Page 1

5105-103M-PDPS

ProLinx Gateway

IEC 60870-5-103 Master to

PROFIBUS Slave Gateway

November 23, 2010

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2010 ProSoft Technology, Inc., all rights reserved.

5105-103M-PDPS User Manual

November 23, 2010

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM,

and are available at no charge from our web site: www.prosoft-technology.com

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1.661.716.5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIV. 2;

B WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

C WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

D THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

ProLinx® Products Warnings

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT – RISQUE D'EXPLOSION – AVANT DE DÉCONNECTER L'EQUIPMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

ProLinx Gateways with Ethernet Ports

Series C ProLinx™ Gateways with Ethernet ports do NOT include the HTML Web Server. The HTML Web Server

must be ordered as an option. This option requires a factory-installed hardware addition. The HTML Web Server now

supports:

8 MB file storage for HTML files and associated graphics files (previously limited to 384K)

32K maximum HTML page size (previously limited to 16K)

To upgrade a previously purchased Series C model:

Contact your ProSoft Technology distributor to order the upgrade and obtain a Returned Merchandise Authorization

(RMA) to return the unit to ProSoft Technology.

To order a ProLinx Plus gateway with the -WEB option

Add -WEB to the standard ProLinx part number. For example, 5201-MNET-MCM-WEB.

Page 4

Markings

Label Markings

CL I Div 2 GPs A, B, C, D

II 3 G

Ex nA nL IIC X

-20°C <= Ta <= 60°C

II – Equipment intended for above ground use (not for use in mines).

3 – Category 3 equipment, investigated for normal operation only.

G – Equipment protected against explosive gasses.

Agency Approvals and Certifications

cULus Class I, Div 2 Groups A, B, C, D T6

-30°C <= Ta <= 60°C

183151

Page 5

5105-103M-PDPS ♦ ProLinx Gateway Contents

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

ProLinx® Products Warnings ............................................................................................................... 3

ProLinx Gateways with Ethernet Ports ............................................................................................... 3

To upgrade a previously purchased Series C model: .................................................................... 3

To order a ProLinx Plus gateway with the -WEB option ................................................................ 3

Markings .............................................................................................................................................. 4

Guide to the 5105-103M-PDPS User Manual 9

1 Start Here 11

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.6.1

1.6.2

1.6.3

1.6.4

1.7.1

1.7.2

1.7.3

1.7.4

1.7.5

1.8.1

1.8.2

1.9.1

1.9.2

1.9.3

1.9.4

1.9.5

System Requirements ............................................................................................. 12

Package Contents ................................................................................................... 13

Setting Debug and Port 0 Configuration Jumpers .................................................. 14

Mounting the Module on the DIN-rail ...................................................................... 15

Connecting Power to the Unit ................................................................................. 16

Configure the Module .............................................................................................. 17

Installing ProSoft Configuration Builder Software ................................................... 17

Adding a Module ..................................................................................................... 18

Quick Start ............................................................................................................... 20

Renaming PCB Objects .......................................................................................... 29

103M Protocol Configuration ................................................................................... 31

[IEC-103 Master Commands] .................................................................................. 31

[IEC-870-5-103 Master] ........................................................................................... 34

[IEC-870-5-103 Master Port x] ................................................................................ 34

[IEC-103 Master Session x]..................................................................................... 36

[IEC-103 Master Session x Sector y] ...................................................................... 38

PDPS Protocol Configuration .................................................................................. 41

[PROFIBUS SLAVE] ............................................................................................... 41

Set_Param (SAP61) ................................................................................................ 43

Using the CommonNet Data Map ........................................................................... 45

From Address .......................................................................................................... 46

To Address .............................................................................................................. 46

Register Count ........................................................................................................ 46

Swap Code .............................................................................................................. 47

Delay Preset ............................................................................................................ 48

Printing a Configuration File .................................................................................... 49

Downloading a File from PC to the Module ............................................................. 50

2 Diagnostics and Troubleshooting 51

2.1

2.1.1

2.1.2

2.1.3

Using ProSoft Configuration Builder (PCB) for Diagnostics.................................... 52

Required Hardware ................................................................................................. 52

Using the Diagnostic Window in ProSoft Configuration Builder .............................. 53

Navigation ............................................................................................................... 55

ProSoft Technology, Inc. Page 5 of 144

November 24, 2010

Page 6

Contents 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

2.2

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

2.2.8

2.2.9

2.2.10

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

2.3.7

2.3.8

2.3.9

2.3.10

2.3.11

2.4

2.4.1

2.4.2

2.4.3

2.5

2.5.1

2.5.2

2.5.3

2.5.4

2.5.5

2.5.6

2.5.7

2.5.8

2.5.9

2.6

2.6.1

2.6.2

2.6.3

2.6.4

2.6.5

2.6.6

2.6.7

2.7

2.7.1

2.7.2

2.7.3

2.7.4

2.7.5

2.8

2.8.1

2.8.2

Main Menu .............................................................................................................. 56

Redisplaying the Menu ........................................................................................... 56

Viewing PROFIBUS Configuration ......................................................................... 56

Viewing Module Configuration ................................................................................ 56

Opening the Database View Menu ......................................................................... 56

Opening the Session Configuration Menu .............................................................. 57

Opening the IEC-103 Master Menu ........................................................................ 57

Sending the Configuration File ............................................................................... 57

Viewing Version Information ................................................................................... 57

Opening the Data Map Menu .................................................................................. 57

Exiting the Program ................................................................................................ 58

Database View Menu .............................................................................................. 59

Viewing Register Pages .......................................................................................... 59

Displaying the Current Page of Registers Again .................................................... 59

Moving Back Through 5 Pages of Registers .......................................................... 60

Moving Forward (Skipping) Through 5 Pages of Registers .................................... 60

Viewing the Previous Page of Registers ................................................................ 60

Viewing the Next Page of Registers ....................................................................... 60

Viewing Data in Decimal Format ............................................................................ 60

Viewing Data in Hexadecimal Format .................................................................... 60

Viewing Data in Floating-Point Format ................................................................... 60

Viewing Data in ASCII (Text) Format ..................................................................... 60

Returning to the Main Menu ................................................................................... 60

PROFIBUS Slave Menu ......................................................................................... 61

Viewing PROFIBUS Slave Configuration ............................................................... 61

Definition of Module’s Extended Diagnostics Data ................................................. 62

Viewing PROFIBUS Status ..................................................................................... 63

IEC-103 Master Driver Menu .................................................................................. 69

Opening the Data Analyzer Menu .......................................................................... 69

Viewing General Configuration ............................................................................... 69

Opening the IEC-870-Master Command List Menu ............................................... 70

Opening the Port Configuration Menu .................................................................... 70

Opening the Port Status Menu ............................................................................... 71

Opening the Session Configuration Menu .............................................................. 71

Opening the Sector Menu ....................................................................................... 71

Viewing Master Driver Version Information ............................................................ 72

Returning to the Main Menu ................................................................................... 72

IEC-870-Master Command List Menu .................................................................... 73

Redisplaying the Menu ........................................................................................... 73

Redisplaying the Current Page ............................................................................... 73

Moving Back Through 5 Pages of Registers .......................................................... 73

Viewing the Previous Page of Registers ................................................................ 73

Moving Forward Through 5 Pages of Registers ..................................................... 73

Viewing the Next Page of Registers ....................................................................... 73

Returning to the Main Menu ................................................................................... 73

Port Configuration Menu ......................................................................................... 74

Redisplaying the Menu ........................................................................................... 74

Redisplaying the Current Page ............................................................................... 74

Displaying the Next Page ....................................................................................... 74

Displaying the Previous Page ................................................................................. 74

Returning to the Main Menu ................................................................................... 74

Port Status Menu .................................................................................................... 75

Redisplaying the Menu ........................................................................................... 75

Redisplaying the Current Page ............................................................................... 75

Page 6 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 7

5105-103M-PDPS ♦ ProLinx Gateway Contents

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

2.8.3

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.8.4

2.8.5

2.9.1

2.9.2

2.9.3

2.9.4

2.9.5

2.9.6

2.9.7

2.9.8

2.9.9

2.9.10

2.10.1

2.10.2

2.11.1

2.11.2

2.11.3

2.11.4

2.11.5

2.11.6

2.12.1

2.12.2

2.12.3

2.12.4

2.13.1

2.13.2

2.13.3

2.13.4

2.14.1

2.14.2

2.15.1

2.15.2

2.15.3

Displaying the Previous Page ................................................................................. 75

Displaying the Next Page ........................................................................................ 75

Returning to the Main Menu .................................................................................... 75

Data Analyzer .......................................................................................................... 76

Analyzing Data for the first application port............................................................. 76

Analyzing Data for the second application port ....................................................... 76

Displaying Timing Marks in the Data Analyzer........................................................ 76

Removing Timing Marks in the Data Analyzer ........................................................ 77

Viewing Data in Hexadecimal Format ..................................................................... 77

Viewing Data in ASCII (Text) Format ...................................................................... 77

Starting the Data Analyzer ...................................................................................... 77

Stopping the Data Analyzer .................................................................................... 78

Data Analyzer Tips .................................................................................................. 78

Returning to the Main Menu .................................................................................... 80

Session Configuration Menu ................................................................................... 81

Online State ............................................................................................................. 81

Session State .......................................................................................................... 81

Sector Configuration Menu...................................................................................... 82

Redisplaying the Menu ............................................................................................ 82

Opening the Sector Database Menu ....................................................................... 82

Redisplaying the Current Page ............................................................................... 82

Displaying the Next Page ........................................................................................ 82

Displaying the Previous Page ................................................................................. 82

Returning to the Main Menu .................................................................................... 82

Sector Database Menu ............................................................................................ 83

Redisplaying the Menu ............................................................................................ 83

Viewing ASDU n Data ............................................................................................. 83

Listing ASDU point counts....................................................................................... 83

Returning to the Main Menu .................................................................................... 83

Data Map Menu ....................................................................................................... 84

Redisplaying the Current Page ............................................................................... 84

Displaying the Next Page ........................................................................................ 84

Displaying the Previous Page ................................................................................. 84

Returning to the Main Menu .................................................................................... 84

LED Indicators ......................................................................................................... 85

LEDs for Port 0 Serial Port ...................................................................................... 85

LEDs for the PROFIBUS Slave Port ....................................................................... 85

Frequently Asked Questions ................................................................................... 86

Why is the module not communicating with the slave? .......................................... 86

The slave is responding but I cannot see the monitor data in the Module database.86

How can I confirm if the configuration was received by the module? ..................... 86

3 Reference 87

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.2

3.2.1

3.2.2

Product Specifications ............................................................................................. 88

General Specifications - ProLinx ............................................................................. 88

Internal Database .................................................................................................... 88

Using ProSoft Configuration Builder ....................................................................... 89

PROFIBUS Slave Port Specifications ..................................................................... 89

Serial Port Specifications ........................................................................................ 90

Functional Overview ................................................................................................ 91

IEC 60870-5-103 Master Protocol Implementation ................................................. 91

PDPS Protocol Implementation ............................................................................. 109

ProSoft Technology, Inc. Page 7 of 144

November 24, 2010

Page 8

Contents 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

3.3

3.4

3.5

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.4.8

3.4.9

3.4.10

3.4.11

3.4.12

3.4.13

3.4.14

3.4.15

3.4.16

3.4.17

3.4.18

3.4.19

3.4.20

3.4.21

3.5.1

3.5.2

Setting the Module's Date and Time ..................................................................... 122

IEC 60870-5-103 Master Protocol Interoperability Documentation ...................... 125

Electrical Interface ................................................................................................ 125

Optical Interface .................................................................................................... 125

Transmission speed .............................................................................................. 126

Link Layer ............................................................................................................. 126

Transmission mode for application data ............................................................... 126

Common Address of ASDU .................................................................................. 126

Selection of standard information numbers in monitor direction .......................... 126

System functions in monitor direction ................................................................... 126

Status indications in monitor direction .................................................................. 127

Supervision indications in monitor direction ......................................................... 127

Earth fault indications in monitor direction ............................................................ 127

Fault indications in monitor direction .................................................................... 128

Auto-reclosure indications in monitor direction ..................................................... 128

Measurands in monitor direction........................................................................... 129

Generic functions in monitor direction .................................................................. 129

Selection of standard information numbers in control direction ............................ 129

System functions in control direction .................................................................... 129

General commands in control direction ................................................................ 129

Generic functions in control direction ................................................................... 130

Basic application functions ................................................................................... 130

Miscellaneous ....................................................................................................... 130

103M Network Design Forms ............................................................................... 131

Form to Define Sector Database .......................................................................... 131

Form to Define Command List .............................................................................. 132

4 Support, Service & Warranty 133

Contacting Technical Support ........................................................................................................ 133

4.1

4.2

4.1.1

4.1.2

4.1.3

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

4.2.7

4.2.8

4.2.9

4.2.10

Return Material Authorization (RMA) Policies and Conditions ............................. 135

Returning Any Product .......................................................................................... 135

Returning Units Under Warranty ........................................................................... 136

Returning Units Out of Warranty ........................................................................... 136

LIMITED WARRANTY .......................................................................................... 137

What Is Covered By This Warranty ...................................................................... 137

What Is Not Covered By This Warranty ................................................................ 138

Disclaimer Regarding High Risk Activities ............................................................ 138

Intellectual Property Indemnity ............................................................................. 139

Disclaimer of all Other Warranties ........................................................................ 139

Limitation of Remedies ** ..................................................................................... 140

Time Limit for Bringing Suit ................................................................................... 140

No Other Warranties ............................................................................................. 140

Allocation of Risks ................................................................................................ 140

Controlling Law and Severability .......................................................................... 140

Index 141

Page 8 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 9

5105-103M-PDPS ♦ ProLinx Gateway Guide to the 5105-103M-PDPS User Manual

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

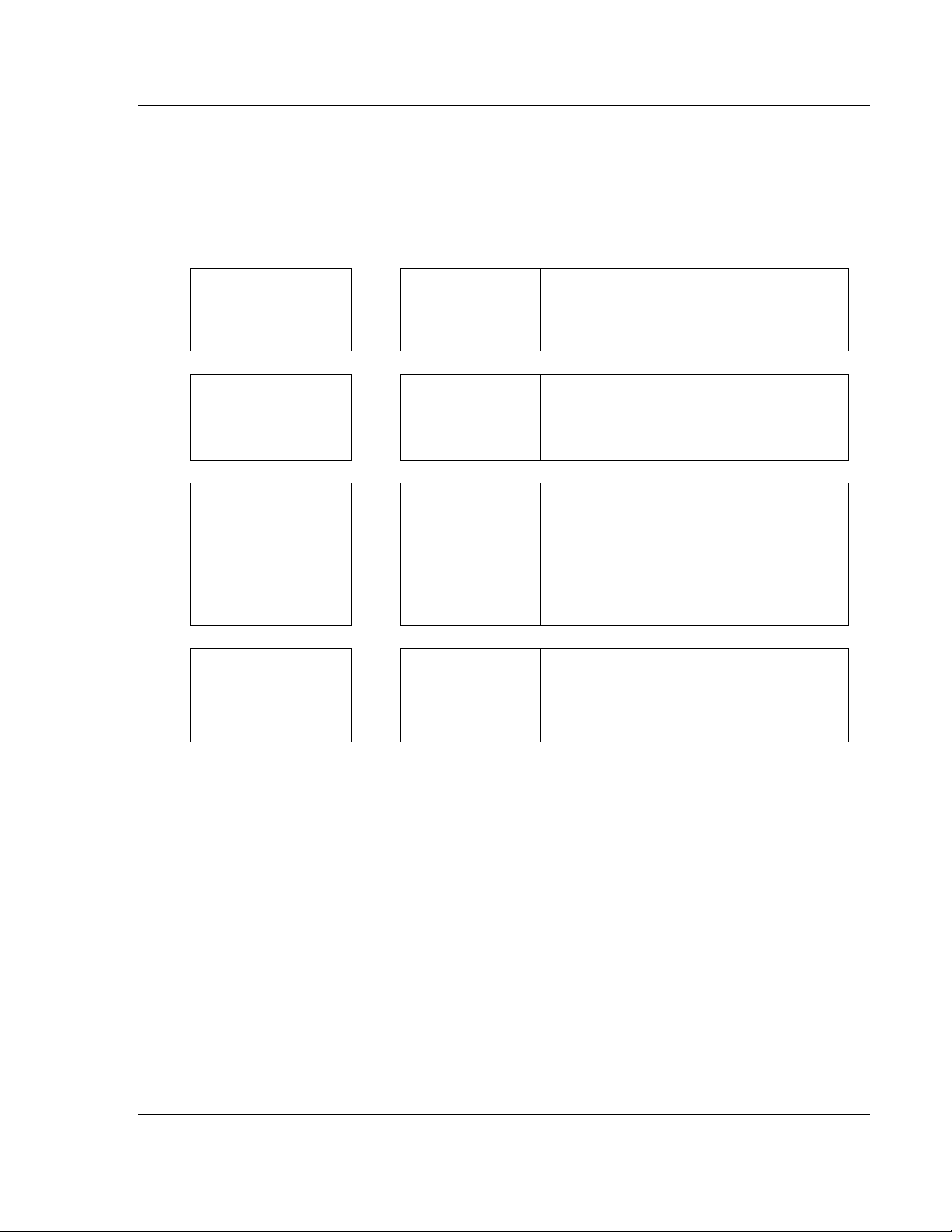

Guide to the 5105-103M-PDPS User Manual

Function

Introduction

(Must Do)

Diagnostic and

Troubleshooting

Reference

Product Specifications

Functional Overview

Support, Service, and

Warranty

Index

Section to Read Details

Start Here (page 10) This section introduces the customer to the

→

Diagnostics and

→

Troubleshooting

(page 51)

Reference (page 87)

→

Product

Specifications (page

88)

Functional Overview

(page 91)

Support, Service

→

and Warranty (page

133)

Index

gateway. Included are: package contents,

system requirements, hardware installation, and

basic configuration.

This section describes Diagnostic and

Troubleshooting procedures.

These sections contain general references

associated with this product, Specifications, and

the Functional Overview.

This section contains Support, Service and

Warranty information.

Index of chapters.

ProSoft Technology, Inc. Page 9 of 144

November 24, 2010

Page 10

Guide to the 5105-103M-PDPS User Manual 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

Page 10 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 11

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

1 Start Here

In This Chapter

System Requirements ........................................................................... 12

Package Contents ................................................................................. 13

Setting Debug and Port 0 Configuration Jumpers ................................. 14

Mounting the Module on the DIN-rail ..................................................... 15

Connecting Power to the Unit ................................................................ 16

Configure the Module ............................................................................ 17

103M Protocol Configuration ................................................................. 31

PDPS Protocol Configuration ................................................................ 41

Using the CommonNet Data Map .......................................................... 45

Printing a Configuration File .................................................................. 49

Downloading a File from PC to the Module ........................................... 50

For most applications, the installation and configuration steps described in this

section will work without additional programming. ProSoft Technology strongly

recommends that you complete the steps in this chapter before developing a

custom application.

ProSoft Technology, Inc. Page 11 of 144

November 24, 2010

Page 12

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

1.1 System Requirements

The ProSoft Configuration Builder configuration software for the 5105-103MPDPS gateway requires the following minimum hardware and software

components:

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o

Microsoft Windows Vista

o

Microsoft Windows XP Professional with Service Pack 1 or 2

o

Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o

Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 × 768 recommended)

CD-ROM drive

Page 12 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 13

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

1.2 Package Contents

The following components are included with your 5105-103M-PDPS module, and

are all required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

Qty. Part Name Part Number Part Description

1 5105-103M-PDPS

Module

1 Cable Cable #15, RS232

3 Cable RJ45 to DB9 Male

2 Adapter 1454-9F Two Adapters, DB9 Female to Screw

1 ProSoft Solutions CD Contains sample programs, utilities and

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

5105-103M-PDPS IEC 60870-5-103 Master to PROFIBUS

Slave Gateway

For RS232 Connection to the CFG Port

Null Modem

For DB9 Connection to Module’s Port

Adapter

Terminal. For RS422 or RS485

Connections to Port 1 and 2 of the Module

documentation for the 5105-103M-PDPS

module.

ProSoft Technology, Inc. Page 13 of 144

November 24, 2010

Page 14

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

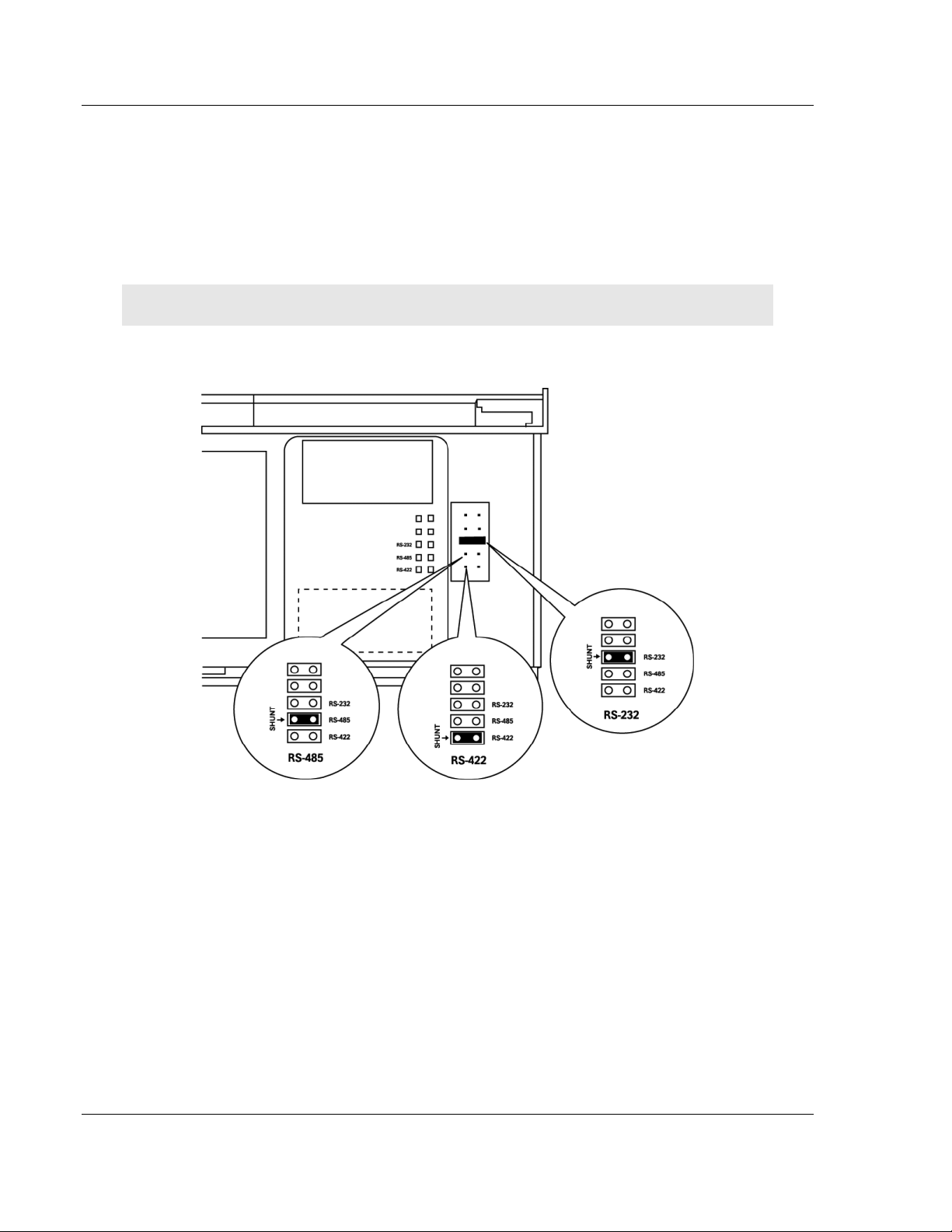

1.3 Setting Debug and Port 0 Configuration Jumpers

The Debug Port operates in RS232 mode only on Series C gateways. No

jumpers are provided for the Debug Port on them.

Before mounting the gateway on the DIN-rail, you must set a jumper for

application Port 0 to select RS-232, RS-422, or RS-485 mode. The port is set at

the factory for RS-232 mode. Verify correct jumper setting before startup to

minimize problems.

Note: Series A gateways have active jumpers for both the Debug and application Port 0.

The following diagram details the jumper position for the ProLinx 5000/6000

series gateways.

Page 14 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 15

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

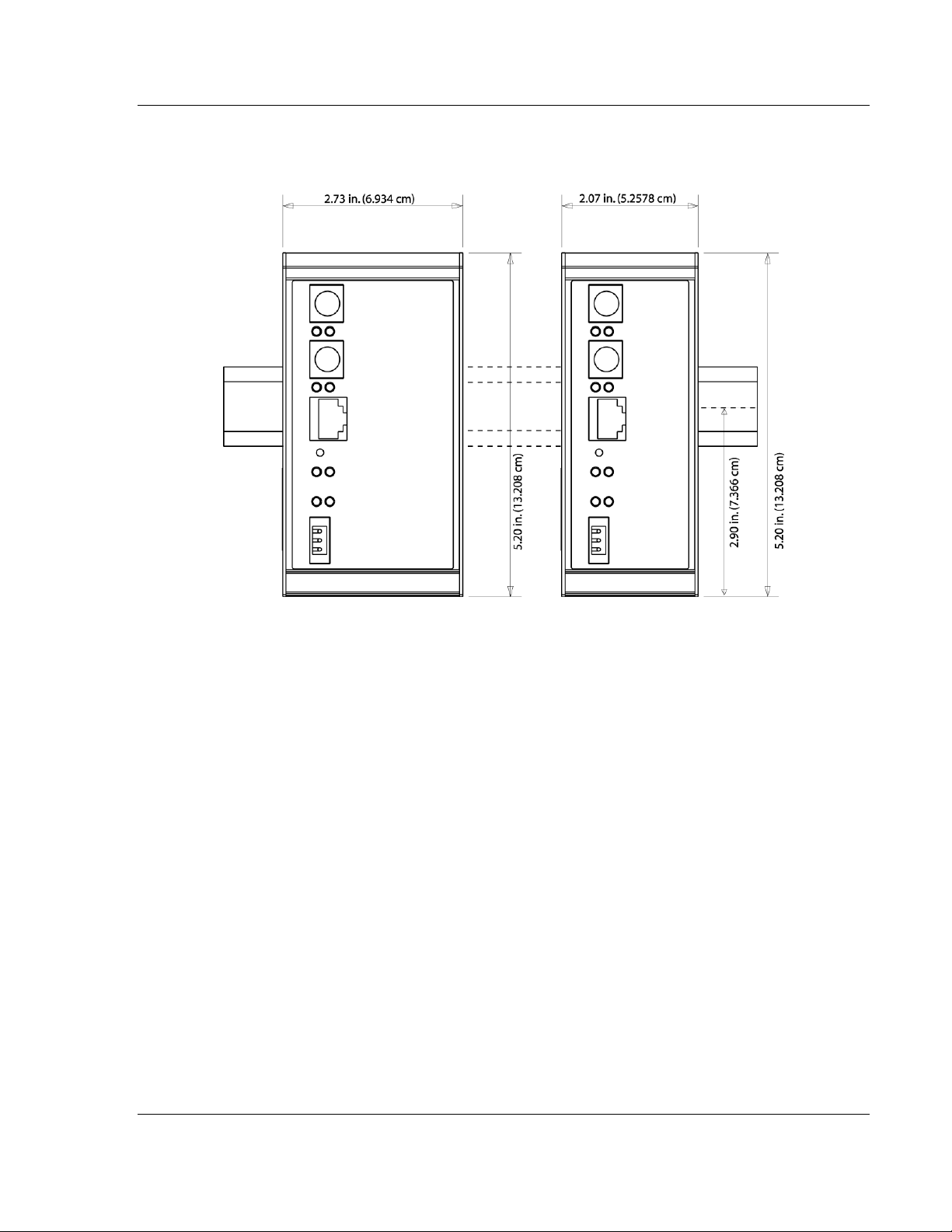

1.4 Mounting the Module on the DIN-rail

ProLinx 5000/6000 Series gateways

ProSoft Technology, Inc. Page 15 of 144

November 24, 2010

Page 16

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

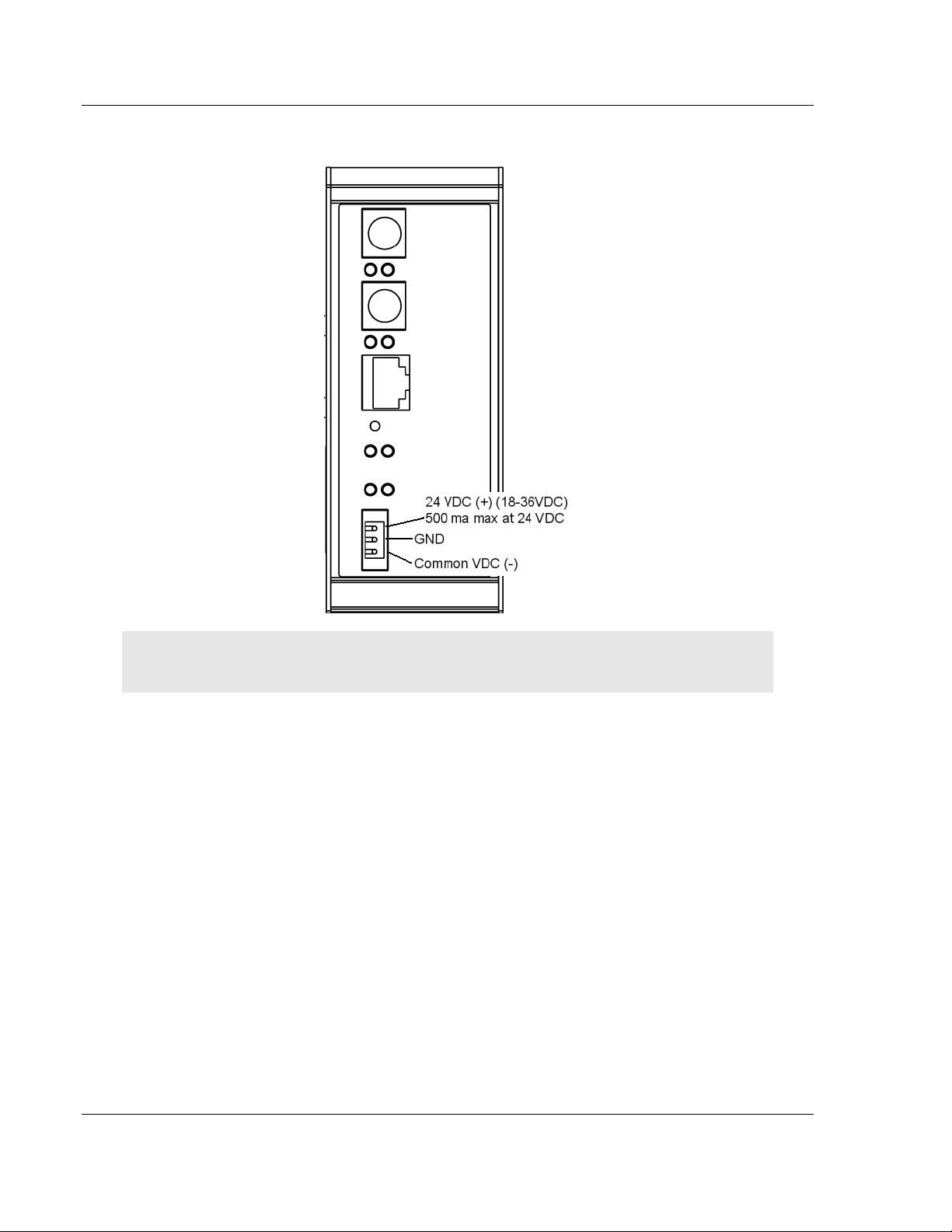

1.5 Connecting Power to the Unit

WARNING: Ensure that you do not reverse polarity when applying power to the gateway. This

could cause damage to the gateway’s internal systems.

Page 16 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 17

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

1.6 Configure the Module

Because the task of configuring the ProLinx module can be complicated, ProSoft

Technology has provided a configuration tool called ProSoft Configuration

Builder (PCB) that will help you with the following tasks:

Creating a configuration project

Setting module parameters

Configuring the protocols

o

103M (page 31)

o

PDPS (page 41)

Copying the project to the module.

The following topics of this chapter explain each task step-by-step.

1.6.1 Installing ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software to configure

the gateway. You can always get the newest version of ProSoft Configuration

Builder from the ProSoft Technology website.

Installing ProSoft Configuration Builder from the ProSoft website

1 Open your web browser and navigate to http://www.prosoft-

technology.com/pcb

2 Click the D

Configuration Builder.

3 Choose S

4 Save the file to your Windows Desktop, so that you can find it easily when

you have finished downloading.

5 When the download is complete, locate and open the file, and then follow the

instructions on your screen to install the program.

If you do not have access to the Internet, you can install ProSoft Configuration

Builder from the ProSoft Solutions Product CD-ROM, included in the package

with your gateway.

OWNLOAD HERE

AVE

or S

AVE FILE

link to download the latest version of ProSoft

when prompted.

ProSoft Technology, Inc. Page 17 of 144

November 24, 2010

Page 18

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

Installing ProSoft Configuration Builder from the Product CD-ROM

1 Insert the ProSoft Solutions Product CD-ROM into the CD-ROM drive of your

PC. Wait for the startup screen to appear.

2 On the startup screen, click P

RODUCT DOCUMENTATION

. This action opens a

Windows Explorer file tree window.

3 Click to open the U

TILITIES

folder. This folder contains all of the applications

and files you will need to set up and configure your gateway.

4 Double-click the S

PCB_*.

EXE

file and follow the instructions on your screen to install the

ETUP CONFIGURATION TOOL

folder, double-click the

software on your PC. The information represented by the "*" character in the

file name is the PCB version number and, therefore, subject to change as

new versions of PCB are released.

Note: Many of the configuration and maintenance procedures use files and other utilities on the

CD-ROM. You may wish to copy the files from the Utilities folder on the CD-ROM to a convenient

location on your hard drive.

Using the Online Help

Most of the information needed to help you use ProSoft Configuration Builder is

provided in a Help System that is always available whenever you are running

ProSoft Configuration Builder. The Help System does not require an Internet

connection.

To view the help pages, start ProSoft Configuration Builder, open the H

menu, and then choose C

ONTENTS

.

ELP

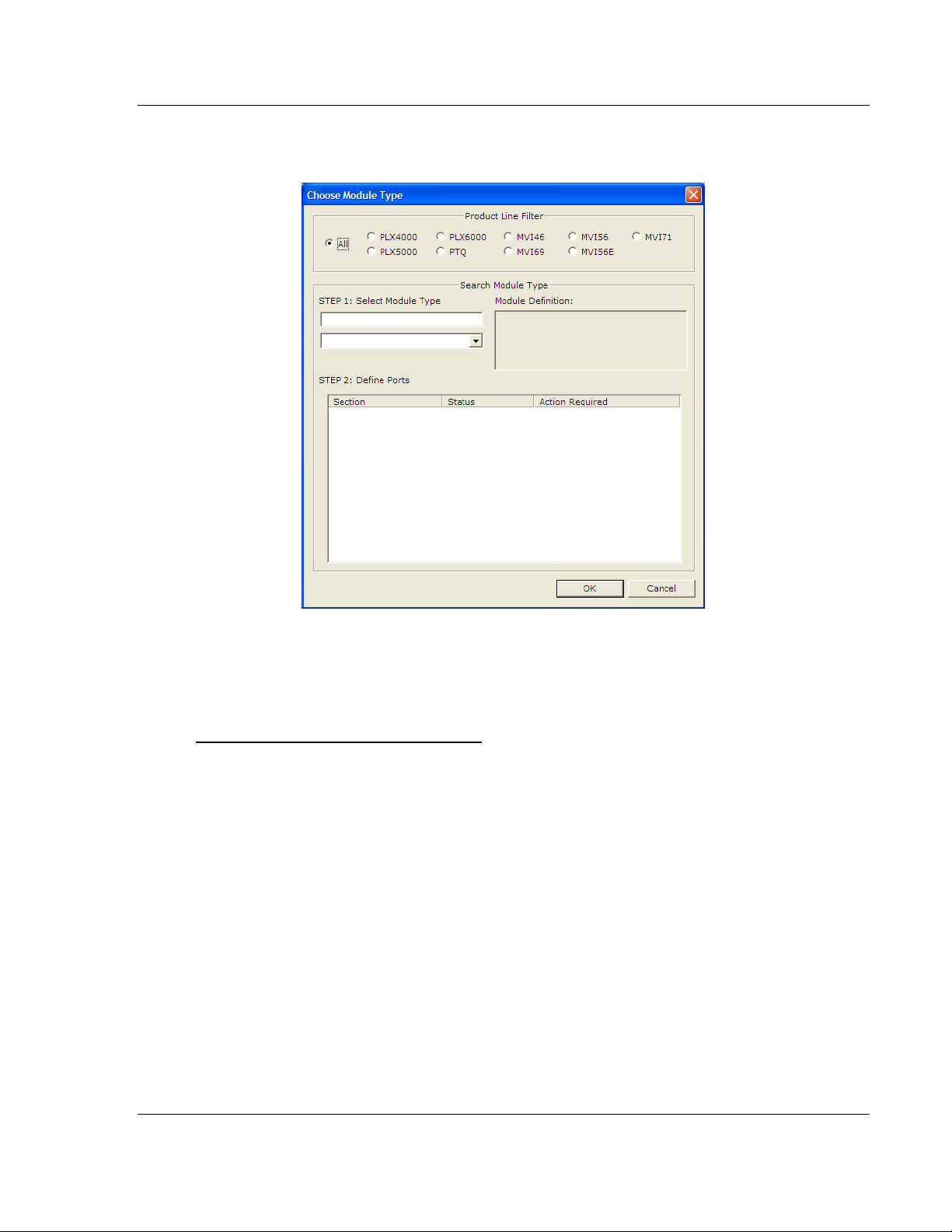

1.6.2 Adding a Module

Begin the process of creating your custom application configuration by selecting

the module type of your ProLinx gateway.

Page 18 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 19

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

1 Double-click the D

EFAULT MODULE

icon to open the Choose Module Type

dialog box.

2 On the Choose Module Type dialog box, select the M

Or

1 Open the P

2 On the L

To add a module to a different location

1 Right-click the L

ROJECT

OCATION

menu and choose L

menu, choose A

OCATION

folder and choose A

OCATION.

DD MODULE

.

DD MODULE

icon appears.

Or

1 Select the L

2 From the P

OCATION

ROJECT

icon.

menu, select L

OCATION

, and then select A

ODULE

. A new M

type.

ODULE

DD MODULE

.

ProSoft Technology, Inc. Page 19 of 144

November 24, 2010

Page 20

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

1.6.3 Quick Start

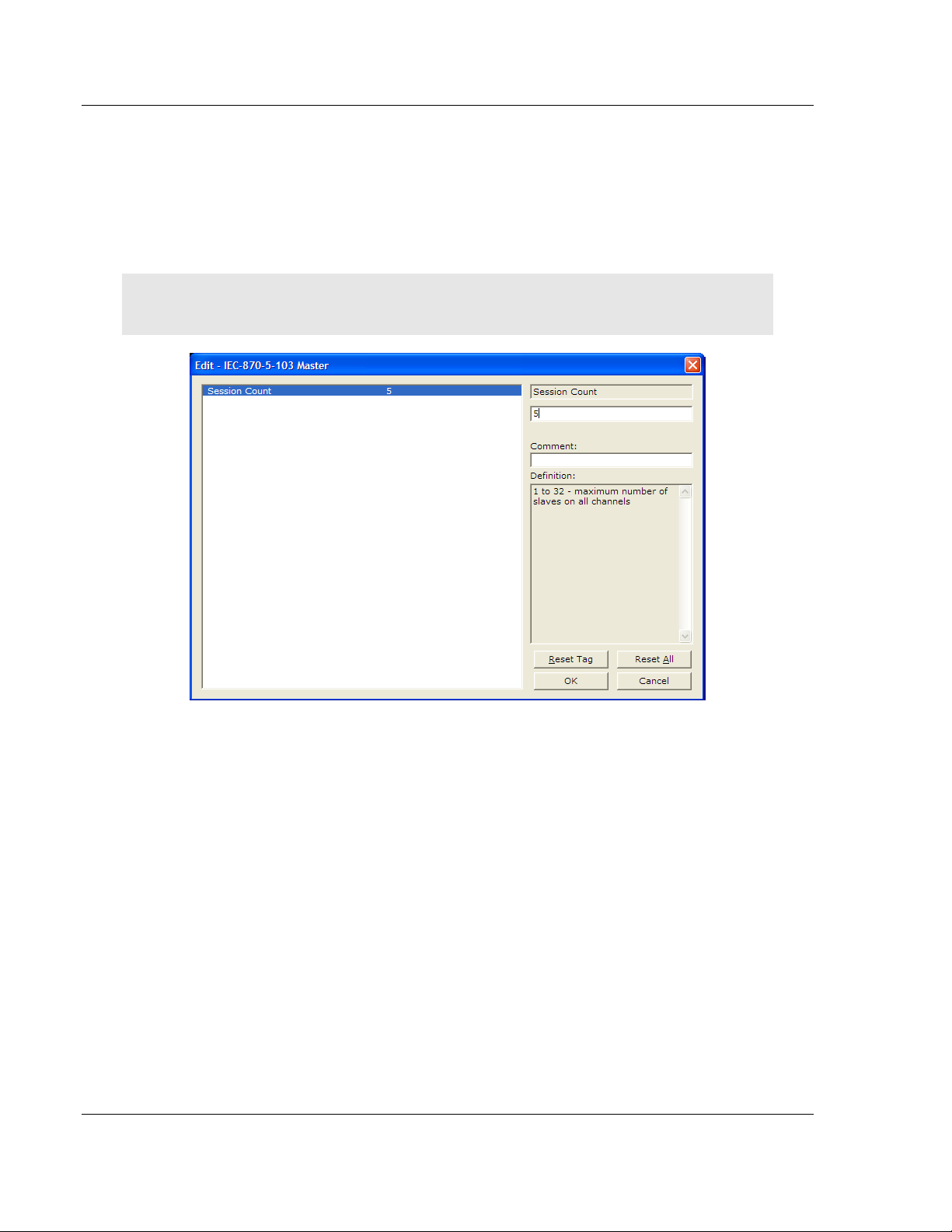

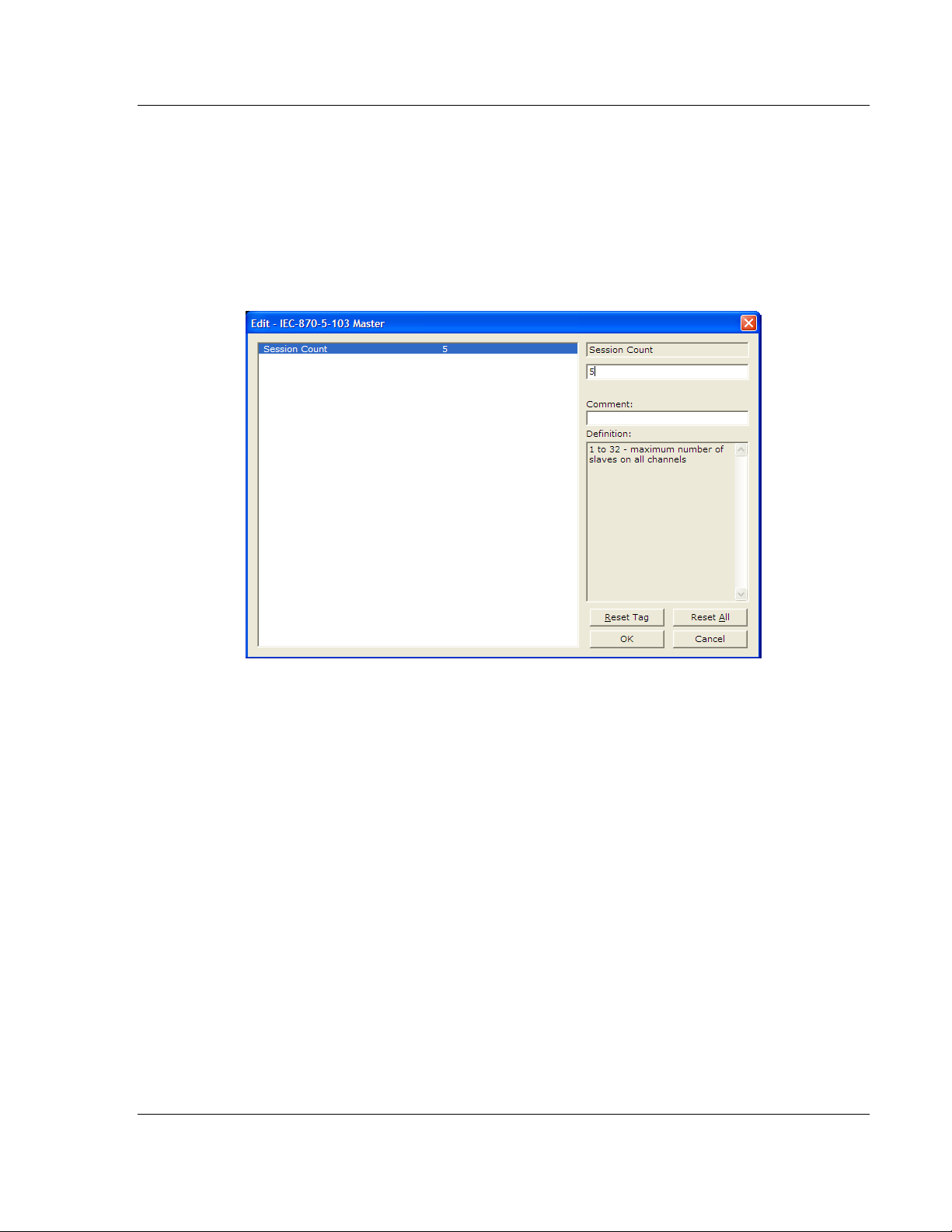

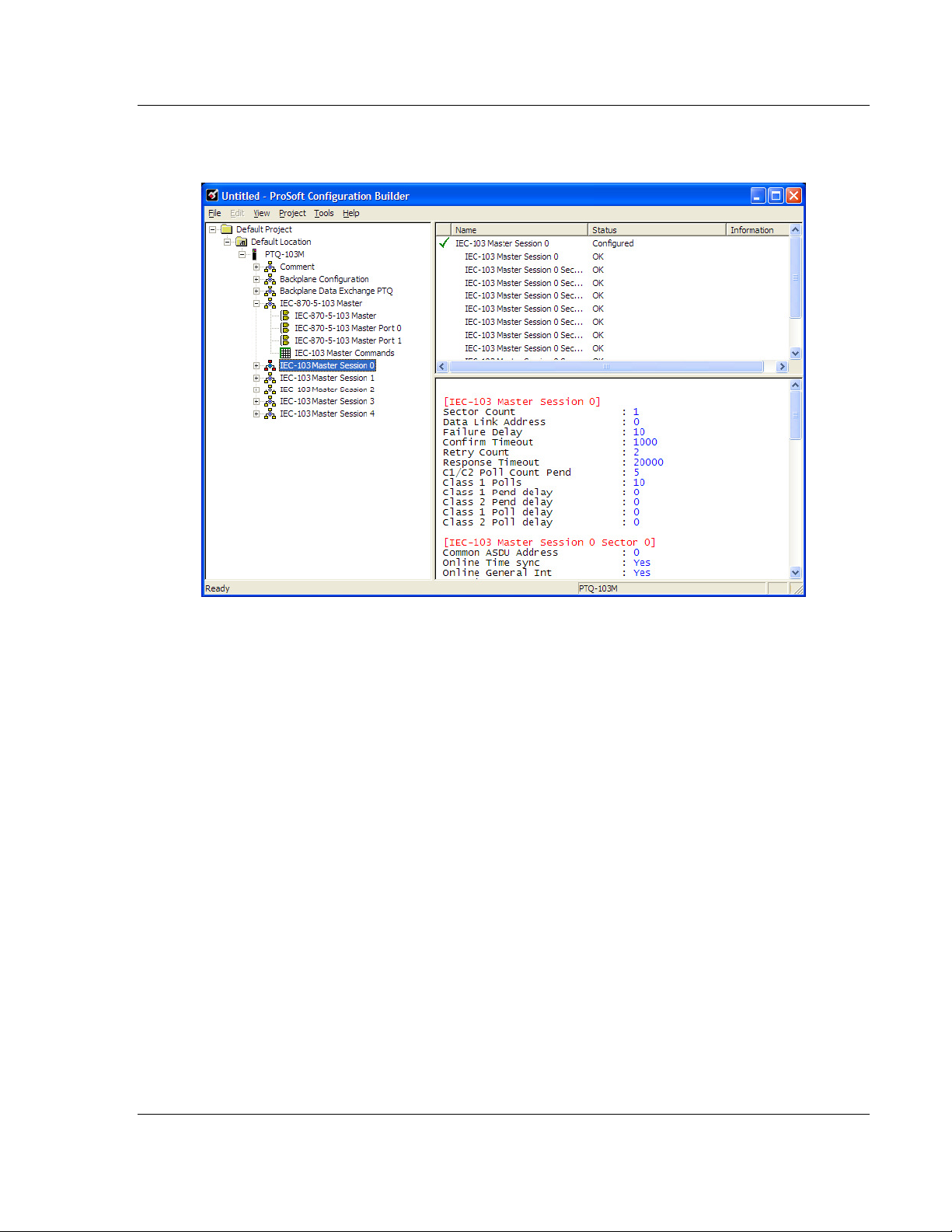

Step 1: Configure the Number of Slaves (Sessions)

The IEC 60870-5-103 protocol is a master-slave protocol where the slaves are

typically protection equipments for substations. The 5105-103M-PDPS module

supports a total 16 slaves (sessions) connected to the module's two application

ports.

Note: The actual number of available sessions (slaves) will depend on the total number of

sessions and sectors (configured. The recommended maximum number of sessions is sixteen.

In the example above, the module will only poll sessions 0 to 4. The module

would not poll sessions 5 to 31.

In Step 3, you will configure each session as an actual slave in the network.

Page 20 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 21

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

Step 2: Configure the Port Communication Parameters

The user should configure the port communication parameters in order to enable

data transfer between the master and the slave(s). The port communication

parameters include baud rate, parity, RTS ON, RTS OFF, and Minimum Delay.

The IEC 60870-5-103 protocol uses two baud rates: 19200 or 9600 kb/s and

even parity.

Refer to the [IEC-870-5-103 Master Port 0] section in the configuration file in

order to configure the communication parameters for the 103M port:

You must also configure the port jumpers to select the correct communication

mode: RS-232, RS-422, or RS-485.

ProSoft Technology, Inc. Page 21 of 144

November 24, 2010

Page 22

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

Step 3: Configure the Session (Slave) Poll Parameters

According to the IEC 60870-5-103 protocol, the master cyclically polls data from

the slaves. The data is classified as Class 1 or Class 2. Events belong to Class

1, and analog data to Class 2. The module can request data through Class 1 or

Class 2 requests. Responses to control command and general interrogation

commands are also sent as Class 1 data.

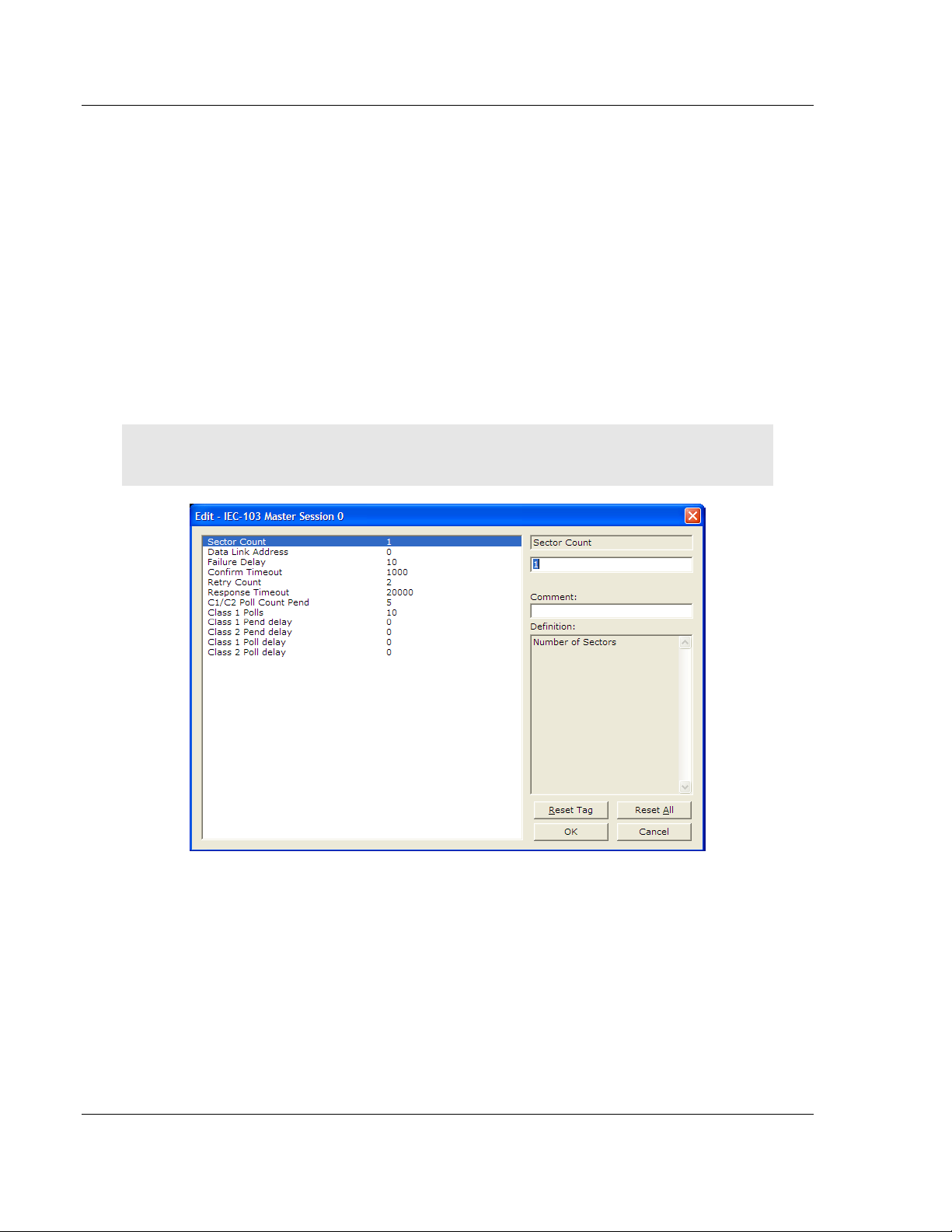

Refer to the [IEC-103 Master Session x] section in the configuration file in order

to configure how each slave will be polled.

These parameters include the Data Link Address, which is the slave address that

identifies each piece of protection equipment in the network. There should be a

unique number for each slave in the network. There are also certain parameters

that pertain to how the Class 1 and Class 2 polls will be used for data transfer.

You must enter the number of sectors for each session using the Sector Count

parameter. The module accepts up to five sectors per session.

Note: Actual number of available sectors per session will depend on the total number of sessions

and sectors configured. The recommended maximum number of sectors is three.

Page 22 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 23

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

Repeat this step for each session. For example, if you configured 5 sessions

during Step 1, configure Sessions 0 to 4.

ProSoft Technology, Inc. Page 23 of 144

November 24, 2010

Page 24

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

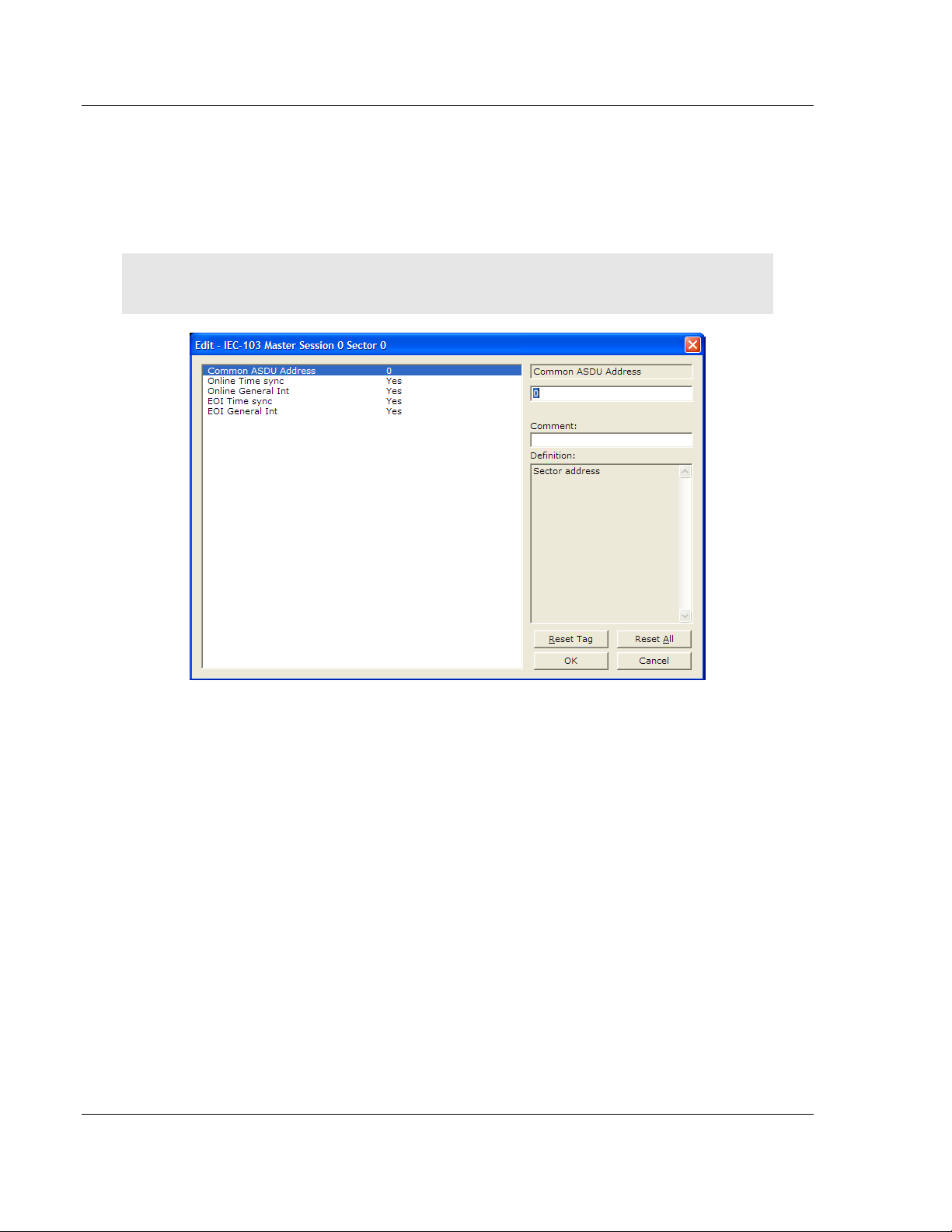

Step 4: Sector (Data Set) Configuration

For each session (slave), you must configure one or more sectors. A sector is a

data set defined by the vendor. Each sector is identified by the Common ASDU

Address parameter in the [IEC-103 Master Session x Sector 0] area in the

configuration. This area also contains some parameters that will affect the

module initialization procedure.

Note: The actual number of available sectors per session will depend on the total number of

sessions and sectors configured. The recommended maximum number of sectors is three.

Repeat this step for each sector used by the application. The module will only

use the sectors configured in the previous step.

Page 24 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 25

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

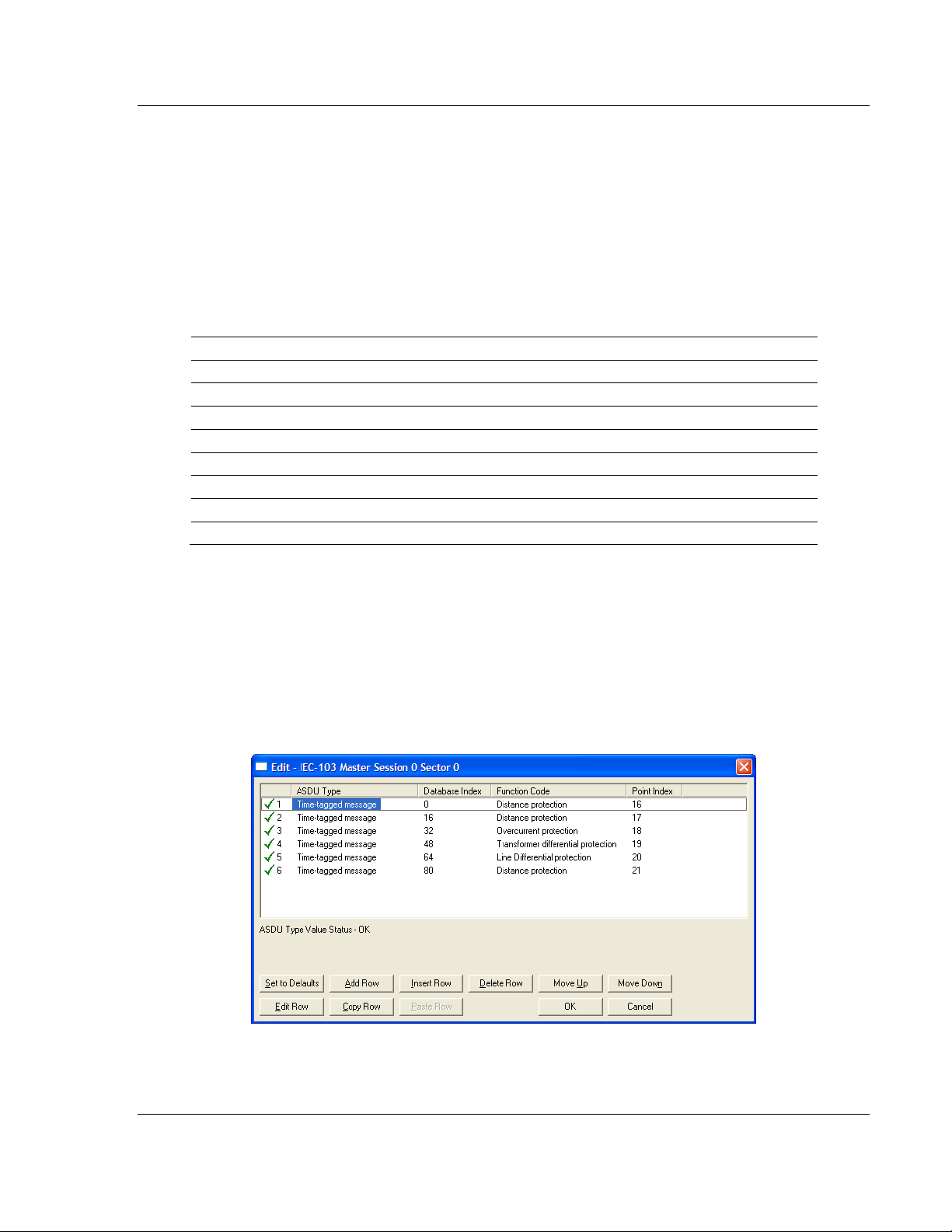

Step 5: Monitor Point Configuration (Monitor Direction)

When a slave receives a Class 1 or Class 2 request from the master, it responds

with a message containing data. Each piece of equipment is normally configured

to respond with specific points when it is being polled with a Class 2 request.

During a Class 2 response, the slave may set a control bit (ACD) to inform the

master that there are new events to be transmitted. Then, the master will send a

Class 1 poll to read the events from the slave.

The IEC 60870-5-103 protocol states that the data is transferred between the

master and slave using an ASDU (Application Service Data Unit) format. Each

format is given by:

Type Identification

Variable Structure Qualifier

Cause Of Transmission

Common Address of ASDU

Function Type

Information Number

Data…

Data…

…

Refer to the protection equipment specification for the following information about

each point:

Type: Type of the message

Function Type: Type of protection function

Information Number: Point Identification

This information identifies each point in the configuration. You must configure the

points that will be updated in the module database when a Class 2 or Class 1

response containing data is sent from the slave. Refer to [IEC-103 M

S

ESSION X SECTOR

0] to configure each point.

ASTER

ProSoft Technology, Inc. Page 25 of 144

November 24, 2010

Page 26

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

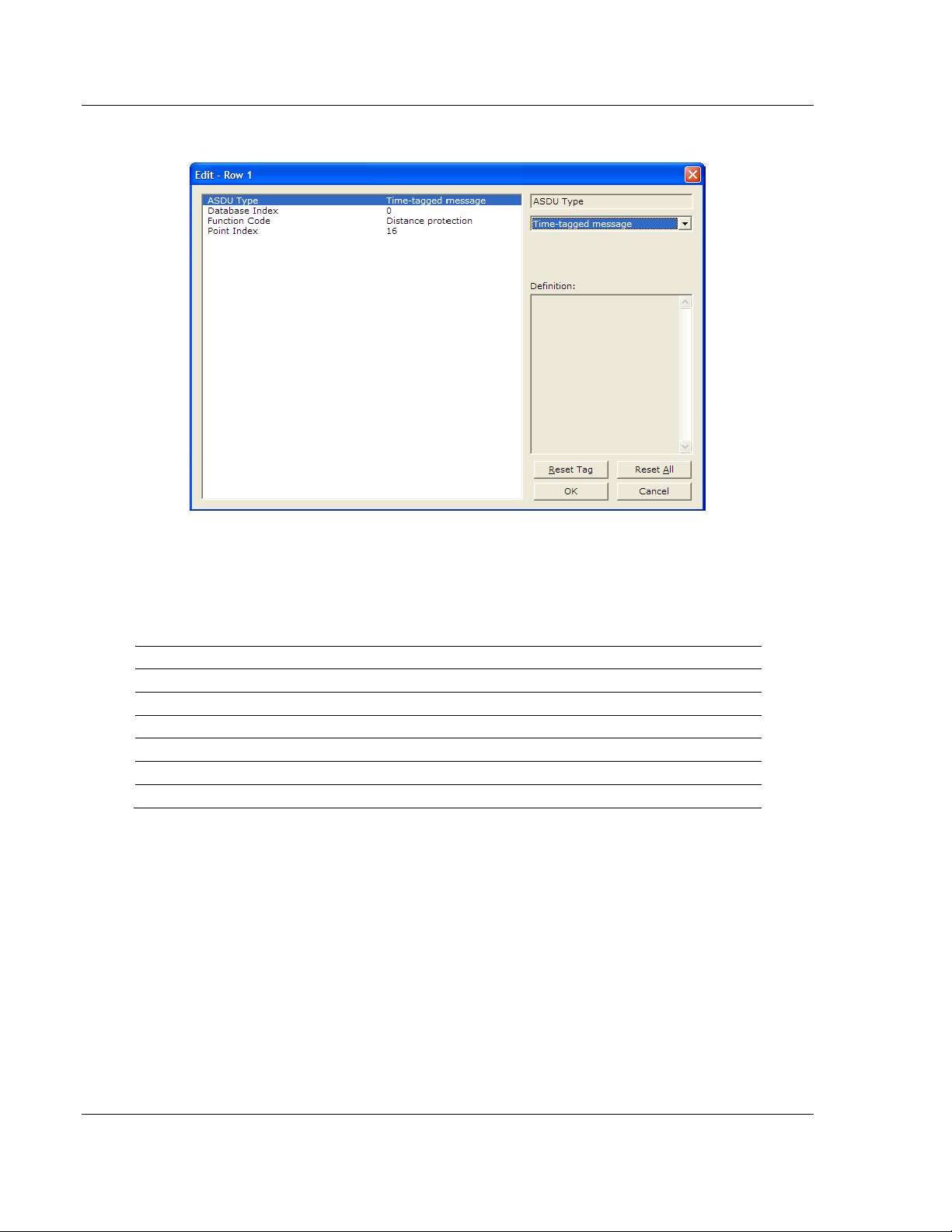

For each point, configure the following values.

ASDU Type: ASDU type for the point

Function Type: Function type for the point

Point Index: Information number for the point

Database Index: The module database location where the value will be copied.

The type of addressing will depend on the ASDU type:

ASDU Type DB Addressing

1 Bit address with each point occupying 2 bits

2 Bit address with each point occupying 2 bits

3 Word address with each point occupying 4 words

4 Double-word address for the single float value

5 Byte address with each point occupying 12 bytes

9 Word address with each point occupying 9 words

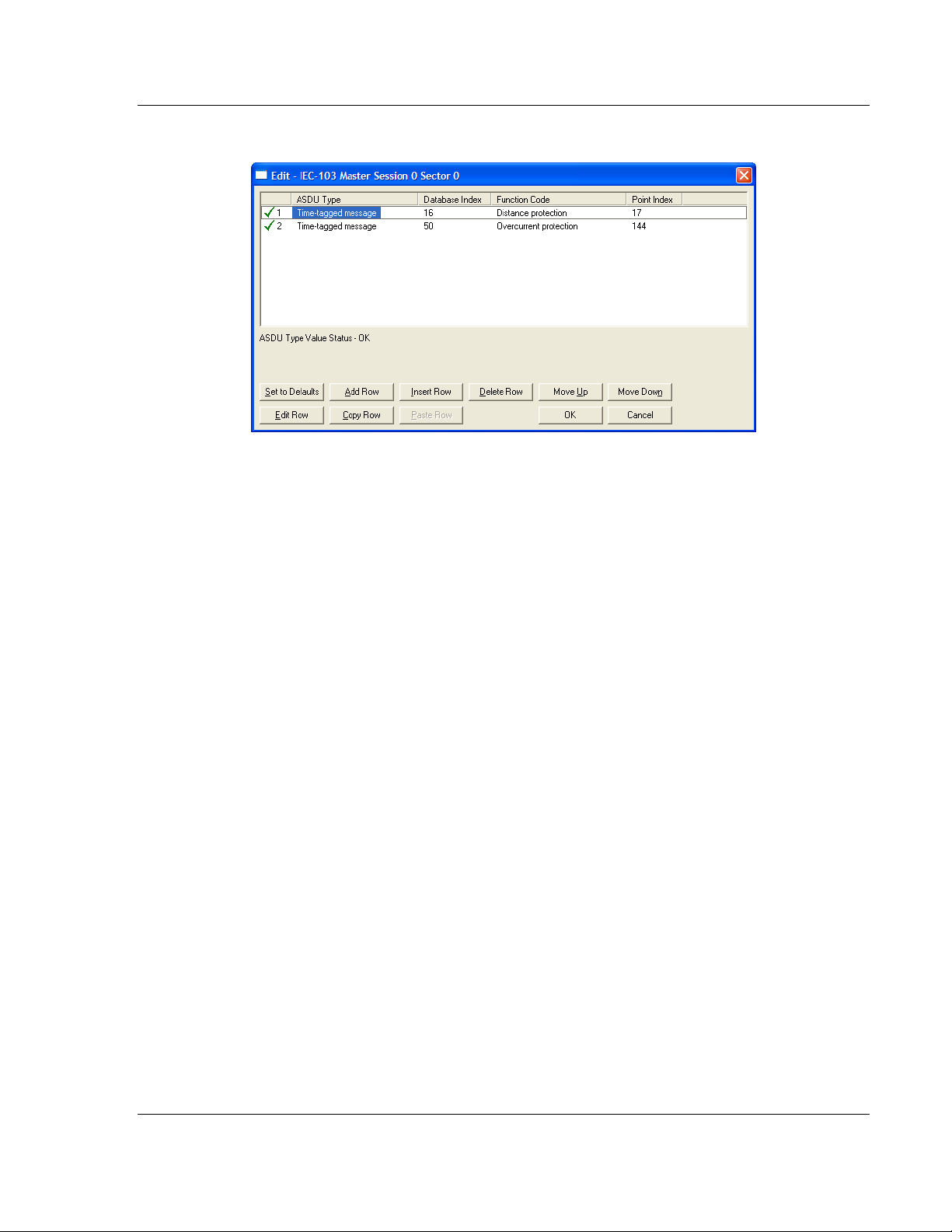

For example, to configure the following points,

Time-tagged message point with information number 17 (teleprotection

active) and distance protection function (128). The value will be copied to bits

0 and 1 in word 1 (second word) in the module database.

Measurands I point with information number 144 (measurands I) and

overcurrent protection function (160). The value will be copied to word 50 in

the module Database.

Page 26 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 27

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

Use the following configuration.

Every time the module responds with a Class 1 or Class 2 poll with these points,

the module will copy the value to the database.

All the points configured in this section are sent from the slave to the master. The

protocol specification refers to this data flow as the Monitor Direction.

Repeat this step for each sector.

ProSoft Technology, Inc. Page 27 of 144

November 24, 2010

Page 28

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

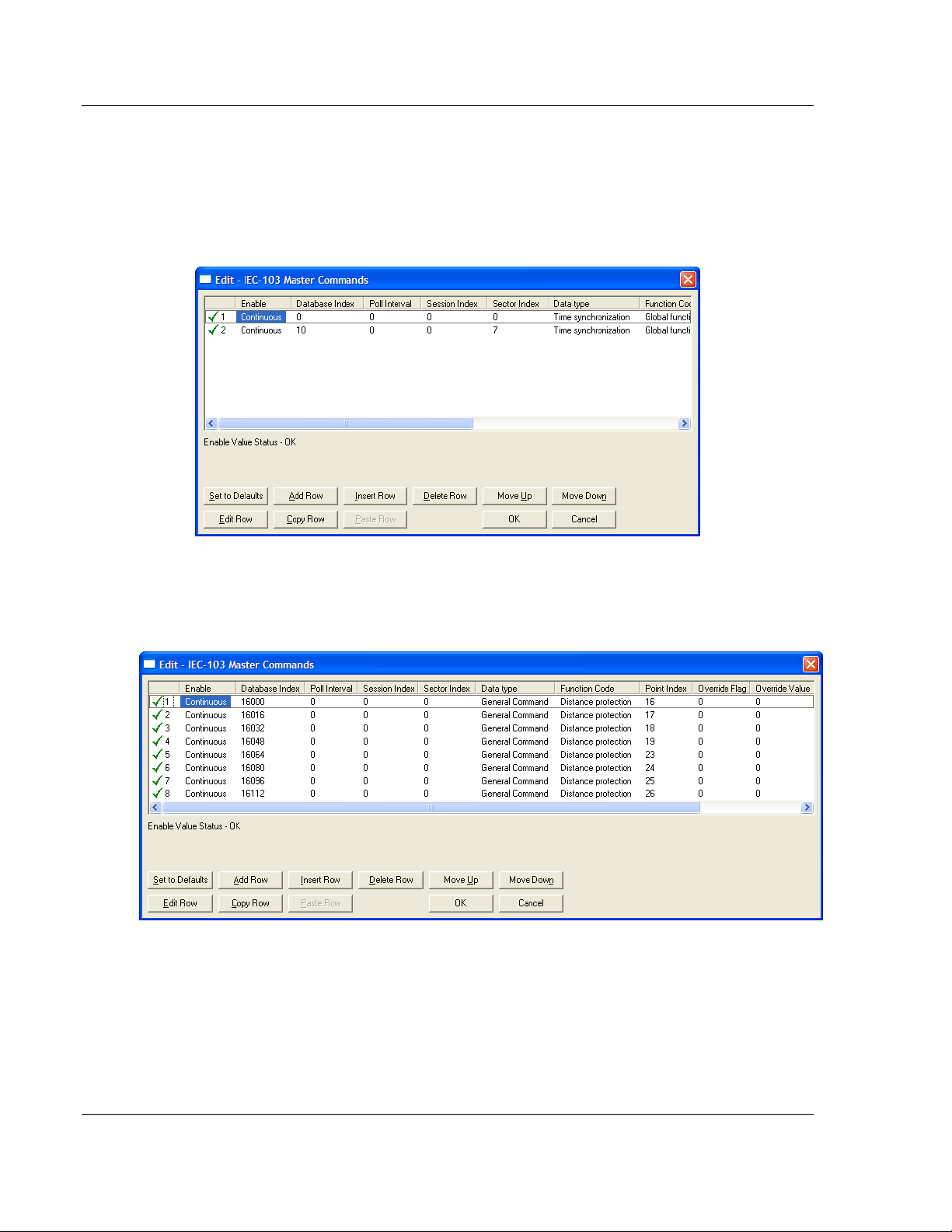

Step 6: Command Configuration (Control Direction)

You can also configure the master to send commands to slaves. The IEC 608705-103 protocol specification refers to this data flow as Control Direction. The

commands include general commands, interrogation requests, and time

synchronization requests. In order to configure a command, refer to the [IEC-103

Master Commands] section:

To send a General Command, you can associate the source data with a register

in the module database to be sent to the remote slave. The following example

will send 8 commands to the slave configured as Session 0/Sector 0. Use bit

addressing to send a General Command.

Refer to the device specification for the Point Index (Information Number) listing

available for control direction.

The module can also send a periodic General Interrogation command in order to

initialize and refresh the event-updated points in its database. The slave keeps a

list of all data subject to General Interrogation.

Page 28 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 29

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

Step 7: Set the module’s Data and Time (optional)

If the module will be sending time synchronization commands to the slave, you

must set the date and time on the module (page 122).

Step 8: Transfer the Configuration from the Computer to the module.

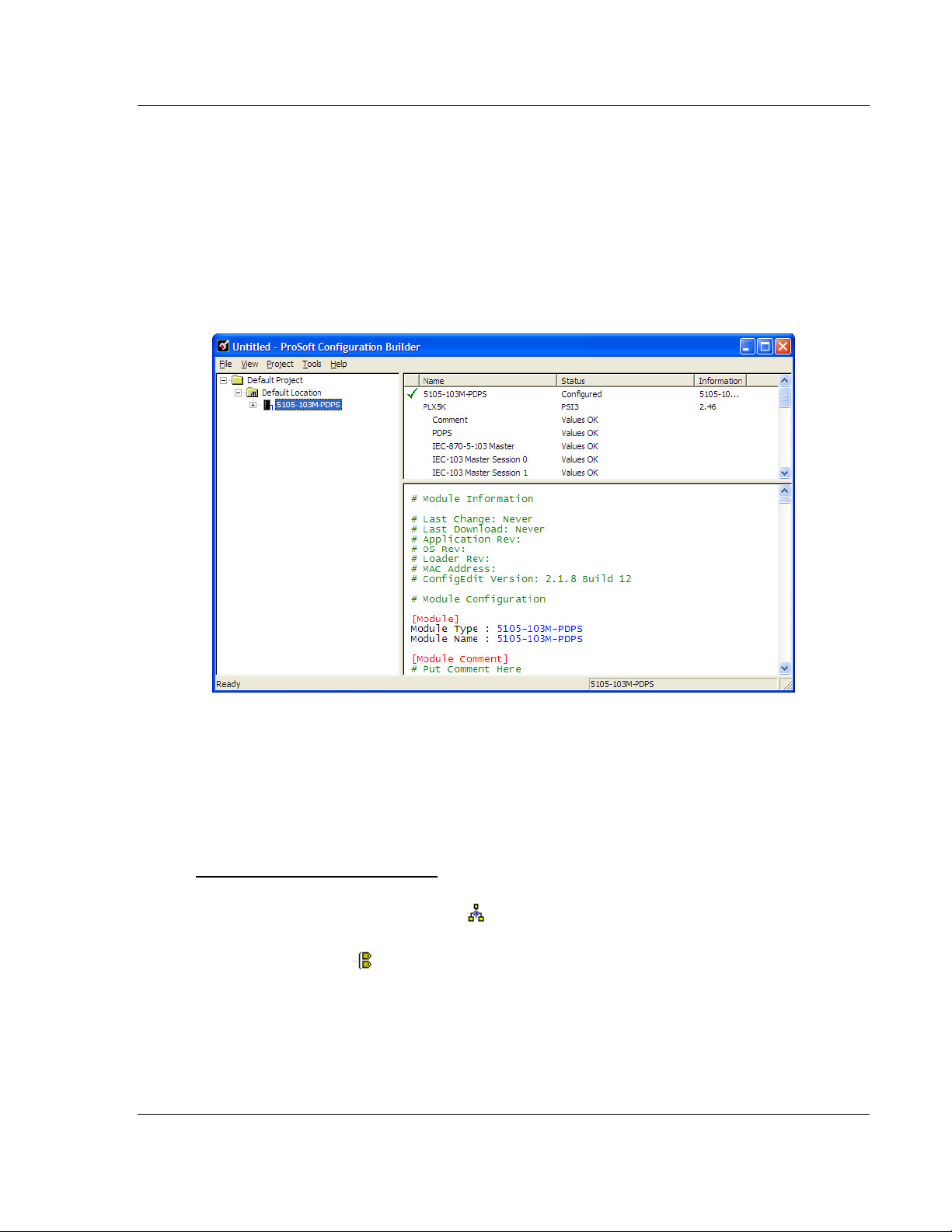

1.6.4 Renaming PCB Objects

Notice that the contents of the information pane and the configuration pane

changed when you added the gateway to the project.

At this time, you may wish to rename the Default Project and Default Location

folders in the tree view.

1 Select the object, and then click the right mouse button to open a shortcut

menu. From the shortcut menu, choose R

ENAME

.

2 Type the name to assign to the object.

3 Click away from the object to save the new name.

Configuring Module Parameters

1 Click on the [+] sign next to the gateway icon to expand gateway information.

2 Click on the [+] sign next to any icon to view gateway information and

configuration options.

3 Double-click any icon to open an Edit dialog box.

4 To edit a parameter, select the parameter in the left pane and make your

changes in the right pane.

5 Click OK to save your changes.

ProSoft Technology, Inc. Page 29 of 144

November 24, 2010

Page 30

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

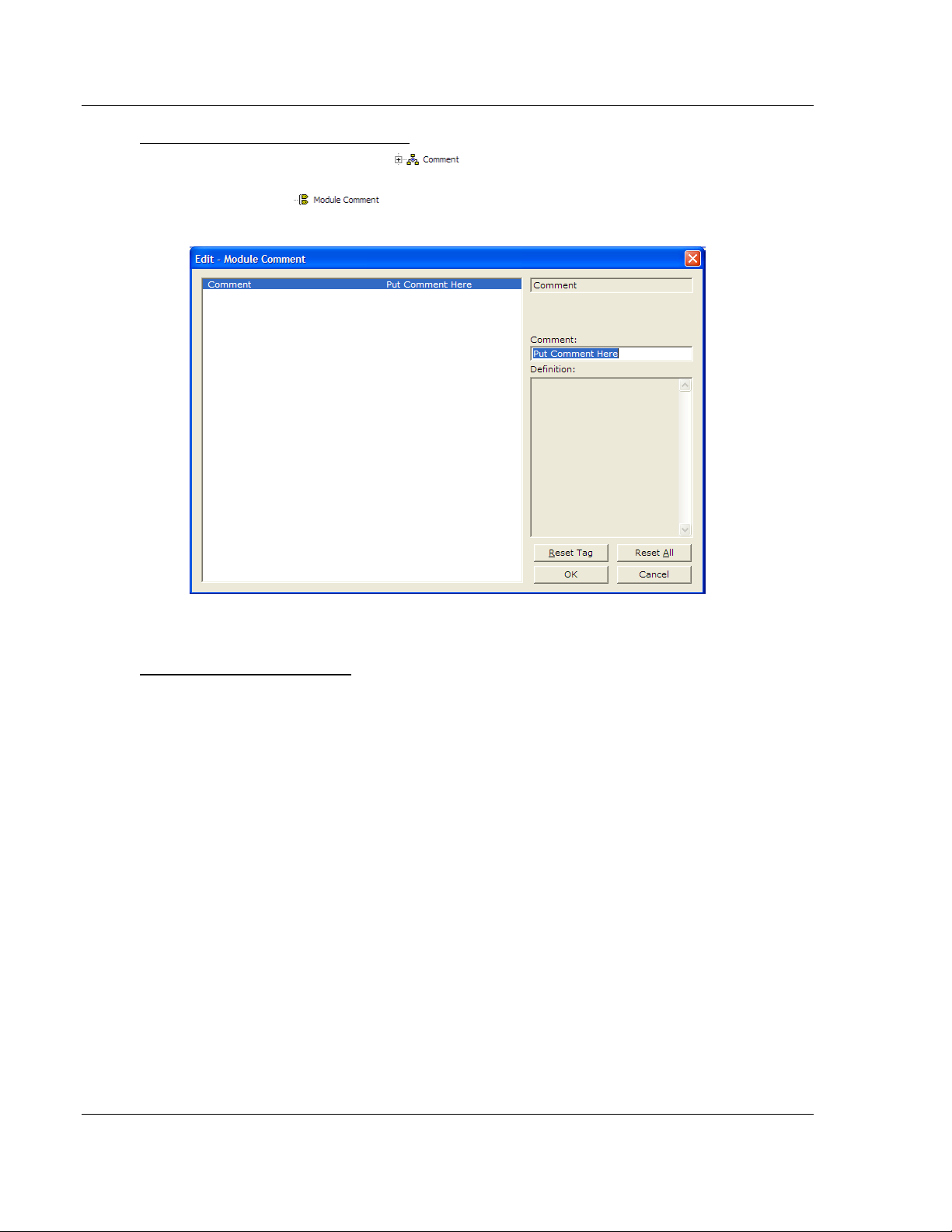

Creating Optional Comment Entries

1 Click the [+] to the left of the icon to expand the module

comments.

2 Double-click the icon. The Edit - Module Comment dialog box

appears.

3 Enter your comment and click OK to save your changes.

Printing a Configuration File

1 Select the gateway icon, and then click the right mouse button to open a

shortcut menu.

2 On the shortcut menu, choose V

IEW CONFIGURATION

. This action opens the

View Configuration window.

3 In the View Configuration window, open the F

ILE

menu, and choose P

RINT.

This action opens the Print dialog box.

4 In the Print dialog box, choose the printer to use from the drop-down list,

select printing options, and then click OK.

Page 30 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 31

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

1.7 103M Protocol Configuration

The following is excerpted from a configuration file showing typical examples

used for configuration of the 103M driver. A default configuration file for each

module application that includes the 103M interface card is available for

download from the www.prosoft-technology.com web site. This default

configuration can easily form the basis for a working solution. This file can either

be downloaded from the ProSoft web site at www.prosoft-technology.com, or

transferred from the module.

The configuration file contains the following topics:

[Section] Description

[IEC-870-5-103 Master] General configuration for the driver.

[IEC-870-5-103 Master Port n] Configuration for one of the application ports.

[IEC-103 Master Session x] Definition of each control unit.

[IEC-103 Master Session x Sector y] Definition for each sector in the controlled unit.

[IEC-103 Master Commands] Command list to control slave units.

1.7.1 [IEC-103 Master Commands]

This section can contain up to 1000 user defined commands to be executed by

the module and sent to the controlled devices. There is no need to place Class 1

or Class 2 polls in this list for the controlled devices as the master driver for each

port will execute these automatically when the port is idle. In order for the port to

be idle, make sure that there is idle time available, and that the commands do not

constantly utilize the ports.

ProSoft Technology, Inc. Page 31 of 144

November 24, 2010

Page 32

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

Enable Code

0 = Disabled

1 = Enabled, will execute using Poll Interval parameter (page 32) (seconds)

2 = Conditional (executed when point in database changes)

This field defines whether the command is to be executed, and under what

conditions. To disable the command, set this parameter to 0 (Disabled). You can

still execute commands through the processor, using a Special Function block.

To enable the command, set this parameter to 1.

Set the Poll Interval Time to 0 to execute the command during each scan of

the command list.

Set the Poll Interval Time to a value in seconds, to execute the command at

the specified interval (page 32).

To execute the command only if the internal data associated with the command

changes, set this parameter to 2. This value is valid only for write commands.

Database Index

Database Index is the location in the module's database to use as the source for

the data in the command. Refer to Data Type for specific information on

addressing (page 33).

The data type field determines the meaning of the database index as follows:

Type Description DB Index type

6 Clock synchronization NA

7 General interrogation NA

20 General Command Bit address

Poll Interval

This parameter specifies the minimum frequency at which the module should

execute the command when the Enable Code is set to one 1. The value is

entered in units of seconds. For example, to execute a command every 10

seconds, enter a value of 10 in the field. A value of 0 for the parameter implies

that the command should be executed every scan of the list, as quickly as

possible.

Session Index

0 to 31

Session Index represents the session index in the module to associate with the

command. This index is set when the session is read in from this file. The range

of values for this field is 0 to 31.

Sector Index

0 to 4

Sector Index represents the sector index for the specific session. There are a

maximum of five (5) sectors per session.

Page 32 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 33

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

Data Type

Data type file represents the ASDU type as follows:

Type Description

6 Clock synchronization

7 General interrogation

20 General Command

Function Code

Code Definition

128 Distance protection

160 Overcurrent protection

176 Transformer differential protection

192 Line Differential protection

255 Global function type

133 Meter Data for SIEMENS Devices

1 Reset Process

2 Class 2 Polls

x User-defined

Note: The last item in the Function Code dropdown list is user-defined. If you select U

SER DEFINED

from the dropdown list, a text box will appear below the list. You may enter any function code in

this text box that will be accepted by the destination slave.

Point Index

Point Index specifies the address in the remote slave device of the point to

interact with.

Index Value Description

1 Bit address with each point occupying 2 bits

2 Bit address with each point occupying 2 bits

3 Word address with each point occupying 4 words

4 Double-word address for the single float value

5 Byte address with each point occupying 12 bytes

9 Word address with each point occupying 9 words

Override Flag

0 or 1

Override Flag field is used for general commands to determine the value to be

written. If the override flag is clear (0), the value in the database will be utilized. If

the override flag is set (1), the value specified in the override value field will be

used.

ProSoft Technology, Inc. Page 33 of 144

November 24, 2010

Page 34

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

Override Value

If the Override Flag is set to "Yes", you can use this setting to always force a

control parameter to a fixed value. Use Enable code C

database value for the command to determine when the value should be written.

ONDITIONAL

and the

1.7.2 [IEC-870-5-103 Master]

This section establishes the total number of slaves to communicate with through

both application serial ports.

[IEC-870-5-103 Master]

Session Count : 1 #1 to 32 - maximum number of slaves on all channels

Session Count

1 to 16

This parameter specifies the maximum number of sessions (slaves) to interface

with the module's 103M application ports. This value represents the total number

of slaves on all ports.

1.7.3 [IEC-870-5-103 Master Port x]

These settings configure the communication parameters for each application port

on the module. The following illustration shows typical settings for a Master port.

Page 34 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 35

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

Baud Rate

Baud Rate Value

This is the baud rate to be used on the port. Enter the baud rate as a value. For

example, to select 19K baud, enter 19200. Valid entries for this field include: 110,

150, 300, 600, 1200, 2400, 4800, 9600, 19200 (may also enter as 192 or 1920),

28800 (may also enter 288 or 2880), 38400 (may also enter as 384 or 3840),

57600 (may also enter as 576 or 5760), and 115200 (may also enter as 115,

1152, or 11520).

Parity

N, O, E, M, or S

This parameter sets the parity to be used on the port. The values correspond to

the following settings: N=None, O=Odd, E=Even, M=Mark and S=Space.

Note: The 103M specification supports only Even Parity.

RTS On

0 to 65535 milliseconds

This parameter sets the number of milliseconds to delay after Ready To Send

(RTS) is asserted before data will be transmitted.

RTS Off

0 to 65535 milliseconds

This parameter sets the number of milliseconds to delay after the last byte of

data is sent before the RTS modem signal will be set low.

Minimum Delay

1 to 60000 milliseconds

This parameter specifies the minimum number of milliseconds to delay before

sending the message (setting RTS high). This can be used when the serial

network requires time for units to turn off their transmitters.

Receive Timeout

1 to 65535 milliseconds

This value represents the number of milliseconds to wait on a port from the time

the first character is received until the last character in the longest message is

received. This parameter will be dependent on the baud rate. A value of 2000

should work with most applications.

Single char ACK F0, 1, or 3

Yes or No

This parameter specifies if the signal E5 character will be used for ACK

messages.

ProSoft Technology, Inc. Page 35 of 144

November 24, 2010

Page 36

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

1.7.4 [IEC-103 Master Session x]

This section defines Session y, which runs on Port x. The Session Count

parameter in the [IEC-870-5-103 Master] section of the configuration (page 34)

determines the number of sessions (controlled devices) for this port.

The sessions are referenced by a zero-based index value. For example, if the

module is configured for four sessions, the configuration file should contain

sections for Sessions 0 to 3 (that is, [IEC-103 Master Session 0] to [IEC-103

Master Session 3]).

The parameters in [IEC-103 Master Session y] define the characteristics of the

specific controlled device to interface.

Communication Port

0 or 1

This parameter sets the port to which the controlled device is connected. On this

module, values of 0 and 1 are permitted.

Sector Count

1 to 3

This parameter sets the number of Sectors (separate databases or Multiple

Application Layer ASDU addresses) contained in this Session (controlled

device). This version of the application supports 1 to 3 sectors for each session.

Data Link Address

0 to 254

This parameter uniquely defines the data link address for this unit on the

communication channel. The ranges of values are from 0 to 254. Address 255 is

the broadcast address.

Failure Delay

0 to 2000 seconds

This parameter sets the minimum number of seconds to delay before polling this

session when it is not online. This parameter is only used in unbalanced mode.

Confirm Timeout

0 to 4,294,967,295 (two raised to the power of 32, minus one) milliseconds

This parameter sets the number of milliseconds to wait for a confirm response

from the controlled device.

Retry Count

0 to 255

In balanced mode, this parameter specifies the number of retries (0 to 255) if a

response is not received. In unbalanced mode, this parameter is ignored.

Page 36 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 37

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

C1/C2 Poll Count Pend

0 to 65535

This parameter sets the maximum number of Class 1 and Class 2 polls

performed on this session before trying the next session. This parameter

prevents a session from monopolizing the communication port.

Class 1 Polls

0 to 100

This parameter sets the maximum number of Class 1 polls performed on this

session before switching to another session. This parameter prevents a session

from monopolizing the communication port.

Class 1 Pend Delay

0 to 4,294,967,295 (two raised to the power of 32, minus one) milliseconds

This parameter sets the minimum number of milliseconds to delay between Class

1 polls for pending data.

Class 2 Pend Delay

0 to 4,294,967,295 (two raised to the power of 32, minus one) milliseconds

This parameter sets the minimum number of milliseconds to delay between Class

2 polls for pending data.

Class 1 Poll Delay

0 to 4,294,967,295 (two raised to the power of 32, minus one) milliseconds

This parameter sets the minimum number of milliseconds to delay between each

Class 1 poll.

Class 2 Poll Delay

0 to 4,294,967,295 (two raised to the power of 32, minus one) milliseconds

This parameter sets the minimum number of milliseconds to delay between each

Class 2 poll.

Auto Clock Req Mode

0=Sync Only, 1=Load delay/sync, 2=Acquire delay/load delay/sync

This parameter specifies the method used to perform automatic clock

synchronization. 0 performs a synchronization without delay, 1 performs

synchronization using the fixed Propagation Delay and 2 computes the delay and

use this value when synchronization takes place.

Propagation Delay

0 to 65535

This parameter sets the fixed propagation delay to be utilized if the Auto Clock

Req Mode parameter is set to a value of 1.

ProSoft Technology, Inc. Page 37 of 144

November 24, 2010

Page 38

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

Response Timeout

0 to 4,294,967,295 milliseconds

This parameter sets the maximum number of milliseconds to wait for a

confirmation from the controlled station to a request from this module.

ACTTERM with setpoint

Yes or No

This parameter determines if an ACTTERM will be sent. If the parameter is set to

Yes, then setpoint commands will issue an ACTTERM when the command is

complete. If the parameter is set to No, ACTCON is the last response to a

setpoint command.

1.7.5 [IEC-103 Master Session x Sector y]

This section defines Sector z, which belongs to Session y. The Sector Count

parameter (page 36) in the [IEC-870-5-103 Master Session y] section specifies

the number of sectors for the session.

Each sector has a corresponding [IEC-103 Master Session y Sector z] section,

where y represents the session index and z represents the sector index.

The sectors are referenced by a zero-based index value. For example, if Session

0 is configured for four sectors, the configuration file should contain sections for

Sectors 0 to 3 (that is, [IEC-103 Master Session 0 Sector 0] to [IEC-103 Master

Session 0 Sector 3]).

Page 38 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 39

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

Common ASDU Address

0 to 255

This parameter sets the common ASDU address to association with this sector of

the specified session. This parameter is usually set the same as the Data Link

Address when only one sector is used.

Online Time Sync

Yes or No

This parameter specifies if the sector in the controlled device will be sent a time

synchronization command when the unit is first recognized as being online. This

should only be used for devices that do not send an EOI message after

initializing.

Online General Int

Yes or No

This parameter specifies if the sector in the controlled device will be sent a

general interrogation command when the unit is first recognized as being online.

This should only be used for devices that do not send an EOI message after

initializing.

EOI Time Sync

Yes or No

This parameter specifies if the sector in the controlled device will be sent a time

synchronization command after this module received an EOI message from the

controlled unit.

EOI General Int

Yes or No

This parameter specifies if the sector in the controlled device will be sent a

general interrogation command after this module received an EOI message from

the controlled unit.

ASDU Type

This field contains the ASDU type code for the data contained in the message.

1 = Time-tagged message (bit addressed with 2 bits/point)

2 = Time-tagged message with relative time (bit addressed with 2 bits/point)

3 = Measurands I (4 word values using word address using double-word

address)

4 = Time-tagged measurands with relative time (1 float value)

5 = Identification (12 characters using a byte address)

9 = Measurands II (9 word values using word address)

205 = Siemens meter data

ProSoft Technology, Inc. Page 39 of 144

November 24, 2010

Page 40

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

Database Index

Database Index is the location in the module's database to use as the source for

the data in the command. Refer to Data Type for specific information on

addressing (page 33).

The data type field determines the meaning of the database index as follows:

Type Description DB Index type

6 Clock synchronization NA

7 General interrogation NA

20 General Command Bit address

Function Code

Code Definition

128 Distance protection

160 Overcurrent protection

176 Transformer differential protection

192 Line Differential protection

133 For SIEMENS ASDU type 205

255 Global function type

x User-defined

Note: The last item in the Function Code dropdown list is user-defined. If you select U

SER DEFINED

from the dropdown list, a text box will appear below the list. You may enter any function code in

this text box that will be accepted by the destination slave.

Point Index

Point Index specifies the address in the remote slave device of the point to

interact with.

Index Value Description

1 Bit address with each point occupying 2 bits

2 Bit address with each point occupying 2 bits

3 Word address with each point occupying 4 words

4 Double-word address for the single float value

5 Byte address with each point occupying 12 bytes

9 Word address with each point occupying 9 words

Page 40 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 41

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

1.8 PDPS Protocol Configuration

The following illustration from ProSoft Configuration Builder shows the

PROFIBUS Slave configuration for a ProLinx PDPS module.

1.8.1 [PROFIBUS SLAVE]

The PROFIBUS Slave section contains the data that applies to the PROFIBUS

Slave parameters.

Slave Address

0 to 125

The parameter specifies the node address on the PROFIBUS network for the

slave emulated in the module. Each node on the network must have a unique

address.

Note: Although valid PROFIBUS Node addresses range from 0 to 125, Node 0 is not a valid node

number for a Slave module and that Nodes 0, 1, and 2 are usually reserved for PROFIBUS

Masters. Users are advised to use Node numbers 3-125

Swap Input Bytes

Yes or No

This parameter specifies if the data in the input data area of the module is to be

byte swapped. If the order of the bytes in the words stored in the database is not

correct, use this option. A value of Yes causes the module’s program to swap the

bytes in each word. A value of No indicates no byte swapping will occur.

ProSoft Technology, Inc. Page 41 of 144

November 24, 2010

Page 42

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

Swap Output Bytes

Yes or No

This parameter specifies if the data in the output data area of the module is to be

byte swapped. If the order of the bytes in the words stored in the database is not

correct, use this option. A value of Yes causes the module’s program to swap the

bytes in each word. A value of No indicates no byte swapping will occur.

Comm Failure Mode

No xfer on fail

Xfer on comm fail

This parameter sets the data transfer mode of the module's PROFIBUS output

image to the internal database when a communication failure on the PROFIBUS

interface is detected. If the parameter is set to "No xfer on fail", the output image

will continue to be transferred. If the parameter is set to "xfer on comm fail", the

output image will not be transferred and the last values will be retained.

Comm Timeout Multiplier

1 to 10

This parameter sets the communication timeout value for the module. The value

entered is multiplied by 125 milliseconds to determine the actual timeout value.

For example, a value of 1 specifies a communication timeout of 125 milliseconds.

Use Database Paging

Yes or No

This Parameter Enables or disables user access to the PDPS’s Database area

outside the section reserved for the PROFIBUS Protocol in the range of Word

400 to Word 3999.

Page 42 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 43

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

1.8.2 Set_Param (SAP61)

ProSoft PROFIBUS Slave (PDPS) devices have a configurable parameter for

SPC3 User Prm Byte. The following illustrations show the value of this parameter

in Sycon, the configuration tool for ProLinx PROFIBUS DPV0 Master devices,

and in ProSoft Configuration Builder for PROFIBUS, the configuration tool for

ProSoft and ProLinx PROFIBUS DPV1 Master devices.

ProSoft Technology, Inc. Page 43 of 144

November 24, 2010

Page 44

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

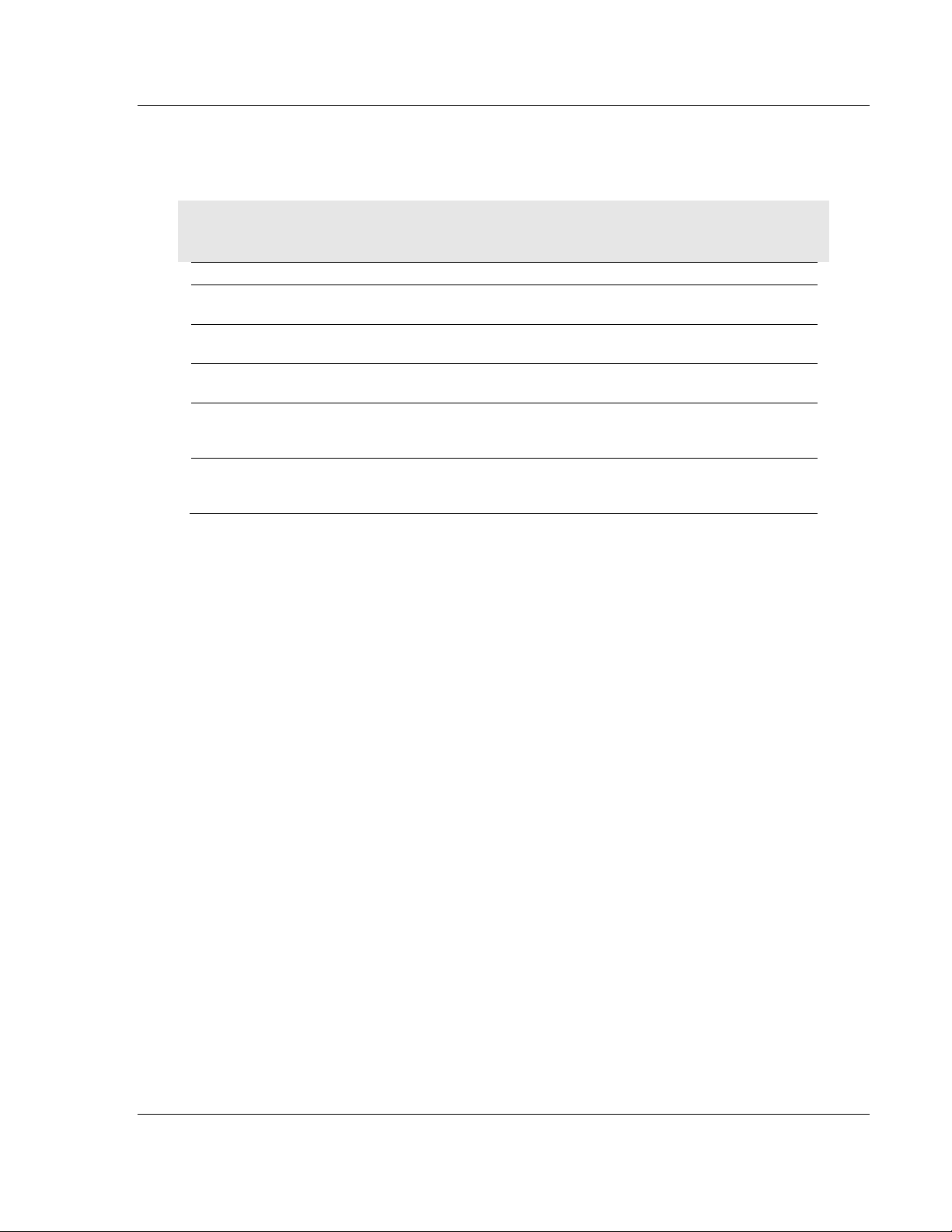

Parameter Data Structure

SPC3 evaluates the first seven data bytes (without user prm data), or the first

eight data bytes (with user prm data). The first seven bytes are specified

according to the standard. The eighth byte is used for SPC3-specific

communications. The additional bytes are available to the application.

Byte Bit Position Designation

7 6 5 4 3 2 1 0

0 Lock

Reg

1

2

3

4

5

6

7

8 to 243

Byte 7 Spec_User_Prm_Byte

Bit Name Significance Default State

0 Dis_Startbit The start bit monitoring in the receiver

1 Dis_Stopbit Stop bit monitoring in the receiver is

2 WD_Base This bit specifies the time base used to

3 to 4 Res To be parameterized with 0 0

5 Publisher_Enable DXB-publisher-functionality of the

6 to 7 Res To be parameterized with 0 0

Unio

Req

Sync

Req

Free

Req

WD on Res Res Res Station status

is switched off with this bit

switched off with this bit

clock the watchdog.

WD_Base = 0: time base 10 ms

WD_Base = 1: time base 1 ms

SPC3 is activated with this bit

WD_Fact_1

WD_Fact_2

MinTSDR

Ident_Number_High

Ident_Number_Low

Group_Ident

Spec_User_Prm_Byte

User_Prm_Data

Dis_Startbit = 1,

That is, start bit monitoring is disabled.

Dis_Stopbit = 0

That is, stop bit monitoring is enabled

WD_Base = 0

That is, the time base is 10 ms.

Publisher_Enable = 0, DXB-requesttelegrams are ignored;

Publisher_Enable = 1, DXB-requesttelegram are processed

Page 44 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 45

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

1.9 Using the CommonNet Data Map

The Data Map section allows you to copy data between areas in the gateway's

internal database.

You can copy a maximum of 100 registers per Data Map command, and you can

configure a maximum of 200 separate copy commands.

You can copy data from the error or status tables in upper memory to internal

database registers in the User Data memory area.

You can rearrange the byte and/or word order during the copy process. For

example, by rearranging byte or word order, you can convert floating-point values

to the correct format for a different protocol.

You can also use the Data Map to condense widely dispersed data into one

contiguous data block, making it easier to access.

ProSoft Technology, Inc. Page 45 of 144

November 24, 2010

Page 46

Start Here 5105-103M-PDPS ♦ ProLinx Gateway

User Manual IEC 60870-5-103 Master to PROFIBUS Slave Gateway

1.9.1 From Address

0 to highest Status Data address

This field specifies the beginning internal database register address for the copy

operation. This address can be any valid address in the User Data Area or the

Status Data Area of the gateway.

1.9.2 To Address

0 to 3999

This parameter specifies the beginning destination register address for the copy

operation. This address must always be within the User Data registers area.

Take care to specify a destination address that will not overwrite data that has

been stored in memory by one of the communication protocols running on the

gateway.

1.9.3 Register Count

1 to 100

This parameter specifies the number of registers to copy.

Page 46 of 144 ProSoft Technology, Inc.

November 24, 2010

Page 47

5105-103M-PDPS ♦ ProLinx Gateway Start Here

IEC 60870-5-103 Master to PROFIBUS Slave Gateway User Manual

1.9.4 Swap Code

NO C

HANGE

You may need to swap the order of the bytes in the registers during the copy