*36HULHV

+DUGZDUH0DQXDO

Preface

Thank you for purchasing Pro-face’s GP-4100 Series Programmable Operator Interface (Hereafter referred to as the “GP

unit”).

Before operating your GP unit, be sure to read this manual to familiarize yourself with the GP unit’s operation procedures

and features.

NOTICE

1. Copying this manual’s contents, either in whole or in part, is prohibited wi thout the express permission of Digital

Electronics Corporation, Japan.

2. The information contained in this manual is subject to change without notice.

3. If you should you find any errors or omissions in this document, please contact Digital Electronics Corporation to

report your findings.

4. Regardless of Clause 3 above, Digital Electronics Corporation shall not be held responsible for any damages,

losses or third-party damages resulting from the use of this product.

Copyright

Product names used in this manual are the trademarks / registered trademarks of their respective owners.

© 2012.11 Digital Electronics Corporation. All Rights Reserved.

1

Essential Safety Precautions

All safety-related procedures stated in this document must be followed to operate the GP correctly and safely. Be sure to

read this and any related documents thoroughly to understand the correct operation and functions of the GP unit.

Safety Icons

Throughout this manual, these icons provide essential safety information for GP operation procedures requiring special

attention. These icons indicate the following levels of danger:

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided,

can result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided,

can result in minor or moderate injury.

CAUTION

CAUTION, used without the safety alert symbol, indicates a potentially haz-

ardous situation which, if not avoided, can result in equipment damage.

2

WARNING

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• NEVER touch a live power terminal. Doing so could cause an electrical shock or a machine malfunction.

• Do not use voltage beyond the GP unit's specified range. Doing so may cause a fire or an electric shock.

• Do not disassemble or modify the GP unit. Doing so may cause a fire or an electric shock.

• Do not operate the GP in an environment where flammable gases are present since it may cause an

explosion.

• Do not allow water, liquids or metal fragments to enter inside the GP unit’s case, since they can cause

either a malfunction or an electric shock. The allowable pollution degree is 2.

• To prevent electrical shock or equipment damage, unplug the GP unit's power cord from the power supply

prior to installing or wiring the GP.

• The GP unit's wiring should be checked to confirm that both the operating voltage and wiring terminal

locations are correct. If either the voltage or the wiring terminal location is incorrect, it can cause a fire or

accident.

• Be sure to use only the designated torque to tighten the GP unit's terminal block screws. If these screws

are not tightened firmly, it may cause a short-circuit, fire or incorrect unit operation.

• Be sure that metal particles and wiring debris do not fall inside the GP unit. They can cause a fire, malfunction or incorrect unit operation.

• To prevent an electric shock, be sure to disconnect your GP unit's power cord from the power supply

before wiring the GP.

• Be sure to ground the GP unit's FG wire separately from other equipment FG lines. Also, be sure to use a

2

grounding resistance of 100Ω or less and a 2mm

standard. Otherwise, electric shock or malfunctions may result.

• To prevent an electrical shock, unplug the GP unit's power cord before either cleaning the GP or attaching/

detaching the power terminal attachment screws.

• Do not connect or disconnect Host and GP unit communication cab les while the GP is turned ON.

Failure to follow these instructions will result in death or serious injury, or unintended equipment

damage.

(14 AWG) or thicker wire, or your country’s applicable

3

WARNING

UNINTENDED EQUIPMENT OPERATION OR LOSS OF CONTROL

• Do not make switches using the switches on the touch panels which may cause operator injury and

machine damage. An output may remain either ON or OFF and a major accident can occur. To prevent

this, set up circuits such as limiters that will monitor vital output signals. Design switches for important

operations to be performed by separate devices. An incorrect output or malfunction can occur and thereby

cause an accident.

• Do not create GP touch panel switches to control machine safety operations, such as an emergency stop

switch. Install these switches as separate hardware switches, otherwise severe bodily injury or equipment

damage can occur.

• Do not use the GP as a warning device for critical alarms that can cause serious operator injury, machine

damage or can halt system operation. Critical alarm indicators and their control/activator units must be

designed using stand-alone hardware and/or mechanical interlocks.

• Be sure to design your system so that a communication interruption between the GP and its host controller

will not cause equipment to malfunction. This is to prevent any possibil ity of bodily injury or equipment

damage.

• Do not use the GP with aircraft control devices, aerospace equipment, central trunk data transmission

(communication) devices, nuclear power control devices, or medical life support equipment, due to these

devices' inherent requirements of extremely high levels of safety and reliability.

• When using the GP with transportation vehicles (trains, cars, and ships), disaster and crime prevention

devices, various types of safety equipment, and medical devices that are not life-support related, use

redundant and/or failsafe system designs to ensure proper reliability and safety.

• After the GP unit's backlight burns out the touch panel is still active, unlike the GP unit's "Standby Mode".

If the operator fails to notice that the backlight is burned out and touches the panel, a potentially dangerous machine operation error can occur. Therefore, do not create GP unit touch panel switches that may

cause injury and/or equipment damage. If your GP unit's backlight suddenly turns OFF, use the following

steps to determine if the backlight is actually burned out.

1) If the GP unit's "Backlight Control" is not set and the screen has gone blank, your backlight is

burned out.

2) If the GP unit's "Backlight Control" is set to Standby Mode and the screen has gone blank, and

touching the screen or performing another input operation does not cause the display to reappear,

your backlight is burned out.

• To prevent a GP unit malfunction due to excessive noise, isolate all GP input/output signal lines from all

power wiring or power cables via a separate wiring duct.

Failure to follow these instructions will result in death or serious injury, or unintended equipment

damage.

4

WARNING

UNINTENDED EQUIPMENT OPERATION OR LOSS OF CONTROL

• The cables connected to the GP should be secured by cable clamps to prevent weight or tension of the

cables added to the connectors or terminals.

• Be sure all cable connectors are securely attached to the GP unit. A loose connection may cause incorrect input or output signals.

• Do not press on the GP unit’s display with excessive force or with a hard object, since it can damage the

display. Also, do not press on the touch panel with a pointed object, such as the tip of a mechanical pencil

or a screwdriver, since doing so can damage the touch panel.

• Do not install the GP where the ambient temperature exceeds the specified range. Doing so may cause a

unit malfunction.

• To prevent abnormally high temperatures from occurring inside the GP, do not restrict or block the GP

unit's rear-face ventilation slots.

• Do not operate the GP in areas where large, sudden temperature changes can occur. These changes can

cause condensation to form inside the GP, possibly causing it to malfunction.

• Do not operate or store the GP in locations where it can be exposed to direct sunlight, high temperatures,

excessive dust, moisture or vibration.

• Do not operate or store the GP where chemicals evaporate, or where chemicals are present in the air.

Corrosive chemicals: Acids, alkalines, liquids containing salt

Flammable chemicals: Organic Solvents

• Do not use paint thinner or organic solvents to remove dirt or oil from the GP unit's surface. Instead, use a

soft cloth moistened with a diluted neutral detergent.

• Do not use or store the GP in areas with direct sunlight, since the sun's ultraviolet rays may cause the

LCD's quality to deteriorate.

• Do not store the GP in an area where the temperature is lower than that recommended in the GP unit's

specifications. Doing so may cause the LCD display's liquid to congeal, which can damage the LCD.

Also, if the storage area's temperature becomes higher than the specified level, the LCD's liquid may

become isotropic, causing irreversible damage to the LCD. Therefore, only store the GP in areas where

temperatures are within the GP unit's specifications.

• After turning OFF the GP, be sure to wait a few seconds before turning it ON again. The GP may not operate correctly if it is restarted too quickly.

Failure to follow these instructions will result in death or serious injury, or unintended equipment

damage.

5

CAUTION

EYE IRRITANT

• The unit's liquid crystal panel contains a powerful irritant. If, for any reason, the panel is damaged and this

liquid enters your eyes, flush your eyes for 15 minutes with running water and contact a physician immediately.

Failure to follow the instruction can result in injury.

CAUTION

LOSS OF DATA

• Be sure to back up the GP screen data in case they are lost accidentally.

Failure to follow the instruction can result in loss of data.

CAUTION

PROPER EQUIPMENT DISPOSAL REQUIREMENTS

• The unit should be disposed of in a manner appropriate to, and in accordance with, the user country's

industrial machinery disposal standards.

Failure to follow the instruction can result in equipment or environment damage.

6

LCD Panel Usage Precautions

• The LCD panel’s liquid contains an irritant. If the panel is damaged and any of this liquid contacts your skin,

immediately rinse the area with running water for at least 15 minutes. If the liquid gets in your eyes, immediately

rinseyour eyes with running water for at least 15 minutes and consult a doctor.

• The GP unit’s LCD screen may flicker or show unevenness in the brightness of certain images or at some contrast

settings. This is an LCD characteristic and not a product defect.

• There’s an individual dif ference in brightness and tone of LCD screen. Please be aware of this difference before using

the lined-up plural units.

• Depending on the ambient temperature, LCD displays may sometimes look whitish (at high temperatures) or blackish

(at low temperatures). This is an LCD characteristic and not a product defect.

• Some of GP unit’s LCD screens may contain light or dark pixels. This is an LCD characteristic and not a product

defect.

• Extended shadows, or “Crosstalk” may appear on the sides of screen images. This is an LCD characteristic and not a

product defect.

• The color displayed on the GP unit’s LCD screen may appear different when seen from outside the specified viewing

angle. This is an LCD characteristic and not a product defect.

• When the same image is displayed on the GP unit’s screen for a long period, an afterimage may appear when the image

is changed. This is an LCD characteristic and not a product defect.

• To prevent an afterimage:

* Set the GP unit’s display OFF feature when you plan to display the same screen image for a long period of time.

* Change the screen image periodically and try to not display the same image for a long period of time.

• Please be aware that characteristics of the GP unit’s LCD screen with a white/red LED backlight may change gradually

owing to the deterioration of the backlight LED. The white LCD display may look bluish when it turns on.

7

About the Manuals

For the detailed information on GP-4100 Series, refer to the following manuals.

• Maintenance/Troubleshooting

For the Offline Settings, see Maintenance/Troubleshooting (Offline Settings Guide).

• GP-Pro EX Device/PLC Connection Manual

• GP-Pro EX Reference Manual

The manuals can be downloaded from Pro-face Home Page “Otasuke Pro!”.

URL “Otasuke Pro!”

http://www.pro-face.com/otasuke/

Information Symbols

This manual uses the following icons:

Indicates a warning or a product limitation. Be sure to follow the instructions given with

this icon to ensure the safe operation of the GP.

Screen Editor Indicates the GP-Pro EX software.

PLC Abbreviation for Programmable Logic Controller.

* Indicates useful or importan t supplemental information.

Contains additional or useful information.

SEE

Indicates pages containing related information.

8

Model name

GP-4100 Series Model Name Indication

G P 41

A 1 GP-4100 Series (3.4-inch, 200 x 80 dots)

B 0 Normal resolution

C

D

E D DC24V type power supply is used.

0 * * 1

ABC ED

4 Ethernet type

5 RS-232C type

6 RS-422/485 type

7 RS-485 (isolation) type

G STN Monochrome Green/Orange/Red

W STN Monochrome White/Pink/Red

D

GP-4100 Series Model Names

Series Names Models

GP-4104

GP4104G1D

GP4104W1D

GP-4105

GP4000 Series GP-4100 Series

GP-4106

GP-4107

GP4105G1D

GP4105W1D

GP4106G1D

GP4106W1D

GP4107G1D

GP4107W1D

Global Code

A global code is assigned to every Pro-face product as a universal model number.

For more information on product models and their matching global codes, please refer to the following URL.

http://www.pro-face.com/product/globalcode.html

9

Package Contents

The following items are included in the GP unit’s package . Before using t he GP, please check that all items listed her e are

present.

GP Unit: 1

COM I/F Connector (1)

(For RS-232C and

RS-422/485 types)

(Attached to the GP unit)

*1 Not included with models that have the following type of power connector.

• English and

Japanese Installation

Guide (1)

• Warning/Caution

Information (1)

DC Power Supply

Connector (1)

(For the Ethernet

type and a portion of

models

(Attached to the GP

unit)

*1

)

Installation Gasket: 1

(Attached to the GP unit)

Installation Fasteners:

Set of 2

This unit has been carefully packed, with special attention to quality. However, should you find anything damaged or

missing, please contact your local GP distributor immediately .

10

• UL listed products

UL/c-UL Approval

Industrial Control Equipment refer to UL508

Suitable for use in Class I, Division 2,

Groups A, B, C, and D Hazardous

(classified) locations, or NonHazardous Locations.

• c-UL listed products

Process Control Equipment

Suitable for use in Class I, Division 2,

Groups A, B, C, and D Hazardous

(classified) locations, or NonHazardous Locations.

• Product List

Product Model No.

GP4104G1D 3910017-11 9999

GP4104W1D 3910017-12 9999

GP4105G1D 3910017-01 9 - 9 -

GP4105W1D 3910017-02 9 - 9 -

GP4106G1D 3910017-03 9 - 9 -

GP4106W1D 3910017-04 9 - 9 -

GP4107G1D 3910017-05 9 - 9 -

GP4107W1D 3910017-06 9 - 9 -

Registration Model

No.

ANSI/ISA12.12.01

refer to CSA-C22.2

No.142

refer to CSA-C22.2

No.213

UL c-UL

[a] [b] [c] [d]

see [a] in the

“Product List“

see [b] in the

“Product List“

see [c] in the

“Product List“

see [d] in the

“Product List“

UL/c-UL File No.: E220851, E210412

<Cautions>

Be aware of the following items when building the GP into an end-use product:

• For use on a flat surface of a Type 4X (Indoor Use Only) and/or Type 13 Enclosure.

<Compliance and Handling Cautions in Hazardous Locations>

(1) Suitable for use in Class I, Division 2, Groups A, B, C, and D Hazardous Locations, or Non-Hazardous

Locations Only.

(2) W ARNING: Explosion hazard-substitution of any components may impair suitability for Class I, Division 2

(3) WARNING: Explosion hazard-do not disconnect equipment while the circuit is live or unless the area is

known to be free of ignitable concentrations.

11

(4) Control Drawing of USB (Type A) Interface (USB1)

The information below concerns the use of the USB interface used in Class I, Division 2, Groups A, B, C,

and D hazardous locations (from Doc No. 3910017-USB).

USB Pin Description

1. Vcc

2. D-

3. D+

4. GND

(See Note 1 for details)

Shield GND

1 2 3 4

Notes:

1. Nonincendive Circuit Parameters:

USB interface:

Voc = 5.25 V

Isc = 0.7 A

Ca = 16 µF

La = 10 µH

2. Selected Associated Nonincendive Field Wiring Apparatus shall satisfy the following:

Associated Nonincendive Field

Wiring Apparatus for USB (Type A)

interface of the GP-4100 Series

Voc ≤ Vmax

Isc ≤ lmax

Ca

La

-

≥ Ci + C cable

≥ Li + L cable

Nonincendive Field Wiring

Nonincendive Field

Wiring Apparatus

Apparatus

12

3. If the electrical parameters of the cable are unknown, the following values may be used:

Capacitance = 60 pF/ft

Inductive = 0.20 µH/ft

4. Nonincendive Field Wiring must be installed in accordance with article 501.10(B) of the National

Electrical Code ANSI/NFPA 70.

5. Nonincendive Field Wiring Apparatus shall not contain or be connected to another source of power.

(5) USB (mini-B) Interface (USB2) is for temporary connection only during maintenance and setup of the

device. Do not use, connect, or disconnect unless area is known to be non-hazardous. Connection or

disconnection in an explosive atmosphere could result in an explosion.

CE Marking

The following units are CE marked products complying with the EMC Directive.

They comply with EN61000-6-2, EN61000-6-4. and EN61131-2

GP4104G1D GP4104W1D

GP4105G1D GP4105W1D

GP4106G1D GP4106W1D

GP4107G1D GP4107W1D

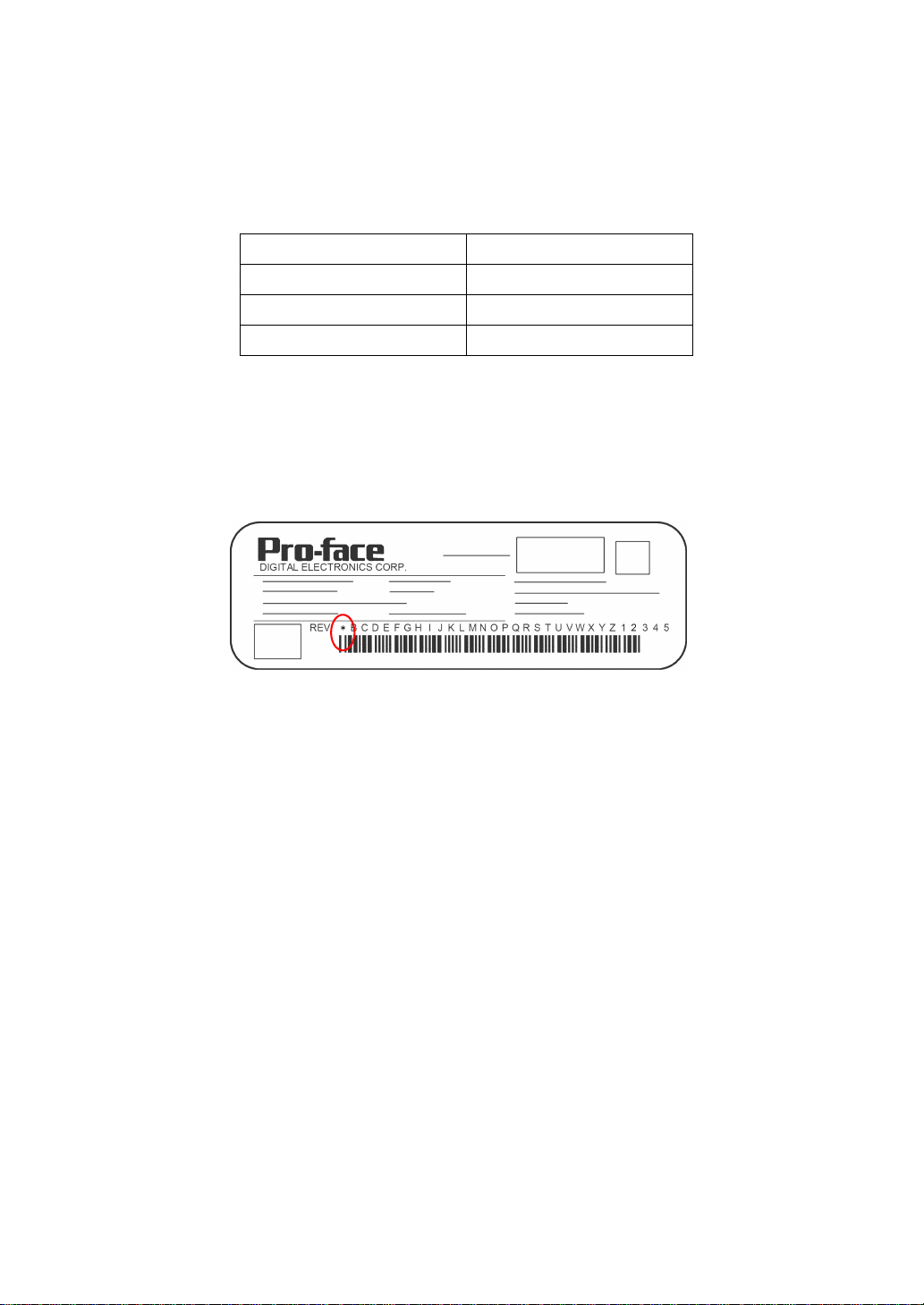

About Revision

The nameplate on the GP has the revision number of the GP . In the example below , the asterisk, which is placed at the “A”

position, shows that the revision number is “A”.

13

Contents

Preface ...................................................................................................................... 1

Essential Safety Precautions .................................................................................... 2

About the Manuals.................................................................................................... 8

Information Symbols ................................................................................................. 8

GP-4100 Series Model Name Indication................................................................... 9

GP-4100 Series Model Names ................................................................................. 9

Global Code.............................................................................................................. 9

Package Contents................................................................................................... 10

UL/c-UL Approval.....................................................................................................11

CE Marking ............................................................................................................. 13

About Revision........................................................................................................ 13

Contents.................................................................................................................. 14

Chapter 1 Accessories/System Design

1.1 Accessories ....................................................................................................1-2

1.1.1 Serial Interface Item....................................................................... ... ... ... .... ... ... ....1-2

1.1.2 USB (Type A) Interface.........................................................................................1-2

1.1.3 USB (mini-B) Interface............................................ ... .... ... ... ... .... ..........................1-2

1.1.4 Option Items............................... ....................................... ... ... .... ... ... ....................1-2

1.1.5 Maintenance Items................................................................................................1-3

1.2 System design ................................................................................................ 1-4

1.2.1 GP RUN Mode Peripherals.................................. ... ... .... ... ....................................1-4

1.2.2 Edit Mode Peripherals...........................................................................................1-7

Chapter 2 Part Names and Functions

2.1 GP-4100 Series .............................................................................................. 2-2

Chapter 3 Specifications

3.1 GP-4100 Series .............................................................................................. 3-2

3.1.1 General Specifications............................................................ .... ... ... ... .................3-2

3.1.2 Performance Specifications.......................... .... ... ... ... ....................................... ... .3-4

3.1.3 Serial Interface . ....................................... ... ... .... ... ... ....................................... ... ... .3-7

3.1.4 Dimensions................................... .... ... ... ... ....................................... ... ... .... ... ... ..3-10

Chapter 4 Installation and Wiring

4.1 Installation....................................................................................................... 4-2

14

4.2 Wiring Precautions..........................................................................................4-7

4.2.1 Connecting the Power Cord..................................................................................4-7

4.2.2 Connecting the Power Supply ............................................................................4-12

4.2.3 Grounding...........................................................................................................4-13

4.2.4 Wiring Precautions..............................................................................................4-14

4.3 USB Cable Clamp Attachment/Removal ......................................................4-15

4.3.1 USB (Type A) Interface.......................................................................................4-15

4.3.2 USB (mini-B) Interface........................................................................................4-17

Chapter 5 Maintenance

5.1 Cleaning the Display.......................................................................................5-2

5.2 Periodic Check Points.....................................................................................5-3

5.3 Replacing the Installation Gasket ...................................................................5-4

5.4 Replacing the Backlight ..................................................................................5-6

15

16

1 Accessories/

System Design

1. Accessories

2. System design

1-1

GP-4100 Series Hardware Manual

1.1 Accessories

All accessories listed here are produced by Pro-face.

1.1.1

Serial Interface Item

Product Name Model No. Description

Mitsubishi PLC A-Series

Cable (5 m)

Mitsubishi PLC Q-Series

CPU I/F Cable (3 m)

Mitsubishi PLC FX-Series

CPU I/F Cable (1 m)

Mitsubishi PLC FX-Series

CPU I/F Cable (5 m)

Panasonic Electric Works

PLC FP Series CPU Cable

(2 m)

MPICable

ZC9CBA51

ZC9CBQ31

ZC9CBFX1 1

ZC9CBFX51

ZC9CBFP21

CA3-MPI-PGN-PFE

(3.5m)

CA3-MPI-PG1-PFE

(3.5m)

1.1.2 USB (Type A) Interface

Connects the GP directly to the CPU

programming port on the Mitsubishi Electric

PLC A/QnA series. (3.4 inch)

Connects the GP directly to the CPU

programming port on the Mitsubishi Electric

PLC Q series. (3.4 inch)

Connect the GP directly to the CPU

programming port on the Mitsubishi Electric

PLC FX series. (3.4 inch)

Connects the GP directly to the CPU port on

the Panasonic Electric Works PLC FP series.

(3.4 inch)

Connects a host controller to the GP-4107 for

MPI communication.

Product Name Model No. Description

USB Panel-mount Extension

Cable (USB Type A) (1 m)

USB-Serial (RS-232C)

Conversion Cable (0.5 m)

1.1.3 USB (mini-B) Interface

Product Name Model No. Description

USB Transfer Cable

(USB A/mini-B) (1.8 m)

USB Panel-mount Extension

Cable (USB mini-B) (1 m)

1.1.4 Option Items

Product Name Model No. Description

3.4-inch Screen Protection

Sheet

CA5-USBEXT-01

CA6-USB232-01

ZC9USCBMB1

ZC9USEXMB1

ZC9DS31

Extension cable attaching to the USB (Type

A) port on the front side of the operation

panel.

Cable for converting a GP unit’s USB

interface (Type A) into a serial interface (RS232C). Only available for communication

using the Screen Creation Softw a re ’s

Expanded SIO Feature.

Cable for transferring screen data from a PC

(USB A) to the GP (USB mini-B).

Extension cable attaching to the USB (mini-B)

port on the front side of the operation panel.

Disposable, dirt-resistant sheet for the GP

unit’s screen. (5 sheets/set) (Hard type)

1-2

1.1.5 Maintenance Items

Product Name Model No. Description

3.4-inch Installation

Fastener

3.4-inch Installation Gasket ZC9WG31

USB Clamp Type A

(1 port)

USB Clamp Type mini-B

(1port)

3.4-inch COM I/F Connector ZC9CMC1

3.4-inch DC Power Supply

Connector

ZC9AF31

ZC9USCL1

ZC9USCLMB1

ZCACNDCS1

Chapter 1 Accessories/System Design

Used to install the GP into a solid panel.

(2 pieces/set)

Provides dust and moisture resistance

when GP is installed into a so li d panel.

(1 gasket)

USB (Type A) Cable clamp for 1 port

products to prevent disconnection.

(5 clamps/set)

USB (mini-B) Cable clamp for 1 port

products to prevent disconnection.

(5 clamps/set)

Connector for Serial I/F

(3.4-inch, 1 connector)

Connector for attaching power supply to

3.4-inch GP units. (Set of 5 connectors)

Limited to models using the DC power

supply connector pictured below.

1-3

GP-4100 Series Hardware Manual

1.2

System design

The following diagram illustrates the standard range of items that can be connected to GP-4100 Series units.

For host controller (PLC, etc.) connection information, refer to the “GP-Pro EX Device/PLC Connection

Manual”.

1.2.1 GP RUN Mode Peripherals Serial Communication

GP-4100 Series

For instructions on how to connect to other devices,

always refer to the “GP-Pro EX Device/PLC Connection Manual”.

Serial Interface

(COM1)

Mitsubishi PLC Q Series CPU I/F Cable

ZC9CBQ31

Panasonic Electoric Works PLC FP Series CPU Cable

ZC9CBFP21

RS-232C Cable

(Prepared by user)

Mitsubishi PLC A Series Cable

ZC9CBA51

Mitsubishi PLC FX Series CPU I/F Cable

ZC9CBFX51

ZC9CBFX11

RS-422 Cable

(Prepared by user)

PROFIBUS Cable

(Prepared by user)

MPI Cable

CA3-MPI-PG1-PFE

CA3-MPI-PGN-PFE

RS-232C Port

RS-422/485 Port

RS-485 (isolation) Port

RS-232C type

RS-422/485 type

RS-485 Cable

(Prepared by user)

RS-485(isolation) type

Programming

Console Port

1-4

RS-232C Cable

(Prepared by user)

+

Siemens TTY Converter Cable

CA6-CBLTTY/5M-01

RS-422 Cable

(Prepared by user)

+

Mitsubishi PLC A, QnA, FX Series’s Port Adapter II

GP070-MD11

RS-232C type

Programming

Console Port

RS-422/485 type

Host Controller

PLC etc.

Loading...

Loading...