Page 1

3170-PDP

FLEX Platform

FLEX I/O™ PROFIBUS Adapter

User Manual

August 23, 2007

Page 2

Please Read This Notice

Successful application of this module requires a reasonable working knowledge of the Rockwell

Automation hardware, the 3170-PDP Module and the application in which the combination is to be

used. For this reason, it is important that those responsible for implementation satisfy themselves

that the combination will meet the needs of the application without exposing personnel or

equipment to unsafe or inappropriate working conditions.

This manual is provided to assist the user. Every attempt has been made to assure that the

information provided is accurate and a true reflection of the product's installation requirements. In

order to assure a complete understanding of the operation of the product, the user should read all

applicable Rockwell Automation documentation on the operation of the Rockwell Automation

hardware.

Under no conditions will ProSoft Technology be responsible or liable for indirect or consequential

damages resulting from the use or application of the product.

Reproduction of the contents of this manual, in whole or in part, without written permission from

ProSoft Technology is prohibited.

Information in this manual is subject to change without notice and does not represent a

commitment on the part of ProSoft Technology Improvements and/or changes in this manual or the

product may be made at any time. These changes will be made periodically to correct technical

inaccuracies or typographical errors.

Solid state equipment has operational characteristics differing from those of electromechanical

equipment. "Safety Guidelines for the Application, Installation and Maintenance of Solid State

Controls" (Publication SGI-1.1) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons responsible for applying

this equipment must satisfy themselves that each intended application of this equipment is

acceptable.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of

the many variables and requirements associated with any particular installation, ProSoft

Technology, Inc. cannot assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by ProSoft Technology, Inc. with respect to use of information,

circuits, equipment, or software described in this manual.

Throughout this manual we use notes to make you aware of safety considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage, or economic loss.

Attentions help you:

identify a hazard

avoid the hazard

recognize the consequences

Important: Identifies information that is especially important for successful application and

understanding of the product.

Microsoft is a registered trademark of the Microsoft Corporation.

Windows is a trademark of the Microsoft Corporation.

FLEX I/O and PLC-5 are trademarks of the Rockwell Automation Company, Inc.

PROFIBUS is a trademark of the PROFIBUS User Organization

Page 3

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have

suggestions, comments, compliments or complaints about the product, documentation or support,

please write or call us.

ProSoft Technology

1675 Chester Avenue, Fourth Floor

Bakersfield, CA 93301

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

http://www.prosoft-technology.com

Copyright © ProSoft Technology, Inc. 2000 - 2007. All Rights Reserved.

3170-PDP User Manual

August 23, 2007

PSFT.PDP.3170.UM.07.08.23

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk® and RadioLinx ® are Registered Trademarks

of ProSoft Technology, Inc.

Page 4

Page 5

Contents 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

Contents

PLEASE READ THIS NOTICE.............................................................................................................................. 2

Your Feedback Please ...................................................................................................................................... 3

1 ABOUT THIS USER MANUAL..................................................................................................................... 9

1.1 Purpose ................................................................................................................................................... 9

1.2 Vocabulary............................................................................................................................................... 9

1.3 Publication references ............................................................................................................................. 9

1.4 Related Publications ................................................................................................................................ 9

1.5 Compliance to European Union Directives .............................................................................................10

1.5.1 EMC Directive ...............................................................................................................................10

2 OVERVIEW OF FLEX I/O AND YOUR PROFIBUS ADAPTER MODULE..................................................11

2.1 The FLEX I/O System.............................................................................................................................11

2.2 Mount and Remove your System Easily .................................................................................................12

2.3 Optional Accessories..............................................................................................................................13

2.3.1 Extender Cables (1794-CE1 or -CE3)...........................................................................................13

2.3.2 Mounting Kit (1794-NM1) ..............................................................................................................14

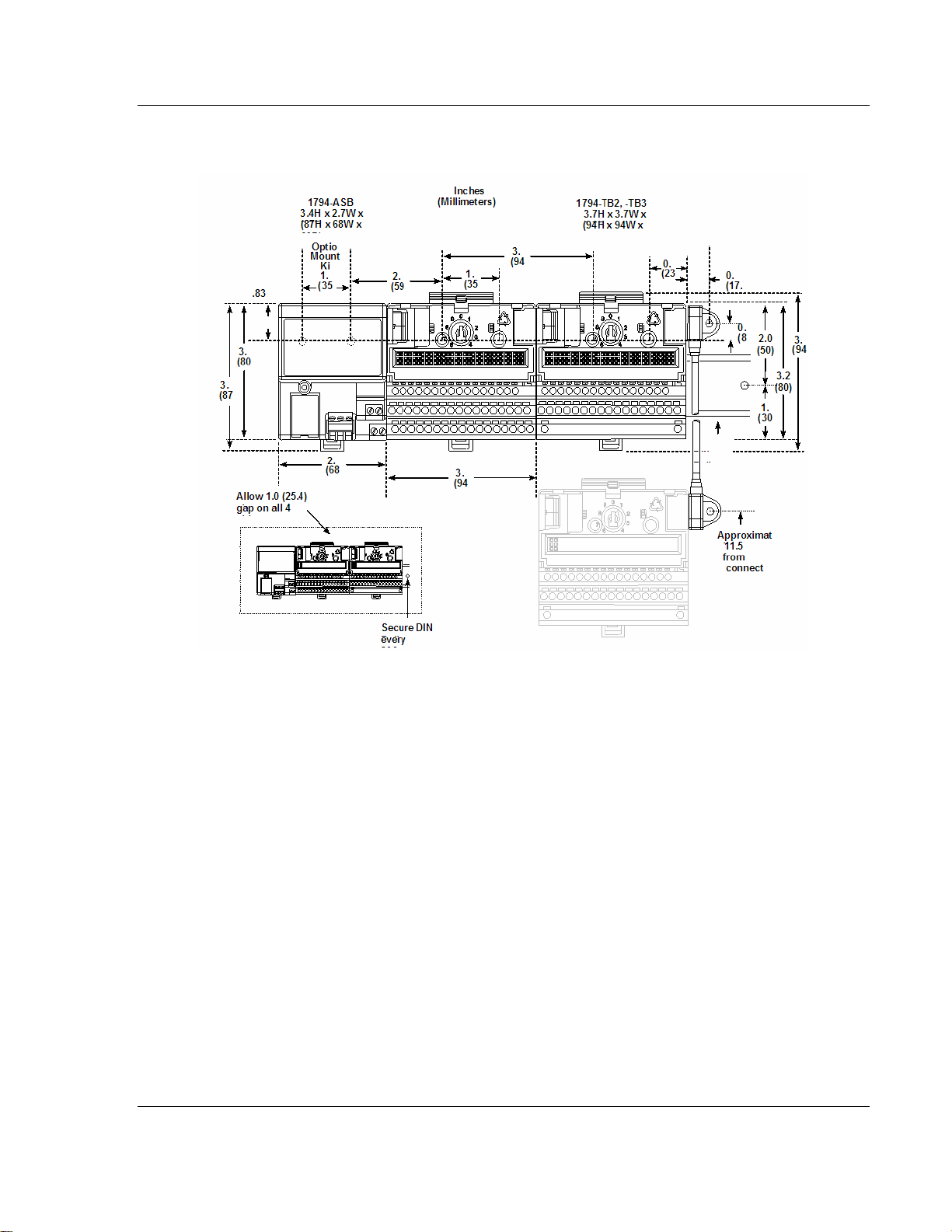

2.3.3 Mounting Dimensions and Spacing Requirements........................................................................15

2.4 Purpose of the 3170-PDP.......................................................................................................................16

2.5 PROFIBUS Adapter Components...........................................................................................................17

2.5.1 Diagnostic Indicators.....................................................................................................................17

2.5.2 Network Connector........................................................................................................................17

2.5.3 Setting the Node Address Switches ..............................................................................................18

2.5.4 Power Wiring.................................................................................................................................18

3 HOW COMMUNICATION TAKES PLACE AND I/O IMAGE TABLE MAPPING........................................19

3.1 Polled I/O Structure.................................................................................................................................20

3.1.1 Adapter Input Status Word ............................................................................................................20

3.2 Mapping Data into the Image Table........................................................................................................22

3.2.1 1794-IB16 – 16-point Discrete Input Module Image Table Mapping..............................................23

3.2.2 1794-OB16 – 16-point Discrete Output Module Image Table Mapping .........................................24

3.2.3 1794-IB8S – 8-point Discrete Sensor Input Module Image Table Mapping...................................25

3.2.4 1794-IA8 – 8-point Discrete Input Module Image Table Mapping .................................................26

3.2.5 1794-OA8 – 8-point Discrete Output Module Image Table Mapping .............................................27

3.2.6 1794-OW8 – 8-point Discrete Relay Output Module Image Table Mapping..................................27

3.2.7 1794-IE8 – 8 Input Analog Module................................................................................................28

3.2.8 1794-OE4 – 4 Output Analog Module Image Table Mapping........................................................30

3.2.9 1794-IE4XOE2 – Analog Combo Module Image Table Mapping ..................................................33

3.2.10 1794-IR8 – RTD Input Analog Module Image Table Mapping .......................................................35

3.2.11 1794-IT8 – Thermocouple Input Module Image Table Mapping....................................................38

3.2.12 1203-FM1 – SCANport Module Image Table Mapping..................................................................41

3.3 Connection Status Word Definition.........................................................................................................42

3.4 Logic Status/Analog Feedback Definition ...............................................................................................42

3.5 Connection Enable Word Definition........................................................................................................42

3.6 Logic Command/Analog Reference Definition........................................................................................42

3.7 Defaults...................................................................................................................................................43

4 CONNECT THE ADAPTER TO THE PROFIBUS DP NETWORK..............................................................45

ProSoft Technology, Inc. Page 5 of 152

August 23, 2007

Page 6

3170-PDP ♦ FLEX Platform Contents

FLEX I/O™ PROFIBUS Adapter

4.1 The DP Physical Layer ...........................................................................................................................45

4.2 Cabling and Equipment Required for Line A Type..................................................................................46

4.2.1 Cables...........................................................................................................................................46

4.2.2 T-junction Connectors ...................................................................................................................46

4.2.3 Termination Blocks........................................................................................................................46

4.2.4 Bus Connector ..............................................................................................................................46

4.3 Cabling and Equipment Required for Line B Type..................................................................................47

4.3.1 Cables...........................................................................................................................................47

4.3.2 T-junction Connectors ...................................................................................................................47

4.3.3 Termination Blocks........................................................................................................................47

4.3.4 Bus Connector ..............................................................................................................................47

4.4 Connect the Adapter to the Network.......................................................................................................48

4.4.1 Connect to the Adapter .................................................................................................................48

4.5 Terminate the Network ...........................................................................................................................49

4.5.1 Terminate at the Adapter Using Line A .........................................................................................49

4.5.2 Terminate at the Adapter Using Line B .........................................................................................49

5 CONFIGURE THE ADAPTER FOR MASTER/SLAVE COMMUNICATION................................................51

5.1 How Master/Slave Communication Takes Place....................................................................................51

5.2 Entering User Parameter Data ...............................................................................................................52

5.2.1 User Parameter Data ....................................................................................................................52

5.2.2 Auto Configure Format..................................................................................................................53

5.2.3 Condensed Format .......................................................................................................................54

5.2.4 Entering Check Configuration Data...............................................................................................58

5.3 Read Configuration Response Data .......................................................................................................60

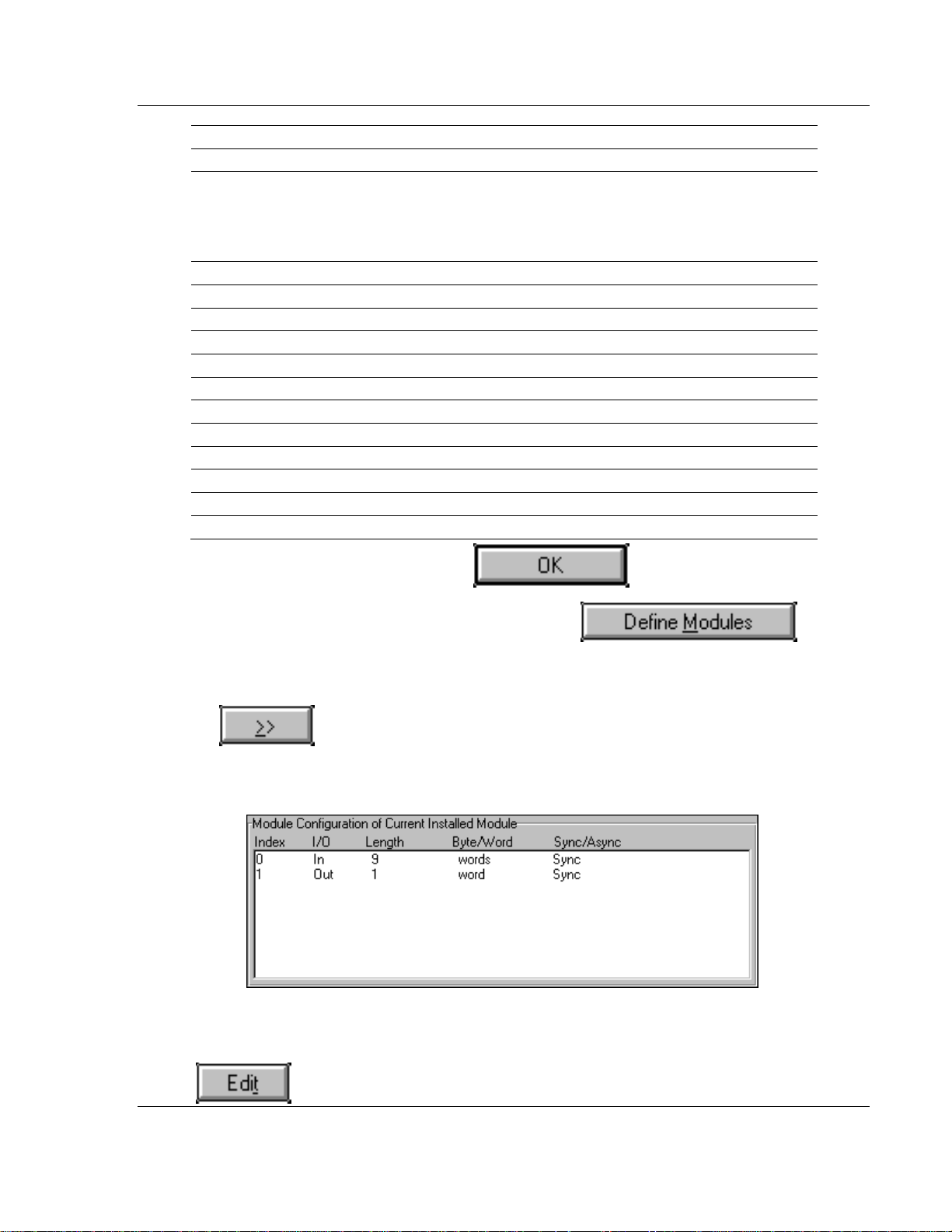

5.4 Configuration Example Using PROFIBUS Manager Software................................................................61

6 TROUBLESHOOTING.................................................................................................................................65

6.1 What this Chapter Contains....................................................................................................................65

6.2 Troubleshooting with the Indicators........................................................................................................65

6.3 Configuration differences between 1794-APB and 3170-PDP................................................................67

6.3.1 User parameter data for 1794-APB:..............................................................................................68

6.3.2 User parameter data for 3170-PDP:..............................................................................................68

7 REFERENCE...............................................................................................................................................69

7.1 Product Specifications ............................................................................................................................69

7.2 Device Data Base File ............................................................................................................................70

8 GLOSSARY...............................................................................................................................................131

9 PROSOFT TECHNOLOGY, INC., SUPPORT, SERVICE & WARRANTY................................................141

9.1 How to Contact Us: Sales and Support ................................................................................................142

9.2 Return Material Authorization (RMA) Policies and Conditions..............................................................143

9.2.1 All Product Returns .....................................................................................................................143

9.3 Procedures for Return of Units Under Warranty...................................................................................143

9.4 Procedures for Return of Units Out of Warranty...................................................................................144

9.4.1 Un-repairable Units .....................................................................................................................144

9.4.2 Purchasing Warranty Extension..................................................................................................145

9.5 LIMITED WARRANTY..........................................................................................................................145

9.5.1 What Is Covered By This Warranty.............................................................................................145

9.5.2 What Is Not Covered By This Warranty ......................................................................................146

9.5.3 DISCLAIMER REGARDING HIGH RISK ACTIVITIES................................................................147

Page 6 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 7

Contents 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

9.5.4 DISCLAIMER OF ALL OTHER WARRANTIES...........................................................................147

9.5.5 LIMITATION OF REMEDIES**....................................................................................................147

9.5.6 Time Limit for Bringing Suit .........................................................................................................147

9.5.7 No Other Warranties ...................................................................................................................148

9.5.8 Intellectual Property.....................................................................................................................148

9.5.9 Additional Restrictions Relating To Software And Other Intellectual Property.............................148

9.5.10 Allocation of risks ........................................................................................................................148

9.5.11 Controlling Law and Severability .................................................................................................149

INDEX.................................................................................................................................................................151

ProSoft Technology, Inc. Page 7 of 152

August 23, 2007

Page 8

3170-PDP ♦ FLEX Platform Contents

FLEX I/O™ PROFIBUS Adapter

Page 8 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 9

About this User Manual 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

1 About this User Manual

In This Chapter

¾ Purpose.................................................................................... 9

¾ Vocabulary ............................................................................... 9

¾ Publication references.............................................................. 9

¾ Related Publications ................................................................ 9

¾ Compliance to European Union Directives............................. 10

1.1 Purpose

Use this manual to install and configure your FLEX I/OTM PROFIBUS Adapter,

cat. no. 3170-PDP.

1.2 Vocabulary

In this manual, we refer to:

the FLEX I/O PROFIBUS adapter module as the "adapter"

the programmable controller as the "processor"

1.3 Publication references

All publications this document refers to are Rockwell Automation publications.

1.4 Related Publications

For additional information on planning and installing your PROFIBUS system

using FLEX I/O modules, refer to the following publications:

Catalog

Number

3170-PDP 24V dc PROFIBUS Adapter Installation Instructions 801.09

1794-TB2

1794-TB3

1794-TBN Terminal Base Unit Installation Instructions 1794-5.16

1794-TBNF Fused Terminal Base Unit Installation Instructions 1794-5.17

1794-PS1 Power Supply Installation Instructions 1794-5.35

1794-IB16 24V dc 16 Input Module Installation Instructions 1794-5.4

Description

2-wire Terminal Base

3-wire Terminal Base

Related Publications

Pub. Type Pub. Number

Installation Instructions 1794-5.2

ProSoft Technology, Inc. Page 9 of 152

August 23, 2007

Page 10

3170-PDP ♦ FLEX Platform About this User Manual

FLEX I/O™ PROFIBUS Adapter

Catalog

Number

1794-OB16 24V dc 16 Output Module Installation Instructions 1794-5.3

1794-IR8

1794-IT8

1794-IE8

1794-OE4

1794IE4XOE2

1794-IB8S 24V dc Sensor Input Module Installation Instructions 1794-5.7

1794-IA8 120V ac 8 Input Module Installation Instructions 1794-5.9

1794-OA8 120V ac 8 Output Module Installation Instructions 1794-5.10

1794-OW8 24V dc 8 Relay Output Module Installation Instructions 1794-5.19

1794-CE1 Extender Cable Installation Instructions 1794-5.12

1794-NM1 Mounting Kit Installation Instructions 1794-5.13

Description

24V dc RTD Analog 8 Input

Module

24V dc Thermocouple Analog 8

Input Module

24V dc Selectable Analog 8 Input

Module

24V dc Selectable Analog 4

Output Module

24V dc 4 Input/2 Output Analog

Combo Module

Related Publications

Pub. Type Pub. Number

Installation Instructions

User Manual

Installation Instructions

User Manual

Installation Instructions

User Manual

Installation Instructions

User Manual

Installation Instructions

User Manual

1794-5.22

1794-6.5.4

1794-5.21

1794-6.5.7

1794-5.6

1794-6.5.2

1794-5.5

1794-6.5.2

1794-5.15

1794-6.5.2

To order these publications, contact your local Rockwell Automation

representative.

1.5 Compliance to European Union Directives

If this product has the CE mark it is approved for installation within the European

Union and EEA regions. It has been designed and tested to meet the following

directives.

1.5.1 EMC Directive

This product is tested to meet Council Directive 89/336/EEC Electromagnetic

Compatibility (EMC) and the following standards, in whole or in part, documented

in a technical construction file:

EN 50081-2EMC – Generic Emission Standard, Part 2 – Industrial

Environment

EN 50082-2EMC – Generic Immunity Standard, Part 2 – Industrial

Environment

This product is intended for use in an industrial environment.

Page 10 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 11

Overview of FLEX I/O and Your PROFIBUS Adapter Module 3170-PDP ♦ FLEX Platform FLEX I/O™ PROFIBUS Adapter

2 Overview of FLEX I/O and Your PROFIBUS

Adapter Module

In This Chapter

¾ The FLEX I/O System ............................................................ 11

¾ Mount and Remove your System Easily ................................ 12

¾ Optional Accessories ............................................................. 13

¾ Purpose of the 3170-PDP ......................................................16

¾ PROFIBUS Adapter Components.......................................... 17

This chapter describes

what the FLEX I/O system is and what it contains

how to mount and remove your system easily

optional accessories

mounting dimensions and spacing requirements

3170-PDP

adapter components

how to connect power wiring

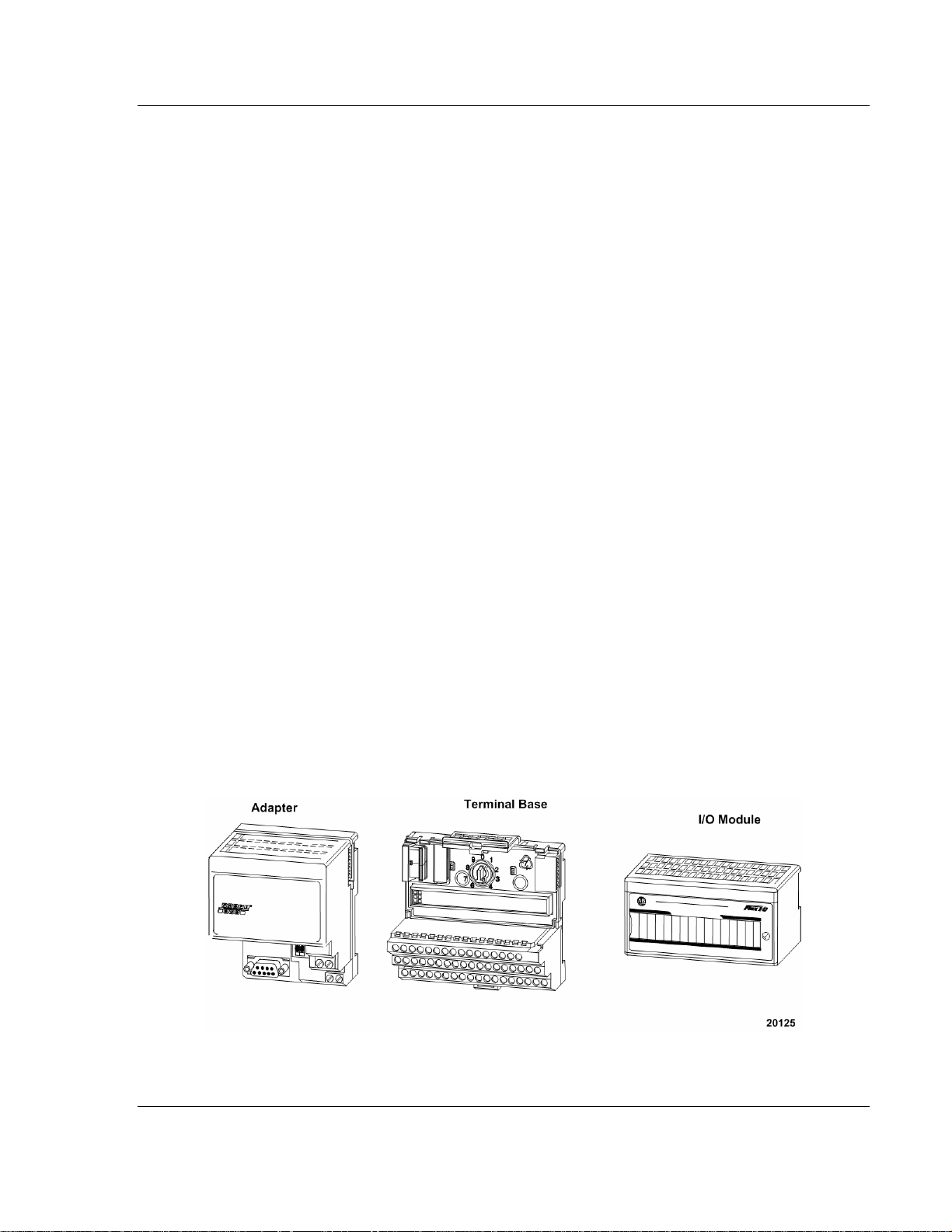

2.1 The FLEX I/O System

FLEX I/O is a small, modular I/O system for distributed applications that performs

all of the functions of rack-based I/O. The FLEX I/O system contains the following

components:

PROFIBUS adapter/power supply - powers the internal logic for as many as

eight I/O modules

ProSoft Technology, Inc. Page 11 of 152

August 23, 2007

Page 12

3170-PDP ♦ FLEX Platform Overview of FLEX I/O and Your PROFIBUS Adapter Module

FLEX I/O™ PROFIBUS Adapter

terminal base - contains a terminal strip to terminate wiring for two- or three-

wire devices

I/O module - contains the bus interface and circuitry needed to perform

specific functions related to your application

For information on how communication occurs over the FLEX I/O system

backplane, refer to Chapter 2.

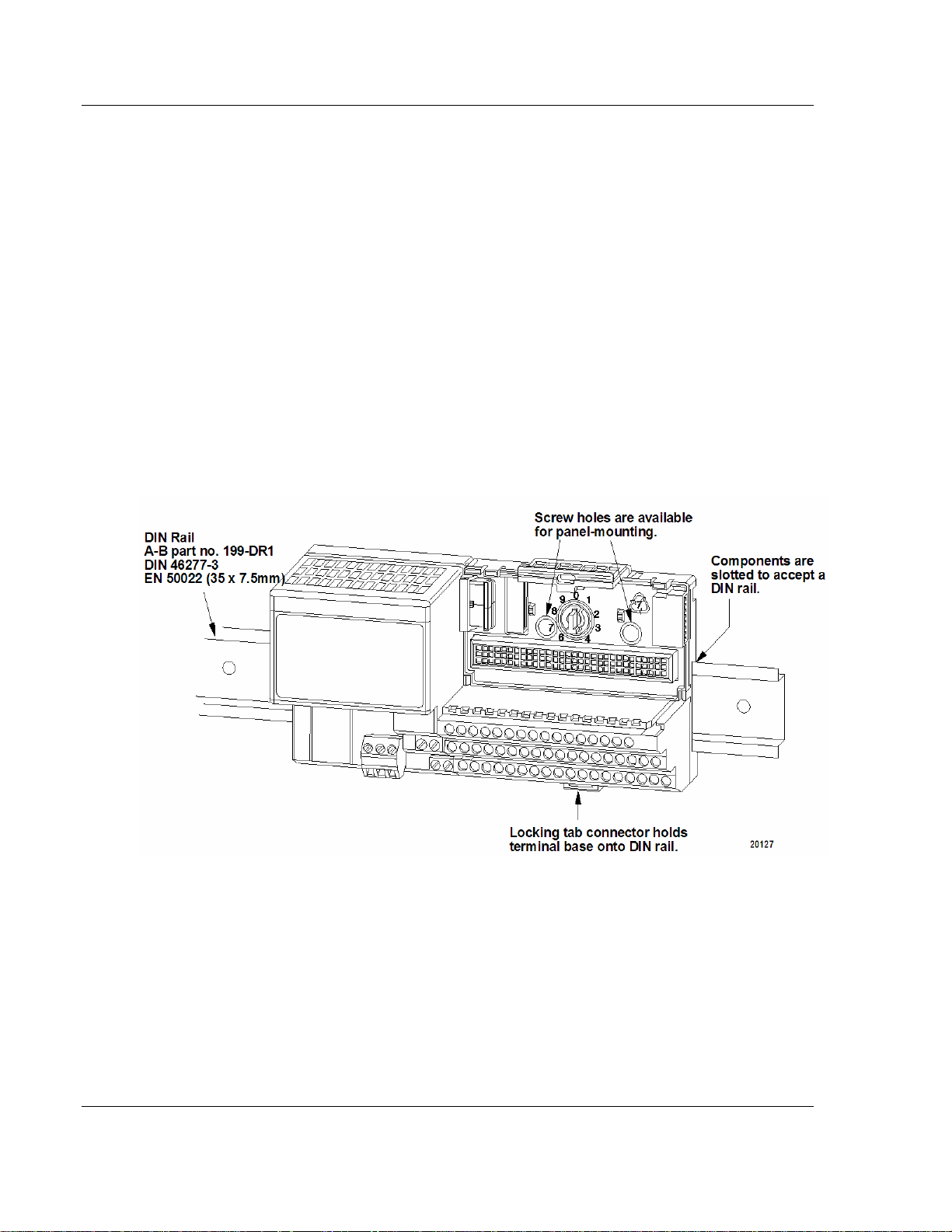

You can horizontally or vertically mount the FLEX I/O system on a standard DIN

rail. The adapter and terminal base easily snap on the DIN rail by hand. Refer to

the installation instructions shipped with these components.

2.2 Mount and Remove your System Easily

Screw holes are also provided to horizontally or vertically panel-mount your

system in an enclosure. To panel-mount your FLEX I/O system, use the optional

mounting kit (1794-NM1).

An example of a DIN-rail mounted system is shown below.

Page 12 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 13

Overview of FLEX I/O and Your PROFIBUS Adapter Module 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

2.3 Optional Accessories

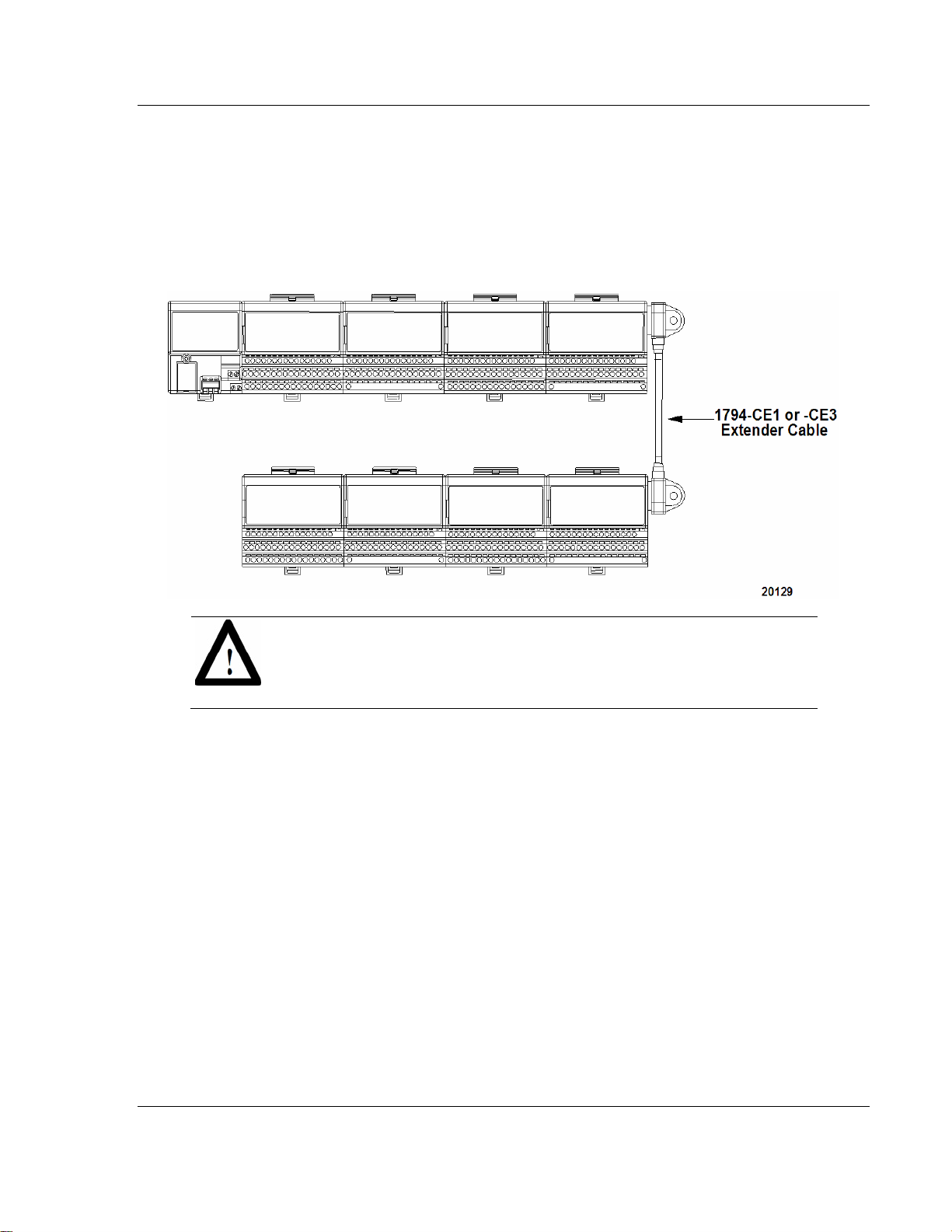

2.3.1 Extender Cables (1794-CE1 or -CE3)

Use the optional 1794-CE1 (0.3m) or -CE3 (0.9m) extender cable (one per

system) to arrange your system in two rows or split your system into horizontal

and vertical orientation.

ATTENTION: This cable can only be used between I/O modules. Do not use

between the adapter and I/O modules. Do not use more than one cable per

system.

ProSoft Technology, Inc. Page 13 of 152

August 23, 2007

Page 14

3170-PDP ♦ FLEX Platform Overview of FLEX I/O and Your PROFIBUS Adapter Module

FLEX I/O™ PROFIBUS Adapter

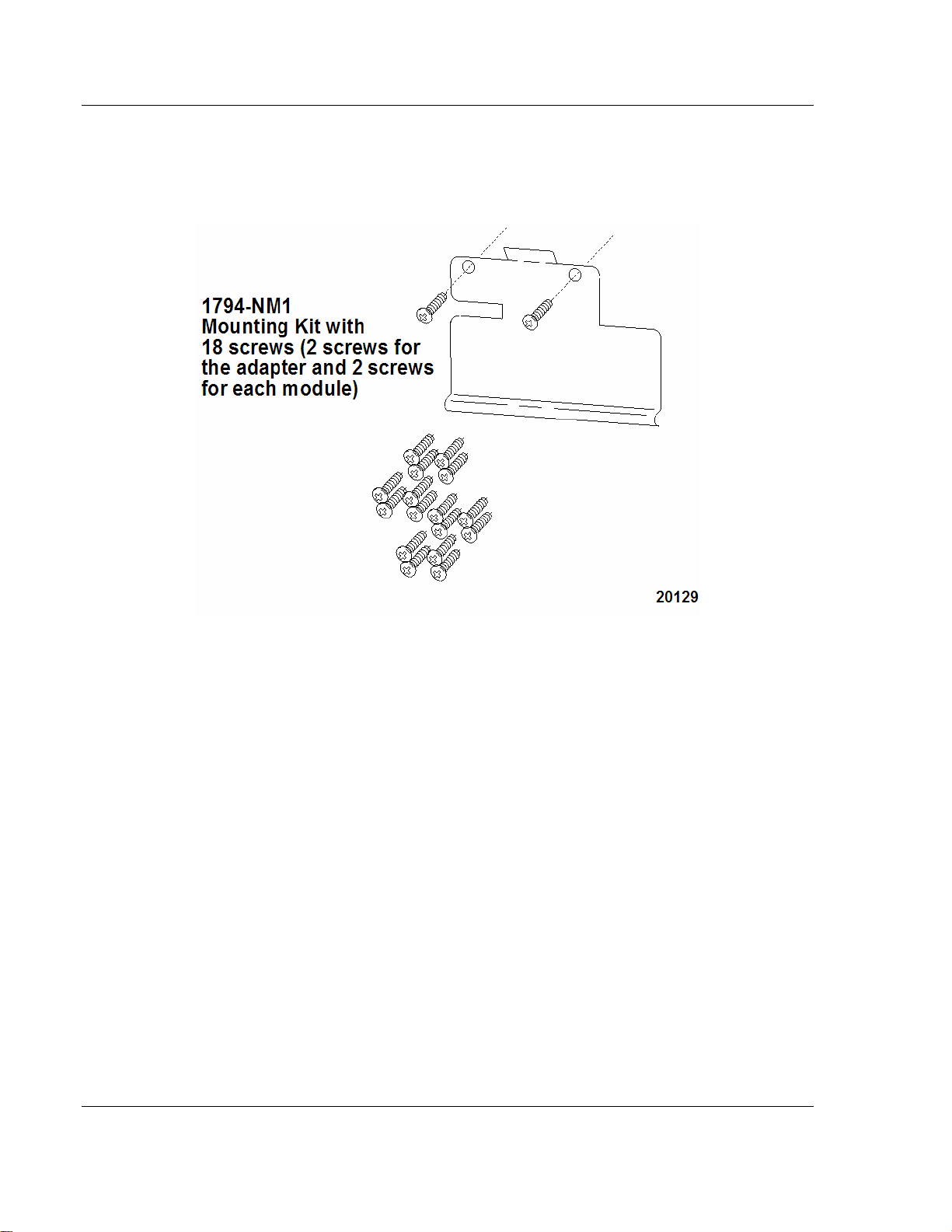

2.3.2 Mounting Kit (1794-NM1)

Use the optional 1794-NM1 mounting kit to mount your system on a panel or wall

without a DIN rail.

Page 14 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 15

Overview of FLEX I/O and Your PROFIBUS Adapter Module 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

2.3.3 Mounting Dimensions and Spacing Requirements

ProSoft Technology, Inc. Page 15 of 152

August 23, 2007

Page 16

3170-PDP ♦ FLEX Platform Overview of FLEX I/O and Your PROFIBUS Adapter Module

FLEX I/O™ PROFIBUS Adapter

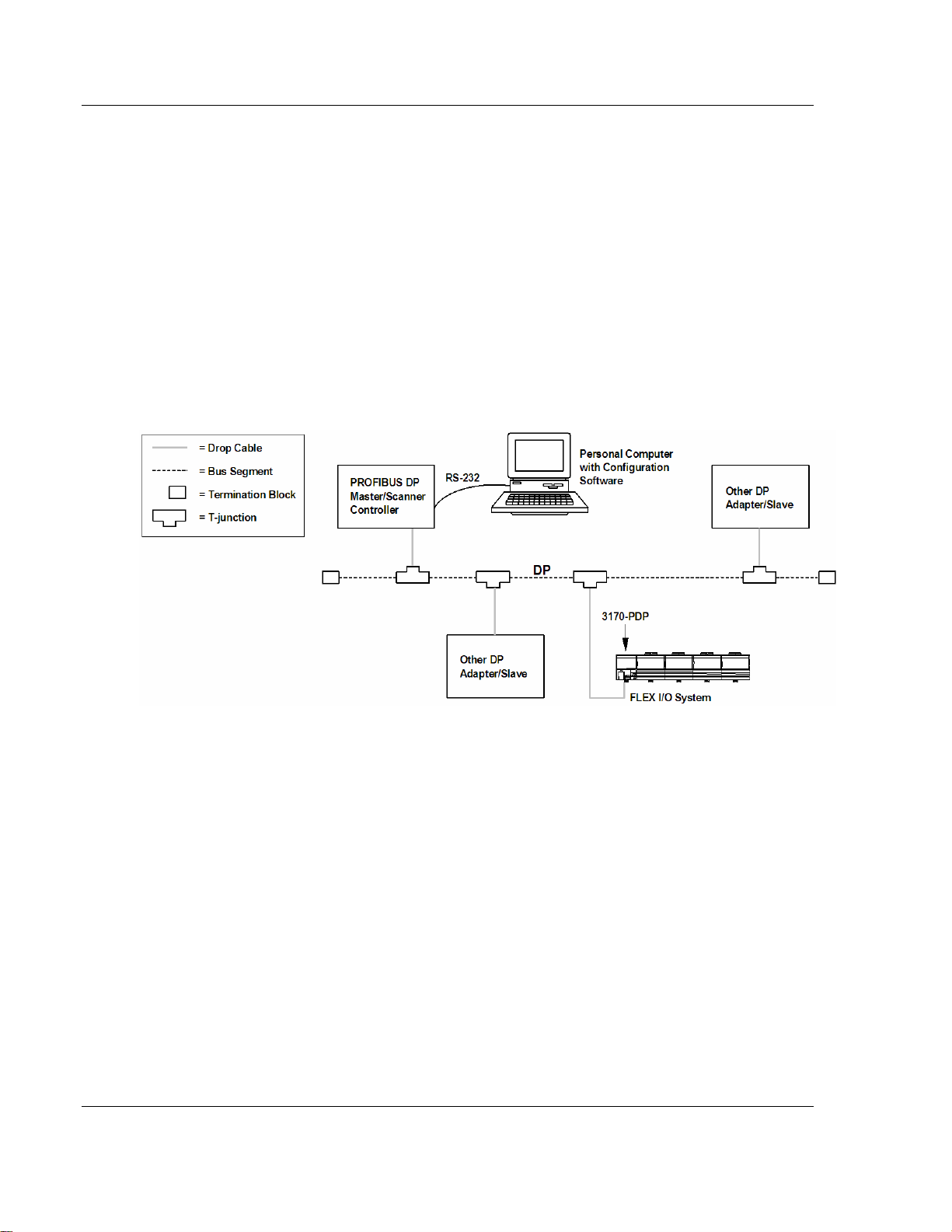

2.4 Purpose of the 3170-PDP

The 3170-PDP is a FLEX I/O adapter that interacts with the FLEX I/O backplane

and any PROFIBUS DP master/scanner controller on a PROFIBUS DP network.

The 3170-PDP module is a slave device to the DP master/scanner, and is a

master controller of the FLEX I/O system where it is installed.

The I/O data exchange occurs as follows: Output data is sent from the DP

master/scanner controller across the PROFIBUS DP network to the 3170-PDP

adapter. The adapter then automatically transfers the data across the FLEX I/O

backplane to the output modules. Inputs from the input modules are collected by

the FLEX I/O adapter via the backplane and sent across the PROFIBUS DP

network to the DP master/scanner controller.

Page 16 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 17

Overview of FLEX I/O and Your PROFIBUS Adapter Module 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

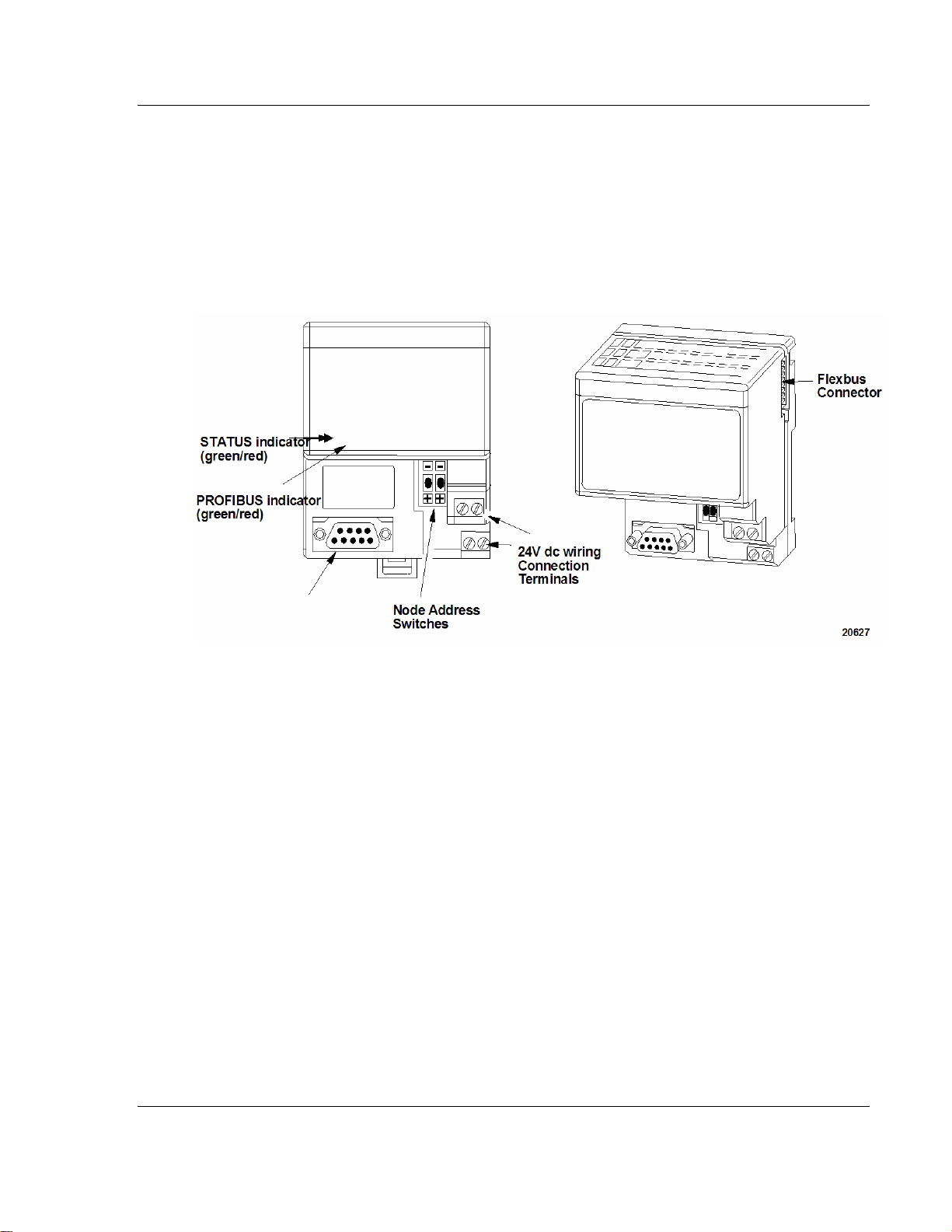

2.5 PROFIBUS Adapter Components

The adapter module consists of the following components:

two diagnostic indicators

PROFIBUS DP network connector

24V dc power wiring connection terminals

two node address switches

2.5.1 Diagnostic Indicators

Diagnostic indicators are located on the front panel of the adapter module. They

show both normal operation and error conditions in your FLEX I/O system. The

indicators are:

Device status (STATUS)

Communication link status (PROFIBUS)

Upon power-up, the adapter goes to an initialization state and performs a selftest (memory check, data memory clear. The indicators also go through a selftest sequence. If a failure occurs, the adapter transitions to a faulted state and

waits for reset (cycle power). Otherwise, the adapter begins monitoring the

network (run state) for messages.

Chapter 5 describes the diagnostic indicators and how to use them for

troubleshooting.

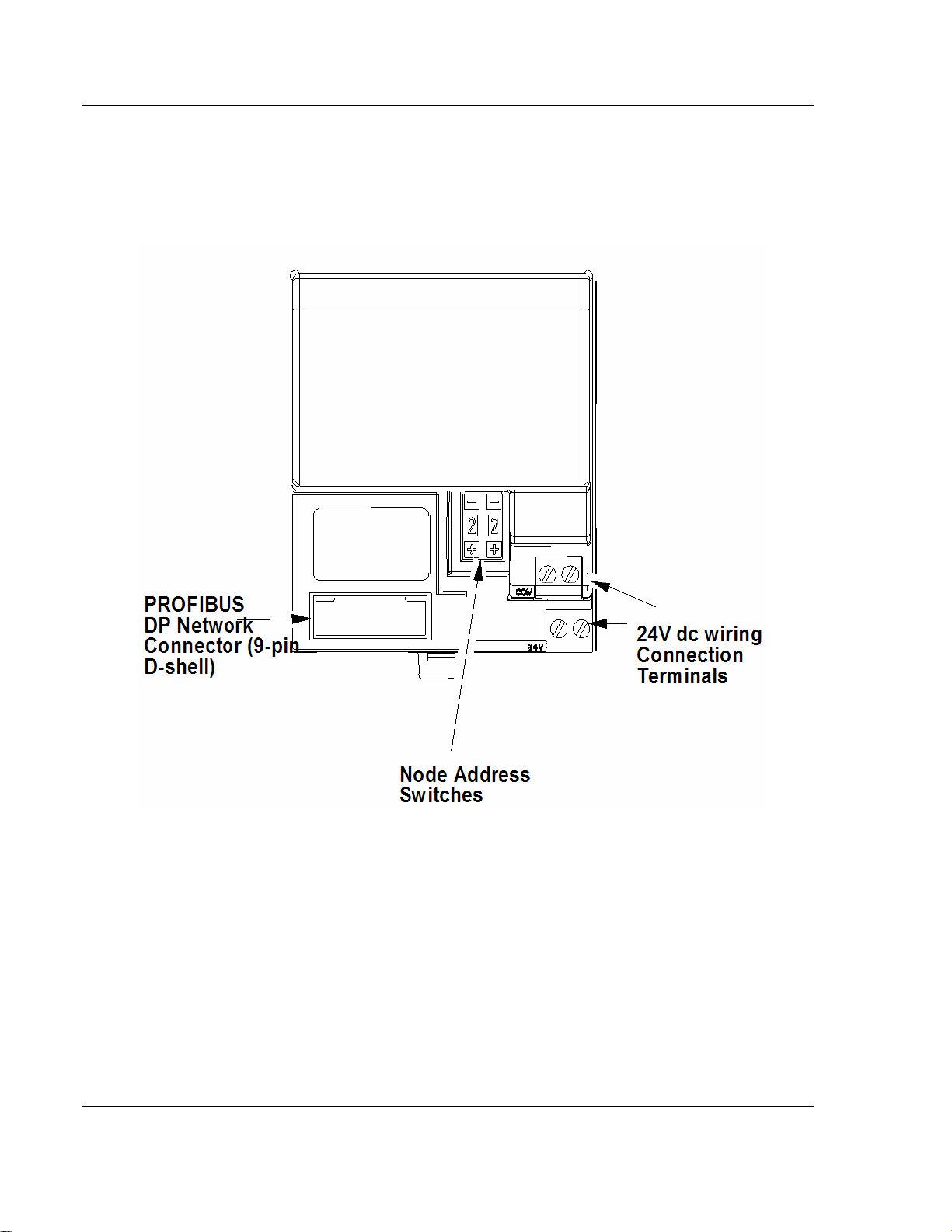

2.5.2 Network Connector

Use the 9-pin D-shell connector to connect your adapter to the PROFIBUS

network.

ProSoft Technology, Inc. Page 17 of 152

August 23, 2007

Page 18

3170-PDP ♦ FLEX Platform Overview of FLEX I/O and Your PROFIBUS Adapter Module

FLEX I/O™ PROFIBUS Adapter

2.5.3 Setting the Node Address Switches

Set the node address using the 2-position thumbwheel switch. Valid settings

range from 01 to 99. Use a pen to press either the + or - buttons to change the

number.

2.5.4 Power Wiring

Connections are provided for connecting the required 24V dc power to the front

of the module. The power wiring can be daisy-chained to the terminal base unit

located next to the adapter to supply power to the module installed in that base

unit.

Refer to the Installation Instructions (pub. no. 801.09) you received with your

adapter to learn how to install and wire the adapter.

Page 18 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 19

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform FLEX I/O™ PROFIBUS Adapter

3 How Communication Takes Place and I/O

Image Table Mapping

In This Chapter

¾ Polled I/O Structure................................................................ 20

¾ Mapping Data into the Image Table .......................................22

¾ Connection Status Word Definition ........................................42

¾ Logic Status/Analog Feedback Definition............................... 42

¾ Connection Enable Word Definition .......................................42

¾ Logic Command/Analog Reference Definition ....................... 42

¾ Defaults.................................................................................. 43

In this chapter, you will learn about:

communication over the FLEX I/O backplane (between the PROFIBUS

adapter and the I/O modules)

how data is mapped into the I/O image table

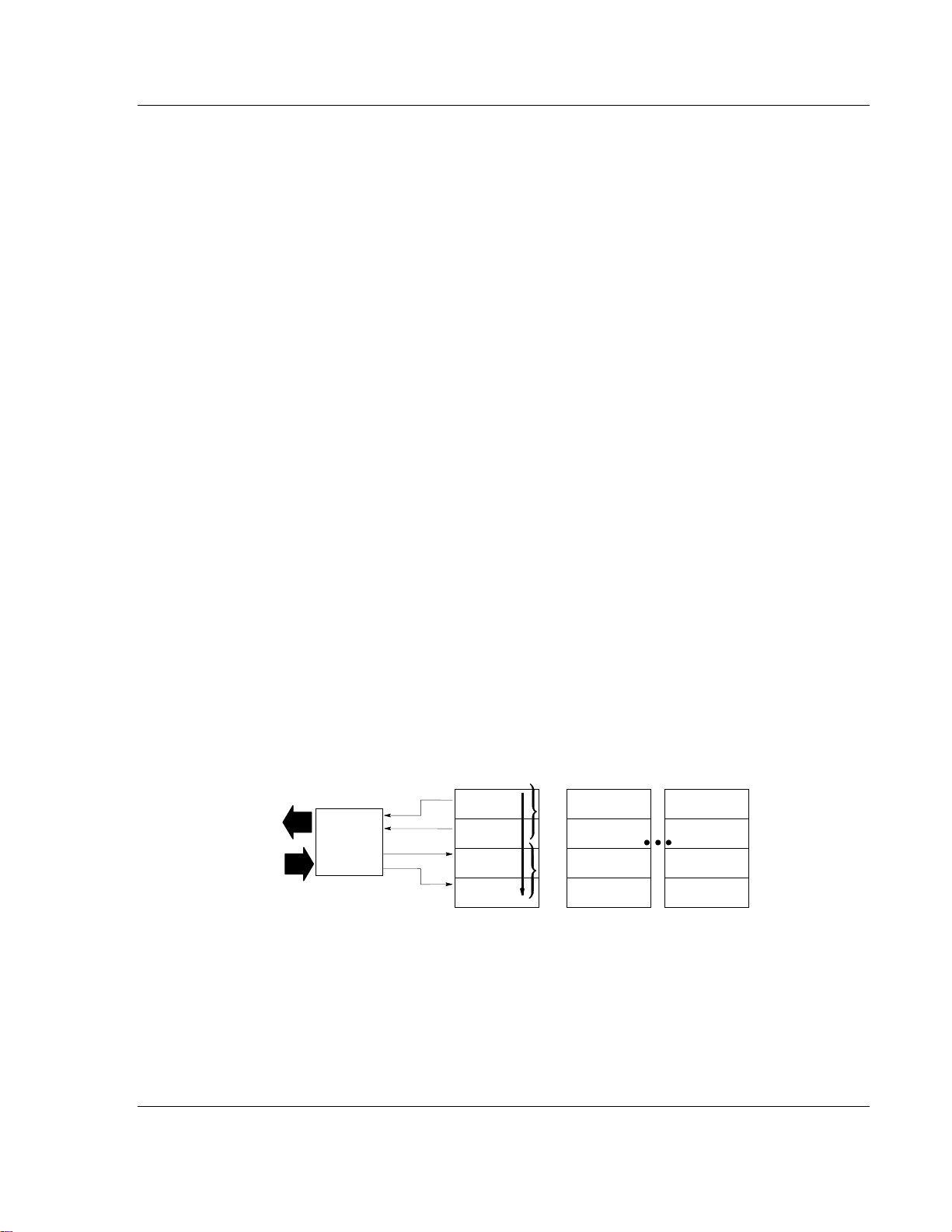

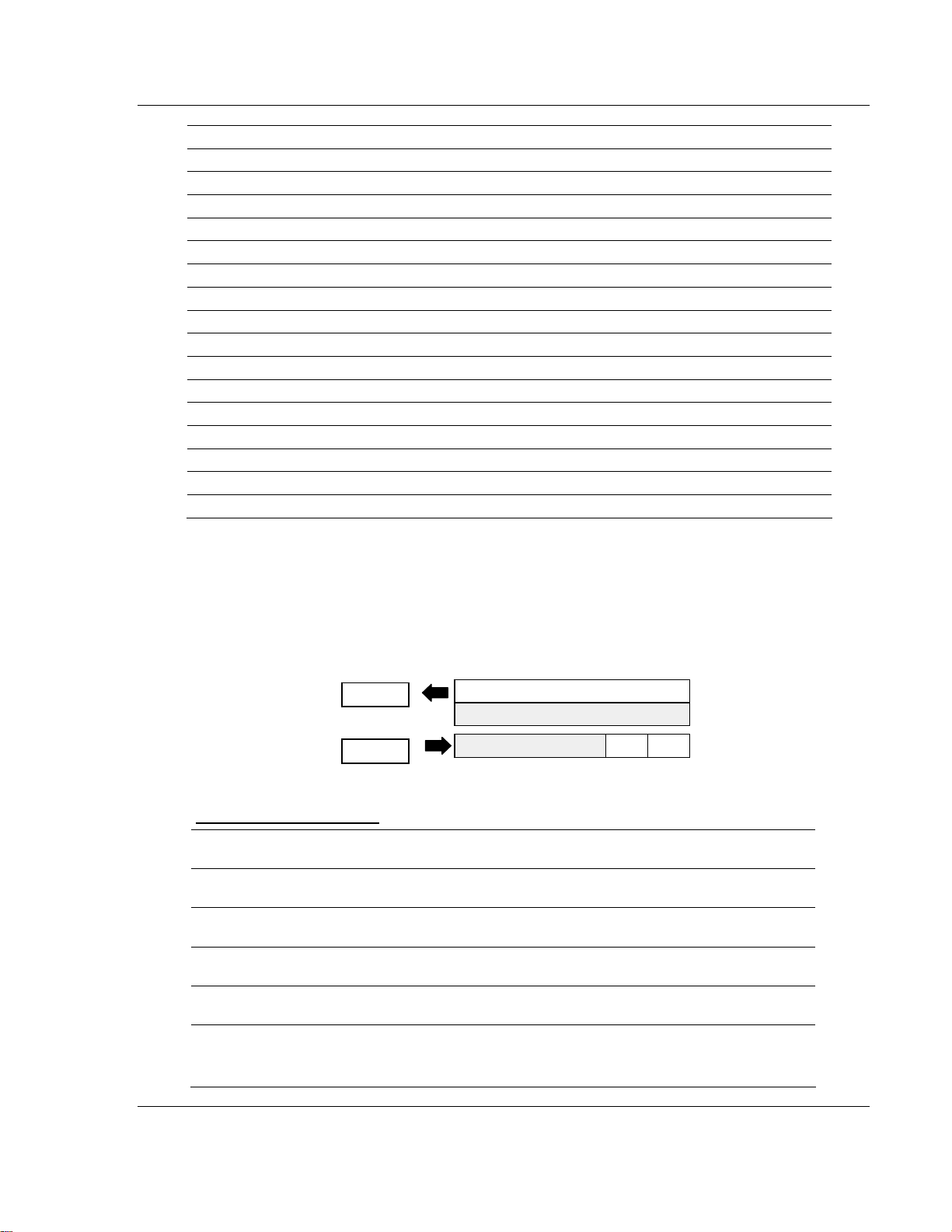

One 3170-PDP PROFIBUS adapter can interface with up to eight terminal base

units with installed FLEX I/O modules, forming a FLEX I/O system of up to eight

slots. The adapter communicates to other network system components over the

PROFIBUS network. The adapter communicates with its I/O modules over the

backplane.

Network

PROFIBUS

Adapter

I/O Module

Inputs

Read

Write

Status

Outputs

Configuration

Slot 1

0

Write

Words

1

Read

Words

I/O Module

Inputs

Status

Outputs

Configuration

Slot 2

I/O Module

Inputs

Status

Outputs

Configuration

Slot 8

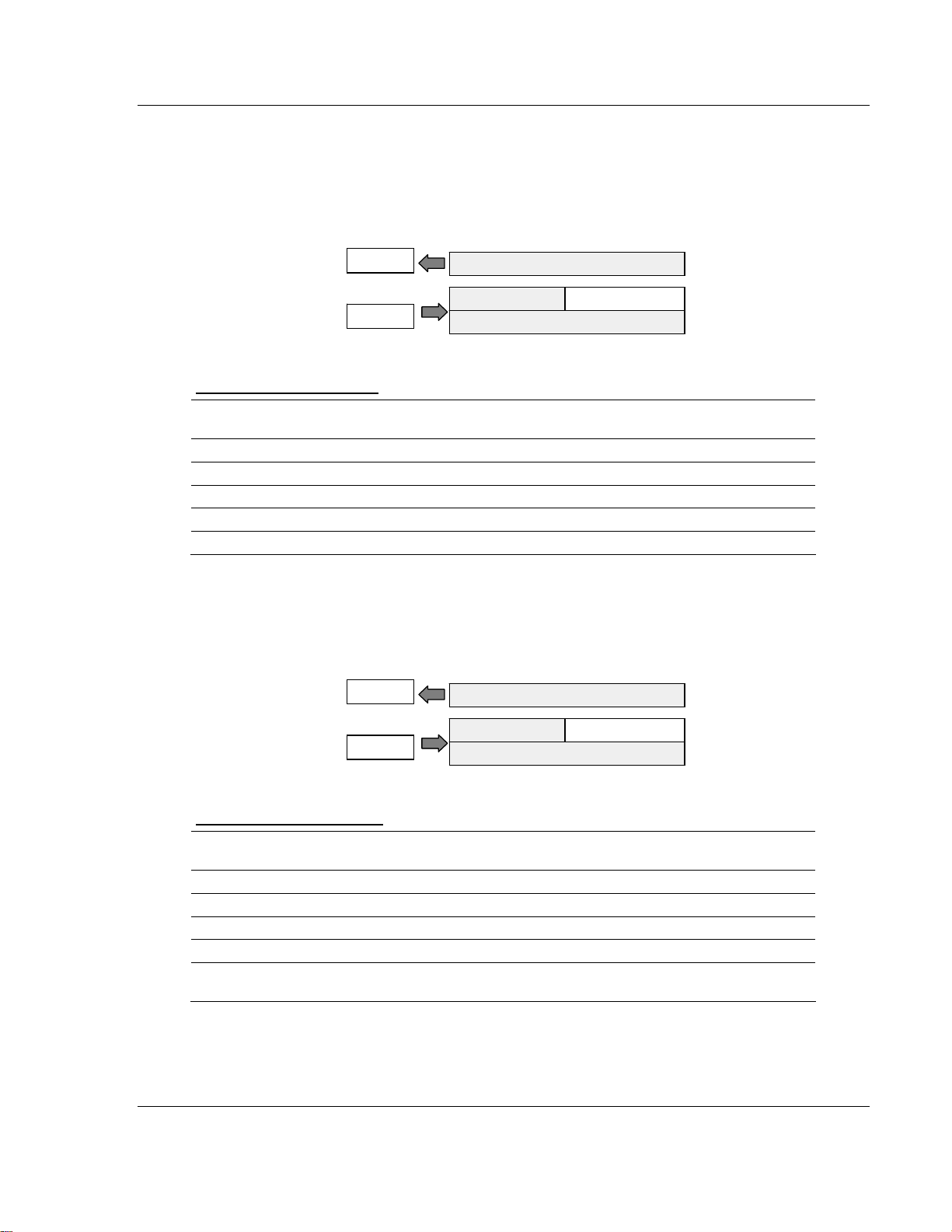

The I/O map for a module is divided into read words and write words. Read

words consist of input and status words, and write words consist of output and

configuration words. The number of read words or write words can be 0 or more.

The length of each I/O module's read words and write words vary in size

depending on module complexity. Each I/O module will support at least 1 input

word or 1 output word. Status and configuration are optional, depending on the

module.

ProSoft Technology, Inc. Page 19 of 152

August 23, 2007

Page 20

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

For example, a 16 point discrete input module will have up to 2 read words and 1

write word.

16-point Discrete Input Module

Refer to the I/O map for each module for the exact mapping.

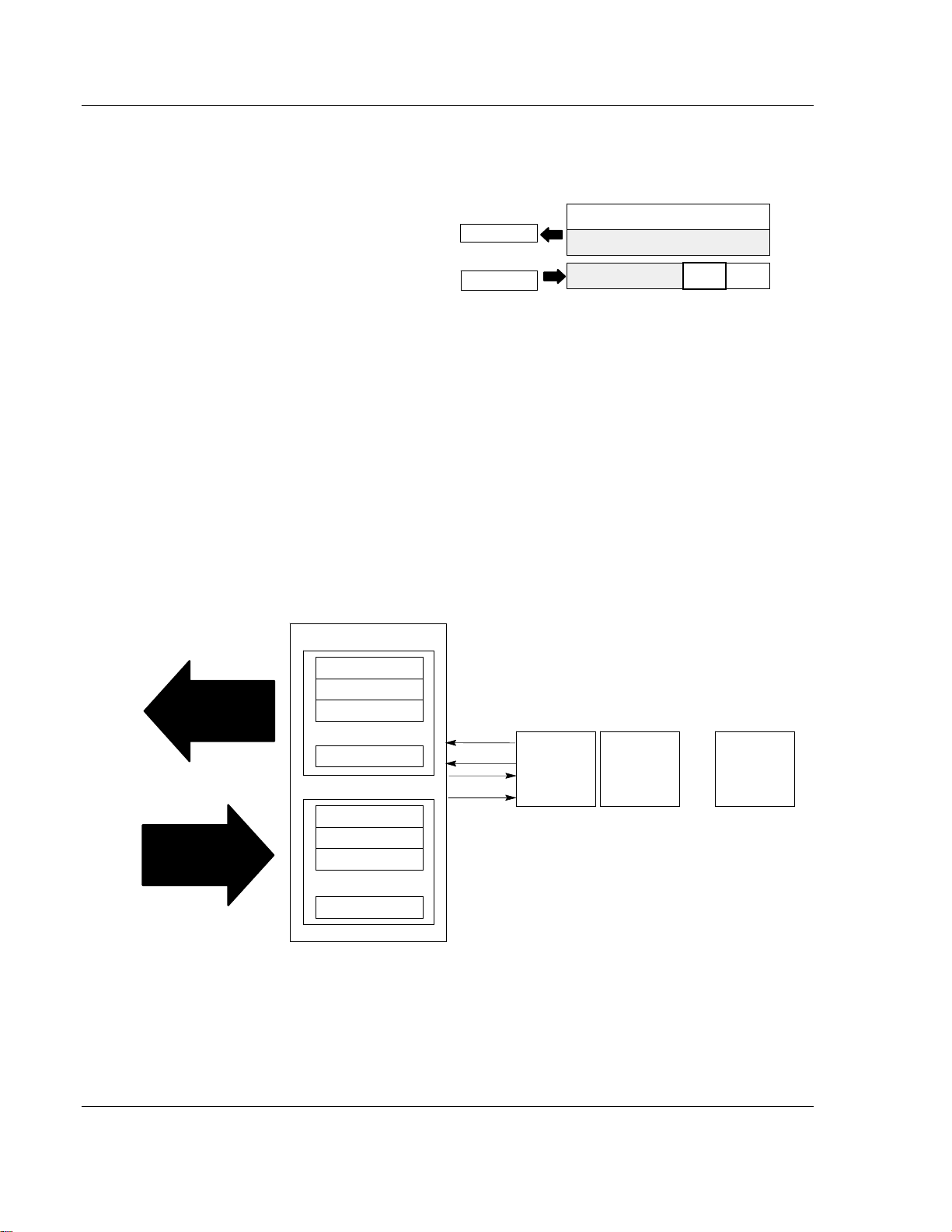

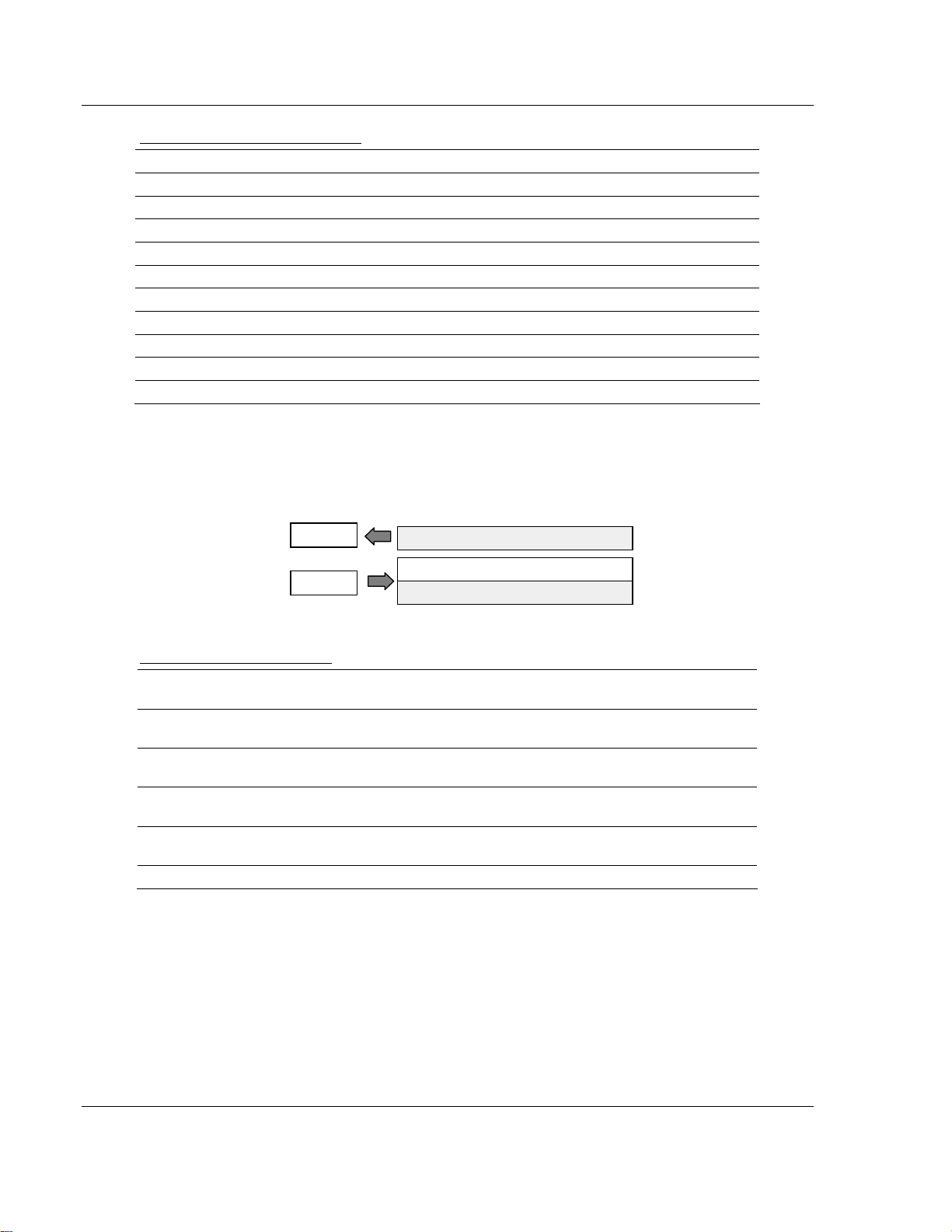

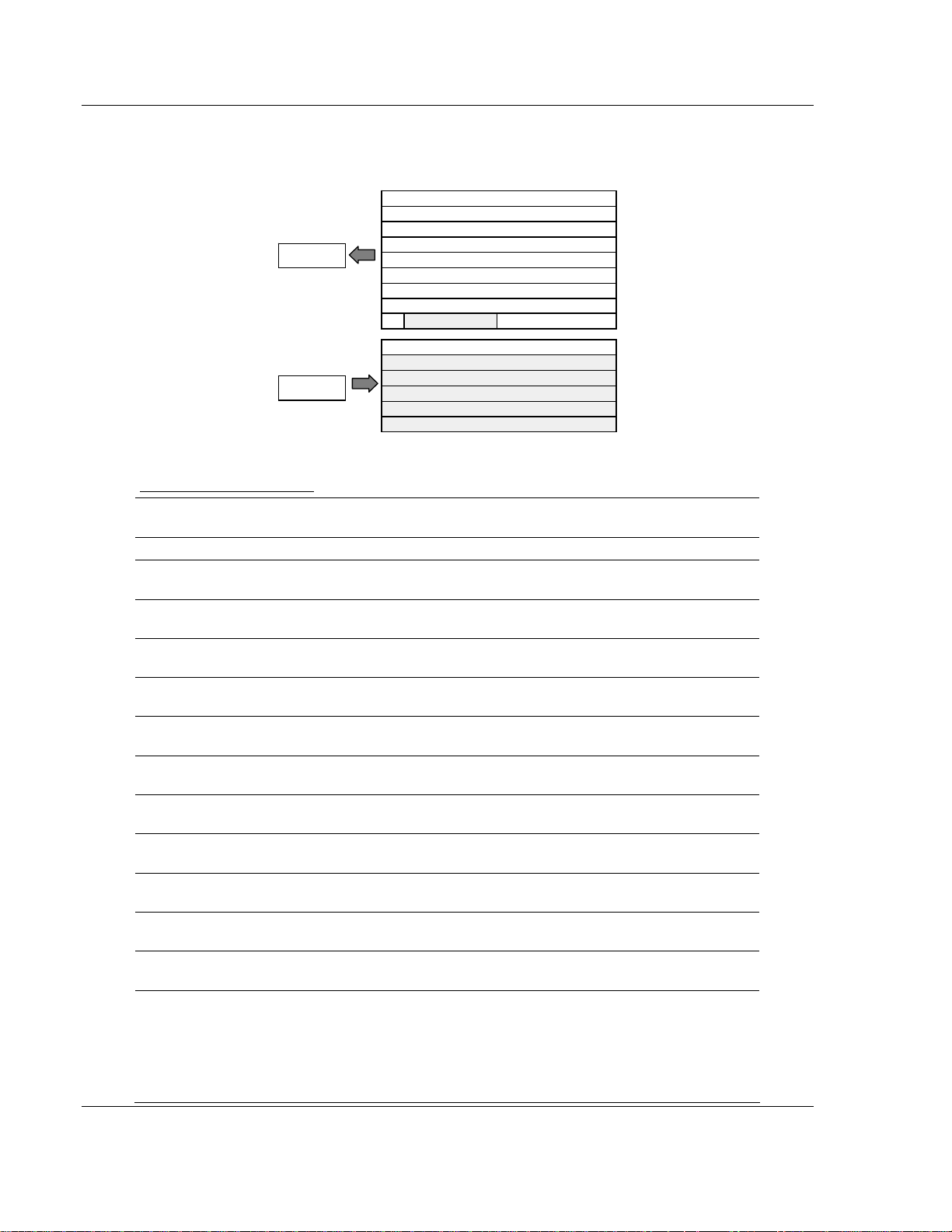

3.1 Polled I/O Structure

The first word of output data sent by the adapter is the Adapter Status Word.

Output data is received by the adapter in the order of the installed I/O modules.

The Output data for Slot 1 is received first, followed by the Output data for Slot 2,

and so on up to slot 8. All bits in the output status word are reserved

The first word of input data sent by the adapter is the Adapter Status Word. This

is followed by the input data from each slot, in the order of the installed I/O

modules. The Input data from Slot 1 is first after the status word, followed by

Input data from Slot 2, and so on up to slot 8.

PROFIBUS Adapter

Adapter Status

Slot 1 Input Data

Network READ

Slot 2 Input Data

... ...

Slot 8 Input Data

Read Data

Write Data

I/O Image

Input Size

1 or 2 Words

Output Size

0 or 1 Word

Module Image

Inputs

Not used

Not used

Delay

Time

Delay

Time

Read

Write

I/O Module

Slot 1

I/O Module

Slot 2

...

I/O Module

Slot 8

Adapter Status

Slot 1 Output Data

Network WRITE

Slot 2 Output Data

...

...

Slot 8 Output Data

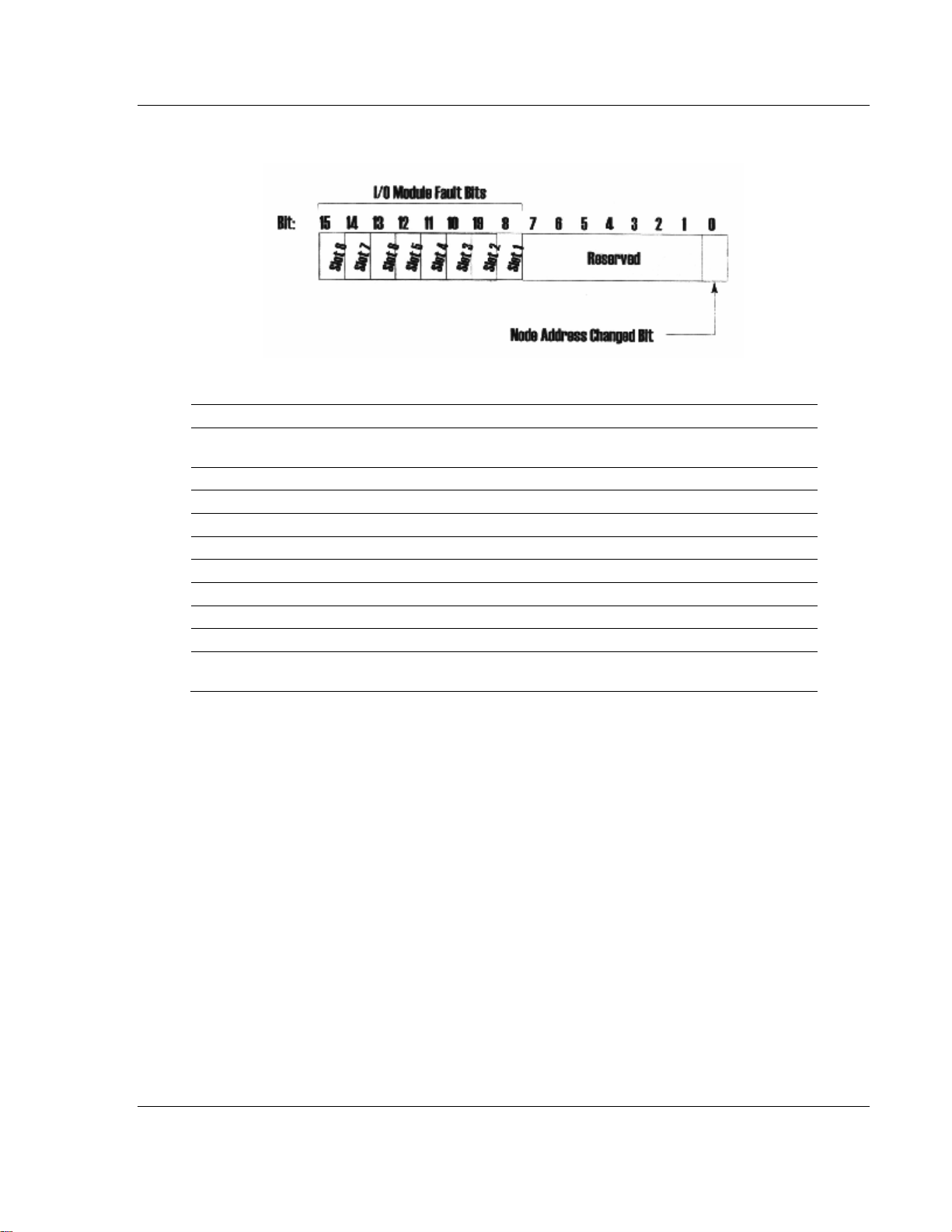

3.1.1 Adapter Input Status Word

The input status word consists of:

I/O module fault bits – 1 status bit for each slot

Page 20 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 21

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

node address changed – 1 bit

The adapter input status word bit descriptions are shown in the following table.

Bit Description Bit Explanation

I/O Module

Fault

9 This bit is set (1) when an error is detected in slot position 2.

10 This bit is set (1) when an error is detected in slot position 3.

11 This bit is set (1) when an error is detected in slot position 4.

12 This bit is set (1) when an error is detected in slot position 5.

13 This bit is set (1) when an error is detected in slot position 6.

14 This bit is set (1) when an error is detected in slot position 7.

15 This bit is set (1) when an error is detected in slot position 8.

Reserved 1 to 7 Reserved

Node Address

Changed

8 This bit is set (1) when an error is detected in slot position 1.

0

This bit is set (1) when the node address switch setting has been

changed since power up.

Possible causes for an I/O module fault are:

transmission errors on the FLEX I/O backplane

a failed module

a module removed from its terminal base

incorrect module inserted in a slot position

the slot is empty

The node address changed bit is set when the node address switch setting has

been changed since power up. The new node address does not take affect until

the adapter has been powered down and then powered back up. Until this power

cycling occurs, the node address switches will not match the actual node

address.

ProSoft Technology, Inc. Page 21 of 152

August 23, 2007

Page 22

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

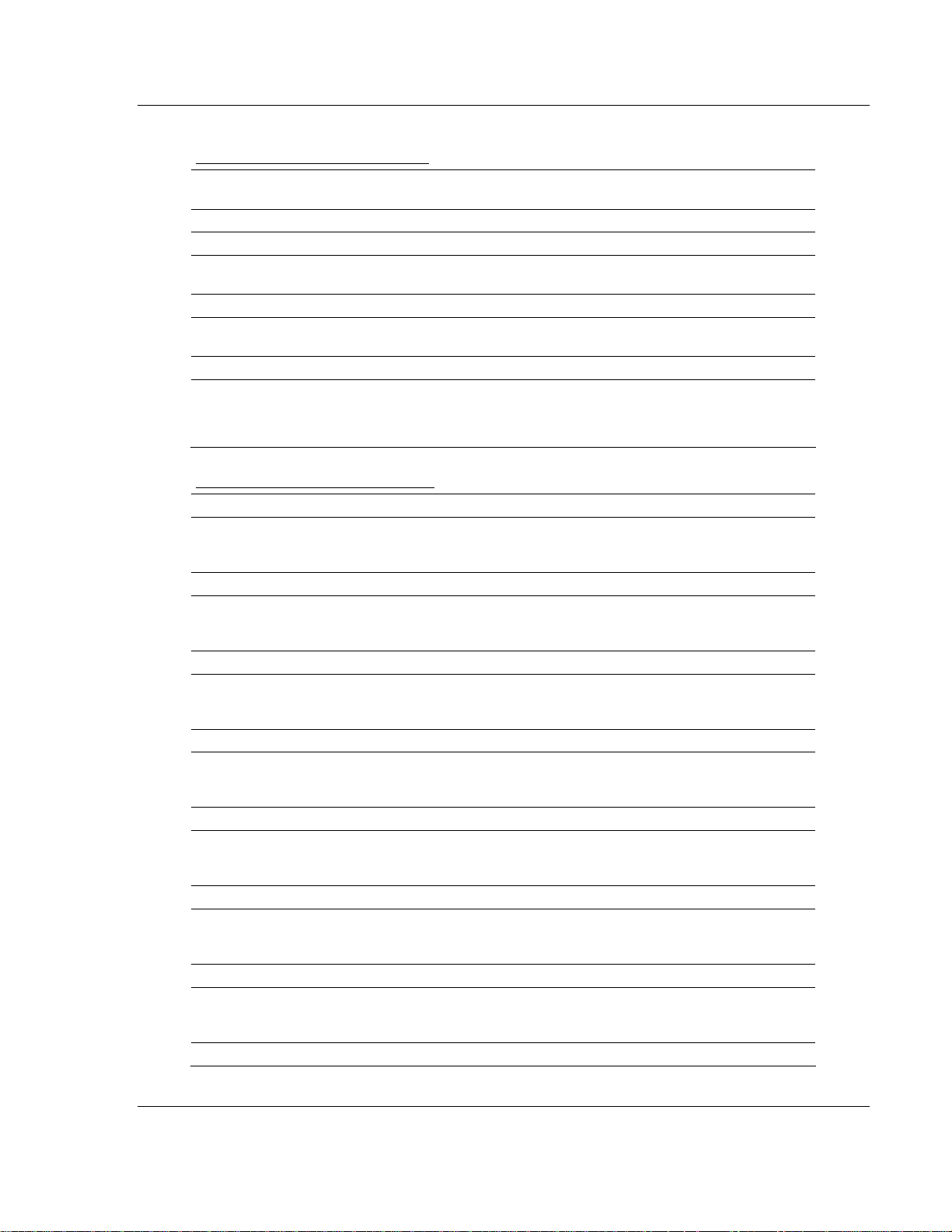

3.2 Mapping Data into the Image Table

All FLEX I/O modules in the following table are supported by the PROFIBUS

adapter. Presently, these consist of:

Module Description Catalog Number

AC Modules 1794-IA8

1794-IA8I

1794-IA16

1794-OA8

1794-OA8I

1794-OA16

1794-IM8

1794-OM8

DC Modules 1794-IB8

1794-IB8S

1794-IB16

1793-IB16/A, S/A

1794-IV16

1793-IV16/A, S/A

1794-OB8

1794-OB16

1794-OB16P

1793-OB16P/A, S/A

1794-OV16

1794-OV16P

1793-OV16P/A, S/A

1794-OB8EP

1794-IB10XOB6

1794-IC16

1794-OC16

1793-IB4(S)

1793-OB4P(S)

1793-IB2XOB2P(S)

1794-IB32/A

1794-OB32P

1794-IB16XOB16P

Analog Modules 1794-IE8

1794-OE4

1794-IE4XOE2

1793-IE4(S)

1793-OE2(S)

1793-IE2XOE1(S)

Page 22 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 23

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

W

FLEX I/O™ PROFIBUS Adapter

Module Description Catalog Number

Isolated Analog Modules 1794-IF4I

1794-OF4I

1794-IF2XOF2I

Relay Modules 1794-OW8

1793-OW4(S)

Special Modules 1794-IR8

1794-IRT8

1794-IT8

1794-IJ2

1794-ID2

1794-IP4

1203-FM1

Bentley Nevada Autoc BN 1701-15 Rad Vib Mon

BN 1701-15 Thrust Mon

BN 1701-25 Vel In Mon

BN 1701-25 Acc In Mon

The following topics show typical examples from Rockwell Automation product

literature.

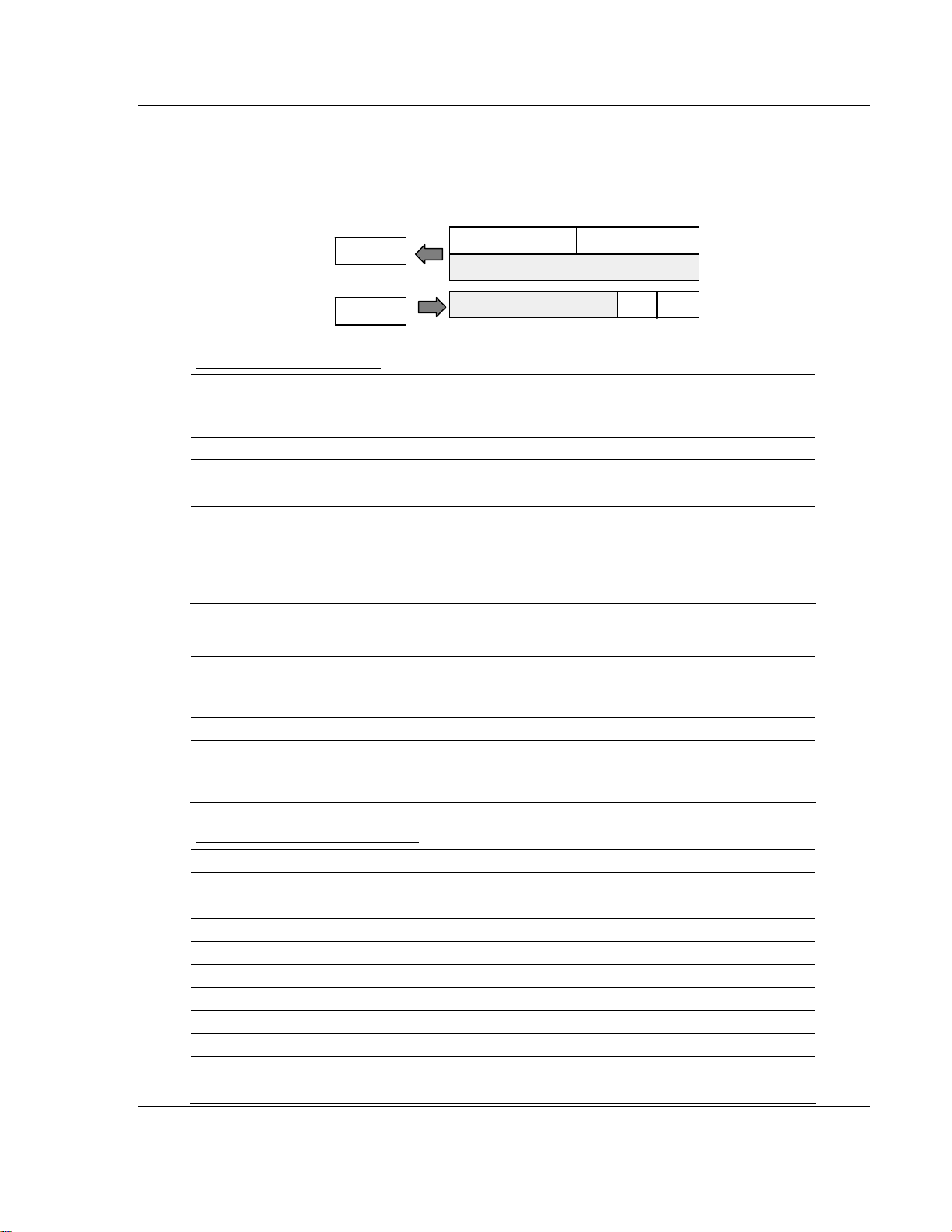

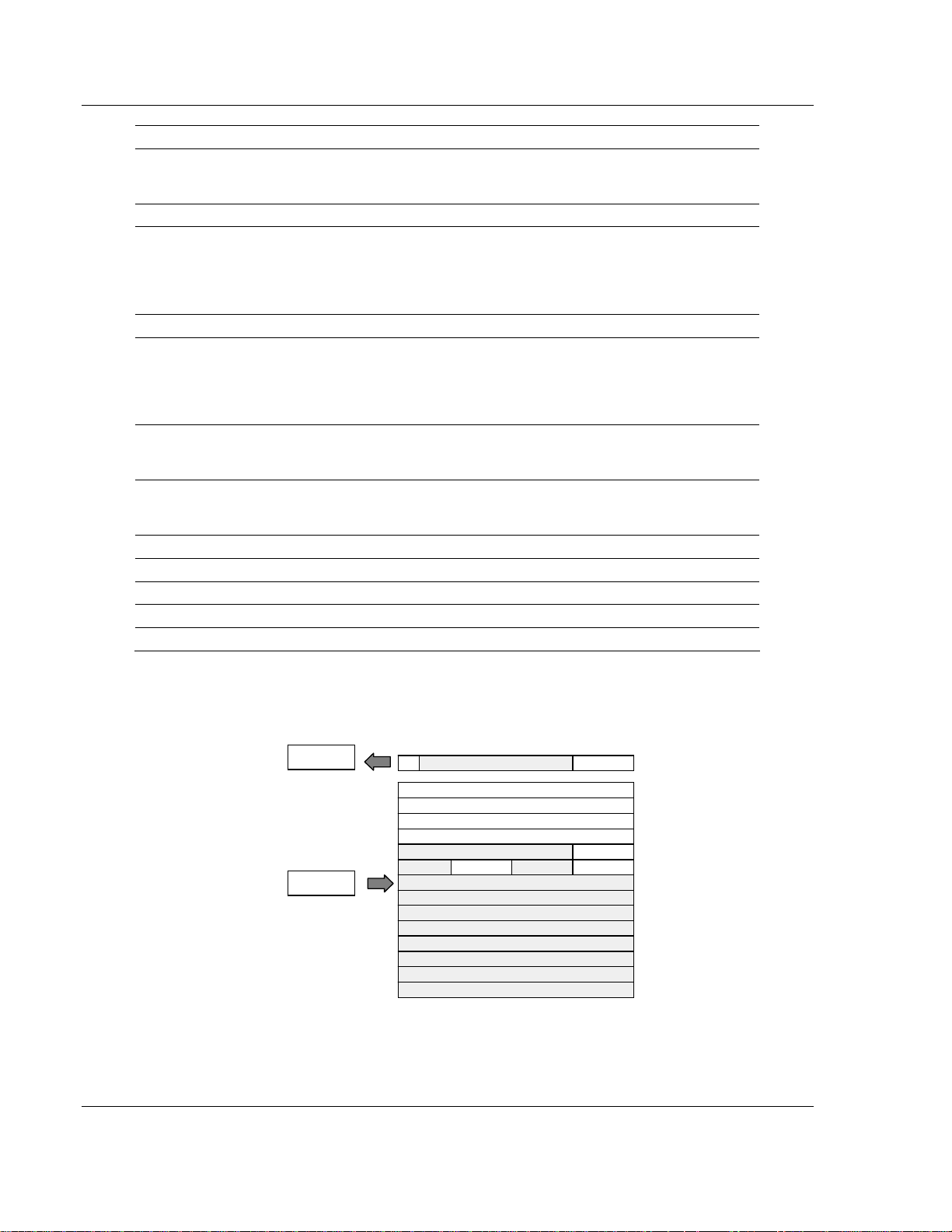

3.2.1 1794-IB16 – 16-point Discrete Input Module Image Table

Mapping

I/O Image

Input Size

1 or 2 Words

Read

Output Size

0 or 1 Word

rite

1794-IB16 Memory Map

Decimal

Bit

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00 Read

Where D = Input Data (D0 corresponds to input 0, D1 corresponds to input 1, etc.

DT = Input Delay Time (DT 00 to 11 corresponds to inputs 0 thru 11; DT 12 to 15 corresponds to

inputs 12 thru 15)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Size

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 Read

Not used Read

Not used DT 12 to

Module Image

Inputs

Not used

Not used

Delay

Time

15

Delay

Time

DT 00 to 11 Write

Words

Word 1

Word 2

Word 1

ProSoft Technology, Inc. Page 23 of 152

August 23, 2007

Page 24

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

1794-IB16 Input Delay Times

Bits Description Selected Delay Time

02 01 00 Delay Time for Inputs 00 to 11

05 04 03 Delay Time for Inputs 12 to 15

0 0 0 Delay Time 0 (default) 512µs

0 0 1 Delay Time 1 1ms

0 1 0 Delay Time 2 2ms

0 1 1 Delay Time 3 4ms

1 0 0 Delay Time 4 8ms

1 0 1 Delay Time 5 16ms

1 1 0 Delay Time 6 32ms

1 1 1 Delay Time 7 64ms

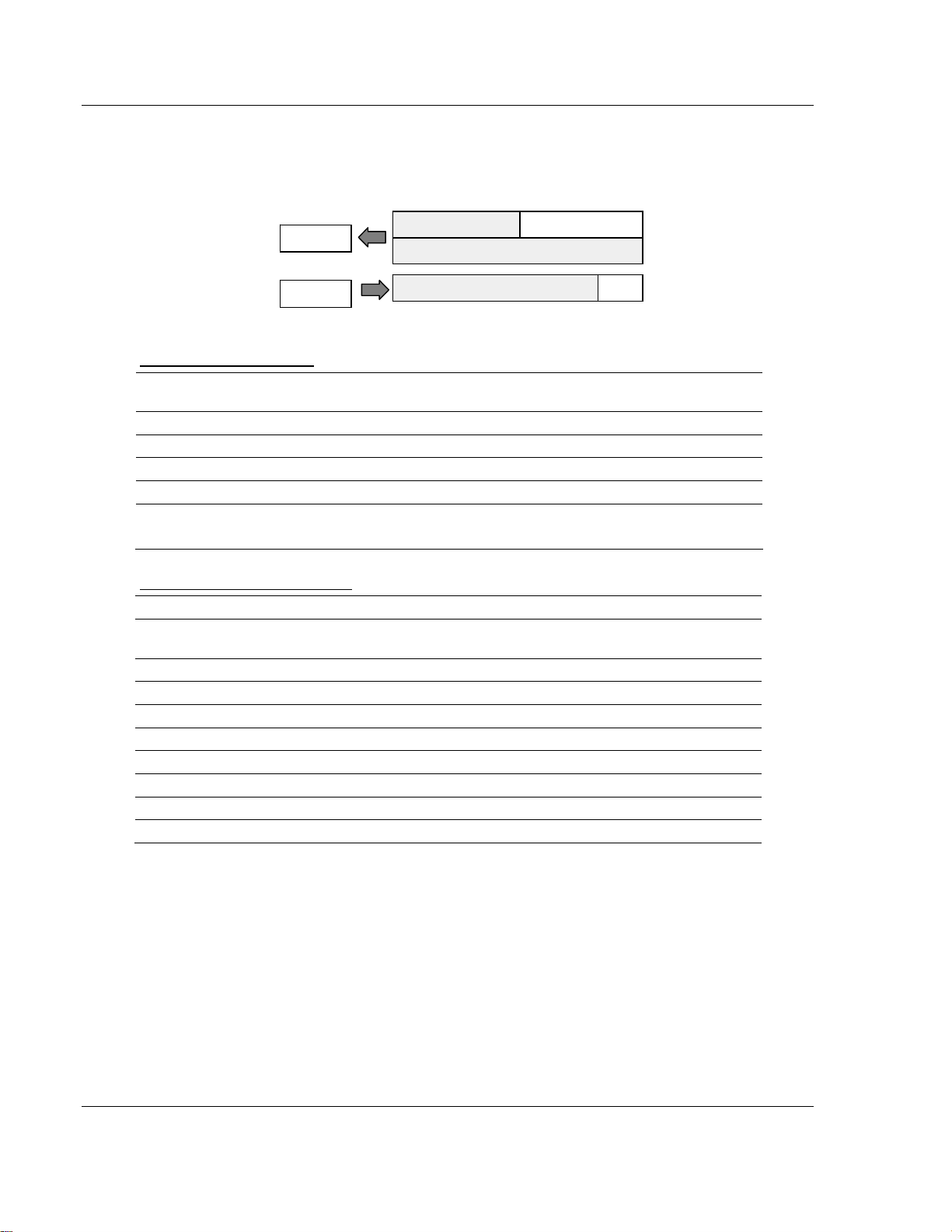

3.2.2 1794-OB16 – 16-point Discrete Output Module Image Table

Mapping

I/O Image

Input Size

0 or 1 Word

Read

1 or 2 Words

Write

Output Size

Module Image

Not used

Outputs

Not used

1794-OB16 Memory Map

Decimal

Bit

Octal. Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00 Read

Where O = Output value (O0 corresponds to output 0, O1 corresponds to output 1, etc.)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Size

Words

Not used Read

Word 1

O15 O14 O13 O12 O11 O10 O9 O8 O7 O6 O5 O4 O3 O2 O1 O0 Write

Word 1

Not used Write

Word 2

Page 24 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 25

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

3.2.3 1794-IB8S – 8-point Discrete Sensor Input Module Image Table

Mapping

I/O Image

Input Size

Read

1 or 2 Words

Output Size

Write

0 or 1 Word

Status

1794-IB8S Memory Map

Decimal

Bit

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00 Read Words

Where S = Status of input (where S1 corresponds to the diagnostic bit for input 1, S2 corresponds

to the diagnostic bit for input 2, etc.)

D = Input Data (where D0 corresponds to input 0, D1 corresponds to input 1, etc.

DT = Input Delay Time (where DT 00 to 11 corresponds to inputs 0 thru 11; DT 12 to 15

corresponds to inputs 12 thru 15.

The delay time for 00 to 11 must be the same as the delay time for 12 to 15.

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Size

S7 S6 S5 S4 S3 S2 S1 S0 D7 D6 D5 D4 D3 D2 D1 D0 Read Word 1

Not used Read Word 2

Not used DT 12 to 15 DT 00 to 11 Write Word 1

Smart Sensor

Bits

08 to 15

Standard Sensor

Bits

08 to 15

S = Diagnostic data – 1 = Fault present

(Smart)

0 = Normal (no errors)

S = Diagnostic data – 1 = Diagnostics not

disabled

0 = Normal (Disabled)

Module Image

Not used

Not used

Bits

00 to

07

Bits

00 to

07

Inputs

Delay

Time

Delay

Time

D = Input data 1 = Sensor on

0 = Sensor off

D = Input data 1 = Sensor on

0 = Sensor off

1794-IB8S Input Delay Times

Bits Description Selected Delay Time

02 01 00 Delay Time for Inputs 00 to 11

05 04 03 Delay Time for Inputs 12 to 15

0 0 0 Delay Time 0 (default) 512µs

0 0 1 Delay Time 1 1ms

0 1 0 Delay Time 2 2ms

0 1 1 Delay Time 3 4ms

1 0 0 Delay Time 4 8ms

1 0 1 Delay Time 5 16ms

1 1 0 Delay Time 6 32ms

1 1 1 Delay Time 7 64ms

ProSoft Technology, Inc. Page 25 of 152

August 23, 2007

Page 26

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

W

FLEX I/O™ PROFIBUS Adapter

3.2.4 1794-IA8 – 8-point Discrete Input Module Image Table Mapping

I/O Image

Input Size

Read

1 or 2 Words

Output Size

0 or 1 Word

rite

Not used

1794-IA8 Memory Map

Decimal

Bit

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00 Read Words

Where D = Input Data (where D0 corresponds to input 0, D1 corresponds to input 1, etc.

DT = Input Delay Time (where DT 00 to 07 corresponds to inputs 0 thru 7)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Size

Not used D7 D6 D5 D4 D3 D2 D1 D0 Read Word 1

Not used Read Word 2

Not used Write Word 1

Module Image

Not used

Not used

Inputs

Delay

Time

1794-IA8 Input Delay Times

Bits Description Maximum Delay Time

02 01 00

0 0 0 Delay Time 0 (default) 8.6ms 26.6ms

0 0 1 Delay Time 1 9ms 27ms

0 1 0 Delay Time 2 10ms 28ms

0 1 1 Delay Time 3 12ms 30ms

1 0 0 Delay Time 4 17ms 35ms

1 0 1 Delay Time 5 26ms 44ms

1 1 0 Delay Time 6 43ms 61ms

1 1 1 Delay Time 7 78ms 96ms

Delay Time for Inputs 00

to 07

Off to On On to Off

Page 26 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 27

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

W

W

FLEX I/O™ PROFIBUS Adapter

3.2.5 1794-OA8 – 8-point Discrete Output Module Image Table

Mapping

I/O Image

Input Size

Read

0 or 1 Word

Output Size

rite

1 or 2 Words

1794-OA8 Memory Map

Decimal

Bit

Oct. Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00 Read Words

Where O = Output value (where O0 corresponds to output 0, O1 corresponds to output 1, etc.)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Size

Not used Read Word 1 Read Word 1

Not used 07 06 O5 O4 O3 O2 O1 O0 Write Word 1

Not used Write Word 2 Write Word 2

Not used

Module Image

Not used

Not used

Outputs

3.2.6 1794-OW8 – 8-point Discrete Relay Output Module Image Table

Mapping

I/O Image

Input Size

Read

0 or 1 Word

Output Size

rite

1 or 2 Words

1794-OW8 Memory Map

Decimal

Bit

Oct. Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00 Read Words

Where O = Output value: where O0 corresponds to output 0, O1 corresponds to output 1, etc., and

when bit = 0, the output is off; when bit = 1, the output is on.

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Size

Not used Read word 1 Read Word 1

Not used 07 06 O5 O4 O3 O2 O1 O0 Write Word 1

Not used Write word 2 Write Word 2

Not used

Module Image

Not used

Not used

Outputs

ProSoft Technology, Inc. Page 27 of 152

August 23, 2007

Page 28

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

3.2.7 1794-IE8 – 8 Input Analog Module

I/O Image

Input Size

1 to 9 Words

0 or 1 Word

PU

Output

Module

Input Data Channel 0

Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Input Data Channel 4

Input Data Channel 5

Input Data Channel 6

Input Data Channel 7

Underrange

Configure select

Not used

Not used

Not used

Not used

Not used

1794-IE8 Memory Map

Decimal

Bit

Oct. Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00 Read Words

Where: PU = Power up bit – included in series B modules only.

U = Underrange bits for 4 to 20mA inputs

C = Configure select bit

F = Full range bit

S = sign bit (in 2's complement)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Size

S Analog Value Channel 0 Read Word 1 Read Word

1

S Analog Value Channel 1 Read Word 2 Read Word

2

S Analog Value Channel 2 Read Word 3 Read Word

3

S Analog Value Channel 3 Read Word 4 Read Word

4

S Analog Value Channel 4 Read Word 5 Read Word

5

S Analog Value Channel 5 Read Word 6 Read Word

6

S Analog Value Channel 6 Read Word 7 Read Word

7

S Analog Value Channel 7 Read Word 8 Read Word

8

PU Not used – set to zero U7 U6 U5 U4 U3 U2 U1 U0 Read Word

9

C7 C6 C5 C4 C3 C2 C1 C0 F7 F6 F5 F4 F3 F2 F1 F0 Write Word

1

Not used – set to 0 Write Word

2 thru 6

Page 28 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 29

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

1794-IE8 Range Selection Bits

Channel

No.

Decimal Bit 00 08 01 09 02 10 03 11 04 12 05 13 06 14 07 15

0 to 10V dc/0

to 20mA

4 to 20mA 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1

–10 to +10V

dc

Do Not Use1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

C = Configure select bit

F = Full range bit

1 Do not use this configuration. Individual channels revert to 4 to 20mA if bit selection is all zeroes.

Channel 0 Channel 1 Channel 2 Channel 3 Channel 4 Channel 5 Channel 6 Channel

7

F0 C0 F1 C1 F2 C2 F3 C3 F4 C4 F5 C5 F6 C6 F7 C7

1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1794-IE8 Word/Bit Descriptions

Word Decimal Bit Definition

Read Word 1 Bits 00 to 14

Bits 15 Channel 0 analog data sign bit.

Read Word 2 Bits 00 to 14

Bits 15 Channel 1 analog data sign bit.

Read Word 3 Bits 00 to 14

Bits 15 Channel 2 analog data sign bit.

Read Word 4 Bits 00 to 14

Bits 15 Channel 3 analog data sign bit.

Read Word 5 Bits 00 to 14

Bits 15 Channel 4 analog data sign bit.

Read Word 6 Bits 00 to 14

Bits 15 Channel 5 analog data sign bit.

Read Word 7 Bits 00 to 14

Bits 15 Channel 6 analog data sign bit.

Channel 0 analog data – 12-bit left justified two's

complement number; unused lower bits are zero; 4 to 20mA

uses all 16 bits.

Channel 1 analog data – 12-bit left justified two's

complement number; unused lower bits are zero; 4 to 20mA

uses all 16 bits.

Channel 2 analog data – 12-bit left justified two's

complement number; unused lower bits are zero; 4 to 20mA

uses all 16 bits.

Channel 3 analog data – 12-bit left justified two's

complement number; unused lower bits are zero; 4 to 20mA

uses all 16 bits.

Channel 4 analog data – 12-bit left justified two's

complement number; unused lower bits are zero; 4 to 20mA

uses all 16 bits.

Channel 5 analog data – 12-bit left justified two's

complement number; unused lower bits are zero; 4 to 20mA

uses all 16 bits.

Channel 6 analog data – 12-bit left justified two's

complement number; unused lower bits are zero; 4 to 20mA

uses all 16 bits.

ProSoft Technology, Inc. Page 29 of 152

August 23, 2007

Page 30

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

W

FLEX I/O™ PROFIBUS Adapter

Word Decimal Bit Definition

Read Word 8 Bits 00 to 14

Bits 15 Channel 7 analog data sign bit.

Read Word 9 Bits 00 to 07

Bits 08 to 14 Not used – set to 0.

Bit 15

Write Word 1 Bits 00 to 07

Bits 08 to 15

Write Word 2 Bits 00 to 15 Not used – set to 0.

Write Word 3 Bits 00 to 15 Not used – set to 0.

Write Word 4 Bits 00 to 15 Not used – set to 0.

Write Word 5 Bits 00 to 15 Not used – set to 0.

Write Word 6 Bits 00 to 15 Not used – set to 0.

Channel 7 analog data – 12-bit left justified two's

complement number; unused lower bits are zero; 4 to 20mA

uses all 16 bits.

Underrange bits (U) for individual channels (4 to 20mA

current input only)- Bit 00 corresponds to input channel 0, bit

01 corresponds to input channel 1, and so on. When set (1),

indicates either a broken or open input wire, or input current

below 4 to 20mA.

Power Up bit – included in series B modules only. This bit is

0 in series A modules. This bit is set to 1 when all bits in the

configuration register are 0 (unconfigured state). The

configuration register can be cleared by either of the reset

inputs, or by the user writing all zeroes to it.

Full range bits (F) for individual channels – Bit 00

corresponds to input channel 0, bit 01 corresponds to input

channel 1, and so on. Refer to range selection above.

Configure select bits (C) for individual channels – Bit 08

corresponds to input channel 0, bit 09 corresponds to input

channel 1, and so on. Refer to range selection above.

3.2.8 1794-OE4 – 4 Output Analog Module Image Table Mapping

I/O Image

Input Size

0 or 1 Word

Read

1 or 6 Words

rite

Output

PU

Not used Not used

Page 30 of 152 ProSoft Technology, Inc.

Module Image

Not used

Analog Data Channel 0

Analog Data Channel 1

Analog Data Channel 2

Analog Data Channel 3

Not used

Config. Select

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Diagnostics

OE

Full Range

August 23, 2007

Page 31

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

1794-OE4 Memory Map

Decimal

Bit

Oct. Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00 Read Words

Where: PU = Power up bit – included in series B modules only.

W = Diagnostic bits for current output wire broken or load resistance high. (Not used on voltage

outputs.)

S = Sign bit (in 2's complement)

OE = Output enable bits (bit 00 corresponds to output 0, bit 01 corresponds to output 1 and so on.

ATTENTION: These bits must be

set to 1.

C = Configure select bit

F = Full range bit

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Size

PU Not used – set to 0 W3 W2 W1 W0 Read Word 1

S Analog Data – Channel 0 Write Word 1

S Analog Data – Channel 1 Write Word 2

S Analog Data – Channel 2 Write Word 3

S Analog Data – Channel 3 Write Word 4

Not used – set to 0 OE3 OE2 OE1 OE0 Write Word 5

Not used – set to 0 C3 C2 C1 C0 Not used – set to 0 F3 F2 F1 F0 Write Word 6

Not used – set to 0 Write Words 7

thru 14

1794-OE4 Range Selection Bits (Write Word 6)

Channel No. Channel 0 Channel 1 Channel 2 Channel 3

Decimal Bit 00 08 01 09 02 10 03 11

4 to 20mA 0 1 0 1 0 1 0 1

0 to 10V dc/0 to 20mA 1 0 1 0 1 0 1 0

to 10 to +10V dc 1 1 1 1 1 1 1 1

Off1 0 0 0 0 0 0 0 0

C = Configure select bit

F = Full range bit

1 When configured to off, individual channels will return 0V.

F0 C0 F1 C1 F2 C2 F3 C3

ProSoft Technology, Inc. Page 31 of 152

August 23, 2007

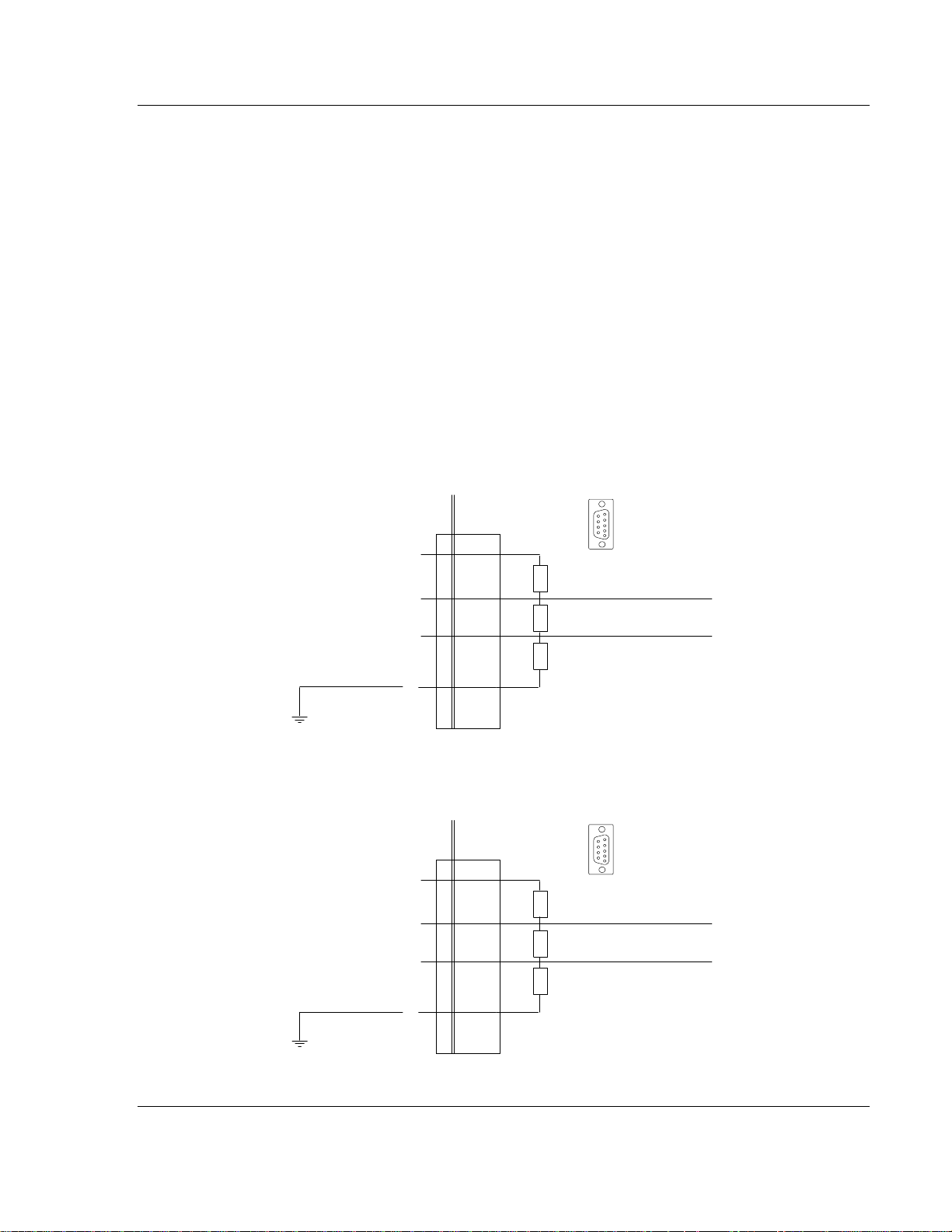

Page 32

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

1794-OE4 Word/Bit Descriptions

Word Decimal Bit Definition

Read Word 1 Bits 00 to 03

Bits 04 to 14 Not used – set to 0.

Bit 15

Write Word 1 Bits 00 to 14

Bits 15 Channel 0 analog data sign bit.

Write Word 2 Bits 00 to 14

Bits 15 Channel 1 analog data sign bit.

Write Word 3 Bits 00 to 14

Bits 15 Channel 2 analog data sign bit.

Write Word 4 Bits 00 to 14

Bits 15 Channel 3 analog data sign bit.

Write Word 5 Bits 00 to 03

Bits 04 to 15 Not used – set to 0.

Write Word 6 Bits 00 to 03

Bits 04 to 07 Not used – set to 0.

Bits 08 to 11

Bits 12 to 15 Not used – set to 0.

Write Word 7 Bits 00 to 15 Not used – set to 0.

Write Word 8 Bits 00 to 15 Not used – set to 0.

Write Word 9 Bits 00 to 15 Not used – set to 0.

Write Word 10 Bits 00 to 15 Not used – set to 0.

Write Word 11 Bits 00 to 15 Not used – set to 0.

Write Word 12 Bits 00 to 15 Not used – set to 0.

Write Word 13 Bits 00 to 15 Not used – set to 0.

Write Word 14 Bits 00 to 15 Not used – set to 0.

Current outputs only – When set (1), the wire on the output is

broken or the load resistance is too high. Bit 00 corresponds to

channel 0, bit 01 corresponds to channel 2, and so on.

Power Up bit – included in series B modules only. This bit is 0 in

series A modules. This bit is set to 1 when all bits in the

configuration register are 0 (unconfigured state). The configuration

register can be cleared by either of the reset inputs, or by the user

writing all zeroes to it.

Channel 0 analog data – 12-bit left justified two's complement

number; unused lower bits are zero; 4 to 20mA uses all 16 bits.

Channel 1 analog data – 12-bit left justified two's complement

number; unused lower bits are zero; 4 to 20mA uses all 16 bits.

Channel 2 analog data – 12-bit left justified two's complement

number; unused lower bits are zero; 4 to 20mA uses all 16 bits.

Channel 3 analog data – 12-bit left justified two's complement

number; unused lower bits are zero; 4 to 20mA uses all 16 bits.

Output Enable bits. Bit 00 corresponds to input 0, bit 01

corresponds to input 1, bit 02 corresponds to input 2, and bit 03

corresponds to input 3. These bits must be set to 1.

Full range bits (F) for individual channels – Bit 00 corresponds to

output channel 0, bit 01 corresponds to output channel 1, and so

on. Refer to range selection above.

Configure select bits (C) for individual channels – Bit 08

corresponds to output channel 0, bit 09 corresponds to output

channel 1, and so on. Refer to range selection above.

Page 32 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 33

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

W

FLEX I/O™ PROFIBUS Adapter

3.2.9 1794-IE4XOE2 – Analog Combo Module Image Table Mapping

I/O Image

Input Size

0 to 5 Words

Read

PU

Output

rite

0 to 4 Words

Not used Full Range and Configure Select

Module Image

Input Data Channel 0

Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Underrange & Diag.

Output Data Channel 0

Output Data Channel 1

Not used

Not used

Not used

Not used

Not used

Not used

Not used

OE

1794-IE4XOE2 Memory Map

Decimal

Bit

Oct. Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00 Read Words

Where: PU = Power up bit – included in series B modules only.

W = Diagnostic bits for current output wire broken or load resistance high. (Not used on voltage

outputs.)

U = Underrange bits for 4 to 20mA inputs

OE = Output enable bits (bit 00 corresponds to output 0, bit 01 corresponds to output 1).

ATTENTION: These bits must be set to 1.

S = Sign bit (in 2's complement)

C = Configure select bit

F = Full range bit

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00 Size

S Analog Value Input Channel 0 Read Word 1

S Analog Value Input Channel 1 Read Word 2

S Analog Value Input Channel 2 Read Word 3

S Analog Value Input Channel 3 Read Word 4

PU Not used – set to 0 W1 W0 U3 U2 U1 U0 Read Word 5

S Analog Data – Output Channel 0 Write Word 1

S Analog Data – Output Channel 1 Write Word 2

Not used – set to 0 OE1 OE0 Write Word 3

Not used C5 C4 C3 C2 C1 C0 0 0 F5 F4 F3 F2 F1 F0 Write Word 4

Not used – set to 0 Write Word 5

thru 10

ProSoft Technology, Inc. Page 33 of 152

August 23, 2007

Page 34

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

1794-IE4XOE2 Range Selection Bits

Channel

No.

Decimal Bit 00 08 01 09 02 10 03 11 04 12 05 13

4 to 20mA 0 1 0 1 0 1 0 1 0 1 0 1

0 to 10V dc/0

to 20mA

to 10 to +10V

dc

Off1 0 0 0 0 0 0 0 0 0 0 0 0

C = Configure select bit

F = Full range bit

1When configured to off, individual channels will return either 0V or 0mA.

Input

Channel 0

F0 C0 F1 C1 F2 C2 F3 C3 F4 C4 F5 C5

1 0 1 0 1 0 1 0 1 0 1 0

1 1 1 1 1 1 1 1 1 1 1 1

Input

Channel 1

Input

Channel 2

Input

Channel 3

Output

Channel 0

Output

Channel 1

1794-IE4XOE2 Word/Bit Descriptions

Word Decimal Bit Definition

Read Word 1 Bits 00 to 14 Channel 0 analog data – 12-bit left justified two's complement number; unused

lower bits are zero; 4 to 20mA uses all 16 bits.

Bits 15 Channel 0 analog data sign bit.

Read Word 2 Bits 00 to 14 Channel 1 analog data – 12-bit left justified two's complement number; unused

lower bits are zero; 4 to 20mA uses all 16 bits.

Bits 15 Channel 1 analog data sign bit.

Read Word 3 Bits 00 to 14 Channel 2 analog data – 12-bit left justified two's complement number; unused

lower bits are zero; 4 to 20mA uses all 16 bits.

Bits 15 Channel 2 analog data sign bit.

Read Word 4 Bits 00 to 14 Channel 3 analog data – 12-bit left justified two's complement number; unused

lower bits are zero; 4 to 20mA uses all 16 bits.

Bits 15 Channel 3 analog data sign bit.

Read Word 5 Bits 00 to 03 Underrange bits (U) for individual channels (4 to 20mA current inputs only) – Bit 00

corresponds to input channel 0, bit 01 corresponds to input channel 1, and so on.

Bits 04 to 05 Wire Off bits (W) – Current outputs only – When set (1), the wire on the current

output is broken or the load resistance is too high. Bit 00 corresponds to channel 0,

bit 01 corresponds to channel 2, and so on.

Bits 06 to 14 Not used – set to 0.

Bit 15 Power Up bit – included in series B modules only. This bit is 0 in series A modules.

This bit is set to 1 when all bits in the configuration register are 0 (unconfigured

state). The configuration register can be cleared by either of the reset inputs, or by

the user writing all zeroes to it.

Write Word 1 Bits 00 to 14 Channel 0 analog data – 12-bit left justified two's complement number; unused

lower bits are zero; 4 to 20mA uses all 16 bits.

Bits 15 Channel 0 analog data sign bit.

Write Word 2 Bits 00 to 14 Channel 1 analog data – 12-bit left justified two's complement number; unused

lower bits are zero; 4 to 20mA uses all 16 bits.

Bits 15 Channel 1 analog data sign bit.

Write Word 3 Bits 00 to 01 Output Enable bits. Bit 00 corresponds to output 0, bit 01 corresponds to output 1.

These bits must be set to 1.

Page 34 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 35

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

Word Decimal Bit Definition

Bits 02 to 15 Not used – set to 0.

Write Word 4 Bits 00 to 05 Full range bits (F) for individual channels – Bit 00 corresponds to input channel 0,

bit 01 corresponds to input channel 1, bit 02 corresponds to input channel 3, bit 03

corresponds to input channel 3, bit 04 corresponds to output channel 1, and bit 05

corresponds to output channel 2. Refer to range selection above.

Bits 06 to 07 Not used – set to 0.

Bits 08 to 13 Configure select bits (C) for individual channels – Bit 08 corresponds to input

channel 0, bit 09 (11) corresponds to input channel 1, bit 10 (12) corresponds to

input channel 2, bit 11 (13) corresponds to input channel 3, bit 12 (14) corresponds

to output channel 0, and bit 13 (15) corresponds to output channel 1. Refer to range

selection above.

Bits 14 to 15 Not used – set to 0.

Write Word 5 Bits 00 to 15 Not used – set to 0.

Write Word 6 Bits 00 to 15 Not used – set to 0.

Write Word 7 Bits 00 to 15 Not used – set to 0.

Write Word 8 Bits 00 to 15 Not used – set to 0.

Write Word 9 Bits 00 to 15 Not used – set to 0.

Write Word 10 Bits 00 to 15 Not used – set to 0.

3.2.10 1794-IR8 – RTD Input Analog Module Image Table Mapping

I/O Image

Input Size

1 to 11 Words

Overrange

Output Size

0 to 3 Words

Calibration Mask

1794-IR8 Read

Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Oct. Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read Word 1 Reserved

Read Word 2 Channel 0 Input Data

Read Word 3 Channel 1 Input Data

Read Word 4 Channel 2 Input Data

Read Word 5 Channel 3 Input Data

Read Word 6 Channel 4 Input Data

Module Image

Reserved

Input Data Channel 0

Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Input Data Channel 4

Input Data Channel 5

Input Data Channel 6

Input Data Channel 7

Underrange

Calibration Status

Configuration

RTD Type

RTD Type

ProSoft Technology, Inc. Page 35 of 152

August 23, 2007

Page 36

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Read Word 7 Channel 5 Input Data

Read Word 8 Channel 6 Input Data

Read Word 9 Channel 7 Input Data

Read Word 10 Overrange Bits Underrange Bits

Read Word 11 0 0 0 0 0 Bad

Cal

Cal

Done

Cal

0 Diagnostic Status

Range

Bits

Pwr

0 0 0

Up

1794-IR8 Write

Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Oct. Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Write Word 1 8-bit Calibration Mask Cal

Write Word 2 RTD 3 Type RTD 2 Type RTD 1 Type RTD 0 Type

Write Word 3 RTD 7 Type RTD 6 Type RTD 5 Type RTD 4 Type

Where: Enh = Enhanced

MDT = Module Data Type

Clk

Cal Hi

Filter Cutoff Enh MDT

Cal Lo

1794-IR8 Word/Bit Descriptions

Word

Read Word 1 00 to 15 (00 to 17) Reserved

Read Word 2 00 to 15 (00 to 17) Channel 0 Input data

Read Word 3 00 to 15 (00 to 17) Channel 1 Input data

Read Word 4 00 to 15 (00 to 17) Channel 2 Input data

Read Word 5 00 to 15 (00 to 17) Channel 3 Input data

Read Word 6 00 to 15 (00 to 17) Channel 4 Input data

Read Word 7 00 to 15 (00 to 17) Channel 5 Input data

Read Word 8 00 to 15 (00 to 17) Channel 6 Input data

Read Word 9 00 to 15 (00 to 17) Channel 7 Input data

Read Word 10 00 to 07

08 to 15 (10 to 17)

Read Word 11 00 to 01 Not used – set to 0

02 Reserved

03

04 to 06

07 Unused – set to 0

Dec. Bits (Octal

Bits)

Description

Underrange bits – these bits are set if the input signal is

below the input channel's minimum range.

Overrange bits – these bits are set if 1), the input signal is

above the input channel's maximum range, or 2), an open

detector is detected.

Powerup bit – this bit is set (1) until configuration data is

received by the module.

Critical Error bits – If these bits are anything other than all

zeroes, return the module to the factory for repair

Page 36 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 37

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

Word

08 (10)

09 (11)

10 (12)

11 to 15 (13 to 17) Unused – set to 0

Write word 1 00 to 01 Module Data Type

Bit 01 00

0 0 °C (default)

0 1 °F

1 0

1 1

02

03 to 05 A/D Filter First Notch Frequency

Bit 05 04 03 Definition

0 0 0 10Hz (default)

0 0 1 25Hz

0 1 0 50Hz

0 1 1 60Hz

1 0 0 100Hz

1 0 1 250Hz

1 1 0 500Hz

1 1 1 1000hZ

06

07

08 to 15

Write Word 2 00 to 03 Channel 0 RTD Type

Bit 03 02 01 00 RTD Type – Range

0 0 0 0 Resistance (default)

0 0 0 1 No sensor connected – do not scan

0 0 1 0

0 0 1 1

0 1 0 0

Dec. Bits (Octal

Bits)

Description

Calibration Range bit – set to 1 if a reference signal is out of

range during calibration

Calibration Done bit – set to 1 after an initiated calibration

cycle is complete.

Calibration Bad bit – set to 1 if the channel has not had a

valid calibration.

Bipolar counts scaled between –32768 and

+32767

Unipolar counts scaled between 0 and

65535

Enhanced mode select – measures voltage drop across a

precision resistor in the module to compare with the

unknown input.

Calibration High/Low bit – This bit is set during gain

calibration; reset during offset calibration.

Calibration clock – this bit must be set to 1 to prepare for a

calibration cycle; then reset to 0 to initiate calibration.

Calibration mask – The channel, or channels, to be

calibrated will have the correct mask bit set. Bit 0

corresponds to channel 0, bit 1 to channel 1, and so on.

100 ohm Pt = 0.00385 Euro (–200 to

+870°C)

100 ohm Pt = 0.003916 U.S. (–200

to +630°C)

200 ohm Pt = 0.00385 (–200 to

+630°C)

ProSoft Technology, Inc. Page 37 of 152

August 23, 2007

Page 38

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

Word

Dec. Bits (Octal

Bits)

0 1 0 1

0 1 1 0 Reserved

0 1 1 1 10 ohm Copper (–200 to +260°C)

1 0 0 0 120 ohm Nickel (–60 to +250°C)

1 0 0 1 100 ohm Nickel (–60 to +250°C)

1 0 1 0 200 ohm Nickel (–60 to +250°C)

1 0 1 1 500 ohm Nickel (–60 to +250°C)

1 1 0 0 Module data time stamp

1101 to 1111 – Reserved

04 to 07 Channel 1 RTD Type (see bits 00 to 03)

08 to 11 Channel 2 RTD Type (see bits 00 to 03)

12 to 15 Channel 3 RTD Type (see bits 00 to 03)

Write Word 3 00 to 03 Channel 4 RTD Type (see write word 2, bits 00 to 03)

04 to 07 Channel 5 RTD Type (see write word 2, bits 00 to 03)

08 to 11 Channel 6 RTD Type (see write word 2, bits 00 to 03)

12 to 15 Channel 7 RTD Type (see write word 2, bits 00 to 03)

Description

500 ohm Pt = 0.00385 (–200 to

+630°C)

3.2.11 1794-IT8 – Thermocouple Input Module Image Table Mapping

Module Image

Reserved

Input Data Channel 0

I/O Image

Input Size

1 to 11 Words

Output Size

0 to 3 Words

Calibration Mask

1794-IT8 Read

Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read Word 1 Reserved

Read Word 2 Channel 0 Input Data

Read Word 3 Channel 1 Input Data

Read Word 4 Channel 2 Input Data

Read Word 5 Channel 3 Input Data

Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Input Data Channel 4

Input Data Channel 5

Input Data Channel 6

Input Data Channel 7

Overrange

Calibration Status

Underrange

Configuration

Thermocouple Type

Thermocouple Type

Page 38 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 39

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read Word 6 Channel 4 Input Data

Read Word 7 Channel 5 Input Data

Read Word 8 Channel 6 Input Data

Read Word 9 Channel 7 Input Data

Read Word

Overrange Bits Underrange Bits

10

Read Word

11

0 0 0 0 0 Bad

Cal

Cal

Done

Cal

0 Diagnostics Pwr

Range

Up

Bad

Structure

CJC

over

CJC

Under

1794-IT8 Write

Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Write Word 1 8-Bit Calibration Mask Cal

Write Word 2 Thermocouple 3 Ty pe Thermocouple 2 Type Thermocouple 1 Type Thermocouple 0 Type

Write Word 3 Thermocouple 7 Ty pe Thermocouple 6 Type Thermocouple 5 Type Thermocouple 4 Type

Where: FDF = fixed digital filter bit

Clk

Cal hi

Filter Cutoff FDF Data Type

Cal lo

1794-IT8 Word/Bit Descriptions

Word Decimal Bit

(Octal Bit)

Read Word 1 00 to 15 (00 to 17) Reserved

Read Word 2 00 to 15 (00 to 17) Channel 0 Input data

Read Word 3 00 to 15 (00 to 17) Channel 1 Input data

Read Word 4 00 to 15 (00 to 17) Channel 2 Input data

Read Word 5 00 to 15 (00 to 17) Channel 3 Input data

Read Word 6 00 to 15 (00 to 17) Channel 4 Input data

Read Word 7 00 to 15 (00 to 17) Channel 5 Input data

Read Word 8 00 to 15 (00 to 17) Channel 6 Input data

Read Word 9 00 to 15 (00 to 17) Channel 7 Input data

Read Word 10 00 to 07 (00 to 07)

08 to 15 (10 to 17)

Read Word 11 00 (00)

01 (01)

02 (02)

Description

Underrange bits – these bits are set if the input signal is below

the input channel's minimum range.

Overrange bits – these bits are set if 1), the input signal is

above the input channel's maximum range, or 2), an open

detector is detected.

Cold Junction sensor underrange bit. – this bit is set if the cold

junction temperature is below 0°C.

Cold Junction sensor overrange bit. – this bit is set if the cold

junction temperature is above 70°C.

Bad Structure – this bit is set if there is an invalid

thermocouple type selected.

ProSoft Technology, Inc. Page 39 of 152

August 23, 2007

Page 40

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

Word Decimal Bit

(Octal Bit)

03 (03)

04 to 06 (04 to 06)

07 (07) Unused – set to 0

08 (10)

09 (11)

10 (12)

11 to 15 (13 to 17) Unused – set to 0

Write Word 1 00 to 01 (00 to 01) Module Data Type

Bit 01 00 Definition

0 0 °C (default)

0 1 °F

1 0 Bipolar counts scaled between –32768 and +32767

1 1 Unipolar counts scaled between 0 and 65535

Bit 02 (02)

03 to 05 (03 to 05) A/D Filter First Notch Frequency

Bit 05 04 03 Definition

0 0 0 10Hz (default)

0 0 1 25Hz

0 1 0 50Hz

0 1 1 60Hz

1 0 0 100Hz

1 0 1 250Hz

1 1 0 500Hz

1 1 1 1000hZ

06 (06)

07 (07)

08 to 15 (10 to 17)

Write Word 2 00 to 03 (00 to 03) Channel 0 Thermocouple Type

Bit 03 02 01 00 Thermocouple Type – Range

0 0 0 0 Millivolts (default)

0 0 0 1 300 to 1800°C (572 to 3272°F)

0 0 1 0 –270 to 1000°C (–454 to 1832°F)

Description

Powerup bit – this bit is set (1) until configuration data is

received by the module.

Critical Fault bits – If these bits are anything other than zero,

return the module to the factory for repair.

Calibration Range bit – set to 1 if a reference signal is out of

range during calibration

Calibration Done bit – set to 1 after an initiated calibration

cycle is complete.

Calibration Bad bit – set to 1 if the channel has not had a valid

calibration.

Fixed Digital Filter – When this bit is set (1), a software digital

filter is enabled. This filter settles to 100% of a Full Scale step

input in 60 scans.

Calibration High/Low bit – This bit is set during gain

calibration; reset during offset calibration.

Calibration clock – this bit must be set to 1 to prepare for a

calibration cycle; then reset to 0 to initiate calibration.

Calibration mask – The channel, or channels, to be calibrated

will have the correct mask bit set. Bit 8 corresponds to

channel 0, bit 9 to channel 1, and so on.

Page 40 of 152 ProSoft Technology, Inc.

August 23, 2007

Page 41

How Communication Takes Place and I/O Image Table Mapping 3170-PDP ♦ FLEX Platform

FLEX I/O™ PROFIBUS Adapter

Word Decimal Bit

(Octal Bit)

0 0 1 1 –210 to 1200°C (–346 to 2192°F)

0 1 0 0 –71 to 1372°C (–95 to 2502°F)

0 1 0 1 –50 to 1768°C (–58 to 3214°F)

0 1 1 0 –50 to 1768°C (–58 to 3214°F)

0 1 1 1 –73 to 400°C (–99 to 752°F)

1 0 0 0 0 to 2315°C (32 to 4199°F)

1 0 0 1 –270 to 1300°C (–450 to 2372°F)

1 0 1 0 Reserved

1 0 1 1 Reserved

1 1 0 0

1 1 0 1

1 1 1 0 Reserved

1 1 1 1 No sensor connected (do not scan)

04 to 07 (04 to 07) Channel 1 Thermocouple Type (see bits 00 to 03)

08 to 11 (10 to 13) Channel 2 Thermocouple Type (see bits 00 to 03)

12 to 15 (14 to 17) Channel 3 Thermocouple Type (see bits 00 to 03)

Write Word 3 00 to 03 (00 to 03) Channel 4 Thermocouple Type (see word 13, bits 00 to 03)

04 to 07 (04 to 07) Channel 5 Thermocouple Type (see word 13, bits 00 to 03)

08 to 11 (10 to 13) Channel 6 Thermocouple Type (see word 13, bits 00 to 03)

12 to 15 (14 to 17) Channel 7 Thermocouple Type (see word 13, bits 00 to 03)

Description

Module reports cold junction temperature

for channels 00 to 03

Module reports cold junction temperature

for channels 04 to 07

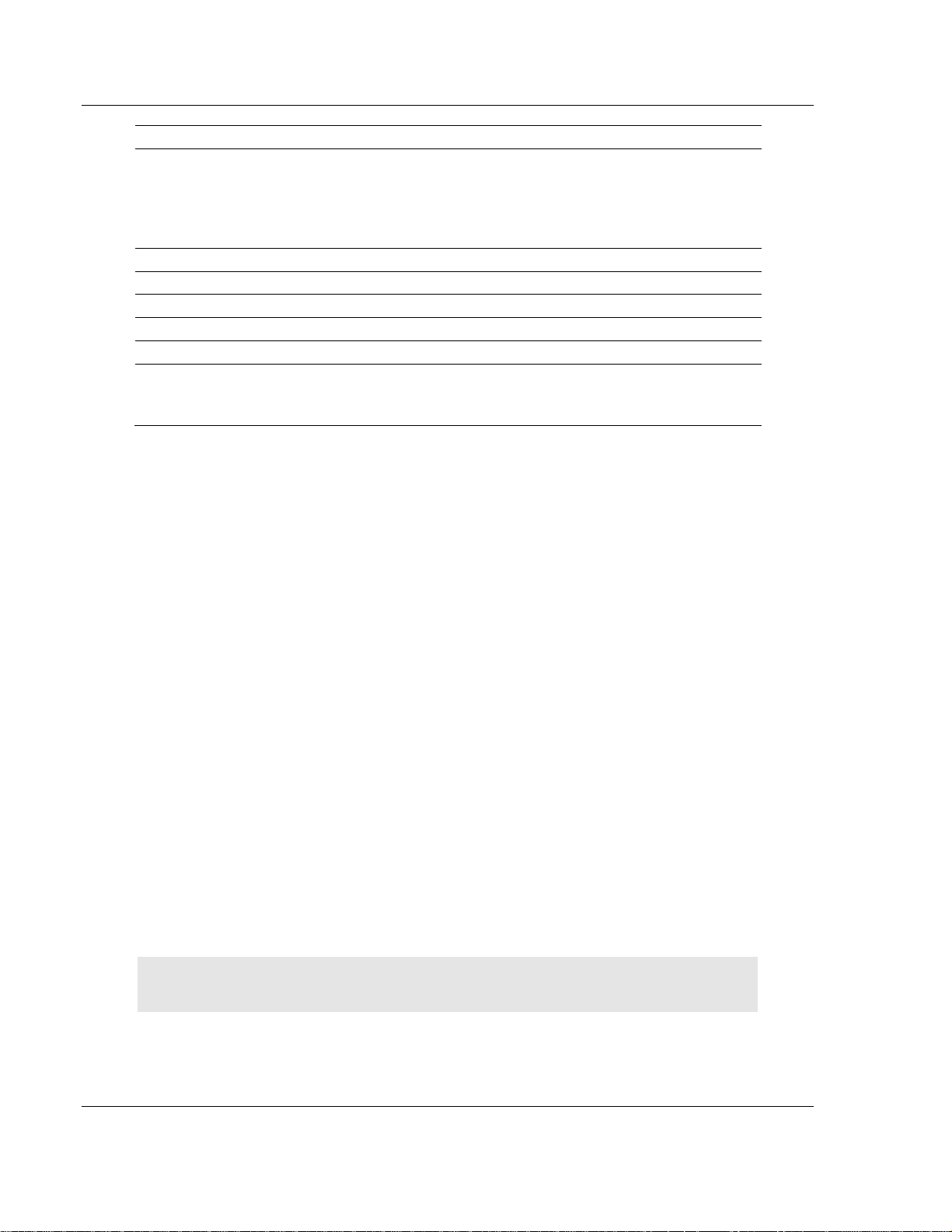

3.2.12 1203-FM1 – SCANport Module Image Table Mapping

I/O Image

Connection StatusChannel 2

Read

6 Words

Connection Enable Channel 2

Write

5 Words

ProSoft Technology, Inc. Page 41 of 152

August 23, 2007

Module Image

0

Connection Status Channel 1

Logic Status Channel 1

Analog Feedback Channel 1

Logic Status Channel 2

Analog Feedback Channel 2

1 Word

Connection Enable Channel 1

Logic Command Channel 1

Analog Reference Channel 1

Logic Command Channel 2

Analog Reference Channel 2

Not Used

Page 42

3170-PDP ♦ FLEX Platform How Communication Takes Place and I/O Image Table Mapping

FLEX I/O™ PROFIBUS Adapter

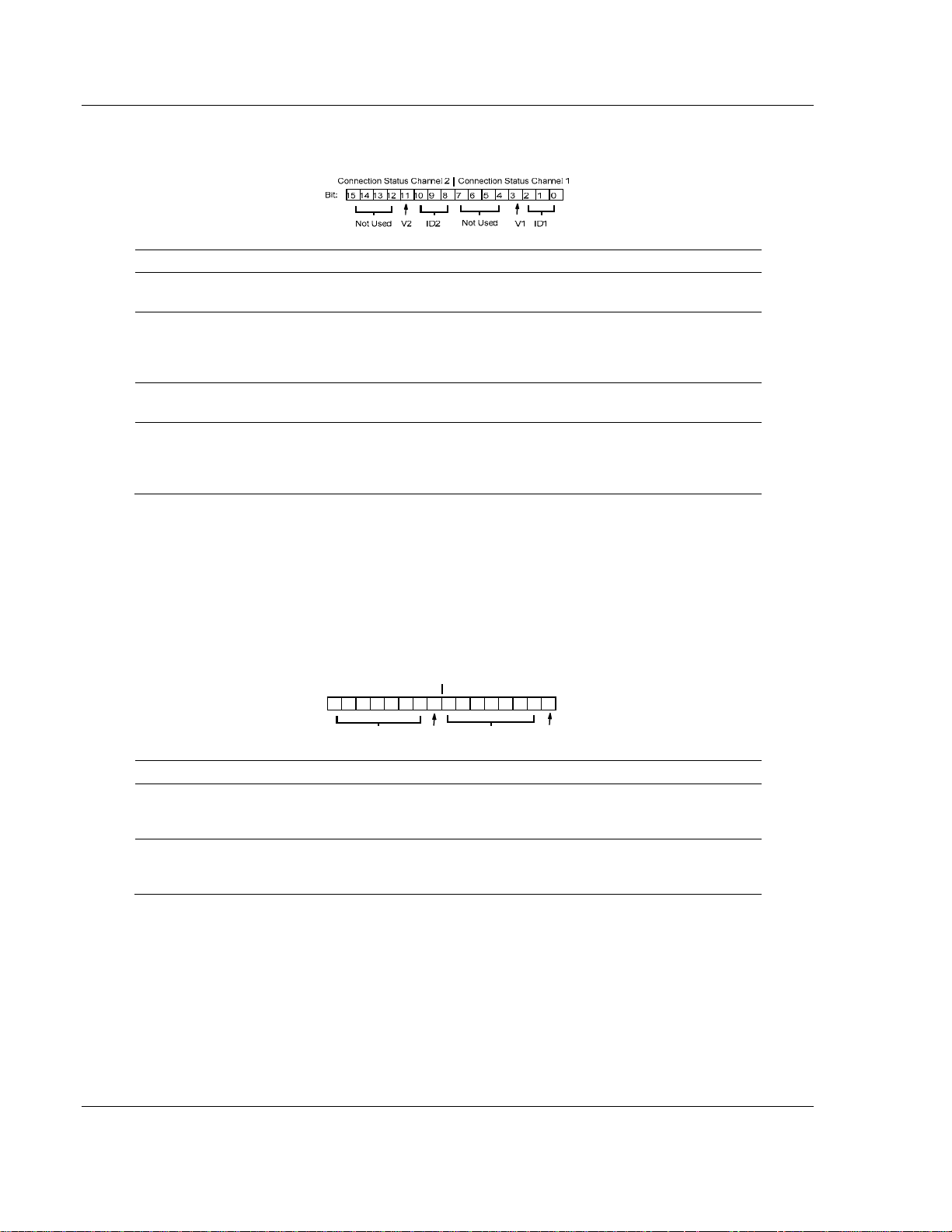

3.3 Connection Status Word Definition

Description

SCANport channel 1 valid data bit. When high (1), the Logic Status and Analog Feedback

V1

values are valid and can be used. When low (0), the values should not be used.

SCANport channel 1 connected peripheral port ID number. This three bit field contains the

ID1

port number that channel 1 is connected to on the SCANport device. It should contain a

value between 1 and 7. If this field is 7, then the channel is not connected to the SCANport

device, or the SCANport device may not be powered.

SCANport channel 2 valid data bit. When high (1), the Logic Status and Analog Feedback

V2

values are valid and can be used. When low (0), the values should not be used.

SCANport channel 2 connected peripheral port ID number. This three bit field contains the

ID2

port number that channel 2 is connected to on the SCANport device. It should contain a

value between 1 and 7. If this field is 7, then the channel is not connected to the SCANport

device, or the SCANport device may not be powered.

3.4 Logic Status/Analog Feedback Definition

The Logic Status and Analog Feedback values are defined within the product