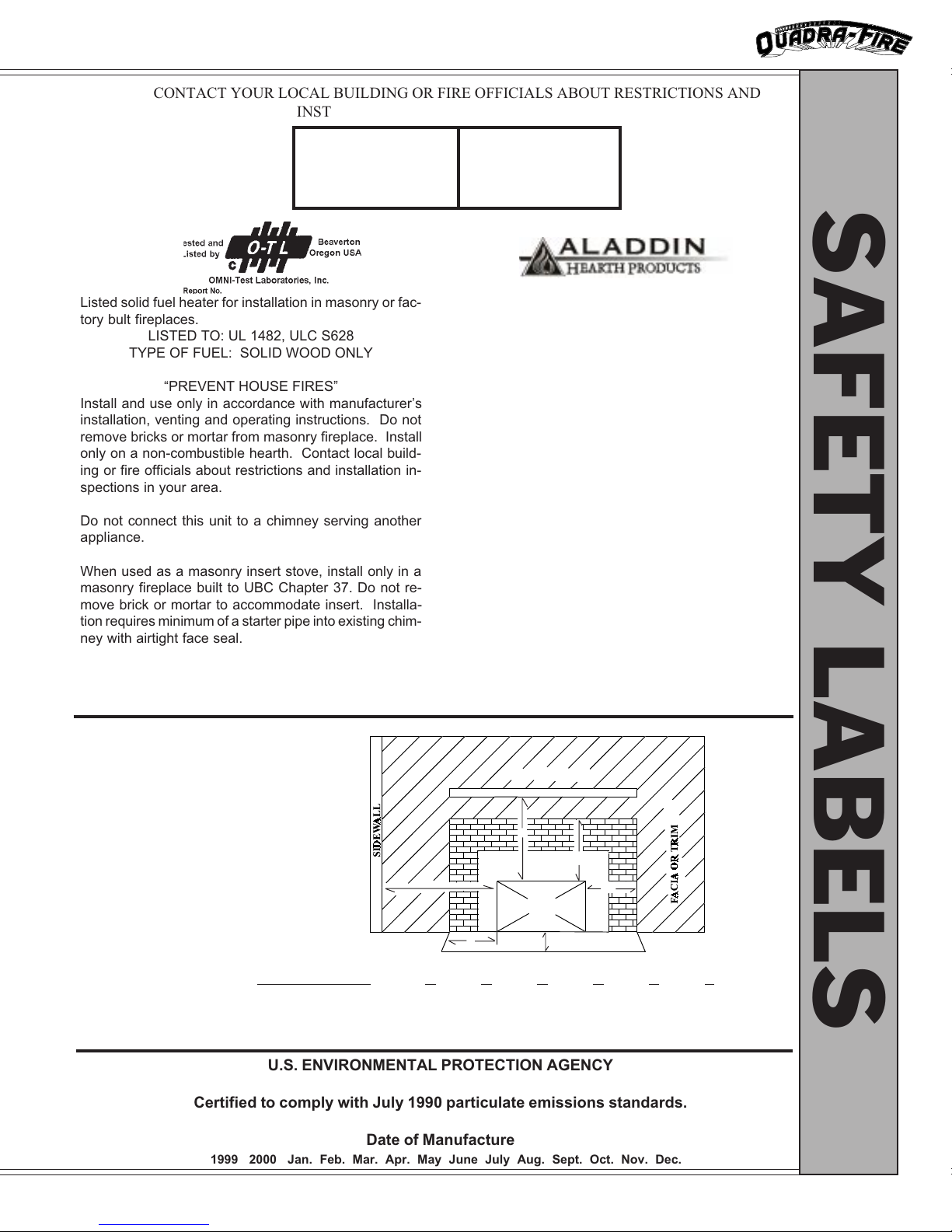

CONTACT YOUR LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION INSPECTION IN YOUR AREA

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

Model: Serial No.

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

QUADRA-FIRE

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

3100-I

2345678901234567890123456789012123456789012345678901234567890

2345678901234567890123456789012123456789012345678901234567890

MANUFACTURED BY:

SAFETY LABELS

Listed solid fuel heater for installation in masonry or factory bult fireplaces.

LISTED TO: UL 1482, ULC S628

TYPE OF FUEL: SOLID WOOD ONLY

PREVENT HOUSE FIRES

Install and use only in accordance with manufacturers

installation, venting and operating instructions. Do not

remove bricks or mortar from masonry fireplace. Install

only on a non-combustible hearth. Contact local building or fire officials about restrictions and installation inspections in your area.

Do not connect this unit to a chimney serving another

appliance.

When used as a masonry insert stove, install only in a

masonry fireplace built to UBC Chapter 37. Do not remove brick or mortar to accommodate insert. Installation requires minimum of a starter pipe into existing chimney with airtight face seal.

Operate only with doors closed. Replace glass only with

5mm ceramic available from your dealer.

Minimum Clearances to Combustible Materials (in inches)

Install insert with a mimimum of

32 clearance to combustible

sidewall, 10 to side and 14 to top

trim, 22 from top of insert to mantel. Floor protector must be 3/8

mimimum non-combustible material or equivalent, extending 16 in

front and 8 to both sides.

Approved for installation and use in factory built zeroclearance fireplaces conforming to minimum fire

chamber specifications.

Components required for installation: positive or direct

flue connection assembly or listed vent liner. Inspect

and clean vent system frequently in accordance with

manufacturers instructions.

In Canada a full length S635 flue liner is required.

For use with solid wood fuel only. Do not use grate or

elevate fire. Build wood fire directly on hearth.

Route power cord away from unit. Do not route cord

over or under appliance.

DANGER: Risk of electrical shock. Disconnect power

supply before servicing.

Optional component:

Blower Assembly: Part #831-1101

Electrical Rating:

115 VAC, .6 Amps, 60 Hz.

MANTEL

B

C

A

D

INSERT

INSTALLATION A B C D E F

UNITED STATES 32 22 14 10 16 8

CANADA 32 27 14 12 16 8

U.S. ENVIRONMENTAL PROTECTION AGENCY

Certified to comply with July 1990 particulate emissions standards.

1999 2000 Jan. Feb. Mar. Apr. May June July Aug. Sept. Oct. Nov. Dec.

Date of Manufacture

F

HEARTH EXTENSION

E

815mm 685mm 355mm 305mm 405mm 200mm

Page 7 March 1999

Page 8

2100-I & 3100-I FIREPLACE INSERT

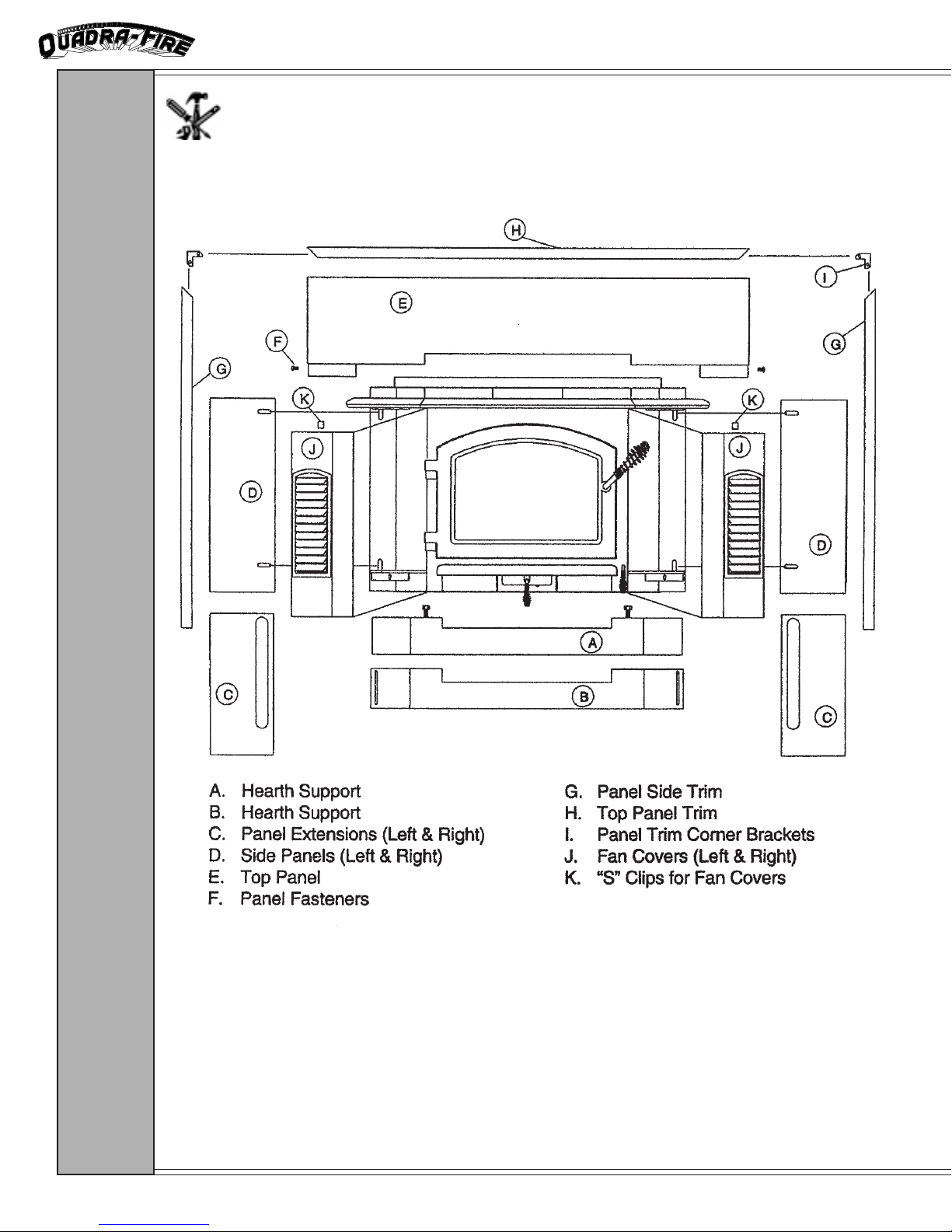

COMPONENT PARTS DIAGRAM

COMPONENTS

Page 8

March 1999

Page 9

2100-I & 3100-I FIREPLACE INSERT

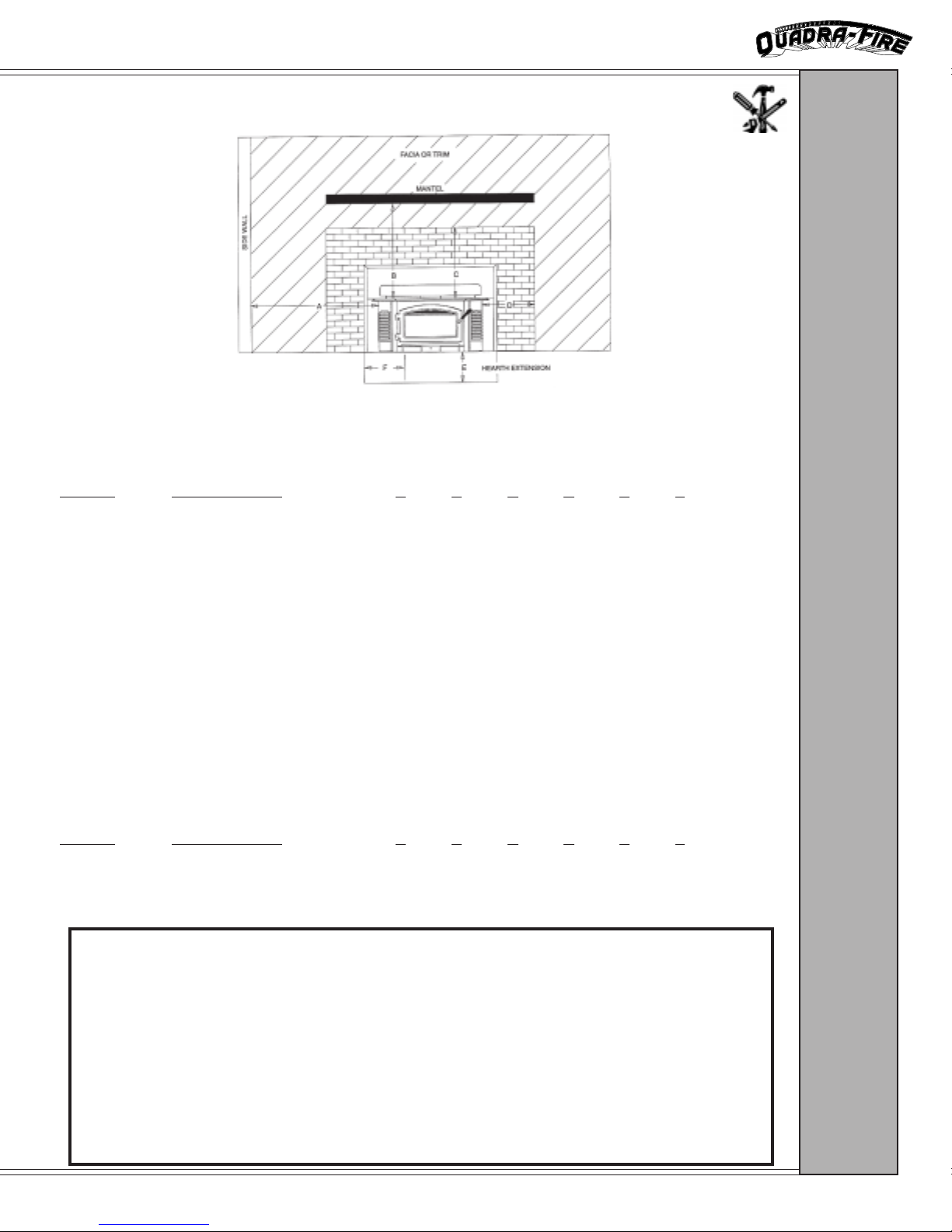

CLEARANCES TO COMBUSTIBLES

UNITED STATES INSTALLATION

MINIMUM CLEARANCES TO COMBUSTIBLES IN INCHES

MODEL INSTALLATION A B C D E F

2100-I Masonry or Heat Exchanger 26 22 14 10 16 8

Zero Clearance 26 22 14 10 16 8

3100-I Masonry or Heat Exchanger 32 22 14 10 16 8

Zero Clearance 32 22 14 10 16 8

CLEARANCES

NOTE: When installing into a masonry fireplace, the fireplace must be built to UBC Chapter 37

standards. Do not remove brick or mortar from masonry fireplace to accommodate insert.The

permanent metal warning plate label provided must be attached to the back of the fireplace stating the fireplace may have been altered to accomodate the insert and must be returned to original

condition for use as a conventional fireplace.

INSTALLATION IN CANADA

MINIMUM CLEARANCES TO COMBUSTIBLES

IN INCHES & MILLIMETERS

MODEL INSTALLATION A B C D E F

2100-I Masonry or Heat Exchanger 32 27 14 12 16 8

815mm 685mm 355mm 305mm 405mm 200mm

3100-I Masonry or Heat Exchanger 32 27 14 12 16 8

815mm 685mm 355mm 305mm 405mm 200mm

HEARTH REQUIREMENTS

There must be 3/8 minimum non-combustible material or equivalent extending 16 in

front of insert and 8 to both sides. If the hearth extension is lower than the fireplace

opening, the portion of the insert extending onto the hearth requires support. Manufacturer support kits can be ordered by the necessary adjustment size.

ADJUSTMENT 2100-I PART # 3100-I PART #

2 - 4 831-1370 831-1400

4 - 7 831-1380 831-1410

7 - 10 831-1390 831-1420

Page 9 March 1999

Page 10

2100-I & 3100-I FIREPLACE INSERT

INSTALLATION RECOMMENDATIONS

The Quadra-Fire 2100-I and 3100-I have met and surpassed the most stringent emissions

standards in the United States. The sophistication of the interior firebox design requires that a

proper draft be supplied by the chimney, therefore adherance to the following factors will enable

your stove to operate at its optimum capability:

REQUIRED

A minimum starter pipe reaching to the base of the existing chimney and an airtight face seal.

BETTER

Direct connection to the first flue liner in accordance with the requirements of the NFPA 211.

BEST

A complete relining of the chimney system with a six inch (6) diameter listed, stainless liner.

INSTALLATION IN CANADA

MASONRY, HEAT-EXCHANGER & FACTORY-BUILT

Whether installed in a masonry, heat-exchanger or factory-built fireplace, a

full chimney liner meeting ULC S635, CLASS III (stainless steel) must be

installed from the insert to the chimney top and securely attached to both.

Do not remove bricks or mortar from fireplace to accommodate insert.

The permanent metal warning label provided must be affixed to the back of

the fireplace stating that the fireplace may have been altered to accommodate the insert, and must be returned to original condition for use as a

conventional fireplace.

INSTALLATION

The face of the fireplace must be sealed to prevent room air passage into the

chimney cavity.

Circulating air chambers in factory-built fireplaces may not be blocked.

FIREPLACES

Page 10

March 1999

Page 11

2100-I & 3100-I FIREPLACE INSERT

GENERAL INSTALLATION PROCEDURE

Install liner, if required, for your chosen installation.

Attach metal warning plate to the back of the fireplace.

Set appliance on the hearth (See Hearth Requirements and Support Kits

information on page 9.)

Complete the vent connection required for your installation type.

Install optional blower, if purchased.

Install panel set. (See instructions on page 13)

Install trim. (See instructions on page 13)

Position unit into fireplace leaving width enough for fiberglass batt to be

inserted around face seal.

Work unit securely into the fireplace.

Install door handle. (See instructions on page 13)

Ensure that all labels are removed from glass prior to building first fire.

Ensure that gold plated surfaces are cleaned prior to building first fire.

(See instructions on page 22)

Read Operation Instructions found on pages 20-22.

INSTALLATION

UNPACKING AND USE OF LEVELING BOLTS

Your Quadra-Fire insert is secured to the pallet by means of two 1/2 x 6 bolts which

also serve as leveling bolts in the event that the hearth is higher than the fireplace floor. Follow

the procedures below for moving the insert from the pallet and use of the leveling bolts.

1. Remove 1/2 nuts from 1/2 x 6 bolts.

2. Bring 1/2 bolts up level to bottom of insert.

3. Position insert on hearth with rear of insert extending into fireplace opening.

4. Extend leveling bolts downward to level insert.

5. Make proper connection for desired venting technique.

Page 11 March 1999

Page 12

Available through your Quadra-Fire Dealer: Order Part #831-0911 for model 2100-I

BLOWER

ASSEMBLY

:

Tools Needed:

Large Phillips screwdriver

Pliers

2100-I & 3100-I FIREPLACE INSERT

BLOWER ASSEMBLY

(OPTIONAL PURCHASE ACCESSORY)

Order Part #831-1101 for model 3100-I

Parts Supplied: (2) Fan mounts/fan assemblies. (1) speed control, power cord/wire assembly.

(1 Set) Fan connector wires, must be high temperature wire. (1) Strain relief.

1. Remove fan covers.

2. Install fan mounts to outer wall with panel mounting screws.

3. Feed fan and motor wires up through large hole in floor.

NOTE: Power cord can be mounted on left or right side.

4. Connect white and black wires to fan motor terminals.

5. Feed #3 fan motor wires through smaller hole in bottom and across

to #2 fan motor.

6. Install strain relief onto power cord.

7. Using a pair of pliers, squeeze strain relief and push through large

hole in floor.

8. Plug in and test blower operation.

9. Replace screens. (Power cord comes out through opening in

bottom of screen.)

The blower speed control is pre-set at the factory. However, if you determine that an adjustment

is needed, follow these steps:

1. With the unit plugged in, turn the speed control knob to slow.

(Full clockwise.)

2. Use a small screwdriver to adjust the fan speed by turning the adjustment mechanism through the hole on the side of the speed control.

3. Adjust the speed so the fan runs slowly but does not stop. Turn clockwise to slow the fan and counterclockwise to increase the speed.

INSTALLATION

Page 12

March 1999

Page 13

2100-I & 3100-I FIREPLACE INSERT

INSTALLATION OF PANEL SET

Materials needed: Phillips Screwdriver and double sided tape or contact adhesive.

1. Remove four 1/4 - 20 screws from nuts attached to insert outer wall.

2. Slide side panels in front on insert outer wall, align horizontal and

vertical slots and install 1/4 - 20 screws (do not tighten).

3. Remove two 1/4 - 20 screws from top panel.

4. Attach top panel by means of two clips welded on the back side of panel.

5. Insert two 1/4 - 20 screws through holes in outer edges of side panels

into nuts welded inside top panel. Tighten.

6. Center the panels and tighten screws holding side panels.

7. Install screen covers.

8. Attach insulation strip to the outside edge of the backside of top and side

panels. Use double sided tape or a contact adhesive to hold insulation in

place.

INSTALLATION OF FACE TRIM PACKAGE

INSTALLATION:

(For use with part # 831-1150, Black Side Screens Only)

(TOP VIEW)

FIREBOX

PANEL

Press fit the trim between

face and decorative screen.

FAN

FACE

INSTALLATION OF DOOR HANDLE

DOOR HANDLE ASSEMBLY

SPRING HANDLE

PANEL, TRIM &

DOOR HANDLE

NOTE: SPRING HANDLE IS NOT

INCLUDED IN ASSEMBLY. MUST

BE ORDERED SEPARATELY.

SPRING HANDLE ORDER #832-0620

DOOR HANDLE

DOOR

KEY

WASHERS

LATCH CAM

NUT

Page 13 March 1999

Page 14

2100-I & 3100-I FIREPLACE INSERT

CHIMNEY REQUIREMENTS

To insure that insulation or any other combustible material does not contact the chimney,

a chimney inside the house must have at least two (2) inches of air space clearance around the

chimney. A chimney outside the house must have at least one (1) inch clearance to the combustible structure. Fire stops must be installed at the spaces where the chimney passes through floors

and/or ceilings. Refer to Figures 1 & 2 below. Canadian installations require a full re-line of

the chimney.

FIGURE 1

MINIMUM 1 INCH CLEARANCE

FROM EXTERIOR CHIMNEY TO

SHEATHING

FLOOR

(SECOND STORY)

MINIMUM 2 INCH CLEARANCE FROM

COMBUSTIBLE MATERIAL AND

INSULATION

NONCOMBUSTIBLE

FIRESTOPPING

MATERIAL

Firestopping

FLOOR

CEILING

CAULK

FIGURE 2

CHIMNEY

Page 14

CEILING

NONCOMBUSTIBLE FIRE-

STOPPING MATERIAL

March 1999

Page 15

2100-I & 3100-I FIREPLACE INSERT

A chimney must be the required height above the roof or other obstruction for safety

and for proper draft operation. The requirement is that the chimney must be at least three (3)

feet higher than the highest point where it passes through the roof, and at least two (2) feet

higher than the highest part of the roof or structure that is within ten (10) feet of the chimney,

measured horizontally. Refer to Figure 3 below.

FIGURE 3

AT

LEAST 2

AT LEAST

3 FEET

FEET

10 FEET

CHIMNEY

FIGURE 4

CHIMNEY HEIGHT

5/8 FIRECLAY

FLUE LINER

FLUE

CHIMNEY

WALL 4

(NOMINAL)

1/2 AIRSPACE

FOUNDATION

CHIMNEY TOP VIEW

Page 15 March 1999

Page 16

2100-I & 3100-I FIREPLACE INSERT

INSTALLATION OPTIONS

Please refer to:

Clearances to Combustibles on page 9.

Canadian Installation requirements on page 9 & 10.

Hearth Requirements and Support Kits on page 9.

MASONRY

FIREPLACE

:

1482 in all respects, and are approved to UL safety standards for installation and use within a

fireplace with a masonry chamber in accordance with NFPA No. 211, with or without a direct

flue collar connection. A starter pipe is required to reach to the bottom of the existing flue.

The Quadra-Fire 2100-I and 3100-I models conform with the UL Standard for Safety

1. Secure the fireplace damper in the open position. If this cannot be

2. Seal either the damper area around the chimney liner with a high

3. The chimney should be examined for cracks, loose mortar, and other

MASONRY FIREPLACE

USING DIRECT-CONNECT METHOD

accomplished, it will be necessary to remove the damper.

temperature sealant or the fireplace front with fiberglass batting.

signs of deterioration and blockage. The insert should not be installed

until it is determined that the chimney is safe for use. Since an oversized flue contributes to the accumulation of creosote, the size of the

flue should be checked to determine that it is not too large for the

insert. The chimney should also be checked to assure it meets the

minimum standard of the National Fire Protection Association

(NFPA) Standard 211. The following bullets list the more critical

requirements for a properly constructed chimney:

The masonry wall of the chimney, if brick or modular block, must be a

minimum of four (4) inches nominal thickness. A chimney of rubble

stone must be at least twelve (12) inches thick.

The chimney must have a fire clay flue liner (or equivalent) with a

minimum thickness of 5/8 and must be installed with refractory

mortar. An equivalent liner must be a listed chimney liner system or

other approved material.

A chimney inside the house must have at least two (2) inches of

clearance to the combustible structure. A chimney outside the house

must have at least one inch clearance to the combustible structure.

Fire stops must be installed at the spaces where the chimney passes

through floors and/or ceiling (See Figure 1 on page 14). In Canada,

a full reline is required.

INSTALLATION

Page 16

March 1999

Page 17

MASONRY CHIMNEY

FLUE TILE

2100-I & 3100-I FIREPLACE INSERT

INSTALLATION:

MANTEL

AIRTIGHT FACE SEAL

DAMPER AREA

SEAL DAMPER AREA OR FACE SEAL

FULL LISTED

LINER OPTION

DIRECT CONNECT

SEAL OPTION

MINIMUM STARTER

PIPE OPTION

FIREPLACE

MASONRY

SAMPLE INSTALLATION INTO MASONRY FIREPLACE

Page 17 March 1999

Page 18

METAL HEAT EXCHANGER MASONRY

The Quadra-Fire 2100-I and 3100-I models conform with the safety standard UL1482 in all respects and is approved to UL safety standards for installation and use within a

fireplace with masonry chamber, in accordance with NFPA No. 211, with or without a

HEAT

direct flue collar connection. A starter pipe is required into existing chimney.

SAMPLE INSTALLATION INTO METAL HEAT EXCHANGER

EXCHANGER

:

SHOSHO

SHO

SHOSHO

MANTEL

LISTED LINER

2100-I & 3100-I FIREPLACE INSERT

WING USE OF STWING USE OF ST

WING USE OF ST

WING USE OF STWING USE OF ST

ARAR

AR

ARAR

TER PTER P

TER P

TER PTER P

IPIP

IP

IPIP

EE

E

EE

Page 18

SEAL DAMPER AREA OR FACE SEAL

FACTORY BUILT FIREPLACE

(ZERO CLEARANCE)

The Quadra-Fire 2100-I and 3100-I are also listed to UL Standards for Safety 127, and

approved for installation and use in factory built zero clearance fireplaces conforming to the

following specifications:

2100-I 3100-I

Minimum Width of cavity opening: 29 (737mm) 32 (813mm)

Minimum Height: 21 (533mm) 23 (584mm)

Depth of the firebox may vary according to brand name, however the top rear corners of

the insert require a 2 (51mm) space between the insert and the side and back walls of the fireplace unit. Installation into larger sizes of factory built fireplaces of the above-named brands is

permissible.

The following modifications of factory built fireplaces are permissible. 1) Removal of

damper. 2) Removal of smoke shelf or baffle. 3) Removal of ember catches. 4) Removal of fire

INSTALLATION

grate. 5) Removal of viewing screen/curtain. 6) Removal of doors.

March 1999

Page 19

2100-I & 3100-I FIREPLACE INSERT

NOTE: Installation into fireplaces without a permit will void the listing.

The factory built chimney must be listed per UL 127 (US) or ULC S610 (Canada), and

meet the type HT requirements of UL 103 (US) or ULC S629M (Canada). Factory built fireplace

chimneys tested to UL 127-1998 are tested to the same criteria as UL 103 HT requirements. If the

chimney is not listed as meeting HT requirements (factory built fireplaces tested prior to 1988), a

full height listed chimney liner must be installed from the appliance flue collar to the chimney

top. The liner must meet type HT requirements (2100ºF) per UL 1777 (US) or ULC S635 (Canada).

The liner must be securely attached to the insert flue collar and the chimney top. To prevent room

air passage to the chimney cavity of the fireplace, seal either the damper area around the chimney

liner with high temperature sealant or the fireplace front with fiberglass batting.

The fireplace must not be altered, except that the damper may be removed to accommodate a direct-connect starter pipe or chimney liner, and external trim pieces which do not affect

the operation of the fireplace may be removed providing they can be stored on or within the

fireplace for reassembly if the insert is removed. The permanent metal warning label provided

must be attached to the back of the fireplace, stating that the fireplace may have been altered to

accommodate the insert, and must be returned to original condition for use as a conventional

fireplace.

The air flow within and around the fireplace shall not be altered by the installation of the

insert (no louvers or cooling air inlet or outlet ports blocked). The circulating air chambers (in a

steel fireplace liner or metal heat circulator) shall be blocked.

If the hearth extension is lower than the fireplace opening, the portion of the insert extending onto the hearth must be supported. Manufacturer designed support kits can be ordered by size

(see page 9).

Final approval of this installation type is contingent upon the authority having jurisdiction.

INSTALLATION:

MANTEL

LISTED

LINER

SEAL DAMPER AREA OR FACE SEAL

SAMPLE INSTALLATION INTO A FACTORY BUILT FIREPLACE

(ZERO CLEARANCE)

FACTORY BUILT

FIREPLACE

Page 19 March 1999

Page 20

2100-I & 3100-I FIREPLACE INSERT

OPERATION

WOOD SELECTION AND STORAGE

Burn only dry seasoned wood. Dry, well-seasoned wood will not only minimize the

chance of creosote formation but will give you the most efficient heat output. Even dry wood

contains at least 15% moisture by weight and should be burned hot enough to keep the chimney

high enough to maintain particulate (smoke) burning. Burning unseasoned wood of any variety

defeats the stoves efficiency.

Dead wood lying on the forest floor should be considered wet, and requires full seasoning

time. Standing wood can be considered to be about two-thirds seasoned. Wood is dry enough to

burn if the ends of the logs have cracks radiating in all directions from the center. If your wood

sizzles in the fire, even though the surface is dry, it may not be fully cured.

Drying time can be reduced by splitting wood prior to storage. Since the majority of

drying occurs through the cut ends rather than the sides, stack the wood so both ends of each piece

are exposed to air. Store wood under cover, such as in a shed, or covered with a tarp, plastic,

tarpaper, sheets of scrap plywood, etc.

OVERFIRING

Do not overfire. Overfiring can result in crazing, an effect causing a white, non-removable film to be deposited on the inside of the glass. Using flammable liquids or too much wood,

or burning trash in the insert, may result in overfiring. If the chimney connector or insert glows

red, or worse, white, the insert is overfired. This condition may ignite creosote in the chimney,

possibly causing a house fire. If any part of the insert starts to glow, you are in an overfire

situation. If you overfire, immediately close the insert dampers and door, if open, to reduce the air

supply to the fire. Overfiring your insert voids your warranty.

BUILDING A FIRE

NOTE: Remove all labels from glass front prior to lighting the first fire.

There are many ways to build a fire. The basic principle is to light easily ignitable tinder

or paper, which ignites the fast-burning kindling, which in turn ignites the slow burning firewood. Here is one method that works well:

1. Ensure that no matches or other combustibles are in the immediate area of the insert, that the

room is adequately ventilated, and the flue is unobstructed.

OPERATION

2. Open primary and secondary air controls fully.

3. Place several wads of crushed paper on the firebox floor.

4. Lay small dry sticks of kindling on top.

5. Light the wadded paper in the insert. Never light or rekindle insert with kerosene, gasoline,

or charcoal lighter fluid; results can be fatal.

6. Once kindling is burning quickly, add several full length logs three or four inches in diameter. Be careful not to smother the fire. Stack the pieces of wood carefully, near enough to

keep each other hot, but far enough away to allow adequate air flow between them. Large logs

burn slowly, holding a fire longer. Small logs burn fast and hot, giving quick heat.

7. Adjust the primary and secondary air controls, maintaining flames above the fuel. The

more you close down the controls, the lower and slower the fire will burn. The more you open

Page 20

March 1999

Page 21

2100-I & 3100-I FIREPLACE INSERT

the controls the more heat will be produced. Remember: PUSH IN air controls to OPEN for

ventilation, PULL OUT air controls to CLOSE ventilation.

As long as there are hot coals, repeating steps 6 and 7 will maintain a continuous fire.

NOTE: The special high temperature finish paint applied to the insert will cure as your insert

heats. You will notice an odor and perhaps see some vapor rise from the insert surface, this is

normal. We recommend that you open a window until the odor dissipates and the paint is

cured.

OPERATING TIPS

1. When loading the insert leave both controls open until the new wood load is burning well

enough to maintain flames above the fuel.

2. Regulate the heat output by using the secondary air control (located in the center of the insert

under the ash catcher). The primary air control, on the right of insert, is mainly for initial startup, reloading, or high burns.

3. Heat output settings: To obtain the following desired heat output setting, first follow step 1,

above. Then follow the Primary and Secondary air control openings as described below:

HIGH BURN RATE

Fully open both controls by pushing in completely. It is especially important to fully

open both controls when reloading the insert as failure to do so could result in excessive emissions, also referred to as opacity.

OPERATION

MEDIUM BURN RATE

After a wood load has been burning on high for 5 to 15 minutes, or longer for very large

pieces, close the primary air control (located on the right side of the insert) by pulling it out.

Leave the secondary air control (under the ash catcher) open (pushed in).

LOW BURN RATE

After a wood load has been burning on high for 5 to 15 minutes, or longer for very large

pieces, close the primary air control. Then gradually close down the secondary air control by

pulling out. Ensure that flames are maintained in the insert. It is very important to maintain

flames in your insert during the first few hours of a low burn to avoid excessive air pollution.

OPACITY

Opacity is the measure of how clean your insert is burning and is measured in percentages. An opacity of 100% in the smoke column from a chimney will totally obscure an object.

Whereas 0% opacity means that no smoke column can be seen. A periodic check of the opacity

emitted from your chimney will enable you to burn your insert as smoke free as possible.

SUMMARY OF OPERATING INSTRUCTIONS

BTU/HR. Primary 2100-I Secondary 3100-I

Below 10,000 Closed after 5 min. Pull to stop Pull to stop

10-15,000 Closed after 5 min. 1 3/8 - 1 1/2 Open 7/8 - 1 1/8 Open

15-30,000 Closed after 5 min. 7/8 - 2 1/8 Open 1 5/8 - 1 7/8 Open

Max. Heat Full Open Full Open Full Open

Page 21 March 1999

Page 22

2100-I & 3100-I FIREPLACE INSERT

FAN OPERATING INSTRUCTIONS

Follow these instructions if your Quadra-Fire insert is equipped with a fan:

1. Initial (cold) startup: Leave fan off until your insert is hot and a good coal bed is

established, approximately 30 minutes after fuel is lit.

2. High Burn Setting: The fan may be left on throughout the burn.

3. Medium Burn Setting: The fan should be left off until a good burn is established, then

turned on a medium or high rate.

4. Low burn Setting: The fan tends to cool the insert. Leave fan off until the burn is well

established. Then if you wish, turn the fan on at a low rate. Too high a fan setting with

a low burn rate may adversely affect emissions.

5. The fan is equipped with a rheostat. The highest fan speed is obtained by turning the

rheostat on, then adjusting back towards OFF as far as possible without turning the fan

off. For a low fan speed, turn the control knob clockwise as far as possible.

MAINTENANCE

CARE AND CLEANING OF GOLD PLATED SURFACES

IMPORTANT: You must clean all the fingerprints and oils from the 24K gold plated

surfaces before firing the insert for the first time. Use warm soapy water and a soft rag, glass

cleaner and a paper towel, or vinegar and a paper towel to remove the oils. DO NOT use abrasive

cleaners! If not cleaned properly prior to lighting the first fire, the oils can cause permanent

stains. The gold plating will be cured upon firing of the insert and oils will no longer affect the

finish. Subsequently, little maintenance is then required. Wipe clean as needed with a soft towel.

CARE AND CLEANING OF GLASS

NOTE: Remove all labels from glass prior to lighting the first fire.

Quadra-Fire stoves are equipped with Pyroceram II super heat resistant glass which can

only be broken by impact or misuse. Do not slam stove door or impact the glass. When closing

door, make sure that logs do not protrude against glass. The glass is coated with a thin layer of

infra-red reflective material which cannot be washed off and does not wear out. When the glass

is cool it has a rainbow effect. Clean glass with any non-abrasive glass cleaner as abrasive

cleaners may scratch and cause glass to crack. Inspect glass regularly. If you find a crack or

break, immediately put fire out and return door to your dealer for replacement of glass before

further use. Do not substitute materials for glass replacement.

MAINTENANCE

1. Remove door from stove and lay on a padded flat surface.

2. Remove glass tabs and screws with a Phillips screwdriver.

3. Lift glass frame pieces and glass out of the door frame.

4. Lay new glass with fiberglass tape around it into door frame making sure the Quadra-Fire

logo reads correctly to the outside.

Page 22

GLASS REPLACEMENT INSTRUCTIONS

March 1999

Page 23

2100-I & 3100-I FIREPLACE INSERT

5. Place glass frame pieces over the fiberglass tape on the edges of the glass. Be sure glass

is centered in the opening (i.e. same space top and bottom, left and right).

6. Reinstall screws and glass tabs tightly enough to hold frame and glass in place.

7. Check again for centering of glass in door frame and give all screws a final tightening.

GLASS

DOOR CROSS SECTION

FIBERGLASS TAPE

DOOR GASKET

GLASS TAB

GLASS

GLASS

CHIMNEY

When wood is burned slowly it produces tar and other organic vapors which combine

with expelled moisture, which in turn forms creosote. These creosote vapors condense in the

relatively cool chimney flue when a fire is newly started, or from a slowly burning fire, and

accumulate on the flue lining of the chimney.

A build up of creosote can then be ignited by sparks rising up the chimney. When ignited,

this situation makes an extremely hot fire which may damage the chimney and even destroy your

home. Therefore it is extremely important that this residue is removed at regular intervals, usually once a year depending on your burning habits, to prevent the occurance of a chimney fire. It

is highly recommended that you contact a professional chimney cleaner for this area of maintenance.

If your type of installation involves a full re-line of the chimney, it will be necessary to

either remove the baffle from the insert, or remove the insert from the fireplace and disconnect

the vent prior to cleaning the chimney. Refer to pages 24-25 in this manual for instructions on

Baffle Removal.

If your type of installation is direct connect within a masonry chimney, the insert will

need to be pulled out from the fireplace and disconnected from the flue prior to cleaning the

chimney. The creosote can either be caught in a large garbage bag secured to the pipe or swept

MAINTENANCE

Remove cold ashes (not hot) from the insert at regular intervals, depending on your usage, by shoveling them into a metal container with a tight-fitting lid. Always treat ashes as if they

contain hot coals and store the container on a non-combustible floor away from combustible

material pending final disposal.

The firebox of your Quadra-Fire insert is

lined with high quality firebrick which has exceptional insulating properties. There is no need

for a grate, simply build a fire on the firebox of

your insert.

ASH REMOVAL

FIREBRICK

2100-I

3100-I

BRICK PATTERNS

Page 23 March 1999

Page 24

2100-I & 3100-I FIREPLACE INSERT

BAFFLE REMOVAL & INSTALLATION

PLEASE NOTE:

Baffles in Quadra-Fire stoves are heavy. The 2100-I baffle weighs 25 lbs. The

3100-I baffle weighs 29 lbs. Moving the baffle around inside the stove takes strength

and patience. Removing hardware exposed to combustion processes can be frustrating.

Please read the following instructions thoroughly before proceeding.

REMOVAL &

Note: The illustrations shown in this section depict the freestanding models. However, the

procedures for removing and installing the baffles are the same for the 2100-I and 3100-I

inserts.

RE-INSTALLATION

1. Remove all ash from the firebox

and extinguish all hot embers before

disposal.

2. Remove the Kaowool blanket

from above the baffle.

3. Remove the firebrick from the

sides of the stove. See Figure 1.

FIGURE 1

4. Soak the secondary combustion

tube retainer bolts, on the secondary

air channel under the end of each

tube, with penetrating oil for at least

15 minutes. Use a 3/16 Allen

Wrench to remove the bolts.

BAFFLE:

See Figure 2.

Page 24

FIGURE 2

March 1999

Page 25

2100-I & 3100-I FIREPLACE INSERT

5. To remove the secondary combustion tubes, slide them to one side until

one end is out of its hole. Then, while

lifting that end of the baffle plate, pull

the tube up over the secondary air channel and out of the hole at its other end.

See Figure 3

Note: When replacing the second-

ary tubes on the 3100-I, the tube with

the larger holes is installed in front.

6. To remove the baffle plate, use both

hands to lift it off of the alignment pin

at the center rear. One edge of the bent

baffle front will have a diagonal cut.

Tilt this side up as you slide the baffle

towards that side until the other side

clears its shelf and the baffle can be

lowered. See Figure 4.

FIGURE 3

BAFFLE:

TUBES

PIN

FIGURE 4

7. Keep the baffle tilted as you lift it

out the door. See Figure 5.

8. To install the baffle, reverse Steps 1

through 7. The hole in the baffle must

be on its alignment pin on the rear shelf.

See Figure 6.

FIGURE 6

FIGURE 5

ALIGNMENT

PIN

RE-INSTALLATION

REMOVAL &

Page 25 March 1999

Page 26

2100-I & 3100-I FIREPLACE INSERT

AIR QUALITY AND YOUR QUADRA-FIRE INSERT

In recent years there has been an increasing concern about the quality of our air. Much of the blame for

poor air quality has been placed on the burning of wood for home heating. In order to improve this situation we at

Quadra-Fire have developed cleaner burning inserts that surpass the stringent requirements for emissions established by our governing agencies.

PROPER OPERATION AND MAINTENANCE GIVES YOU MORE HEAT FROM YOUR FUEL . . .

Properly operated and maintained, your 2100-I or 3100-I wood burning insert will obtain the peak efficiency and lowest emissions possible, resulting in better air quality for your community and more heat output per

pound of wood. Improper operation and maintenance may cause any wood burning unit to release more particulate, adversely affecting the environment.

THE STORY OF THE THREE BURNING STAGES . . .

It helps to know a little about the actual burn process, what our Lab at AHP refers to as pyro physics, in

order to understand what is happening inside the firebox. This process entails three discernible burning stages.

The first stage is called the kindling stage. During this stage the fuel reaches the boiling temperature of water,

212°F, evaporating the moisture found to some degree in all wood.

Because the process takes heat from the insert during this initial drying stage, each new load of wood

reduces the chances for a good, clean burn. For this reason it is always best to burn dry, seasoned firewood, and

operate the controls properly. The control on the right side of your insert is called the primary control, and is used

primarily during this first kindling stage of burning, or later to activate a secondary stage to achieve a maximum

burn rate. Opening this control will enable the insert to operate at a higher burn setting which is necessary to

quickly ignite the fuel.

During the secondary stage, the wood gives off flammable gases which burn above the fuel with bright

flames. These flames above the fuel must be maintained until the third stage to insure proper burning. During this

stage you may adjust your insert for a low burn rate. To achieve a low burn rate it is necessary to close down the

air while still maintaining some flames. If the flames tend to go out, the setting is too low. The secondary control,

located in the center of the insert beneath the ash catcher, will assist you in adjusting the insert for a low burn rate.

The third stage of burning is the charcoal stage. This happens when the flammable gases have been

burned and the charcoal remains. The coals burning with hot blue flames is a naturally clean portion of the burn.

It is very important to reload your insert while enough lively hot coals remain in order to provide the amount of heat

needed to dry and rekindle the next load of wood. Open up both controls for a short while before reloading to liven

up the coal bed. You should also break up any large chunks and distribute the coals so the new wood is laid on hot

coals. Leave both controls open until the new wood load is burning well enough to maintain the secondary stage of

burning and then set controls to your desired heat output setting. (See Summary of Operating Instructions box on

page 21.)

Primary control = Primary Air System : The primary combustion air enters at the rear of the firebox through the

primary air tubes. This air supply is controlled by the push rod located at the front right side of the insert. For

maximum burn rates (more heat) push rod in, for minimum burn rates (less heat) pull rod out.

Secondary control = Secondary Air System : The secondary air enters at the upper front of the firebox near the top

AIR QUALITY

of the glass door. This preheated air supplies the necessary fresh oxygen to mix with the unburned gases, helping

to create secondary, tertiary and quaternary combustion. This air is regulated by the push rod beneath the ash

catcher. For more secondary air (more heat), push rod in. For less secondary air (less heat), pull rod out.

Pulling either control towards you closes off the air available to the insert in that area. Pushing either

control opens it, allowing air circulation to the area. A good analogy to remember for this procedure is the gas

pedal on your car. Pushing in the gas pedal makes the engine run faster. Letting off (pulling the control back)

makes the car run slower.

Page 26

MORE ABOUT THOSE CONTROLS . . .

IN OTHER WORDS . . .

March 1999

Page 27

2100-I & 3100-I FIREPLACE INSERT

North Americas Best

Lifetime Warranty

Aladdin Hearth Products, warrants their wood heating appliances to the original purchaser for the lifetime of the appliance, to be free

from defects in material and workmanship. This warranty gives you specific legal rights; you may have other rights which may vary

from state to state.

This limited Lifetime Warranty covers items such as, but not limited to, combustion chambers, doors, gold plating, steel baffles, manifold tubes, ash removal systems, and glass damaged by thermal breakage.

All parts to be replaced must be returned to an authorized Aladdin Hearth Products dealer at purchasers expense for inspection and

approval by Aladdin Hearth Products prior to repair or replacement. No repair or replacement costs will be honored without approval of

Aladdin Hearth Products.

WARRANTY

This new Quadra-Fire product must be installed by a competent, authorized service contractor. It must be installed and operated at all

times in accordance with the Installation and Operating Instructions in this manual, as well as any applicable local and national codes.

Any alteration, willful abuse, accident, or misuse of the product shall void this warranty.

Any installation, construction, transportation, or other related costs or expenses arising from defective part(s), repair, replacement, etc.,

will not be covered by this warranty, nor will Aladdin Hearth Products assume responsibility for them. Further, Aladdin Hearth

Products will not be responsible for any incidental, indirect, or consequential damages, except as provided by law.

All electrical components such as, but not limited, to blowers, wiring, speed controls, and thermodisc switches are covered by Aladdins

one year warranty program.

Aladdin Hearth Products will not be responsible for any alteration to the unit which causes sooting that results in damage to the interior

or exterior of the building in which this appliance is installed.

This warranty is void if the stove has been operated in atmospheres contaminated by chlorine, fluorine, or other damaging chemicals, of

if the stove is subjected to prolonged periods of dampness or condensation, or there is any damage to the stove or other components due

to water or weather damage which is the result of, but not limited to, improper chimney or venting installation.

This limited Lifetime Warranty does not extend to or include paint, door gasketing, glass gasketing, firebrick, kaowool or other ceramic

insulating materials. It does not cover installation or operational-related problems such as overfiring, use of corrosive driftwood,

downdrafts or spillage caused by environmental conditions, nearby trees, buildings, hilltops, mountains, inadequate venting or ventilation,

excessive offsets, or negative air pressures caused by mechanical systems such as furnaces, fans, clothes dryers, etc.

This limited Lifetime Warranty does not apply to venting components, hearth components or other accessories used in conjunction with

the installation of this product not manufactured by Aladdin Hearth Products.

This limited Lifetime Warranty is effective on all wood stoves sold after September 1, 1996, and supersedes any and all warranties

currently in existence.

This warranty is not valid unless the warranty registration card has been properly completed in full and returned within 10 days from the

date of purchase.

IMPORTANT--

Copyright Aladdin Hearth Products, September 1997 (832-3060)

Page 27 March 1999

Page 28

2100-I & 3100-I FIREPLACE INSERT

OWNERS MANUAL

Part #832-0520

Loading...

Loading...