Page 1

RFID Smart Label

Developer’s Kit

and

Smart Label Pilot Printer

Quick Setup Guide

The Printronix T5000

e

T M Series of Thermal Printers

Page 2

This Quick Setup Guide contains a CD-ROM with

the following materials:

• The User’s Manual

• Programmer’s Reference Manuals

• Useful utility programs

The CD-ROM is located in a plastic pocket in the back cover.

Do not discard this guide. If you move or pack the printer in the future,

you will need to follow the instructions in this guide.

For technical assistance, contact your

Distributor/VAR/Reseller for service.

For further assistance, contact the Printronix Customer Support Center.

The Customer Support Center offers technical support with:

• Installation

• Configuration and Setup

• Operation and Supplies Loading

• Specifications of Proper Print Media and Ribbons

• Answers to Post-Sales Service Support Questions

Printronix Customer Support Center contact information:

Americas 1-714-368-2686

Europe, Middle East, and Africa (31) 24 6489 410

Asia Pacific (65) 65484114

Web site: http://www.printronix.com/public/servicessupport/default.aspx

Genuine Printronix Supplies:

Americas 1-800-733-1900

Europe, Middle East, and Africa 33.1.46.25.1900

Asia Pacific (65) 65484116 or (65) 65484182

Web site: http://www.printronix.com/public/supplies/default.aspx

Or visit the Printronix web site at www.printronix.com

Page 3

The Printronix T5000 e Series of Thermal Printers

RFID Smart Label Developer’s Kit

and Smart Label Pilot Printer

Quick Setup Guide

Page 4

Software License Agreement

CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS BEFORE USING THIS PRINTER.

USING THIS PRINTER INDICATES YOUR ACCEPTANCE OF THESE TERMS AND CONDITIONS. IF YOU

DO NOT AGREE TO THESE TERMS AND CONDITIONS, PROMPTLY RETURN THE PRINTER AND ALL

ACCOMPANYING HARDWARE AND WRITTEN MATERIALS TO THE PLACE YOU OBTAINED THEM, AND

YOUR MONEY WILL BE REFUNDED.

Definitions.

“Software” shall mean the digitally encoded, machine-readable data and program. The term “Software

Product” includes the Software resident in the printer and its documentation. The Software Product is licensed

(not sold) to you, and Printronix, Inc. either owns or licenses from other vendors who own, all copyright, trade

secret, patent and other proprietary rights in the Software Product.

License.

1. Authorized Use. You agree to accept a non-exclusive license to use the Software resident in the printer

solely for your own customary business or personal purposes.

2. Restrictions.

a. To protect the proprietary rights of Printronix, Inc., you agree to maintain the Software Product and

other proprietary information concerning the typefaces in strict confidence.

b. You agree not to duplicate or copy the Software Product.

c. You shall not sublicense, sell, lease, or otherwise transfer all or any portion of the Software Product

separate from the printer, without the prior written consent of Printronix, Inc.

d. You may not modify or prepare derivative works of the Software Product.

e. You may not transmit the Software Product over a network, by telephone, or electronically using any

means; or reverse engineer, decompile or disassemble the Software.

f. You agree to keep confidential and use your best efforts to prevent and protect the contents of the

Software Product from unauthorized disclosure or use.

3. Transfer. You may transfer the Software Product with the printer, but only if the recipient agrees to accept

the terms and conditions of this Agreement. Your license is automatically terminated if you transfer the

Software Product and printer.

Limited Software Product Warranty

Printronix, Inc. warrants that for ninety (90) days after delivery, the Software will perform in accordance with

specifications published by Printronix, Inc. Printronix, Inc. does not warrant that the Software is free from all

bugs, errors and omissions.

Remedy

Your exclusive remedy and the sole liability of Printronix, Inc. in connection with the Software is replacement

of defective software with a copy of the same version and revision level.

Disclaimer of Warranties and Limitation of Remedies

1. THE PARTIES AGREE THAT ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE AND MERCHANTABILITY ARE

EXCLUDED.

Printronix, Inc. does not warrant that the functions contained in the Software will meet your requirements

or that the operation of the Software will be uninterrupted or error free.

Printronix, Inc. reserves the right to make changes and/or improvements in the Software without notice at

any time.

Page 5

2. IN NO EVENT WILL PRINTRONIX, INC. BE LIABLE FOR LOST PROFITS, LOST DATA, BUSINESS

INTERRUPTIONS, OR ANY OTHER DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF THE USE OF OR INABILITY TO USE THIS PRODUCT, EVEN IF

PRINTRONIX, INC. HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, OR ANY

DAMAGES CAUSED BY THE ABUSE OR MANIPULATION OF THE SOFTWARE. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

3. Printronix, Inc. will not be liable for any loss or damage caused by delay in furnishing a Software Product

or any other performance under this Agreement.

4. Our entire liability and your exclusive remedies for our liability of any kind (including liability for

negligence except liability for personal injury caused solely by our negligence) for the Software Product

covered by this Agreement and all other performance or nonperformance by us under or related to this

Agreement are limited to the remedies specified by this Agreement.

5. California law governs this Agreement.

Termination of License Agreement

This License shall continue until terminated. This license may be terminated by agreement between you and

Printronix, Inc. or by Printronix, Inc. if you fail to comply with the terms of this License and such failure is not

corrected within thirty (30) days after notice. When this License is terminated, you shall return to the place you

obtained them, the printer and all copies of the Software and documentation.

U.S. Government Restricted Rights

Use, duplication or disclosure by the Government is subject to restrictions as set forth in the Rights in

Technical Data and Computer Software clause at FAR 242.227-7013, subdivision (b) (3) (ii) or subparagraph

(c) (1) (ii), as appropriate. Further use, duplication or disclosure is subject to restrictions applicable to

restricted rights software as set forth in FAR 52.227-19 (c) (2).

Acknowledgement of Terms and Conditions

YOU ACKNOWLEDGE THAT YOU HAVE READ THIS AGREEMENT, UNDERSTAND IT, AND AGREE TO

BE BOUND BY ITS TERMS AND CONDITIONS. NEITHER PARTY SHALL BE BOUND BY ANY

STATEMENT OR REPRESENTATION NOT CONTAINED IN THIS AGREEMENT. NO CHANGE IN THIS

AGREEMENT IS EFFECTIVE UNLESS WRITTEN AND SIGNED BY PROPERLY AUTHORIZED

REPRESENTATIVES OF EACH PARTY. BY USING THIS PRINTER, YOU AGREE TO ACCEPT THE

TERMS AND CONDITIONS OF THIS AGREEMENT.

Communication Notices

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct the interference at

his own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission limits.

Printronix is not responsible for any radio or television interference caused by using other than recommended

cables and connectors or by any unauthorized changes or modifications to this equipment. Unauthorized

changes or modifications could void the user’s authority to operate the equipment.

Page 6

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Any change or modification to this product voids the user’s authority to operate it per FCC Part 15 Subpart A

Section 15.21 regulations.

CAUTION: This product should be positioned so that personnel in the area for prolonged periods may safely

remain at least 23 cm (9 in) from the readers antenna surface in an uncontrolled environment. See FCC OET

Bulletin 56 “Hazards of radio frequency and electromagnetic fields” and Bulletin 65 “Human exposure to radio

frequency electromagnetic fields.”

This product contains an intentional radiator with the following parameters:

Operating Frequency: 902-928 MHz

Typical RF Power: 25-100 miliwatts

Maximum RF Power: 1 Watt under abnormal conditions

Canadian Department of Communications Compliance Statement: This Class A digital apparatus

complies with Canadian ICES-003.

Avis de conformite aux normes du ministere des Communcations du Canada: Cet appareil numerique

de la classe A est conform á norme NMB-003 du Canada.

European Community (EC) Conformity Statement:

This product is in conformity with the protection requirements of EC Council Directive 89/336/EEC on the

approximation of the laws of the Member States relating to electromagnetic compatibility. Printronix cannot

accept responsibility for any failure to satisfy the protection requirements resulting from a non-recommended

modification of the product, including the fitting of non-Printronix option cards.

German Conformity Statement:

Zulassungsbescheinigung Gesetz über die elektromagnetische Verträglichkeit von Geraten (EMVG) vom 30.

August 1995

Dieses Gerät ist berechtigt in Übereinstimmung mit dem deutschen das EG-Konformitätszelchen - CE - zu

führen.

Der Außteller der Konformitätserklärung ist die Printronix......(1)

Informationen in Hinsicht EMVG Paragraph 3 Abs. (2) 2:

Das Gerät erfüllt die Schutzanforderungen nach EN 55024 und

EN 55022 Klasse A.

EN 55022 Klasse A Geräte bedürfen folgender Hinweise:

Nach dem EMVG: “Geräte dürfen an Orten, für die sie nicht asreichend entstört sind, nur mit besonderer

Genehmigung des Bundesminesters für Post und Telekommunikation oder des Bundesamtes für Post und

Telekommunikation betrieben werden. Die Genehmigung wird erteilt, wenn keine elektromagnetischen

Störungen zu erwarten sind.” (Auszug aus dem EMVG, Paragraph 3, Abs. 4) Dieses Genehmigungsverfahren

ist nach Paragraph 9 EMVG in Verbindung mit der entsprechenden Kostenverordnung (Amtsblatt 14/93)

kostenpflichtig.

Nach der EN 55022: “Dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im Wohnbereich

Funkstörungen verursachen; in diesem Fall kann vom Betreiber verlangt werden, angemessene Maßnahmen

durchzuführen und dafür aufzkommen.”

Anmerkung: Um die Einhaltung des EMVG sicherzustellen sind die Geräte, wie in den Handbüchern

angegeben, zu installieren und zu betreiben.

Page 7

This product has been tested and found to comply with the limits for Class A Information Technology

Equipment according to European Standard EN 55022. The limits for Class A equipment were derived for

commercial and industrial environments to provide reasonable protection against interference with licensed

communication equipment.

Warning

This is a Class A product. In a domestic environment

this product may cause radio interference in which

case the user may be required to take adequate

measures.

Page 8

Printronix makes no representations or warranties of any kind regarding this material, including, but not limited

to, implied warranties of merchantability and fitness for a particular purpose. Printronix shall not be held

responsible for errors contained herein or any omissions from this material or for any damages, whether

direct, indirect, incidental or consequential, in connection with the furnishing, distribution, performance or use

of this material. The information in this manual is subject to change without notice.

This document contains proprietary information protected by copyright. No part of this document may be

reproduced, copied, translated or incorporated in any other material in any form or by any means, whether

manual, graphic, electronic, mechanical or otherwise, without the prior written consent of Printronix.

COPYRIGHT © 2004 PRINTRONIX, INC. All rights reserved.

Trademark Acknowledgements

Alien Technology is a trademark of Alien Technology Corporation.

Manhattan Associates is a registered trademark of Manhattan Associates, Inc.

Printronix, PGL, and PrintNet are registered trademarks of Printronix, Inc.

T5000e is a trademark of Printronix, Inc.

Uniform Code Council is a registered trademark of Uniform Code Council, Inc.

Zebra and ZPL are trademarks of Zebra Technologies Corporation.

Page 9

Table of Contents

1 RFID Smart Label Application

And Reference Notes.............................. 11

Overview............................................................................. 11

What To Expect When Running Your RFID Application..... 12

Factors Affecting Smart Label Performance ................ 12

Overstruck Smart Labels.............................................. 13

Smart Label Characteristics ......................................... 13

Transitioning From UCC/GTIN Applications Using

Printronix Software Migration Tools (SMT)......................... 14

How Printronix Makes It Easy ...................................... 14

How It Works................................................................ 14

How To Order More Smart Labels...................................... 15

Printronix Professional Services......................................... 15

What We Can Do ......................................................... 15

Contact Information ...................................................... 15

Hardware/Infrastructure Considerations............................. 16

Useful Industry Web Links.................................................. 17

Reference Material ....................................................... 17

2 Printer Setup ........................................... 19

Unpacking And Installing The Printer ................................. 19

Unpacking The Printer ................................................. 19

Removing The Internal Packing Material ..................... 20

Installation .................................................................... 21

Controls And Indicators ...................................................... 22

Power Switch ............................................................... 22

Control Panel ............................................................... 22

Loading Media And Ribbon ................................................ 26

Loading Roll Media ...................................................... 26

Loading Ribbon ............................................................ 31

9

Page 10

Table of Contents

Printing Adjustments............................................................34

Printhead Pressure Adjustment ....................................34

Printhead Pressure Block Adjustments.........................34

Positioning The Media Sensors ....................................35

Running Auto Calibrate .......................................................36

Saving The Configuration ....................................................37

Run A Barcode Demo Test..................................................37

QUICK SETUP Menu ..........................................................38

QUICK SETUP Submenus............................................39

For More Information ...........................................................47

3 Smart Label Development.......................49

Overview..............................................................................49

RFID CONTROL Menu........................................................50

RFID CONTROL Submenus .........................................51

Admin User Menu Items................................................54

RFID PGL Commands.........................................................56

Write Tag ......................................................................56

Read Tag ......................................................................57

EPC Programming Example .........................................58

ASCII Programming Example .......................................59

RFID PPI1 Commands ........................................................60

Get Tag Unique ID ........................................................60

Set Tag Type ................................................................60

Read Tag ......................................................................61

Write Tag ......................................................................62

Host Verification ............................................................63

EPC Programming Example .........................................64

Software Migration Tools (SMT)..........................................65

Tools List.......................................................................65

Selecting The Tools ......................................................67

Error Messages ...................................................................68

Troubleshooting...................................................................69

10

Page 11

1 RFID Smart Label

Overview

Application And

Reference Notes

Congratulations on your purchase of the industry’s first Smart Label

Developer’s Kit or Smart Label Pilot Printer. The intent of the kit is

to provide a complete environment for the printing and encoding of

RFID smart labels right out of the box. Printronix has specifically

designed this kit to help you fast track your RFID pilot printer

application through the use of a suite of Software Migration Tools

(SMT).

The Printronix Smart Label Developer’s Kit and the Smart Label

Pilot Printer contain:

• T5000e thermal printer: a web-enabled, industrial-grade

thermal bar code printer designed for exacting label

applications

• Integrated RFID UHF encoder

• Software Migration Tools that permit the seamless encoding of

smart labels

• Media starter kit (100 4 inch x 6 inch standard labels, 50 m

8500 thermal premium wax resin ribbon, and a printhead

cleaning pen)

• Programming manuals (CD)

11

Page 12

Chapter 1 What To Expect When Running Your RFID Application

• Smart Label Developer’s Quick Setup Guide (this manual)

• Application and reference notes (this chapter)

• Technical support

The Printronix Smart Label Developer’s Kit also contains:

• Two rolls of 500 smart labels with Alien Technology™ Class 1

64 data bits, 915MHz inlays

• One 625 m thermal premium wax ribbon

• Network interface card, which includes Printronix’s PrintNet

Enterprise, a remote network printer management software

application.

®

What To Expect When Running Your RFID Application

Factors Affecting Smart Label Performance

Smart labels are based on an EEPROM technology that requires

some time to be programmed. You may notice this minor pause

between labels. This time is necessary to better ensure consistent

quality and improved reliability.

12

When dealing with smart labels, it is possible that an occasional

RFID tag may need to be written and verified more than once (retry)

before being considered acceptable. In this event each retry time

will be added to the inter-label pause.

Static electricity can damage the smart labels. Open the media

cover of the printer and touch an unpainted metal part of the printer

before you handle smart labels. This will discharge any static

electricity that may have built up on your hands.

Page 13

Overstruck Smart Labels

Overstruck Smart Labels

If an RFID tag within a smart label is deemed unacceptable after

execution of the defined number of retries, the following actions are

performed:

• If Error Handling is set to Overstrike (the default), the

unacceptable smart label will print with a grid or error message

over the label. If the Label Retry Count is greater than zero (the

default is 10), the next smart label will be tried until the label

retry count is exhausted.

• If Error Handling is set to Stop, the printer will stop, give an

error message, and discard the failing label data.

• If Error Handling is set to None, the printer will continue to the

next smart label with the next form and discard the failing label

data.

Smart Label Characteristics

The smart labels currently supported have the following

characteristics:

• UHF 915MHz radio frequency identification tag

• EPC Class 1 tags – 64 data bits Write Few / Read Many

• 4 x 6 inch label stock

• Nominal roll size is 500 smart labels. An additional number of

smart labels may be added to the Printronix smart label rolls to

compensate for tags that are deemed unacceptable. This is so

you can have 500 good labels.

NOTE: It is highly recommended that additional smart labels are

purchased directly from Printronix to assure the highest

level of performance and reliability. See “How To Order

More Smart Labels” on page 15.

13

Page 14

Chapter 1 Transitioning From UCC/GTIN Applications Using Printronix Soft-

Transitioning From UCC/GTIN Applications Using Printronix Software Migration Tools (SMT)

It is likely that your software is already set up to create bar codes.

You may have also spent a lot of time creating compliance label

templates & integrating them into your system. The Smart Label

Developer’s Kit Software Migration Tools will allow you to

effortlessly transition from printing compliance labels to smart

labels.

How Printronix Makes It Easy

If you are printing bar codes now, you can print smart labels — no

change to your host data stream or existing compliance templates

is required.

How It Works

A set of Software Migration Tools has been created to intercept the

bar code data in the host data stream and copy the data to a smart

label RFID tag according to a set of rules. Each tool has been

designed for a specific end-use application. By simply selecting the

desired Software Migration Tool from the printer’s operator panel,

you automatically enable the printer to create an RFID smart label

from your existing software application even if it does not have the

functionality to program RFID tags. The tools include:

14

• GTIN: Copies the Global Trade Identification Number (GTIN)

bar code data for case and pallet labels onto the smart label’s

RFID tag.

• EAN-8, EAN13, UPCA, and UCC128: These tools copy the

data from their respective bar code symbologies to a smart

label’s RFID tag. This enables the achievement of supply-chain

efficiencies with RFID-ready trading partners while at the same

time remaining compatible with those who are not.

Page 15

• EPC: This tool allows EPC data to be directly encoded into the

smart label’s RFID tag. Simply have your existing software

application write the desired EPC number to a Code 3 of 9

barcode. The printer will then write the EPC data to the RFID

tag without printing the bar code.

The existing toolset will meet the needs of many RFID early

adopters. If you have a requirement for a Software Migration Tool

not included in this kit, feel free to contact Printronix.

To select and use the tools, see “Software Migration Tools (SMT)”

on page 65.

How To Order More Smart Labels

To order more RFID smart labels, contact Printronix:

1-800-733-1900

www.printronix.com

Part Number

Roll of 500 4 x 6 inch EPC Class 1 smart labels with squiggle

antenna inlay:

204932-001

What We Can Do

Printronix Professional Services

What We Can Do

Printronix can partner with you on your RFID pilot project to make

your existing software applications RFID/smart label capable. We

specialize in AutoID Consulting, compliance labeling, third party

software integration, and label generation.

Contact Information

Printronix Customer Support Center

1-714-368-2686

Ask for Professional Services Support

15

Page 16

Chapter 1 Hardware/Infrastructure Considerations

Hardware/Infrastructure Considerations

Once your smart labels have been applied to their target container

or pallet you will need external readers to track them through your

supply chain. Such readers are typically networked devices that are

deployed at key points in the warehouse or distribution center to

track incoming and outgoing packages. The readers are managed

through a server for gathering and filtering all the RFID information.

Readers may have multiple antennas to maximize read range and

reliability.

The readers you purchase must be compatible with the smart

labels programmed by the printer. Specifically, they should be EPC

Class 1 compliant. Fixed position readers and their antennas can

be purchased from Alien Technology (www.alientechnology.com).

Handheld readers with integrated antennas can be purchased from

AWID (www.awid.com).

The data that are gathered by the reader servers must be managed

for tracking and archiving purposes. Software applications that

perform these tasks are available from companies such as

Manhattan Associates

®

(www.manh.com).

16

Page 17

Useful Industry Web Links

Reference Material

EPCglobal, Inc.

www.epcglobalinc.org

Auto-ID Labs

www.autoidlabs.org

Uniform Code Council, Inc.

www.uc-council.org

RFID Journal

www.rfidjournal.com

Alien Technology

www.alientechnology.com

Applied Wireless Identifications Group, Inc.

www.awid.com

®

Reference Material

®

Corporation

17

Page 18

Chapter 1 Useful Industry Web Links

18

Page 19

2 Printer Setup

Unpacking And Installing The Printer

Unpacking The Printer

The printer is shipped in a carton and protective bag. Keep all

packing material in case shipping is required.

CAUTION

CAUTION

Avoid touching the electrical connectors to prevent

electrostatic discharge damage while setting up the printer.

The discharge of accumulated electrostatic energy can

damage or destroy the printhead or electronic components

used in this device.

Do not place the printer on its backside during unpacking or

handling, because damage to the printer interface connector

may occur.

19

Page 20

Chapter 2 Unpacking And Installing The Printer

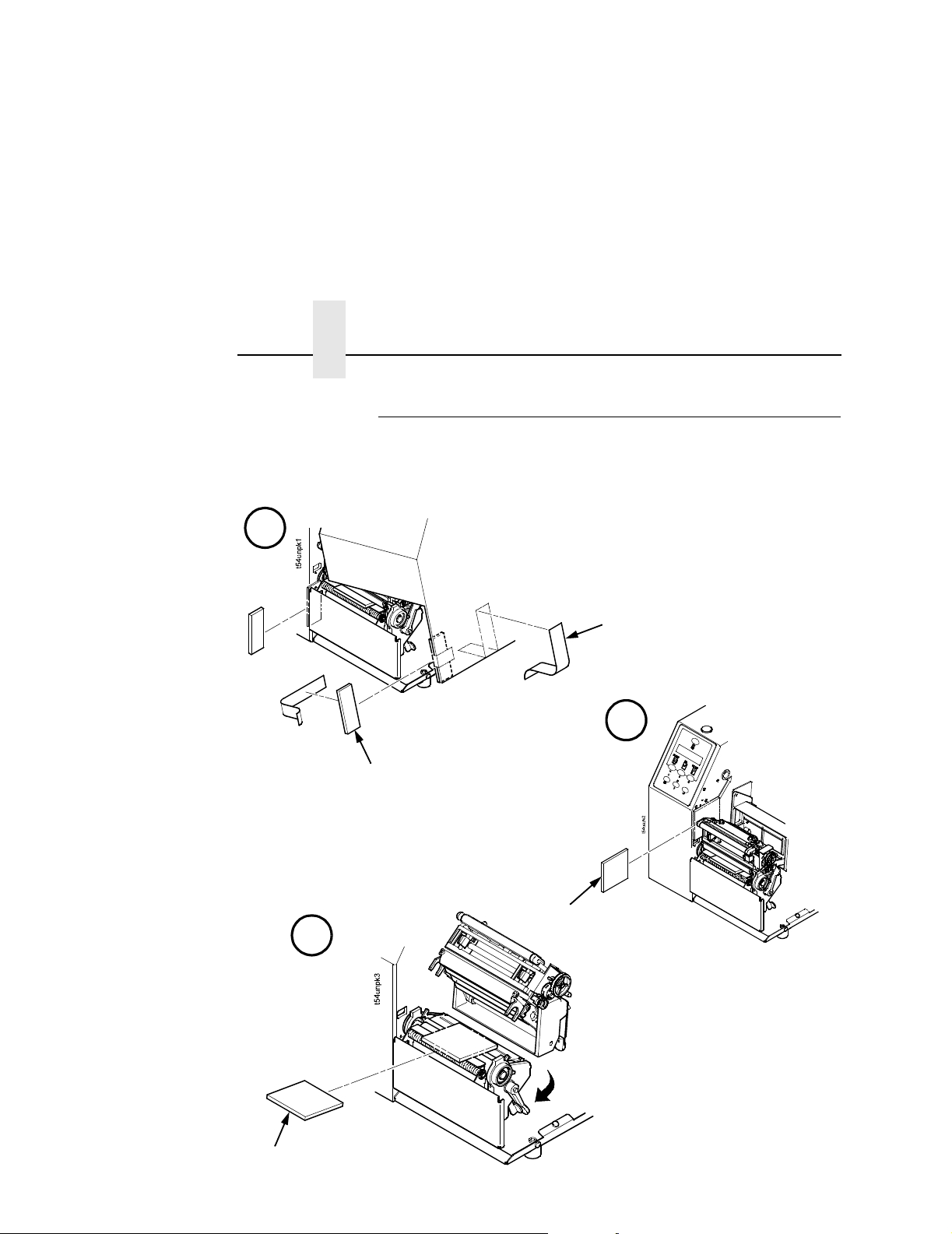

Removing The Internal Packing Material

Remove the tape strips and foam pads from the printer as indicated

below. (The top lid of the shipping carton also displays these

instructions.)

A

Tape Strips (2)

Foam Pads (2)

B

Foam Pad

20

Foam Pad

C

Unlock

Page 21

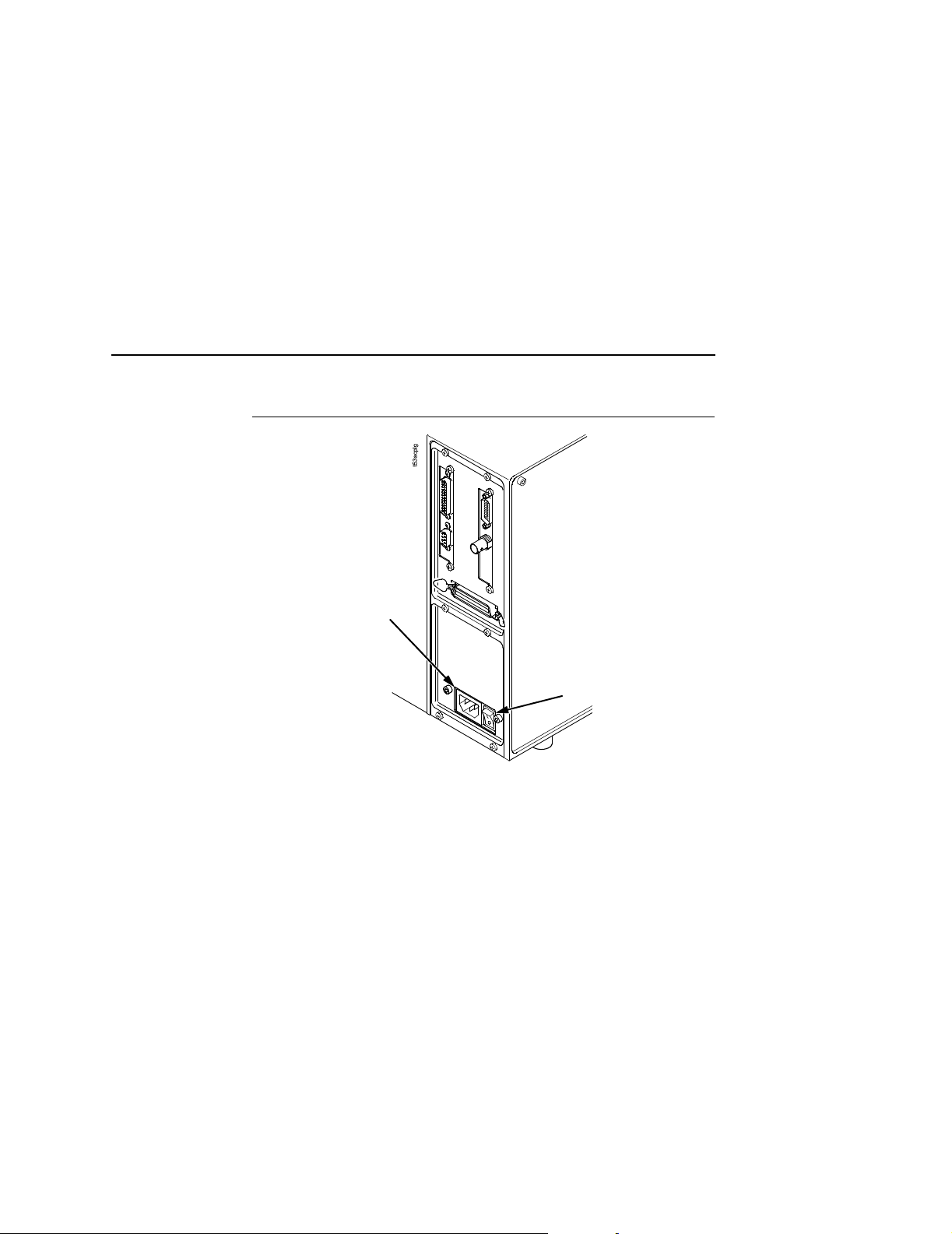

Installation

Installation

AC Power

Receptacle

Power Switch

1. Place the printer on a flat level surface that allows easy access

to all sides of the printer.

CAUTION

WARNING

CAUTION

Never operate the printer on its side or upside down.

2. Make sure the printer power switch is in the Off (O) position.

Failure to properly ground the printer may result in electric

shock to the operator.

In compliance with international safety standards, this printer

has been equipped with a three-pronged power cord. Do not

use adapter plugs or remove the grounding prong from the

cable plug. If an extension cord is required, ensure that a

three-wire cable with a properly grounded plug is used.

3. Attach the AC power cord to the AC power receptacle in the

back of the printer.

Verify the required voltage on the printer’s model number label

on the back of the printer.

4. Attach the AC power cord to a grounded (three prong) electrical

outlet of the proper voltage.

21

Page 22

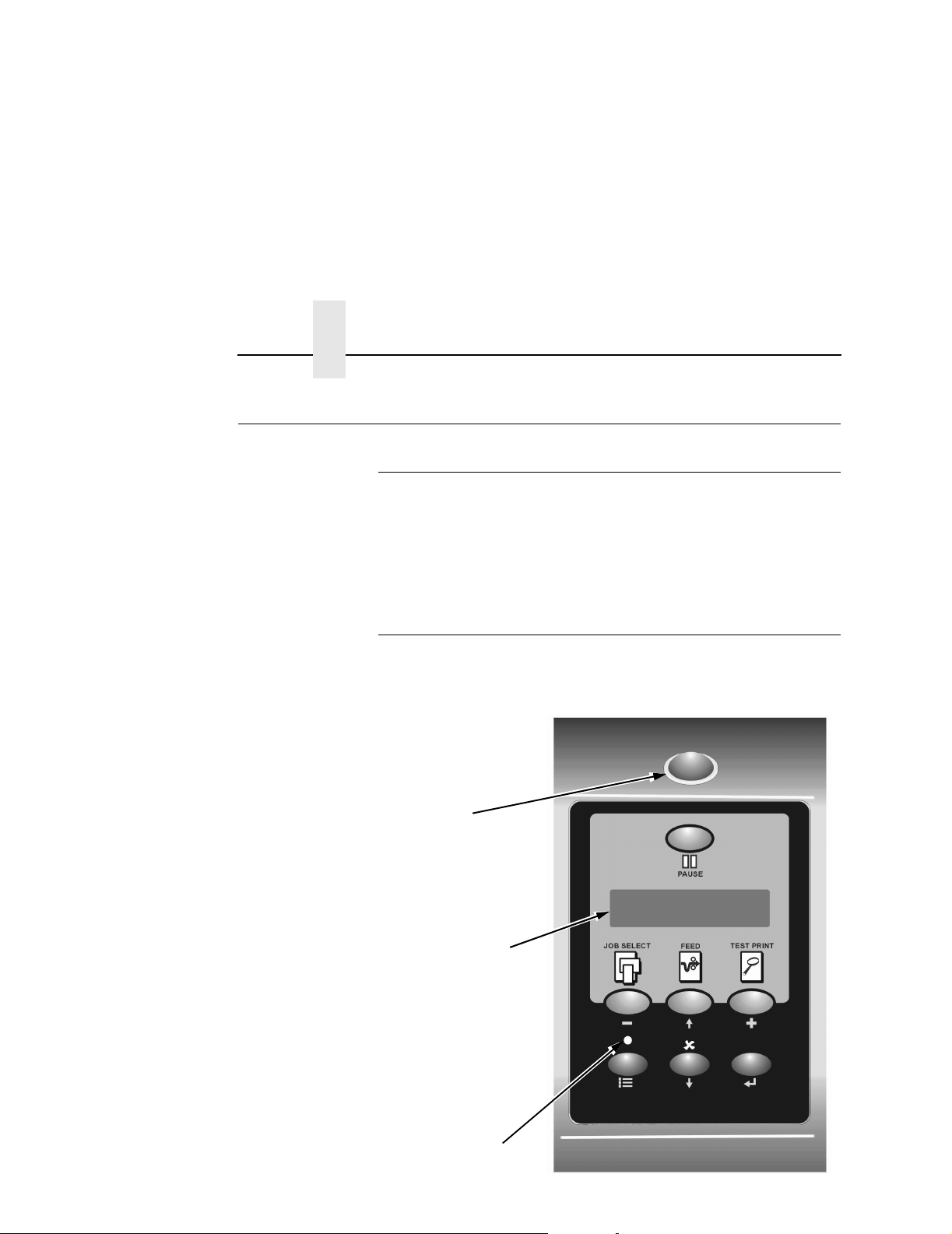

Chapter 2 Controls And Indicators

Controls And Indicators

Power Switch

The power switch is located on the bottom back panel of the printer.

To apply power, place the switch in the | (On) position. When you

first power on the printer, a series of initialization messages

appears on the Liquid Crystal Display (LCD) on the control panel.

To remove power, place the power switch in the O (Off) position.

Control Panel

The control panel is located on the front of the printer and includes

an LCD, indicators, and control keys (buttons). These are described

in the following tables.

22

Online Status

Indicator

Liquid Crystal

Display (LCD)

Job In Process

Indicator

Page 23

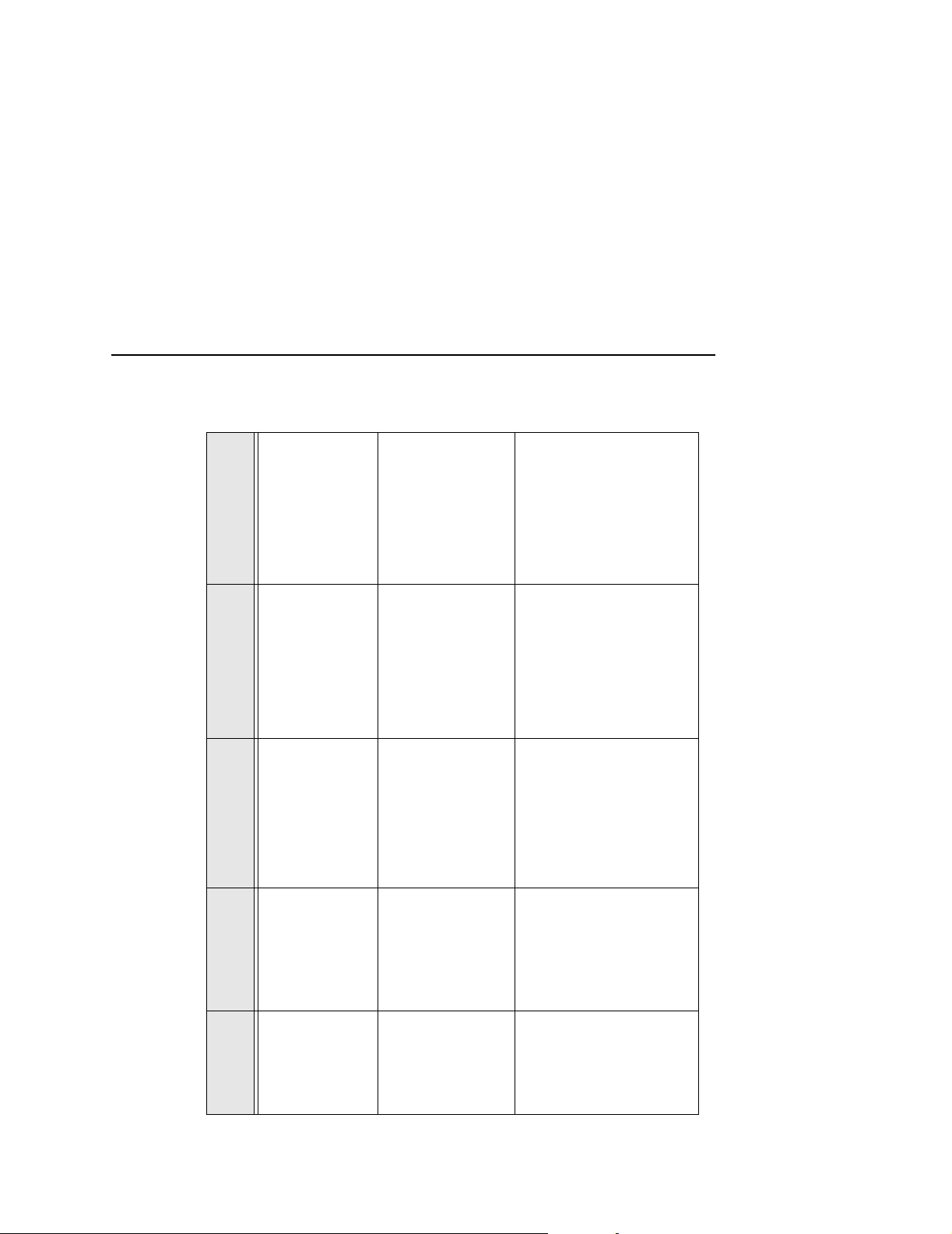

Status And Display Indicators

Function in

Menu Mode

Control Panel

Function in

Offline Mode

Function in

Online Mode

Off.

Off when the printer is

Stays lit when the

offline.

printer is online, ready

to print, and accept

printer is online,

offline, or when

Flashes during a fault

condition.

Displays “OFFLINE”

and a main menu,

submenu, or option.

During a fault condition,

displays the specific

fault message and the

corrective action.

None

Flashes during a fault

condition.

Displays “OFFLINE.”

data from the host.

Flashes during a fault

condition.

Displays “ONLINE,” the

interface type, and

there is a fault

condition.

A backlighted

liquid crystal

During a fault condition,

displays the specific

fault message and the

corrective action.

Flashes when receiving

data.

Stays lit when data has

been processed and is

waiting to be printed.

Off when no data is

being received or when

no data remains in the

buffer.

emulation in use.

During a fault condition,

displays the specific

fault message and the

corrective action.

Flashes when receiving

data.

Stays lit when data has

been processed and is

waiting to be printed.

Off when no data is

being received or when

no data remains in the

buffer.

display with two

rows of 16

characters each.

Indicates when the

printer is receiving

or processing

data.

Indicator Description

Online Status Indicates when the

Liquid Crystal

Display (LCD)

Job In

Process

23

Page 24

Chapter 2 Controls And Indicators

Control Panel Keys

Function in

Menu Mode

Scrolls left through main

menus.

Decrements option values

within submenus.

Function in

Offline Mode

Sets printer to Online mode. Sets printer to Offline mode.

number of the last loaded

configuration and allows

you to load the factory and/

or pre-stored printer

configurations.

Scrolls the current menu

selection one level up.

Advances the media one

label length.

Scrolls right through main

menus.

Increments option values

Print patterns.

within submenus.

24

Function in

Online Mode

Sets printer to

Offline mode.

PAUSE Key

Toggles the printer

between Online and

Offline modes.

JOB SELECT Key None Displays the name and

Button Description

Advances the

media one label

length.

DECREMENT Key in

Menu mode

FEED Key

UP Key in Menu mode

-

None Scrolls through the Test

TEST PRINT Key

Pressing the ↵

(ENTER) key with a

Diagnostic Test

displayed initiates the

test. Pressing ↵ again

INCREMENT Key in

Menu mode

terminates the test.

+

Page 25

Function in

Menu Mode

Function in

Offline Mode

Function in

Online Mode

Control Panel Keys (cont.)

Scrolls the current

menu selection one

level down.

in the printer

data buffer

when enabled.

Scrolls between main

Selects the

menu selections.

Menu mode.

menu value and

displays an asterisk

Control Panel

(*) next to the value.

None Clears all data

CANCEL Key

When the CANCEL key is

enabled, pressing it will clear all

data in the printer buffer and

prevent printing of that data.

Note: The default = Disable.

However, when the Coax/

Twinax Interface option is

installed, the default = Enable.

DOWN Key in Menu mode

Button Description

selects the Menu mode.

MENU Key Takes the printer Offline and

None None Selects the current

ENTER Key

Pressing the ↵ (ENTER) key in

Menu mode selects the

displayed option or value. An

asterisk then appears next to

the option or value indicating it

has been selected.

Note: If the ENTER key is

locked, “ENTER SWITCH

LOCKED” displays on the LCD

for one second. Press the

(DOWN) and ↵ (ENTER) keys

at the same time to unlock the

ENTER key.

25

Page 26

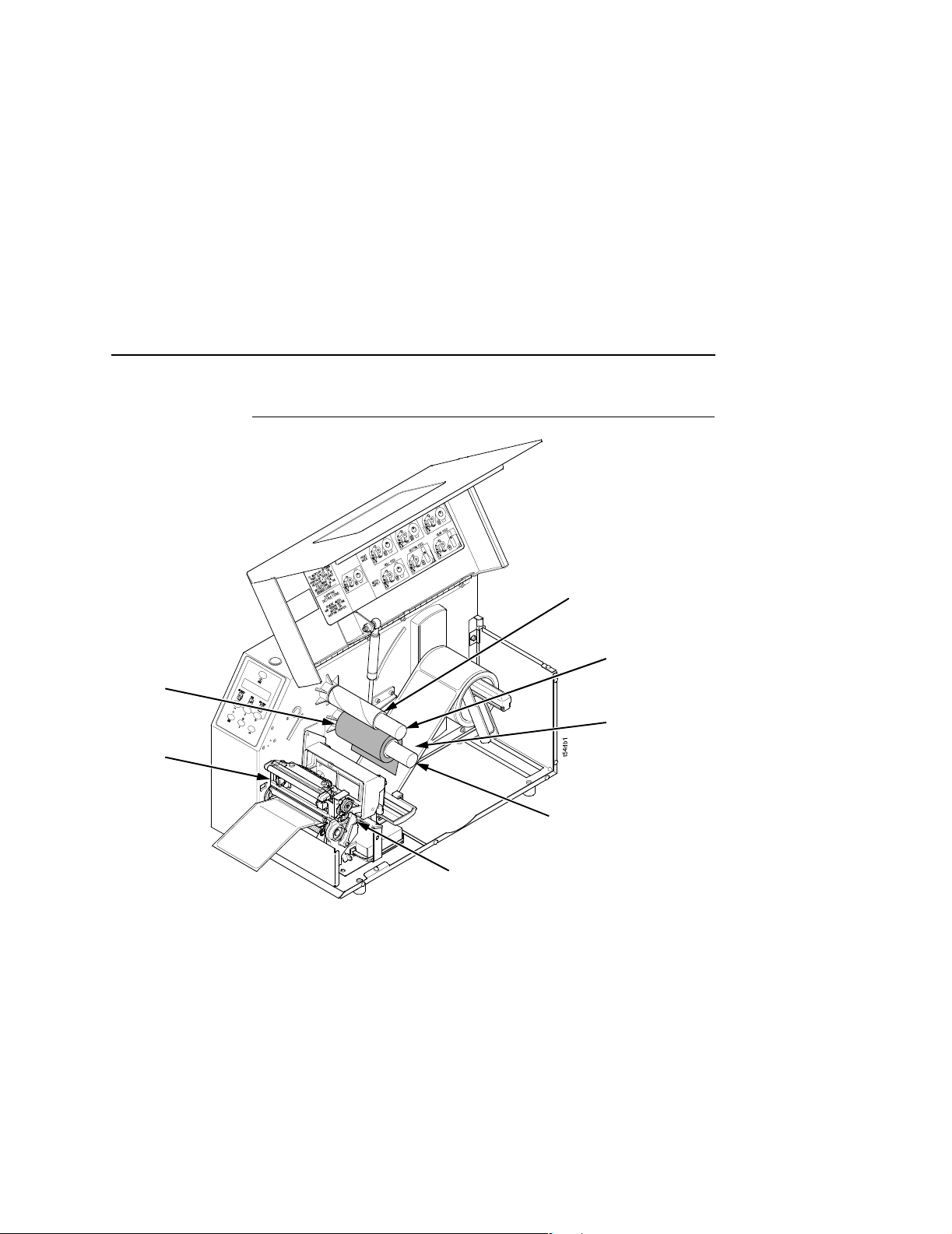

Chapter 2 Loading Media And Ribbon

Loading Media And Ribbon

IMPORTANT

CAUTION

CAUTION

Printronix recommends using the supplied starter roll of 100

labels to set up and verify printer operation. This will avoid

expending the more expensive smart labels for this task.

DO NOT TOUCH the printhead or the electronic components

under the printhead assembly.

Do not close the pivoting deck without label stock installed

between the printhead and the platen, because debris on the

platen may damage the printhead.

Loading Roll Media

Media Hanger

Pivoting

Deck

Media Hanger

Guide

26

Deck Lock

Lever

1. Slide the media hanger guide outward to the end of the media

hanger, and flip it down into the horizontal position (as shown).

2. Open the pivoting deck by rotating the deck lock lever fully

clockwise.

RFID Encoder

Page 27

Loading Roll Media

Media Roll

Media Hanger

Media Hanger

Guide

Media Width

Guide

Media Damper

3. Slide the media width guide close to the outside end of the

media damper.

4. Slide the supplied starter media roll onto and towards the back

of the media hanger.

5. Place the media hanger guide under the media hanger and

against the lower part of the label core at a 45 degree angle

(as shown). This position provides the required tension for a

new label roll and the desired drag for a partial label roll.

27

Page 28

Chapter 2 Loading Media And Ribbon

Media and

Ribbon Loading

Instructions

Media

28

Media Damper

Antenna

RFID Encoder

6. Raise the media damper.

7. Route the media as illustrated on the media and ribbon loading

instructions (or refer to the arrows on the printer frame).

NOTE: The media must rest on top of the RFID encoder and the

RFID tag must be in proximity of the antenna when the

RFID tag is programmed.

Page 29

Media

Guard

Loading Roll Media

Lower

Media Sensor

Fixed

Guide

Media Width

Guide

Media

Damper

8. Lower the media damper.

9. Verify that the left edge of the media is against the fixed guide

on the bottom of the media damper.

10. Push the media width guide in until it is flush with the outer

edge of the media.

11. Check the horizontal position of the lower media sensor (shown

above) and the upper media sensor (shown on page 34).

(See “Positioning The Media Sensors” on page 35.)

29

Page 30

Chapter 2 Loading Media And Ribbon

Platen (left edge)

Media (left edge)

12. Align the left (inside) edge of the media with the left straight

edge of the platen (rubber drive roller).

Pivoting

Deck

30

Deck Lock

Lever

13. Close the printhead by pressing down on the pivoting deck and

rotating the deck lock lever fully counterclockwise.

14. Power on the printer (place the power switch in the | position).

Page 31

Spindle

Flange

Pivoting

Deck

Loading Ribbon

Loading Ribbon

Ribbon

Take-Up Core

Ribbon

Take-Up Spindle

Ribbon

Roll

Ribbon Supply Spindle

Deck Lock Lever

1. Install the ribbon take-up core on the ribbon take-up spindle.

NOTE: The first ribbon take-up core comes with the printer.

Thereafter, use the core from the old (used up) ribbon.

2. Slide the ribbon roll onto the ribbon supply spindle until it stops

against the spindle flange.

3. Open the pivoting deck by rotating the deck lock lever fully

clockwise until the deck swings upward.

31

Page 32

Chapter 2 Loading Media And Ribbon

Printhead

Media

32

Rear Ribbon Guide Roller

4. Thread the end of the ribbon under the rear ribbon guide roller,

then between the platen and the printhead.

Page 33

Loading Ribbon

Media and

Ribbon Loading

Instructions

Ribbon

Take-up Core

Ribbon

Take-up Spindle

IMPORTANT

5. Route the ribbon as illustrated on the media and ribbon loading

instructions (or refer to the arrows on the printer frame).

Do not attach the ribbon to the ribbon take-up spindle without

a ribbon take-up core installed.

6. Attach the ribbon to the ribbon take-up core on the ribbon

take-up spindle using the adhesive on the ribbon leader.

7. Manually rotate the spindle clockwise until the clear leader has

passed the printhead.

8. Close the pivoting deck.

33

Page 34

Chapter 2 Printing Adjustments

Printing Adjustments

Left

Pressure

Block

Right Pressure

Block

Right Pressure

Block Pointer

Pressure

Bold Mark

Printhead Cover/

Upper Media

Sensor

Left

Block

Handle

Pressure Block

Adjustment Scale

Printhead Pressure Adjustment

Adjust the printhead pressure to the setting of 4.

Printhead Pressure Block Adjustments

Lead Screw

Knob

Printhead Pressure

Adjustment Dial

34

Left Pressure Block

Manually adjust the left pressure block so its handle is aligned with

the bold mark on the pressure block adjustment scale.

Right Pressure Block

Use the lead screw knob to position the right pressure block with its

pointer near the right edge of the media in use.

Page 35

Positioning The Media Sensors

Positioning The Media Sensors

Lower

Media Sensor

Lower

Media Sensor

Handle (2)

Your printer is equipped with upper and lower media sensors that

detect the top-of-form position on media with label length indicators

(gaps, notches, holes, or black marks). The media sensors also

detect Paper Out conditions.

Use the handles on the lower media sensor to horizontally position

it in the center of the installed media. Slide the upper media sensor,

located in the slot under the printhead cover (see figure on

page 34), directly over the lower sensor.

35

Page 36

Chapter 2 Running Auto Calibrate

Running Auto Calibrate

Due to manufacturing differences in media and ribbon, the media

sensor may have difficulty distinguishing between the label and the

liner (gap).

To ensure proper operation, you must now run Auto Calibrate:

1. Power on the printer by pressing the power switch. (For the

location of the power switch and various panel keys, refer to

“Controls And Indicators” on page 22.)

.

2. Press the key until QUICK SETUP displays.

NOTE: For a complete description of the QUICK SETUP menu,

3. If necessary, press ↓ and ↵ at the same time to unlock the

↵ key.

.

.

see page 38.

4. Press ↑ or ↓

5. Press

6. Press

7. Press ↓

8. Press

length indicators and then stops at the top-of-form position. The

sensed distance value then displays for one second.

9. Auto Calibrate is successful when the sensed distance value

correctly matches that of the installed media. For the Gap

option, the sensed distance value is the physical length of one

label plus the length of one gap.

10. If GAP NOT DETECTED or PAPER OUT displays, check the

horizontal position of the media sensors (see “Positioning The

Media Sensors” on page 35), press PAUSE, and run Auto

Calibrate again.

11. Press the PAUSE key to take the printer offline.

12. Press the FEED key several times. Each time you press FEED,

the media should advance one label length and stop.

until Gap/Mark Sensor / Disable* displays.

+ or – until Gap displays.

↵. An asterisk (*) displays next to Gap.

until Auto Calibrate/Run Calibrate displays.

↵. Media advances until it can accurately detect the label

36

Page 37

13. Once the sensed distance value and performance is confirmed,

save it to the desired configuration menu as described below

before powering off the printer.

Saving The Configuration

.

14. Press the key until QUICK SETUP displays.

15. Press ↑ or ↓

.

.

until Save Config./1* displays.

Positioning The Media Sensors

16. Press

↵. Saving Configuration displays briefly.

Run A Barcode Demo Test

IMPORTANT

Printronix recommends using the supplied starter roll of 100

labels to set up and verify printer operation. This will avoid

expending the more expensive smart labels for this task.

Before you send an actual print job, run a barcode demo test:

1. Press the PAUSE key until OFFLINE displays.

2. Press TEST PRINT until Printer Tests/Barcode Demo displays.

3. Press ↵. The Barcode Demo test pattern will start and print two

barcodes.

4. Check the test pattern. If necessary, reposition the pressure

blocks to obtain a uniform print quality. In most cases, you will

need to adjust only the right pressure block.

5. If desired, you can run additional printer tests, such as Grey,

Grid, and Checkerboard. See step 1 above to start other tests.

NOTE: These tests run continuously by default. Press ↵ to end the

test.

37

Page 38

Chapter 2 QUICK SETUP Menu

QUICK SETUP Menu

QUICK SETUP

Print Intensity

Print Speed

Print Mode

Media Handling

Paper Feed Shift

Label Length

Label Width

Ver Image Shift

Hor Image Shift

Orientation

Gap/Mark Sensor

Auto Calibrate

Save Config.

Power-Up Config.

(cont. on next page)

-3* -15 to 15

6 ips* 2-10 ips

1

Transfer* Direct

Tear-Off Strip* Tear-Off Peel-Off Cut

0.00 inches*

4 or 6 inches*

2

2, 4

4.1, 6.6, or 8.5 inches*

0.00 inches*

2

2

-0.50 to X inches

00.1 to 99.0 inches

2, 4

00.1 to 8.5 inches

-1.00 to X inches

-1.00 to 1.00 inches 0.00 inches*

3

5

4

3

Portrait* Landscape Inv. Portrait Inv. Landscape

Disable* Mark Gap Advanced NotchAdvanced Gap

Run Calibrate

Notes:

1* 1-8

Factory* 1-8

* = Default

1

Maximum value depends on the width of the

printer model and printhead.

2

You can change the unit value from inches to

millimeters under Units (in MEDIA CONTROL)

Refer to the

3

Based on the current value setting for the Label

User’s Manual

for information.

Length menu, up to a maximum of 12.80 inches.

4

Maximum value depends on the width of the

printer model.

5

Maximum value depends on model width and size

of DRAM installed.

Continuous

38

Page 39

QUICK SETUP

(cont. from previous page)

QUICK SETUP Submenus

SMT: Status

SMT: Sel Toolset

SMT: Select Tool

Disabled* Enabled

Toolset [1]* Toolset [1] to Toolset [4]

EPC

zEPC

1

2, 3

GTIN

zGTIN

1

2, 3

1

UPCA

zUPCA

Notes:

* = Default.

1

Appears only if Toolset [1] is selected under

SMT: Sel Toolset.

2

Appears only if Toolset [2] is selected under

SMT: Sel Toolset.

3

Undocumented options are reserved for internal

use and future design.

2, 3

EAN8

zEAN8

QUICK SETUP Submenus

Print Intensity

1

2, 3

EAN13

zEAN13

1

2, 3

UCC128

zUCC128

1

2, 3

Specifies the level of thermal energy from the printhead to be used

for the type of media and ribbon installed.

Large numbers imply more heat (thermal energy) to be applied for

each dot. This has a significant effect on print quality. The print

intensity and speed must match the media and ribbon type to obtain

the best possible print quality and barcode grades.

The range is -15 through +15:

• In Transfer mode, the default is -3.

• In Direct Thermal mode, the default is 0.

39

Page 40

Chapter 2 QUICK SETUP Menu

Print Speed

Specifies the speed in inches per second (ips) at which the media

passes through the printer while printing.

The range is 2 through 10 ips (in increments of 1 ips).

The default is 6 ips.

NOTE: The maximum print speed varies based on maximum

printer width and dot per inch (dpi) resolution of the

printhead installed (203 or 300 dpi).

Print Mode

Specifies the type of printing to be done.

• Transfer. Indicates Thermal Transfer printing (ribbon installed).

• Direct. Indicates Direct Thermal printing (no ribbon) and

requires special heat sensitive media.

The default is Transfer.

40

Media Handling

Specifies how the printer will handle the media (labels or tag stock).

• Tear-Off Strip. Printer prints on the media and sends it out the

front until the print buffer is empty, then positions the last label

over the tear bar for removal.

• Tear-Off. After each label is printed, the printer positions the

label over the tear bar and waits for you to tear off the label

before printing the next one (on-demand printing). A “Remove

Label” message displays to remind you to remove the label

before the next one can be printed.

• Peel-Off. When the optional rewinder is installed, prints and

peels die-cut labels from the liner without assistance. The

printer waits for you to remove the label before printing the next

one (on-demand printing). The label liner is rewound on the

internal rewinder. A “Remove Label” message displays to

remind you to remove the label before the next one can be

printed.

Page 41

QUICK SETUP Submenus

• Cut. When the optional media cutter is installed, it

automatically cuts media after each label is printed or can cut

after a specified number of labels have been printed using a

software cut command. It cuts continuous roll paper, labels, or

tag stock.

NOTE: This feature is currently not supported using the RFID

encoder.

• Continuous. Printer prints on the media and sends it out the

front.

The default is Tear-Off Strip.

Paper Feed Shift

Represents the distance to advance a label (+ shift) or pull back

(– shift) when the Tear-Off Strip, Tear-Off, Peel-Off, or Cut Media

Handling option is enabled. The allowable range is -0.50 inches to

the current Label Length value setting up to a maximum of 12.80

inches in 0.01 inch increments.

The default is 0.00 inches.

Label Length

In most applications, the user-selected Label Length will match the

physical label length. Physical label length is the actual label length

of the media installed. Following is a list of different media types:

• Die-cut labels: measurable length of the removable label

(leading edge to trailing edge). This does not include the

liner material or gap.

• Tag stock with notches or holes: measurable length from

the trailing edge of one notch or hole to the trailing edge of

the next notch or hole.

• Tag stock with black marks on the underside: measurable

length from the leading edge of one black mark to the

leading edge of the next black mark.

• Continuous media (no label length indicators): measurable

length should be within +

entered.

1-2% of the Label Length value

41

Page 42

Chapter 2 QUICK SETUP Menu

4”

Label Width

The allowable range in inches is 00.1 to the maximum print width of

the printer. The allowable range in millimeters is 2.5 to the

maximum width of the printer.

Ver Image Shift

Specifies the amount to shift an image up (-) or down (+) for precise

positioning on the label. The actual height of the image is not

affected by this parameter. The allowable range is -1.00 inches to

the current Label Length value setting, up to a maximum of 12.80

inches in 0.01 inch increments.

The default value is 0.00 inches.

Hor Image Shift

Specifies the amount to shift an image left (-) or right (+) for precise

positioning on the label. The actual width of the image is not

affected by this parameter. The allowable range is -1.00 through

+1.00 inches in 0.01 inch increments, displayed as

The default value is 0.00 inches.

xx

/100.

42

Orientation

Specifies the image orientation to be used when printing the label.

• Portrait. The default. Portrait refers to vertical page orientation,

where the height of a page is greater than its width. The top

edge of the image is parallel to the leading edge of the media.

The following example is viewed from the front of the printer.

FEED

the media.

6”

leading edge of

parallel to the

the image is

The top edge of

Leading Edge

Page 43

QUICK SETUP Submenus

• Inv. Portrait. Inverse Portrait refers to vertical page orientation,

where the height of a page is greater than its width. The top

edge of the image is parallel to the trailing edge of the media.

The following example is viewed from the front of the printer.

Trailing Edge

4”

FEED

The top edge of

the image is

parallel to the

trailing edge of the

media.

Leading Edge

6”

• Landscape. Landscape refers to horizontal orientation, where

the width of a page is greater than its height. The top edge of

the image is parallel to the left edge of the media. The following

example is viewed from the front of the printer.

4”

FEED

6”

The top edge of

the image is

parallel to the left

edge of the media.

Leading Edge

43

Page 44

Chapter 2 QUICK SETUP Menu

• Inv. Landscape. Inverse Landscape refers to horizontal

orientation, where the width of a page is greater than its height.

The top edge of the image is parallel to the right edge of the

media. The following example is viewed from the front of the

printer.

FEED

Gap/Mark Sensor

Specifies the sensor type needed for detecting the top-of-form

position on media with label length indicators (gaps, notches, holes,

or black marks).

4”

parallel to the right

edge of the media.

Leading Edge

The top edge of

the image is

6”

44

• Disable. Select when using media with no label length

indicators (no gaps, notches, holes, or black marks), or

you want the printer to ignore all existing label length indicators

on the installed media.

NOTE: When you select Disable, the length of each label is based

on the Label Length value entered.

when

• Mark. Select when using media that has horizontal black marks

located on the underside of the label liner or tag stock. The

top-of-form position is the leading edge of the black mark.

• Gap. Select

die-cut labels or when using tag stock with notches or holes as

label length indicators on white background media. The

top-of-form position is the leading edge of the die cut label

(trailing edge of the gap, notch, or hole).

when using media with a liner space between

Page 45

QUICK SETUP Submenus

• Advanced Gap. Select when using media that has liner gaps

between die cut labels with black background. The top-of-form

position is the leading edge of the die cut label (trailing edge of

the gap, notch, or hole).

• Advanced Notch. Select when using media with notches or

holes that interrupt a black vertical line on the underside of the

media. The top-of-form position is the leading edge of the die

cut label (trailing edge of the gap, notch, or hole).

The default is Disable.

Auto Calibrate

This feature is used to improve the sensitivity and reliability of the

media sensor in detecting gaps, notches, holes, or black marks on

the installed media, as well as a Paper Out condition.

To initiate Auto Calibrate, scroll to the “Auto Calibrate” menu and

press the

needed to accurately detect the label length indicators, then stop at

the top-of-form position and momentarily display the Sensed

Distance. This process takes a few seconds and results in an

update of the printer values.

↵ key. The printer will advance media the distance

Auto Calibrate is completed successfully when the Sensed

Distance displayed correctly matches that of the installed media.

When you select Gap, the Sensed Distance should match the

length from the trailing edge of one gap to the trailing edge of the

next gap (one label + one gap). When you select Mark, the Sensed

Distance should match the length from the leading edge of one

black mark to the leading edge of the next black mark.

Auto Calibrate supports label lengths up to 24 inches.

Save Config.

Allows you to save up to eight unique configurations to meet

different print job requirements. This eliminates the need to change

the parameter settings for each new job. The configurations are

stored in memory and will not be lost if you turn off the printer. The

default is 1.

45

Page 46

Chapter 2 QUICK SETUP Menu

Power-Up Config.

You can specify one of the eight configurations as the power-up

configuration. The default is Factory.

SMT: Status

See “Software Migration Tools (SMT)” on page 65.

• Disabled.The printer disables the use of the Software

Migration Tools.

• Enabled. The printer enables the use of the Software Migration

Tools.

SMT: Sel Toolset

See “Software Migration Tools (SMT)” on page 65.

• Toolset [1]. SMTs for PGL

• Toolset [2]. SMTs for PPI1 emulation.

• Toolset [3] and Toolset [4]. Reserved for internal use and

future design.

®

emulation.

46

SMT: Select Tool

See “Software Migration Tools (SMT)” on page 65.

• EPC, GTIN, UPCA, EAN8, EAN13, and UCC128. SMTs

displayed if Toolset [1] is selected under SMT: Sel Toolset.

• zEPC, zGTIN, zUPCA, zEAN8, zEAN13, and zUCC128. SMTs

displayed if Toolset [2] is selected under SMT: Sel Toolset.

NOTE: Undocumented options are reserved for internal use and

future design.

Page 47

For More Information

This chapter has provided general information for use of your

printer. The next chapter provides information about the RFID

encoder.

QUICK SETUP Submenus

Refer to the

User’s Manual

for more detailed information including:

• Other Configuration Menus

• Interfaces

• Diagnostics and Troubleshooting

• Printer Options

• Specifications

• Glossary of Terms

47

Page 48

Chapter 2 For More Information

48

Page 49

3 Smart Label

Overview

Development

This chapter describes how to use the RFID encoder. The RFID

encoder is designed to be transparent to the printer operation. It

provides the capability of programming smart labels (with

embedded RFID tags) while printing the label format. The smart

labels are provided with the printer or purchased separately from

Printronix.

There are several ways to program RFID tags in smart labels:

• Use the Software Migration Tools (SMT) to enable the printer to

automatically create RFID commands from your existing bar

code commands. These tools are described on page 65.

• Incorporate RFID commands into new or existing Printronix

PGL programs. Command details start on page 56.

• Incorporate RFID commands into new or existing ZPL™

programs. By selecting the Printronix PPI1 emulation you can

seamlessly upgrade from Zebra™ printers. Command details

start on page 60.

49

Page 50

Chapter 3 RFID CONTROL Menu

RFID CONTROL Menu

RFID CONTROL

RFID Reader

Tag Type

Error Handling

Label Retry

Max Retry Error

Tag Write Cnt

Failed Tag Cnt

Clear Tag Stat

RFID Test

Auto Retry

F/W-Version

1

Enable* Disable

Alien Squig 64

RAF Omni 313 64 RAF Omni 313 96 Matrics X2020 96

Overstrike* None

10* 1 to 10

Enable* Disable

1

1

2

*

*

Alien Squig 96 Alien M-TAG 64 Alien M-TAG 96

Stop

Notes:

* = Default.

Italicized items are available only when you enable

Admin User in the PRINTER CONTROL menu.

1

Display item only.

1 to 9

Precheck Tags

Overstrike Style

Custom Tag

Custom Tag

Custom Pwr Set

(cont. on next page)

50

1

Disable* Enable

Grid* Error Type Msg

Disable

*

5

*

Enable Duplicate

1 to 20

Page 51

RFID CONTROL

(cont. from previous page)

RFID CONTROL Submenus

Custom Tag Len

Custom Tag Class

8

*

Class 1

8 to 32

*

Class 0 Class 0+

Notes:

* = Default.

Italicized items are available only when you enable

Admin User in the PRINTER CONTROL menu.

RFID CONTROL Submenus

RFID Reader

This menu item enables or disables the RFID encoder. The default

is Enable.

Error Handling

This menu item selects the error handling mode for RFID failures.

The default is Overstrike.

In Overstrike mode, each failed label prints with the Overstrike

pattern and the form retries on a new label until the Label Retry

count is exhausted. At this time, the error message “RFID Error:

Check Media” displays. The failed label will not reprint.

In None mode, no specific action is taken when a tag fails to be

programmed.

In Stop mode, when a tag fails to be programmed, the printer will

halt and display the error message “RFID Error: Check Media.” The

label is discarded and reprinting of the label (if desired) must be

initiated from the host. When the error is cleared, the label with the

failed tag moves forward until the next label is in position to be

printed.

51

Page 52

Chapter 3 RFID CONTROL Menu

Label Retry

NOTE: Label Retry only applies when the Error Handling mode is

set to Overstrike.

This menu item selects the number of label retries that the RFID

encoder will attempt before declaring a fault. This may indicate a

problem with the RFID encoder, the antenna assembly, the printer

setup, or the label stock. The default is 10.

Max Retry Error

This menu item enables or disables the Max Retry Error menu item.

If it is set to Disable, errors are not declared and the print content

for the current label is discarded. The default is Enable.

Tag Writ e Cnt

This menu item displays on the control panel’s LCD the number of

tags written since the last Clear Tag Stat operation has been

initiated. (See “Clear Tag Stat” below.)

52

Failed Tag Cnt

This menu item displays on the control panel’s LCD the number of

failed tag write attempts since the last Clear Tag Stat operation has

been initiated. (See “Clear Tag Stat” below.)

Clear Tag Stat

This menu item clears the Tag Write Cnt and Failed Tag Cnt menu

items.

F/W-Version

This menu item displays on the control panel’s LCD the reader

firmware version.

Page 53

RFID CONTROL Submenus

Precheck Tags

When this menu item is set to Enable, the RFID encoder checks the

tags for a pre-programmed quality code. If the code is absent, the

tag immediately fails and the selected Error Handling mode is

performed (Overstrike, None, or Stop). The default is Disable.

Overstrike Style

This menu item selects the style of the overstrike pattern. The

default is Grid.

When it is set to Grid, a grid pattern prints when it overstrikes.

When it is set to Error Type Msg, an error message prints that

indicates which error occurred (see Table 1).

Table 1. Printed Overstrike Error Messages

Error Message Explanation

Tag R / W Err

Check media

Tag Comm Err

Check cable

Precheck Fail

Check media

x

x

x

NOTE: The

The printer software attempted to write to or read from the

RFID tag, but the RFID encoder indicated that the tag could

not be written to or read from.

The printer software temporarily lost communication with the

RFID encoder, or communication between the printer

software and the RFID encoder was not synchronized and

had to be forced.

This failure occurs only when the Precheck Tags menu item

is set to Enable. It indicates that the RFID tag was

automatically failed since it did not contain the correct

pre-programmed quality code.

x

in the error messages represents a number code that

identifies the area in the printer software where the failure

occurred.

53

Page 54

Chapter 3 RFID CONTROL Menu

Admin User Menu Items

To see these menu items, set Admin User to Enable in the

PRINTER CONTROL menu. (Refer to the

User’s Manual

.)

IMPORTANT

IMPORTANT

Admin User menu items should only be used for

troubleshooting.

Tag Type

This menu item selects the tag type in use. The default is Alien

Squig 64. Other classes may be added in the future.

If you have a T5000e printer, do not use Alien M-TAG 64, Alien

M-TAG 96, or Matrics X2020 96. Only a T5000e SR or SL5000e

printer can program these tag types properly.

RFID Test (This Test Reads A Tag)

This menu item reads the tag in range of the internal RFID antenna

and reports the tag data to the debug port and momentarily displays

it on the control panel’s LCD. It is primarily intended for

development verification by checking that the system is working.

Auto Retry

This menu item selects the number of automatic (internal) retries

that the RFID encoder will attempt on the same tag before declaring

a tag error and performing the Error Handling mode selected

(Overstrike, Stop, or None). The default is 2.

54

Custom Tag

This menu item enables or disables the Custom Pwr Set, Custom

Tag Len, and Custom Tag Class menu items (custom tag menus).

The default is Disable.

The custom tag menus allow the RFID encoder to work with tag

types that are not listed in the Tag Type menu item.

NOTE: Printronix cannot guarantee the performance of tag types

not certified by Printronix.

Page 55

Admin User Menu Items

When Custom Tag is set to Disable, the settings in the custom tag

menus are ignored by the RFID encoder.

When it is set to Enable, the RFID encoder uses the settings in the

custom tag menus, which must be set to match the characteristics

of the custom tag.

When it is set to Duplicate, the settings of the selected Tag Type

menu item are copied into the custom tag menus.

Custom Pwr Set

NOTE: To enable this menu item, set Custom Tag to Enable.

This menu item selects the power level to be used in the RFID

encoder. 1 is the lowest power level setting, and 20 is the highest.

The default is 5.

Custom Tag Len

NOTE: To enable this menu item, set Custom Tag to Enable.

This menu item selects the number of bytes in the tag.

The default is 8.

Custom Tag Class

NOTE: To enable this menu item, set Custom Tag to Enable.

This menu item selects the class of the custom tag. Class 1 and

Class 0+ tags are read/write. Class 0 tags are read only.

The default is Class 1.

55

Page 56

Chapter 3 RFID PGL Commands

RFID PGL Commands

Write Tag

Purpose To program non-incremental data into an RFID tag

(embedded in the smart label).

MODE CREATE

Format

RFWRITE;[HEX;][EPC

RFWRITE; The RFID Write Tag command.

HEX; Optional parameter to indicate that the

EPC

m

m

;][RFn;L;][LOCK;]ATp;[(D)

text in

datafield

and that it will be converted to binary

format.

; Optional parameter to indicate that the

data in

an EPC number. When this parameter is

used, the HEX option is automatically

enabled and the data field is limited to a

maximum of 14 digits. The AT parameter

is ignored. The tag is then programmed

as follows:

datafield

is in hexadecimal format

should be converted to

datafield

(D)]

56

Bits 0 to 1 are programmed with the

EPC value 0 to 3, specified in

Bits 2 to 57 are programmed with the

hexadecimal characters in the data field

(14 maximum). If the data field has less

than 14 hexadecimal characters, zeros

are assumed for the remaining digits.

Bits 58 to 63 are set to zero.

RF

n;L

; Optional parameter to indicate that this

field has dynamic data. Replace

number ranging from 1 to 512 to identify

the field number of this RFWRITE field.

Replace

data string. If this option is used, the

L

with the length of the dynamic

m

.

n

with a

Page 57

Read Tag

datafield

must be entered via the RF command in

the EXECUTE mode. The length of the

dynamic data must be equal to

LOCK; Optional parameter to write-protect the

data. Currently not supported.

AT

p

;

(D) Delimiter designating the start and end of

datafield

NOTE: RFWRITE fields are not expandable in VDUP and/or

HDUP sections.

p

specifies the decimal start position

where data will be written to the tag.

Subsequent bits will be shifted and

previous bits are nulled.

static data for the RFWRITE field.

Replace (D) with any printable character,

except the SFCC and “/” (the slash

character).

The static data of the RFWRITE field.

is ignored, and dynamic data

L

.

Read Tag

Read Tag is not a command, but an element of the ALPHA and

BARCODE commands. See “Alphanumerics” and “Bar Codes” in

the

IGP/PGL Programmer’s Reference Manual

information.

for more

Purpose Embed RFID data into an ALPHA or BARCODE data

field.

Format <RDI>

position,length[,format];

<RDI> The RFID Data Indicator character, as

defined by the RFREAD parameter in the

ALPHA or BARCODE commands. See

the ALPHA and/or BARCODE command

description for details.

position

The decimal number that specifies the

starting position of the data inside the

transponder.

57

Page 58

Chapter 3 RFID PGL Commands

length

format

The decimal number that specifies the

length of the data to be read.

Replace the optional

with any non-zero number to convert the

data to hexadecimal format.

format

parameter

EPC Programming Example

This programming example shows reading and writing dynamic

EPC data to a tag.

~CREATE;HEX;431

//Create a form named HEX.

RFWRITE;HEX;RF3;16;AT1;

//Write Tag with data from dynamic RFID element 3.

//Length of data is 16, format is HEX.

ALPHA

//The following ALPHA element is defined below.

//It will be used to print the contents of the tag.

RFREAD@;AF1;16;10;10;0;0

//Read Tag Indicator character is “@”. Incorporate read

//data into Dynamic ALPHA field number 1. Length of

//ALPHA field is 16 characters. Place ALPHA field at

//dot position (10,10) on the form.

STOP

//Terminate the ALPHA element definition.

58

END

~EXECUTE;HEX

//Execute the form with dynamic data.

~RF3;“68656C6C6F746167”

//Dynamic data (in HEX) for Tag Write is

//“68656C6C6F746167”.

~AF1;*@1,16,1;*

//Print the data in AF1.

~NORMAL

Page 59

ASCII Programming Example

ASCII Programming Example

This programming example shows reading and writing dynamic

ASCII data to a tag.

~CREATE;READTAG

//Create a form named READTAG.

RFWRITE;RF3;8;AT1;

//Write Tag with data from dynamic RFID element 3.

//Length of data is 8.

ALPHA

//The following ALPHA element is defined below.

//It will print the contents of the tag.

RFREAD@;AF1;8;10;10;0;0

//Read Tag Indicator character is “@”. Incorporate read

//data into Dynamic ALPHA field number 1. Length of

//ALPHA field is 8 characters. Place ALPHA field at dot

//position (10,10) on the form.

STOP

//Terminate the ALPHA element definition.

END

~EXECUTE;READTAG

~RF3;“hellotag”

//Dynamic data for Tag Write is “hellotag”.

~AF1;*@1,8;*

//Execute READTAG form with dynamic and RFID data

//from the first eight bytes in the Tag.

~NORMAL

59

Page 60

Chapter 3 RFID PPI1 Commands

RFID PPI1 Commands

Get Tag Unique ID

Purpose Read the unique identification number of the RFID tag

(embedded in the smart label).

Format ^RI

Comments

x

^RI Get Tag Unique ID command.

x

The PPI1 only supports Alien Technology Class 1a

tags, which do not have the unique identification

numbers. Therefore, the PPI1 absorbs this command.

The field number to which the data will be

assigned. The default is 0, and other

acceptable values range from 1 to 9999.

Set Tag Type

Purpose Select the type of the RFID tag (embedded in the smart

label).

Format ^RS

Comments

x

^RS Set Tag Type command.

x

The PPI1 only supports Alien Technology Class 1a

tags. There are no alternative choices. Therefore, the

PPI1 absorbs this command.

Number assigned to the type of the tag.

The default is 0, and other acceptable

values range from 1 to 9999.

60

Page 61

Read Tag

Purpose This command allows data from the RFID tag

(embedded in the smart label) to merge into any

previously defined dynamic data field. It is equivalent to

the Field Number command (^FN) except that the data

come from the RFID tag.

Format ^RT

x, start, length, hex, retries, motion, reserved

^RT Read Tag command.

Read Tag

x

start

length

hex

retries

Specified Field Number. The default is 0.

The acceptable value range is 1 to 9999.

Location where data will be read from the

RFID tag. The PPI1 only supports Alien

Technology Class 1a tags, which have

only one 8–byte block. Therefore,

will be set to 0, regardless of the

specified value.

The number of blocks to be read from the

RFID tag. The PPI1 only supports Alien

Technology Class 1a tags, which have

only one 8–byte block. Therefore,

will be set to 1, regardless of the

specified value.

This flag indicates whether the data, after

being read from the RFID tag, should be

translated into hexadecimal format. The

default is 0, meaning the data will not be

translated. The other acceptable value is

1, meaning the data will be translated

into hexadecimal format.

The number of automatic attempts to

read data from the tag if previous reads

failed. The PPI1 absorbs the number and

uses the value on the control panel’s

LCD.

start

length

61

Page 62

Chapter 3 RFID PPI1 Commands

motion

reserved

Comments

This command is only executed by the demand for

data from any dynamic field. The PPI1 absorbs this

command if there are no demands for the data.

Set this flag to 1 to read data from the tag

without moving the label. The printer may

adjust the label position while it reads

data from the tag, but this adjustment will

reverse before any subsequent normal

label movement. Even if this flag is set to

1, other commands (i.e., alpha or

barcode) may move the label.

This is a reserved flag. The PPI1 absorbs

this number.

Write Tag

Purpose This command programs data into an RFID tag

(embedded in the smart label).

Format ^WT

start, retries, motion, protect, reserved

^WT Write Tag command.

start

Starting block location where data will be

programmed into the RFID tag. The PPI1

only supports Alien Technology Class 1a

tags, which have only one 8–byte block.

Therefore,

regardless of the specified value.

start

will be set to 0,

62

retries

motion

The number of automatic attempts to

write data into the tag if previous writes

failed. The PPI1 absorbs the number and

uses the value on the control panel’s

LCD.

Set this flag to 1 to program data into the

tag without moving the label. The printer

may adjust the label position while it

writes data into the tag, but this

adjustment will reverse before any

subsequent normal label movement.

Page 63

protect

Host Verification

Even if this flag is set to 1, other

commands (i.e., alpha or barcode) may

move the label.

This flag indicates whether the data

should be protected from being

overwritten later. The default is 0,