Page 1

Online Data Validator User’s Manual

™

™

SL5000r and T5000

r

RFID Smart Label and Thermal Printers

Page 2

Page 3

SL5000r and T5000

RFID Smart Label and Thermal Printers

r

Online Data Validator User’s Manual

Page 4

Software License Agreement

CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS BEFORE USING THIS PRINTER.

USING THIS PRINTER INDICATES YOUR ACCEPTANCE OF THESE TERMS AND CONDITIONS. IF YOU

DO NOT AGREE TO THESE TERMS AND CONDITIONS, PROMPTLY RETURN THE PRINTER AND ALL

ACCOMPANYING HARDWARE AND WRITTEN MATERIALS TO THE PLACE YOU OBTAINED THEM, AND

YOUR MONEY WILL BE REFUNDED.

Definitions.

“Software” shall mean the digitally encoded, machine-readable data and program. The term “Software

Product” includes the Software resident in the printer and its documentation. The Software Product is licensed

(not sold) to you, and Printronix, Inc. either owns or licenses from other vendors who own, all copyright, trade

secret, patent and other proprietary rights in the Software Product.

License.

1. Authorized Use. You agree to accept a non-exclusive license to use the Software resident in the printer

solely for your own customary business or personal purposes.

2. Restrictions.

a. To protect the proprietary rights of Printronix, Inc., you agree to maintain the Software Product and

other proprietary information concerning the typefaces in strict confidence.

b. You agree not to duplicate or copy the Software Product.

c. You shall not sublicense, sell, lease, or otherwise transfer all or any portion of the Software Product

separate from the printer, without the prior written consent of Printronix, Inc.

d. You may not modify or prepare derivative works of the Software Product.

e. You may not transmit the Software Product over a network, by telephone, or electronically using any

means; or reverse engineer, decompile or disassemble the Software.

f. You agree to keep confidential and use your best efforts to prevent and protect the contents of the

Software Product from unauthorized disclosure or use.

3. Transfer. You may transfer the Software Product with the printer, but only if the recipient agrees to accept

the terms and conditions of this Agreement. Your license is automatically terminated if you transfer the

Software Product and printer.

Limited Software Pr oduct Warranty

Printronix, Inc. warrants that for ninety (90) days after delivery, the Software will perform in accordance with

specifications published by Printronix, Inc. Printronix, Inc . does not warrant that the Software is free from all

bugs, errors and omissions.

Remedy

Your exclusive remedy and the sole liability of Printronix, Inc. in connection with the Software is replacement

of defective software with a copy of the same version and revision level.

Disclaimer of Warranties and Limitation of Remedies

1. THE PARTIES AGREE THAT ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE AND MERCHANTABILITY ARE

EXCLUDED.

Printronix, Inc. does not warrant that the functions contained in the Software will meet your requirements

or that the operation of the Software will be uninterrupted or error free.

Printronix, Inc. reserves the right to make changes and/or improvements in the Software without notice at

any time.

Page 5

2. IN NO EVENT WILL PRINT R O NIX, INC. BE LIABLE FOR LOST PRO FI T S, LOST DAT A, BUSINESS

INTERRUPTIONS, OR ANY OTHER DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF THE USE OF OR INABILITY TO USE THIS PRODUCT, EVEN IF

PRINTRONIX, INC. HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, OR ANY

DAMAGES CAUSED BY THE ABUSE OR MANIPULATION OF THE SOFTWARE. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAM AGES, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

3. Printronix, Inc. will not be liable for any loss or damage caused by delay in furnishing a Software Product

or any other performance under this Agreement.

4. Our entire liability and your exclusive remedies for our liability of any kind (including liability for

negligence except liability for personal injury caused solely by our negligence) for the Software Product

covered by this Agreement and all other performance or nonperformance by us under or related to this

Agreement are limited to the remedies specified by this Agreement.

5. California law governs this Agreement.

Termination of License Agreement

This License shall continue until terminated. This license may be terminated by agreement between you and

Printronix, Inc. or by Printronix, Inc. if you fail to comply with the terms of this License and such failure is not

corrected within thirty (30) days after notice. When this License is terminated, you shall return to the place you

obtained them, the printer and all copies of the Software and documentation.

U.S. Government Restricted Rights

Use, duplication or disclosure by the Government is subject to restrictions as set forth in the Rights in

Technical Data and Computer Software clause at FAR 242.227-7013, subdivision (b) (3) (ii) or subparagraph

(c) (1) (ii), as appropriate. Further use, duplication or disclosure is subject to restrictions applicable to

restricted rights software as set forth in FAR 52.227-19 (c) (2).

Acknowledgement of Terms and Conditions

YOU ACKNOWLEDGE THAT YOU HAVE READ THIS AGREEMENT, UNDERSTAND IT, AND AGREE TO

BE BOUND BY ITS TERMS AND CONDITIONS. NEITHER PARTY SHALL BE BOUND BY ANY

STATEMENT OR REPRESENTATION NOT CONTAINED IN THIS AGREEMENT. NO CHANGE IN THIS

AGREEMENT IS EFFECTIVE UNLESS WRITTEN AND SIGNED BY PROPE R LY AU T HO R I ZE D

REPRESENTATIVES OF EACH PARTY. BY U SI N G THI S PRINTER, YOU AGREE TO AC CEPT THE

TERMS AND CONDITIONS OF THIS AGREEMENT.

Page 6

Communication Notices

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Unauthorized changes or modifications could void the user’s authority to operate the equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Any change or modification to this product voids the user’s authority to operate it per FCC Part 15 Subpart A

Section 15.21 regulations.

This product contains an intentional radiator with the following parameters:

Operating Frequency: 902 to 928 MHz

Typical RF Power: 25 to 100 milliwatts (SL5x04 MP) or 25 to 205 milliwatts (SL5x04 C1)

Maximum RF Power: 1 Watt under abnormal conditions

Printronix SL5000

r

and T5000

r

Tested To Comply

With FCC Standards

FOR HOME OR OFFICE USE

Canada

This Class B digital apparatus complies with Canadian ICES-003 and RSS 210.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that may cause undesired operation of the device.

This device has been designed to operate with the antennas listed below, and having a maximum gain of

–18 dBi. Antennas not included in this list or having a gain greater than –18 dBi dB are strictly prohibited for

use with this device. The required antenna impedance is 50 ohms.

To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that

the equivalent isotropically radiated power (e.i.r.p.) is not more than that permitted for successful

communication.

Page 7

CE Notice (European Union)

Marking by the CE symbol indicates compliance of this Printronix system to the EMC Directive and the Low

Voltage Directive of the European Union. Such marking is indicative that this Printronix system meets the

following technical standards:

• EN 300 220-1 (2000), Electromagnetic Compatibility and Radio Spectrum Matters; Short Range Devices;

Radio equipment to be used in the 25 MHz to 1000 MHz frequency range with power levels ranging up to

500 mW.

• EN 55022 — “Limits and Methods of Measurement of Radio Interference Characteristics of Information

Technology Equipment.”

• EN 50082-1: 1992 — “Electromagnetic compatibility—Generic immunity standard Part 1: Residential,

commercial, and light industry.”

• EN 60950 — “Safety of Information Technology Equipment.”

This printer is a Class B product for use in a typical Class B domestic environment.

CE Symbol

Taiwan

Lithium B att e ry Warning

The controller board contains a lithium battery sealed inside the real-time clock chip. Do not disassemble the

chip to replace the battery. Do not dispose of the chip by incineration. Failure to comply may cause the battery

to explode. Contact your local waste agency for the correct disposal procedure.

Page 8

Printronix makes no representations or warranties of any kind regarding this material, including, but not limited

to, implied warranties of merchantability and fitness for a particular purpose. Printronix shall not be held

responsible for errors contained herein or any omissions from this material or for any damages, whether

direct, indirect, incidental or consequential, in connection with the furnishing, distribution, performance or use

of this material. The information in this manual is subject to change without notice.

This document contains proprietary information protected by copyright. No part of this document may be

reproduced, copied, translated or incorporated in any other mat erial in any form or by any means, whether

manual, graphic, electronic, mechanical or otherwise, without the prior written consent of Printronix.

COPYRIGHT © 2005, 2006 PRINTRONIX, INC. All rights reserved.

Trademark Acknowledgements

Printronix, LinePrinter Plus, IGP, and PGL are registered trademarks of Printronix, Inc.

Code V is a trademark of Quality Micro Systems, Inc.

IPDS is a trademark of International Business Machines Corporation.

SL5000r and T5000r are trademarks of Printronix, Inc.

Page 9

Table of Contents

1 Installation Instructions............................11

Overview..............................................................................11

Safety Notices .....................................................................14

Installation and Removal .....................................................15

Prepare The Printer.......................................................15

Install The Ferrite ..........................................................16

Install The Brackets.......................................................22

Attach The Grounding Wire And Power/Data Cable.....24

Restore The Printer To Operation .......................................25

Enable The Validator...........................................................26

Adjust The Scanning Beam .................................................27

Continuous, Tear-Off, and Tear-Off Strip........... ....... .... 27

Peel-Off Media Handling Mode.....................................28

Cut Media Handling Mode.............................................29

Shifting The Scanning Beam...............................................33

Calibration ...........................................................................34

Bar Code Validation Demo Page..................................36

2 Operation ................................................ 39

Basic Validator Setup ..........................................................39

VALIDATOR Menu........................................................41

Configuring The Validator......... ....... ...... ...... ....... ...... ...........44

Enabling And Disabling The Validator...........................44

Validator Reporting .......................................................45

Validator Statistics.........................................................49

Defining Validator Options ............................................50

Advanced Validator Options..........................................55

General Process For Barcode Analysis........................73

9

Page 10

Table of Contents

Operation.............................................................................74

Print Speed Limits.........................................................74

On-Demand Printing ....................................... ....... ...... .77

Bar Code Failures........... ....... ...... ....... ...... ....... ...... ....... ...... .78

Bad Bar Code Error Detection ......................................78

Missing Bar Code Error Detection.................................78

Error Action...................................................................79

Error Messages.............................................................86

Troubleshooting...................................................................92

Maintenance........................................................................94

A Contact Information.................................95

Printronix Customer Support Center.............................95

Printronix Supplies Department ....................................96

Corporate Offices..........................................................96

10

Page 11

1 Installation

Overview

Instructions

The online data validator (validator) is an external bar code

scanning device attached above the paper exit of the printer. When

activated, it scans the printed output looking for bar codes. When it

finds a bar code, it determines what type of bar code it is and

monitors the bar code quality as it passes through the scan area.

After the entire bar code has passed under the scanning beam, the

validator grades the bar code and sends a report to the printer. How

the printer responds is determined by the validator settings,

explained in “Configuring The Validator” on page 44.

Operational Parameters

The design parameters of the validator are as follows:

• The validator can track the performance of up to four horizontal

bar codes at one time.

• The validator requires a minimum distance of 1/2 inch or 20

times the minimum element width (x-dimension), whichever is

greater, between bar codes.

• The validator recognizes the following linear, picket fence bar

codes: Codabar, Code 39, Code 93, Code 128, Interleaved 2 of

5, and UPC/EAN.

11

Page 12

Chapter 1 Overview

• The validator can also evaluate PDF 417 bar codes. For PDF

417 Limited, the validator works best with security level 5 or

higher, using the current default printer settings for Defects

Percentage, Percent Decode, and Decodeability. For lower

security levels, lower the Defects Percentage to 5% to enable

checking for bar code damage.

• Stacked, 2D, and vertical (ladder) bar codes are not supported.

• Bar codes must have a minimum x-dimension of 10 mil

(0.010 inch) to be recognized by the full width of the scanning

beam. The validator can recognize bar x-dimension as narrow

as 6.6 mil (0.0066 inch) for 300 dpi printers, and 10 mil

(0.010 inch) for 203 dpi printers. The validator cannot recognize

x-dimensions smaller than 6.6 mil (0.0066 inch) or larger than

40 mil (0.040 inch).

Refer to Table 1 for the minimum x-dimension requirements for

each printer size of a 300 dpi printer.

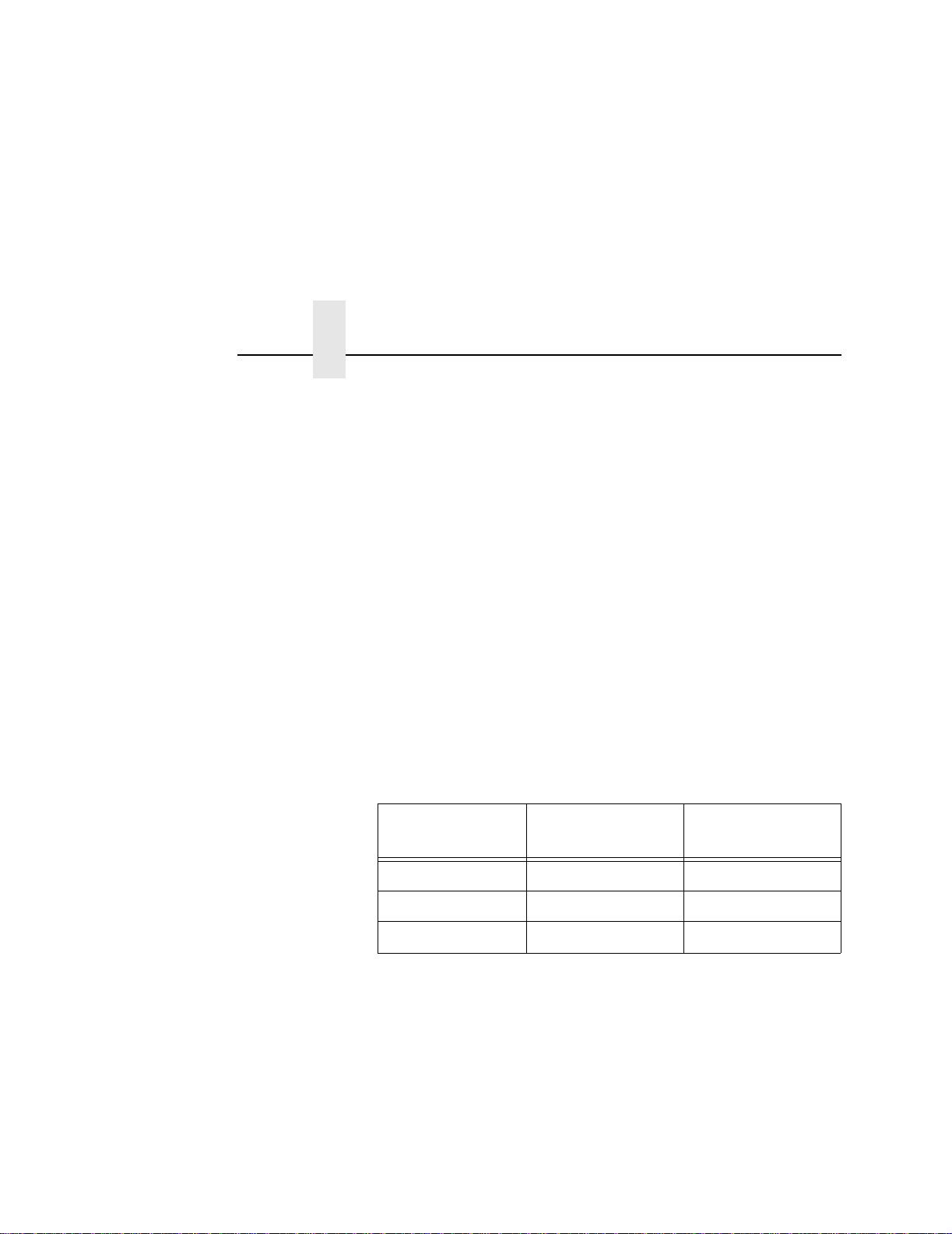

Table 1: Minimum X-Dimension and Beam Width for

a 300 dpi Printer

12

Printer Size Beam Width

4 inch 4.5 inches 6.6 mil

6 inch 6.5 inches 10 mil

8 inch 8.5 inches 13 mil

X-Dimension

Minimum

Page 13

Tools And Materials You W ill Need

•

SL5000r/T5000r User’s Manual

• Static wrist strap*

• 2.5 mm hex key*

Parts List

• 3 mm hex key

• Validator/ Upper bracket

• Lower bracket

• Grounding wire

• Overlays

• Bar code calibration card

• Ferrite*

• Cable assembly*

• Wire saddle*

• Grommet*

* Only for a field installation

13

Page 14

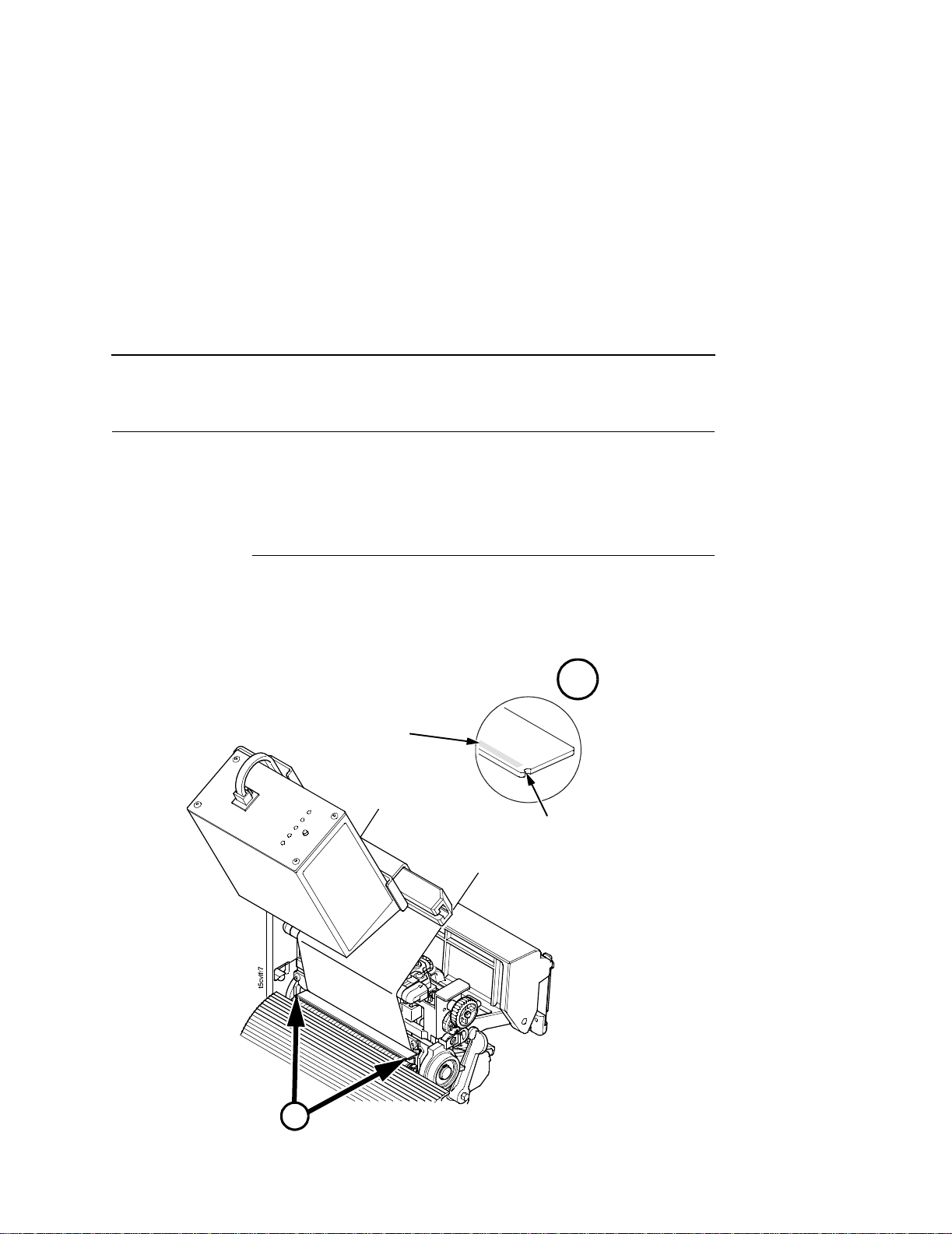

Chapter 1 Safety Notices

Safety Noti ces

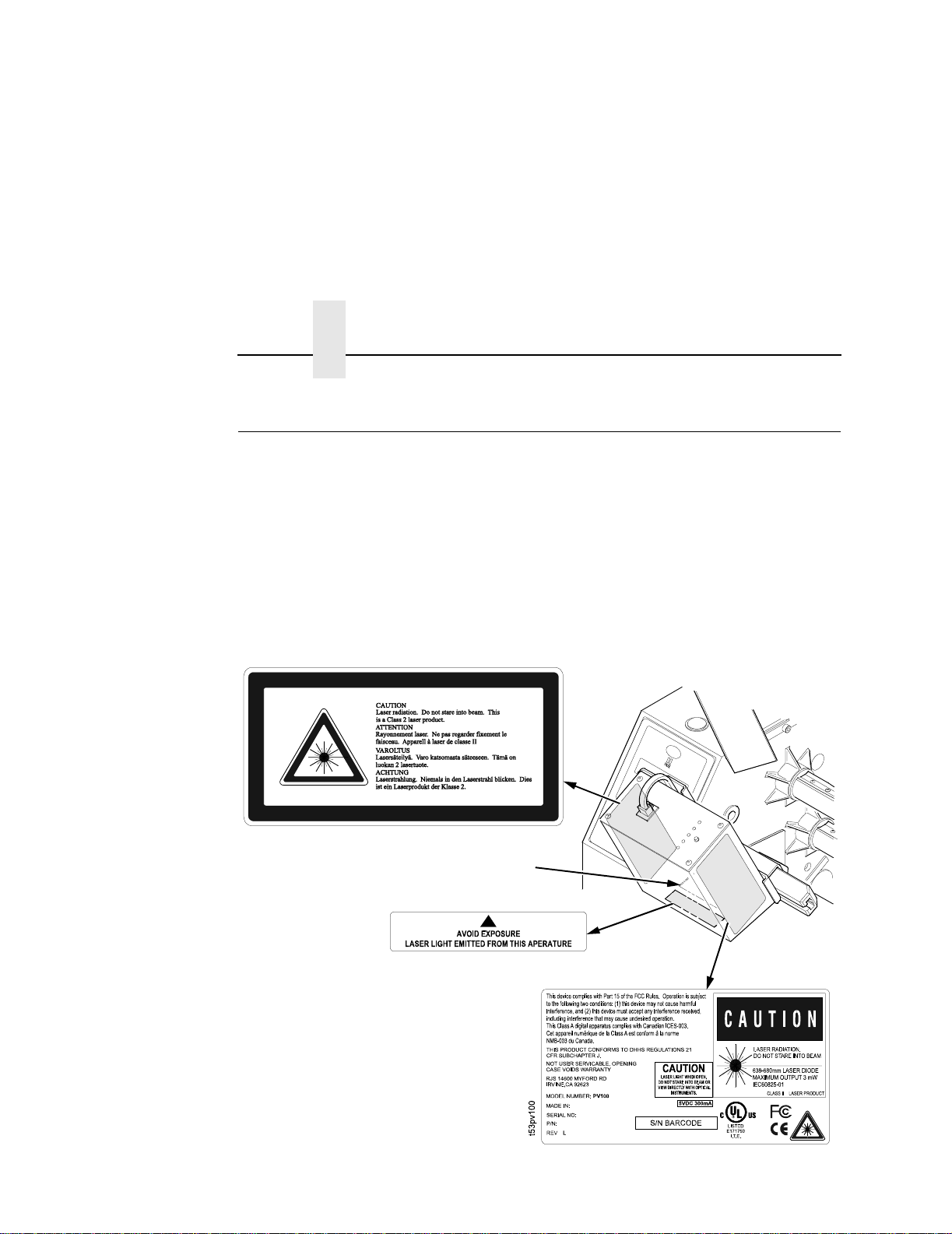

The validator is a Class 2 laser product. The following notices apply

at all times when the printer is powered on and the validator is

active:

WARNING

WARNING

Note: This is the laser exit window.

Class 2 laser light. Do not stare into the laser beam or a

reflected image of the laser beam.

Using controls, making adjustments, or performing

procedures other than those specified herein may result in

hazardous radiation exposure.

14

Figure 1. Safety Warnings

Page 15

Installa tion and Removal

This section describes how to install the validator. To remove the

validator, reverse the steps of this procedure.

Prepare The Printer

1. Set the printer power switch to O (Off).

Prepare The Printer

WARNING

Always unplug the printer power cord from the printer or

power outlet before doing any installation procedure. Failure

to remove power could result in injury to you and damage the

equipment. You will be instructed when to apply power.

2. Unplug the printer power cord from the printer or the AC power

source.

Factory Installation

If your printer has a factory installed validator, the ferrite, cable, wire

saddle, and grommet have already been installed. Go to “Install

The Brackets” on page 22.

Field Installation

If you are doing a field installation, you must install the ferrite, cable,

wire saddle, and grommet. Go to “Install The Ferrite” on page 16.

15

Page 16

Chapter 1 Installation and Removal

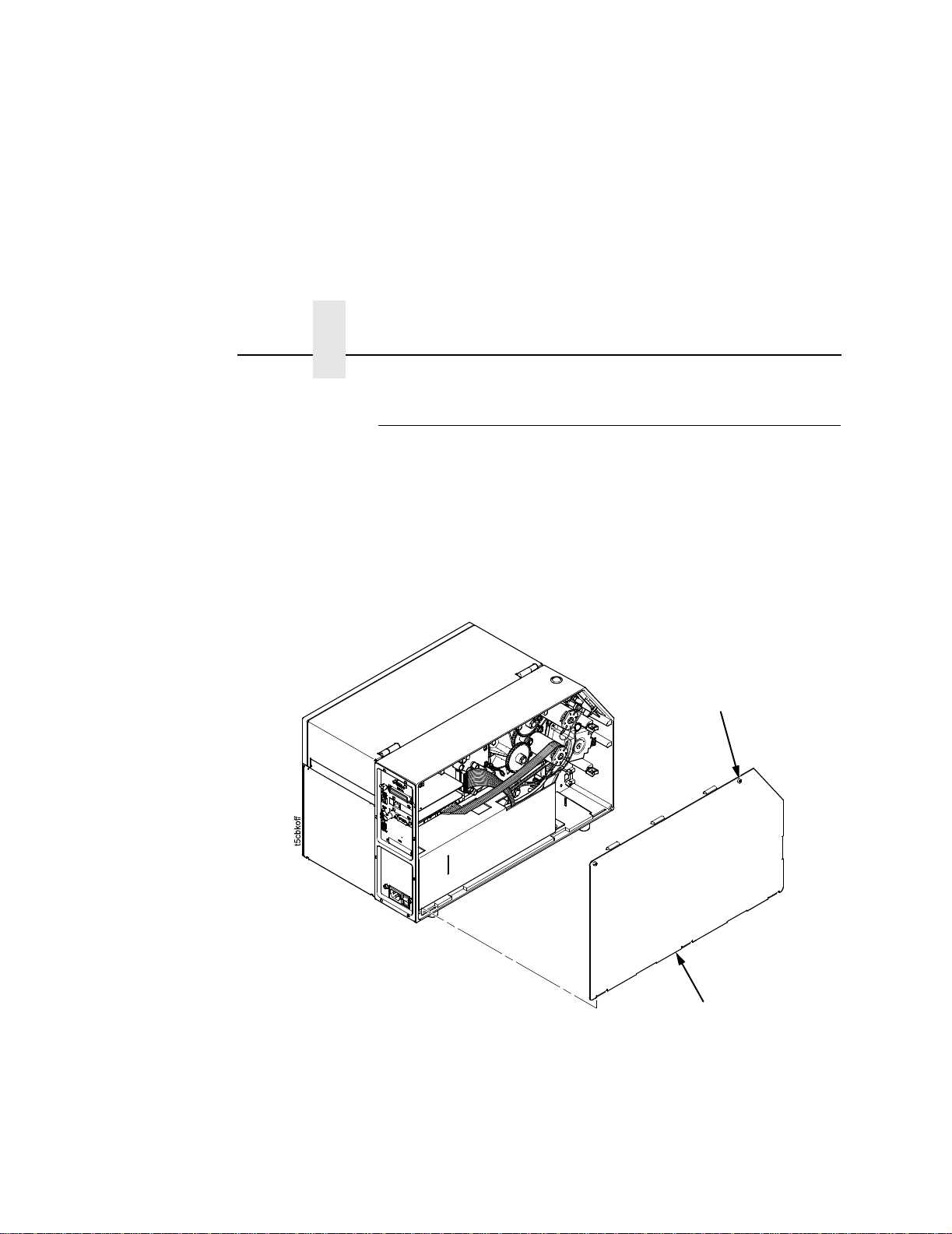

Install The Ferrite

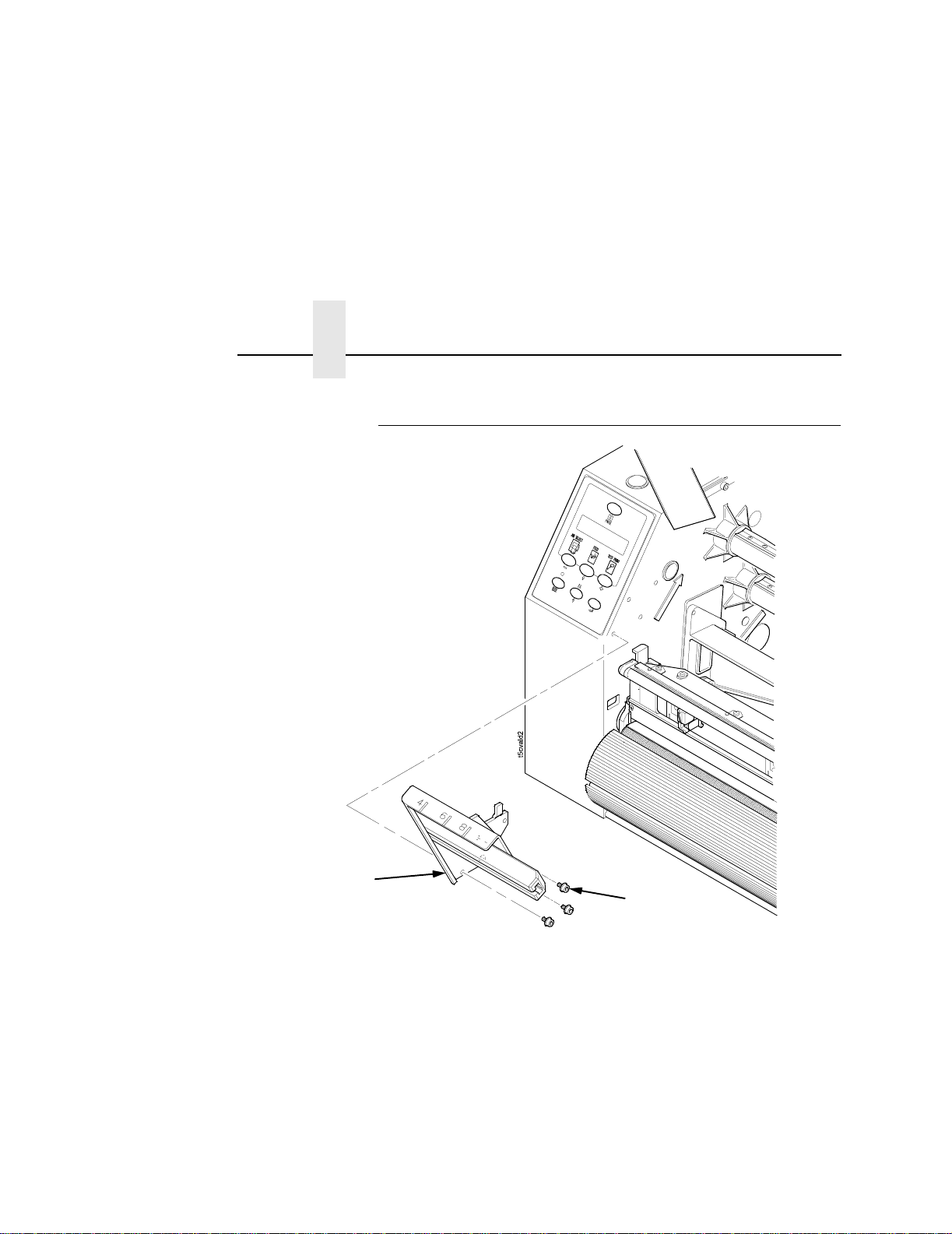

1. Loosen the two captive screws securing the top of the frame

side cover. (Figure 2.)

2. Tilt the frame side cover back from the top and lift it until the

tabs along the lower edge disengage from the slots in the

printer frame.

Captive Screw (2)

16

Frame Side Cover

Figure 2. Removing the Frame Side Cover

Page 17

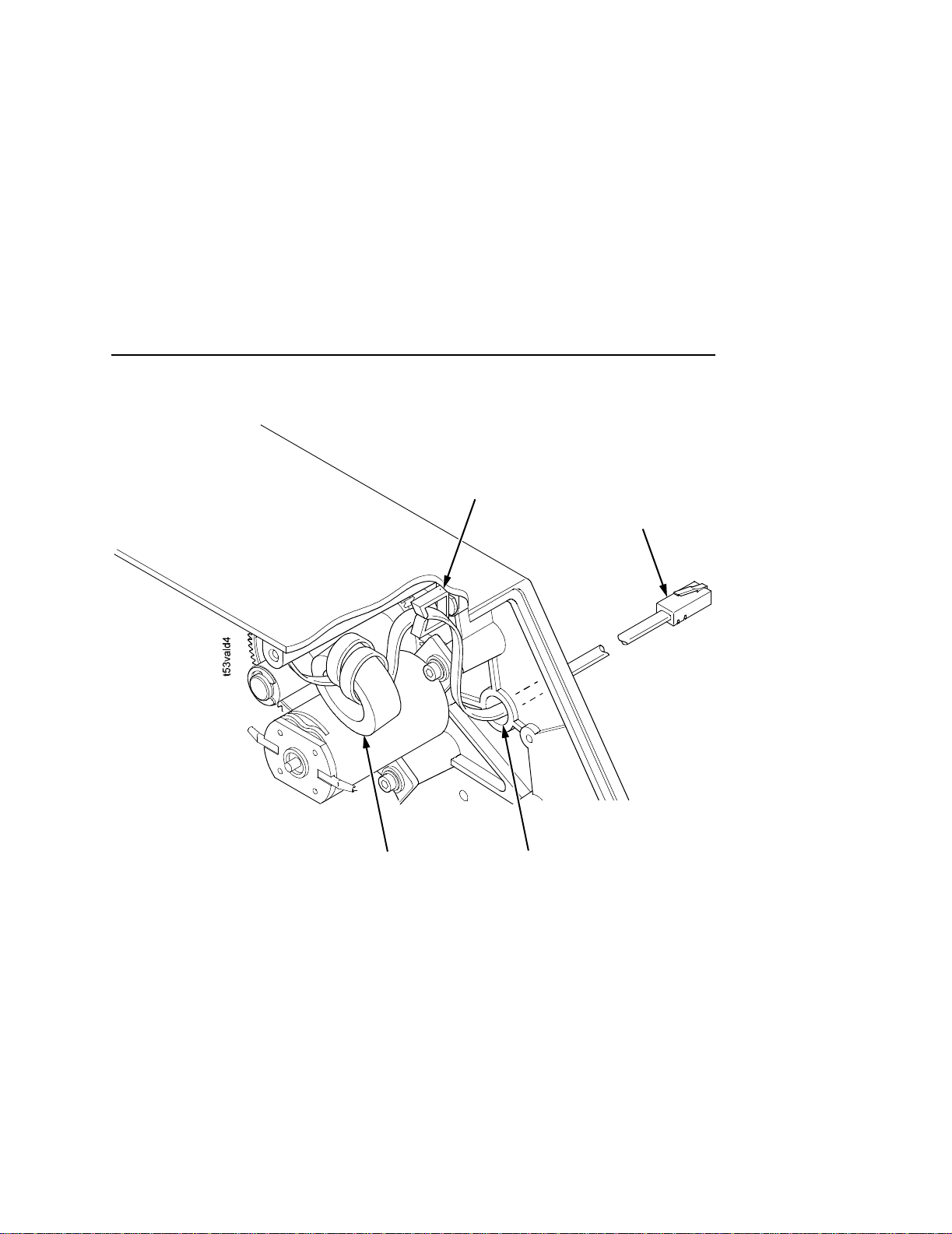

Install The Ferrite

RJ-11 Connector

(to validator)

Figure 3. Wrapping the Power/Data Cable Around the Ferrite

Power/Data Cable

Second Wrap

20.0 ± 0.5

inches

Power/Data Cable

First Wrap

Ferrite

Wide P10 Connect or

(to controller board)

3. Using the RJ-11 connector end of the power/data cable, insert

the cable through the ferrite. (Figure 3.)

4. Wrap the power/data cable around the ferrite twice.

5. Adjust the position of the ferrite so that the length from the

ferrite to the RJ-11 connector is 20 ± 0.5 in

ches.

17

Page 18

Chapter 1 Installation and Removal

Wire Saddle

Frame Boss

18

Figure 4. Inserting the Wire Saddle Into the Frame Boss

6. Insert the wire saddle into the frame boss. (Figure 4.)

Page 19

Install The Ferrite

Ferrite

Wire Saddle

RJ-11 Connector

(to validator)

Frame

Opening

Figure 5. Inserting the Power/Data Cable Through the Hole in the Frame Wall

7. Raise the media cover and remove the solid grommet from the

frame opening.

8. On the electronics side of the printer, push the RJ-11 connector

end of the power/data cable through the frame opening.

(Figure 5.)

9. Route the power/data cable through the wire saddle.

19

Page 20

Chapter 1 Installation and Removal

Split

Grommet

RJ-11

Connector

Power/Data Cable

(approximately

17 inches exposed)

Inserted Split

Grommet

(media side)

20

Figure 6. Adding the Grommet to the Power/Data Cable

10. On the media side of the printer, slide the split grommet onto

the power/data cable and insert it into the frame opening.

(Figure 6.)

11. Inspect the power/data cable to ensure approximately

17 inches of cable is exposed from the grommet to connect it to

the validator.

NOTE: You will plug the power/data cable into the validator later.

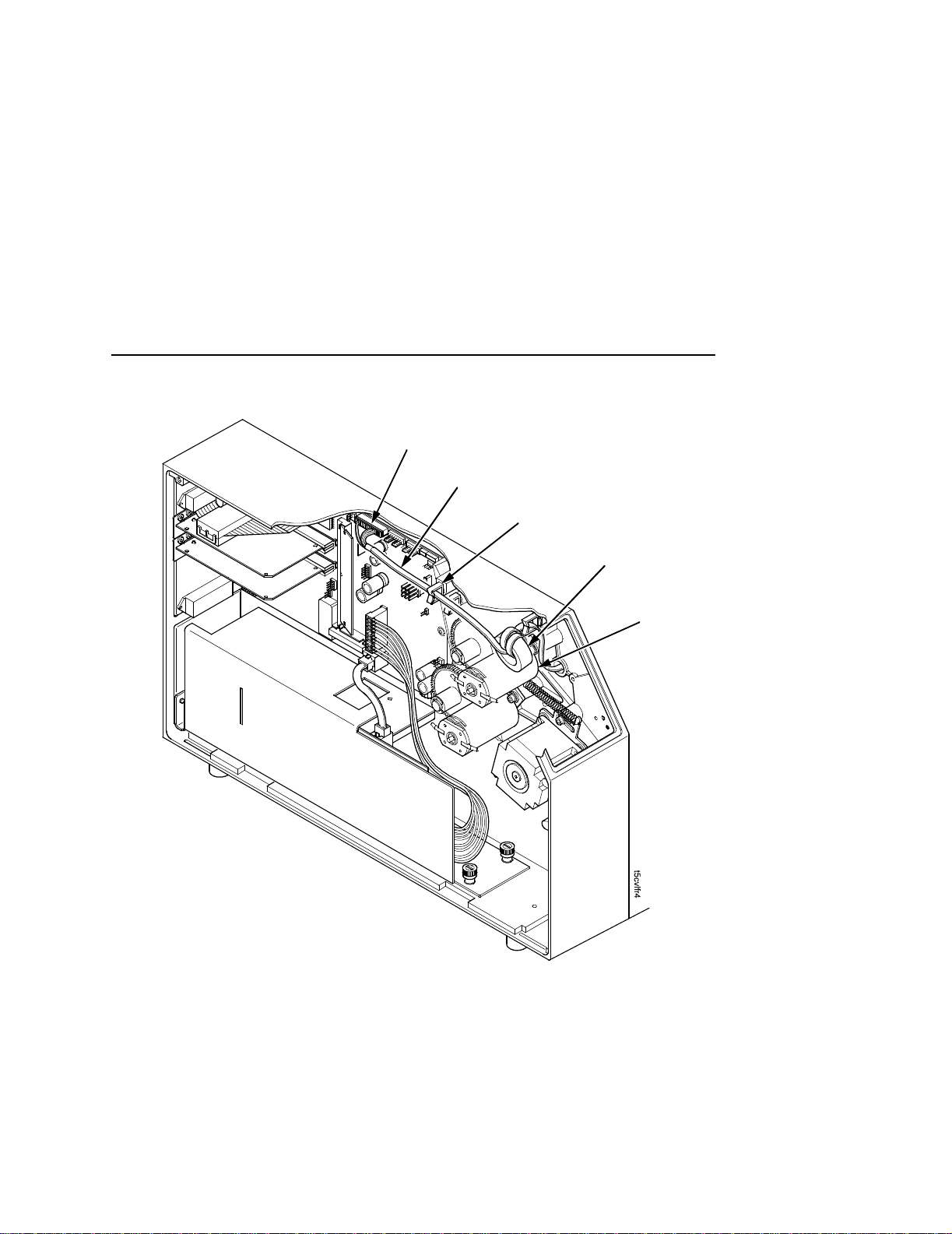

Page 21

J10

Power/Data Cable

Install The Ferrite

Wire Saddle

Ferrite

Upper

DC Motor

Figure 7. Position the Ferrite

12. On the electronics side of the printer, position the ferrite on top

of the upper DC motor. (Figure 7.)

13. Route the power/data cable through the wire saddle as shown

in Figure 7.

14. Plug the wide P10 connector end of the power/data cable into

the J10 receptacle on the controller board.

21

Page 22

Chapter 1 Installation and Removal

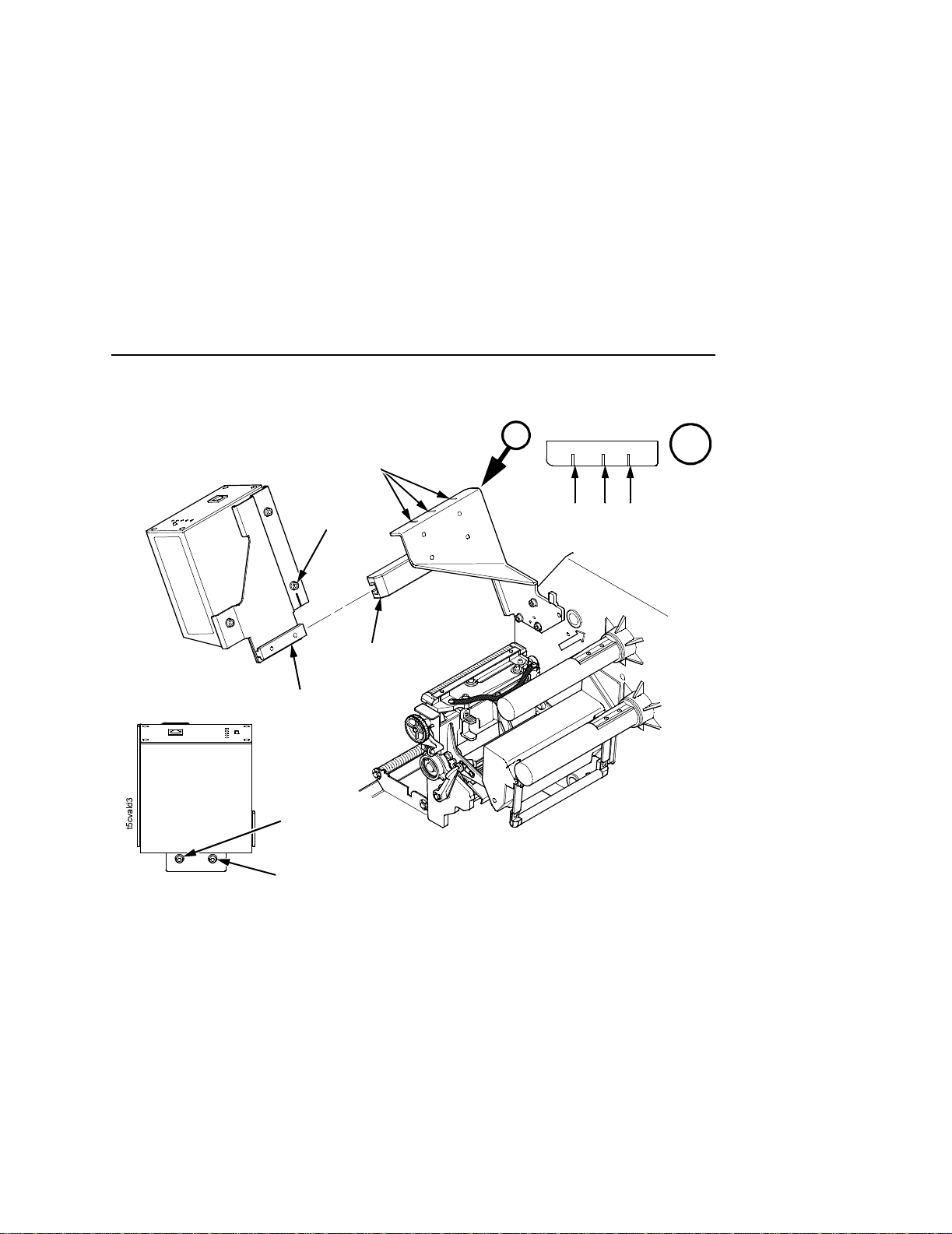

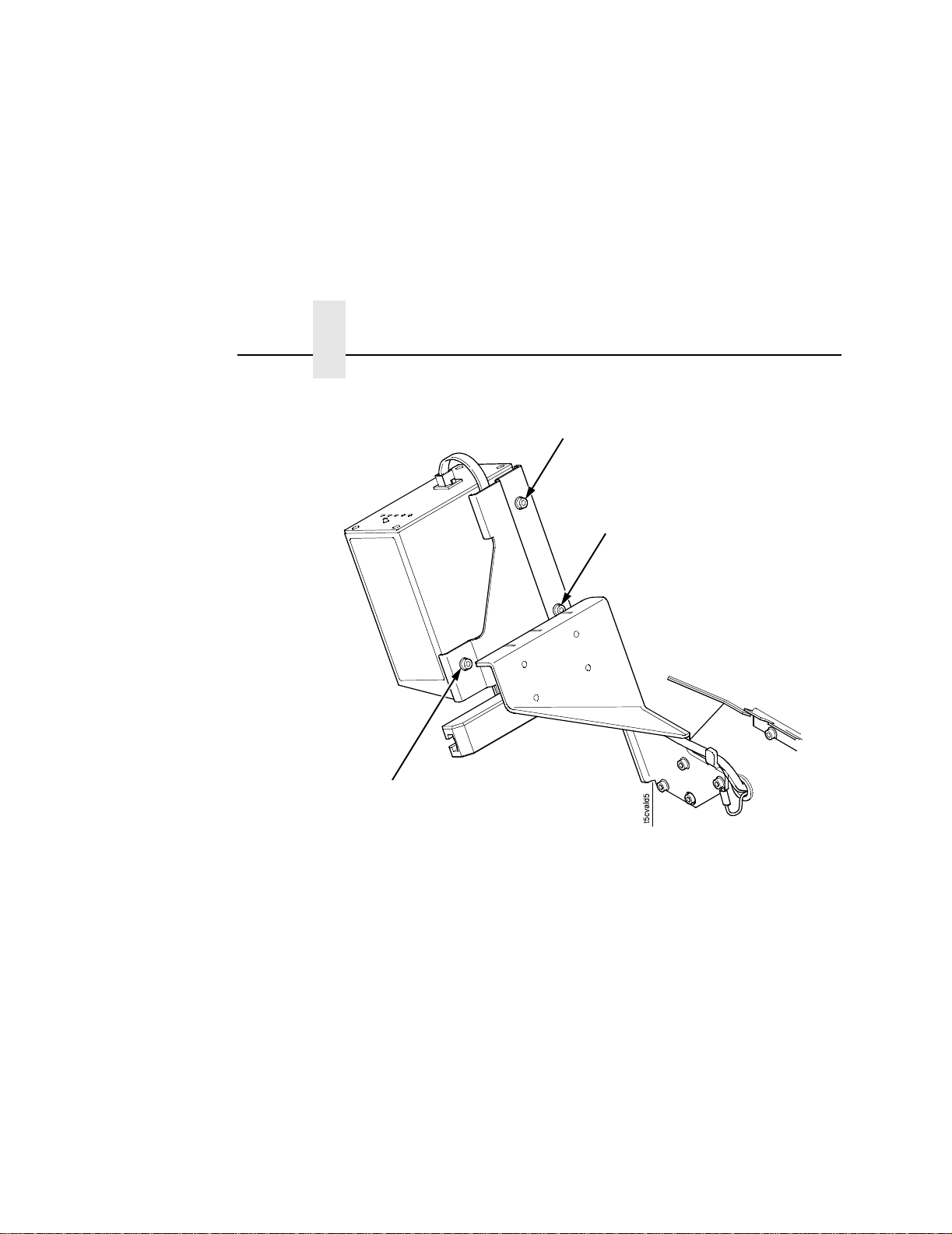

Install The Brackets

22

Lower

Bracket

M4x10mm

Screw (3)

Figure 8. Installing the Lower Bracket

1. Using three of the four M4x10mm screws, install the lower

bracket as shown in Figure 8.

NOTE: You will use the fourth screw later in this procedure.

Page 23

Install The Brackets

A

4 in.

6 in. 8 in.

Printer

Validator

(Rear View)

Validator

(Front View)

Hash

Marks

Alignment

Screw

Lower

Bracket

Upper

Bracket

Inside

Adjustment

Screw

Outside

Adjustment

Screw

Figure 9. Installing the Validator/Upper Bracket Unit onto the Lower Bracket

A

2. Face the front of the printer while installing the validator/upper

bracket unit.

3. Loosen the outside adjustment screw and remove the inside

adjustment screw on the bottom of the validator.

4. Slide the validator/upper bracket unit onto the lower bracket and

align the hash marks with the alignment screw accordingly.

NOTE: Refer to Figure 9, Detail A for location of the validator hash

mark for each printer model size. The printer model size is

also inscribed on the lower bracket.

5. When the unit is positioned correctly, tighten the outside

adjustment screw on the validator to lock the unit into place.

23

Page 24

Chapter 1 Installation and Removal

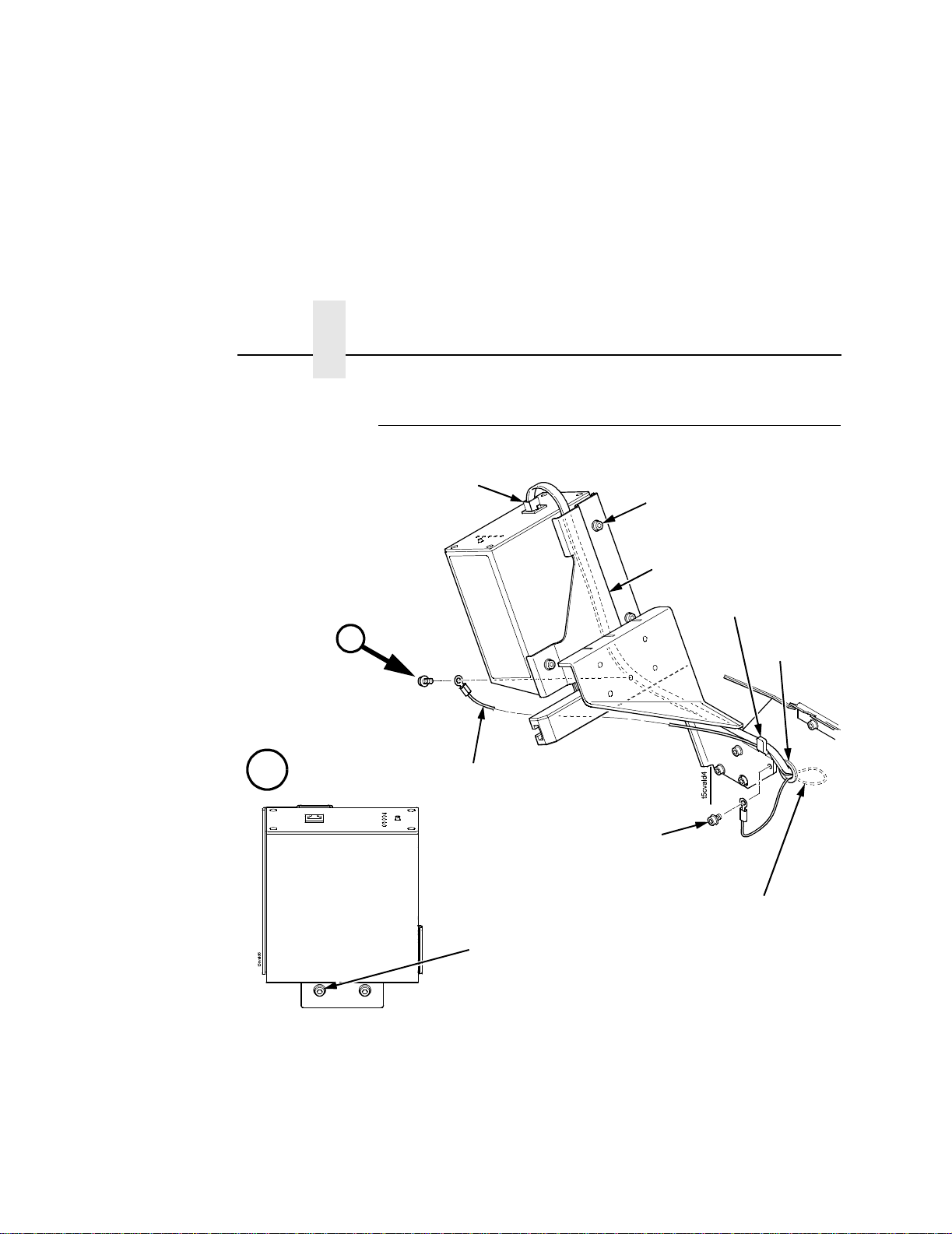

Attach The Grounding Wire And Power/Dat a Cable

Power/Data Cable

(Long Connector)

Upper Bracket

Screw (3)

Cable

Channel

Bracket Tab

A

A

Validator

(Front View)

Figure 10. Attaching the Grounding Wire and Power/Data Cable

1. Attach one end of the grounding wire to the validator using the

Grounding

Wire

Bracket Moun ting Screw

Grounding Wire

Slack

Inside

Adjustment

Screw

inside adjustment screw as shown in Figure 10.

Grommet

24

2. Attach the other end of the grounding wire to the lower bracket

using the fourth bracket mounting screw as shown in Figure 10.

3. Push any excess grounding wire slack through the grommet.

Page 25

Attach The Grounding Wire And Power/Data Cable

4. Loosen the three upper bracket screws and route the

power/data cable through the cable channel in the upper

bracket, as shown in Figure 10.

5. Plug the RJ-11 connector end of the power/data cable into the

validator.

6. Route the power/data cable behind the bracket tab as shown in

Figure 10.

NOTE: If necessary, loosen the bracket mounting screws enough

to slip the power/data cable behind the bracket tab, then

retighten the bracket mounting screws.

7. Pull the cable to minimize the slack behind the lower bracket.

Push any excess slack through the grommet.

8. Tighten the three upper bracket screws.

Restore The Printer To Operation

1. Lower the media cover.

2. Engage the tabs on the bottom of the frame side cover in the

slots in the printer frame.

3. Rotate the cover into position.

4. Tighten the two captive screws. (Figure 2.)

5. Plug the AC power cord into the printer and the power source.

6. Set the printer power switch to | (On).

25

Page 26

Chapter 1 Enable The Validator

Enable The V a lidator

NOTE: If you make any changes to the default configuration menu

items, you will be prompted to save the configuration.

See “Auto Save Configuration” in the

Software can automatically detect an installed validator when the

printer is powered up. If the printer is powered up with Power-Up

Config. set to Factory, the VALIDATOR menu will be available and

Validator Funct. is set to Enable in the QUICK SETUP and

VALIDATOR menus.

If Power-Up Config. is not set to Factory, the VALIDATOR menu

appears, but Validator Funct. is set to Disable. Enable Validator

Funct. by completing the following steps. (This is a one-time setting

once you save the configuration.)

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

Quick Setup Guide

.

26

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key. (This key combination can be changed by the user. Use

the customer’s key combination if necessary.)

.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ until Validator Funct. displays.

5. Press + or – until the Enable displays.

6. Press

7. Press ↓ and

8. Press PAUSE again to put the printer online.

↵ to enable the validator. An asterisk (*) should appear

after Enable. Once enabled, the printer will command the

validator to begin scanning and reporting errors, and the

counters will be incremented.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

.

.

Page 27

Adjust The Scanning Beam

,

NOTE: Make sure the printer is on and the scanning beam is on. If

the beam is off, press the RESET button for less than 2

seconds to turn on the beam.

Continuous, Tear- Off, and Tear-Off Strip

When the validator is first installed, the scanning beam may need to

be aligned with the two notches on the sides of the tear bar, as

shown in Detail A of Figure 11. When the scanning beam is

properly aligned it will line up with the two notches.

Scanning Beam

Continuous, Tear-Off, and Tear-Off Strip

A

Notch in Tear Bar

t5lsrlc2

Ju ne 19

2000

A

Figure 11. Aligning the Scanning Beam: Continuous, Tear-Off, and Tear-Off Strip

Media Handling Modes Only

27

Page 28

Chapter 1 Adjust The Scanning Beam

Peel-Off Media Handling Mode

If your printer is configured for Peel-Off Media Handling mode (use

of optional internal rewinder), you may need to align the beam

further behind the notches (0.20 to 0.30 inches [5.08 mm to

7.62 mm] from the front edge of the tear bar) so that the peeled

label remains on the tear bar and the trailing edge of the last bar

code can still pass completely under the scanning beam. See

Figure 12.

Aligning the scanning beam to any position other than the notches

on the tear bar should only be done if the last printed bar code

image does not clear the beam when the label is at the peel-off

position after printing. In addition, the distance the beam moves

back from the tear bar edge must correspond to a distance from the

leading edge of the label that does not have bar code printing. For

example, aligning the beam 0.20 inches from the front edge of the

tear bar requires that 0.20 inches of the leading edge of the label

must not have bar code images.

0.30 inches

(7.62 mm)

Figure 12. Aligning the Scanning Beam: Peel-Off Media Handling Mode Only

28

Page 29

Cut Media Handling Mode

Cut Media Handling Mode

If your printer has a cutter installed and is configured for Cut Media

Handling Mode, align the beam with the notches at each side of the

opening on the hinged upper lid, as shown in Detail A of Figure 13.

Scanning Beam

A

Notch in Tear Bar/

Figure 13. Aligning the Scanning Beam: Cutter Installed

A

Cutter

29

Page 30

Chapter 1 Adjust The Scanning Beam

Top Left Screw

Bottom Right Screw

Bottom Left Screw

30

Figure 14. Scanning Beam Adjustment Screws

Figure 14 shows the screws used to adjust the parallelism and

position of the scanning beam. The positions of the screws assume

that you are in front of the validator unit and facing the printer. The

following instructions and illustrations show how to adjust the

validator according to how the beam appears.

1. Power the printer on and make sure the scanning beam is on. If

the beam is off, press the RESET button for less than 2

seconds to turn on the scanning beam.

2. Use the Allen key provided to adjust the screws.

NOTE: You may have to loosen all three screws and allow the

rubber spacers to expand (relax) before making any

adjustments.

Page 31

Cut Media Handling Mode

Correct alignment of the

scanning beam. The beam lines

up with the end notches and is

parallel to the long edge of the

tear bar.

Tighten the to p left screw to

move the scanning beam

downward. If the screw is

already tight, loosen both bottom

screws to lower the beam.

Tighten both bottom screws to

move the scanning beam

upward. If they are already tight,

loosen the top left screw to move

the beam upward.

Loosen the bottom right screw to

rotate the scanning beam

clockwise. If it is already loose,

tighten the bottom left screw.

Loosen the bottom left screw to

rotate the scanning beam

counterclockwise. If it is already

loose, tighten the bottom right

screw.

31

Page 32

Chapter 1 Adjust The Scanning Beam

Summary Of Scanning Beam Adjustment

To Move Beam

Down

Tighten top left

screw

or or or or

Loosen both

bottom screws

To Move Beam

Up

Tighten both bottom

screws

Loosen top left screw Tighten bottom

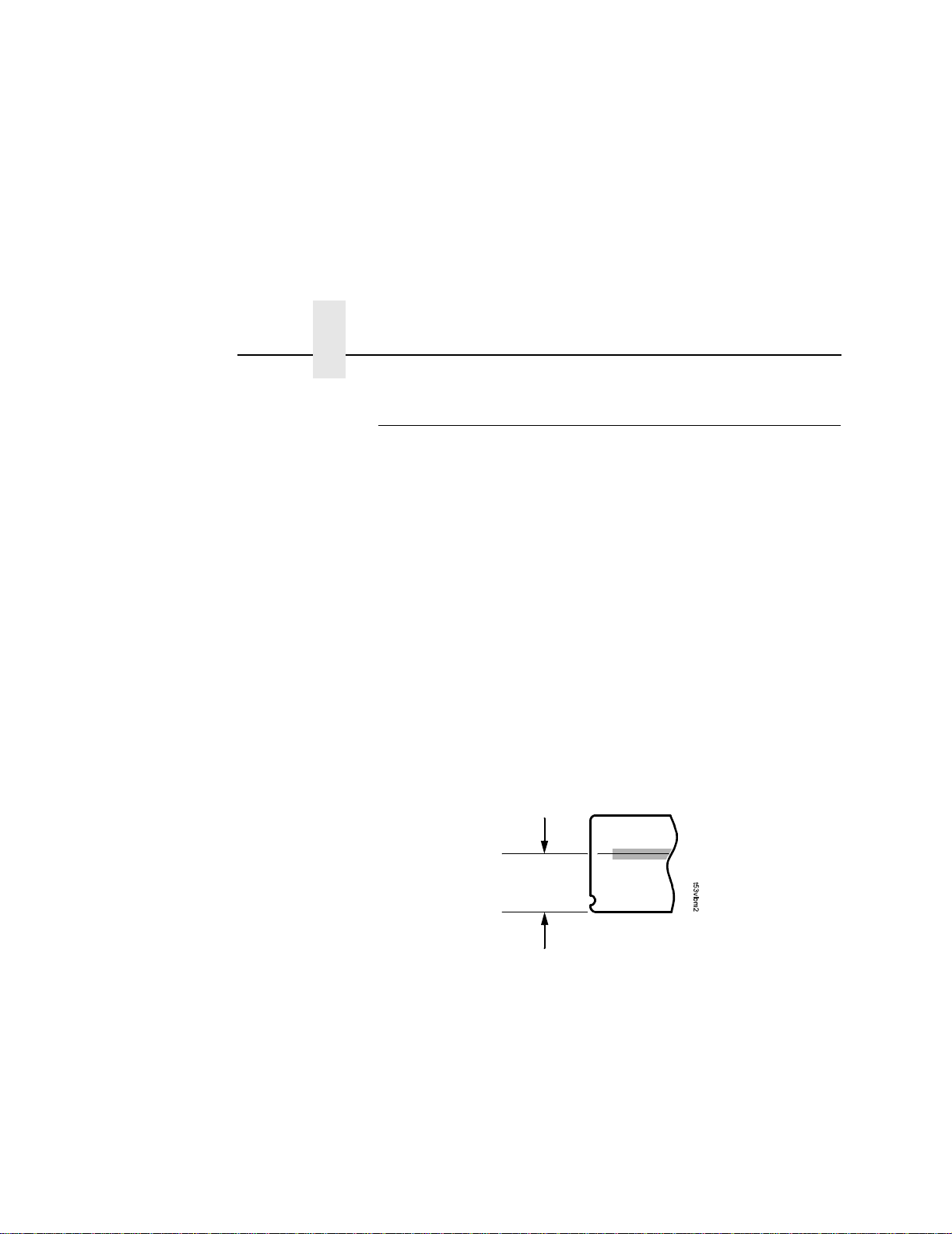

NOTE: If the printer does not have a tear bar with notches at the

ends, adjust the scanning beam so that the center of the

beam is approximately 0.06 inches (1.52 mm) from the

lower edge as shown in Figure 15.

0.06 inches

(1.52 mm)

T o Rotate Beam

Clockwise

Loosen bottom

right screw

left screw

Counterclockwise

Loosen bottom left

screw

Tighten bottom

right screw

To Rotate Beam

32

Figure 15. Adjusting the Center of the Scanning Beam

Page 33

Shif ting The Scanning Beam

This option enables you to shift the scanning beam horizontally to

the left or right. The left edge of the beam should be approximately

0.13 inches (3.3 mm) past the left edge of the tear bar. After you set

this value, save it as part of the configuration for future use.

The value range is from –99 to 99. The default is 0. Lower values

will move the beam to the left.

NOTE: You must set Admin User to Enable in the PRINTER

CONTROL menu to access the Beam Shift option.

(Refer to the

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

User’s Manual

Cut Media Handling Mode

.)

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ until Validator Funct. displays.

5. Make sure Enable is selected.

6. Press ↓ until Beam Shift displays.

7. Press + or – to scroll through the values: –99 to 99. The default

is 0. Lower values will move the beam to the left. Press

accept the shift value.

Keep selecting the new value until the beam width is at the

desired position. The left edge of beam should be

approximately 0.13 inches (3.3 mm) from the left edge of the

tear bar.

8. Save the configuration for future use.

.

.

↵ to

33

Page 34

Chapter 1 Calibration

Calibration

WARNING

WARNING

Time RESET Button Is Depressed Result

Less than 2 seconds Turns on the scanning beam

More than 4 but less than 6 seconds Validator goes into calibration mode

More than 6 seconds Resets validator to the last good calibration

Class 2 laser light. Do not stare into the laser beam or a

reflected image of the laser beam.

Using controls, making adjustments, or performing

procedures other than those specified herein may result in

hazardous radiation exposure.

The validator should be calibrated when it is first installed or when

the printer displays Calibration warning. A special calibration bar

code card is included with the validator package.

1. Make sure the printer is on and the scanning beam is on. If the

beam is off, press the RESET button for less than 2 seconds to

turn on the beam.

Table 2. RESET Button Settings

settings and turns off the scanning beam

34

2. Raise the media cover. Open the pivoting deck by rotating the

deck lock lever fully clockwise. The pivoting deck will swing

upward, exposing the bottom of the printhead assembly.

3. If the printer has the cutter option, put the cutter in the open

(down) position.

4. Remove the calibration bar code card from its protective sleeve

and slide it into the open printhead and under the scanning

beam. (Figure 16.)

5. Make sure the bar code is under the scanning beam and the

CALIBRATION light is on.

6. Press and hold the RESET button on the validator until the

CALIBRATION light begins flashing.

Page 35

CALIBRATION Light

Cut Media Handling Mode

RESET Button

Deck Lock

Lever

Calibration Bar Code Card

Figure 16. Calibrating the Validator

7. The scanning beam should turn off for a few seconds then back

on, and the CALIBRATION light should turn off. This indicates a

successful calibration.

NOTE: If the scanning beam does not turn back on and/or the

calibration light is still on or flashing, the calibration has

failed. In this case, refer to Table 2 on page 34 to repeat

the calibration procedure or to reset the validator settings

back to factory default.

8. Once you have a successful calibration, remove the calibration

bar code card.

9. Close the pivoting deck and rotate the deck lock lever fully

counterclockwise.

10. Close the media cover.

35

Page 36

Chapter 1 Calibration

11. Power the printer off, wait a few seconds, then power the

printer on.

If the calibration was successful, the scanning beam is on and

the CALIBRATION light is off.

If the calibration was not successful, the scanning beam

remains on and the CALIBRATION light stays lit without

flashing. Repeat the calibration procedure. If repeated attempts

fail, check the room for excessive ambient light, including direct

sunlight. You may need to move the printer to a darker area of

the room.

NOTE: In some cases the validator can detect and indicate to the

Bar Code Validation Demo Page

The bar code validation demo page allows you to test or

demonstrate the validator operation without a host computer. This

page contains some text and two good bar code symbologies: one

in Code 39, the other in Code 128.

To print and validate the bar code validation demo page:

printer that calibration is required. See “Calibration

warning” in Table 6, page 86.

36

1. Load the factory default configuration. (Refer to the

Manual

2. In the VALIDATOR menu, set Validator Funct. to Enable.

3. In the CALIBRATE CTRL menu, set Gap/Mark Sensing to Gap.

4. Load media.

5. In the CALIBRATE CTRL menu, run Auto Calibrate for proper

gap sensing.

6. The printer must be offline. If the printer is in Menu mode, press

the PAUSE key to take the printer offline.

7. Press the TEST PRINT key to enter the Test Print menu.

Continue to press TEST PRINT until Barcode Demo displays.

8. Press the

key is locked, unlock it by pressing ↓ and

.)

↵ key to print and validate the demo page. (If the ↵

↵ at the same time.)

User’s

Page 37

Bar Code Validation Demo Page

9. The printer will print one demo page containing two good bar

codes.

NOTE: In the QUICK SETUP or MEDIA CONTROL menu, if Label

Length is set between 0.5 and 1.0 inches, only one good

bar code will print.

If Label Length is less than 0.5 inches and Label Width is

less than 2.0 inches, no demo page will print.

10. To demonstrate a bad bar code reading, block the scanning

beam with an opaque object while the bar code moves under

the beam. When you block the beam, the validator will generate

a reading error and will perform a default error action. The

default setting for the Validator Action in the VALIDATOR menu

is Retry Form.

11. Press PAUSE to take the printer offline.

12. Press ↓ and

PAUSE to put the printer back online.

↵ at the same time to lock the ↵ key, then press

37

Page 38

Chapter 1 Calibration

38

Page 39

2 Operation

Basic V alid ator Setup

Unit Positioning

The validator must be positioned so that the scanning beam covers

the entire area containing the bar codes, including the area

required for quiet zones. The validator can be moved along the

lower bracket and aligned with any of the inscribed hash marks,

depending on the size of the labels printed and the positioning of

the bar codes on those labels. In addition, the beam width can be

moved horizontally to the left or right (see “Shifting The Scanning

Beam” on page 33).

If a bar code is completely outside of the scanning area, straddles

an edge, or does not pass completely under the scanning beam,

the validator interprets it as a missing bar code and generates error

conditions.

V alidato r Front Pan el

The front panel of the validator has the following controls and

indicators:

• POWER: Indicates the validator is at full power.

• CALIBRATION: Flashes when the validator is in calibration

mode. See page 34 for calibration instructions .

• READ: Flashes when the validator is reading a bar code.

• 1 and 2: Used for maintenance purposes only.

• RESET: This button is used in the calibration procedure and

possible troubleshooting situations. Except in these specific

circumstances, the RESET button should not be used.

39

Page 40

Chapter 2 Basic Validator Setup

Table 3. RESET Button Settings

Time RESET Button Is Depressed Result

Less than 2 seconds Turns on the scanning beam

More than 4 but less than 6 seconds Validator goes into calibration mode

More than 6 seconds Resets validator to the last good calibration

settings and turns off the scanning beam

CAUTION

CAUTION

Do not lift the printer by the validator unit or by the lower

bracket.

The validator contains sensitive electronic equipment. Do not

jar or drop the unit.

40

Page 41

VALIDATOR

VALIDATOR Menu

VALIDAT OR Menu

Validator Funct.

page 44

Auto Report

page 45

Auto Report Time

page 46

Clear Data

page 47

Good Barcodes

page 49

Good Forms

page 49

Overstrike Forms

page 49

Average BWD

page 49

Last BWD

page 49

Telemetry Pat h

page 47

1

1

Enable* Disable

Disable* Enable

1 second* 1 to 10 seconds

1

1

1

Disabled* Network Port

Notes:

* = Default

Italicized items appear only when

Admin User is set to Enable (in the

PRINTER CONTROL menu).

1

Display item only

Telemetry Data

page 48

Number of Codes

page 50

Validator Ac t i on

page 79

Quiet Zones

page 50

(cont. on next page)

Short Report*

Auto* 1 to 99

Retry Form* Stop & Retry Grade&Report

Rescan&Retry Stop Overstrike

Enable* Disable

Full Report Validation Mode

Rescan Form

Rescan&Stop

41

Page 42

Chapter 2 Basic Validator Setup

VALIDATOR

(cont. from previous page)

Min. Code Height

page 74

Min. Code Gap

page 76

Skip Labels

page 52

F/W Revision

page 51

Overstrike Style

page 52

I2of5 Checksum

page 53

Num Retry

page 54

Num Rescan

page 54

Max Retry Action

page 54

Decodeability

page 55

Percent Decode

page 56

Defects

page 56

Overall Grade

page 57

Modulation

page 59

0.13 to 1.00 inches0.30 inches*

0.15 to 1.00 inches0.30 inches*

Minimum* Maximum

Version: xxxx

Grid* Error Typ e MsgCheckerboard

Disable* Enable

5* 3

1* 1 to 5

Dump Form* Keep Form

1

Grey

4

37%* 30% to 90%

60%* 0% to 99%

20%* 0% to 100%

0.5* 0.0 to 4.0

50%* 0% to 100%

Notes:

* = Default

Italicized items appear

only when Admin User

is set to Enable (in the

PRINTER CONTROL

menu).

1

Display item only.

(cont. on next page)

42

EC Min

page 59

15%* 0% to 100%

Page 43

VALIDATOR

(cont. from previous page)

VALIDATOR Menu

Rmin

page 60

Symbol Contrast

Symbol Contrast

page 61

page 61

Gain

page 61

Offset

page 62

SN Threshold

page 62

Scan Report

page 63

Scan Profile

page 65

Profile H Mag

page 67

Print Settings

page 68

Scanner Settings

page 70

0% to 100%50%*

0% to 100%30%*

1 to 255

1 to 255

5 to 19970*

1* 1 to 4

Default 4xx, Default 6yy, or Default 8zz*

2

feature files

3

Beam Width

page 71

Beam Shift

page 72

1800, 2550, or 3100*

0* –99 to 99

4

250 to 3100

Notes:

* = Default

Italicized items appear only when Admin User is set to Enable (in the PRINTER CONTROL menu).

2

Depends on the printer model: 4, 6, and 8 inch printers respectively.

xx, yy, zz

= file revision

numbers.

3

Appears only if feature files have been downloaded to the printer. Up to seven files can appear.

4

Depends on the printer model: 4, 6, and 8 inch printers respectively.

43

Page 44

Chapter 2 Configuring The Validator

Configuring The Validator

Setting validator options is done through the printer configuration

menu. The validator comes equipped with a default setting for each

configuration option, and it works without having to change any of

these options. However, in some cases it is necessary to adjust

these options, which are described below.

NOTE: If you make any changes to the default configuration menu

items, you will be prompted to save the configuration.

See “Auto Save Configuration” in the

Enabling And Disabling The V alidator

Software can automatically detect an installed validator when the

printer is powered up. If the printer is powered up with Power-Up

Config. set to Factory, the VALIDATOR menu will be available and

Validator Funct. is set to Enable in the QUICK SETUP and

VALIDATOR menus.

If Power-Up Config. is not set to Factory, the VALIDATOR menu

will be available, but Validator Funct. is set to Disable. Enable

Validator Funct. by completing the following steps. (This is a onetime setting once you save the configuration.)

Quick Setup Guide

.

IMPORTANT

44

Do not disable or enable the validator with data in the buffer.

See “Resetting Validator Data” on page 47.

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

.

.

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ until Validator Funct. displays.

5. Press + or – until Enable displays.

6. Press

↵ to enable the validator. An asterisk (*) should appear

after Enable. Once enabled, the printer will command the

validator to begin scanning and reporting errors, and the

counters will be incremented.

.

.

Page 45

Validator Reporting

7. Press ↓ and ↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

NOTE: To disable the validator once it has been enabled, repeat

steps 1 to 8 and select Disable in step 5.

RFID Encoder

If you have an RFID encoder but are not encoding RFID tags, make

sure RFID Reader is set to Disable (in the RFID CONTROL menu),

otherwise the validation process will slow down considerably as the

RFID encoder attempts to scan for non-existent RFID tags.

V alidat or Reporting

After any completed print job, you can request a report from the

printer which describes the validation statistics since the printer was

turned on, or since the last data reset (for information on resetting

data, see page 47).

Requesting A Validator Report

This procedure prints a summarized validator report. (This report

also includes RFID data if the printer has an RFID encoder.)

1. Press the PAUSE key to take the printer offline.

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

3. Press TEST PRINT. Printer Tests displays.

4. Press + unti l RFID/O DV Report disp lay s.

5. Press

6. Press ↓ and

7. Press PAUSE again to put the printer online.

↵ to print the report.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

Setting Auto Report

This function allows you to disable or enable an automatic validator

report printout after a batch job. The default is Disable.

45

Page 46

Chapter 2 Configuring The Validator

You can determine the end of a batch job in two ways:

• by using an Execute command, or

• by enabling the Auto Report Time (see below).

To enable Auto Report:

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

.

.

4. Press ↓ until Auto Report displays.

5. Press + or – to scroll through the choices: Enable or Disable.

The default is Disable.

6. When Enable displays, press

7. Press ↓ and

↵ at the same time to lock the ↵ key, then press

↵ to activate Auto Report.

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

Setting Auto Report T ime

This function allows you to set, in seconds, the timeout for the Auto

Report. If the printer is idle for the set number of seconds, an Auto

Report will be generated if Auto Report is set to Enable (see

“Setting Auto Report” on page 45.) The default is 1 second.

To set the Auto Report Time:

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

↵ key.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ until Auto Report Time displays.

.

.

↵ at the same time to unlock the

.

.

.

46

5. Press + or – to scroll through the choices: 1 to 10 seconds. The

default is 1 second.

6. When the desired number of seconds displays, press

↵ to set

the Auto Report Time.

Page 47

Validator Reporting

7. Press ↓ and ↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

Resetting Validator Data

The validator reports on all bar codes it detects since the last data

reset. For example, you print a large batch of labels with bar codes

and then print a validator report. Then you print another batch of

labels with bar codes and print another report. The report will

contain information on both batch jobs. However, if you reset the

validator data between batch jobs, the second report will only

contain information on the second batch job.

To reset Validator Data:

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

.

.

4. Press ↓ until Clear Data displays.

5. Press

6. Press ↓ and

↵ to clear validator data.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

7. Press PAUSE again to put the printer online.

Defining The Data Output Destination (Telemetry Path)

You may want to send a streaming flow of validation data to an

external device during the print job. The default is Disabled. Follow

the procedure below to select the data output destination.

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

↵ key.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ until Telemetry Path displays.

.

.

↵ at the same time to unlock the

.

.

.

47

Page 48

Chapter 2 Configuring The Validator

5. Press + or – to cycle through the choices:

• Disabled. Default setting. The validator does not send any

data to an external device.

• Network Port. The printer outputs the bar code analysis

and underlying data from the validator to a device

connected to the network port so the validator data can be

seen and analyzed with the optional remote management

software.

6. When your select i on displ ay s, pres s

reports are output to your selection.

↵ to activate it. All future

7. Press ↓ and

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

↵ at the same time to lock the ↵ key, then press

Selecting The Type Of Report For the Data Output Destination (Telemetry Data)

By default, the validator sends the Short Report to the selected data

output destination, but there are two other report options available:

Full Report and Validation Mode.

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

↵ key.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ until Telemetry Data displays.

5. Press + or – to cycle through the choices:

• Short Report. Default setting. Provides the encoded failure

• Full Report. Provides a completed report of all the data

.

.

↵ at the same time to unlock the

.

.

.

cause or pass indication and the bar width deviation,

shown as a percentage.

captured by the validator.

48

• Validation Mode. Provides the same data as the Short

Report, but adds the actual bar code data read.

6. When your select i on displ ay s, pres s

↵ to activate it.

Page 49

Validator Statistics

7. Press ↓ and ↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

V alidator Statistics

The validator displays a number of statistics directly on the printer

LCD, without having to print a report. To view any of the statistics:

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ to scroll through the following statistics on the printer

display:

• Good Barcodes: The number of bar code reports sent

from the validator since the last Clear Data command.

• Good Forms: The number of good (non-overstruck) forms

printed since the last Clear Data command.

• Overstrike Forms: The number of forms containing a bar

code that fell below the minimum acceptable level since the

last Clear Data command.

• Average BWD: The average of all Bar Width Deviations

reported since the last Clear Data command, shown as a

percentage.

• Last BWD: The Bar Width Deviation included in the most

recent report received from the validator, shown as a

percentage.

NOTE:

A bar code’s Bar Width Deviation is determined by

comparing the bar width the validator expects to the bar

width that is actually printed. For example, if the bar width is

printed exactly as the validator expects, the BWD is 0%.

However, if the bar width as printed is 25% wider or narrower

than the validator expects it to be, it reports a BWD of 25%.

5. Press ↓ and ↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

.

.

6. Press PAUSE again to put the printer online.

49

Page 50

Chapter 2 Configuring The Validator

Defining Validator Options

A number of validator options which define specific parameters for

certain print jobs can be set from the printer configuration menu.

Setting Number Of Bar Codes On A Form

You can define how many bar codes the validator should expect on

a form. This setting is required when bar codes are produced as a

part of a larger bitmapped image. When set to a specific number,

the printer checks after a form has printed and passed the validator

and determines if it has received an analysis report for each bar

code. If the printer does not have as many reports as it expects, it

assumes a gross bar code failure.

When Auto (the default) is selected, the printer only expects as

many bar code analyses as bar codes printed using printer bar

code commands defined by the host software.

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

↵ key.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ until Number of Codes displays.

5. Press + or – to scroll through the choices: Auto, 1 to 99. The

default is Auto.

.

.

↵ at the same time to unlock the

.

.

.

50

6. Press

7. Press ↓ and

8. Press PAUSE again to put the printer online.

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

Checking Quiet Zones

Quiet zones are the white spaces surrounding the bar code. Each

bar code requires a minimum quiet zone distance in order for the

bar code to be scanned properly.

NOTE: The validator requires a minimum distance of 1/2” or 20

times the minimum element width (x-dimension), whichever

is greater, between bar codes.

Page 51

Defining Validator Options

When set to Enable (the default), then the bar code quiet zone is

included as part of the pass/fail criteria.

.

1. Press to take the printer offline and place the printer in

.

.

Menu mode.

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

.

.

4. Press ↓ until Quiet Zones displays.

5. Press + or – to scroll through the choices: Enable or Disable.

The default is Enable.

6. Press

7. Press ↓ and

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

NOTE: The validator does not recognize x-dimensions greater

than 40 mil with Quiet Zones enabled.

Checking The Firmware Revision Number

For troubleshooting purposes, you may need to reference the

firmware revision number.

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

↵ key.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ until F/W Revision displays. The firmware revision

number displays.

.

.

↵ at the same time to unlock the

.

.

.

5. Press ↓ and

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

6. Press PAUSE again to put the printer online.

51

Page 52

Chapter 2 Configuring The Validator

Setting For Skip Labels

This option is used for skipping blank labels after bad labels have

been marked. It is useful when you want to have extra blank labels

in between bad and good ones. The settings are Minimum (the

default) and Maximum. Minimum allows up to one blank label, and

Maximum allows up to two blank labels.

NOTE: Minimum and Maximum blank labels are only applicable for

forms 2 inches (5.08 cm) high or more. For labels less than

2 inches high, the minimum and maximum blank labels

may vary.

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

IMPORTANT

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

.

.

4. Press ↓ until Skip Labels displays.

5. Press + or – to scroll through the choices: Minimum or

Maximum. The default is Minimum.

6. Press

7. Press ↓ and

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

Setting Overstrike Style

This option is used for marking bad labels with different overstrike

styles: Grid (the default), Grey, Checkerboard, or Error Type Msg.

If you are using an RFID encoder, set the validator Overstrike

Style different than the RFID Overstrike Style (in the RFID

CONTROL menu). This will help you differentiate between a

validator error and an RFID error.

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

↵ key.

3. If necessary, press until VALIDATOR displays.

.

.

↵ at the same time to unlock the

.

.

.

52

Page 53

Defining Validator Options

4. Press ↓ until Overstrike Style displays.

5. Press + or – to scroll through the choices: Grid, Grey,

Checkerboard, or Error Type Msg. The default is Grid.

6. Press

7. Press ↓ and

8. Press PAUSE again to put the printer online.

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

Setting I2of5 Checksum

This option allows you to include or exclude the checksum option in

the Interleaved 2 of 5 code as part of the grading. For example, if

you enable this option, then any incoming bar code data without

checksum digits will be graded as a failure, and a Checksum

Failure error will display. The default is Disable.

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

↵ key.

3. If necessary, press until VALIDATOR displays.

4. Press ↓ until I2of5 Checksum displays.

5. Press + or – to scroll through the options: Enable or Disable.

The default is Disable.

6. Press

.

.

↵ at the same time to unlock the

.

.

.

↵ to accept the desired value.

7. Press ↓ and

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

↵ at the same time to lock the ↵ key, then press

53

Page 54

Chapter 2 Configuring The Validator

Num Retry

This option allows you to set the number of times a form will be

reprinted before the printer stops. After you clear the error

message, the printer will print the same form or the next form,

depending on the setting for Max Retry Action (see “Max Retry

Action” below).

The options are 3, 4, and 5. The default is 5.

NOTE: This setting is utilized only when Validator Action is set to

Retry Form, Stop & Retry, or Rescan&Retry. See “Error

Action” on page 79.

Num Rescan

This option allows you to set the number of times a form will be

rescanned before the printer stops. After you clear the error

message, the printer will print the same label or the next label,

depending on the setting for Max Retry Action (see “Max Retry

Action” below).

The options are 1 to 5. The default is 1.

54

NOTE: This setting is utilized only when Validator Action is set to

Rescan, Rescan&Retry, or Rescan&Stop. See “Error

Action” on page 79.

Max Retry Action

This option determines what the printer will do with the current form

once the Num Retry or Num Rescan counter has been exhausted

(see “Num Retry” or “Num Rescan” above).

If Max Retry Action is set to Dump Form, after you clear the fault

the form will be dumped and printing will resume with the next form.

If Max Retry Action is set to Keep Form, after you clear the fault

printing will resume with the same form again. It will not attempt to

print the next form until the problem form has printed correctly.

NOTE: This setting is utilized only when Validator Action is set to

Retry Form, Stop & Retry, Rescan Form, Rescan&Retry, or

Rescan&Stop. See “Error Action” on page 79.

Page 55

Advanced Validator Options

Advanced Validator Options

The following items are considered advanced items and are only

visible if Admin User is set to Enable (in the PRINTER CONTROL

menu). Refer to the configuration section of your

more information.

Decodeability

NOTE: This parameter factors into the Overall Grade (page 57).

You can determine how strict the validator grades the wide/narrow

bars and spaces which compose the bar code by setting the

Decodeability parameter to a percentage value from 30% to 90%.

The higher the percentage value chosen, the stricter the validator

grades. The default is 37%.

For example, if the Decodeability value is set to 37%, the validator

gives the bar code a failing grade if the decodeability of the bar

code is at or below 37%.

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

User’s Manual

for

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

4. Press ↑ until Decodeability displays.

5. Press + or – to scroll through the percentage values: 30% to

90%. The default is 37%.

6. Press

7. Press ↓ and

8. Press PAUSE again to put the printer online.

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

.

.

55

Page 56

Chapter 2 Configuring The Validator

Percent Decode

NOTE: This parameter factors into the Overall Grade (page 57).

You can set how strict the validator grades each bar code. For

example, the Percent Decode default is 60%. This means that 60%

of the scanned bar code must be readable for the validator to give

the bar code a passing grade. You can set the Percent Decode

parameter to a percentage value from 0% to 99%. The higher the

percentage value chosen, the stricter the validator grades.

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

.

.

4. Press ↑ until Percent Decode displays.

5. Press + or – to scroll through the percentage values: 0% to

90%. The default is 60%.

6. Press

7. Press ↓ and

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

Defects

NOTE: This parameter factors into the Overall Grade (page 57).

You can set how strict the validator grades the irregularities such as

voids and spots found within elements and quiet zones for each bar

code. For example, the Defects default is 20%. This means that if

the bar code and quiet zone defects exceed 20%, the validator

gives the bar code a failing grade. You can set the Defects

parameter to a percentage value from 0% to 100%. The lower the

percentage value chosen, the stricter the validator grades.

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

56

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

.

.

Page 57

Advanced Validator Options

4. Press ↑ until Defects displays.

5. Press + or – to scroll through the percentage values: 0% to

100%. The default is 20%.

6. Press

7. Press ↓ and

8. Press PAUSE again to put the printer online.

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

Overall Grade

This menu item sets the value used by the validator for pass/fail

threshold during the analysis of bar codes. Instead of a letter grade,

numbers are used to allow for more resolution. The numbers can

be translated to letter grades according to the 4.0 grade table

below.

T a ble 4. Grading Scale for Overall Grade

Letter Grade Grade Numerical Range

A 3.5 to 4.0

B 2.5 to 3.4

C 1.5 to 2.4

D 0.5 to 1.4

F 0.0 to 0.4

Any bar code with a grade below this threshold value will cause the

printer to display the Overall Grade Fail error message (see “Error

Messages” on page 86) and take the appropriate error action.

Higher values create a stricter pass criterion.

The Overall Grade is determined by taking the lowest grade

obtained for any of these bar code quality parameters:

Decodeability, Percent Decode, Defects, Modulation, EC Min,

Rmin, and Symbol Contrast.

You can set the Overall Grade parameter to a value from 0.5 to 4.0.

The default is 0.5.

57

Page 58

Chapter 2 Configuring The Validator

Overall Grade Calculations

The validator follows the specified algorithm defined in the ANSI

X3.182 specification for determining the Overall Grade based on an

average. Although it is not defined, the validator truncates the result

of all analysis parameters averages for a slightly stricter grading.

A side effect of the ANSI specified algorithm is that the Overall

Grade may be lower than any of the averaged analysis parameters.

This occurs because the Overall Grade is based on the lowest

grade on any scan converted to a single digit grade (A to F, 4 to 0)

which is then averaged. This usually occurs when a single analysis

parameter has a value just above or just below the Overall Grade.

Example

The Decodeability value of 51 displays as B, but the Overall Grade

displays as C.

The bar code was scanned five times: three scans had values of

0.49 (grade C) and two scans had values of 0.54 (grade B).

The Decodeability grading cal c ula tio n is:

(3 x 0.49) + (2 x 0.54) = 2.55

2.55 ÷ 5 = 0.51 (grade B)

The Overall Grade calculation is:

(3 x 2.0) + (2 x 3.0) = 12

12 ÷ 5 = 2.4 (grade C)

58

Also, with certain combinations of multiple analysis parameters and

possibly the truncation used on the analysis parameter’s average,

the Overall Grade may be higher than an individual analysis

parameter grade.

Example

The Decodeability value of 48 displays as C, but the Overall Grade

displays as B.

The bar code was scanned five times: four scans had values of

0.51 (grade B) and one scan had a value of 0.40 (grade C).

The Decodeability grading cal c ula tio n is:

(4 x 0.51) + (1 x 0.40) = 2.44

2.44 ÷ 5 = 48.8 (grade C)

The Overall Grade calculation is:

(4 x 3.0) + (1 x 2.0) = 14

14 ÷ 5 = 2.8 (grade B)

Page 59

Advanced Validator Options

Modulation

NOTE: This parameter factors into the Overall Grade (page 57).

Modulation measures how well the scan laser sees the wide

elements (bars or spaces) relative to the narrow elements. In

general, scanning lasers see bars better than spaces and wide

elements better than the narrow elements. This menu item sets the

value used by the validator for pass/fail threshold during the

analysis of bar codes. Higher values create a stricter criterion for

passing.

You can set the Modulation parameter to a percentage value from

0% to 100%. The default is 50%.

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

2. If necessary, press ↓ and

↵ at the same time to unlock the

↵ key.

.

3. If necessary, press until VALIDATOR displays.

.

.

4. Press ↑ until Modulation displays.

5. Press + or – to scroll through the percentage values: 0% to

100%. The default is 50%.

6. Press

7. Press ↓ and

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

8. Press PAUSE again to put the printer online.

EC Min

NOTE: This parameter factors into the Overall Grade (page 57).

The higher the value, the stricter the criterion for passing.

This menu item sets the minimum edge contrast, which is the worst

edge transition (bar to space or space to bar) used by the validator

for pass/fail threshold during the analysis of bar codes. Bar codes

with an edge contrast below this threshold will fail.

You can set the EC Min parameter to a percentage value from 0%

to 100%. The default is 15%.

.

1. Press to take the printer offline and place the printer in

Menu mode.

.

.

59

Page 60

Chapter 2 Configuring The Validator

2. If necessary, press ↓ and ↵ at the same time to unlock the

↵ key.

3. If necessary, press until VALIDATOR displays.

4. Press ↑ until EC Min displays.

5. Press + or – to scroll through the percentage values: 0% to

100%. The default is 15%.

.

.

.

6. Press

7. Press ↓ and

8. Press PAUSE again to put the printer online.

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

Rmin

NOTE: This parameter factors into the Overall Grade (page 57).

This menu item sets the minimum reflectance value used by the

validator for pass/fail threshold used during the analysis of bar

codes. A bar code will fail if all the bar reflectance values are above

the percentage of space reflectance set by this threshold. For

example, an Rmin setting of 50% requires that at least one bar

reflectance value fall under the mid point of the reflectance value

read for the highest space reflectance.

You can set the Rmin parameter to a percentage value from 0% to

100%. The default is 50%.

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

↵ key.

3. If necessary, press until VALIDATOR displays.

4. Press ↑ until Rmin displays.

.

.

↵ at the same time to unlock the

.

.

.

60

5. Press + or – to scroll through the percentage values: 0% to

100%. The default is 50%.

6. Press

7. Press ↓ and

8. Press PAUSE again to put the printer online.

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

Page 61

Advanced Validator Options

Symbol Contrast

NOTE: This parameter factors into the Overall Grade (page 57).

The higher the value, the stricter the criterion for passing.

Symbol Contrast represents the contra st betwe en the bars and

spaces in the bar code used by the validator for pass/fail threshold

used during the analysis of bar codes. The bar code must have a

certain level of contrast to be recognized by the validator. Bar

codes with a symbol contrast below the threshold will fail.

You can set the Symbol Contrast parameter to a percentage value

from 0% to 100%. The default is 30%.

NOTE: To disable this parameter, set Symbol Contrast to 0%.

.

1. Press to take the printer offline and place the printer in

Menu mode.

2. If necessary, press ↓ and

↵ key.

3. If necessary, press until VALIDATOR displays.

4. Press ↑ until Symbol Contrast displays.

5. Press + or – to scroll through the percentage values: 0% to

100%. The default is 30%.

.

.

↵ at the same time to unlock the

.

.

.

6. Press

7. Press ↓ and

8. Press PAUSE again to put the printer online.

↵ to select the desired value.

↵ at the same time to lock the ↵ key, then press

PAUSE to take the printer offline.

Gain

This menu item sets the scanner gain setting. This allows you to

adjust the amplitude (height) of the space/bar transitions as seen

on a Scan Profile to optimize the validator hardware for applications

where standard settings make the bar codes unreadable.

NOTE: This menu does not have a default setting because the

value is hardware dependent. The initial value is read from

the validator’s flash memory.

After the initial value has been determined, you can set the Gain

parameter to a value from 1 to 255.

61

Page 62