Page 1

PDPM

ProLinx Gateway

PROFIBUS DP Master

June 24, 2013

PROTOCOL MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2013 ProSoft Technology, Inc., all rights reserved.

PDPM Driver Manual

June 24, 2013

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed DVD and are

available at no charge from our web site: http://www.prosoft-technology.com

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS

I, DIV. 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

ProLinx® Products Warnings

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT – RISQUE D'EXPLOSION – AVANT DE DÉCONNECTER L'EQUIPMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Page 3

ProLinx Gateways with Ethernet Ports

Series C ProLinx™ Gateways with Ethernet ports do NOT include the HTML Web Server. The HTML Web Server

must be ordered as an option. This option requires a factory-installed hardware addition. The HTML Web Server now

supports:

8 MB file storage for HTML files and associated graphics files (previously limited to 384K)

32K maximum HTML page size (previously limited to 16K)

1.1.1 To upgrade a previously purchased Series C model

Contact your ProSoft Technology distributor to order the upgrade and obtain a Returned Merchandise Authorization

(RMA) to return the unit to ProSoft Technology.

1.1.2 To order a ProLinx Plus gateway with the -WEB option

Add -WEB to the standard ProLinx part number. For example, 5201-MNET-MCM-WEB.

Markings

Label Markings

<cULus>

E183151

Class I Div 2

Groups A,B,C,D T6

-30°C <= Ta <= 60°C

<Ex>

II 3 G

Ex nA IIC T4

-20°C <= Ta <= 50°C

II – Equipment intended for above ground use (not for use in mines).

3 – Category 3 equipment, investigated for normal operation only.

G – Equipment protected against explosive gasses.

Page 4

Page 5

PDPM ♦ ProLinx Gateway Contents

PROFIBUS DP Master Protocol Manual

Contents

Your Feedback Please ........................................................................................................................ 2

Important Installation Instructions ....................................................................................................... 2

ProLinx® Products Warnings ............................................................................................................... 2

ProLinx Gateways with Ethernet Ports ............................................................................................... 3

1.1.1 To upgrade a previously purchased Series C model ................................................ 3

1.1.2 To order a ProLinx Plus gateway with the -WEB option ........................................... 3

Markings .............................................................................................................................................. 3

2 Functional Overview 7

2.1 About the PROFIBUS Protocol ................................................................................. 7

2.2 PROFIBUS DP Architecture ...................................................................................... 7

2.2.1 Bus Access ................................................................................................................ 8

2.2.2 Token Passing ........................................................................................................... 8

2.2.3 Master/Slave Polling .................................................................................................. 8

2.3 Communication Types ............................................................................................... 8

2.4 Master/Slave Communication Phases ...................................................................... 9

2.5 Module Internal Database ......................................................................................... 9

2.5.1 PROFIBUS Master Port Specifications ................................................................... 10

2.5.2 PROFIBUS Master Port Access to Database ......................................................... 10

2.6 Master/Slave Communication Phases .................................................................... 11

2.7 Port Physical and Protocol Specifications ............................................................... 11

2.7.1 Serial Port Specifications ........................................................................................ 12

3 Configuration 13

3.1 Using the ProLinx SyCon PROFIBUS Configurator ................................................ 13

3.1.1 Install ProLinx Sycon Configurator .......................................................................... 13

3.1.2 Installation ............................................................................................................... 13

3.1.3 Configuring a PROFIBUS Using PROLINX SyCon ................................................ 16

3.1.4 Inserting a Master .................................................................................................... 17

3.1.5 Master Configuration ............................................................................................... 18

3.1.6 Inserting a Slave Device.......................................................................................... 18

3.1.7 Settings.................................................................................................................... 23

3.1.8 Project Information .................................................................................................. 28

3.1.9 Path ......................................................................................................................... 29

3.1.10 Language ................................................................................................................ 29

3.1.11 View the Configuration ............................................................................................ 30

3.1.12 Printing the Configuration File ................................................................................. 32

3.1.13 Saving the Configuration ......................................................................................... 32

3.1.14 Downloading the Configuration ............................................................................... 32

3.1.15 Online Functions ..................................................................................................... 33

4 PDPM Protocol Configuration 43

4.1 [PROFIBUS Master] ................................................................................................ 43

4.1.1 Swap Input Bytes .................................................................................................... 44

4.1.2 Swap Output Bytes .................................................................................................. 44

4.1.3 Comm Failure Mode ................................................................................................ 44

ProSoft Technology, Inc. Page 5 of 70

June 24, 2013

Page 6

Contents PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

4.1.4 Watchdog Parameters ............................................................................................ 44

4.2 [PROFIBUS Master Commands] ............................................................................ 45

4.2.1 66 - Read Diag ........................................................................................................ 45

4.2.2 70 - Global Cmd ...................................................................................................... 45

4.2.3 254 - Read Cntrs .................................................................................................... 46

4.2.4 Command 70 Control Byte ..................................................................................... 46

5 Diagnostics and Troubleshooting 47

5.1 LED Indicators ........................................................................................................ 47

5.1.1 LEDs for the PROFIBUS Master Port ..................................................................... 47

5.2 PROFIBUS Master Error and Status Data ............................................................. 48

5.2.1 Viewing Error and Status Data ............................................................................... 48

5.3 PROFIBUS Master: Error and Status Data ............................................................ 48

5.3.1 General Status ........................................................................................................ 49

5.3.2 Command Status .................................................................................................... 49

5.3.3 Standard PROFIBUS Slave Diagnostic Bytes ........................................................ 49

5.3.4 Byte 0 - Station Status 1 Bits .................................................................................. 49

5.3.5 Byte 1 - Station Status 2 Bits .................................................................................. 50

5.3.6 Byte 2 - Station Status 3 Bits .................................................................................. 50

5.3.7 Byte 3 - Master Address ......................................................................................... 51

5.3.8 Byte 4 - Ident Number High .................................................................................... 51

5.3.9 Byte 5 - Ident Number Low ..................................................................................... 51

5.3.10 Device Error Listing ................................................................................................ 51

5.4 Error Numbers ........................................................................................................ 51

5.4.1 Serial Driver Error Numbers (-20 … -71) ................................................................ 51

5.4.2 RCS Error Numbers (4 to 93) ................................................................................. 52

5.4.3 Data Server Error Numbers (1001 … 1009) ........................................................... 54

5.4.4 Command Administrator Error Numbers (2001 … 2006) ....................................... 54

5.4.5 Converting Functions Error Numbers (4000 … 4098) ............................................ 54

5.4.6 Data Base Functions Error Numbers (5001 … 5008)............................................. 57

6 Reference 59

6.1 RS-232 Configuration/Debug Port .......................................................................... 59

6.2 DB9 to Mini-DIN Adaptor (Cable 09) ...................................................................... 60

6.3 PROFIBUS Master Port .......................................................................................... 60

6.4 Supported PROFIBUS Services ............................................................................. 60

6.5 Constructing a Bus Cable for PROFIBUS DP ........................................................ 61

7 Support, Service & Warranty 67

Contacting Technical Support .......................................................................................................... 67

7.1 Warranty Information .............................................................................................. 68

Index 69

Page 6 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 7

PDPM ♦ ProLinx Gateway Functional Overview

In This Chapter

About the PROFIBUS Protocol ................................................................ 7

PROFIBUS DP Architecture .................................................................... 7

Communication Types ............................................................................. 8

Master/Slave Communication Phases ..................................................... 9

Module Internal Database ....................................................................... 9

Master/Slave Communication Phases ................................................... 11

Port Physical and Protocol Specifications ............................................. 11

PROFIBUS DP Master Protocol Manual

2 Functional Overview

The PROFIBUS Master protocol driver exists as a single port implementation.

The driver can be configured as a Class 1 PROFIBUS Master to interface with

other PROFIBUS slave devices. The unit is also used for configuration of the

nodes on the PROFIBUS network. It provides access to both standard as well as

extended diagnostic information and freeze/sync capability. The PROFIBUS

master port can be used to continuously interface with PROFIBUS slave devices

over a serial communication interface (RS-485).

2.1 About the PROFIBUS Protocol

PROFIBUS (Process Field Bus) is a widely-used, open-standards protocol

created by a consortium of European factory automation suppliers in 1989.

PROFIBUS is a master/slave protocol. The master establishes a connection to

the remote slave. When the connection is established, the master sends the

PROFIBUS commands to the slave. The PDPM module works as a master only.

The module uses an internal database to pass data and commands between the

processor and the client and server devices on the PROFIBUS network.

PROFIBUS supports a variety of network types. The network type supported by

the PDPM module is PROFIBUS DP (Device Bus), which is designed for remote

I/O systems, motor control centers, and variable speed drives.

2.2 PROFIBUS DP Architecture

The PROFIBUS DP Master network supports multiple Master systems with

several slaves.

The following table shows the most important features of PROFIBUS DP Master:

ProSoft Technology, Inc. Page 7 of 70

June 24, 2013

Page 8

Functional Overview PDPM ♦ ProLinx Gateway

Standard

EIN 501 70

DIN 19245

Transmission equipment (Physical)

EIA RS-485

IEC 1158-2 (through link or coupler)

Fiber Optic Cable (not available)

Transfer procedure

Half-duplex

Bus topology

Linear bus with active bus termination

Bus cable type

Shielded twisted pair conductors

Connector

9-pin D-Sub

Number of nodes on the bus

Max: 32 with no repeaters

Max: 125 with 3 repeaters in 4 segments

Protocol Manual PROFIBUS DP Master

2.2.1 Bus Access

Two different bus access procedures handle the various communication

requirements for the PROFIBUS DP Master topology:

Token Passing

Polling

2.2.2 Token Passing

Token passing ring is the basis for communication between the more complex,

active stations. All stations have the same rights in that a token is passed from

station to station in a logical ring. The token is passed to each station with a

maximum, definable token cycle time. A station is given transmission rights for

the duration of time that it has the token.

2.2.3 Master/Slave Polling

Master/slave polling guarantees a cyclic, real-time based data exchange

between the station with transmission rights, the active station, and its

subordinates, the passive stations. In this case, the Master is able to pass data to

the slave and/or receive data. The services in layer 2 (field-bus data link in ISOOSI reference model) organize this communication.

2.3 Communication Types

In addition to point-to-point data transfer, the PROFIBUS protocol can also

handle the following types of communication.

Broadcast communication: An active node sends an unacknowledged

message to all other nodes (Master and slaves)

Multicast communication (control instructions): An active node sends an

unacknowledged message to a group of nodes (Master and slaves)

Page 8 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 9

PDPM ♦ ProLinx Gateway Functional Overview

Input

Image

Data

Other

ProLinx

Protocol

Driver

0

ProLinx

Communication

Gateways

Internal

Database

Output

Image

Data

PROFIBUS

Master

Status &

User Data

Register range

255

556

555

300

3999

PROFIBUS

Master

Driver

PROFIBUS DP Master Protocol Manual

2.4 Master/Slave Communication Phases

The communication between the Master and the slaves takes place in the

following phases:

Parameterization and configuration phase

Usable data transfer phase

Before a DP slave can be integrated into the usable data transfer phase, the

parameterization and configuration phase runs a device identification test that

verifies that the planned configuration matches the actual device configuration for

each slave in the PROFIBUS network. The test verifies that:

The device is actually there

It is the right type of device

The station address set on the device matches the station address in the bus

configuration

The formats, telegram length information, and bus parameters are correct

and

The number of configured inputs and outputs is correct

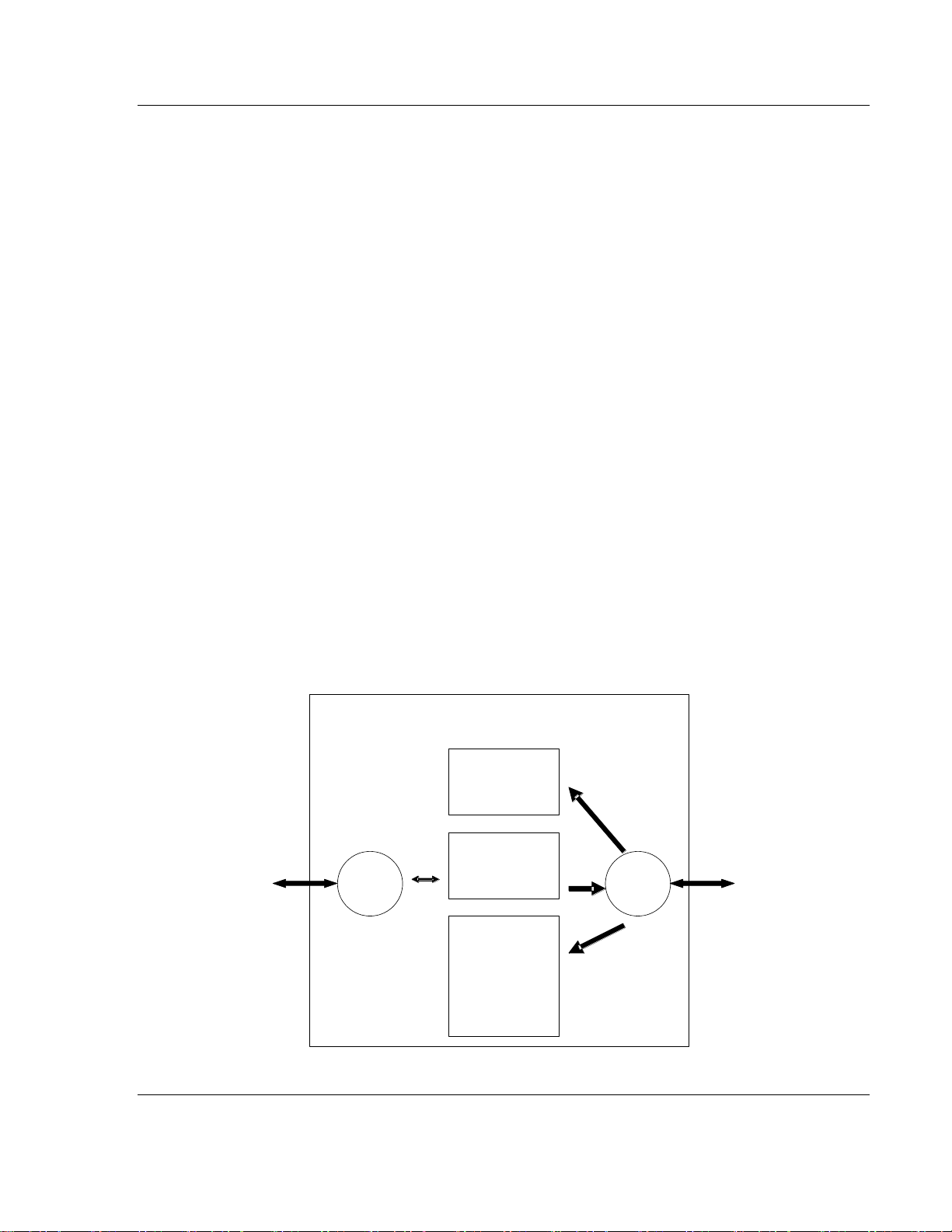

2.5 Module Internal Database

The internal database is central to the functionality of the module. This database

is shared between all the ports on the module and is used as a conduit to pass

information from one device on one network to one or more devices on another

network. This permits data from devices on one communication port/network to

be viewed and controlled by devices on another port/network. In addition to data

from the master port, status and error information generated by the module can

also be mapped into the internal database.

ProSoft Technology, Inc. Page 9 of 70

June 24, 2013

Page 10

Functional Overview PDPM ♦ ProLinx Gateway

Type

Specifications

General Parameters

Internal Database

Up to 4000 registers (words) available.

Communication parameters

Baud Rate: 9.6 kbps to 12 Mbps

PROFIBUS Master

Command List

Read Diag

Global Cmd

Read Cntrs

Reset Cntrs

Status Data

Error codes available on an individual command

basis. In addition, a slave status list is maintained

per active PROFIBUS Master port.

PROFIBUS Master

Node address

0 to 125 (software selectable)

Status Data

Error codes, counters and port status available per

configured slave on the network.

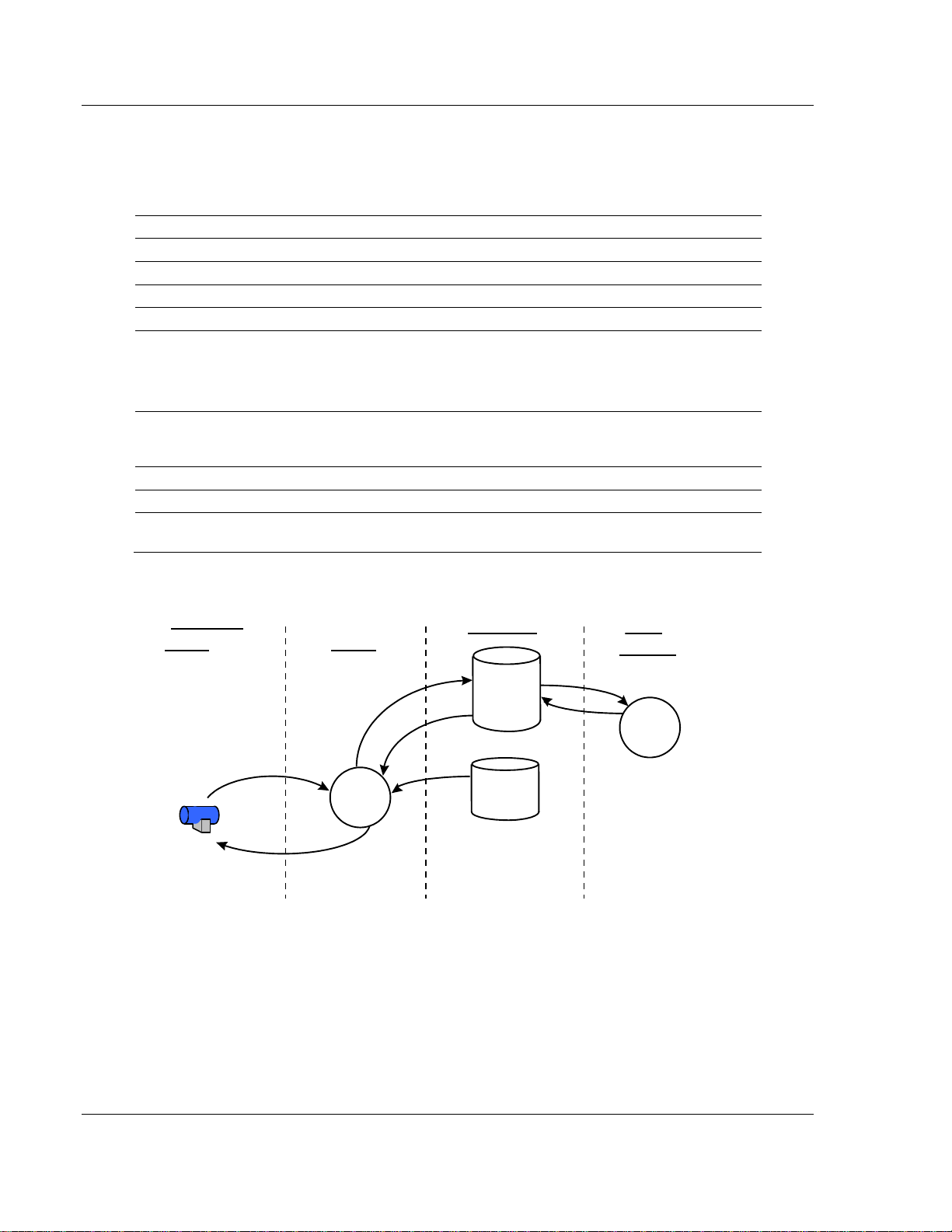

Virtual

Database

Command

List

Other

Driver

PROFIBUS

Driver

Slave

Device

Databases

Other

Protocol

PROFIBUS

Master

PROFIBUS

Slaves

Request

Response

Read

Read for

Write Command

Write for Read

Command

Write

Read

Protocol Manual PROFIBUS DP Master

2.5.1 PROFIBUS Master Port Specifications

2.5.2 PROFIBUS Master Port Access to Database

The Master driver uses the database in two ways:

1 A read command issued to a slave device by the master driver will return the

slave data into the internal database.

2 A write command issued to a slave device by the master driver uses the data

in the internal database to write to the slave device.

Page 10 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 11

PDPM ♦ ProLinx Gateway Functional Overview

ACTIVE

ERR

Port 0

ACTIVE

ERR

Debug

ACTIVE

ERR

Port 0

Config

TKN

ERR RUN

RDY

Profibus Master

PROFIBUS DP Master Protocol Manual

In addition to data from the master port, status and error information generated

by the module can also be mapped into the internal database.

2.6 Master/Slave Communication Phases

The communication between the Master and the slaves takes place in the

following phases:

Parameterization and configuration phase

Usable data transfer phase

Before a DP slave can be integrated into the usable data transfer phase, the

parameterization and configuration phase runs a device identification test that

verifies that the planned configuration matches the actual device configuration for

each slave in the PROFIBUS network. The test verifies that:

The device is actually there

It is the right type of device

The station address set on the device matches the station address in the bus

configuration

The formats, telegram length information, and bus parameters are correct

and

The number of configured inputs and outputs is correct

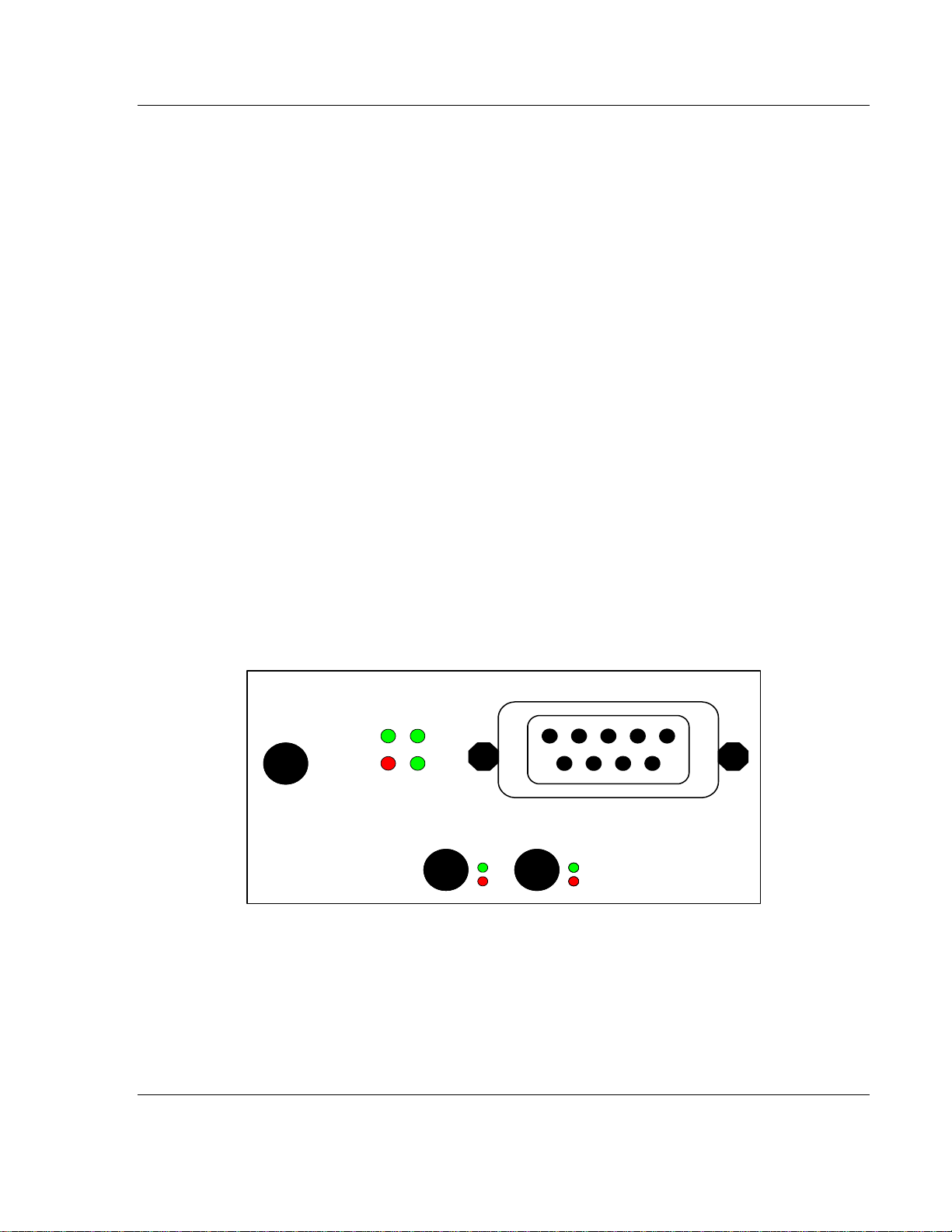

2.7 Port Physical and Protocol Specifications

The ProLinx module supports the PROFIBUS Master protocol as a Master on

either a Mono-Master or Multi-Master network.

ProSoft Technology, Inc. Page 11 of 70

June 24, 2013

Page 12

Functional Overview PDPM ♦ ProLinx Gateway

Port Label

Function

Debug

Debug/Configuration

Port 0

Communication Port 0

Config

PROFIBUS Master Configuration Port

PROFIBUS Master

PROFIBUS Master Port

Type

Specifications

Serial Ports

Serial Port Adapter Cables

One Mini DIN to DB-9M adapter cable included for

each configurable serial port

Config Port Connector/ Pinout

DB-9F connector / DTE pinout

Serial Port Isolation

2500V RMS port-to-port isolation per UL 1577.

3000V DC min. port to ground and port to logic

power isolation.

Serial Port Protection

RS-485/422 port interface lines TVS diode protected

at +/- 27V standoff voltage.

RS-232 port interface lines fault protected to +/- 36V

power on, +/- 40V power off.

Protocol Manual PROFIBUS DP Master

The relationship between the port labeling on the front of the ProLinx module and

the application is as follows:

2.7.1 Serial Port Specifications

Note: On all ProLinx modules, data from the application port on the main board, serial Port 0, is not

buffered. Packets go directly to and from the serial chipset to the processor. This has the potential

to cause the serial communications to become erratic at baud rates above 38,400 baud.

ProLinx modules with 4 serial ports have a separate serial interface board for serial Ports 1, 2, and

3. These serial ports are buffered and can handle communications up to 115,200 baud.

Page 12 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 13

PDPM ♦ ProLinx Gateway Configuration

In This Chapter

Using the ProLinx SyCon PROFIBUS Configurator .............................. 13

PROFIBUS DP Master Protocol Manual

3 Configuration

3.1 Using the ProLinx SyCon PROFIBUS Configurator

The ProLinx SyCon PROFIBUS is a PROFIBUS-DP configurator that provides an

automatic means of configuring a PROFIBUS Master Module. All devices are

configured using a single tool which checks dependencies between devices and

thereby only allows configurations that make sense.

In addition, ProLinx SyCon documents the fieldbus system. Detailed

configuration documentation may be printed out that includes details between the

bus topology and the utmost detail of a single device. ProLinx SyCon supports

standardized files that contain information about all features and limitations of the

slave device and uses these files for configuration.

Lastly, the ProLinx SyCon is equipped with a diagnostic mode that allows viewing

of fieldbus status information.

3.1.1 Install ProLinx Sycon Configurator

PROLINX SyCon requires:

A DVDdrive

486 or better CPU

20Mb of free hard disk space

Minimum 16 Mb RAM

Serial (RS232) Communication Port (COM1, COM2, COM3 or COM4)

A screen and graphics card capable of 800x600 resolution

Windows 95, Windows 98, Win NT4 with Service Pack 3 or higher

For Windows 95, minimum Service Pack 1

For Windows NT 4.0, minimum Service Pack 3

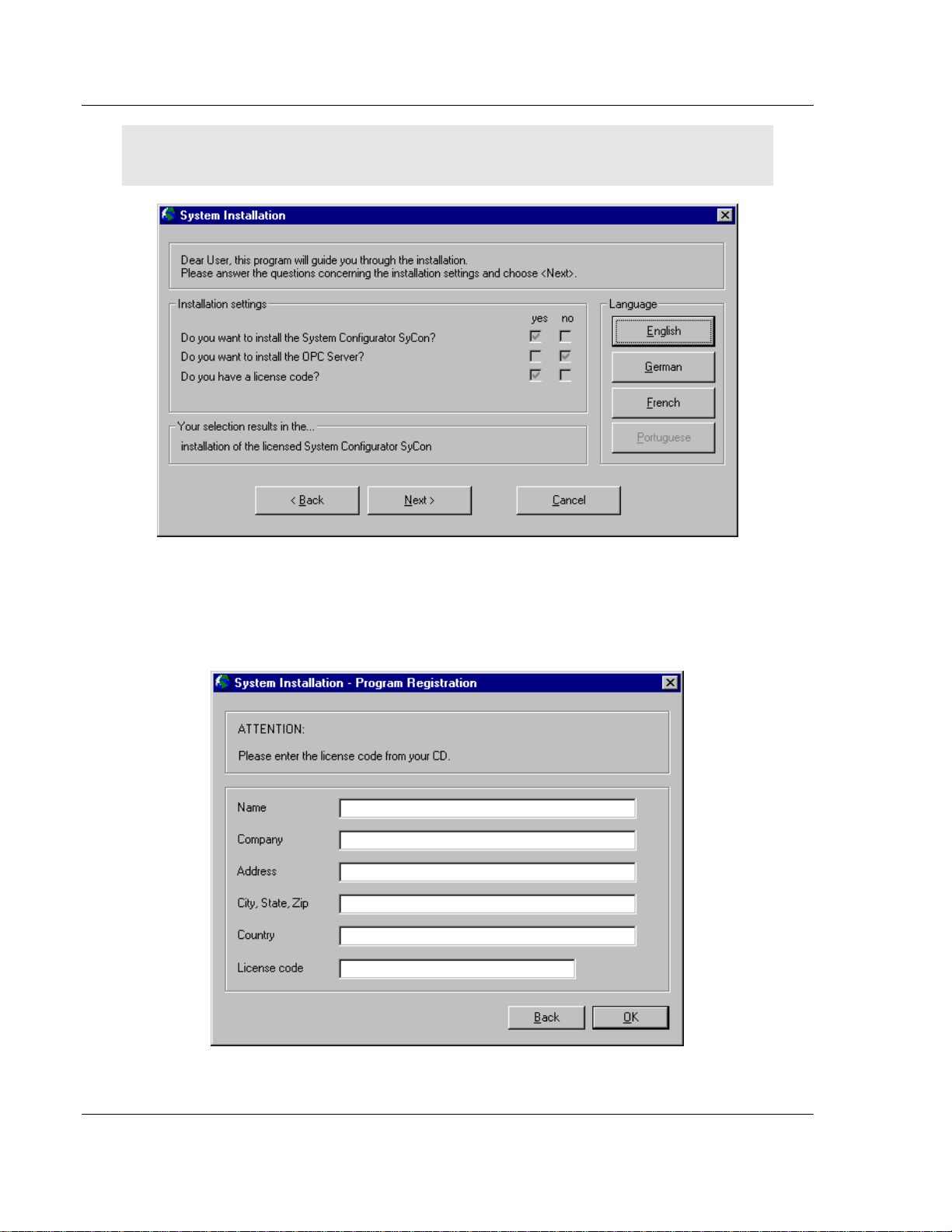

3.1.2 Installation

Close all active applications before starting the installation program and perform

the following:

1 Start the installation by running \ProLinx\Utilities\Sycon\SyCon\Setup.exe

from the installation DVD.

2 As the setup program runs, the program prompts you to make selections as

to what components to install.

3 Select the appropriate components based on the following example.

ProSoft Technology, Inc. Page 13 of 70

June 24, 2013

Page 14

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

Note: ProLinx SyCon does not use the OPC server and a license number must be entered in order

to complete the installation.

4 Enter the license code and company information when prompted. You will

find the license code in E:\ProLinx\Utilities\Sycon\SyCon\LIC_044.TXT

(double-click the filename to open in Notepad.exe)

Page 14 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 15

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

The System Installation program automatically launches the PROLINX SyCon

installation program. When prompted for components to install, choose

Configurator and CIF Device Driver.

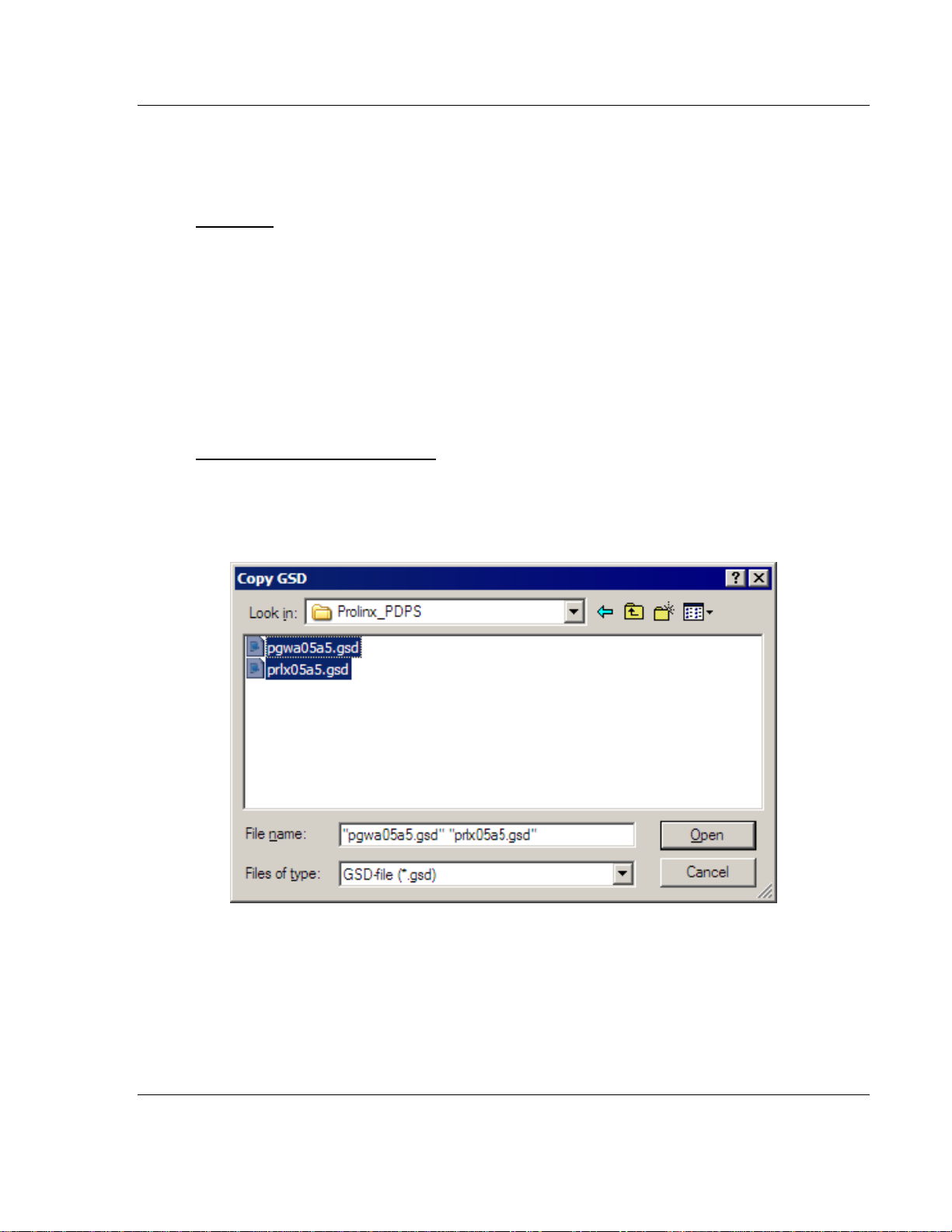

GSD Files

Each PROFIBUS-DP manufacturer uses standard device description files to

define the PROFIBUS-DP device functionalities on the network. These definitions

are called GSD files. The set of device description files (GSD files) build the

device database.

PROLINX Devices

The GSD files for PROLINX devices are located on the ProLinx Solutions DVDin

the \ProLinx\Utilities\PDPS_GSD folder.

Refer to E:\ProLinx\Utilities\PDPS_GSD\ProLinx_PDPS\readme.pdf to determine

the correct GSD files to use.

To import the ProLinx GSD files:

1 In SyCon, open the File menu, and choose Copy GSD.

2 In the Copy GSD dialog box, navigate to your DVDdrive, and select the path

\ProLinx\Utilities\PDPS_GSD.

3 Press [Ctrl][A] to select all the GSD files in that folder, and then click Open.

4 You will be prompted to import the BMP files that accompany the GSD files.

Click Open to import each of the selected BMP files.

Other Devices

For other devices, these files should be provided and updated by the device

manufacturer.

ProSoft Technology, Inc. Page 15 of 70

June 24, 2013

Page 16

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

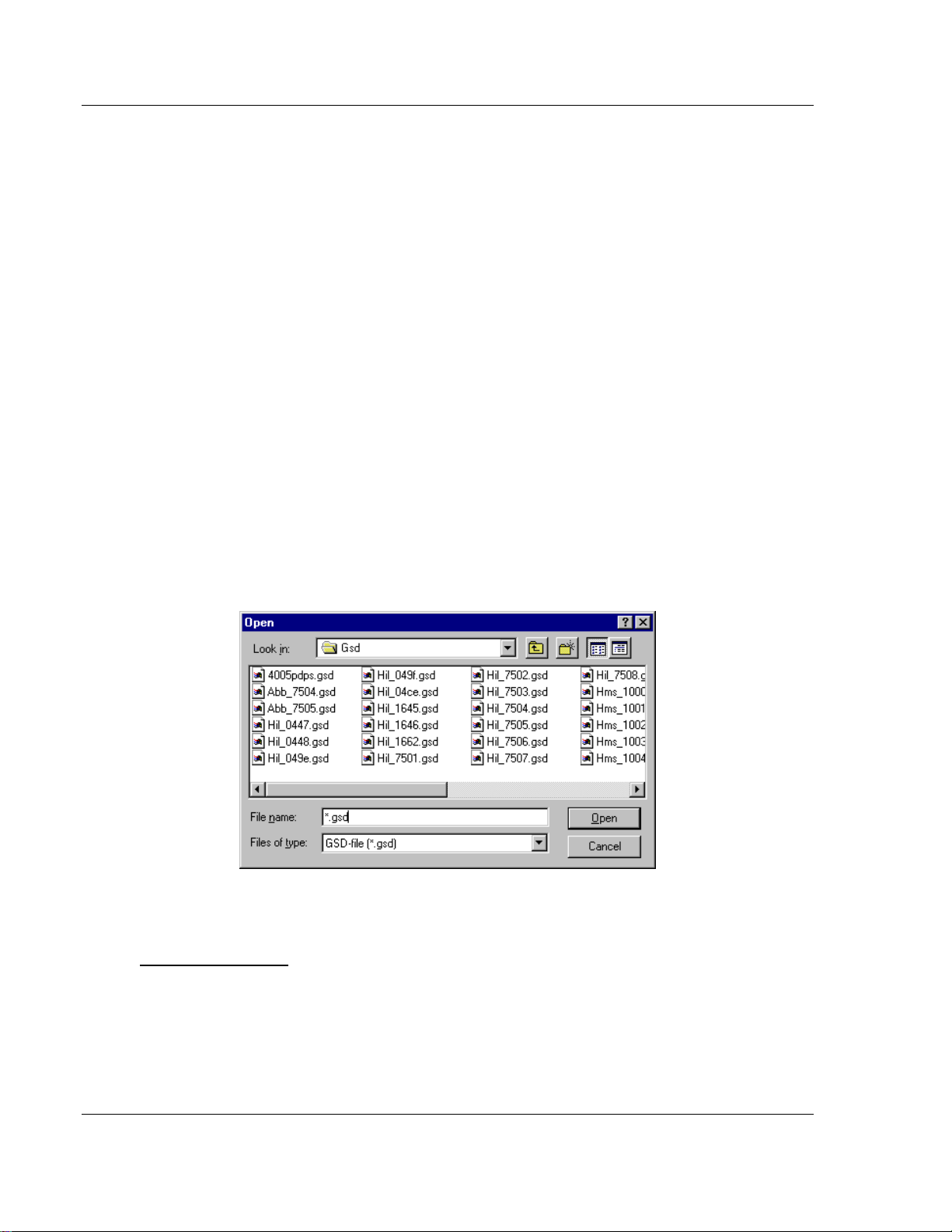

You can also get the GSD files from the homepage of the PROFIBUS user

association:

http://www.PROFIBUS.com (http://www.profibus.com)

For all available configurations, GSD files must be contained in the directory

GSD. During installation of the program PROLINX SyCon, the available files will

be included. If you need another GSD file during PROLINX SyCon runtime you

have to copy this file with the menu item File - Copy GSD.

The GSD directory path is changeable. To modify it from the default to another

path use the menu Settings - Path.

All GSD files have to be present in this directory. The default path for ProLinx

SyCon GSD files is

C:\Program Files\HMS\SyCon\Fieldbus\PROFIBUS\GSD

At program startup, PROLINX SyCon automatically reads in all GSD files that are

present in the GSD directory. Because of this, device names are placed in an

internal list. The device-specific data is taken online directly from the GSD file

during the configuration phase.

If you must use a GSD file that is not included in the selection list during the

configuration phase, you have to copy the file to the GSD using the File - Copy

GSD command. If you use this option or manually copy a file to the directory

using Windows Explorer, you must activate the Reread command using the

menu Settings - Path and OK acknowledgement.

In the menu Tools - GSD Viewer all GSD files of the directory are shown.

3.1.3 Configuring a PROFIBUS Using PROLINX SyCon

Basic Configuration

ProLinx SyCon configures the PROFIBUS system quickly and easily.

Perform the following procedure to configure the PROFIBUS system.

1 Select File - New from the menu.

2 ProLinx SyCon will start the configuration mode and open the window with

the bus line.

Page 16 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 17

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

3 Insert the master you are defining on the bus.

4 Insert DP slaves and assign them to the master.

5 Configure these DP slaves with the actual I/O modules, parameter data, and

so on. Ensure that the right addressing mode has been selected.

6 If using a multi-master network, look at the dependencies/connections

between the devices by selecting one master after the other as actual master

to check your configuration.

7 Select the baud rate and bus parameters.

8 Set up the device assignment that defines how ProLinx SyCon is to

communicate with the devices.

9 Save the configuration.

10 Select the port to be configured and perform the download process to all

devices.

11 Connect the PROFIBUS cable to the device.

12 Start the debug mode to check the communication.

13 Print out the documentation produced by the PROFIBUS system. If

PROFIBUS is running, start with the installation of the application.

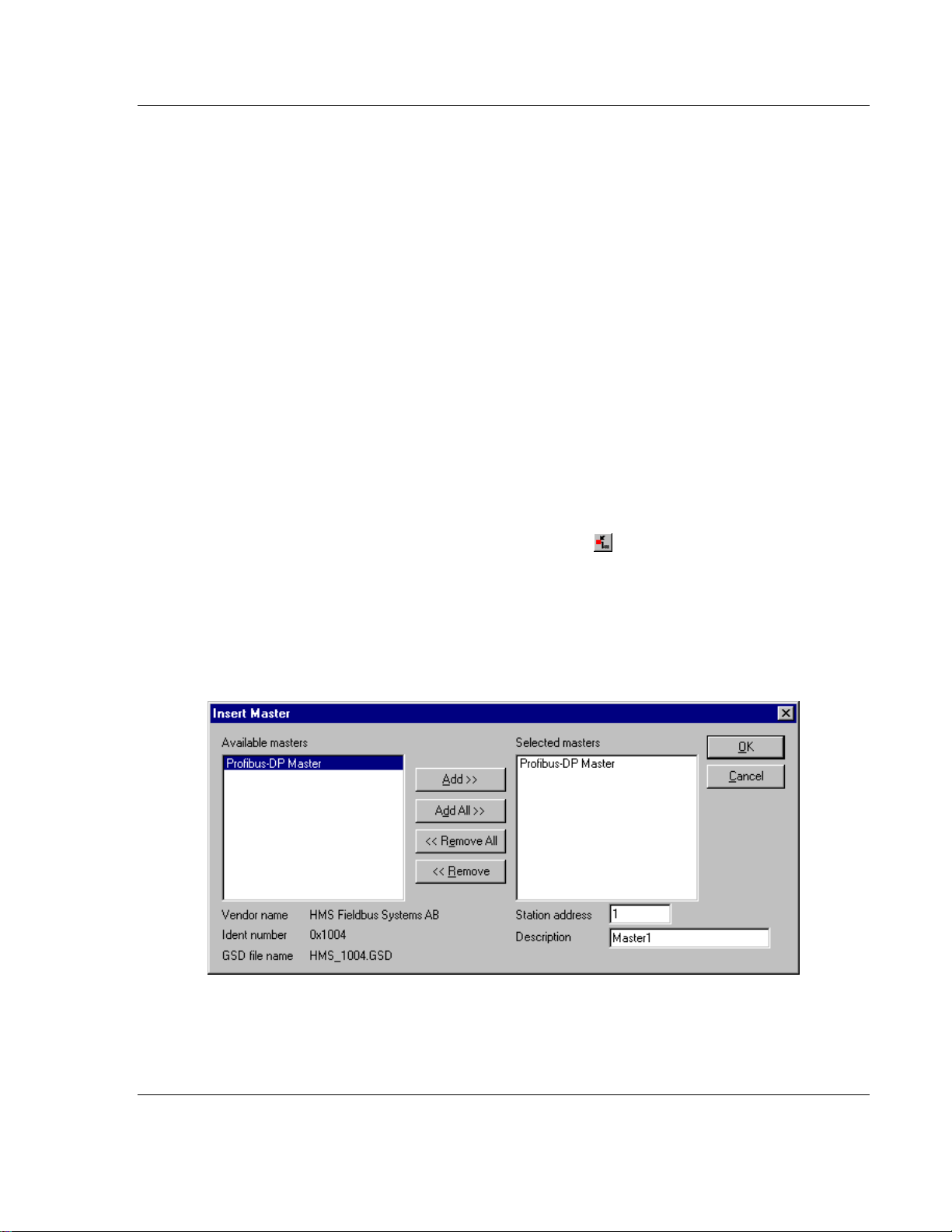

3.1.4 Inserting a Master

To insert a master in the configuration, select the Insert - Master menu to open

the selection dialog box or click the following button:

The mouse cursor changes automatically to the insert master cursor. Click on the

position where you want to insert the new master. A dialog box appears where

you can select one or more masters. You can select different master types

(depending on the vendor brand).

If you chose the ProLinx PROFIBUS Master, the Vendor information is displayed

exactly as shown in the following example:

In this example, a PROFIBUS-DP Master will be added with Station Address 1

and the Description Master 1.

ProSoft Technology, Inc. Page 17 of 70

June 24, 2013

Page 18

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

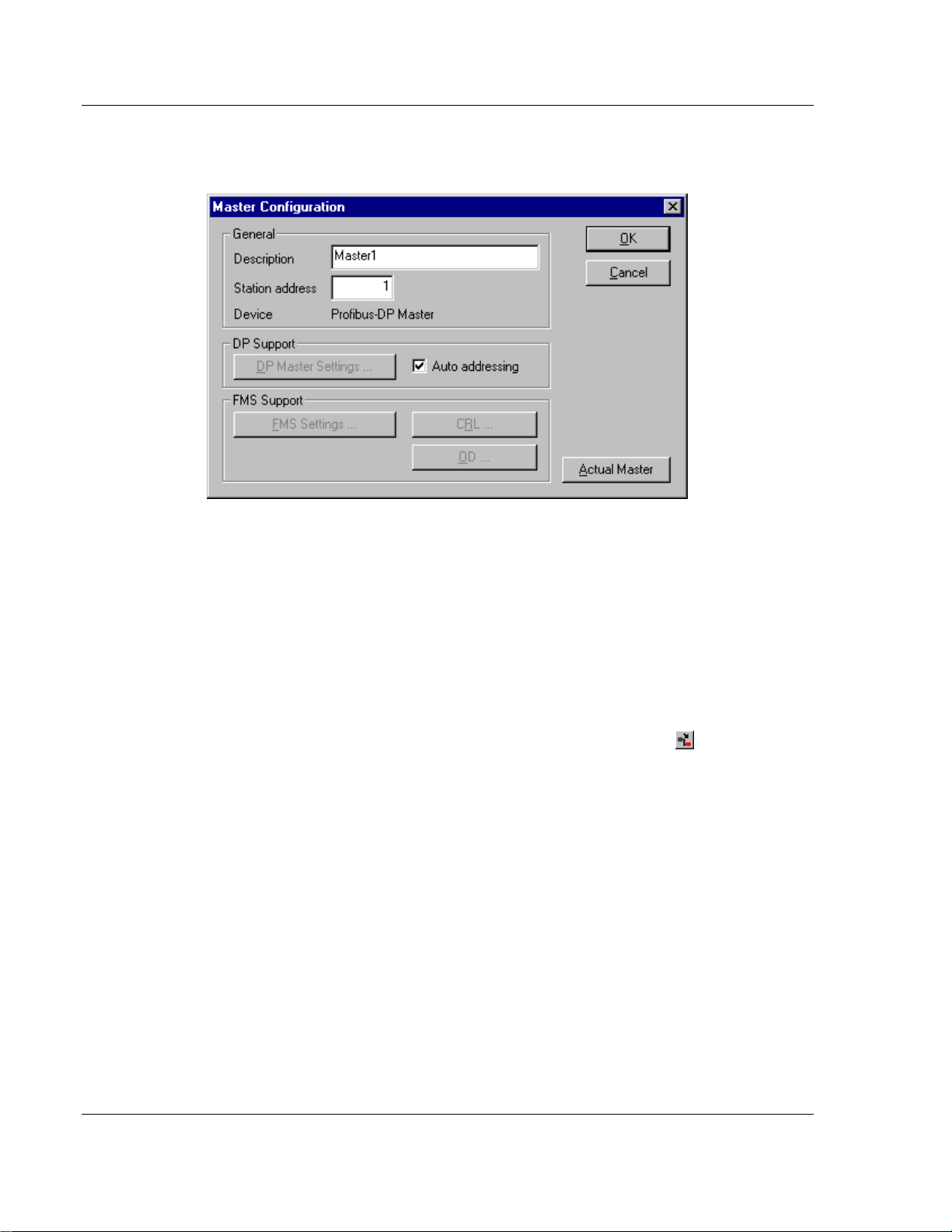

3.1.5 Master Configuration

Double-click the master to configure it. The following dialog box appears.

This configuration window allows you to:

Specify the station address of the master

Specify a (symbolic) description for this master

Set this master as the actual master (to do a download for example)

Activate or deactivate the auto addressing

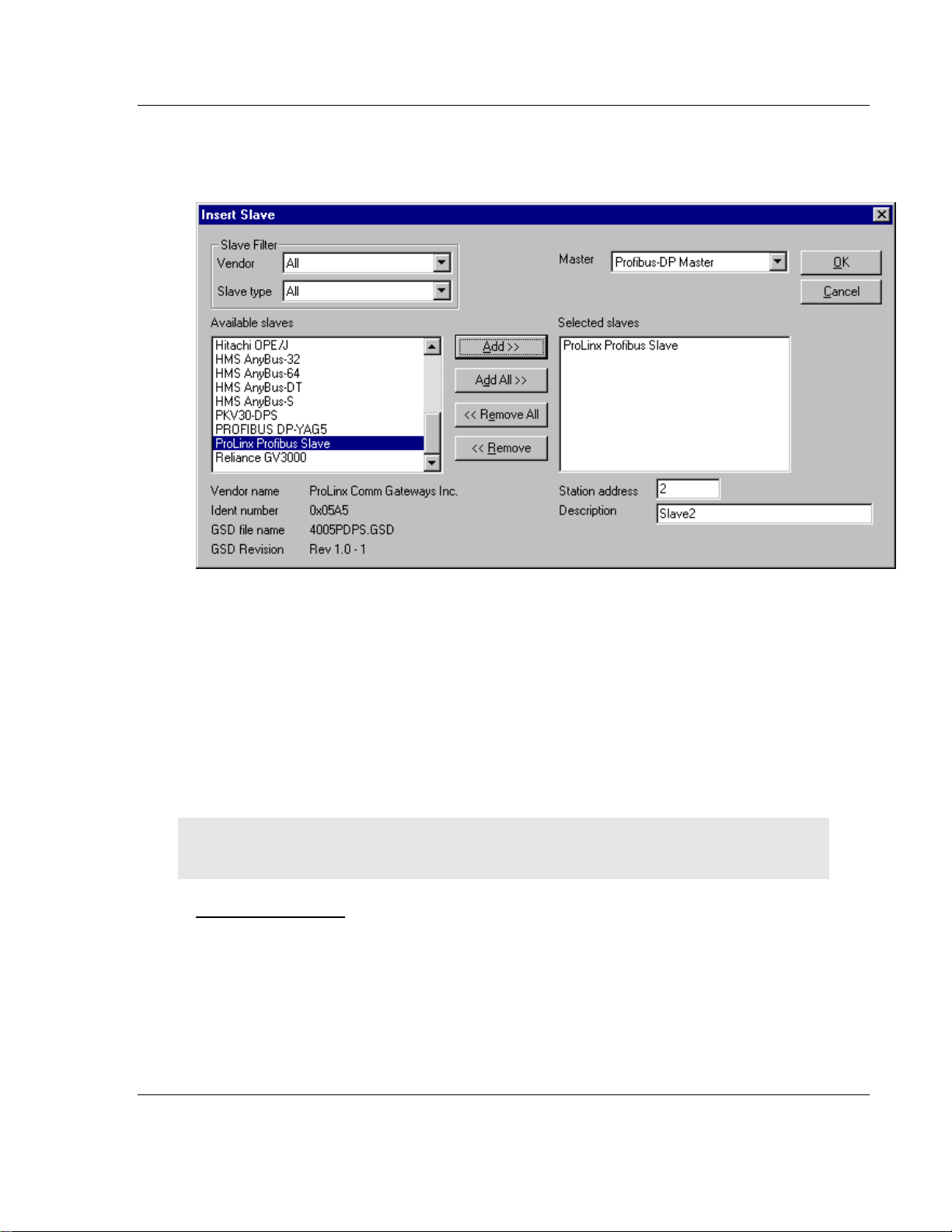

3.1.6 Inserting a Slave Device

To insert new PROFIBUS-DP slaves in the configuration, select the Insert Slave menu to open the selection window or click the following button:

Page 18 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 19

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

The mouse cursor changes automatically to the insert slave cursor. Click on the

position where you want to insert the new slave. A dialog box appears where you

have to select one or more slaves.

The Available slaves list-box displays all slave devices present in the GSD

directory. A filtering feature is available is you want to view by a special slave

family. If a slave is selected, information about that slave appears below the

Available slaves list box..

With a double click or with the button Add, the slave appears in the right list box.

All devices in this box will be connected to the active master displayed in the

Master window. You must select each slave one-by-one. You can also give each

a device a name or a short description in the Description Field.

The Station address field increments with each addition of a new slave. However,

this address may be overwritten.

Note: It is possible to choose one slave several times but each device must have its own station

address to distinguish them on the network.

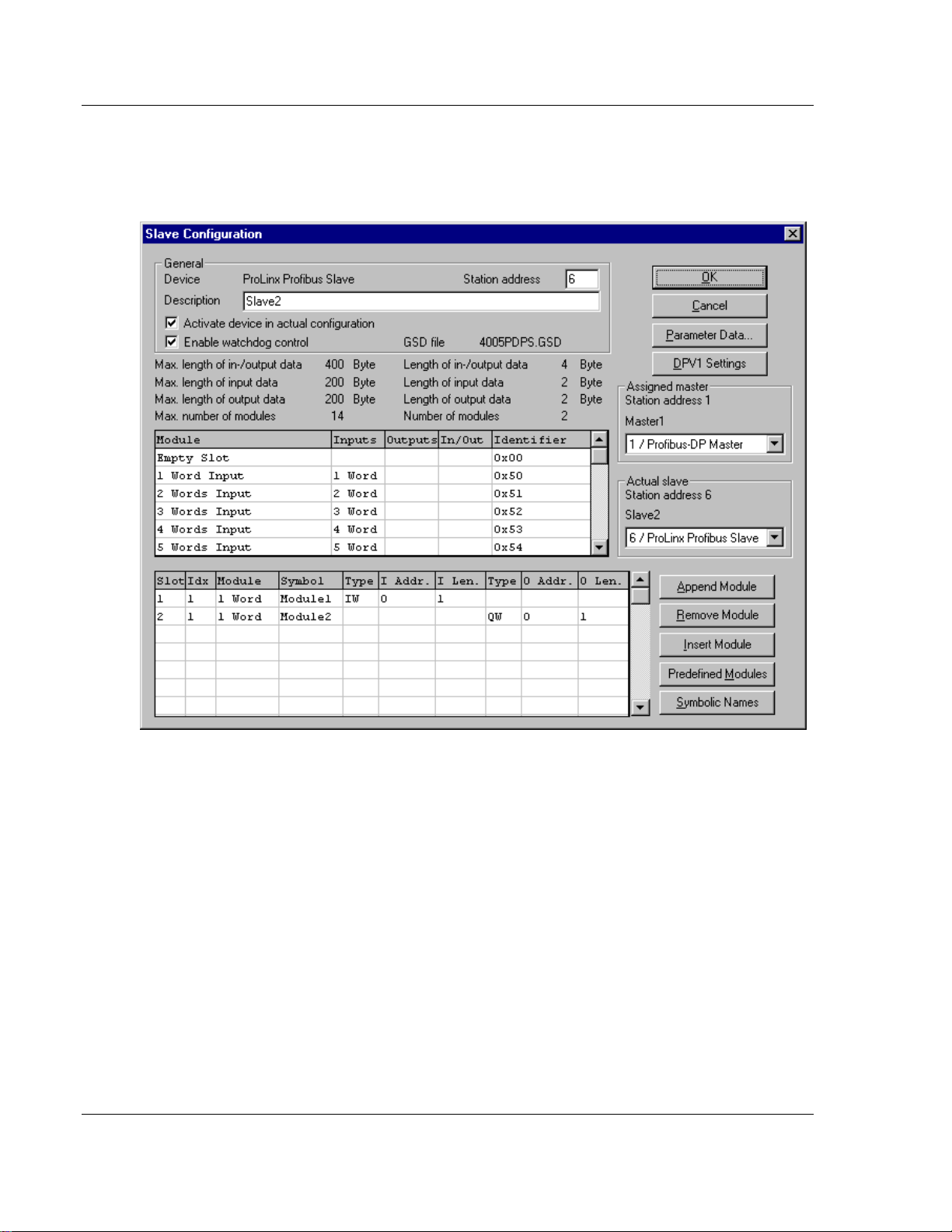

Configuring a Slave

Slave-specific configuration is accomplished using the Slave Configuration dialog

box. Here, modules and associated data are assigned to the address of the

process data image in the master device. These addresses correspond to the

application in the PLC.

Select the menu Settings - DP Slave Configuration or double-click on a slave

to open Slave Configuration dialog box.

ProSoft Technology, Inc. Page 19 of 70

June 24, 2013

Page 20

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

There are two types of DP-slaves; simple and modular. A simple slave has a

fixed data length. A modular slave's data length is configurable. This type of

slave can be understood as an assembly of one or more simple slaves with one

bus address.

The upper table contains all available modules of the slave. In the case of a

simple slave, there is only one module that is automatically copied into the lower

table by ProLinx SyCon. A modular slave must be copied by the user by doubleclicking on the module or selected module in combination with the Append

Module button.

If a module has several inputs or outputs (sub modules), more lines appear in the

configuration table. These additional lines will be signed with a higher index in

the column Idx. The column Slot counts the modules.

Perform the following steps to configure the modules of the slave:

1 If not already present, select all modules from the upper table and insert them

in the lower table to be configurable.

2 The sequence of the modules in the lower list is important and must

correspond to the real physical slave configuration.

Page 20 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 21

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

3 Assign the addresses of the module data in the process image for each

module in the lower table. This is done in the columns Type and Address for

input and output separately.

4 The I/O address can be entered by the user or set automatically by ProLinx

SyCon. Therefore the flag Auto Addressing must be set in the window

Master Settings. If active, ProLinx SyCon will place all I/O data offsets in

physical order. This is done during the download procedure and the assigned

addresses can be checked in the Address Table. If the addresses are

entered manually the default address 0 in the field I Address respectively O

Address must be overwritten.

Note: Offset addresses are entered as a word (16-bit) address.

With the flag Watchdog Control activated it is fixed how the slave will react to

the interruption of the communication with the belonging master. Is this flag

activated and the slave recognized the interrupted communication over the

control interval, the slave will set all outputs to 0 and will set itself into the main

mode.

Caution: If Watchdog Control is switched off, possible set outputs will not be reset by the slave,

although the communication is broken.

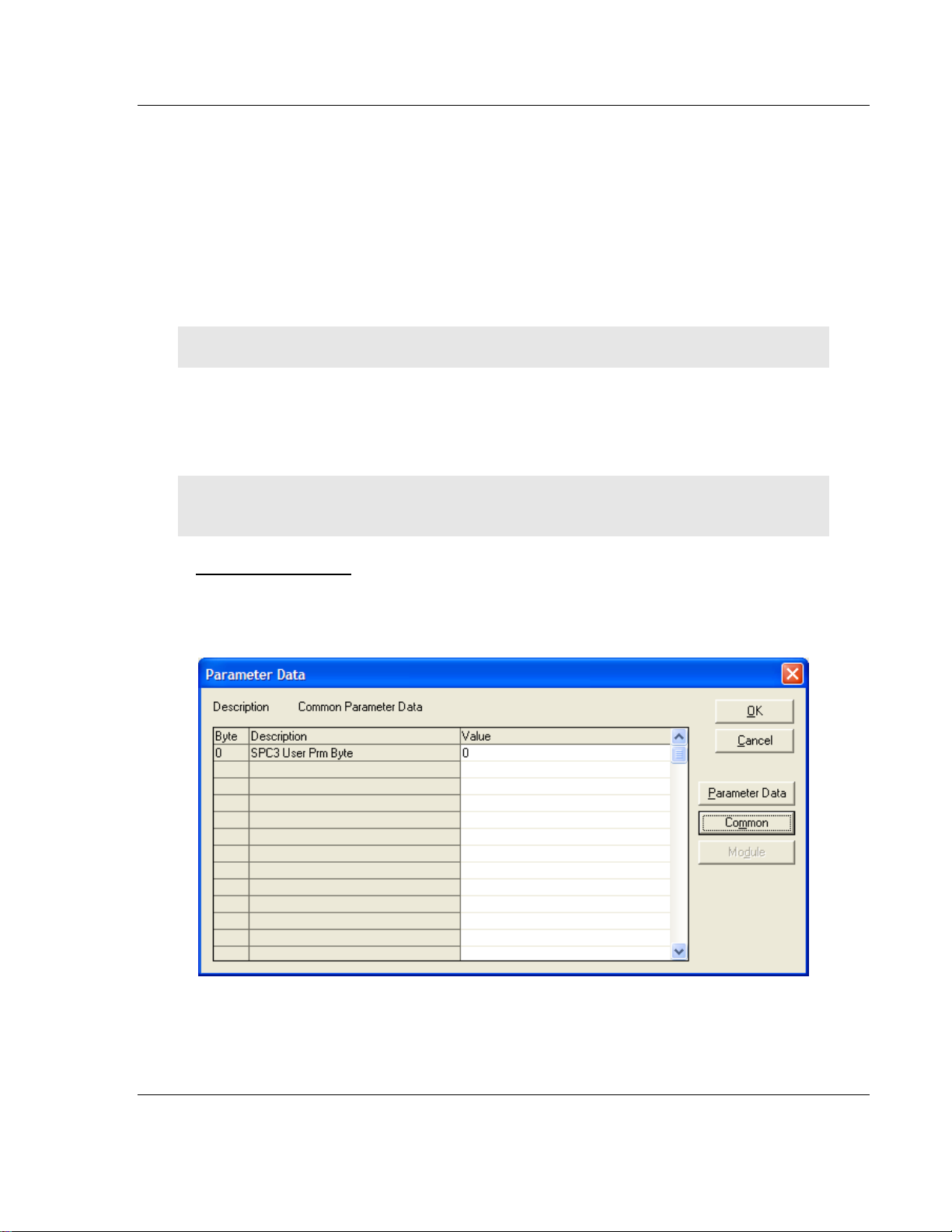

Set_Param (SAP61)

ProSoft PROFIBUS Slave (PDPS) devices have a configurable parameter for

SPC3 User Prm Byte. The following illustration shows the value of this parameter

in Sycon, the configuration tool for ProLinx PROFIBUS Master devices.

ProSoft Technology, Inc. Page 21 of 70

June 24, 2013

Page 22

Configuration PDPM ♦ ProLinx Gateway

Byte

Bit Position

Designation

7 6 5 4 3 2 1 0

0

Lock

Reg

Unio

Req

Sync

Req

Free

Req

WD

on

Res

Res

Res

Station status

1

WD_Fact_1

2

WD_Fact_2

3

MinTSDR

4

Ident_Number_High

5

Ident_Number_Low

6

Group_Ident

7

Spec_User_Prm_Byte

8 to

243

User_Prm_Data

Byte 7

Spec_User_Prm_Byte

Bit

Name

Significance

Default State

0

Dis_Startbit

The start bit monitoring in the

receiver is switched off with

this bit

Dis_Startbit = 1,

That is, start bit monitoring is

switched off.

1

Dis_Stopbit

Stop bit monitoring in the

receiver is switched off with

this bit

Dis_Stopbit = 0

That is, stop bit monitoring is not

switched off.

2

WD_Base

This bit specifies the time

base used to clock the

watchdog.

WD_Base = 0: time base 10

ms

WD_Base = 1: time base 1 ms

WD_Base = 0

That is, the time base is 10 ms.

3 to 4

Res

To be parameterized with 0

0

5

Publisher_Enable

DXB-publisher-functionality of

the SPC3 is activated with this

bit

Publisher_Enable = 0, DXBrequest-telegrams are ignored;

Publisher_Enable = 1, DXBrequest-telegramme are processed

6 to 7

Res

To be parameterized with 0

0

Protocol Manual PROFIBUS DP Master

Parameter Data Structure

SPC3 evaluates the first seven data bytes (without user prm data), or the first

eight data bytes (with user prm data). The first seven bytes are specified

according to the standard. The eighth byte is used for SPC3-specific

communications. The additional bytes are available to the application.

Page 22 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 23

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

3.1.7 Settings

Device Assignment

PROLINX SyCon is able to configure different devices in a PROFIBUS network.

To run the online functions of such a device, it must be defined how PROLINX

SyCon can communicate with it. This is done in the menu item Device

Assignment.

The external connection can be checked with the buttons Connect COM 1 to

Connect COM 4. PROLINX SyCon sends a request on that COM port and asks

for the firmware. If there is a Master device connected, the firmware is displayed

otherwise there will be a timeout error.

Bus Parameter

For a PROFIBUS DP system with one master, the only parameter that must be

selected is the baud rate.

ProSoft Technology, Inc. Page 23 of 70

June 24, 2013

Page 24

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

The baud rate of the PROFIBUS is common for all bus devices. Changing the

baud rate has the consequence that all other parameters will be re-calculated.

The System Configurator checks if the baud rate is supported by all configured

devices on basis of the entries in the GSD file.

If the System Configurator finds at least one device in the configuration that does

not support the selected baud rate, an error message appears. Some parameters

can be changed individually by opening the Edit Bus Parameter dialog box. Use

the Edit button to look at the actual parameters.

Note that if any changes are made in the bus parameters, the parameter for the

field Optimize must be changed from standard to by user.

Caution: Changing the bus parameter individually can force a communication break.

The Highest Station Address is the highest bus address up to which the master

will search for other active master stations to pass the send permission. This

value should not be set below the master address.

DP Master Settings

The current version of PROLINX SyCon does not allow changing of DP-Master

settings. These are the default parameters:

Watchdog time: 1000 ms

Addressing mode: Word addresses

Storage formats: Big Endian

Parameter Data

User parameter data may be edited in the Parameter Data window by choosing

Settings - Parameter Data.

Page 24 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 25

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

If default parameters are configured in the GSD file for this slave, they are

inserted automatically when the menu is chosen the first time.

Some DP-Slave devices need some further parameterization data to change for

example, a measurement limitation or a value range. This data is slave-specific

and the functionality cannot be explained at this point.

The explanation can normally be found in the corresponding slave manual.

This following dialog box shows an example of parameter data for a slave.

A modular PROFIBUS-DP slave station may need parameter data for one or

more modules and for the slave station itself (head station). There are three

selections possible:

Hex: All parameters of the slave are shown in hexadecimal representation

Common: Parameter data of the head station

Module: Parameter data of the separate modules

ProSoft Technology, Inc. Page 25 of 70

June 24, 2013

Page 26

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

After selecting the Common button, the following dialog box appears with the

common parameter data. These parameters are for the head station.

It is possible to change back into the hexadecimal description by selecting the

Hex button.

With a double click on one row of the parameter data, you are able to change the

value using the following dialog box.

Page 26 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 27

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

The description can also be selected by common adjustment.

If there is more than one module configured, the relevant module must be

selected first.

All parameter dialogs are taken from the GSD file. If there is no text dialog, the

input is only possible as a hex value.

Group Membership

After a master is chosen, the slaves can be assigned to 8 different groups. These

groups can be parameterized using the following dialog box.

Choose Settings, then Group Membership from the menu.

Select which group should support the DP-Freeze and DP-Sync command.

The Group Assignment button allows you to assign slaves to with the desired

characteristics.

ProSoft Technology, Inc. Page 27 of 70

June 24, 2013

Page 28

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

The following table shows all configured slave devices from the main editor

window. Use this dialog box to assign slaves to selected groups.

The chosen group selection is transferred to the slaves within their startup

sequence. The group selection serves as a filter for a special DP command

called ´global control´, which can be sent as a broadcast message to selective

groups.

This command is normally used by an application program to send the output

data Sync and the input data Freeze command.

3.1.8 Project Information

Common information regarding the project can be written to the configuration

documentation by choosing Settings, then Project Information from the menu.

This information can be printed or displayed in the window.

Page 28 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 29

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

3.1.9 Path

To view the path of the GSD files, select Settings, then Path from the menu.

3.1.10 Language

Select Settings, then Language to display the Select Language dialog box. Use

this dialog box to specify the appropriate language for the configurator.

Select the desired language, and confirm the entry with the OK button.

A comment appears, and prompts you to restart the application to make the

changes effective. After restart, PROLINX SyCon will be uses the selected

language.

ProSoft Technology, Inc. Page 29 of 70

June 24, 2013

Page 30

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

3.1.11 View the Configuration

View Device Table

Choose View, then Device Table to display the list of present devices.

Address Table

Choose View, then Address Table to display the list of addresses.

Select the master as actual master to display the address table. You can sort the

addresses by station addresses or by data addresses.

Page 30 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 31

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

Select the Address Overview button to display an overview about the addresses

in the input and output area.

1 The Auto Addressing mode must be inactive in order to change address

assignments.

2 Click on a cross and hold down the left mouse button. The pointer changes to

an arrow.

ProSoft Technology, Inc. Page 31 of 70

June 24, 2013

Page 32

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

3 While holding down the left mouse button, move the arrow to the desired new

(still not used) position and release the mouse button.

4 The system prompts you to verify if the change should be executed.

Choose the Slave Configuration menu to select offset assignments.

Overlapped addresses are shown with a red cross (indicating that the same

address is used by more than one module.

View the slave address information by double-clicking on the corresponding

cross. The Byte Information Window opens.

Note: While the addresses are given in bytes (8-bit), a block of data can only be placed on a word

(16-bit) boundary.

3.1.12 Printing the Configuration File

Set up the appropriate printer using the Print Setup menu. Select Print to receive

a printout of the configuration.

3.1.13 Saving the Configuration

Choose Save to save the configuration if the configuration has already been

saved with a filename, otherwise, use the Save as function to assign the

configuration a filename.

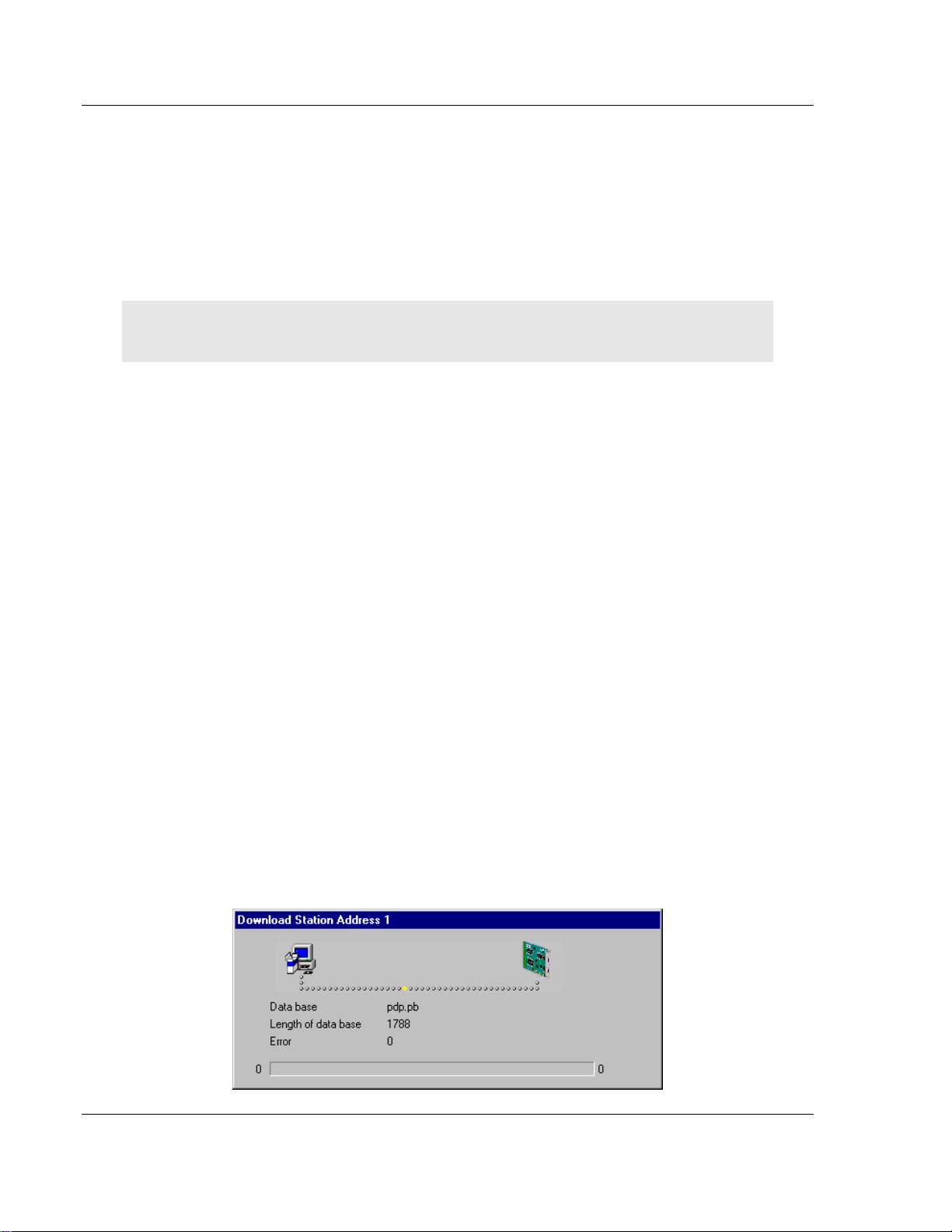

3.1.14 Downloading the Configuration

To enable the configuration and network access, the configuration must be

downloaded to the master. Choose Online, then Download from the menu. This

triggers a warning that the communication on the PROFIBUS will be interrupted.

This has to be confirmed.

Before the download is accomplished, the configurator checks the configuration.

If any error messages appear, the configuration should be checked. The most

common errors are overlapped addresses, which can be located by viewing the

Address Table overview.

If slave addressing is performed automatically, chose Auto addressing from the

Master Configuration window.

The configuration is transmitted to the selected device and stored into FLASH

memory statically. This enables it to be available after the power is switched off

and on in the device.

Page 32 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 33

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

After the download procedure, the device executes an internal restart and begins

with the communication if the start condition in DP Master Settings has been set

to Automatic release of the communication by the device.

3.1.15 Online Functions

Starting Debug Mode

Choose Online, then Start Debug Mode from the menu. The system configurator

cyclically interrogates the status of the network communication on the master

and individual condition of the devices. To end Debug Mode, select Online, then

Debug Mode from the menu.

The Debug Window

When the debug session is started, the Configuration Window changes to the

Debug window. The devices and the line between them are displayed in green or

red color depending on the established network communication.

When the debugger starts, PROLINX SyCon requests the status of all devices

from the master. If there is an error on a device, the bus line to this device is

drawn in red otherwise it is green.

PROLINX SyCon also displays the letters Diag if the device signals diagnostic

information. This information is displayed closer if you click with the mouse onto

the corresponding device in debug mode.

ProSoft Technology, Inc. Page 33 of 70

June 24, 2013

Page 34

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

To activate Debug mode select Online, the Start Debug Mode. The menu

Online - Device Diagnostic activates the PROFIBUS device diagnostic. To end

Debug Mode, select Online, then Stop Debug Mode.

If diagnostic information is available for a specific device, the text Diag appears

next to the device icon in red. To access additional device-specific diagnostic

information, double-click on the device itself, or select the device, then select

Online - Device Diagnostic.

Page 34 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 35

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

Device Diagnostic

The following example shows a diagnostic dialog box.

Device Diagnostic Descriptions

Master_Lock

The slave has already been parameterized by another master and is locked.

Search for another master on the network and delete its assignment to this

slave station, or remove the other assigned master from the network to

enable communication with this slave.

Parameter_Fault

This bit is automatically set by the slave when the parameters sent by the

master contain wrong or insufficient data. On every received parameter

telegram, the slave executes a check routine on the entire parameter

telegram. If the slave detects a faulty parameter value or detects illegal data

during its check, it reports the "parameterization error". During the check

routine, the slave compares its ident_number with the ident_number sent

by the master. If the slave reports this error, compare the real ident_number

shown in the slave diagnostic field in debugger mode with the one read out of

the GSD-File. Use the View/Device Table menu to view this information.

If parameter data is configured in PROLINX SyCon, but the slave does not

support it, reduce the parameter data in PROLINX SyCon to a length of zero.

Invalid_Slave_Response

ProSoft Technology, Inc. Page 35 of 70

June 24, 2013

Page 36

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

This bit is set by the master when the master receives an invalid answer from

the slave. The physical contact to the slave works, but the logical does not or

was interrupted. This may occur if a PROFIBUS-FMS slave is connected to

the DP-master. The slave does not understand the DP-Telegrams and rejects

them. It is handled as "Invalid_Slave_Response".

Not_Supported

This bit is set by the slave when a function should be performed that is not

supported. Newer releases of slave stations normally support the Sync and

Freeze Mode for I/O data. This is set in the GSD file, read by PROLINX

SyCon, and transferred to the slave in the parameter telegram. If

"Not_Supported" is reported, the GSD file declares at least one of these

commands as supported, but the slave does not. Ask the manufacturer of the

slave device for another GSD file or ask if the slave reports "Not_Supported"

on other wrong parameter data.

Extended_Diag

This bit is set by the slave if optional extended diagnostic data are a

containment of the slave diagnostic field. A slave station normally uses

extended diagnostic data if module-specific diagnostic information, for

example, exceeded analog values or low power should be reported to the

master. Click the Extended Diagnostic button to view a Hex-dump of the

reported values.

Configuration_Fault

During the PROFIBUS-DP startup procedure, the slave compares its internal

I/O configuration with the one configured in the master. If the slave detects

differences, it reports the "Cfg_Fault" error. This indicates that the master has

a different I/O module constellation for this slave configured, than the slave

device physically holds down. First compare visually all configured I/O

modules in the configuration data of PROLINX SyCon for this slave with its

real physical constellation. Note that the order of the module is important and

should also be compared. Some slaves need virtual I/O modules to be

configured first or empty slot modules to get an even number of modules to

run. This slave specific I/O module behavior can normally be read out in the

slave documentation. Last help to get the slave module constellation is to

read out its constellation by a PROFIBUS-DP command Compare

Configuration. Click on this button in the diagnostic field and get a HexDump of the real slave configuration data and the configured one (Real

Configuration and PROLINX SyCon Configuration). Note that the DPconfiguration data is coded in bit defined byte arrays to hold the I/O

information very compressed. The DP configuration is coded in a very

compact form. The code for the modules is shown in the slave

configuration.

Station_Not_Ready

When or at which event the slave sets this bit is not defined in the norm

specification. The meaning "Not_Ready" can be seen as not ready to perform

the I/O data exchange. This may indicate several slave specific reasons.

Usually the bit is set in combination with one of the other fault bits.

Station_Non_Existent

Page 36 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 37

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

This bit is automatically set by the master if this slave is not responding on

the bus. If this error occurs, compare the configured station address with the

physical one of the slave. Then ensure that the slave module supports the

configured baud rate. Some old modules only support bps rates up to 1.5

Mbps. Other modules must be jumpered to DP-Norm behavior first, to be

operative with a DP-Norm master. Then check your bus cable. Only the

TX/RX-pins 3<->3 and 8<->8 must be connected to get the contact between

two PROFIBUS components.

Slave_Deactivated

This bit is automatically set by the master if the slave in its parameter set is

marked as inactive, in order to be taken out of cyclic I/O processing.

Sync_Mode

This bit is set by the slave when it has received the sync control command.

Freeze_Mode

This bit is set by the slave when is has received the freeze control command.

Watchdog_ON

This bit is set by the DP-slave when its watchdog control is active to

supervise its corresponding master connection.

Static_Diag

The slave sets this bit to indicate that the master system is not operative for

I/O due to a general error. In a case of a set static diagnostic bit, the master

has to collect diagnostic information as long as this bit is active. On which

events or at what time this bit can be set by a slave device is not defined in

the norm description.

Parameter_Req_used

The slave sets this bit to force the master system to do a new

parameterization. This bit is set as long as new parameterization must be

performed.

Ext_Diag_Overflow

This bit is set if there is more extended diagnostic information to report to the

master than can be given to the master in one DP-diagnostic telegram. The

DP-slave sets this bit, for example, if there is more diagnostic channel

information than the slave can hold down in its diagnostic buffer.

Assigned_Master_Address

In this octet, the address of the DP-master that has done the

parameterization of the slave is entered. If the DP-slave is not parameterized

from any DP-master, the DP-slave puts the address 255 dec here.

Real_Ident_Number

With the Ident_Number, the slave reports its own unchangeable identification

number that was assigned by the PROFIBUS user organization. This

identification code can serve in PROLINX SyCon to compare it with the Ident

code of the GSD file of the configured slave if a parameterization error is

reported.

ProSoft Technology, Inc. Page 37 of 70

June 24, 2013

Page 38

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

Firmware Download

If you want to make a Firmware download, select Online, then Firmware

Download from the menu. The Open window appears. Select the new Firmware

and confirm your entry with the Open button.

Firmware / Reset

Choose Online, then Firmware Reset from the menu to display the name and

version of the firmware of the selected device. The Reset button resets the

device.

Extended Device Diagnostic

The menu item, Online - Extended Device Diagnostic helps to detect possible

bus and configuration faults while trying to get the bus fully operative. When the

normal debugger does not supply any helpful information, use this option to

obtain fault localization information. This menu activates a list of available

structures. The listed structures can be displayed to show the values.

Several task states are available.

Note: All items in this list do not work for this master.

Page 38 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 39

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

Global State Field

Select the menu Online - Global State Field to see information about the global

state field. The first row shows the Online master main state for example,

OPERATE, STOP. The next row shows the collective status bits. An activated bit

is red. Further contents are given:

Collective online error location and corresponding error

Statistic bus information

Device specific status bits: Parameterized Devices, Activated Devices and

Devices with Diagnostic are shown if you click on that button. The activated

addresses are white numbers.

This application updates the status online in the global state field. You can see

the diagnostic by double-clicking at a selected station address of a device. The

meaning of the shortcuts is listed below:

Collective Status Bits

TOUT (TIMEOUT-ERROR) The device has detected an overstepped timeout

supervision time because of rejected PROFIBUS telegrams. This is an

indication for bus short circuits while the master interrupts the

communication. The number of detected timeouts is fixed in the statistic bus

information variable. The bit will be set when the first timeout was detected

and will not be deleted.

ProSoft Technology, Inc. Page 39 of 70

June 24, 2013

Page 40

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

NRDY (HOST-NOT-READY-NOTIFICATION) Indicates if the host program

has set its state to operative or not. If this bit is set the host program is not

ready to communicate.

EVE (EVENT-ERROR) The device has detected bus short circuits. The

number of detected events is fixed in the statistic bus information variable.

The bit will be set when the first event was detected and will not be deleted

any more.

FAT (FATAL-ERROR) Because of a heavy bus error, no further bus

communication is possible.

NEXC (NON-EXCHANGE-ERROR) At least one slave has not reached the

data exchange state and no process data exchange is possible with it.

ACLR (AUTO-CLEAR-ERROR) Device stopped the communication to all

slaves and reached the auto-clear end state.

CTRL (CONTROL-ERROR) Parameterization error.

Live List

If the menu Online - Live List is selected, an overall view of all active devices on

your PROFIBUS network is shown. A green number (the number is the station

address) for the master and a blue number for the slave is norm. The status of

the live list is not automatically updated online.

Click on the Update button after you change your inputs to update this window.

Page 40 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 41

PDPM ♦ ProLinx Gateway Configuration

PROFIBUS DP Master Protocol Manual

If you click on a colored station address you are given the Device type and

Device state.

I/O Monitor

This is a simple tool used to display and enter only the first 32 bytes of the

process image.

Note: The I/O monitor cannot be used with the ProLinx PROFIBUS Master unit.

ProSoft Technology, Inc. Page 41 of 70

June 24, 2013

Page 42

Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

Set Slave Address

Select the Online - Set Slave Address menu to change a slave address.

Write the new address in the row New Station Address. If no further changes

shall be allowed, select the field No additional changing. If necessary, add

additional parameters in hex in the field Slave parameter.

Activate the command with the Set Address button.

Start/Stop Communication

Manually start or stop the communication between masters and slaves by

selecting menu Online - Start Communication and Stop Communication

respectively.

Device Info

Select the menu Online - Device Info to see information about the selected

hardware in the configuration.

Page 42 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 43

PDPM ♦ ProLinx Gateway PDPM Protocol Configuration

In This Chapter

[PROFIBUS Master] .............................................................................. 43

[PROFIBUS Master Commands] ........................................................... 45

PROFIBUS DP Master Protocol Manual

4 PDPM Protocol Configuration

The following is excerpted from a configuration file showing typical examples of

the PROFIBUS Master Port and PROFIBUS Master Command sections of a

CFG file for a PDPM port. Shipped with each unit (or available from the web) is a

default configuration file that can easily form the basis for a working solution. This

file can either be downloaded from the ProSoft web site at

www.prosoft-technology.com, or transferred from the module.

# This is the data area for setting the Profibus Master parameters

[Profibus Master]

Swap Input Bytes : No #Swap bytes in input image (yes or no)

Swap Output Bytes : No #Swap bytes in output image (yes or no)

Comm Failure Mode : 1 #0=x-fer on comm fail, 1=no x-fer on fail

Watchdog Register : 1000 #DB register to monitor for change (1=watchdog not used)

Watchdog Timeout : 50 #.1 second intervals for watchdog timeout

Watchdog Reset Value : 255 #Value to set Profibus outputs to on timeout

condition

# This section contains the Profibus Master commands to be processed by the

# module.

[Profibus Master Commands]

# Database Register Poll Command Data

# Enabled Address Count Interval Node Code Length

START

1 600 10 0 3 66 32

1 610 7 0 4 66 32

2 620 0 10 3 254 2

2 0 0 1200 0 254 0

END

4.1 [PROFIBUS Master]

# This is the data area for setting the Profibus Master parameters

[Profibus Master]

Swap Input Bytes : No #Swap bytes in input image (yes or no)

Swap Output Bytes : No #Swap bytes in output image (yes or no)

Comm Failure Mode : 1 #0=x-fer on comm fail, 1=no x-fer on fail

Watchdog Register : 1000 #DB register to monitor for change

ProSoft Technology, Inc. Page 43 of 70

June 24, 2013

Page 44

PDPM Protocol Configuration PDPM ♦ ProLinx Gateway

Protocol Manual PROFIBUS DP Master

#(-1=watchdog not used)

Watchdog Timeout : 50 #.1 second intervals for watchdog timeout

Watchdog Reset Value : 255 #Value to set Profibus outputs to on

#timeout condition

4.1.1 Swap Input Bytes

Yes or No

This parameter specifies if the data in the input data area of the module is to be

byte swapped. If the order of the bytes in the words stored in the database is not

correct, use this option. A value of Yes causes the module’s program to swap the

bytes in each word. A value of No indicates no byte swapping will occur.

4.1.2 Swap Output Bytes

Yes or No

This parameter specifies if the data in the output data area of the module is to be

byte swapped. If the order of the bytes in the words stored in the database is not

correct, use this option. A value of Yes causes the module’s program to swap the

bytes in each word. A value of No indicates no byte swapping will occur.

4.1.3 Comm Failure Mode

0 or 1

This parameter sets the data transfer mode of the module's PROFIBUS input

image to the internal database when a communication failure on the PROFIBUS

interface is detected. If the parameter is set to 0, the input image will continue to

be transferred. If the parameter is set to 1, the input image will not be transferred

and the last values will be retained.

4.1.4 Watchdog Parameters

Watchdog Register : 1000 #DB register to monitor for change

#(-1=watchdog not used)

Watchdog Timeout : 50 #.1 second intervals for watchdog timeout

Watchdog Reset Value : 255 #Value to set Profibus outputs to on

#timeout condition

The watchdog functionality allows the module to set the PROFIBUS output

registers to a pre-defined value once a communication failure occurs. The

watchdog is implemented through the monitoring of a specific database register

(configured through the Watchdog Register parameter). The remote node should

write a new value to this database register faster than the timeout period

(configured through the Watchdog Timeout parameter). If this time period

elapses but no change is detected then the module will force all PROFIBUS

output registers to a specific value (configured through the Watchdog Reset

Value parameter).

In order to disable this functionality set the Watchdog Register to -1.

Page 44 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 45

PDPM ♦ ProLinx Gateway PDPM Protocol Configuration

Column #

1

2

3

4

5

6

7

Function Type

Enabled

Database

Address

Register

Count

Polling

Interval

Node

Address

Command

Code

Data Length

Read Diag

1 or 2

0 to 3999

1 to 122

0 to 65535

0 to126

66

32 or 106

Global Cmd

1 or 2

0 to 3999

0

0 to 65535

0 to126

70

Group

Read Cntrs

1 or 2

0 to 3997

0

0 to 65535

0 to126

254

1 to 40

Reset Cntrs

1 or 2

0 0 0 to 65535

0

254

0

PROFIBUS DP Master Protocol Manual

4.2 [PROFIBUS Master Commands]

The [PROFIBUS MASTER COMMANDS] section of the CFG file sets the

PROFIBUS master port command list. This list polls slave devices attached to a

master port. The module supports three commands. This permits the module to

interface with a wide variety of PROFIBUS slave devices.

The command list is formatted differently than the other sections of the

configuration file. Commands are present in a block between the labels START

and END. These labels inform the program where the list resides. The module's

program will parse all commands after the START label until it reaches the END

label or until the command count entered for the port is reached.

The format of each command in the list is the same with the content dependent

on the operation to perform. The following table describes the format and list of

PROFIBUS Master functions supported:

Command list example:

[PROFIBUS Master Commands]

# Database Register Poll Command Data

# Enabled Address Count Interval Node Code Length

START

1 600 10 0 3 66 32

1 610 7 0 4 66 32

2 620 0 10 3 254 2

2 0 0 1200 0 254 0

END

4.2.1 66 - Read Diag

Execute a station diagnostic command to the specified node placing the

response message at the Database Address specified but only using the number

of registers entered in the Register Count field.

4.2.2 70 - Global Cmd

Execute global command using the value at the specified Database Address to

the Node Address. The Data Length field specifies the Group Select parameter.

ProSoft Technology, Inc. Page 45 of 70

June 24, 2013

Page 46

PDPM Protocol Configuration PDPM ♦ ProLinx Gateway

Bit

Definition

0

Reserved

1

Clear output data

2

Unfreeze input data

3

Freeze input data

4

Neutralize the sync command

5

Freeze output data until sync command is neutralized

6

Reserved

7

Reserved

Bit 2 or 4

Bit 3 or 5

Definition

0 0 No function

0 1 Function will be activated (that is, Freeze input data)

1 0 Function will be inactivated (that is, Unfreeze input data)

1 1 Function will be inactivated (that is, Unfreeze input data)

Protocol Manual PROFIBUS DP Master

4.2.3 254 - Read Cntrs

If the Data Length parameter is set to zero, the command will reset the counters

for all slaves. If the Data Length is specified, it represents the number of slaves

to read the static counter data. The Node Address specifies the first slave node

to consider in the request. The counter data returned is placed at the Database

Address in the command.

4.2.4 Command 70 Control Byte

The Freeze and Sync commands are used for synchronization purposes. The

Freeze command causes a slave to freeze its inputs and the Sync command

causes a slave to hold the outputs.

Page 46 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 47

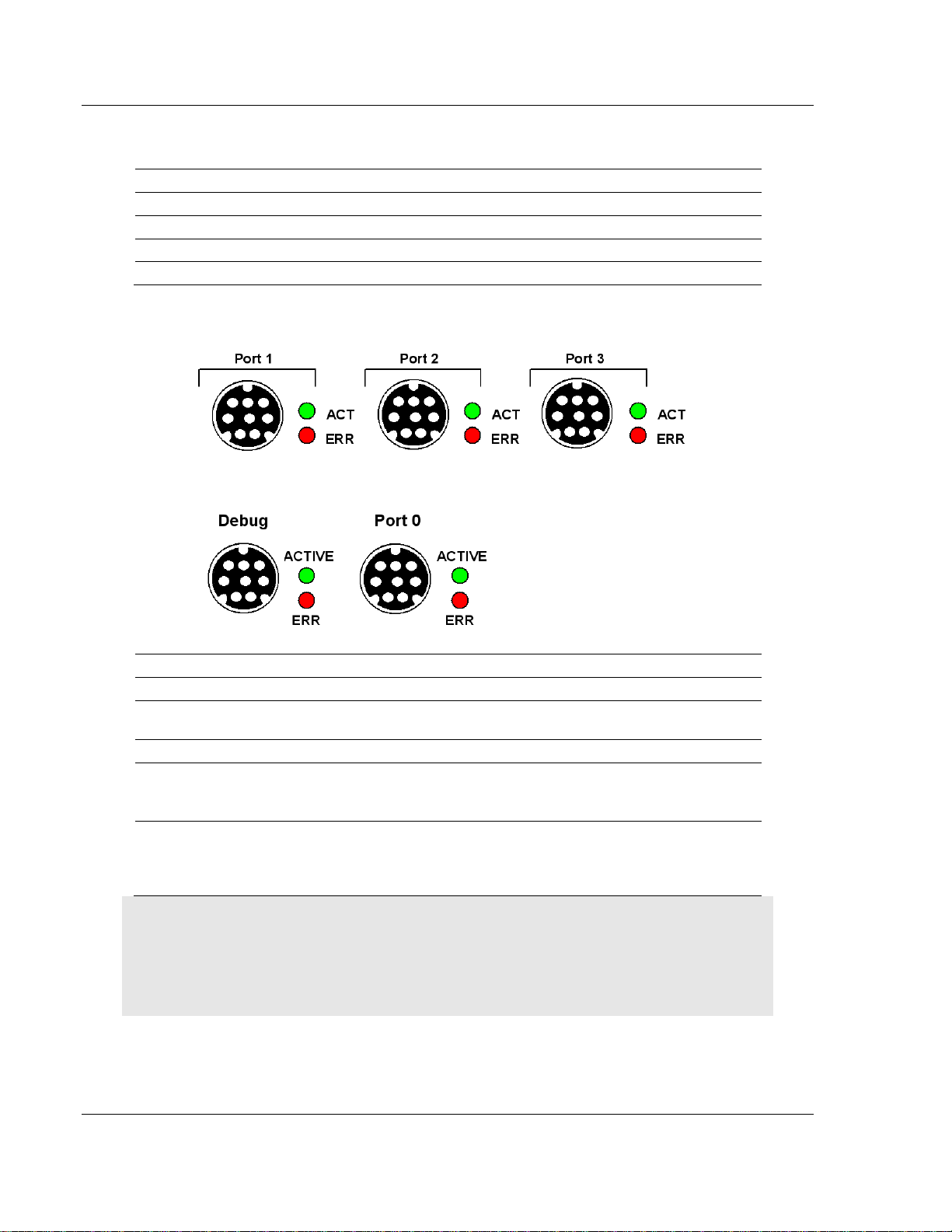

PDPM ♦ ProLinx Gateway Diagnostics and Troubleshooting

In This Chapter

LED Indicators ....................................................................................... 47

PROFIBUS Master Error and Status Data............................................. 48

PROFIBUS Master: Error and Status Data............................................ 48

Error Numbers ....................................................................................... 51

TKN

ERR RUN

RDY

LED

Color

Description

TKN - Token

Green On

PROFIBUS Master owns token.

PROFIBUS DP Master Protocol Manual

5 Diagnostics and Troubleshooting

The module provides information on diagnostics and troubleshooting in the

following forms:

LED status indicators on the front of the module provide general information

on the module's status.

You can view status data contained in the module through the

Configuration/Debug port or the Ethernet port, using the troubleshooting and

diagnostic capabilities of ProSoft Configuration Builder (PCB).

You can transfer status data values from the module to processor memory

and can monitor them in the processor manually or by customer-created

logic. For details on Status Data values, see Status Data Table.

5.1 LED Indicators

Troubleshooting the operation of the PROFIBUS Master ports can be performed

using several methods.

The first and quickest is to scan the LEDs on the module to determine the

existence and possible cause of a problem. This section provides insight into the

operation of the PROFIBUS Master Port status LEDs. Information on the

module’s other LEDs can be found in the ProLinx Reference Guide.

5.1.1 LEDs for the PROFIBUS Master Port

ProSoft Technology, Inc. Page 47 of 70

June 24, 2013

Page 48

Diagnostics and Troubleshooting PDPM ♦ ProLinx Gateway

LED

Color

Description

RDY - Ready

Off

Hardware error.

Green On

Module OK.

Green cyclic flash, approx.

1 Hz.

Flash only contains boot loader, no valid

firmware stored in flash.

Green cyclic flash, approx.

4 Hz.

Hardware or system error or

firmware/configuration database download in

progress.

ERR - Error

Red Off

No errors detected.

Red On

Error on communication line. Shows if a bus

error has occurred, for example, a remote node

was not found.

RUN - Run

Green On

Communication running.

Green cyclic flash, approx.

4 Hz.

Ready for communication.

Green acyclic flash

Configuration error or fatal error.

Protocol Manual PROFIBUS DP Master

5.2 PROFIBUS Master Error and Status Data

The second and most thorough troubleshooting method for debugging the

operation of the PDPM driver (and the module in general) is the powerful Debug

port on the module which provides much more complete access to the internal

operation and status of the module. Accessing the Debug capabilities of the

module is accomplished easily by connecting a PC to the Debug port and loading

a terminal program such as ProSoft Configuration Builder or HyperTerminal.

5.2.1 Viewing Error and Status Data

The following topics list the register addresses that contain error and status data.

Use the Database View option from the ProLinx Main Menu to view the contents

of each register. The ProLinx Reference Guide provides the information on using

this option.

5.3 PROFIBUS Master: Error and Status Data

The PROFIBUS Master Error and Status Data register areas are discussed in

this section.

The data area is initialized with zeros whenever the module is initialized. This

occurs during a cold-start (power-on), reset (reset push-button pressed) or a

warm-boot operation (commanded or loading of new configuration). The format

of this data area is displayed below:

Page 48 of 70 ProSoft Technology, Inc.

June 24, 2013

Page 49

PDPM ♦ ProLinx Gateway Diagnostics and Troubleshooting

Database Address

Offset

Description

10400

0

State

Code Definition

-1 Master not in run or ready mode (restarting)

0 Waiting for initialization

1 Initialized and ready to run or running

10401

1

Mailbox State

10402

2

Scan Counter

10403

3

Mailbox Data Move Counter

10404