SX 2

TM

Film Processor

Operation Manual

English

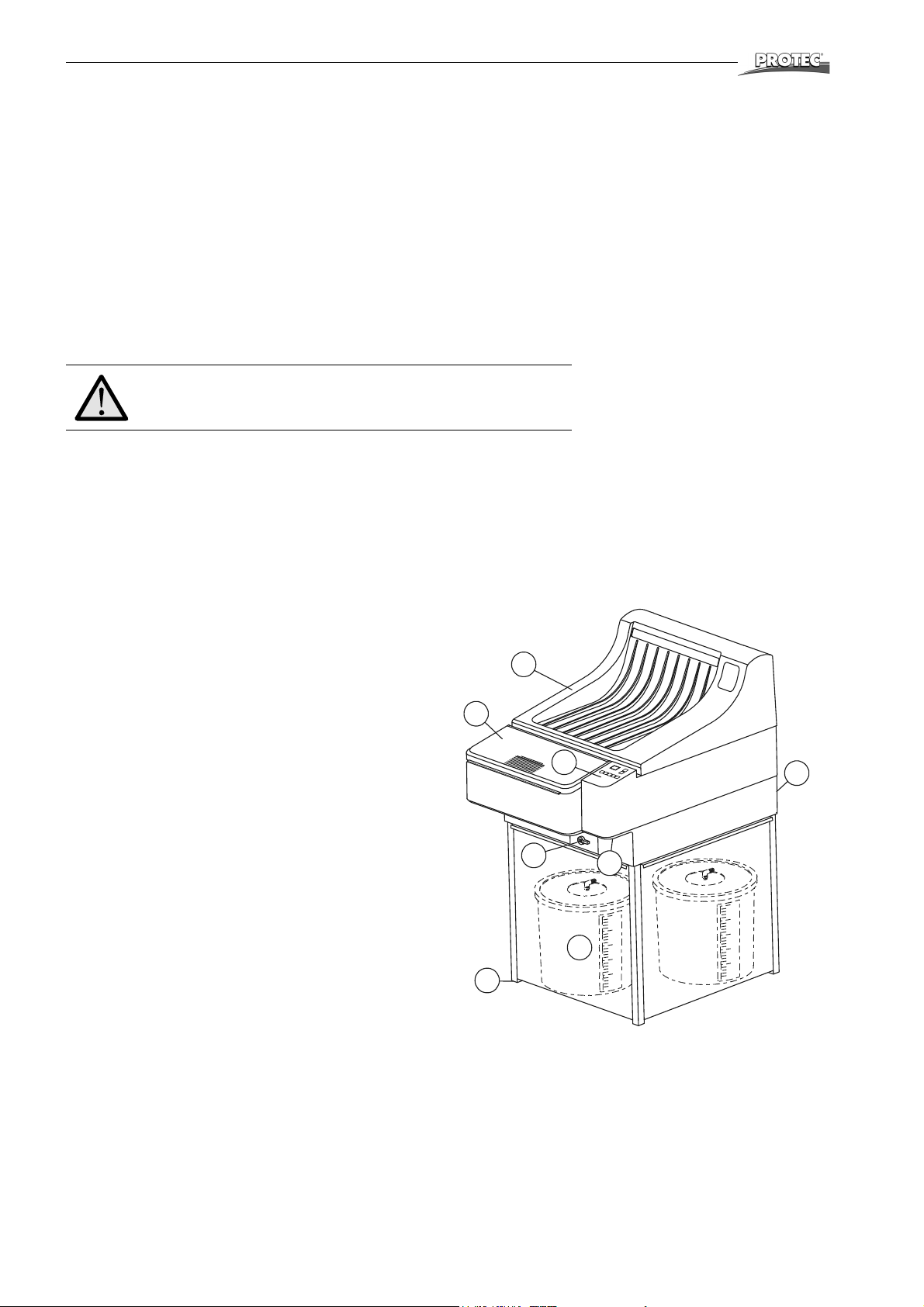

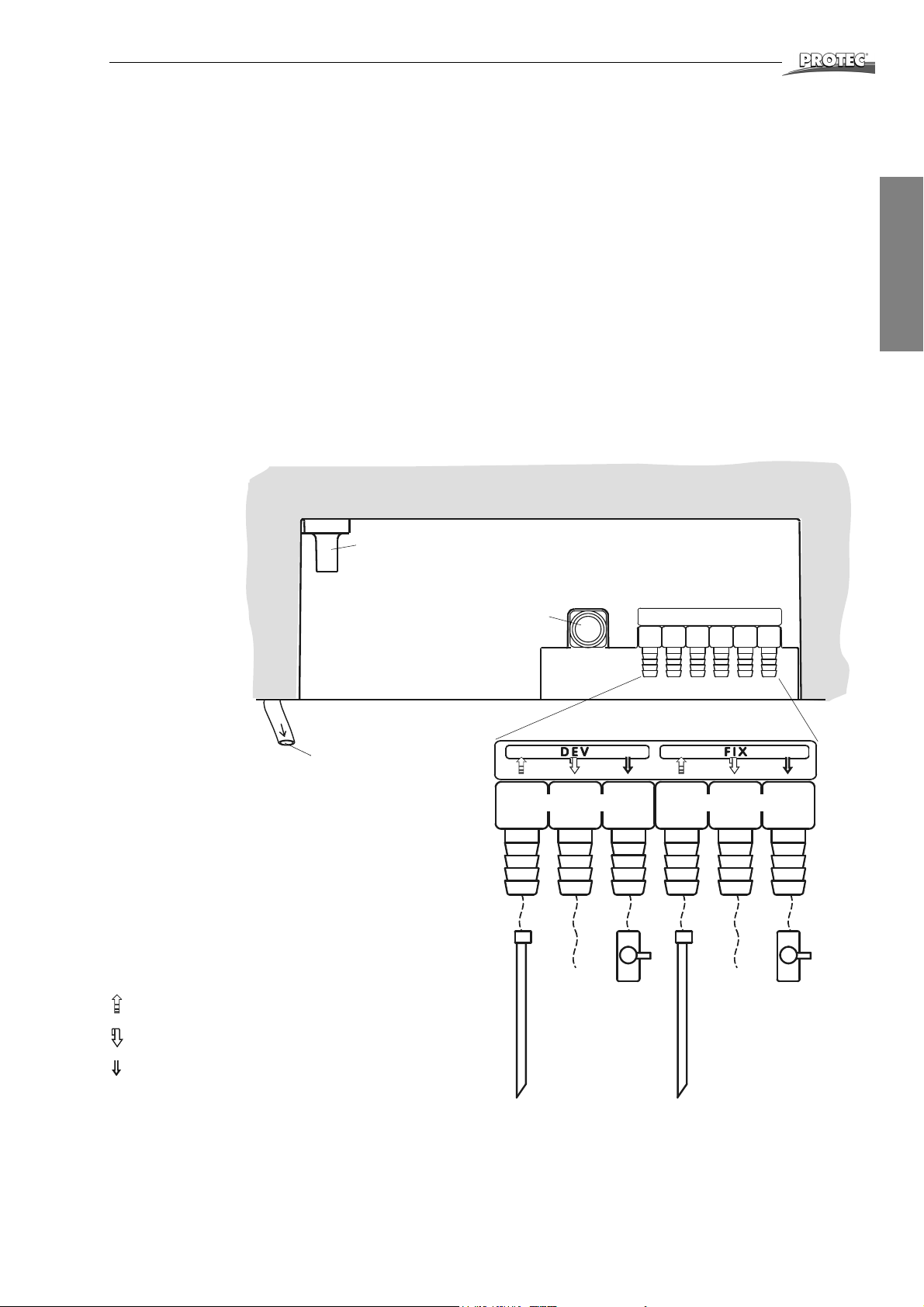

Depending on model type the Compact 2 has either an open stand or like shown here a closed

cabinet.

PROTEC® Medizintechnik GmbH & Co. KG

Lichtenberger Straße 35, D-71720 Oberstenfeld, Germany

Telephone: +49-7062-9255-0 e-mail: service@protec-med.com

Machine No.:

Type:

Date of installation:

Issued: 05-2006/2.9

Subject to technical alterations

EU-Declaration of Conformity

EU-Declaration of Conformity

PROTEC® Medizintechnik declares, that the product

Description:

COMPACT 2

TM

®

Machine type:

Model no.

conforms to the following harmonized standards:

Safety:

EMC:

according to the regulations of:

X-Ray-Film Processor

117x-y-0000

x is a number between 0 and 9, y is a number between 1 and 9

IEC 61010-1:2001 + A1:92 + A2:95; DIN 1988 T4:12/1988; UL 3101-1; CSA 22.2-1010-1

EN 50081 Part 1, 03/1993; EN 50082 Part 1, 03/1993

• the Medical Device Directive 93/42/EEC “class 1”,

• the Low Voltage Directive 73/23/EEC and the

• EMC Directive 89/336/EG

PROTEC® Medizintechnik GmbH & Co. KG, Lichtenberger Straße 35, D-71720 Oberstenfeld, Germany

Supplementary

Guidelines:

Place and date of issue:

Oberstenfeld, 23. May 2006, Jochen Krupp (Technical Manager Analogue Systems)

• DIMDI: DE / 0000042967

• WEEE: DE 55471807

2 COMPACT 2

TM

EU-Declaration of Conformity

Introduction .......................................................................................................... 3

Technical Specifications ..................................................................................... 4

Safety Instructions............................................................................................... 5

Installation ............................................................................................................ 6

Initial Operation.................................................................................................... 8

Mode of Operation ............................................................................................... 9

Operation

Short Overview and Control Panel .............................................................. 10

Switching the Machine On........................................................................... 12

Automatic Mode........................................................................................... 12

Anticrystallisation/Automatic Replenishment ............................................... 12

Working Parameters.................................................................................... 13

Dimmer Function of Display ........................................................................ 15

Machine Cover Safety Disconnection.......................................................... 15

Autofill Function ........................................................................................... 16

Manual Mode............................................................................................... 16

Use of Memory Function ............................................................................. 17

Lock Function .............................................................................................. 18

Stop Film Transport ..................................................................................... 18

Infrared Sensitive Materials ......................................................................... 18

Rollfilms and Paper Films............................................................................ 18

Automatic Cooling Function......................................................................... 18

Removal and Installation of Dryer Rack (two-parts) .................................... 19

Care

Daily Care.................................................................................................... 20

Weekly Care ................................................................................................ 20

Thorough Cleaning ...................................................................................... 21

Maintenance / Disposal ..................................................................................... 22

Problems and Solutions

Advise on Film Defects................................................................................ 25

Advice on Machine Errors ........................................................................... 26

Error messages ........................................................................................... 28

Accessories ........................................................................................................ 30

Service Manual as appendix see page 33

Additional Information for the Version Compact 2 NDT................................. 57

Copyright

®

© 2004 by PROTEC

the limitation by the copyright law, needs written authorization by PROTEC

intechnik.

Information on Liability

This manual has been checked for correctness. The instructions and specifications

were correct at the time it was published. Future models may have modifications

without prior notice. PROTEC® Medizintechnik does not take responsibility for dam-

age caused direct or indirect by error, omission or non-conformity of the manual.

Medizintechnik. All rights reserved. Any reproduction, out of

®

Mediz-

®

English

Introduction

You are the proud owner of a modern, automatic processor. Due to the precision

roller transport system, both sheet and roll films can be processed. The automatic

film registration is activated immediately when a film is fed in. The film materials are

developed, fixed, rinsed and dried. With the easy to operate micro-processor, the

processing conditions can be adjusted to suit the various film and chemical types.

The developing solutions are temperature-regulated, circulated and automatically

replenished.

This Operation Manual contains the most important instructions for installation, operation and servicing of this machine. Please read the provided information carefully to ensure reliable and satisfactory operation of your film processor.

COMPACT 2

TM

3

Technical Specifications

Technical Specifications

®

Film transport:

Film formats:

Processing capactiy:

Process time:

Linear speed:

Developing time:

Tank capacities:

Circulation system:

Replenishment:

Continuous roller transport system

Sheet and roll films up to 45.1 cm (17.7 ) width;

Roll films with leader from 70 mm (2.8'') width;

smallest film format 10x10 cm (4x4''). In processor

type 1191 roll films in cassettes can also be processed. Cassette box (LxWxH): 53x19x16 cm

(20.6x7.5x6.3'').

232 films 24x30 cm (10x12“) per hour (standard

model, film fed in crosswise, at 90 s)

1-5 min.; in 0.1-min. steps adjustable.

30-151 cm/min., depending on selected process

time.

14-71 s, depending on selected process time.

12.5 l developer, 12 l fixer,13 l water.

Developer and fixer are continiuously circulated by

a circulation pump.

Automatic by film surface measurement in relation

to processed film; quantity adjustable; time replenishment can be activated.

Developer temperature:

Fixer temperature:

Dryer temperature:

Water connection:

Water consumption:

Drain capacity:

Noise level:

Heat emission:

Environmental conditions:

Adjustable 28-40 °C (82.4-104 °F).

Adjusted to developer temperature by heat

exchanger.

Adjustable 35-70 °C (95-158°F), achievable temperature depends on mains voltage..

Permissible water pressure 2 - 10 bar (29 - 145

psi), permissible water temperature 5 - 30 °C

(41 - 86 °F).

1.9 litre per minute when processing.

11 litres per minute

Less than 59 dB(A).

During processing approx. 1.5 kJ/s.

1 Temperature 18- 40 °C (51,6 - 104 °F), venti-

lated room, room temperature should be lower

than set bath temperature.

2 Relative humidity lower than 80 % up to 31 °C

(88 °F), linearly decreasing to 50 % at 40 °C

(104 °F)

3 Height above sea level less than 2000 m

(6666 ft.)

4 Indoor use

4 COMPACT 2

TM

Technical Specifications

®

Pollution degree:

System protection:

Electrical connections:

Type 119x-1

Type 119x-2-y000:

Type 119x-7-y000:

Power consumption:

Weight (processor):

Dimensions (LxWxH):

Floor space required:

-y000:

2

IP 20

220 - 240 V~, 10 A, 50 Hz

220 - 240 V~, 14 A, 60 Hz

208 - 240 V~, 14 A, 60 Hz

Unit tested to IEC 61010

(EN 61010, UL 3101, CSA 22.2-1010) overvoltage

category II 2.5 kW

Stand-by: 0.23 kWh

Processing: 2.4 kWh

Empty 77 [91] kg

(170 [200] lbs)

Filled 115 [129] kg

(254 [284] lbs)

Values with open working table,

[in brackets: values with closed base cabinet]

97 x 68 x 127 cm (38.2x26.8x50'')

2

0.67 m

(7.2 sqft)

English

Safety Instructions

To ensure the safe operation of this processor, installation and use should

always conform to the instructions contained in this manual.

DThe developer and fixer chemicals used in the processor should be handled

according to the manufacturers instructions. In general: Non-diluted chemicals

are caustic. For this reason, chemicals should be handled very carefully. Avoid

contact with skin, always wear protective clothing, gloves and glasses when handling the chemicals - for example, when mixing and refilling. Also when taking the

racks out for cleaning or servicing. In case of chemicals getting into the eyes,

rinse eyes immediately with cold, running water for approximately 15 minutes,

and contact a doctor afterwards. Inhalation of chemicals can be dangerous to

your health and should be avoided. For this reason, always ensure that the room

in which the processor is installed is adequately ventilated.

Environmental regulations regarding the storage and disposal of waste chemicals should be obtained from the local water authorities and complied with.

Before opening the processor switch off the unit and unplug it from the electrical

socket. Service and repairs must be performed by trained service technicians

only. Use only manufacturers replacement parts.

COMPACT 2

TM

5

Installation

s

Installation

1. Requirements for installation

a. Fresh water connection: Stop cock with 3/4" outer-thread diameter (washing

machine connection), Water pressure 2 - 10 bar (29 - 145 psi).

b. Drainage connection: Plastic tube - inner diameter 50 mm ”or larger. A ven-

tilated syphon which serves as odour preventor should be included in the

planning. The drainage tubes should be installed with a fall of minimum 5 %.

Local Water Authorities regulations should be complied with.

c. Electrical connection: Fused wall socket with earth connection according to

electrical data (see technical specifications, page 5). It is also required to

install an earth-leakage switch (with 25 A / 30 mA nominal error current).

Electrical connections should be carried out according to regulations by an electrician.

2. Installation of processor

a. Unpack and assemble base table/ base cabinet respectively according

enclosed manual.

b. Unpack Processor and mount onto base table/ base cabinet respectively

according to manual. Remove the transport securing bars of the roller-racks.

Fit the gear and dryer plates to the water/dryer-rack.

®

1 Machine cover

2 Light protection cover on film infeed

3 Control panel

4 Power switch and main fuses

5 Replenishment tanks

6 Stop cock of water

7 Connections for freshwater, replenishment and

drainage respective overflow

8 Levelling feet

Depending on model type the Compact 2 has either an open

tand or like shown here a closed cabinet.

1

2

3

6

4

7

5

8

6 COMPACT 2

TM

Installation

3. Connecting the processor

Water connection: Fit water-inlet hose (grey) at the rear of the machine and connect

to the prepared fresh water supply.

All other hoses (see diagram ): Connect the enclosed hoses according to colour

system to backside of machine. Put hose clip (enclosed in accessory bag) over

hose end, before attaching to connection. Warm up hose end (with hot water or

lighter) and push onto the respective connection. Finally push clip over hose and

connection.

Cut hoses to required length. Integrate the stop cocks into the drainage hoses in

such a position, that they are easy to reach.

Connect the suction pipes to the hose ends for the replenishment tanks using hose

clips. Put suction pipes through cover opening into respective replenishment tanks

and snap them in.

The overflow and drainage hoses from the developer and fixer should be guided

into their respective collecting containers.

The overflow and the drainage of the water can either be guided into the drainage

syphon or into respective collection containers.

®

English

Connection water drainage

Fresh water connection

Connection water outlet

Pay attention to the correct colour connections:

Developer: red;

Fixer: blue;

Water: clear

Replenishment

Overflow

Developer (red)

Overflow

Outlet

Fixer (blue)

Overflow

Outlet

Outlet

COMPACT 2

TM

Replenishment tanks

Replenishment tanks

7

Initial Operation

Danger of Overflow!

Use the included cable binders (accessory bag) to secure the

hoses. Fix all hose ends which guide into syphon or collecting

container, so that they do not drop into the liquid.

Very important:

The hose piping should be straight (without the hoses going

up and down) with a constant fall. The hoses should be as

short as possible and without bends and kinks. This is very

important for the water overflow hose. Bad piping work will

cause the machine to overflow!

Inform yourself of the local water board regulations regarding

drainage. These regulations may differ from information in

this manual, but they should be complied with.

Initial Operation

®

Levelling of machine: Place machine in working position and level with spirit level.

To do this, take off machine cover and place spirit level across the two intermediary

rinsing channels. Level machine by adjusting the feet on the table legs. Accurate

levelling is essential to avoid possible overflows at a later point in time.

Connect power cord: Lay power cord so that it will not be tripped over and not be

bent or frayed. If an extension cord is required use only cords that have been approved for usage with respective current.

1. Test run

Important!

Processor should not be run dry!

a. Close the three drainage stop cocks (front and rear). Fill the developer- and

fixertank and also the replenishment containers with water. Open water inflow

tap. Switch the machine on at the main switch. Water now flows into water

tank.

b. The circulation pump runs after switching on the machine and ventilates itself.

If this does not occur, switch the machine off again. Open the stop cock of the

respective chemical for five seconds and close it afterwards again. Switch the

machine on again. Repeat this procedure until the pump is ventilated.

c. Before filling with chemicals, check all hose connections again for leakage.

Switch machine off and drain water out.

2. Fill processor with chemicals

Prepare chemicals inside the replenishment containers according to manufacturers

instructions. By using a suitable container, pour chemicals into the respective tanks.

When filling, be sure that chemicals do no splash from one bath into another. Fixer

chemicals destroy developer chemicals! Depending on the chemical type add starter solution. Place the floating cover into developer replenishment container. Close

container cover firmly and insert the suction tubes. Pay attention to the colours:

Red = Developer, Blue = Fixer.

8 COMPACT 2

TM

Mode of Operation

Mode of Operation

The processor develops, fixes, rinses and dries your films. The temperatures,

speed and replenishment rates required for processing various types of film-materials can be individually selected and stored in the microprocessor control unit.

Automatic filling and heating

When the machine is switched on, the water tank fills and chemical baths heat up

automatically. During this procedure the display shows two serifs “--” and the developer temperature button blinks until the set temperature has been reached. The two

serifs show the operator, that the machine is not yet ready for processing. Once the

set temperature is reached, the machine is ready for processing. The developer

button no longer blinks.

Stand-by mode

After a film has been processed, the machine automatically switches to the standby mode during which the bath temperatures are maintained. The bath temperature

is maintained. The built-in circulation pumps ensure that the bath liquids are circulated and the temperature is evenly maintained and constant. Every 20 minutes an

anti-crystallisation programme starts to rotate the rollers, which avoids the building

up of aggressive crystals on the rollers within the machine. During very long standby periods, and after a set time, the control unit activates a replenishment cycle to

avoid oxidation of the chemicals in the machine (time replenishment).

Film registration

The special impulse-reflex-lightbarrier for film registration has been constructed in

such a manner that even infrared sensitive films are not exposed. When a film is

fed in, the lightbarrier starts the machine.

Automatic replenishment

The quality of the developer and fixer chemicals is reduced when films run through

the baths and for this reason a regular replenishment of the chemicals is necessary.

By means of the lightbarrier, the film surface of processed films is measured. After

approx. 0.25 m

During this cycle, chemicals are pumped up from the replenishment containers into

the machine. The replenishment quantity can be adjusted by setting the replenishment rate.

2

of film has passed through, a replenishment cycle is activated.

®

English

COMPACT 2

TM

9

Operation

Operation

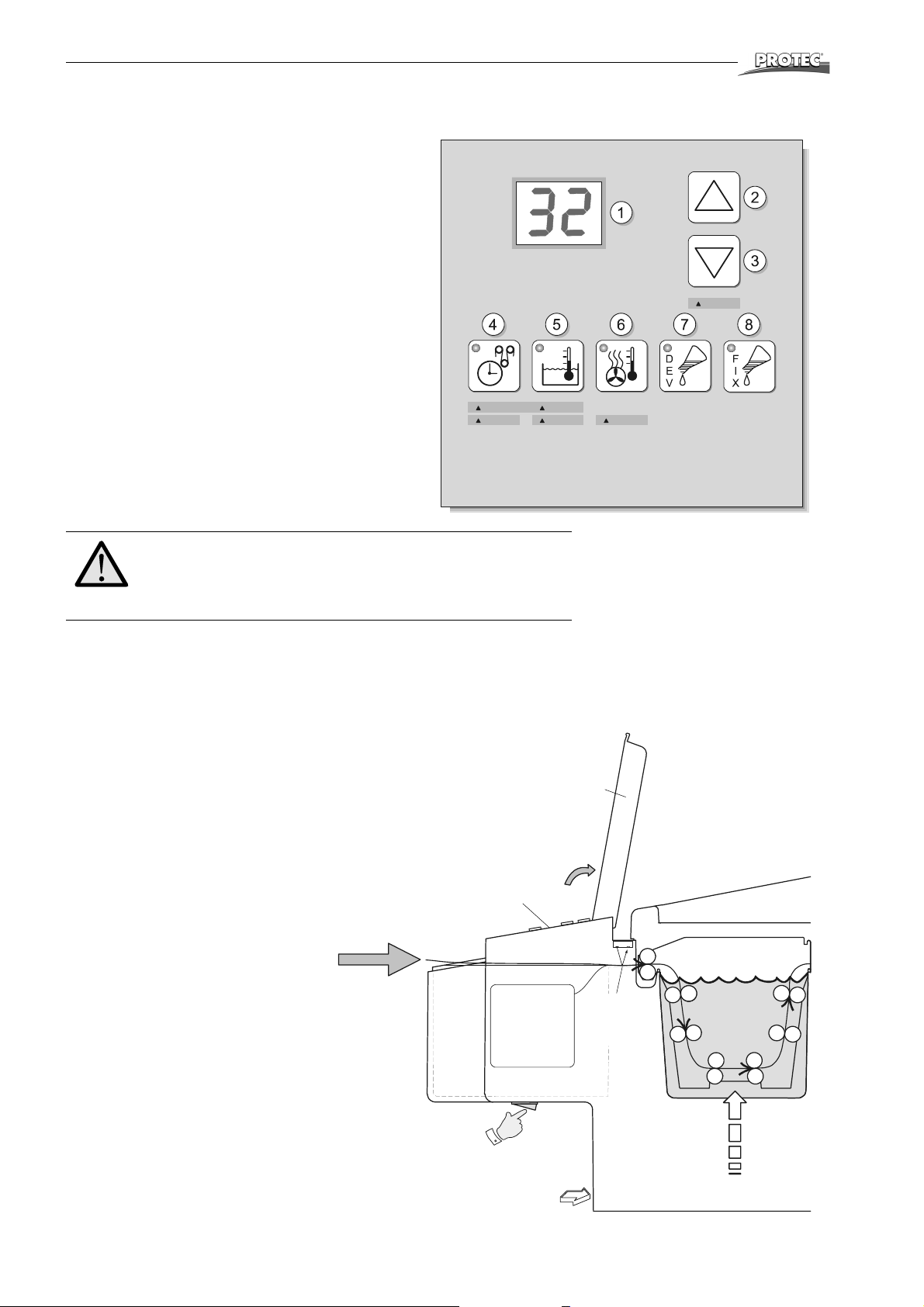

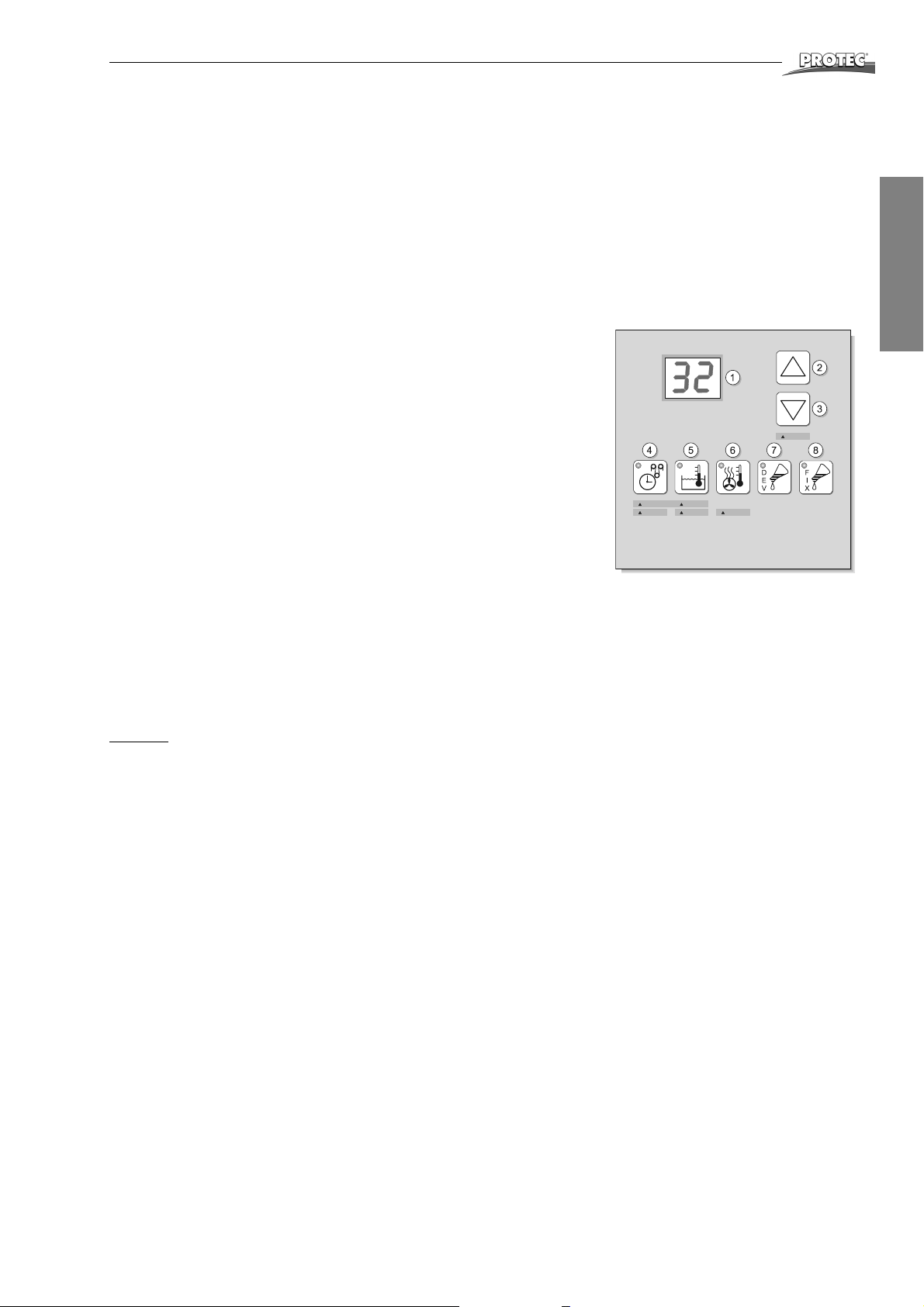

Short Overview and Control Panel

c Display working parameters

d Arrow button “Up” = increase parameter

e Arrow button “down” = decrease parameter

Mode Buttons

f Processing time in minutes

g Developer temperature in °C

h Dryer temperature in °C

i Replenishment developer time in seconds

j Replenishment fixer time in seconds

Enter Memory

Recall Store

®

Select

Power on Autofill

Exit

Important!

Safety function stops film transportation when cover is removed. Therefore keep cover placed on the machine when

processing films.

*When processing roll films in cassettes, pull approx. 15 cm of film out of the cassette and fold the corners (see page 18). Place cassette into cassette box and feed

film into the infeed. Only machines with cassette box.

Light protection cover

Control unit

Film input

LS

Developing

*Roll film

cassette

Power switch

Water drainage cock

Film detection

Replenishment Developer

10 COMPACT 2

TM

Operation

Attention:

Upon first operation and each refilling of a developer check

the function of the circulation pump and vent the pump if required (see page 8).

Before use...

1. Close water-drainage stop cock.

2. Open water tap.

3. Switch processor on.

4. Check liquid level in replenishment and drainage collecting containers.

5. Wait until the start-cycle has been completed or until Developer temperature

is reached.

6. Run cleaning films through processor.

Working procedure

7. Processing films:Open light protection cover, insert film on side of infeed tray

and feed in, during infeed please watch the Infeeding-film-display “– –”.

®

English

After work...

8. Switch processor off.

9. Close water tap.

10. Open water drainage stop cock

Stand-by mode:

When no film is being processed, the machine switches to Stand-by. The chemicals

remain at a constant temperature. The film transport and water inflow activate at intervals to avoid crystalisation of the chemicals on the transport rollers. Entry of the

next film is possible at any time.

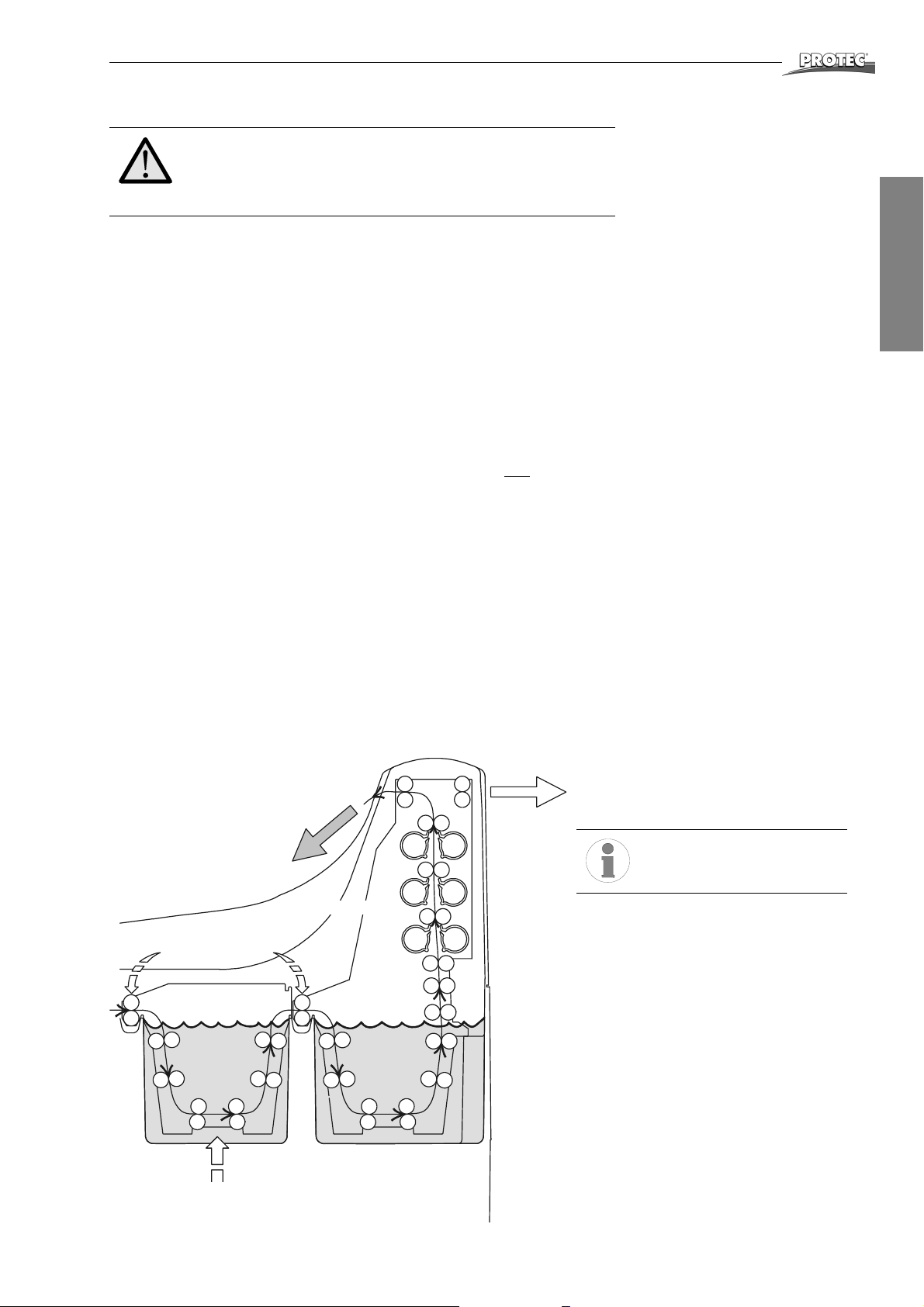

Film exit at rear of machine optional with

“Through the wall mounting film output” kit.

Film exit

Drying

Intermediate rinsing

Fresh water inflow

Do not place any object

on the processor.

Fixing

Replenishment fixer

COMPACT 2

TM

Washing

11

Operation

Switching the Machine On

Before switching the machine on, open the fresh water tap and close the water

drainage tap (under control panel). Then switch the machine on (main switch is situated under the control panel). Once the machine is switched on, a “Start-cycle” of

eight minutes duration is activated: A replenishment cycle is carried out, the water

tank fills automatically and the chemical baths heat up. During this “Start-cycle” no

films can be fed into the machine. The display shows two bars “– –” when the processor is not ready and no films can be fed in. This is the case during the “start-cycle”

and also when the baths have not reached the temperature. Until the developer

temperature is not reached, the developer temperature button (5) is flashing. It is

possible that the chemical bath has not reached the required temperature even after the “Start-cycle” has been completed. You need to wait until the developer temperature is reached, before inserting films. Wait until the bars “– –” disappear from

the display.

Automatic Mode

After completion of the “Start-cycle” and after a film-processing, the machine automatically goes into the stand-by mode. In the stand-by mode the processor can be

started at any time by placing a film into infeed tray. Note that films can only be processed when the developer temperature is reached. When the display shows two

bars “– –” no films can be fed into the machine. The temperature in the bath is too

high or too low. However, when a film was fed into the machine, two bars with decimal points “–. –.“. To avoid a jamming of films wait before feeding the next film in

until this display disappears (which is also signaled by an acoustic sound).

A film in the infeed-tray is registered by the light barrier and the machine starts up.

The film is pulled into the machine and transported through the developer, fixer and

water baths. The remaining time of processing i.e. until the film finally leaves the

machine is displayed, when no more film is in the infeed-tray and the processing

time button was pressed. Each working-parameter can be called up on the display

by pressing the respective mode-button, however, during processing, parameters

cannot be altered. The temperatures of the developer and dryer are automatically

regulated. The replenishment rate of developer and fixer chemicals is activated according to the processed film-surface (film-surface measurement). Before a film is

passed on from the developer bath into the fixer bath, it is rinsed with clean water

which minimises pollution of the fixer chemicals with developer chemicals. The film

is then dried in the dryer before passing out of the machine and falling into the catch

tray. The machine then goes into the stand-by mode. To keep the machine in working condition during the stand-by mode, the electronics have been furnished with

two specialities: The Anticrystalisation Function and the Time Replenishment.

®

Anticrystalisation Function

During the stand-by mode, the film transport, the dryer ventilation and the water inflow are activated every 20 minutes for a period of 15 seconds. This prevents the

build-up of crystals on the rollers. This function cannot be switched off.

12 COMPACT 2

TM

Operation

Time Replenishment (Antioxidation function, Flood replishment)

Also during the stand-by, the developer chemicals are subject to change which

causes their deterioration. By means of the time replenishment, a replenishment cycle is activated after a set time. With this function, the quality of the developer chemicals are maintained even when standing idle for long periods. The setting-range for

the time-replenishment is from 5 up to 99 minutes. When “0” is set, the time-replenishment is de-activated.

Setting of time-replenishment:

1. Switch processor off.

2. Press the buttons processing speed (4) and replenishment time developer (7)

simultaniously and keep pressed.

3. Switch the machine on again and release the pressed buttons.

4. Select the replenishment interval time (min.) by pressing the arrow buttons (2

and 3). The arrow up button (2) increases and the arrow down button (3)

decreases the value.

5. Switch machine off again.

Example: At the setting “45” a replenishment cycle is activated every 45 minutes.

®

English

Working Parameters

The processing machine develops, fixes, rinses and dries the film materials automatically. The film and chemical requirements can be adjusted accordingly and

stored in the control unit.

Display of working parameters:

1. Switch processor on.

2. Press the respective mode button (4-8) and keep pressed to display the

required working parameter or Press the respective mode button (4-8) and

release to display the momentary value.

Setting the working parameters:

1. Switch processor on.

2. Machine must be in the stand-by mode and no film must be in the processor.

3. Press the respective mode button (4-8) and keep pressed: The display shows

the set working parameter.

4. Change value by means of the arrow buttons (2 and 3) until required value

appears on the display. The upward arrow button (2) increases and the downward arrow button (3) decreases the value.

5. Release the mode button.

COMPACT 2

TM

13

Operation

Processing time

The processing time, is the time, it takes the front end of a film from the infeed of

the processor until it reaches the film exit. The processing time is set by the speed

with which the film is transported through the machine. Depending on the requirements, this time can be varied from 1 to 5 minutes adjusted in 0.1-minute-steps (Adjusting the processing time: see page 13 “Setting the working parameters”).

Processing and developer time relation

Processing time (min) Developer time (s) Infeed speed (cm/min)

1,0 14 151

1,5 21 101

2,0 28 76

2,5 35 60

3,0 43 50

3,5 50 43

4,0 57 38

4,5 64 34

5,0 71 30

®

Developer temperature

The developer temperature of the different film-materials depends on the developing time. The faster a film has to be developed, the higher the temperature must be.

The developer temperature can be set between 28-40 °C according to the individual

requirements (Setting the developer temperature: see page 13 “Setting the working

parameters”). If the temperature is lower or higher than the set value, then the bath

temperature button (5) is flashing and the display shows two bars “– –”. Before feeding a film into the machine, wait until the temperature has been reached and the displayed bars “– –” disappear.

The following chart demonstrates guide value relations between developer temperatures and processing times. Variations are possible depending on the various films

and chemicals.

Processing time and developer temperature relation

Processing time “Dry to Dry” (min s) Developer temperature(°C)

1,0 34 - 36

2,0 32 - 34

3,0 30 - 32

4,0 29 - 30

5,0 28 - 29

Dryer temperature

The dryer temperature can be adjusted within a range of 35-70 °C according to the

different film-materials. To avoid dryer spots on the film, the dryer temperature may

not be set too high. Adjust the temperature so that the film just gets dry (Setting the

dryer temperature: see page 13 “Setting the working parameters”).

Remark:

certain circumstances not be reached.

Replenishment time

The replenishment of the developer and fixer chemicals is automatic. By means of

the light barrier electronic at the film-infeed, the surface of the processed films are

calculated and after 0.25 m2 a replenishment cycle is automatically activated. The

replenishment quantity can be adjusted varying for developer and fixer by adjusting

the replenishment time. The time can be varied from 3-60 seconds.

Depending on mains voltage dryer temperatures above 65°C may under

14 COMPACT 2

TM

Operation

®

The chart below shows the replenishment time to be set for the requested replenisher rate per m

isher rate per m2 film surface. The replenisher rate has to be adjusted depending

on film material, chemicals and film throughput.

Replenisher rate

2

-film surface. The standard setting is 10 sec. with 500 ml replen-

Replenishment time and replenishment rate relation

2

)

(ml/m

200 4(4) 50

300 6(5) 75

400 8(7) 100

500 10(9) 125

600 13(11) 150

700 15(12) 175

800 17(14) 200

900 19(16) 225

1000 21(18) 250

Values in brackets for 60 Hz power connection.

Values when pump is set at 100% pump capacity.

Replenisher time (s) Replenisher rate

(ml per cycle)

Dimmer Function of Display

With the dimmer function the intensity of the control panel display can be changed.

The intensity can be reduced to avoid possible exposure of high-sensitive films.

Normal-sensitive films are not affected by the display.

Setting the intensity of the display:

1. Switch processor on.

2. Press “arrow down” button (3) for about 5 seconds. The intensity changes.

Two intensity-levels are available: bright and dark. During film-throughput this

function is not available.

English

Machine Cover Safety Disconnection

The machine cover may only be removed for service and maintenance purposes.

The processor cannot be started without the cover. In the event that the machine

cover is removed during film-throughput, the film transport will be stopped. On the

display the error message “E1” will be displayed. The error will be reset when the

machine cover has been replaced.

COMPACT 2

TM

15

Operation

Autofill Function

In case new chemicals have to be filled into the processor (after installation, tank

cleaning), the tanks can be filled automatically by means of the autofill function.

Herewith, the tank is filled for a fixed period of 17 minutes, e.g. chemicals are

pumped up from the replenisher tanks into the machine. Also the water bath will

be filled (8 min. period). The display will show two symbolized tanks (see right).

When the autofill function has been completed, the machine enters the stand-by

mode. In the event of the respective baths being full before the time is up, the

autofill function can be manually stopped.

Starting up the autofill function:

1. Switch processor off.

2. Filling developer and fixer tank: Keep both replenishment buttons for developer (7) and fixer (8) pressed down and switch the machine on. or filling

developer or fixer tank: Keep respective replenishment button (7 or 8)

pressed down and switch the machine on.

Manual cancellation of the Autofill function:

• Stop developer tank filling:

• Keep developer replenishment button (7) pressed down and press “arrow

down” button (3).

• Stop fixer tank filling:

• Keep fixer replenishment button (8) pressed down and press “arrow down”

button (3).

The filling of the water bath will be stopped once the automatic filling of both chemical baths has been stopped.

®

Manual Mode

In the manual mode, the processor works without the lightbarrier. The film transport

has to be started and stopped manually. All the set values in the manual mode are

also valid in the automatic mode. Please note that the Infeeding-film-display (“– –”)

is deactivated. In the Manual Mode the replenishment function does not use film

surface measurement, instead it uses a standard value. In the manual mode, a replenishment cycle can also be activated manually.

Switching to manual mode:

Switch machine on. During stand-by press arrow-buttons “up” and “down” (2 and 3)

simultaneously. When in manual mode the display is flashing.

Switch back to automatic mode:

In manual mode when in stand-by press arrow-buttons “up” (2) and “down” (3) simultaneously.

Manual starting and stopping the film transport:

1. Switch to manual mode.

2. Press Processing time button (4) - button illuminates.

3. Start film transport by pressing arrow-button “up” (2) and stop film transport by

pressing arrow-button “down” (3).

16 COMPACT 2

TM

Operation

Manual replenishment:

1. Switch to manual mode.

2. Press required replenishment button for developer (7) or fixer (8) - respective

button illuminates.

3. Start replenishment cycle by pressing arrow-button “up” (2) or cancel replenishment cycle by pressing arrow-button “down” (3).

In the memory five sets of parameters can be stored and be recalled into working

memory.

®

Use of Memory Function

In the memory five sets of parameters can be stored and be recalled into working

memory.

Store processing parameters

1. Set machine to preferable parameters e.g. bath tem-perature, processing

time etc. (see manual).

2. Press buttons 4 and 5 “Enter Memory” simultaneously to enter the memory

mode.

3. Use buttons 2 and 3 “Select” to select the parameter memory (P1 to P5).

Inside this the parameters will be stored, old values will be overwritten.

4. Press button 5 “Store” to store parameters and to leave the memory mode.

Recall processing parameters

1. Press buttons 4 and 5 “Enter Memory” simultaneously to enter memory

mode.

2. Use buttons 2 and 3 “Select” to select the parameter memory (P1 to P5)

from which the parameters shall be recalled.

3. Press button 4 “Recall” to recall parameters (copy into working memory) and

to leave the memory mode.

To leave memory mode without change

Press button 6 “Exit”.

Important

parameters cannot be stored - when trying to do this, an error message “LO” will

be displayed. Despite locked input, the processing parameters can be recalled.

Choose the same bath temperature for all stored programmes. Of course different bath temperatures can be stored too, but when changing the programme you

always have to wait until the changed bath temperature is reached.

: Please note, if input is locked (via lock function), then processing

Enter Memory

Recall Store

English

Select

Power on Autofill

Exit

COMPACT 2

TM

17

Operation

Lock Function

To prevent unintentional change of operation parameters the input can be locked.

If the input is locked any attempt to change the parameters will display an error “LO”

(locked).

Activating and de-activating of the input lock:

1. Press buttons 4 and 5 “Enter Memory” simultaneously to enter the memory

mode (see diagram on page 17).

2. Press several times the button 3 “Select” until the display will show “L.0”(Lock

off input unlocked) or “L.1” (Lock on: input locked).

3. Now by pressing one of the buttons 4 or 5 change the display: “L.0” if you

want to unlock the input or “L.1” if you want to lock the input.

4. To finalize the changes press button 6 “Exit”.

Please note:

Even when the input lock is activated it is possible to recall (previously stored)

procesing parameters of the memory-function.

Important: Please note, if input is locked via lock function, then processing parameters cannot be stored - when trying to do this, an error message “LO” will be displayed.

®

Stop Film Transport

In a case of a film-jam inside the machine, the film transportation can be manually

interrupted. To stop the film transport press both arrow-buttons (2 and 3) simultaneously.

Related topics:

“Manual starting and stopping the film transport” page 16

“Film is caught up in the racks” page 27

Infrared Sensitive Materials

Infra-red sensitive film material can be processed without danger of exposure by

the light-barrier.

Rollfilms and Paper Films

Roll films with a polyester lead of at least 10 cm length can be transported. The

adhesion must be chemical resistant.

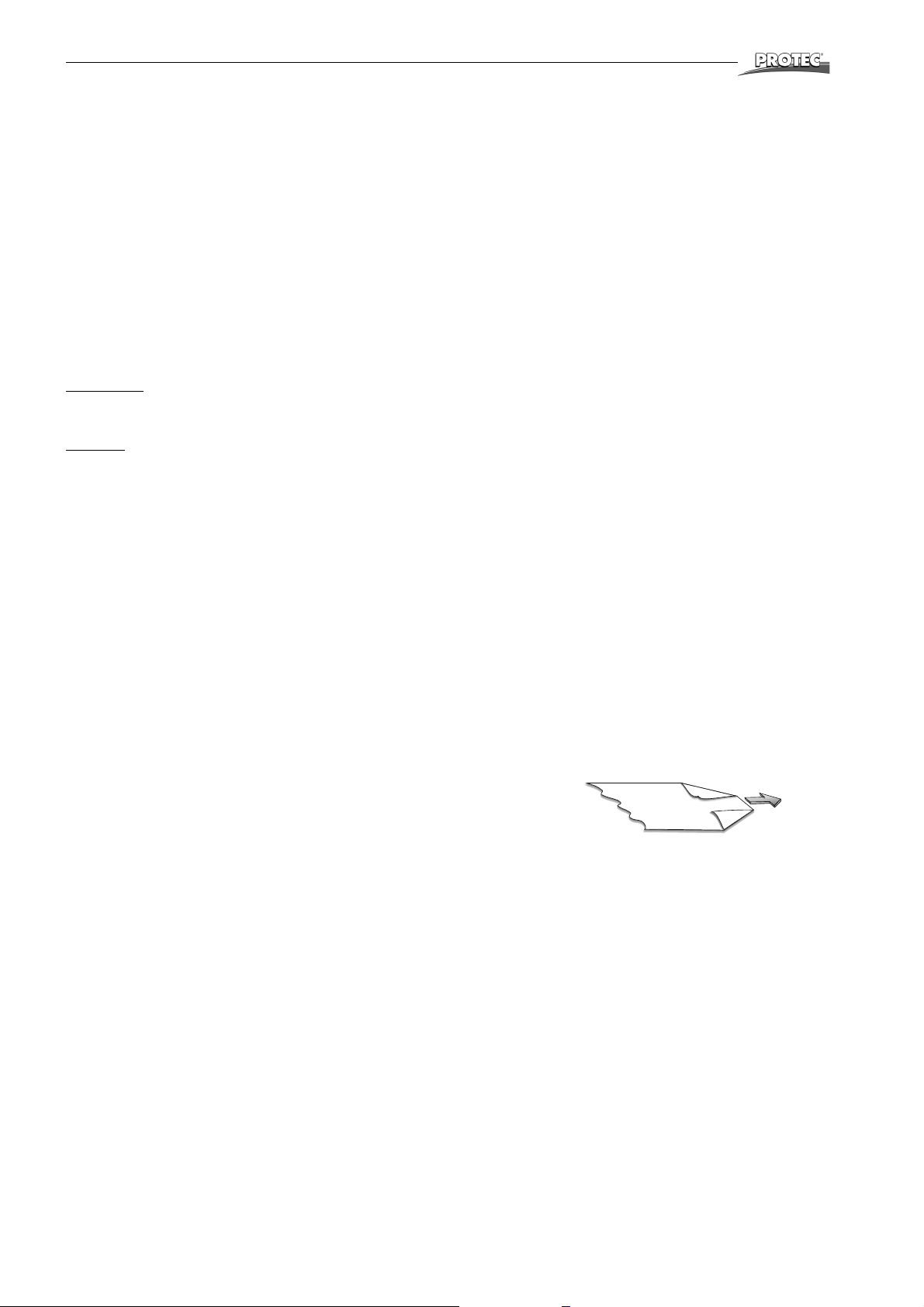

Roll films without lead and paper-films must be folded on the corners, as shown

in the diagram, before being fed into the machine.

Automatic Cooling Function

If the developer temperature exceeds the set value, the automatic cooling function

will be activated. The fan runs for a fast cooling of the bath. The same happens

when the temperature is decreased by pressing the arrow button.

18 COMPACT 2

TM

Loading...

Loading...