Page 1

3170-MBS

Flex Platform

Modbus Slave Interface Module

October 18, 2010

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2010 ProSoft Technology, Inc., all rights reserved.

3170-MBS User Manual

October 18, 2010

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM,

and are available at no charge from our web site: www.prosoft-technology.com

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1.661.716.5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIV. 2;

B WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

C WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

D THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Warnings

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in Hazardous Locations, turn off power before replacing or rewiring

modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be nonhazardous.

C Suitable for use in Class I, division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage:

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Warning: This module is not hot-swappable! Always remove power from the rack before inserting or removing this

module, or damage may result to the module, the processor, or other connected devices.

Battery Life Advisory

The MVI46, MVI56, MVI56E, MVI69, and MVI71 modules use a rechargeable Lithium Vanadium Pentoxide battery to

backup the real-time clock and CMOS. The battery should last for the life of the module. The module must be

powered for approximately twenty hours before the battery becomes fully charged. After it is fully charged, the battery

provides backup power for the CMOS setup and the real-time clock for approximately 21 days. When the battery is

fully discharged, the module will revert to the default BIOS and clock settings.

Note: The battery is not user replaceable.

Page 4

Markings

Electrical Ratings

Backplane Current Load: 800 mA @ 5 Vdc

Operating Temperature: 0°C to 60°C (32°F to 140°F)

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

Shock: 30g Operational; 50g non-operational; Vibration: 5 g from 10 Hz to 150 Hz

Relative Humidity 5% to 95% (without condensation)

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground conductors must be at least

4mm(squared).

Label Markings

Agency Approvals and

CertificationsANSI / ISA

CSA/cUL C22.2 No. 213-1987

CSA CB Certified IEC61010

ATEX EN60079-0 Category 3, Zone 2

ISA 12.12.01 Class I Division 2, GPs A, B, C, D

EN60079-15

243333

Page 5

3170-MBS ♦ Flex Platform Contents

Modbus Slave Interface Module User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

MVI (Multi Vendor Interface) Modules ................................................................................................ 3

Warnings ............................................................................................................................................. 3

Battery Life Advisory ........................................................................................................................... 3

Markings .............................................................................................................................................. 4

1 Product Specifications 7

1.1

1.2

General Specifications .............................................................................................. 8

Modbus Specifications .............................................................................................. 9

2 Functional Overview 11

2.1

2.2

Modbus Addressing Concepts ................................................................................ 11

The Data Space in the module ................................................................................ 12

3 Module Configuration and Installation 13

3.1

3.2

3.3

3.4

3.3.1

Mounting on a DIN-rail before installing the terminal base units............................. 14

Mounting (or Replacing) the module on an existing system ................................... 15

Wiring ...................................................................................................................... 16

RS-485 Tip .............................................................................................................. 16

Setting the switches ................................................................................................ 17

4 Module Addressing 19

4.1

4.2

Reading Discrete Inputs .......................................................................................... 20

Writing Discrete Outputs ......................................................................................... 21

5 Status Information 23

5.1

5.2

5.3

5.4

5.5

5.5.1

Adapter Status Word ............................................................................................... 24

Module Status Words .............................................................................................. 25

Module Information .................................................................................................. 26

Modbus Function Counters ..................................................................................... 27

Modbus Status ........................................................................................................ 28

Error Codes ............................................................................................................. 28

6 Diagnostics and Troubleshooting 29

6.1

6.2

LED Indicators ......................................................................................................... 30

Troubleshooting: General ........................................................................................ 31

ProSoft Technology, Inc. Page 5 of 55

October 27, 2010

Page 6

Contents 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

7 Example Address Mapping 33

7.1

7.2

7.3

7.4

Application Example ............................................................................................... 34

Address Map ........................................................................................................... 35

Function Code Address Ranges ............................................................................. 37

Work Sheets ........................................................................................................... 38

8 Support, Service & Warranty 45

Contacting Technical Support .......................................................................................................... 45

8.1

8.2

8.1.1

8.1.2

8.1.3

8.2.1

8.2.2

8.2.3

8.2.4

8.2.5

8.2.6

8.2.7

8.2.8

8.2.9

8.2.10

Return Material Authorization (RMA) Policies and Conditions ............................... 47

Returning Any Product ............................................................................................ 47

Returning Units Under Warranty ............................................................................. 48

Returning Units Out of Warranty ............................................................................. 48

LIMITED WARRANTY ............................................................................................ 49

What Is Covered By This Warranty ........................................................................ 49

What Is Not Covered By This Warranty .................................................................. 50

Disclaimer Regarding High Risk Activities .............................................................. 50

Intellectual Property Indemnity ............................................................................... 51

Disclaimer of all Other Warranties .......................................................................... 51

Limitation of Remedies ** ....................................................................................... 52

Time Limit for Bringing Suit ..................................................................................... 52

No Other Warranties ............................................................................................... 52

Allocation of Risks .................................................................................................. 52

Controlling Law and Severability ............................................................................ 53

Index 55

Page 6 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 7

3170-MBS ♦ Flex Platform Product Specifications

Modbus Slave Interface Module User Manual

1 Product Specifications

In This Chapter

General Specifications............................................................................. 8

Modbus Specifications............................................................................. 9

The 3170-MBS Modbus Slave Communication Adapter can interface up to 8

Rockwell Automation FLEX and/or Integra I/O modules directly with any Modbus

Master. The following functionality is available:

Multi-drop on an RS-485 link with other Modbus compatible devices

Interface Analog and/or Discrete I/O directly to a Host

Add FLEX I/O into applications where other manufacturer’s devices are

already in use

The 3170-MBS module is simple to use, requiring only the setting of several dipswitch options. The Flex and Integra module data images are pre-mapped into

Modbus addresses to simplify reading and writing using standard Modbus

commands.

The 3170-MBS has read/write access to all Flex and Integra modules. This

allows a Host system to perform all functions necessary to get all I/O modules

functioning. All register data values can be accessed using Function Codes 3, 4,

6 and 16. Bit level Function Codes 1, 2, and 5 are also supported.

ProSoft Technology, Inc. Page 7 of 55

October 27, 2010

Page 8

Product Specifications 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

1.1 General Specifications

I/O Capacity: 8 I/O modules (Flex and/or Integra)

RS-485 Communication port - 3 screw termination

Status LEDs

o

Power / Control Status

o

Serial TX, RX and ERROR Status

Input Voltage: 24 VDC (19.2-31.2 VDC)

Max Input Power: 8.6 W

Max Backplane Output Current: 640 ma @ 5V

Operating Temp.: 0 to 55°C

Storage Temp.: -40 to 85°C

Dimensions: 87x68x69 mm (3.4x2.7x2.7 inches)

UL Class I Div 2 Groups A,B,C,D

Page 8 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 9

3170-MBS ♦ Flex Platform Product Specifications

Modbus Slave Interface Module User Manual

1.2 Modbus Specifications

The 3170-MBS product support the following features:

RTU mode (binary) with CRC-16 error checking

ASCII 7 and 8-bit modes with LRC error checking

Accepts broadcast commands from the Master

Function codes:

1: Read Output Coils (Horizontal addressing only)

2: Read Discrete Inputs (Horizontal addressing only)

3: Read Multiple Holding Registers

4: Read Multiple Input Registers

5: Force (Write) Single Coil (Horizontal addressing only)

6: Preset (Write) Single Holding Register

16: Preset (Write) Multiple Holding Registers

Pre-assigned Modbus memory map

Parameters configured via dip switches:

o

Address: 1 to 247

o

Parity: None, Odd or Even

o

Stop Bits: 1 or 2

o

Baud Rate: 1200, 2400, 4800, 9600, 19200, 38400, 62500

ProSoft Technology, Inc. Page 9 of 55

October 27, 2010

Page 10

Product Specifications 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

Page 10 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 11

3170-MBS ♦ Flex Platform Functional Overview

Modbus Slave Interface Module User Manual

2 Functional Overview

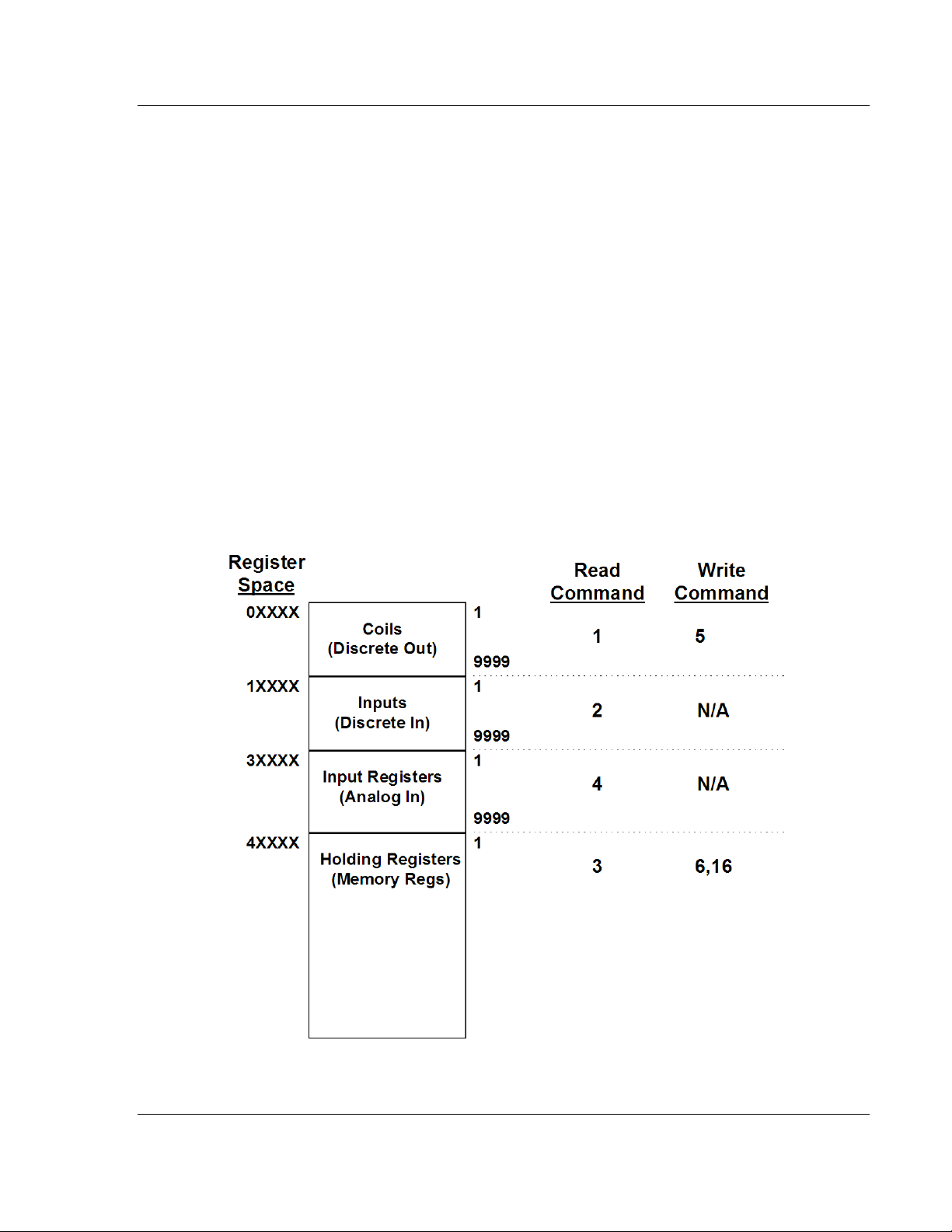

2.1 Modbus Addressing Concepts

Modicon developed the Modbus addressing scheme around the data table and

I/O structure in Modicon PLCs. As a result, the Modbus protocol supports access

to the various data spaces in the Modicon PLC.

By far the most common data space used is the 4xxxx space using the Function

Codes 3, 6 and 16. This space is used to transfer 16 bit register values and can

be used to transfer bit mapped data. Using formal Modbus addressing

terminology, this data space actually starts at address 40001.

Access to the different data spaces is determined by the Function Code that is

used. The following chart shows the four different types of data spaces, the

numerical range of these spaces, and the Function Codes that are used to

execute read and write instructions within these data spaces. The following

illustration shows the relationship between the Modbus Function Codes and the

Modbus addressing scheme.

ProSoft Technology, Inc. Page 11 of 55

October 27, 2010

Page 12

Functional Overview 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

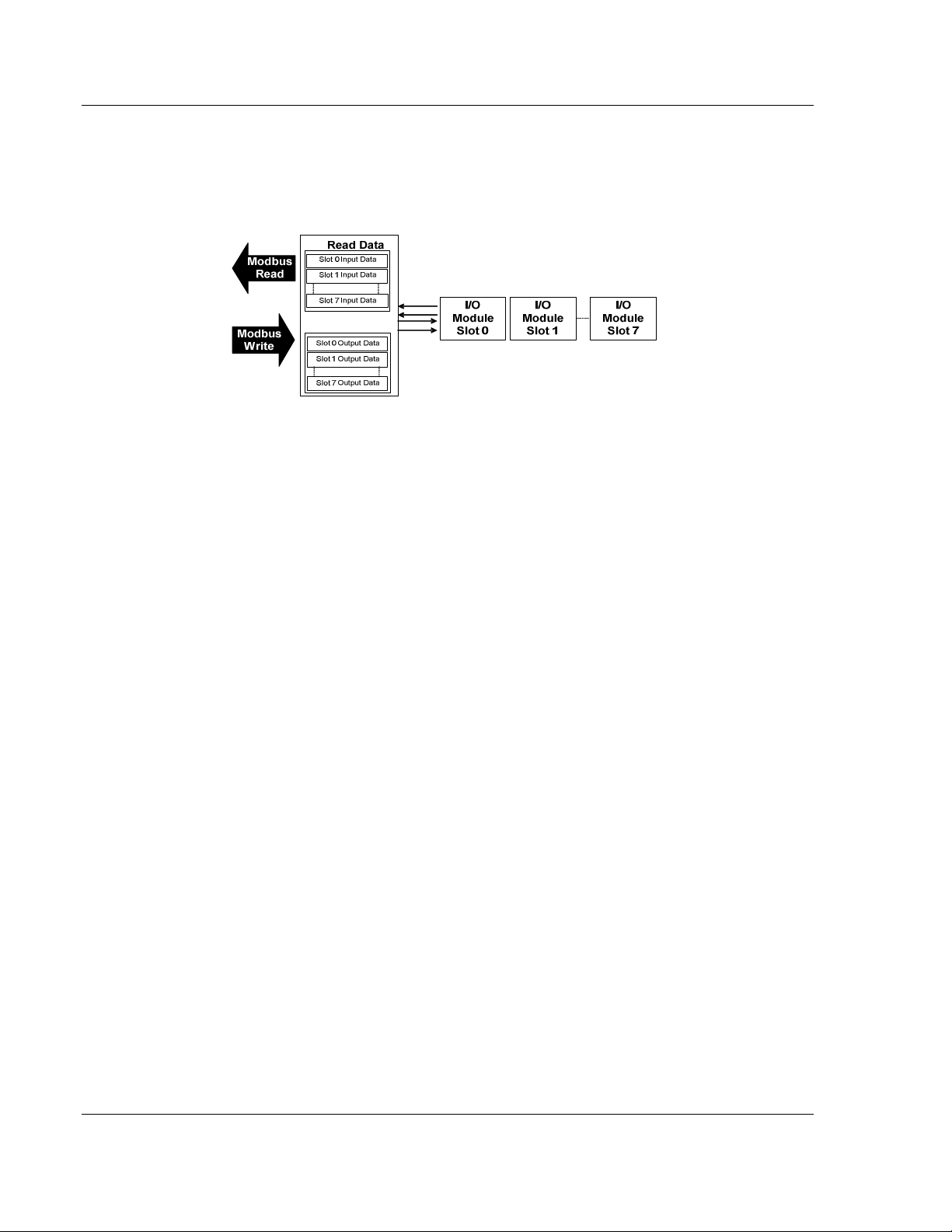

2.2 The Data Space in the module

One of the concepts, which are important to develop an understanding of, is the

relationship between the data space in the module and how this data can be

moved between the module and the Modbus Master.

Page 12 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 13

3170-MBS ♦ Flex Platform Module Configuration and Installation

Modbus Slave Interface Module User Manual

3 Module Configuration and Installation

In This Chapter

Installation ............................................................................................. 14

Mounting (or Replacing) the module on an existing system .................. 15

Wiring .................................................................................................... 16

Setting the switches .............................................................................. 17

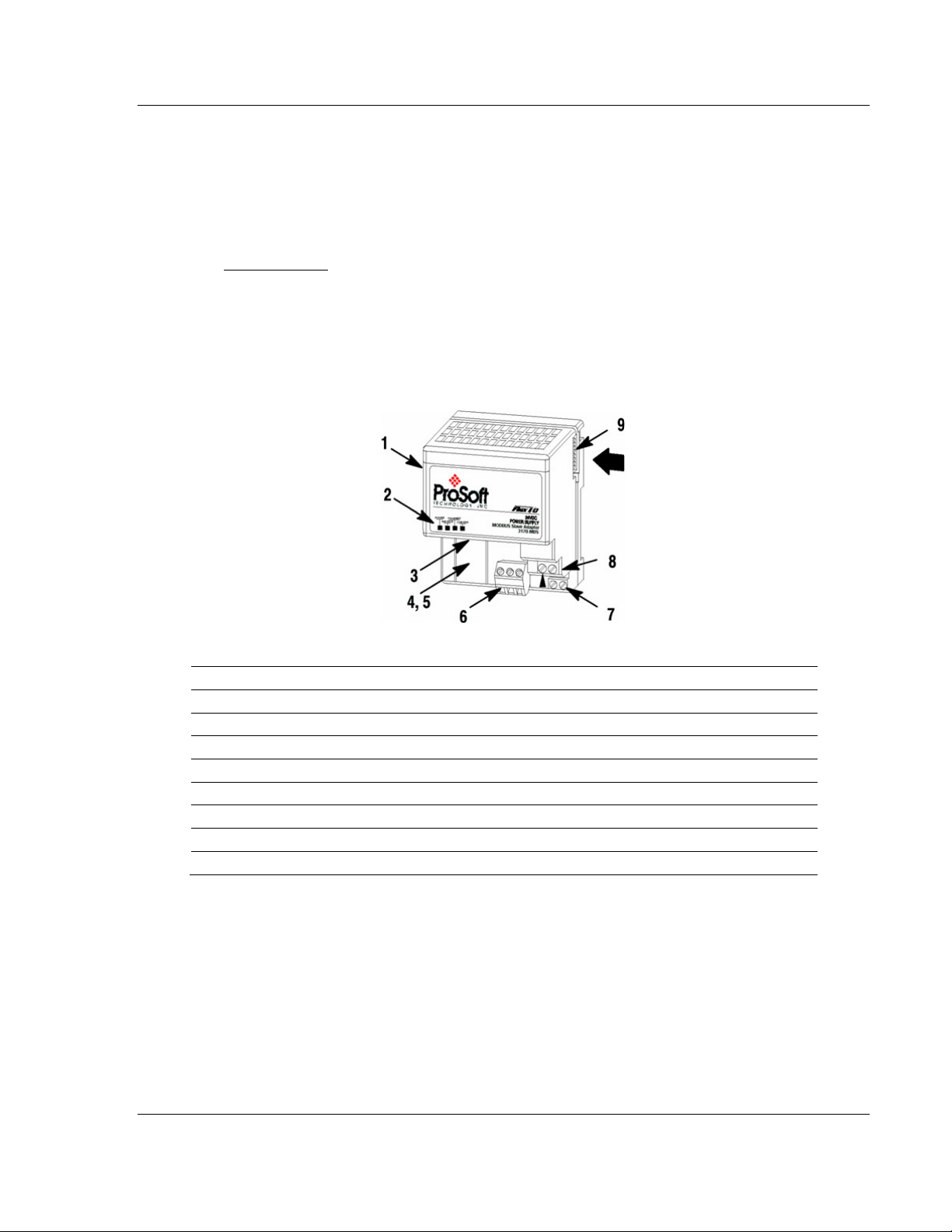

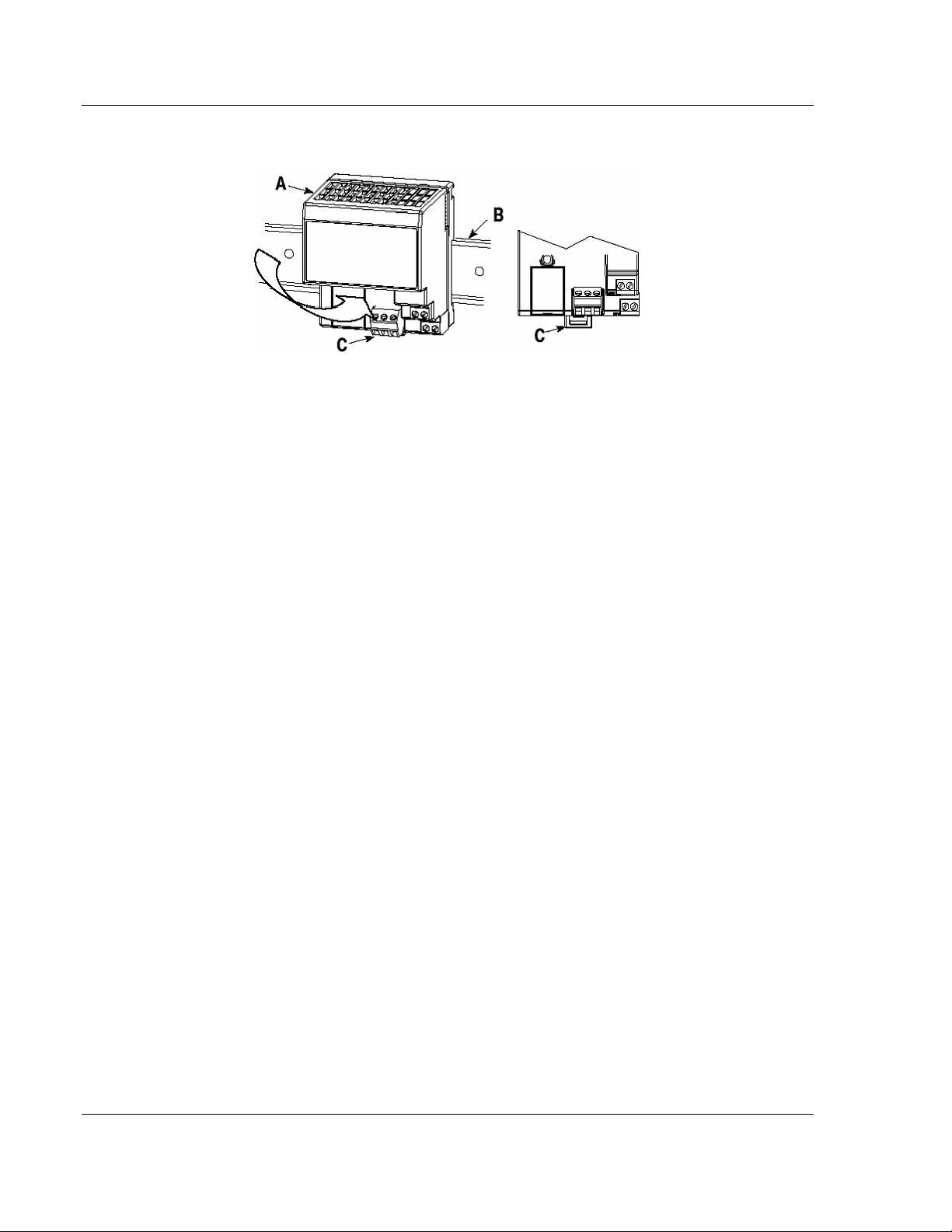

Component Identification

1 Modbus Adapter Module

2 Indicators

3 Communication reset pushbutton (PRL)

4 Access door to switches S1 and S2

5 Switches S1 and S2 (behind access door)

6 Modbus cable connector

7 +24V dc connections

8 24V common connections

9 Flexbus connector

ProSoft Technology, Inc. Page 13 of 55

October 27, 2010

Page 14

Module Configuration and Installation 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

3.1 Mounting on a DIN-rail before installing the terminal base units

1 Position the Modbus adapter module A on a 35 X 7.5mm DIN-rail B

(Rockwell Automation pt. no. 199-DR1: 46277-3; EN 50022) at a slight angle.

2 Hook the lip on the rear of the adapter (A) onto the top of the DIN-rail (B),

and rotate the adapter module onto the rail.

3 Press the adapter module down onto the DIN-rail until flush. Locking tab (C)

will snap into position and lock the adapter module to the DIN-rail.

4 If the adapter module does not lock in place, use a screwdriver or similar

device to move the locking tab down while pressing the adapter module flush

onto the DIN-rail and release the locking tab to lock the adapter module in

place. If necessary, push up on the locking tab to lock.

5 Connect the adapter wiring as shown under "Wiring" later in this document.

Page 14 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 15

3170-MBS ♦ Flex Platform Module Configuration and Installation

Modbus Slave Interface Module User Manual

3.2 Mounting (or Replacing) the module on an existing system

1 Remove the Modbus plug-in connector from the front of the adapter.

2 Disconnect any wiring jumpered to the adjacent terminal base.

3 Using a screwdriver or similar tool, open the lock and remove the module

from the base unit to which the adapter will be attached.

4 Push the flexbus connector toward the right side of the terminal base to

unplug the backplane connection.

5 Release the locking tab and remove the adapter.

6 Before installing the new adapter, notice the notch on the right rear of the

adapter. This notch accepts the hook on the terminal base unit. The notch is

open at the bottom. The hook and adjacent connection point keep the

terminal base and adapter tight together, reducing the possibility of a break in

communication over the backplane.

7 Complete the adapter mounting as shown below.

Attention: Make certain that the hook on the terminal base is properly hooked into the adapter.

Failure to lock the hook into the adjacent base/adapter can result in loss of communication on the

backplane.

8 If the adapter module does not lock in place, use a screwdriver or similar

device to move the locking tab C down while pressing the adapter module

flush onto the DIN-rail. Then release the locking tab to lock the adapter

module in place. If necessary, push up on the locking tab to lock.

9 Reinstall the module into the terminal base unit.

ProSoft Technology, Inc. Page 15 of 55

October 27, 2010

Page 16

Module Configuration and Installation 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

3.3 Wiring

Attention: When connecting wiring, torque terminal screws to 7 to 9 inch-pounds.

Connect To

TxRxD- 1

TxRxD+ 2

1 Connect the Modbus cable to the removable connector.

2 Connect +24V dc input to the left side of the lower connector, terminal E.

3 Connect 24V common to the left side of the upper connector, terminal D.

4 Connections G and F are used to pass 24V dc power (G) and 24V common

(F) to the next module in the series (if required).

3.3.1 RS-485 Tip

If communication in the RS-485 mode does not work at first, despite all attempts,

try switching termination polarities. Some manufacturers interpret + and -, or A

and B, polarities differently.

Page 16 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 17

3170-MBS ♦ Flex Platform Module Configuration and Installation

Modbus Slave Interface Module User Manual

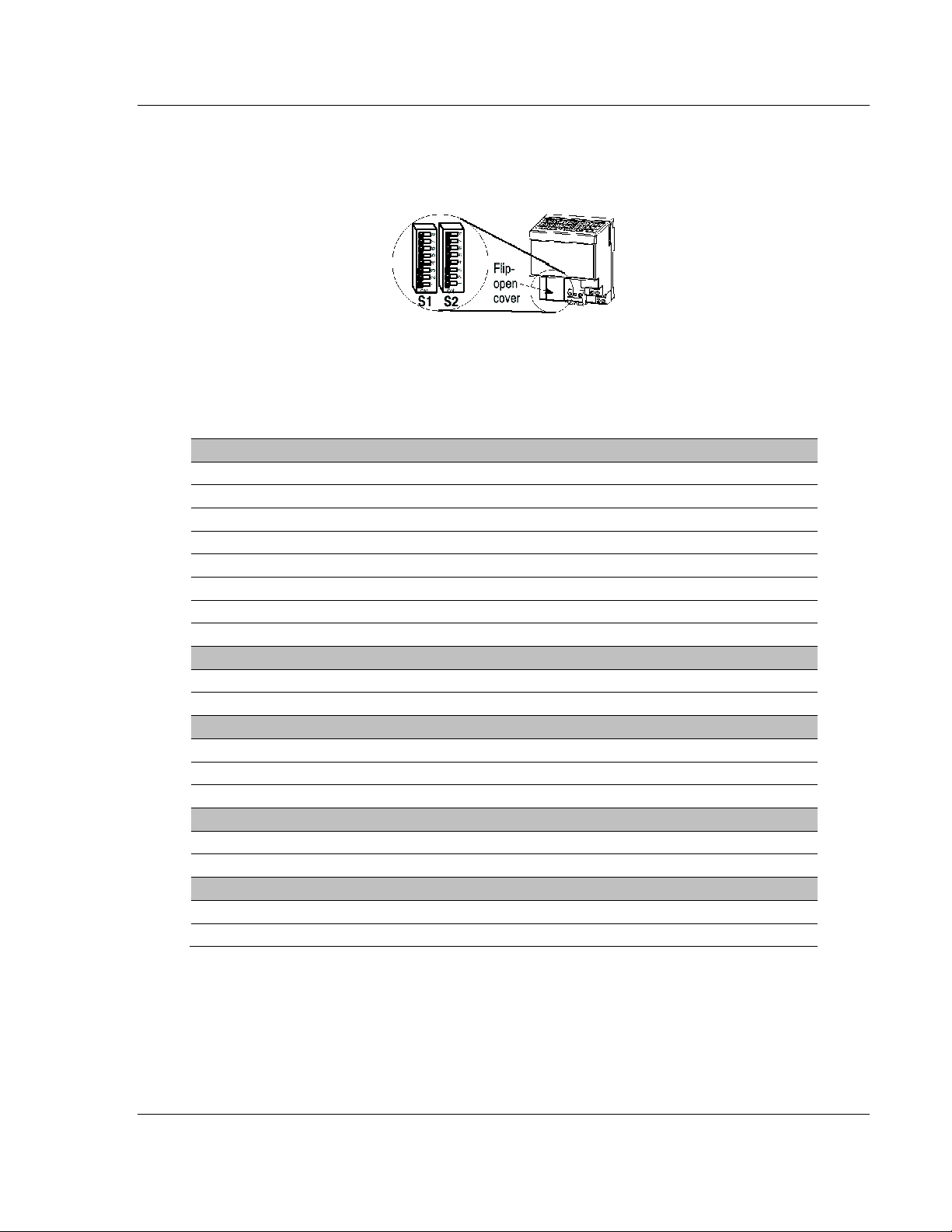

3.4 Setting the switches

The adapter switches are located under a flip-open cover on the front of the

adapter Set the switches as shown below.

1 Lift the hinged switch cover on the front of the adapter to expose the

switches.

2 Set the switches as shown below.

3 Cycle power to the adapter after setting the switches.

Baud Rate S1-1 S1-2 S1-3

1200 OFF OFF OFF

2400 ON OFF OFF

4800 OFF ON OFF

9600 ON ON OFF

19200 OFF OFF ON

38400 ON OFF ON

62.5K OFF ON ON

Undefined(Defaults to 19200) ON ON ON

Stop Bit S1-4

1 OFF

2 ON

Parity S1-5 S1-6

None OFF OFF

Odd ON OFF

Even OFF ON

Data Bits S1-7

8 OFF

7 ON

Modbus Mode S1-8

RTU OFF

ASCII ON

ProSoft Technology, Inc. Page 17 of 55

October 27, 2010

Page 18

Module Configuration and Installation 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

Address S2-1 S2-2 S2-3 S2-4 S2-5 S2-6 S2-7

0 OFF OFF OFF OFF OFF OFF OFF

1 ON OFF OFF OFF OFF OFF OFF

2 OFF ON OFF OFF OFF OFF OFF

3 ON ON OFF OFF OFF OFF OFF

4 ON OFF ON OFF OFF OFF OFF

5 OFF ON ON OFF OFF OFF OFF

6 ON ON ON OFF OFF OFF OFF

127 ON ON ON ON ON ON ON

Last State S2-8

Off OFF

Hold ON

Address 0 - Test Mode - Puts unit into a transmit only mode. Connect a terminal

at 19200 baud, 8N1 to view data.

Address 1 to 127 Valid Slave addresses.

Page 18 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 19

3170-MBS ♦ Flex Platform Module Addressing

Modbus Slave Interface Module User Manual

4 Module Addressing

In This Chapter

Reading Discrete Inputs ........................................................................ 20

Writing Discrete Outputs........................................................................ 21

Each Flex or Integra module has 60 words of address space. 30 Input or Read

address and 30 Output or Write addresses. Data is mapped in two ways

Horizontal and Vertical.

With Horizontal addressing the adapter address the first input and output word

for each module incrementally. 40001 for module 0, 40002 for module 1 and so

on.

Vertical addressing increments the words for each module. For example, the

vertical read words for slot 0 start with 41001 and increment to 41015.

ProSoft Technology, Inc. Page 19 of 55

October 27, 2010

Page 20

Module Addressing 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

4.1 Reading Discrete Inputs

Each word address consists of 16 bits. These bits can be read as discrete inputs.

Word address 40001 corresponds to discrete inputs 10001 to 10016. 40002

corresponds to discrete inputs 10017 to 10032.

((Address - 40001) X 16) + 10001 This will give you Input address 0 of the

word.

Page 20 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 21

3170-MBS ♦ Flex Platform Module Addressing

Modbus Slave Interface Module User Manual

4.2 Writing Discrete Outputs

Each word address consists of 16 bits. These bits can be written as discrete

outputs. Word address 40201 corresponds to discrete outputs 3201 to 3216.

40202 corresponds to discrete outputs 3217 to 3232.

((Address - 40001) X 16) + 1 This will give you the Output address 0 of the

word.

ProSoft Technology, Inc. Page 21 of 55

October 27, 2010

Page 22

Module Addressing 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

Page 22 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 23

3170-MBS ♦ Flex Platform Status Information

Modbus Slave Interface Module User Manual

5 Status Information

In This Chapter

Adapter Status Word ............................................................................. 24

Module Status Words ............................................................................ 25

Module Information ................................................................................ 26

Modbus Function Counters ................................................................... 27

Modbus Status ...................................................................................... 28

ProSoft Technology, Inc. Page 23 of 55

October 27, 2010

Page 24

Status Information 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

5.1 Adapter Status Word

Bit: 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 40121

Not

Used

The input status word consists of:

I/O module fault bits - 1 status bit for each slot

I/O Last state Dip Switch S2-8(See 3170-MBS installation manual)

Bit Description Bit Explanation

I/O Module Fault

I/O Last State

0 This bit is set (1) when an error is detected in slot position 0.

1 This bit is set (1) when an error is detected in slot position 1.

2 This bit is set (1) when an error is detected in slot position 2.

3 This bit is set (1) when an error is detected in slot position 3.

4 This bit is set (1) when an error is detected in slot position 4.

5 This bit is set (1) when an error is detected in slot position 5.

6 This bit is set (1) when an error is detected in slot position 6.

7 This bit is set (1) when an error is detected in slot position 7.

8 = 1 for hold last state = 0 for off

9 to 15 Not used set to 0

I/O

Address

Slot 7 Slot 6 Slot 5 Slot 4 Slot 3 Slot 2 Slot 1 Slot 0

State

The adapter input status word bit descriptions are shown in the following table.

Page 24 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 25

3170-MBS ♦ Flex Platform Status Information

Bit:

Modbus Slave Interface Module User Manual

5.2 Module Status Words

Slot Status: indicates the general health of the installed I/O module

Number of Words: either 3 or 15 words indeterminate if slot is empty.

Number of Read Words: the number of words which are to be read from the

I/O module, indeterminate if slot is empty.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 40122

Status Total

Words

Type ID: a byte when combined with the Number of Words and Number of

Read Words form the Module ID which uniquely identifies a specific module

function, series and revision, indeterminate if slot is empty. Note that all of

bits 0 through 12 should be used in identifying a module.

Bit 15 1 = No answer, empty slot or dead module

Bit 14 1 = Either positive edge of bit 15 or bit 13 detected

Bit 13 1 = Bit failure, bad data on SerBus

Bit 12 1 = Number of words is 15, = 0 number of words is 3

Bits 11 to 8 Value = number of read words

Bits 7 to 0 Value = Type ID

Read

Words

Type

Identity

Address

to 40129

ProSoft Technology, Inc. Page 25 of 55

October 27, 2010

Page 26

Status Information 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

5.3 Module Information

3170-MBS Information Address

3170-MBS Product Revision Level 40154

3170-MBS Product Batch Number 40155

Page 26 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 27

3170-MBS ♦ Flex Platform Status Information

Modbus Slave Interface Module User Manual

5.4 Modbus Function Counters

Modbus Port Function Code Counter Address

Function Code 1 40156

Function Code 2 40157

Function Code 3 40158

Function Code 4 40159

Function Code 5 40160

Function Code 6 40161

Reserved 40162

Function Code 16 40163

Modbus Status Address

Modbus Port: Responses to Host 40171

Modbus Port: No Responses to Host 40172

Modbus Port: Last Detected Error Condition 40173

ProSoft Technology, Inc. Page 27 of 55

October 27, 2010

Page 28

Status Information 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

5.5 Modbus Status

Responses to Host: This rollover counter increments every time a response is

issued by the 3170-MBS. Note that this counter increments whether the

response is a data response or an error code response.

No Responses to Host: This rollover counter increments every time a command

is seen on the Modbus port, which is not for this slave. This counter may be used

as a network activity counter.

Last Detected Error Condition: This value is the last error code transmitted to the

master by the 3170-MBS.

5.5.1 Error Codes

Code Name Description

0 All OK The port is operating as desired

1 Illegal Function An illegal function code request is being attempted

2 Bad Data Address The address, or the range of addresses, covered by a

3 Bad Data Value The value in the data field of the command from the host

4 Incomplete Response

Detected

10 Buffer Overflow The receive buffer has overflowed and reset the

254 Checksum Error The slave determined that the message checksum was in

request from the host is not within allowed limits

is not allowed.

This error indicates that an incomplete query was

received from a host query. This indicates that the slave

port is timing out too quickly (that is, application may

require some Inter-character Timeout Delay) or that the

host query is getting abbreviated, possibly by the

transmitting modem (last character getting dropped).

character count to 0. If this condition occurs try reading

fewer parameters at one time

error, and therefore discarded the message

Page 28 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 29

3170-MBS ♦ Flex Platform Diagnostics and Troubleshooting

Modbus Slave Interface Module User Manual

6 Diagnostics and Troubleshooting

In This Chapter

LED Indicators ....................................................................................... 30

Troubleshooting: General ...................................................................... 31

The module provides information on diagnostics and troubleshooting in the

following forms:

LED status indicators on the front of the module provide general information

on the module's status.

Several hardware diagnostic capabilities have been implemented using the LED

indicator lights on the front of the adapter module. The following topics explain

the meaning of the individual LEDs and provide some troubleshooting tips.

ProSoft Technology, Inc. Page 29 of 55

October 27, 2010

Page 30

Diagnostics and Troubleshooting 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

6.1 LED Indicators

The following explains the operation of the LEDs.

LED Color Status Indication

Power Green On

Transmit Green Blink The Modbus port is transmitting data.

Receive Green Blink The Modbus port is receiving data. LED flashes on any character

COM

ERR

Amber Off

Normal state: The module is operating normally, with

communications being detected on the link

Blink

Modbus Communication Timeout: The port has not detected any

communications on the link for over 1 second. If the HOLD LAST

STATE dip switch is not set, the Input and Output images will be

forced to zero(0).

FLEX Backplane Communications Fail: The communication

adapter either does not detect any I/O modules plugged into the

backplane, or the backplane communications have failed.

activity, valid or invalid.

Normal State: When the error LED is off and the related port is

actively transferring data, there are no communication errors

Blink Periodic communication errors are occurring during data

communications. Error conditions that cause LED to blink include:

Bad Function Code

Invalid Register Address in command

Invalid Count value in command

Insufficient Characters in Modbus Packet

Checksum Error detected in packet

FLEX Backplane Communications Fail: The communication

adapter either does not detect any I/O modules plugged into the

backplane, or the backplane communications have failed

On This LED will stay on under several conditions:

Configuration Error

Recurring communication error

Page 30 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 31

3170-MBS ♦ Flex Platform Diagnostics and Troubleshooting

Modbus Slave Interface Module User Manual

6.2 Troubleshooting: General

In order to assist in the troubleshooting of the adapter, the following table has

been put together. Use the following table to assist in application of the module,

but if additional questions or problems arise, please do not hesitate to contact us.

Problem Description Steps to take

No communications with

Host

RX LED on continuously Verify the polarity of the RS-485 communications connections. Not

COMM ERR LED blinks

periodically

Outputs Toggle Off If the HOLD LAST STATE dip switch is not set, the Output Image

ProSoft Technology, Inc. Page 31 of 55

October 27, 2010

If connected to the host and no communications are occurring, verify

the following:

Polarity of RS-485 cable connections (Either RX LED on

continuously or not toggling at all)

Slave Address: Valid addresses range from 1 to 127. Verify that

the address is encoded into the dip switch correctly

Baud Rate

Stop Bits, Parity, and Modbus Mode. There are valid

combinations of these parameters which are supported by the

adapter hardware. Verify that the configuration is one of the

following:

Modbus RTU and ASCII Modes

8 Data Bits, No Parity, 1 Stop

8 Data Bits, No Parity, 2 Stop

8 Data Bits, Odd Parity, 1 Stop

8 Data Bits, Even Parity, 1 Stop

Modbus ASCII Mode Only:

7 Data Bits, No Parity, 2 Stop

7 Data Bits, Odd Parity, 1 Stop

7 Data Bits, Even Parity, 1 Stop

7 Data Bits, Odd Parity, 2 Stop

7 Data Bits, Even Parity, 2 Stop

Modbus Mode: Verify that the host and the adapter are talking the

same implementation of the protocol, either RTU or ASCII.

all manufacturers adhere to the same +/- and A/B labeling

conventions. Do not be afraid to experiment with swapping the

polarity, no damage will occur to the hardware.

Periodic communication errors are occurring during data

communications. Error conditions which cause LED to blink include:

Bad Function Code

Invalid Register Address in command

Invalid Count value in command

Insufficient Characters in Modbus Packet

Checksum Error detected in packet

FLEX Backplane Communications Fail: The communication

adapter either does not detect any I/O modules plugged into the

backplane, or the backplane communications have failed

(and the Input Image) in the adapter will be forced to zero whenever

communications with the host has not been detected for over 1

second. The Outputs will be re-established by the adapter as soon

as a valid write command is received from the host.

To prevent the Toggling of the outputs, either set the HOLD LAST

STATE dip switch (S2 position 8), and/or assure the reliability of the

communications.

Page 32

Diagnostics and Troubleshooting 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

Page 32 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 33

3170-MBS ♦ Flex Platform Example Address Mapping

Modbus Slave Interface Module User Manual

7 Example Address Mapping

In This Chapter

Application Example .............................................................................. 34

Address Map ......................................................................................... 35

Function Code Address Ranges ............................................................ 37

Work Sheets .......................................................................................... 38

ProSoft Technology, Inc. Page 33 of 55

October 27, 2010

Page 34

Example Address Mapping 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

7.1 Application Example

Use the information provided with your I/O to fill in the work sheets (page 38).

This will help you to decide the best way to address each I/O block.

In most applications Analog I/O will be addressed using the Vertical method.

Discrete I/O must be addressed using the Horizontal method only.

The Input Data will be read vertically as holding registers

The Underrange bits will be read as inputs

The Configuration Selection bits will be written as coils.

Page 34 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 35

3170-MBS ♦ Flex Platform Example Address Mapping

Modbus Slave Interface Module User Manual

7.2 Address Map

Slot 0-H Slot 0-V Slot 1-H Slot 1-V Slot 2-H Slot 2-V Slot 3-H Slot 3-V

READ 40001 41001 40002 41016 40003 41031 40004 41046

40009 41002 40010 41017 40011 41032 40012 41047

40017 41003 40018 41018 40019 41033 40020 41048

40025 41004 40026 41019 40027 41034 40028 41049

40033 41005 40034 41020 40035 41035 40036 41050

40041 41006 40042 41021 40043 41036 40044 41051

40049 41007 40050 41022 40051 41037 40052 41052

40057 41008 40058 41023 40059 41038 40060 41053

40065 41009 40066 41024 40067 41039 40068 41054

40073 41010 40074 41025 40075 41040 40076 41055

40081 41011 40082 41026 40083 41041 40084 41056

40089 41012 40090 41027 40091 41042 40092 41057

40097 41013 40098 41028 40099 41043 40100 41058

40105 41014 40106 41029 40107 41044 40108 41059

40113 41015 40114 41030 40115 41045 40116 41060

Slot 4-H Slot 4-V Slot 5-H Slot 5-V Slot 6-H Slot 6-V Slot 7-H Slot 7-V

READ 40005 41061 40006 41076 40007 41091 40008 41106

40013 41062 40014 41077 40015 41092 40016 41107

40021 41063 40022 41078 40023 41093 40024 41108

40029 41064 40030 41079 40031 41094 40032 41109

40037 41065 40038 41080 40039 41095 40040 41110

40045 41066 40046 41081 40047 41096 40048 41111

40053 41067 40054 41082 40055 41097 40056 41112

40061 41068 40062 41083 40063 41098 40064 41113

40069 41069 40070 41084 40071 41099 40072 41114

40077 41070 40078 41085 40079 41100 40080 41115

40085 41071 40086 41086 40087 41101 40088 41116

40093 41072 40094 41087 40095 41102 40096 41117

40101 41073 40102 41088 40103 41103 40104 41118

40109 41074 40110 41089 40111 41104 40112 41119

40117 41075 40118 41090 40119 41105 40120 41120

Slot 0-H Slot04-V Slot 1-H Slot 1-V Slot 2-H Slot 2-V Slot 3-H Slot 3-V

ProSoft Technology, Inc. Page 35 of 55

October 27, 2010

Page 36

Example Address Mapping 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

Slot 0-H Slot04-V Slot 1-H Slot 1-V Slot 2-H Slot 2-V Slot 3-H Slot 3-V

WRITE 40201 41201 40202 41216 40203 41231 40204 41246

40209 41202 40210 41217 40211 41232 40212 41247

40217 41203 40218 41218 40219 41233 40220 41248

40225 41204 40226 41219 40227 41234 40228 41249

40233 41205 40234 41220 40235 41235 40236 41250

40241 41206 40242 41221 40243 41236 40244 41251

40249 41207 40250 41222 40251 41237 40252 41252

40257 41208 40258 41223 40259 41238 40260 41253

40265 41209 40266 41224 40267 41239 40268 41254

40273 41210 40274 41225 40275 41240 40276 41255

40281 41211 40282 41226 40283 41241 40284 41256

40289 41212 40290 41227 40291 41242 40292 41257

40297 41213 40298 41228 40299 41243 40300 41258

40305 41214 40306 41229 40307 41244 40308 41259

40313 41215 40314 41230 40315 41245 40316 41260

Slot 4-H Slot 4-V Slot 5-H Slot 5-V Slot 6-H Slot 6-V Slot 7-H Slot 7-V

WRITE 40205 41261 40206 41276 40207 41291 40208 41306

40294 41262 40214 41277 40215 41292 40216 41307

40383 41263 40222 41278 40223 41293 40224 41308

40472 41264 40230 41279 40231 41294 40232 41309

40561 41265 40238 41280 40239 41295 40240 41310

40650 41266 40246 41281 40247 41296 40248 41311

40739 41267 40254 41282 40255 41297 40256 41312

40828 41268 40262 41283 40263 41298 40264 41313

40917 41269 40270 41284 40271 41299 40272 41314

41006 41270 40278 41285 40279 41300 40280 41315

41095 41271 40286 41286 40287 41301 40288 41316

41184 41272 40294 41287 40295 41302 40296 41317

41273 41273 40302 41288 40303 41303 40304 41318

41362 41274 40310 41289 40311 41304 40312 41319

41451 41275 40318 41290 40319 41305 40320 41320

Page 36 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 37

3170-MBS ♦ Flex Platform Example Address Mapping

Modbus Slave Interface Module User Manual

7.3 Function Code Address Ranges

Function Address

Type

1 Bit 0 to 1919 40001 to

Bit 3200 to 5119 40200 to

2 Bit 0 to 1919 40001 to

Bit 3200 to 5119 40200 to

3 Register 0 to 119 40001 to

Register 200 to 319 40200 to

4 Register 0 to 119 40001 to

Register 200 to 319 40200 to

5 Bit N/A N/A 3200 to 5119 40201 to

6 Register N/A N/A 200 to 319 40201 to

16 Register N/A N/A 200 to 319 40201 to

Horizontal

Read

Modbus

Address

40120

40320

40120

40320

40120

40320

40120

40320

Horizontal

Write

N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A

N/A N/A 1000 to

N/A N/A 1200 to

N/A N/A 1000 to

N/A N/A 1200 to

Modbus

Address

40320

40320

40320

Vertical

Read

1119

1319

1119

1319

Modbus

Address

41001 to

41120

41201 to

41320

41001 to

41120

41201 to

41320

Vertical

Write

Modbus

Address

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A N/A N/A

N/A N/A 1200 to

1319

N/A N/A 1200 to

1319

41201 to

41320

41201 to

41320

ProSoft Technology, Inc. Page 37 of 55

October 27, 2010

Page 38

Example Address Mapping 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

7.4 Work Sheets

Slot 0 Module Image Input Data HORIZ VERT

40001 41001

40009 41002

40017 41003

40025 41004

40033 41005

40041 41006

40049 41007

40057 41008

40065 41009

40073 41010

40081 41011

40089 41012

40097 41013

40105 41014

40113 41015

Slot 0 Module Image Output Data HORIZ VERT

40201 41201

40209 41202

40217 41203

40225 41204

40233 41205

40241 41206

40249 41207

40257 41208

40265 41209

40273 41210

40281 41211

40289 41212

40297 41213

40305 41214

40313 41215

Slot 1 Module Image Input Data HORIZ VERT

40002 41016

40010 41017

40018 41018

40026 41019

Page 38 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 39

3170-MBS ♦ Flex Platform Example Address Mapping

Modbus Slave Interface Module User Manual

Slot 1 Module Image Input Data HORIZ VERT

40034 41020

40042 41021

40050 41022

40058 41023

40066 41024

40074 41025

40082 41026

40090 41027

40098 41028

40106 41029

40114 41030

Slot 1 Module Image Output Data HORIZ VERT

40202 41216

40210 41217

40218 41218

40226 41219

40234 41220

40242 41221

40250 41222

40258 41223

40266 41224

40274 41225

40282 41226

40290 41227

40298 41228

40306 41229

40314 41230

Slot 2 Module Image Input Data HORIZ VERT

40003 41031

40011 41032

40019 41033

40027 41034

40035 41035

40043 41036

40051 41037

40059 41038

40067 41039

40075 41040

ProSoft Technology, Inc. Page 39 of 55

October 27, 2010

Page 40

Example Address Mapping 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

Slot 2 Module Image Input Data HORIZ VERT

40083 41041

40091 41042

40099 41043

40107 41044

40115 41045

Slot 2 Module Image Output Data HORIZ VERT

40203 41231

40211 41232

40219 41233

40227 41234

40235 41235

40243 41236

40251 41237

40259 41238

40267 41239

40275 41240

40283 41241

40291 41242

40299 41243

40307 41244

40315 41245

Slot 3 Module Image Input Data HORIZ VERT

40004 41046

40012 41047

40020 41048

40028 41049

40036 41050

40044 41051

40052 41052

40060 41053

40068 41054

40076 41055

40084 41056

40092 41057

40100 41058

40108 41059

40116 41060

Page 40 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 41

3170-MBS ♦ Flex Platform Example Address Mapping

Modbus Slave Interface Module User Manual

Slot 3 Module Image Output Data HORIZ VERT

40204 41246

40212 41247

40220 41248

40228 41249

40236 41250

40244 41251

40252 41252

40260 41253

40268 41254

40276 41255

40284 41256

40292 41257

40300 41258

40308 41259

40316 41260

Slot 4 Module Image Input Data HORIZ VERT

40005 41061

40013 41062

40021 41063

40029 41064

40037 41065

40045 41066

40053 41067

40061 41068

40069 41069

40077 41070

40085 41071

40093 41072

40101 41073

40109 41074

40117 41075

Slot 4 Module Image Output Data HORIZ VERT

40205 41261

40213 41262

40221 41263

40229 41264

40237 41265

40245 41266

ProSoft Technology, Inc. Page 41 of 55

October 27, 2010

Page 42

Example Address Mapping 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

Slot 4 Module Image Output Data HORIZ VERT

40253 41267

40261 41268

40269 41269

41277 41270

41285 41271

41293 41272

41301 41273

41309 41274

41317 41275

Slot 5 Module Image Input Data HORIZ VERT

40006 41076

40014 41077

40022 41078

40030 41079

40038 41080

40046 41081

40054 41082

40062 41083

40070 41084

40078 41085

40086 41086

40094 41087

40102 41088

40110 41089

40118 41090

Slot 5 Module Image Output Data HORIZ VERT

40206 41276

40214 41277

40222 41278

40230 41279

40238 41280

40246 41281

40254 41282

40262 41283

40270 41284

40278 41285

40286 41286

40294 41287

Page 42 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 43

3170-MBS ♦ Flex Platform Example Address Mapping

Modbus Slave Interface Module User Manual

Slot 5 Module Image Output Data HORIZ VERT

40302 41288

40310 41289

40318 41290

Slot 6 Module Image Input Data HORIZ VERT

40007 41091

40015 41092

40023 41093

40031 41094

40039 41095

40047 41096

40055 41097

40063 41098

40071 41099

40079 41100

40087 41101

40095 41102

40103 41103

40111 41104

40119 41105

Slot 6 Module Image Output Data HORIZ VERT

40207 41291

40215 41292

40223 41293

40231 41294

40239 41295

40247 41296

40255 41297

40263 41298

40271 41299

40279 41300

40287 41301

40295 41302

40303 41303

40311 41304

40319 41305

ProSoft Technology, Inc. Page 43 of 55

October 27, 2010

Page 44

Example Address Mapping 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

Slot 7 Module Image Input Data HORIZ VERT

40008 41106

40016 41107

40024 41108

40032 41109

40040 41110

40048 41111

40056 41112

40064 41113

40072 41114

40080 41115

40088 41116

40096 41117

40104 41118

40112 41119

40120 41120

Slot 7 Module Image Output Data HORIZ VERT

40208 41306

40216 41307

40224 41308

40232 41309

40240 41310

40248 41311

40256 41312

40264 41313

40272 41314

40280 41315

40288 41316

40296 41317

40304 41318

40312 41319

40320 41320

Page 44 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 45

3170-MBS ♦ Flex Platform Support, Service & Warranty

Modbus Slave Interface Module User Manual

8 Support, Service & Warranty

In This Chapter

Contacting Technical Support ............................................................... 45

Return Material Authorization (RMA) Policies and Conditions ............... 47

LIMITED WARRANTY ........................................................................... 49

Contacting Technical Support

ProSoft Technology, Inc. (ProSoft) is committed to providing the most efficient

and effective support possible. Before calling, please gather the following

information to assist in expediting this process:

1 Product Version Number

2 System architecture

3 Network details

If the issue is hardware related, we will also need information regarding:

1 Module configuration and associated ladder files, if any

2 Module operation and any unusual behavior

3 Configuration/Debug status information

4 LED patterns

5 Details about the serial, Ethernet or fieldbus devices interfaced to the module,

if any.

Note: For technical support calls within the United States, an after-hours answering system allows

24-hour/7-days-a-week pager access to one of our qualified Technical and/or Application Support

Engineers.

ProSoft Technology, Inc. Page 45 of 55

October 27, 2010

Page 46

Support, Service & Warranty 3170-MBS ♦ Flex Platform

Internet

User Manual Modbus Slave Interface Module

Web Site: www.prosoft-technology.com/support

E-mail address: support@prosoft-technology.com

Asia Pacific

(location in Malaysia)

Asia Pacific

(location in China)

Europe

(location in Toulouse,

France)

Europe

(location in Dubai, UAE)

Tel: +603.7724.2080, E-mail: asiapc@prosoft-technology.com

Languages spoken include: Chinese, English

Tel: +86.21.5187.7337 x888, E-mail: asiapc@prosoft-technology.com

Languages spoken include: Chinese, English

Tel: +33 (0) 5.34.36.87.20,

E-mail: support.EMEA@prosoft-technology.com

Languages spoken include: French, English

Tel: +971-4-214-6911,

E-mail: mea@prosoft-technology.com

Languages spoken include: English, Hindi

North America

(location in California)

Tel: +1.661.716.5100,

E-mail: support@prosoft-technology.com

Languages spoken include: English, Spanish

Latin America

(Oficina Regional)

Tel: +1-281-2989109,

E-Mail: latinam@prosoft-technology.com

Languages spoken include: Spanish, English

Latin America

(location in Puebla, Mexico)

Tel: +52-222-3-99-6565,

E-mail: soporte@prosoft-technology.com

Languages spoken include: Spanish

Brasil

(location in Sao Paulo)

Tel: +55-11-5083-3776,

E-mail: brasil@prosoft-technology.com

Languages spoken include: Portuguese, English

Page 46 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 47

3170-MBS ♦ Flex Platform Support, Service & Warranty

Modbus Slave Interface Module User Manual

8.1 Return Material Authorization (RMA) Policies and Conditions

The following Return Material Authorization (RMA) Policies and Conditions

(collectively, "RMA Policies") apply to any returned product. These RMA Policies

are subject to change by ProSoft Technology, Inc., without notice. For warranty

information, see Limited Warranty (page 49). In the event of any inconsistency

between the RMA Policies and the Warranty, the Warranty shall govern.

8.1.1 Returning Any Product

a) In order to return a Product for repair, exchange, or otherwise, the

Customer must obtain a Return Material Authorization (RMA) number

from ProSoft Technology and comply with ProSoft Technology shipping

instructions.

b) In the event that the Customer experiences a problem with the Product for

any reason, Customer should contact ProSoft Technical Support at one of

the telephone numbers listed above (page 45). A Technical Support

Engineer will request that you perform several tests in an attempt to

isolate the problem. If after completing these tests, the Product is found to

be the source of the problem, we will issue an RMA.

c) All returned Products must be shipped freight prepaid, in the original

shipping container or equivalent, to the location specified by ProSoft

Technology, and be accompanied by proof of purchase and receipt date.

The RMA number is to be prominently marked on the outside of the

shipping box. Customer agrees to insure the Product or assume the risk

of loss or damage in transit. Products shipped to ProSoft Technology

using a shipment method other than that specified by ProSoft Technology,

or shipped without an RMA number will be returned to the Customer,

freight collect. Contact ProSoft Technical Support for further information.

d) A 10% restocking fee applies to all warranty credit returns, whereby a

Customer has an application change, ordered too many, does not need,

etc. Returns for credit require that all accessory parts included in the

original box (i.e.; antennas, cables) be returned. Failure to return these

items will result in a deduction from the total credit due for each missing

item.

ProSoft Technology, Inc. Page 47 of 55

October 27, 2010

Page 48

Support, Service & Warranty 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

8.1.2 Returning Units Under Warranty

A Technical Support Engineer must approve the return of Product under ProSoft

Technology’s Warranty:

a) A replacement module will be shipped and invoiced. A purchase order will

be required.

b) Credit for a product under warranty will be issued upon receipt of

authorized product by ProSoft Technology at designated location

referenced on the Return Material Authorization

i. If a defect is found and is determined to be customer generated, or if

the defect is otherwise not covered by ProSoft Technology s warranty,

there will be no credit given. Customer will be contacted and can

request module be returned at their expense;

ii. If defect is customer generated and is repairable, customer can

authorize ProSoft Technology to repair the unit by providing a

purchase order for 30% of the current list price plus freight charges,

duties and taxes as applicable.

8.1.3 Returning Units Out of Warranty

a) Customer sends unit in for evaluation to location specified by ProSoft

Technology, freight prepaid.

b) If no defect is found, Customer will be charged the equivalent of $100

USD, plus freight charges, duties and taxes as applicable. A new

purchase order will be required.

c) If unit is repaired, charge to Customer will be 30% of current list price

(USD) plus freight charges, duties and taxes as applicable. A new

purchase order will be required or authorization to use the purchase order

submitted for evaluation fee.

The following is a list of non-repairable units:

o

3150 - All

o

3750

o

3600 - All

o

3700

o

3170 - All

o

3250

o

1560 - Can be repaired, only if defect is the power supply

o

1550 - Can be repaired, only if defect is the power supply

o

3350

o

3300

o

1500 - All

Page 48 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 49

3170-MBS ♦ Flex Platform Support, Service & Warranty

Modbus Slave Interface Module User Manual

8.2 LIMITED WARRANTY

This Limited Warranty ("Warranty") governs all sales of hardware, software, and

other products (collectively, "Product") manufactured and/or offered for sale by

ProSoft Technology, Incorporated (ProSoft), and all related services provided by

ProSoft, including maintenance, repair, warranty exchange, and service

programs (collectively, "Services"). By purchasing or using the Product or

Services, the individual or entity purchasing or using the Product or Services

("Customer") agrees to all of the terms and provisions (collectively, the "Terms")

of this Limited Warranty. All sales of software or other intellectual property are, in

addition, subject to any license agreement accompanying such software or other

intellectual property.

8.2.1 What Is Covered By This Warranty

a) Warranty On New Products: ProSoft warrants, to the original purchaser,

that the Product that is the subject of the sale will (1) conform to and

perform in accordance with published specifications prepared, approved

and issued by ProSoft, and (2) will be free from defects in material or

workmanship; provided these warranties only cover Product that is sold as

new. This Warranty expires three (3) years from the date of shipment for

Product purchased on or after January 1st, 2008, or one (1) year from the

date of shipment for Product purchased before January 1st, 2008 (the

"Warranty Period"). If the Customer discovers within the Warranty Period

a failure of the Product to conform to specifications, or a defect in material

or workmanship of the Product, the Customer must promptly notify

ProSoft by fax, email or telephone. In no event may that notification be

received by ProSoft later than 39 months from date of original shipment.

Within a reasonable time after notification, ProSoft will correct any failure

of the Product to conform to specifications or any defect in material or

workmanship of the Product, with either new or remanufactured

replacement parts. ProSoft reserves the right, and at its sole discretion,

may replace unrepairable units with new or remanufactured equipment.

All replacement units will be covered under warranty for the 3 year period

commencing from the date of original equipment purchase, not the date of

shipment of the replacement unit. Such repair, including both parts and

labor, will be performed at ProSoft’s expense. All warranty service will be

performed at service centers designated by ProSoft.

b) Warranty On Services: Materials and labor performed by ProSoft to repair

a verified malfunction or defect are warranteed in the terms specified

above for new Product, provided said warranty will be for the period

remaining on the original new equipment warranty or, if the original

warranty is no longer in effect, for a period of 90 days from the date of

repair.

ProSoft Technology, Inc. Page 49 of 55

October 27, 2010

Page 50

Support, Service & Warranty 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

8.2.2 What Is Not Covered By This Warranty

a) ProSoft makes no representation or warranty, expressed or implied, that

the operation of software purchased from ProSoft will be uninterrupted or

error free or that the functions contained in the software will meet or

satisfy the purchaser’s intended use or requirements; the Customer

assumes complete responsibility for decisions made or actions taken

based on information obtained using ProSoft software.

b) This Warranty does not cover the failure of the Product to perform

specified functions, or any other non-conformance, defects, losses or

damages caused by or attributable to any of the following: (i) shipping; (ii)

improper installation or other failure of Customer to adhere to ProSoft’s

specifications or instructions; (iii) unauthorized repair or maintenance; (iv)

attachments, equipment, options, parts, software, or user-created

programming (including, but not limited to, programs developed with any

IEC 61131-3, "C" or any variant of "C" programming languages) not

furnished by ProSoft; (v) use of the Product for purposes other than those

for which it was designed; (vi) any other abuse, misapplication, neglect or

misuse by the Customer; (vii) accident, improper testing or causes

external to the Product such as, but not limited to, exposure to extremes

of temperature or humidity, power failure or power surges; or (viii)

disasters such as fire, flood, earthquake, wind and lightning.

c) The information in this Agreement is subject to change without notice.

ProSoft shall not be liable for technical or editorial errors or omissions

made herein; nor for incidental or consequential damages resulting from

the furnishing, performance or use of this material. The user guide

included with your original product purchase from ProSoft contains

information protected by copyright. No part of the guide may be duplicated

or reproduced in any form without prior written consent from ProSoft.

8.2.3 Disclaimer Regarding High Risk Activities

Product manufactured or supplied by ProSoft is not fault tolerant and is not

designed, manufactured or intended for use in hazardous environments requiring

fail-safe performance including and without limitation: the operation of nuclear

facilities, aircraft navigation of communication systems, air traffic control, direct

life support machines or weapons systems in which the failure of the product

could lead directly or indirectly to death, personal injury or severe physical or

environmental damage (collectively, "high risk activities"). ProSoft specifically

disclaims any express or implied warranty of fitness for high risk activities.

Page 50 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 51

3170-MBS ♦ Flex Platform Support, Service & Warranty

Modbus Slave Interface Module User Manual

8.2.4 Intellectual Property Indemnity

Buyer shall indemnify and hold harmless ProSoft and its employees from and

against all liabilities, losses, claims, costs and expenses (including attorney’s

fees and expenses) related to any claim, investigation, litigation or proceeding

(whether or not ProSoft is a party) which arises or is alleged to arise from Buyer’s

acts or omissions under these Terms or in any way with respect to the Products.

Without limiting the foregoing, Buyer (at its own expense) shall indemnify and

hold harmless ProSoft and defend or settle any action brought against such

Companies to the extent based on a claim that any Product made to Buyer

specifications infringed intellectual property rights of another party. ProSoft

makes no warranty that the product is or will be delivered free of any person’s

claiming of patent, trademark, or similar infringement. The Buyer assumes all

risks (including the risk of suit) that the product or any use of the product will

infringe existing or subsequently issued patents, trademarks, or copyrights.

a) Any documentation included with Product purchased from ProSoft is

protected by copyright and may not be duplicated or reproduced in any

form without prior written consent from ProSoft.

b) ProSoft’s technical specifications and documentation that are included

with the Product are subject to editing and modification without notice.

c) Transfer of title shall not operate to convey to Customer any right to make,

or have made, any Product supplied by ProSoft.

d) Customer is granted no right or license to use any software or other

intellectual property in any manner or for any purpose not expressly

permitted by any license agreement accompanying such software or other

intellectual property.

e) Customer agrees that it shall not, and shall not authorize others to, copy

software provided by ProSoft (except as expressly permitted in any

license agreement accompanying such software); transfer software to a

third party separately from the Product; modify, alter, translate, decode,

decompile, disassemble, reverse-engineer or otherwise attempt to derive

the source code of the software or create derivative works based on the

software; export the software or underlying technology in contravention of

applicable US and international export laws and regulations; or use the

software other than as authorized in connection with use of Product.

f) Additional Restrictions Relating To Software And Other Intellectual

Property

In addition to compliance with the Terms of this Warranty, Customers

purchasing software or other intellectual property shall comply with any

license agreement accompanying such software or other intellectual

property. Failure to do so may void this Warranty with respect to such

software and/or other intellectual property.

8.2.5 Disclaimer of all Other Warranties

The Warranty set forth in What Is Covered By This Warranty (page 49) are in lieu

of all other warranties, express or implied, including but not limited to the implied

warranties of merchantability and fitness for a particular purpose.

ProSoft Technology, Inc. Page 51 of 55

October 27, 2010

Page 52

Support, Service & Warranty 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

8.2.6 Limitation of Remedies **

In no event will ProSoft or its Dealer be liable for any special, incidental or

consequential damages based on breach of warranty, breach of contract,

negligence, strict tort or any other legal theory. Damages that ProSoft or its

Dealer will not be responsible for include, but are not limited to: Loss of profits;

loss of savings or revenue; loss of use of the product or any associated

equipment; loss of data; cost of capital; cost of any substitute equipment,

facilities, or services; downtime; the claims of third parties including, customers of

the Purchaser; and, injury to property.

** Some areas do not allow time limitations on an implied warranty, or allow the exclusion or

limitation of incidental or consequential damages. In such areas, the above limitations may not

apply. This Warranty gives you specific legal rights, and you may also have other rights which vary

from place to place.

8.2.7 Time Limit for Bringing Suit

Any action for breach of warranty must be commenced within 39 months

following shipment of the Product.

8.2.8 No Other Warranties

Unless modified in writing and signed by both parties, this Warranty is

understood to be the complete and exclusive agreement between the parties,

suspending all oral or written prior agreements and all other communications

between the parties relating to the subject matter of this Warranty, including

statements made by salesperson. No employee of ProSoft or any other party is

authorized to make any warranty in addition to those made in this Warranty. The

Customer is warned, therefore, to check this Warranty carefully to see that it

correctly reflects those terms that are important to the Customer.

8.2.9 Allocation of Risks

This Warranty allocates the risk of product failure between ProSoft and the

Customer. This allocation is recognized by both parties and is reflected in the

price of the goods. The Customer acknowledges that it has read this Warranty,

understands it, and is bound by its Terms.

Page 52 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 53

3170-MBS ♦ Flex Platform Support, Service & Warranty

Modbus Slave Interface Module User Manual

8.2.10 Controlling Law and Severability

This Warranty shall be governed by and construed in accordance with the laws of

the United States and the domestic laws of the State of California, without

reference to its conflicts of law provisions. If for any reason a court of competent

jurisdiction finds any provisions of this Warranty, or a portion thereof, to be

unenforceable, that provision shall be enforced to the maximum extent

permissible and the remainder of this Warranty shall remain in full force and

effect. Any cause of action with respect to the Product or Services must be

instituted in a court of competent jurisdiction in the State of California.

ProSoft Technology, Inc. Page 53 of 55

October 27, 2010

Page 54

Support, Service & Warranty 3170-MBS ♦ Flex Platform

User Manual Modbus Slave Interface Module

Page 54 of 55 ProSoft Technology, Inc.

October 27, 2010

Page 55

3170-MBS ♦ Flex Platform Index

Modbus Slave Interface Module User Manual

Index

A

Adapter Status Word • 24

Address Map • 35

Allocation of Risks • 52

Application Example • 34

B

Battery Life Advisory • 3

C

Contacting Technical Support • 45, 47

Controlling Law and Severability • 53

D

Diagnostics and Troubleshooting • 29

Disclaimer of all Other Warranties • 51

Disclaimer Regarding High Risk Activities • 50

E

Error Codes • 28

Example Address Mapping • 33

F

Function Code Address Ranges • 37

Functional Overview • 11

G

General Specifications • 8

H

How to Contact Us • 2

I

Important Installation Instructions • 3

Installation • 14

Intellectual Property Indemnity • 51

L

LED Indicators • 30

Limitation of Remedies ** • 52

LIMITED WARRANTY • 47, 49

Module Status Words • 25

Mounting (or Replacing) the module on an existing

system • 15

Mounting on a DIN-rail before installing the terminal

base units • 14

MVI (Multi Vendor Interface) Modules • 3

N

No Other Warranties • 52

P

Pinouts • 3, 14, 15, 16

Product Specifications • 7

ProSoft Technology® Product Documentation • 2

R

Reading Discrete Inputs • 20

Return Material Authorization (RMA) Policies and

Conditions • 47

Returning Any Product • 47

Returning Units Out of Warranty • 48

Returning Units Under Warranty • 48

RS-485 and RS-422 Tip • 16

S

Setting the switches • 17

Status Information • 23

Support, Service & Warranty • 45

T

The Data Space in the module • 12

Time Limit for Bringing Suit • 52

Troubleshooting

General • 31

W

Warnings • 3

What Is Covered By This Warranty • 49, 51

What Is Not Covered By This Warranty • 50

Wiring • 16

Work Sheets • 34, 38

Writing Discrete Outputs • 21

Y

Your Feedback Please • 2

M

Markings • 4

Modbus Addressing Concepts • 11

Modbus Function Counters • 27

Modbus Specifications • 9

Modbus Status • 28

Module Addressing • 19

Module Configuration and Installation • 13

Module Information • 26

ProSoft Technology, Inc. Page 55 of 55

October 27, 2010

Loading...

Loading...